Patents

Literature

103 results about "Parametric simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implementing A Circuit Using An Integrated Circuit Including Parametric Analog Elements

ActiveUS20100306722A1CAD circuit designSoftware simulation/interpretation/emulationEngineeringClient machine

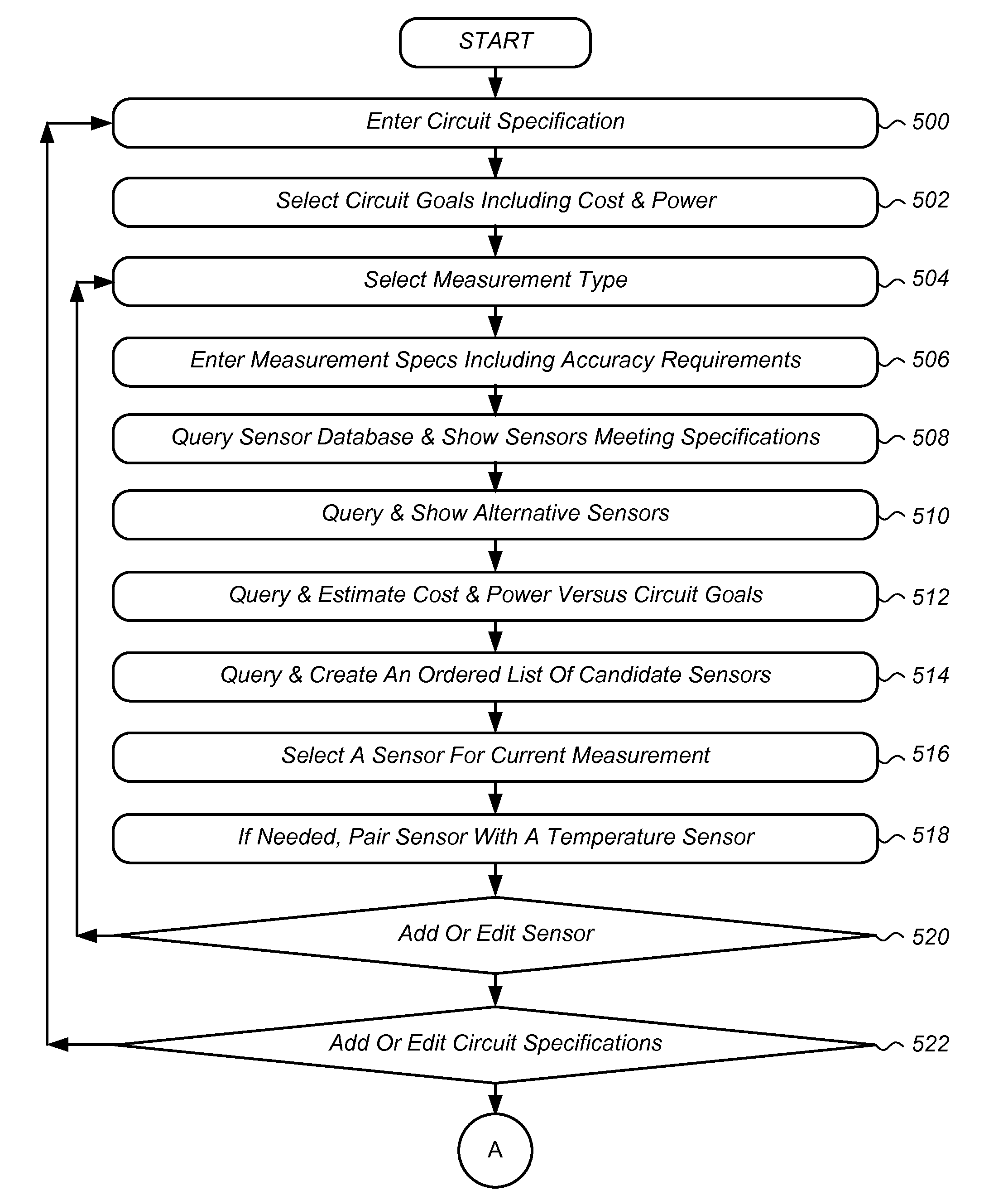

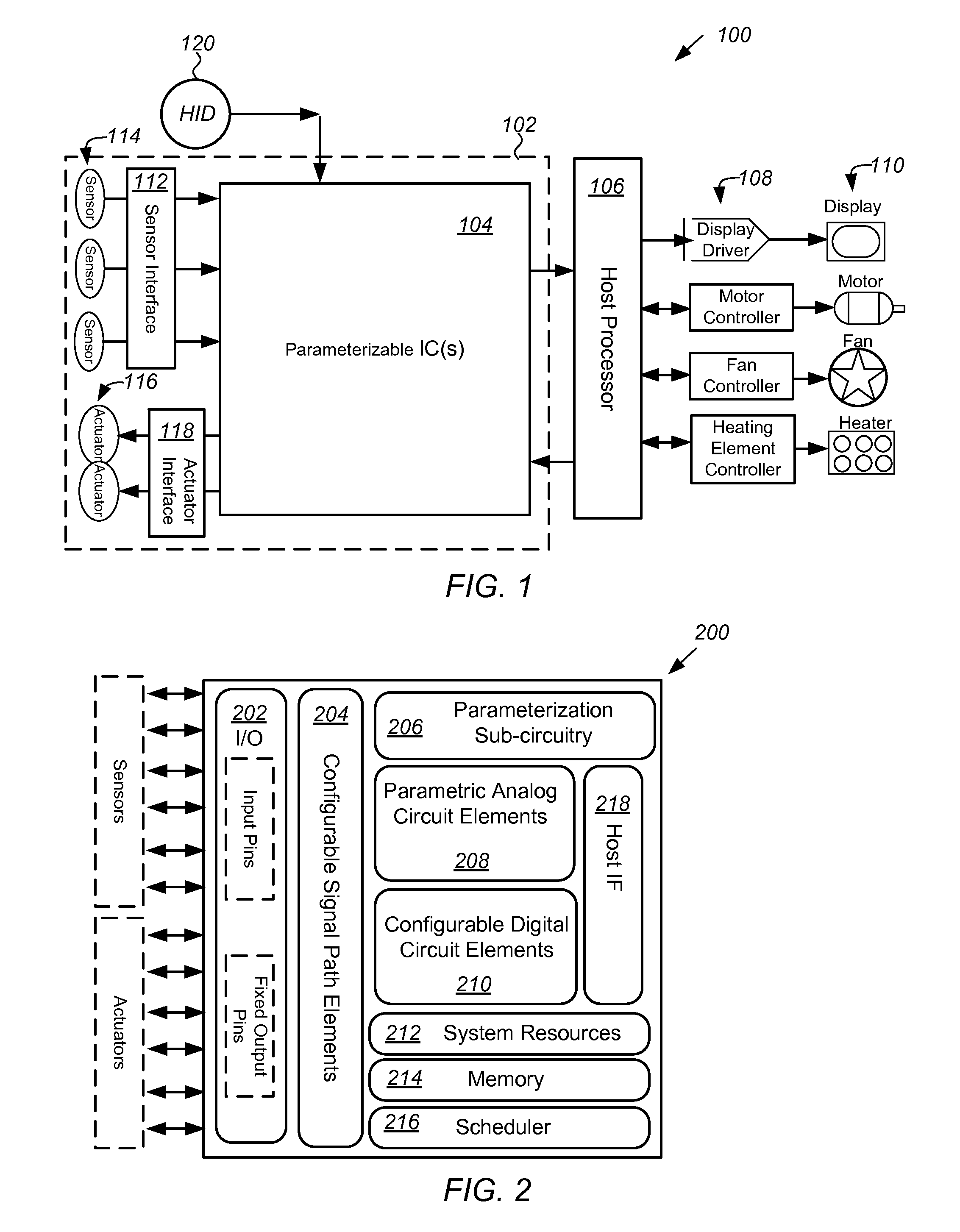

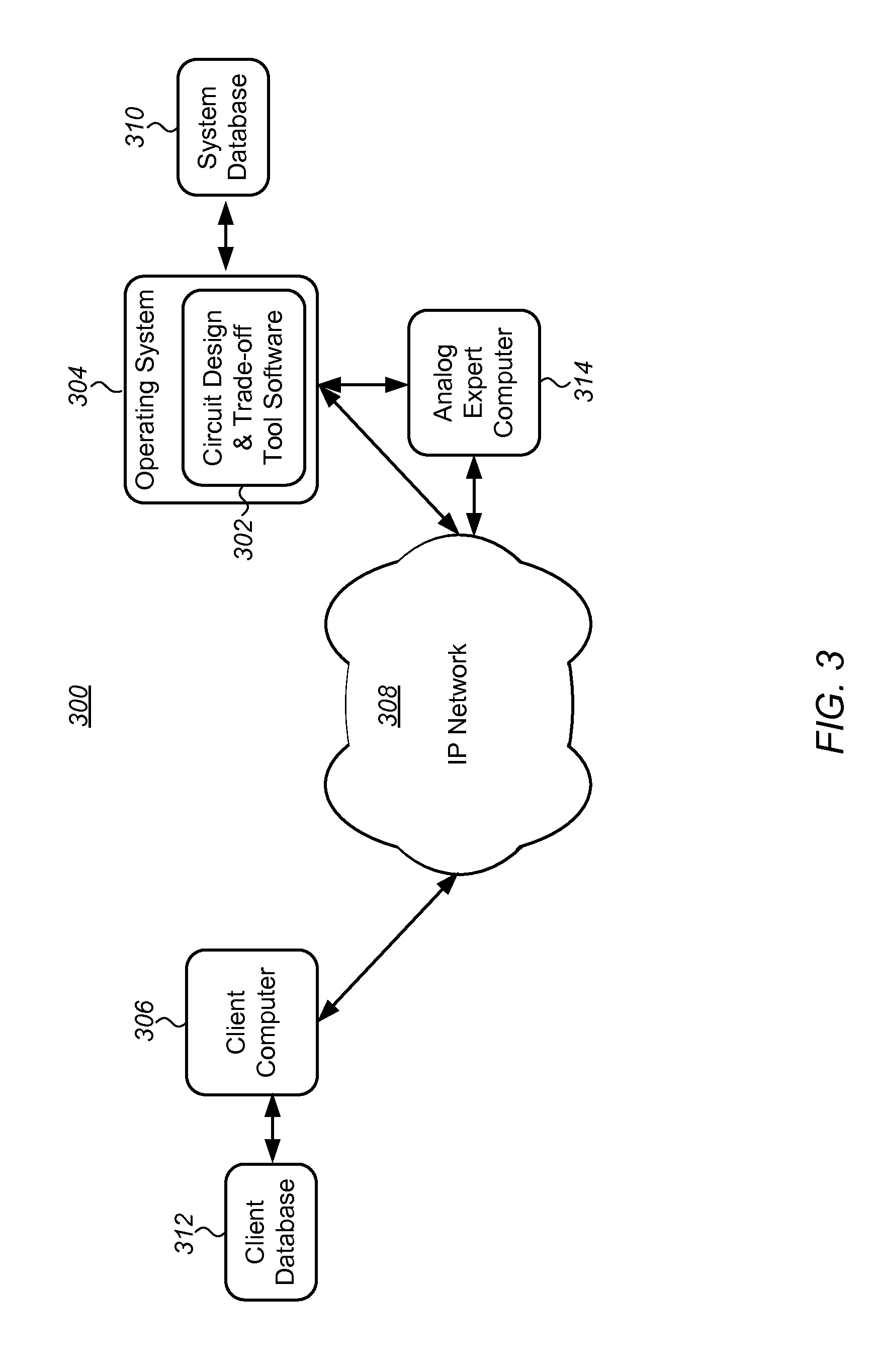

An environment and method are provided for designing and implementing a circuit comprising an integrated circuit (IC) including a number of parametric analog elements for which operating parameters can be set. Generally, the method comprises: specifying requirements for the circuit including physical properties to be sensed by the circuit and actions to be taken by the circuit; designing the circuit based on the specified requirements and resources available on the IC; and setting parameters of at least one of the parametric analog circuit elements of the IC based on the circuit design. In one embodiment, the specifying, designing, and setting parameters steps are performed using a computer executable code embodied in a computer readable medium on a server coupled to a client computer through an internet protocol network. Other embodiments are also provided.

Owner:CYPRESS SEMICON CORP

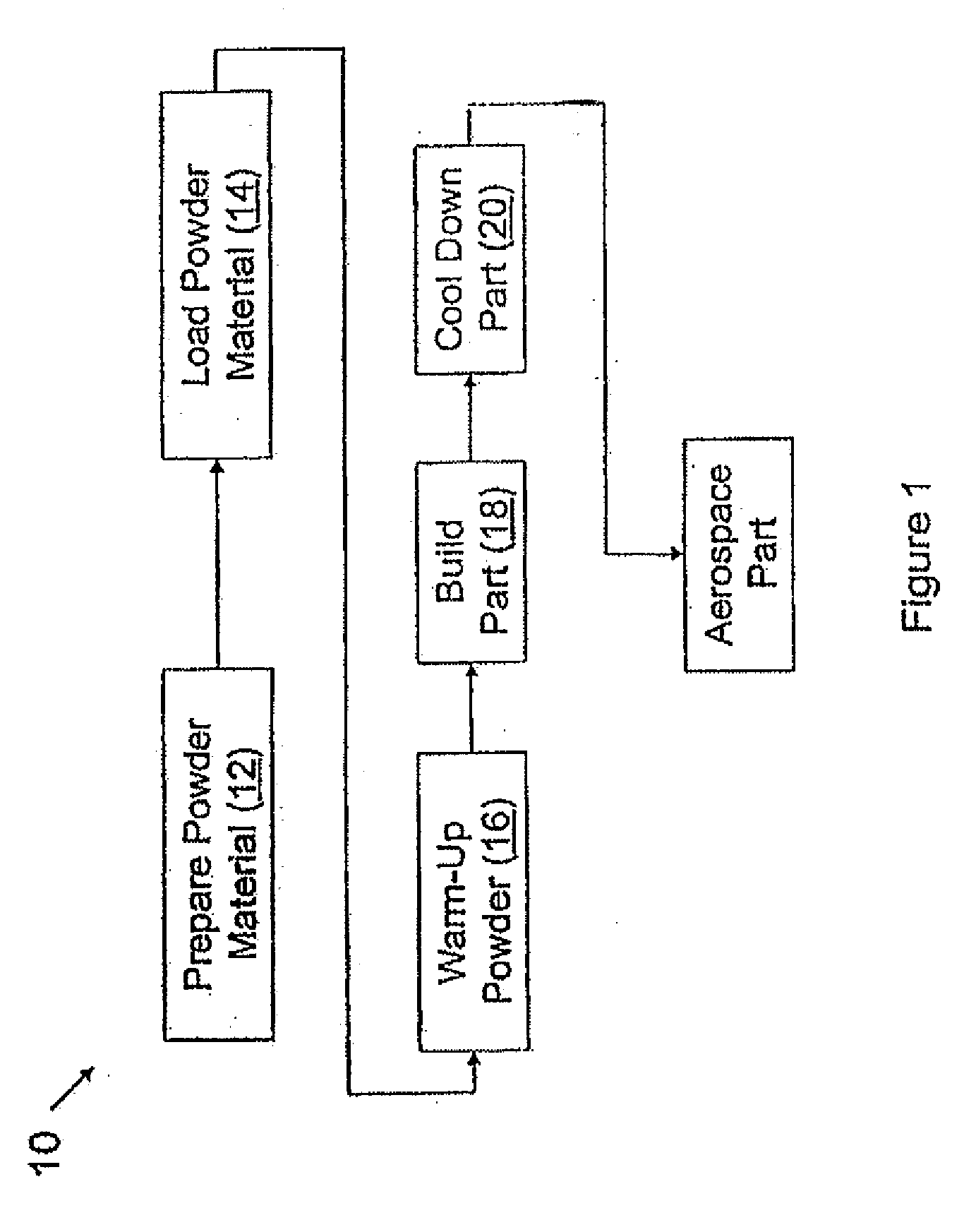

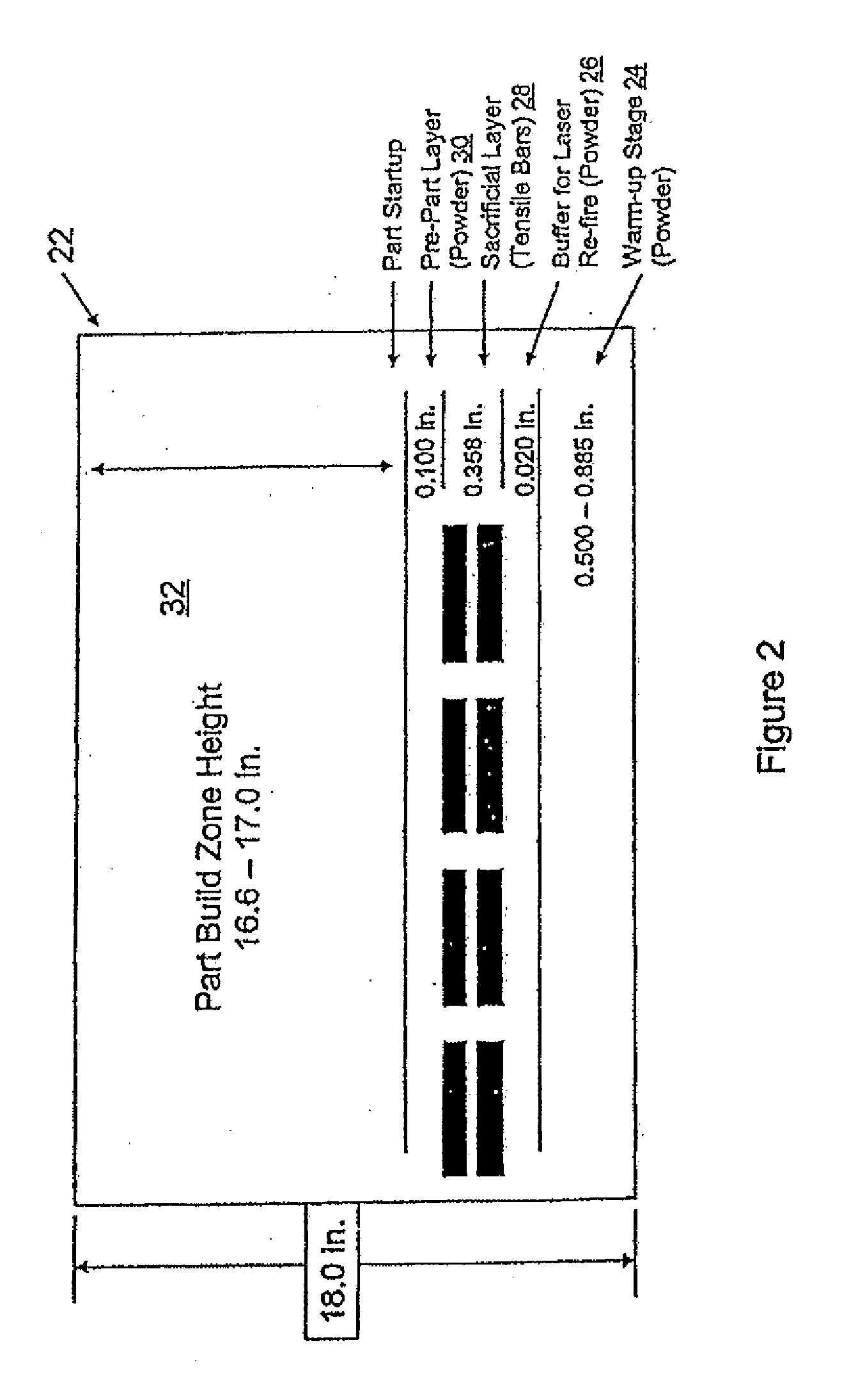

Optimal dimensional and mechanical properties of laser sintered hardware by thermal analysis and parameter optimization

InactiveUS20100174392A1Additive manufacturing apparatusAnalogue computers for control systemsEngineeringMechanical property

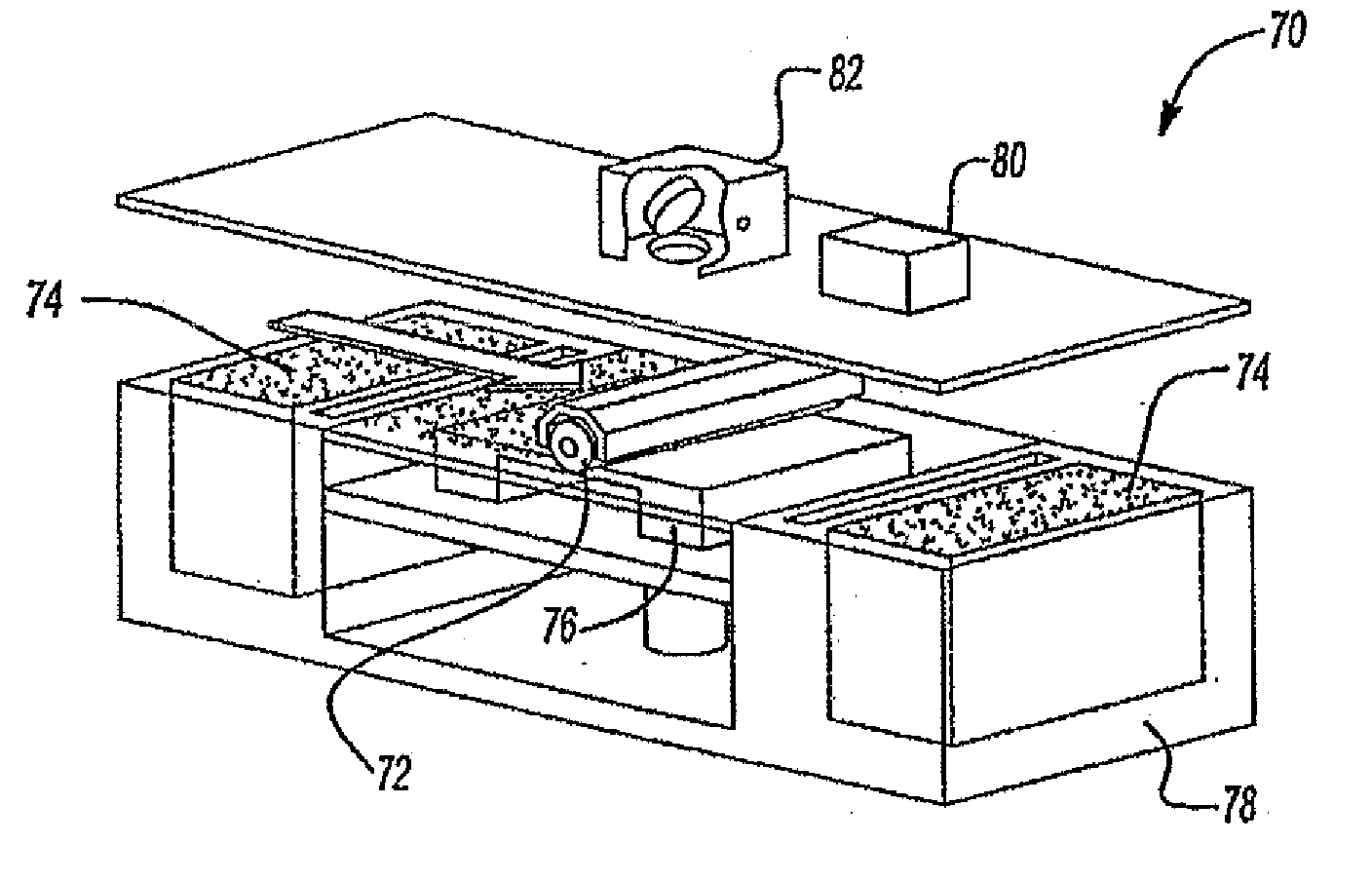

A process for establishing manufacturing parameters includes computer simulating a manufacture of a laser-sintered part based on a set of manufacturing parameters, calculating a set of physical properties of the simulated manufacture, and modifying the set of manufacturing parameters based on the calculated set in order to obtain a desired set of physical properties.

Owner:ROCKETDYNE

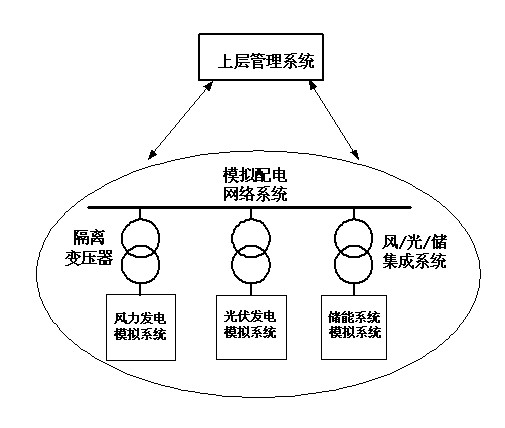

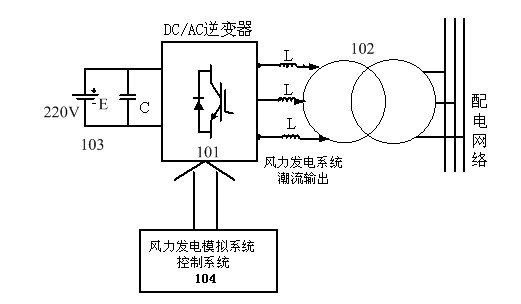

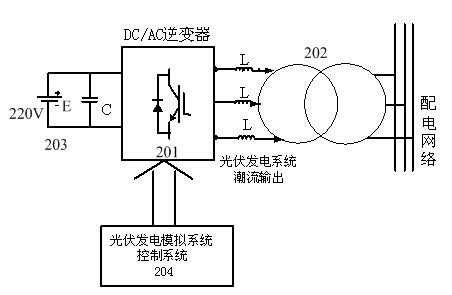

Physical modeling system with wind power generation, photovoltaic power generation and energy storage integration system

ActiveCN102437571AAchieving two-way flowSingle network parallel feeding arrangementsEnergy storagePhysical modelPhysical system

The invention discloses a physical modeling system with a wind power generation, photovoltaic power generation and energy storage integration system. The physical modeling system is based on power output characteristics of a wind power generation system, a photovoltaic power generation system and an energy storage system, and a converter system is utilized to simulate the wind power generation system, the photovoltaic power generation system and the energy storage system. The physical modeling system comprises an upper layer management module, a wind power generation simulation module, a photovoltaic power generation simulation module, an energy storage simulation module and a simulation power distribution network module. The wind power generation simulation module and the photovoltaic power generation simulation module can simulate power trends of a wind power field and a photovoltaic power station according to a set environment parameter. The energy storage simulation module employs a set of reversely connected current transformers to carry out simulation. Charge and discharge characteristics of a storage battery can be simulated, and an instruction of the upper layer management module can be received. According to a practical requirement, active and reactive power is sent or absorbed to stabilize voltage or frequency fluctuation of the power distribution network module. According to the invention, an inverter is utilized to establish a physical model, and a bottleneck problem that wind power, photovoltaic power and energy storage integration generation research can not be realized in a laboratory physical system is solved well.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

