Deformation simulation method for multilayer multi-pass welding of Invar steel plate

A simulation method and steel plate technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of long test period, affecting the production and use time of components, and large residual deformation, so as to optimize the welding scheme and save energy. The effect of cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

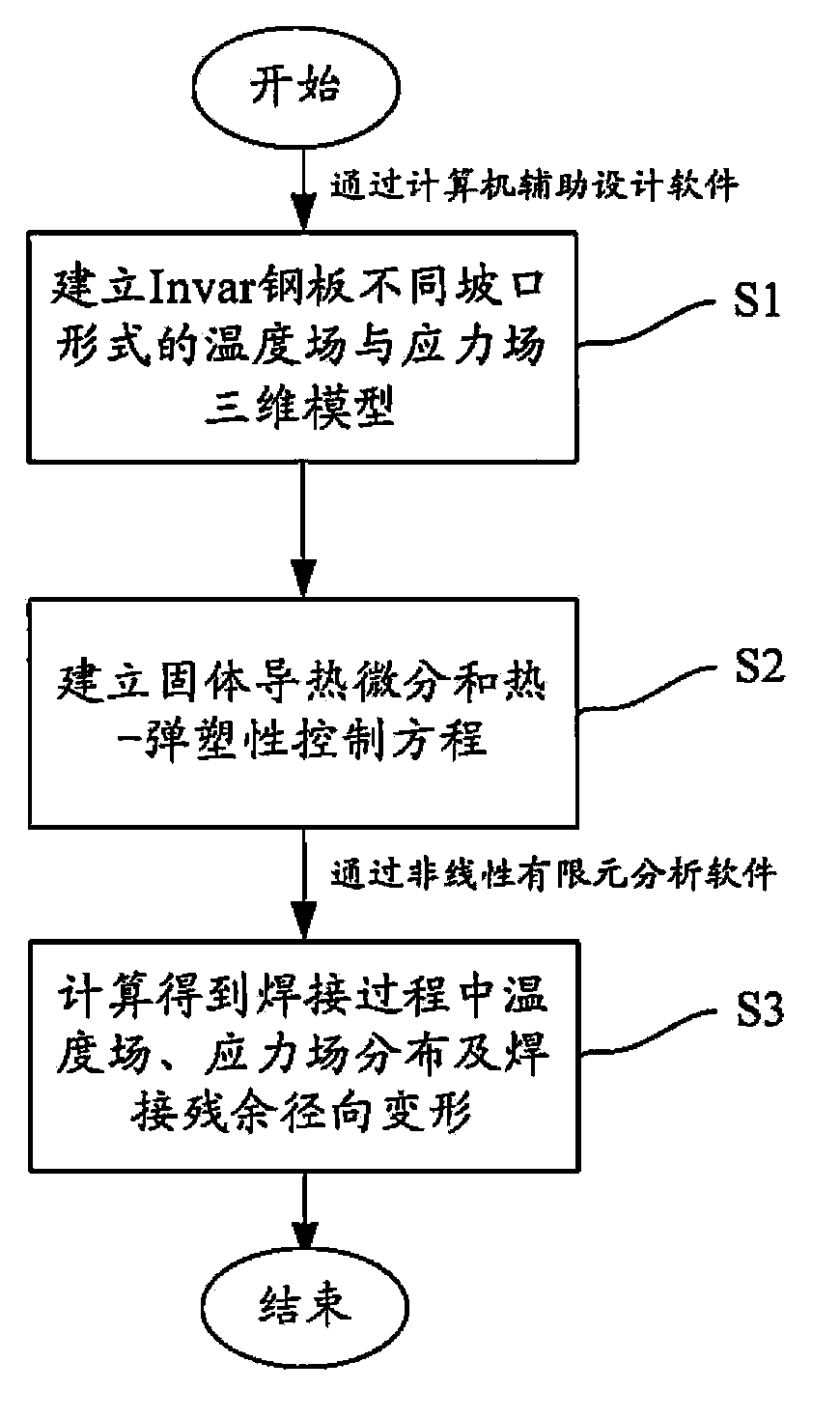

[0037] see figure 1 , a kind of Invar steel plate multi-layer multi-pass welding deformation simulation method, comprising the following steps:

[0038] The first step S1: Establish a three-dimensional model of the temperature field and stress field of the different groove forms of the Invar steel plate:

