Patents

Literature

50 results about "Nonlinear finite element analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonlinear Finite Element Analysis. Having investigated and consulted on hundreds of structures and pressurized equipment components, WJE professionals are experienced providers of specialty nonlinear finite element modeling services for all types of new and existing solid components.

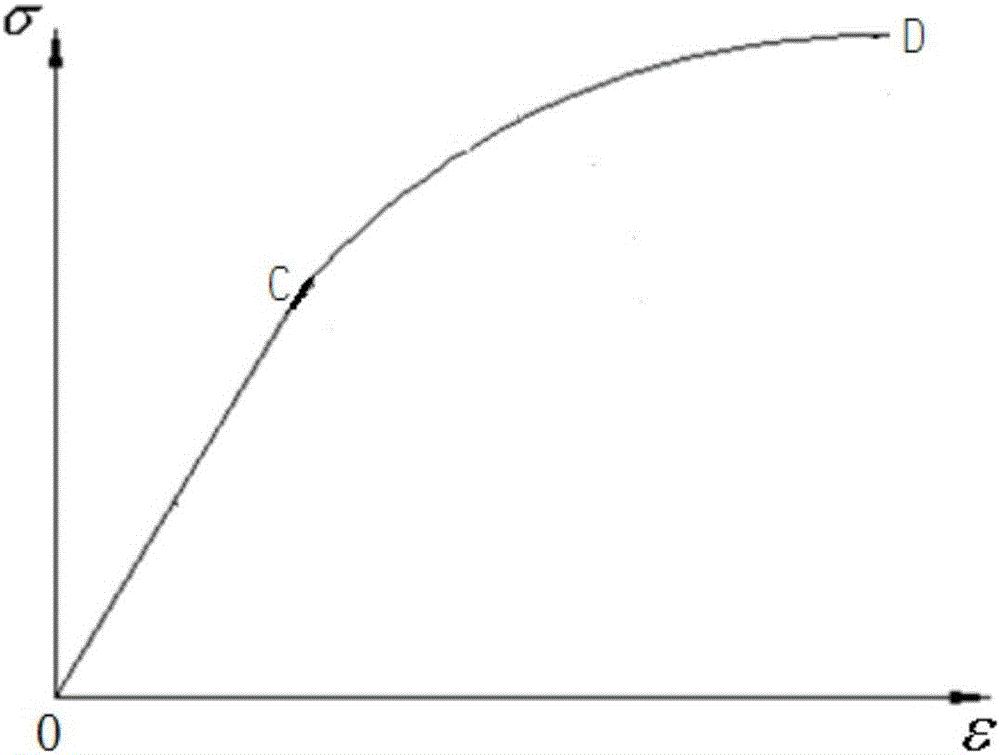

Self-optimizing, inverse analysis method for parameter identification of nonlinear material constitutive models

InactiveUS20130289953A1Error minimizationComputation using non-denominational number representationDesign optimisation/simulationElement analysisGenetic algorithm

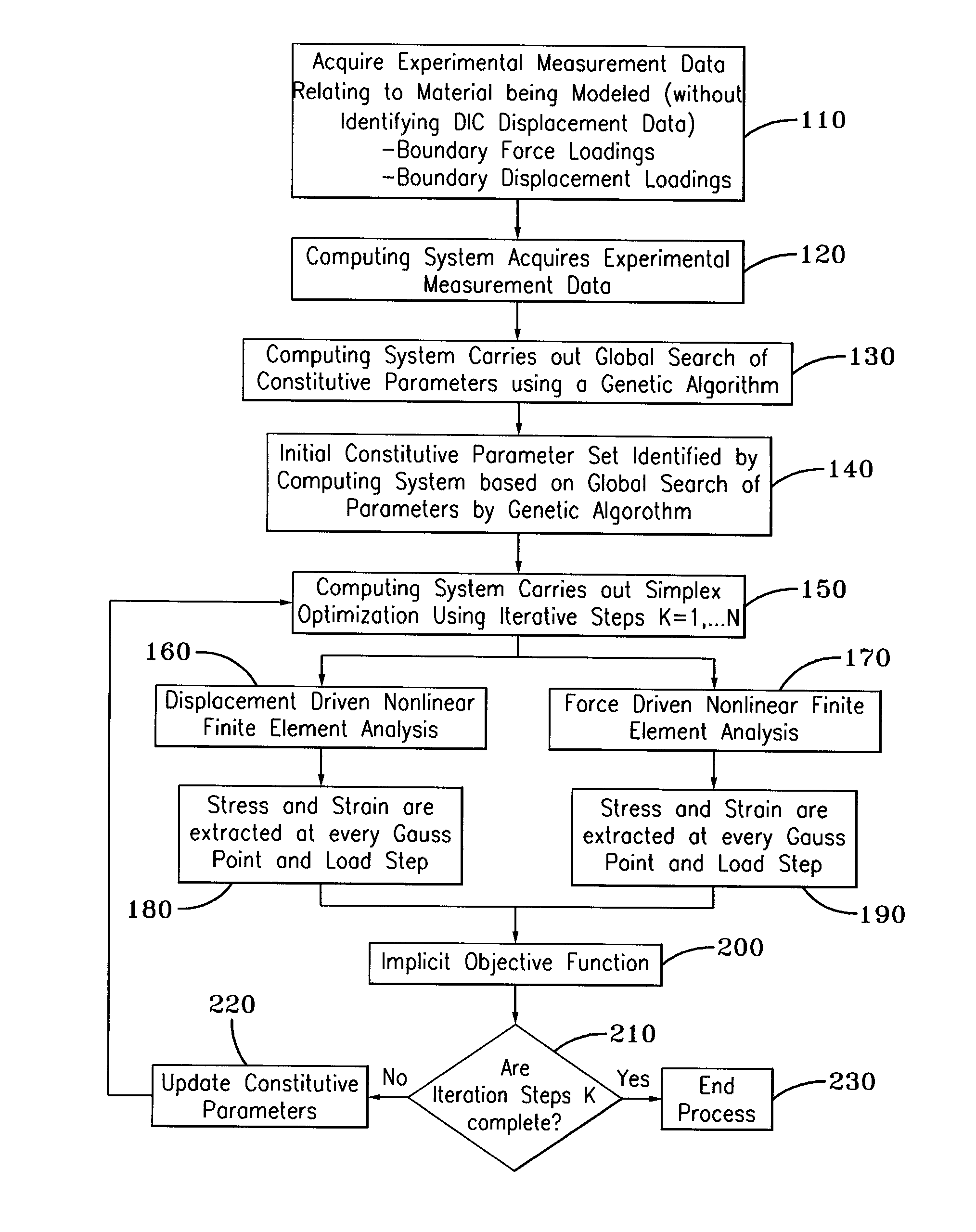

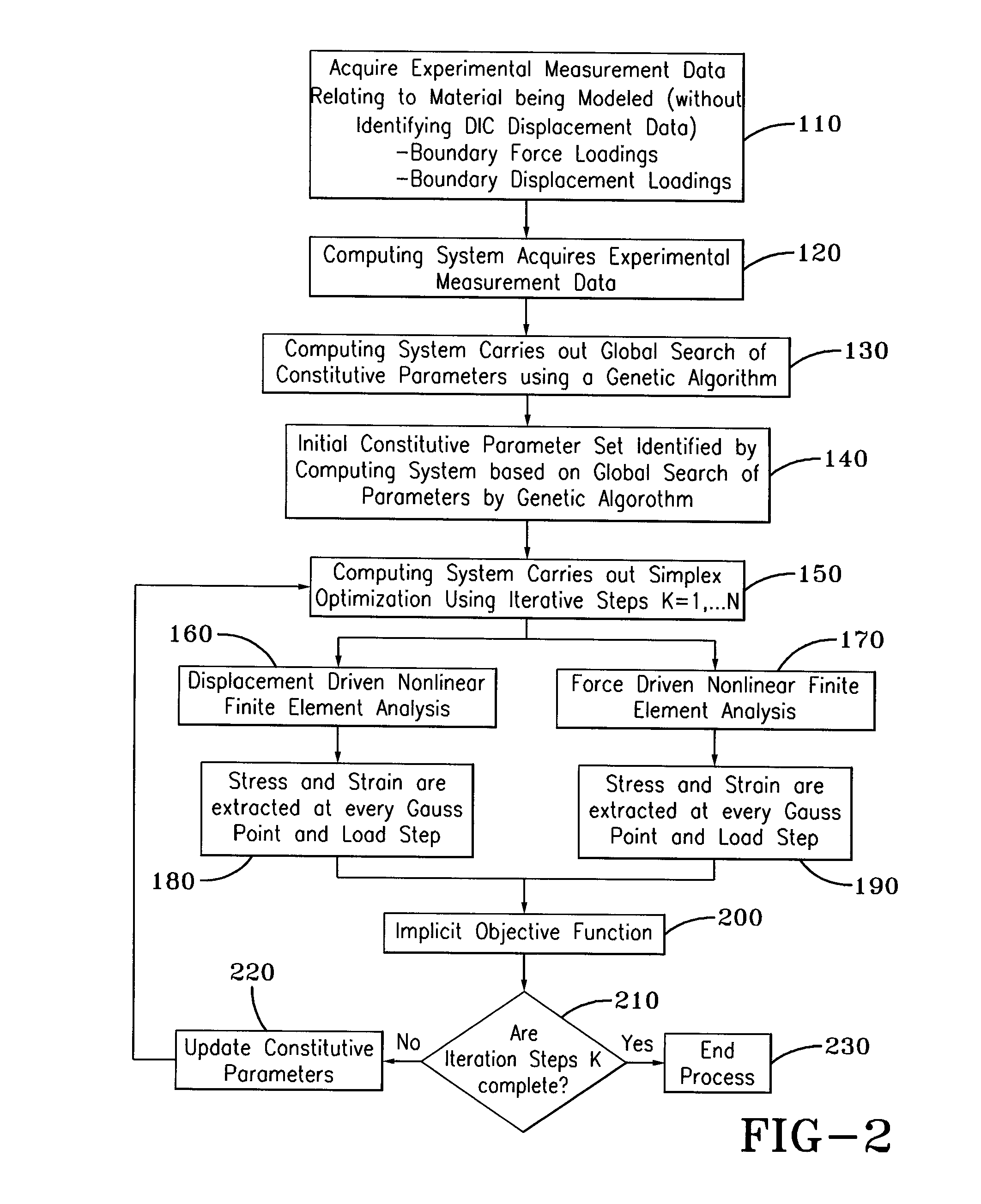

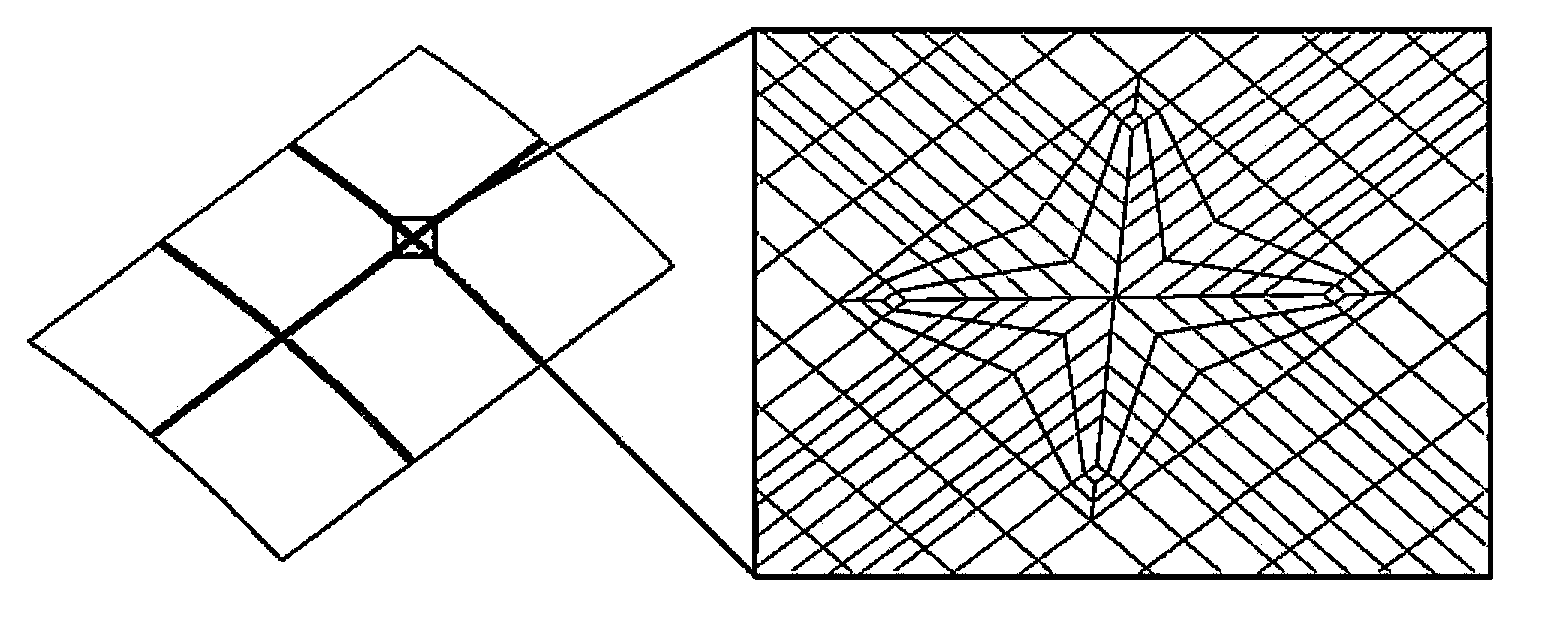

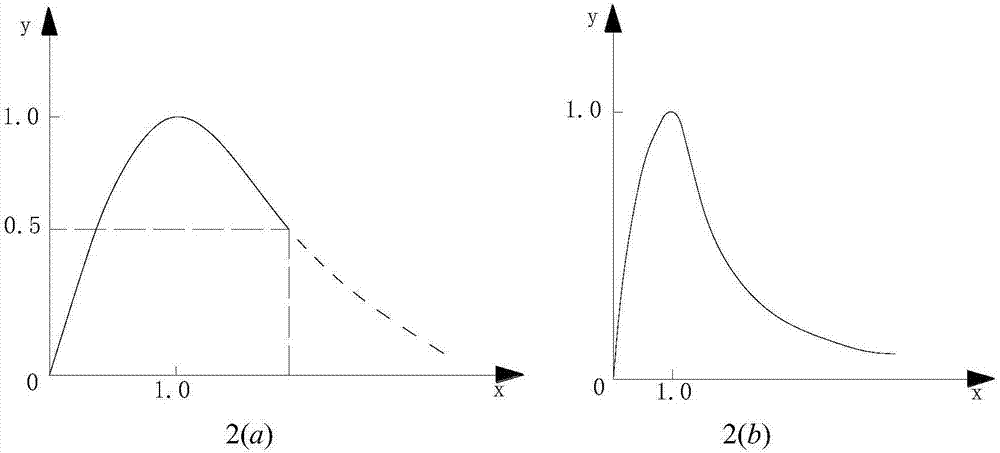

A self-optimizing, inverse analysis method for parameter identification of nonlinear material constitutive models utilizes the global force and displacement boundary loadings that are experimentally identified to globally search for initial constitutive parameters using a genetic algorithm. The initially identified constitutive parameters are then iteratively optimized by a simplex method in which two nonlinear finite element analyses are conducted in parallel using updated material constitutive parameters under the experimentally measured force and displacement boundary loadings. Stress and strain values for both the force and displacement finite element analyses are then input into an implicit objection function. Finally, the simplex optimization is performed for a number of predetermined number of iterations, whereupon the start of each new iteration utilizes the previously optimized set of constitutive parameters.

Owner:THE UNIVERSITY OF AKRON

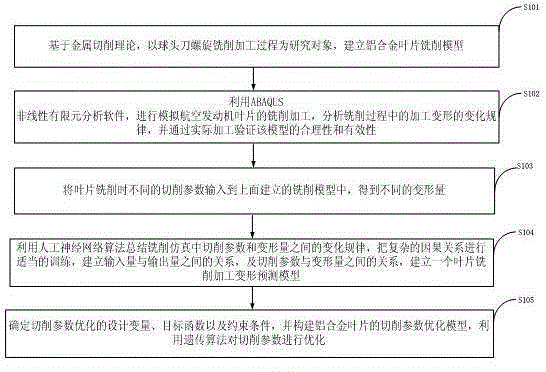

BP and GA based blade machining cutting quantity optimization selection method

InactiveCN105160059AImprove calculation accuracyImprove accuracyGenetic modelsForecastingAviationResearch Object

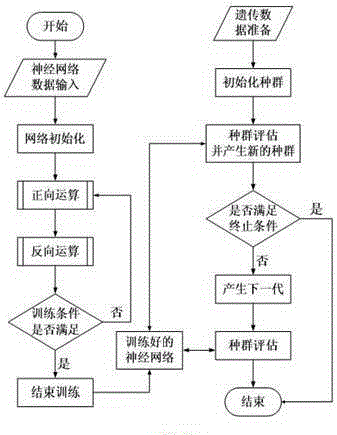

The invention discloses a BP and GA based blade machining cutting quantity optimization selection method. The method comprises: establishing an aluminum alloy blade milling model by taking a spiral milling process of a ball end mill as a research object; simulating milling of blades of an aeroengine by using ABAQUS nonlinear finite element analysis software; summing up a change pattern between a cutting parameter and a deformation amount in milling simulation and a relationship between the cutting parameter and the deformation amount by using an artificial neural network algorithm, and establishing a blade milling deformation prediction model; and determining a design variable, a target function and a constraint condition for cutting parameter optimization, constructing a cutting parameter optimization model of aluminum alloy blades, and optimizing the cutting parameter by using a genetic algorithm. According to the method, the functional relationship between the deformation amount and the cutting parameter is established, and the cutting parameter optimization model is established, thereby providing a reasonable and quick cutting parameter selection method to guide actual production.

Owner:XIAN TECH UNIV

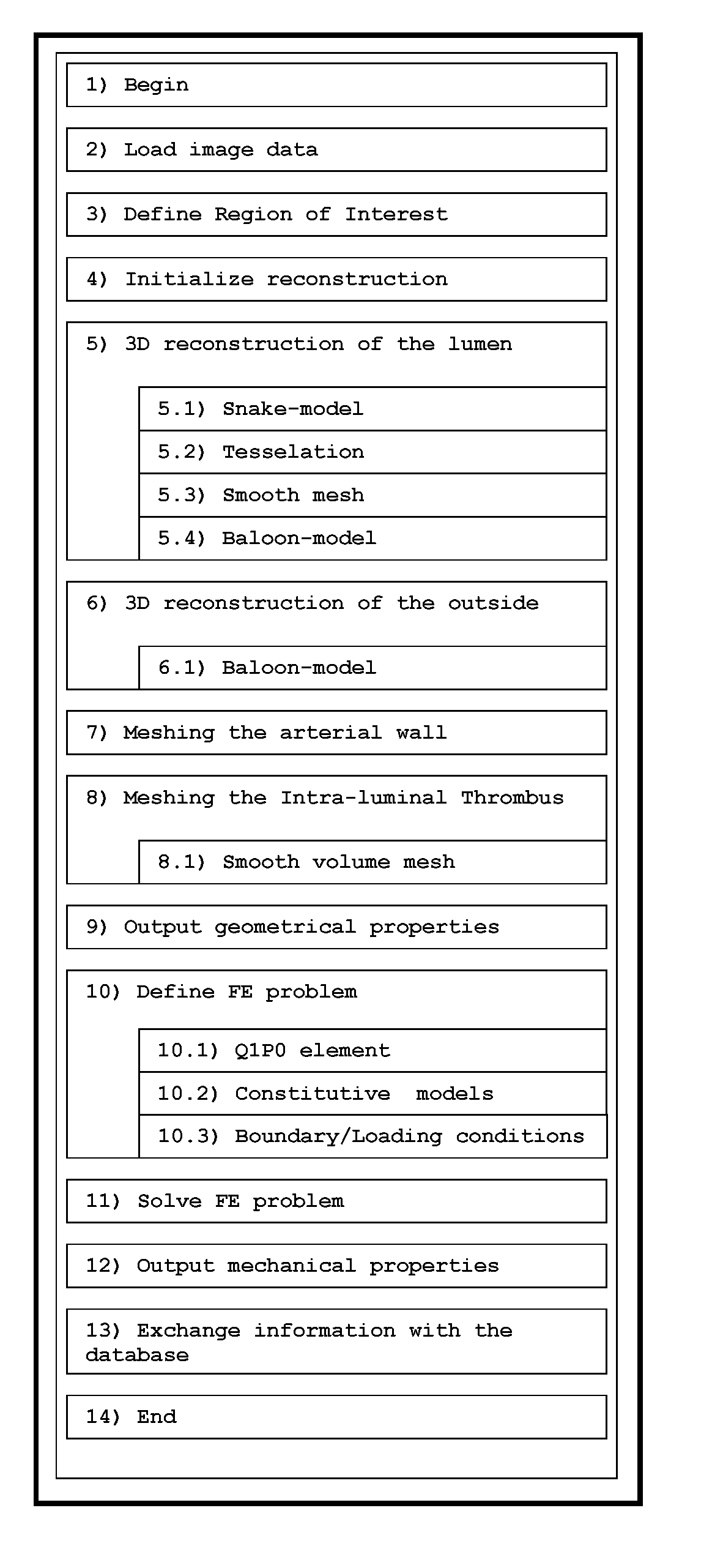

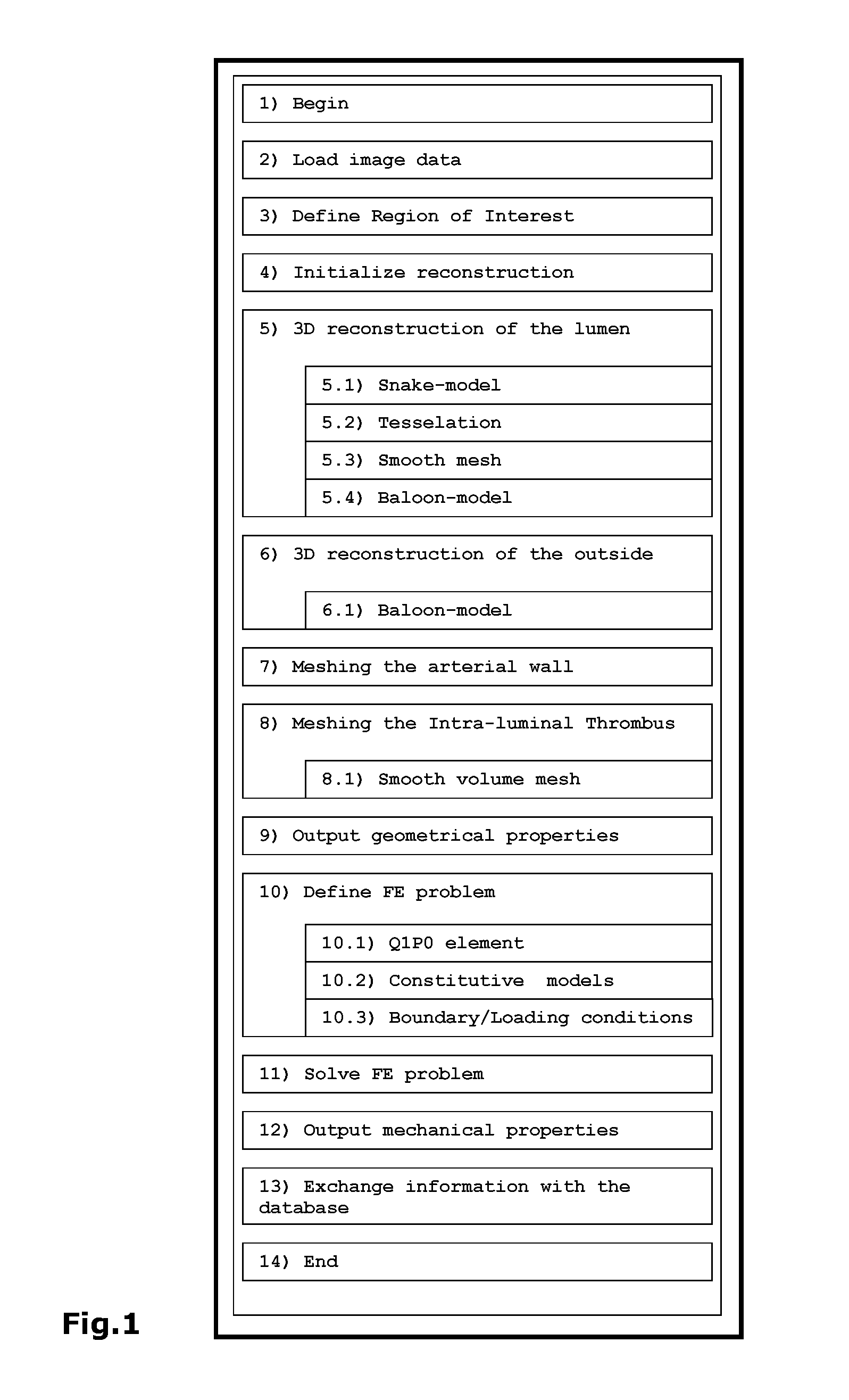

Automatic geometrical and mechanical analyzing method and system for tubular structures

InactiveUS20100290679A1Effective applicationQuality improvementDetails involving processing stepsImage enhancementVascular bodyData set

A method and system for analyzing tubular structures, such as vascular bodies, with respect to their geometrical properties and mechanical loading conditions is disclosed. To this end, geometrical and structural models of vascular bodies are generated from standard sets of image data. The method or system works automatically and the tubular structure is analyzed within clinical relevant times by users without engineering background. Most critical in that sense is the integration of novel volume meshing and 3D segmentation techniques. The derived geometrical and structural models distinguish between structural relevant types of tissue, e.g., for abdominal aortic aneurysms the vessel wall and the intra-luminal thrombus are considered separately. The structural investigation of the vascular body is based on a detailed nonlinear Finite Element analysis. Here, the derived geometrical model, in-vivo boundary / loading conditions and finite deformation constitutive descriptions of the vascular tissues render the structural biomechanical problem. Different visualization concepts are provided and allow an efficient and detailed investigation of the derived geometrical and mechanical data. In addition, this information is pooled and statistical properties, derived from it, can be used to analyze vascular bodies of interest.

