Patents

Literature

37 results about "Elasto plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An elasto-plastic joint is a pipe connection made of flexible, rubber-like material that can either retain shape or take on a new shape depending on the force applied. With both elastic and plastic properties, an elasto-plastic joint has applications for trenchless construction and trenchless rehabilitation.

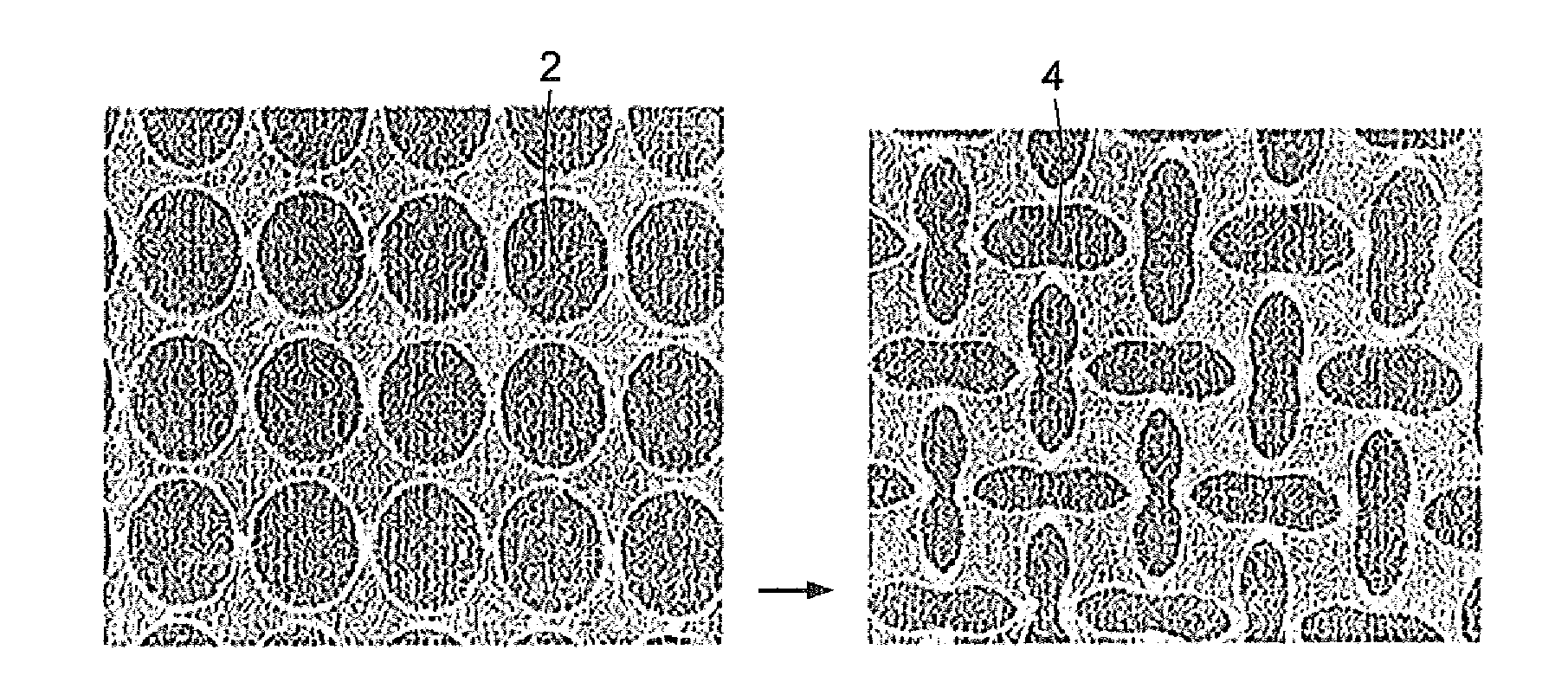

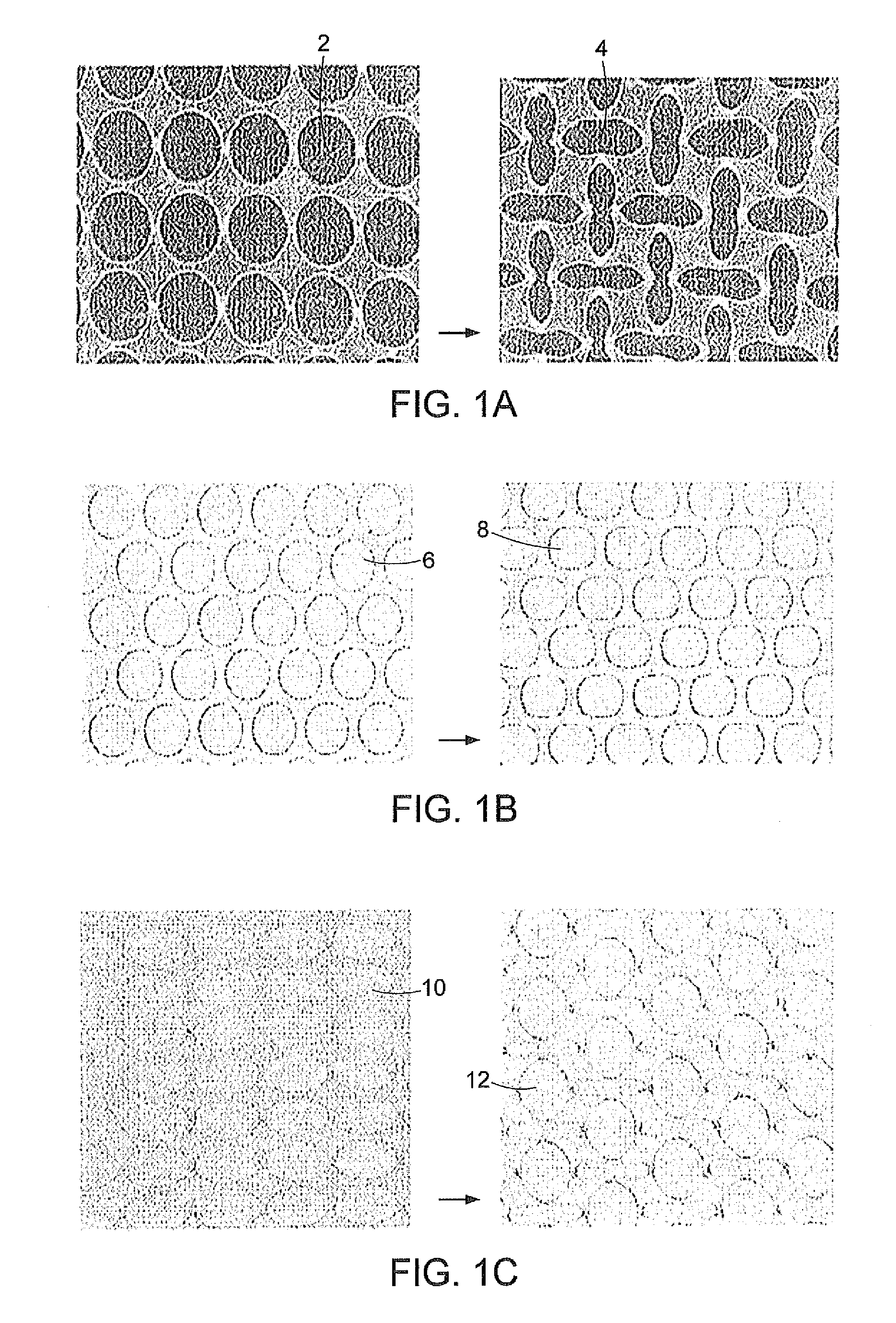

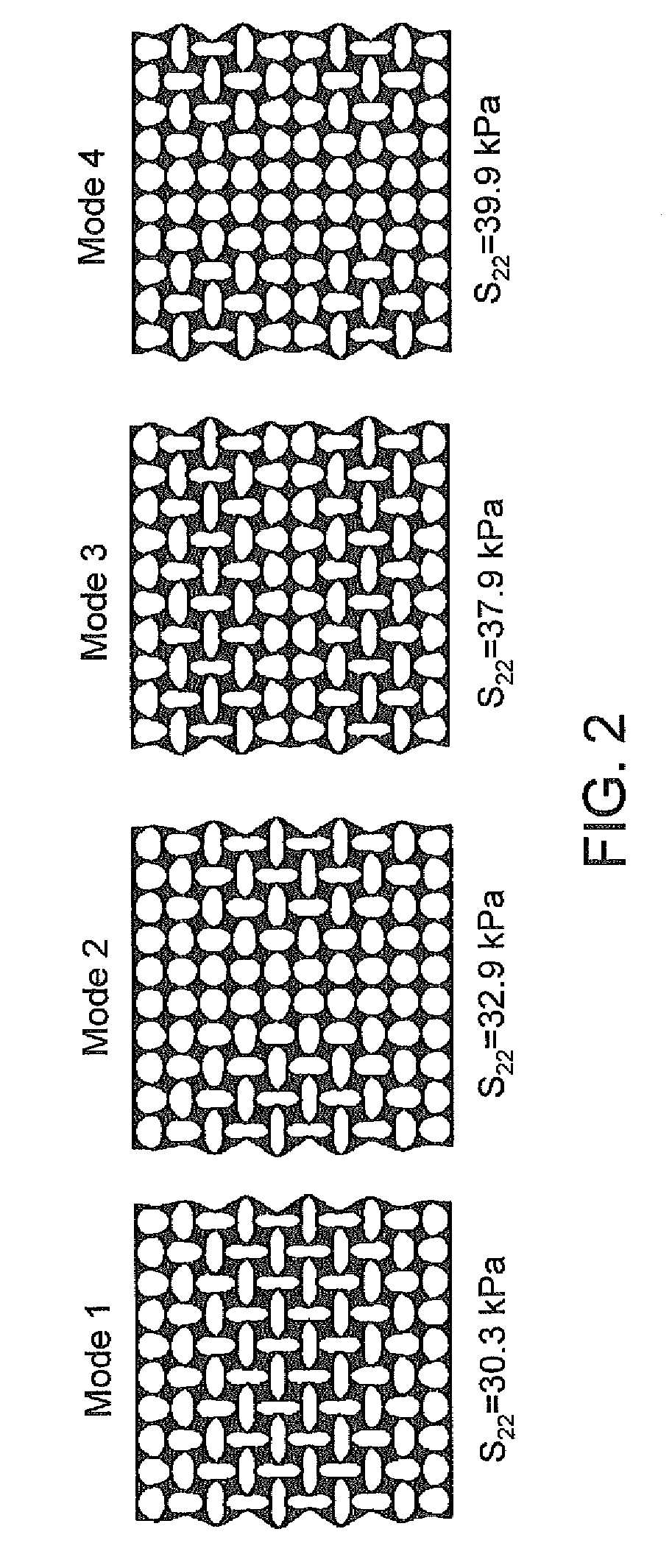

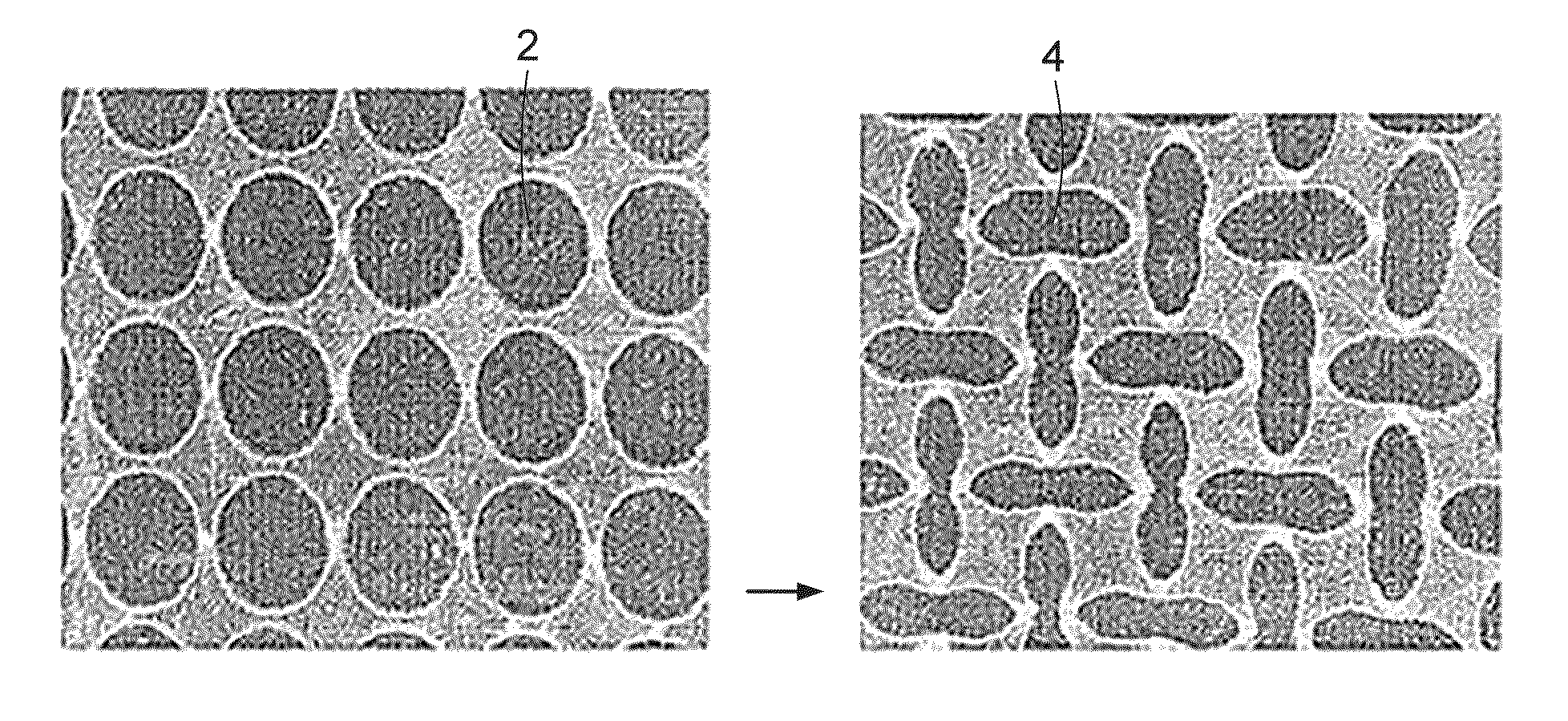

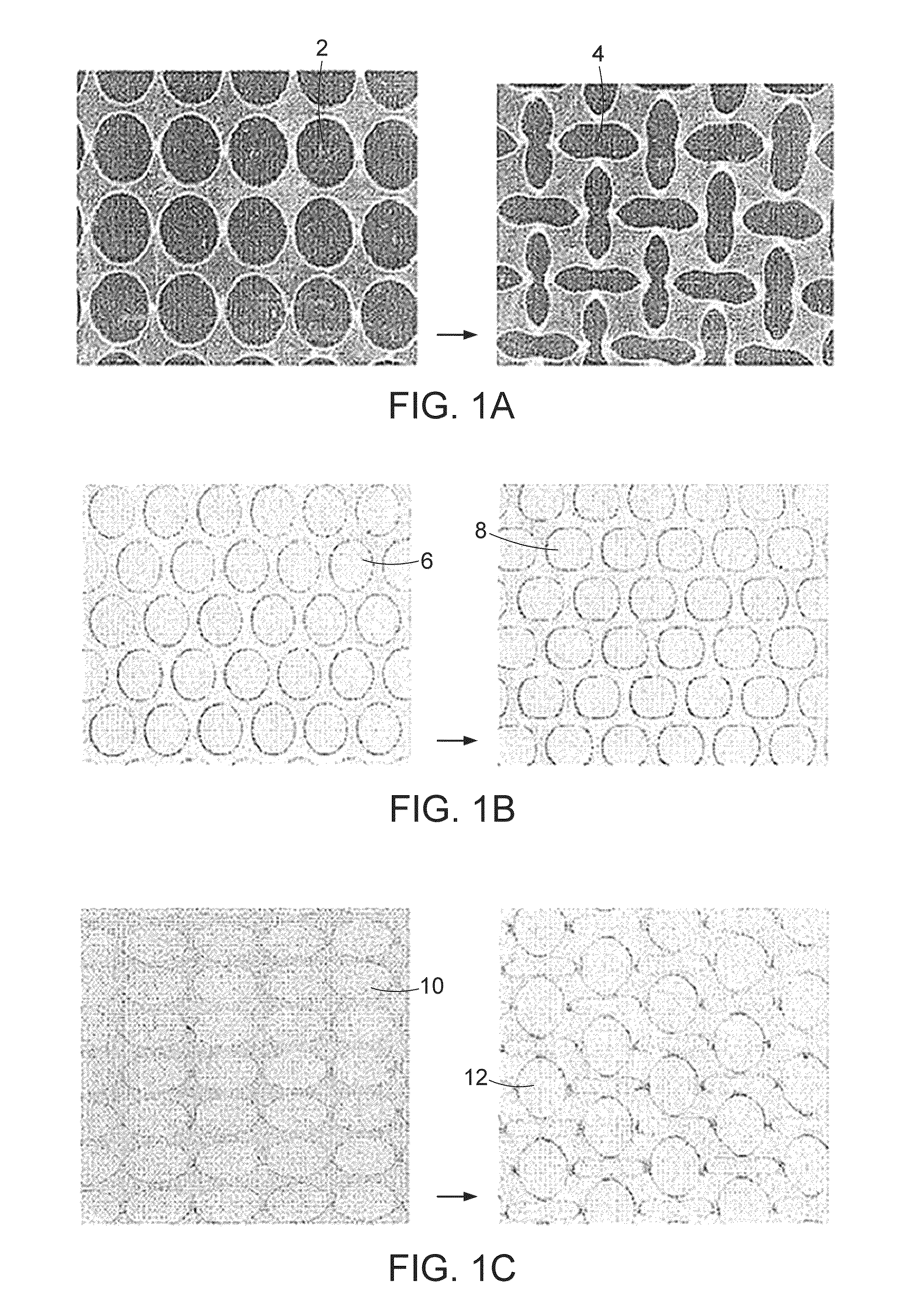

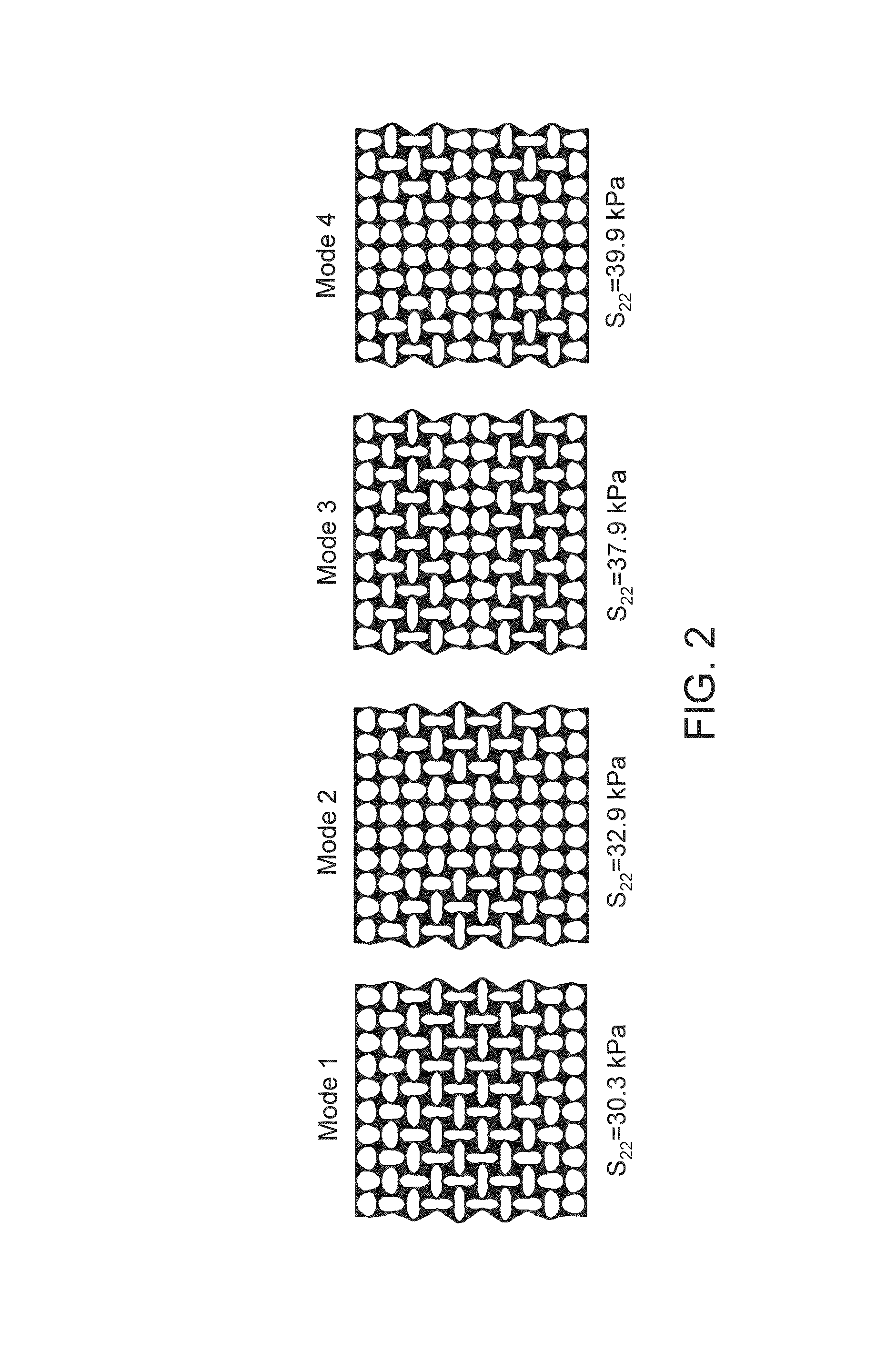

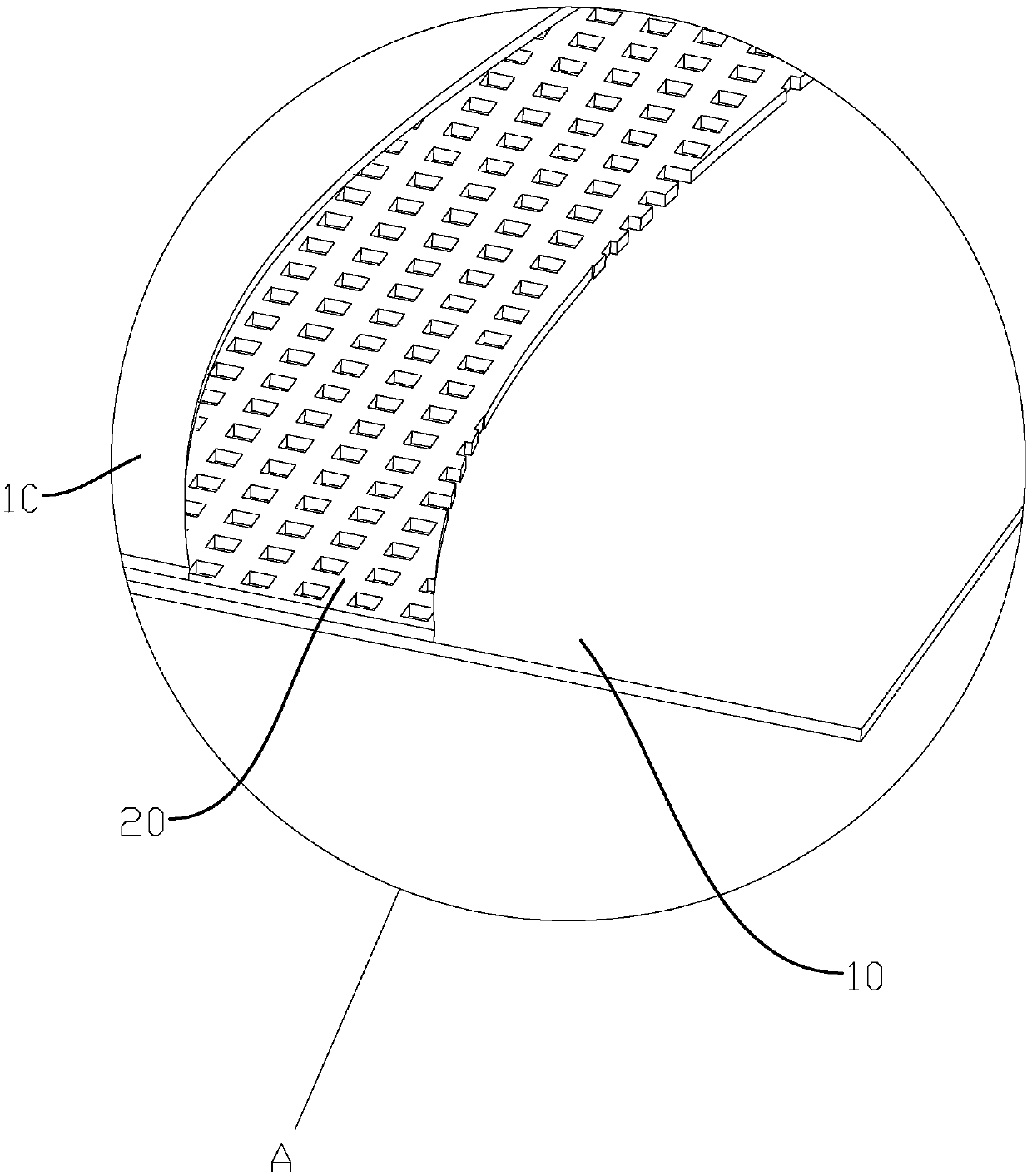

Pattern production and recovery by transformation

A transformative periodic structure includes a plurality of elastomeric or elasto-plastic periodic solids that experiences a transformation in the structural configuration upon application of a critical macroscopic stress or strain. The transformation alters the geometric pattern changing the spacing and the shape of the features within the transformative periodic structure. For the case of elastomeric periodic structures upon removal of the critical macroscopic stress or strain, the transformative periodic solids are recovered to their original form. For the case of elasto-plastic periodic structures upon removal of the critical macroscopic stress or strain, the new pattern is retained. Polymeric periodic solids can be recovered to their original form by heating or plasticizing.