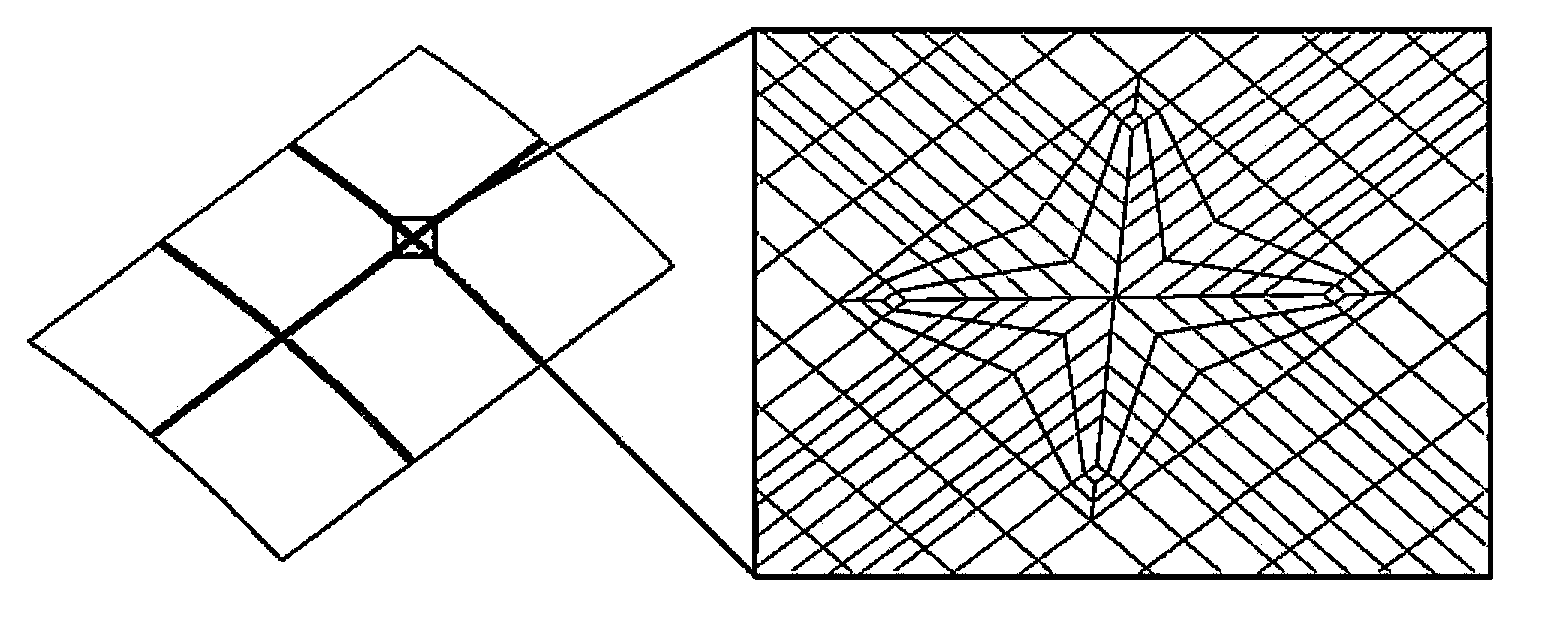

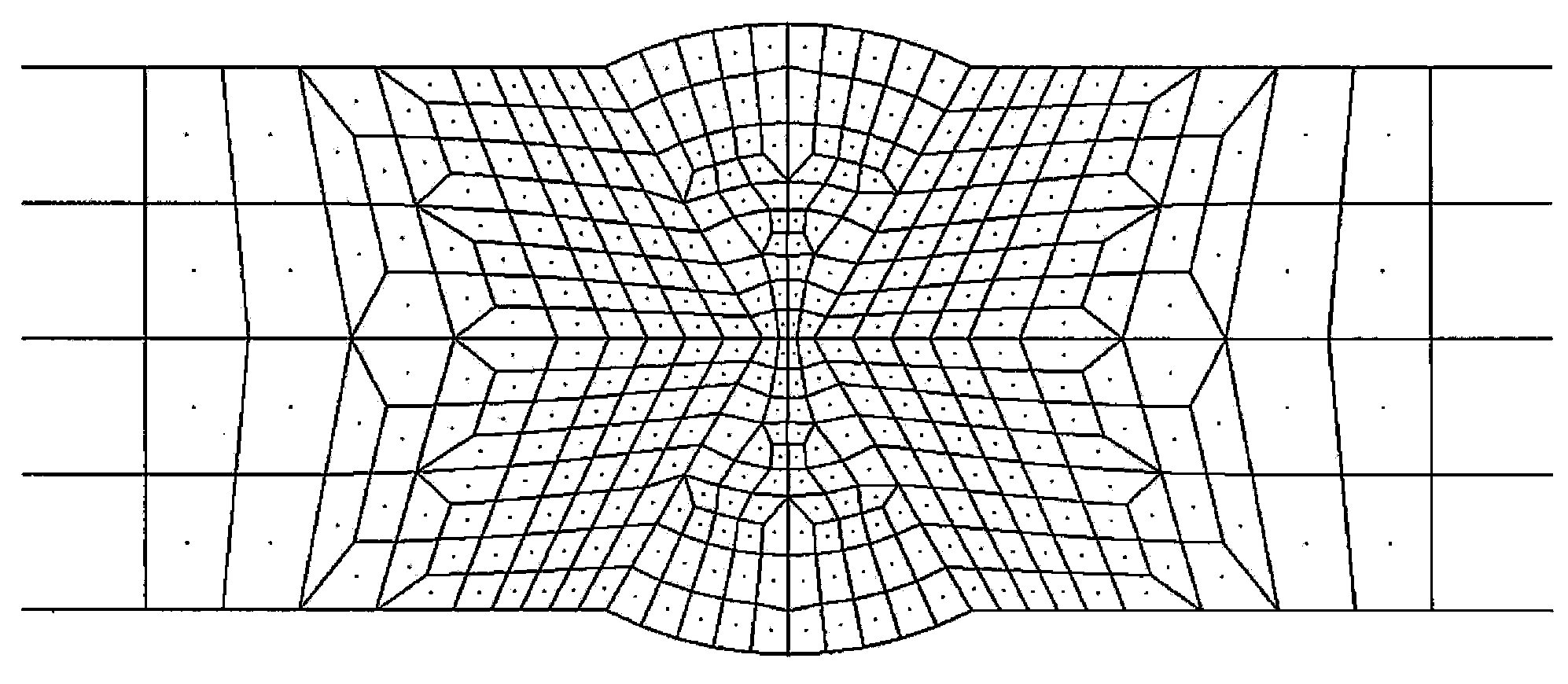

[0039] Specifically, in computer-aided design software such as CAD software, three-dimensional geometric models of different groove forms of components are established, and targeted meshing is carried out for different regions of components; the so-called "targeted meshing" refers to weld seam The area and the area close to the weld are densely divided, and the transition method is adopted, so that the grid size becomes larger as the distance from the weld increases.

[0040] The second step S2: Based on the three-dimensional model of the temperature fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com