Owner:VASCOPS

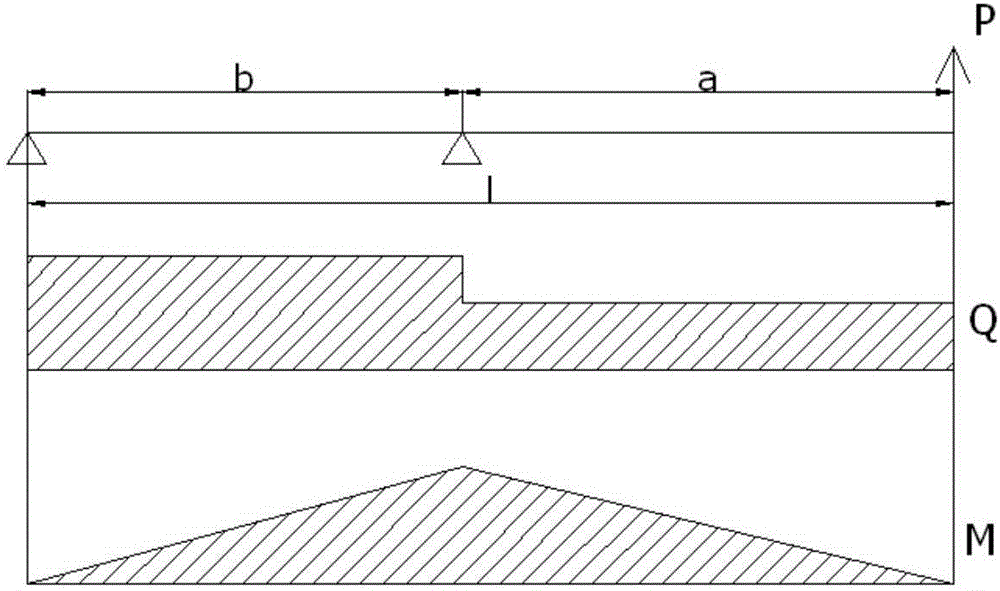

Prejudging method for static-test load carrying capacity of wing structure

ActiveCN105022907AMeet engineering design requirementsSpecial data processing applicationsJet aeroplaneCarrying capacity

The invention belongs to the technology of airplane structural strength and relates to a prejudging method for the static-test load carrying capacity of a wing structure. The prejudging method of the invention comprises the steps as follows: establishing a finite element model according to a wing structure before carrying out an actual test, and performing elastoplasticity and large deflection nonlinear finite element analysis to the model to obtain a wingtip deflection-load curve; determining maximum load carrying capacity of the wing structure according to the variation characteristic of the wingtip deflection-load curve and giving out the breaking load of the wing structure; obtaining a dangerous portion of the wing structure and the process form the unstable condition to the destructive condition and pre-judging the static-test load carrying capacity of the wing structure. According to the invention, the error between the calculated breaking load and the tested breaking load is 6.25 percent. The calculated dangerous part and the tested breaking portion are consistent. The calculated process form the unstable condition to the destructive condition is consistent with the tested unstable process. The method of the invention provides a guarantee for the one-time success of the static test of the structure and provides reference for evaluating the structural strength of the wing.

Owner:上海秦耀航空试验技术有限公司

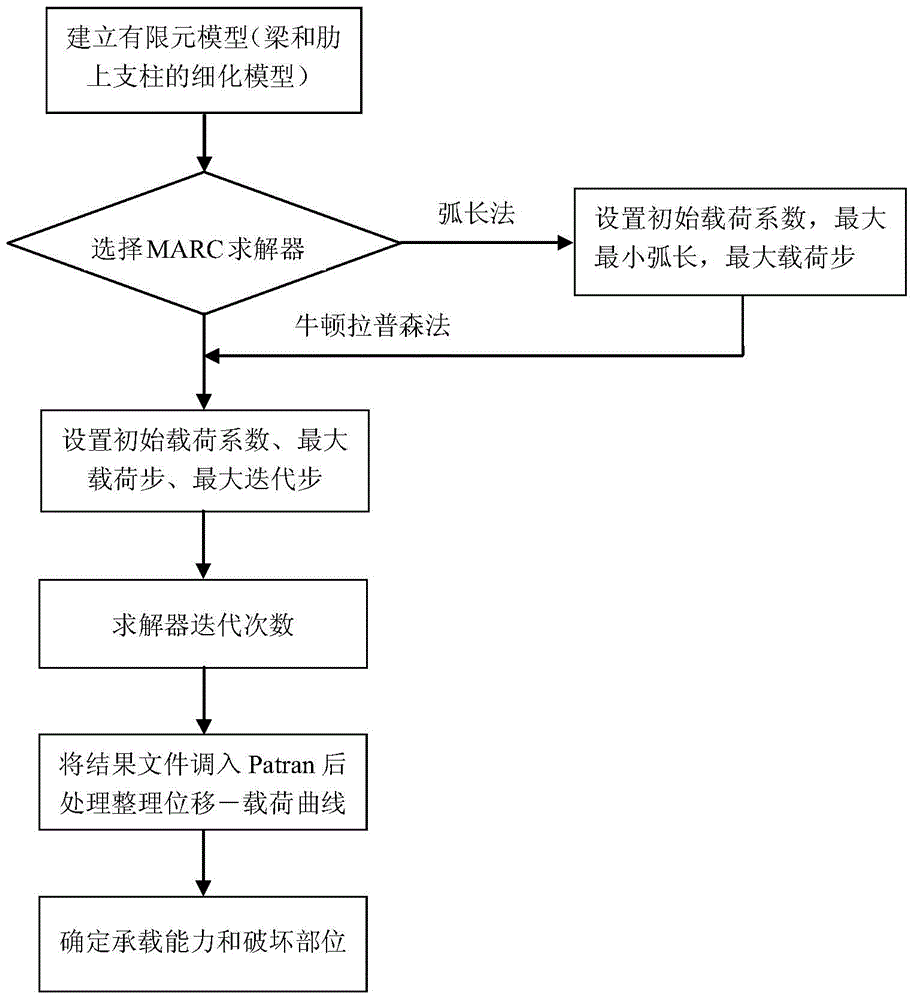

Arc length method nonlinear finite element analysis-based disc burst speed prediction method

InactiveCN106446367APredicted limit speedSolve problems that cannot convergeGeometric CADDesign optimisation/simulationElement modelPredictive methods

The invention discloses an arc length method nonlinear finite element analysis-based disc burst speed prediction method. The method comprises the steps of sampling a disc material and obtaining constitutive model parameters of the material through an experiment; approximately estimating a burst speed of a disc by adopting a conventional method; defining an elastoplastic constitutive model of the disc in finite element software; building a three-dimensional finite element model of the disc material and performing mesh division; for a disc rotor finite element model needed to be calculated, applying constraint and rotary speed loads; performing large-deformation nonlinear finite element calculation by adopting an arc length method; and obtaining a rotary speed or angular speed-disc radial displacement curve in a time postprocessor after calculation, thereby obtaining an extreme critical rotary speed of the disc or a rotor, namely, the burst speed. According to the method, a more reasonable disc burst criterion based on arc length method nonlinear finite element analysis and global plastic instability is adopted, so that the extreme rotary speed of the disc or the rotor can be predicted more accurately.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

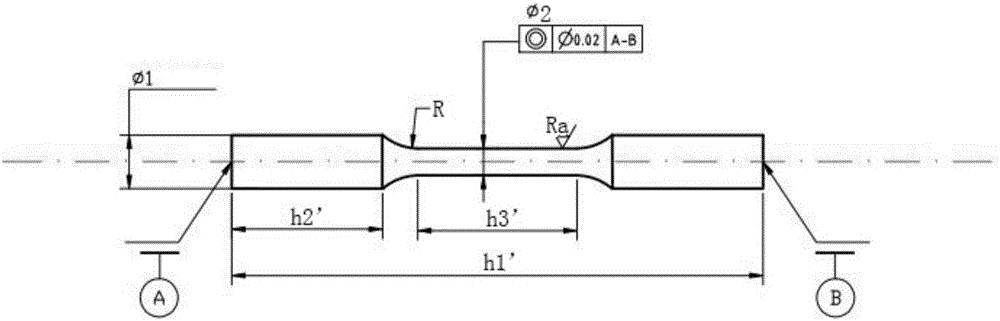

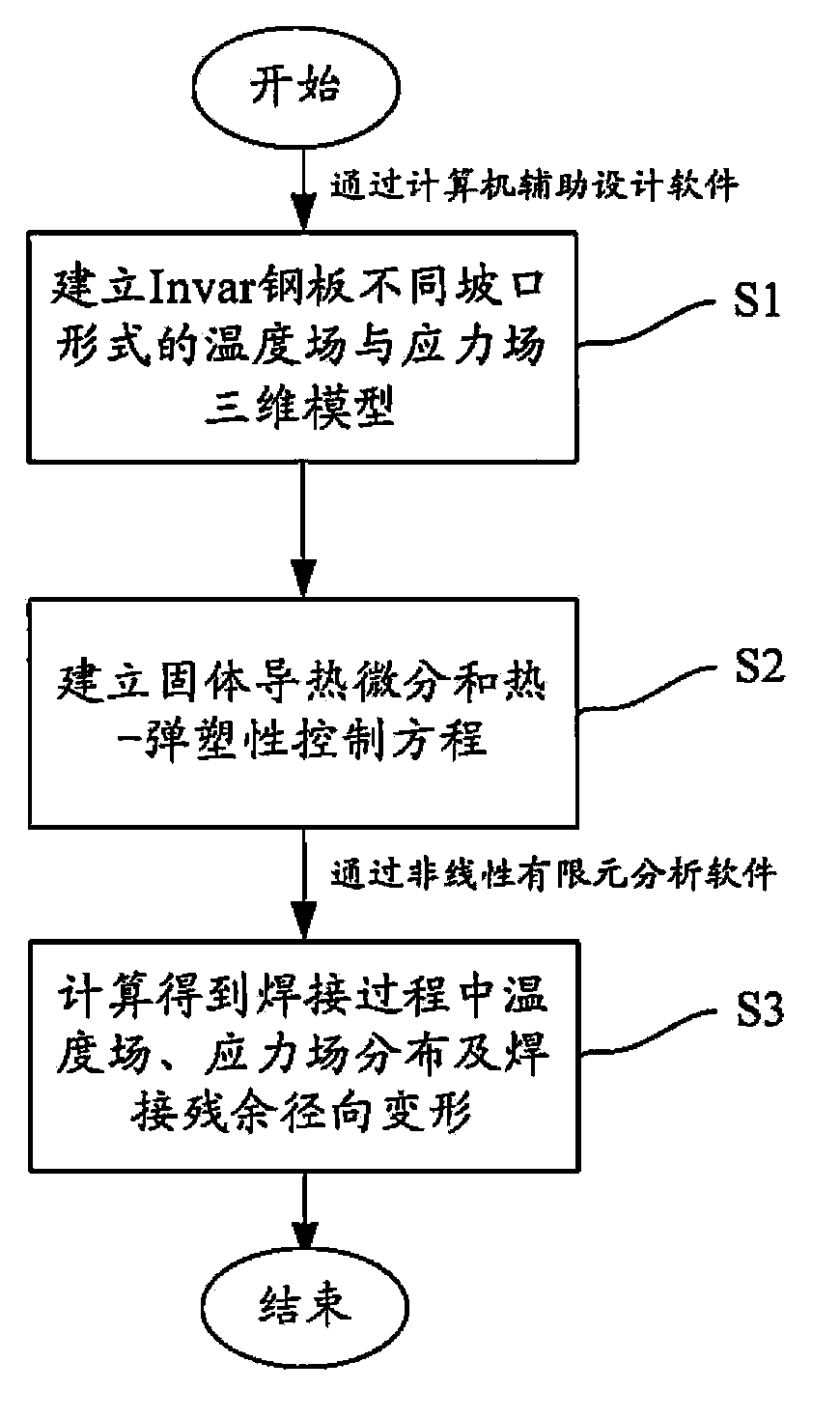

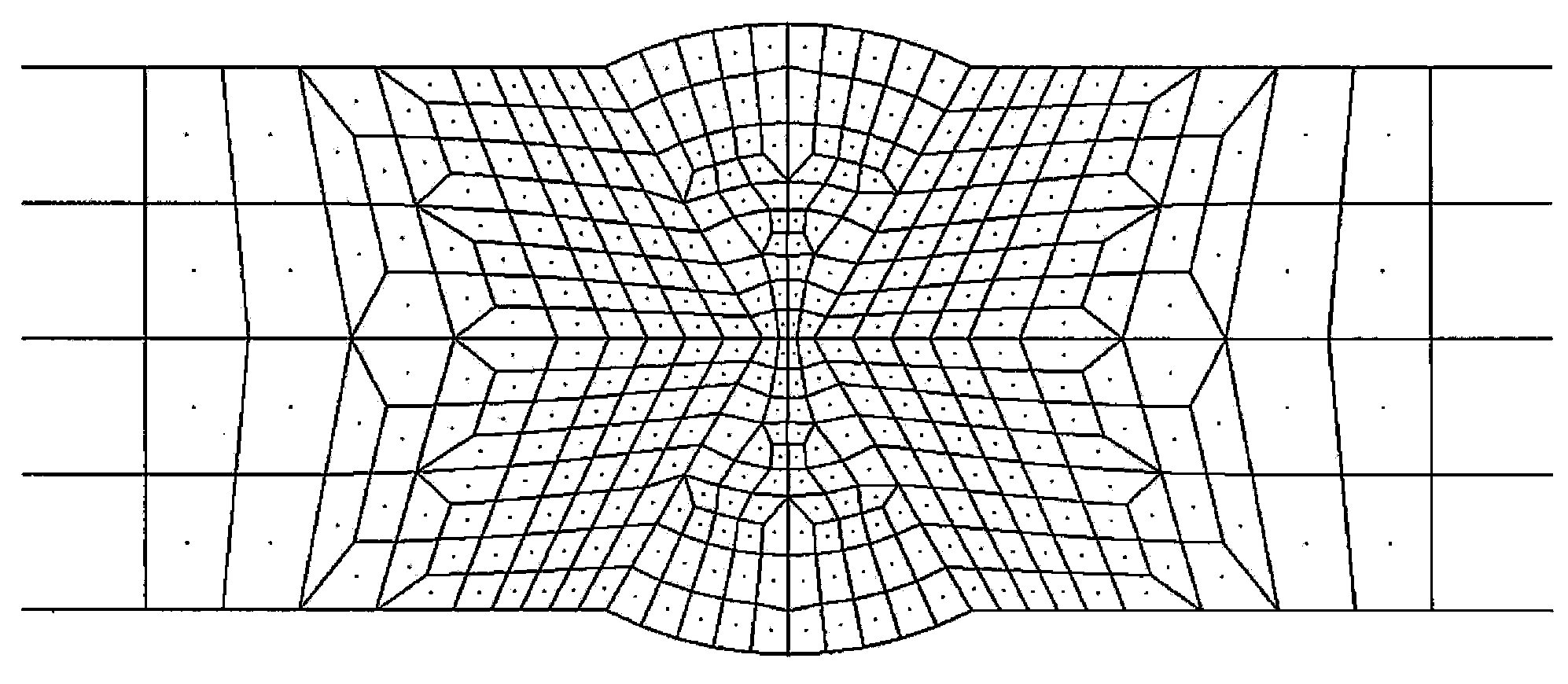

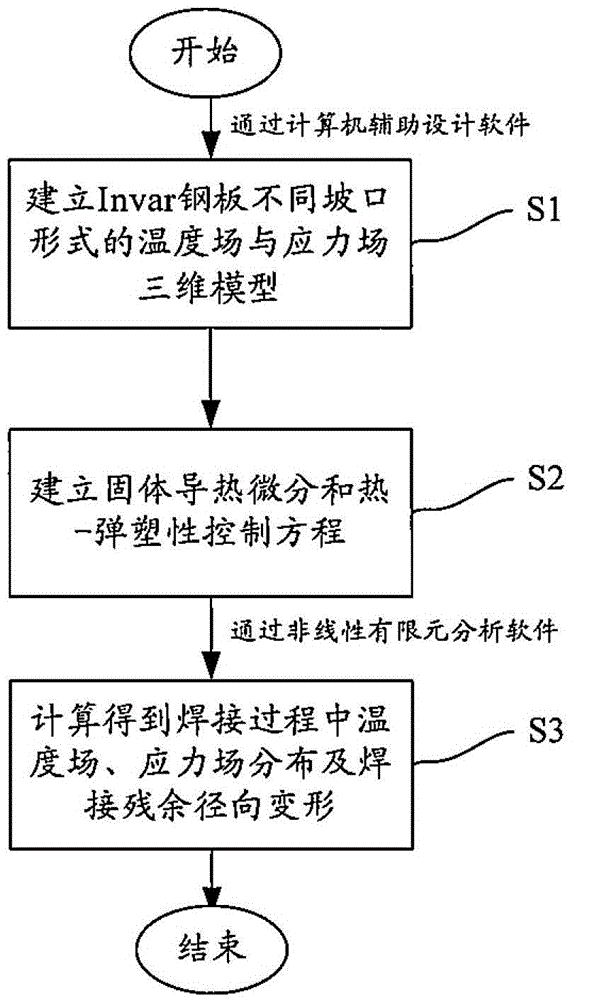

Deformation simulation method for multilayer multi-pass welding of Invar steel plate

ActiveCN103440355AGet Deformation Optimization MethodSave costsSpecial data processing applicationsInteraction problemNonlinear finite element analysis

The invention relates to a deformation simulation method for the multilayer multi-pass welding of an Invar steel plate. The method comprises the following steps of establishing a three-dimensional temperature field and stress field model of the Invar steel plate, and solving radial deformation results under different conditions on the basis of nonlinear finite element analysis software by changing realistic clamping conditions, a welding sequence and the shape of a groove to obtain an optimization method for controlling welding deformation. According to the deformation simulation method for the multilayer multi-pass welding of the Invar steel plate, the three-dimensional temperature field and stress field model of the Invar steel plate is established for the multilayer multi-pass welding process of the Invar steel plate, the problem of interaction between cross welds is also taken into account, and different set boundary conditions are solved to obtain the optimization method for controlling the welding deformation.