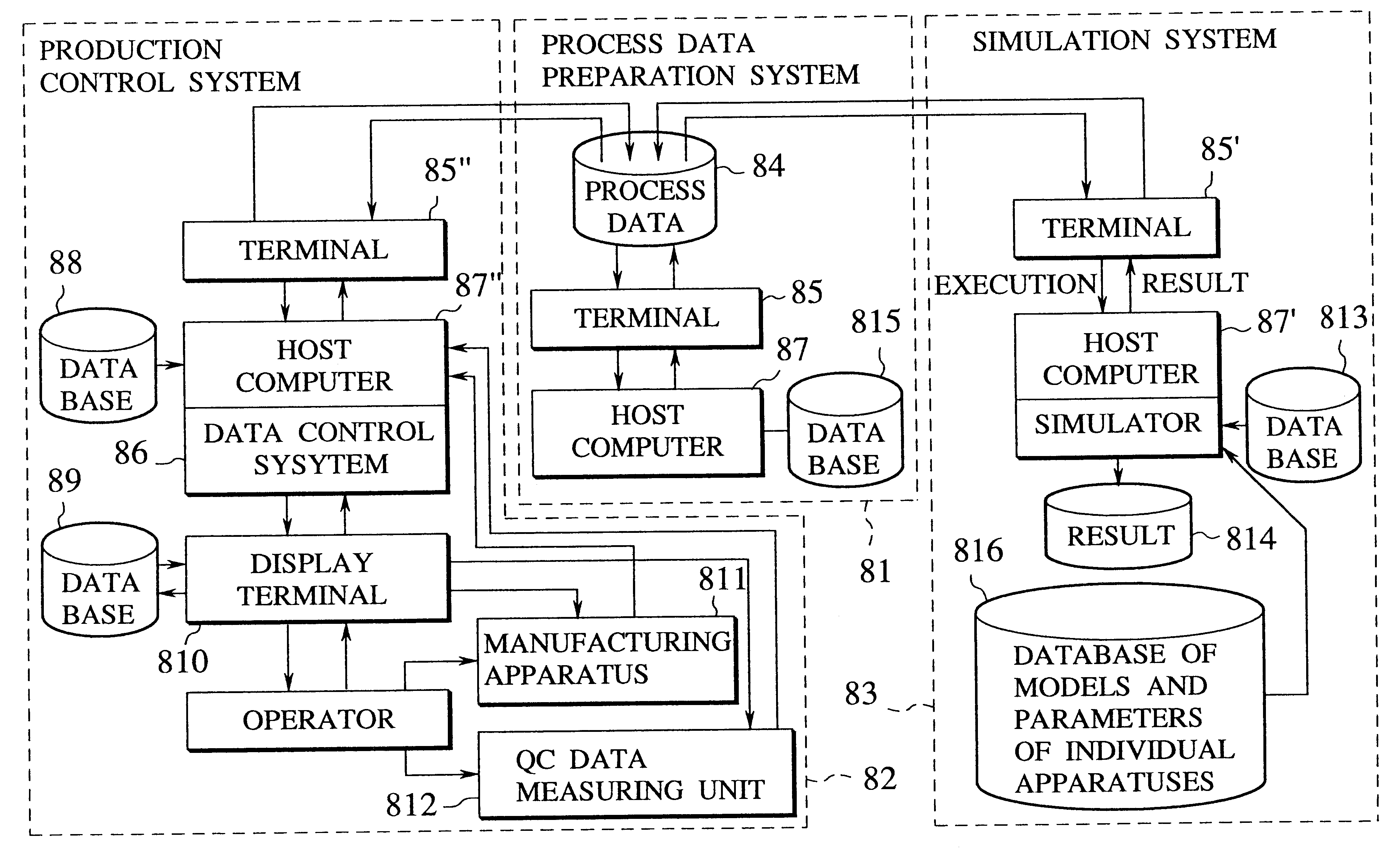

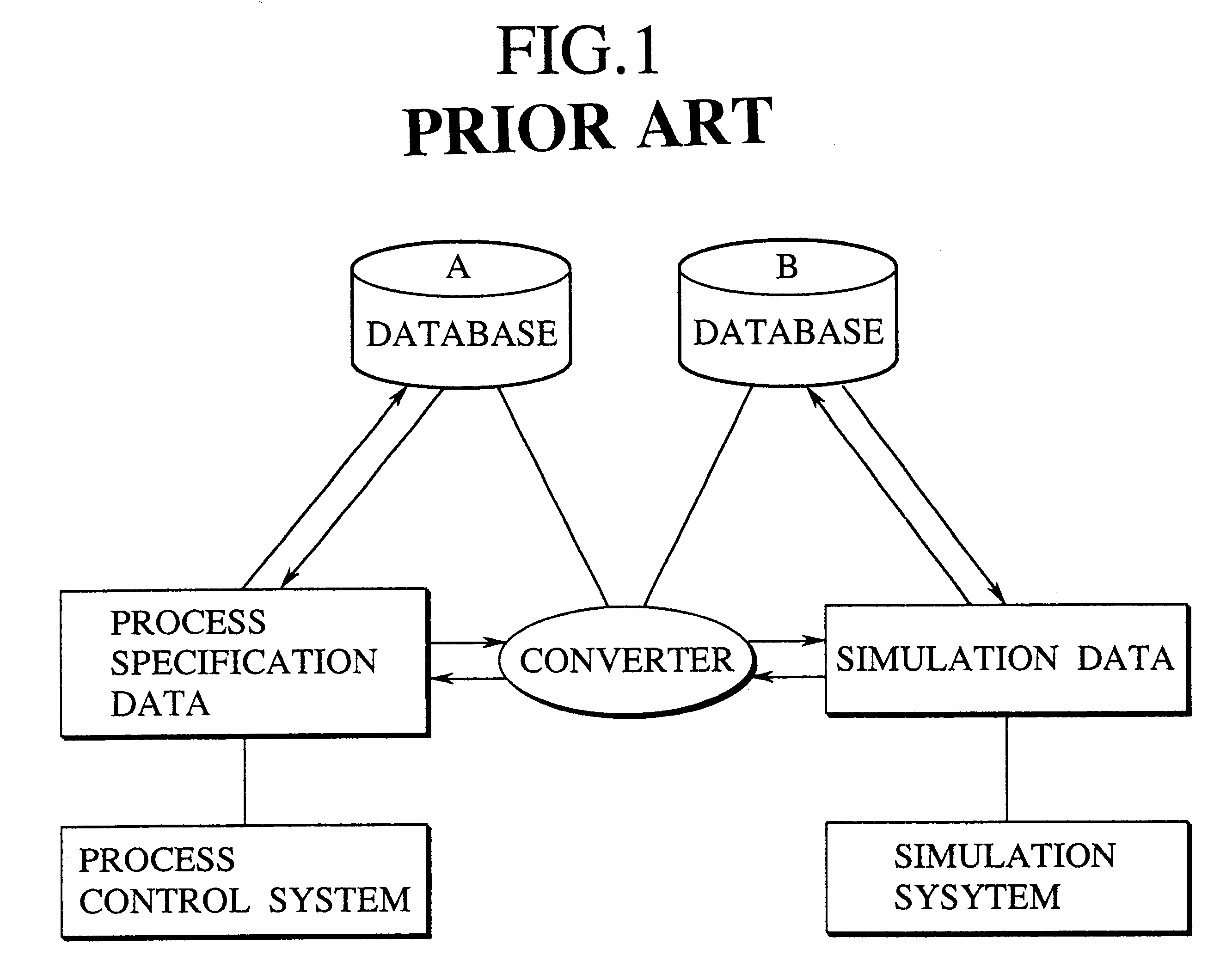

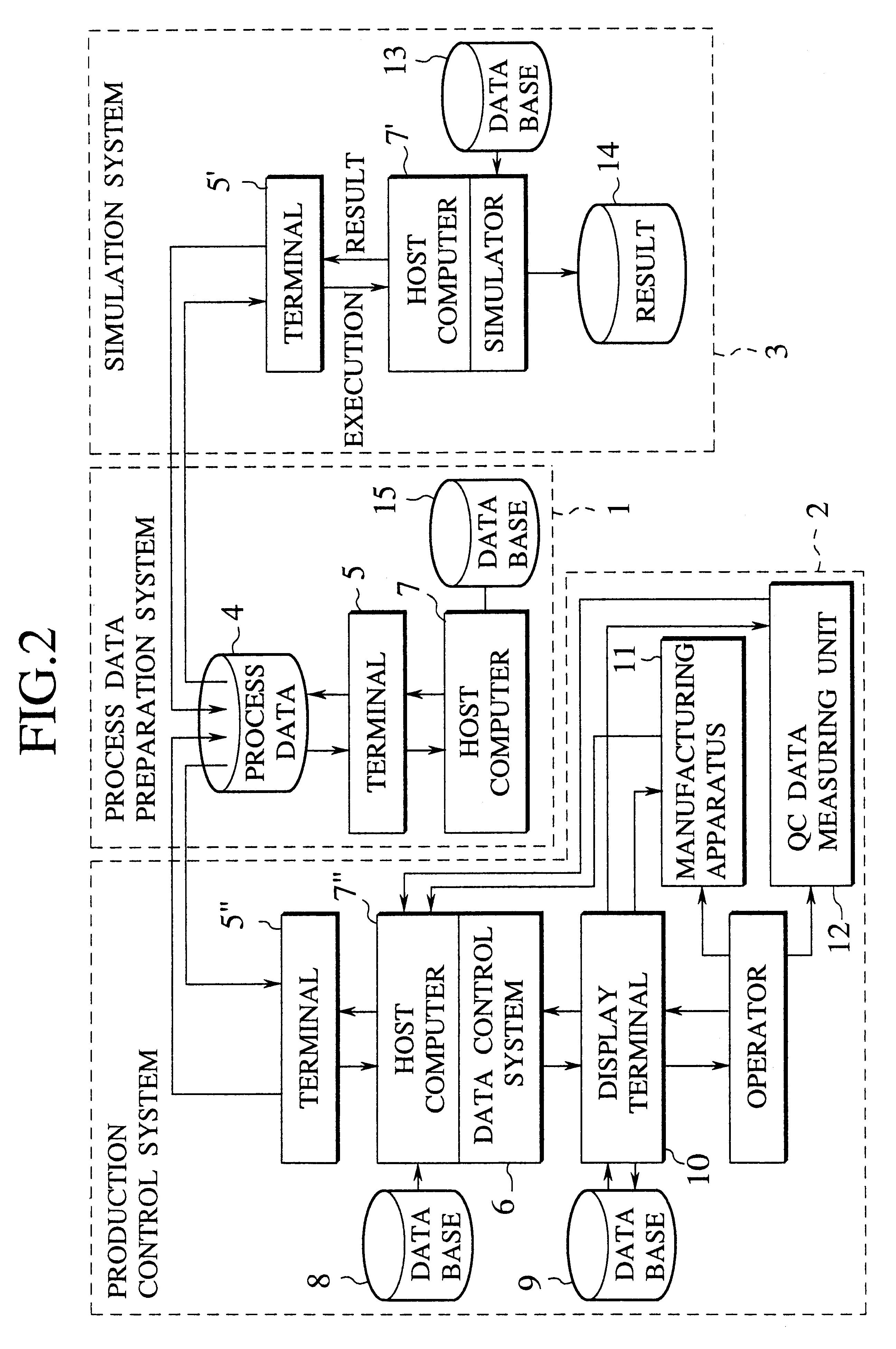

System for and method of preparing manufacturing process specifications and production control system

InactiveUS6516237B1Data processing applicationsSimulator controlManufacturing engineeringSimulation system

A system for preparing manufacturing-process specifications employs process data serving both for a production control system and a simulation system, and effectively uses a result of simulation. The system prepares the manufacturing-process specifications through the steps of controlling apparatuses according to the manufacturing-process specifications, to carry out manufacturing processes; collecting data measured through the manufacturing processes; simulating the manufacturing processes according to corresponding models and parameters; correcting the models and parameters according to the collected data; and amending the manufacturing-process specifications according to a result of the simulation.

Owner:KK TOSHIBA

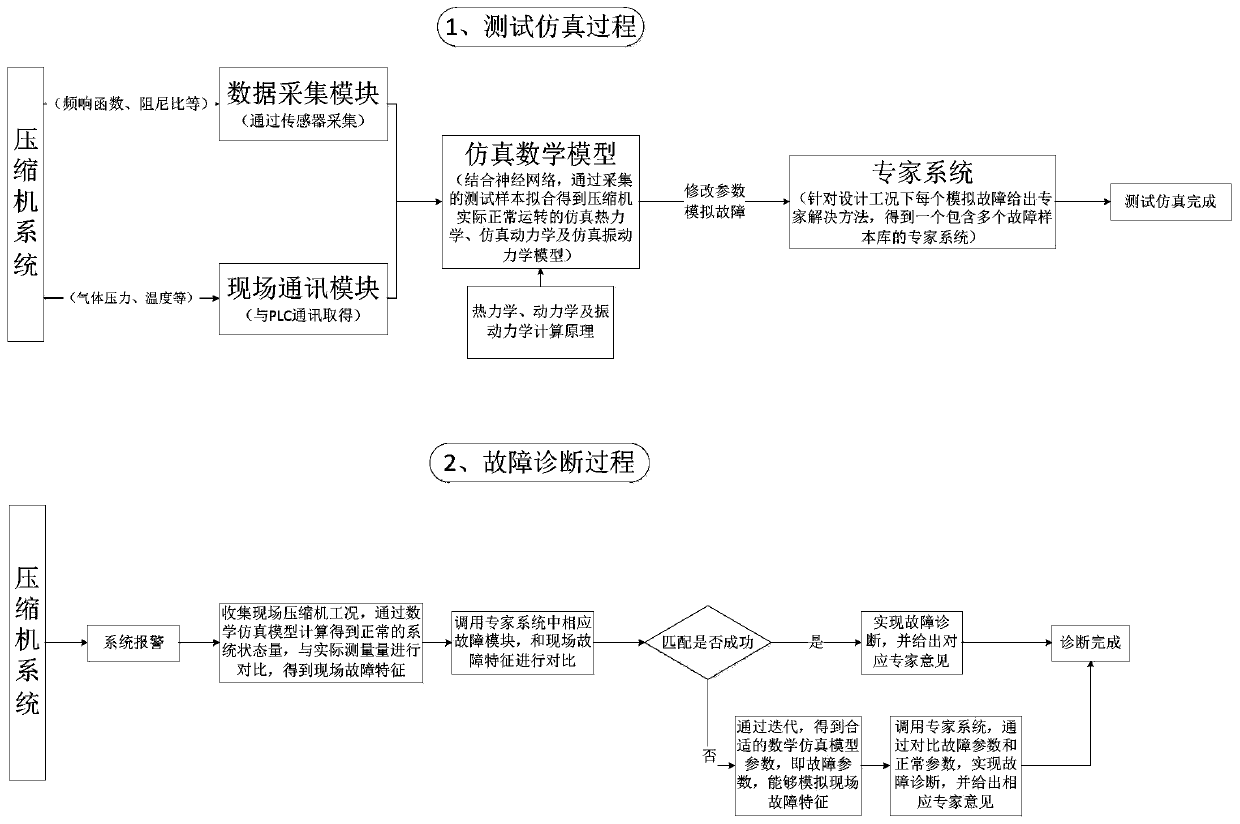

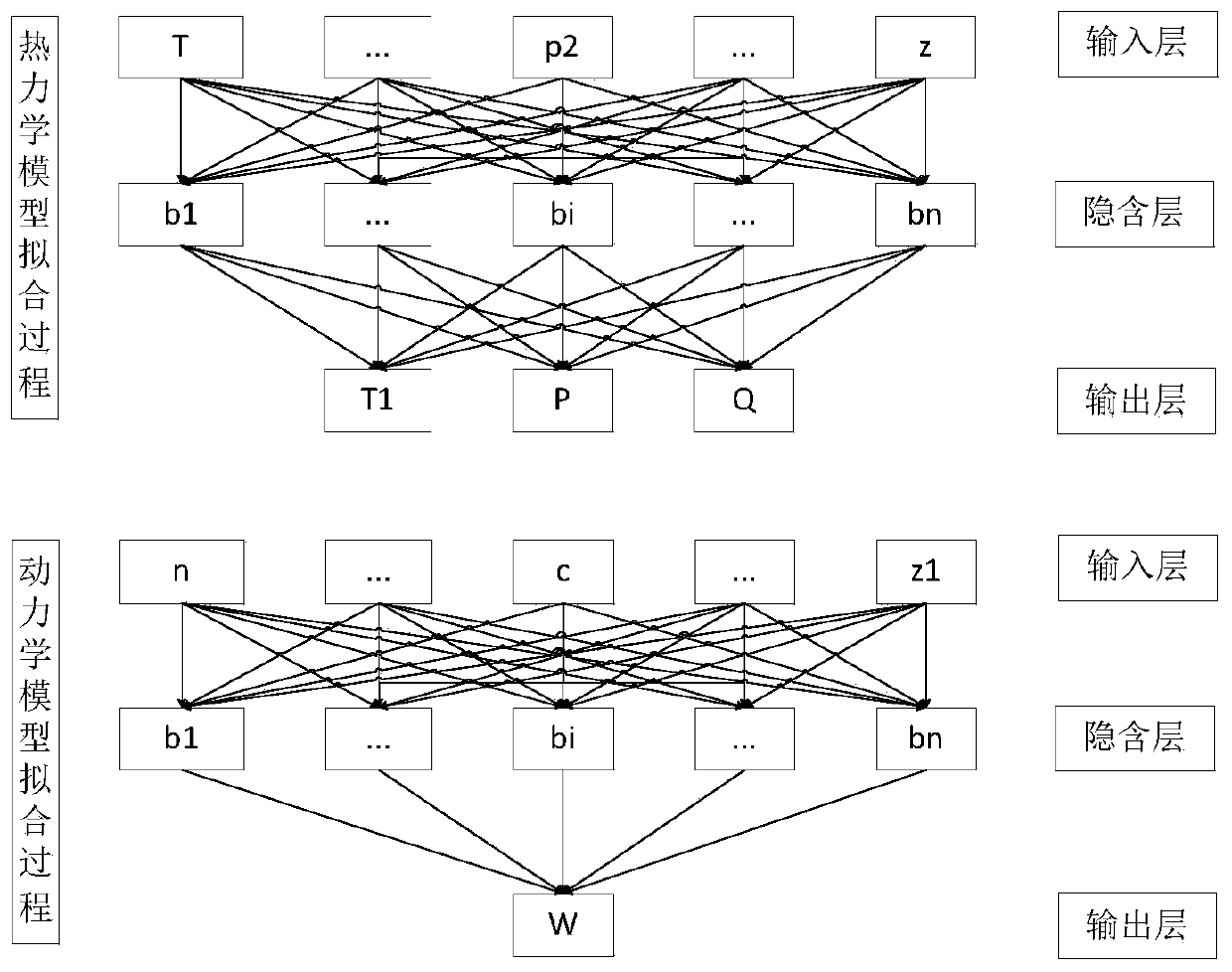

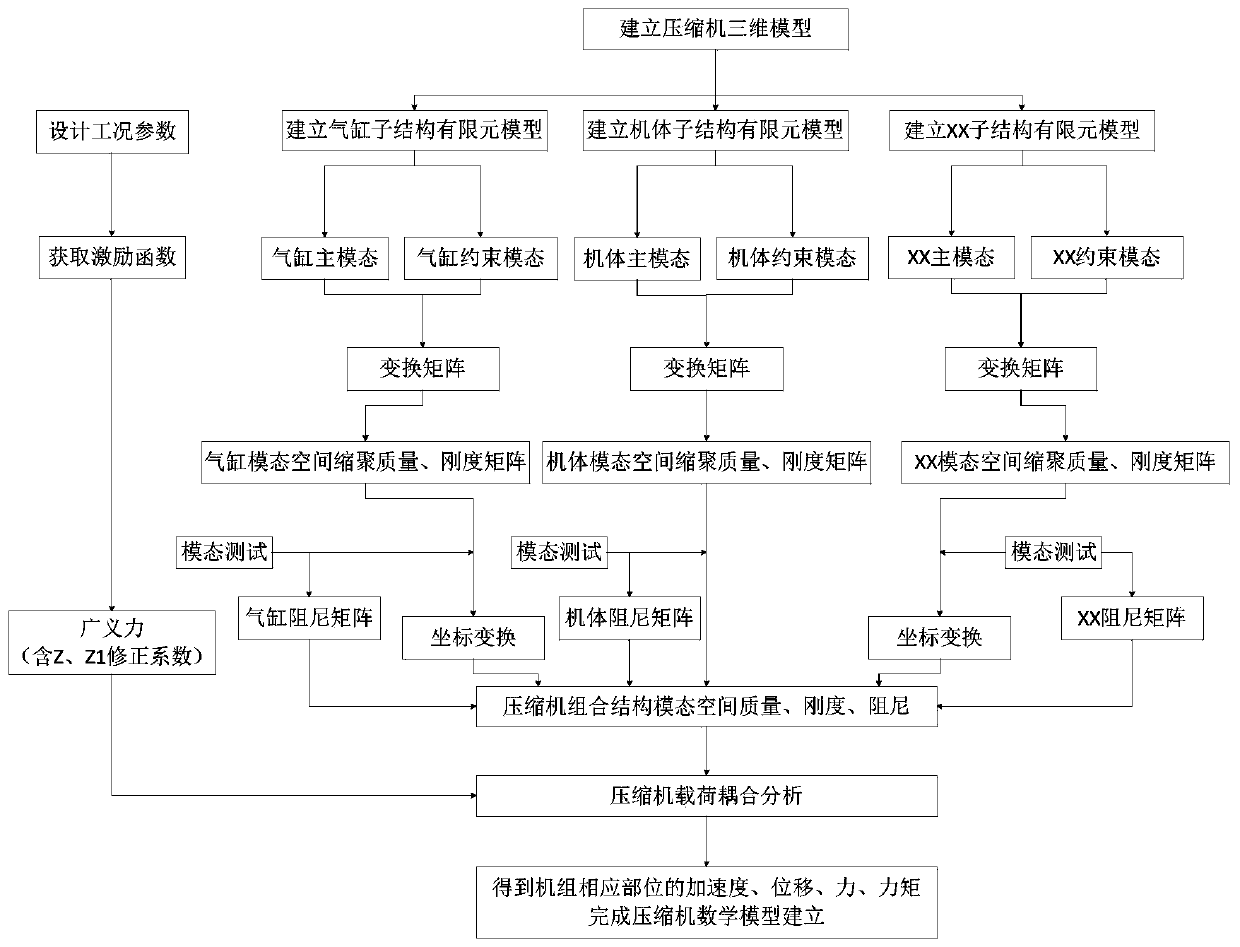

Reciprocating compressor fault diagnosis system and method based on neural network algorithm

ActiveCN109779894AImprove simulation accuracyImprove accuracyPump testingNeural architecturesSimulationData collecting

The invention discloses a reciprocating compressor fault diagnosis system and method based on a neural network algorithm. The reciprocating compressor fault diagnosis system and method based on the neural network algorithm comprises a field communication module, a data collecting module, a simulation model based on neural networks, an expert system module based on standard fault characteristics, afault diagnosis main machine and an upper computer. According to the reciprocating compressor fault diagnosis system and method based on the neural network algorithm, the neural network algorithm isutilized, measured compressor system status parameters are combined, and thus simulation models in all working conditions are acquired; compressor faults are simulated by changing system parameters tocalculate and obtain the standard fault characteristics, after the abnormal operation of the compressor occurs, through the comparison with the standard fault characteristics, fault parts can be accurately located, and elimination methods can be brought; and the diagnosis success rate is high, and real-time monitoring analysis of high precision equipment is not needed, and the diagnosis cost is lowered.

Owner:XI AN JIAOTONG UNIV

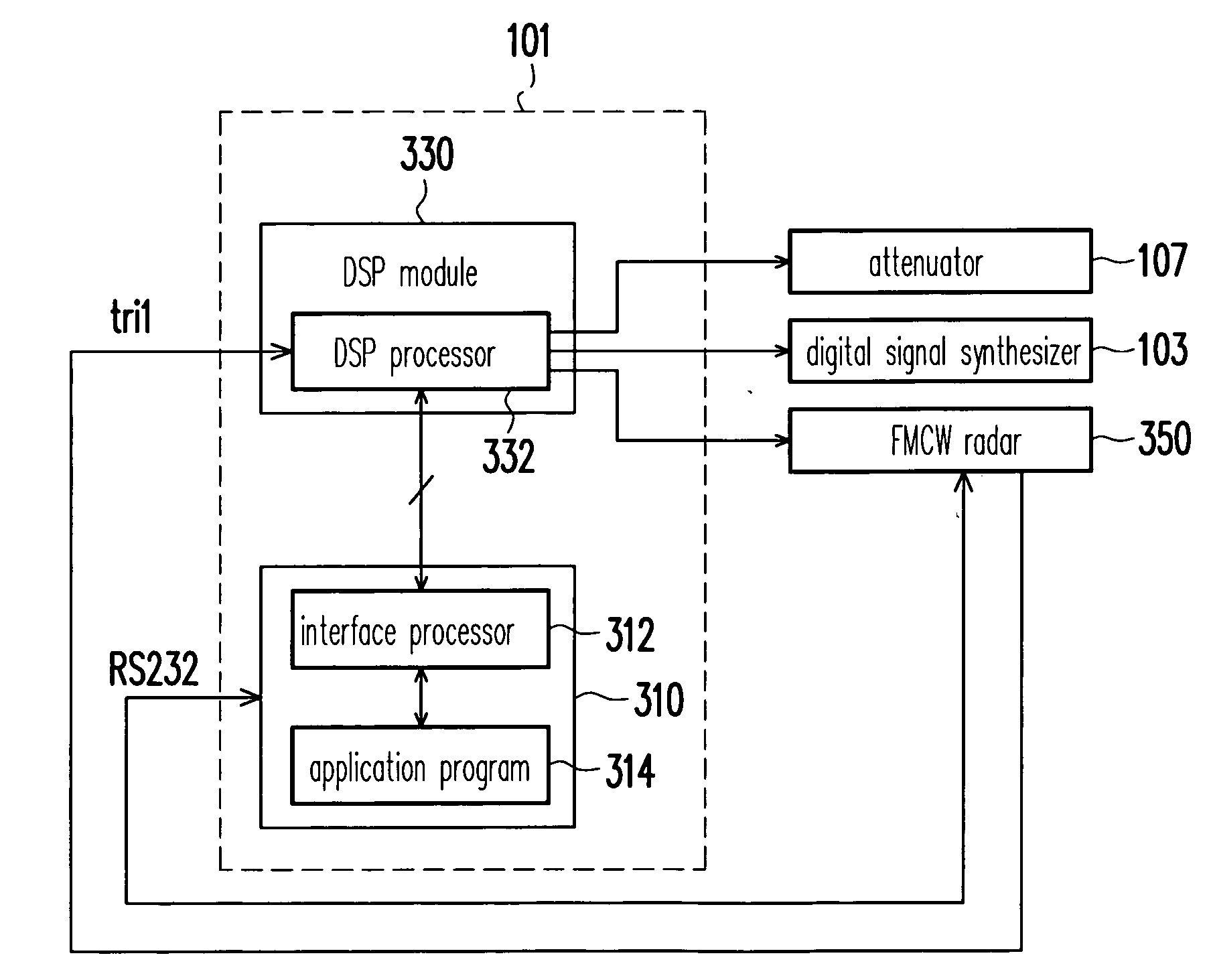

Programmable method and test device for generating target for FMCW radar

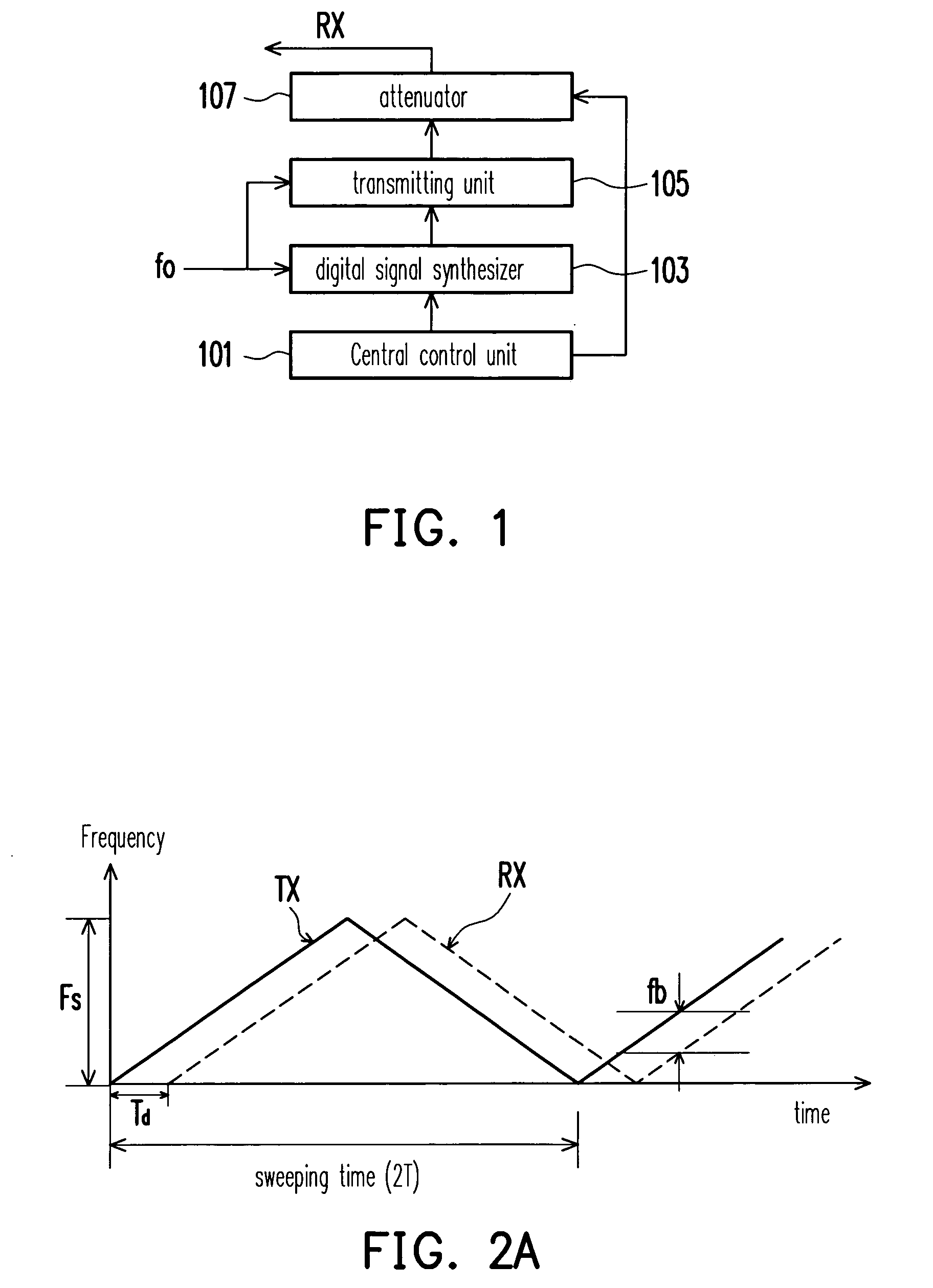

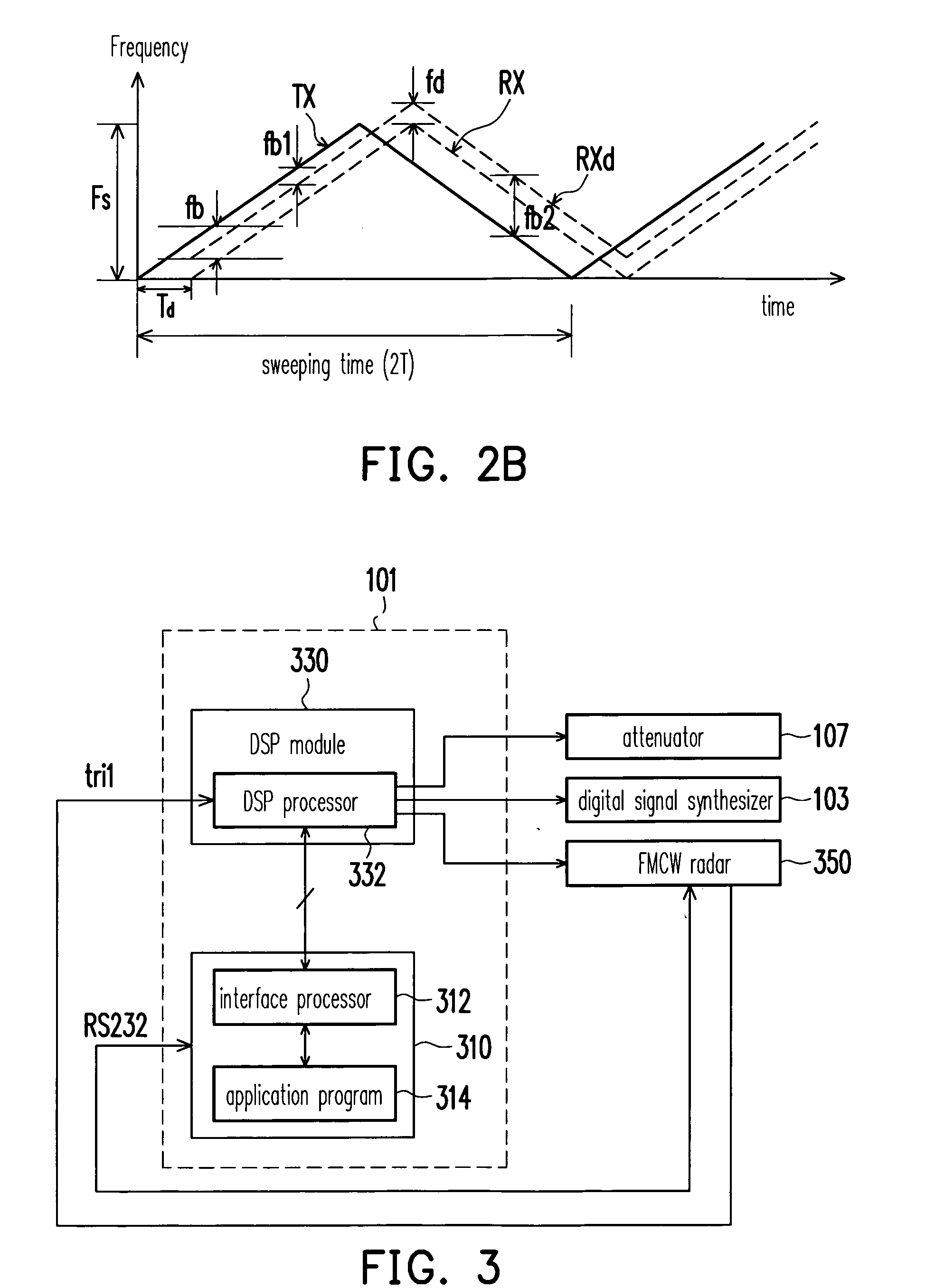

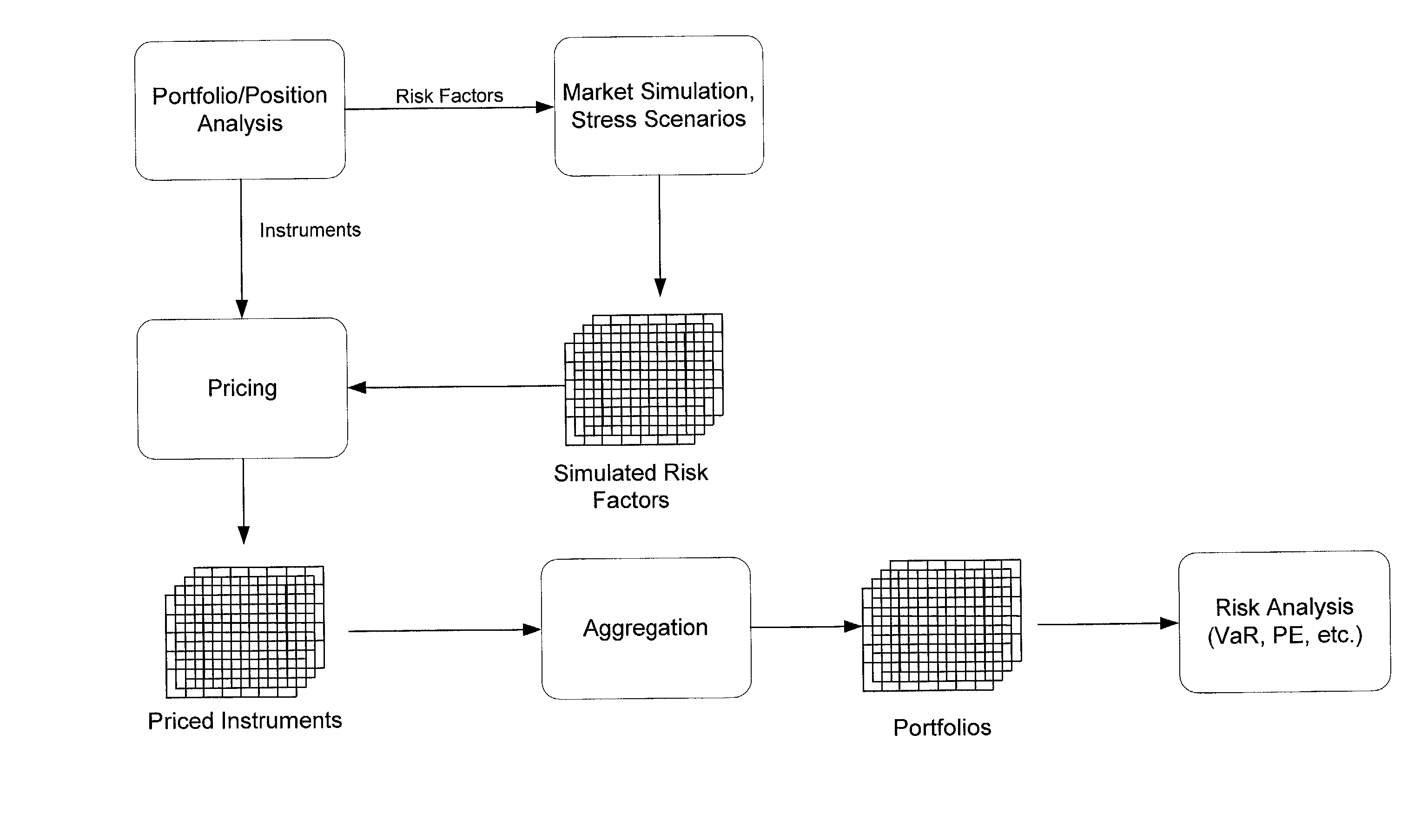

ActiveUS20060244654A1Low production costAvoid interferenceRadio wave reradiation/reflectionWave based measurement systemsRadarIntermediate frequency

A test device for a frequency modulated continuous wave (FMCW) radar is provided. The test device has a central control unit for monitoring the FMCW radar. When the FMCW radar transmits a frequency modulated continuous signal to search for a target, the central control unit of the test device in present invention will simulate the motion of the target according to a plurality of setting parameters and generate an echo signal to the FMCW radar. The present invention also includes a first digital signal synthesizer and a transmitting unit. The first digital signal synthesizer is coupled to the central control unit for generating and transmitting an intermediate-frequency signal to the transmitting unit according to the settings in the central control unit and a reference clock. The transmitting unit generates the echo signal according to the intermediate-frequency signal.

