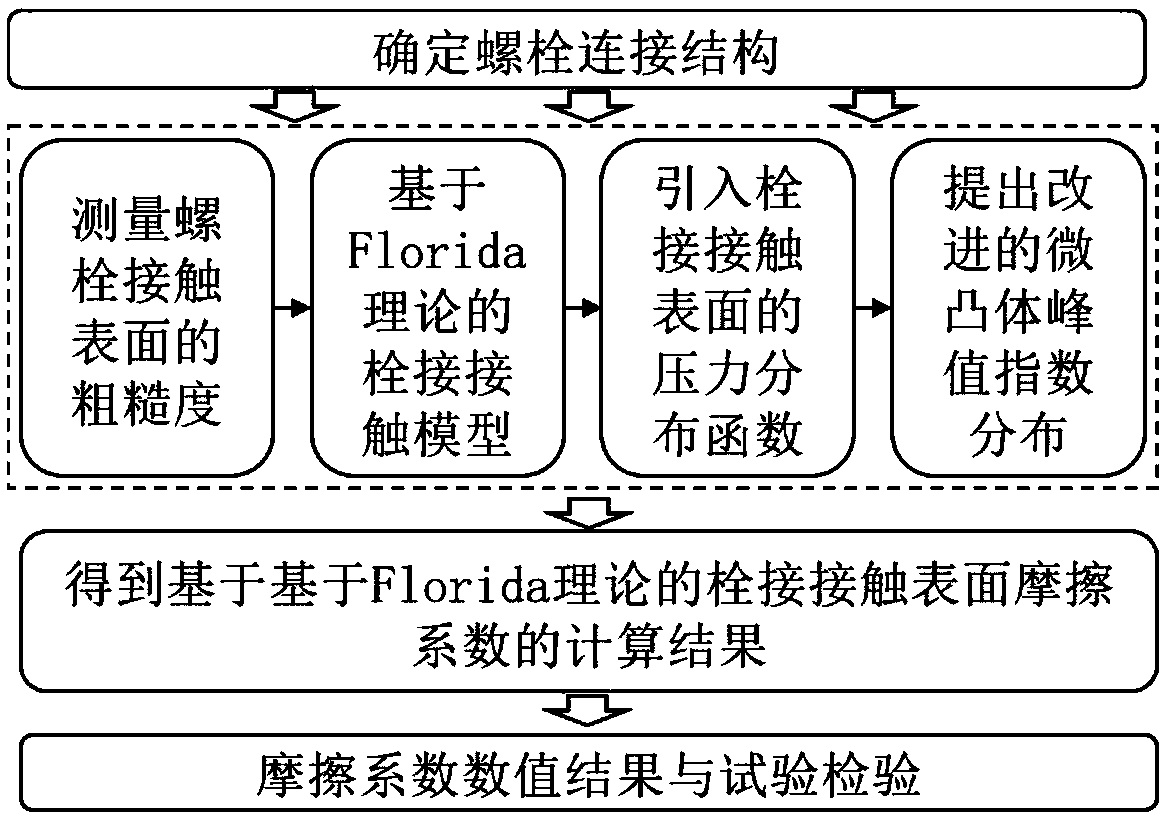

Method for calculating friction coefficient of contact surface of bolted structure

A technology of contact surface and friction coefficient, which is applied to the calculation of the friction coefficient of the contact surface of the bolted structure, and the calculation field of the friction coefficient of the contact surface, which can solve the problem that the friction coefficient of the bolt cannot be measured and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