Owner:SHANGHAI AIRCRAFT MFG +1

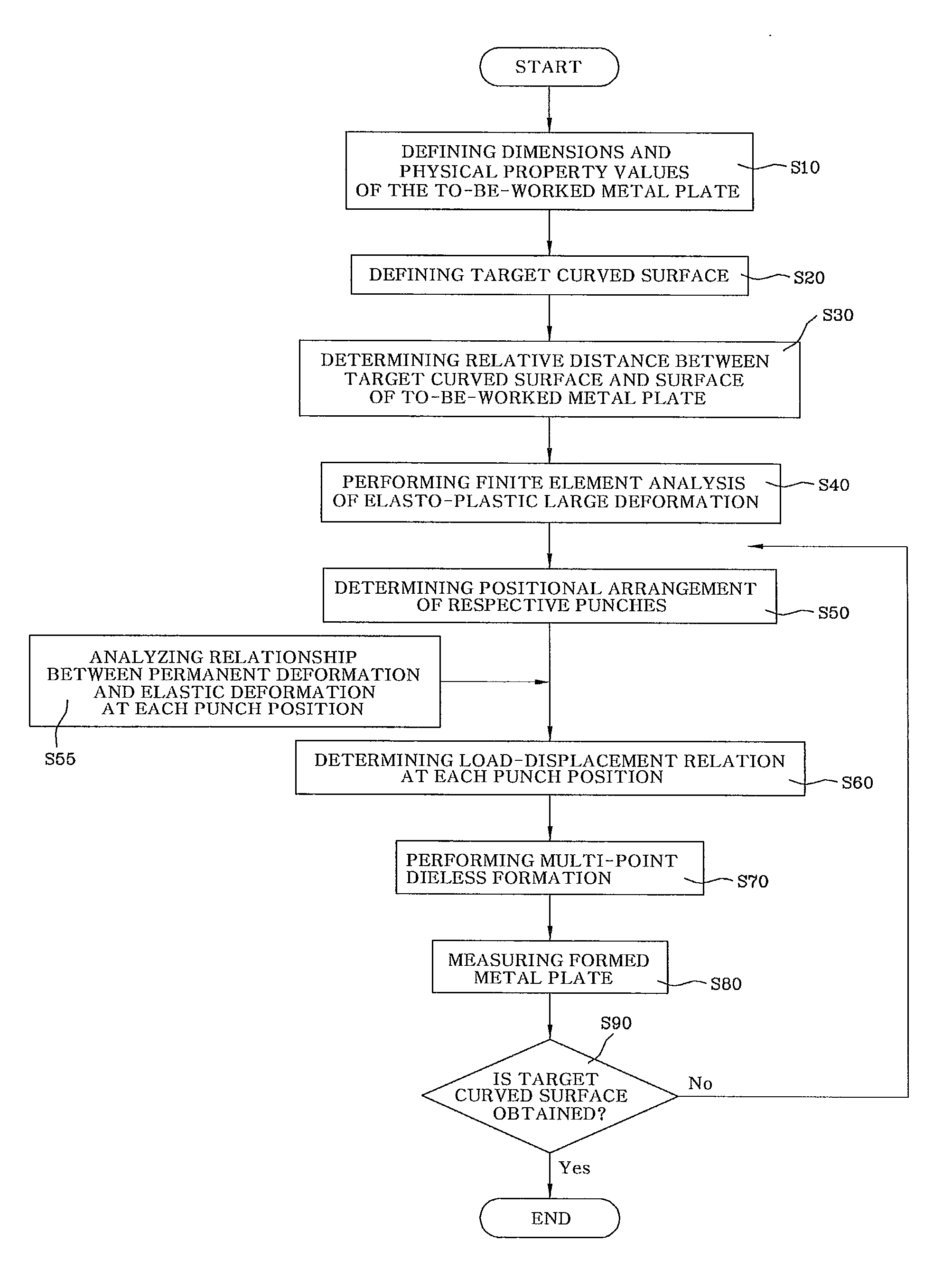

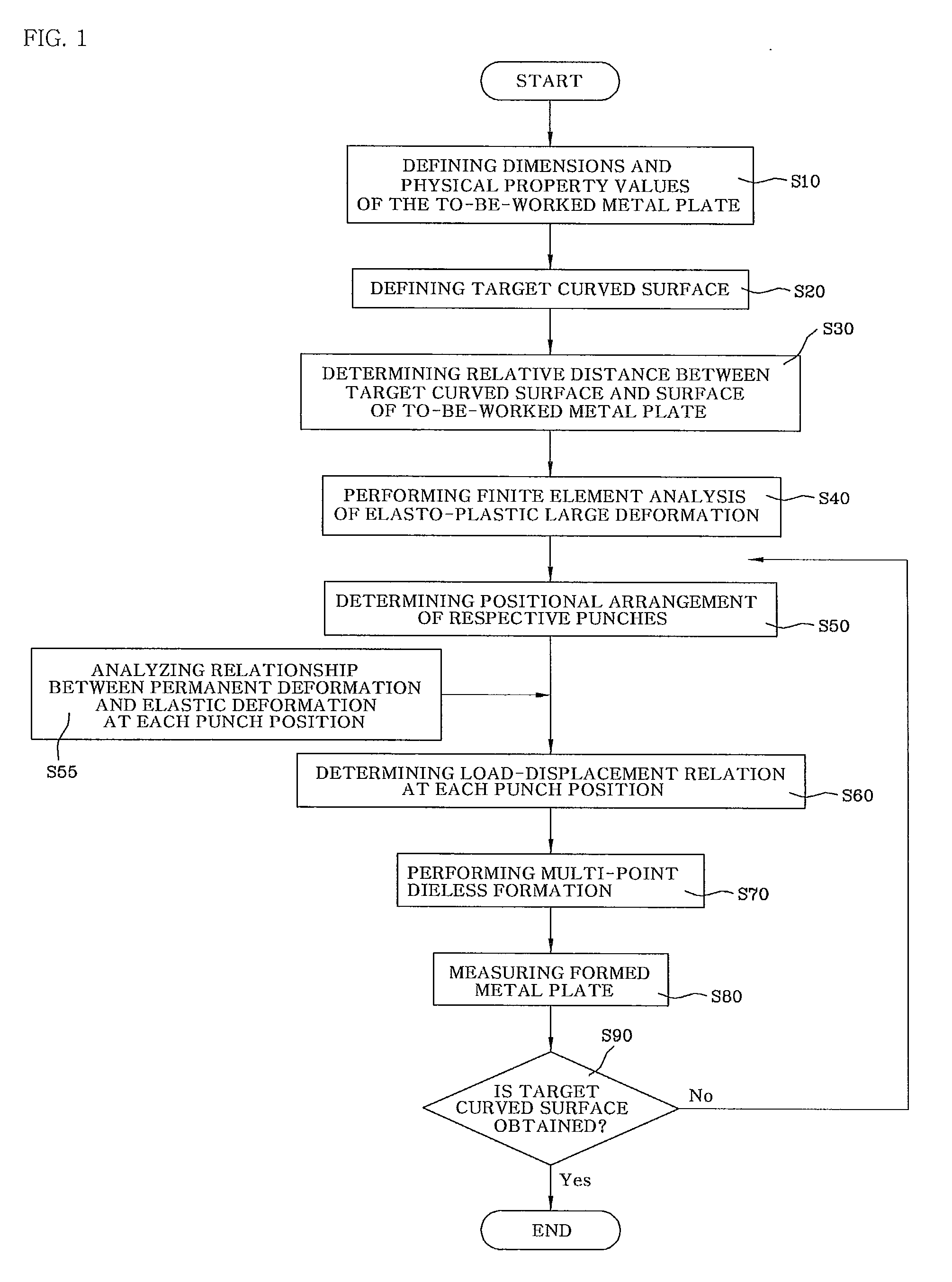

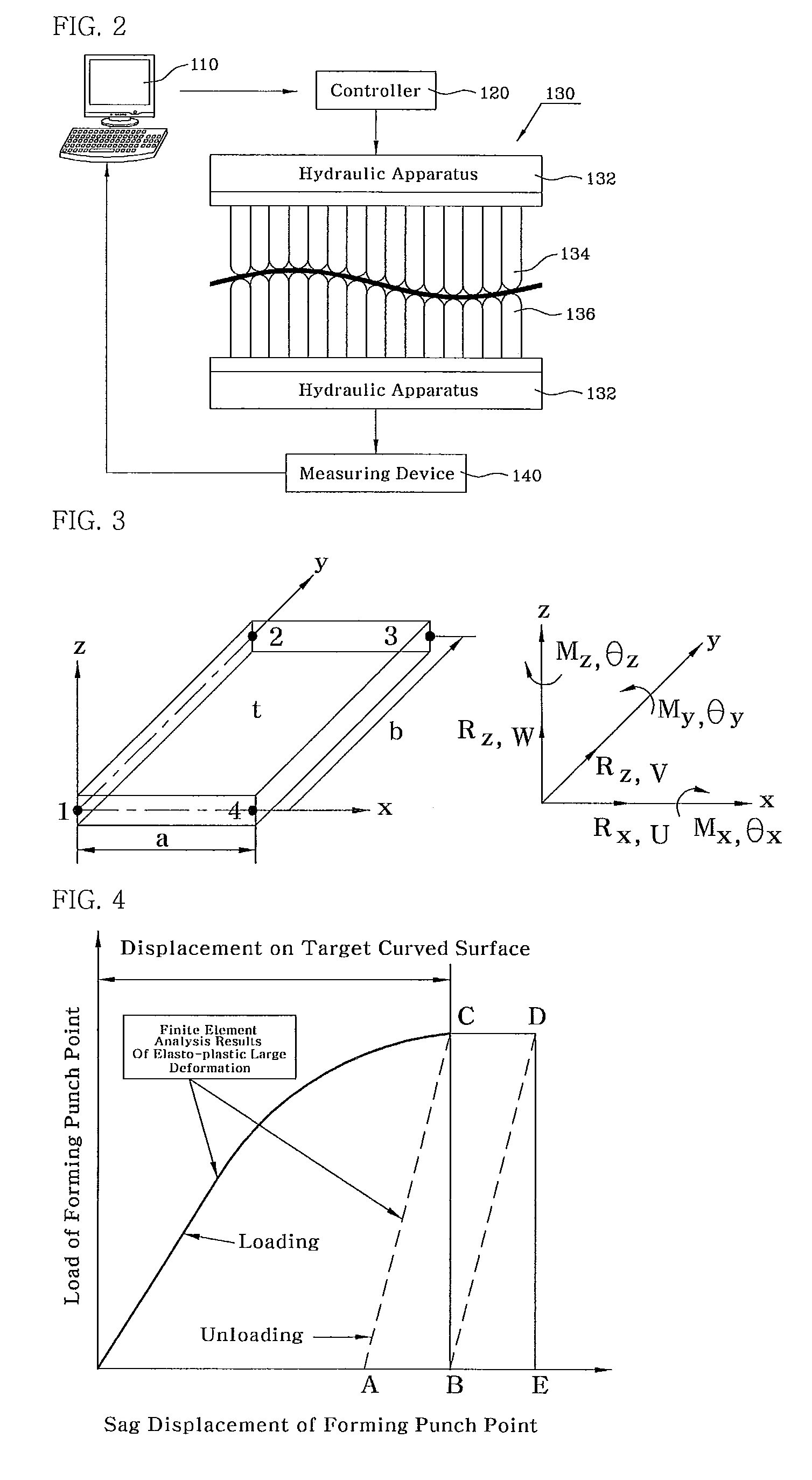

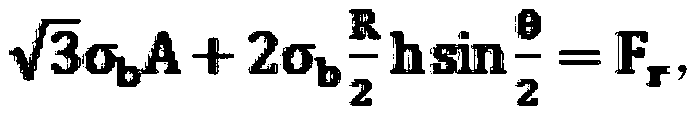

Curved surface forming method of a metal plate

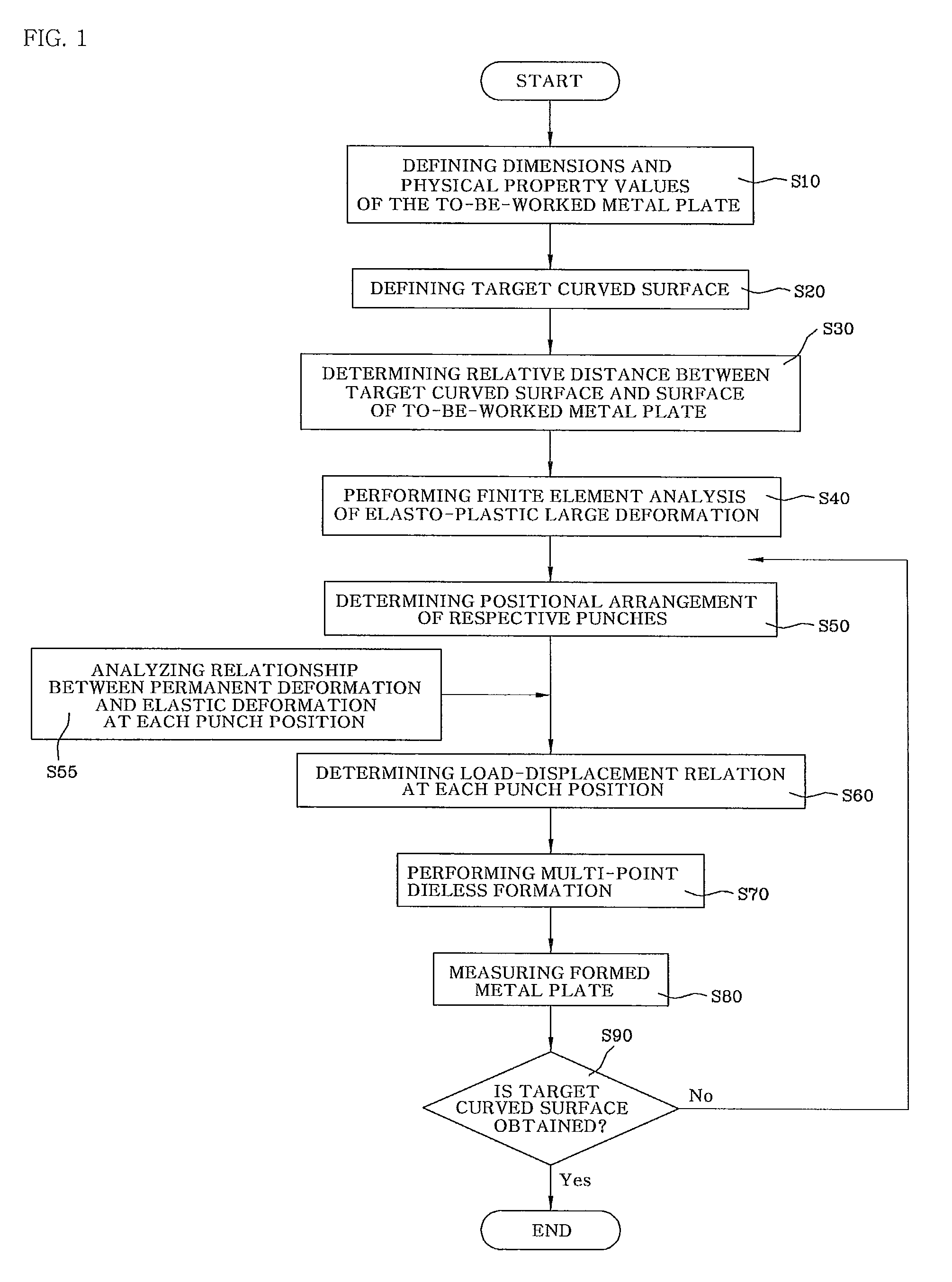

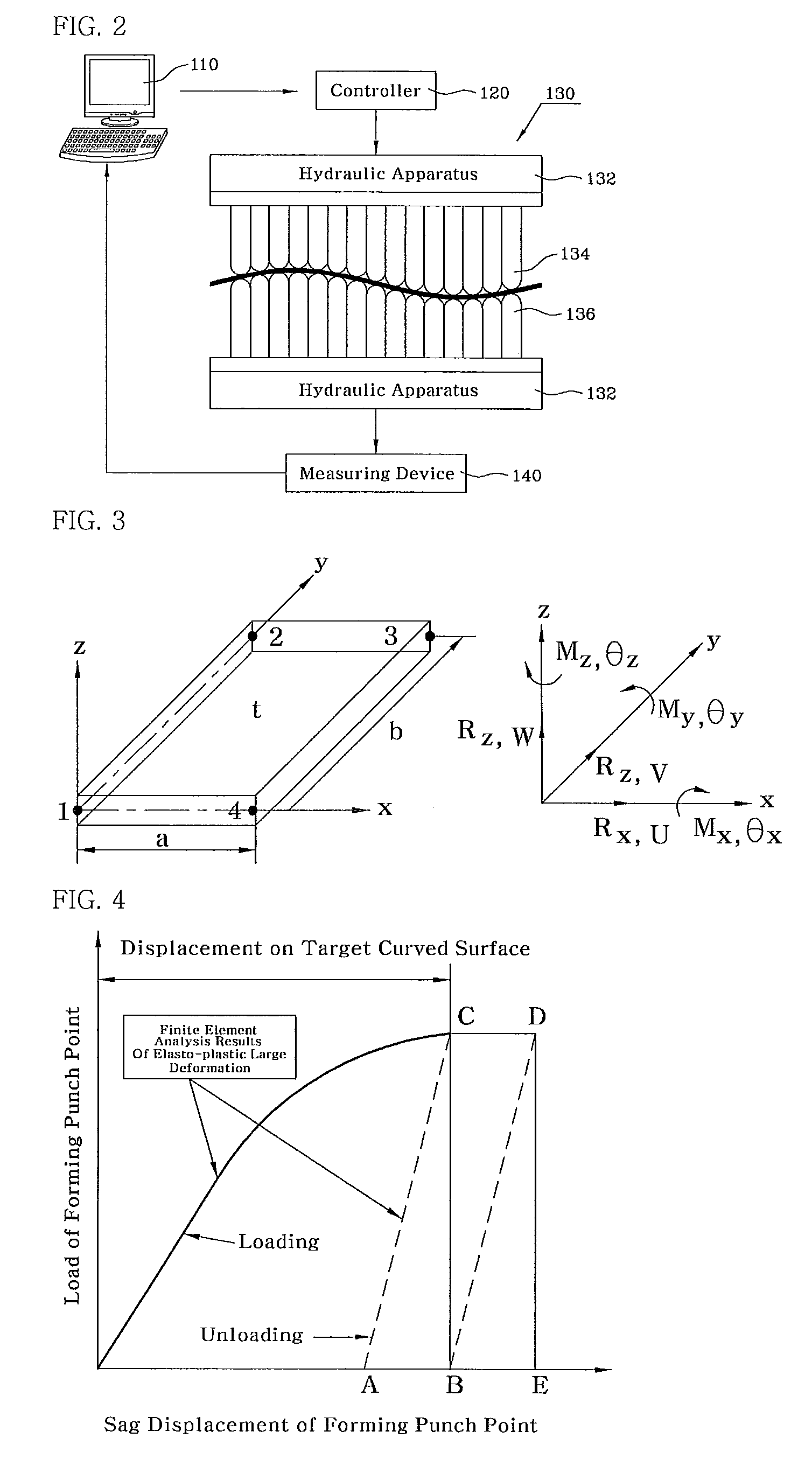

InactiveUS20100030362A1Shorten the timeImprove economyShaping toolsShaping safety devicesNonlinear finite element analysisLarge deformation

Disclosed is a curved surface forming method for a metal plate. Nonlinear finite element analysis of elasto-plastic large deformation is performed on the metal plate. The metal plate to be worked is formed so as to have a three-dimensional target curved surface on the basis of the analysis results using a plurality of forming punches connected to a hydraulic apparatus. The curved surface formation method is very useful when the metal plate is worked for small quantity batch production.

Owner:PAIK JEOM KEE

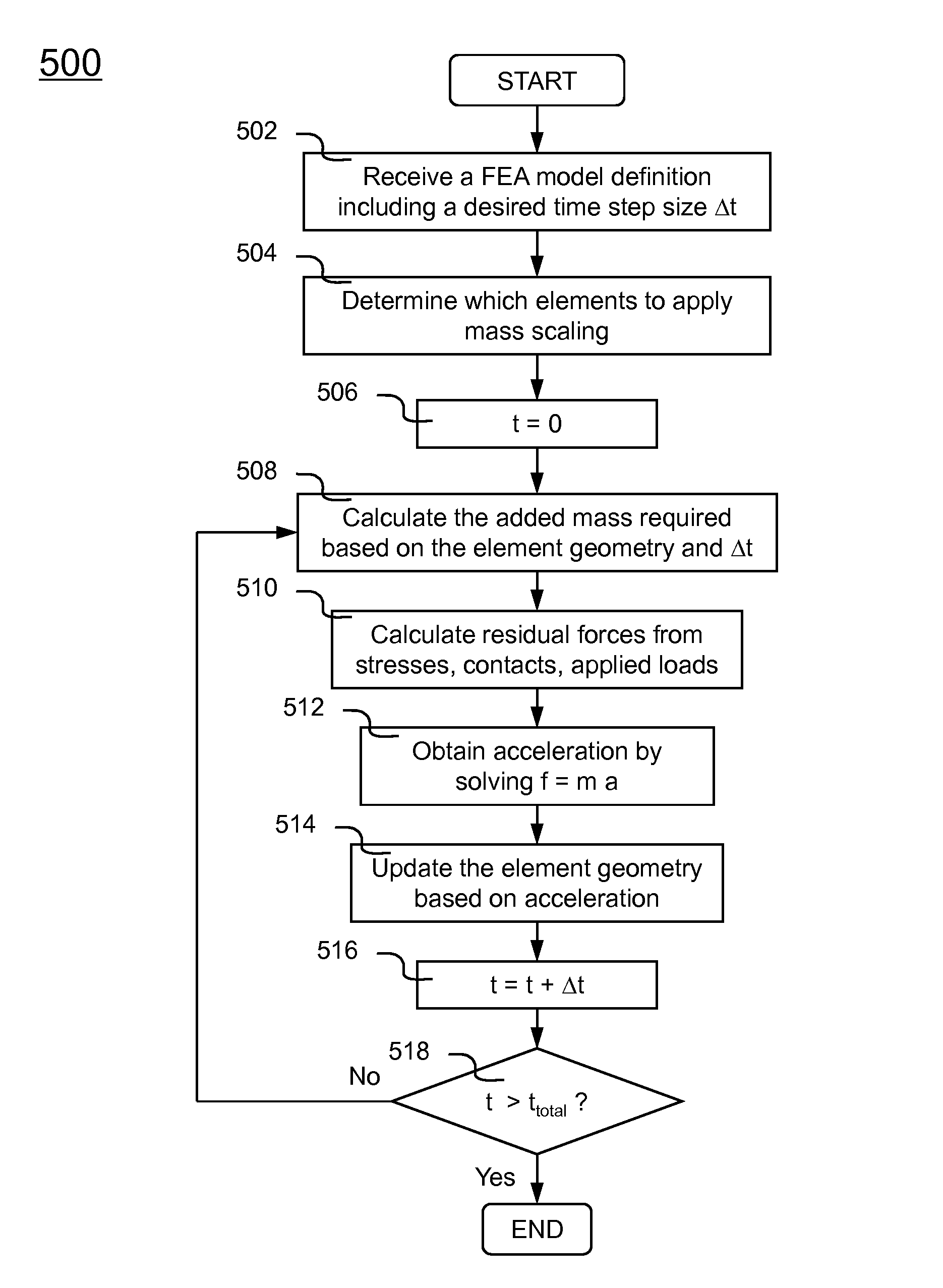

Methods and systems for applying mass scaling in finite element analysis

InactiveUS20120323536A1Reduce the impactIncrease mass densityDesign optimisation/simulationCAD numerical modellingComputational scienceElement analysis

Methods and systems for applying mass scaling in finite element analysis is described. Elements with a critical time step smaller than a user desired time step are identified. Out of these elements, elements located in a particular region requiring realistic simulated dynamic responses are processed with selective mass scaling and the rest are processed with regular mass scaling. Selective mass scaling requires more computation but can better preserve dynamic structural characteristics. The aforementioned method is referred to as a mixed mode mass scaling. Mixed mode mass scaling allows engineering simulation to be conducted within a reasonable turnaround time, because only a portion of the FEA model is subjected to more computation intensive selective mass scaling. Selective mass scaling technique includes reducing effects caused in three translational and three rotational rigid body modes of shell element.