Owner:NAT CHUNG SHAN INST SCI & TECH

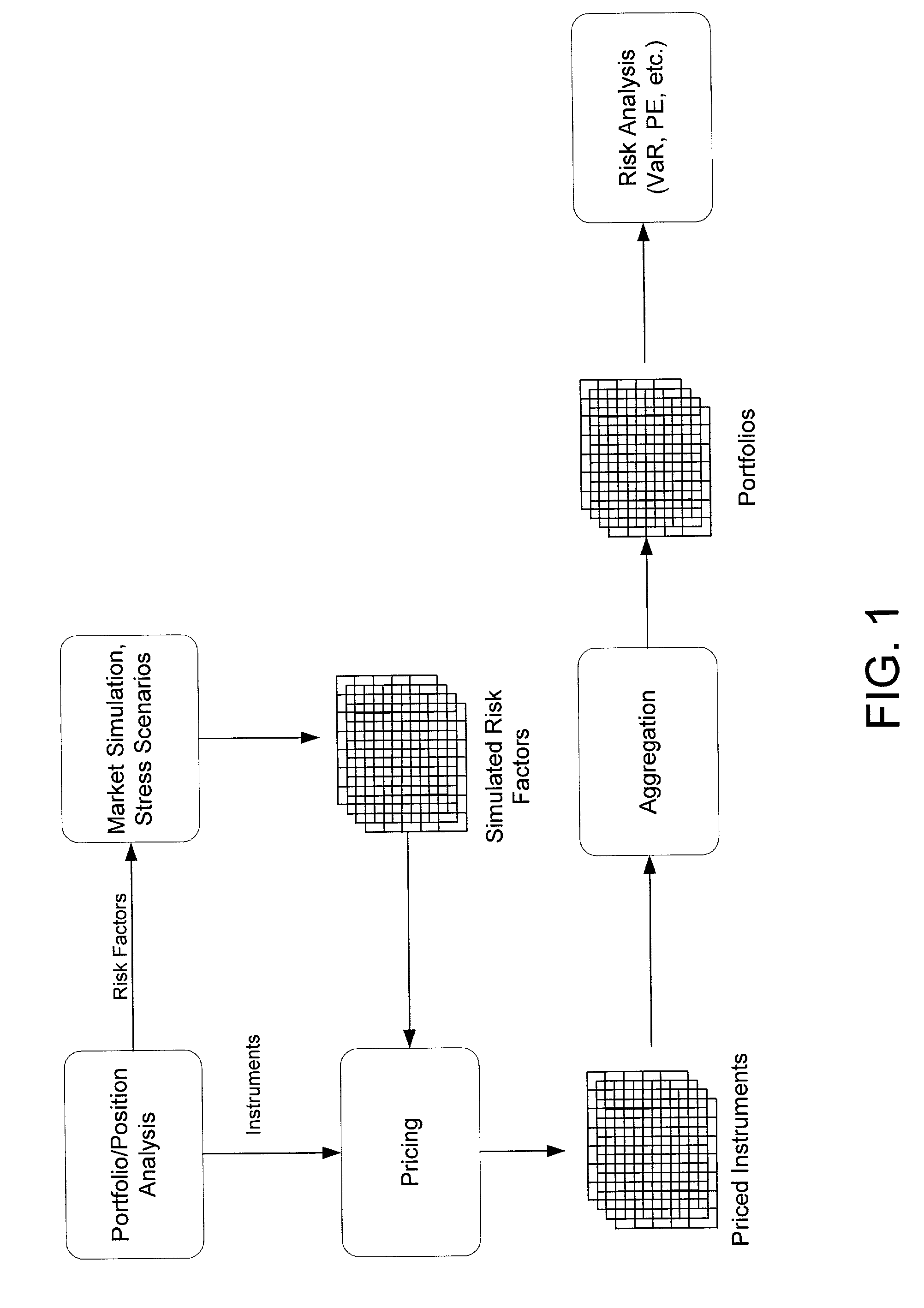

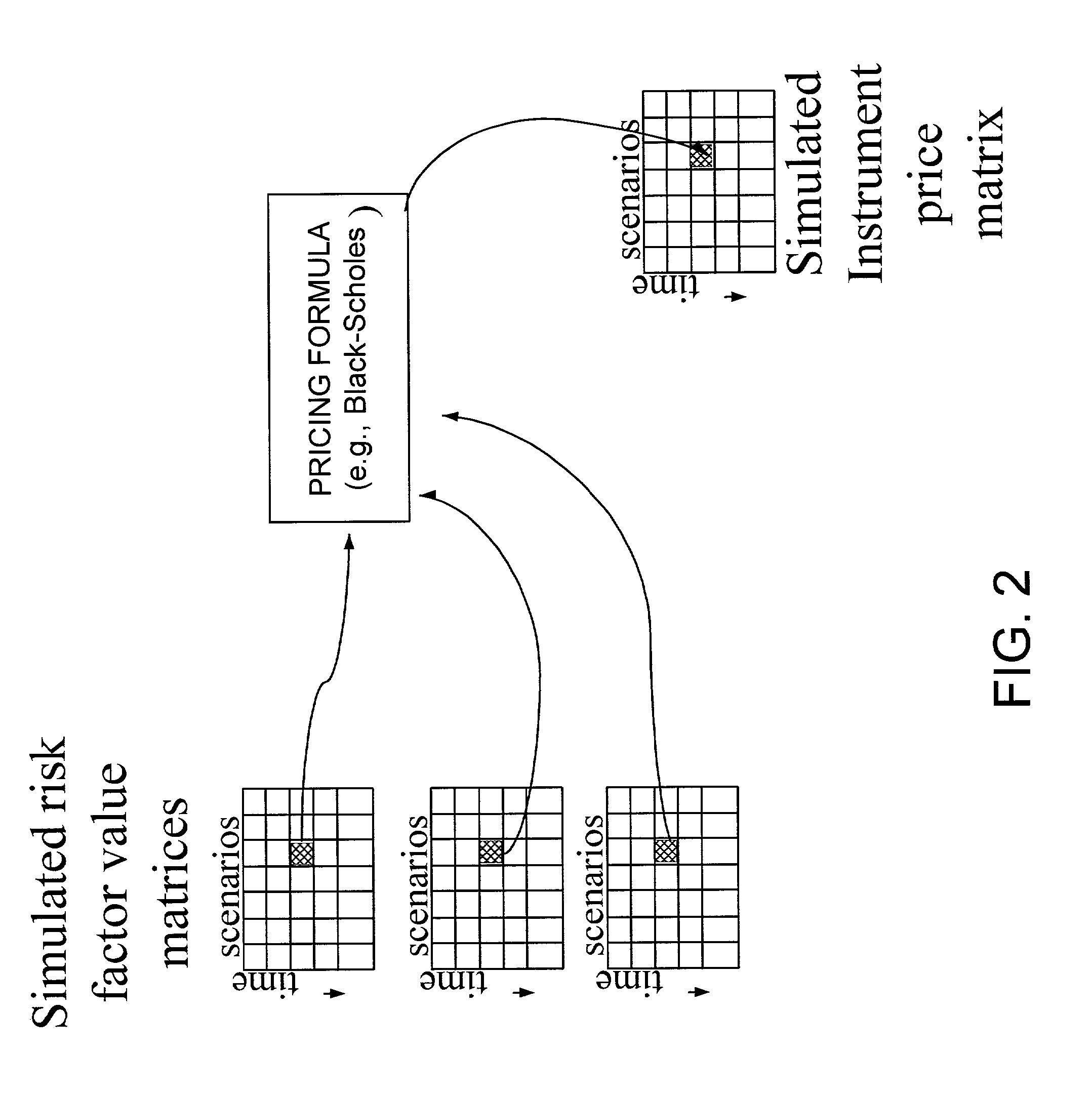

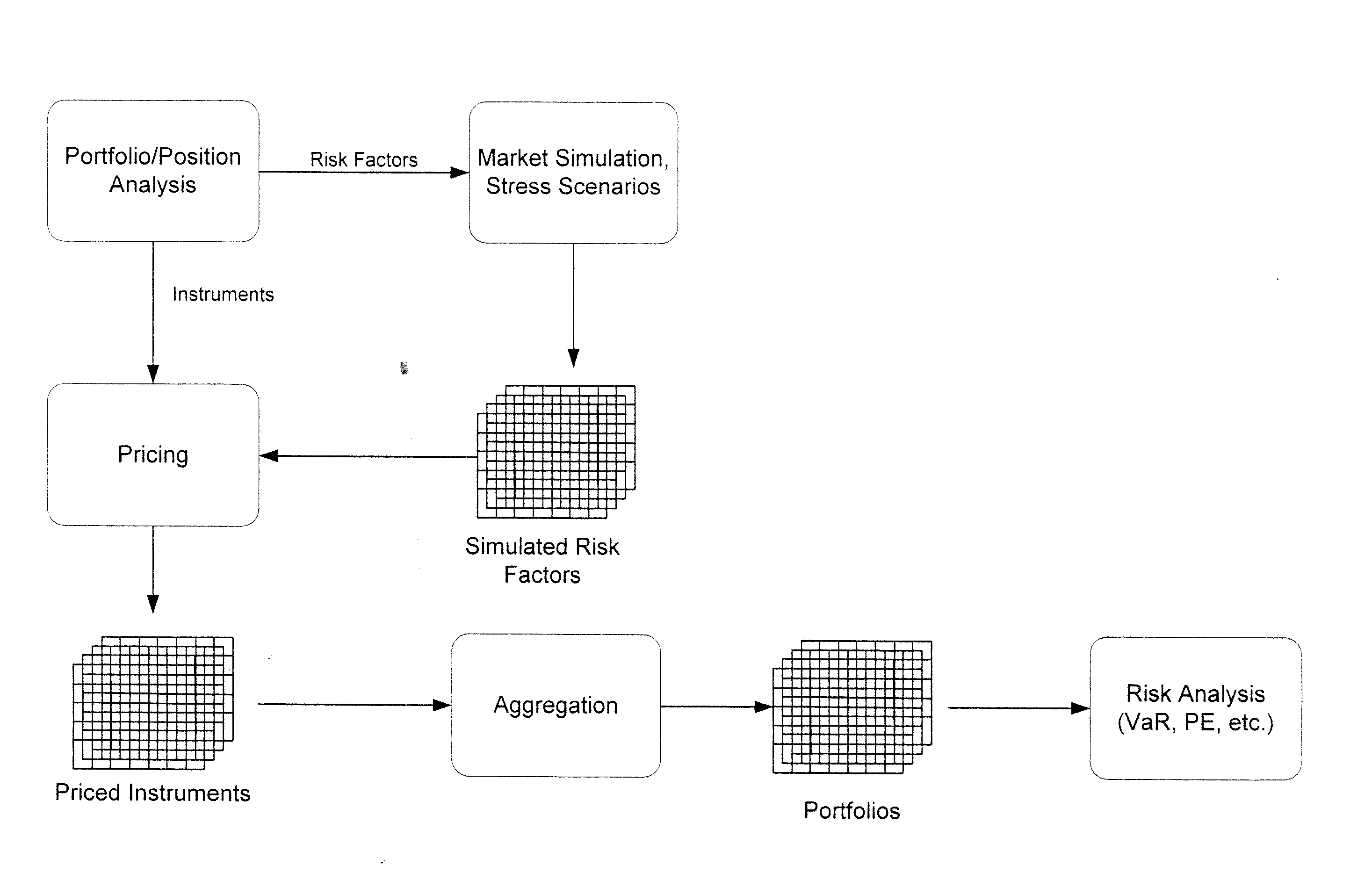

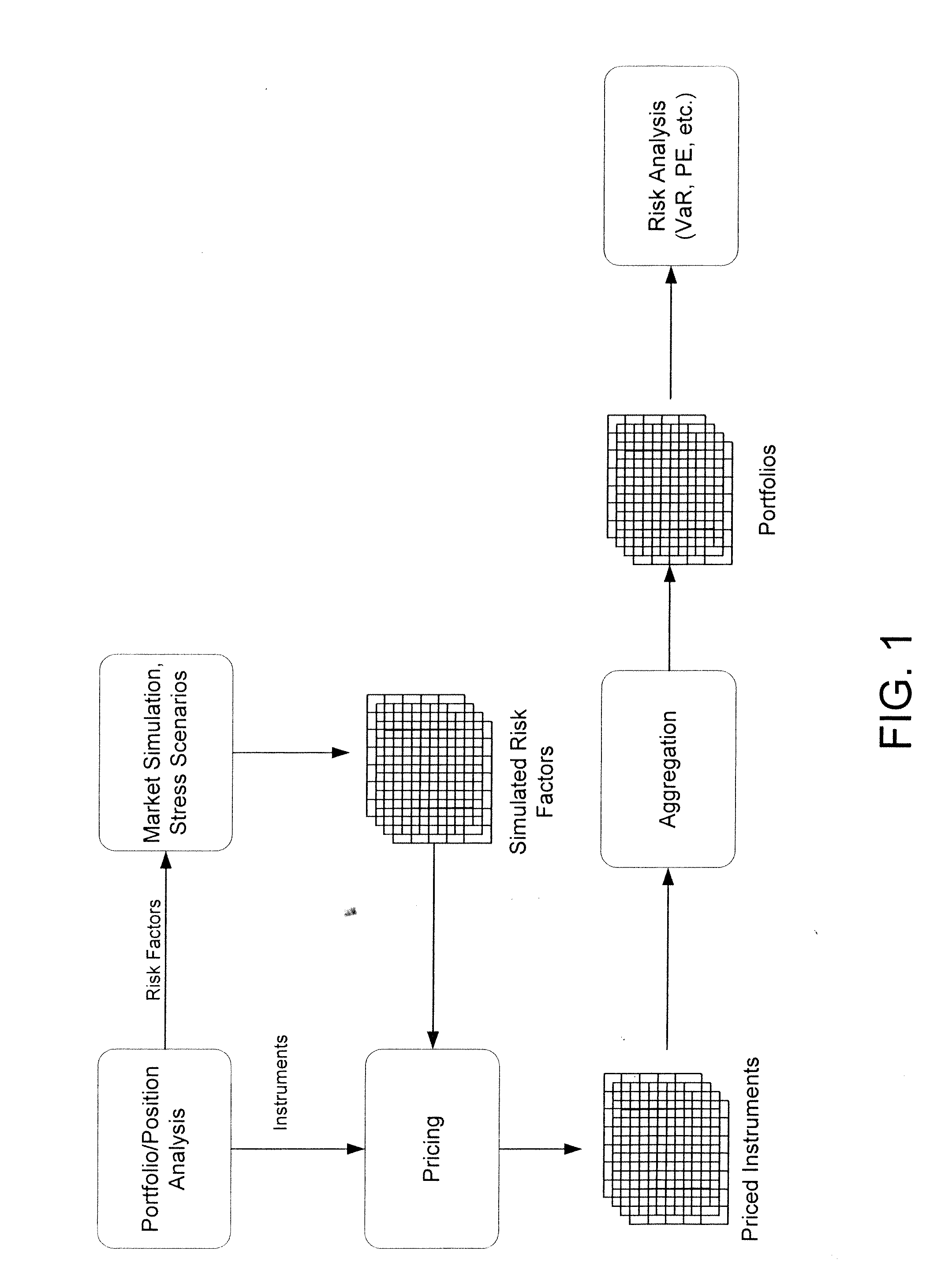

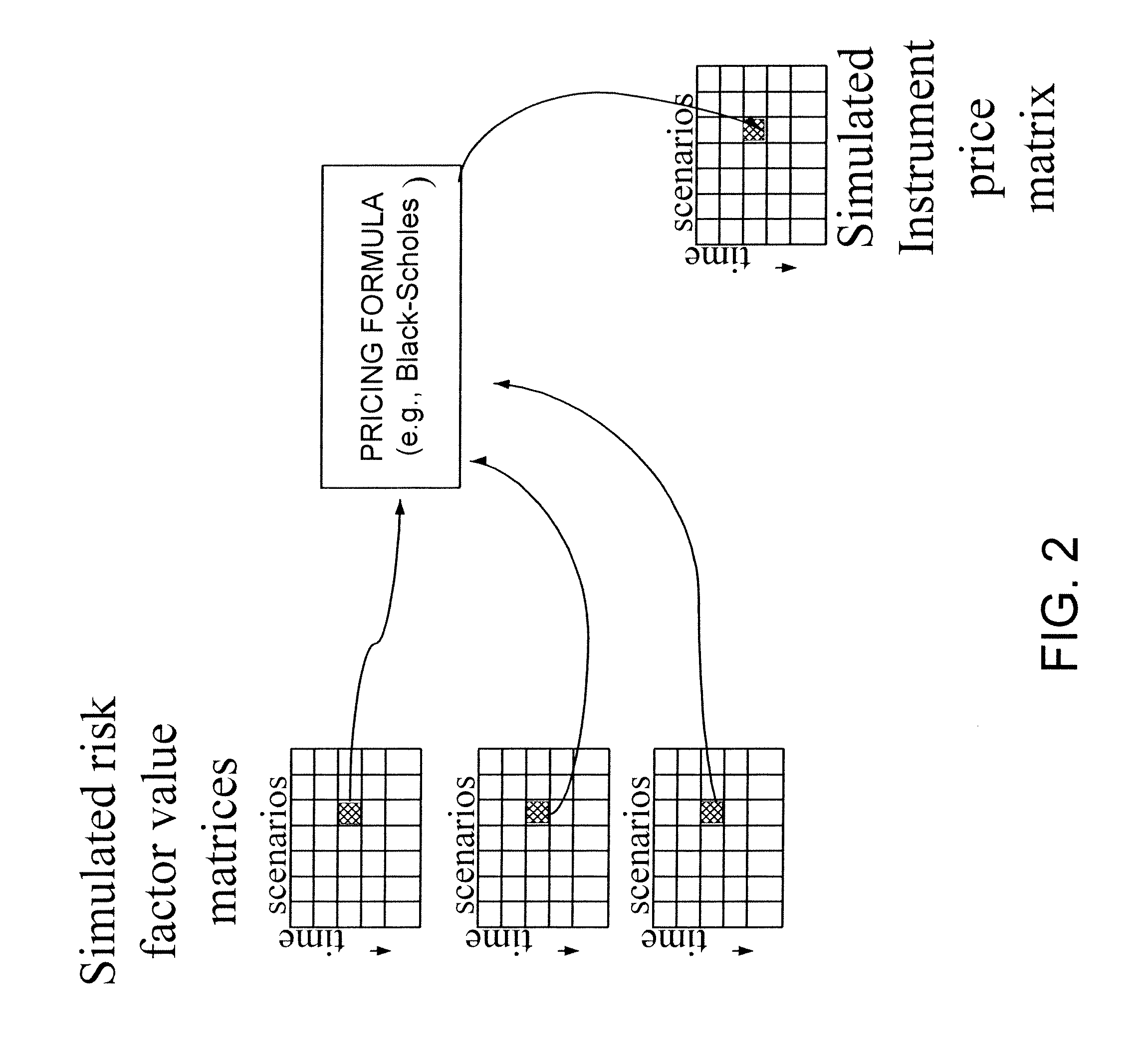

Method and system for simulating risk factors in parametric models using risk neutral historical bootstrapping

An improved method for simulating noise-varying risk factor values in a parametric simulation comprises analyzing historical data to determine the actual value of the risk factors and other attributes in the model and using this data to generate historical residual values which reproduces the historical price when used in the model with corresponding historical attribute values. The set of historical residual values is standardized and can be bootstrapped to increase the number of members in the set or vary the sets properties. Values of the historical residuals are then selected, e.g., at random, and used in place of the random noise components to produce simulated risk factor values which are used in the parametric model to simulate the evolution of the instrument price.

Owner:GOLDMAN SACHS & CO LLC

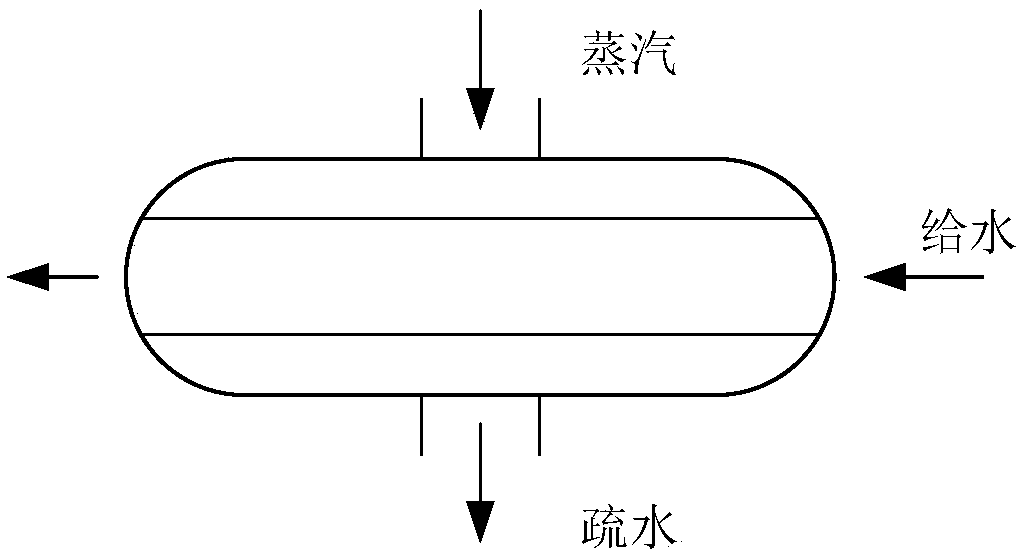

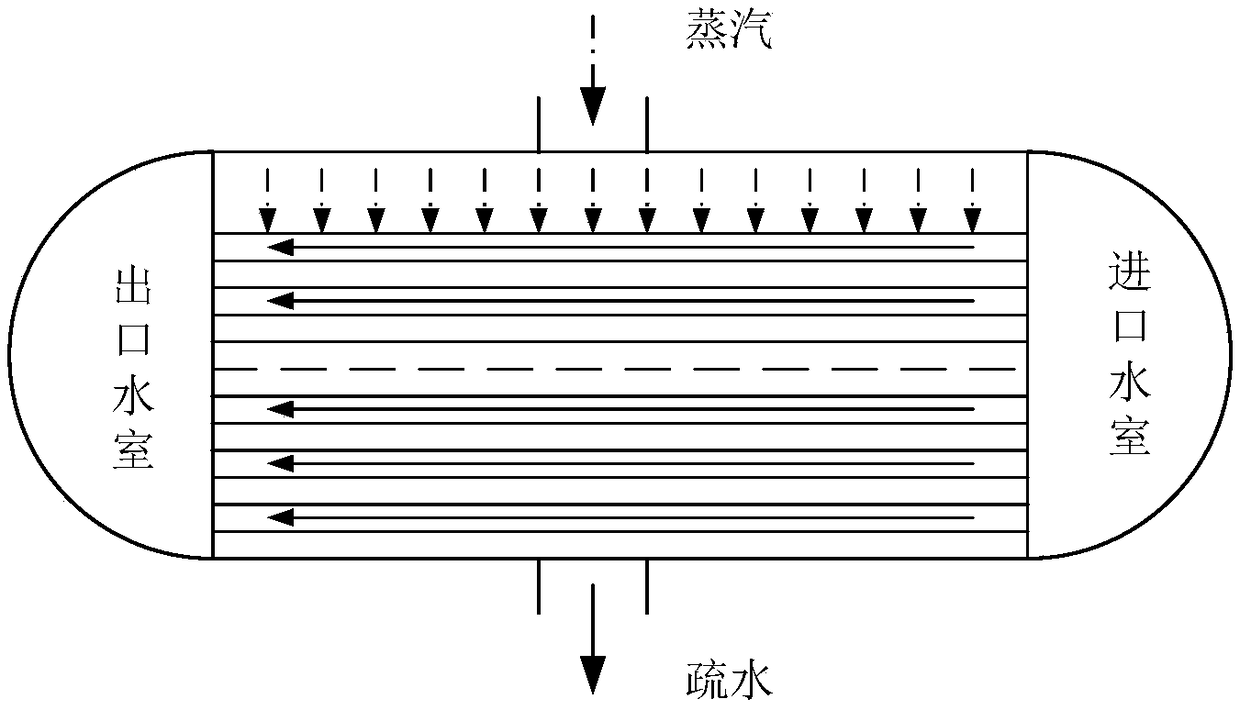

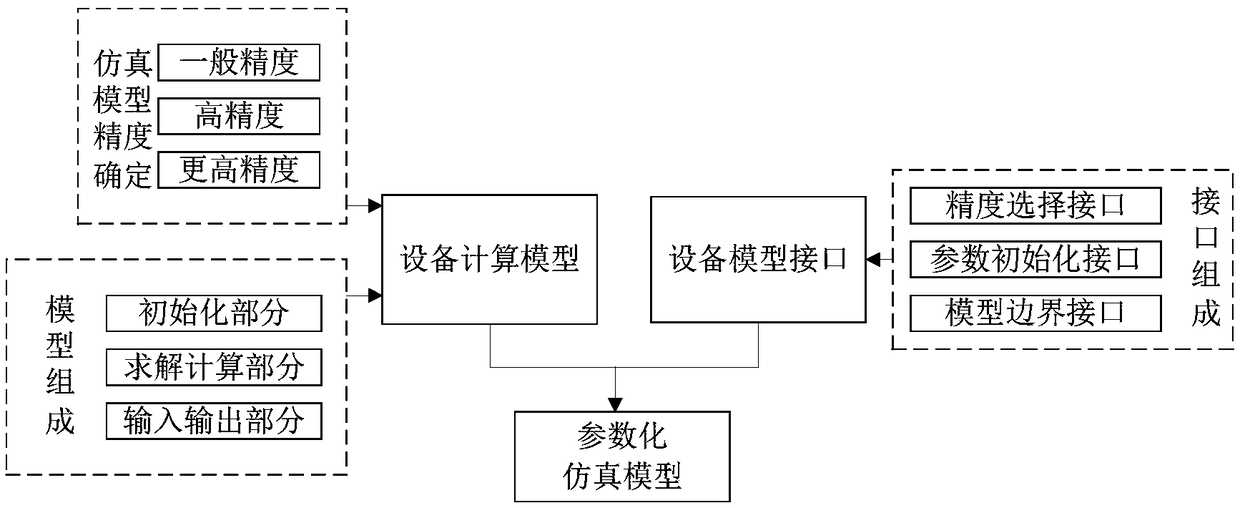

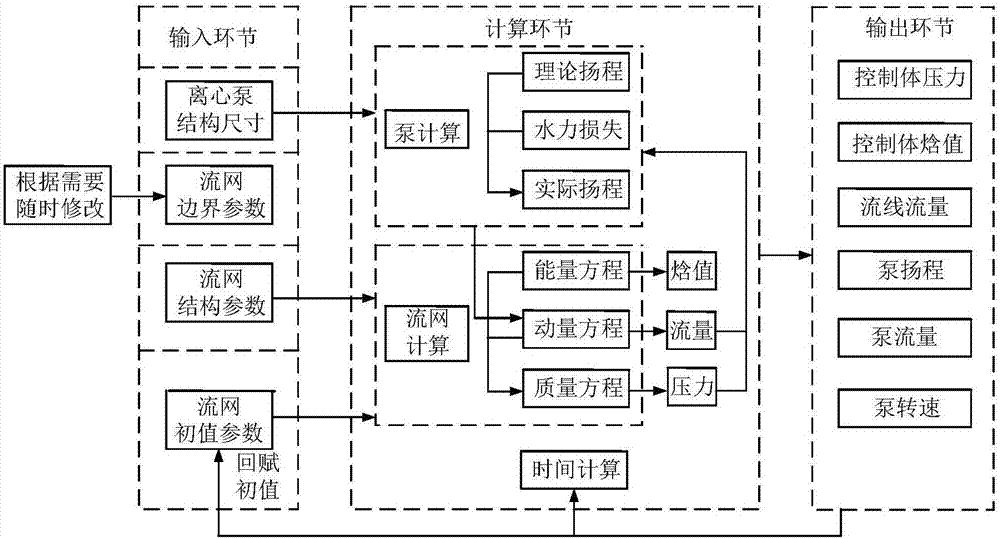

System and method for rapidly constructing nuclear power secondary circuit system parametric simulation models

PendingCN108875151AFast simulationQuick buildDesign optimisation/simulationSpecial data processing applicationsSystems designNuclear power

The invention provides a system and method for rapidly constructing nuclear power secondary circuit system parametric simulation models. According to the system and method, a secondary circuit systemsimulation model with a wider application range is established, and selection, configuration and initialization during the model establishment are realized through a model selection module, a model initialization module and a model boundary module. Through the method for rapidly constructing nuclear power secondary circuit system parametric simulation models, required nuclear power secondary circuit systems can be rapidly constructed, and technical support is provided for the design, assessment and proof of the secondary circuit systems; and meanwhile, an efficient and rapid model establishment way can be provided for the design change, modification and simulation after optimization of the nuclear power secondary circuit systems. According to the system and method, required nuclear power secondary circuit parametric simulation models can be rapidly constructed for different demands in the stages of nuclear power secondary circuit system design, proof and assessment, so as to effectively improve the model establishment and simulation efficiency.

