Quick evaluation method for tensile performance of multi-layer non-sticking flexible pipe

An evaluation method and technology for flexible pipes, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problem of complex structural analysis of non-bonded flexible pipes, without considering the characteristics of frictional contact between layers, and the real force of flexible pipes issues such as feature gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

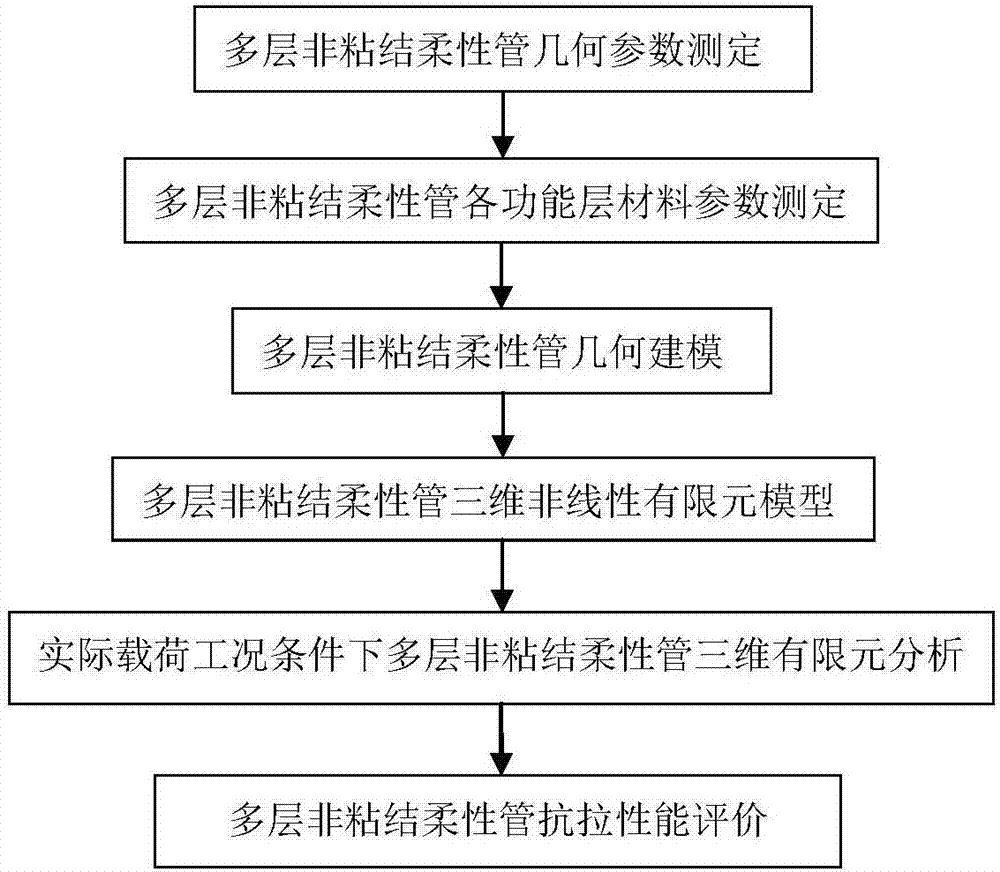

[0034] Example: Determination of Tensile Properties of Multilayer Unbonded Flexible Pipe Using Three-Dimensional Finite Element Analysis Technique

[0035] Use this evaluation method to evaluate a certain multi-layer non-bonded flexible pipe, which includes inner lining layer, compressive armor layer, tensile armor layer, wear-resistant layer, insulation layer, middle cladding layer, and outer cladding layer .

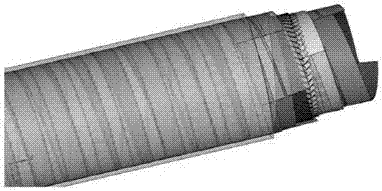

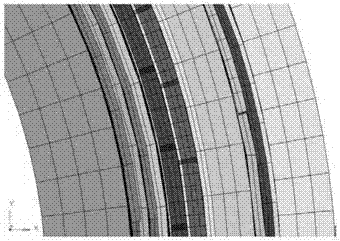

[0036] Use CAD geometric modeling software to establish a three-dimensional geometric model of flexible pipes, such as figure 2 shown. Use the finite element pre-processing software to mesh the flexible pipe, and establish its three-dimensional finite element model, such as image 3 shown.

[0037] According to the material test, the material parameters of the materials used in each layer of the flexible pipe are shown in Table 1. The coefficient of friction within and between layers is 0.1.

[0038] Table 1 Main material parameters of flexible pipe

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com