Method for determining normal contact stiffness of fixed joint surface

A technology of fixing the joint surface and contact stiffness, applied in the direction of material resistance, etc., can solve the problems of not considering the spatial distribution of three-dimensional roughness peaks, the high cost of the contact stiffness measurement test bench, and the high requirements for deformation measurement sensors, so as to achieve convenient and fast testing and high precision. , Overcome the effects that are not easy to measure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

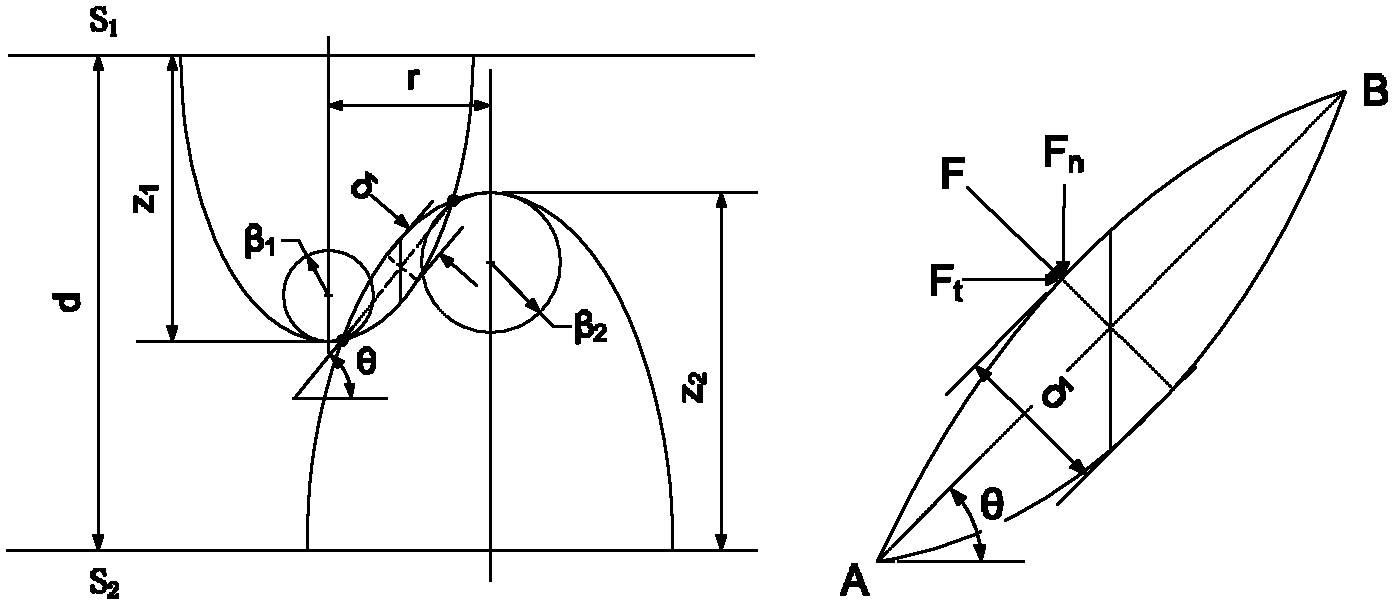

[0035] figure 1 It is the asperity contact force analysis diagram studied by the present invention. In the figure, S 1 , S 2 respectively represent two contact surfaces; d is the distance between two contact surfaces; z 1 ,z 2 are the heights of the contact asperities; β 1 , β 2 are the radius of curvature of the contact asperity peak; r is the distance between the symmetry axes of two asperities; θ is the contact angle; δ is the normal deformation of the contact area.

