Method for rapidly evaluating ultimate tensile performance of multilayered non-bonded marine flexible pipe

A technology of marine flexible pipe and evaluation method, which is applied in the field of rapid evaluation of ultimate tensile performance of multi-layer non-bonded marine flexible pipe, can solve the complex structure analysis of multi-layer non-bonded marine flexible pipe and the multi-layer non-bonded marine flexible pipe. The gap between the real force characteristics of the pipeline and the lack of consideration of the friction and contact characteristics between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

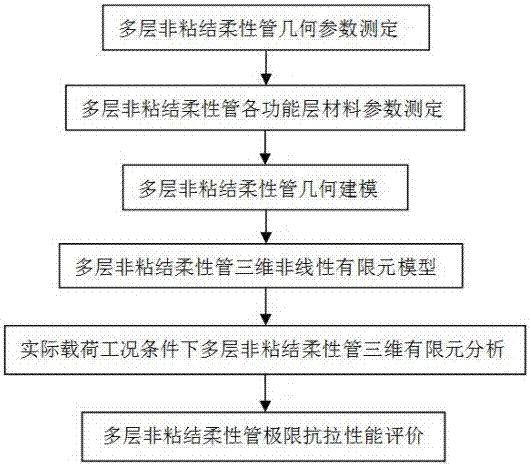

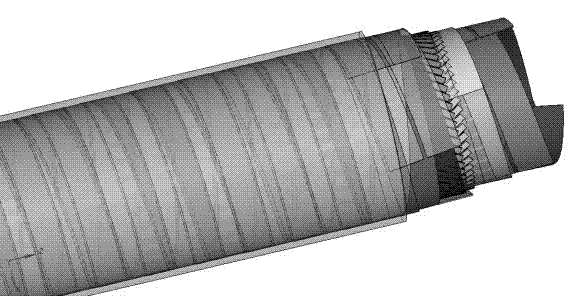

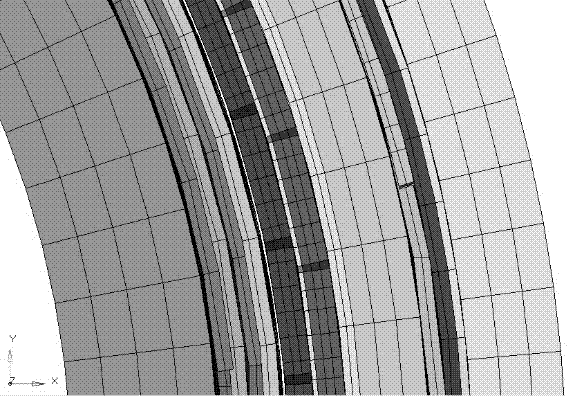

[0029] Use this evaluation method to evaluate a multi-layer unbonded marine flexible pipe, which includes an inner liner, a compressive armor layer (6 layers), a tensile armor layer (2 layers), a wear-resistant layer, an insulation layer, The middle cladding layer and the outer cladding layer have a total of 13 layers. Such as figure 1 As shown, the specific steps are as follows:

[0030] 1) Measure the structural parameters of multi-layer unbonded marine flexible pipes by using special measuring tools such as internal diameter gauge, disc micrometer, thickness gauge, and image measuring instrument. The main measurement results are shown in Table 1.

[0031] Table 1 Main structural parameters of flexible pipe

[0032]

[0033] 2) Using MTS universal testing machine, density measuring instrument and other special material testing equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com