Patents

Literature

35results about How to "Reduce the difficulty of construction work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

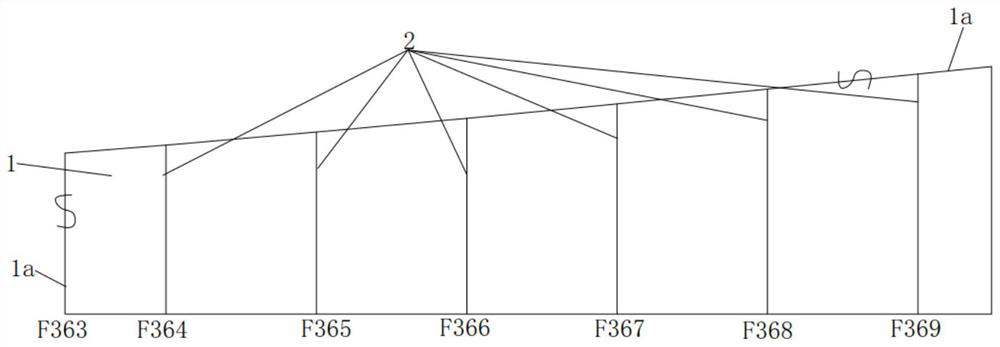

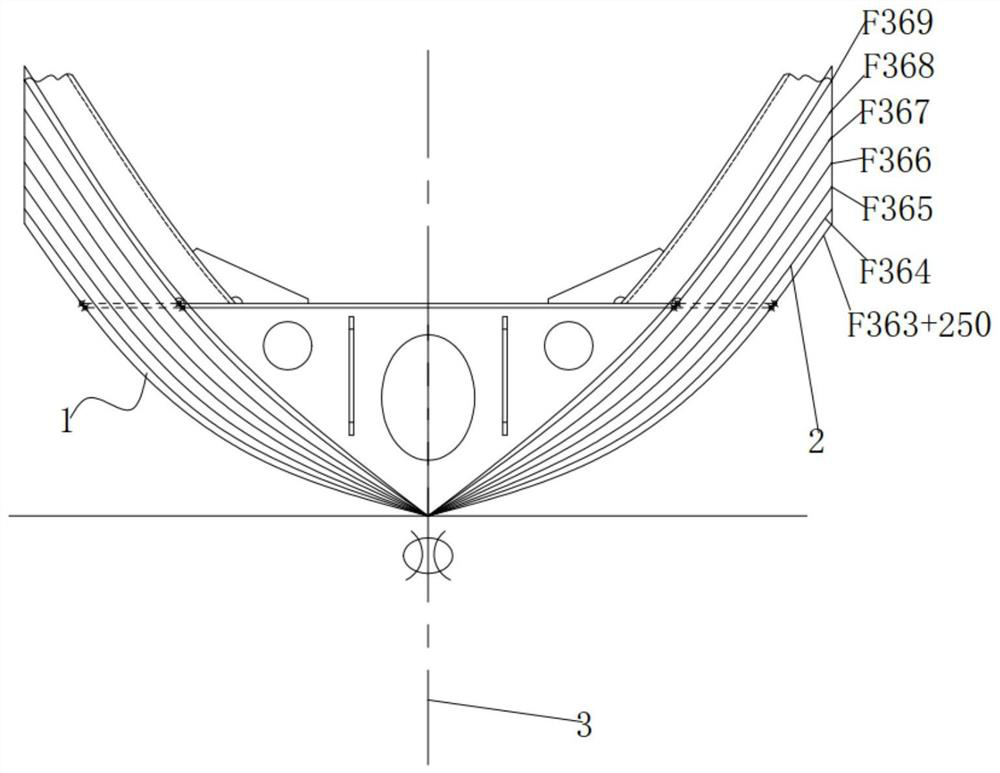

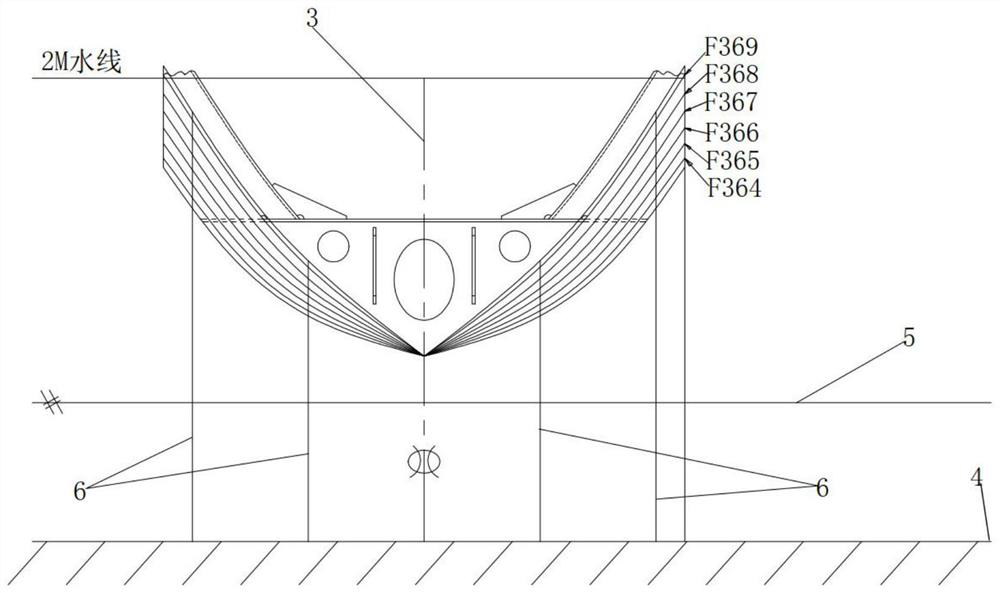

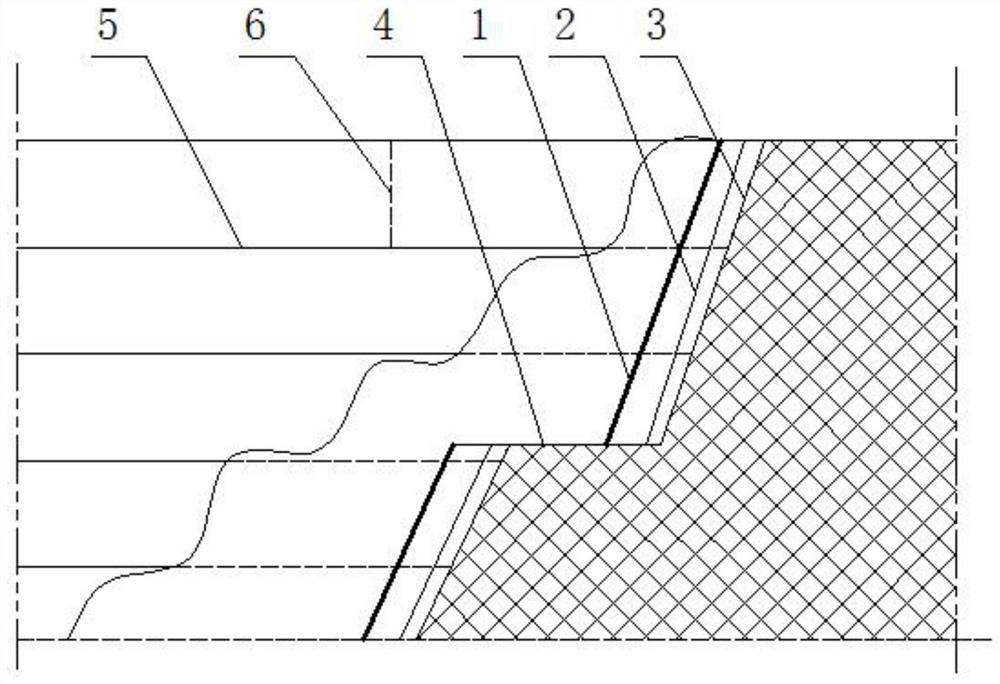

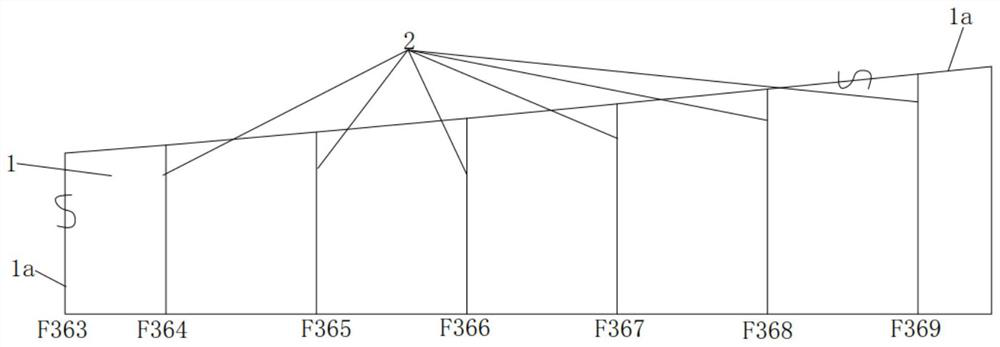

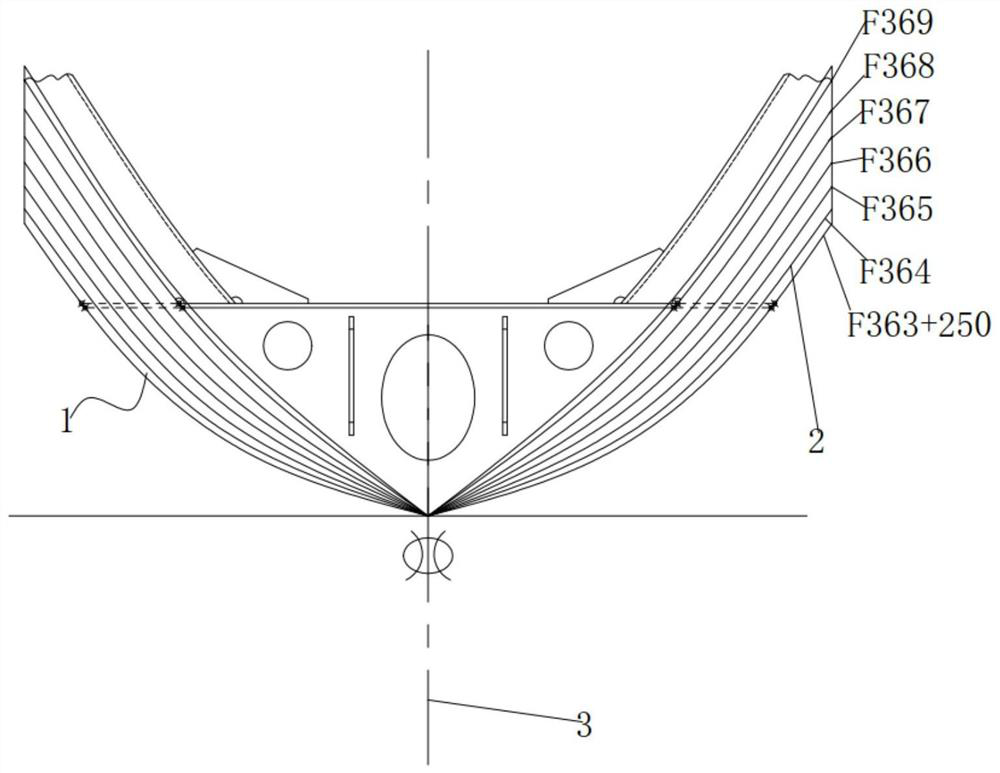

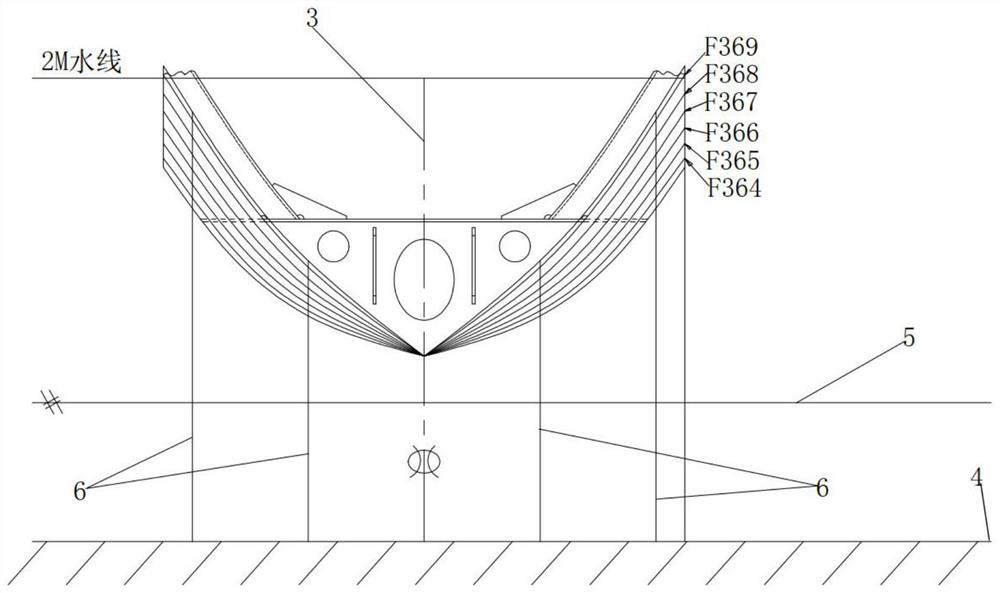

Normal construction method of ship bow section outer plate

ActiveCN113148062AImprove construction efficiencyHigh precisionWatercraft hull designHull stemsFloor planMechanical engineering

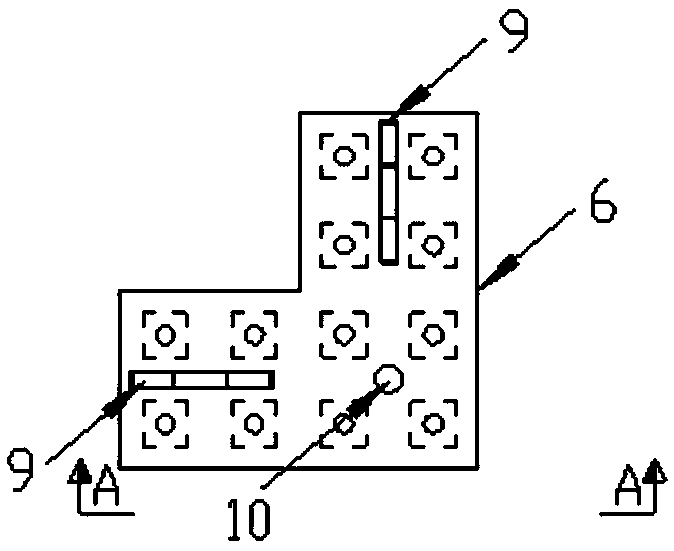

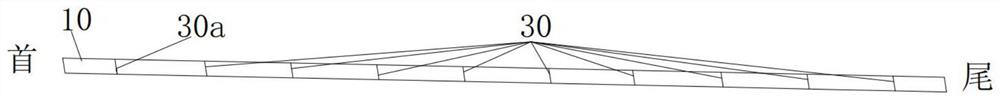

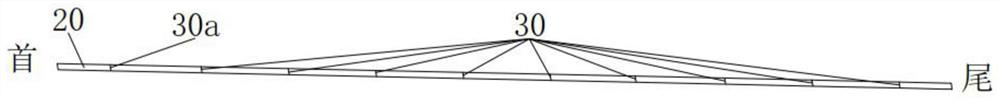

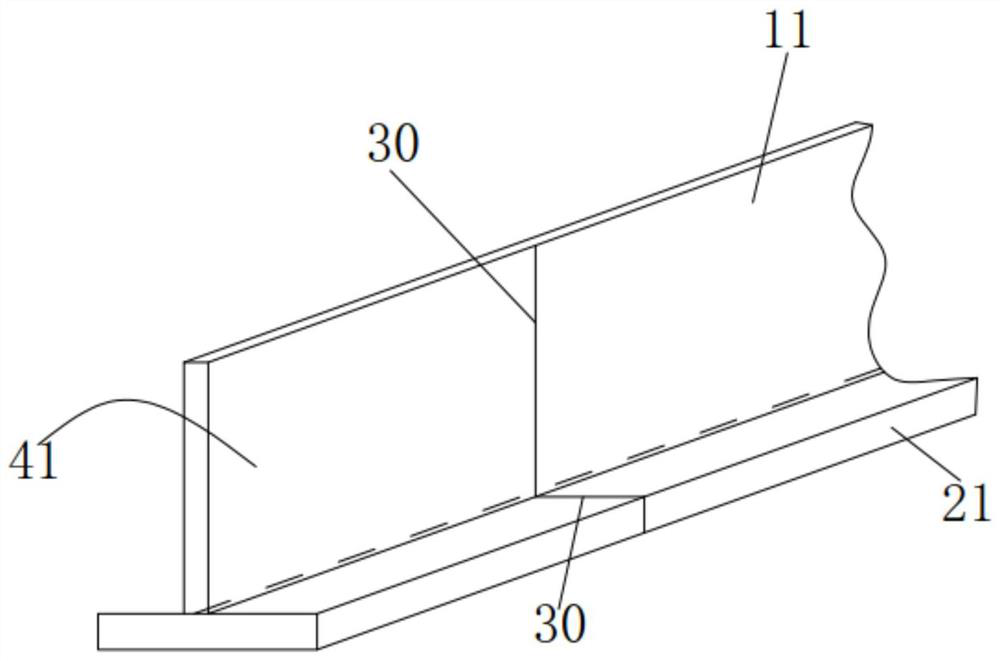

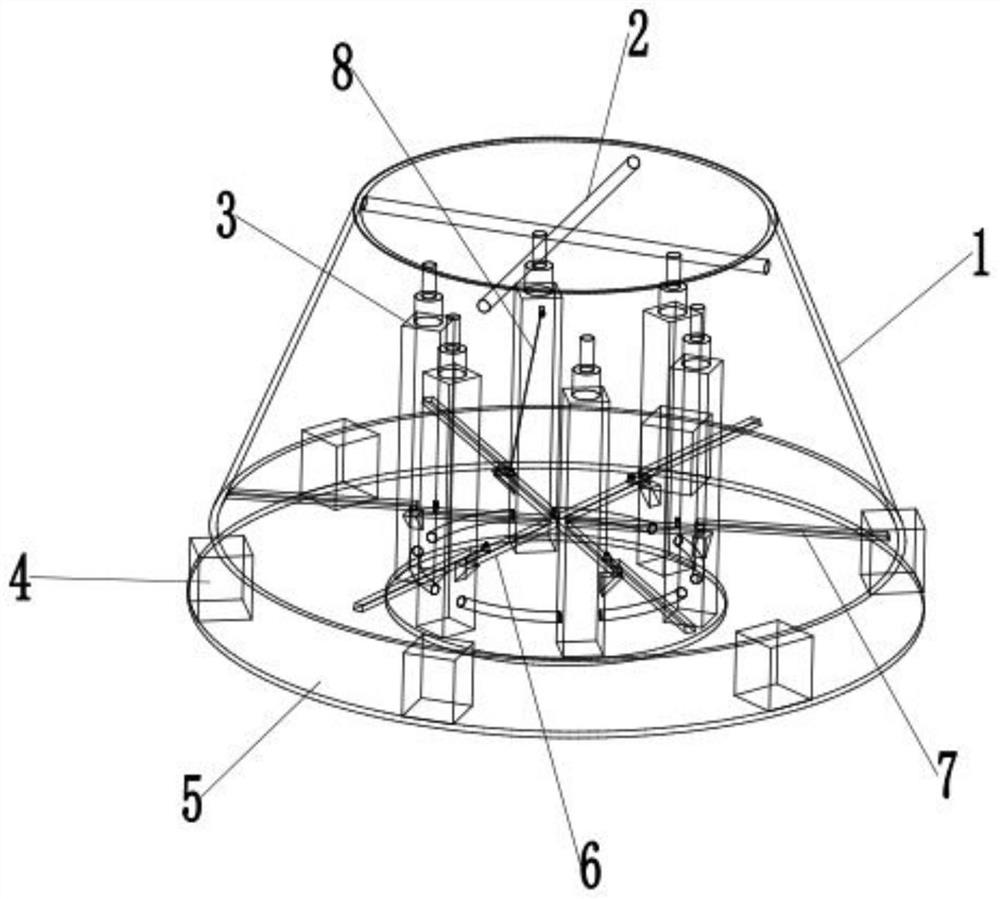

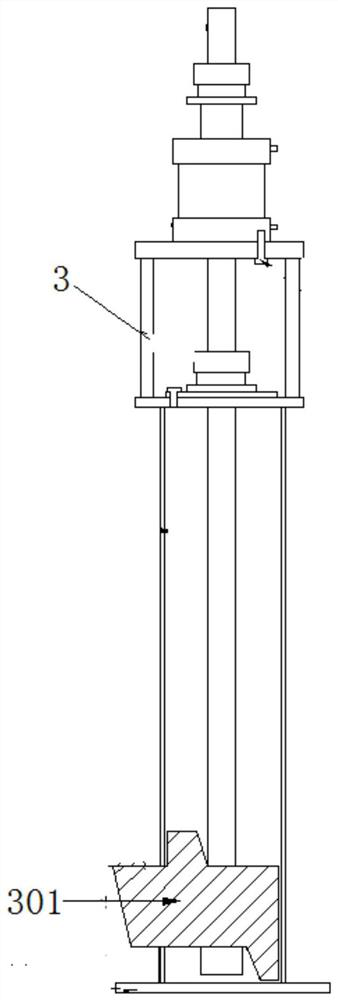

The invention provides a normal construction method of a ship bow section outer plate. The normal construction method comprises the steps that S1, a side view and a cross section view of the bow section outer plate and a rib molded line on a main ship body are made; s2, obtaining a cross section drawing of the jig frame; s3, obtaining a cross section drawing of each rib jig frame template; s4, machining each rib jig frame template; s5, a jig frame field operation plane graph is obtained; s6, the stand column is machined; s7, processing an outer plate; s8, the machined rib jig frame formworks and the corresponding stand columns are subjected to small assembly installation, rib formwork frames are obtained, and all the obtained rib formwork frames are hoisted to the jig frame ground; s9, hoisting an outer plate; the jig frame formworks are built according to the curvature of each rib molded line on the outer plate, it is guaranteed that the working faces of the jig frame formworks are tightly attached to the outer surface of the outer plate, and the supporting stability during operation is guaranteed; in addition, a normal building mode is adopted, turning-over operation of a traditional reverse building mode is avoided, and the construction efficiency and the construction quality are improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

