Welding reverse deformation calculation method

A calculation method and anti-deformation technology, applied in calculation, design optimization/simulation, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

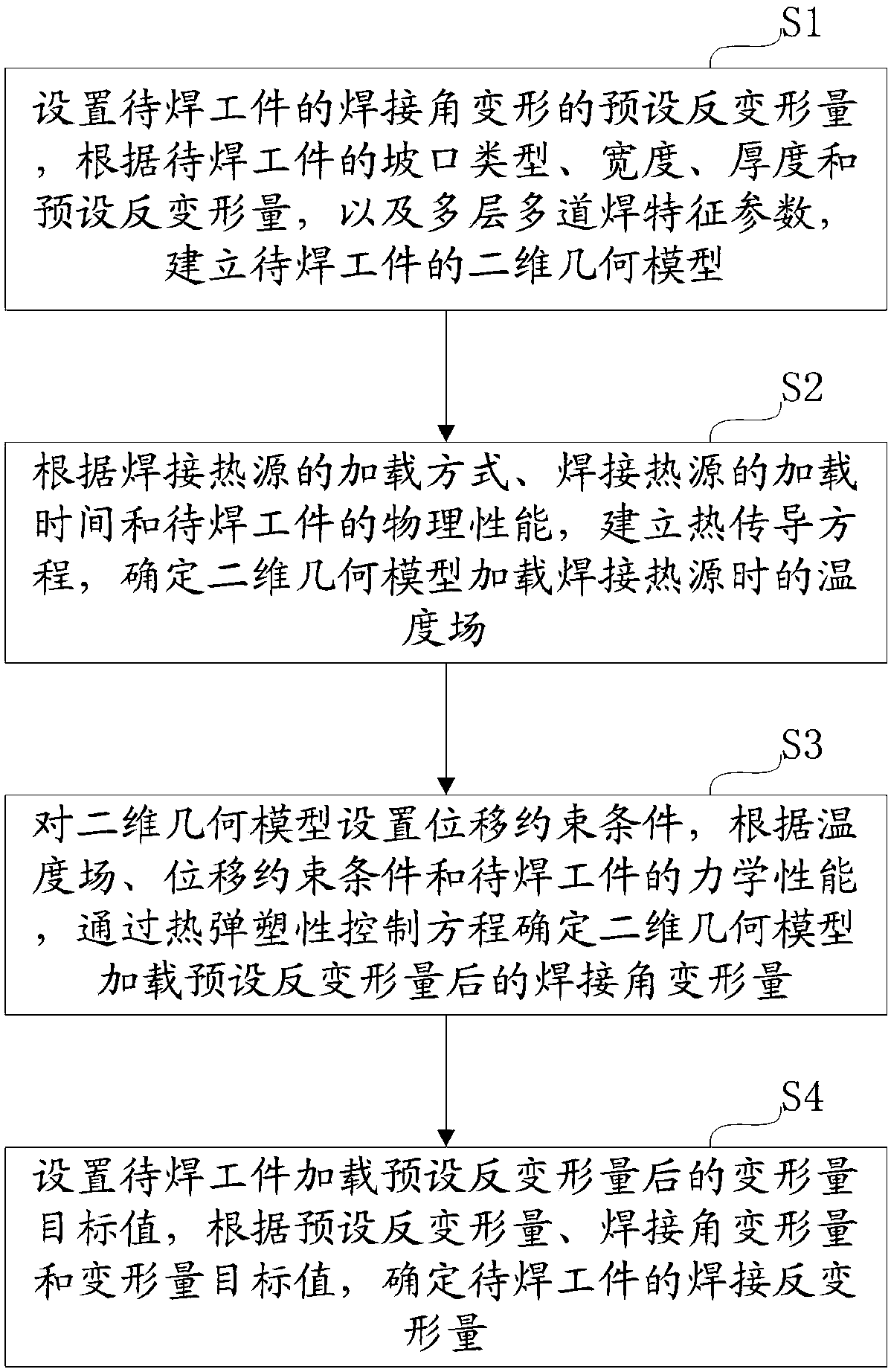

[0023] Such as figure 1 Shown, a kind of calculation method of welding anti-deformation amount of the present invention comprises the following steps:

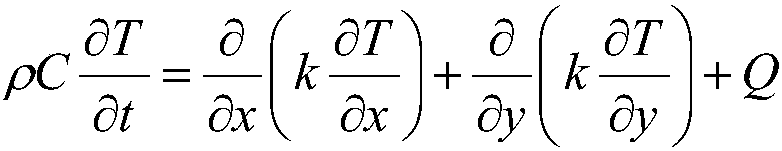

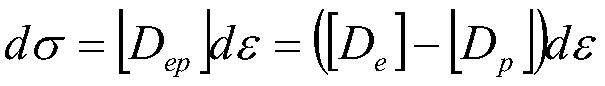

[0024] S1. Set the preset anti-deformation amount of the welding corner deformation of the workpiece to be welded, and establish a two-dimensional geometric model of the temperature field and deformation field of the workpiece to be welded according to the preset anti-deformation amount and welding conditions in the computer-aided design software. Wherein, the welding condition may include the groove type, width, thickness of the workpiece to be welded, and characteristic parameters of multi-layer multi-pass welding, and the characteristic parameters of multi-layer multi-pass welding may include welding passes. By considering the above characteristic parameters, it can be fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com