Ceramic tile mold, expanded ceramic tile mold support and ceramic tile formed through pressing of mold

A ceramic tile and mold technology, which is applied to the ceramic tile mold and the extended tile mold support and the ceramic tile field pressed by the mold, can solve the problems of reducing the pressing accuracy of the ceramic tile, increasing the risk of damage, increasing the failure rate, etc., to simplify the maintenance process, Eliminate mutual influence and reduce the effect of force transfer function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

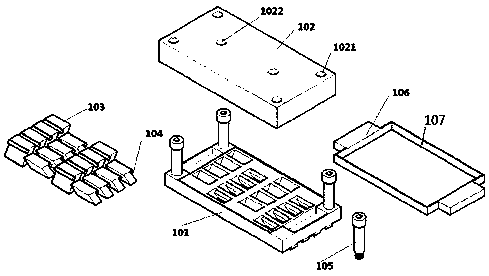

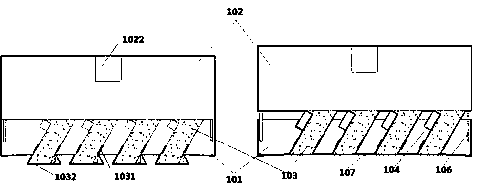

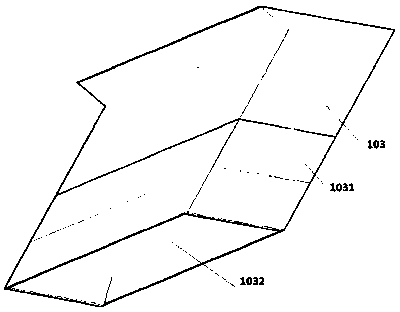

[0023] Such as Figure 1-3 As shown, a tile mold includes a tile mold lower cover plate 101, a tile mold upper cover plate 102, beveled edge forming teeth 103, rebound PU glue or spring 104, mold upper and lower cover limit guide rods 105, upper and lower cover rebound PU elastic rubber plate 106, lateral elastic sealing rubber ring 107, upper cover limit sleeve hole 1021, bevel edge forming tooth sealing rubber ring 1031, bevel edge forming tooth bottom surface inverted notch covered with PU vulcanizate 1032, bevel edge forming tooth 103 is located in the oblique hole of the lower cover plate 101 of the tile mold. The separation of the bevel forming teeth 103 and the lower cover plate 101 of the tile mold is opened by the elastic force of the rebound PU glue or spring 104 between the two, and the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com