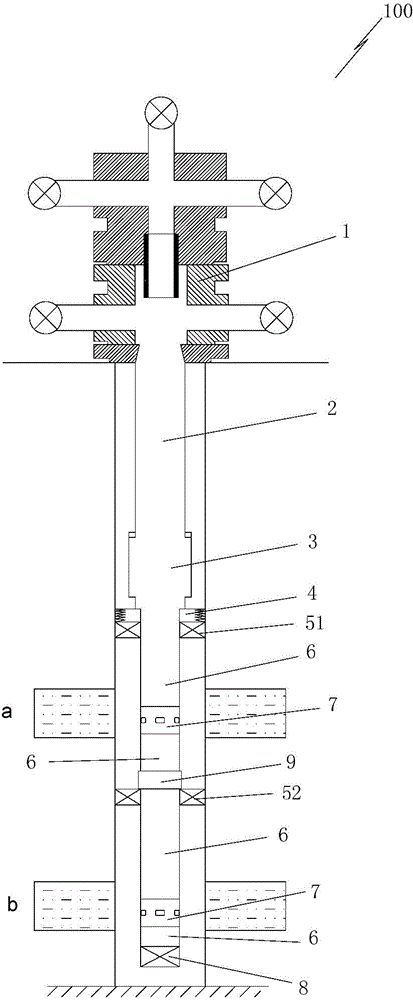

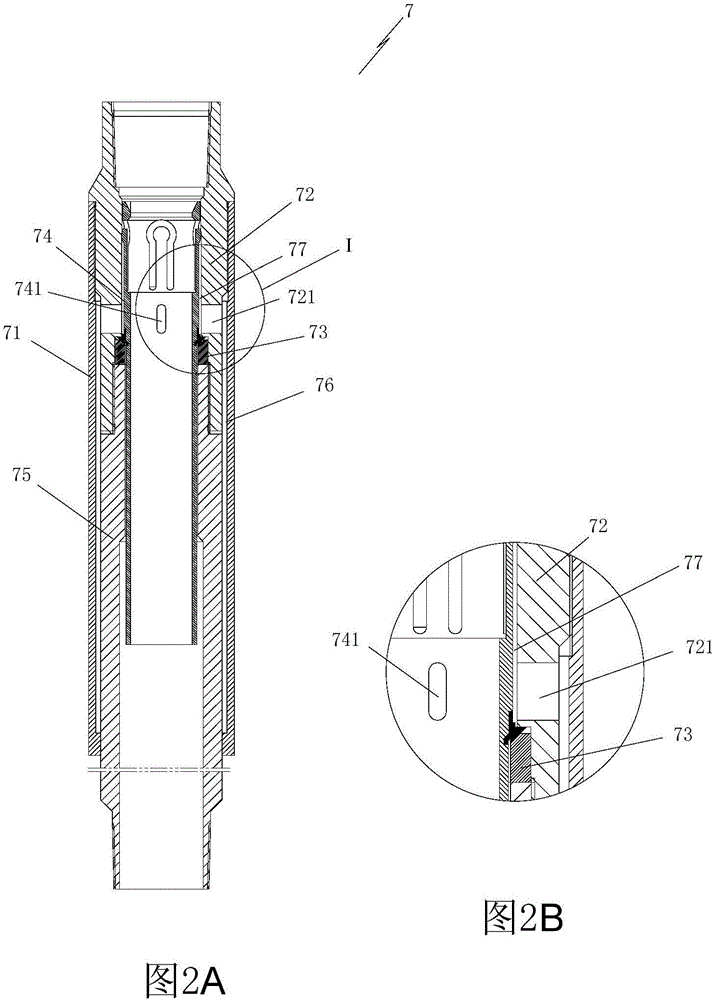

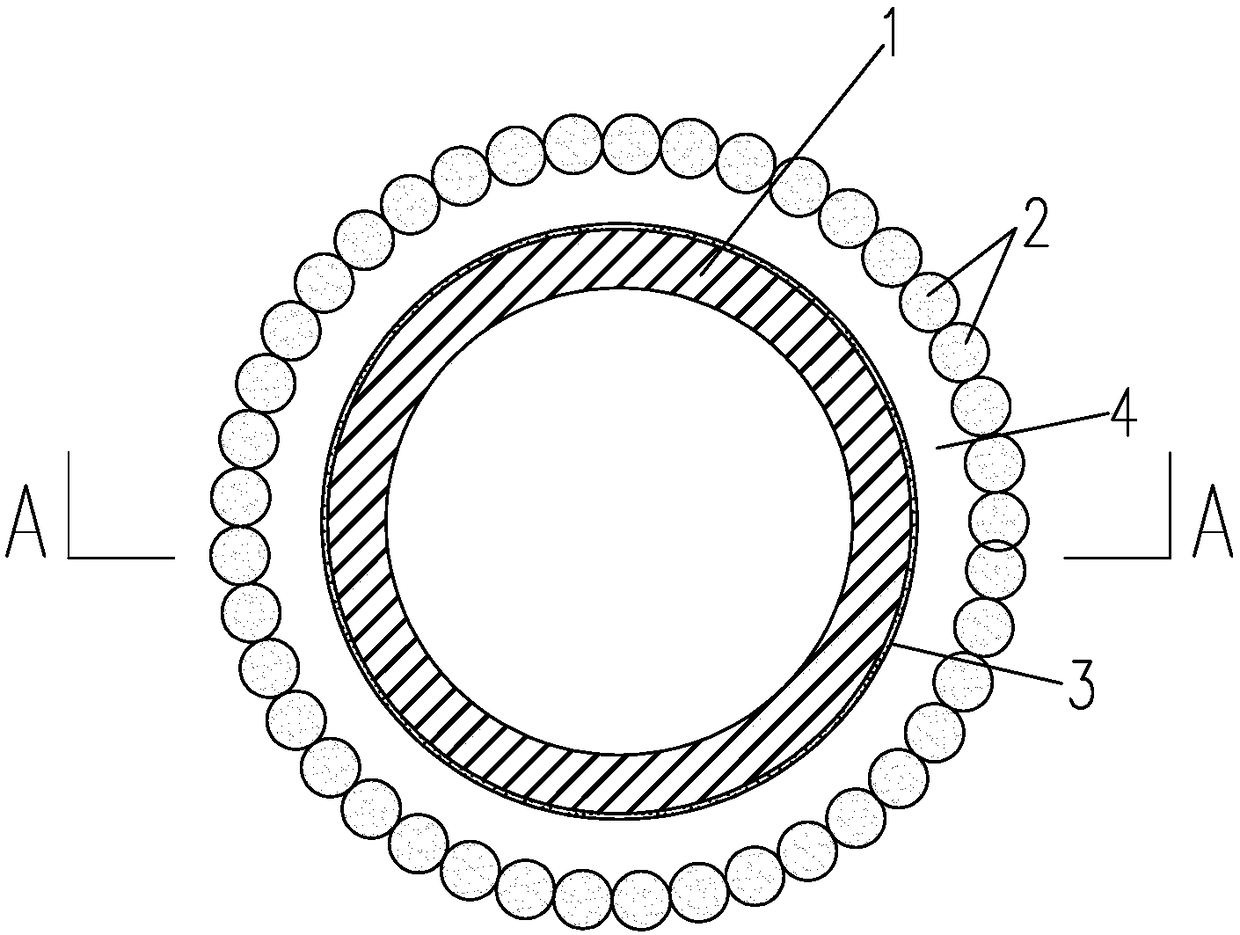

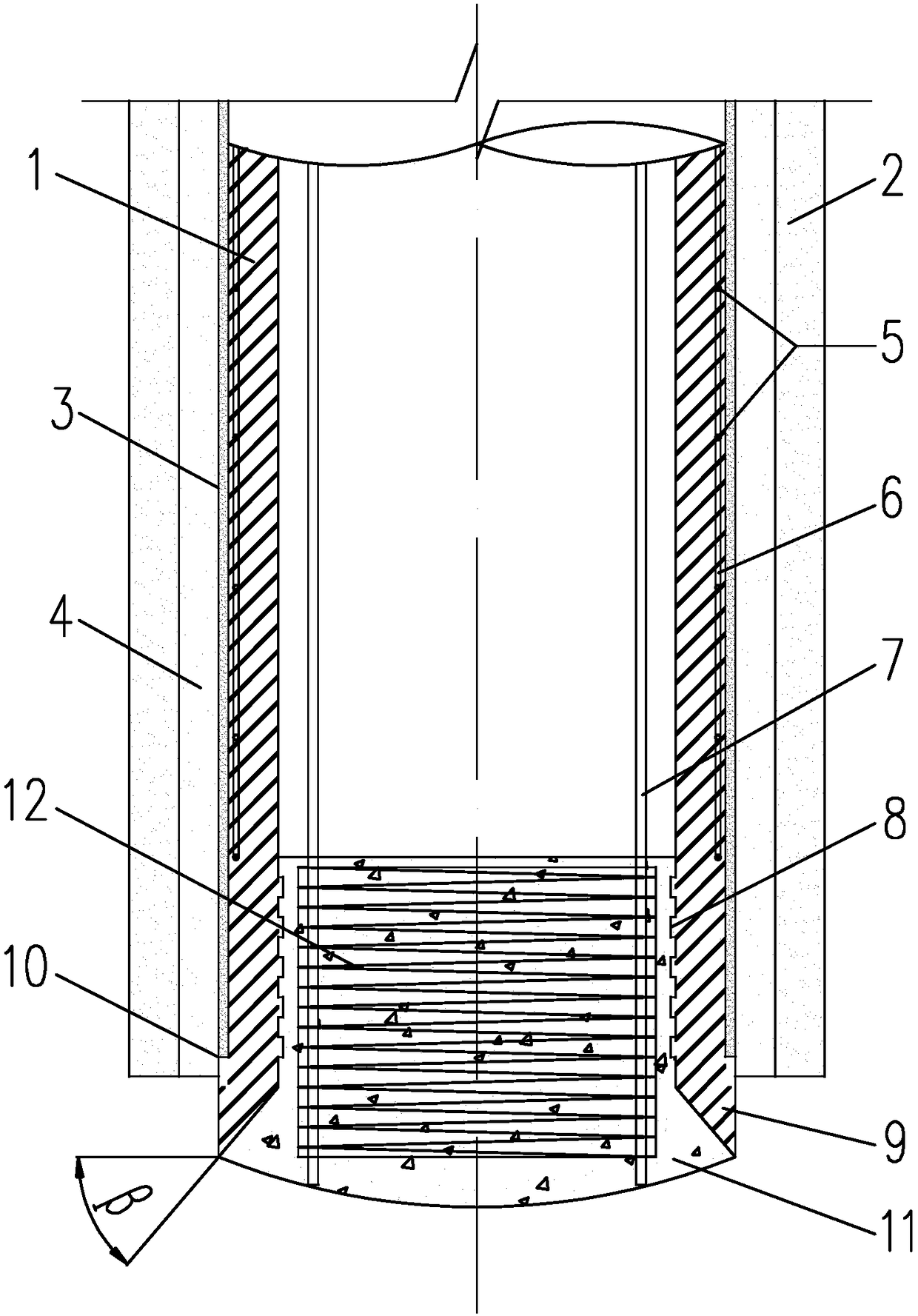

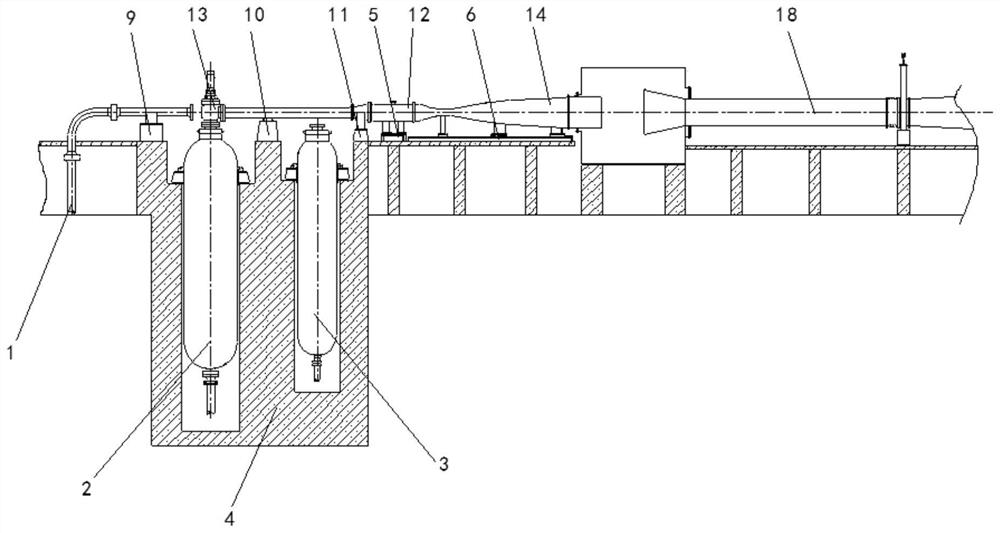

Hollow layering steam injecting system

The invention discloses a hollow layering steam injecting system. An heat preservation oil pipe is connected below a well head device; the lower end of the heat preservation oil pipe is connected with a telescopic pipe; the lower end of the telescopic pipe is connected with a steam distributing pipe column part; the steam distributing pipe column part comprises an anchor, an oil pipe, packers, an oil pipe releaser and a hollow steam injecting valve; the anchor is positioned at the uppermost end of the steam distributing pipe column part; the lower end of the telescopic pipe is connected with the anchor; in the steam distributing pipe column part, a top packer is arranged above a top oil layer, and is connected to the lower end of the anchor; a middle packer is arranged in a gap of adjacent two oil layers; the oil pipe, the hollow steam injecting valve and the oil pipe releaser are connected between adjacent two packers; and the lower end of the middle packer above a lowermost oil layer is connected with the oil pipe, the hollow steam injecting valve, the oil pipe and a plug. The hollow layering steam injecting system can preferably release thermal stress of a pipe column, is more accurate and effective in steam injecting effect, prevents the steam injecting valve from scaling to block a steam injecting channel, and increases the inner diameter of the pipe column for convenient dropping and fishing.

Owner:PETROCHINA CO LTD

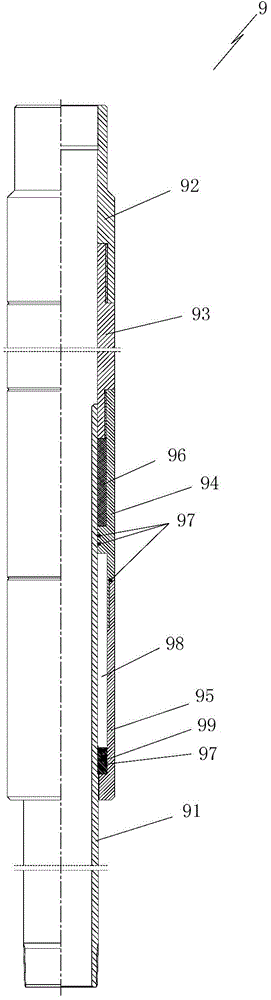

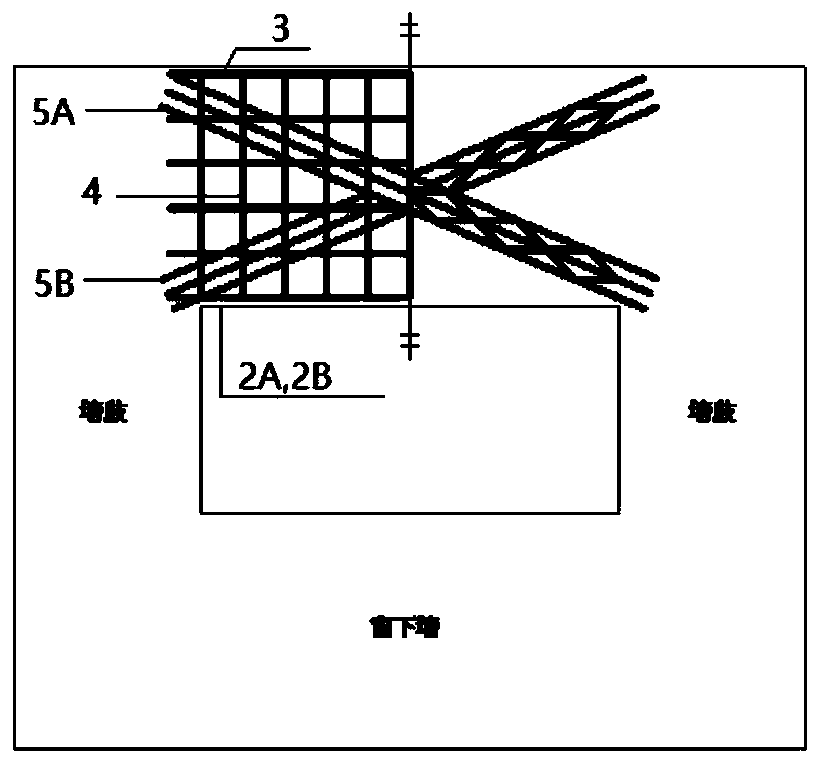

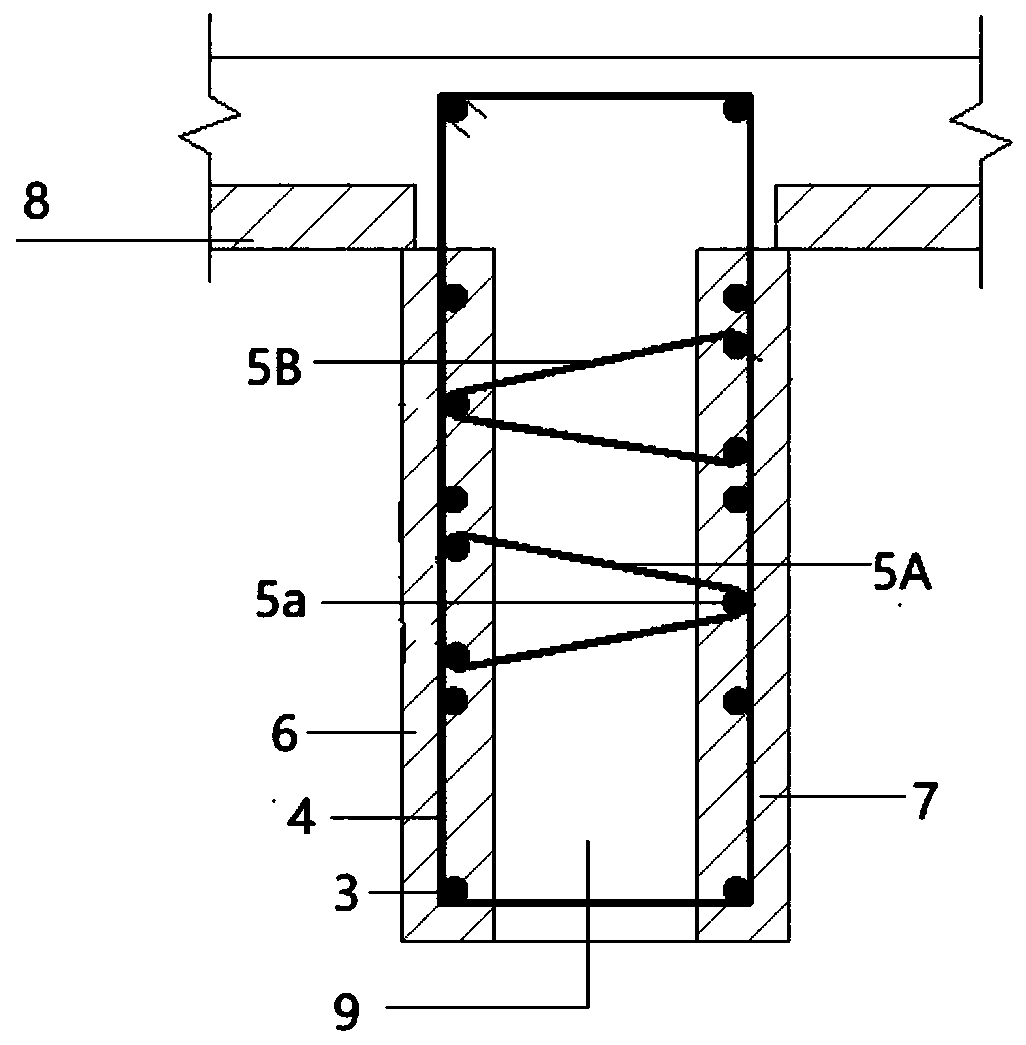

Pipe pile-anchor rod composite foundation capable of bearing pulling and pressing bidirectional loads and construction technology