Owner:HARBIN ENG UNIV

Combined simulation research and development platform for radar mechanical-electric-hydraulic system

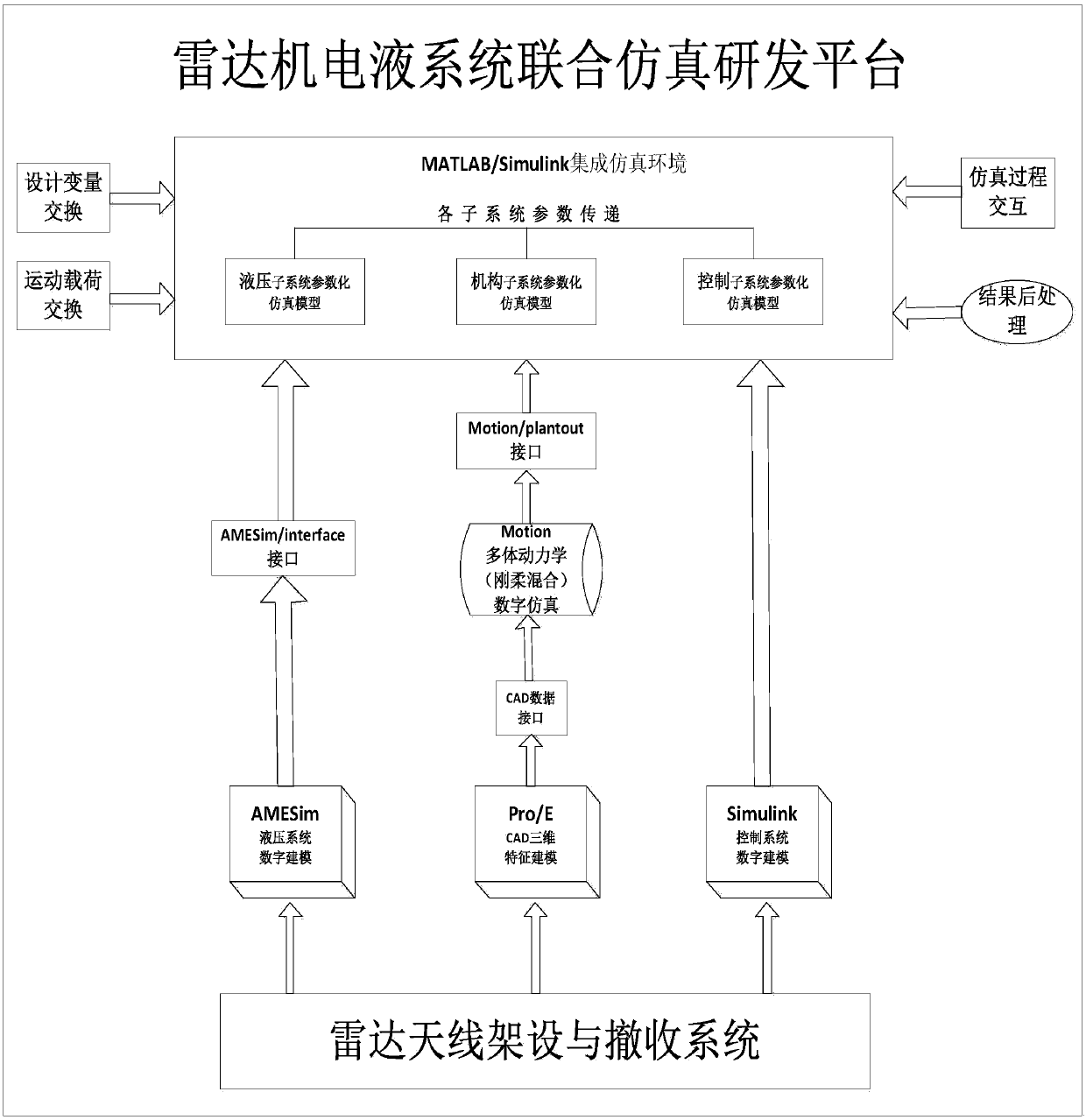

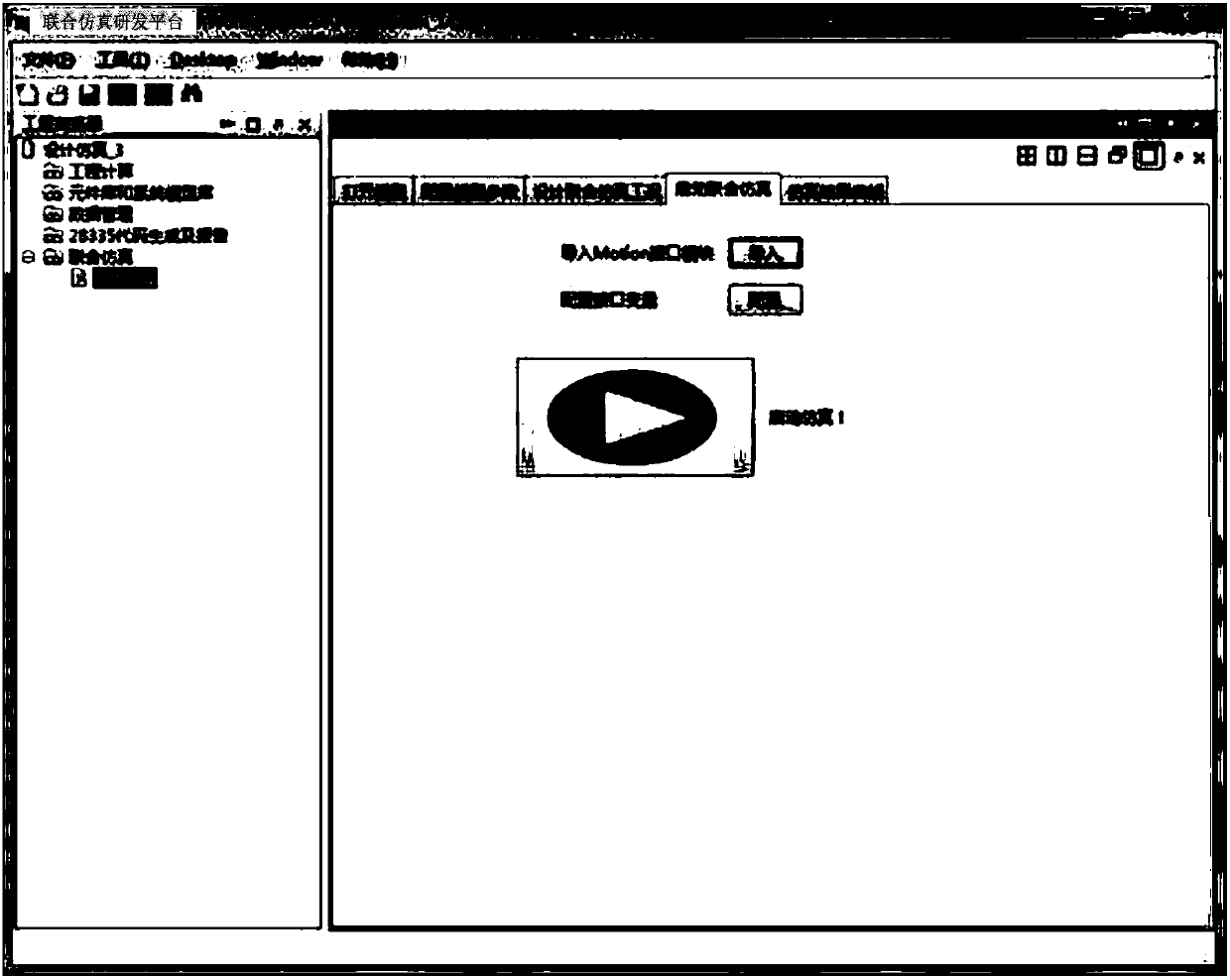

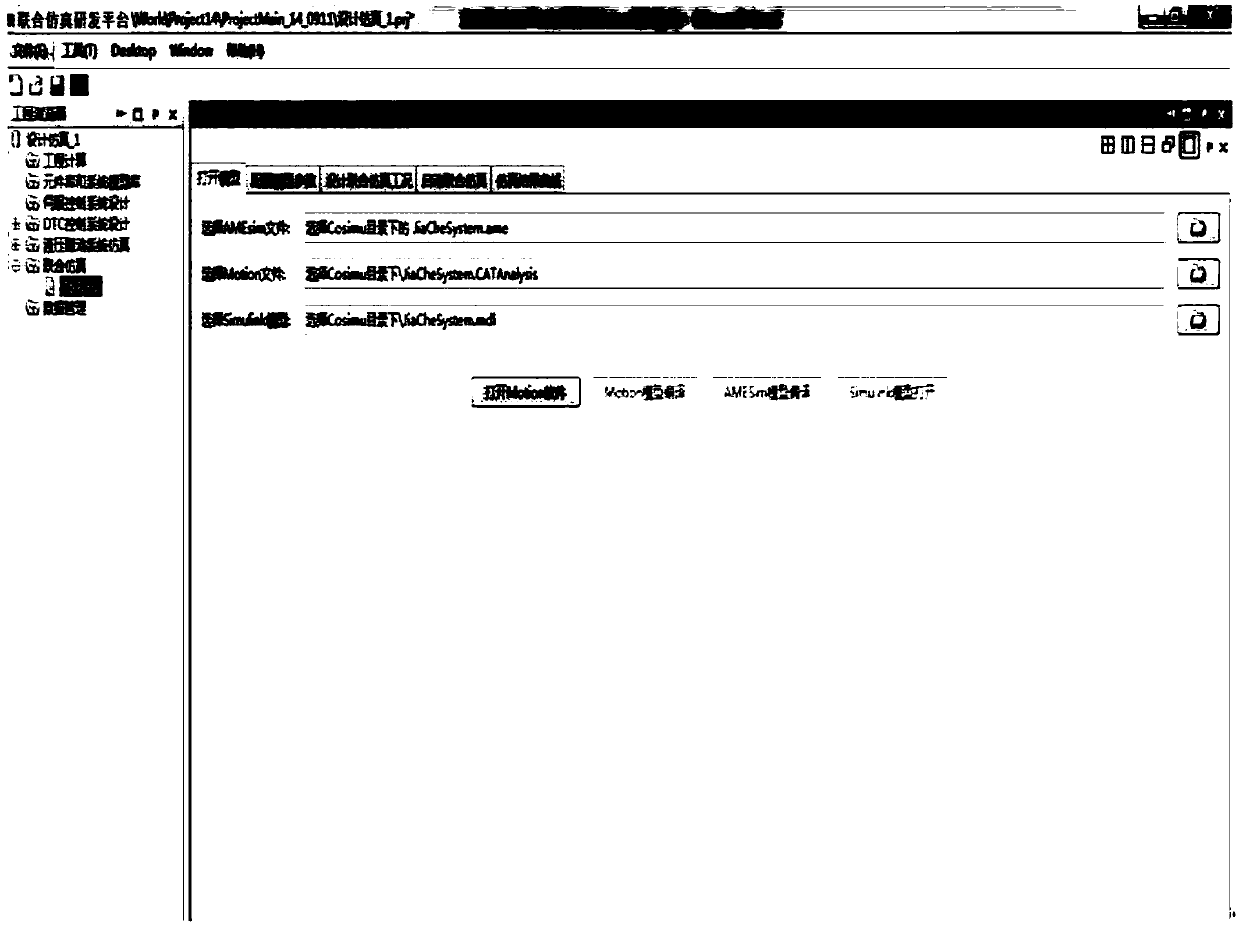

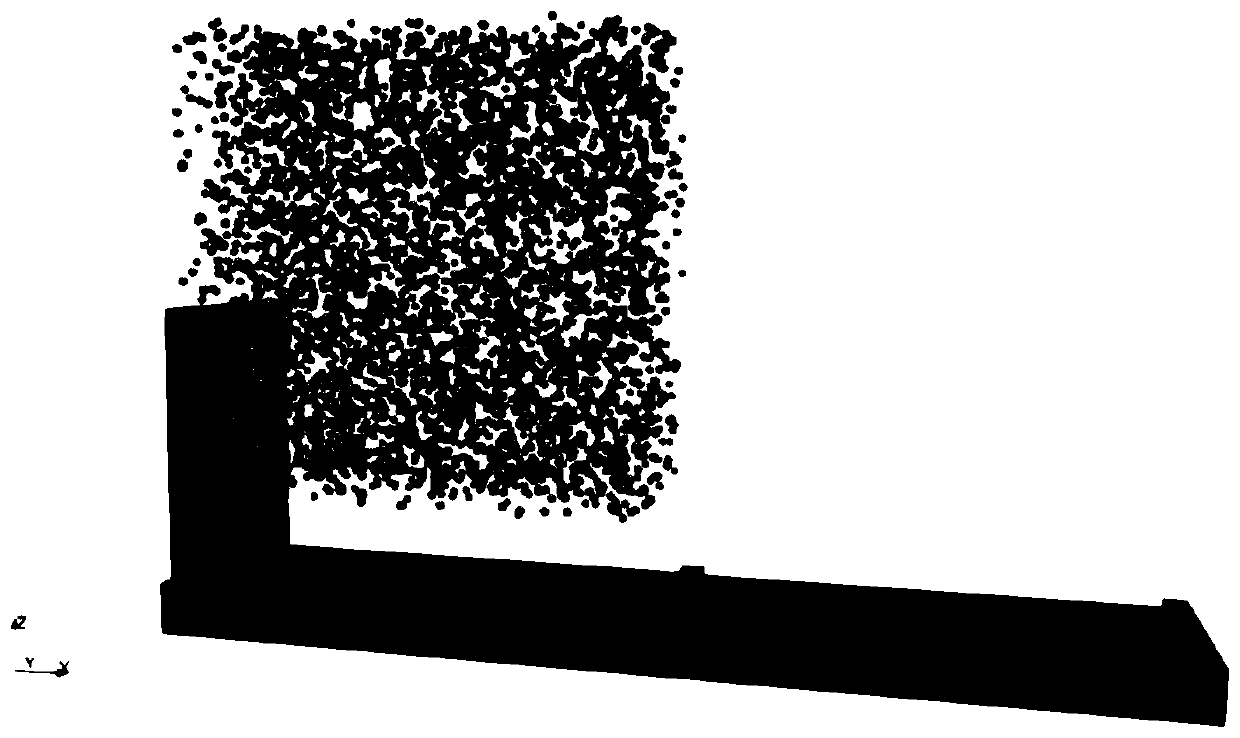

InactiveCN108228995ASimplify the simulation processLower requirementGeometric CADDesign optimisation/simulationRadarMATLAB

The invention discloses a combined simulation research and development platform for a radar mechanical-electric-hydraulic system, comprising a mechanism subsystem parametric simulation model, a hydraulic subsystem parametric simulation model, a control subsystem parametric simulation model and the like. The platform is implemented based on the graphical programming design technique of software MATLAB by means of parameter transmission between the subsystems and the interface technique between mechanical-electric-hydraulic system simulation software. The single simulations for mechanical, control and hydraulic subsystems of a radar antenna setup and withdrawal system are integrated to a complete platform to perform combined simulation analysis, the simulation process of the mechanical-electric-hydraulic system is regularized and simplified, the requirement on simulation personnel is lowered, and structural configuration is optimized. By using the whole-process combined simulation technique for the mechanical-electric-hydraulic system, actual working condition of a radar antenna setup and withdrawal system can be accurately simulated.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Laser powder bed melting additive manufacturing molten bath monitoring and pore controlling method

ActiveCN111283192ADescribe wellReduce dependenceAdditive manufacturing apparatusIncreasing energy efficiencySolidusPowder bed

The invention discloses a laser powder bed melting additive manufacturing molten bath monitoring and pore controlling method. The method includes the steps that (1) a space powder bed three-dimensional geometrical model is established; the powder model is guided into a thermal fluid model, a thermal fluid model of the powder dimension is established, the initial and boundary conditions of computational domains are set, and meshing is performed; a powder bed melting process three-dimensional model governing equation is established, and a molten bath is simulated according to the governing equation and input parameters; (2) three-dimensional profile data, including the molten bath depth, width and length, of the molten bath are extracted according to the solidus temperature and the mesh temperature of powder and a base material at each time step; and (3) a final scanning interval is obtained according to the three-dimensional profile data of the molten bath, and an ultimate molten bath is simulated according to the governing equation, the input parameters of the step (1) and the final scanning interval. In view of the difficulties of long time and high cost of the powder bed meltingexperimental research, the reliability of a solution can be evaluated, the research and development cost can be reduced, and the forming parameters are optimized.

Owner:NANJING UNIV OF SCI & TECH

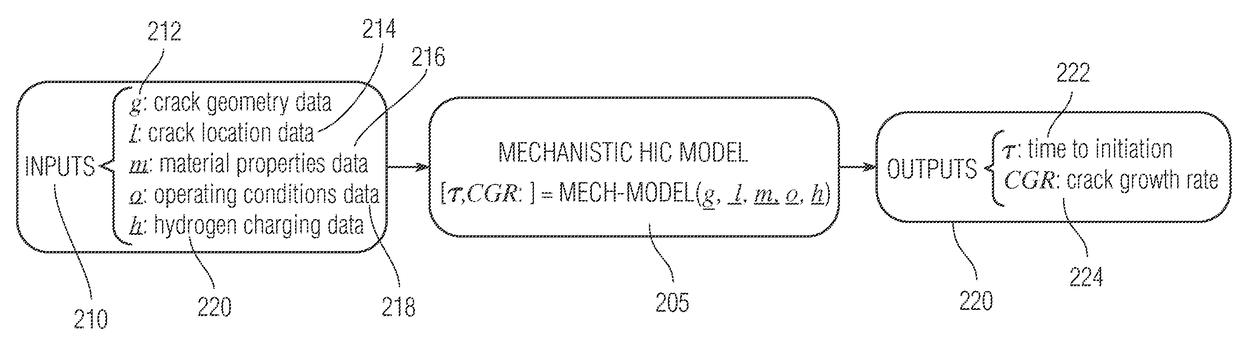

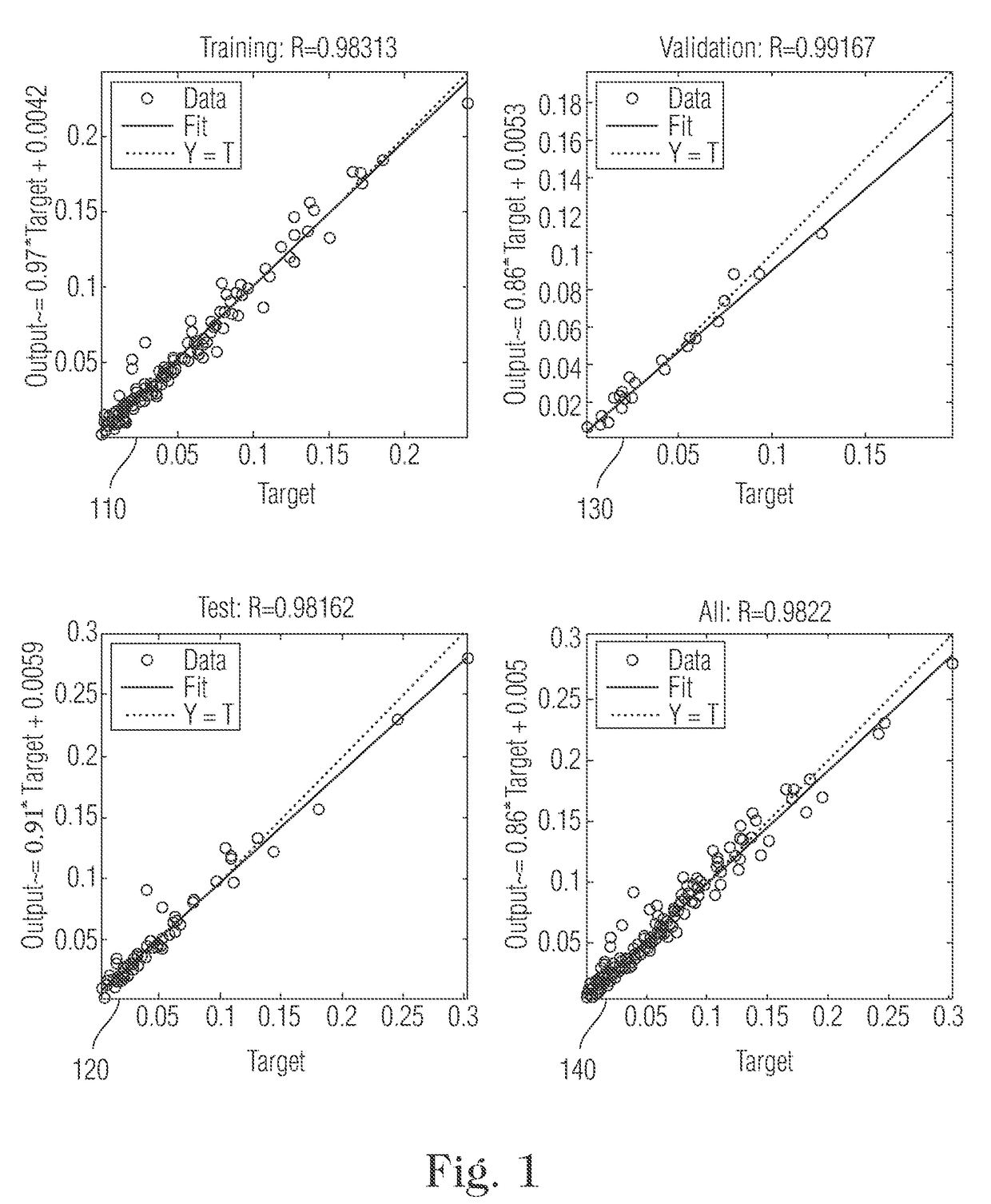

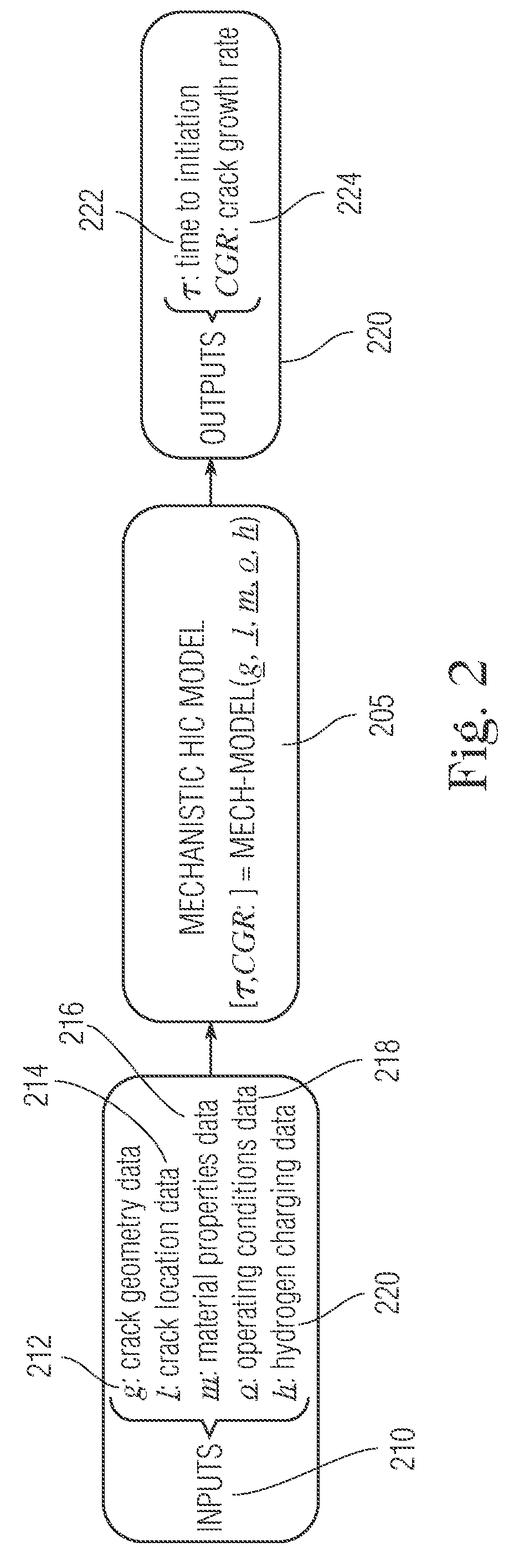

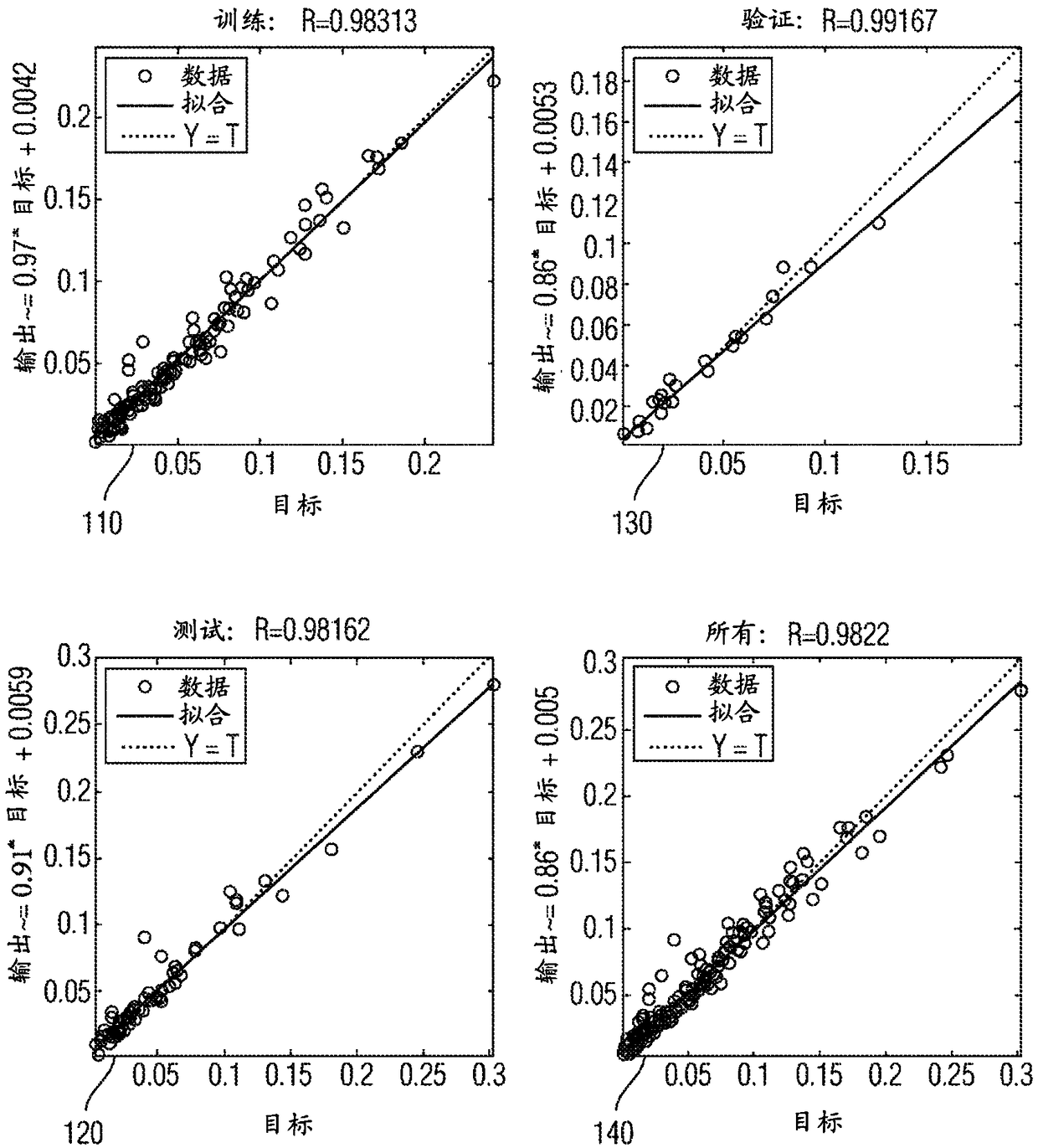

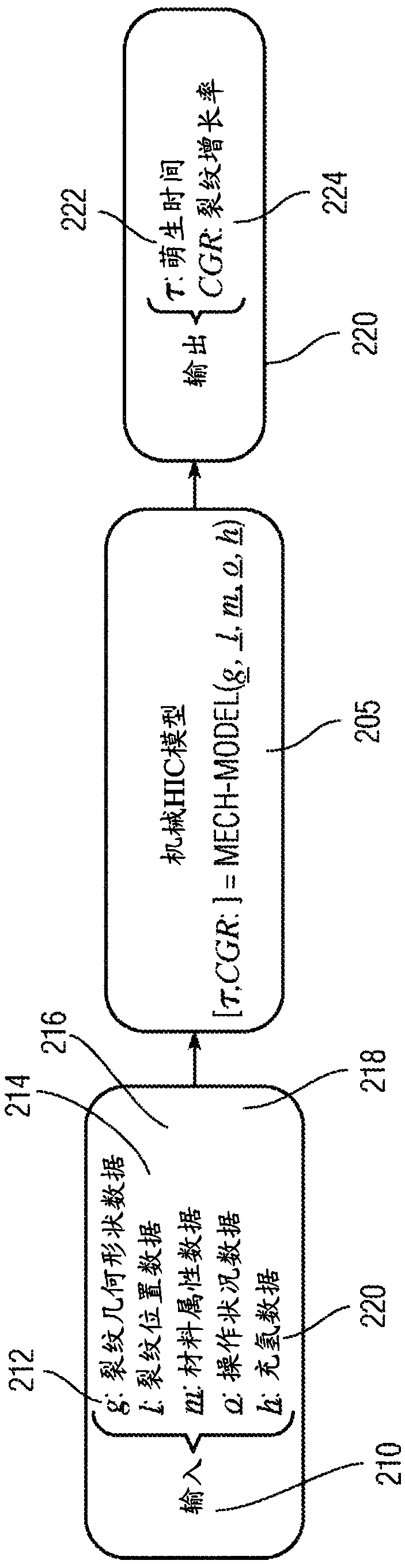

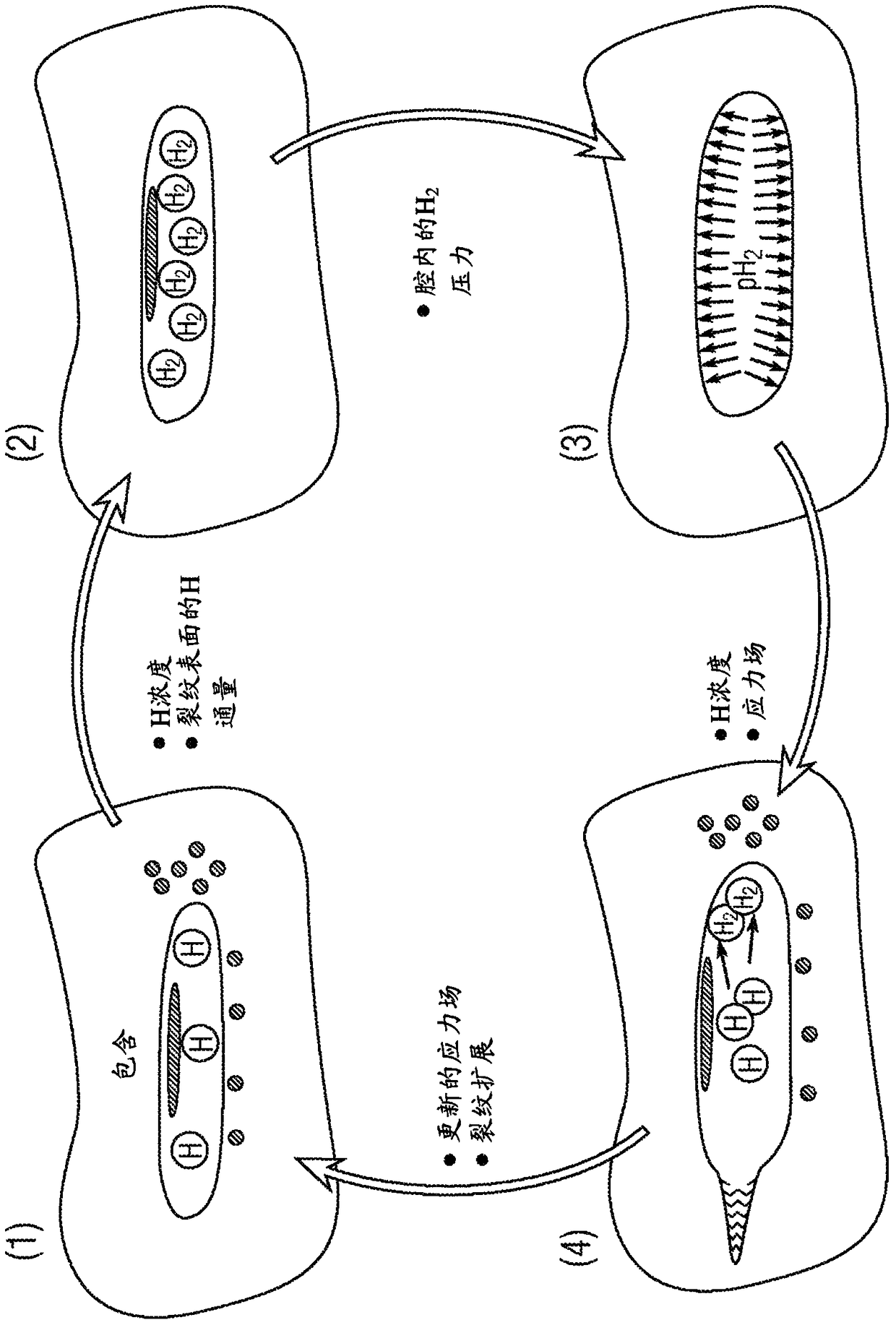

Systems and methods for rapid prediction of hydrogen-induced cracking (HIC) in pipelines, pressure vessels, and piping systems and for taking action in relation thereto

ActiveUS20170372196A1Increase the differenceSimulator controlTesting/monitoring control systemsHydrogenComputer science

Methods and systems of predicting the growth rate of hydrogen-induced cracking (HIC) in a physical asset (e.g., a pipeline, storage tank, etc.) are provided. The methodology receives a plurality of inputs regarding physical characteristics of the asset and performs parametric simulations to generate a simulated database of observations of the asset. The database is then used to train, test, and validate one or more expert systems that can then predict the growth rate and other characteristics of the asset over time. The systems herein can also generate alerts as to predicted dangerous conditions and modify inspection schedules based on such growth rate predictions.