Owner:MASSACHUSETTS INST OF TECH

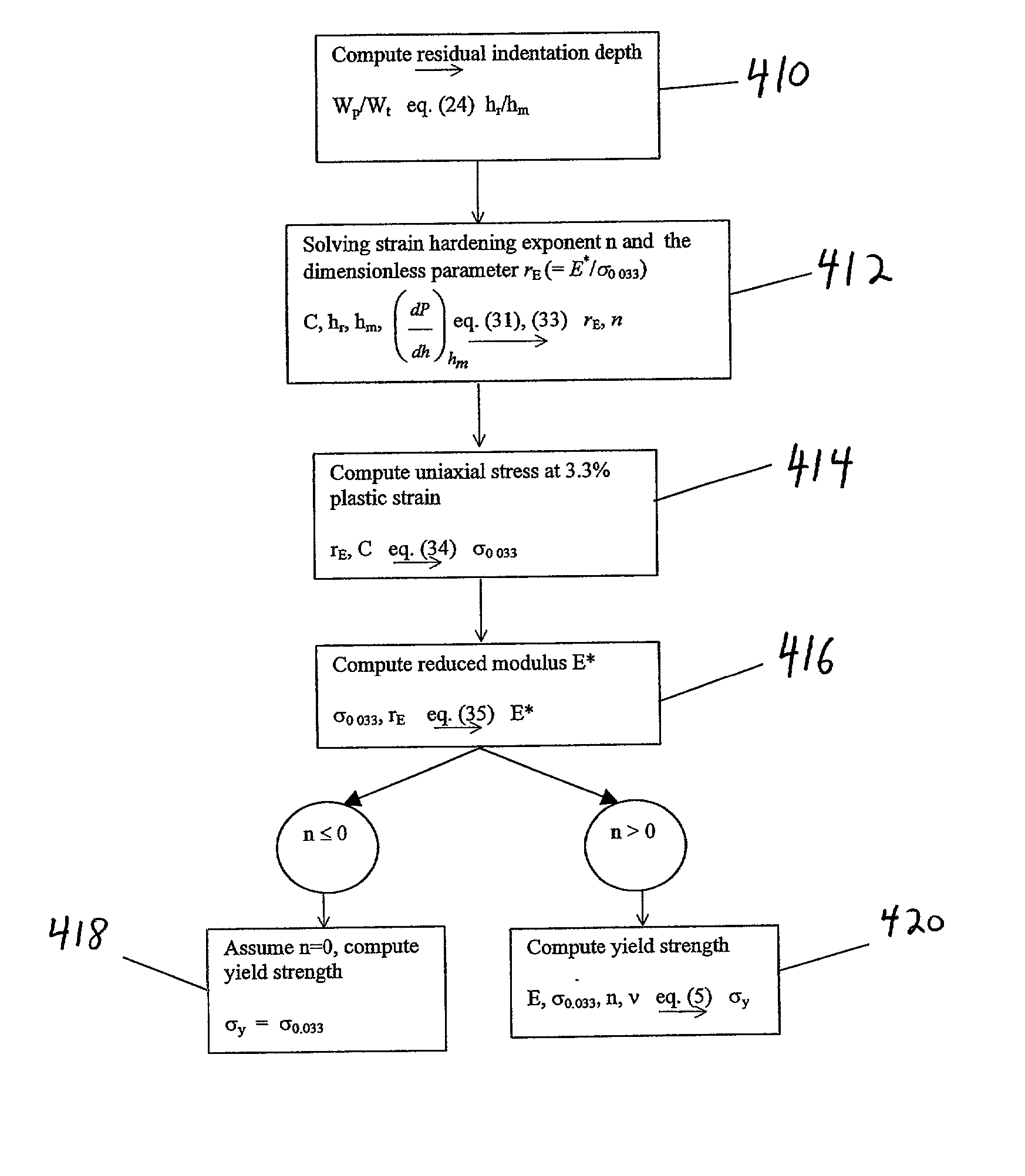

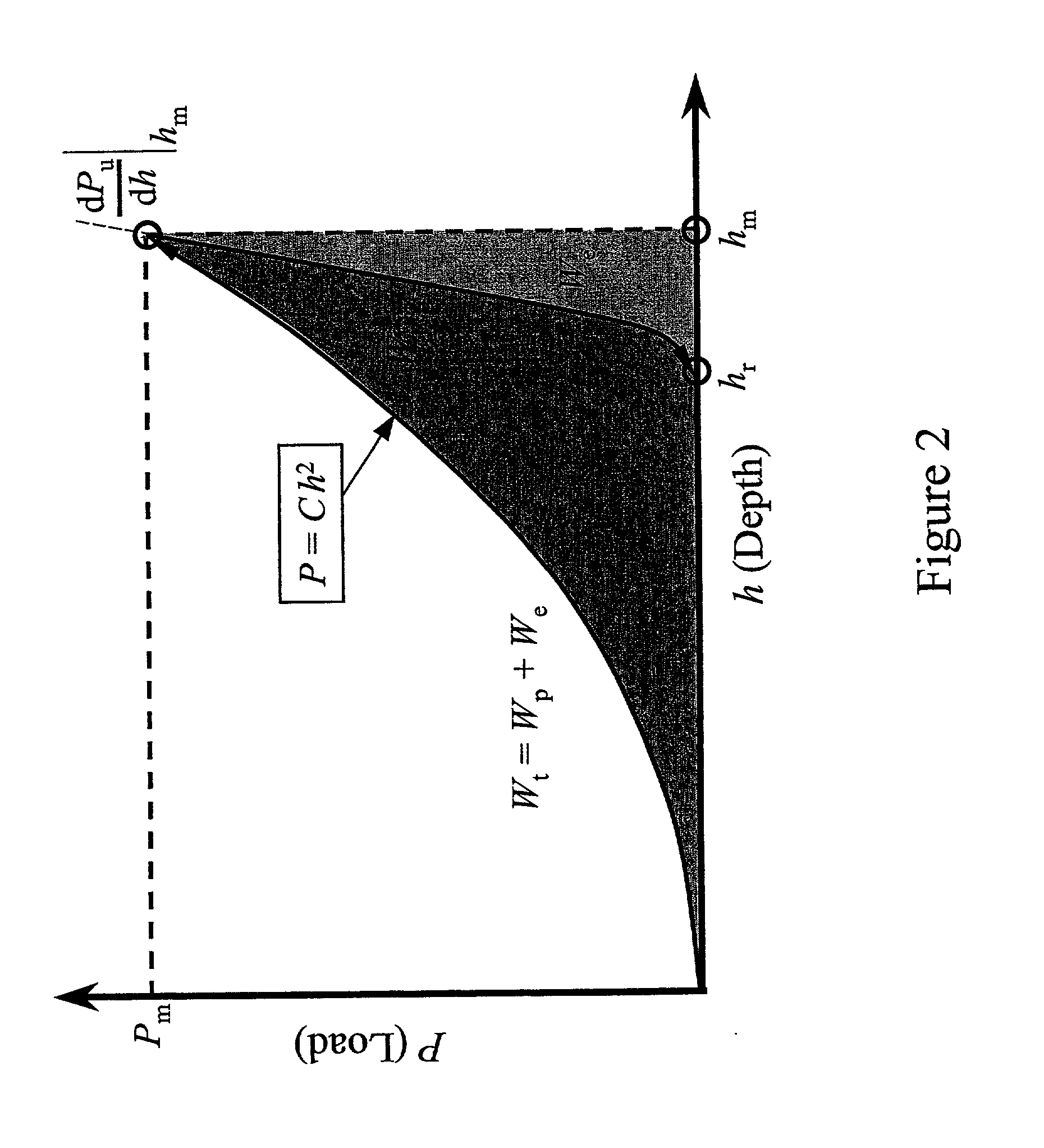

Systems and methods for estimation and analysis of mechanical property data associated with indentation testing

Systems and methods are disclosed that can provide estimates of elasto-plastic properties of material samples using data from instrumented indentation tests. Alternatively, or in addition, estimated load-depth curves can be constructed by certain methods and systems provided based on known mechanical properties. Some disclosed systems and methods use large deformation theory for at least part of the analysis and / or determinations and / or may account for strains of at least 5% in the area of contact between the indenter and the material sample, which can result in more accurate estimates of mechanical properties and / or deformation behavior.

Owner:MASSACHUSETTS INST OF TECH

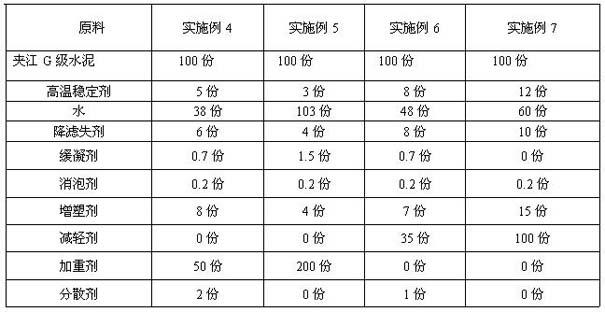

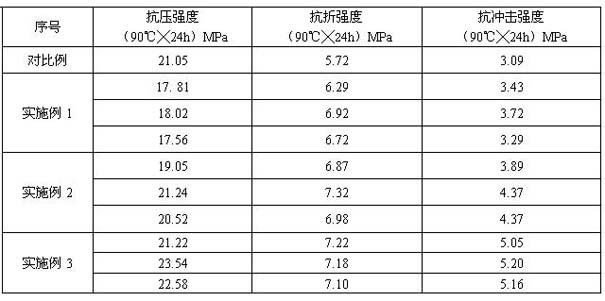

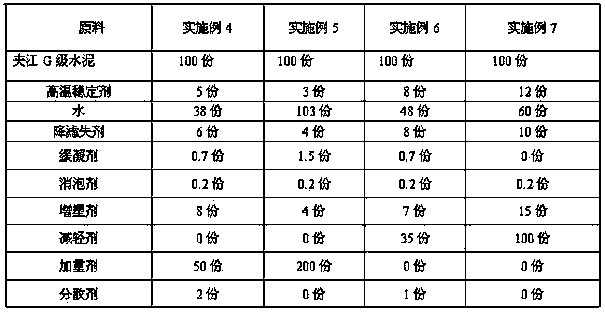

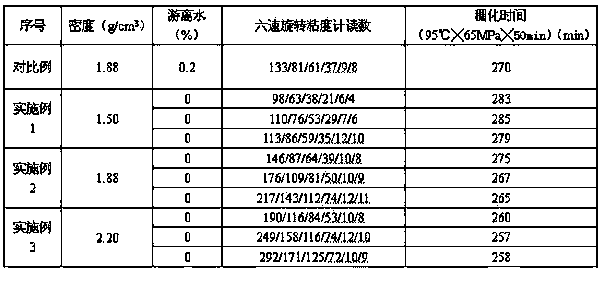

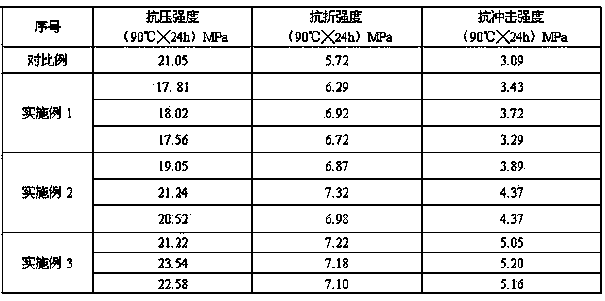

Elasto-plastic well cementing cement slurry and preparation method thereof

ActiveCN102604610ALow elastic modulusImprove impact resistanceDrilling compositionPlasticizerWell cementing

The invention discloses an elasto-plastic well cementing cement slurry which is prepared from the following components in parts by weight: 100 parts of cement, 0-12 parts of high-temperature stabilizing agent, 0-200 parts of density adjuster, 4-10 parts of filtrate loss reducer, 0-2 parts of dispersing agent, 0-1.5 part of retarder, 35-110 parts of water, 0.2 part of defoaming agent and 2-15 parts of plasticizer. The elasto-plastic well cementing cement slurry can improve the bending resisting strength and the impact resisting strength of the cement stone and reduce the elastic modulus of the cement stone. Under high temperature and high pressure, the brittle deformation of the elasto-plastic well cementing cement slurry is converted into the plastic deformation, thus the later exploitation is guaranteed, and the service life of the oil-gas well is prolonged.

Owner:成都欧美克石油科技股份有限公司

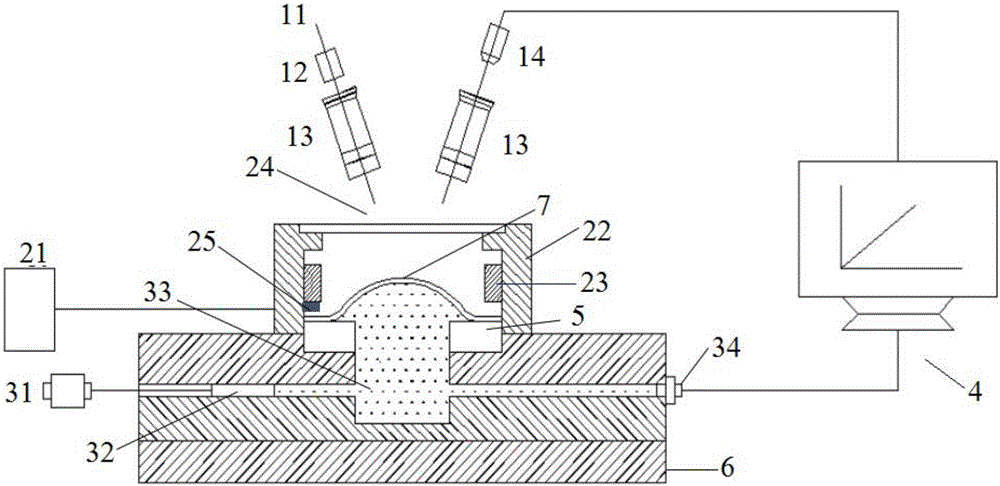

Device and method for measuring mechanical property of film under high temperature

InactiveCN106198206ALoading and unloadingUniform furnace temperatureMaterial strength using tensile/compressive forcesFull fieldOptical measurements

The invention discloses a device and a method for measuring mechanical property of a film under high temperature. The measuring device comprises an optical measurement component, a data processing and displaying component, a dynamic loading component, a heating component and a sample platform, wherein the optical measurement component, the heating component, the sample platform and the dynamic loading component are successively arranged; light sources and light spots sent during measurement are unchanged; due to the bulging effect, the film is deformed; a reflection angle of a light path transmitted to the film is changed due to the deformation of the film; the optical measurement component for receiving a reflected light path is remotely connected to the data processing and displaying component; the received light path is obtained by the optical measurement component; and the data processing and displaying component is used for visually displaying the measurement process and recording the change of the received light path. Through the measuring device, a heating device and a bulging device are combined together to measure the mechanical property of the film under high temperature; the measuring device is compact in structure, is applied to the films of various elasto-plastic systems, and is capable of achieving real-time and full-field measurement of the change of the mechanical property in the heating process.

Owner:XIANGTAN UNIV

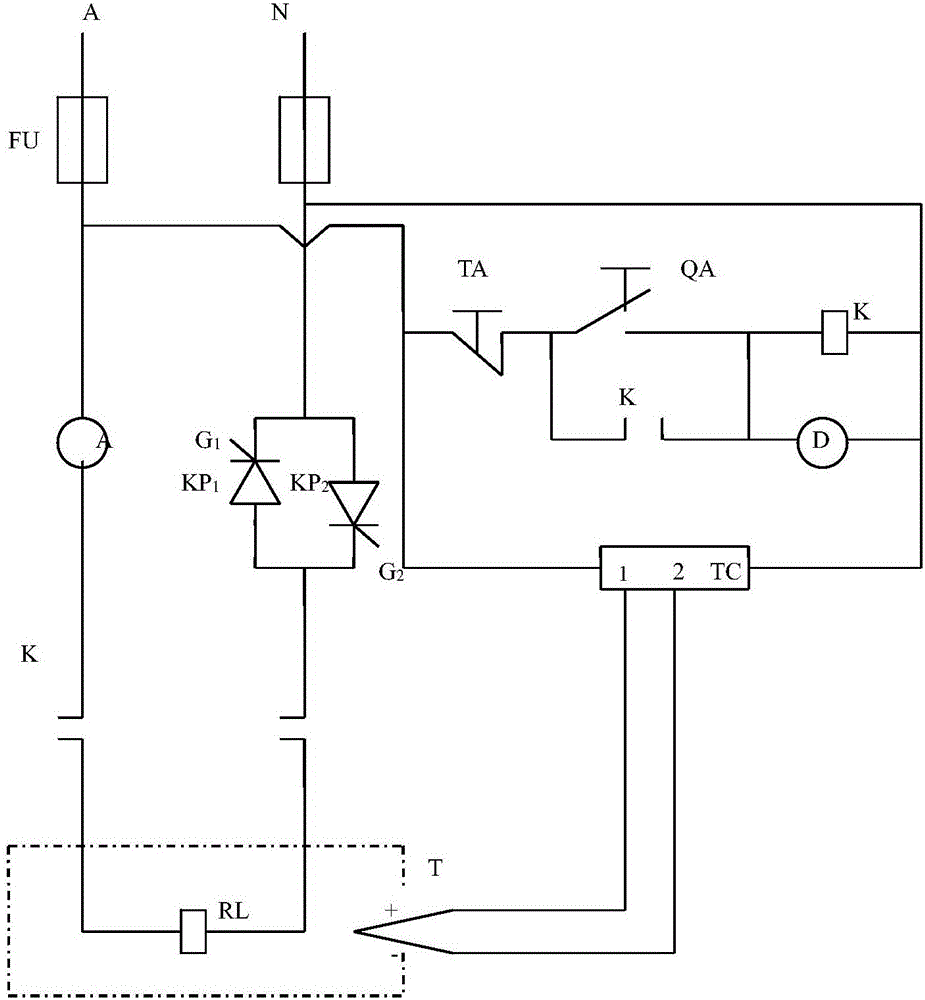

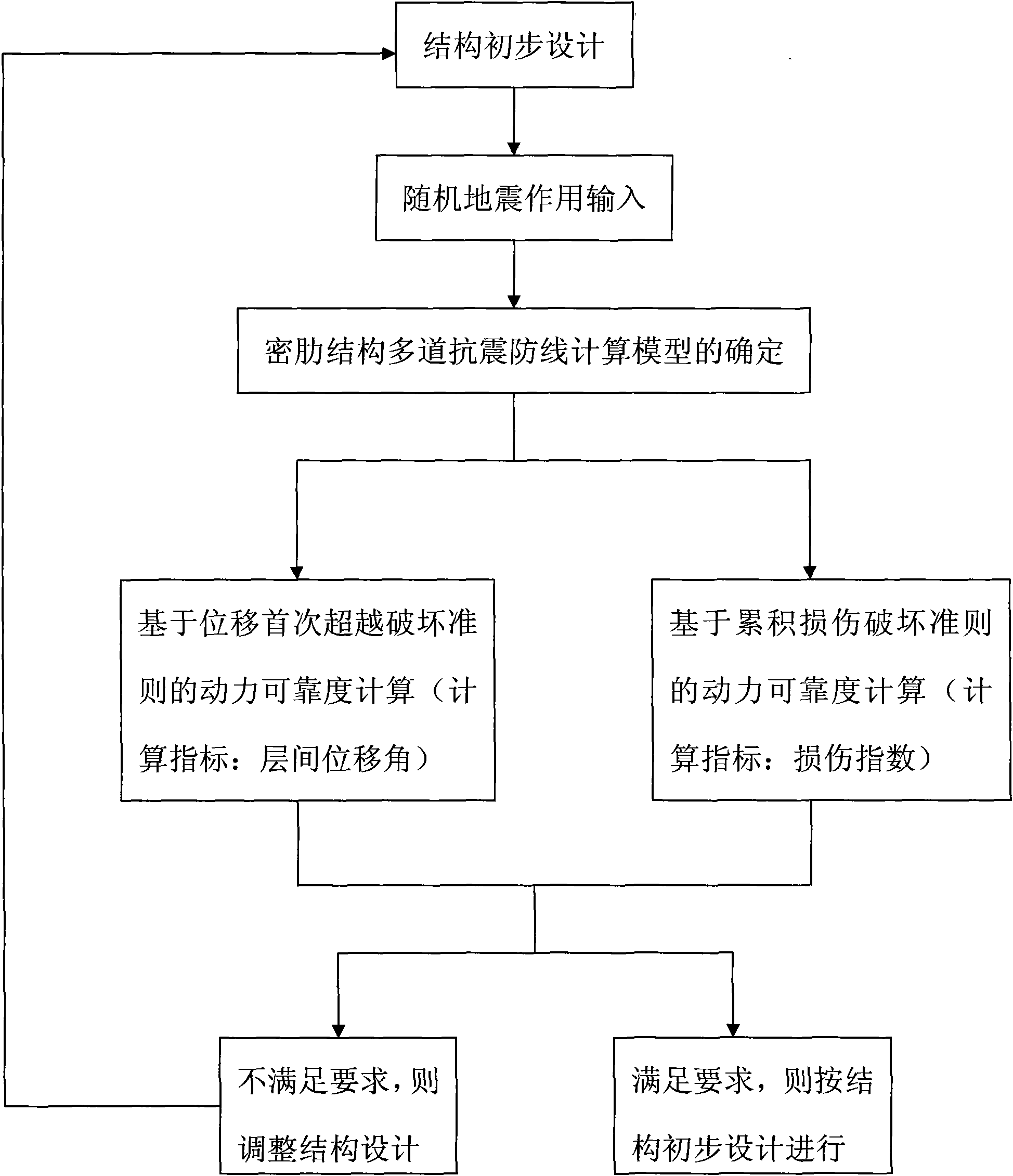

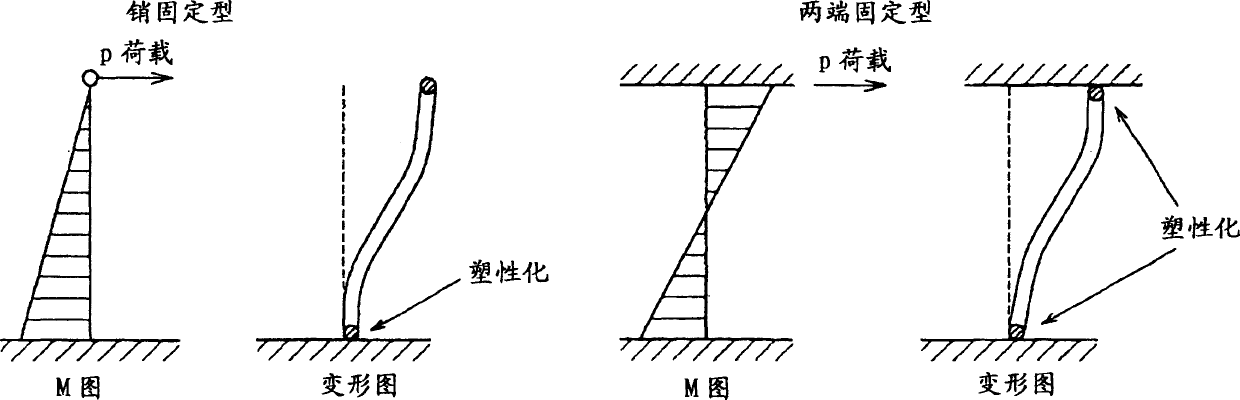

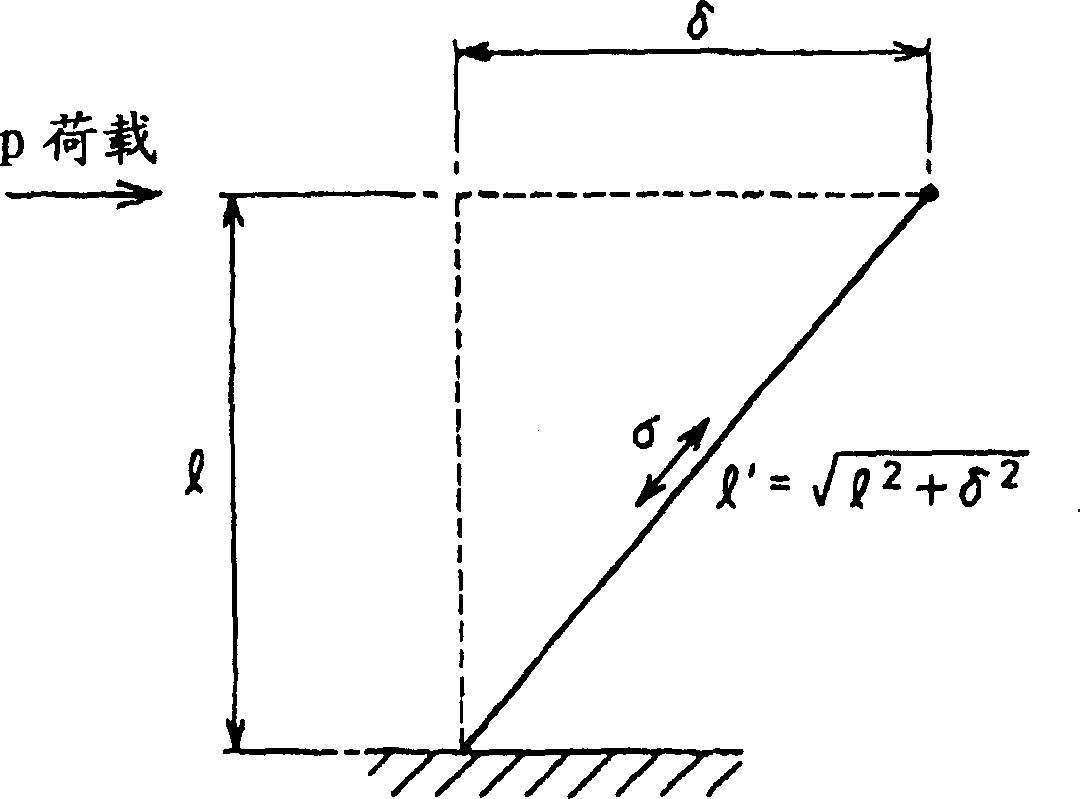

Anti-seismic control design method for ribbed structure with three defensive lines

An anti-seismic control design method for a building structure selects the composition form of all parts according to the application situations of a ribbed structure system, determines the input intensities for frequent earthquake, basic fortification intensity earthquake and rare earthquake, and determines the structural computation model, namely determining the equivalent elastic plate model in the elastic stage, the rigid frame inclined compression bar model in the elasto-plastic stage and the beam-hinged frame model in the damage stage of the ribbed structure. The method considers the structural design control limit value as a random variable, utilizes a dynamical reliability theory to carry out structural design, can divide the earthquake function into a plurality of levels, can consider the variability of the structural parameters, leads the response and damage performance of the designed and built engineering structure to be within the expected range under various possible earthquake functions, ensures the safety of the life and the minimum economic loss, and carries out quantitative control design on the seismic response and damage.