Owner:LIVERMORE SOFTWARE TECH

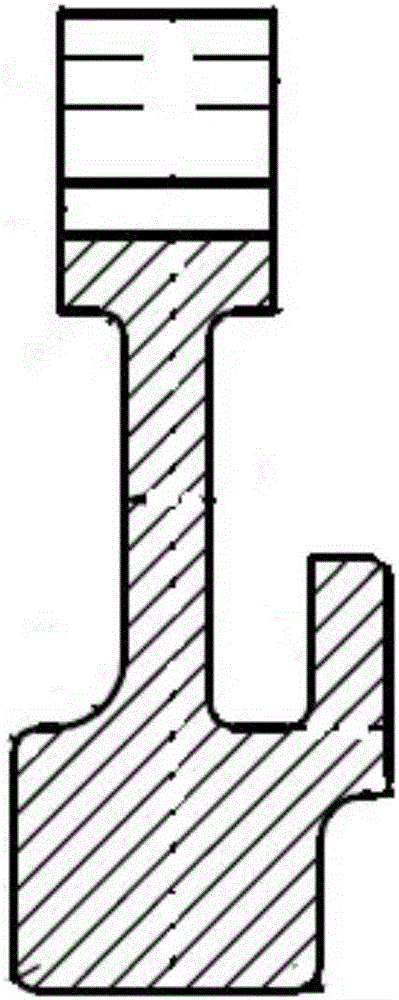

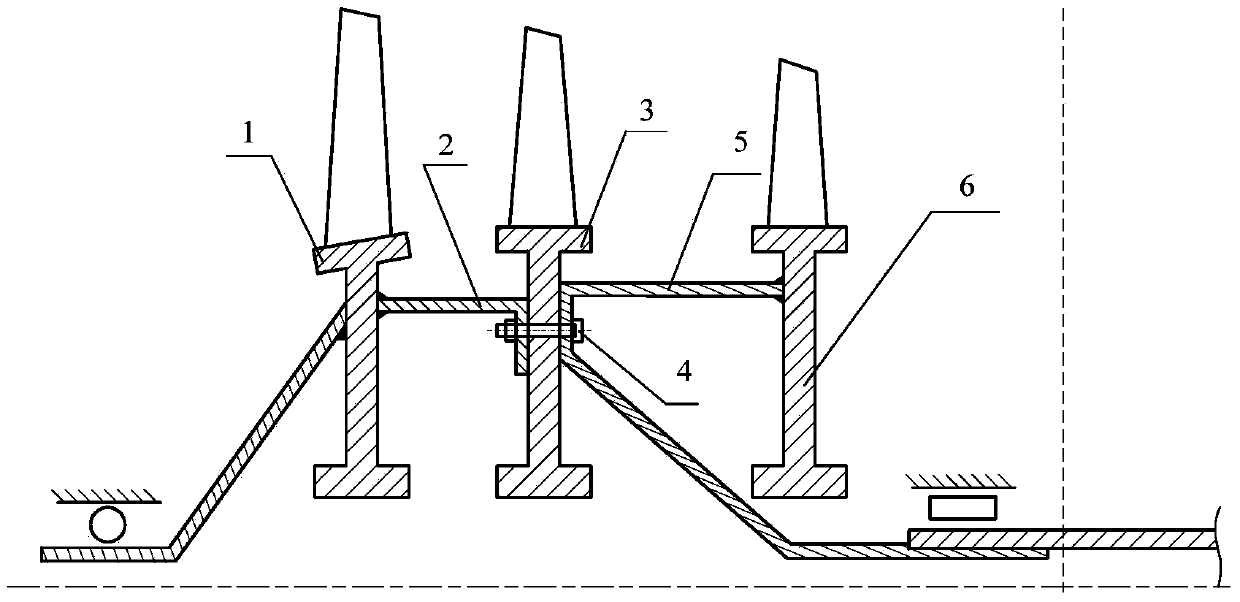

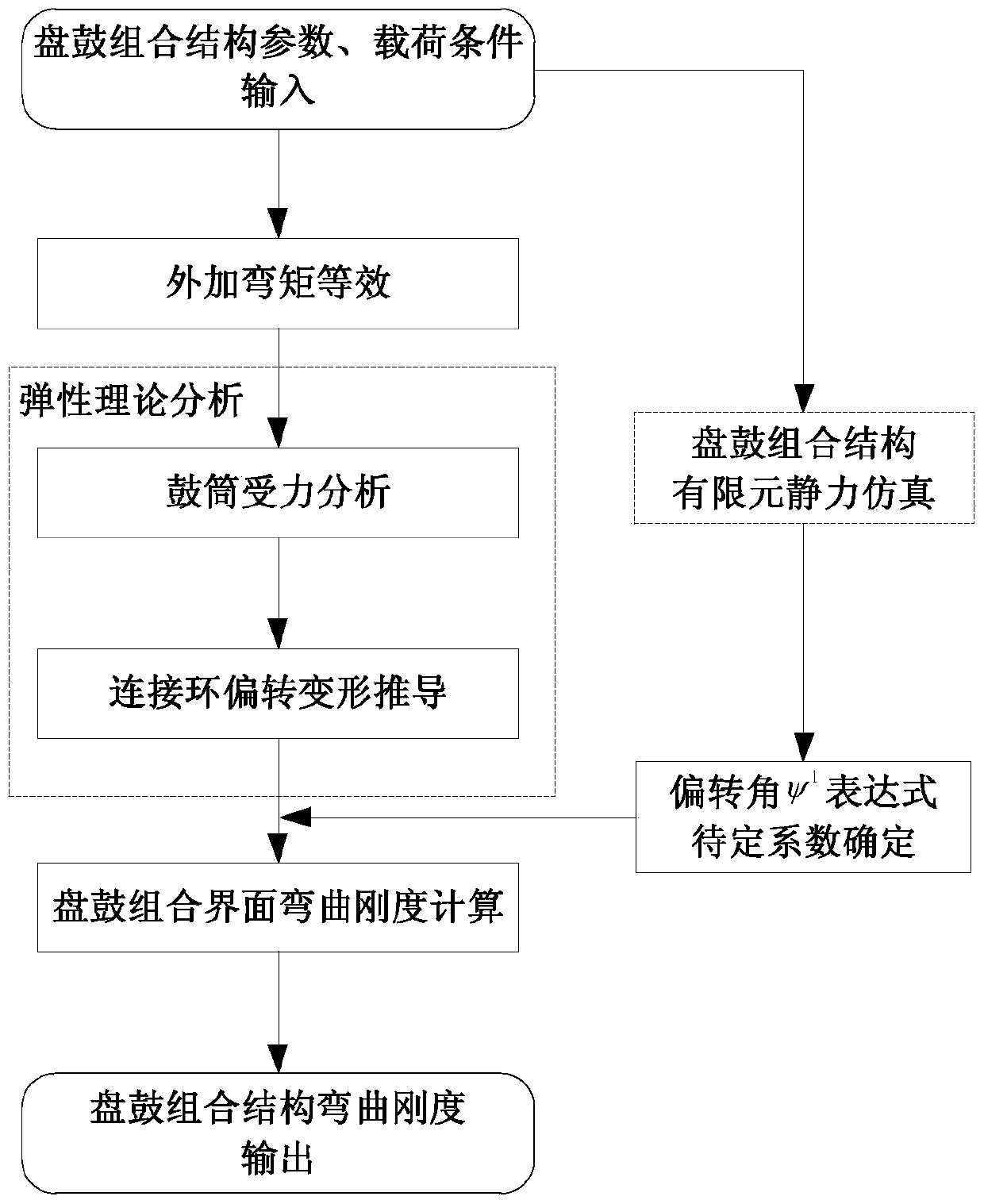

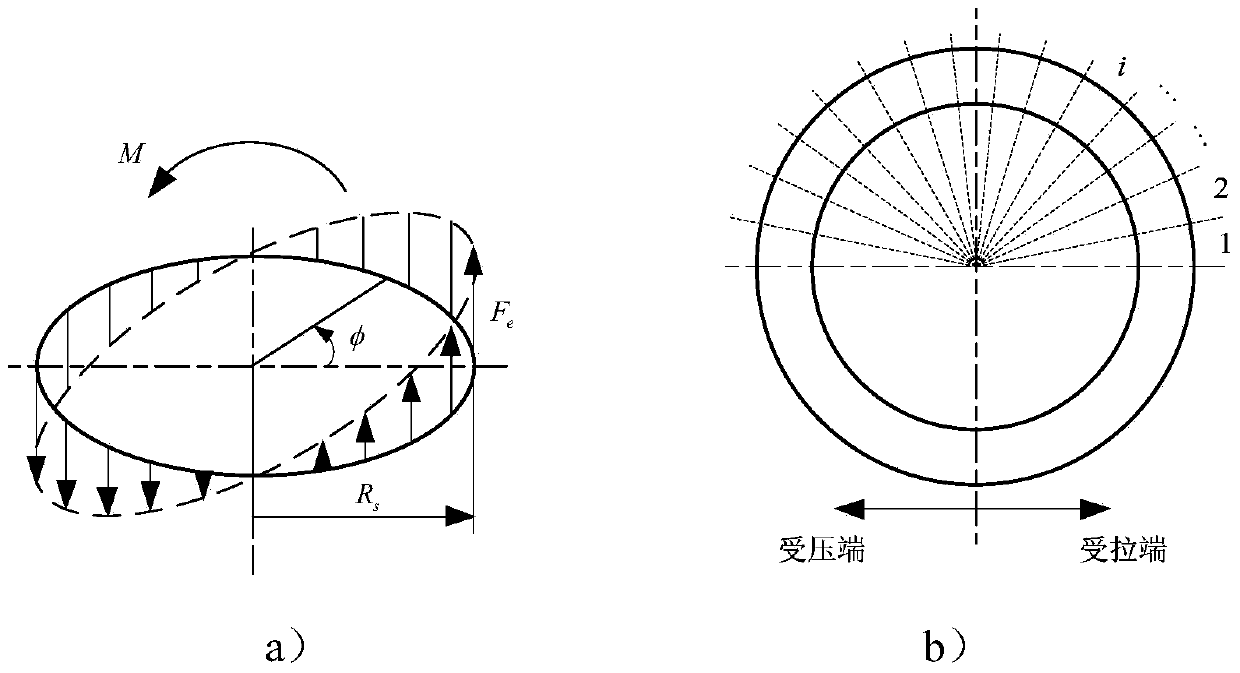

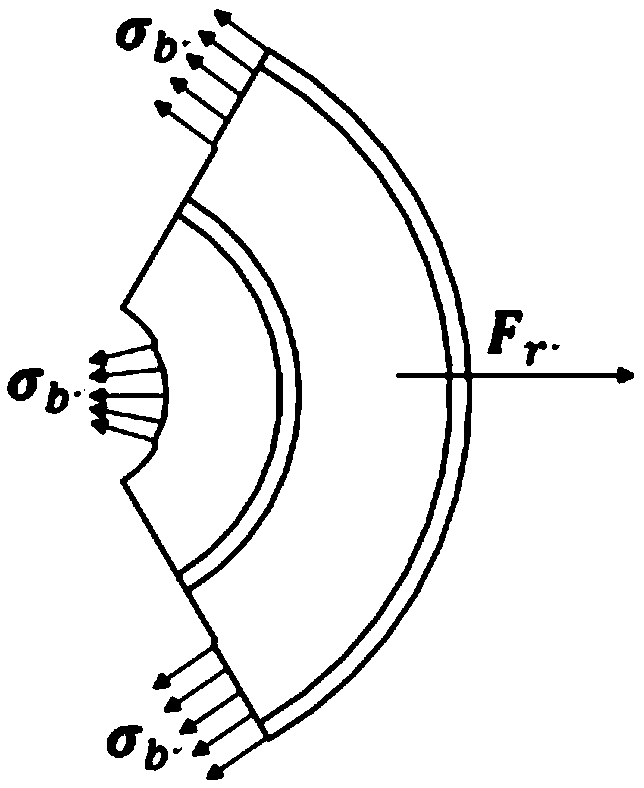

Method for computing bending rigidity of disc and drum combination interface of rotor of aero-engine

InactiveCN103729547AIntuitively reflect the influence law of bending stiffnessThe analytical expression of bending stiffness is accurateSpecial data processing applicationsAnalytical expressionsNonlinear finite element analysis

The invention discloses a method for computing the bending rigidity of a disc and drum combination interface of a rotor of an aero-engine, and belongs to the field of structural mechanics for determining the rigidity of combination interfaces. The method includes particular steps of 1), performing equivalence on external bending moment; 2), analyzing stress on drums; 3), deriving an analytical expression for deflection angles of connecting rings of the drums under the effect of the bending moment by the aid of an elastic deformation theory; 4), determining values of contact parameters in the expression for the deflection angles psi1 on the basis of nonlinear finite element simulation analysis; 5), deriving a relative rotation angle of the disc and drum combination interface from the deflection angles of the connecting rings of the drums and further acquiring an analytical expression for the bending rigidity of the disc and drum combination interface. The method for computing the bending rigidity of the disc and drum combination interface of the rotor of the aero-engine has the advantages that the bending rigidity of the disc and drum combination interface is computed in an analytical manner, and accordingly influence of structural parameters of the disc and drum combination interface, pre-tightening force and the external bending moment on the disc and drum connection rigidity can be visually reflected; contact-related parameters in the analytical expressions are acquired by means of nonlinear finite element analysis, so that the computed bending rigidity of the disc and drum combination interface is close to actual conditions.

Owner:TSINGHUA UNIV

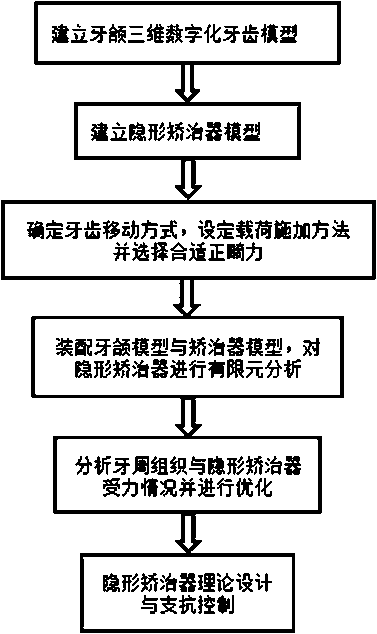

Optimization method of invisible orthodontic appliance

InactiveCN110916820AGuaranteed Simulation AuthenticityEasy to moveOthrodonticsPeriodontiumStress distribution

The invention discloses an optimization method of an invisible dental appliance. The optimization scheme of the invisible dental appliance is reasonable; modelling is indirectly performed through simulating the tooth moving process by finite element software, so that a continuous invisible appliance model which conforms to the actual shape is established, and the continuous invisible appliance model is accurately assembled in a dental model; the integrated effect of an invisible correcting technology to dentition can be researched, and the optimization scheme is applied based on set constraintconditions and a nonlinear finite element analysis method, so that the simulation authenticity of the invisible appliance model is guaranteed; the stressing situation of periodontium and the invisible appliance is analyzed and optimized, the correcting force exerting region is controlled, the stress distribution of anchorage teeth is reduced, counter-acting force is dispersed through balancing force acting on the appliance, the mechanical anchorage consumption is educed, optimal correcting force is exerted, the reconstruction of the periodontium is effectively promoted, ideal moving of the teeth is produced, and the best correcting effect is achieved.

Owner:西安博恩生物科技有限公司

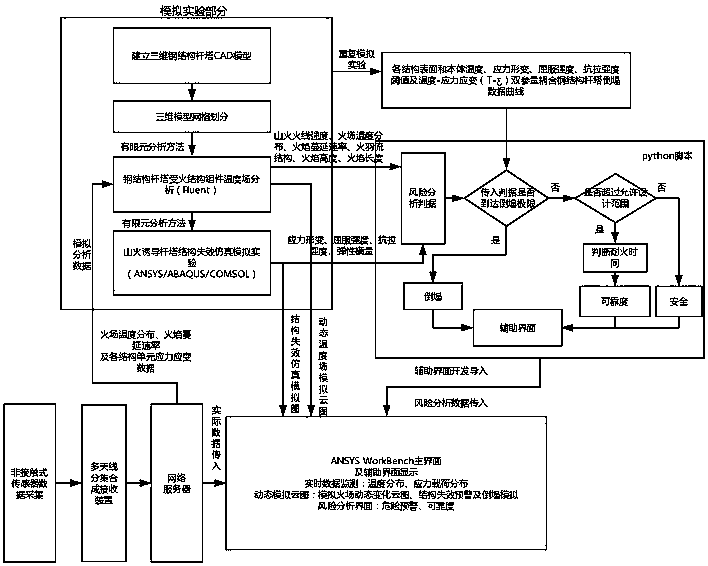

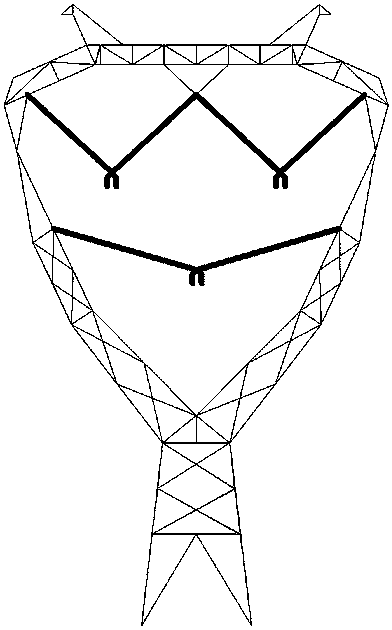

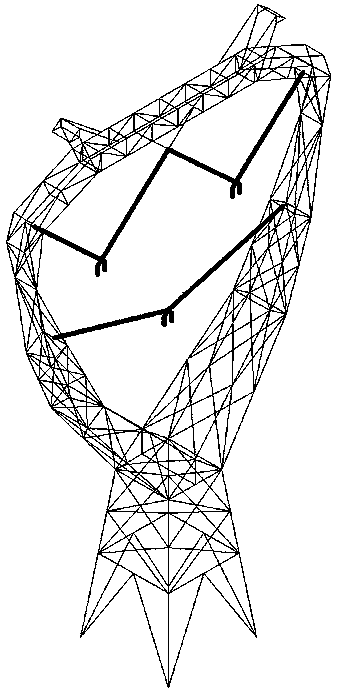

Simulation and safety early warning method for mountain fire induced steel structure tower structure failure

ActiveCN109492925ADisplay propertiesTimely display warning informationDesign optimisation/simulationResourcesElement analysisFire resistance

The invention relates to a simulation and safety early warning method for mountain fire induced steel structure tower structure failure. Based on a distributed non-contact sensor, a multi-antenna diversity into receiving mode and a remote server, the time-varying space temperature field of mountain fire is analyzed by Fluent; structural fire resistance inspection is carried out by using nonlinearfinite element analysis tools such as ANSYS / ABAQUS / COMSOL; and the two models are coupled, dynamic simulation, threshold comparison and image fitting are carried out, and a theoretical calculation, nonlinear finite element simulation and data analysis model for steel structure tower fire resistance characteristic and gradual change stress loss, stress deformation and collapse danger level judgmentis established. The method has the advantages that guidance is provided for planning, design and operation maintenance of power transmission line steel structure towers with various tower shapes andvarious voltage grades, and safe operation and structure failure early warning of the steel structure towers and an intelligent power grid are achieved.

Owner:NANJING UNIV OF TECH

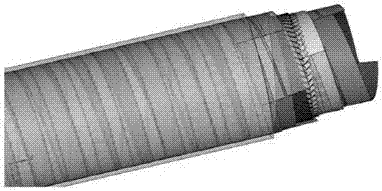

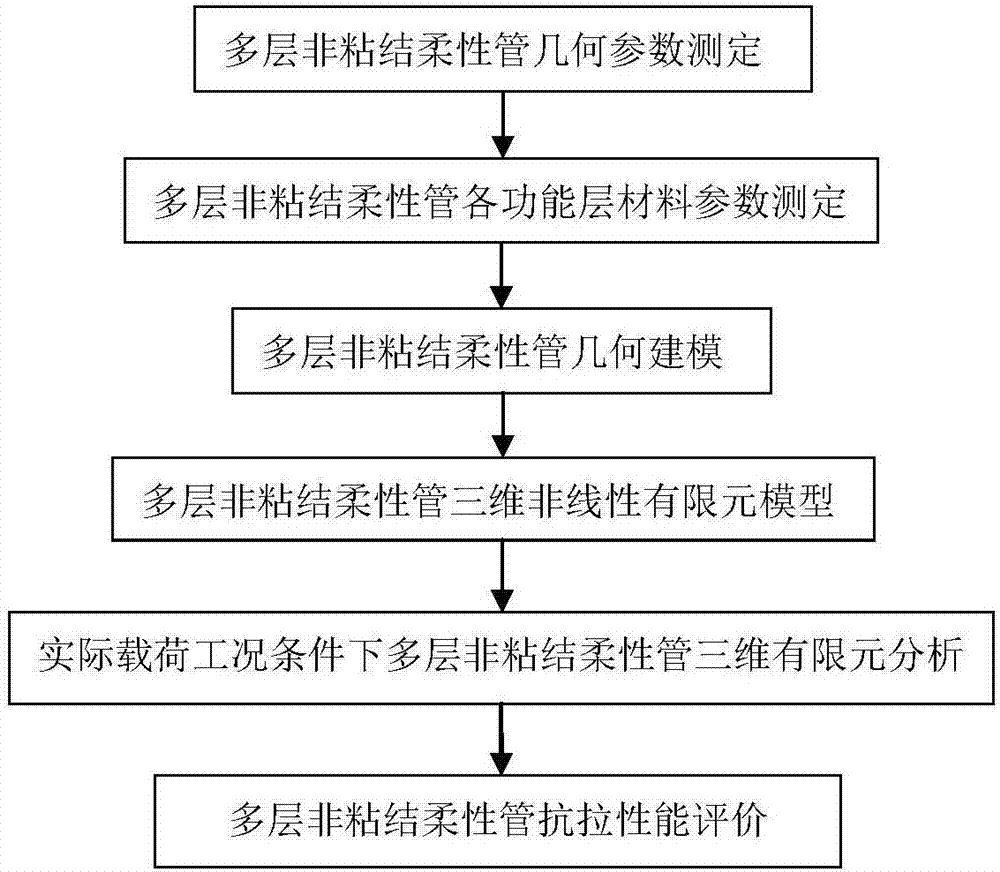

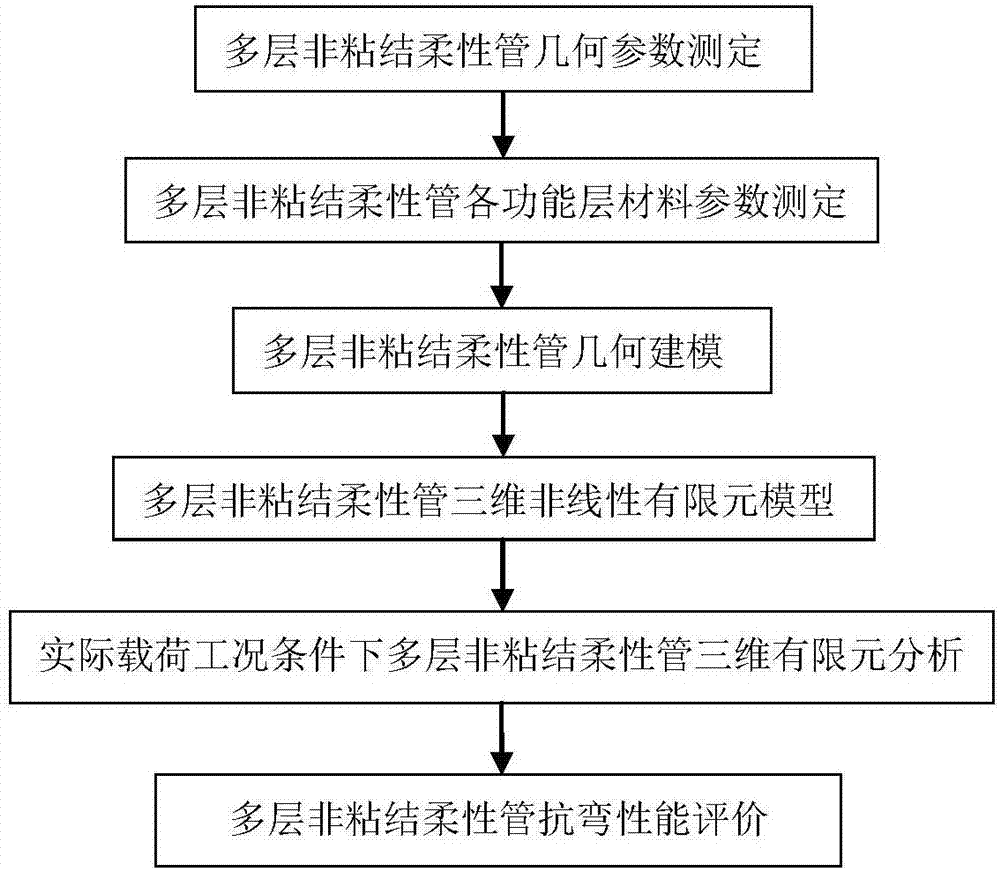

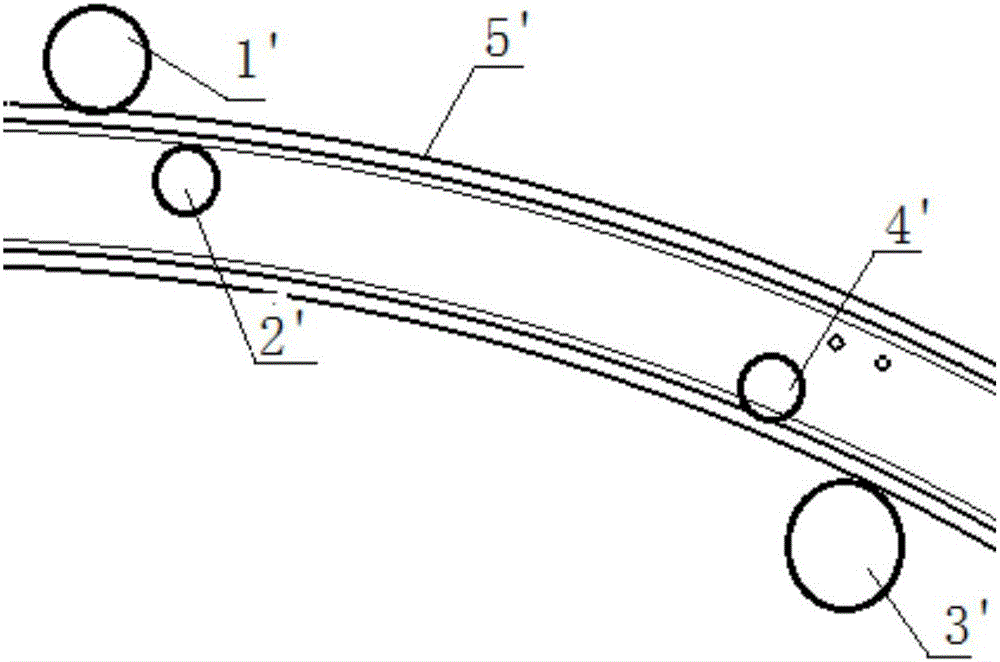

Quick evaluation method for tensile performance of multi-layer non-sticking flexible pipe

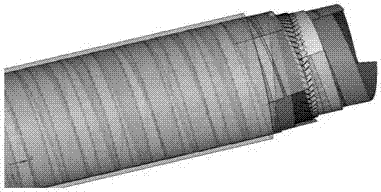

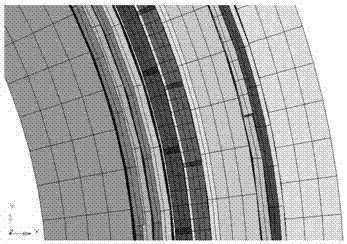

InactiveCN106907534ADetermining Stress CharacteristicsEmbody frictional contact behaviorFlexible pipesDesign optimisation/simulationCurrent loadStress distribution

The invention provides a quick evaluation method for tensile performance of a multi-layer non-sticking flexible pipe. According to the quick evaluation method, the structural parameters of the multi-layer non-sticking flexible pipe are measured through a dedicated measuring tool; the mechanical parameters of materials used by all functional layers of the multi-layer non-sticking flexible pipe are determined through a material tensile test; a three-dimensional geometry model of the multi-layer non-sticking flexible pipe is subjected to grid partition by aid of finite-element pre-processing software; and frictional contact in each layer and between the layers are considered, a flexible pipe three-dimensional finite-element model is established, calculation is conducted through non-linear finite-element analyzing software ABAQUS, and the stress characteristics, under the axial tensile load effect, of the multi-layer non-sticking flexible pipe are obtained. On the basis of the von Mises stress peak values of all the functional layers and the corresponding material yield strength of all the functional layers, the safety coefficients, under the condition of the current load working condition, of all the functional layers are calculated and determined, the minimum values of the safety coefficients of all the functional layers serve as the basis, and the propose of tensile performance evaluation of the multi-layer non-sticking flexible pipe is achieved. The quick evaluation method has very important significations on recognizing the stress distribution characteristics of the multi-layer non-sticking flexible pipe under the axial tensile force effect, clarifying tensile performance of the multi-layer non-sticking flexible pipe and ensuring safe operation.