InactiveCN105350531AReduce the "crowding effect"Low costBulkheads/pilesStructural reliabilityErosion

The invention provides a pipe pile-anchor rod composite foundation capable of bearing pulling and pressing bidirectional loads and a construction technology of the pipe pile-anchor rod composite foundation. The pipe pile-anchor rod composite foundation comprises a pipe pile and an anchor rod. An anchoring hole is reserved in a foundation bottom plate of a building structure, and a stretching end anchorage device is pre-buried in the anchoring hole. The anchor rod is composed of an anchor cable and a prefabricated anchor head, and the prefabricated anchor head is buried in soil below the foundation bottom plate. The upper end of the anchor cable penetrates out of the pipe pile to stretch into the anchoring hole, and is locked by the stretching end anchorage device after being stretched. The pipe pile is supported between the foundation bottom plate and the prefabricated anchor head, and the lower end of the pipe pile is fixedly connected with the upper end of the prefabricated anchor head. In the pipe pile-anchor rod composite foundation, the prefabricated anchor head is additionally arranged at the lower end of the pipe pile so that the pressure resisting bearing capacity of the pipe pile can be improved; a waterproof curtain is formed by the pipe pile with the two closed ends, the erosion effect of underground water and the like on concrete and steel can be resisted, and the impermeability and durability of the anchor rod, the pipe pile and foundation bottom plate joints can be improved; and structural reliability and stress performance are ensured, meanwhile, project quality can be effectively improved, the construction period can be shortened, and the investment can be saved.

Owner:葛建

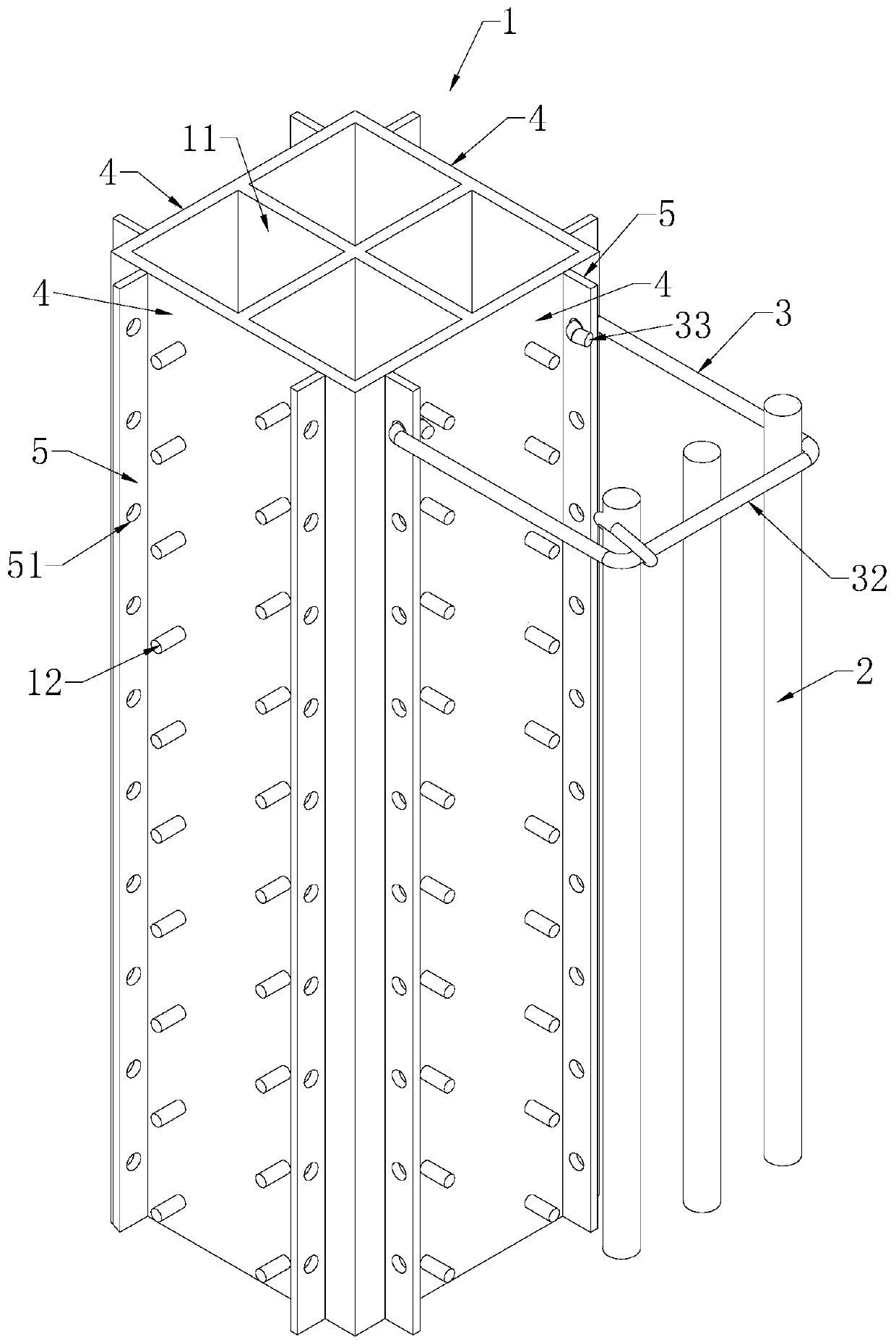

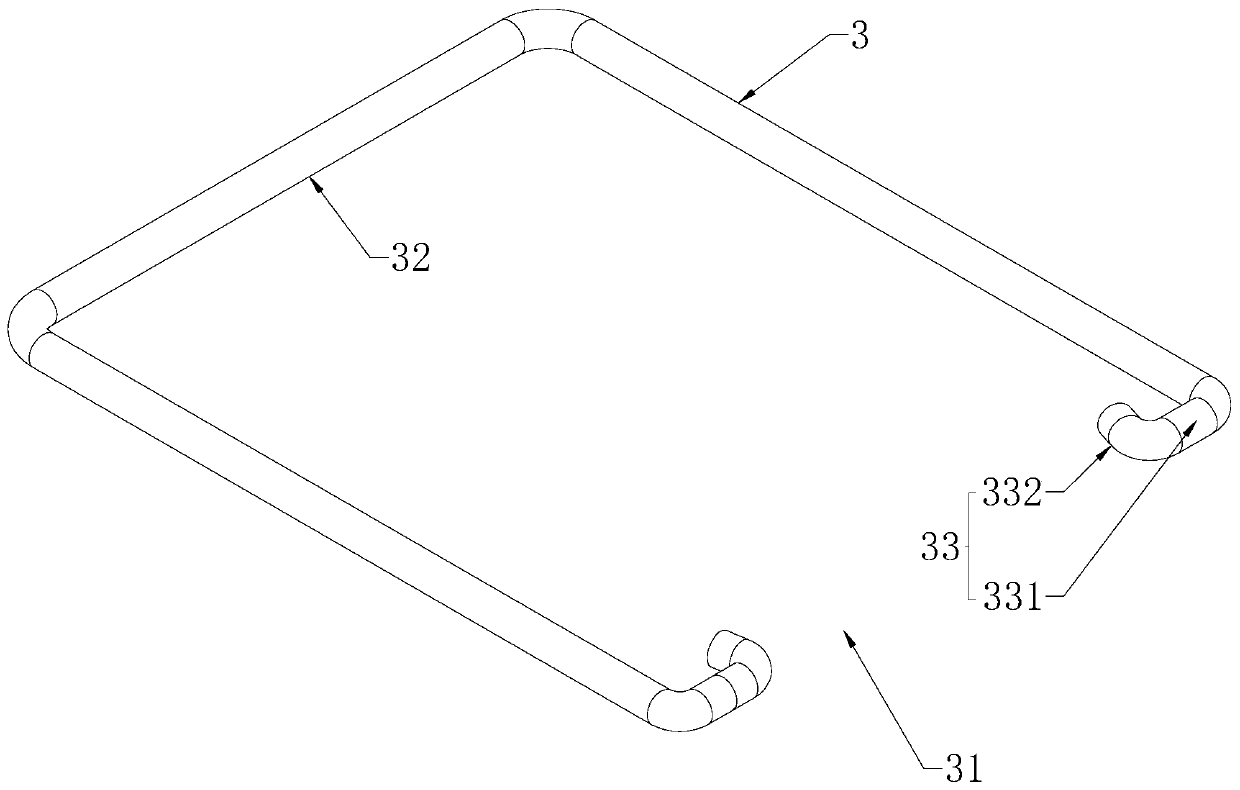

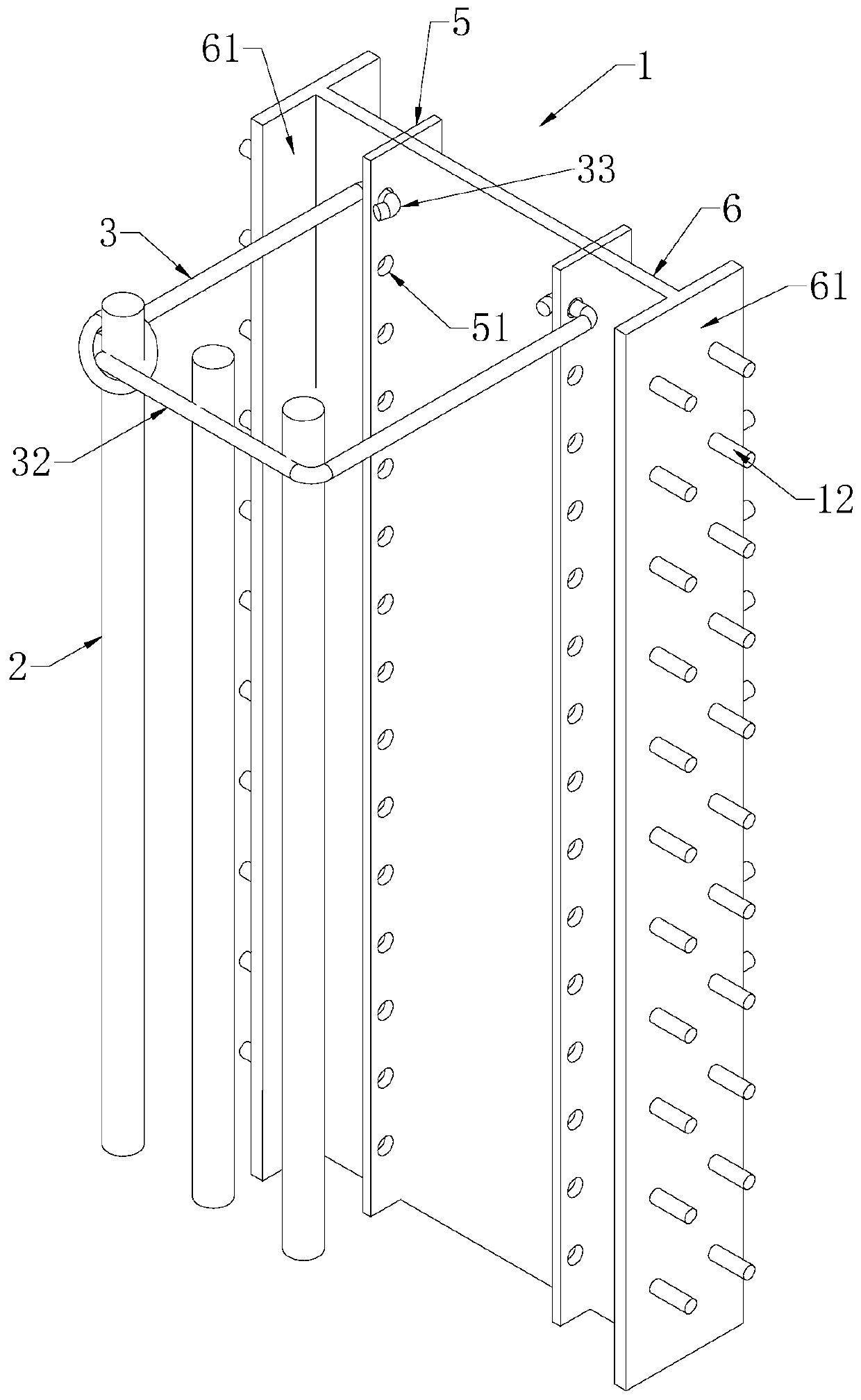

Connecting structure and construction method of steel ribs and hoops of steel rib concrete structure column

InactiveCN111139972AFast constructionReduce construction costsStrutsBuilding reinforcementsRebarSteel columns

The invention discloses a connecting structure and construction method of steel ribs and hoops of a steel rib concrete structure column and relates to the technical field of steel rib concrete structure column construction. The BIM technology is used for establishing data models of profile steel rib columns, longitudinal reinforcing steel bars and the hoops, and meanwhile, the size and the positions of hoop connecting boards and the hole diameter and the forming positions of run-through holes are determined; and binding, buckling and fixing operation of the hoops, the profile steel rib columnsand the longitudinal reinforcing steel bars is finished on the site. In the hoop connection construction process of the profile steel concrete structure column, the longitudinal hoop connecting boards are welded to profile steel column webs, the hoops are buckled to the hoop connecting boards, web perforation and hoop welding construction are not needed, construction operation efficiency can be improved, the profile steel web section loss ratio can be reduced, hoop connection reliability can be guaranteed, the profile steel stress performance is improved, meanwhile, cost can be saved, a construction period can be shortened, and construction operation difficulty and construction personnel labor intensity are reduced.