Owner:BEIJING JIAOTONG UNIV

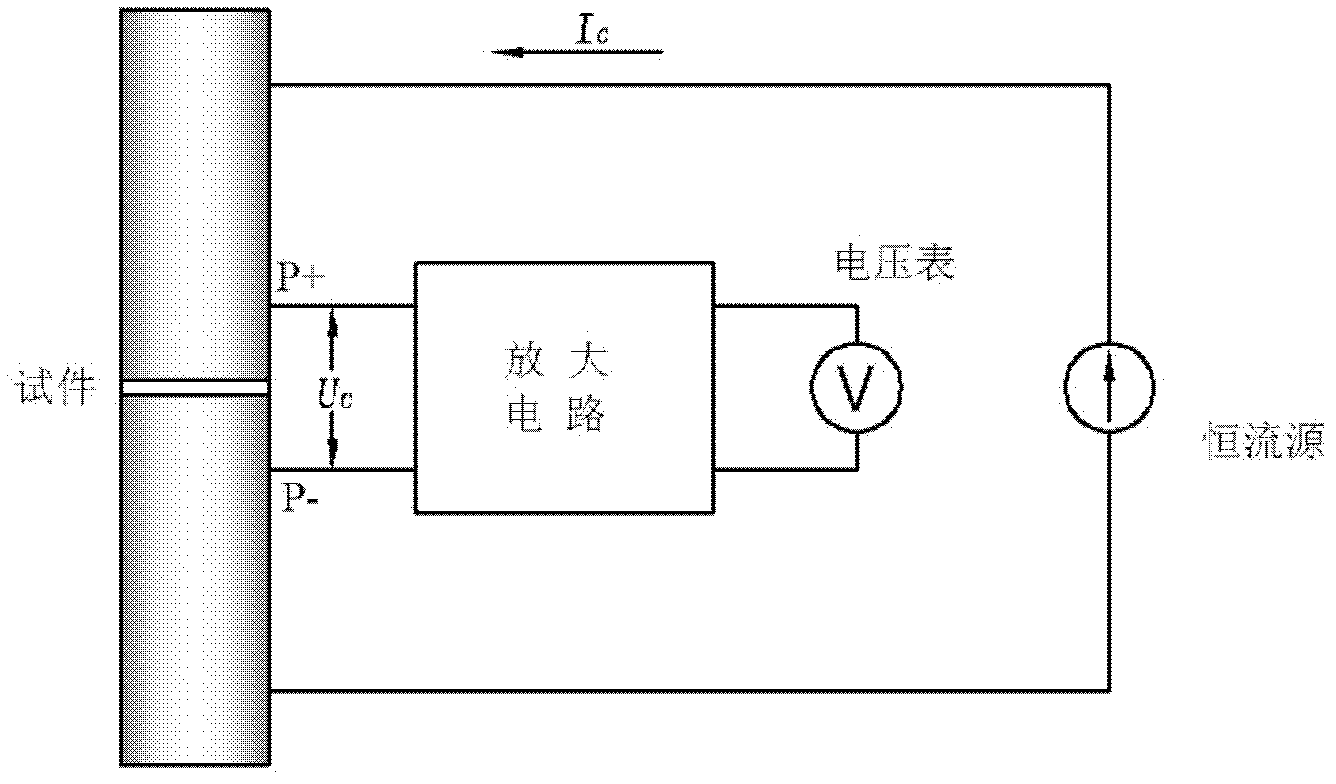

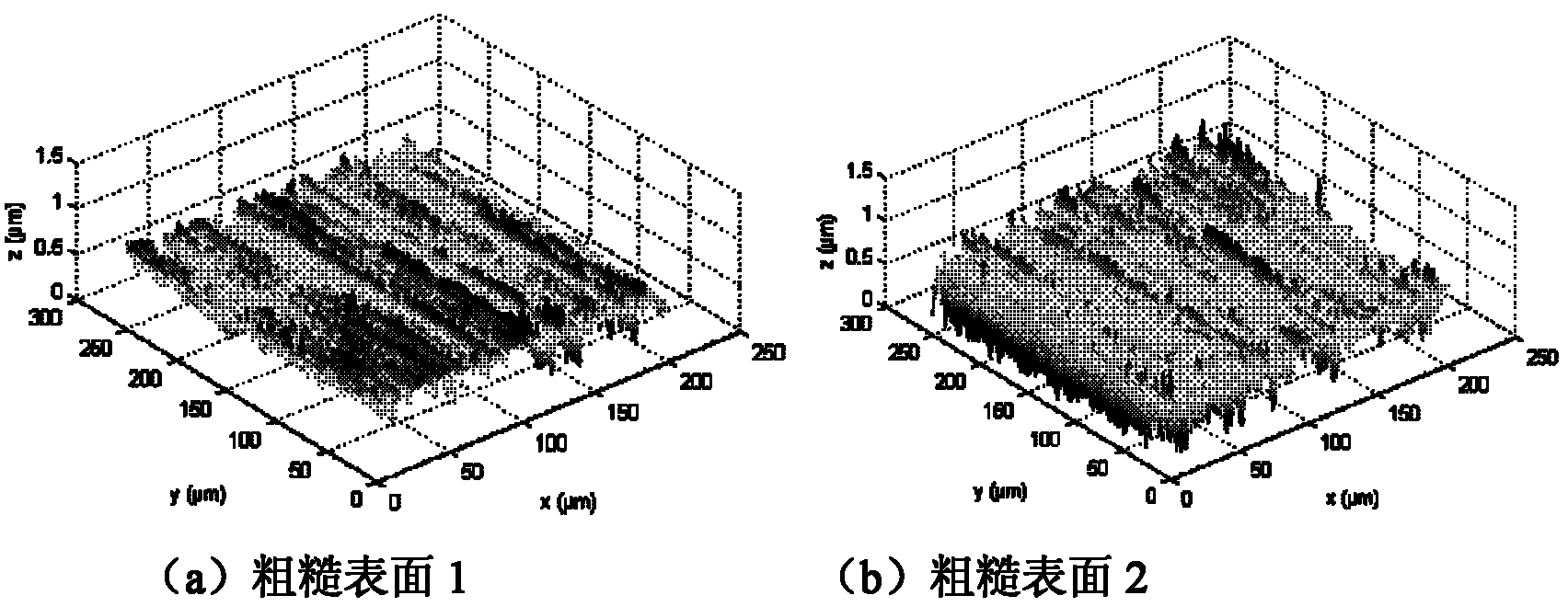

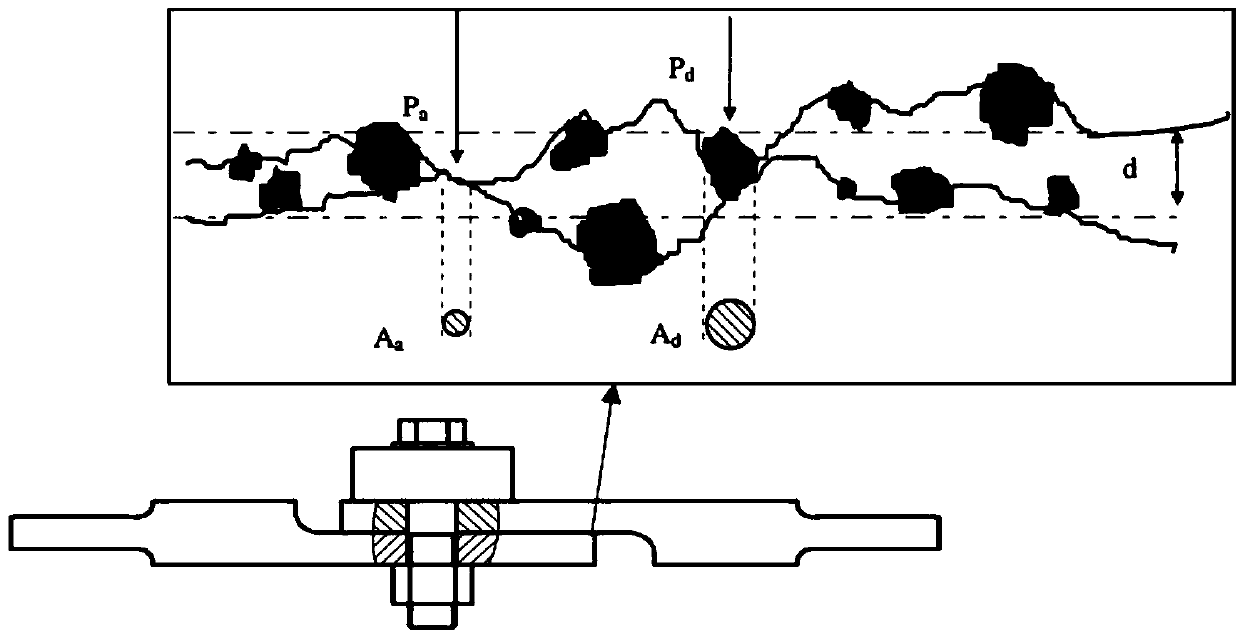

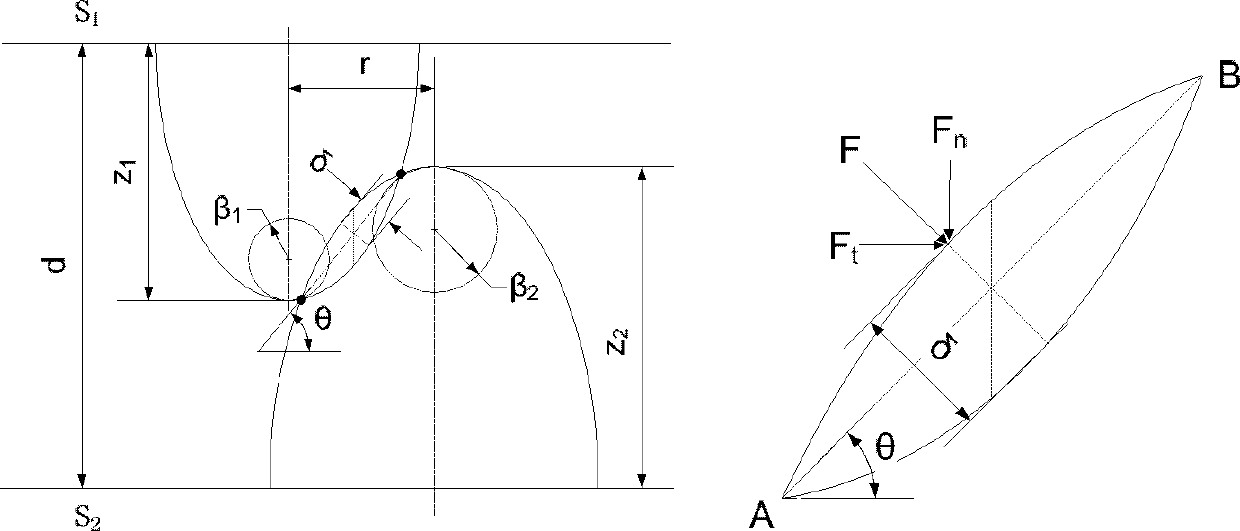

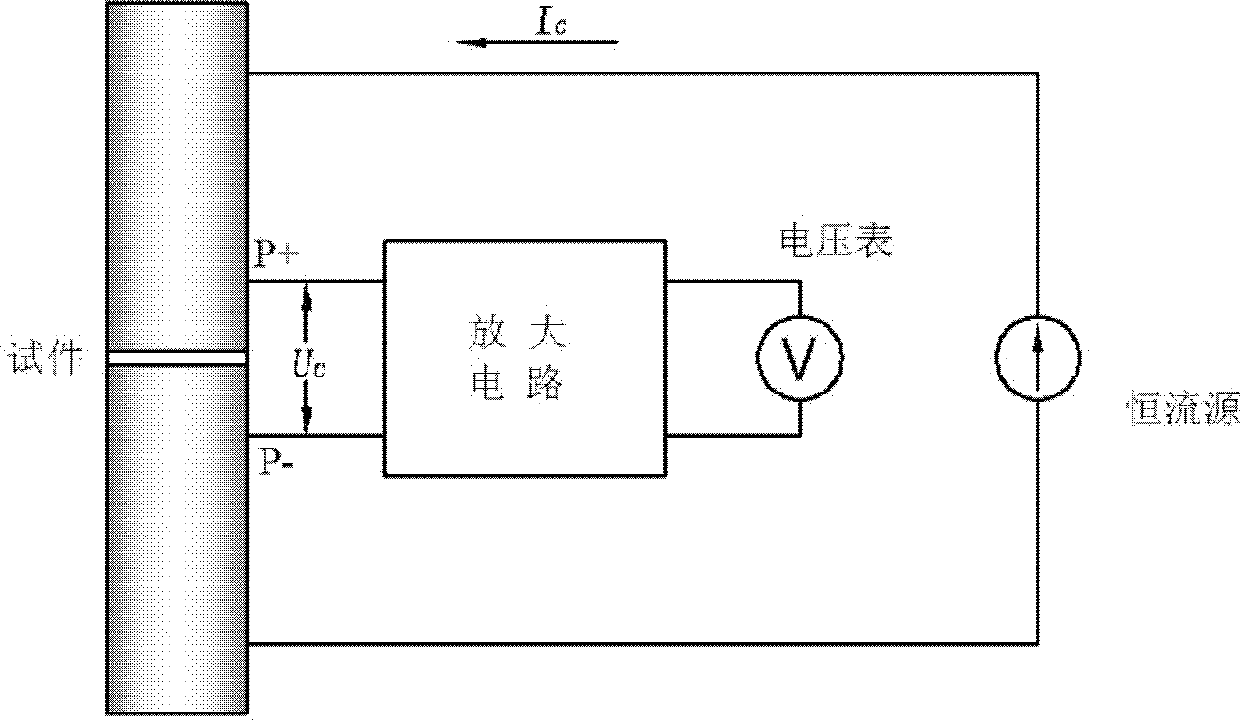

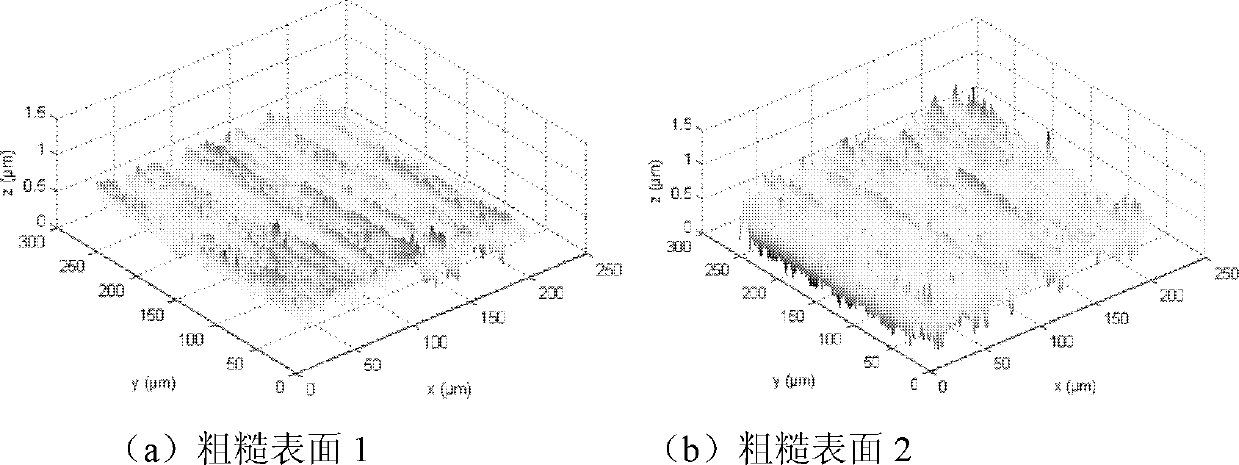

Method for determining normal contact stiffness of fixed joint surface

InactiveCN102608167AOvercome costsImprove objectivityMaterial resistanceElectrical resistance and conductanceMicroscopic scale

The invention provides a new method for indirectly obtaining normal contact stiffness of joint surface according to theoretical calculation and experimental test under the condition that the contact resistance ratio of the fixed joint surface is measured more easily than the normal contact stiffness. Relationship between joint surface contact resistance RC and normal contact stiffness Ktot is established by measurement and aftertreatment for micro appearance of contact surface. Firstly, an expression of the joint surface contact resistance RC is established; then the expression of normal contact stiffness Ktot is established; at the last, the relationship between the joint surface contact resistance RC and the normal contact stiffness Ktot is established. According to the invention, the method overcomes the defect that the normal contact stiffness is measured difficultly; the method considers elasto-plastic contact of two coarse surfaces, and further considers the more comprehensive, accurate actual surface appearance information.

Owner:XI AN JIAOTONG UNIV

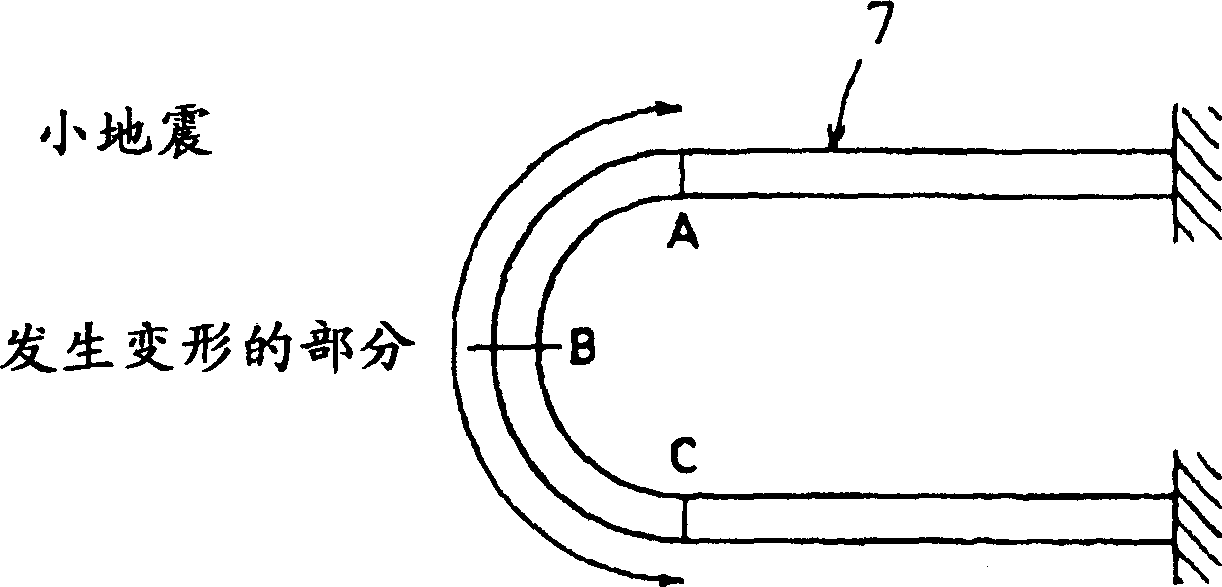

Anti-shock device

ActiveCN1550619AEasy to useReduce distortionNon-rotating vibration suppressionProtective buildings/sheltersElastomerEngineering

To provide a seismic isolator, improved in capability of absorbing the energy of an earthquake, and easily manufactured and constructed at a low price by disposing a damping mechanism formed of a curved member and an isolator between an upper structure and a lower structure. In this seismic isolator, the isolator 1 and both end parts 8, 9 of two or more curved members 7 formed of elasto-plastic material constituting a damping mechanism are disposed between an upper structure 2 and a lower structure 3, and fixed to the upper structure 2 and the lower structure 3. The curved member 7 is formed to draw a circle like a lantern by combination of two or more members or two or more sets of a pair of two curved members opposite to each other symmetrically, and disposed in the periphery of the isolator 1. Thus, the curved member 7 is plastically deformed to absorb the energy of an earthquake.(C)2005,JPO&NCIPI.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

