Arc length method nonlinear finite element analysis-based disc burst speed prediction method

A technology of fracture speed and prediction method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as failure to meet engineering design needs and large error of fracture speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

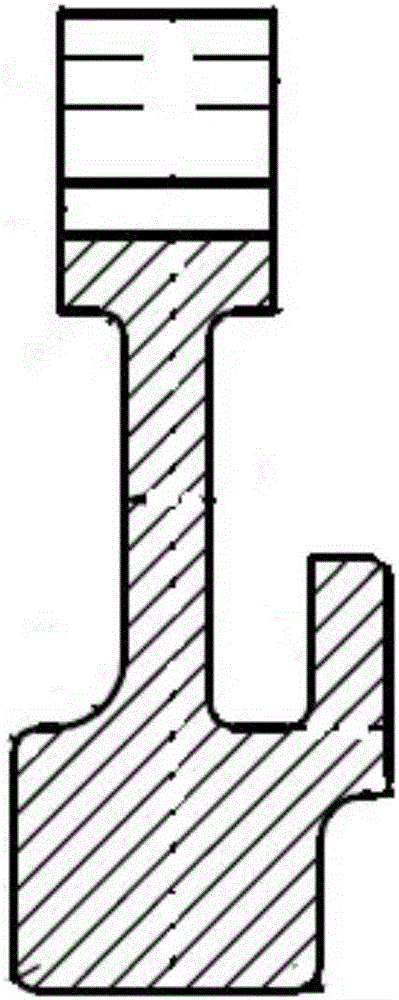

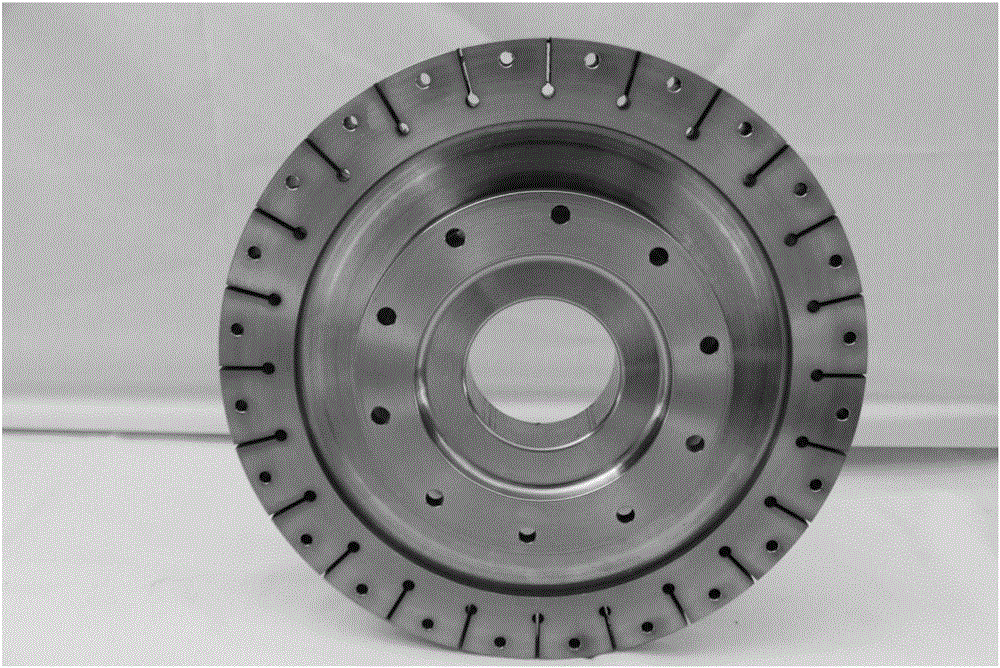

[0055] In the present invention, the simulated roulette sample of the nickel-base superalloy GH4169 is taken as an example, and the rupture speed of the simulated roulette is predicted under room temperature conditions. Sample drawings and physical pictures such as Figure 1a and shown in b.

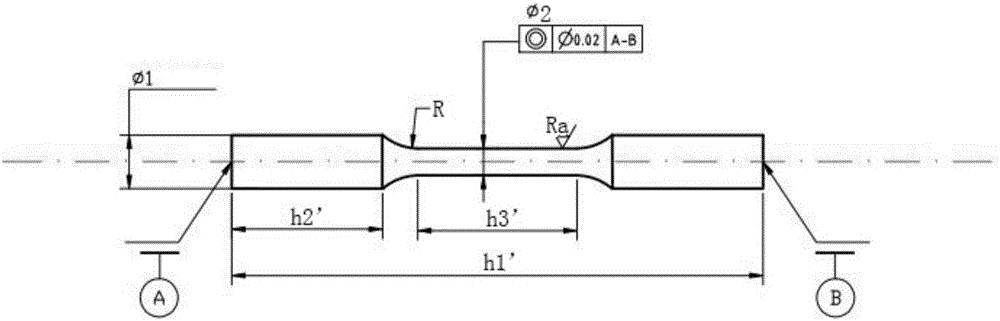

[0056] Step 1. In order to accurately predict the rupture speed of the GH4169 simulated disk, it is necessary to take samples from the simulated disk forging and test its mechanical properties and tensile stress-strain curve, that is, the engineering stress-strain curve of the material. The sample drawings and photos are as follows: Figure 2a As shown in and b, the dimensions in the figure are: h1'=100mm, h2'=28.39mm, h3'=30mm, Φ1=10±0.02mm, Φ2=5±0.02mm, R=10mm, Ra=0.8.

[0057] The GH4169 simulation disk is manufactured by free forging round cakes. After rough machining, direct aging heat treatment is used for heat treatment, and then it is finished according to the drawing to the fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com