Owner:THE FIRST CONSTR CO LTD OF CHINA CONSTR FIRST GRP +1

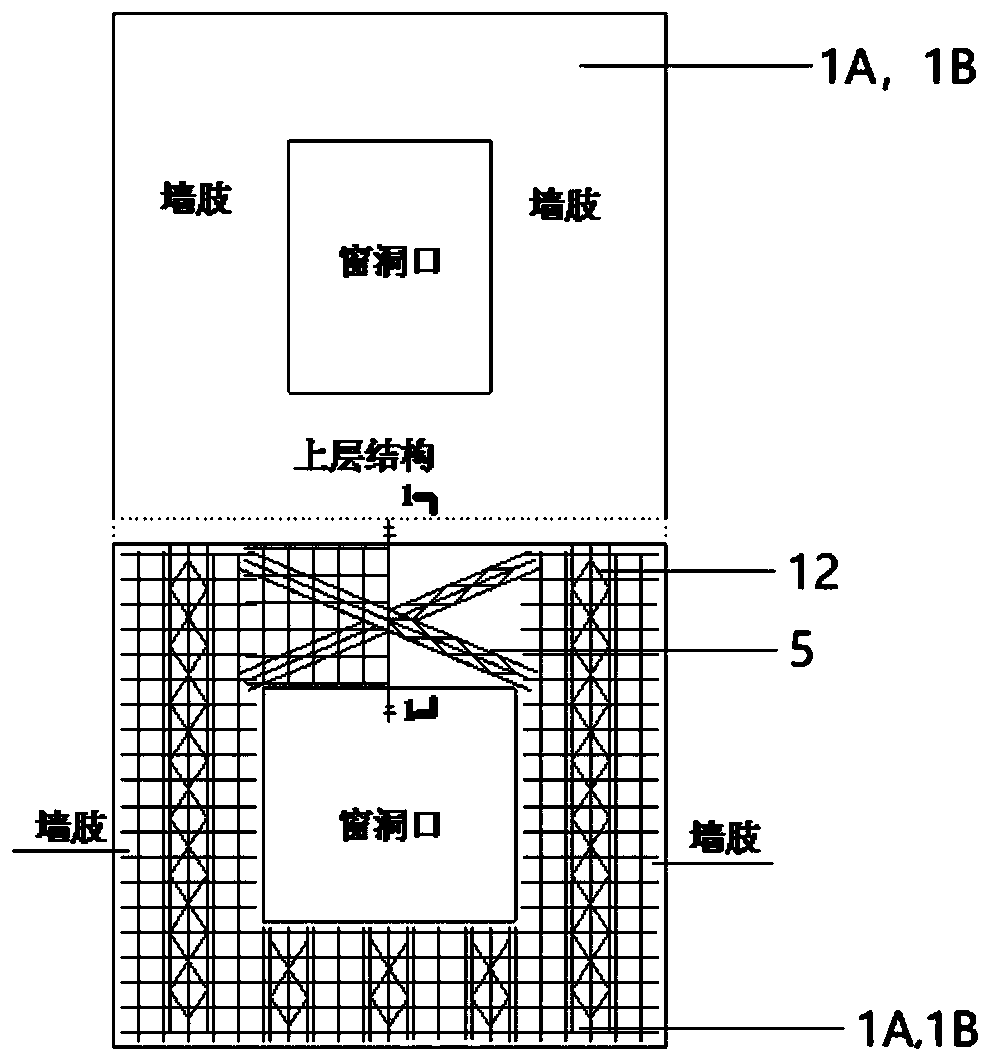

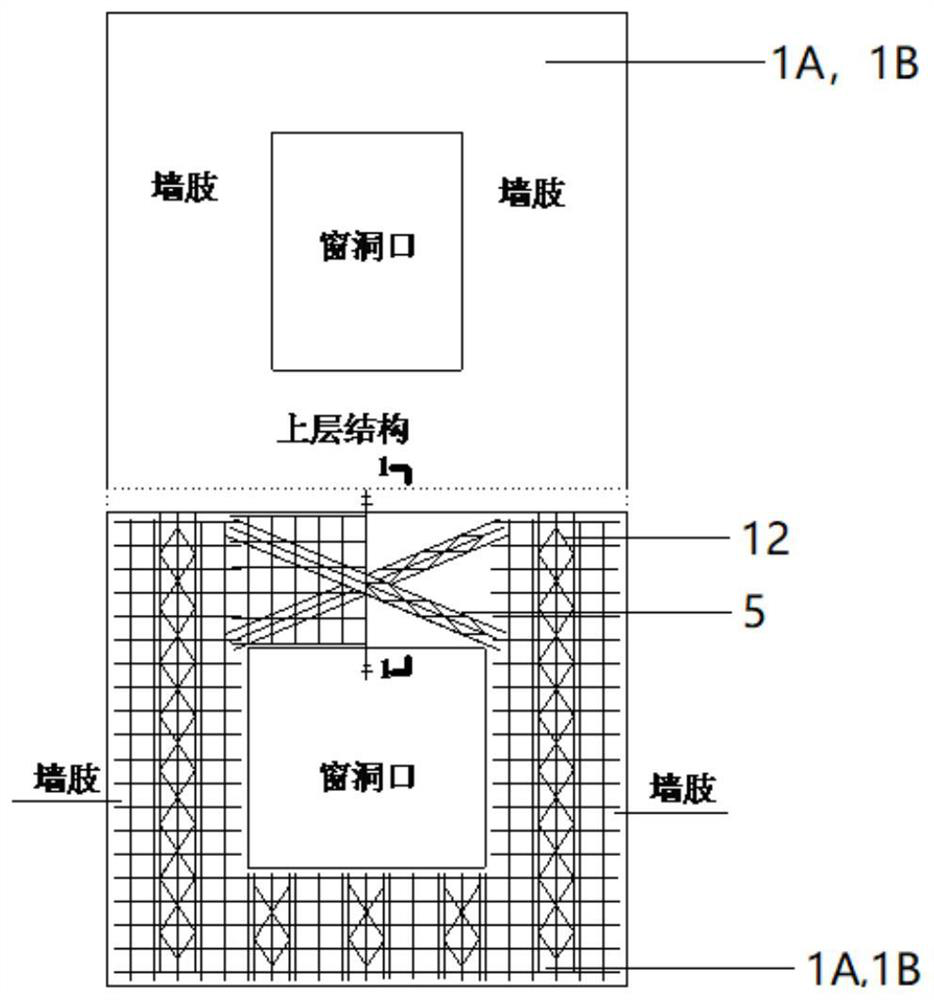

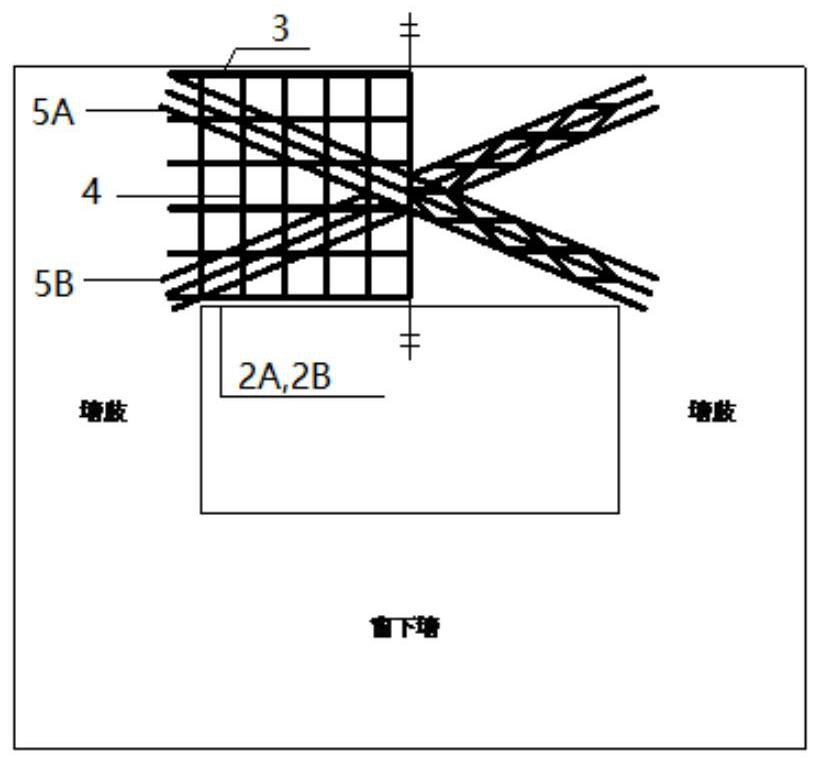

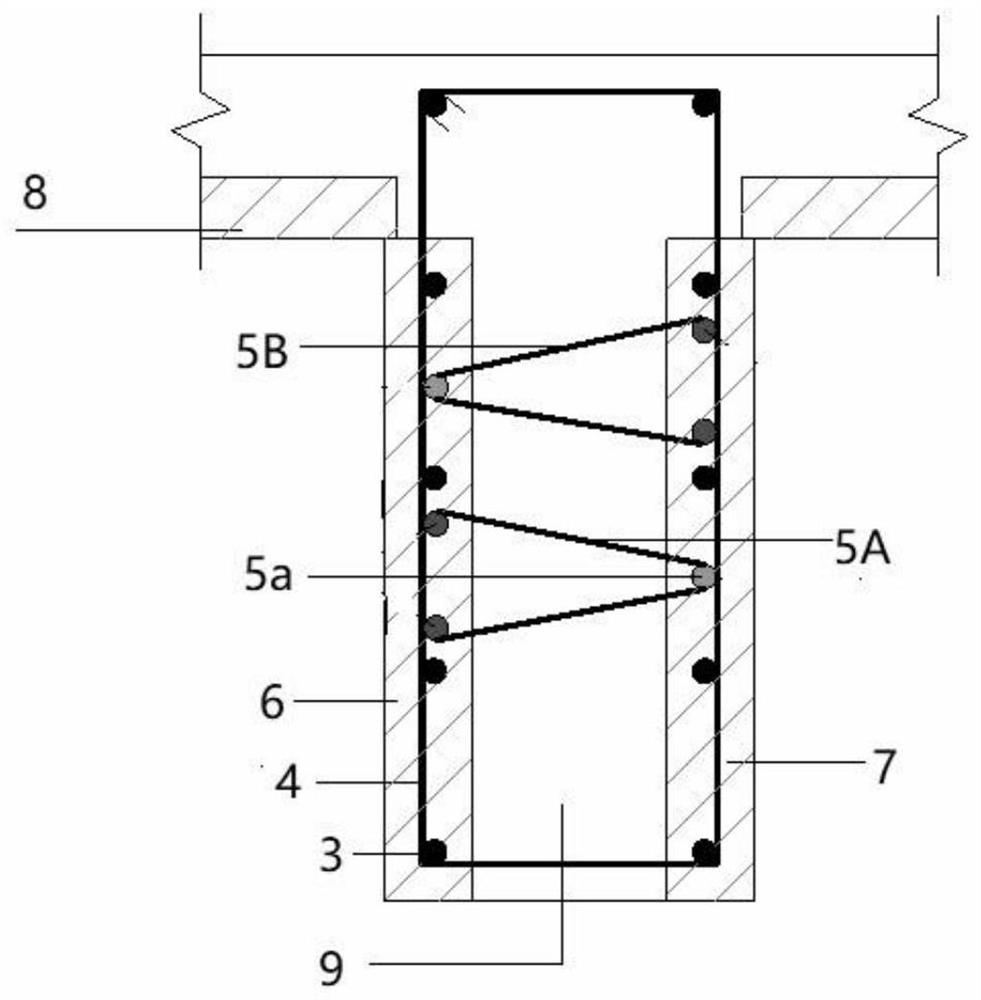

Construction method of hole opening superposed shear wall internally provided with deep connecting beam of diagonal reinforcing steel bar truss

ActiveCN111576881AImprove seismic performanceSolve the construction problem of difficult arrangement of oblique reinforcementConstruction materialWallsMesh reinforcementRebar

The invention relates to a construction method of a hole opening superposed shear wall internally provided with a deep connecting beam of a diagonal reinforcing steel bar truss. The construction method comprises the following steps of manufacturing a prefabricated superposed shear wall in a prefabricating processing plant: when an integral reinforcement cage of the superposed shear wall is manufactured, placing two obliquely arranged reinforcing steel bar trusses in a cross manner between longitudinal stress reinforcing bars of a connecting beam, then connecting the reinforcement cages of theconnecting beam to reinforcement cage meshes in inner and outer blade prefabricated wallboards effectively, and finally pouring wallboard concrete to form the prefabricated superposed shear wall; andtransporting the manufactured prefabricated superposed shear wall to a construction site, and pouring core concrete and carrying out upper structure construction after the core concrete reaches certain strength to finish construction of the whole shear wall structure. The anti-shear ability of the superposed deep connecting beam is improved by means of the obliquely arranged reinforcing steel bartrusses, and a configured reinforcing steel bar truss bearing structure connected to superposed wall sheets is endowed with a novel effect of an internal force, so that the superposed deep connectingbeam can meet the structural stress and anti-quake demand under a circumstance of not adding extra reinforcing bars.

Owner:WUHAN UNIV OF TECH +1

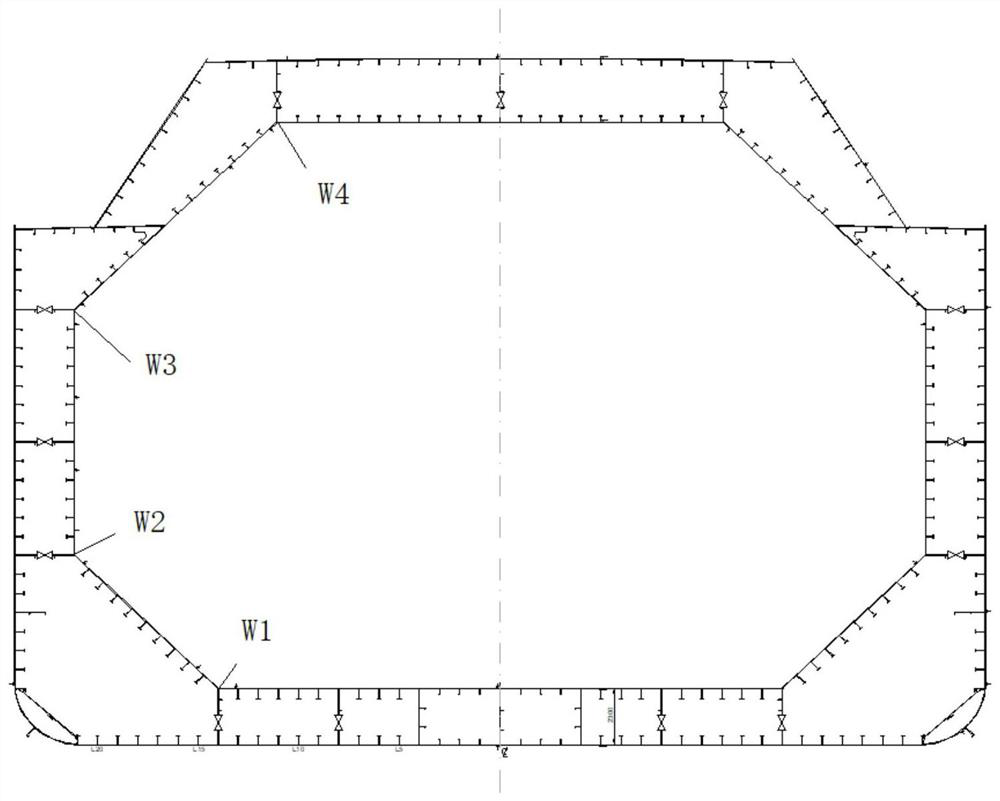

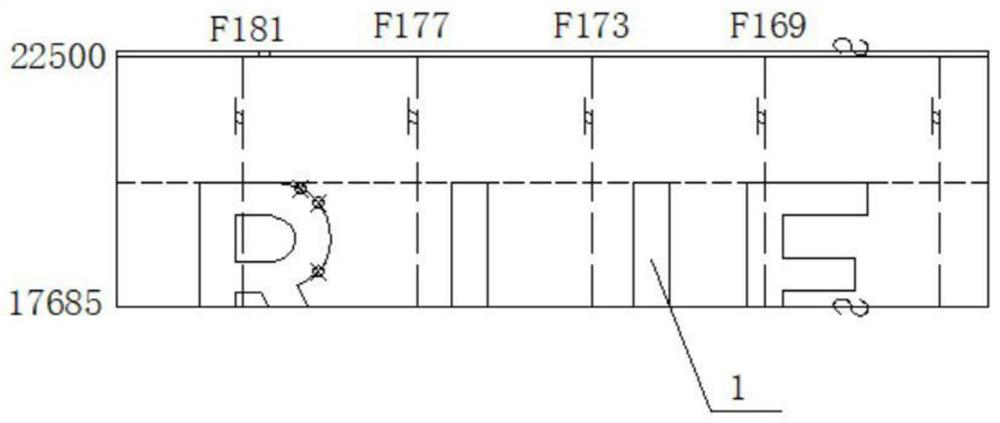

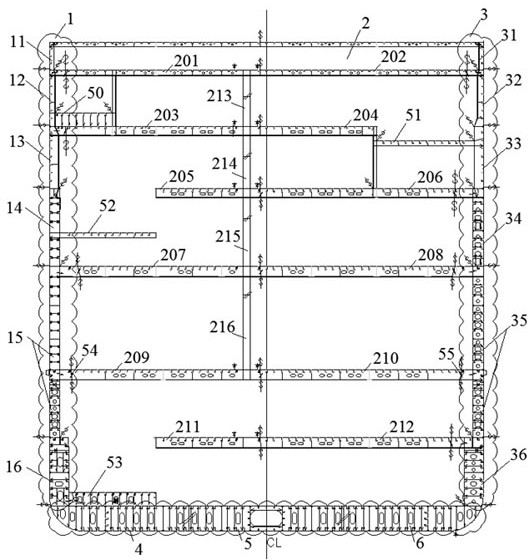

Cargo compartment section division design method and cargo compartment sections of 80,000-cubic-level film type LNG (Liquefied Natural Gas) ship

PendingCN113772042AImprove outfitting integrityReduce in quantityVessel designingFor bulk goodsBilgeMechanical engineering

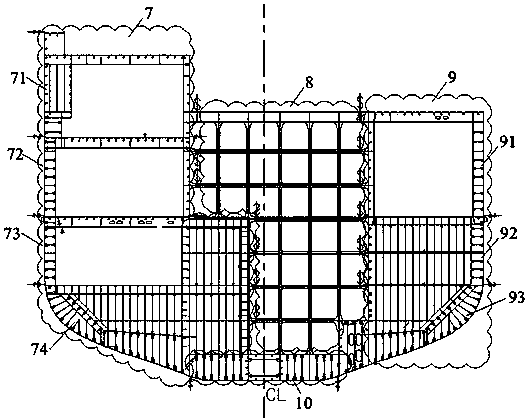

The invention relates to a cargo compartment sectioning design method for a 80,000-cubic-level film type LNG (liquefied natural gas) ship, a cargo compartment is divided into four compartments including a bottom and bilge section, a side section, a bulkhead and a deck section. The method comprises a cargo compartment bottom and bilge section dividing form, a cargo compartment side section dividing form, a cargo compartment bottom and bilge section dividing form, a cargo compartment bottom and bilge section dividing form, a cargo compartment side section dividing form, a cargo compartment bottom and bilge section dividing form and a cargo compartment bottom and bilge section dividing form. A cargo compartment division form and a cargo compartment deck subsection division form are adopted, each of the four cabins is longitudinally divided into three ring sections. Meanwhile, it is guaranteed that the full-width block of the deck is complete, a low-temperature pipe system on the deck is installed in the total assembly stage in advance, and meanwhile ship body key nodes W4 on the inner wall of the cargo compartment are divided into subsection internal nodes; the invention further relates to a cargo compartment section designed and built based on the method. According to the method disclosed by the invention, the cargo compartment is divided and designed in sections, so that high efficiency and high quality of ship construction are ensured, the construction is completed on schedule, Meanwhile, the construction period is shortened and the coating PSPC standard is met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

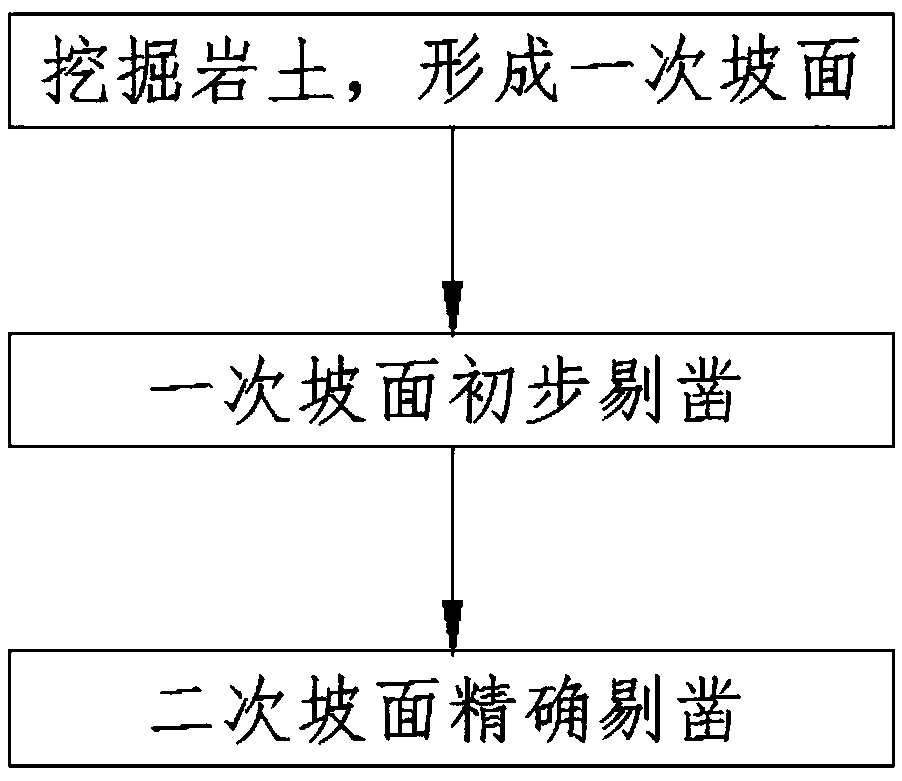

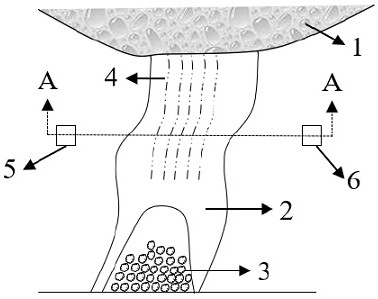

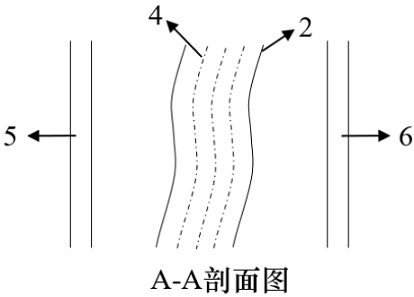

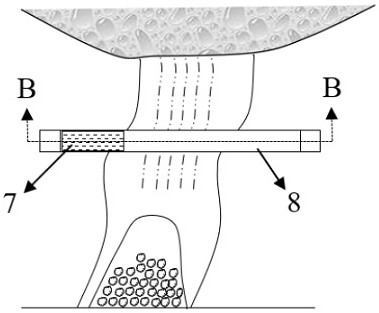

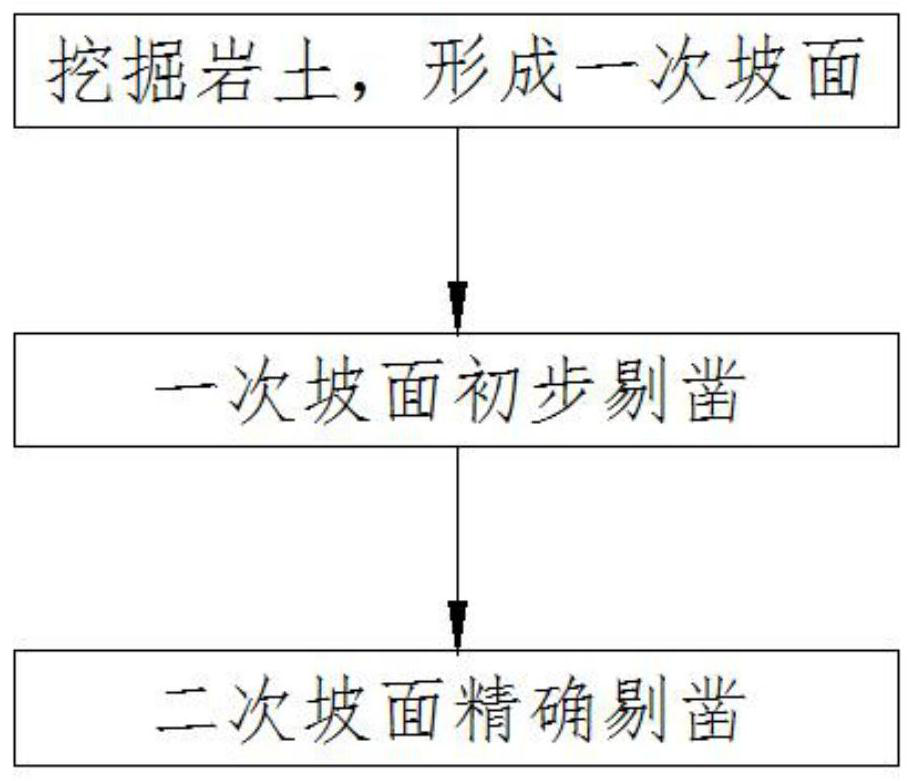

Construction method of road rock side slope

ActiveCN109610483AImprove quality and efficiencyImprove construction efficiencyExcavationsCrusherExcavator