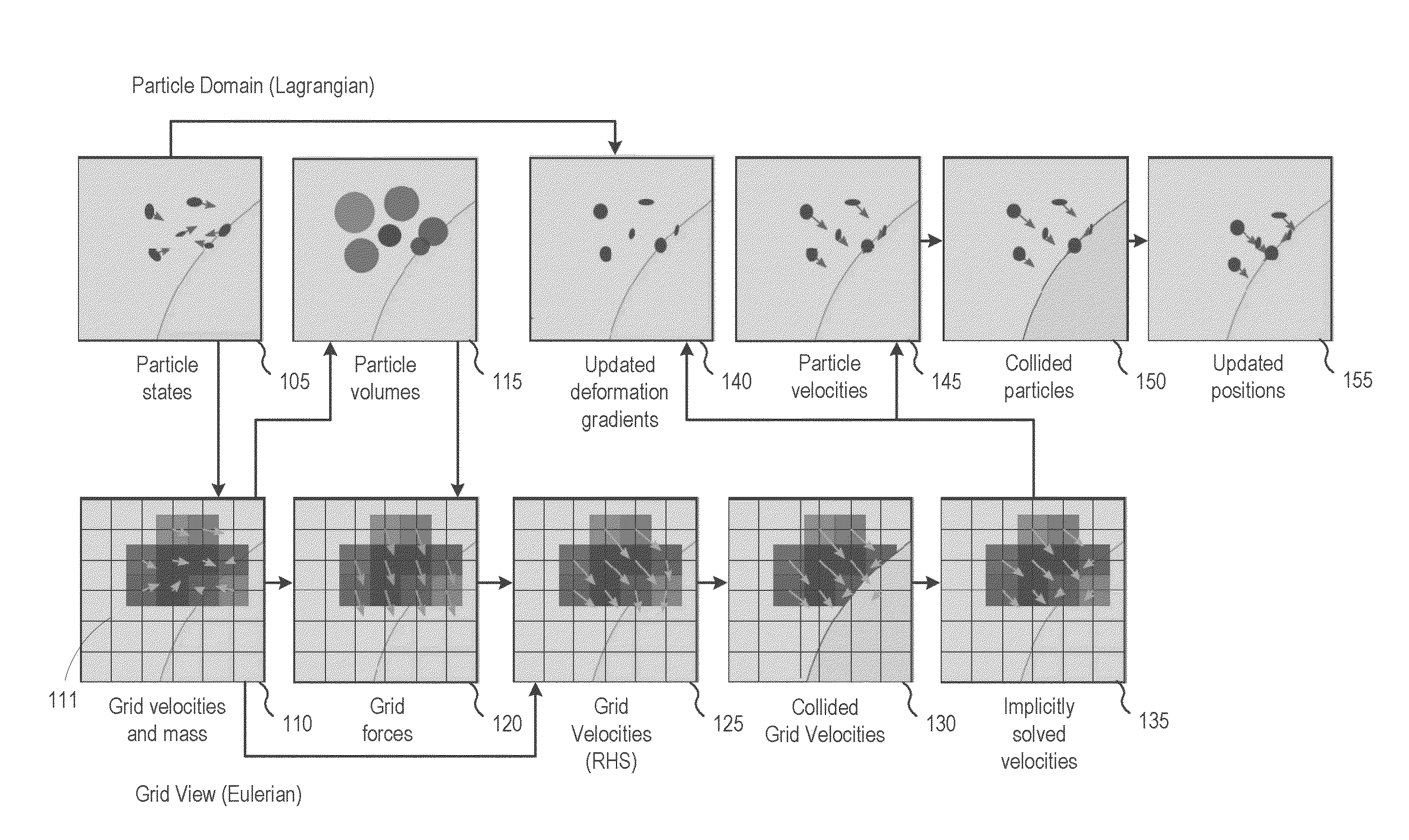

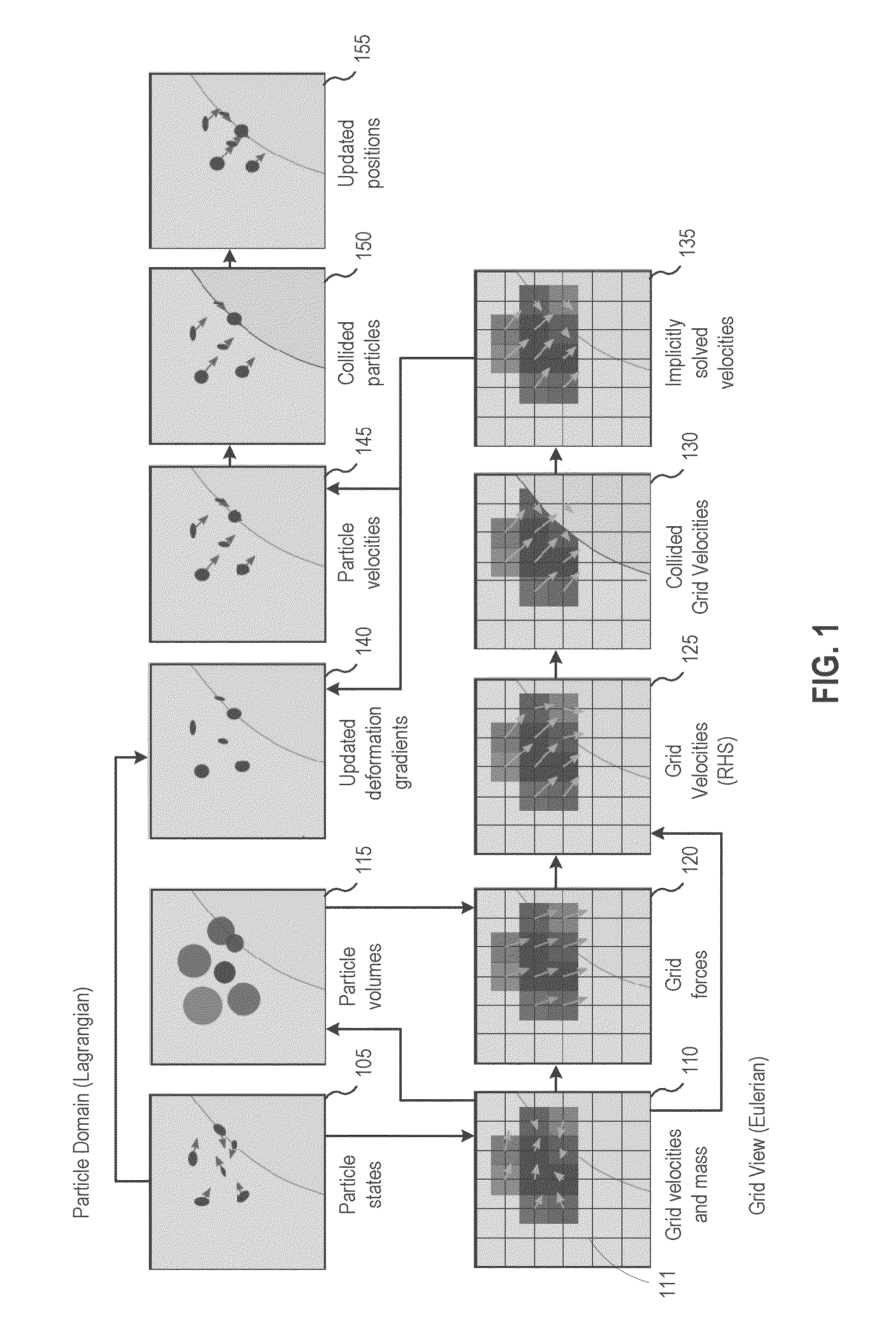

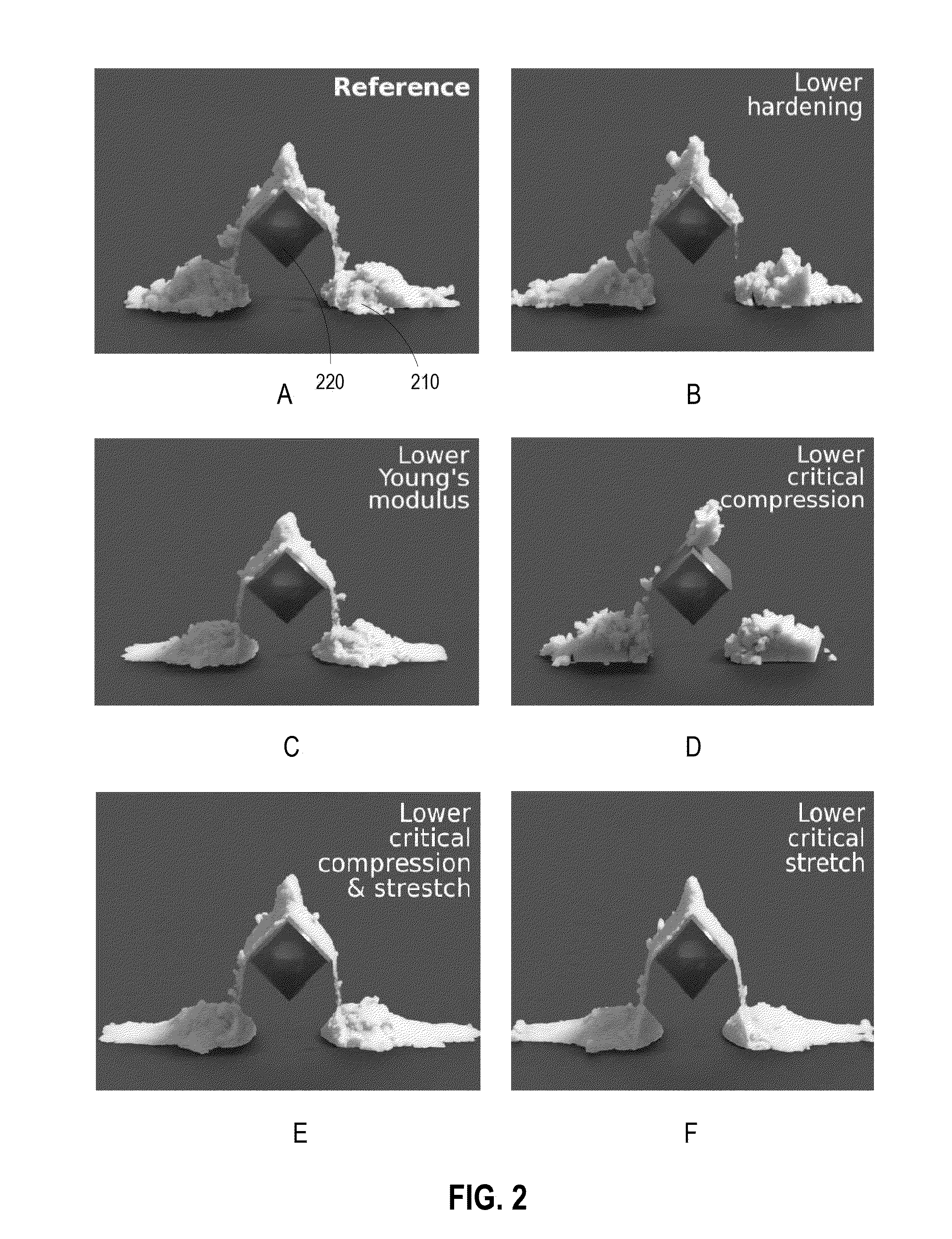

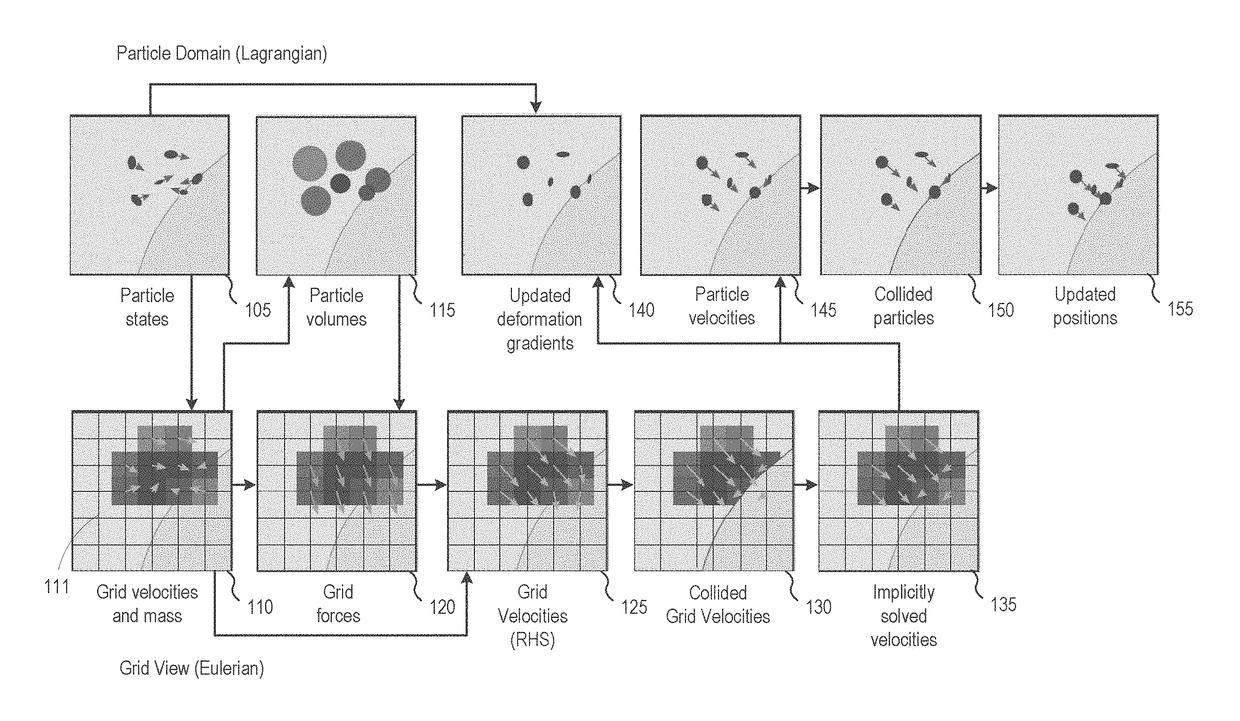

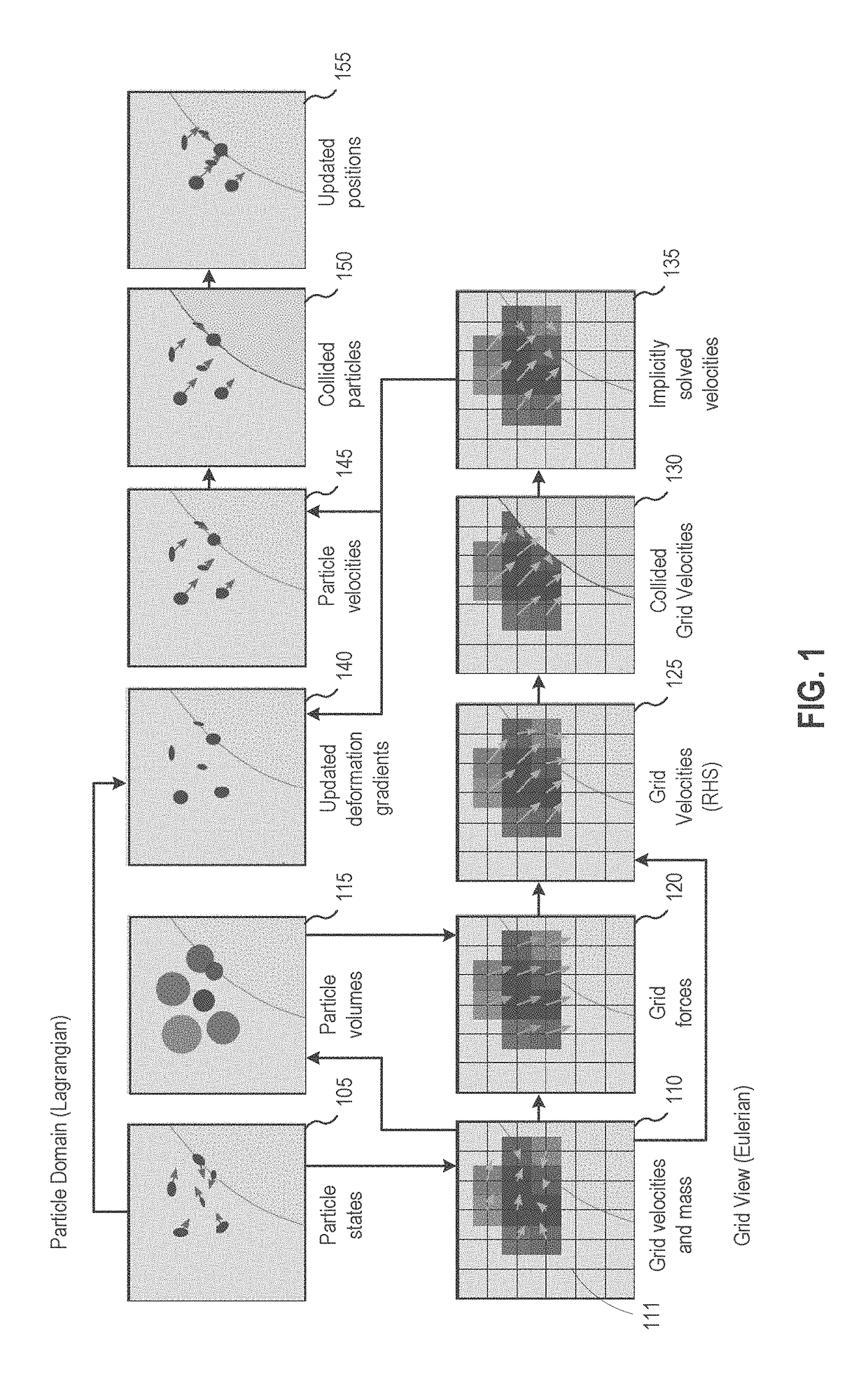

Material point method for simulation of granular materials

The disclosure provides an approach for simulating and rendering granular materials. A simulation application generates video frames depicting a granular material phenomenon using a strain based elasto-plastic constitutive model integrated with a hybrid Eulerian / Lagrangian material point method (MPM). The elasto-plastic constitutive model includes physical equation(s) which dictate forces that affect the granular material during the simulation. In particular, the constitutive model may include user-controllable parameters defining threshold(s) to start plastic deformation, as well as a hardening parameter which controls how fast the granular material packs under compression. The MPM is a procedure in which particles of the granular material and a background grid are coupled, with the grid being used to assist in computing forces dictated by the physical equation(s) of the elasto-plastic constitutive model. In one configuration, the grid may further be rendered with volumetric rendering to generate video frames depicting the granular material.

Owner:DISNEY ENTERPRISES INC

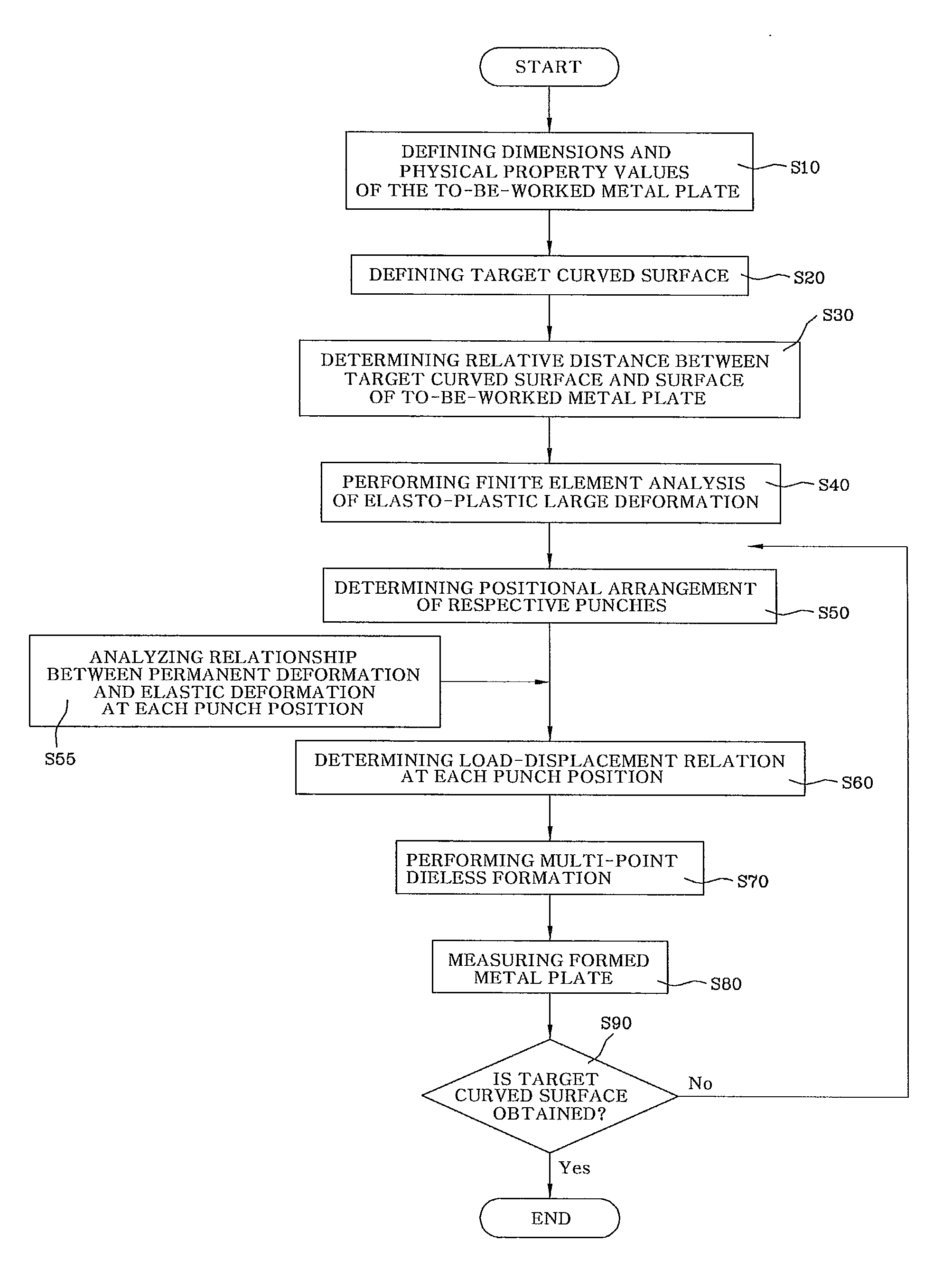

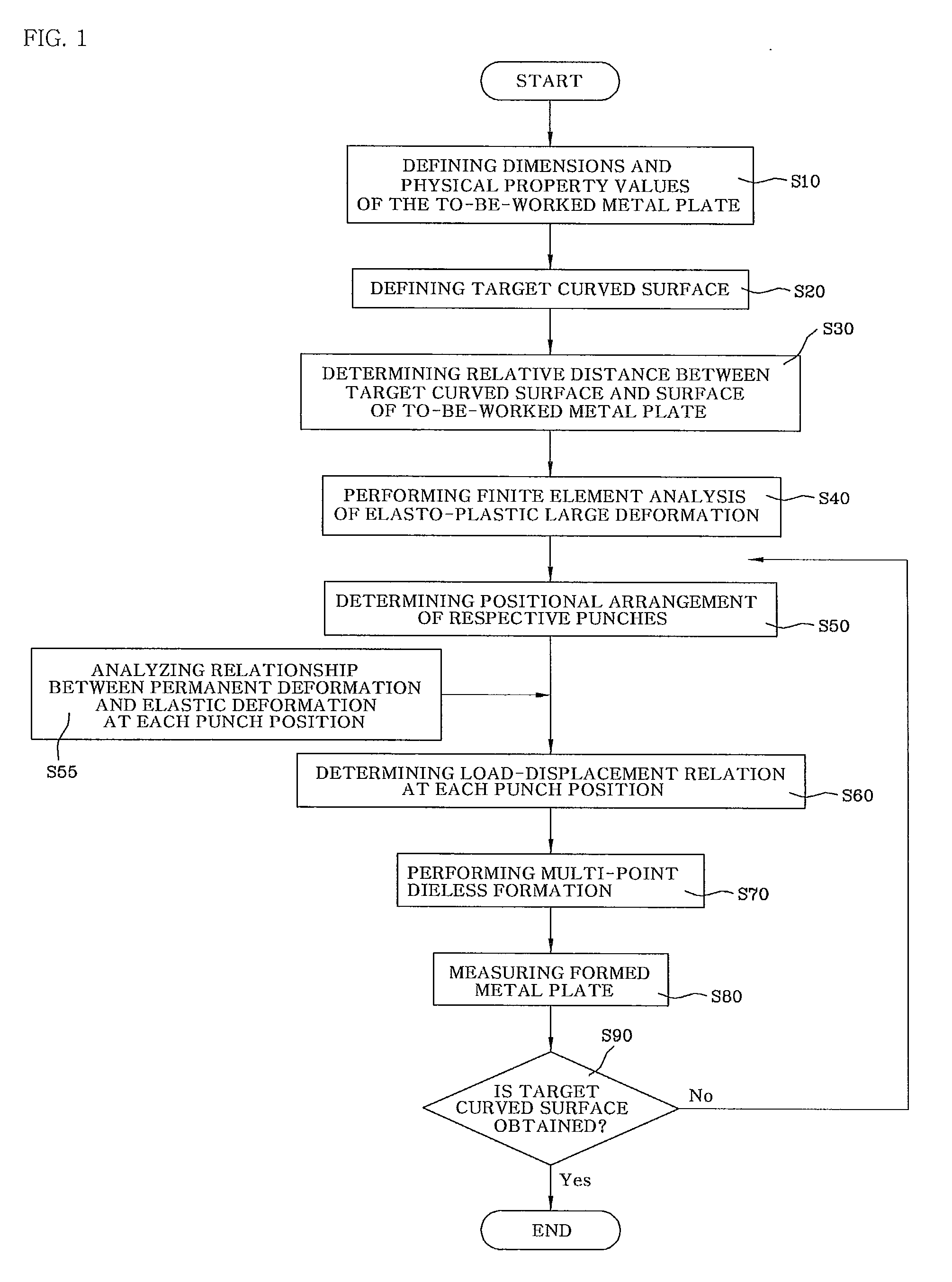

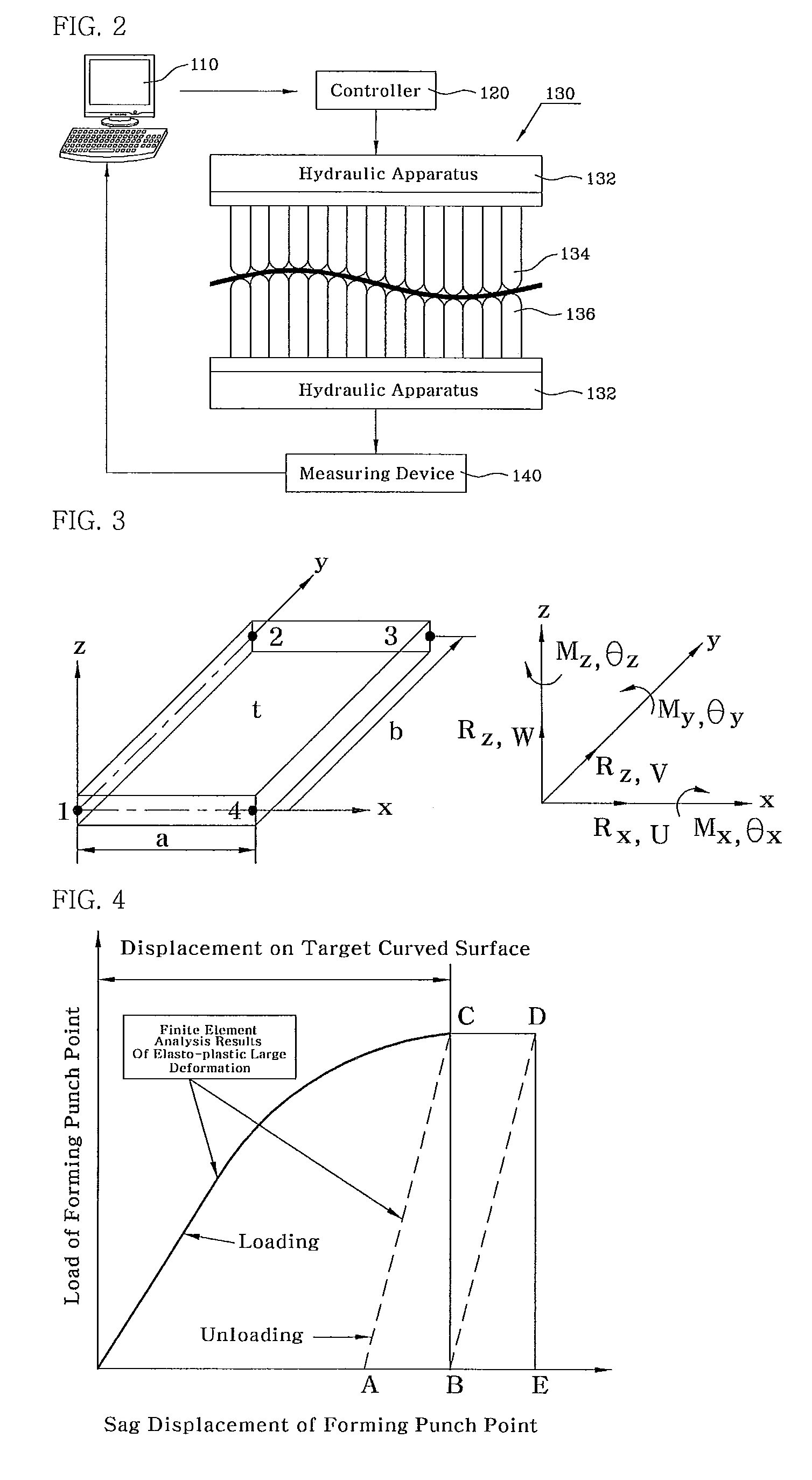

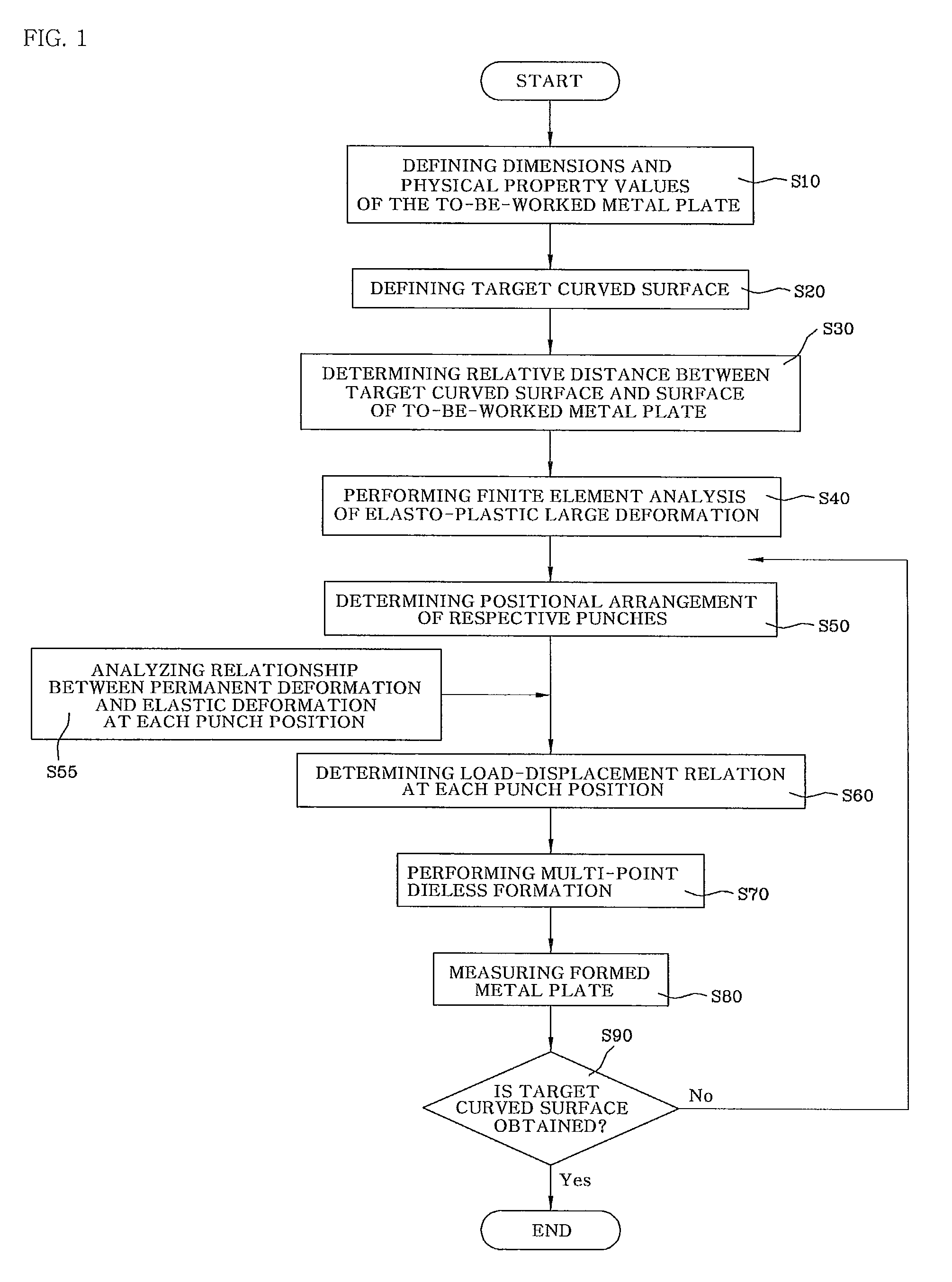

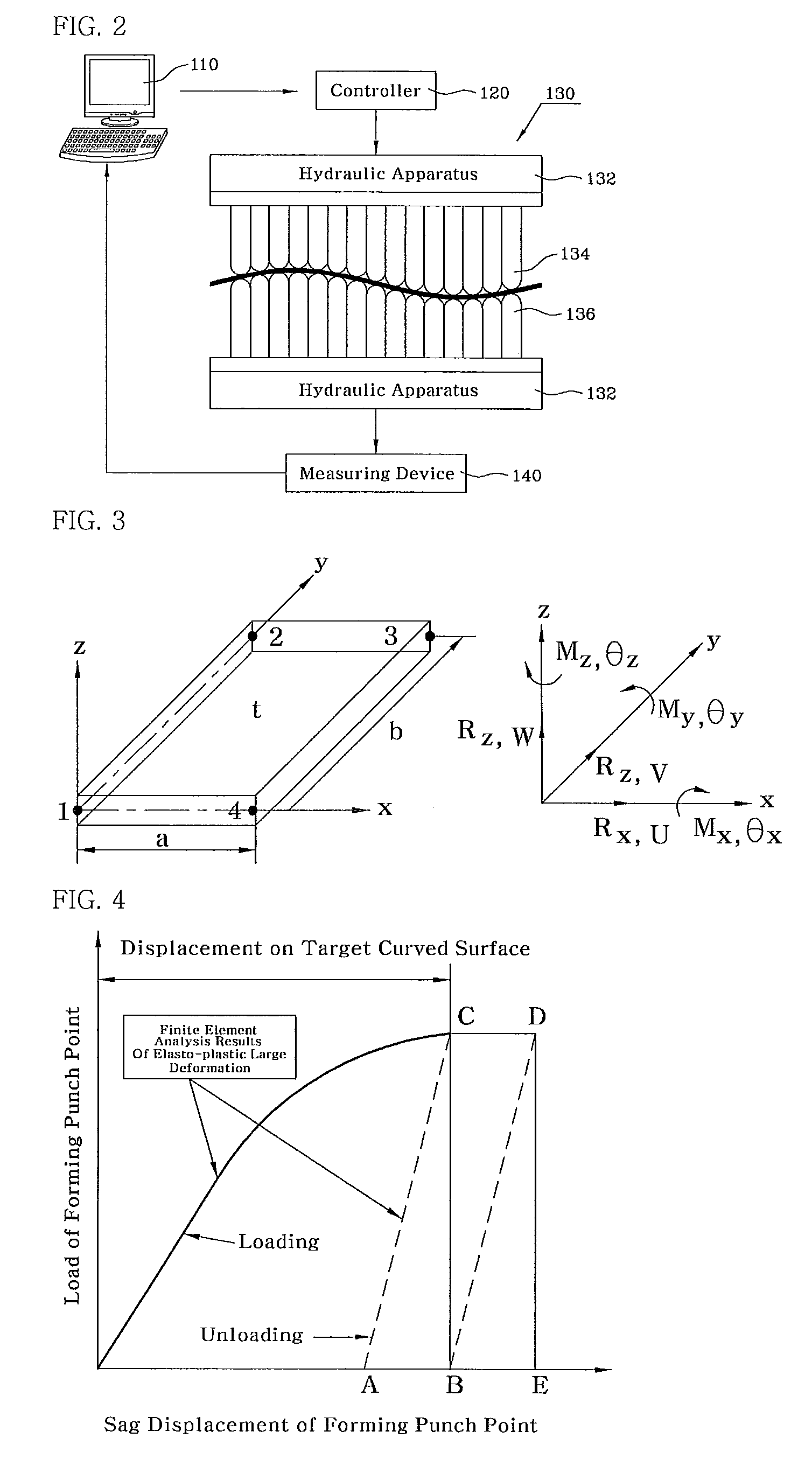

Curved surface forming method of a metal plate

InactiveUS20100030362A1Shorten the timeImprove economyShaping toolsShaping safety devicesNonlinear finite element analysisLarge deformation

Disclosed is a curved surface forming method for a metal plate. Nonlinear finite element analysis of elasto-plastic large deformation is performed on the metal plate. The metal plate to be worked is formed so as to have a three-dimensional target curved surface on the basis of the analysis results using a plurality of forming punches connected to a hydraulic apparatus. The curved surface formation method is very useful when the metal plate is worked for small quantity batch production.

Owner:PAIK JEOM KEE

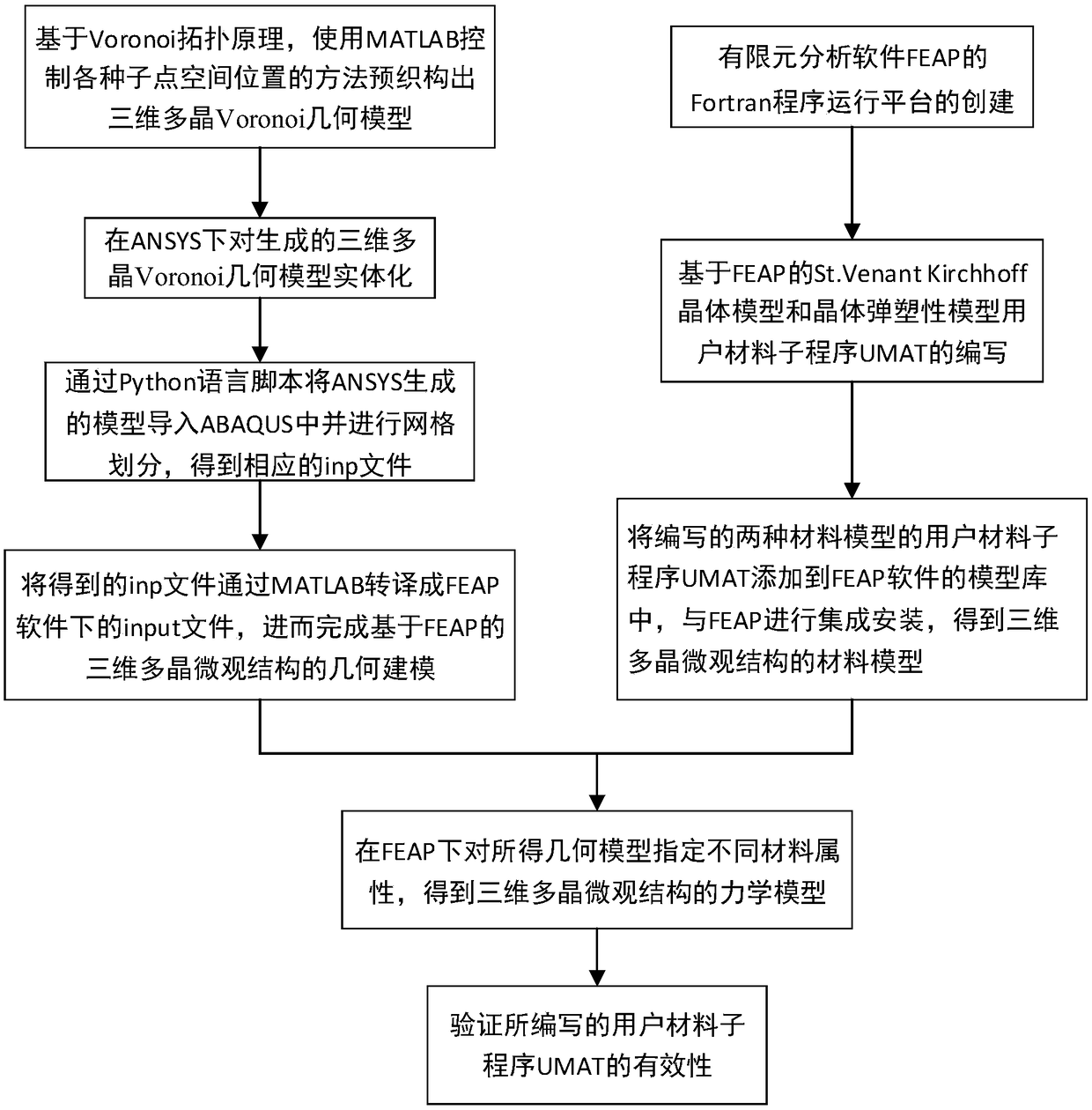

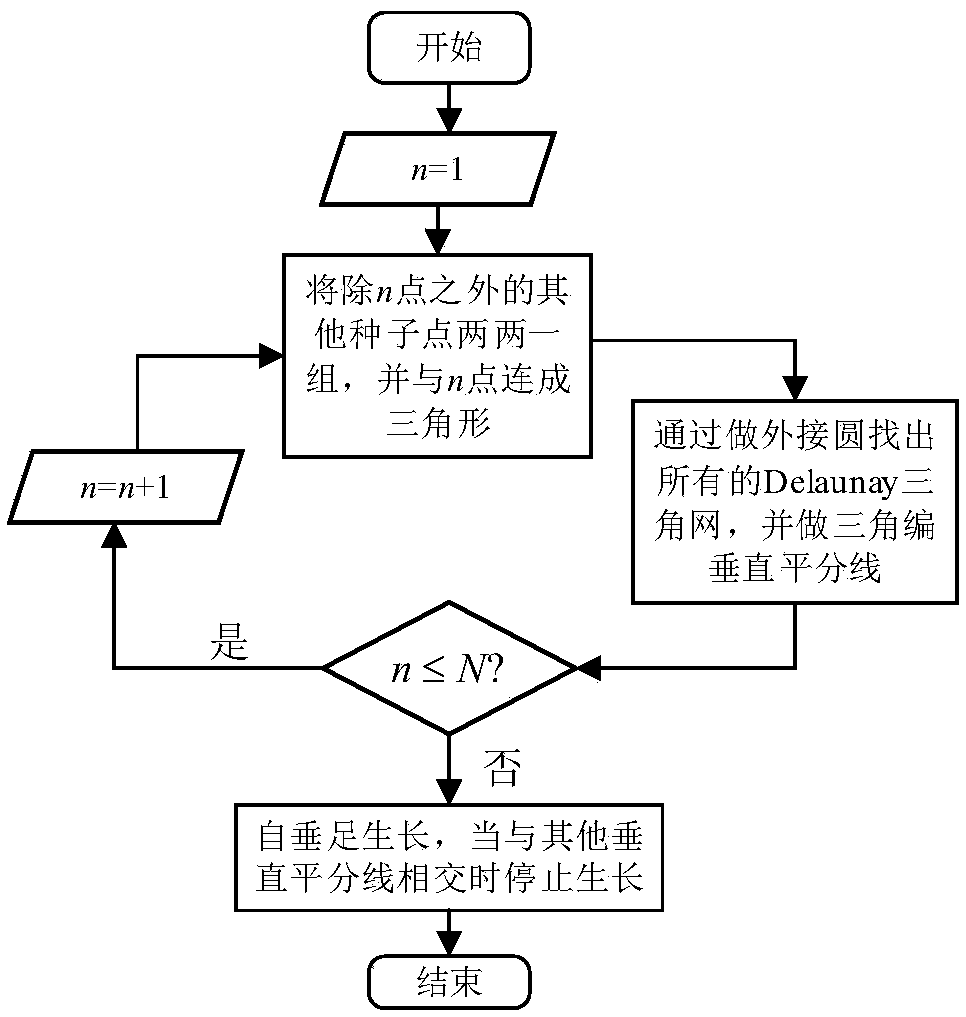

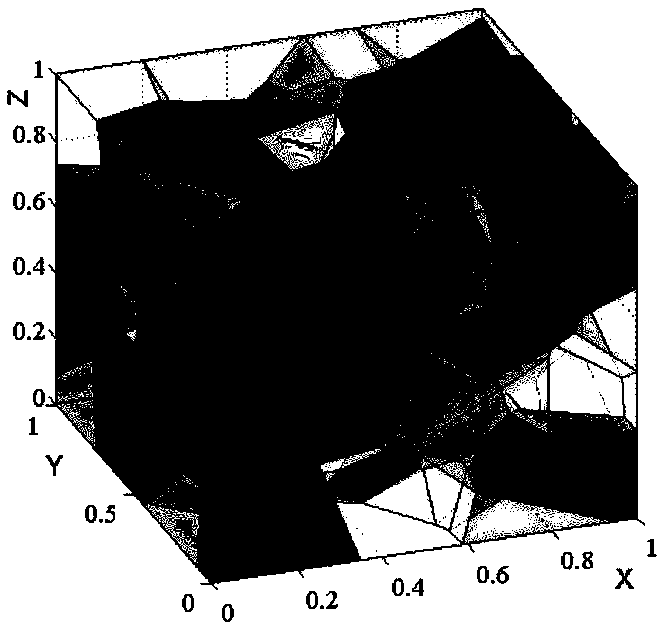

FEAP-based construction method of three-dimensional polycrystalline microstructure material model