Owner:SAUDI ARABIAN OIL CO

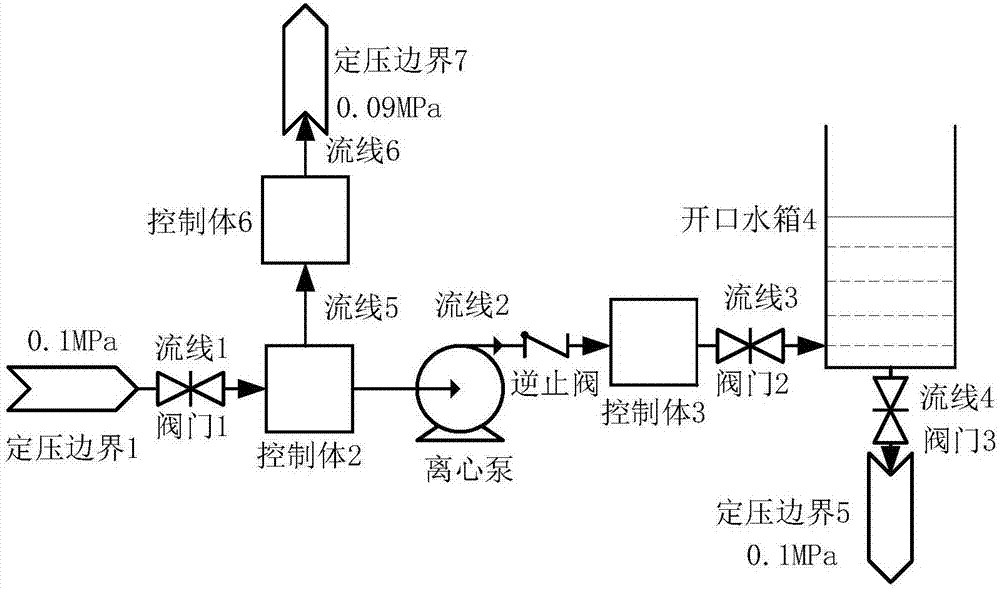

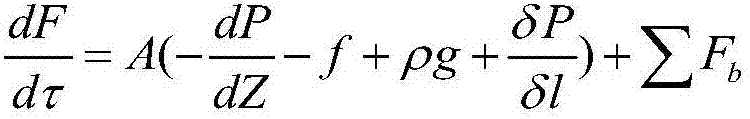

Flow net simulation application-oriented pump internal characteristic-based centrifugal pump parametric simulation method

ActiveCN107315858AIncrease credibilitySimulation is accurateGeometric CADDesign optimisation/simulationMomentumEngineering

The invention provides a flow net simulation application-oriented pump internal characteristic-based centrifugal pump parametric simulation method. The method comprises the steps of (1) inputting structure size design data of a centrifugal pump as a simulation object; (2) calculating a theoretical lift of the centrifugal pump; (3) calculating various hydraulic losses of the centrifugal pump; (4) adding an actual lift of the centrifugal pump into a momentum source phase of a momentum equation in flow net calculation; (5) inputting boundary parameters and structure parameters of a flow net and calculating initial values; (6) performing matrix calculation on thermotechnical parameters of the flow net, wherein the thermotechnical parameters include a pressure and an enthalpy value; and (7) outputting the thermotechnical parameters of the flow net and a performance parameter simulation result of the centrifugal pump. The method is a flow net simulation application-oriented pump internal characteristic-based centrifugal pump simulation method suitable for simulation of the flow net centrifugal pump under the condition of lack of test data.

Owner:HARBIN ENG UNIV

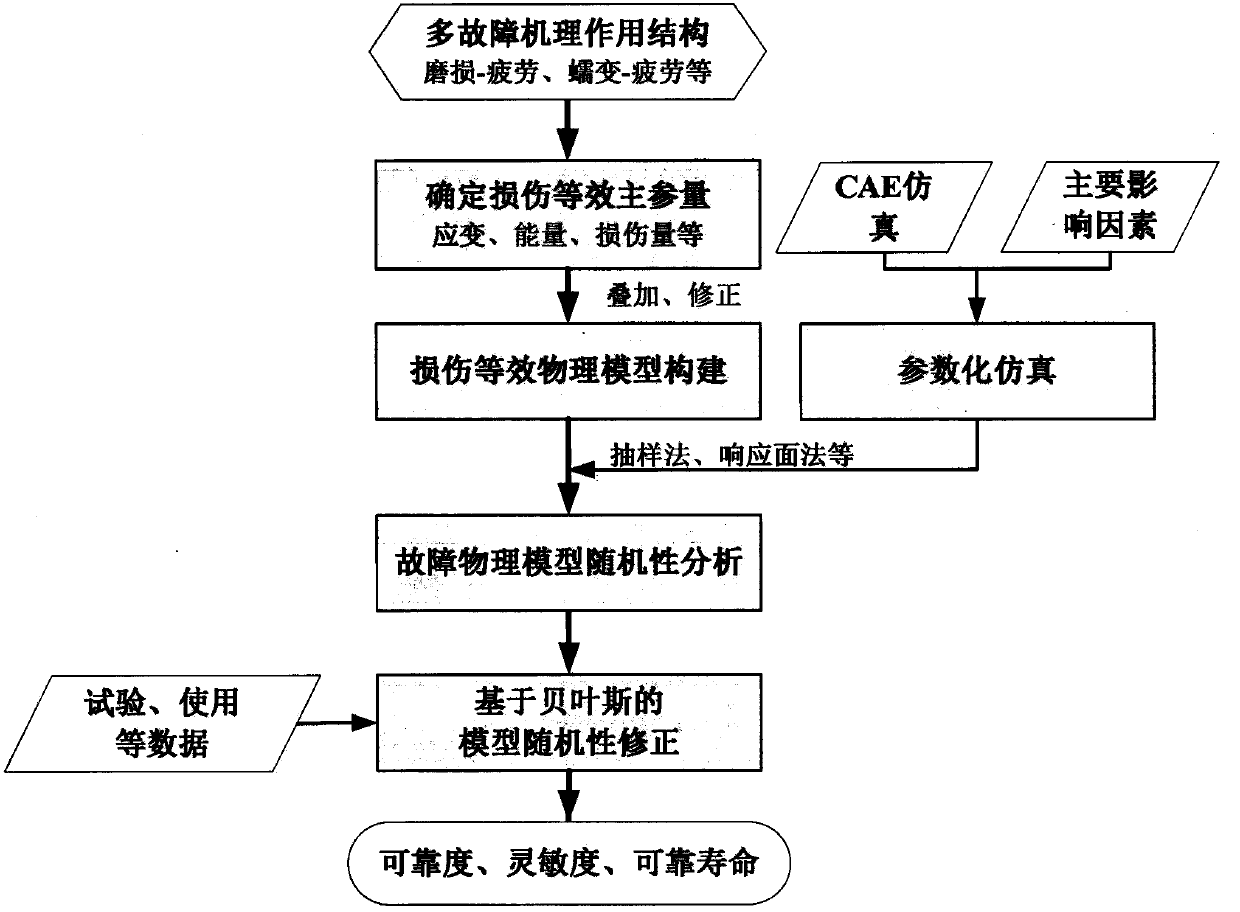

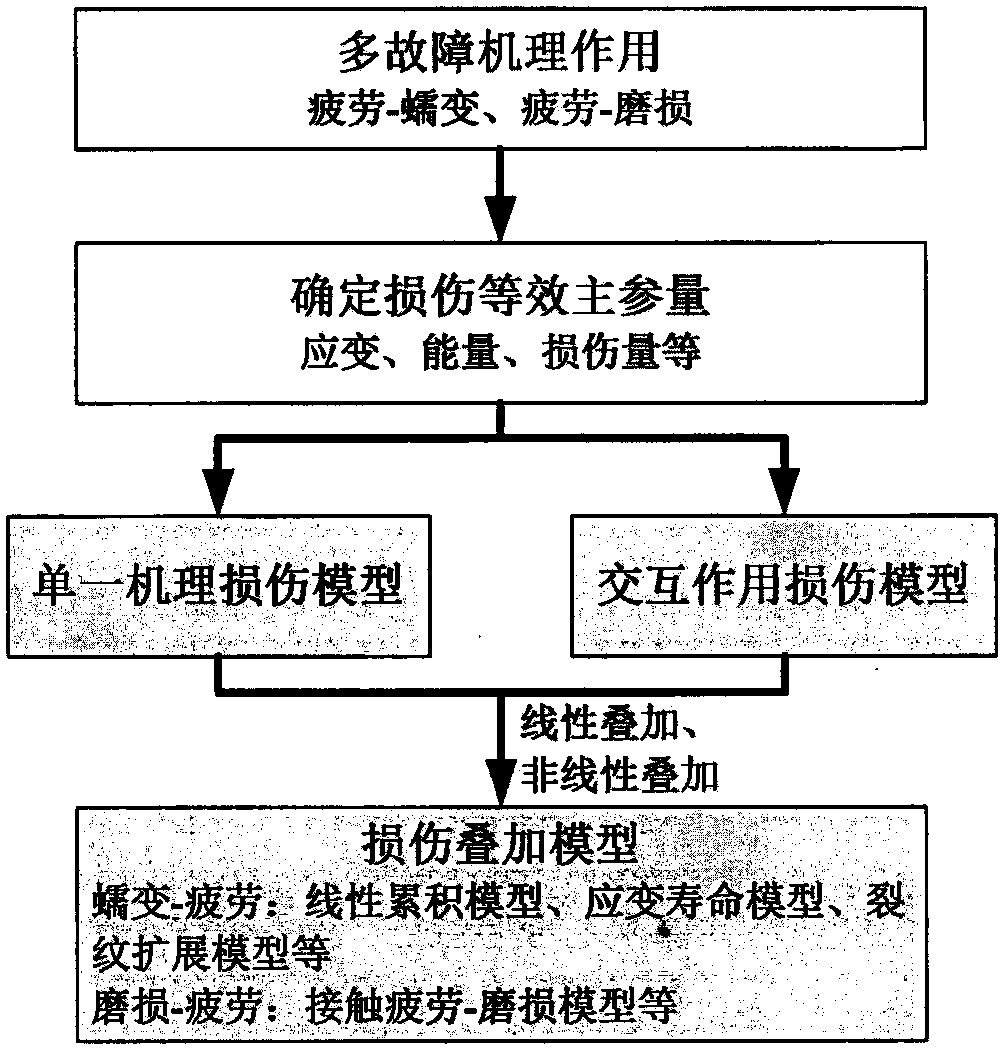

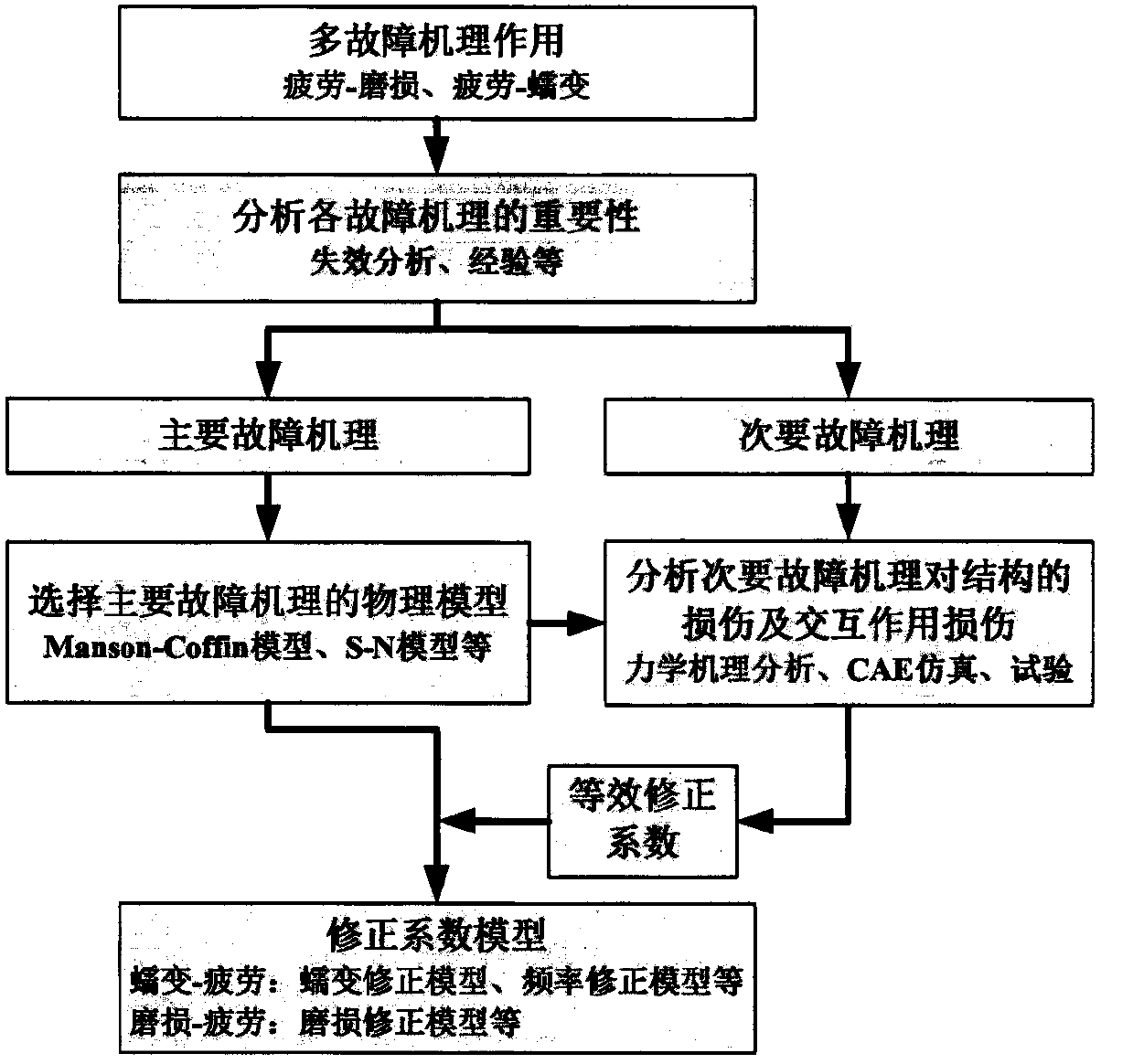

Mechanical structure reliability analyzing method based on coupling of multiple failure mechanisms

ActiveCN107784178AAnalytical reliabilityAnalytical sensitivityGeometric CADDesign optimisation/simulationCouplingPhysical model

The invention provides a method for analyzing reliability of a mechanical structure with an effect of coupling multiple failure mechanisms. Simultaneous actions and interaction of the failure mechanisms can be considered, and the reliability, reliable service life and sensitivity of the structure are analyzed. The method mainly comprises five steps: determining a damage equivalence main parameter,and showing the actions of the multiple failure mechanisms by using the same parameter by taking damage equivalence as a basic principle; constructing a damage equivalence physical model, and establishing a damage superposition model or a correction factor model according to difference of the contribution ratio of the failure mechanisms; carrying out parametric simulation, controlling the geometrical shape, material attribute, load and the like of the structure by adjusting parameters, and automatically reconstructing the damage equivalence physical model; analyzing randomness of the failurephysical model, considering parameter randomness, and analyzing the reliability, reliability sensitivity, reliable service life and the like of the structure with the aid of an improved primary reliability method and the like; and correcting a randomness result of the failure physical model by fully using data in a product development and use process on the basis of Bayes model randomness correction so as to improve analysis precision.

Owner:中国兵器科学研究院

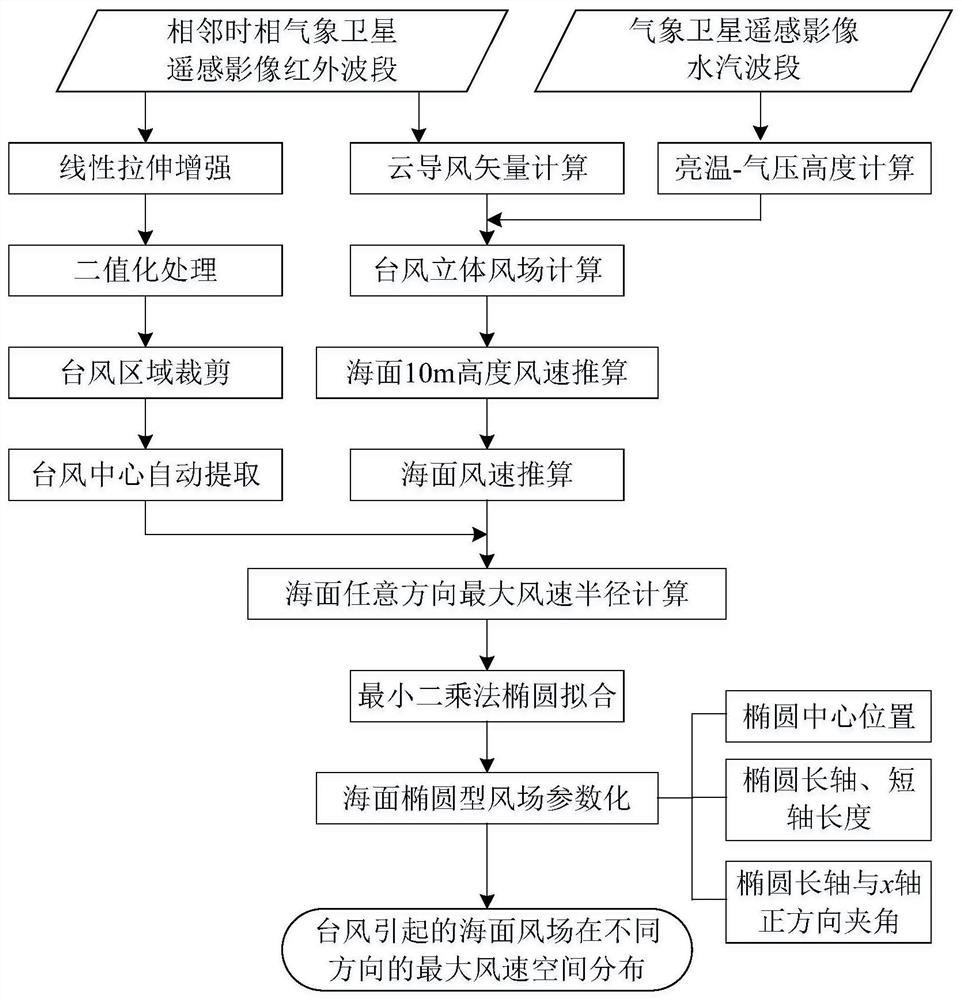

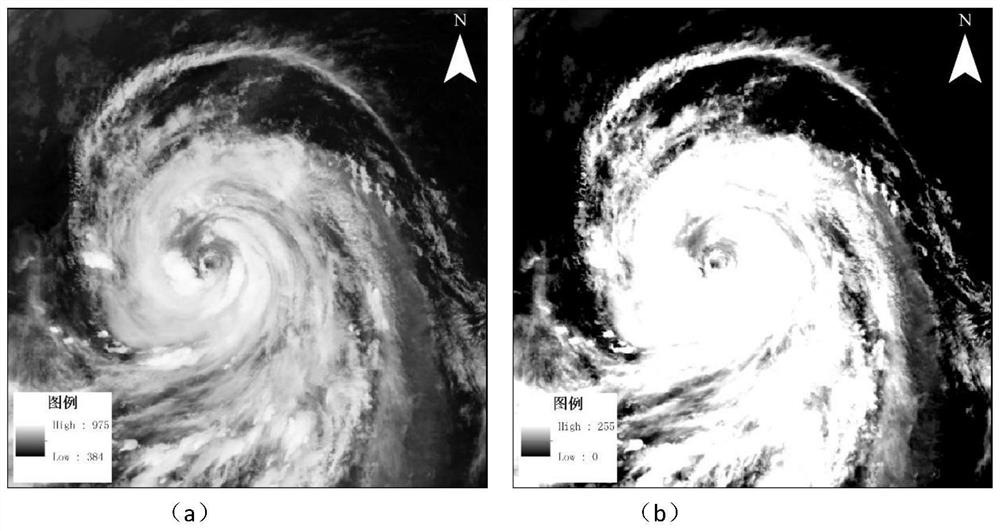

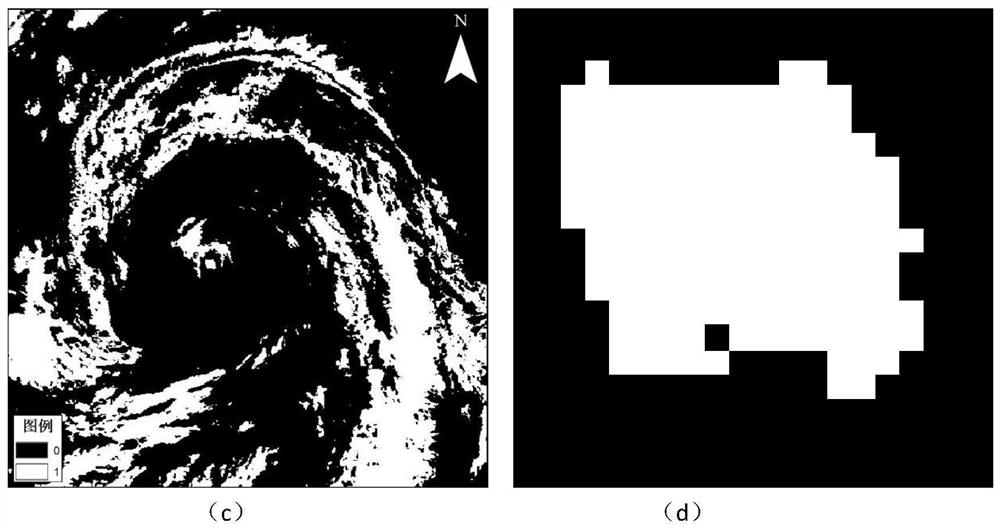

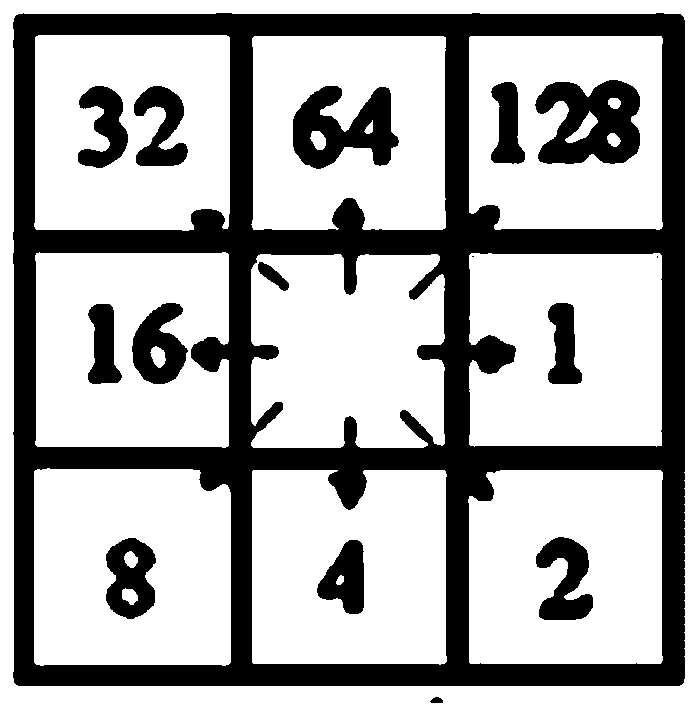

Typhoon elliptical wind field parametric simulation method based on remote sensing image features

PendingCN111723464AReal-time extrapolation of anisotropic distributionsHigh spatio-temporal resolutionDesign optimisation/simulationSpecial data processing applicationsSea wavesImaging analysis

The invention discloses a typhoon elliptical wind field parametric simulation method based on remote sensing image features. The invention relates to the field of satellite meteorological remote sensing information technology application. Through a remote sensing image analysis means and in combination with least square method ellipse fitting, ellipse center coordinates, ellipse long axis and short axis lengths and included angle parameters of the ellipse long axis and the x axis in the positive direction of the sea surface ellipse typhoon wind field are obtained through simulation, and the maximum wind speed space distribution range of the sea surface wind field in different directions is given. The method has the characteristics of simple operation and good real-time performance, the space-time heterogeneity distribution characteristic of the maximum wind speed radius of the sea surface wind field can be simulated, the obtained maximum wind speed point fitting ellipse can effectivelydescribe the space-time distribution range and orientation of sea surface wind field energy, and more accurate external drive can be provided for simulation of ocean dynamic processes such as storm surge and sea waves.

Owner:NANJING NORMAL UNIVERSITY

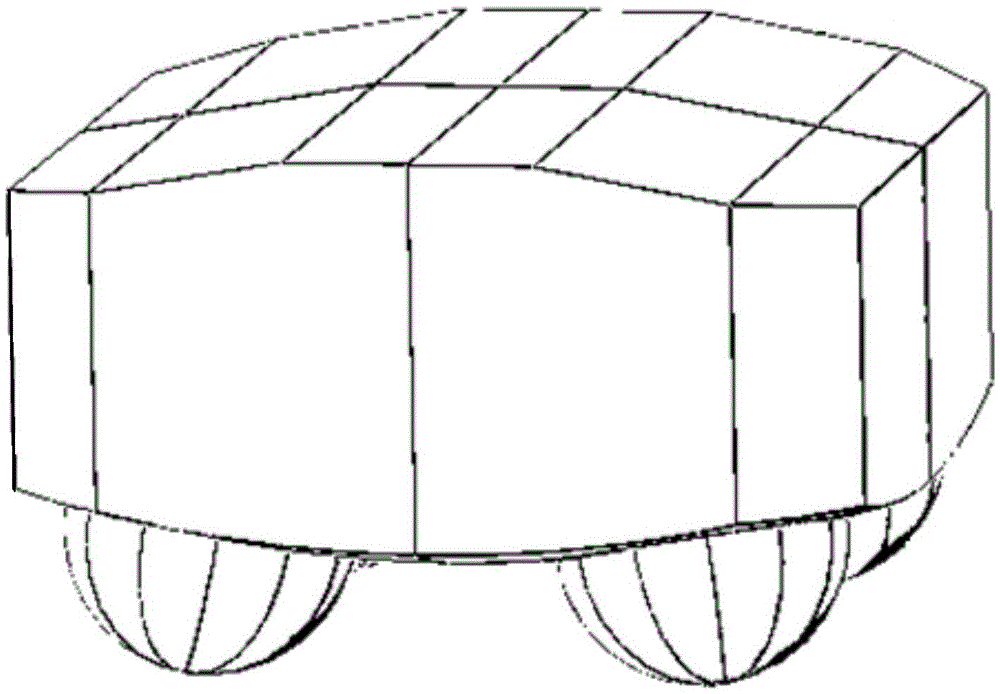

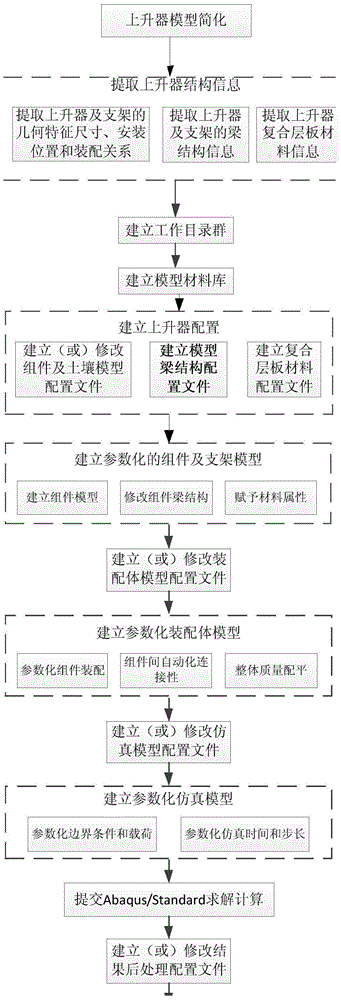

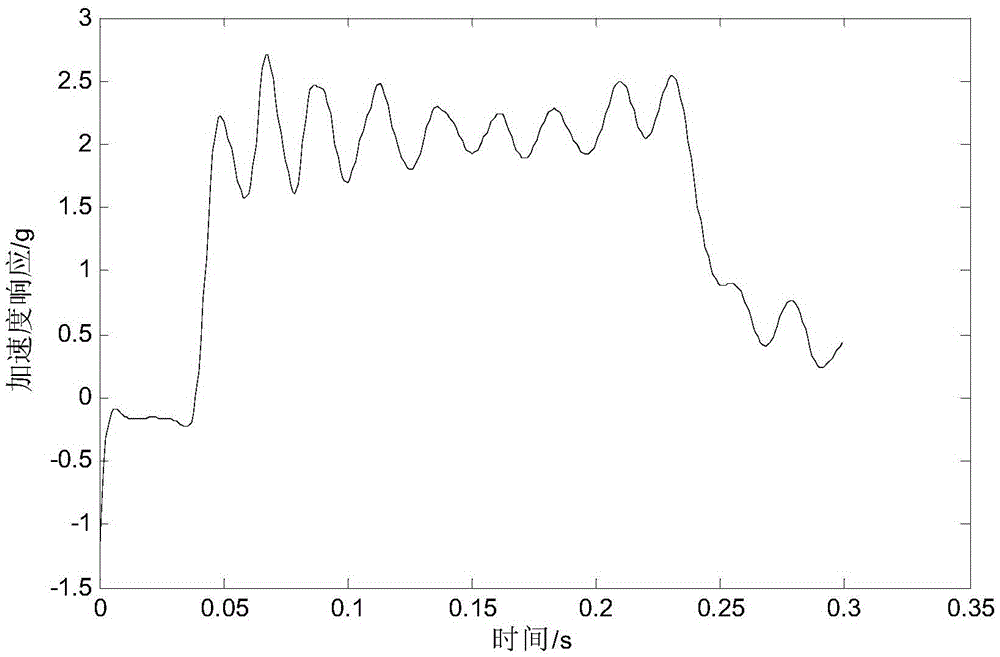

Parametric simulation method based on moon ascender assembly

ActiveCN105468824ASolve efficiency problemsSolve the accuracy problemDesign optimisation/simulationSpecial data processing applicationsDeep space explorationSimulation

The invention relates to a parametric simulation method based on a moon ascender assembly, and belongs to the technical field of deep space exploration. In order to solve the problem of low design efficiency in ascender kinetic analysis in the prior art, the invention provides the parametric simulation method based on the moon ascender assembly. The method combines finite element modeling, solution computation and result postprocessing into a whole, can generate a finite element grid model of each ascender assembly (which comprises an ascender and an ascender storage tank) and automatically finishes assembling, working condition setting, solution computation and result extraction. The automatic establishment of an ascender kinetic parametric model is realized, and repeated labor of design personnel due to remeshing and assembly connection relationship resetting caused by changing a certain feature size in the finite element modeling process of the ascender can be avoided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

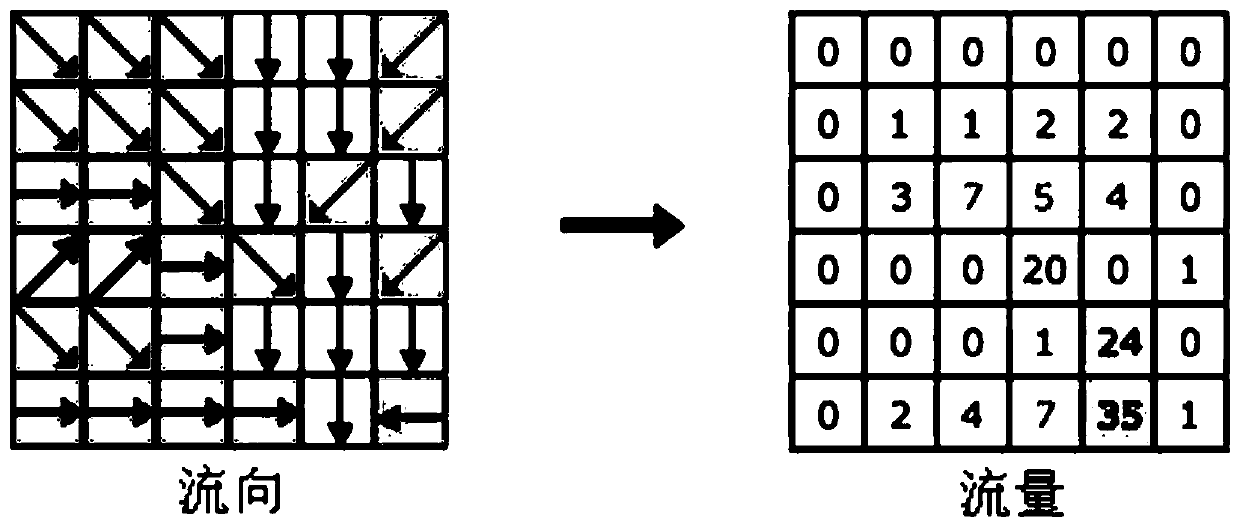

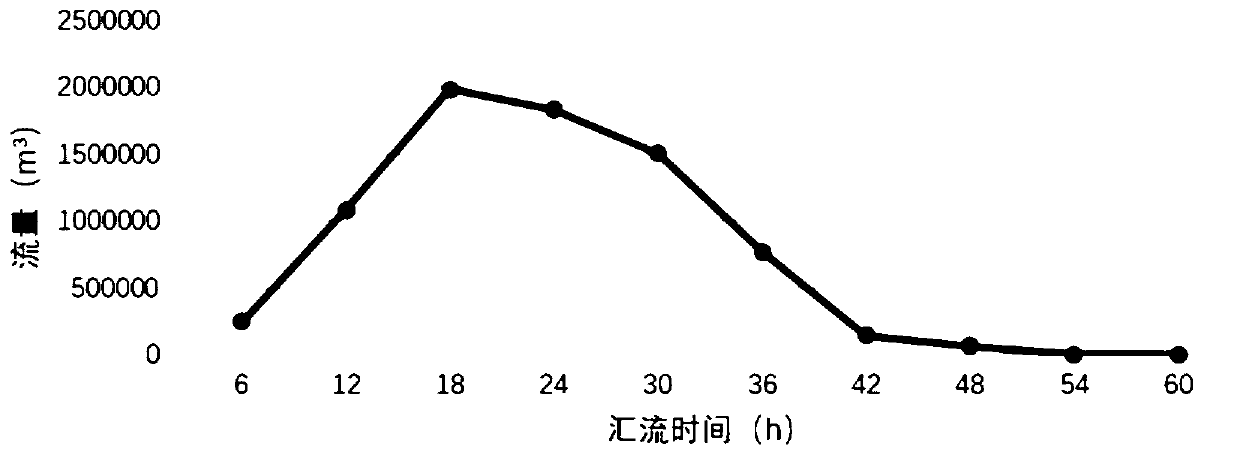

Basin confluence simulation estimation method

PendingCN111062128AHigh precisionIncrease flexibilityMeasuring open water movementMaterial analysis by optical meansHydrometryStream flow

The invention relates to a basin confluence simulation estimation method. A distributed hydrological model is instructed and a basin runoff production process is simulated based on underlying surfacesand rainfall parameters. Then, the basin confluence process is simulated according to the runoff and underlying surface parameters obtained through simulation, so that confluence estimation is achieved, the space distribution difference and the time difference of the basin rainfall flood process are effectively reflected in design, and high precision is achieved for simulation of small and microbasins; in addition, rainfall flood simulation can be carried out without historical data of a hydrological station at a drainage basin outlet, the upstream catchment area drainage basin at any pointin a large-range drainage basin can be simulated, and high flexibility and practicability are achieved; meanwhile, the design method carries out simulation operation completely based on the grid calculation principle, and the operation speed is high; and the analog operation speed can be further increased by adjusting the resolution of the raster data according to application requirements, so thata large number of experiments can be performed quickly.

