Elasto-plastic well cementing cement slurry and preparation method thereof

A cementing cement slurry and elastic-plastic technology, applied in the field of cement, can solve the problems of high construction equipment requirements, poor bonding performance, high mixing requirements, etc., achieve low price, improve mixing unevenness, and easy slurry mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

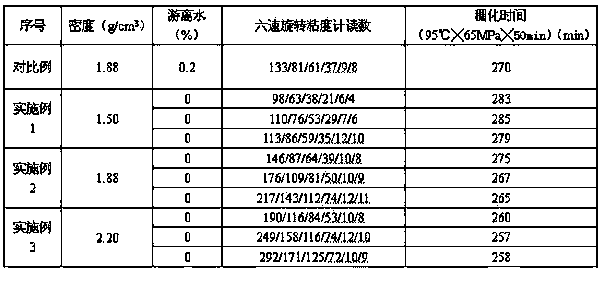

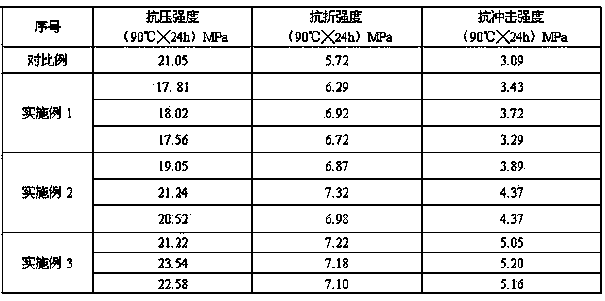

[0022] Example Preparation and Performance Measurement of Cementing Slurry with and without Plasticizer Added

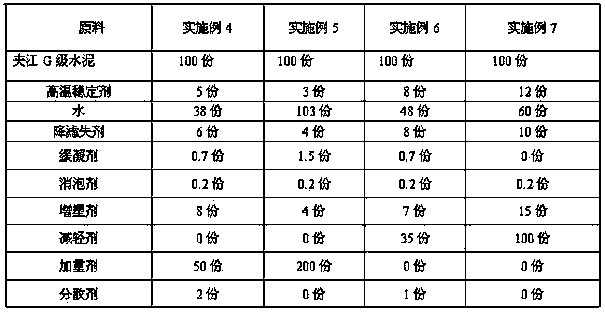

[0023] As shown in table 1, the elastoplastic solid cement slurry of embodiment is made by mixing the raw materials of following weight composition:

[0024] Table 1

[0025]

[0026] After weighing the above components according to the corresponding weight percentages, mixing and stirring, the elastoplastic cementing cement slurry is prepared. Wherein, the plasticizer was surface-treated using a plasma surface treatment apparatus before mixing; the processing parameters of the surface treatment were: power 200W, processing time 30s, working gas as air, and vacuum degree as 10Pa. In Table 1, the high-temperature stabilizer described in each embodiment and comparative example is micro silicon, and the described fluid loss reducer is any one of AMPS polymer, ketone-aldehyde condensation class and PVA system, and the described plasticizer is Polyisoprene high molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com