ActiveCN109063275AHas engineering practical significanceDesign optimisation/simulationSpecial data processing applicationsMechanical modelsCrystal orientation

The invention discloses a method for constructing a three-dimensional polycrystalline microstructure material model based on FEAP, which comprises the following steps: pre-texturing a three-dimensional polycrystalline Voronoi geometric model; The inp file is translated into input file under the FEAP software, and the 3D polycrystalline microstructure is modeled geometrically. Based on Fortran program running platform, UMAT, the user material subprogram of St. Venant Kirchhoff crystal model and crystal elasto-plastic model, is added to the model library of FEAP software, and is integrated withFEAP to obtain the material model of three-dimensional polycrystalline microstructure. The mechanical model of three-dimensional polycrystalline microstructure is obtained by assigning different crystal orientation to different grains. The validity of UMAT is verified by finite element mechanical simulation. The invention completes the compilation of the user material subprogram UMAT of the two material models and carries out the validity verification, which provides the theoretical basis for the homogenization research of the polycrystalline material.

Owner:XIDIAN UNIV

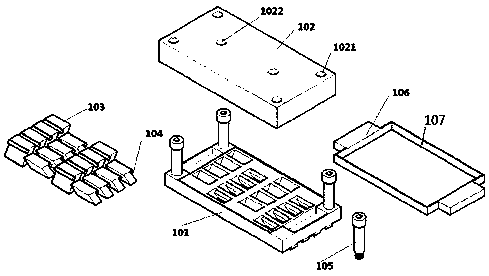

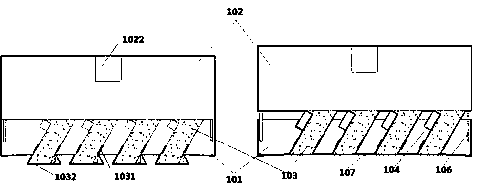

Ceramic tile mold, expanded ceramic tile mold support and ceramic tile formed through pressing of mold

The invention discloses a ceramic tile mold, an expanded ceramic tile mold support and a ceramic tile formed through pressing of the mold. The technical improvement is achieved on the basis of the public technology of a manufacturing equipment and manufacturing method of a ceramic tile back face cross dovetail groove disclosed in the patent CN108466355A, the problems existing in the technology aresolved, an exhaust system is additionally mounted according to the characteristics of the improved mold, the automatic production process is simplified, the production efficiency is improved, and theproduction cost is reduced. Bevel edge grain teeth of a bevel edge grain part of the public technology are optimized, each bevel edge grain tooth is made into an independent bevel edge forming part,upper teeth on a bevel edge grain part in the original public technology are removed, and the elastic force of springback PU elastic rubber or springs of the bevel edge forming parts is used for replacing the retraction function of the upper teeth. Furthermore, the expanded ceramic tile mold support is specifically provided. The ceramic tile mold and ceramic tile molds with the similar function can be made into mold units, the mold units are assembled on a combined mold, the requirements of ceramic tile molds of various different sizes can be met, the maintenance process can be simplified, themold units needing to the maintained can be directly replaced, and other mold units are not influenced.

Owner:陈锐

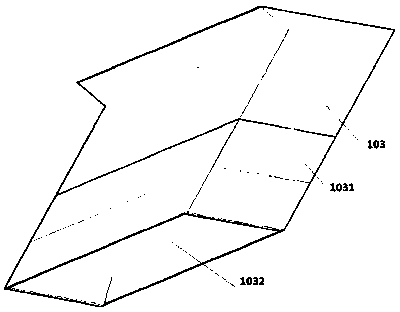

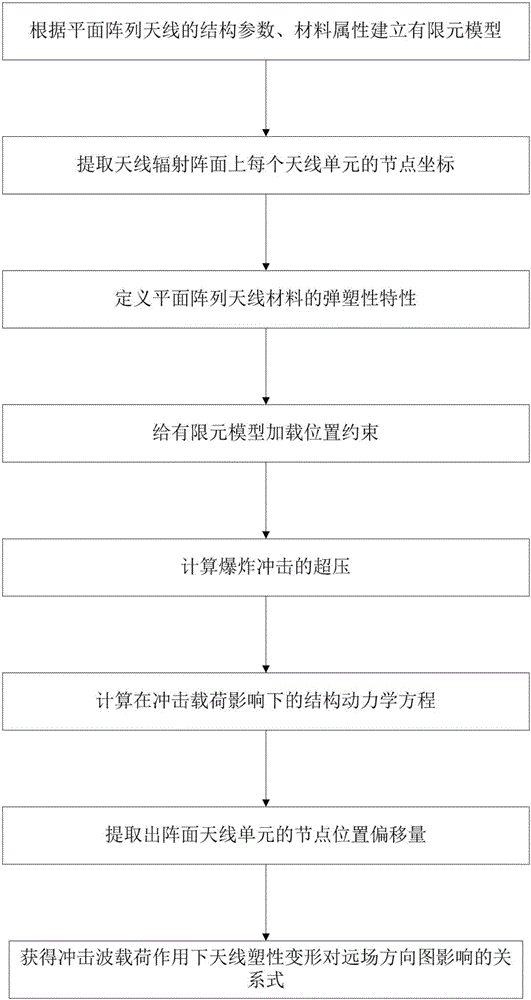

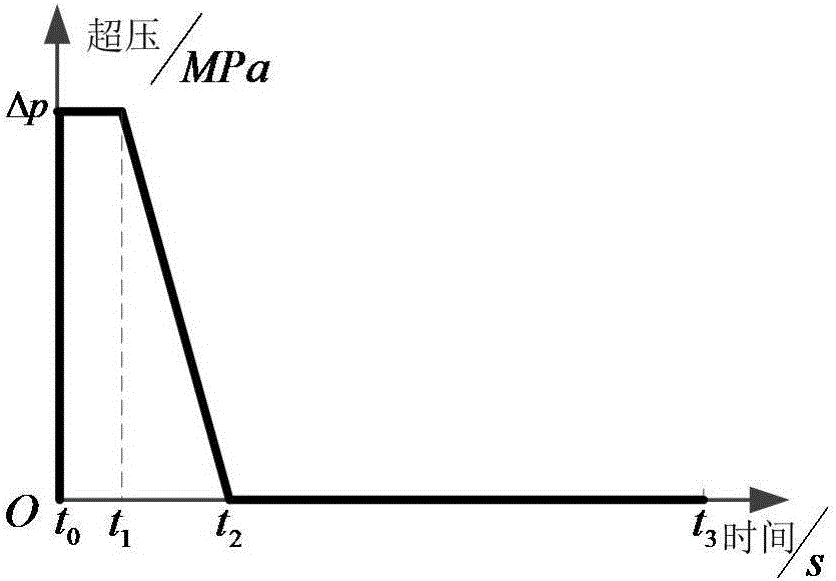

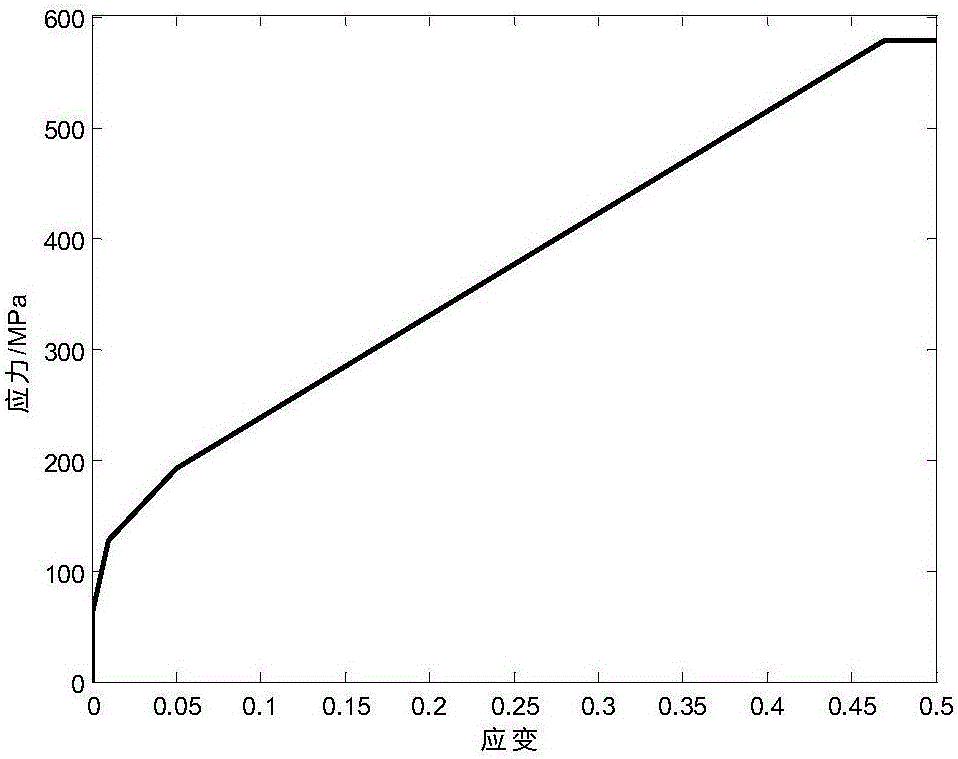

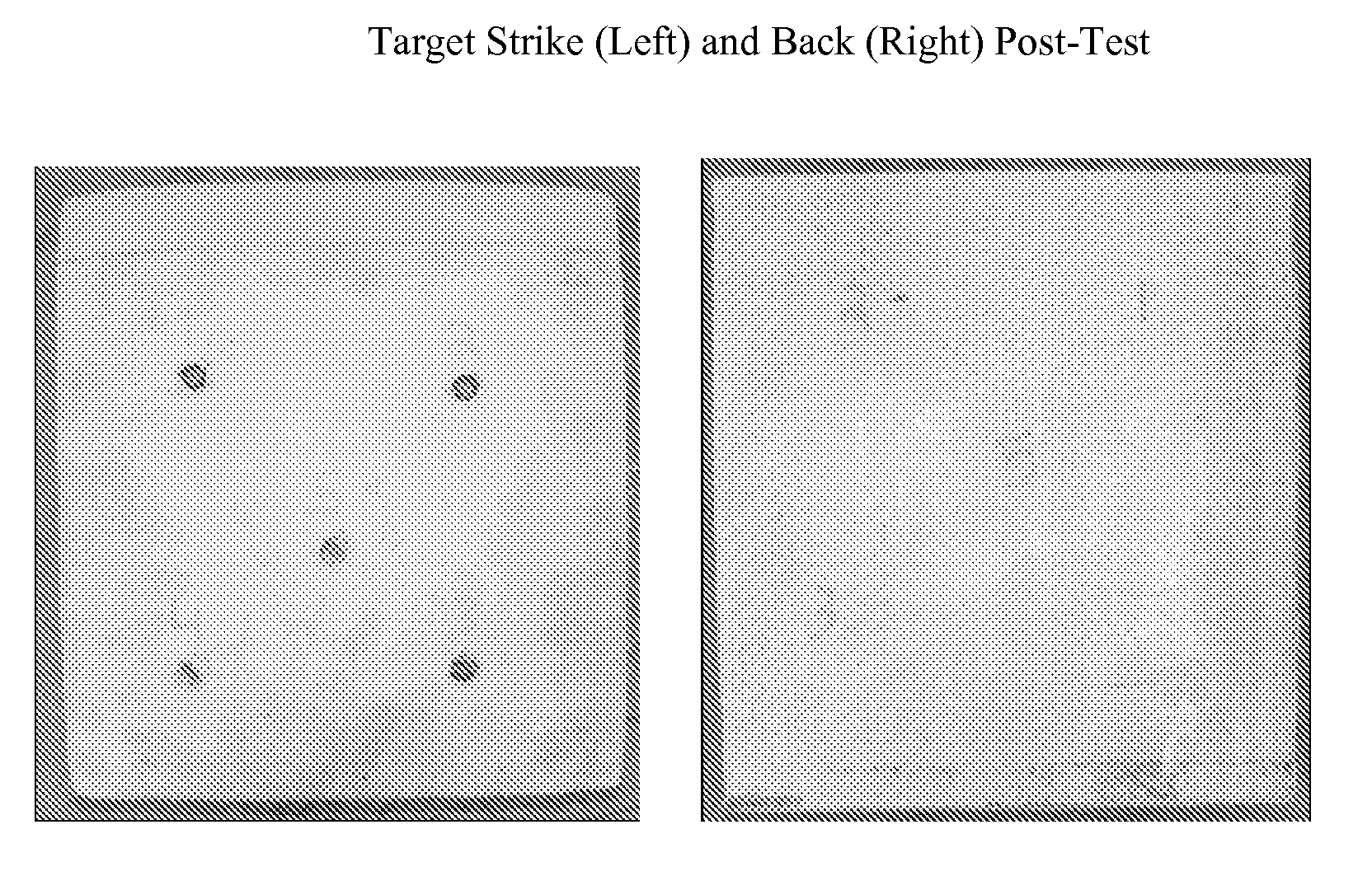

Electrical performance prediction method of planar array antenna under shock wave load

ActiveCN106202657AAntenna Electrical Performance PredictionPredictive performanceDesign optimisation/simulationSpecial data processing applicationsShock waveStructural dynamics

The invention relates to an electrical performance prediction method of a planar array antenna under shock wave load, including: (1) establishing a finite element mode according to the structural parameters and material properties of the planar array antenna; (2) extracting the node coordinates rn of each antenna element on the antenna radiation front; (3) defining the elasto-plastic properties of the planar array antenna; (4) loading the position constraint to the finite element model; (5) calculating the overpressure [Delta]p of the explosion shock and defining the load time history curve; (6) transforming the load time history curve into the impact load F(t) and applying the load to the finite element model, and obtaining the structural dynamic equation under the impact load; (7) solving the kinetic equation to obtain the plastic deformation of the antenna radiation surface under the shock wave load of the planar array antenna, and deriving the node position offset [Delta]rn of the front antenna element; (8) obtaining the relation of effect of the antenna plastic deformation on the far field pattern under the shock wave load.

Owner:JIANGSU LIANHAI COMM

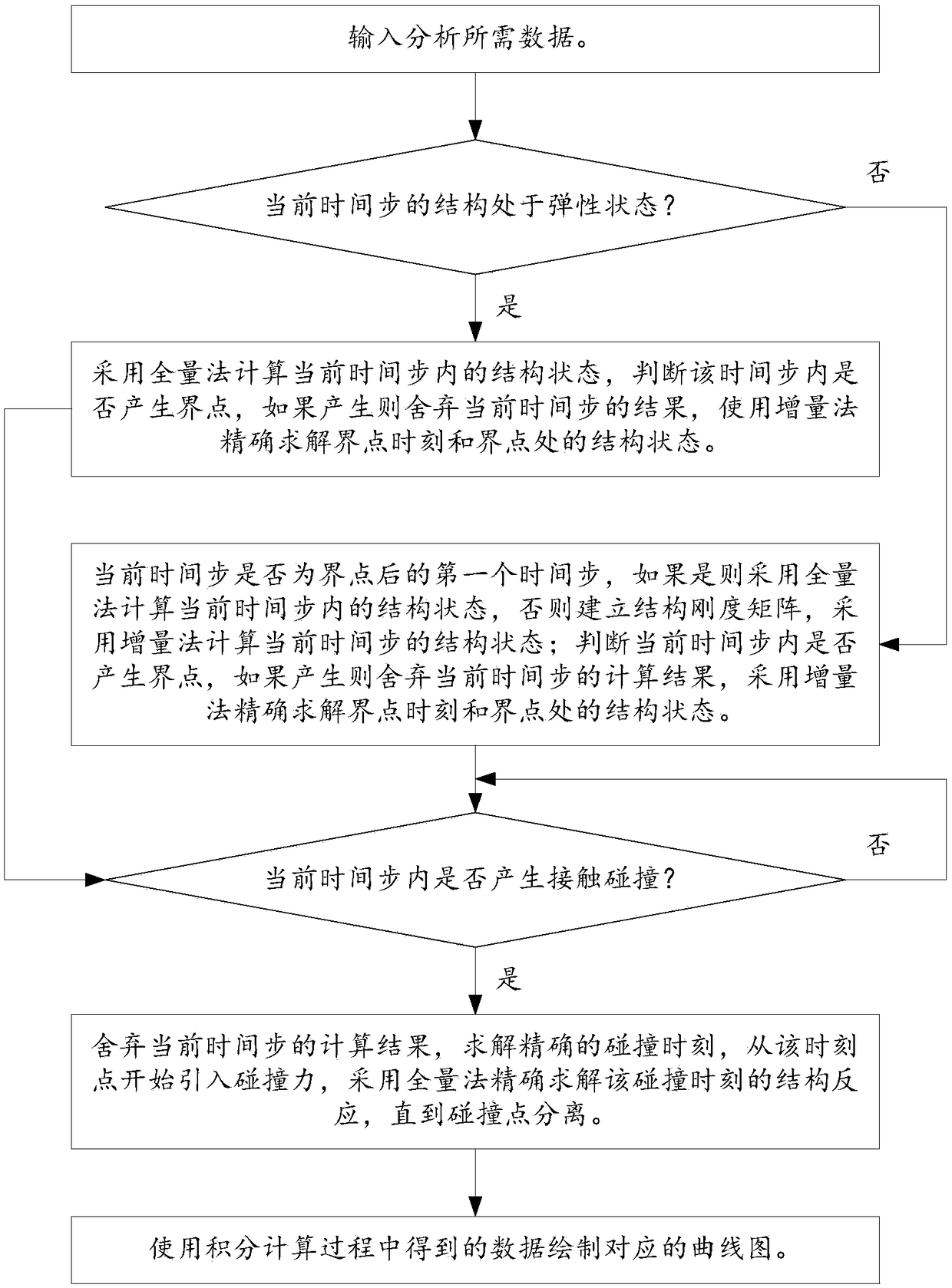

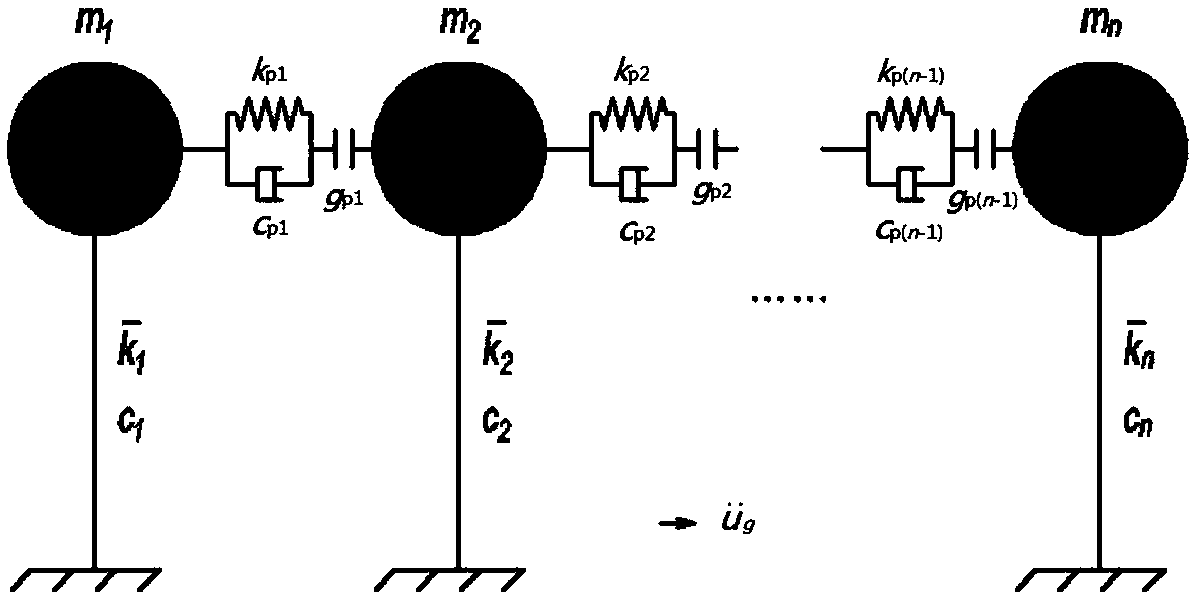

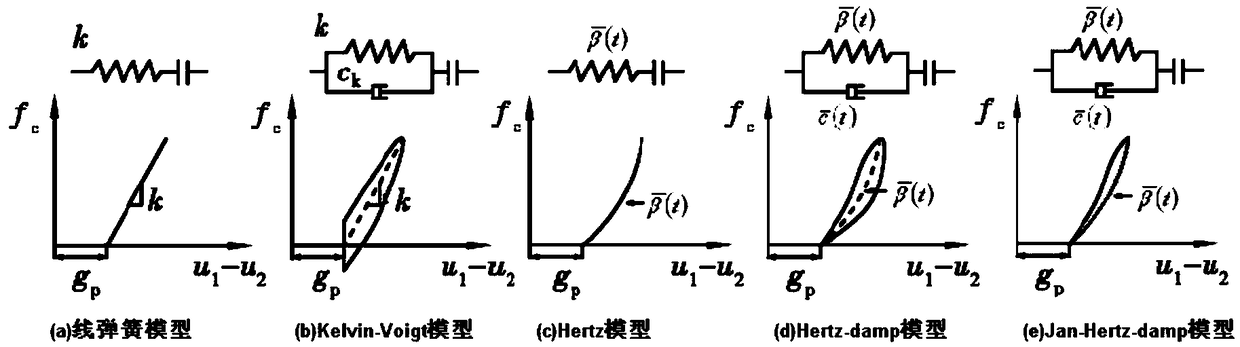

A seismic impact response analysis method for engineering structures

ActiveCN109145386AImprove computing efficiencySolve efficiency problemsSustainable transportationDesign optimisation/simulationSeparated stateDynamic equation

The invention discloses an earthquake impact response analysis method for engineering structures, which relates to the technical field of civil engineering, in particular, the method comprises the following steps: when a structure is in an elastic state, a total equation precise integration formula is adopted for recursive solution; when a plastic state is in an incremental equation precise integration formula for recursive solution; when a structure is in an elastic state, the total equation precise integration formula is adopted for recursive solution; when the elasto-plastic state is transformed, the exact moment of the transition is solved, and the first time step after the transition is solved by the total equation iteration; for the current time step, whether the structure produces contact collision or not is judged; if the collision occurs, the accurate collision time is solved, and the collision force is introduced from this time point, and the recursive calculation of the dynamic equation in the collision stage is carried out until the collision is over; the integral step size of the structure in the collision state is smaller than that in the separation state, which further improves the computational efficiency. Compared with the traditional implicit or explicit integration method, the method is unconditionally stable, computational efficiency is high, accuracy is close to the analytical solution, and the seismic collision process can be accurately simulated.