The invention provides a construction method of a road rock side slope. The construction method comprises the steps that rock and soil are excavated by an excavator, an appropriate amount of chiselingmargin is preserved, and first-time slopes are obtained on both sides of a road; a crusher is used for chiseling the first-time slopes in a top-down order, a part of the chiseling margin in the firststep is chiseled, that is, margin coarse chiseling is performed, and second-time slopes are obtained on both sides of the road; and the crusher is used for chiseling the second-time slopes in a top-down order, the remaining part of the chiseling margin in the first step is chiseled, that is, margin fine chiseling is performed, and formed slopes are obtained on both sides of the road. According tothe technical scheme, the construction method is mainly applicable to the construction operation of a road side slope without the need of the support, so that the slope surface of the rock side slopeformed after the construction is smoother, the appearance is more attractive, the construction operation difficulty is reduced, the investment in construction materials and manpower of enterprises isreduced, the construction quality and construction efficiency of the road side slope are improved, and a foundation for the subsequent construction process is laid.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

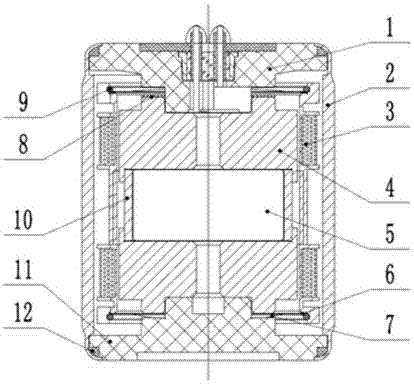

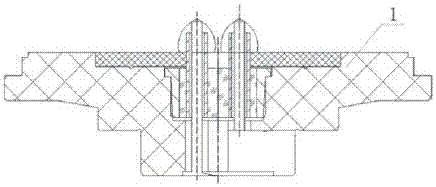

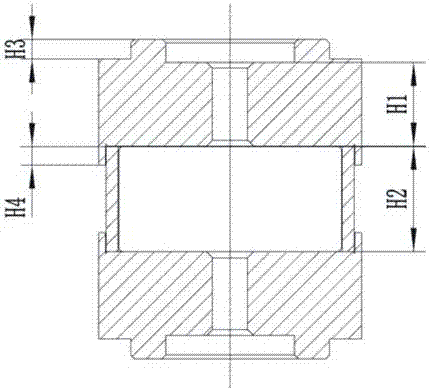

Speed type magnetoelectric high-sensitivity seismic geophone

PendingCN107238858AReduce the difficulty of construction workFlexible handling of diversitySeismic signal receiversGeophoneClassical mechanics

The invention discloses a speed type magnetoelectric high-sensitivity seismic geophone, which comprises a top cap assembly, a bottom cap, an iron shell, a coil assembly, two silver-plated magnetic shoes, a permanent magnet, a leaf spring and a clamp spring, wherein the two silver-plated magnetic shoes are respectively positioned on the upper end and the lower end of the permanent magnet, the permanent magnet is positioned in the middle of the coil assembly, the iron shell is arranged outside the permanent magnet, the magnetized permanent magnet forms a magnetic loop through the silver-plated magnetic shoes and the iron shell, thus forming a magnetic system; the coil assembly consists of an upper leaf spring and a lower leaf spring which are clamped on the upper end and the lower end of the coil assembly through the clamp spring, thus forming a spring-mass damping vibration system; the coil system is at horizontal position through the upward resultant force generated by the upper leaf spring and the lower leaf spring, and suspended in a magnetic field between the silver-plated magnetic shoes and the iron shell. The frequency, damp, sensitivity and parameter precision of the seismic geophone can meet the high-precision fine exploring requirement.

Owner:四川吉赛特科技有限公司 +1

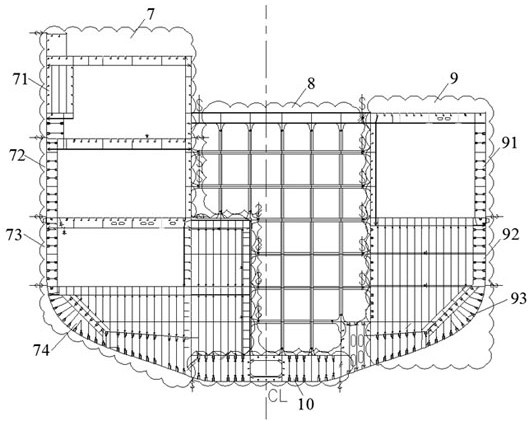

A segmented division design method for a G4 type rolling ship

ActiveCN109850059AReduce construction difficultyReduce the difficulty of precision controlVessel partsEngineeringDesign methods

The invention discloses a segment division design method for a G4 type rolling ship. The method comprises the following steps: A, basis: determining a whole ship segmented division principle and requirements; B, carrying out segmented division: dividing a cargo compartment roll-roll area into a bottom larboard segment, a middle segment, a starboard segment, broadside multi-layer larboard and starboard segments, multi-layer deck larboard and starboard segments, multi-layer ramp segments and multi-layer column segments; dividing a cargo hold cabin mixing area into a bottom full-width segment, multiple layers of larboard channel segments and one layer of starboard channel segment which are asymmetrical on the broadside, semi-three-dimensional segments and independent transverse bulkhead segments which are asymmetrical on the left side and the right side of the broadside cabin; dividing a cabin area into a left bulwark segment, a right bulwark segment, an independent complete square channel segment, left-right asymmetric deck segments, a larboard double-shell segment with asymmetric broadside, a starboard double-shell segment with asymmetric broadside, a cabin semi-three-dimensional segment with asymmetric broadside larboard and starboard, and a bottom full-width segment. The method is more scientific, reasonable and convenient, the integrity of the outfitting piece can be improved, and the dock period is shortened.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

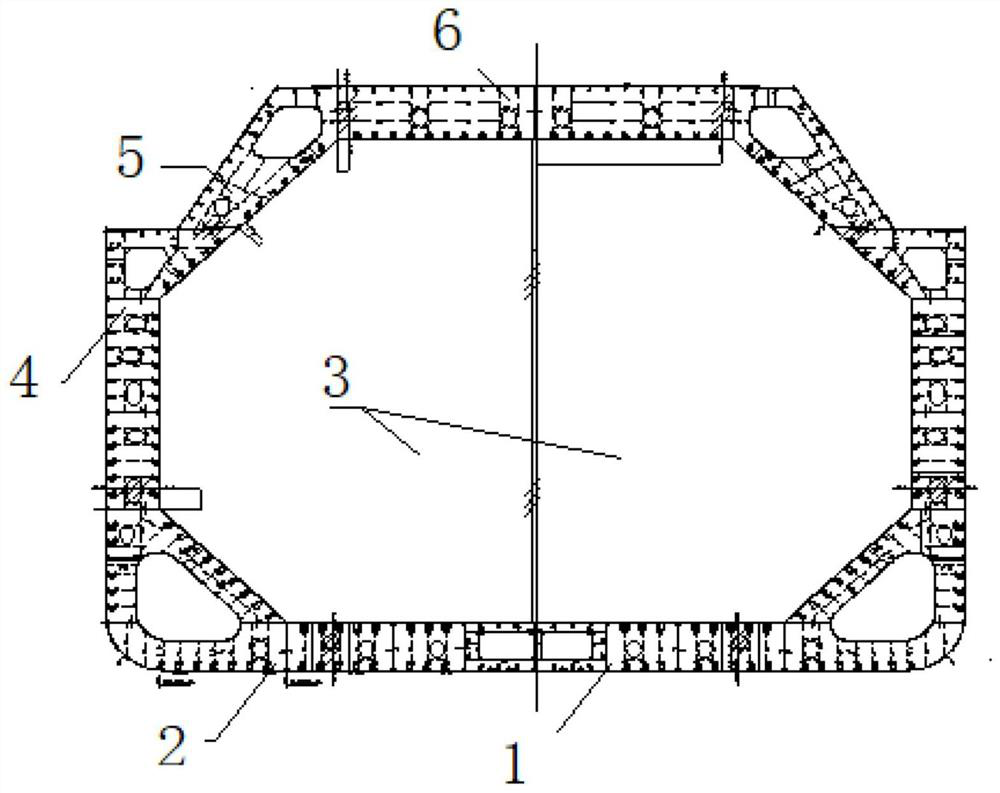

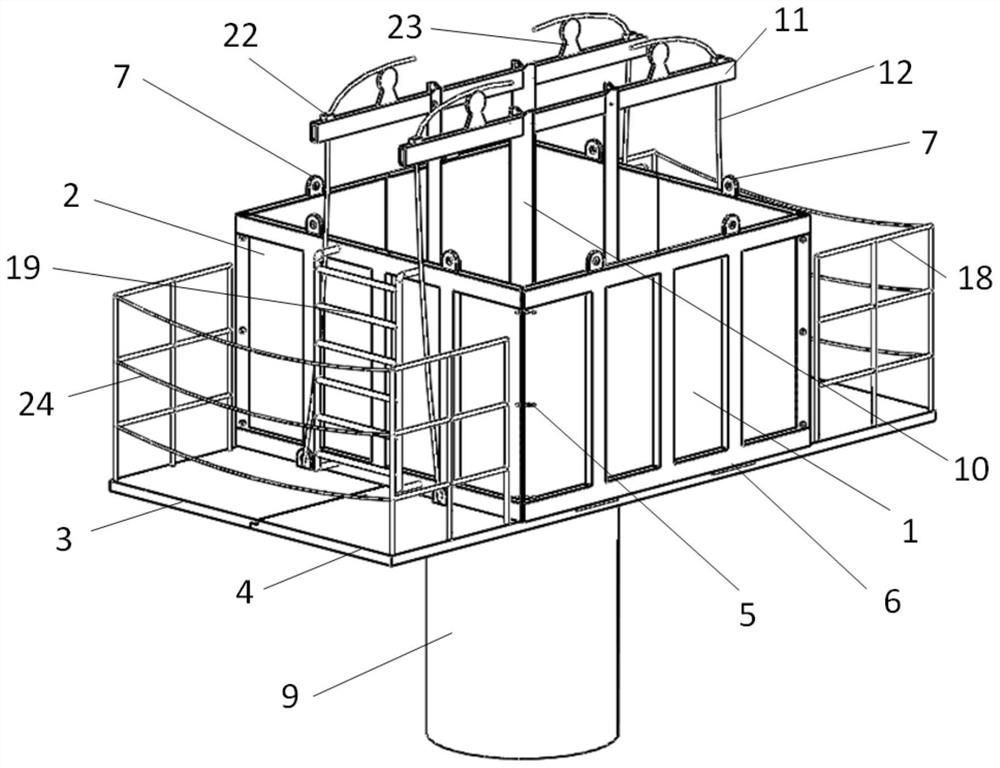

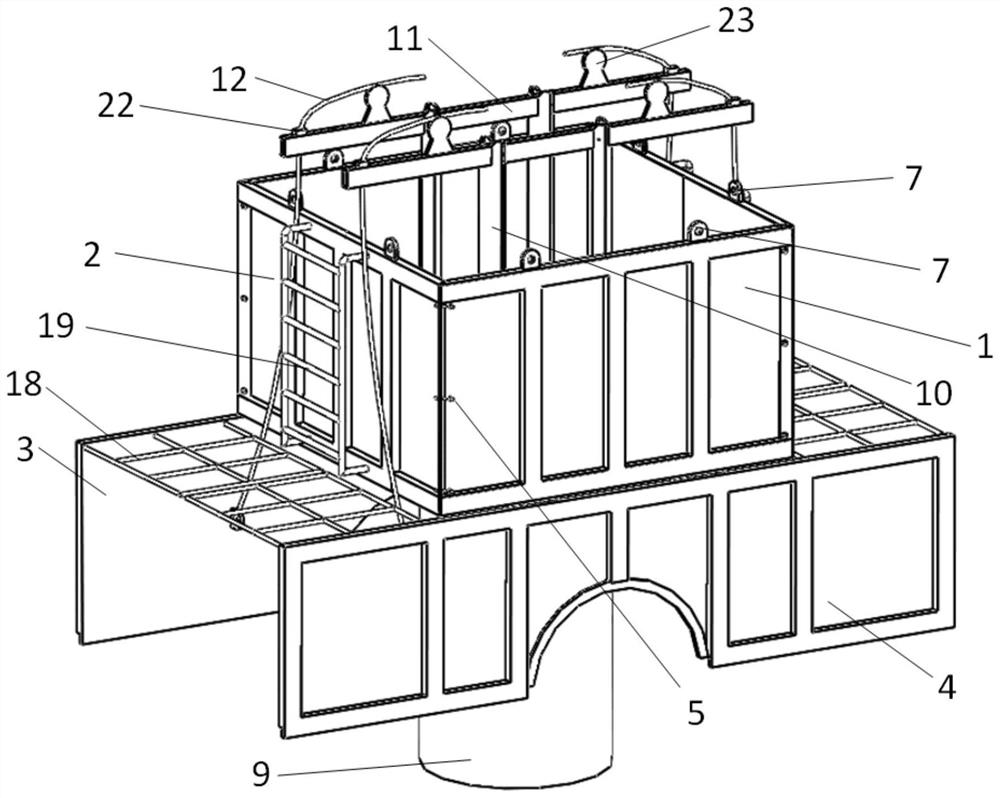

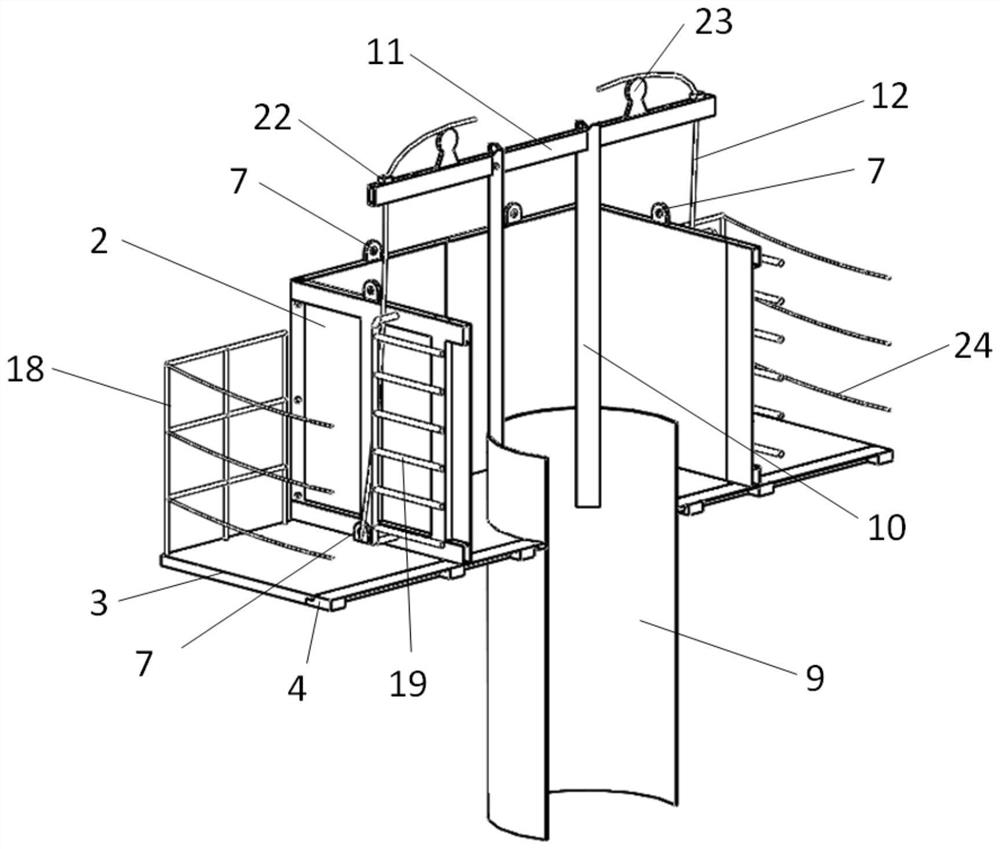

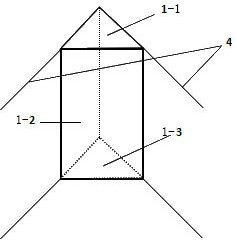

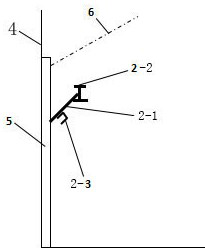

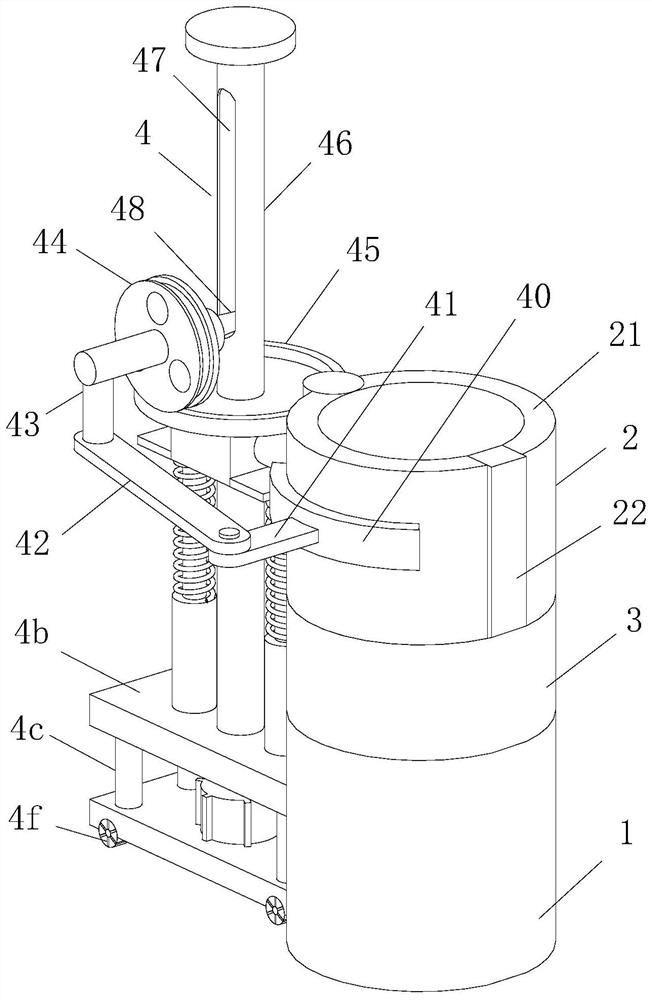

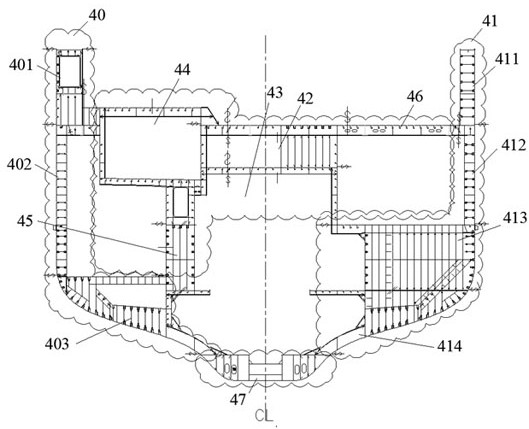

Factory prefabricated elevator well foundation pit and mounting method thereof

PendingCN108978713AHigh speedReduce the difficulty of construction workArtificial islandsUnderwater structuresReinforced concreteRebar