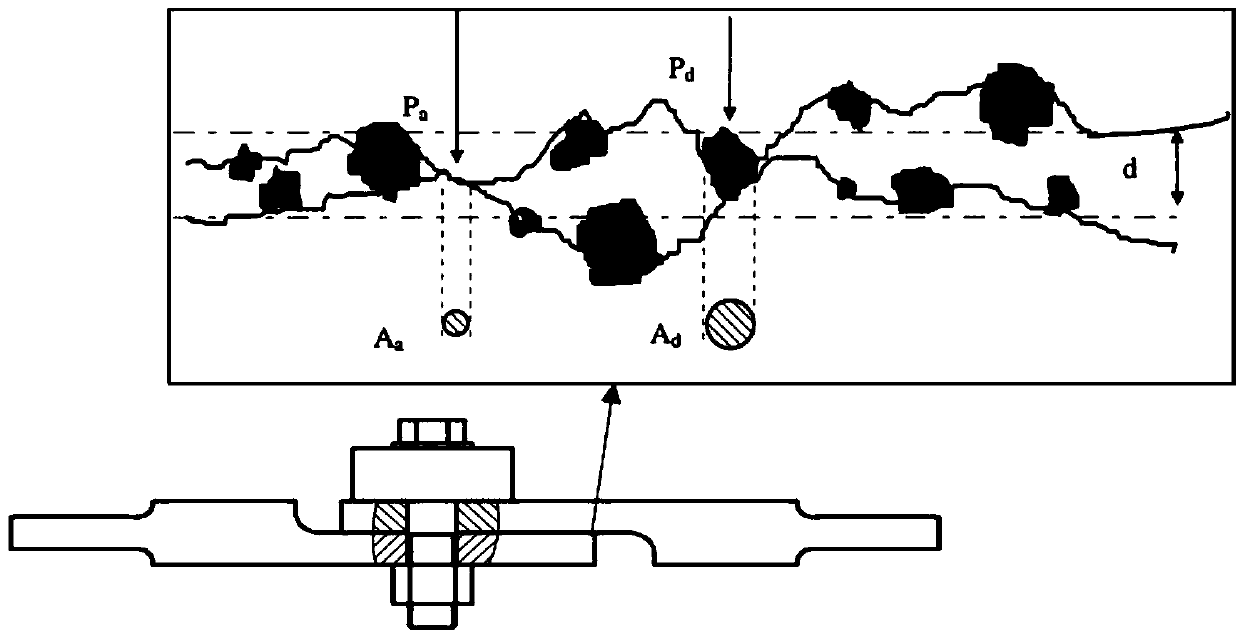

[0020] 1) Generally, the friction coefficient of the dry friction sliding surface is considered to be the result of the joint action of the asperity furrow, the asperity occlusion, and the furrow of the wear particles remaining on the surface after the friction pair wears. refer to figure 2 As shown, according to the Florida contact theory, the Florida contact model based on the bolt connection is established.

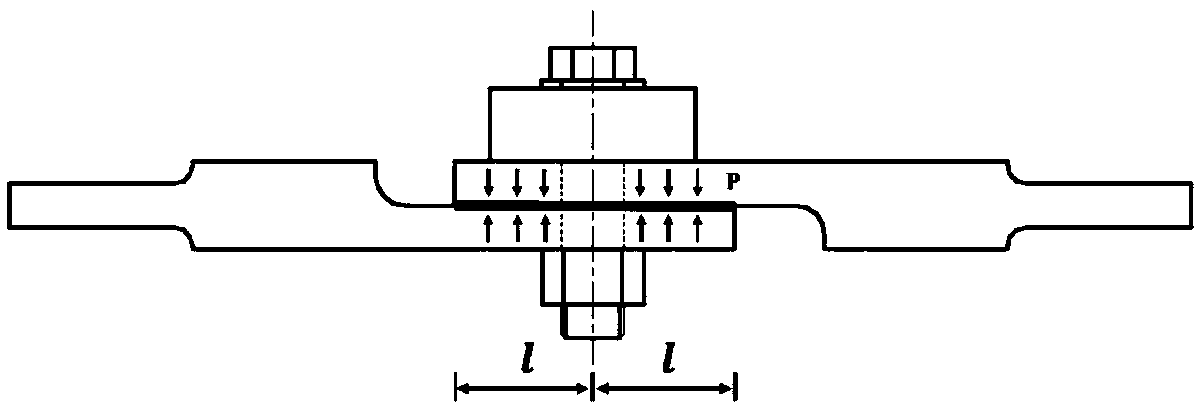

[0021] 2) Considering the average shear stress of each actual contact point of the bolted contact surface, the total plastic deformation energy is equal to the sum of the plastic deformation energy of a single contact point, and the general formula for the dynamic friction coefficient between friction pairs is obtained:

[0022]

[0023] Where: i is the asperity contact point, i=1, 2,..., N j ;

[0024] P is the total load in the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com