Owner:NANJING UNIV

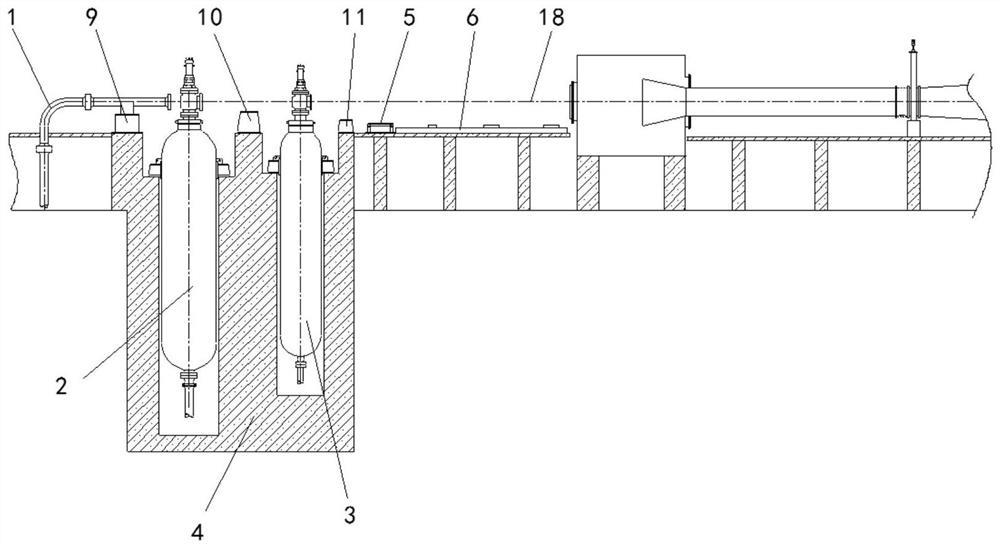

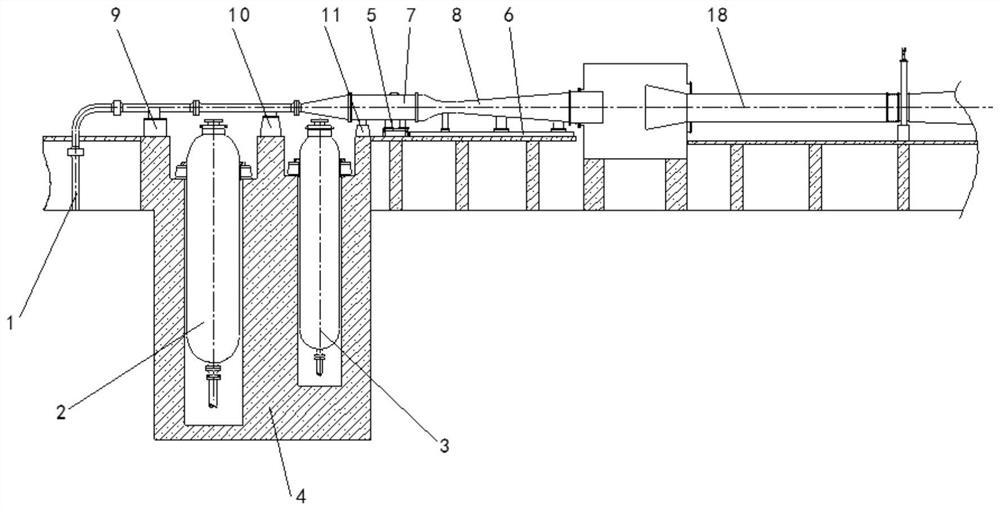

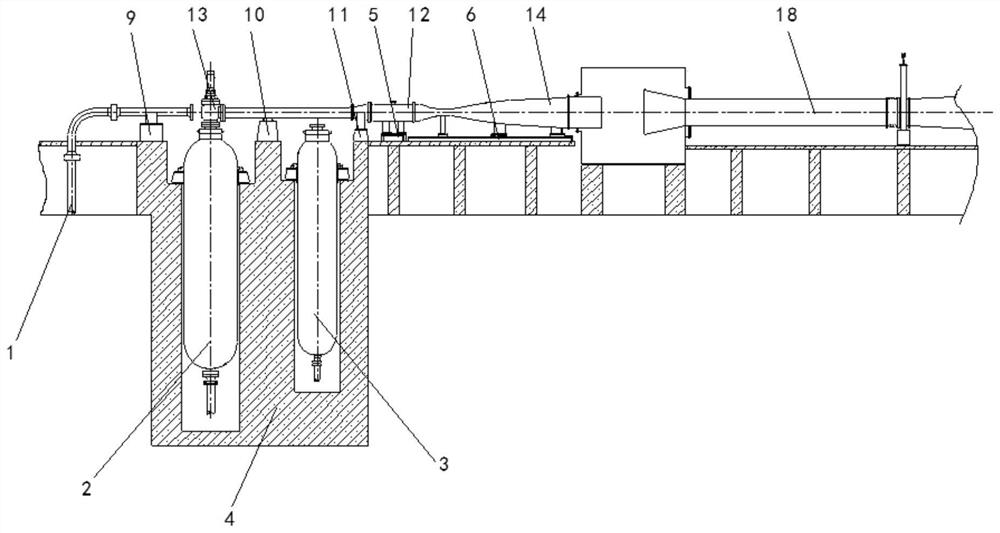

Three-branch series connection type hypersonic wind tunnel overall structure

ActiveCN112729750ARealize the requirement of wide parameter operation simulation rangeFast test capabilityAerodynamic testingCold airEngineering

The invention discloses a three-branch series connection type hypersonic wind tunnel overall structure, and the structure comprises branches dividing the Mach number simulation range of a hypersonic wind tunnel into three branches, wherein the three branches are the large-flow low-pressure cold air branch, the large-flow medium-temperature medium-pressure branch and the medium-small-flow high-temperature high-pressure branch respectively; the Mach number operation range of the large-flow low-pressure cold air branch is smaller than or equal to Mach number 4, the Mach number operation range of the large-flow medium-temperature medium-pressure branch is larger than 4 and smaller than or equal to 7, and the Mach number operation range of the medium-small-flow high-temperature high-pressure branch is larger than 7 and smaller than or equal to 10. According to the three-branch series connection type hypersonic wind tunnel overall structure provided by the invention, the advanced hypersonic wind tunnel requirement of wide parameter simulation can be realized through a step-by-step implementation mode; the wind tunnel operation state is convenient to switch, the wind tunnel layout is concise, and wind tunnel safe operation and standardized management are facilitated.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Method And System For Simulating Risk Factors In Parametric Models Using Risk Neutral Historical Bootstrapping

Owner:GOLDMAN SACHS & CO LLC

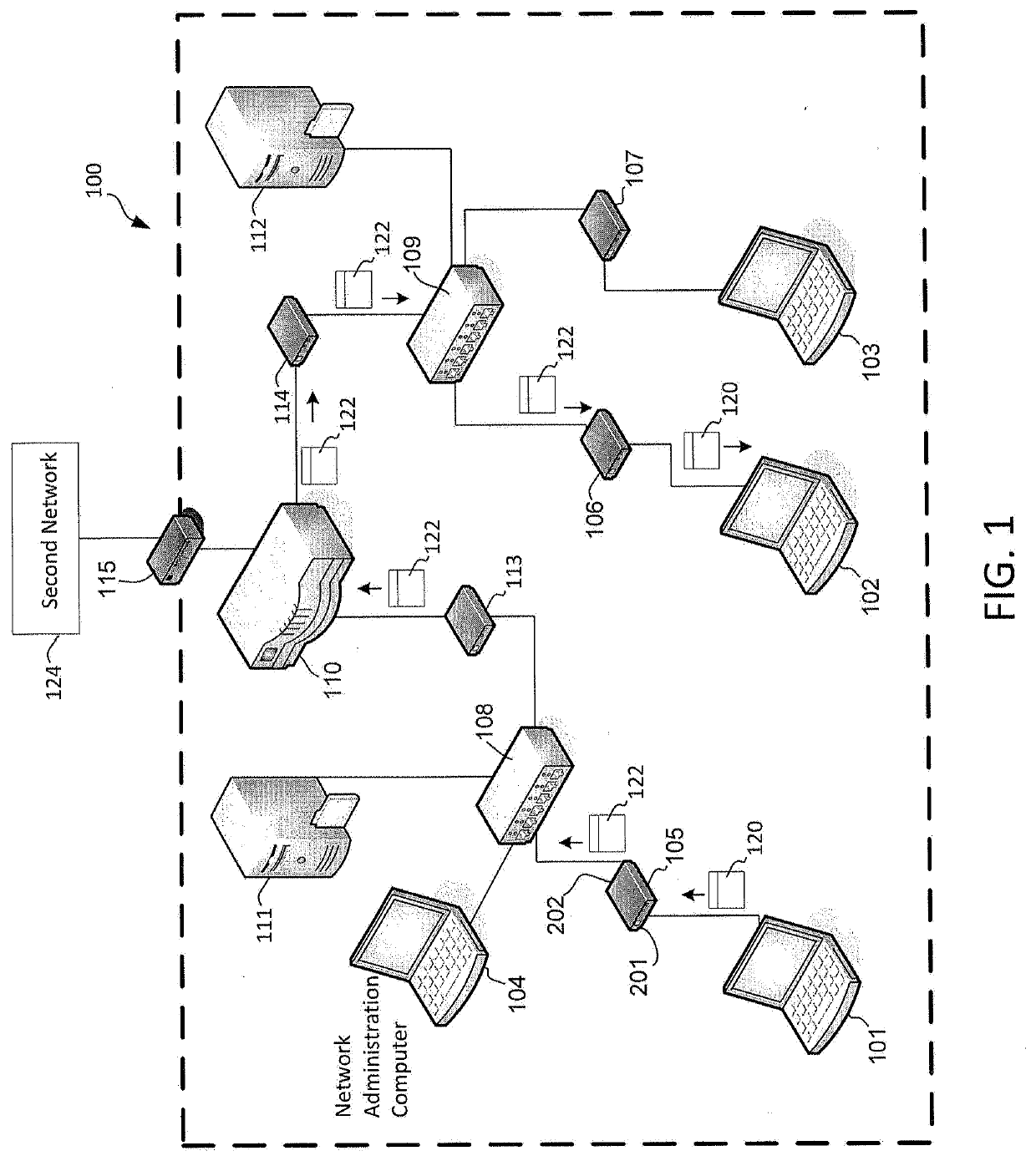

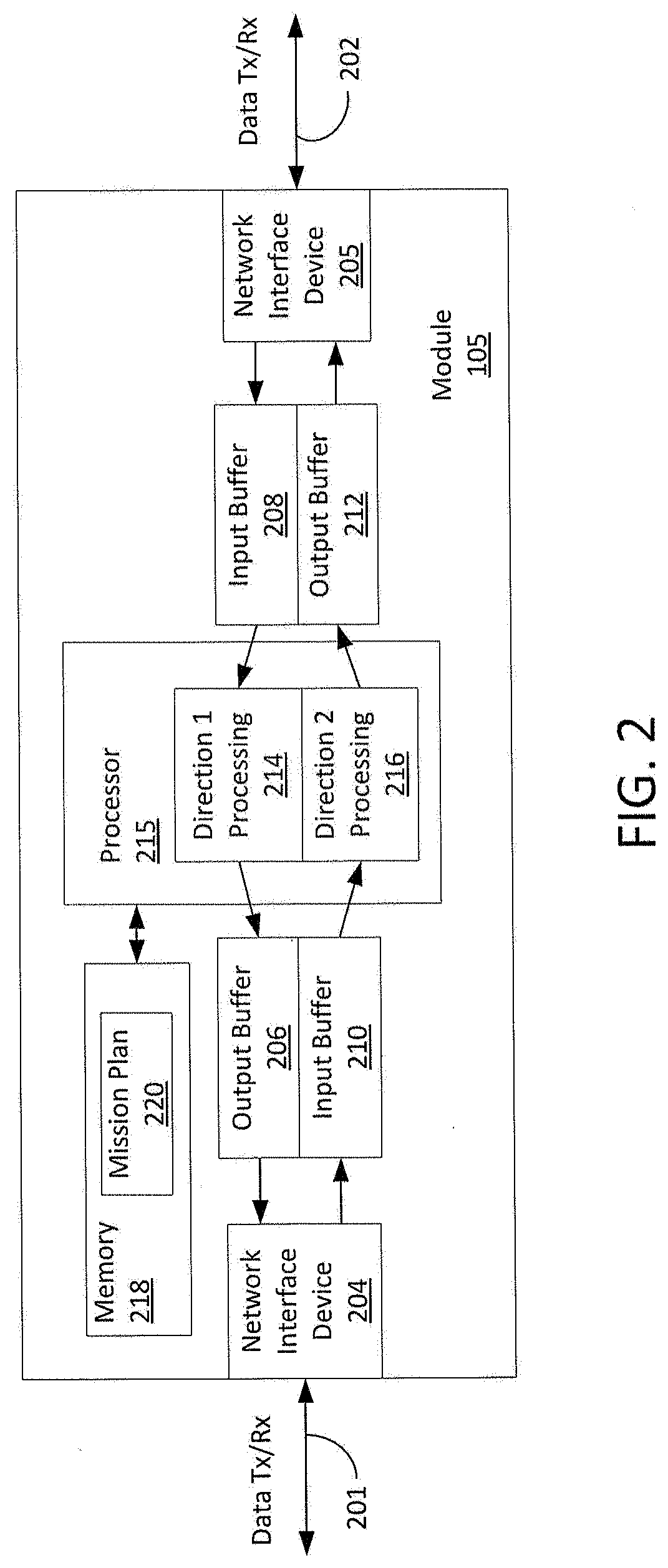

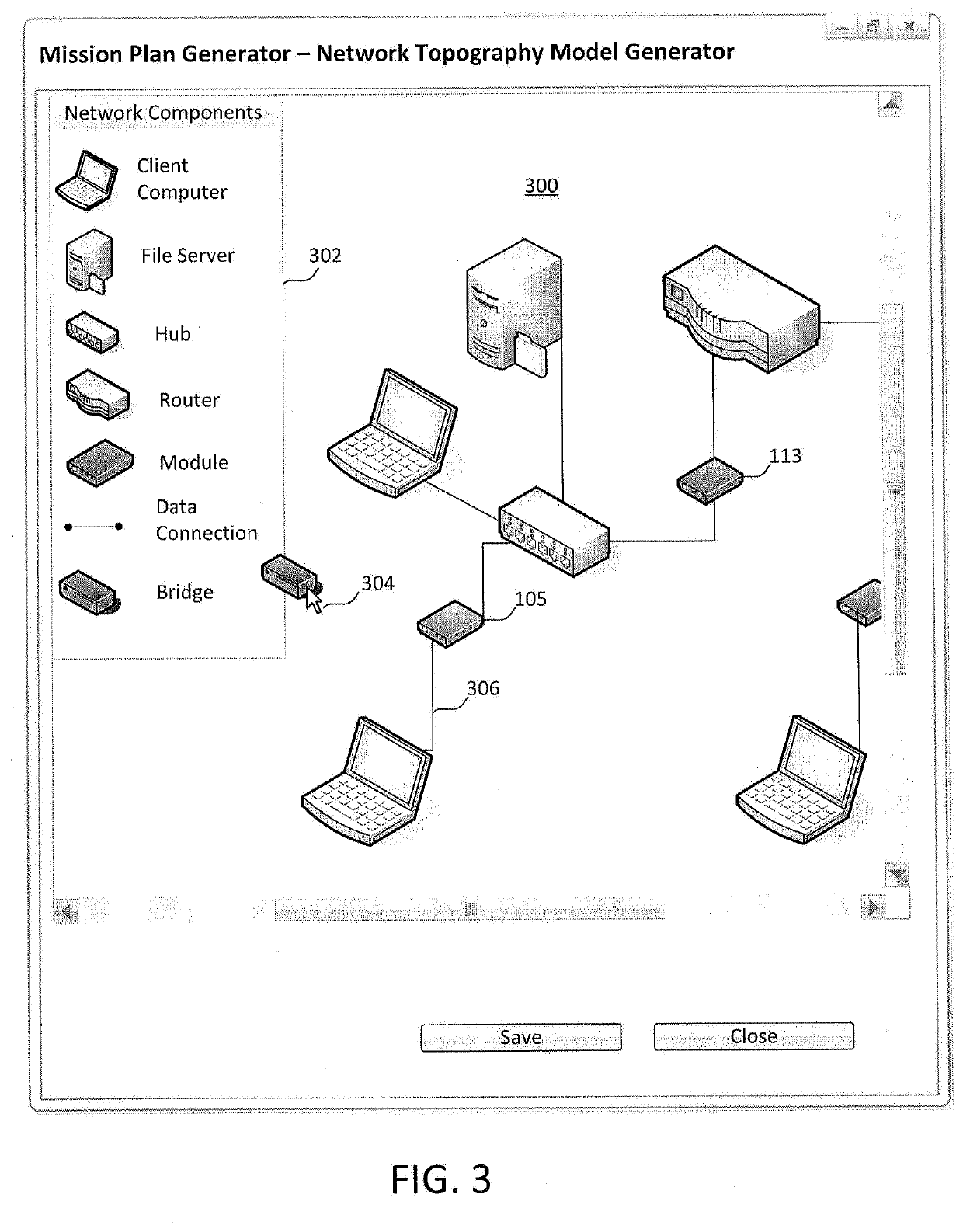

Systems and method for providing an ontogenesis emergence and confidence engine

ActiveUS20210075686A1Easy to controlEasy to optimizeKnowledge representationData switching networksEngineeringData mining

Systems and methods for controlling operations of a Computer System (“CS”). The methods comprise: collecting information about events occurring in CS; performing automated ontogenesis operations using the collected information to determine a context of a given situation associated with CS using stored ontogenetic knowledge, define parameters for different sets of actions that could occur in the context of the given situation, simulate the sets of actions to generate a set of simulation results defining predicted consequences resulting from performance of behaviors by nodes, determine a confidence value for each simulation result that indicates a level of confidence that a successful outcome will result if action(s) associated with the simulation result are performed by CS, and analyze the confidence values to identify a simulation result with the best confidence level; and using the parameters associated with the best simulation result to control and optimize performance of CS.

Owner:EAGLE TECH LLC

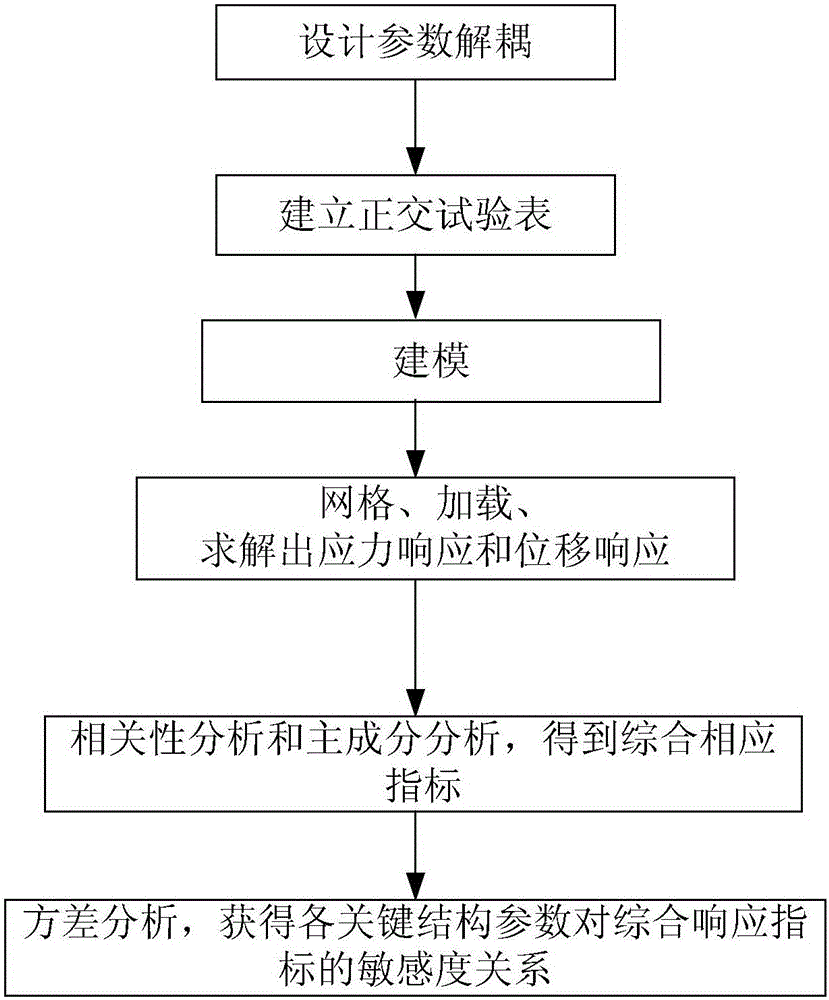

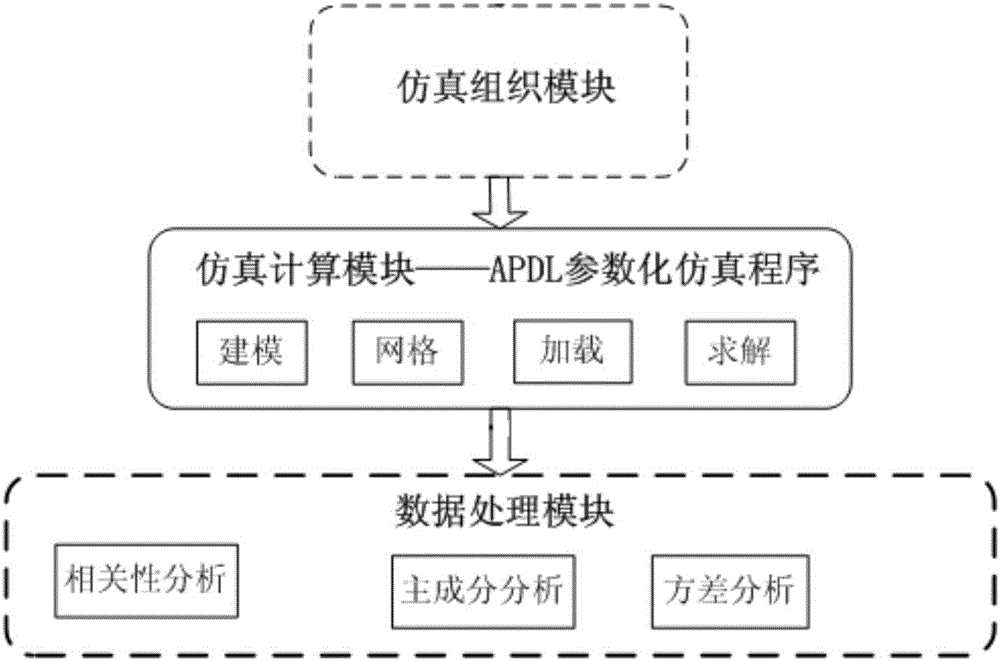

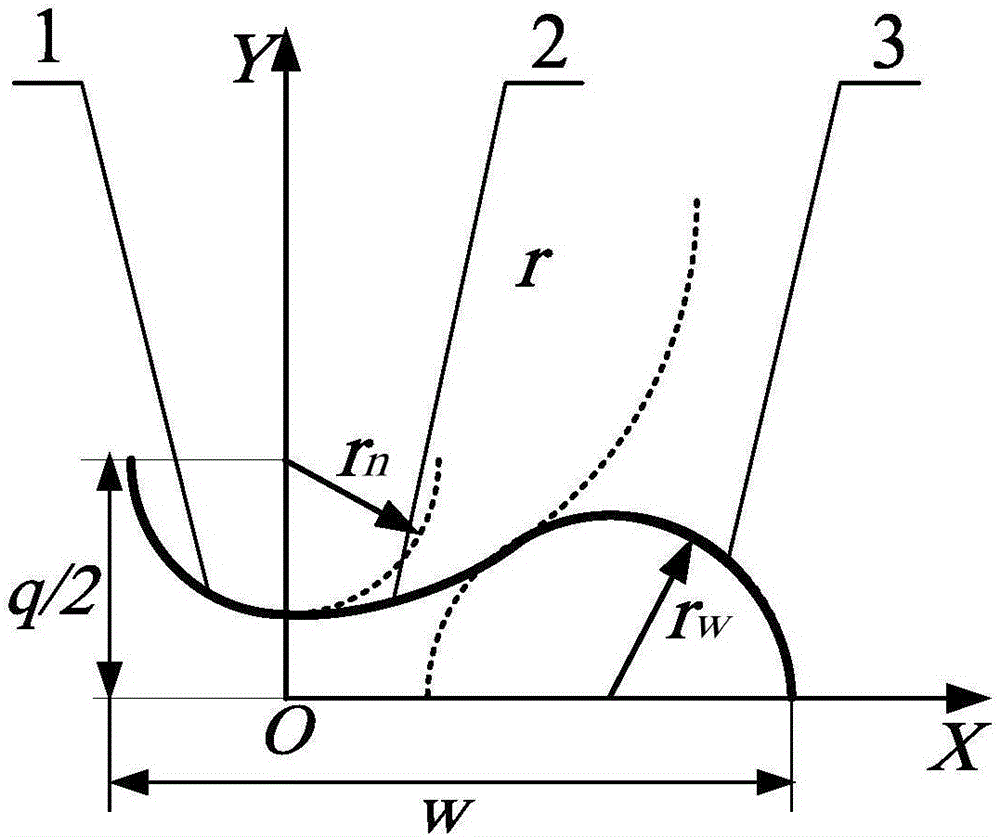

Three-section circular arc primitive corrugated pipe analysis method based on variance sensitiveness sorting

ActiveCN106202643AImprove computing efficiencyReduce labor costsDesign optimisation/simulationSpecial data processing applicationsOrthogonal test designSimulation

The invention relates to a three-section circular arc primitive corrugated pipe analysis method based on variance sensitiveness sorting. The method is characterized in that geometrical characteristics of a multi-layer three-section circular arc primitive tangent corrugated pipe are symmetrically defined, and geometrical parameters of the corrugated pipe are decoupled; a nonlinear finite element analysis program of the multi-layer three-section circular arc primitive tangent corrugated pipe is built based on parameter languages, and modeling, network processing, loading, postprocessign and other finite element calculation steps can be rapidly achieved by freely changing model parameters; a parametric simulation control platform is built, an orthogonal test design module, a parametric finite element simulation module and a sensitiveness analysis module are integrated, large-sample and multi-target optimal calculation can be achieved, and sensitiveness indexes of design modules can be rapidly and systemically obtained. The systematicness and reliability of structural parameter optimization and sensitiveness analysis are improved; on the basis of a platform control technology and a parametric simulation technology, the labor cost is greatly saved, and calculation efficiency is improved.