Owner:HILONG GROUP OF +2

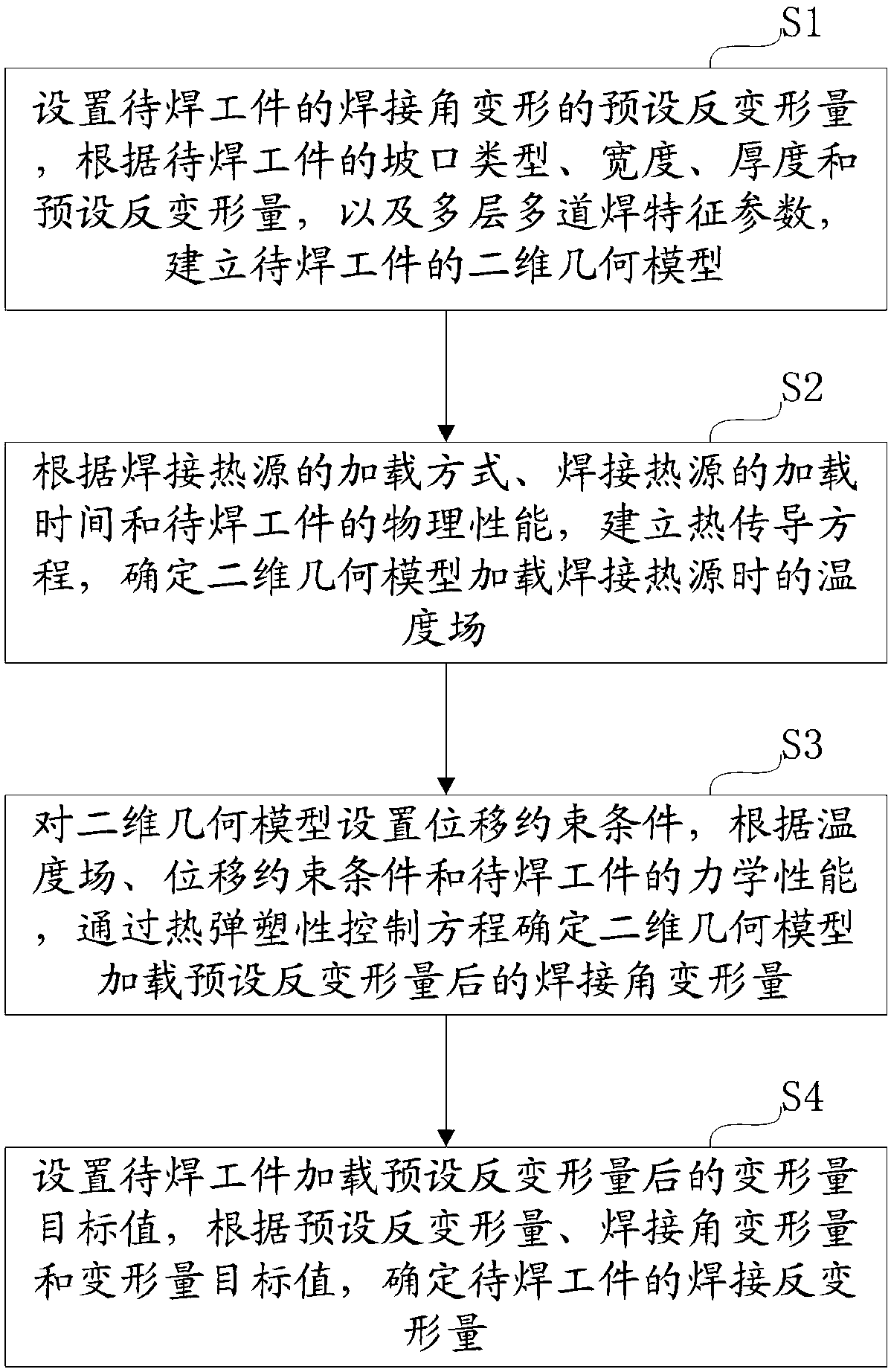

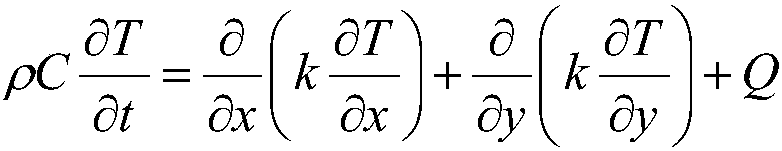

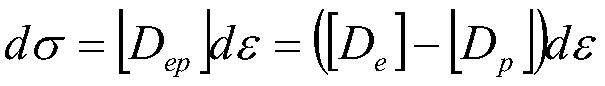

Welding reverse deformation calculation method

InactiveCN108804725AGuaranteed accuracySmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsNonlinear finite element analysisFinite element analyse

The invention discloses a welding reverse deformation calculation method. The method comprises the following steps of: establishing two-dimensional geometric models of a temperature field and a deformation field of a to-be-welded workpiece according to a preset reverse deformation and a welding condition; establishing a heat conduction equation and a thermal elastoplastic control equation on the basis of the two-dimensional geometric models, physical performance and mechanical performance of the to-be-welded workpiece and a welding heat source; solving the solid-state heat conduction equationand the thermal elastoplastic equation on the basis of nonlinear finite element analysis software so as to obtain a temperature field and a welding angle deformation in the welding process; and finally determining a welding reverse deformation of the to-be-welded workpiece according to a preset reverse deformation, the welding angle deformation and a deformation target value. Compared with the traditional manners of carrying out analysis by utilizing three-dimensional models, the welding reverse deformation calculation method is capable of reducing the computational complexity of systems and ensuring the correctness of calculation results while obtaining welding reverse deformations of to-be-welded workpieces in an efficient and low-cost manner.

Owner:BAOSHAN IRON & STEEL CO LTD

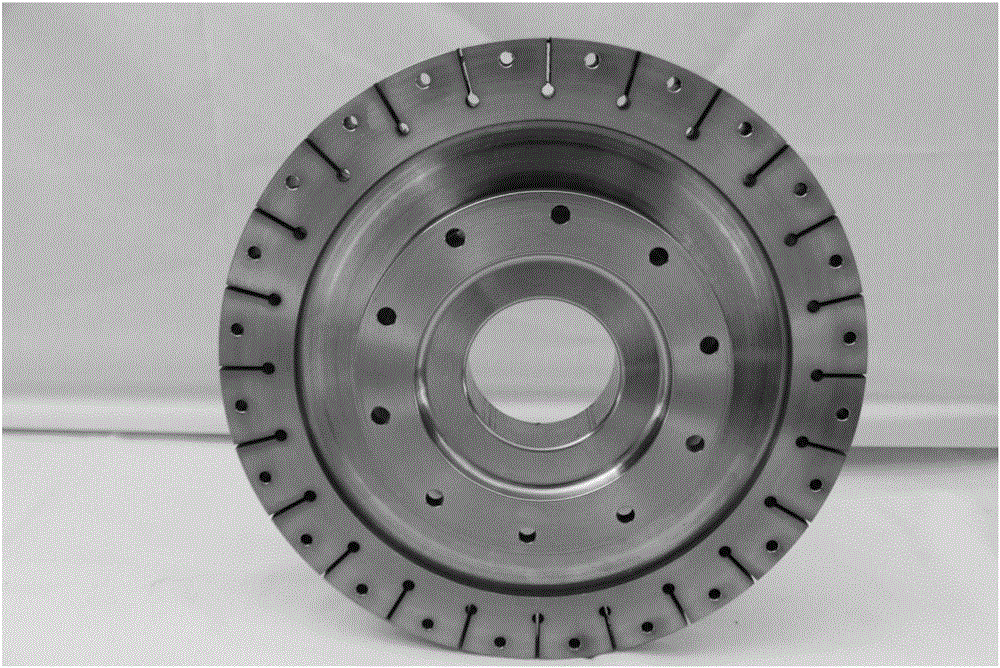

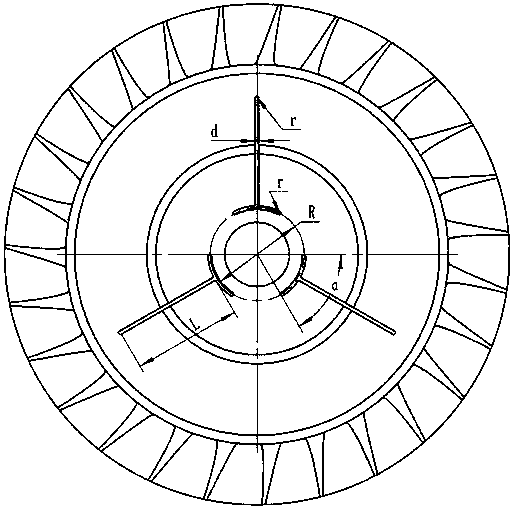

Trisection grooving prefabrication method for disc, blade and shaft integrated turbine rotor with ultrahigh rotation speed

InactiveCN105512408APrecisely control the breaking speedImprove reliabilityDesign optimisation/simulationSpecial data processing applicationsTest efficiencyLower limit

The invention belongs to a burst rotation speed prediction technology and relates to a trisection grooving prefabrication method for a disc, blade and shaft integrated turbine rotor with ultrahigh rotation speed. The required burst rotation speed can be obtained accurately through groove prefabrication. The method mainly adopts an average stress method for theoretical calculation, and an initial grooving structure is obtained. In combination with a nonlinear finite element analysis method, the trisection burst rotation speed of the disc, blade and shaft integrated turbine rotor with the ultrahigh rotation speed is subjected to numerical simulation analysis, impact factors of a grooving process, a grooving width d, a grooving radius r and a grooving depth h are determined, and the grooving structure is further optimized. A gradual grooving method is adopted during a burst test, the residual sectional area after continuous grooving is a product of the square of the quotient when the burst rotation speed lower limit is divided by the burst rotation speed upper limit and the residual sectional area before grooving, and grooving is performed until the required burst rotation speed is obtained. With adoption of the method, the test times are reduced remarkably, the test efficiency is improved, the test cost is reduced, the method has higher practical application values, and the reliability of a starter system is improved, and the performance of a starter is optimized.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

Curved surface forming method of a metal plate

InactiveUS8046098B2Stable quality levelCurved surface forming time of the metal plate is remarkably reducedShaping toolsShaping safety devicesNonlinear finite element analysisLarge deformation

Owner:PAIK JEOM KEE

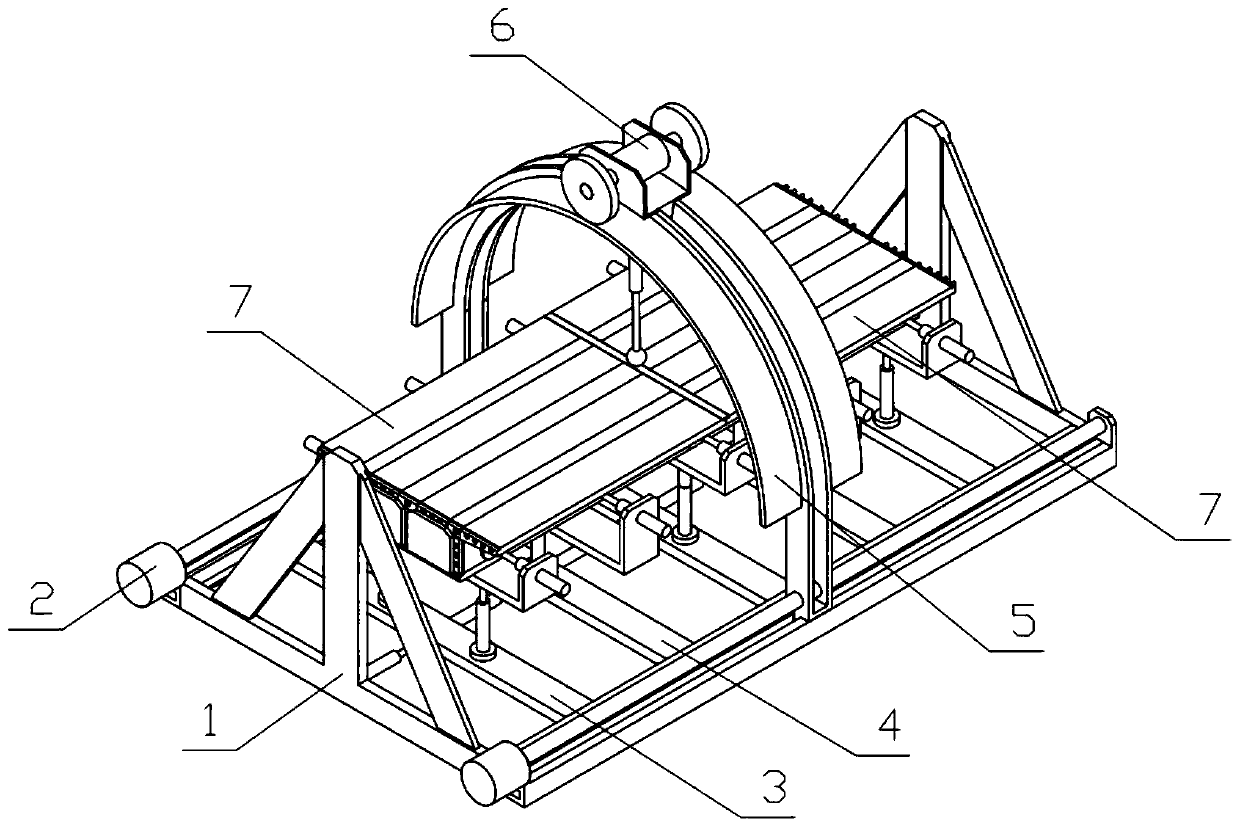

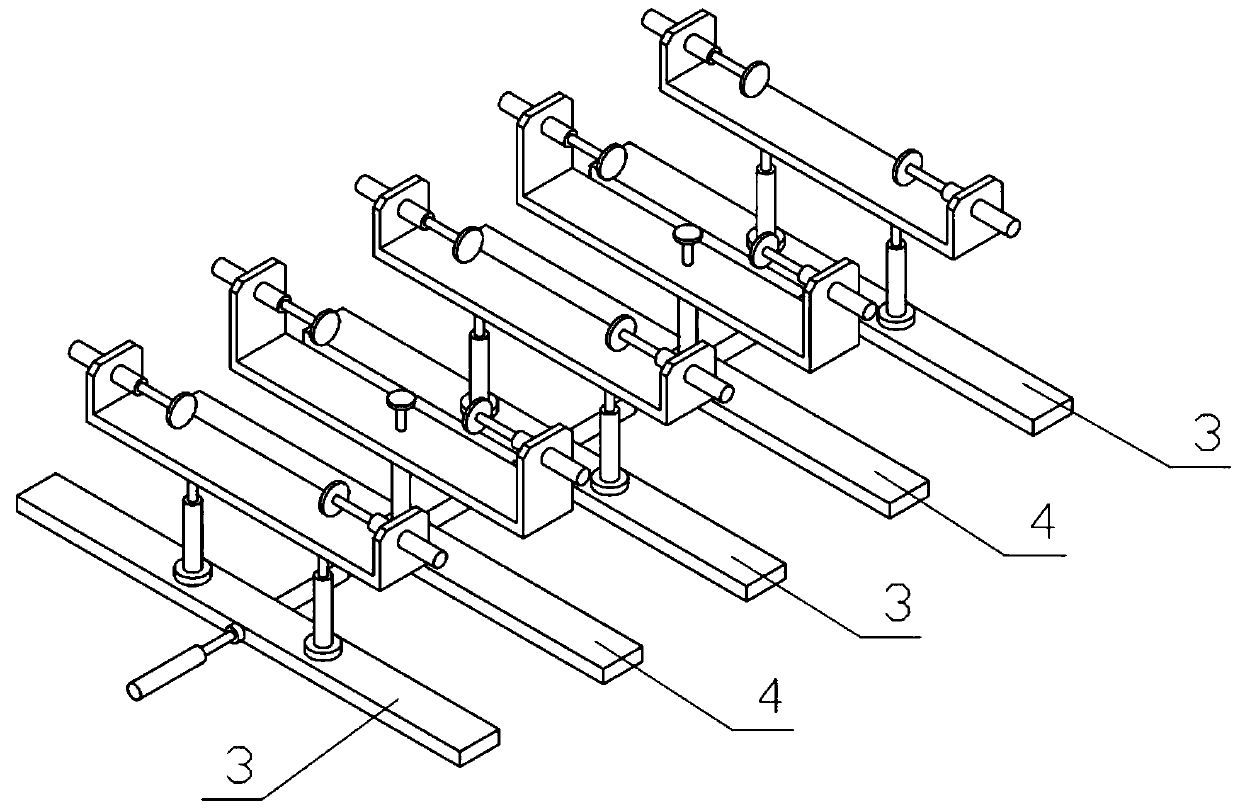

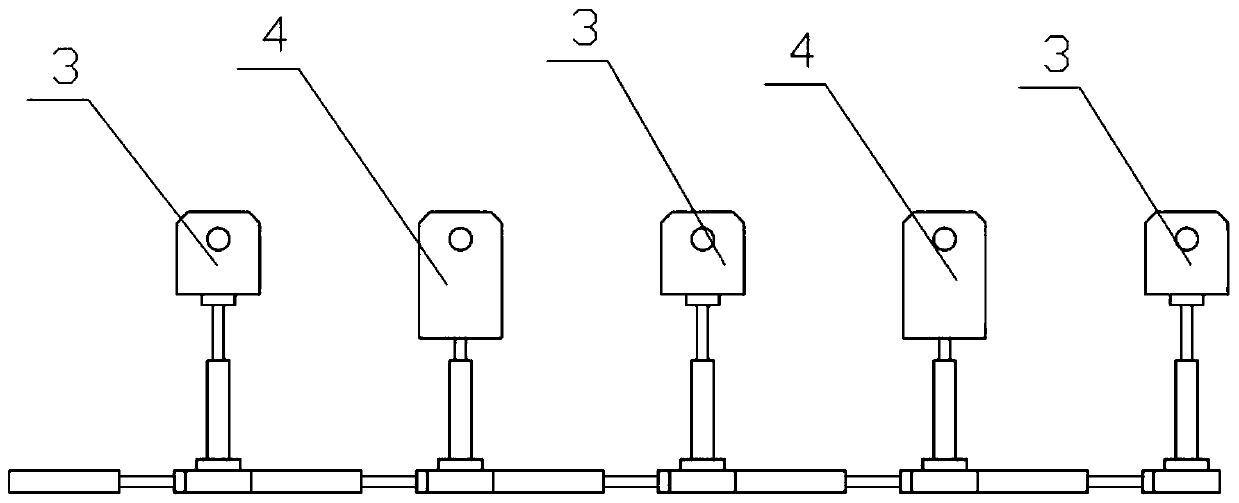

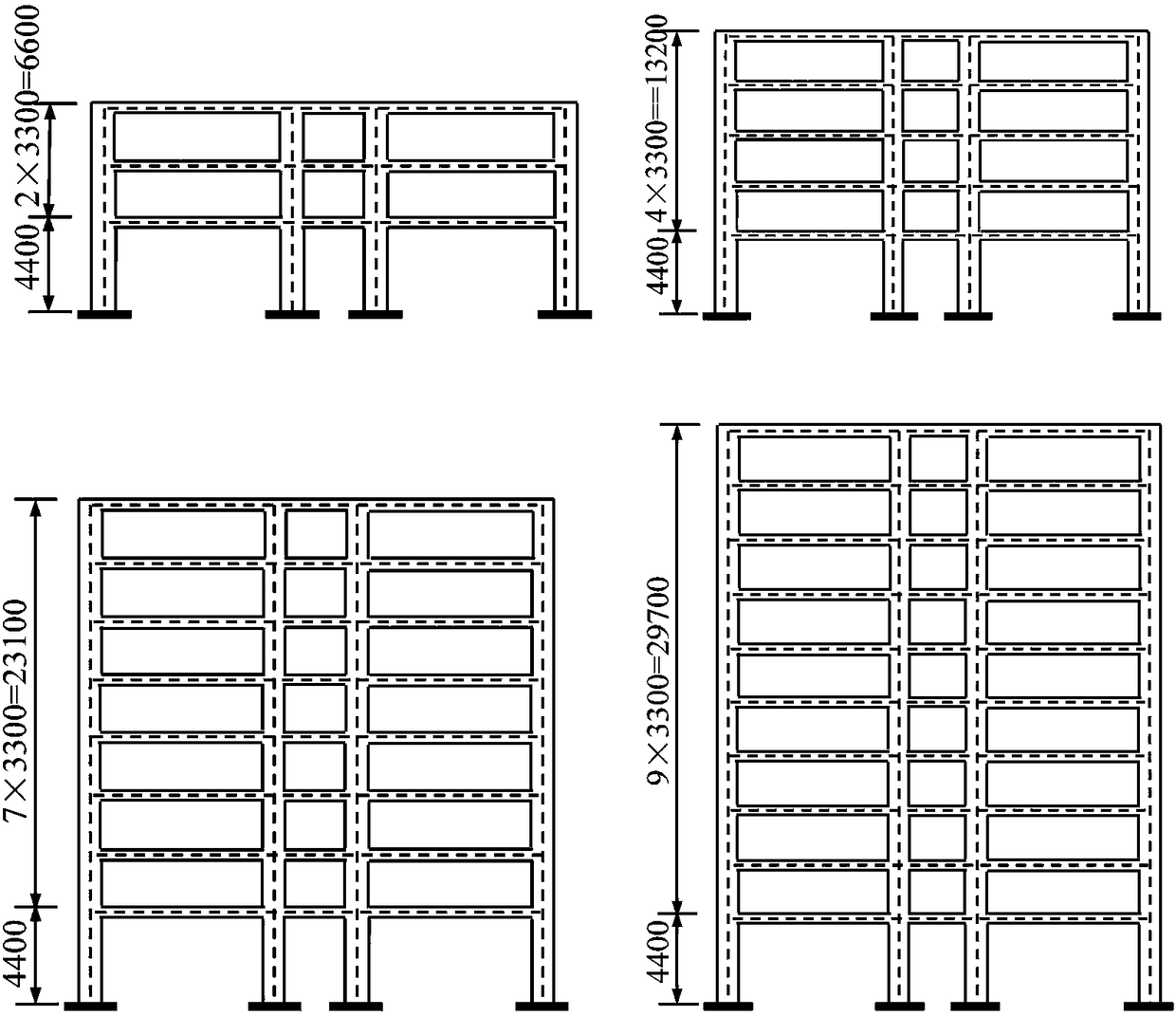

Bridge combination unit space model experimental device

ActiveCN111257120AReduce in quantityMeet different needsMaterial strength using tensile/compressive forcesSimulationElectric machinery

The invention relates to a model experiment device, in particular to a bridge combination unit space model experimental device which comprises a device support, a driving motor I, supporting mechanisms I, supporting mechanisms II, an angle support, a pressurizing mechanism and an experimental bridge. A plurality of supporting mechanisms I and a plurality of supporting mechanisms II can be combinedinto different clamping modes to clamp a bridge unit, and different requirements for supporting the bridge unit in an experiment are met; the angle support is driven by the driving motor I to slide on the device support, the pressurizing position of the pressurizing mechanism is adjusted, the pressurizing mechanism is driven by the driving motor II arranged on the pressurizing mechanism to slideon the angle support, and the pressurizing angle of the pressurizing mechanism is adjusted. The experimental bridge is spliced in a shell and beam combination mode, and the number of units is greatlyreduced while the simulation accuracy is guaranteed; and the calculation cost and the convergence difficulty of nonlinear finite element analysis of the concrete box girder are greatly reduced.

Owner:范佳

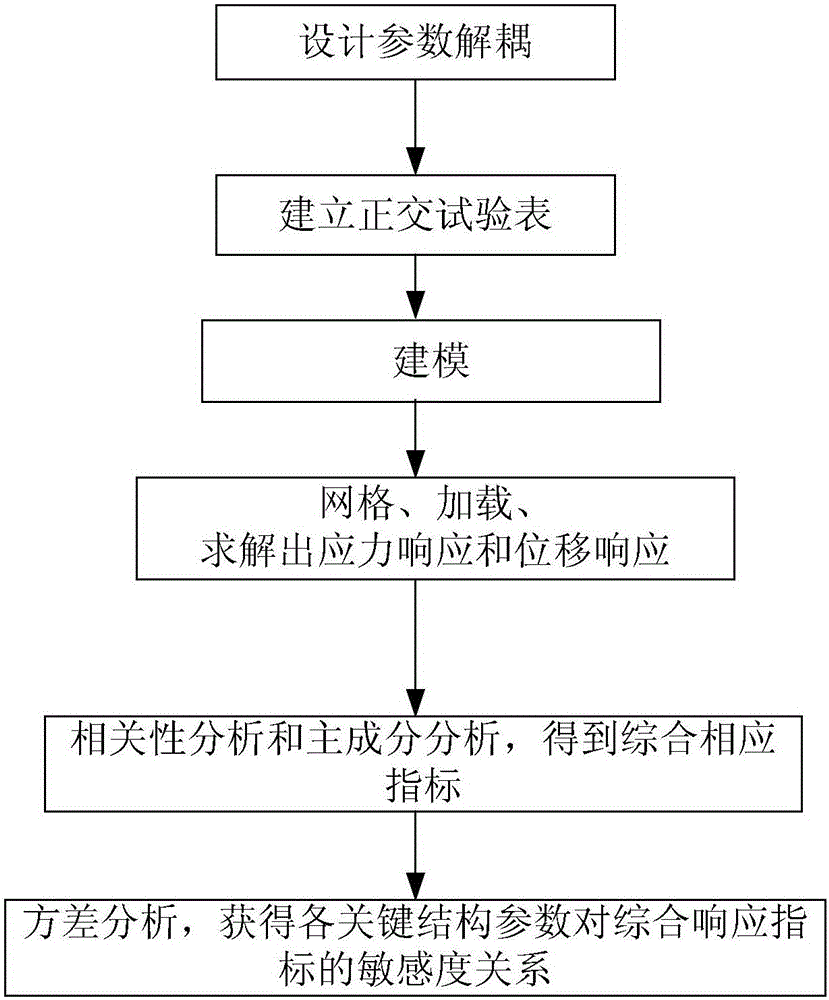

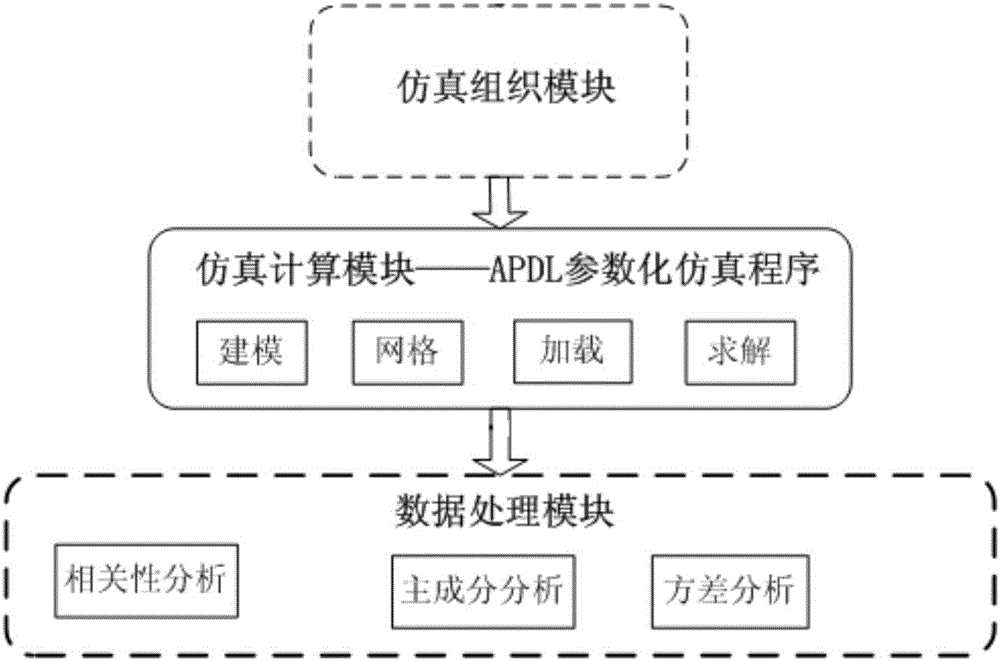

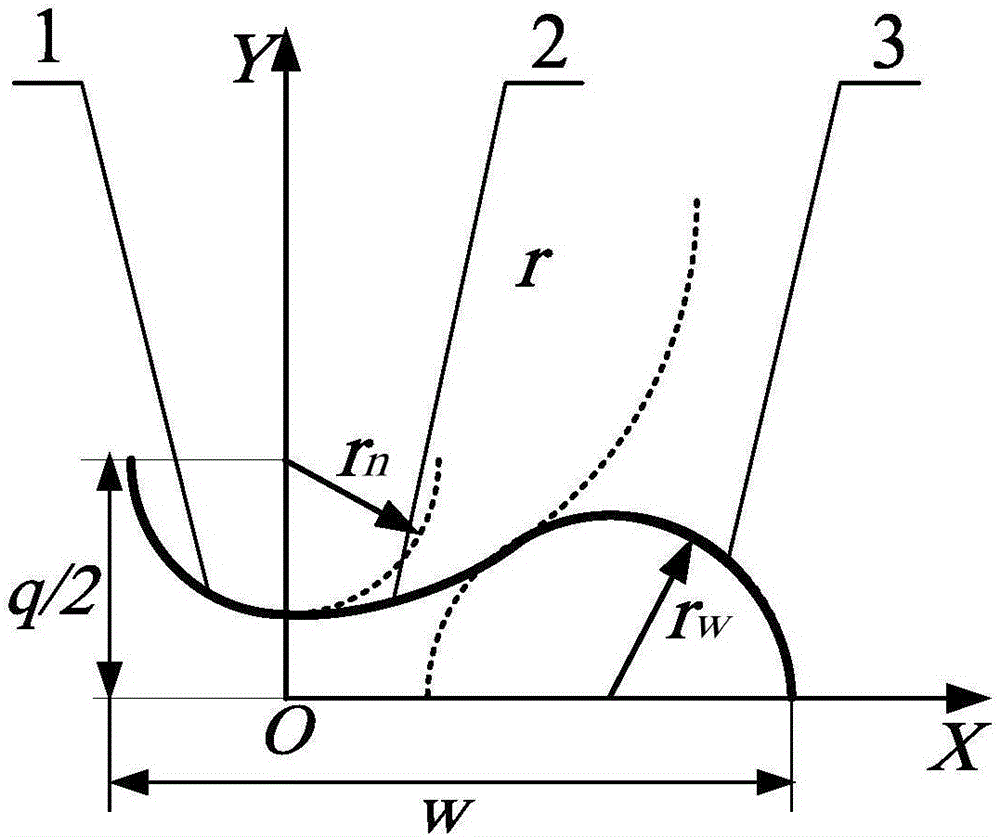

Three-section circular arc primitive corrugated pipe analysis method based on variance sensitiveness sorting