Owner:重庆零拾工程科技有限公司

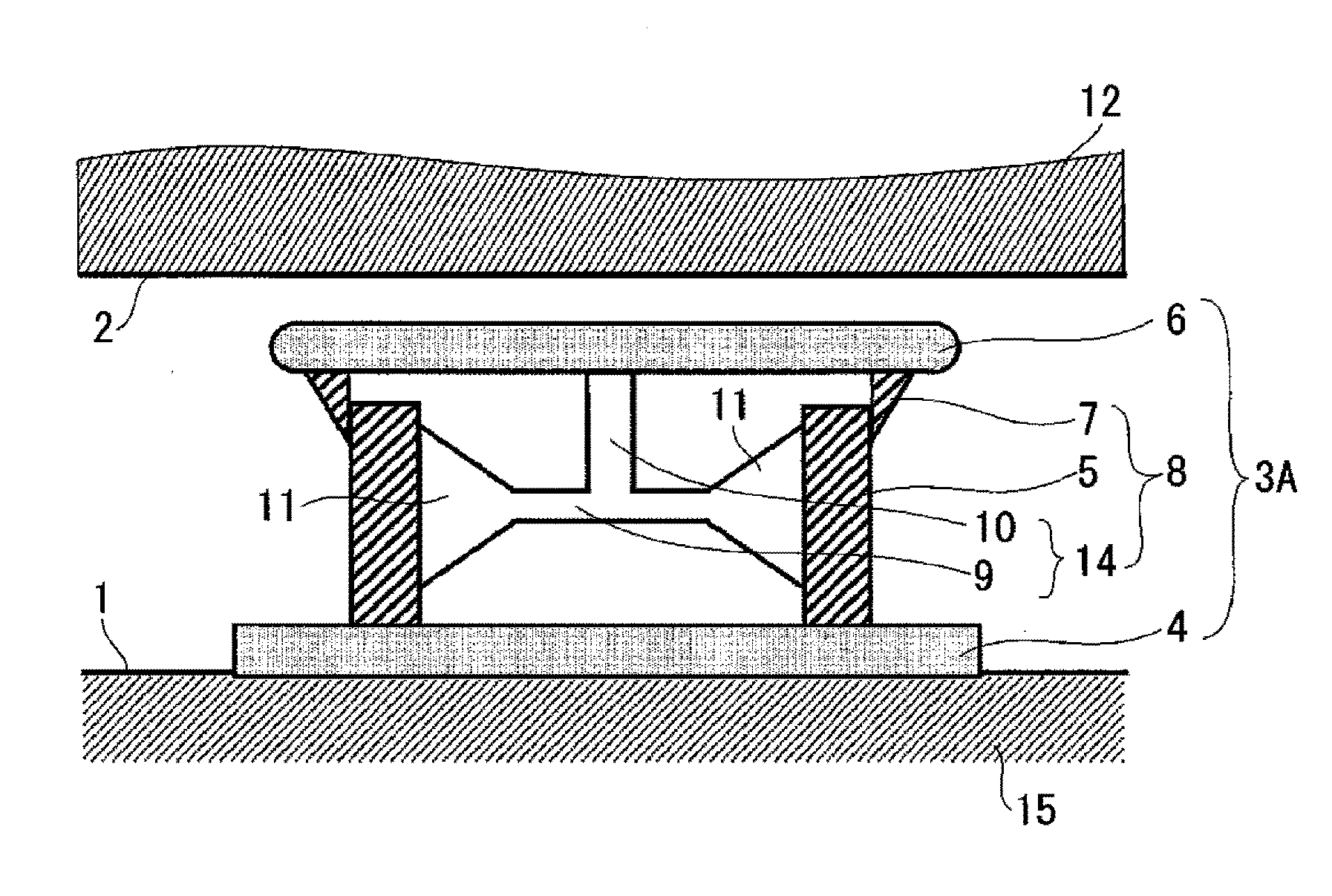

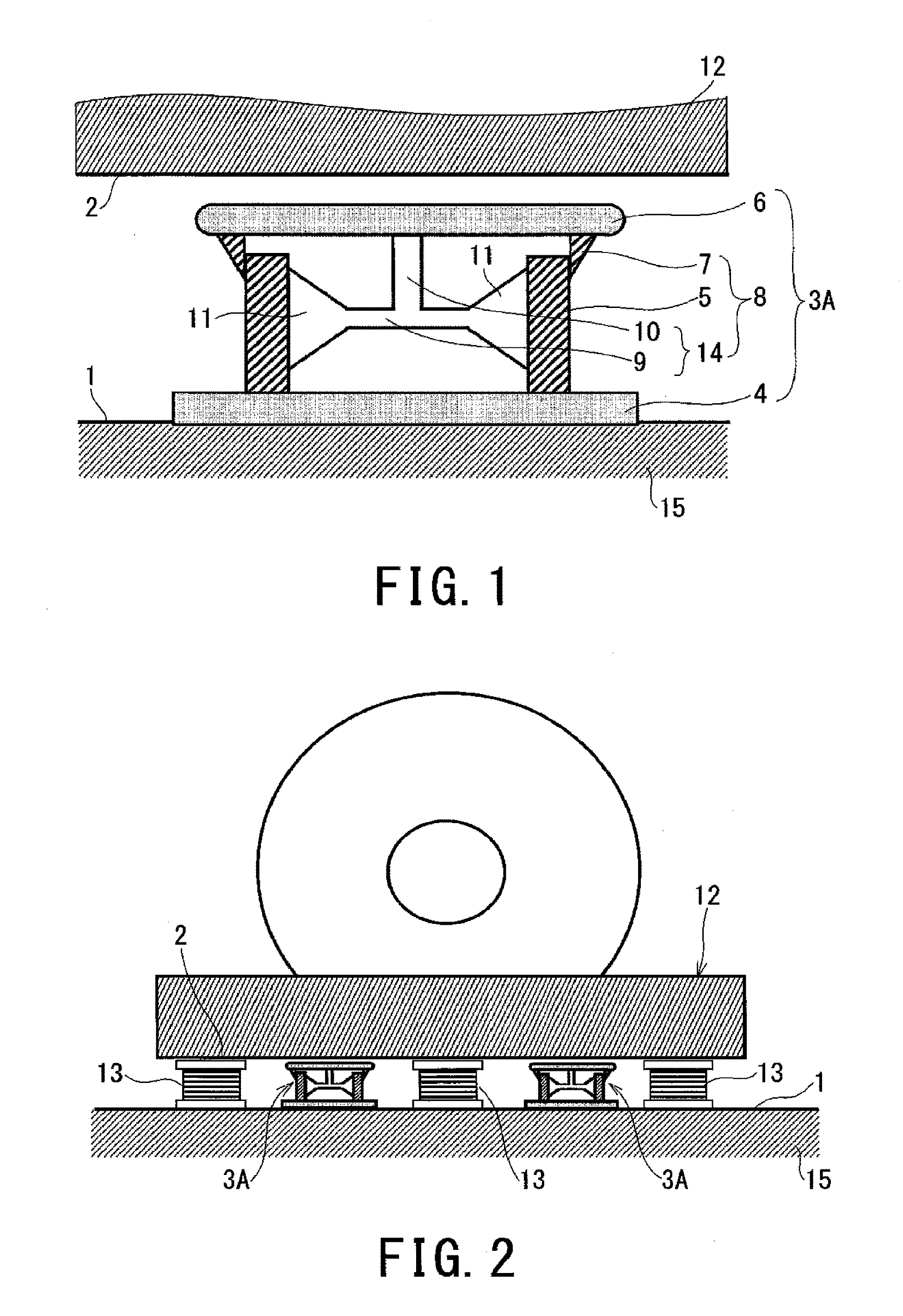

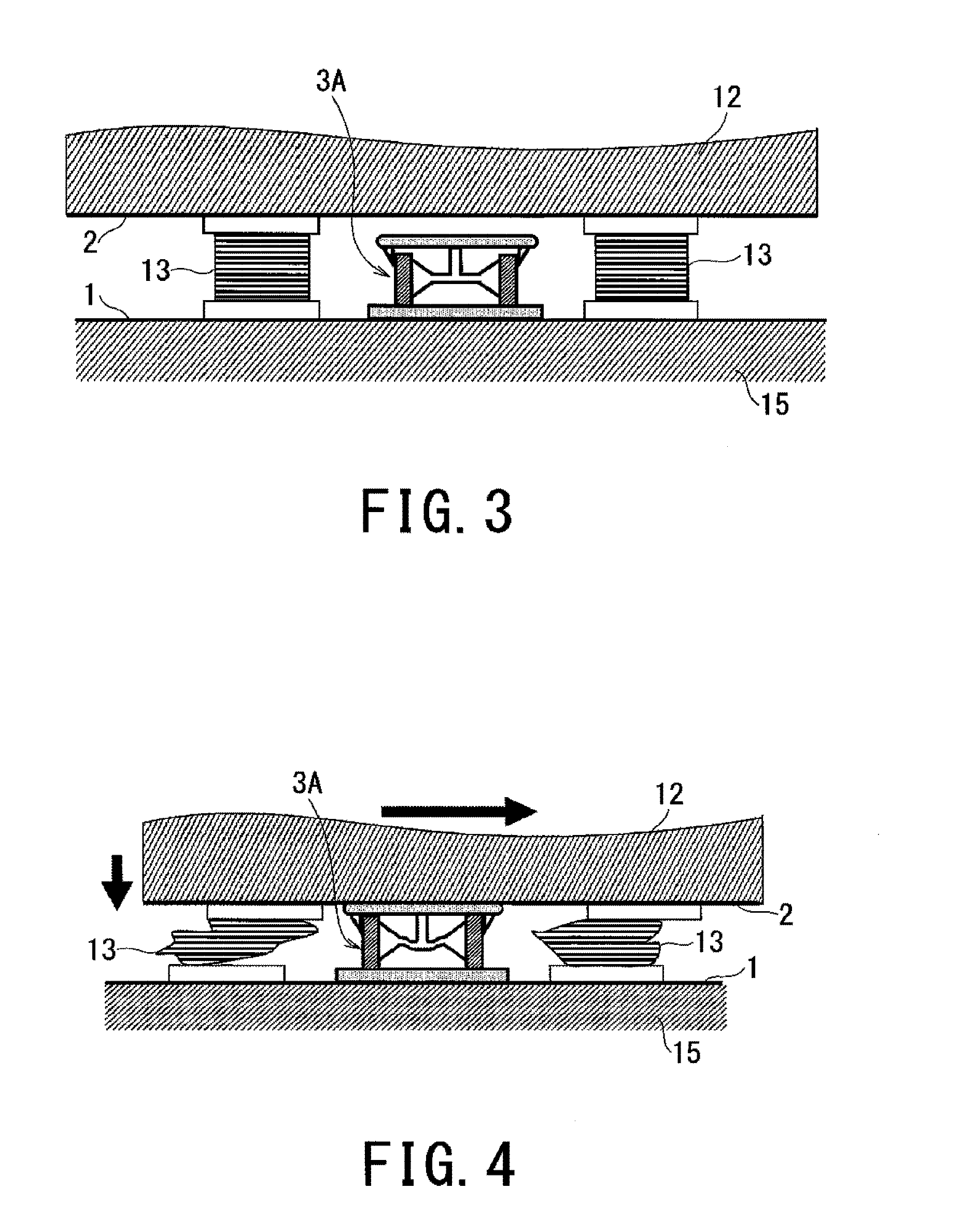

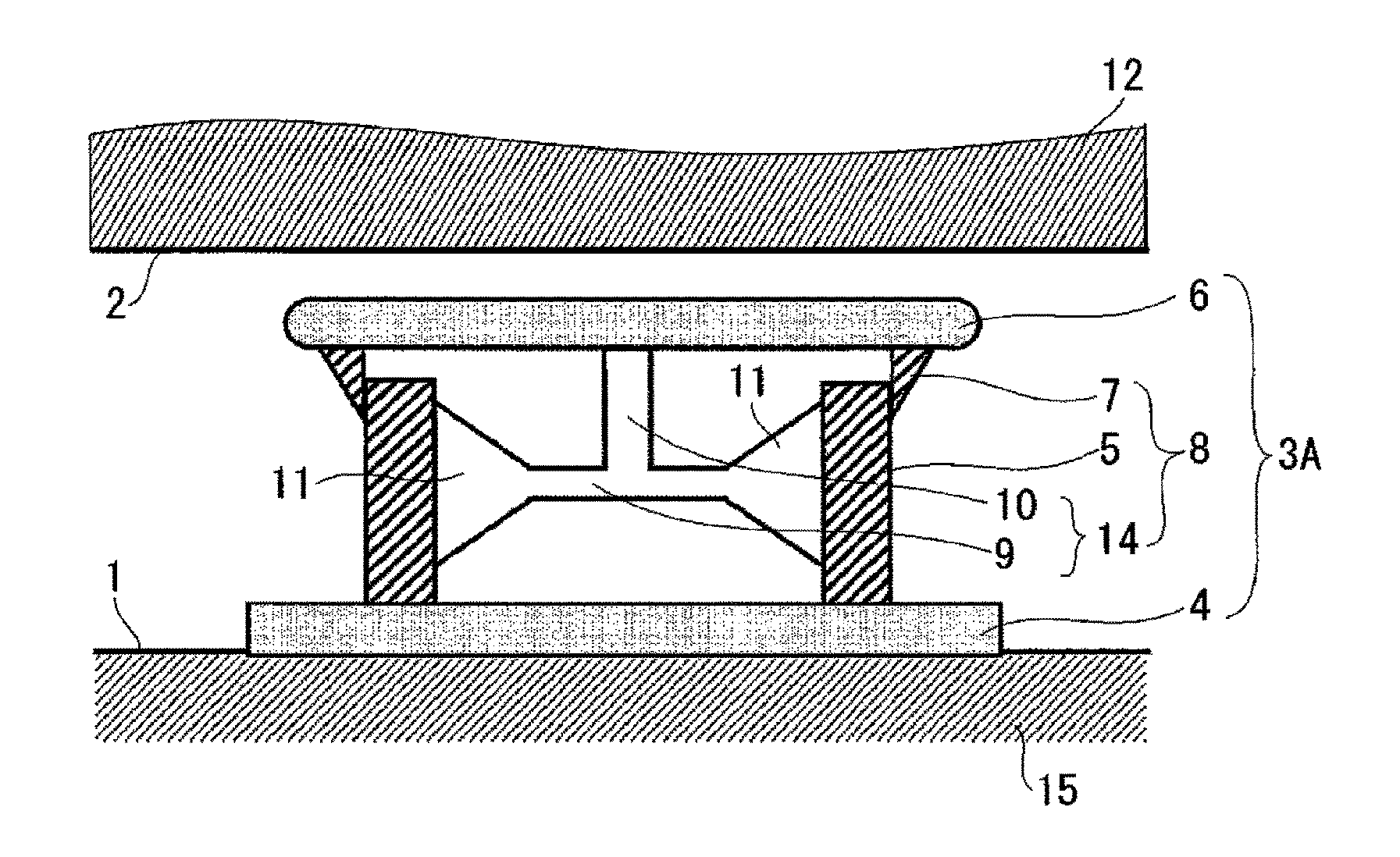

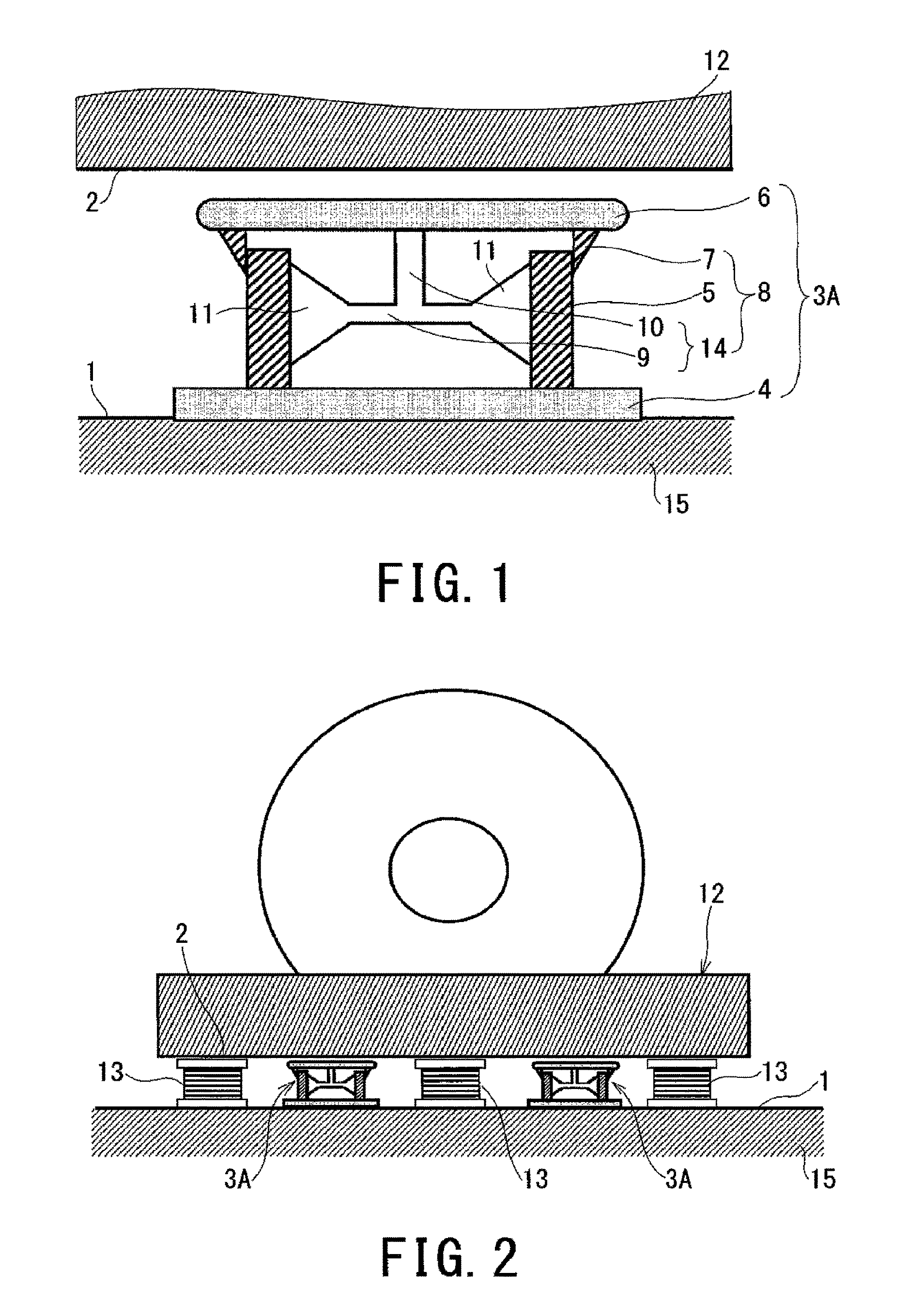

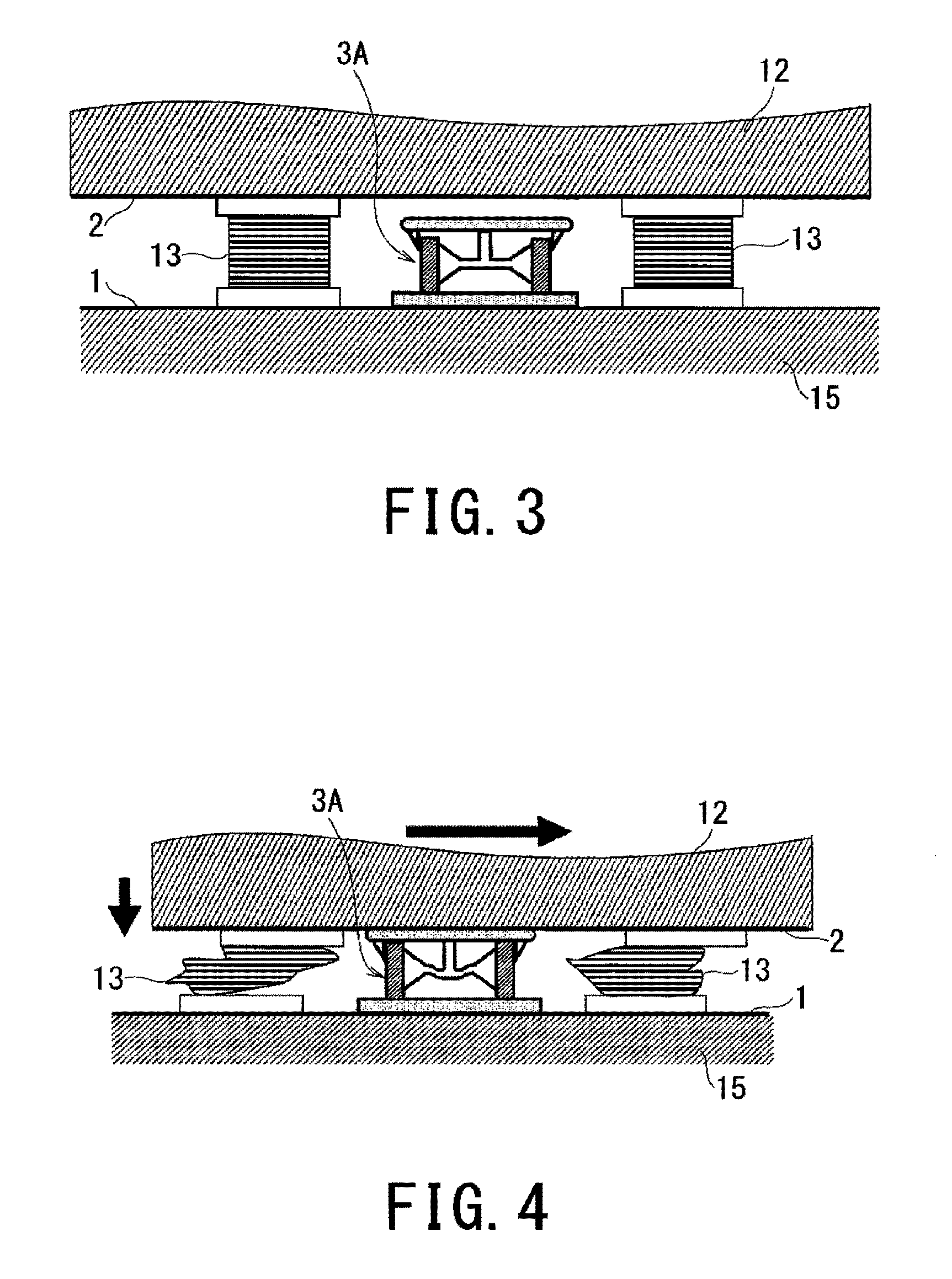

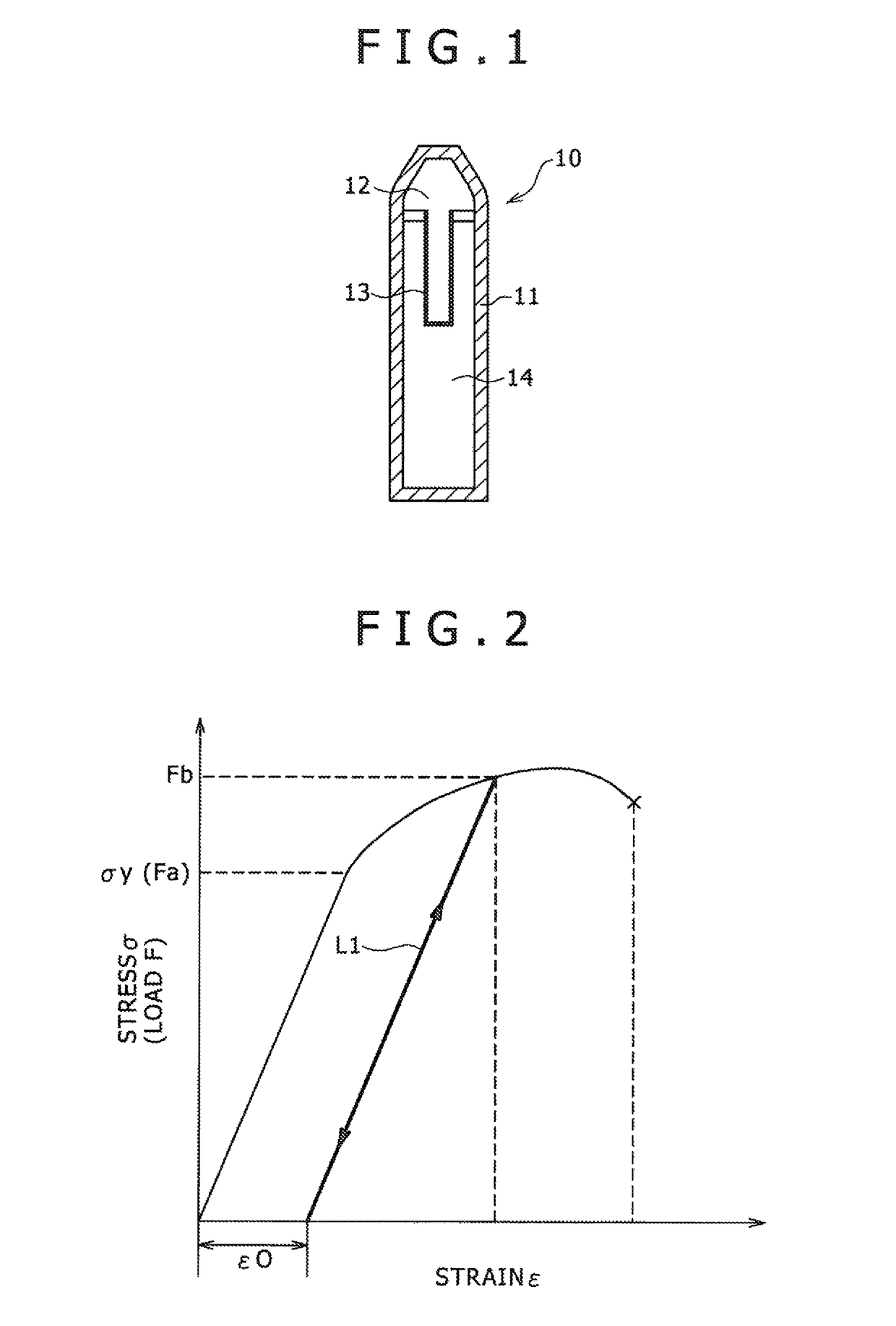

Seismic isolation device and seismic isolation method

ActiveUS20160115703A1Reduce shockRule out the possibilityBuilding repairsProtective buildings/sheltersEngineeringSeismic isolation

A seismic isolation apparatus is provided between a structure and a foundation floor, and the seismic isolation apparatus includes: a support plate that is provided so as to face the structure at a predetermined interval; a base plate that is fixed to the foundation floor; and an elasto-plastic damper that is provided between the support plate and the base plate to be fixed to the support plate and the base plate, and then the elasto-plastic damper includes an inner cylinder inside which an elasto-plastic member is provided and an outer cylinder, and the inner cylinder and the outer cylinder are configured to mutually slide in axis direction thereof.

Owner:KK TOSHIBA

Elasto-plastic well cementing cement slurry and preparation method thereof

The invention relates to an elasto-plastic well cementing cement slurry and a preparation method thereof, which belongs to the field of gas well cementing. The elasto-plastic well cementing cement slurry comprises the following components in parts by weight: 100 parts of cement, 0-40 parts of a high-temperature stabilizing agent, 0-200 parts of a density adjuster, 4-10 parts of a filtrate loss reducer, 0-3 parts of a dispersing agent, 0-2.5 parts of a retarder, 35-110 parts of water, 0.2-0.5 part of a defoaming agent, 3-12 parts of a plasticizer, and 5-8 parts of a nano filler. The elasto-plastic well cementing cement slurry can improve the bending resisting strength and the impact resisting strength of the cement stone and reduce the elastic modulus of the cement stone. Under high temperature and high pressure, the brittle deformation of the elasto-plastic well cementing cement slurry is converted into the plastic deformation, thus the later exploitation is guaranteed, and the service life of the oil-gas well is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

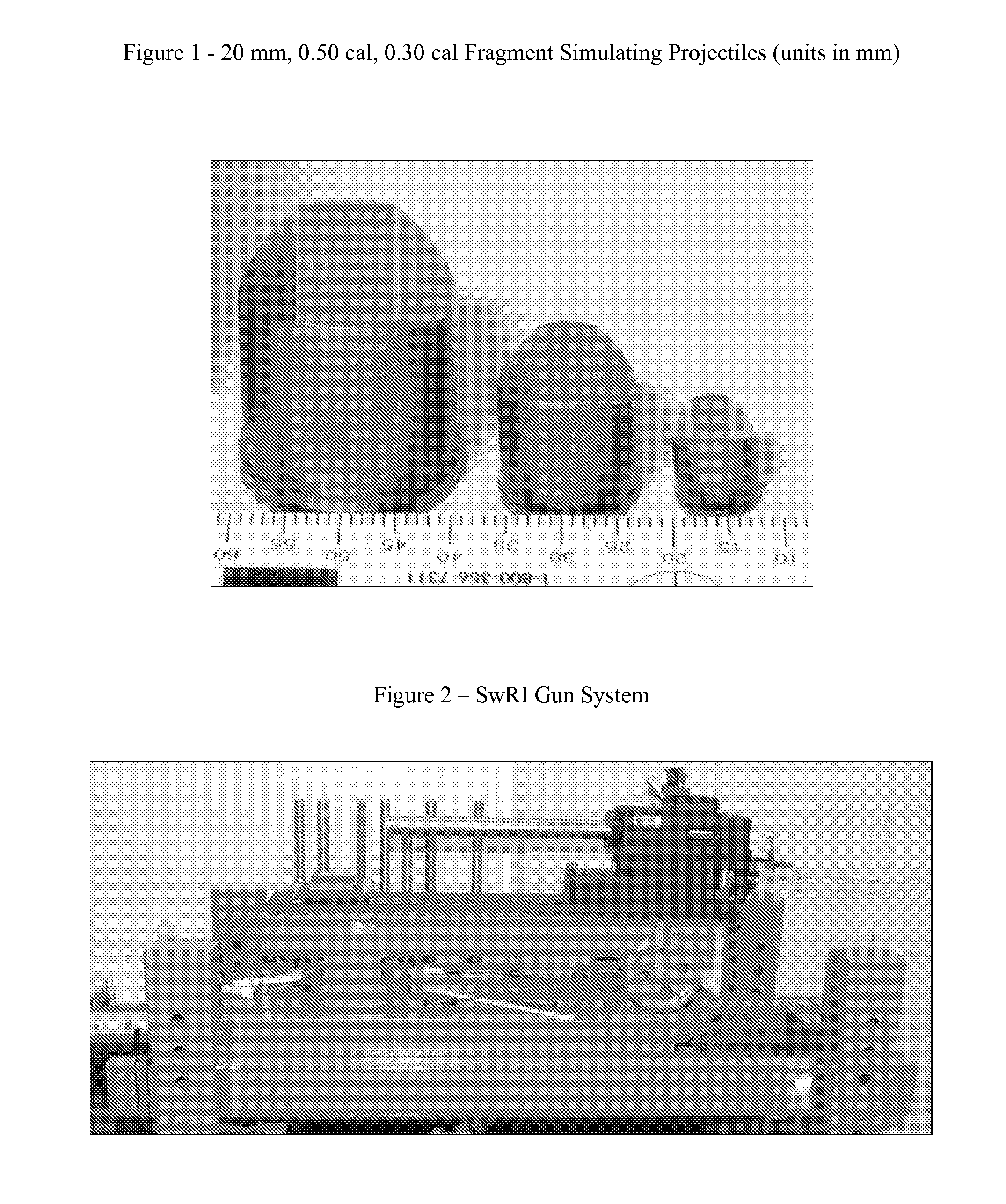

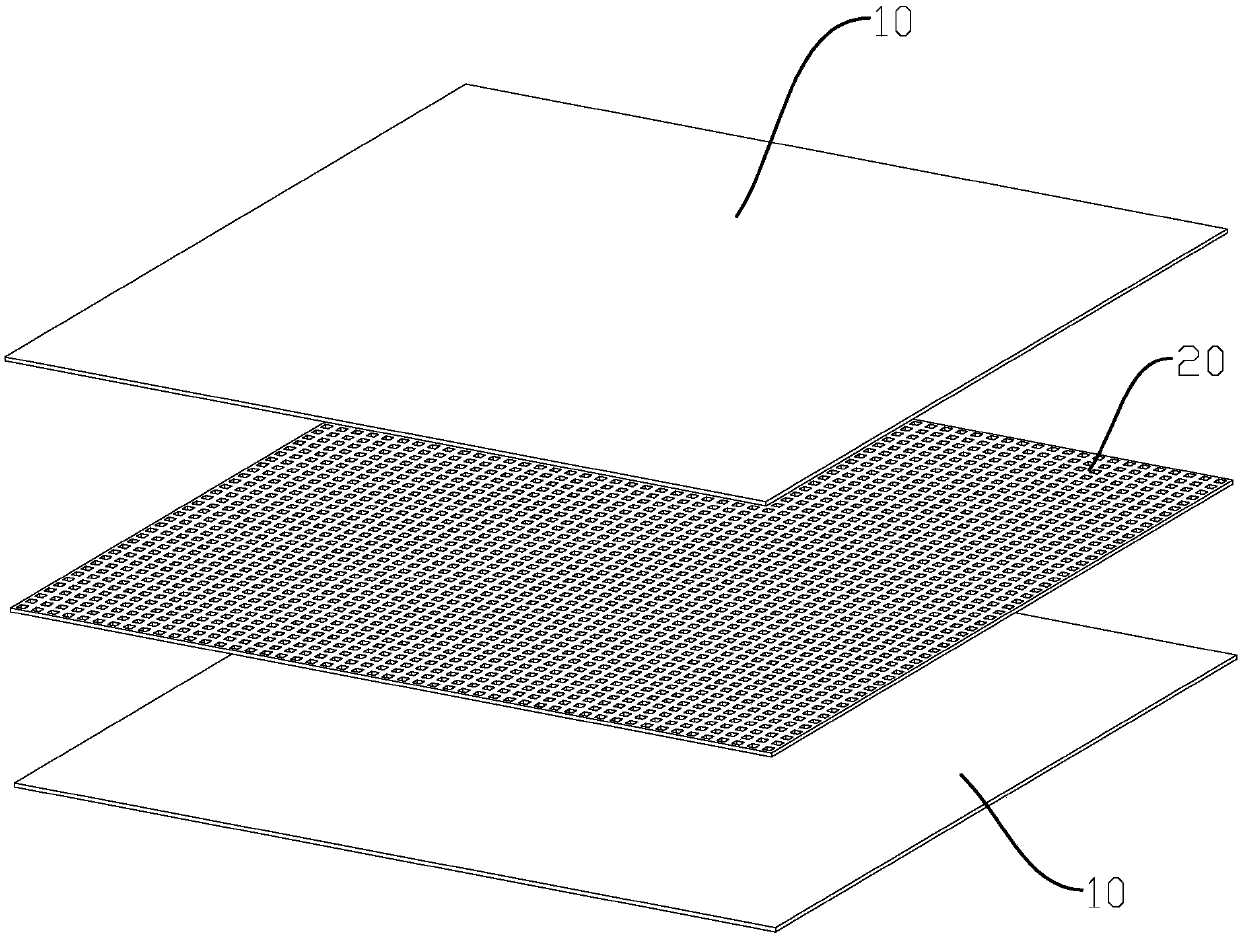

Products and methods for ballistic damage mitigation and blast damage suppression

This invention is directed to energy absorbing or dissipating composite materials used to reduce structural damage from explosive blast energy and ballistic projectiles, either separately or in combination, and to methods of employing such materials. More particularly, this invention is directed to a blast damage suppression and / or ballistic shielding material comprising at least three independent layers; a layer comprising fiber based panels; a spray foam coating material and a coating layer comprising an elasto-plastic material.

