Method for evaluating performance of drill pipe connector

A technology of drill pipe joints and evaluation methods, applied in construction and other fields, can solve the problems of inability to simulate the stress characteristics of threaded joints and the inability to effectively simulate the stress characteristics of threaded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

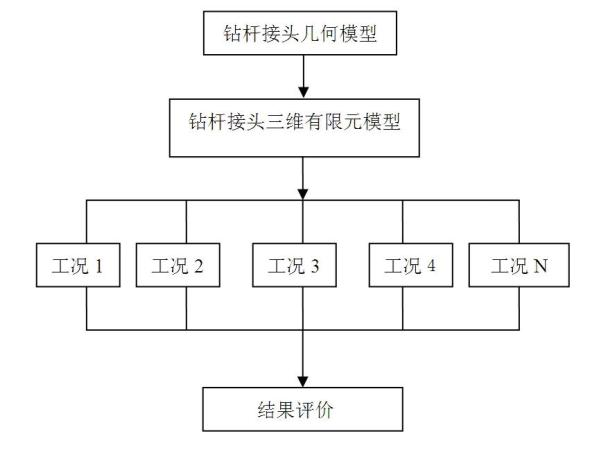

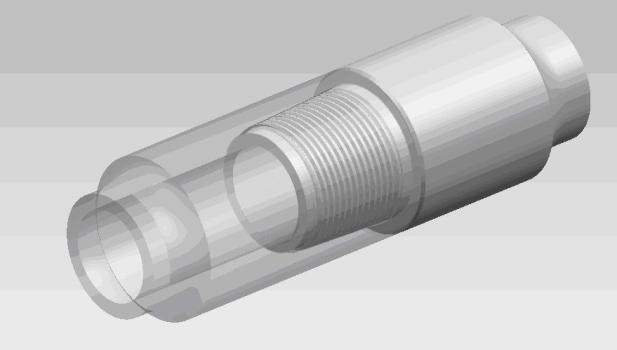

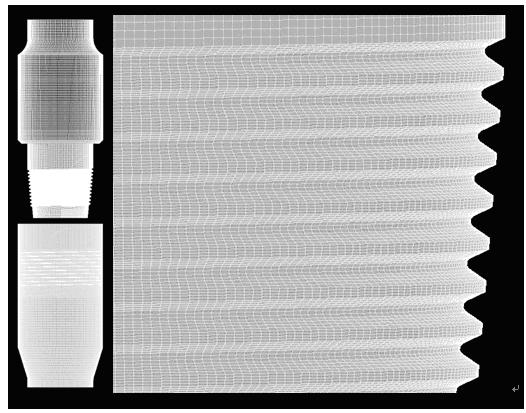

[0029] Example: Evaluating the Performance of Drill Pipe Joints Using Three-Dimensional Finite Element Analysis Technique

[0030] Using this evaluation method to evaluate a drill pipe joint, the main parameters of the drill pipe joint are shown in Table 1.

[0031] Table 1 Main parameters of drill pipe joints

[0032] Outer diameter of thickened part / mm 168.28 Tube outer diameter / mm 130.18 inner diameter / mm 95.25 Thread taper 1:12

[0033] The material used for the drill pipe joint is 37CrMnMoA, which is an isotropic elastic-plastic material with an elastic modulus of 2.06×10 5 MPa, Poisson's ratio is 0.29, the real stress-plastic strain curve of the material is as attached Figure 4 shown. Considering the influence of thread grease containing 40-60% by weight of zinc powder, the coefficient of friction between mating surfaces (including between threads and between shoulder surfaces) is taken as 0.08.

[0034] The von Mises stress distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com