ActiveCN106202643AImprove computing efficiencyReduce labor costsDesign optimisation/simulationSpecial data processing applicationsOrthogonal test designSimulation

The invention relates to a three-section circular arc primitive corrugated pipe analysis method based on variance sensitiveness sorting. The method is characterized in that geometrical characteristics of a multi-layer three-section circular arc primitive tangent corrugated pipe are symmetrically defined, and geometrical parameters of the corrugated pipe are decoupled; a nonlinear finite element analysis program of the multi-layer three-section circular arc primitive tangent corrugated pipe is built based on parameter languages, and modeling, network processing, loading, postprocessign and other finite element calculation steps can be rapidly achieved by freely changing model parameters; a parametric simulation control platform is built, an orthogonal test design module, a parametric finite element simulation module and a sensitiveness analysis module are integrated, large-sample and multi-target optimal calculation can be achieved, and sensitiveness indexes of design modules can be rapidly and systemically obtained. The systematicness and reliability of structural parameter optimization and sensitiveness analysis are improved; on the basis of a platform control technology and a parametric simulation technology, the labor cost is greatly saved, and calculation efficiency is improved.

Owner:XIAN AEROSPACE PROPULSION INST

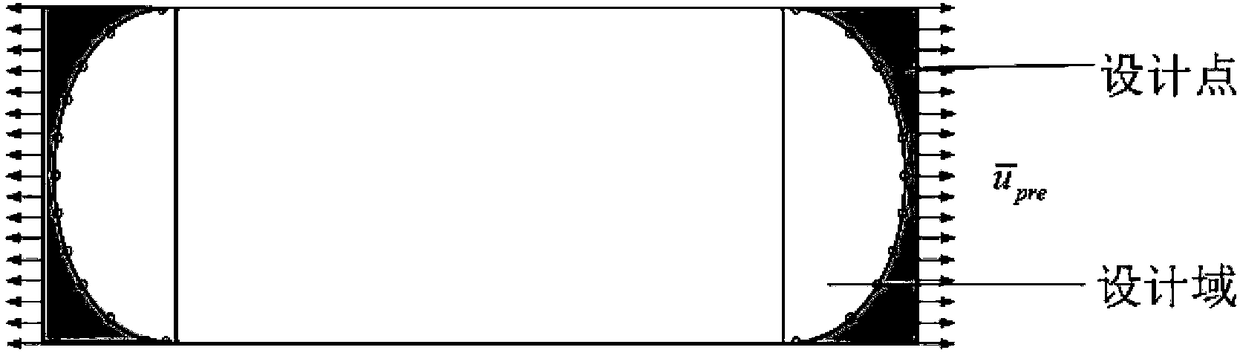

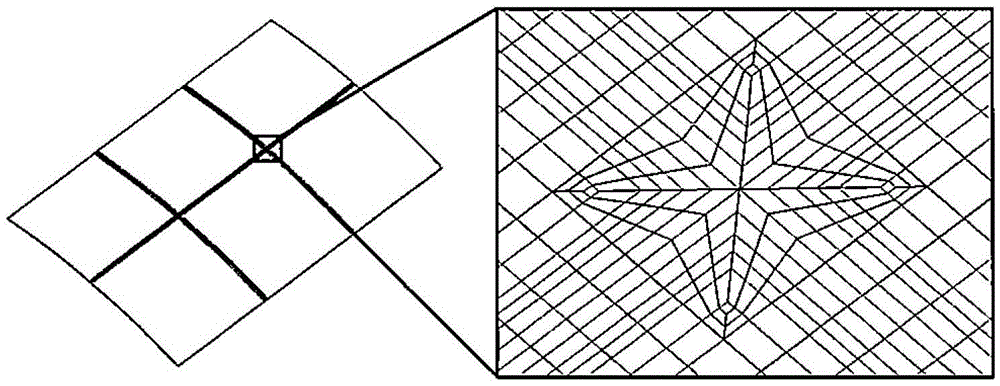

Space thin film structure clamp shape optimization design method for restraining creases

ActiveCN108133097AIncrease the minimum principal stressIncrease working areaGeometric CADDesign optimisation/simulationStress distributionSolar sail

The invention belongs to the field of aerospace thin film structural design, and provides a space thin film structure clamp shape optimization design method for restraining creases. The problem that aspace thin film structure is prone to creases under the tensile effect of a traditional clamp is solved. On the basis of nonlinear finite element analysis, the loading boundary conditions are changedby optimizing the shape of a clamp, the minimum main stress of units in a thin film area is maximized, the main stress distribution of the thin film is adjusted and controlled, the global optimum design is found through a global optimization algorithm, then a novel clamp with arcuate and inverted-T-shaped boundaries is obtained, and the aim of completely restraining the creases is achieved. The creases in the thin film are restrained, the thin film is not tailored, and it can be ensured that the thin film has sufficiently large working area; the method is suitable for designing the clamp fora space antenna, a solar sail and other space thin film structures, the thin film creases are easily restrained, the structure working performance is ensured, and no manufacturing, launching or running cost is added.

Owner:DALIAN UNIV OF TECH

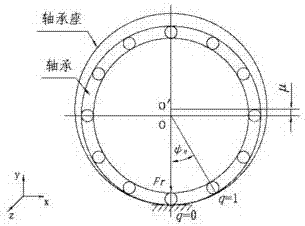

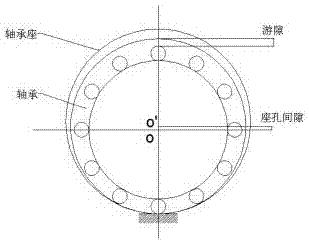

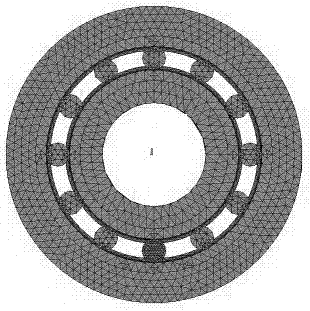

Method of calculating life of thin-walled flexible support bearing

InactiveCN107451374AImprove reliabilityAchieve life optimizationGeometric CADDesign optimisation/simulationElement modelNonlinear finite element analysis

A method of calculating life of a thin-walled flexible support bearing includes: using existing finite element analytical software ANSYS as a platform to establish a thin-walled rolling bearing contact nonlinear finite element analytical model that considers shaft hole fit clearance and radial internal clearance, and calculating the life of the thin-walled rolling bearing. The method has the advantages that the thin-walled rolling bearing contact nonlinear finite element analytical model that considers shaft hole fit clearance, radial internal clearance and other factors is established for the first time, the model gives a full consideration to ferrule deformation and actual boundary conditions, influence law of the bearing fit clearance and radial internal clearance upon the load and life of a bearing roll is analyzed, the nonlinear convergence problem is solved, and the thin-walled rolling bearing finite element model is more practical.

Owner:HENAN UNIV OF SCI & TECH

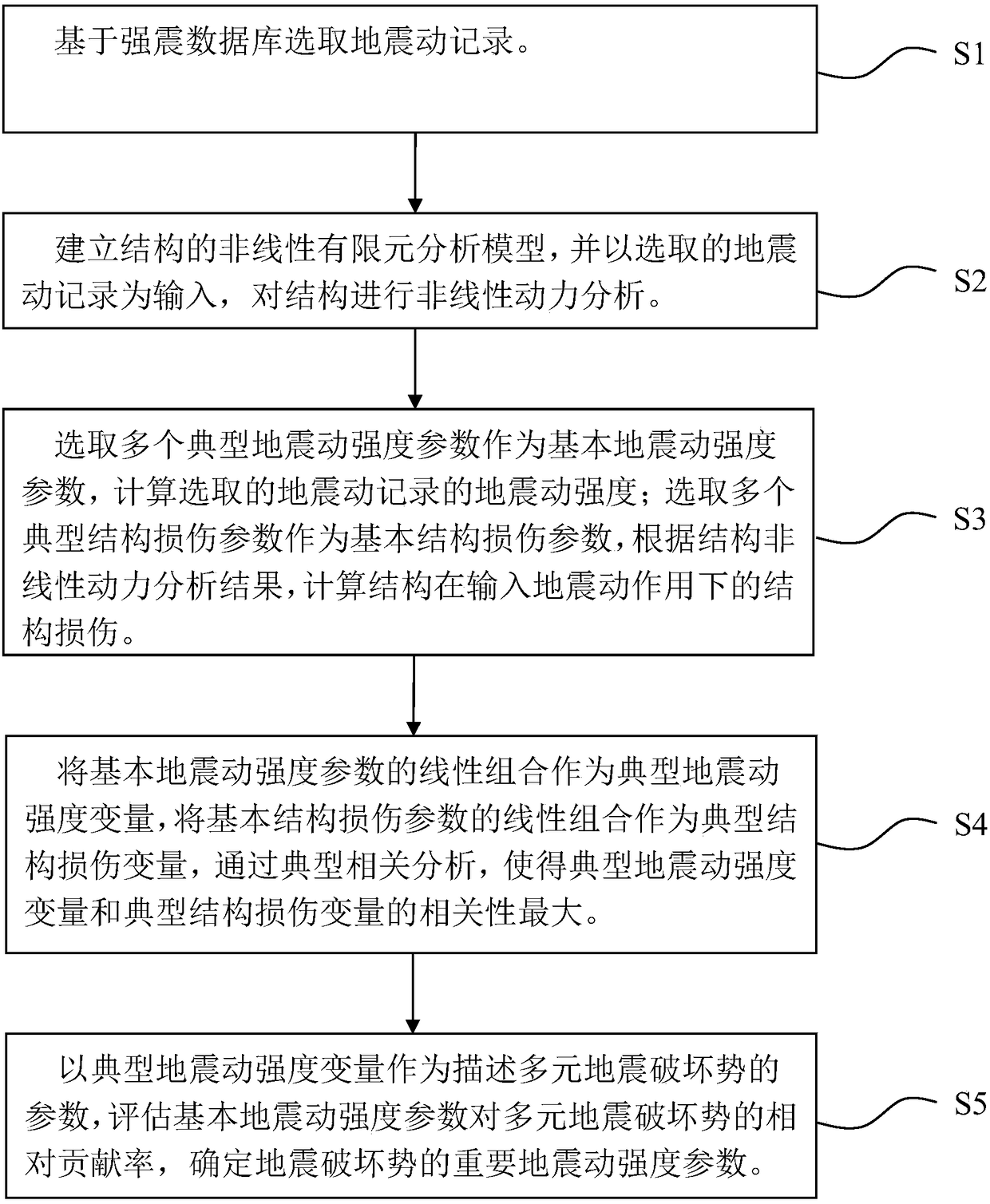

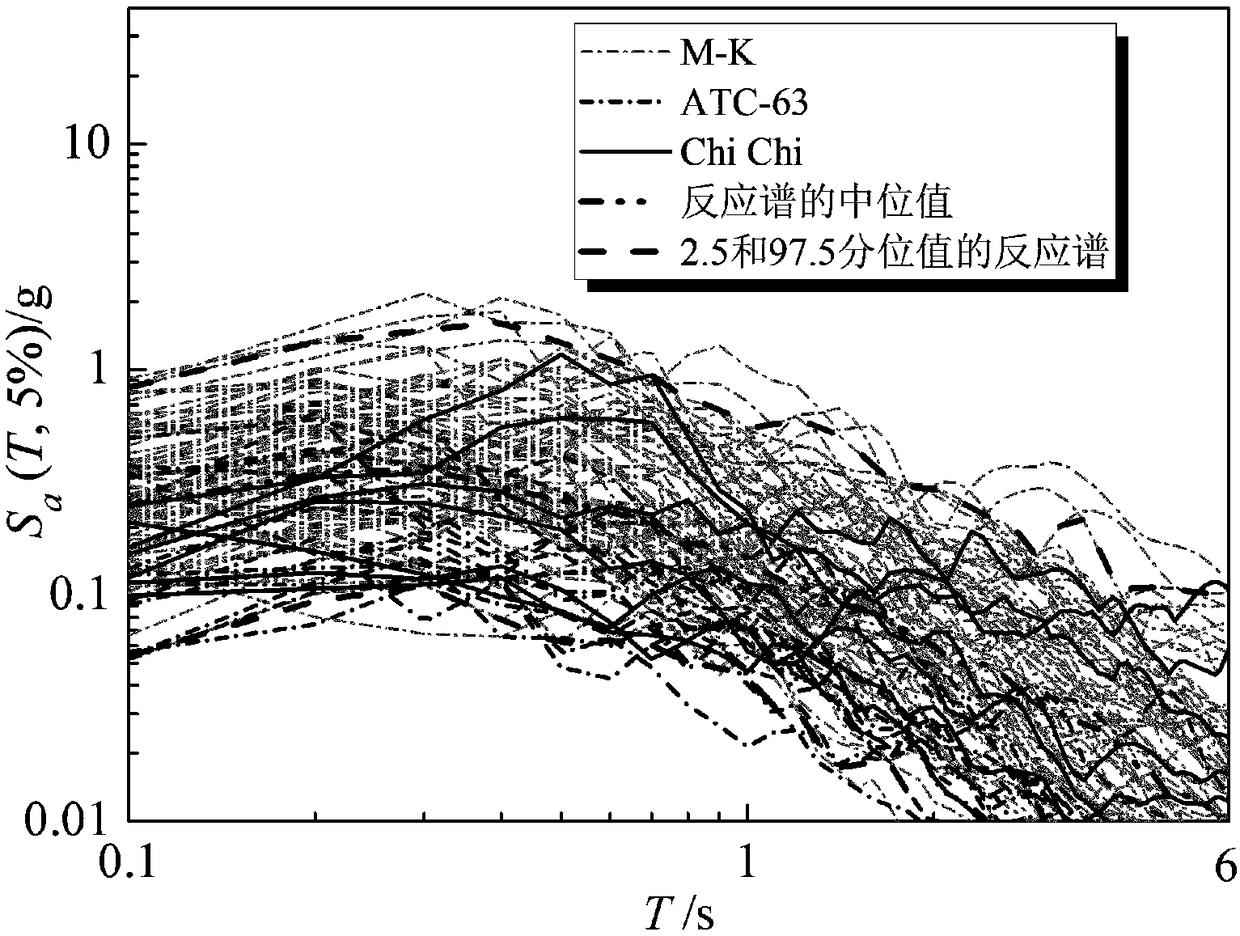

Canonical correlation analysis-based multi-element seismic damage potential assessment method

ActiveCN108170906ADesign optimisation/simulationSpecial data processing applicationsNonlinear finite element analysisPotential assessment

The invention provides a canonical correlation analysis-based multi-element seismic damage potential assessment method. The method comprises the following steps of: selecting a seismic oscillation record; establishing a nonlinear finite element analysis model of a structure; selecting a plurality of canonical seismic oscillation intensity parameters as basic seismic oscillation intensity parameters so as to calculating seismic oscillation intensity of the seismic oscillation record; selecting a plurality of canonical structure damage parameters as basic structure damage parameters so as to calculate structure damage; carrying out canonical correlation analysis to ensure that relevance between a canonical seismic oscillation intensity variable and a canonical structure damage variable is maximum; and taking the canonical seismic oscillation intensity variable as a parameter for describing multi-element seismic damage potential so as to assess relative contribution rates, to the multi-element seismic damage potential, of the basic seismic oscillation intensity parameters and then determining important seismic oscillation intensity parameters of the seismic damage potential. Accordingto the method, influences of a plurality of seismic oscillation intensity parameters are considered, so that the size of the seismic damage potential can be predicted more correctly, and the damage degree sizes of the structure under different seismic oscillation actions can be assessed more reasonably.

Owner:HARBIN INST OF TECH

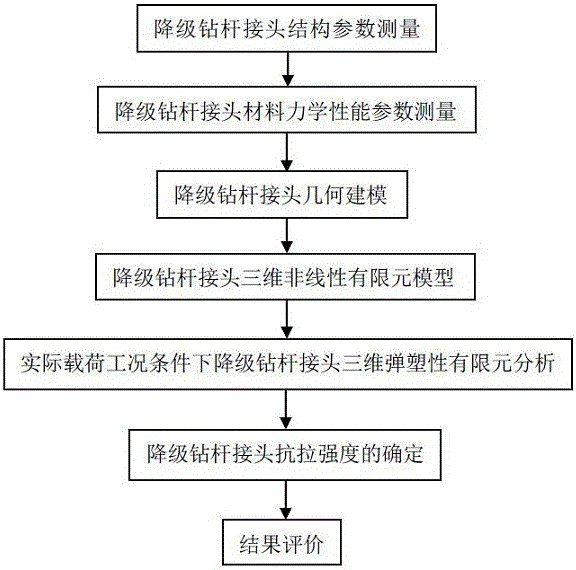

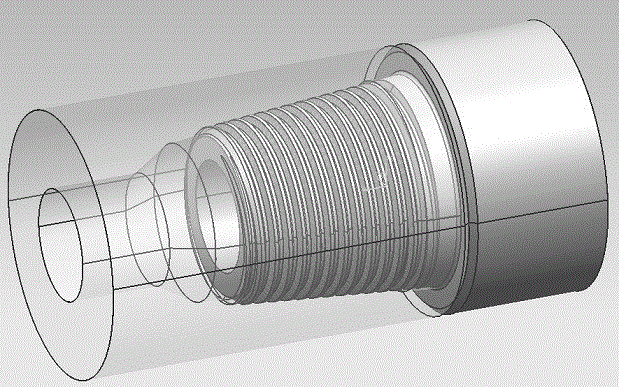

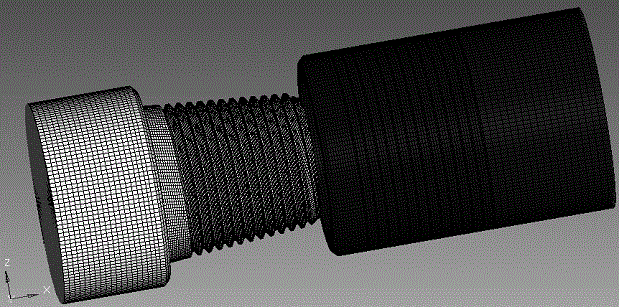

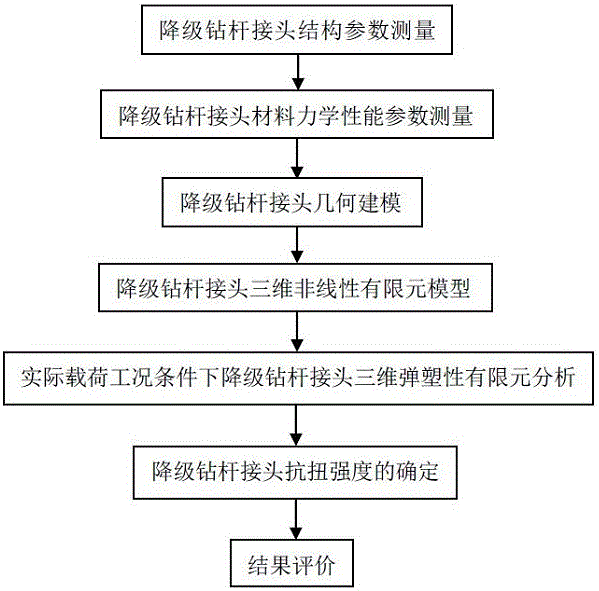

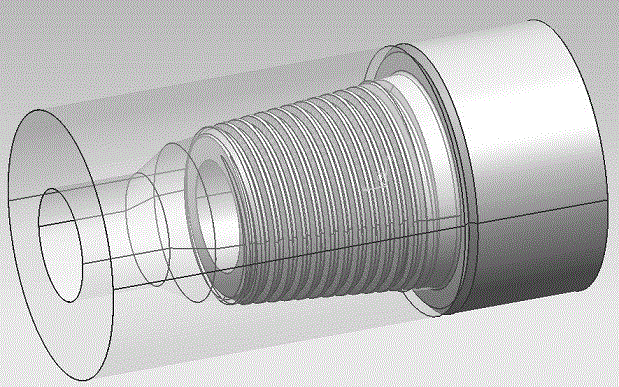

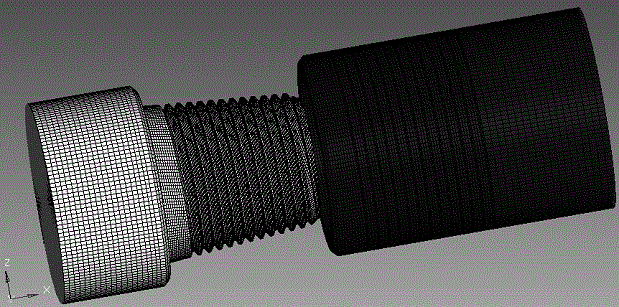

Method for quickly evaluating tensile property of degradation drill rod joint

InactiveCN106339529ATensile strength reflectsReflect stress characteristicsGeometric CADDesign optimisation/simulationStrength of materialsNonlinear finite element analysis

The invention provides a method for quickly evaluating the tensile property of a degradation drill rod joint. The method comprises the following steps: performing grid division on a degradation drill rod joint three-dimensional geometric model by using finite element pre-processing software on the basis of measuring a geometric structure parameter of the degradation drill rod joint and a mechanical property parameter of a material by using a special tool or facility, building the degradation drill rod joint three-dimensional geometric model, performing calculation by using nonlinear finite element analysis software ABAQUS to obtain a three-dimensional stress characteristic of the degradation drill rod joint under the action of a complicated load. On the basis of the three-dimensional stress characteristic, the tensile strength of the degradation drill rod joint can be calculated. The evaluation method can be used for evaluating the tensile property of the degradation drill rod joint under the action of a complicated external load such as a make up torque and an axial tension so as to evaluate the safety of the degradation drill rod joint. The method has very important significance for recognition of a load limit of the degradation drill rod joint, instruction for the use of the degradation drill rod joint and guarantee of the working safety of drilling.