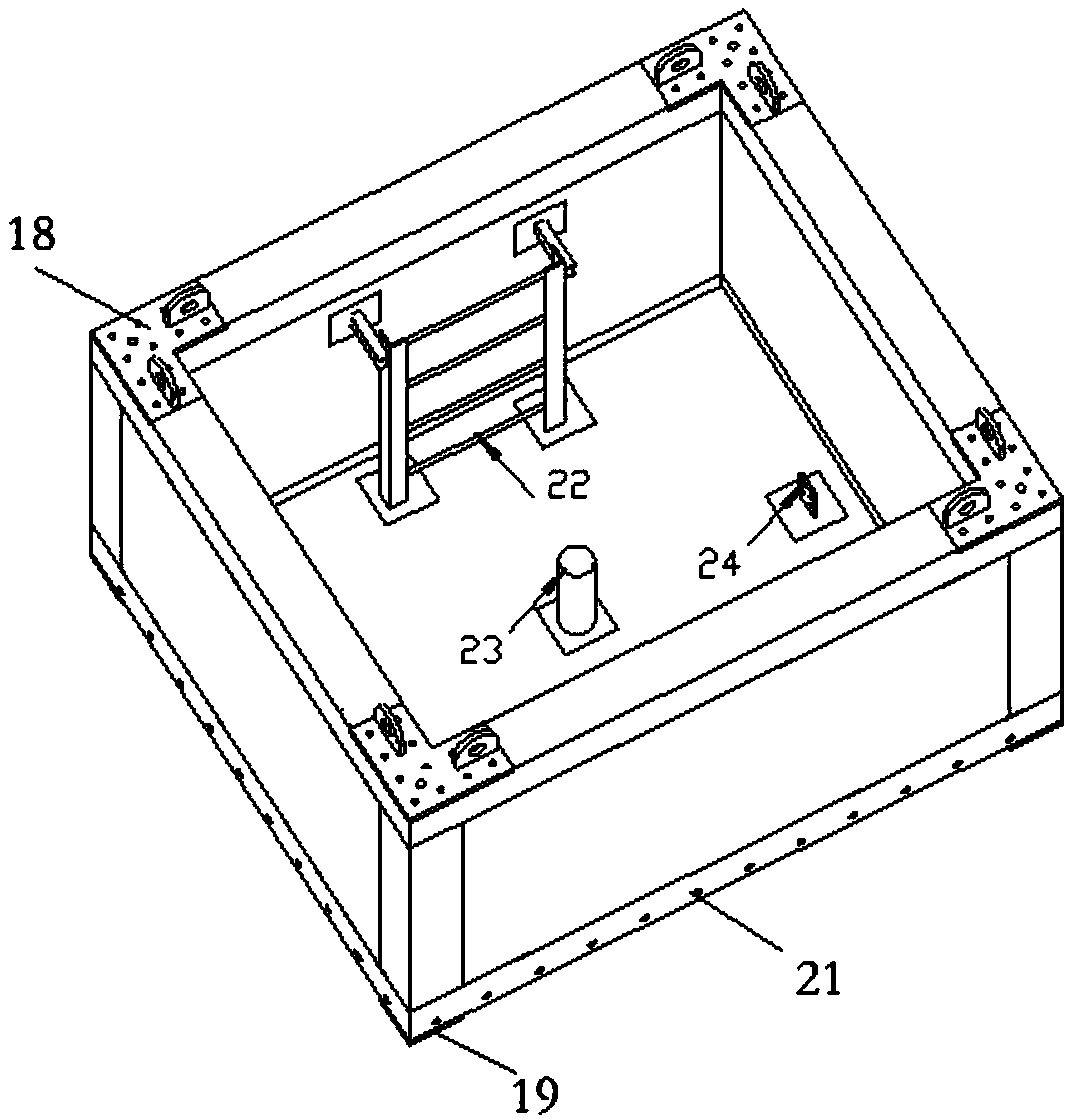

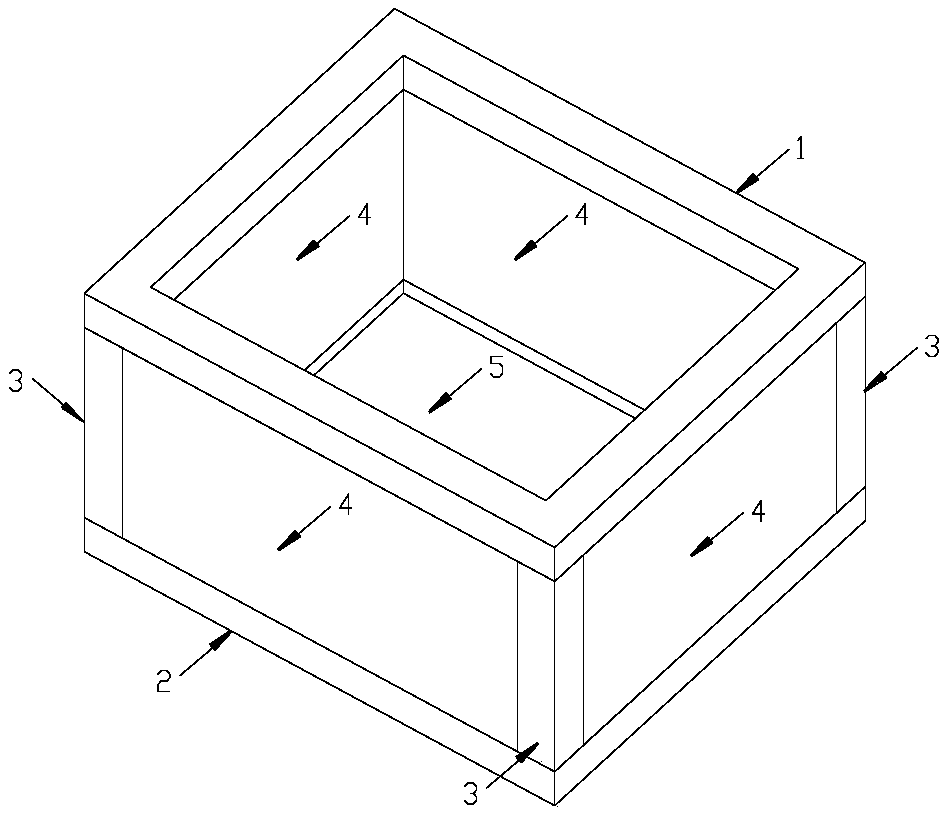

The invention discloses a factory prefabricated elevator well foundation pit, and prefabricating and mounting methods thereof. The elevator well foundation pit adopts a reinforced concrete structure and comprises a top ring beam, a bottom ring beam, four corner columns, walls and a bottom plate; the bottom ring beam is located on the peripheral side of the bottom plate; the upper ends and the lower ends of the corner columns are located at the four corners of the top ring beam and the bottom ring beam correspondingly; the walls are located between the adjacent corner columns, and a cuboid withthe upper end open is defined by the walls, the corner columns, the top ring beam, the bottom ring beam and the bottom plate; and top buried pieces are arranged at the four corners of the top face ofthe top ring beam correspondingly, bottom buried pieces are arranged at the four corners of the bottom face of the bottom ring beam correspondingly, and well inner buried pieces are arranged on the walls and the bottom plate in the foundation pit correspondingly. According to the factory prefabricated elevator well foundation pit, and the prefabricating and mounting methods thereof, the elevatorwell foundation pit is prefabricated in a factory, due to the fact that the elevator well foundation pit is shaped, machined and manufactured in the factory, industrialization can be formed, elevatorwell foundation pits with the same model specification in a batch of orders can be subjected to shaping production, and the speed is high.

Owner:江苏船谷重工有限公司

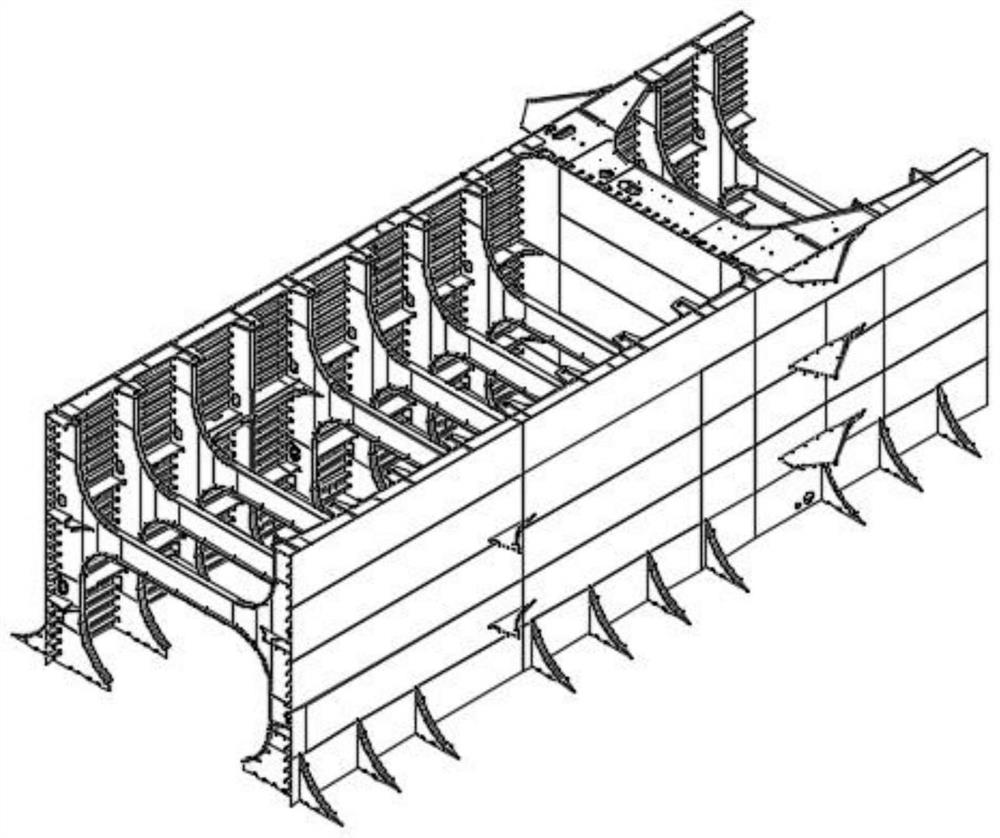

Quick construction method for water tank subsection of ship

ActiveCN113277031AQuick buildGuaranteed precision control requirementsWaterborne vesselsMarine engineeringStructural engineering

The invention provides a quick construction method for a lower water tank subsection of a ship. The quick construction method comprises the steps that S1, longitudinal panels and longitudinal webs are machined; s2, outer plate longitudinal bones and inclined top plate longitudinal bones are obtained; s3, obtaining an insole assembly; s4, machining each rib plate frame; s5, obtaining an inclined top plate and an outer plate; s6, the inclined top plate and the inclined top plate longitudinal bone are hoisted; s7, the inner bottom assembly is hoisted; s8, a rib plate frame is hoisted; s9, outer plate longitudinal bones are hoisted; s10, hoisting an outer plate; in the production and machining process, the positioning datum lines are additionally arranged on all the parts and serve as positioning folding lines for follow-up small assembly installation, middle assembly installation and large assembly hoisting, through line-to-line positioning installation, the installation precision is guaranteed, the construction difficulty is lowered, and the production efficiency is improved. The problem that the installation position of the outer plate longitudinal bone is repeatedly adjusted due to the fact that the installation angle precision of the rib plate frame is not enough in the traditional segmented construction process is effectively solved, the segmented construction efficiency is greatly improved, and quick segmented construction is achieved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Fabricated watertight hanging box formwork for underwater cast-in-place concrete pile cap and construction method

PendingCN114703829AEasy constructionQuick installation and removalBulkheads/pilesSupporting systemPile cap

The invention discloses an assembly type watertight hanging box formwork for an underwater cast-in-place concrete pile cap, which comprises a hanging box body, one sides of two bottom plates of the hanging box body are rotationally connected with the bottom surfaces of two symmetrically arranged side plates respectively, and the other opposite sides and the four side plates jointly form a box body structure which is arranged on a steel pipe pile in a sealing and sleeving manner; a one-way water stop valve is arranged on any bottom plate; the supporting system is fixed in the steel pipe pile; the power system is arranged on the supporting system and used for driving the first bottom plate and the second bottom plate to rotate around the pair of first side plates so as to seal or open the bottom face of the hanging box body. The invention further discloses a construction method of the fabricated watertight hanging box formwork for the underwater cast-in-place concrete pile cap. According to the method, pile cap dry construction operation conditions can be created in a water level change area, so that the construction window period is prolonged, the construction cost is saved, and meanwhile, the watertight hanging box formwork system has the characteristics of simplicity and convenience in construction, rapidness in mounting and dismounting, reusability and the like.