Owner:XIAN AEROSPACE PROPULSION INST

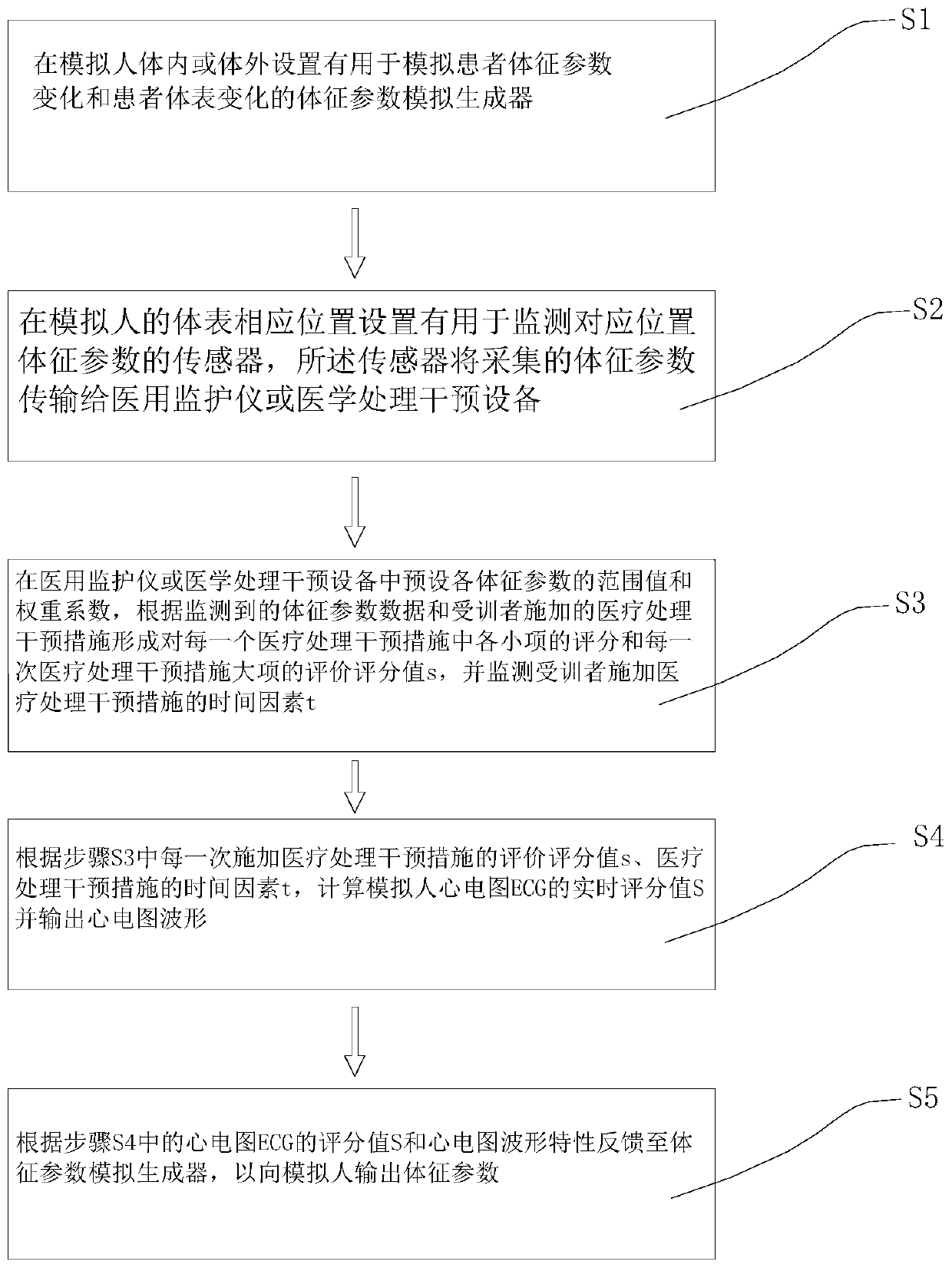

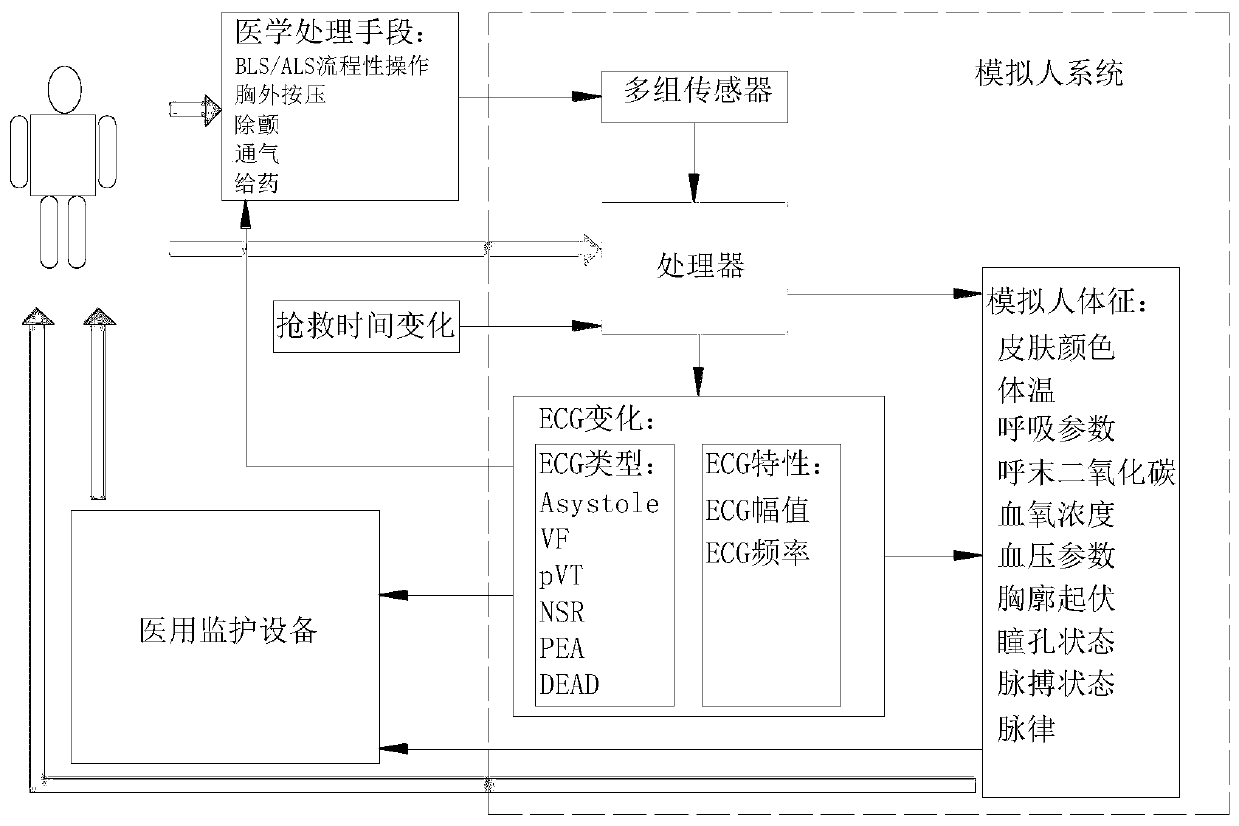

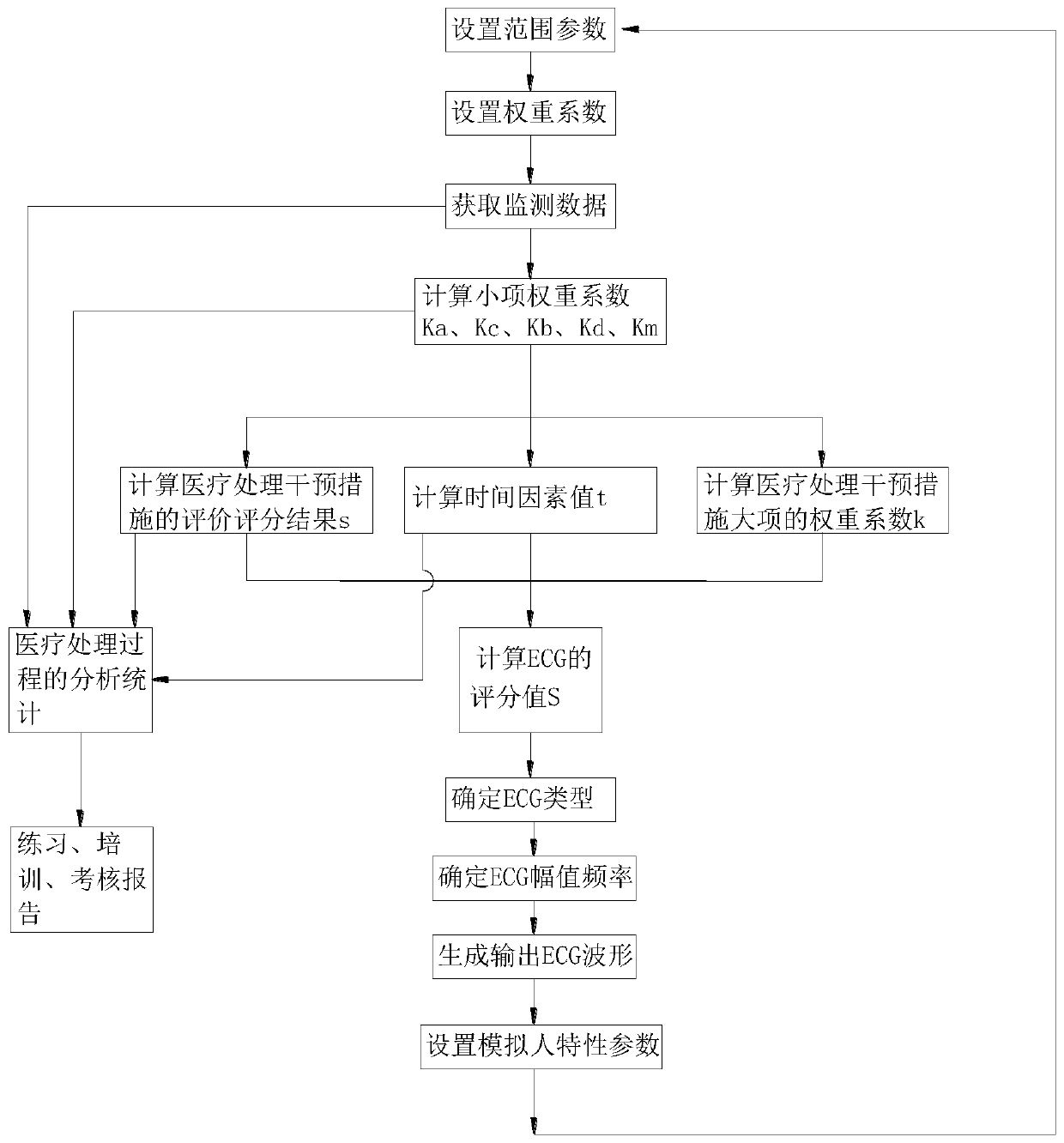

Simulation interactive simulation method for cardio-pulmonary resuscitation training

ActiveCN111179718AImplement Training Exercise FeedbackQuality improvementEducational modelsResourcesHuman bodyIntracardiac Electrogram

The invention discloses a simulation interactive simulation method for cardio-pulmonary resuscitation training. The simulation interactive simulation method comprises the following steps that S1, a sign parameter simulation generator is arranged in a simulation human body or outside the simulation human body; S2, a sign parameter sensor is arranged on the body surface of the simulated human body,and the sensor transmits collected sign parameters to a medical monitor; S3, a range value and a weight coefficient of each sign parameter are preset, a score value of each small item and a score value s of each large item in the medical treatment intervention measures are calculated, and a time factor t of applying the medical treatment intervention measures by the trainee is monitored; S4, a real-time score value S of the simulated human electrocardiogram ECG is calculated and an electrocardiogram waveform is output; and S5, the score value S of the ECG and the waveform characteristics of the ECG are fed back to the sign parameter simulation generator so as to output sign parameters to the simulated person. According to the simulation interactive simulation method for pulmonary resuscitation training, various simulations in the rescue process of a patient with sudden cardiac arrest are realized, so that the training truth and quality are improved.

Owner:SUNLIFE SCI SUZHOU INC

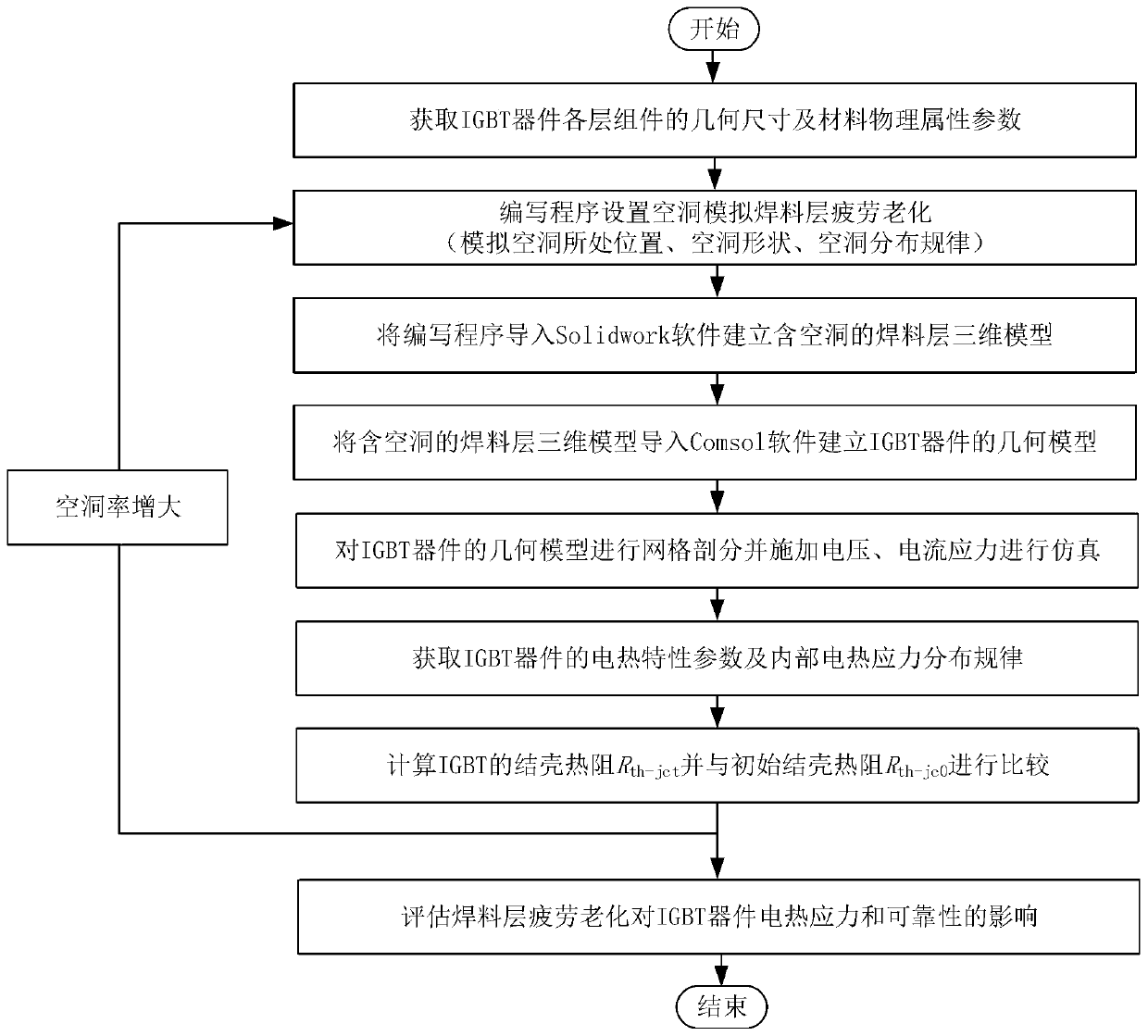

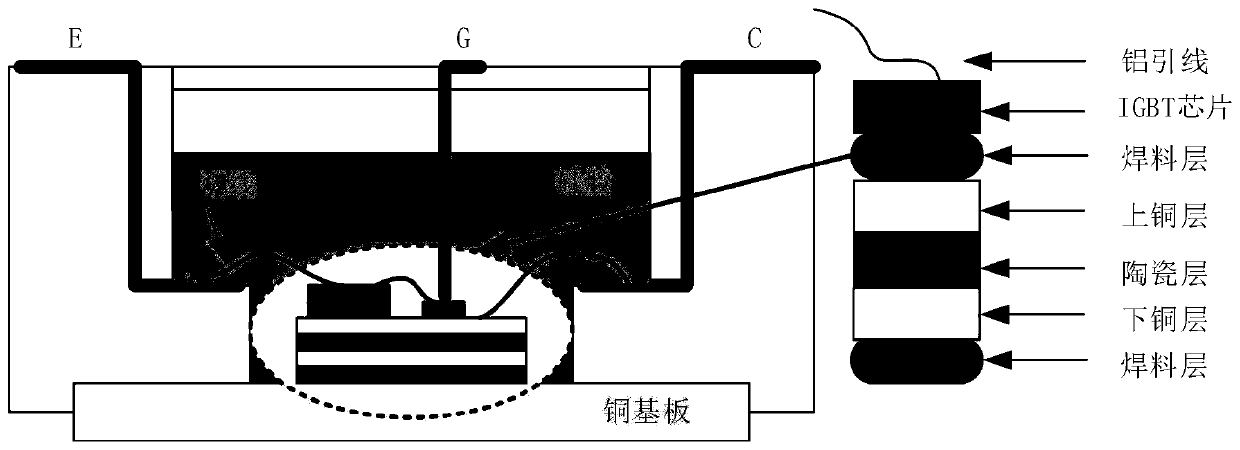

IGBT module solder layer fatigue aging failure simulation method based on voidage

PendingCN111259583AIncrease stressImprove reliabilityDesign optimisation/simulationCAD numerical modellingEngineeringField simulation

The invention relates to an IGBT module solder layer fatigue aging failure simulation method based on voidage, and belongs to the technical field of semiconductors. The method comprises the followingsteps: firstly, acquiring geometric dimensions and material physical attribute parameters of each layer of assembly of the IGBT module, and simulating a fatigue aging failure process of a cavity simulation solder layer; importing the simulation process into Solidwork software to establish a solder layer three-dimensional model containing a cavity; secondly, importing the three-dimensional model ofthe solder layer into Comsol software to establish a geometric model of the IGBT device, and performing mesh generation on the geometric model of the IGBT device; then, voltage and current stresses of actual working conditions are equivalent and applied to an IGBT device for mechanical-thermoelectric multi-coupling field simulation; and finally, evaluating the influence of fatigue aging of the solder layer on the reliability of the IGBT device. According to the method, the failure evolution process of fatigue aging of the solder layer is considered, and the accuracy of reliability evaluationof the IGBT module is improved.

Owner:CHONGQING UNIV

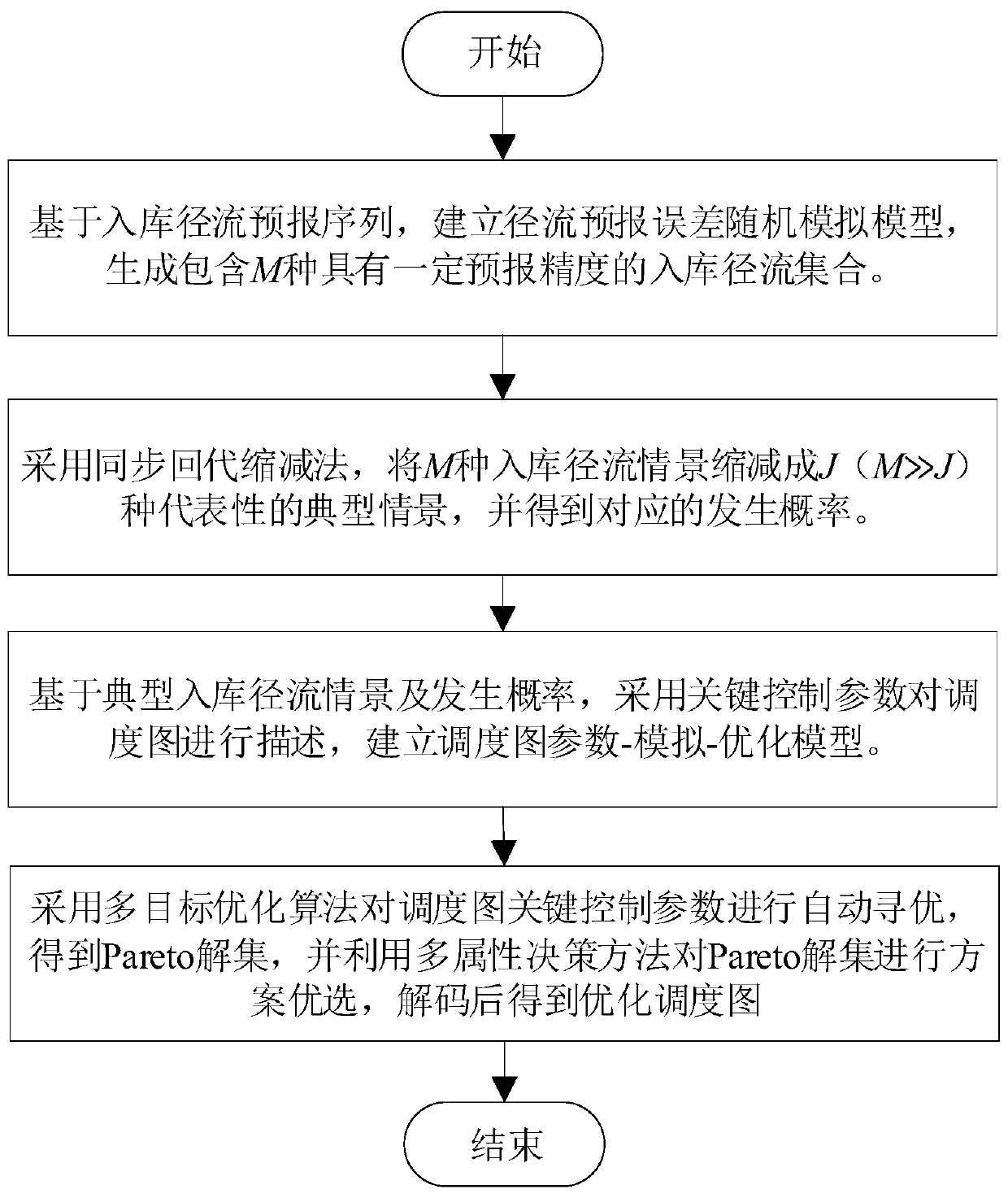

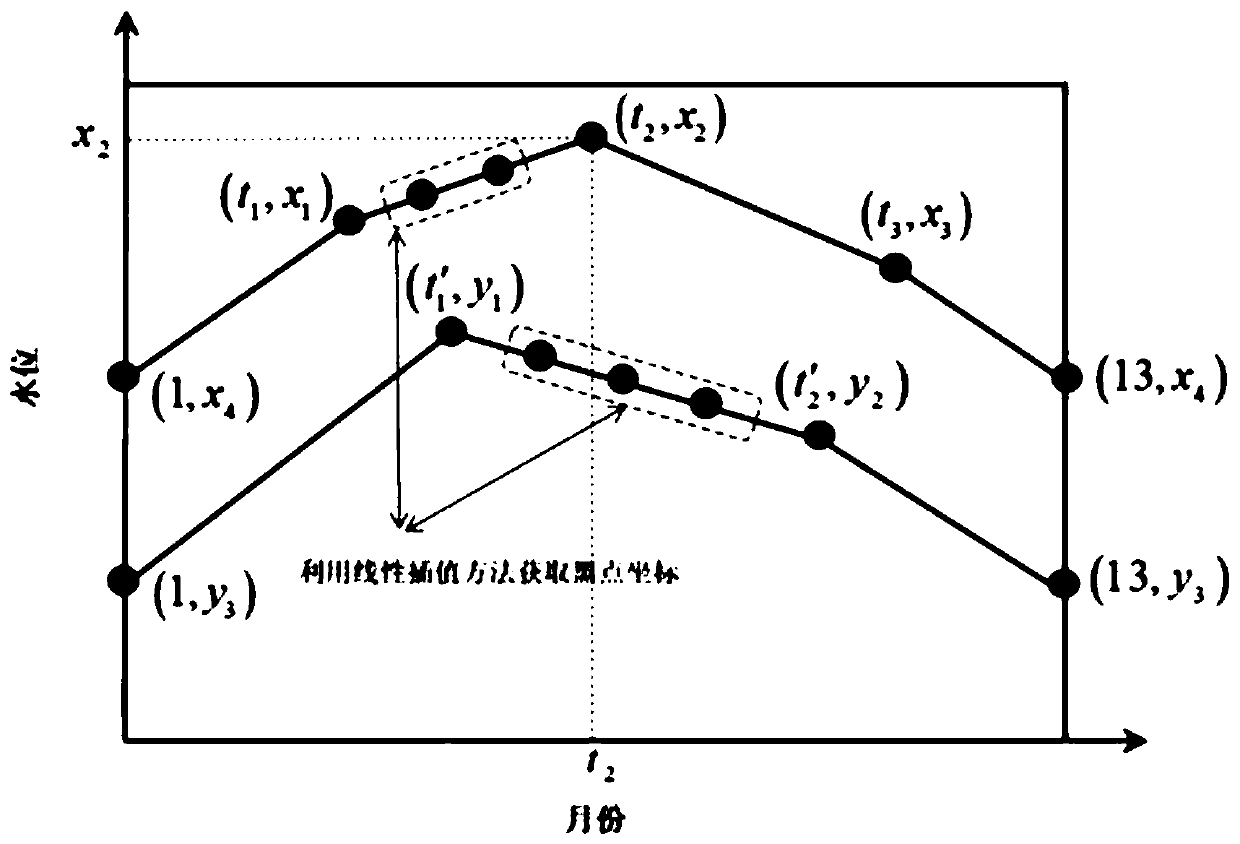

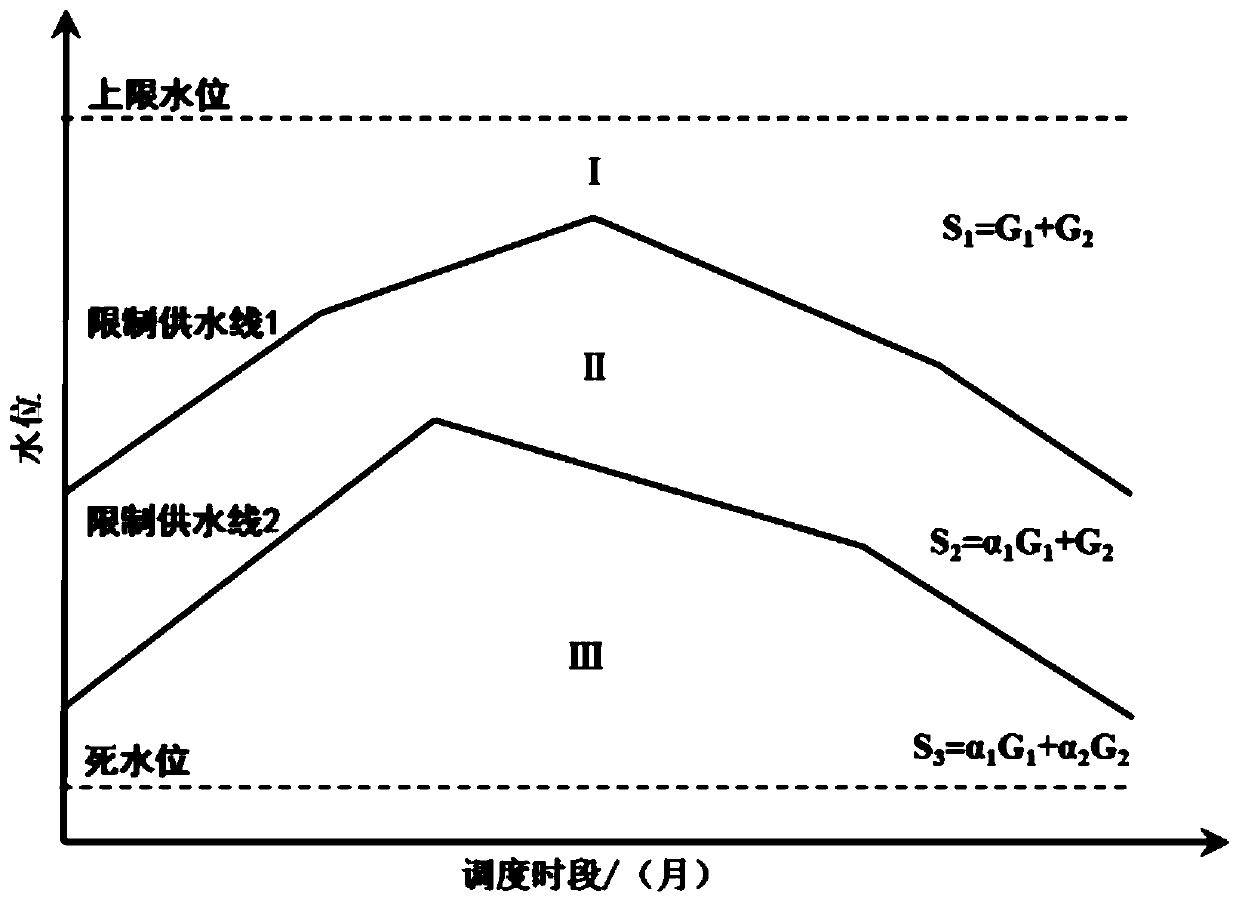

Reservoir scheduling graph drawing method for coupling ensemble forecast information

PendingCN111104750ACharacterize uncertaintyReduce the computational burden of optimal schedulingDrawing from basic elementsDesign optimisation/simulationMulti objective optimization algorithmAlgorithm

The invention discloses a reservoir scheduling graph drawing method for coupling ensemble forecast information, and the method comprises the steps: building a runoff forecast error random simulation model based on an in-reservoir runoff forecast sequence, and generating M in-reservoir runoff sets with certain forecast precision; reducing the M in-reservoir runoff scenes into J (M>>J) representative typical scenes by adopting a synchronous back substitution reduction method, and obtaining corresponding occurrence probabilities; describing the scheduling graph by adopting key control parametersbased on the typical in-reservoir runoff situation and the occurrence probability, and establishing a scheduling graph parameter-simulation-optimization model, namely a multi-objective optimization model; and automatically optimizing the key control parameters of the scheduling graph by adopting a multi-objective optimization algorithm to obtain a Pareto solution set, performing scheme optimization on the Pareto solution set by utilizing a multi-attribute decision-making method, and performing decoding to obtain an optimized scheduling graph. According to the method, the forecast uncertainty can be efficiently coupled in the decision process of the scheduling graph, and meanwhile, the calculation burden is greatly reduced.

Owner:XIAN UNIV OF TECH

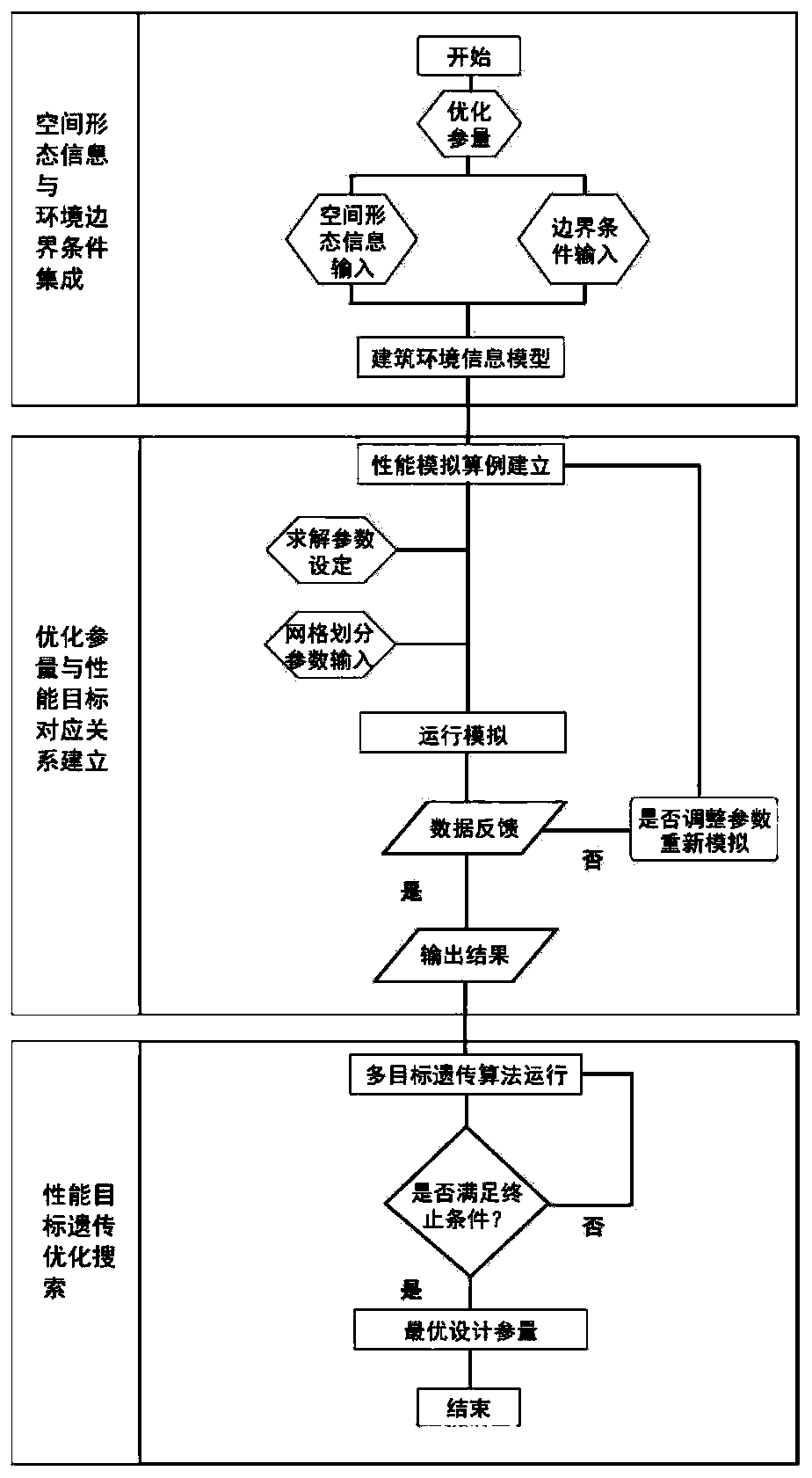

Parameterized design method for natural ventilation of cold region gymnasium building

ActiveCN110532687ARealize visualizationEnergy saving needs fitSpecial data processing applicationsGenetic algorithmsNatural ventilationThermal comfort

The invention relates to a parameterized design method for natural ventilation of a gymnasium building in a cold region. According to the optimization method provided by the invention, natural ventilation parameterized simulation and a multi-objective genetic optimization algorithm are integrated; firstly, CFD performance simulation and a parametric modeling platform are combined, a natural ventilation parametric simulation process and model for a cold region gymnasium building are provided, the complex process of intermediate data conversion is reduced, and the performance simulation efficiency is improved. On the basis, a multi-objective genetic optimization algorithm is utilized to improve the support strength of wind environment simulation to a natural ventilation design decision making process in a gymnasium space form design process. The cold region gymnasium building natural ventilation parameterized simulation optimization design method mainly comprises the steps that buildinggeometrical information and environment boundary condition information are integrated; building a corresponding relation between the building space form optimization parameters and the natural ventilation performance target; and three steps of ventilation and thermal comfort multi-performance target optimization guide search are carried out.

Owner:HARBIN INST OF TECH

Systems and methods for rapid prediction of hydrogen-induced cracking (HIC) in pipelines, pressure vessels, and piping systems and for taking action in relation thereto

Methods and systems of predicting the growth rate of hydrogen-induced cracking (HIC) in a physical asset (e.g., a pipeline, storage tank, etc.) are provided. The methodology receives a plurality of inputs regarding physical characteristics of the asset and performs parametric simulations to generate a simulated database of observations of the asset. The database is then used to train, test, and validate one or more expert systems that can then predict the growth rate and other characteristics of the asset over time. The systems herein can also generate alerts as to predicted dangerous conditions and modify inspection schedules based on such growth rate predictions.

