Method of calculating life of thin-walled flexible support bearing

A bearing life and calculation method technology, which is applied in calculation, design optimization/simulation, special data processing applications, etc., can solve problems affecting bearing load distribution, reduce development costs and cycles, and achieve huge economic and social benefits. Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

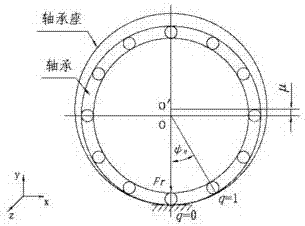

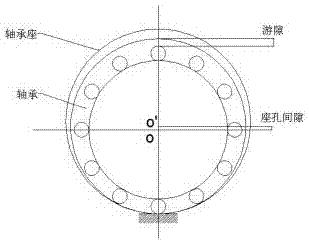

Embodiment 1

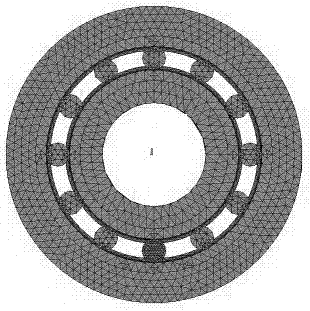

[0045] When the thin-walled bearing has 12 rolling elements, the radial load is 1000N, and there is a gap of m=5μm between the bearing and the bearing seat, change the clearance μ between the bearings to 0μm, 5μm, 10μm, 15μm, 20μm, the force is like Image 6 Shown.

[0046] According to the extracted rolling element load, use APDL parameter expressions and functions to write bearing life calculation statements to analyze the bearing model clearance as a fixed value of 5μm, change the radial clearance, calculate the bearing life value, and find that there is an optimal diameter The backlash makes the flexible support bearing the longest life, such as Figure 7 Shown.

[0047] by Image 6 It can be seen that when the clearance μ between the bearings is less than 15 μm, the life performance of the bearing is significantly improved; when the clearance μ is greater than 15 μm and less than 25 μm, the life performance of the bearing is slowly improved; when the clearance μ is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com