Owner:CCCC SECOND HARBOR ENG +3

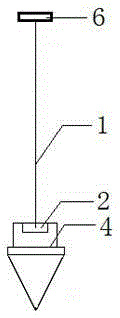

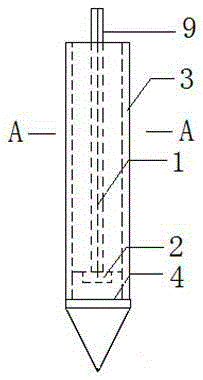

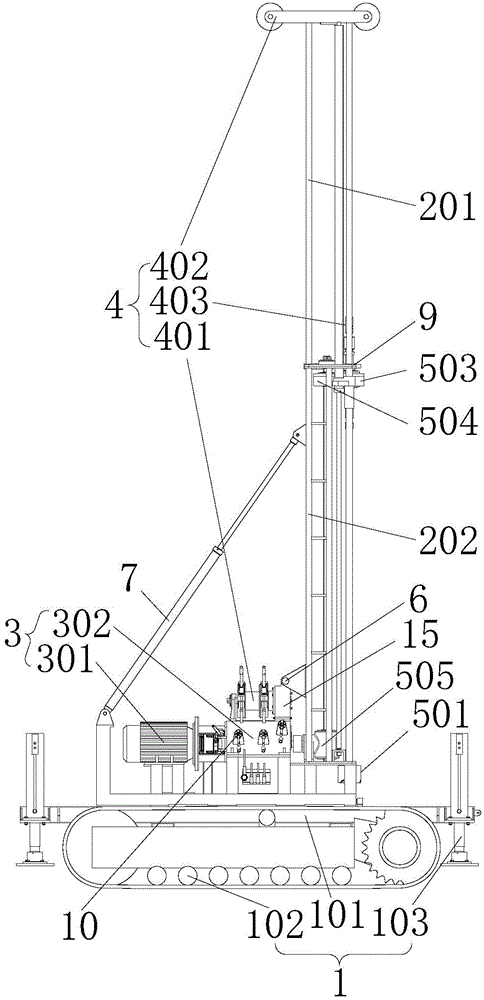

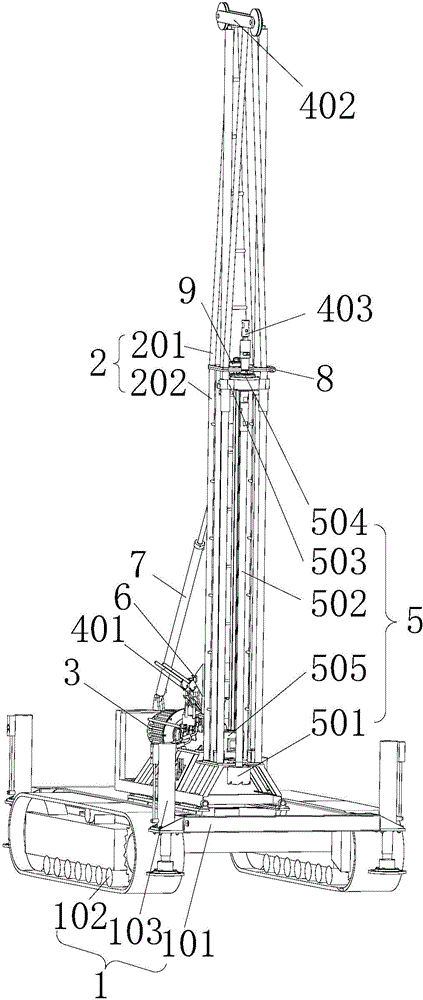

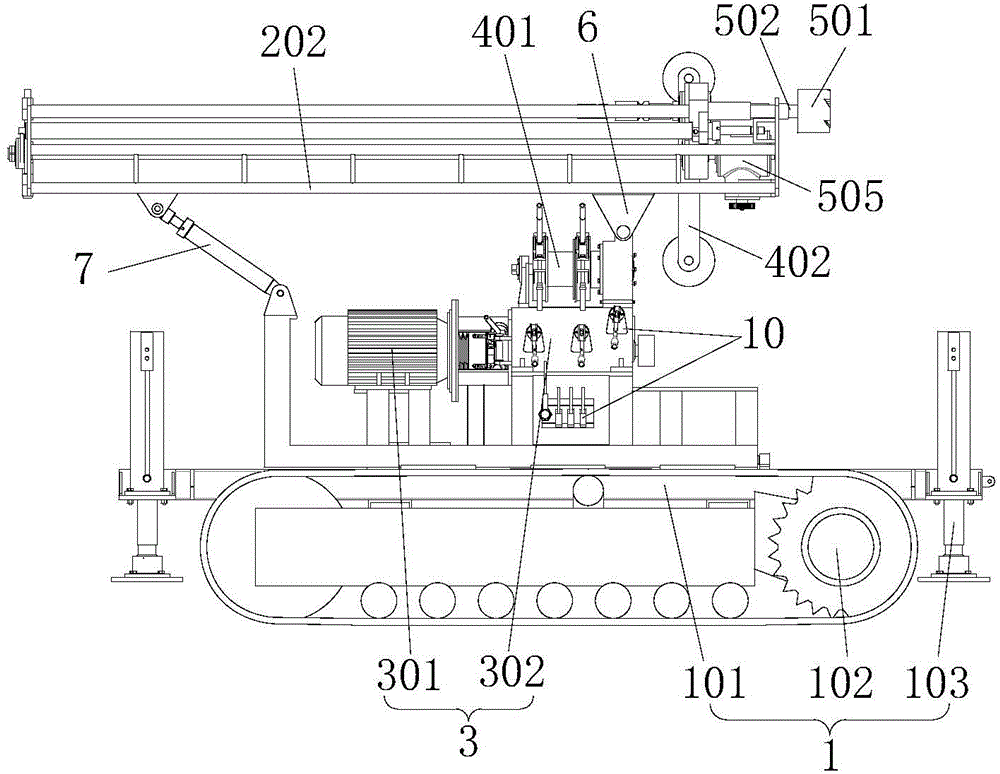

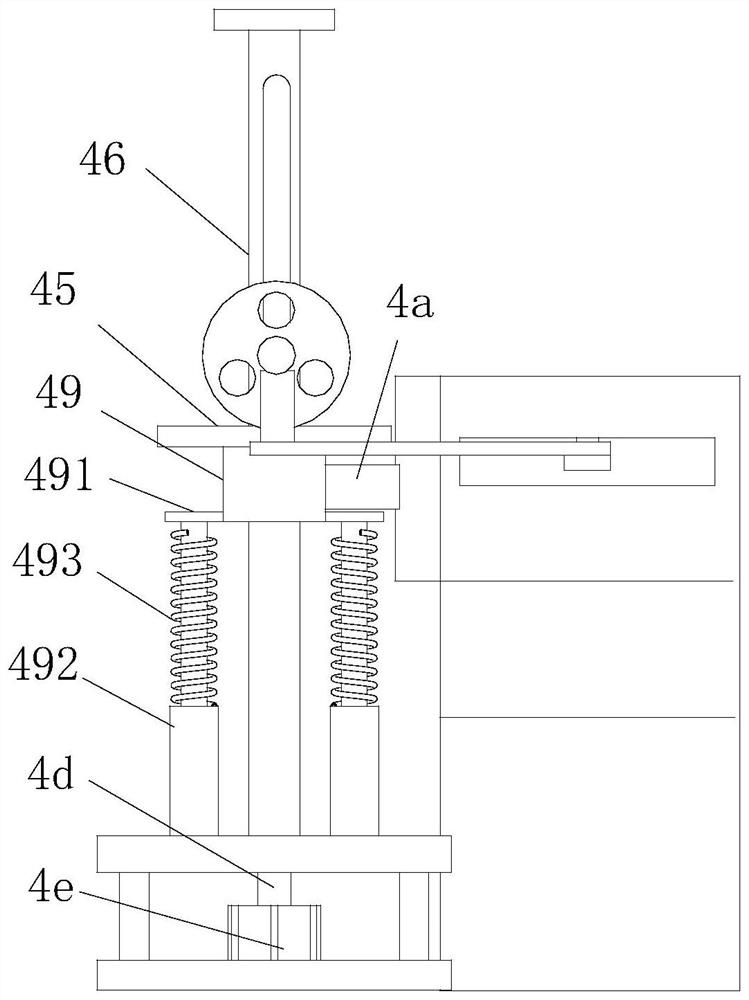

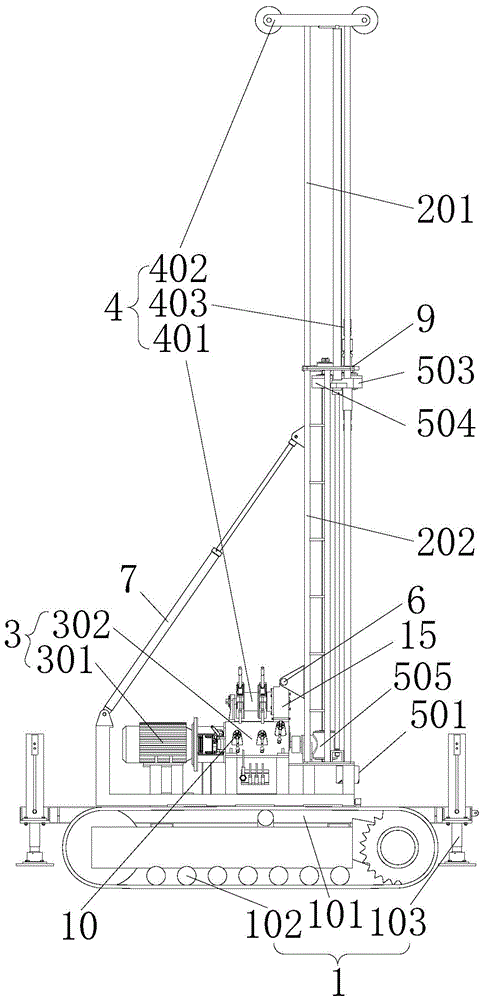

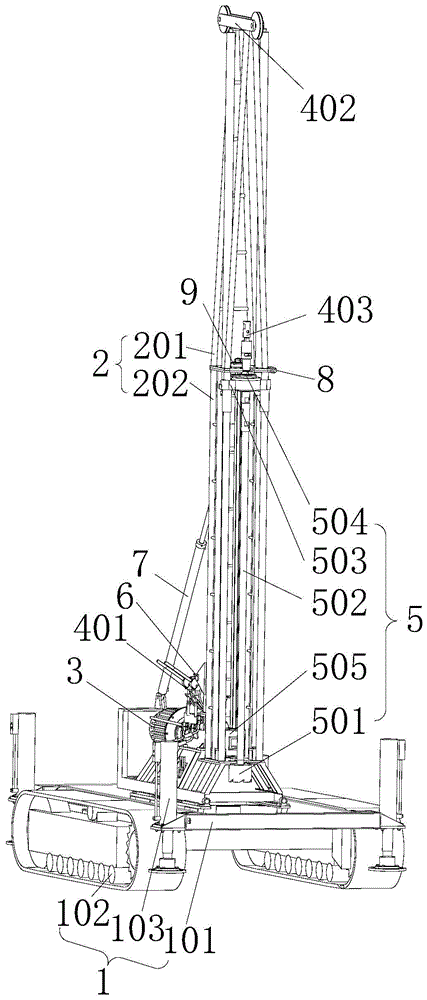

Folded type long-stroke drilling machine

ActiveCN104790878AImprove drilling work strokeSimple structureDerricks/mastsDrilling machines and methodsEngineeringMechanical engineering

The invention discloses a folded type long-stroke drilling machine. A driving mechanism is loaded on a base, output ends of the driving mechanism are connected with a lifting mechanism and a rotary mechanism respectively, a vertical column is connected with the lifting mechanism and the rotary mechanism respectively, the vertical column comprises an upper support and a lower support, the upper support is arranged at the upper end of the lower support, and the lower portion of the lower support is rotatably connected with the driving mechanism or the base through a first rotary piece; the upper portion of the lower support is movably connected with the base through a flexible inclined strut, and the lower support is supported by expanding the flexible inclined strut or the lower support is laid down by shortening the flexible inclined strut; by means of the first rotary piece and the flexible inclined strut, a movable double-support structure of the lower support is formed; the lower end of the upper support is rotatably connected with the upper end of the lower support through a second rotary piece, and a rotating track of the upper support rotating around the second rotary piece and a rotating track of the lower support rotating around the first rotary piece are located in different planes; a fixing piece is arranged between the lower end of the upper support and the upper end of the lower support.

Owner:HUNAN JIAYAO TIANYOU DRILLING & EXPLORING MACHINERY

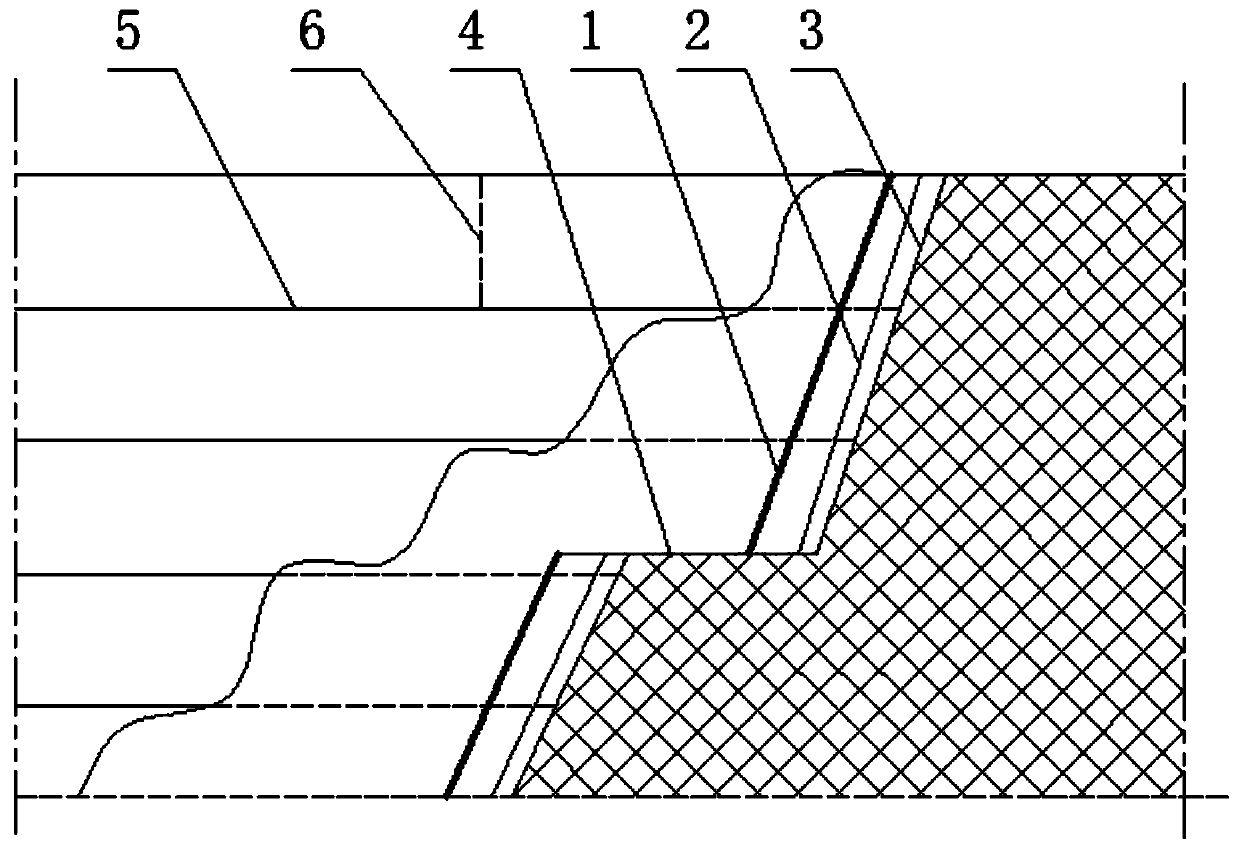

Ship outboard marking method and ship planking

ActiveCN113879480AIncrease productivityReduce the difficulty of construction workWaterborne vesselsPolyesterMarine engineering

The invention provides a ship outboard marking method and a ship planking. The ship outboard marking method comprises the following steps: determining a sub-plate to be surveyed in the ship planking according to the position of an outboard mark to be surveyed in the ship planking and an area covered by a to-be-surveyed outboard mark; carrying out outboard mark assignment on the to-be-assigned sub-plate; before the small assembly stage, completing the welding of the corresponding outboard marks on each split plate; S4, in the large assembly stage, enabling the outboard marks on the split plates to form a complete outboard mark after the ship planking is assembled. According to the method, a look-up welding method that construction workers take polyester paper to attach segmented outer plates upwards to mark outboard letters of the ship outer plates and carry out three-dimensional operation after a large segment is installed on a portal is replaced. According to the assignment method, the welding precision of the ship outer plate in the welding construction process can be improved, the working efficiency is improved, and the construction safety is guaranteed.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Pipe pile-anchor composite foundation and construction technology that can bear bidirectional load in tension and compression

InactiveCN105350531BReduce the "crowding effect"Low costBulkheads/pilesStructural reliabilityErosion

The invention provides a pipe pile-anchor rod composite foundation capable of bearing pulling and pressing bidirectional loads and a construction technology of the pipe pile-anchor rod composite foundation. The pipe pile-anchor rod composite foundation comprises a pipe pile and an anchor rod. An anchoring hole is reserved in a foundation bottom plate of a building structure, and a stretching end anchorage device is pre-buried in the anchoring hole. The anchor rod is composed of an anchor cable and a prefabricated anchor head, and the prefabricated anchor head is buried in soil below the foundation bottom plate. The upper end of the anchor cable penetrates out of the pipe pile to stretch into the anchoring hole, and is locked by the stretching end anchorage device after being stretched. The pipe pile is supported between the foundation bottom plate and the prefabricated anchor head, and the lower end of the pipe pile is fixedly connected with the upper end of the prefabricated anchor head. In the pipe pile-anchor rod composite foundation, the prefabricated anchor head is additionally arranged at the lower end of the pipe pile so that the pressure resisting bearing capacity of the pipe pile can be improved; a waterproof curtain is formed by the pipe pile with the two closed ends, the erosion effect of underground water and the like on concrete and steel can be resisted, and the impermeability and durability of the anchor rod, the pipe pile and foundation bottom plate joints can be improved; and structural reliability and stress performance are ensured, meanwhile, project quality can be effectively improved, the construction period can be shortened, and the investment can be saved.

Owner:葛建

Reinforcing method for improving net section strength of externally-attached plate type old line iron tower

ActiveCN114016803AImprove carrying capacityImprove ultimate carrying capacityBuilding repairsTowersArchitectural engineeringTower

The invention discloses a reinforcing method for improving net section strength of an externally-attached plate type old line iron tower, which comprises the following steps of: determining a part with weak net section area bearing capacity of a main material of the old line iron tower, and then rechecking the bearing capacity of the main material of the old line iron tower under an annual flat working condition; and finally, additionally arranging an externally-attached steel plate at the position where the net sectional area bearing capacity of the old line iron tower main material is weak, and enhancing connection between the externally-attached steel plate and the old line iron tower main material through an auxiliary component. According to the method, the ultimate bearing capacity of the iron tower is improved, the investment cost is saved, the power failure time is shortened, the construction operation difficulty and workload are small, and the feasibility is high.

Owner:GUIZHOU POWER GRID CO LTD

A Vertical Rectangular Cooling Furnace for Sintered Ore

ActiveCN111692886BSuppress escapeImprove wear resistanceIncreasing energy efficiencyHandling discharged materialThermodynamicsFlue gas

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Concrete bridge supporting column construction operation method

InactiveCN112458911AQuick detachmentImprove construction work efficiencyBridge structural detailsBridge erection/assemblyCircular discArchitectural engineering

Owner:潘林妃

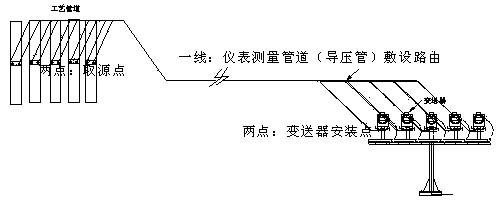

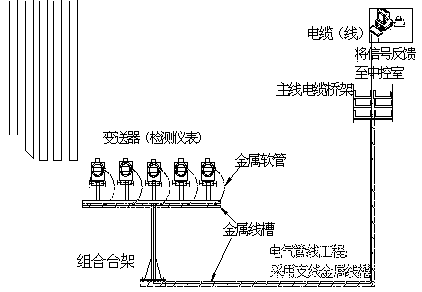

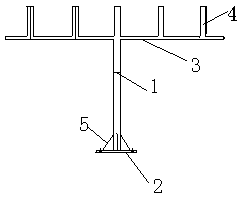

Transmitter combination rack and application method thereof

PendingCN110601057ASmall footprintImprove installation efficiencySubstation mounted on poleApparatus for laying cablesTransmitterBuilding construction

The invention relates to the field of industrial equipment installation, in particular to a transmitter combination rack and an application method thereof. The transmitter combination rack is characterized by comprising a vertical post, an installation base, a cross arm, transmitter installation supports and reinforcement side plates, wherein the vertical post is vertically arranged on the installation base, a lower part of the vertical post communicates with the interior or a side part of the installation base, the cross arm is horizontally arranged at the top of the vertical post, the top ofthe vertical post communicates with the bottom of the cross arm, a plurality of transmitter installation supports are arranged on the cross arm at intervals and are sequentially arranged, the spacingdistance is determined according to the appearance size of a transmitter, and the reinforcement side plates are arranged between the bottom of the vertical post and the installation base in an encircling way. In the structure, penetrating cavities are enabled to be formed between the installation base and the vertical post, between the vertical post and the cross arm and between the cross arm andthe transmitter installation support so as to achieve a cable laying installation path. By the transmitter combination rack, the engineering quality can be improved, the quality risks that a cable ina pipe is scratched and insulation is damaged during laying of a cable penetrating pipe are prevented, and the integral construction of engineering is excellent in perceptual quality.

Owner:SHANGHAI BAOYE GRP CORP

Method for blocking upward pumping of structure development type broken ore body under water body

ActiveCN114776302AAvoid enteringAvoid major mining accidentsUnderground chambersUnderground miningMining engineeringSlurry

The invention provides a method for blocking upward pumping of a structure development type broken ore body under a water body, and belongs to the technical field of mining engineering. The method comprises the following steps: firstly, constructing a drift roadway on each of the two sides of the top outside the plane influence range of a stope area where caving possibly occurs along the trend of an ore body, constructing a transverse drift roadway on a hanging wall drift roadway by using a miniature shield tunneling machine, drilling grouting holes in the vertical, inclined upper and inclined lower positions of the two sides of the transverse drift roadway after the transverse drift roadway is tunneled, and drilling grouting holes in the vertical, inclined upper and inclined lower positions of the transverse drift roadway; after the grouting hole drilling operation is completed, high-pressure grouting is conducted; and after grouting work is completed, a folding type 3D printing columnar high-strength resin net is laid in the transverse drift roadway, and after the resin net is completely unfolded, the transverse drift roadway is filled with concrete slurry. Water can be prevented from entering the stope along the secondary fissures, manpower and financial resources of mine enterprises are saved, and safety and daily production of workers of the mine enterprises are guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

A road rock slope construction method

ActiveCN109610483BImprove quality and efficiencyImprove construction efficiencyExcavationsArchitectural engineeringCrusher

The invention provides a construction method of a road rock side slope. The construction method comprises the steps that rock and soil are excavated by an excavator, an appropriate amount of chiselingmargin is preserved, and first-time slopes are obtained on both sides of a road; a crusher is used for chiseling the first-time slopes in a top-down order, a part of the chiseling margin in the firststep is chiseled, that is, margin coarse chiseling is performed, and second-time slopes are obtained on both sides of the road; and the crusher is used for chiseling the second-time slopes in a top-down order, the remaining part of the chiseling margin in the first step is chiseled, that is, margin fine chiseling is performed, and formed slopes are obtained on both sides of the road. According tothe technical scheme, the construction method is mainly applicable to the construction operation of a road side slope without the need of the support, so that the slope surface of the rock side slopeformed after the construction is smoother, the appearance is more attractive, the construction operation difficulty is reduced, the investment in construction materials and manpower of enterprises isreduced, the construction quality and construction efficiency of the road side slope are improved, and a foundation for the subsequent construction process is laid.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