Owner:SAUDI ARABIAN OIL CO

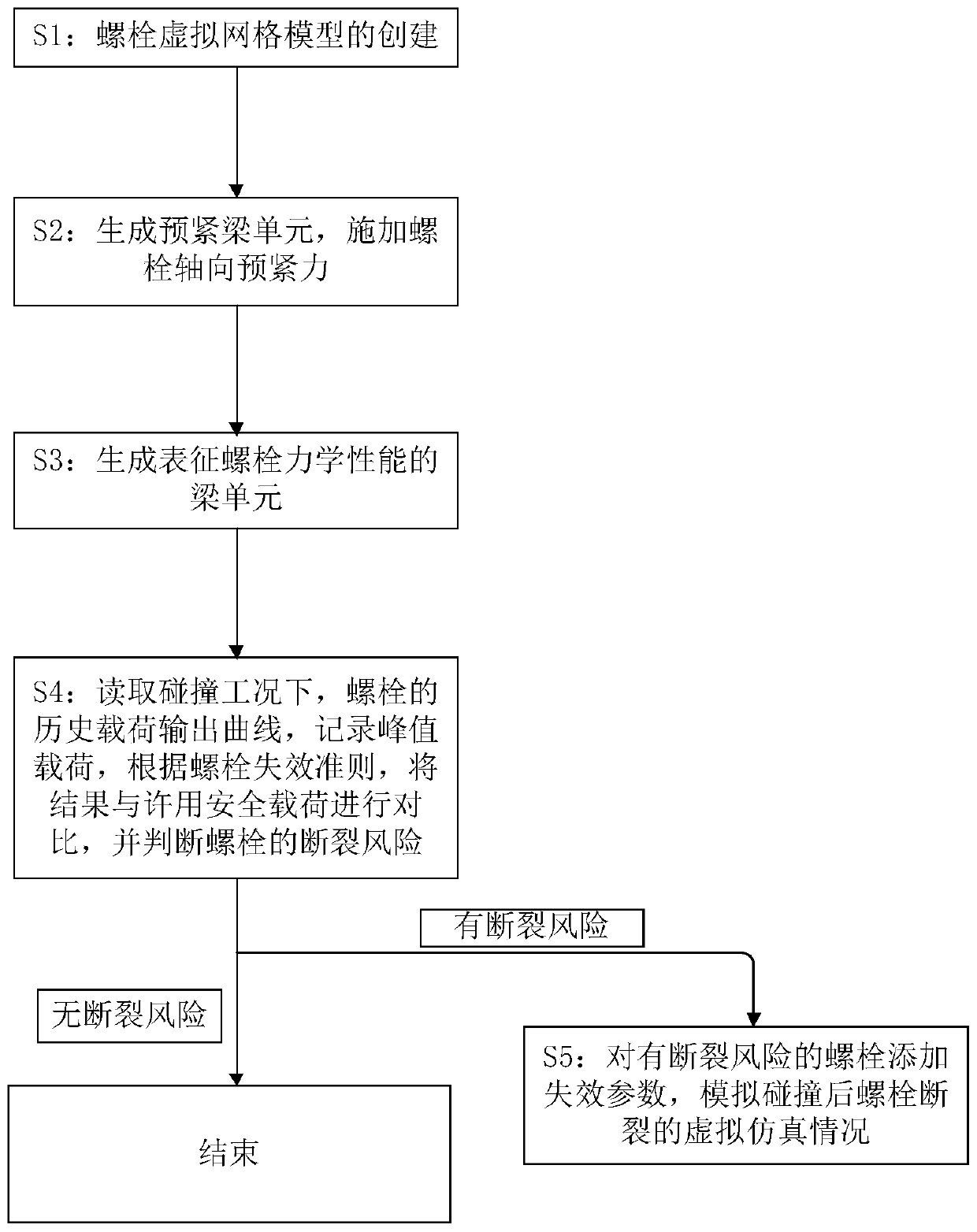

Virtual simulation method for judging bolt breakage under collision working condition

ActiveCN111444654AImprove modeling efficiencyStructural mechanical response is accurateGeometric CADDesign optimisation/simulationSimulationStructural engineering

The invention discloses a virtual simulation method for judging bolt breakage under a collision working condition. The method comprises the following steps: S1, creating a bolt virtual mesh model, S2,generating a pre-tightening beam unit, applying axial pre-tightening force to the bolt; S3, generating a beam unit for representing the mechanical property of the bolt; S4, reading the historical load output curve of the bolt under the collision working condition, comparing a result with an allowable safety load according to a bolt failure criterion, and judging whether the bolt has a fracture risk or not; S5, adding failure parameters to the bolt with the fracture risk, and simulating a virtual simulation condition of bolt fracture after collision. The bolt virtual grid model created by themethod is high in simulation degree, can effectively evaluate whether the bolt is broken or not under the collision working condition, and can also simulate the effect that the broken bolt is separated from the mounting hole.

Owner:CHINA AUTOMOTIVE ENG RES INST

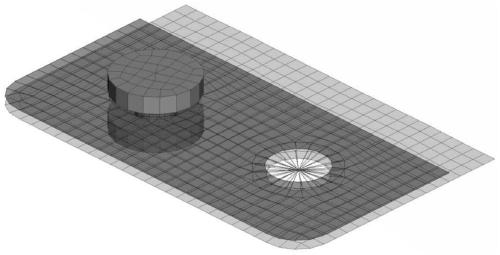

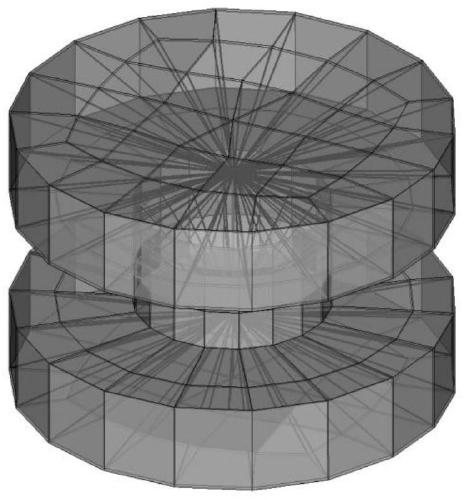

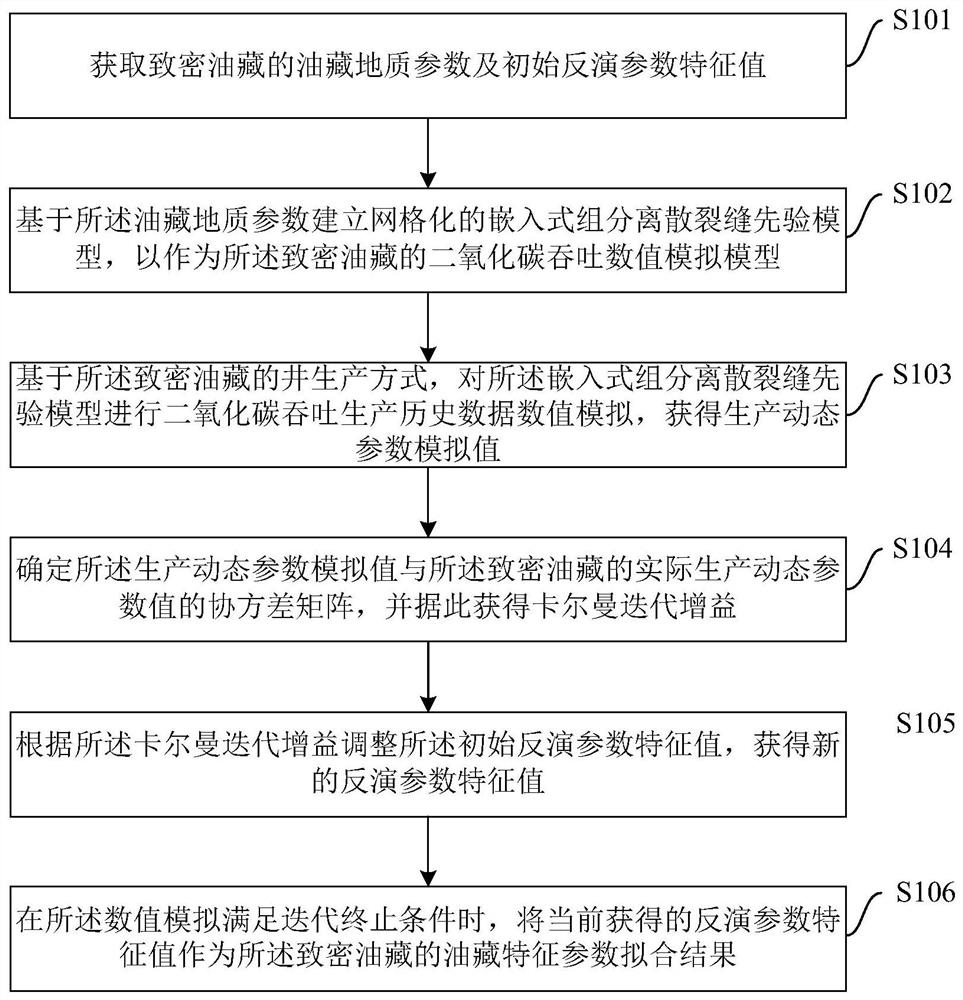

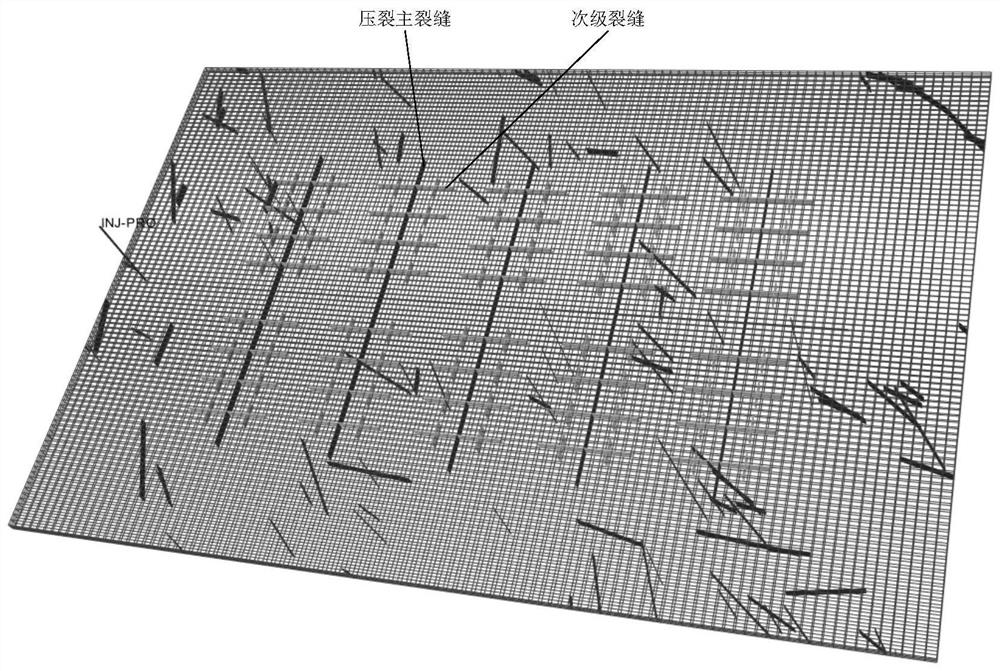

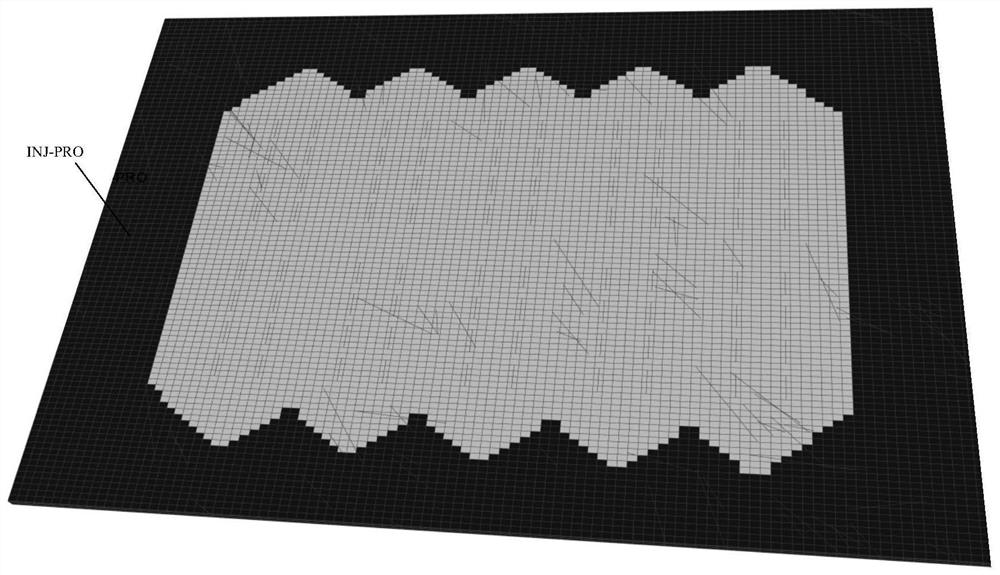

Dense oil carbon dioxide huffing-puffing simulation method and device, and storage medium

PendingCN111677486AHigh degree of fitReduce complexitySurveyOther gas emission reduction technologiesThermodynamicsStatistical physics

The embodiment of the specification provides a dense oil carbon dioxide huffing-puffing simulation method and device, and a storage medium. The method comprises the following steps that a reservoir geological parameter and an initial inversion parameter characteristic value are acquired, and a gridding embedded component discrete crack prior model is established based on the reservoir geological parameter as a carbon dioxide huffing-puffing numerical simulation model; based on a well production mode, the embedded component discrete crack prior model is subjected to carbon dioxide huffing-puffing production historical data numerical simulation, and a production dynamic parameter simulation value is obtained; a covariance matrix of the production dynamic parameter simulation value and an actual production dynamic parameter value is determined, and a Kalman iteration gain is obtained accordingly; the initial inversion parameter characteristic value is adjusted according to the Kalman iteration gain, and a new inversion parameter characteristic value is obtained; and when the numerical simulation meets iteration termination conditions, the currently obtained inversion parameter characteristic value is used as a reservoir characteristic parameter fitting result. The embodiment of the specification can improve accuracy and efficiency of dense oil carbon dioxide huffing-puffing simulation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

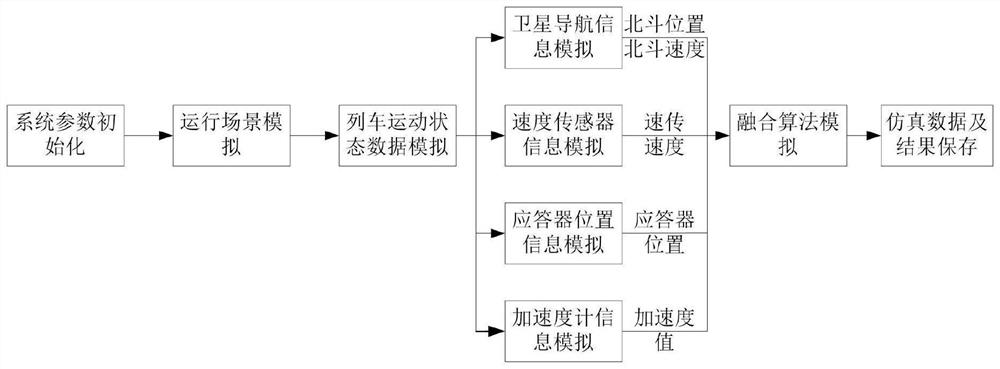

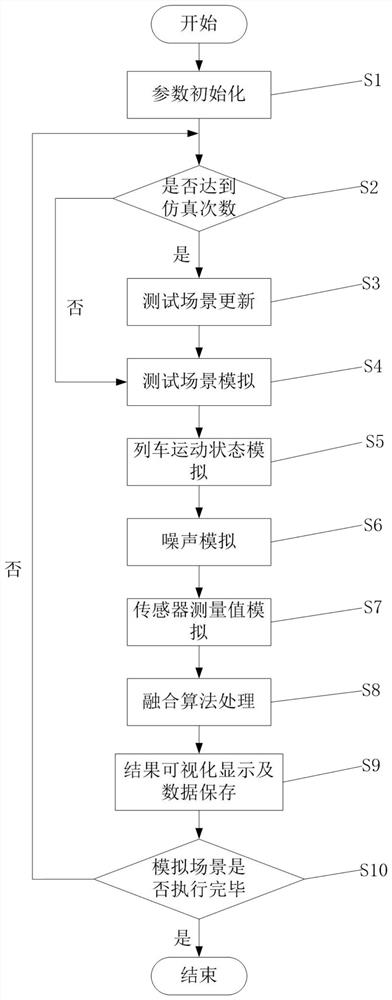

Train positioning analysis method and system based on Monte Carlo simulation

PendingCN114013478AShorten the verification cycleFast iterationRailway traffic control systemsAccelerometerAlgorithm

The invention discloses a train positioning analysis method and system based on Monte Carlo simulation. The method comprises the steps of initializing simulation parameters, simulating an operation scene, simulating train motion state data according to the operation scene, simulating satellite navigation information, speed sensor information, transponder position information and accelerometer information according to the train motion state data, designing a fusion algorithm, and carrying out fusion filtering processing on the simulated satellite navigation information, the speed sensor information, the transponder position information and the accelerometer information, and saving the above simulation data and results. According to the method, the test data are generated through simulation software without depending on hardware equipment, preliminary testing is carried out when system functions are not completed, the verification period of a positioning algorithm is greatly shortened, and rapid iteration of the train positioning algorithm is facilitated.

Owner:CASCO SIGNAL +1

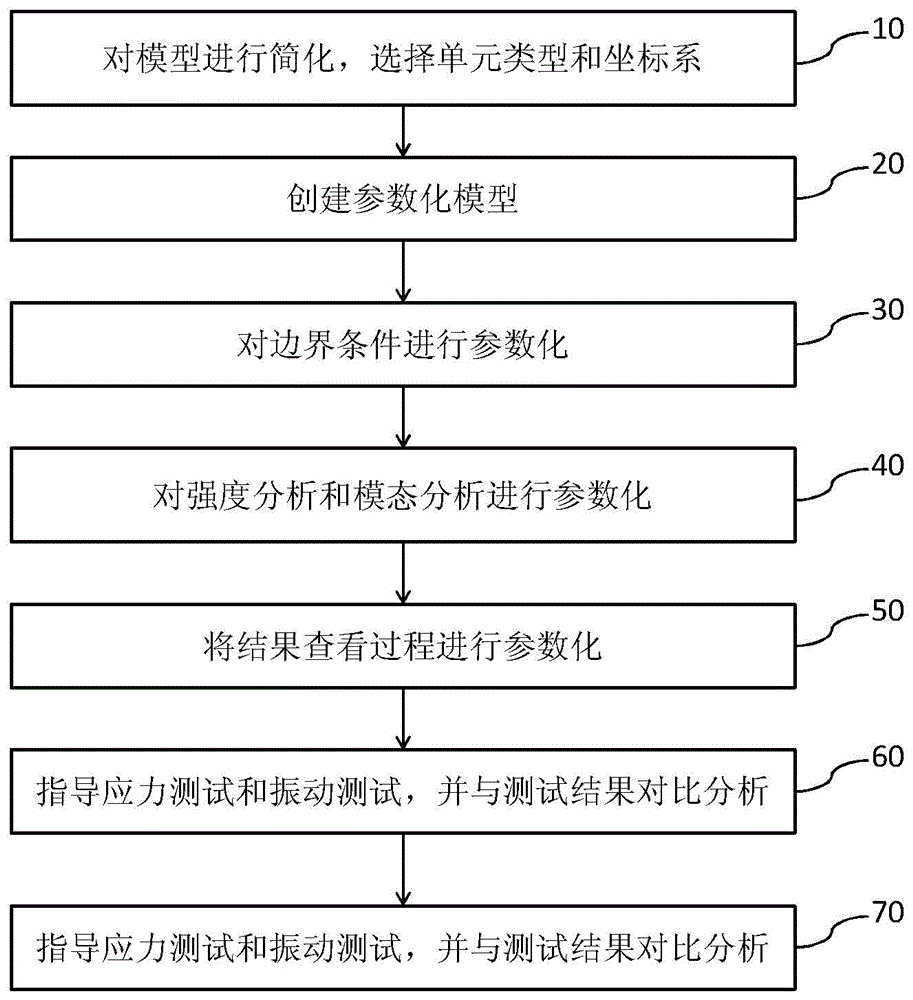

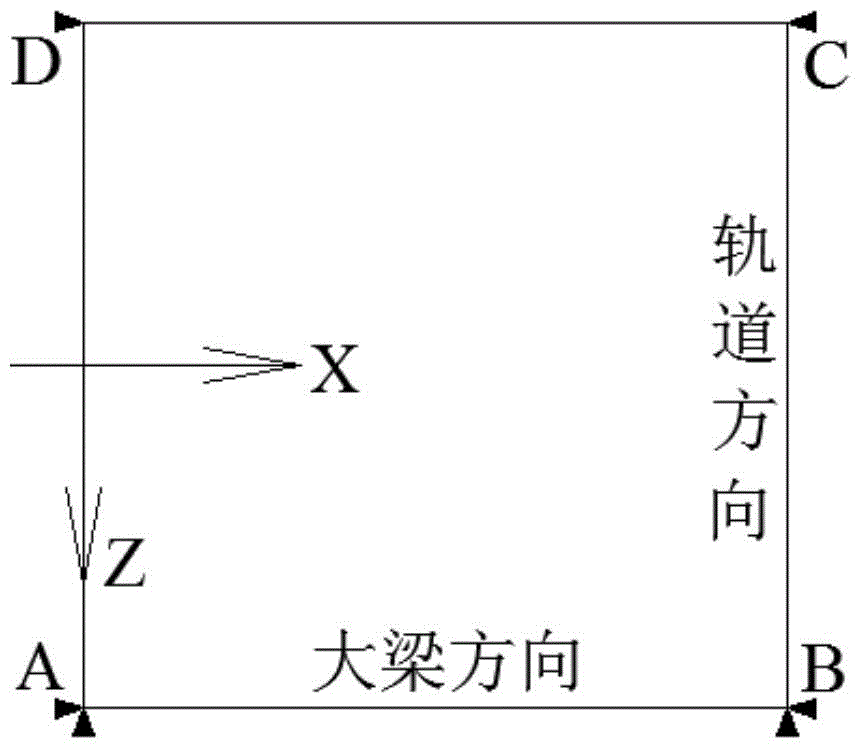

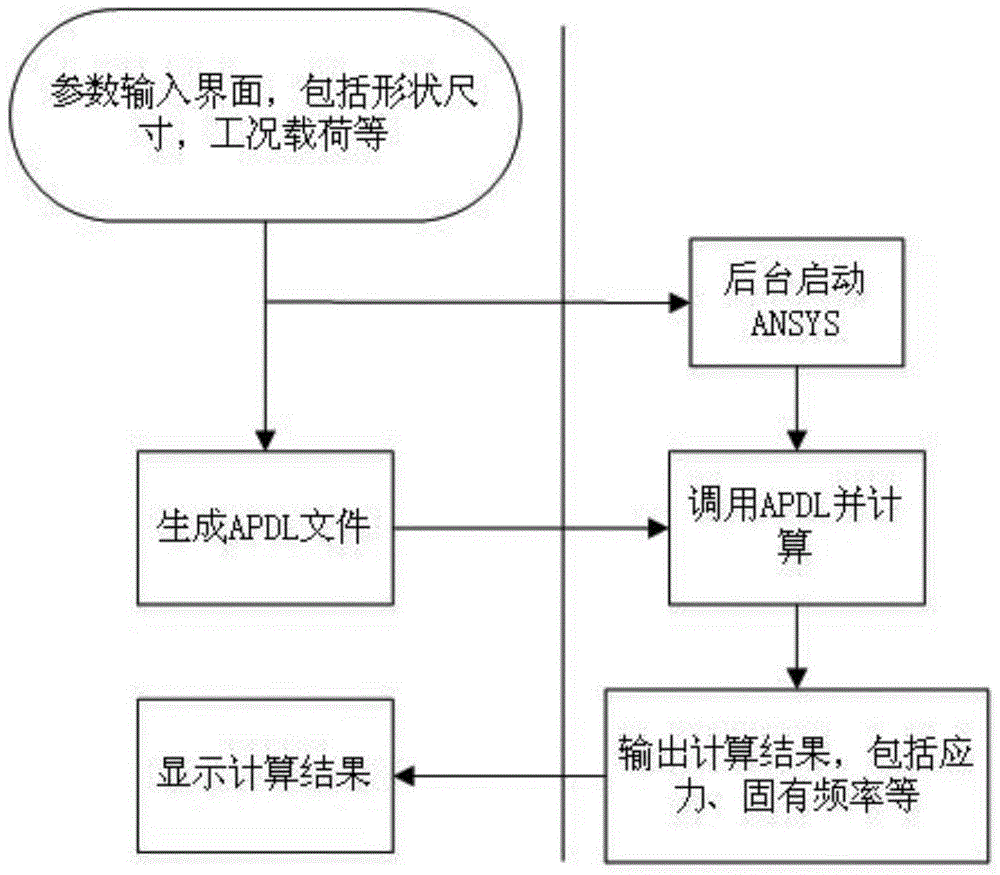

Application method of parametric simulation in safety assessment of bridge grab ship unloader

InactiveCN104915526AFast simulation analysisSimulation analysis is accurateSpecial data processing applicationsEngineeringModal analysis

The invention discloses an application method of parametric simulation in safety assessment of a bridge grab ship unloader. The method comprises the following steps: simplifying a model, and selecting a unit type and a coordinate system; creating a parameterized model; parameterizing boundary conditions; parameterizing intensity analysis and modal analysis, and parameterizing a result viewing process; guiding a stress test and a vibration test according to the intensity analysis and the modal analysis, and comparatively analyzing an intensity analysis result, a modal analysis result and a stress test result respectively; and building a parametric simulation analysis system for the bridge grab ship unloader. According to the practical demand on the safety assessment of the bridge grab ship unloader, a VB development tool is combined with a parameterization technology of ANSYS, and modeling, the boundary conditions, an analysis process, result viewing and the like are parameterized with the parameterization technology to develop a set of parametric simulation analysis system for the bridge grab ship unloader, so that simulation analysis has the characteristics of high speed, accuracy, high practicability and the like.

Owner:GUANGZHOU SPECIAL MECHANICAL & ELECTRICAL EQUIP INSPECTION & RES INST

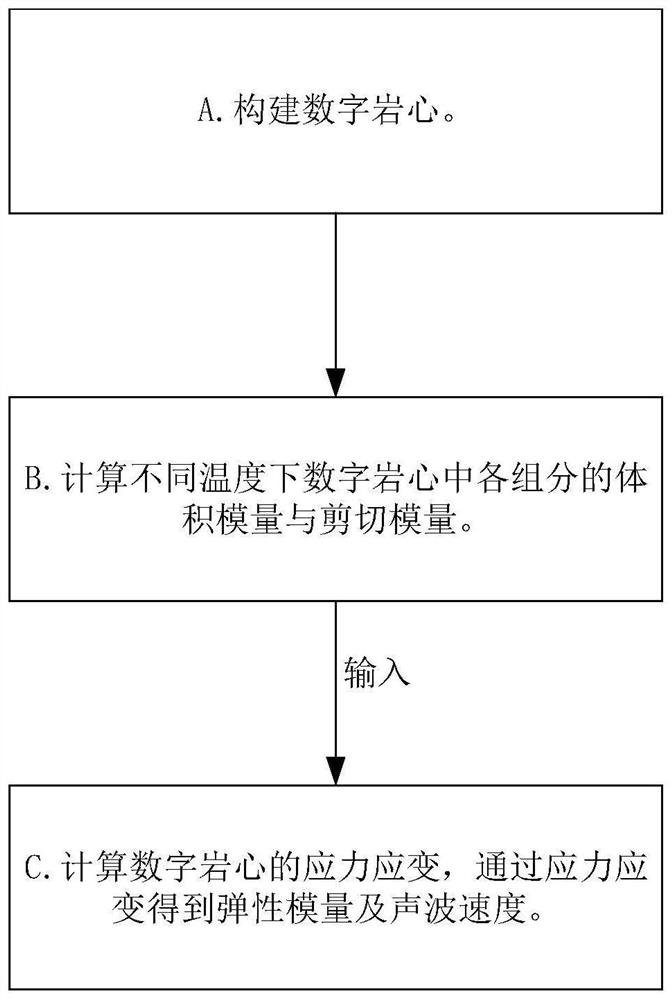

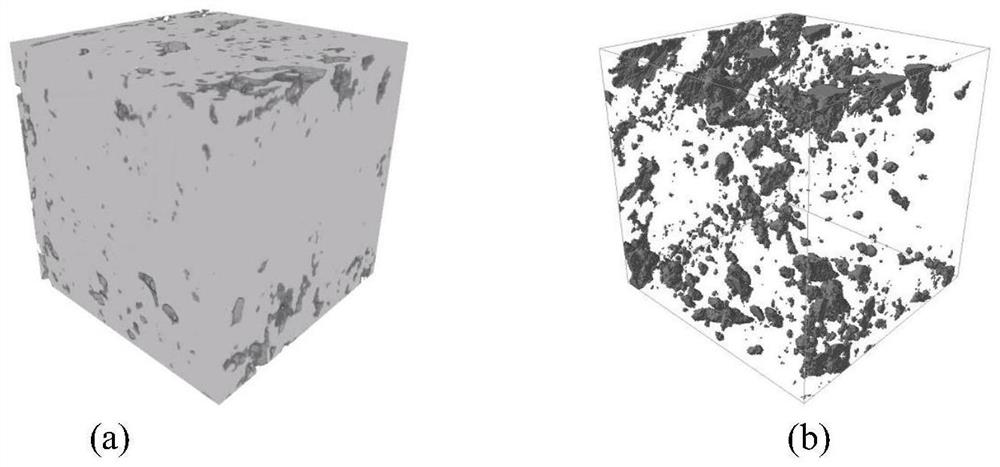

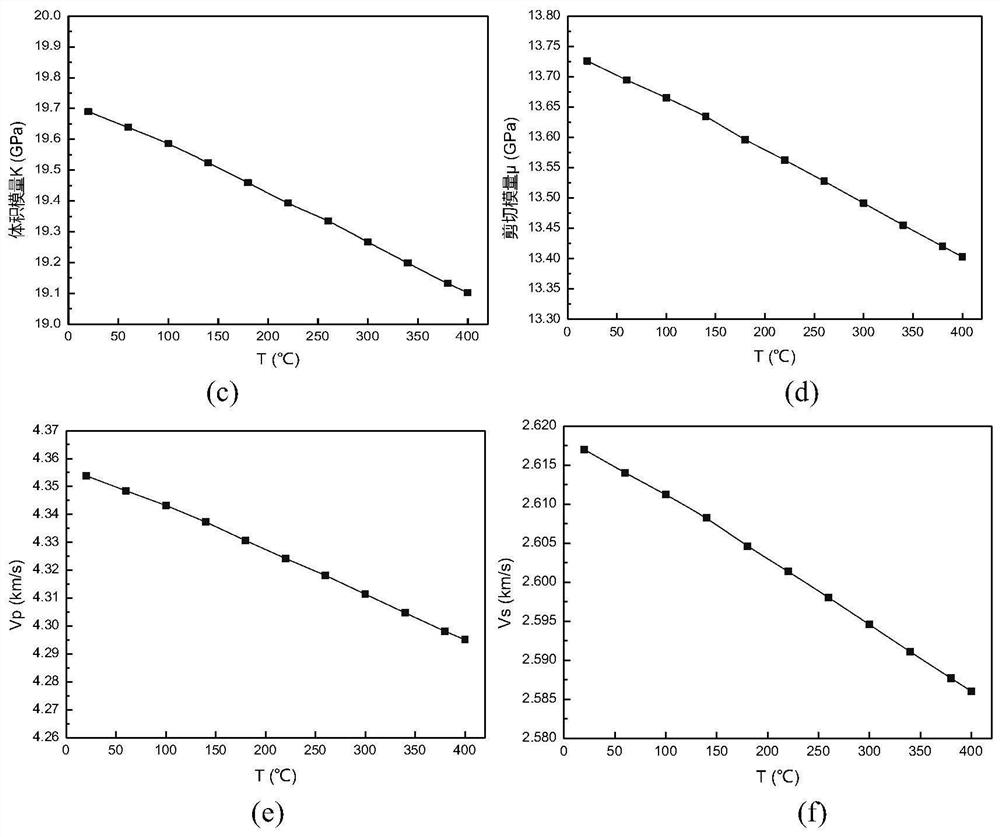

Digital rock core acoustic characteristic analysis method at different temperatures

PendingCN111680440AHigh resolutionDesign optimisation/simulationSpecial data processing applicationsShear modulusRock core

The invention relates to the technical field of petrophysics, in particular to a rock acoustic characteristic analysis method based on a digital rock core. The invention discloses a digital rock coreacoustic characteristic analysis method at different temperatures. The method comprises the following steps: A, constructing a multi-component three-dimensional digital rock core; B, calculating the bulk modulus and shear modulus of each component in the digital rock core at different temperatures; and C, calculating the stress-strain of the digital rock core by taking the result obtained in the step B as an input parameter, and obtaining the elastic modulus and the sound wave speed through the stress-strain. According to the invention, the construction of the high-resolution digital rock coreis realized, the relationship between the elasticity modulus and the temperature is constructed, and a digital rock core acoustic parameter simulation method at different temperatures is developed. By simulating the elasticity modulus and the sound wave speed of the rock core at different temperatures, the change rule of the temperature on the acoustic characteristics and the electrical characteristics of the rock is analyzed.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com