Owner:HONEYWELL INT INC

Curved surface forming method of a metal plate

InactiveUS8046098B2Stable quality levelCurved surface forming time of the metal plate is remarkably reducedShaping toolsShaping safety devicesNonlinear finite element analysisLarge deformation

Owner:PAIK JEOM KEE

Pattern production and recovery by transformation

A transformative periodic structure includes a plurality of elastomeric or elasto-plastic periodic solids that experiences a transformation in the structural configuration upon application of a critical macroscopic stress or strain. The transformation alters the geometric pattern changing the spacing and the shape of the features within the transformative periodic structure. For the case of elastomeric periodic structures upon removal of the critical macroscopic stress or strain, the transformative periodic solids are recovered to their original form. For the case of elasto-plastic periodic structures upon removal of the critical macroscopic stress or strain, the new pattern is retained. Polymeric periodic solids can be recovered to their original form by heating or plasticizing.

Owner:MASSACHUSETTS INST OF TECH

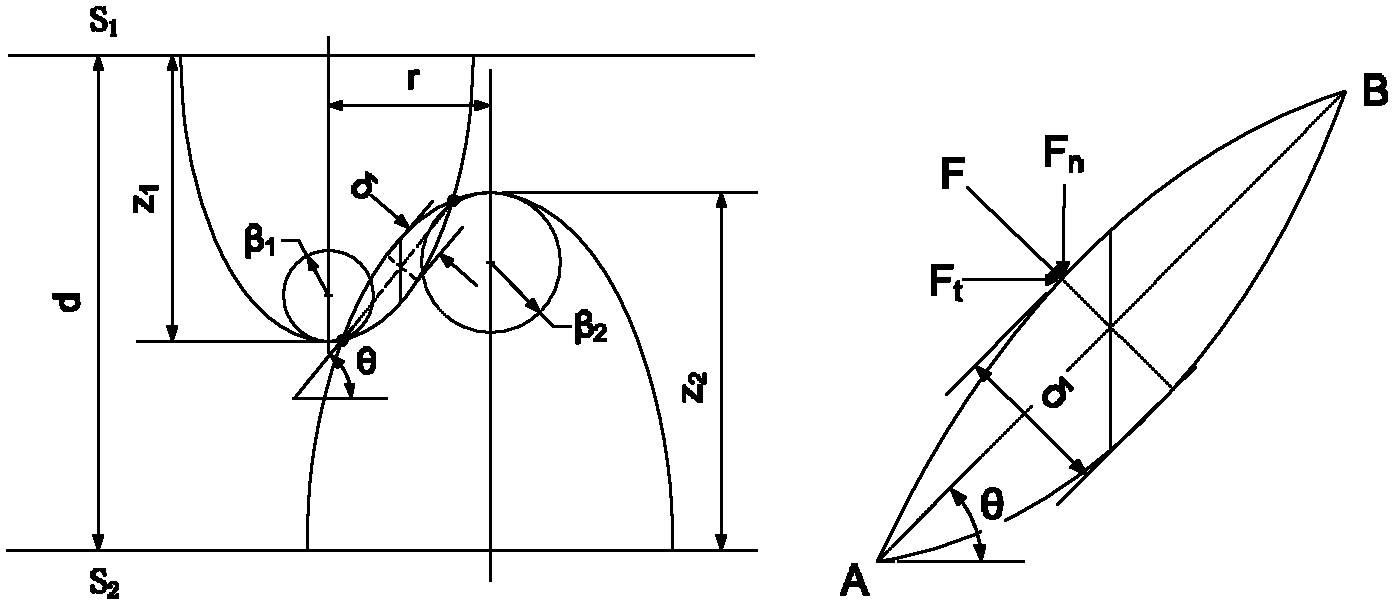

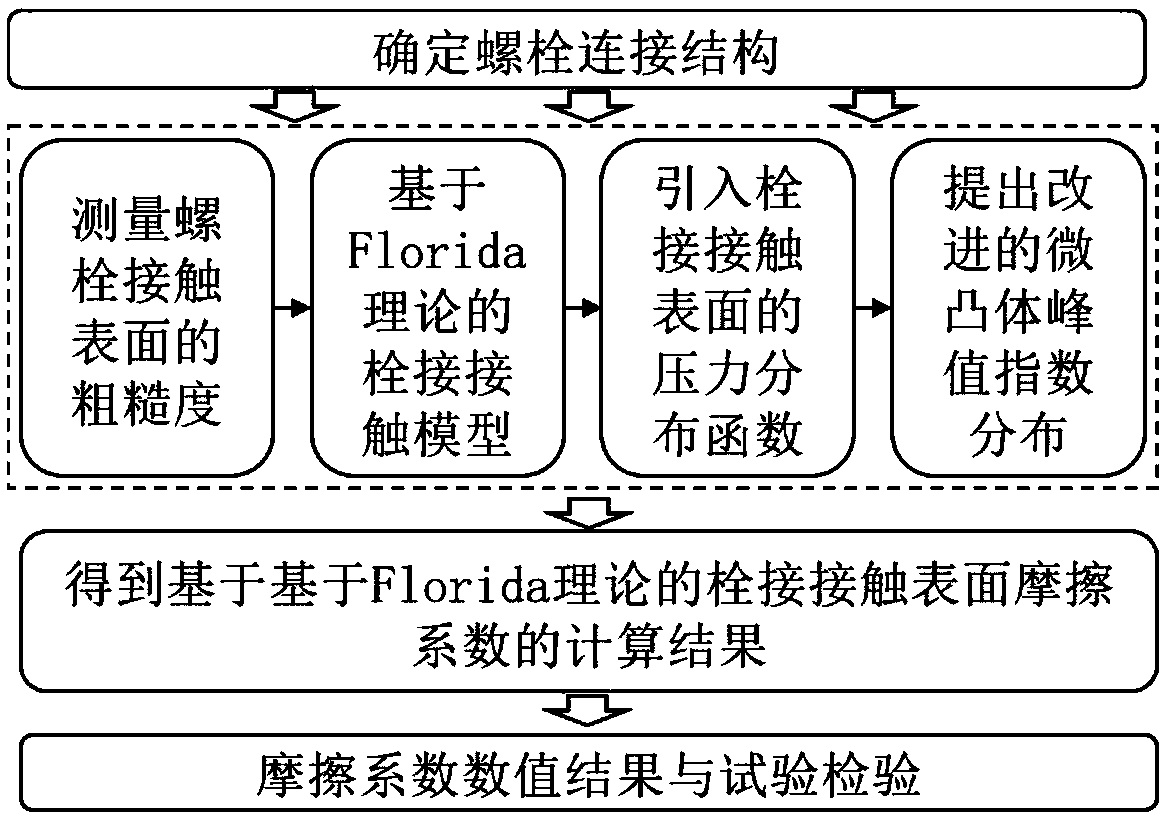

Method for calculating friction coefficient of contact surface of bolted structure

The invention discloses a method for calculating the friction coefficient of a contact surface of a bolted structure, and relates to the technical field of methods for calculating the friction coefficients of contact surfaces. The method is based on a Florida contact model, a pressure distribution function for a bolted contact surface is introduced, the elastic, elasto-plastic and full plastic deformation of micro-bulges on the micro scale are considered to construct an exponential distribution function containing peak height variation parameters of the micro-bulges, and a friction coefficientmathematical model with improved exponential distribution is then established, so that the friction coefficients of different bolted contact surfaces can be accurately calculated. The calculation method involves the parameters of the bolted contact surface, and the feasibility of the method is verified by experiments. At the same time, the calculation result of the friction coefficient of the bolted contact surface based on the Florida theory can be obtained by using the roughness parameter of the bolted surface.

Owner:BEIJING UNIV OF TECH

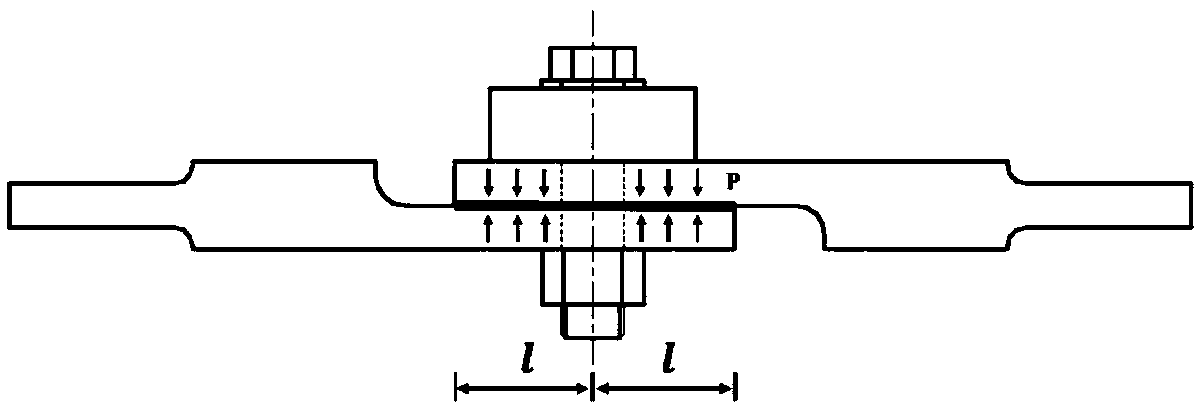

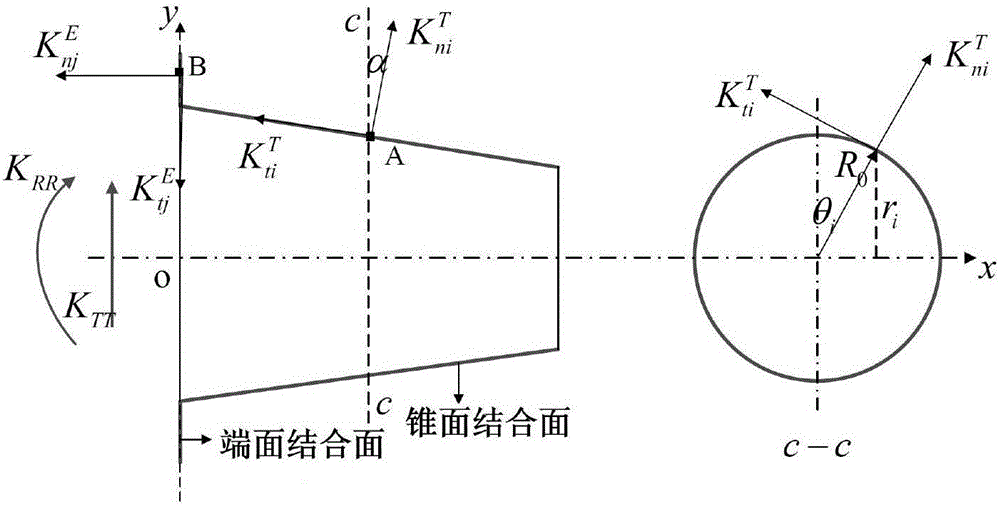

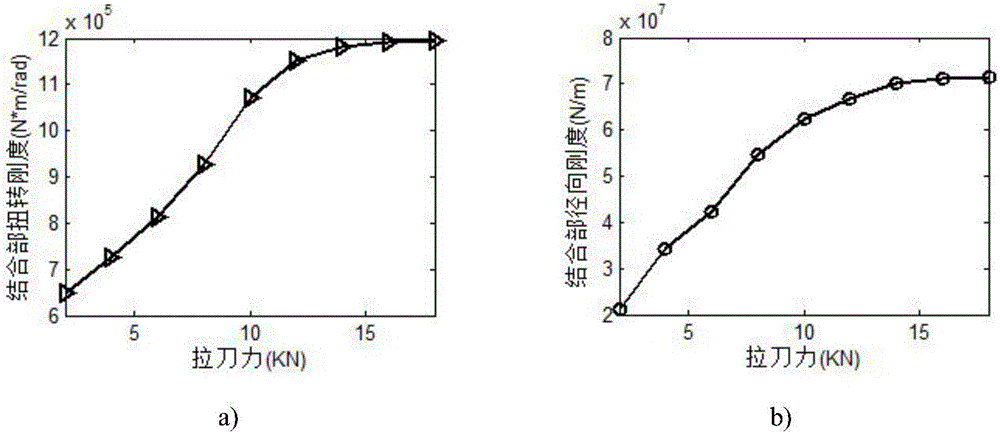

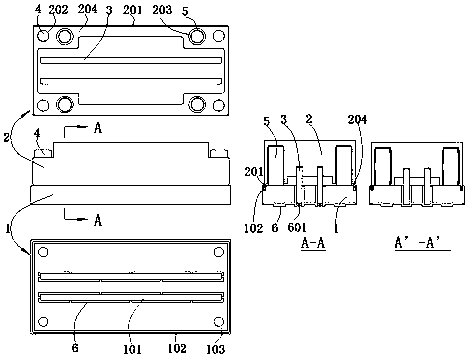

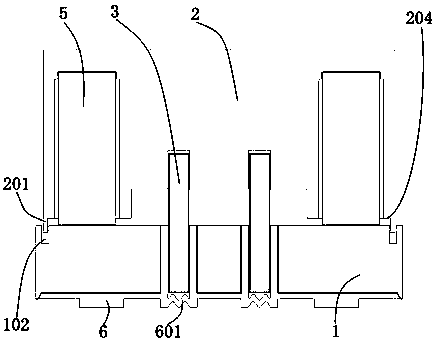

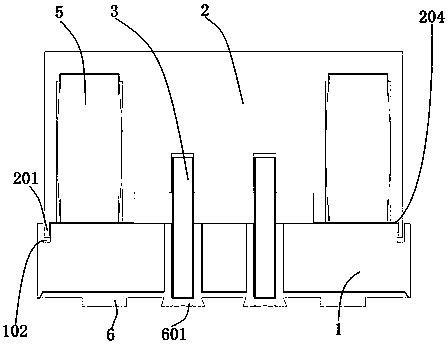

Joint rigidity analyzing method for bi-side locking handle-main shaft under high rotating speed conditions

ActiveCN106525418APrecise 3D Fractal TheoryMachine gearing/transmission testingExpansion factorElement analysis

The invention discloses a joint rigidity analyzing method for a bi-side locking handle-main shaft under high rotating speed conditions, specifically to a joint portion rigidity modeling method taking non-uniform distribution of bi-joint-side pressure, and the system joint rigidity under high rotating speed conditions is analyzed based on the method. The method includes the steps of establishing a three-dimensional fractal normal and tangential rigidity model, analyzing to obtain pressure values of each node on a bi-joint side based on static force, calculating the equivalent rigidity value corresponding to the nodes, and obtaining the torsion and radial rigidity value through a confirmation model, and finally revealing the influence trend of broaching tool force, disk spring rigidity and disc spring pretightening force on the rigidity of the joint portion under different rotation speed and high rotation speed. The method is characterized in that the influence of elasto-plastic deformation and domain expansion factor are taken into consideration in the fractal theory, and nonuniformity of the pressure distribution on the joint surface is considered in the finite element analysis, thereby conducting accurate modeling and analyzing the joint rigidity of T40 handle-main shaft under high rotating speed conditions.

Owner:BEIJING UNIV OF TECH

Back mold core for anti-falling ceramic tile production and combined back mold core thereof as well as made ceramic tile

PendingCN111590732AReduce qualityExtended service lifeCeramic shaping mandrelsCeramic shaping coresVulcanizationElasto plastic

The invention discloses a back mold core for anti-falling ceramic tile production. The back mold core comprises a mold core panel of a mold core panel groove cavity provided with a through hole in aniron piece, a mold core backboard provided with an elastic rubber tank hole and a shoulder screw sliding rod guide hole, mold core face vulcanized rubber which is provided with corrugated vulcanized rubber in the corresponding position of the a mold core panel groove cavity and integrally coats the front face of the mold core panel, embossing insert teeth inserted into the mold core panel groove cavity, PU elastic rubber or springs elastically stretching the mold core panel and the mold core backboard and shoulder screws for positioning and limiting the movable stroke of the mold core panel and the mold core backboard, wherein a circle of dustproof sealing edge with the greater height than the movable stoke is arranged at the outermost side of the contact surface of the mold core panel orthe mold core backboard. The back mold core for anti-falling ceramic tile production comprises a combined mold core frame, a plurality of movable mold core piece groove holes, combined mold core surface vulcanized rubber which is hollowed out in a position corresponding to the movable mold core piece groove hole, and back mold cores for anti-falling ceramic tile production, which are equal to thenumber of the movable mold core piece groove holes.

Owner:陈锐

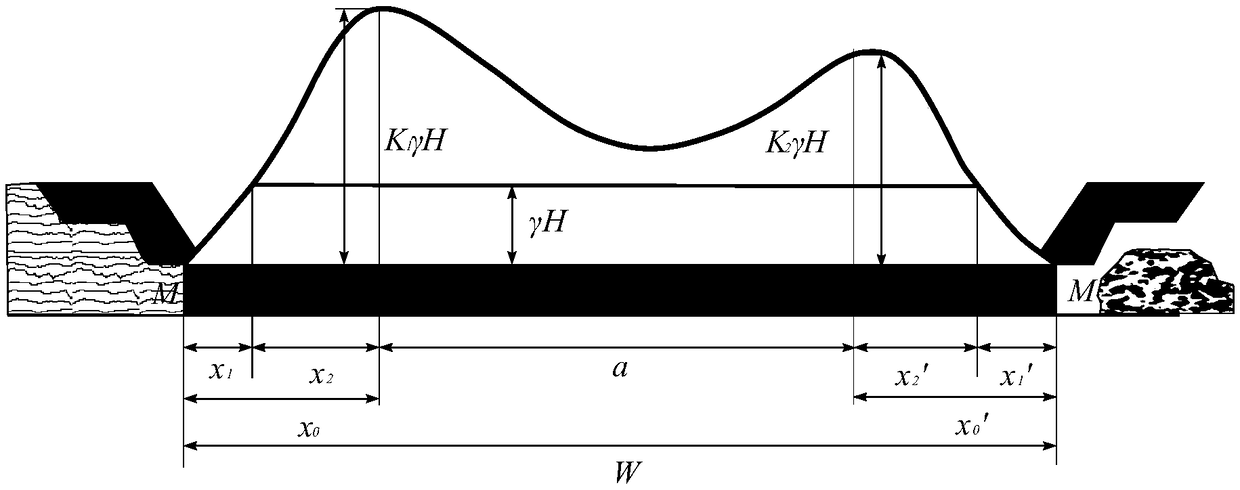

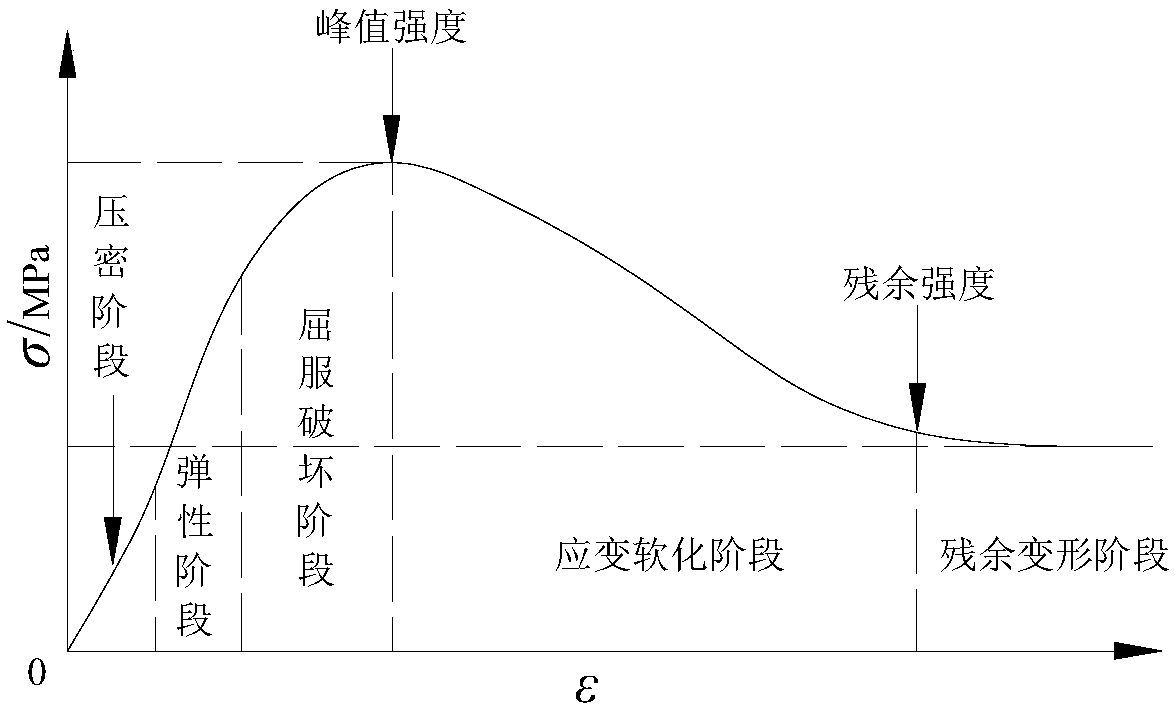

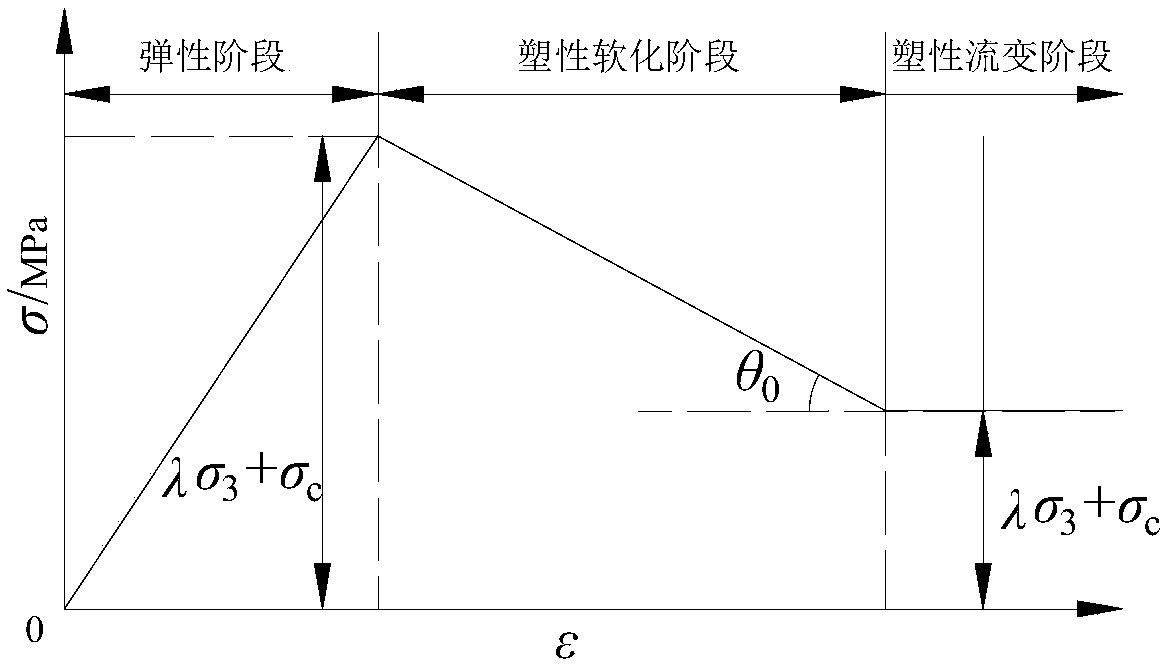

Designing method of coal pillar dam body of coal mine underground reservoir

ActiveCN109441537ASmall amount of calculationSimple design methodMining devicesStress distributionEngineering

The invention relates to a designing method of a coal pillar dam body of a coal mine underground reservoir and belongs to the technical field of comprehensive utilization of mineral engineering and hydraulic engineering. The problems that in the prior art, a designing method of the coal pillar dam body of the underground reservoir has blindness and lacks in scientificity and practicability are solved. The designing method comprises the following steps that firstly, physical and mechanical parameters of coal and rock with different water contents are tested; secondly, deformation and stress distribution models of the coal pillar dam body of the underground reservoir are established; thirdly, a coal body ideal elasto-plastic strain softening model is established; and fourthly, a coal pillardam body elasto-plastic deformation model is established, and a coal pillar dam body width calculation method is obtained. According to the designing method of the coal pillar dam body of the coal mine underground reservoir, the data calculation amount is small, and the reliability and calculation precision in design of the coal pillar dam body of the underground reservoir can be improved.

