Portable handheld electrostatic spinning device

An electrospinning, portable technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of voltage instability, short spinning distance, low fiber yield, etc., to achieve production cost reduction, Stable spinning and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

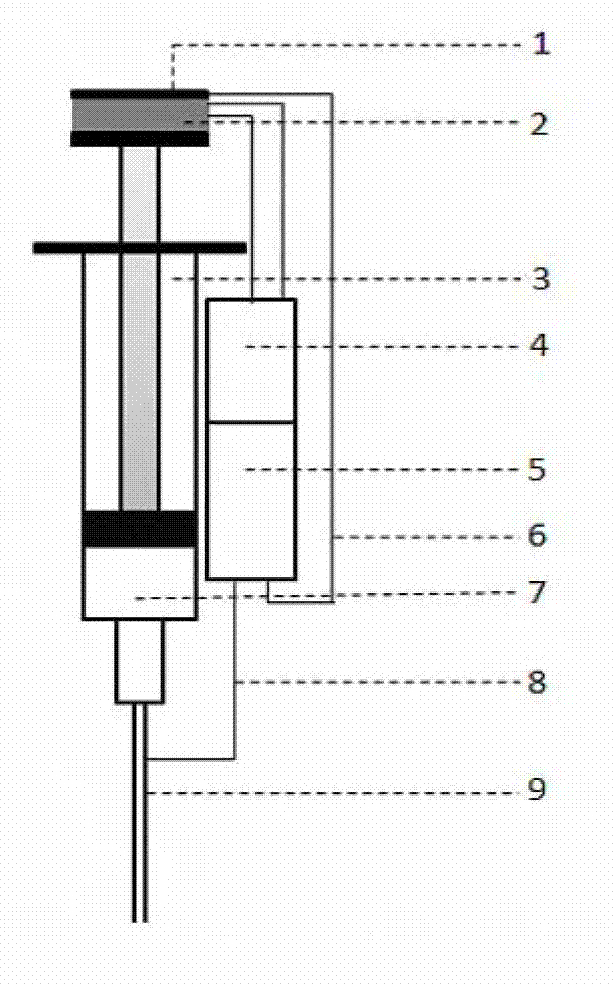

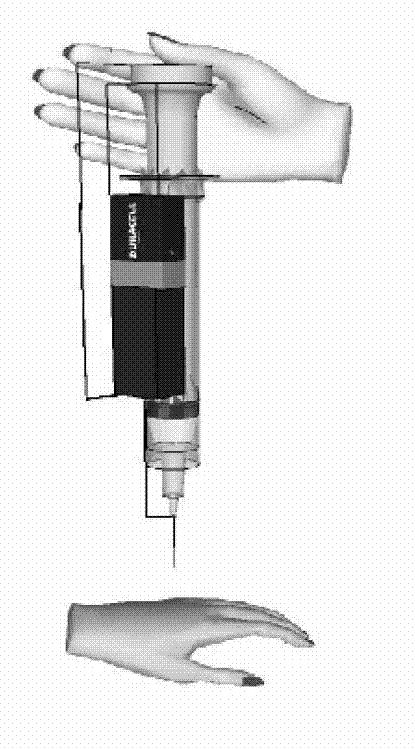

[0012] From the perspective of portability and practicality, this embodiment designs a portable handheld electrospinning device that is cheap, small in size, light in weight, stable in spinning, high in fiber yield, and capable of spinning anytime and anywhere. Its main structure includes a metal foil 1. Crimp switch 2, syringe 3, square battery 4, high voltage DC inverter 5, high voltage DC inverter negative pole 6, spinning solution 7, high voltage DC inverter positive pole 8 and stainless steel needle 9; conventional medical syringe The top of the push rod 3 is provided with a crimping switch 2, and the top side of the flat crimping switch 2 is fixed with a metal foil 1. A spinning solution 7 is placed in the front end cavity of a conventional medical syringe 3, and the side of the syringe 3 The wall is butt-jointed and integrally fixed with a square battery 4 and a high-voltage DC inverter 5, and the bottom end of the syringe 3 is plugged with a stainless steel needle 9 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com