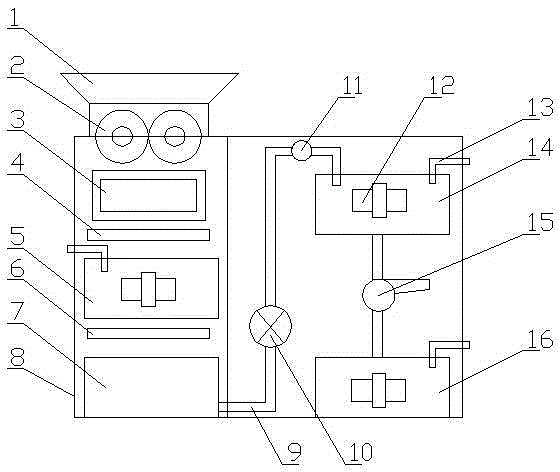

Heavy metal contaminated soil remediation equipment and remediation process thereof

A technology of polluted soil and heavy metals, applied in the restoration of polluted soil, etc., can solve the problems of large equipment footprint, backward repair technology, low degree of automation, etc., to achieve small footprint, avoid secondary pollution, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

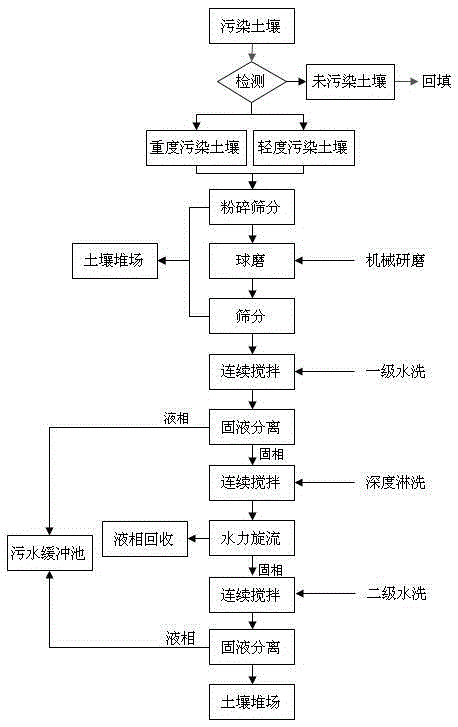

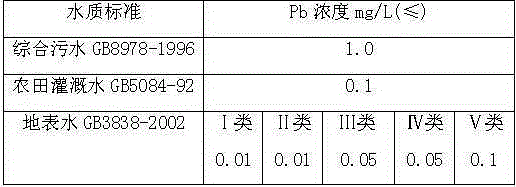

[0030] Such as figure 2 As shown, the remediation process of the above-mentioned heavy metal contaminated soil remediation equipment includes the following steps:

[0031] (1) Soil classification: A three-dimensional inspection was performed on the soil of a lead-contaminated site, and it was classified into heavily polluted soil (average Pd concentration was 3.182mg / g), lightly polluted soil (average Pd concentration was 1.563mg / g) and Uncontaminated soil (with an average Pd concentration of 0.391mg / g) is piled up separately, heavily polluted soil and lightly polluted soil are crushed and screened, and uncontaminated soil is backfilled directly.

[0032] (2) Mechanical grinding: Preliminary crushing and sieving of the contaminated soil, the crushed and sieved soil is put into the wet ball mill through the feeding hopper for mechanical grinding for 30 minutes, and then the material is discharged through a 2mm sieve, and the part above the sieve enters the soil In the storage...

Embodiment 2

[0039] (1) Soil classification: A three-dimensional inspection was performed on the soil of a lead-contaminated site, and it was classified into heavily polluted soil (average Pd concentration was 3.182mg / g), lightly polluted soil (average Pd concentration was 1.563mg / g) and Uncontaminated soil (with an average Pd concentration of 0.391mg / g) is piled up separately, heavily polluted soil and lightly polluted soil are crushed and screened, and uncontaminated soil is backfilled directly.

[0040] (2) Mechanical grinding: Preliminary crushing and sieving of the contaminated soil, the crushed and sieved soil is put into the wet ball mill through the feeding hopper for mechanical grinding for 30 minutes, and then the material is discharged through a 2mm sieve, and the part above the sieve enters the soil In the storage yard, the part under the sieve enters the continuous stirring tank for primary water washing.

[0041] (3) Primary water washing: The heavily polluted soil sieved in ...

Embodiment 3

[0047] (1) Soil classification: A three-dimensional inspection was performed on the soil of a lead-contaminated site, and it was classified into heavily polluted soil (average Pd concentration was 3.182mg / g), lightly polluted soil (average Pd concentration was 1.563mg / g) and Uncontaminated soil (with an average Pd concentration of 0.391mg / g) is piled up separately, heavily polluted soil and lightly polluted soil are crushed and screened, and uncontaminated soil is backfilled directly.

[0048] (2) Mechanical grinding: Preliminary crushing and sieving of the contaminated soil, the crushed and sieved soil is put into the wet ball mill through the feeding hopper for mechanical grinding for 30 minutes, and then the material is discharged through a 2mm sieve, and the part above the sieve enters the soil In the storage yard, the part under the sieve enters the continuous stirring tank for primary water washing.

[0049] (3) Primary water washing: The heavily polluted soil sieved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com