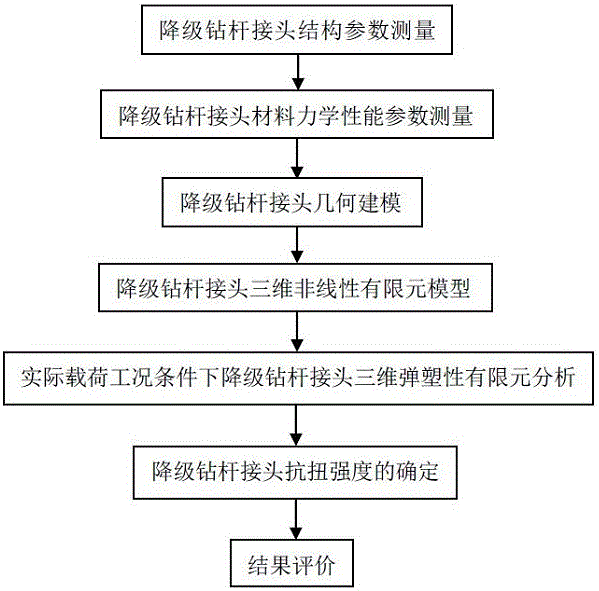

Method for quickly evaluating torsional property of degraded drill rod connector

A technology of drill pipe joint and evaluation method, which is applied in the field of oilfield drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Example: A rapid evaluation method for the torsional performance of a degraded drill pipe joint is used to determine the torsional strength of a degraded drill pipe joint.

[0032] Using this evaluation method to evaluate a degraded drill pipe joint, the main parameters measured are shown in Table 1.

[0033]

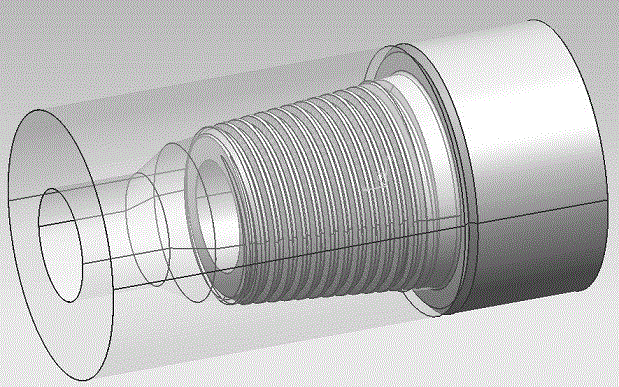

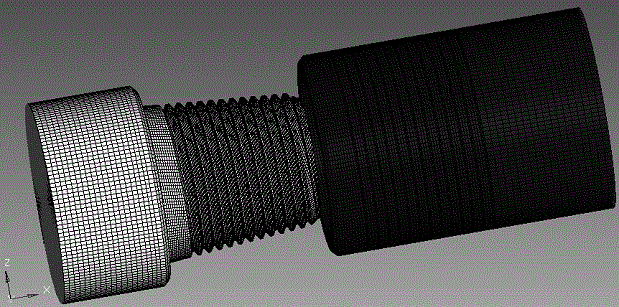

[0034] Use CAD geometric modeling software to establish a three-dimensional geometric model of the downgraded drill pipe joint, such as figure 2 shown. Use the finite element pre-processing software to mesh the degraded drill pipe joint, and establish its three-dimensional finite element model, as shown in image 3 shown.

[0035] The material used for the drill pipe joint is isotropic elastic-plastic material, and the measured elastic modulus is 2.06×10 5 MPa, Poisson's ratio is 0.29, and the true stress-plastic strain data of the material are shown in Table 2. Considering the influence of thread grease containing 40-60% by weight of zinc powder, the coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com