Owner:SHANGHAI UNIV

Method for quickly evaluating torsional property of degraded drill rod connector

InactiveCN106323611AReflect stress characteristicsMachine part testingElement modelStrength of materials

The invention provides a method for quickly evaluating the torsional property of a degraded drill rod connector, and the method comprises the steps: carrying out the grid dividing of a three-dimensional geometric model of the degraded drill rod connector through employing finite-element preprocessing software on the basis of measuring the geometric structure parameters and material mechanics property parameters of the degraded drill rod connector; building a three-dimensional finite element model of the degraded drill rod connector, employing nonlinear finite element analysis software ABAQUS for calculation, and obtaining three-dimensional stress characteristics of the degraded drill rod connector under the action of a complex load; and calculating the torsional property of the degraded drill rod connector on the basis. The method can evaluate the torsional property of the degraded drill rod connector under the action of the complex external loads: make-up torque, axial tension and working torque, and evaluates the safety of the degraded drill rod connector. The system is of great significance to the knowing of the load limit of the degraded drill rod connector, the guiding of the application of the degraded drill rod connector, and the guaranteeing of the safety of drilling operation.

Owner:SHANGHAI UNIV

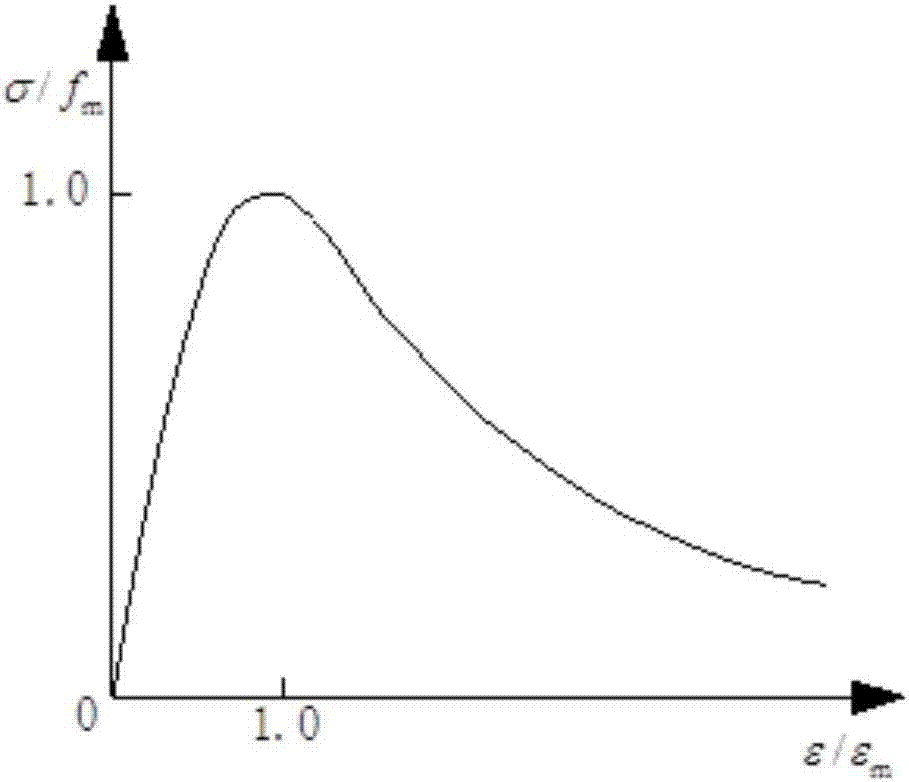

Finite element analysis method for composite self-thermal insulation wall

InactiveCN107239640AAvoid futile trialsImprove trial qualityGeometric CADDesign optimisation/simulationThermal insulationElement analysis

The invention discloses a finite element analysis method for a composite self-thermal insulation wall. The wall is constructed by using composite self-thermal insulation building blocks, concrete and steel bars together. The method includes the steps of firstly, conducting a continuity assumption, an isotropy assumption and a uniformity assumption on the wall, and meanwhile neglecting the slippage between the steel bars in the wall and concrete; secondly, adopting an integral model to conduct modeling on the wall, and after the definition of masonry wall constitutive, concrete constitutive and steel bar constitutive, selecting a concrete damage plasticity model to conduct nonlinear finite element analysis on the wall. Compared with existing experimental calculation methods, the method can use calculation alone to obtain relevant performance data of the wall, and results can be simulated for calculation and improved before experiments, so that invalid experiments are avoided, and the experiment quality is improved.

Owner:JINLING INST OF TECH

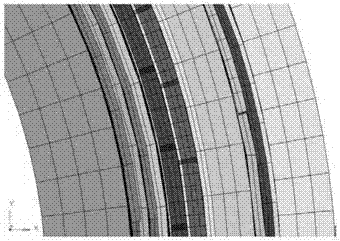

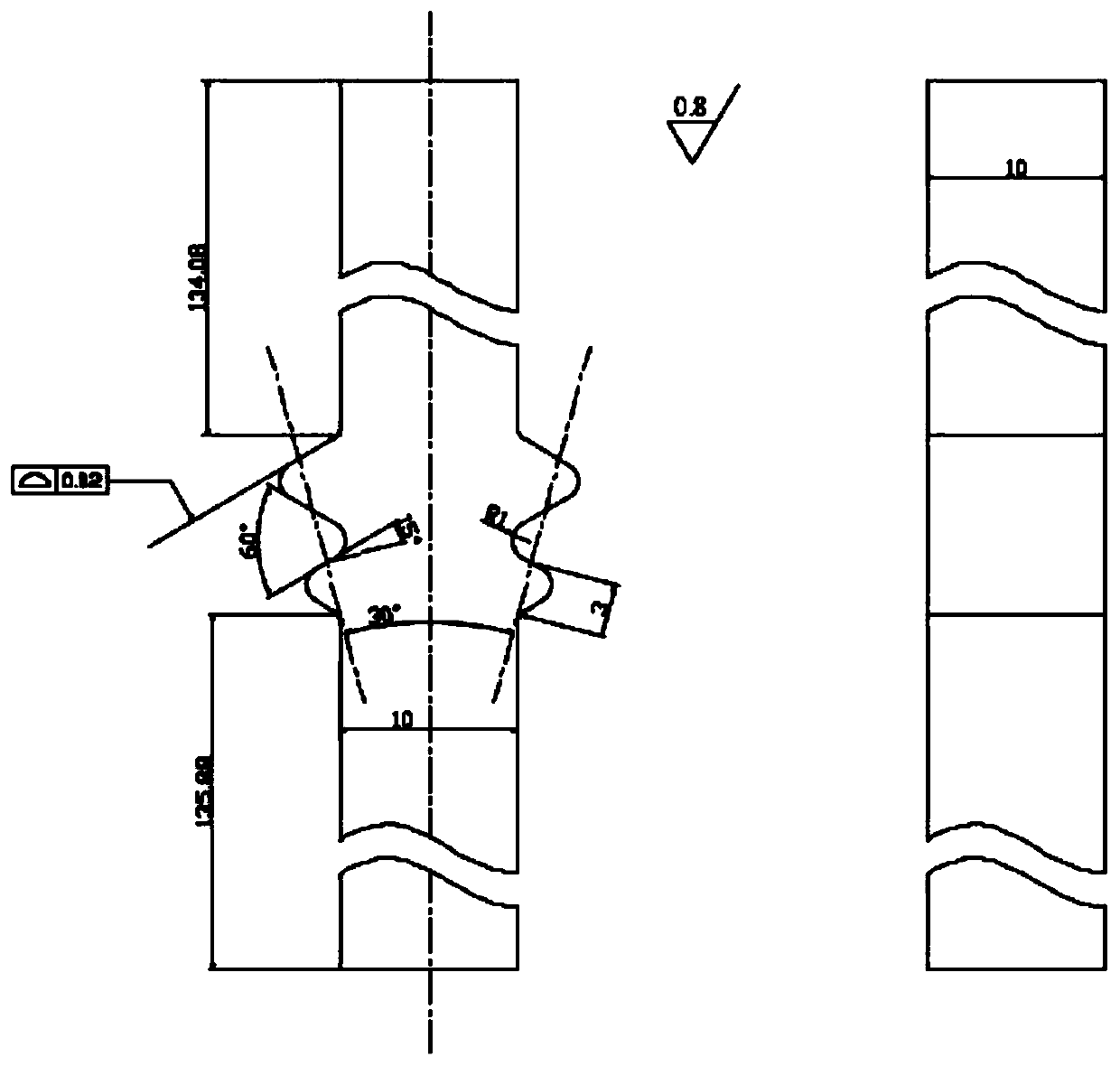

Multi-layer non-adhesive flexible pipe flexural behavior fast evaluation method

PendingCN106909709ADetermining Stress CharacteristicsEmbody frictional contact behaviorDesign optimisation/simulationSpecial data processing applicationsElement modelPeak value

The invention provides a multi-layer non-adhesive flexible pipe flexural behavior fast evaluation method. The method comprises the steps of utilizing a special measuring tool to measure a structural parameter of a multi-layer non-adhesive flexible pipe, determining a mechanical parameter of materials adopted by all functional layers of the multi-layer non-adhesive flexible pipe through a material tensile experiment, conducting mesh dividing on a three-dimensional geometric model of the multi-layer non-adhesive flexible pipe with the help of finite element preprocessing software, considering intra-layer and inter-layer friction contact, establishing a flexible pipe three-dimensional finite element model, and utilizing nonlinear finite element analysis software ABAQUS to calculate so as to obtain stress characteristics of the multi-layer non-adhesive flexible pipe under the action of bending moment. Based on von Mises stress peak values of all the functional layers and corresponding material yield strength of all the functional layers, safety coefficients of all the functional layers under a current load working condition are determined by calculating, and with the minimum value of the safety coefficients of all the functional layers being the basis, the aim of quickly evaluating a flexural behavior of the multi-layer non-adhesive flexible pipe is achieved. The multi-layer non-adhesive flexible pipe flexural behavior fast evaluation method has very significant importance in recognizing a stress distribution characteristic of the multi-layer non-adhesive flexible pipe, clarifying the flexural behavior of the multi-layer non-adhesive flexible pipe and guaranteeing work safety.

Owner:HILONG GROUP OF +2

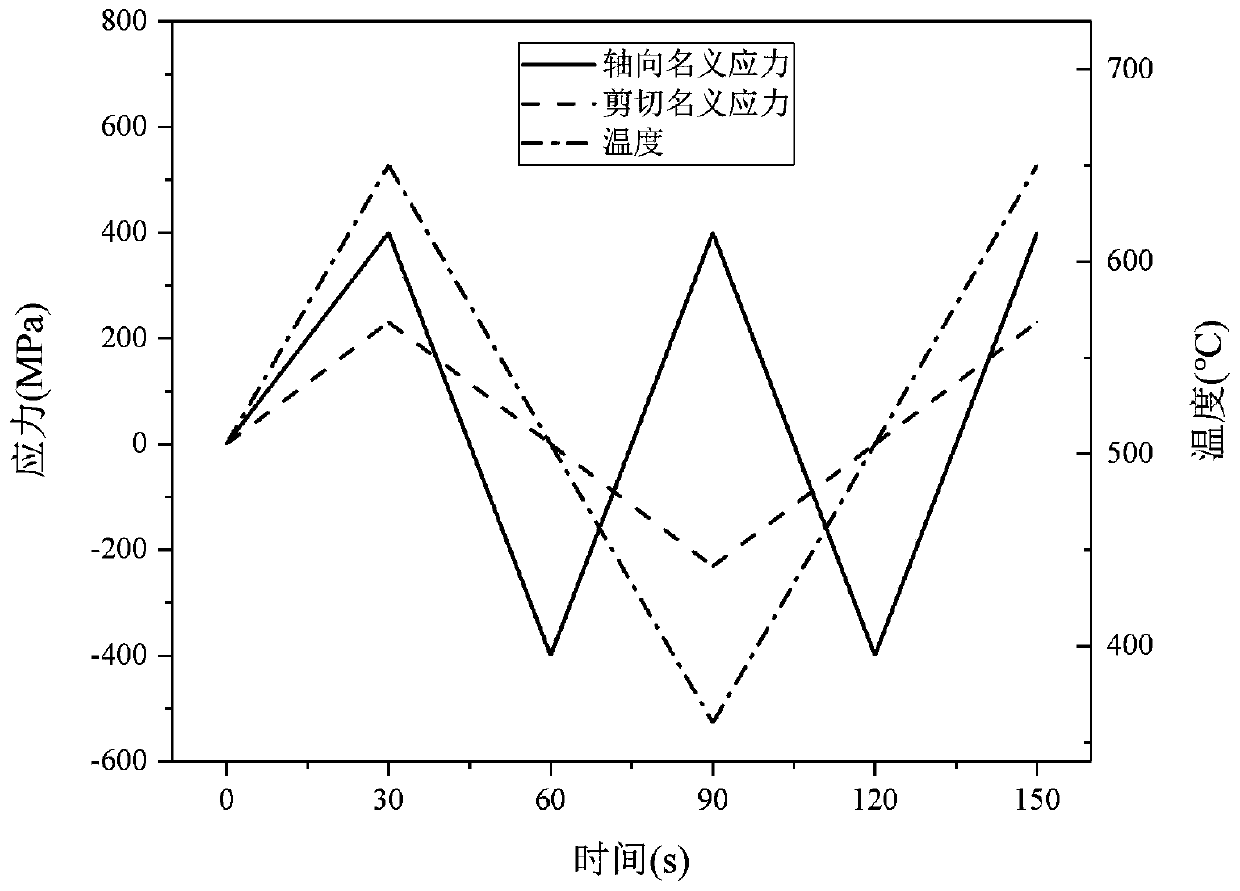

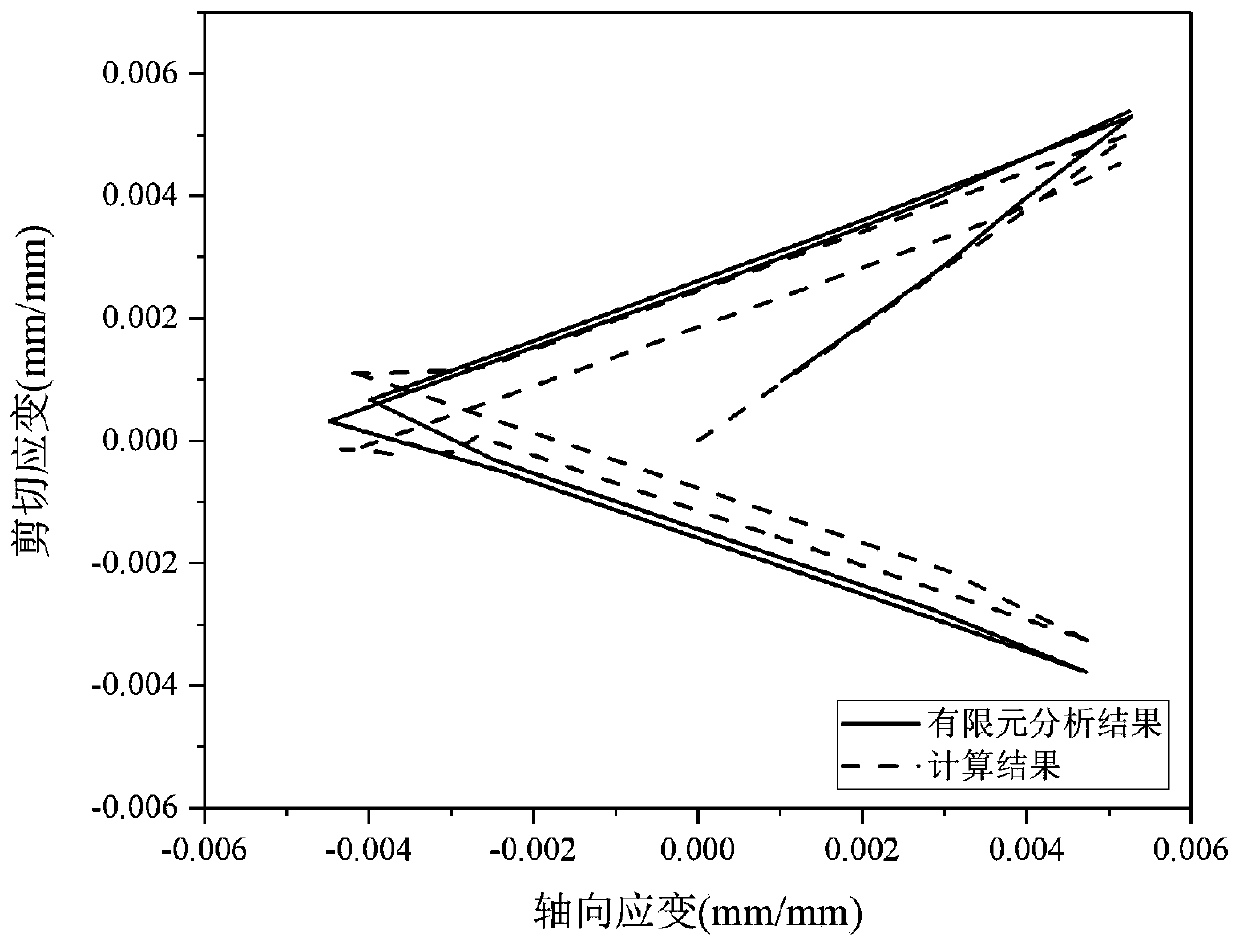

High-temperature structure dangerous point stress-strain calculation method

PendingCN111090957AGuaranteed life prediction accuracySimple methodGeometric CADDesign optimisation/simulationStructural engineeringNonlinear finite element analysis

The invention discloses a high-temperature structure dangerous point stress-strain calculation method, aims to solve the problem of notch stress-strain overestimation in the Neuber criterion, adopts an effective stress concentration coefficient to calculate pseudo stress, and improves the calculation method of the effective stress concentration coefficient. In addition, the proposed notch correction method is combined with a Caboch unified viscoplasticity constitutive model, and the stress-strain state of the dangerous point under the heat engine load is estimated. In order to evaluate the reliability of the method, an estimated result is compared with a nonlinear finite element analysis result, and the result shows that the method can accurately estimate the notch stress and strain underthe multi-axis thermal-mechanical cyclic load. The method is of great significance in guaranteeing the life prediction accuracy of structural parts in actual engineering, safety service of various important devices and accurate life extension.

Owner:BEIJING UNIV OF TECH

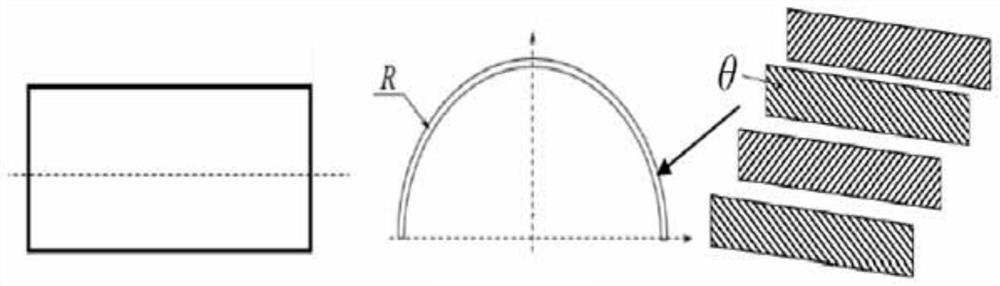

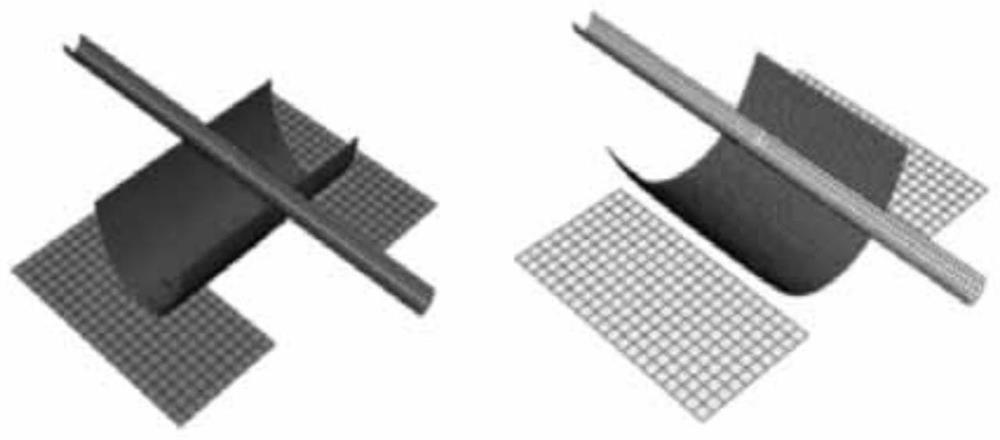

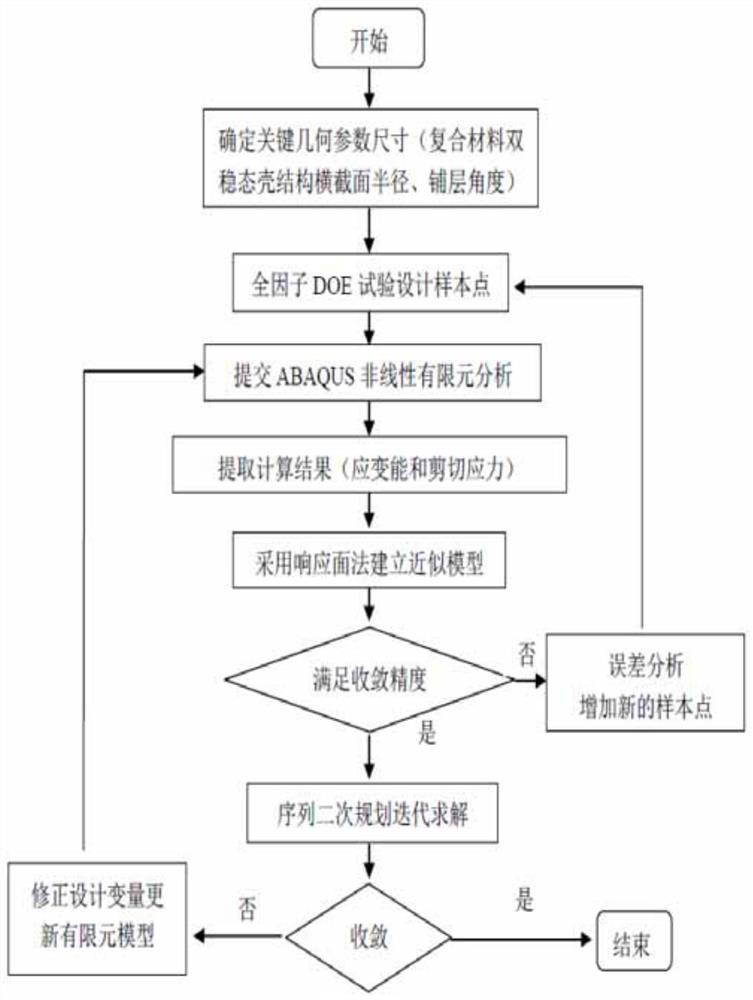

Composite bistable shell structure optimization design method based on full-factor test

PendingCN112364534ASimplify the solution processShorten the structural design cycleDesign optimisation/simulationSpecial data processing applicationsTest designElement model

The invention relates to a composite bistable shell structure optimization design method based on a full-factor test. The method comprises the following steps: (1) establishing a geometric model of acomposite bistable shell structure; (2) establishing a finite element model of the composite bistable shell structure; (3) performing nonlinear finite element analysis based on Abaqus software to obtain strain energy and a stress value of the composite bistable shell structure; (4) establishing an optimization model taking the strain energy of the composite bistable shell structure in the second stable state as a target by taking the cross section radius and the layering angle of the composite bistable shell structure as design variables; (5) employing a response surface method to solve the optimization design problem, selecting sample points in a parameter design space through a full-factor test design method, achieving display of a target function and a constraint function, and checkingthe accuracy of a fitting function; and (6) solving by adopting a sequential quadratic programming algorithm to obtain an optimal result. The method is applied to a composite material bistable state shell structure in the aspect of a space expansion structure.

Owner:BEIJING UNIV OF TECH

Deformation simulation method for multi-layer multi-pass welding of invar steel plate

ActiveCN103440355BGet Deformation Optimization MethodShorten the timeSpecial data processing applicationsInteraction problemEngineering

The invention relates to a deformation simulation method for the multilayer multi-pass welding of an Invar steel plate. The method comprises the following steps of establishing a three-dimensional temperature field and stress field model of the Invar steel plate, and solving radial deformation results under different conditions on the basis of nonlinear finite element analysis software by changing realistic clamping conditions, a welding sequence and the shape of a groove to obtain an optimization method for controlling welding deformation. According to the deformation simulation method for the multilayer multi-pass welding of the Invar steel plate, the three-dimensional temperature field and stress field model of the Invar steel plate is established for the multilayer multi-pass welding process of the Invar steel plate, the problem of interaction between cross welds is also taken into account, and different set boundary conditions are solved to obtain the optimization method for controlling the welding deformation.