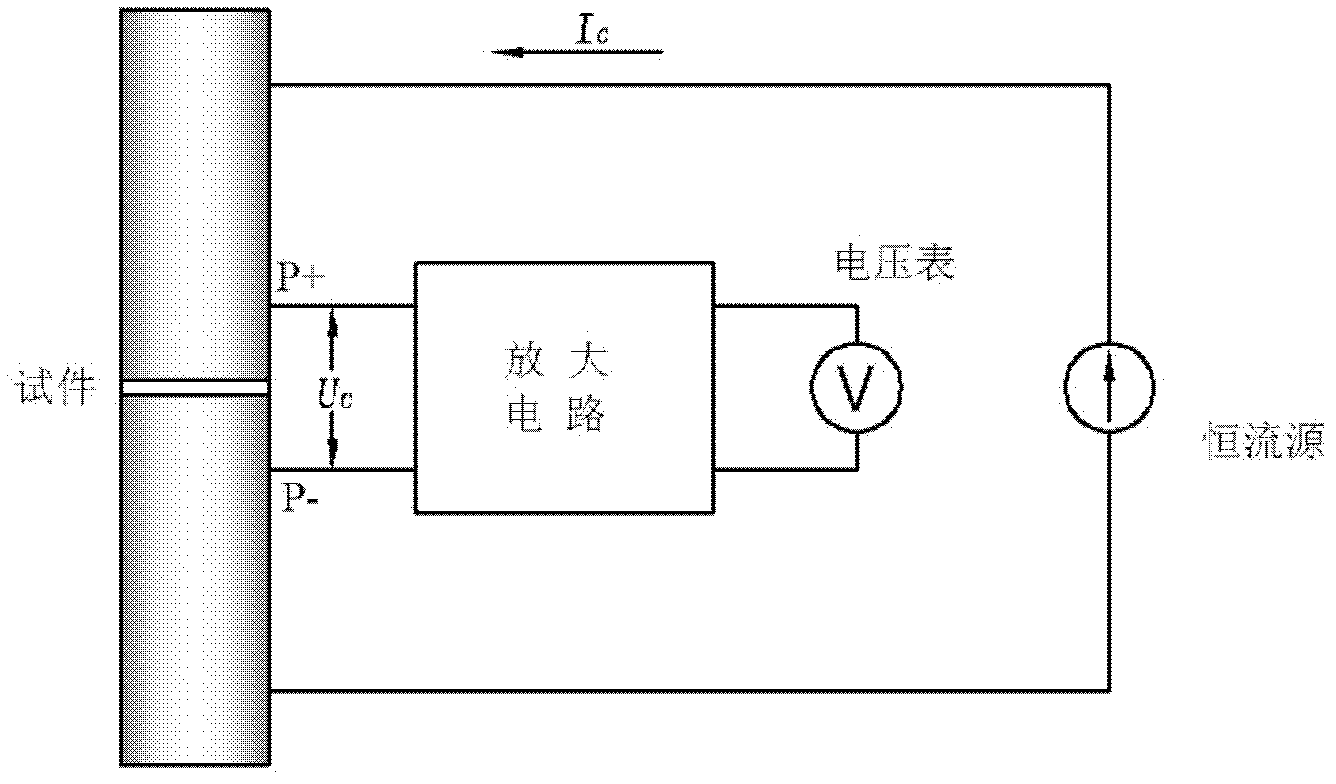

[0036] figure 2 The principle of measuring contact resistance for the four-point method. The method is to provide a constant current for the joint surface, measure the contact voltage of the joint surface, and obtain the contact resistance of the joint surface.

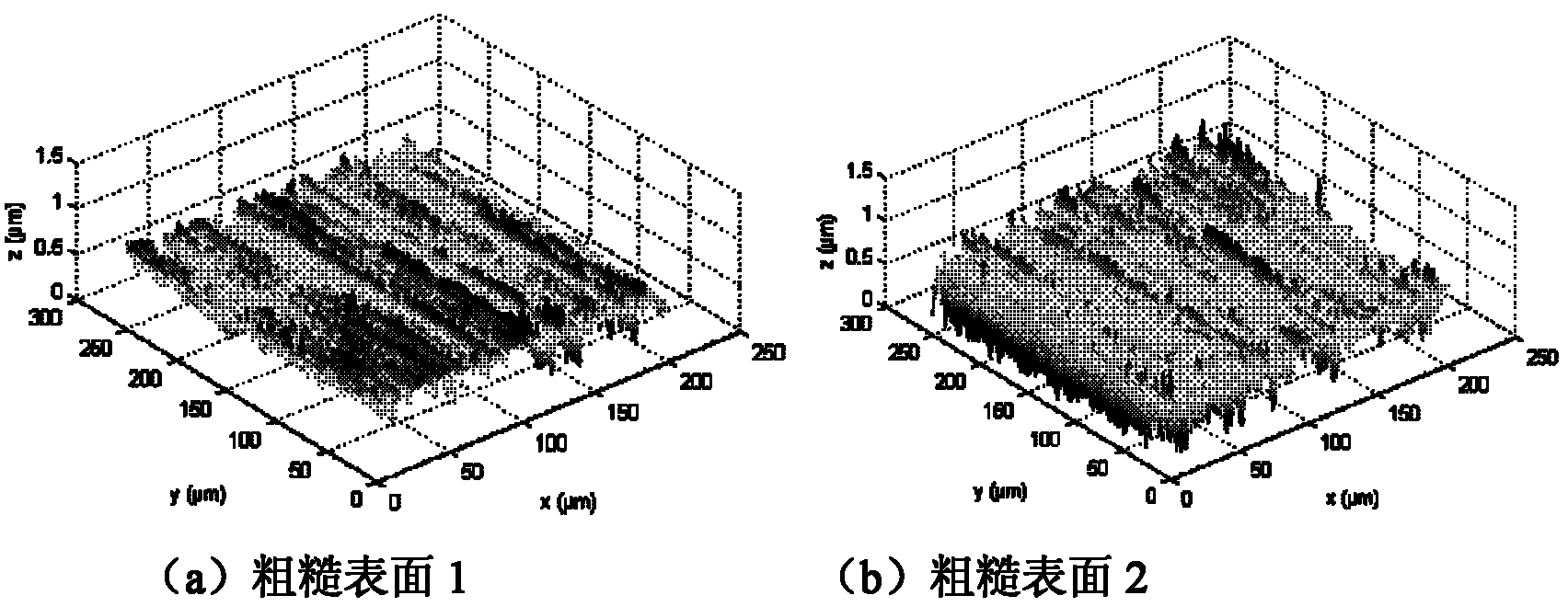

[0037] image 3 It is the microscopic surface morphology of the two rough surfaces of the bonding surface measured in the embodiment of the present invention, and the processing methods of the two rough surfaces are grinding.

[0038] Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com