Three-branch series connection type hypersonic wind tunnel overall structure

A technology of hypersonic speed and overall structure, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., which can solve the problems of difficult heater design, difficult troubleshooting, and high cost, and avoid electromagnetic radiation and noise interference Effects on test equipment and personnel, reduction of damage to personnel, and low workload for equipment replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]According to an embodiment of the present invention,

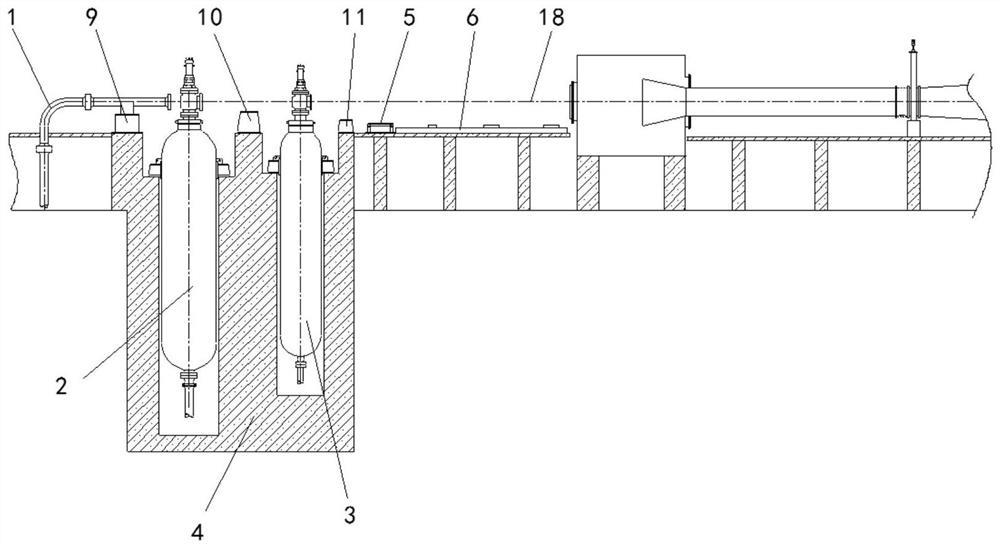

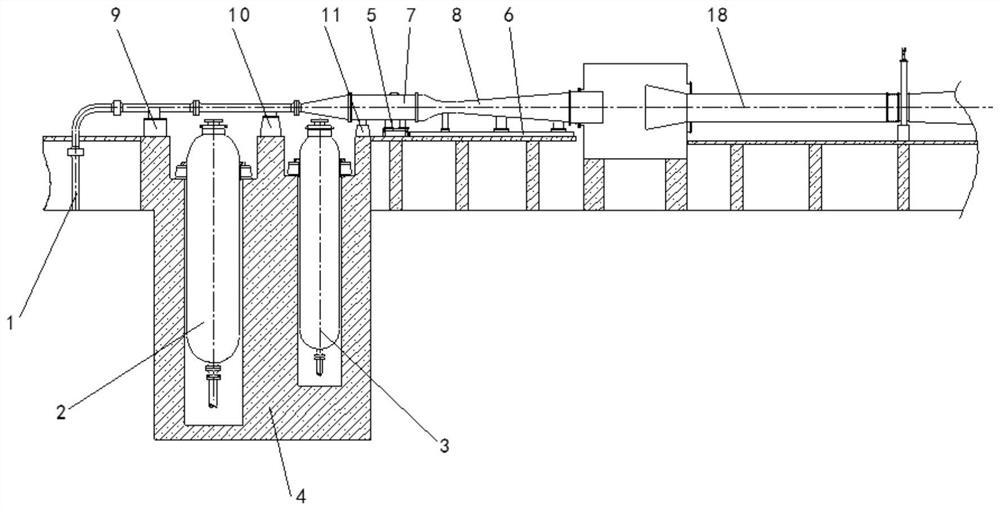

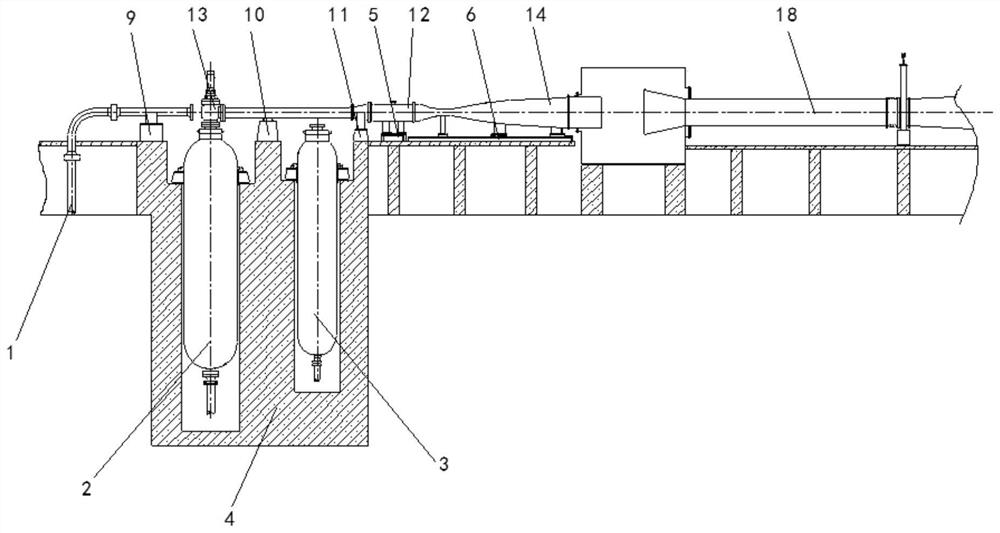

[0035]SeeFigure 1-5A three-way radial high ultrasound speed wind tunnel, including the branch of the high ultrasonic velocity of machon simulation range 3 to 10 into three intervals, and three of the branches are large flow low pressure cold air branches. Road 1, large flow medium temperature medium pressure branch 2 and medium and medium flow high temperature high pressure branch 3, the mass operating range of the large flow low-voltage cooling branch 1 is less than or equal to Mach 4, the large flow medium temperature medium voltage branch 2 Mach number of Mach is more than 4 less than or equal to 7, the medium-small flow high temperature high pressure branch 3 is greater than 7 less than or equal to 10, the large flow low pressure cold air branch 1, large flow medium temperature medium voltage branch Road 2 and medium-speed high-temperature high-temperature high-voltage branch 3 shared one main equipment factory and scient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com