Owner:CHINA UNIV OF MINING & TECH

High-elasticity low-cost adhesive tape for footballs

InactiveCN110791212AIncrease elasticityHigh strengthHollow inflatable ballsFilm/foil adhesivesPolymer scienceThermoplastic polyurethane

The invention discloses a high-elasticity low-cost adhesive tape for footballs, wherein the high-elasticity low-cost adhesive tape for footballs comprises an outer film layer, a screen cloth layer, thermoplastic polyurethane elastic (TPU) films and adhesive layers. When the elastic adhesive tape is manufactured, A, natural rubber is firstly used for manufacturing the high-elasticity outer film layer; B, the screen cloth layer with high elasticity is prepared; C, the prepared outer film layer is heated and then fixedly bonded with the high-elasticity screen cloth layer to form an adhesive tapebase layer; D, the thermoplastic polyurethane elastic (TPU) films are bonded to the surfaces of two sides of the adhesive tape base layer; and E, the adhesive layers are heated, and the surfaces of the thermoplastic polyurethane elastic (TPU) films are coated with the adhesive layers. The adhesive tape has the advantages of good elasticity, high viscosity, environmental protection, aging resistance and low production cost.

Owner:JIANGSU DAHAI PLASTIC

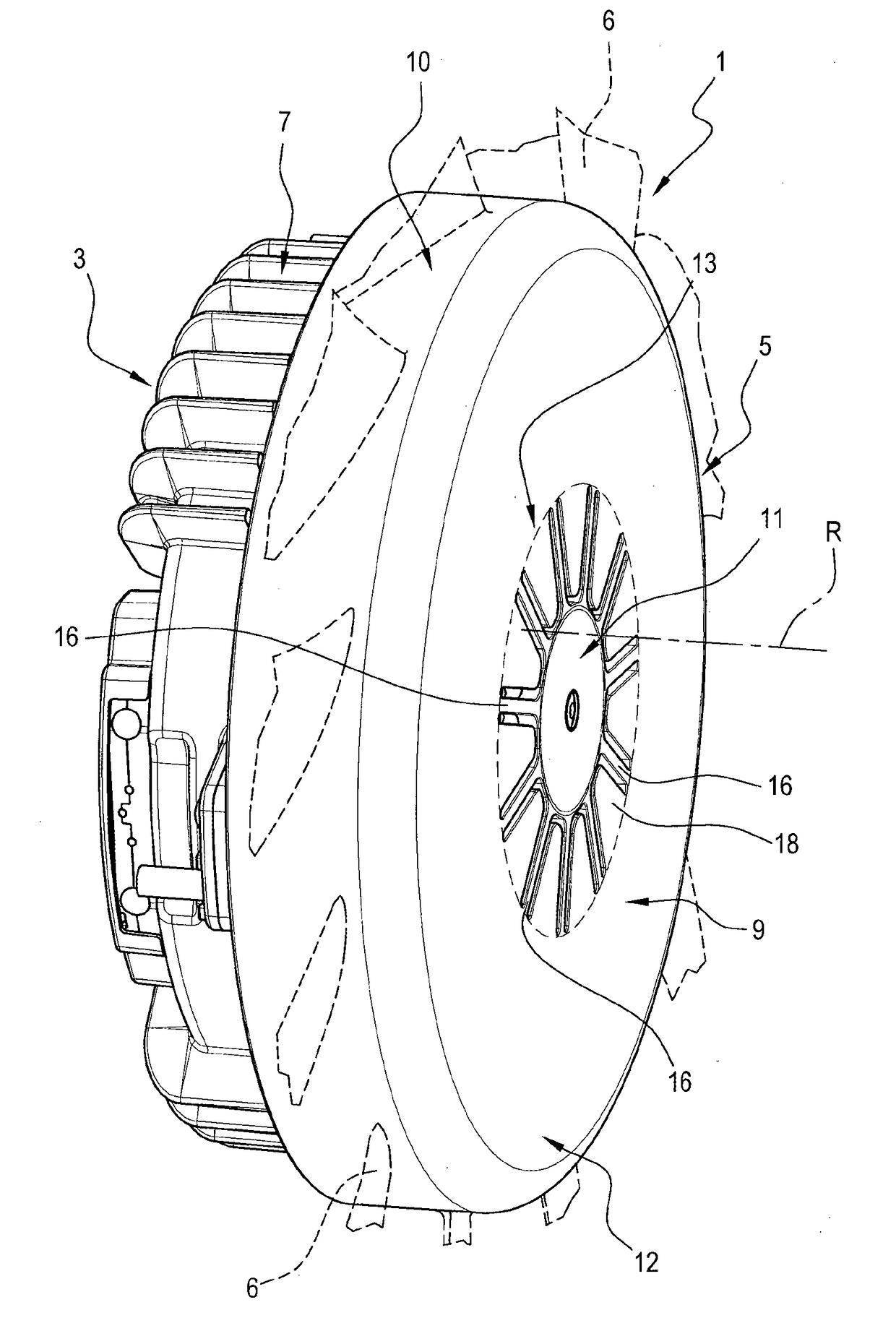

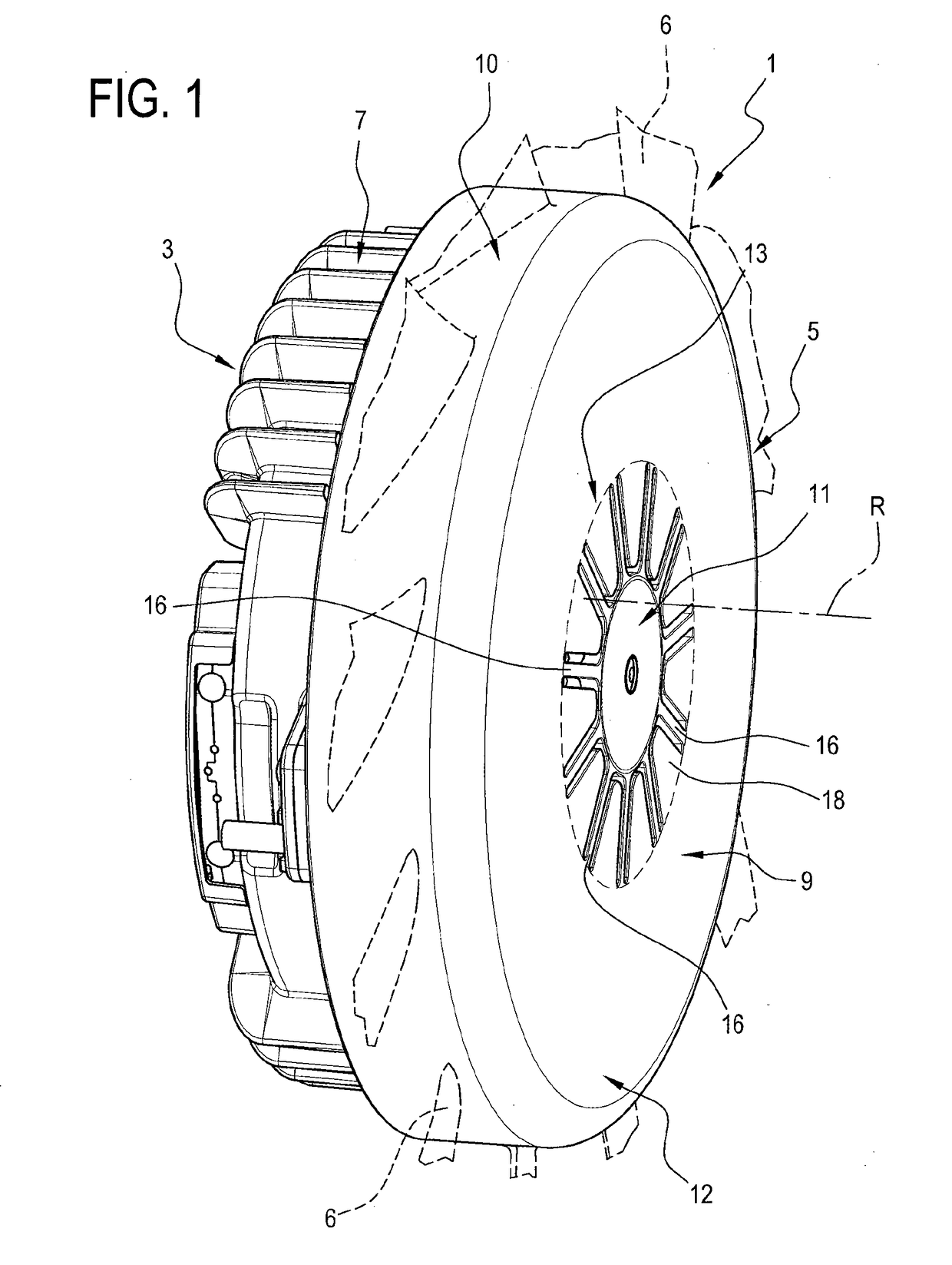

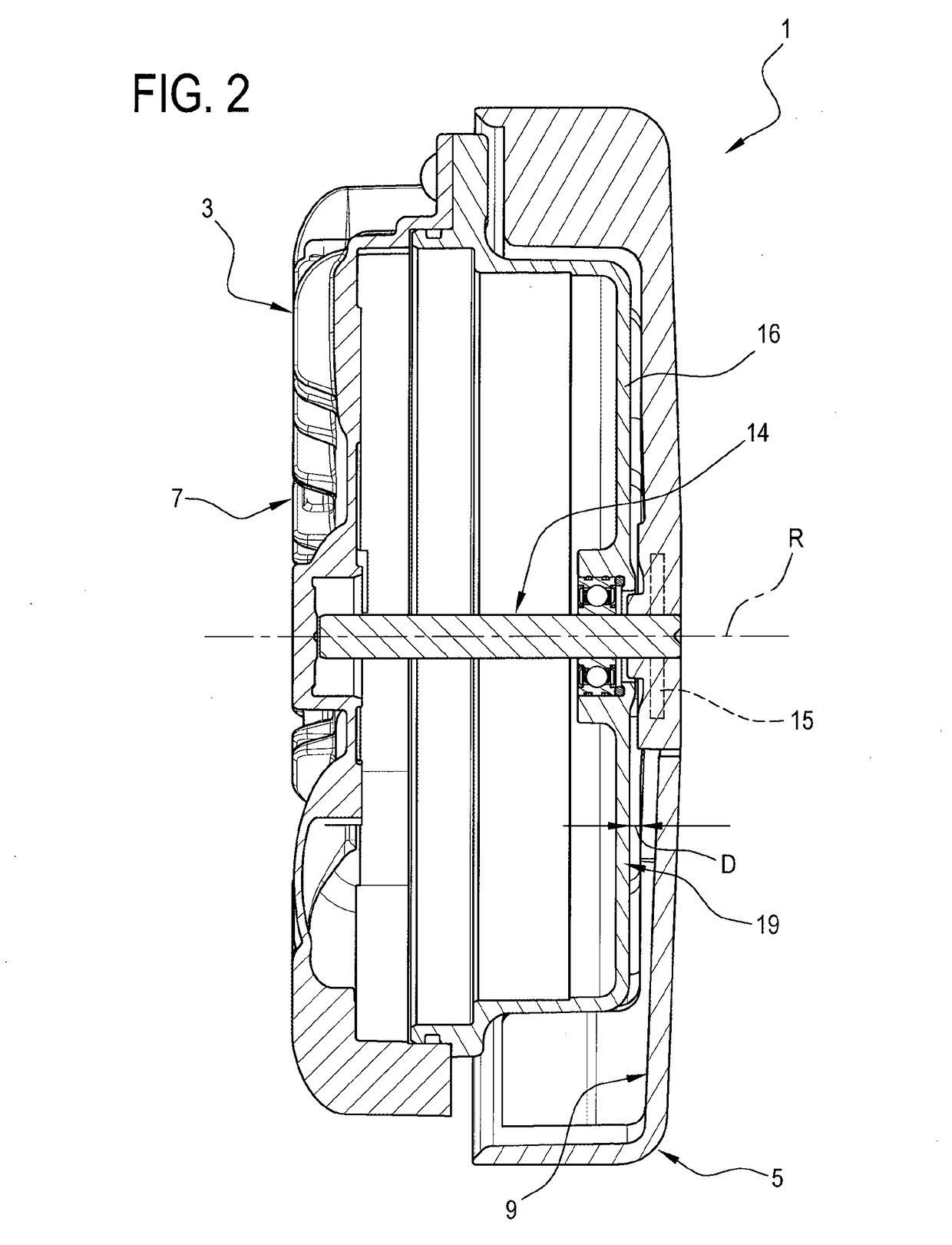

Axial fan

An axial fan includes a motor, an impeller and a hub of the impeller for connecting to a shaft of the motor. A bottom wall of the hub has a central portion, and an outer annular portion connected to the central portion by an intermediate portion defined by a plurality of blades arranged radially and angularly distributed about an axis of rotation. The blades are elasto-plastic blades and are able to prevent the impeller from moving axially parallel to the axis, moving radially perpendicular to the and a bending of the impeller with movements normal to the plane in which the mean surface of the impeller itself lies. The blades allow a movement with torsional bending around the axis to allow the damping of the resonance frequencies of the assembly formed by the impeller-shaft-rotor.

Owner:SPAL AUTOMOTIVE

Seismic isolation device and seismic isolation method

ActiveUS9574364B2Rule out the possibilityProtective buildings/sheltersShock proofingStructural engineeringSeismic isolation

A seismic isolation apparatus is provided between a structure and a foundation floor, and the seismic isolation apparatus includes: a support plate that is provided so as to face the structure at a predetermined interval; a base plate that is fixed to the foundation floor; and an elasto-plastic damper that is provided between the support plate and the base plate to be fixed to the support plate and the base plate. The elasto-plastic damper includes an inner cylinder inside which an elasto-plastic member is provided and an outer cylinder, and the inner cylinder and the outer cylinder are configured to mutually slide in an axis direction thereof.

Owner:KK TOSHIBA

Elasto-plastic well cementing cement slurry and preparation method thereof

ActiveCN102604610BLow elastic modulusImprove impact resistanceDrilling compositionPlasticizerWell cementing

The invention discloses an elasto-plastic well cementing cement slurry which is prepared from the following components in parts by weight: 100 parts of cement, 0-12 parts of high-temperature stabilizing agent, 0-200 parts of density adjuster, 4-10 parts of filtrate loss reducer, 0-2 parts of dispersing agent, 0-1.5 part of retarder, 35-110 parts of water, 0.2 part of defoaming agent and 2-15 parts of plasticizer. The elasto-plastic well cementing cement slurry can improve the bending resisting strength and the impact resisting strength of the cement stone and reduce the elastic modulus of the cement stone. Under high temperature and high pressure, the brittle deformation of the elasto-plastic well cementing cement slurry is converted into the plastic deformation, thus the later exploitation is guaranteed, and the service life of the oil-gas well is prolonged.

Owner:成都欧美克石油科技股份有限公司

Material point method for simulation of granular materials

The disclosure provides an approach for simulating and rendering granular materials. A simulation application generates video frames depicting a granular material phenomenon using a strain based elasto-plastic constitutive model integrated with a hybrid Eulerian / Lagrangian material point method (MPM). The elasto-plastic constitutive model includes physical equation(s) which dictate forces that affect the granular material during the simulation. In particular, the constitutive model may include user-controllable parameters defining threshold(s) to start plastic deformation, as well as a hardening parameter which controls how fast the granular material packs under compression. The MPM is a procedure in which particles of the granular material and a background grid are coupled, with the grid being used to assist in computing forces dictated by the physical equation(s) of the elasto-plastic constitutive model. In one configuration, the grid may further be rendered with volumetric rendering to generate video frames depicting the granular material.

Owner:DISNEY ENTERPRISES INC

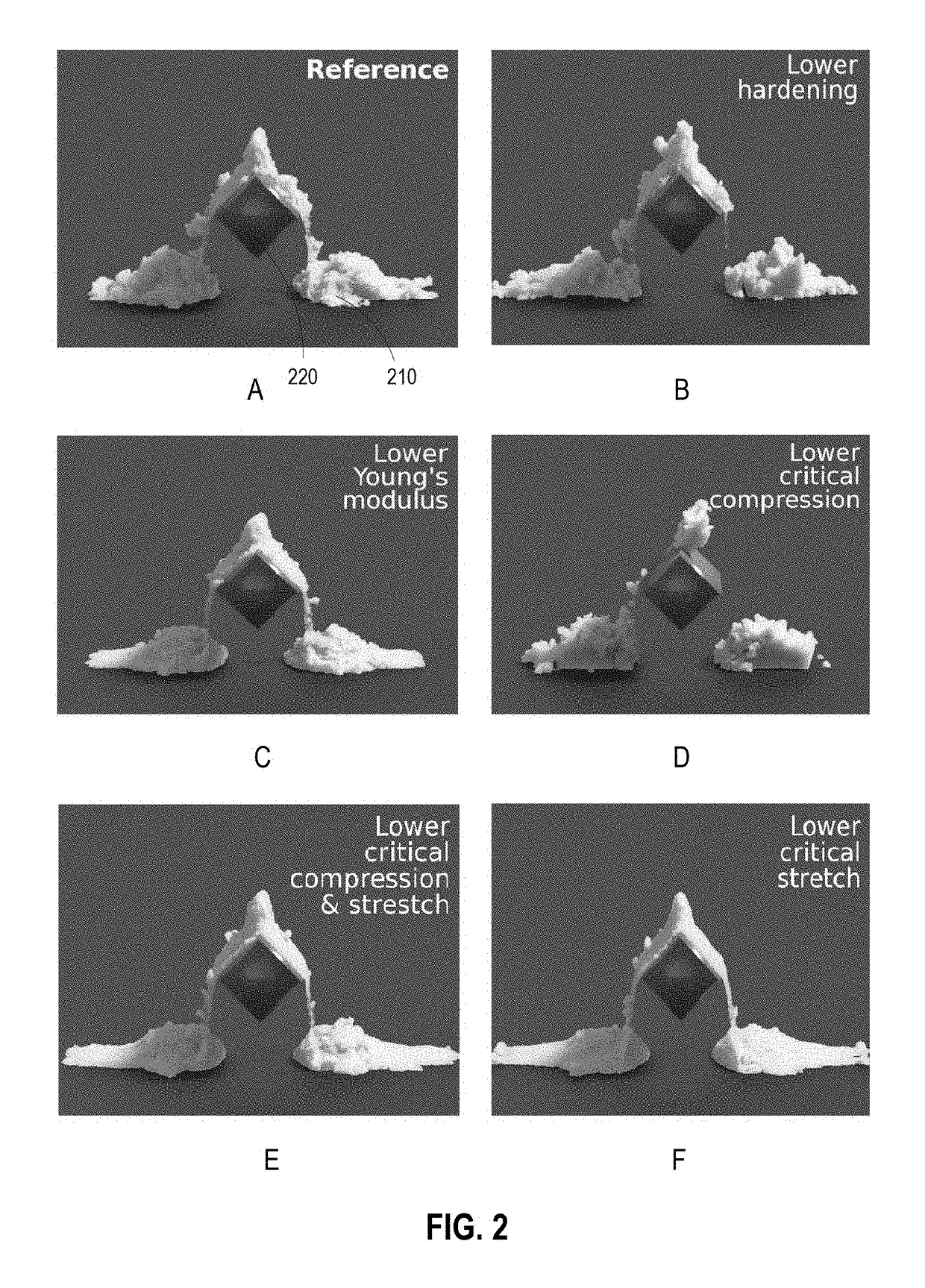

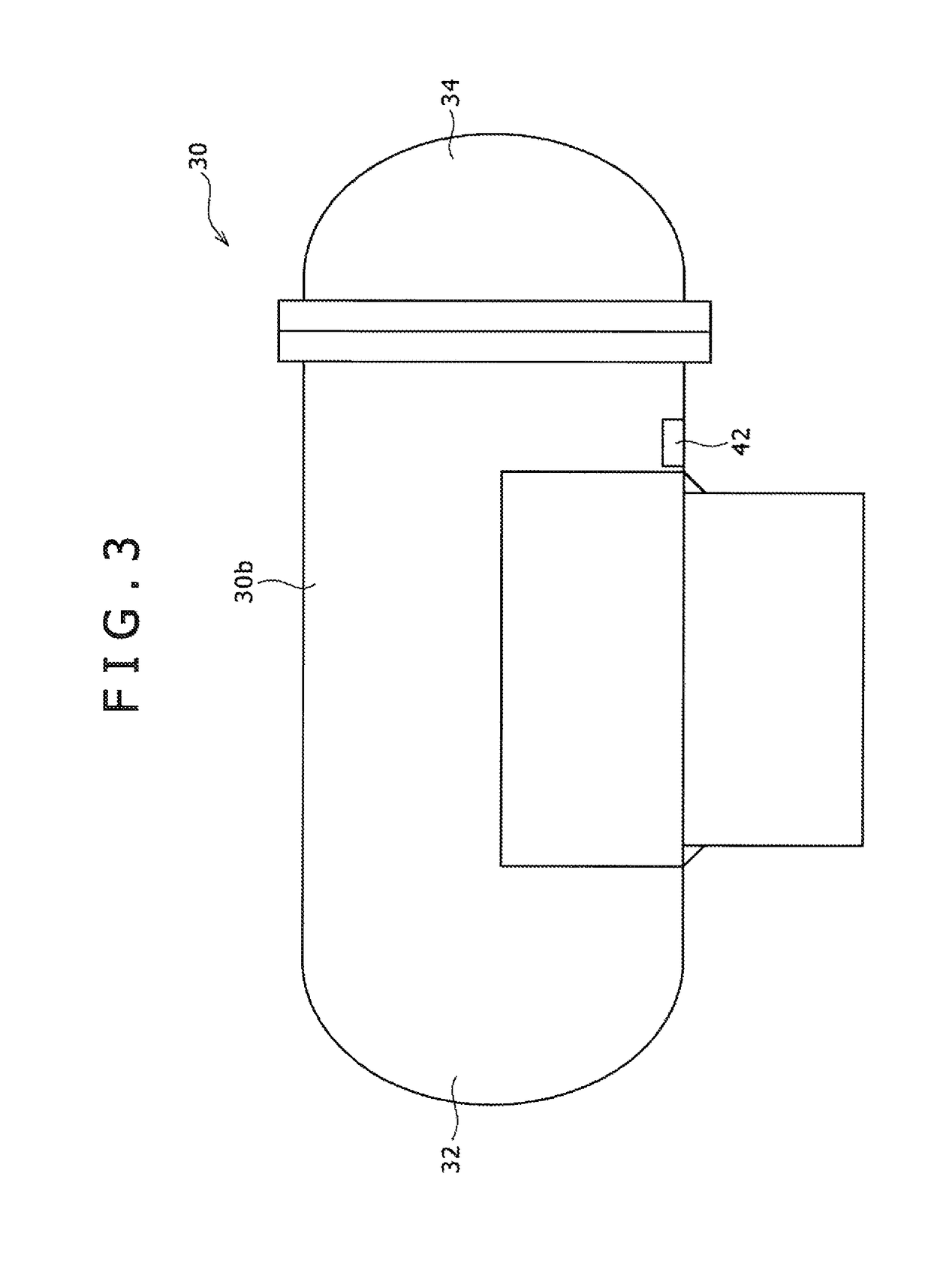

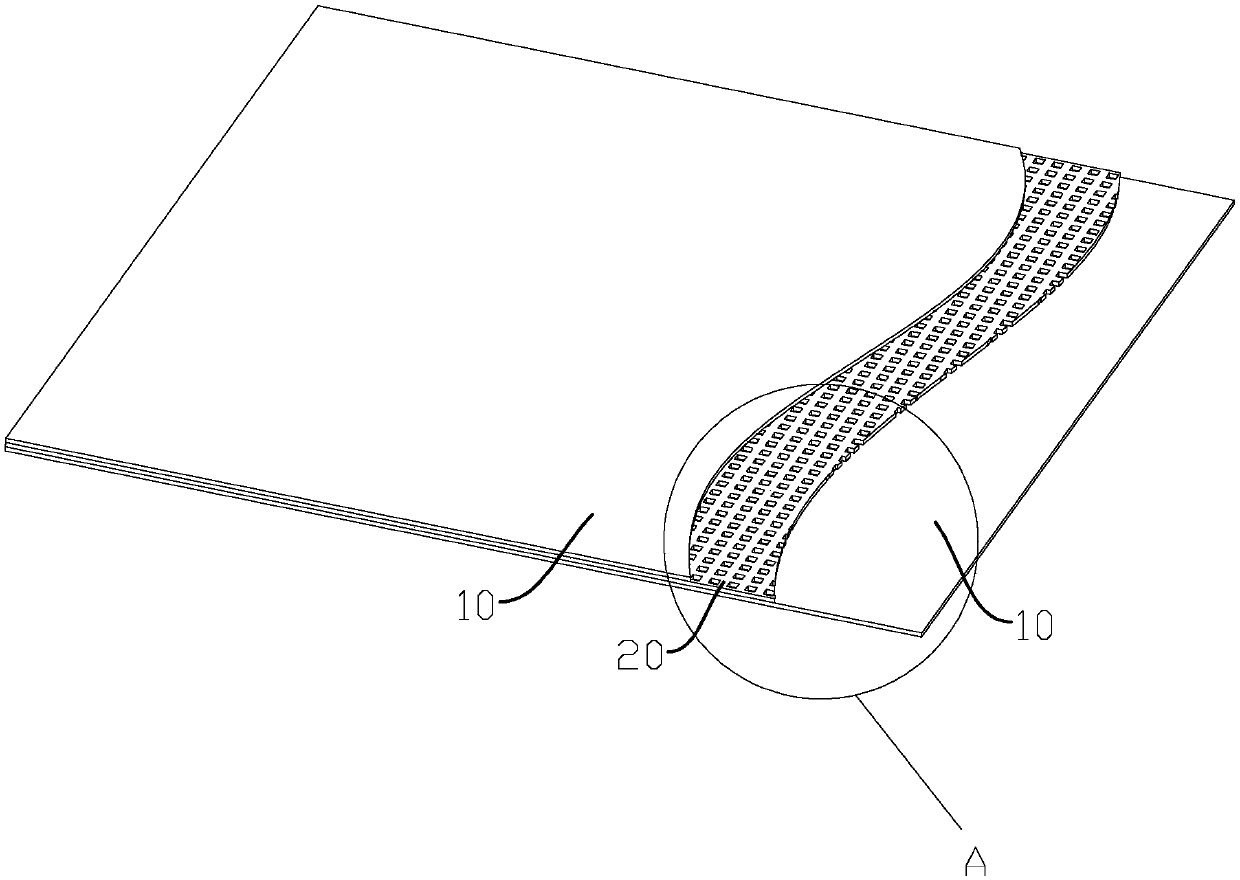

Method for blasting object to be treated in pressure vessel

InactiveUS9618311B2Increase in sizeExcessive plastic deformationAmmunitionFurnace typesEngineeringMetal

A blast treatment method for blasting an object includes: a step in which an explosive is detonated inside a pressure vessel (30) which has an elasto-plastic metal, thereby imparting to the pressure vessel (30) an initial load wherein the primary and secondary stress generated in at least a portion of the pressure vessel becomes high enough to be in a plastic region exceeding the elastic region, thereby generating a shakedown state in the pressure vessel (30); and a subsequent step in which a treatment explosive (50) is detonated within the pressure vessel (30), thereby blasting the object (10).

Owner:KOBE STEEL LTD

Fit type breathable elastic adhesive film

PendingCN107825793AStay flexibleRetain flexibilitySynthetic resin layered productsClothingsEngineeringSurface film

The invention discloses a fit type breathable elastic adhesive film which comprises an adhesive film main body, wherein the adhesive film main body comprises a base film and a surface layer film attached to the base film, the surface layer film is an elastic film, the elasticity of the surface layer film is larger than that of the base film, the base membrane can be broken to make the adhesive film main body generate cracks when being stretched to a certain degree, and the adhesive film main body has a breathable state with the cracks. When the fit type breathable elastic adhesive film disclosed by the invention is stretched to the certain degree, the base film can be broken, the surface layer film attached to the base film can be further broken, and the adhesive film main body can generate crack to have a breathable function; furthermore, the surface layer film cannot be broken into parts and can keep the elasticity, so that the elasticity of the adhesive film main body can be kept; after the adhesive film main body is adhered to an elastic shell fabric, the adhesive film main body can have the breathable function due to stretch generated by first wearing and the like; furthermore, the breathable function cannot disappear in follow-up use, breathability of garments, luggage and the like can be effectively ensured, wearing comfortableness is improved, and more convenience is brought to processing and use.

Owner:中山市广升粘合材料有限公司

Method for determining normal contact stiffness of fixed joint surface

InactiveCN102608167BOvercome costsImprove objectivityMaterial resistanceElectrical resistance and conductanceEngineering

The invention provides a new method for indirectly obtaining normal contact stiffness of joint surface according to theoretical calculation and experimental test under the condition that the contact resistance ratio of the fixed joint surface is measured more easily than the normal contact stiffness. Relationship between joint surface contact resistance RC and normal contact stiffness Ktot is established by measurement and aftertreatment for micro appearance of contact surface. Firstly, an expression of the joint surface contact resistance RC is established; then the expression of normal contact stiffness Ktot is established; at the last, the relationship between the joint surface contact resistance RC and the normal contact stiffness Ktot is established. According to the invention, the method overcomes the defect that the normal contact stiffness is measured difficultly; the method considers elasto-plastic contact of two coarse surfaces, and further considers the more comprehensive, accurate actual surface appearance information.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com