Owner:SHANGHAI AIRCRAFT MFG +1

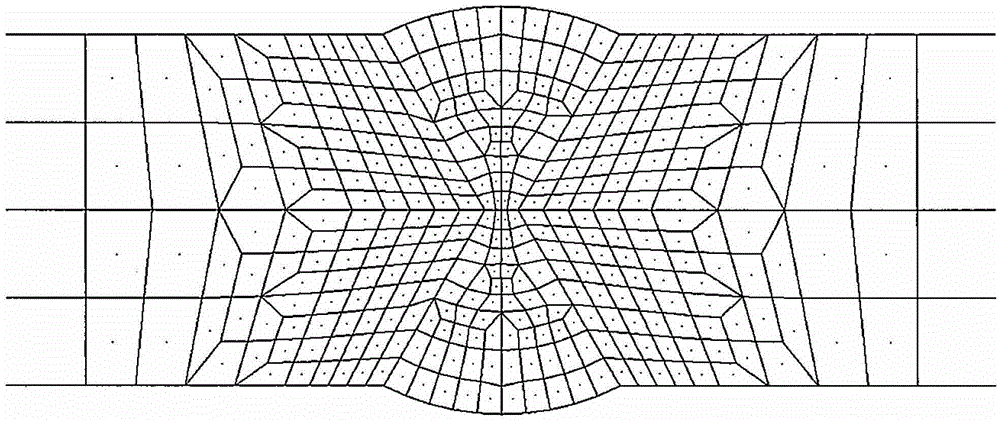

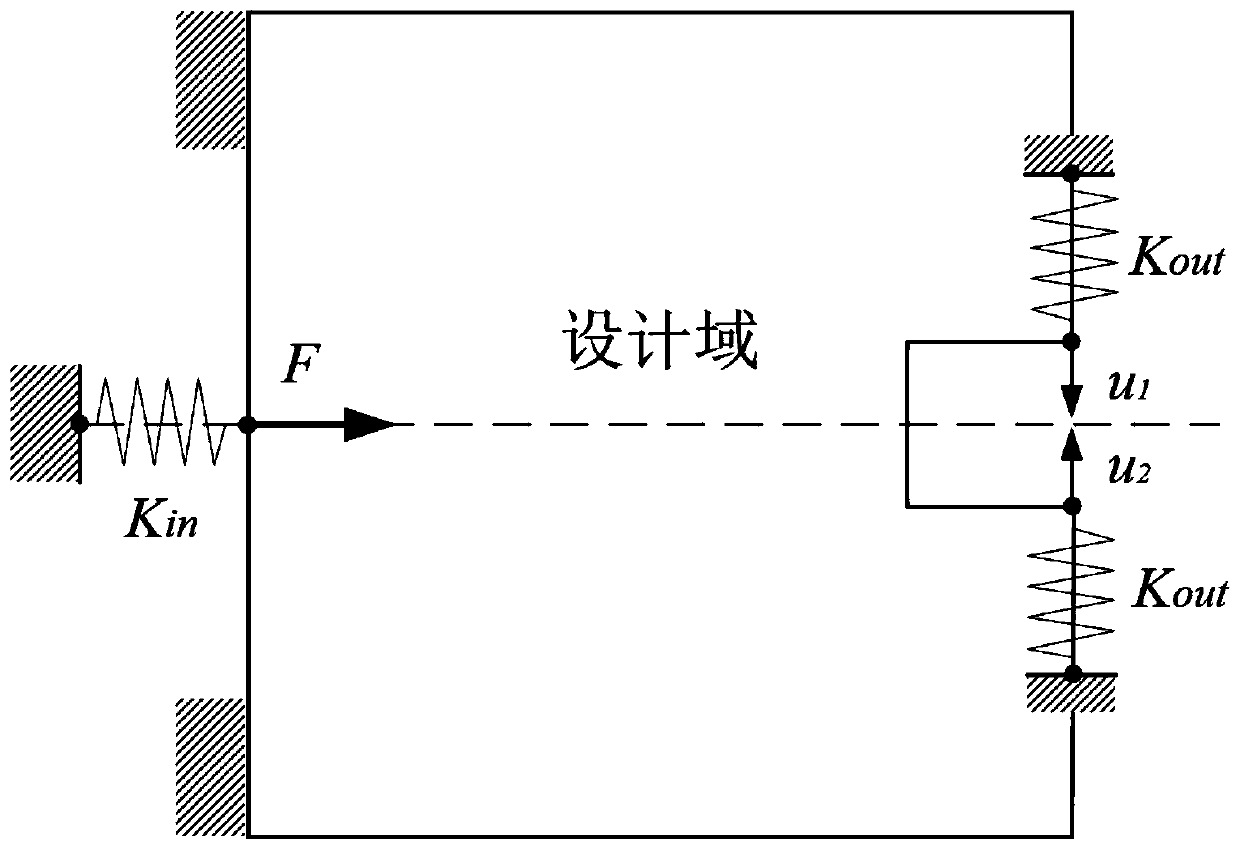

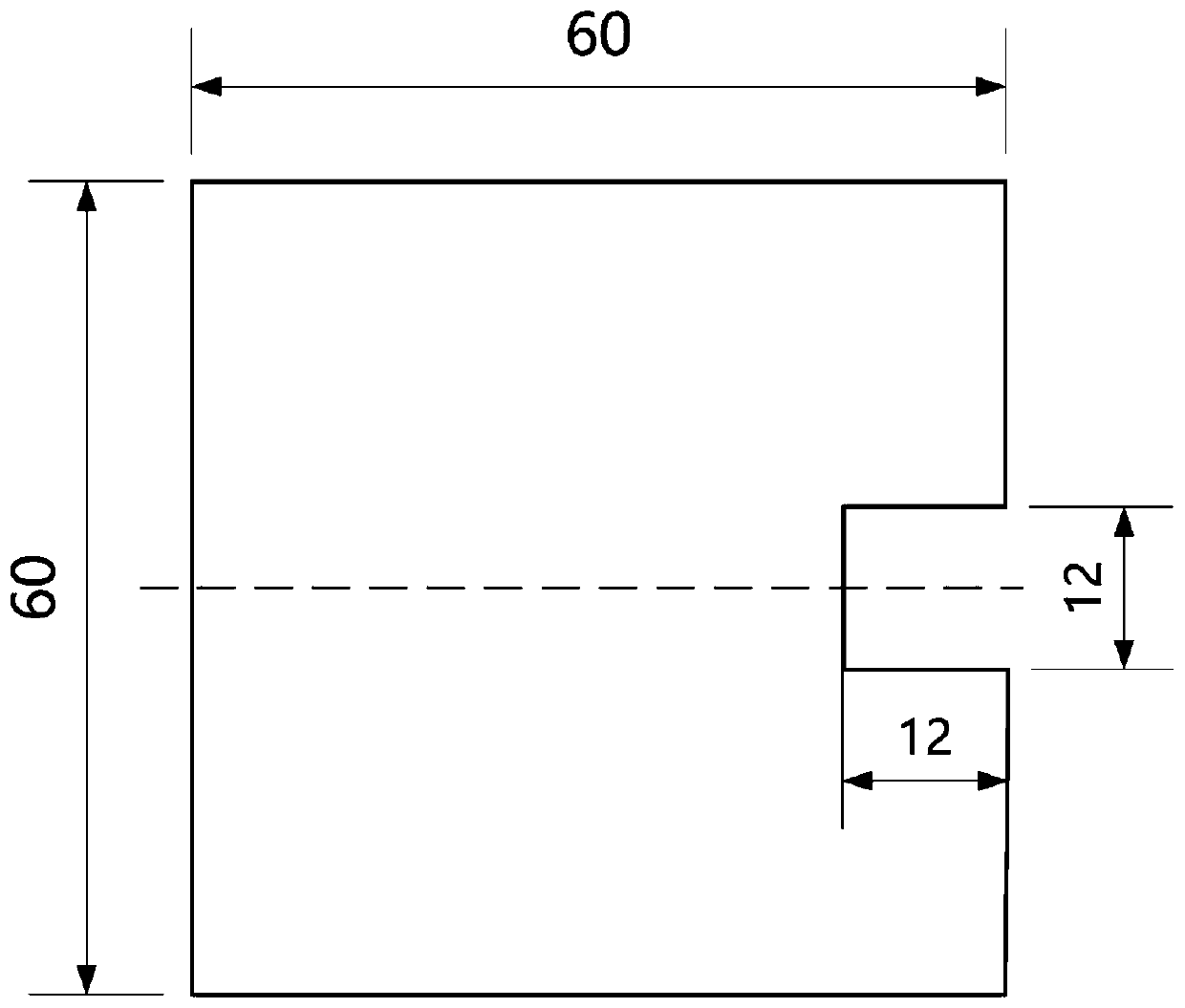

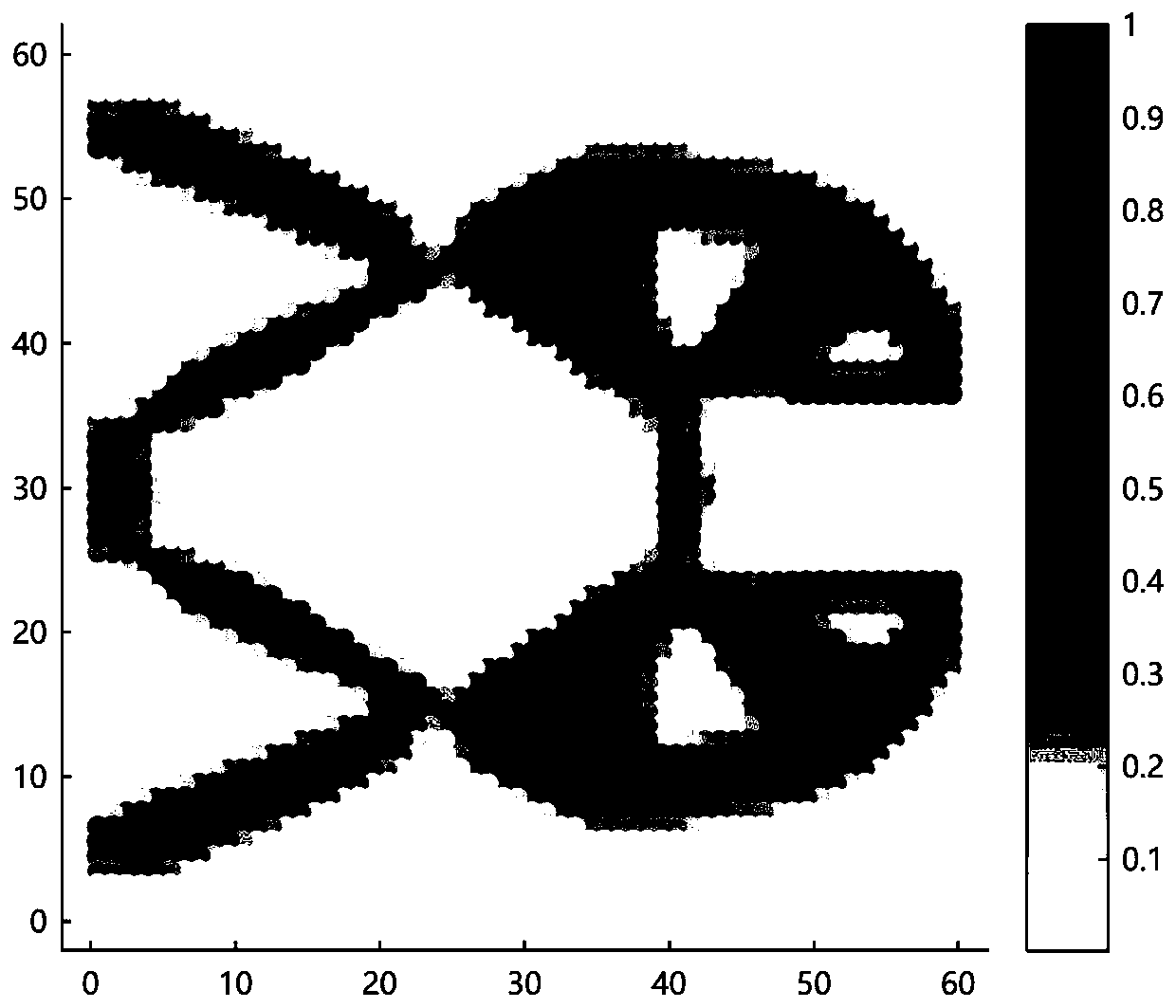

Flexible mechanism joint topology optimization method based on MATLAB and APDL

InactiveCN110059379AImprove computing efficiencyReduce programming difficultyDesign optimisation/simulationSpecial data processing applicationsFlexible MechanismsElement analysis

The invention discloses a flexible mechanism joint topology optimization method based on MATLAB and APDL. A topological optimization model of a flexible mechanism and a finite element analysis model of the flexible mechanism are established. Finite element analysis software ANSYS is used for carrying out geometric nonlinear calculation, and numerical calculation software MATLAB is used for carrying out a topological optimization iteration process. Complex nonlinear finite element analysis is completed by professional finite element analysis software, and numerical calculation is completed by professional numerical software. The advantages of all software are utilized to the maximum extent, the calculation efficiency is greatly improved, and the programming difficulty is reduced. The solving precision is guaranteed. The method has the advantages of high universality, simplicity and convenience in operation, high calculation efficiency and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for calculating contact force of rollers of increasing device

ActiveCN106768547AAccurately obtain payload sizeOvercome the shortcomings of inaccurate simplification of rigid body staticsDesign optimisation/simulationApparatus for force/torque/work measurementContact forceMechanical engineering

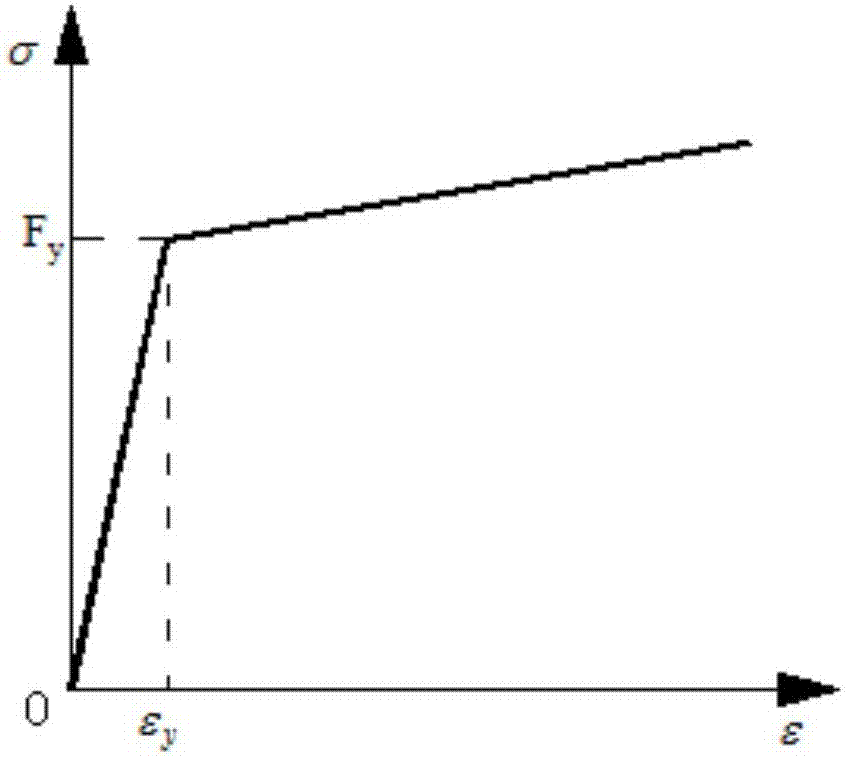

The invention relates to a method for calculating contact force of rollers of an increasing device and belongs to the technical field of structure strength analysis. A nonlinear finite element analysis method is adopted. The method comprises steps of step 1, inputting material plasticity curves of rollers and a slide rail mechanism and establishing elasto-plasticity models of the rollers and the slide rail mechanism; step 2, establishing contact pairs of the rollers and edges trips of the slide rails; step 3, inputting geometric nonlinear restrictions; step 4, dividing partial contact regions of the rollers and the slide rails into hexahedral grids and dividing other regions into tetrahedron grids; and step 5, selecting an iteration solver to carry out nonlinear solving. According to the invention, material nonlinearity, contact nonlinearity and geometric nonlinearity of the rollers and the slide structures are fully considered; statically indeterminate analysis is performed on a three-dimensional entity in a loading process; structural stiffness is actually simulated; load magnitude of the rollers is precisely acquired; and the method is characterized in that precision is high, research and development period can be shortened and cost is reduced.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

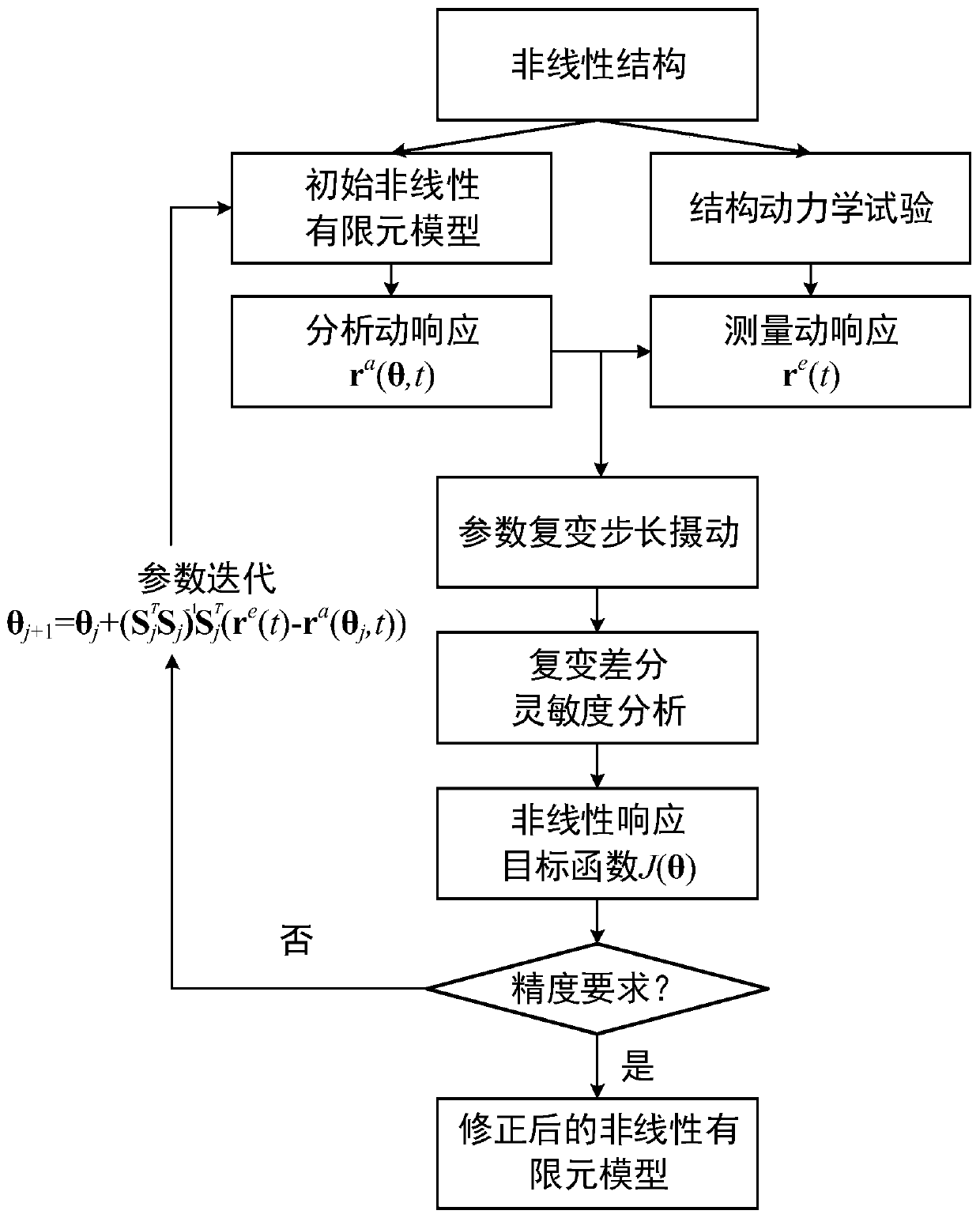

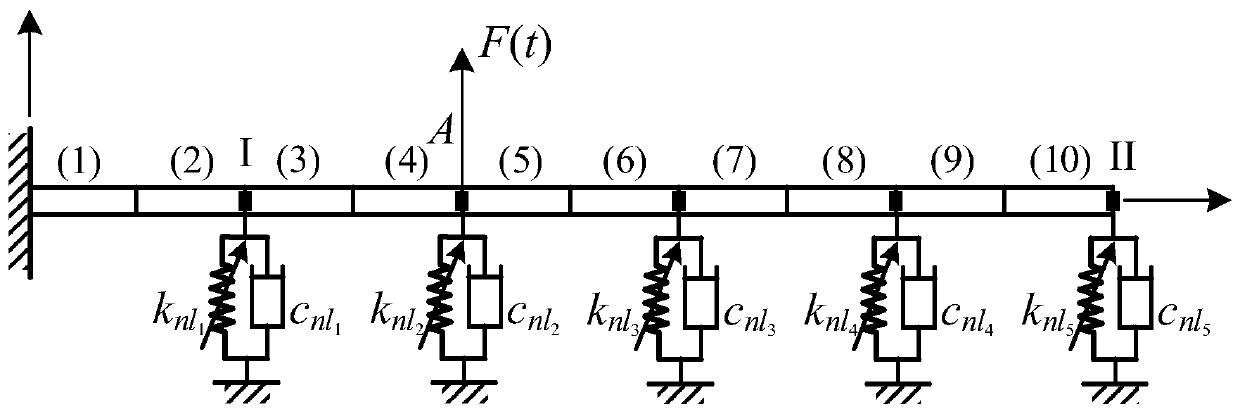

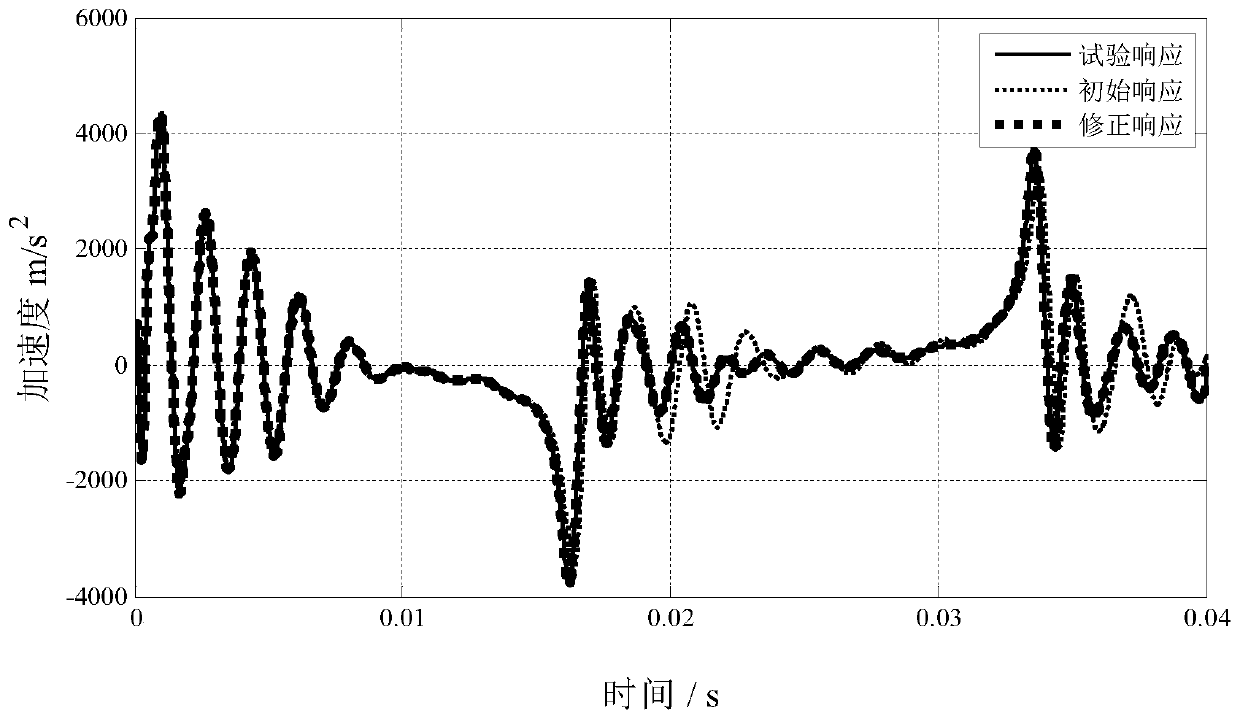

A complex variable differential sensitivity-based nonlinear structure finite element model correction method

ActiveCN109885896AImprove modeling accuracySpecial data processing applicationsElement modelNonlinear model

The invention discloses a complex variable differential sensitivity-based nonlinear structure finite element model correction method, which comprises the following steps of firstly, establishing a nonlinear finite element initial analysis model of a structure; secondly, performing complex step perturbation on a to-be-corrected parameter in the structure, and calculating nonlinear dynamic responsesensitivity; thirdly, measuring response data of the structure, and establishing an objective function of nonlinear model correction; and finally, performing least square optimization on the measureddynamic response and the analyzed dynamic response so as to realize nonlinear finite element model correction, so that the structural parameters of the nonlinear finite element analysis model can be corrected, and the calculation precision of the analysis model is improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com