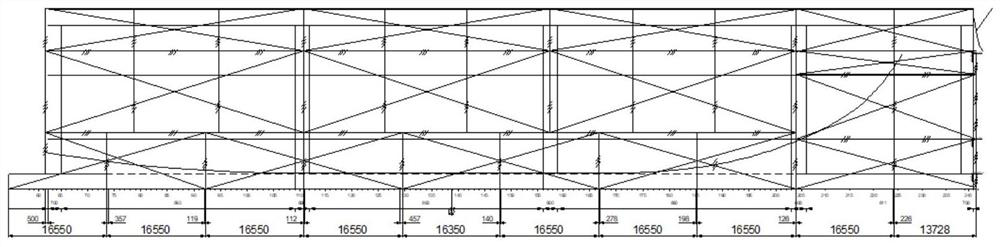

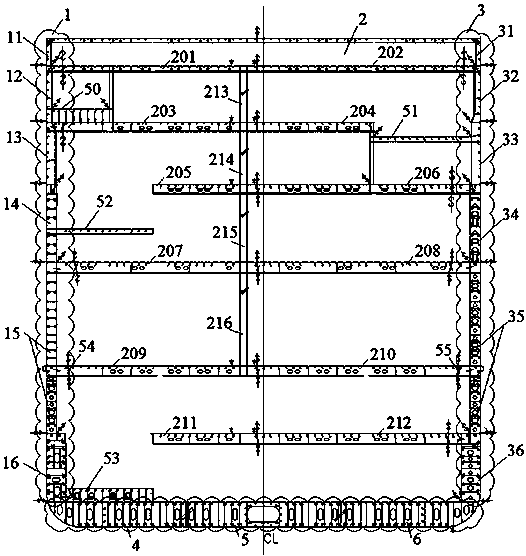

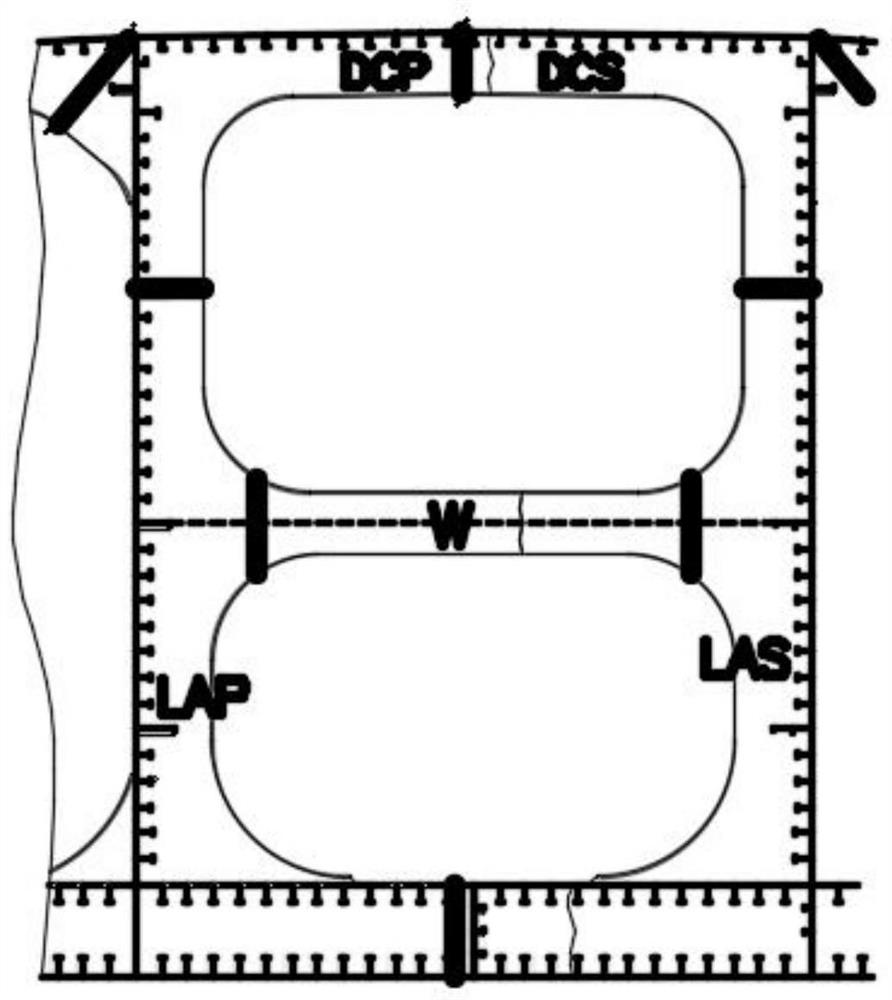

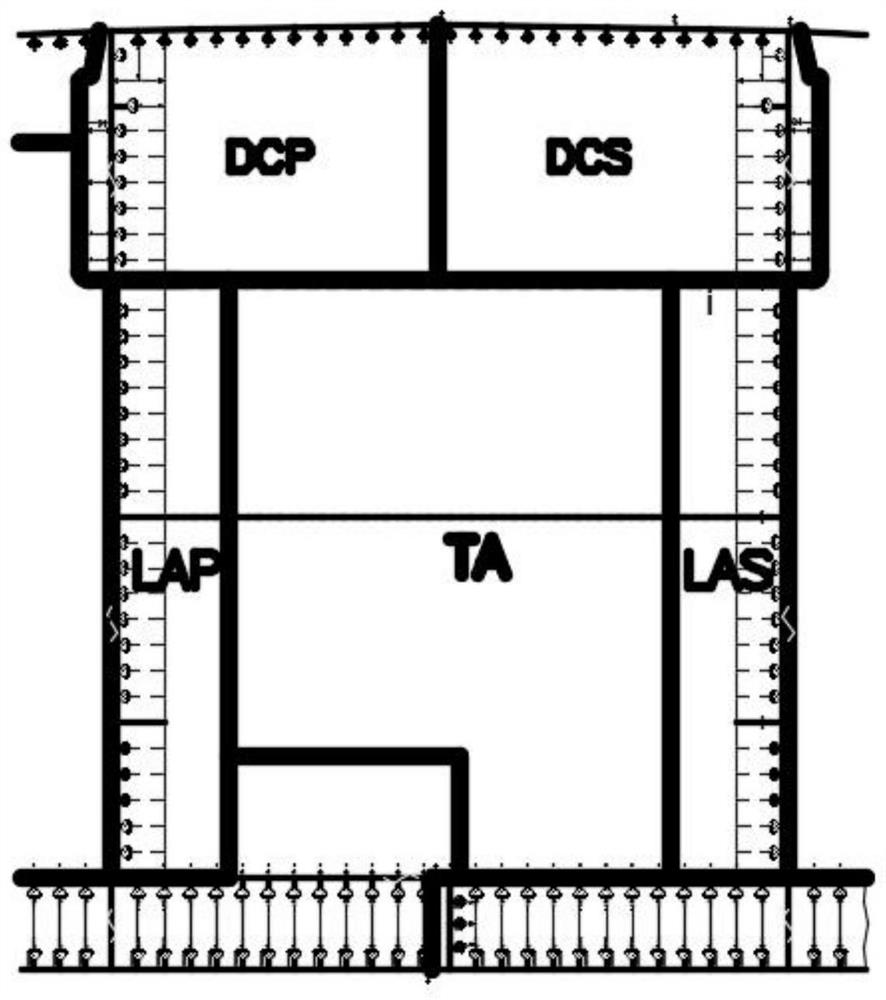

VLCC cargo oil tank segmentation and gantry carrying process

PendingCN113815808AReduce the amount of work at heightReduce operational riskWaterborne vesselsMarine engineeringOil tank

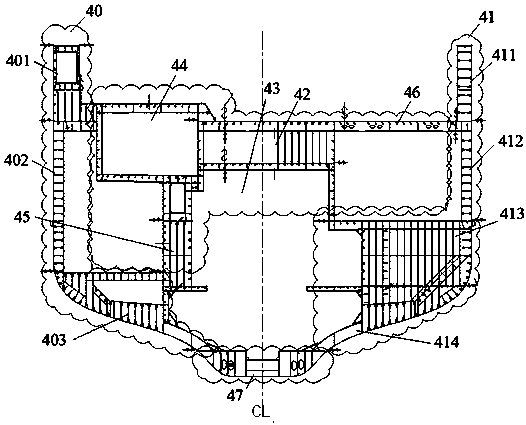

The invention provides a VLCC cargo oil tank segmentation and carrying process, which is characterized in that a VLCC cargo oil tank is divided into a plurality of segments in the length direction; the segments comprise an upper deck, a longitudinal bulkhead and a middle structure segment; the upper deck is divided into a DCS segment and a DCP segment along the symmetry plane; the longitudinal bulkhead is divided into an LAP segment and an LAS segment along the symmetry plane; and the middle structure segment is located between the two segments of the longitudinal bulkhead, the middle structure segment is of a cross beam structure or a sealed transverse bulkhead, and then carrying is conducted according to the segments. The invention belongs to the technical field of cargo oil tank segmentation and carrying, and the original LB segment deck small group and large group integration operation is omitted; and no turning-over fortification exists in a fixed disc in the dock, external field operation is turned into internal field operation, the operation procedure is advanced, the construction time of the in-dock operation is shortened, and the dock period is shortened.

Owner:DALIAN COSCO KHI SHIP ENG

A Design Method of Segmentation for G4 Type Ro-Ro Ship

ActiveCN109850059BReduce construction difficultyReduce the difficulty of precision controlWaterborne vesselsMarine engineeringFitting-out

The invention discloses a segment division design method for a G4 type rolling ship. The method comprises the following steps: A, basis: determining a whole ship segmented division principle and requirements; B, carrying out segmented division: dividing a cargo compartment roll-roll area into a bottom larboard segment, a middle segment, a starboard segment, broadside multi-layer larboard and starboard segments, multi-layer deck larboard and starboard segments, multi-layer ramp segments and multi-layer column segments; dividing a cargo hold cabin mixing area into a bottom full-width segment, multiple layers of larboard channel segments and one layer of starboard channel segment which are asymmetrical on the broadside, semi-three-dimensional segments and independent transverse bulkhead segments which are asymmetrical on the left side and the right side of the broadside cabin; dividing a cabin area into a left bulwark segment, a right bulwark segment, an independent complete square channel segment, left-right asymmetric deck segments, a larboard double-shell segment with asymmetric broadside, a starboard double-shell segment with asymmetric broadside, a cabin semi-three-dimensional segment with asymmetric broadside larboard and starboard, and a bottom full-width segment. The method is more scientific, reasonable and convenient, the integrity of the outfitting piece can be improved, and the dock period is shortened.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Foldable Long Travel Drilling Rig

ActiveCN104790878BImprove drilling work strokeSimple structureDerricks/mastsDrilling machines and methodsMechanical engineeringDrilling machines

The invention discloses a folded type long-stroke drilling machine. A driving mechanism is loaded on a base, output ends of the driving mechanism are connected with a lifting mechanism and a rotary mechanism respectively, a vertical column is connected with the lifting mechanism and the rotary mechanism respectively, the vertical column comprises an upper support and a lower support, the upper support is arranged at the upper end of the lower support, and the lower portion of the lower support is rotatably connected with the driving mechanism or the base through a first rotary piece; the upper portion of the lower support is movably connected with the base through a flexible inclined strut, and the lower support is supported by expanding the flexible inclined strut or the lower support is laid down by shortening the flexible inclined strut; by means of the first rotary piece and the flexible inclined strut, a movable double-support structure of the lower support is formed; the lower end of the upper support is rotatably connected with the upper end of the lower support through a second rotary piece, and a rotating track of the upper support rotating around the second rotary piece and a rotating track of the lower support rotating around the first rotary piece are located in different planes; a fixing piece is arranged between the lower end of the upper support and the upper end of the lower support.

Owner:HUNAN JIAYAO TIANYOU DRILLING & EXPLORING MACHINERY

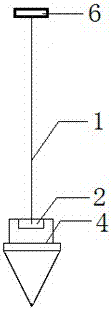

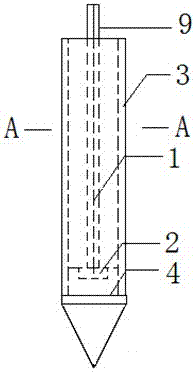

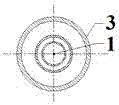

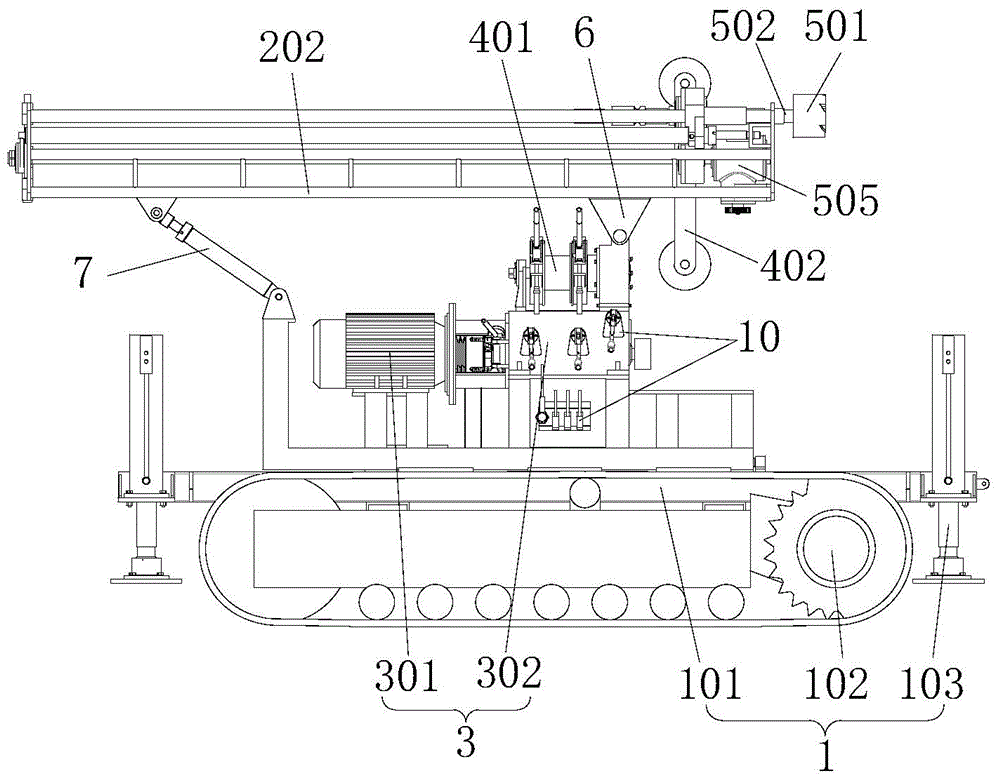

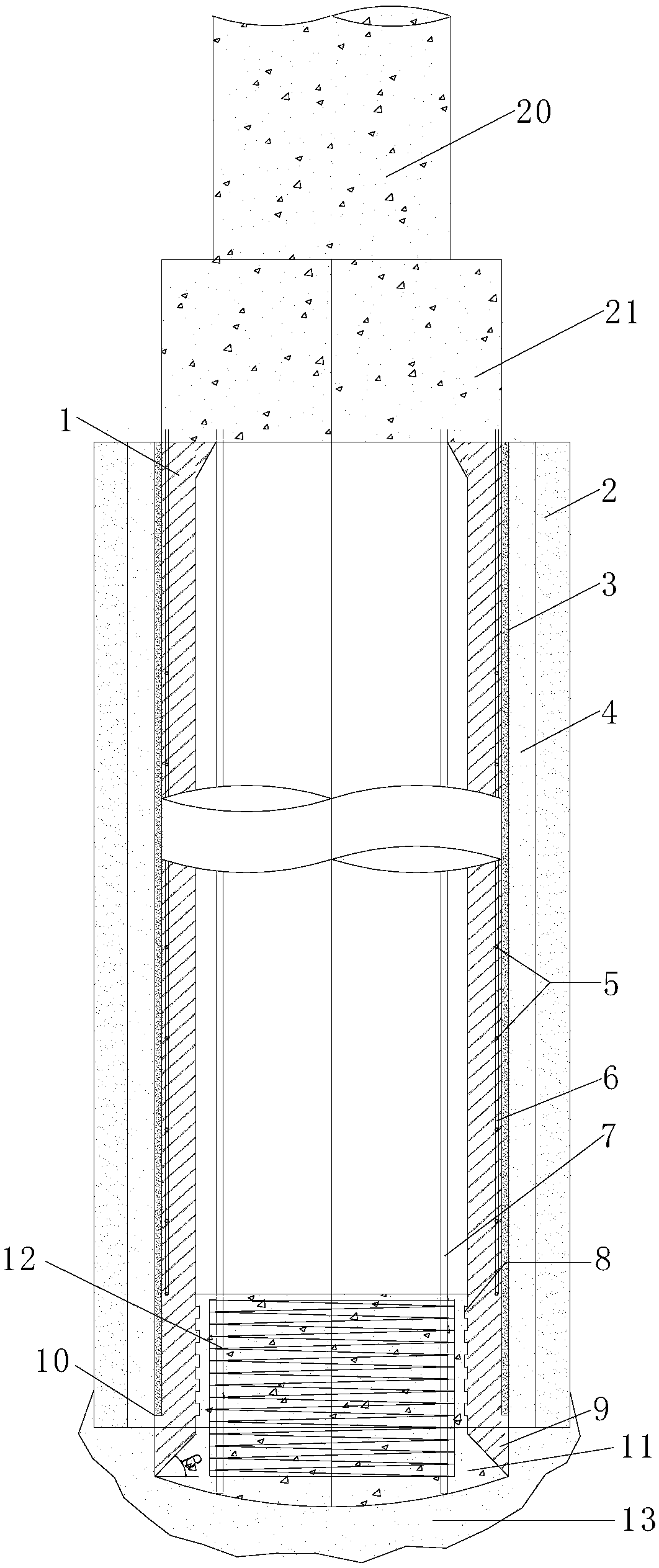

A super-large-diameter hollow independent composite pile foundation and its construction method

ActiveCN107338804BLoad transfer directImprove bearing capacityBulkheads/pilesThick plateReinforced concrete

The invention discloses a super large diameter, hollow, independent and composite pile foundation and a construction method thereof. The composite pile foundation comprises a super large diameter thin wall reinforced concrete hollow pile, cement mixing piles, a pile end reinforced concrete thick plate and a pile surrounding grouted soil body, wherein the cement mixing piles surround the pile foundation to form a closed cement mixing pile wall; the super large diameter thin wall reinforced concrete hollow pile is made through section cast-in-place at the pile site or sectional splicing after prefabricating, and after the hollow pile body sinks to a designed position, the bottom end is sealed by concrete so as to form the hollow pile; after the formation of the hollow pile, high pressure jet grouting of cement grout is carried out at the part between the super large diameter thin wall reinforced concrete hollow pile and the cement mixing piles; and the pressure-injection of cement grout is further carried out at the bottom and the surrounding soil body of the hollow pile for reinforcement through pile bottom grouting pipes, horizontal grouting holes and vertical grouting holes, so as to form the composite pile foundation. According to the super large diameter, hollow, independent and composite pile foundation and the construction method thereof, a higher bearing capacity is achieved, the advantages of good pile quality and high safety are achieved, and meanwhile a better economic performance is achieved.

Owner:ANHUI WATER RESOURCES DEV +1

A normal construction method for the outer plate of a ship's bow section

ActiveCN113148062BImprove construction efficiencyHigh precisionWatercraft hull designHull stemsHullRib cage

Owner:JIANGNAN SHIPYARD GRP CO LTD

A Quick Installation Method of Tapered Straight Chimney

ActiveCN110847687BExtended use timeReduce the difficulty of construction workTowersButtressEngineering

Owner:SHANDONG GUOSHUN CONSTR GRP

Overall structure of a three-branch series hypersonic wind tunnel

ActiveCN112729750BRealize the requirement of wide parameter operation simulation rangeFast test capabilityAerodynamic testingCold airClassical mechanics

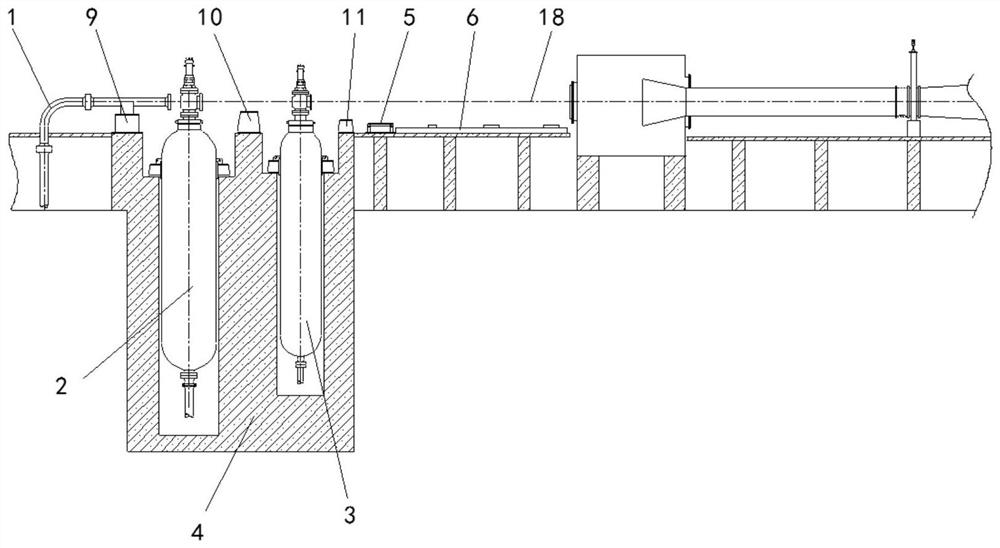

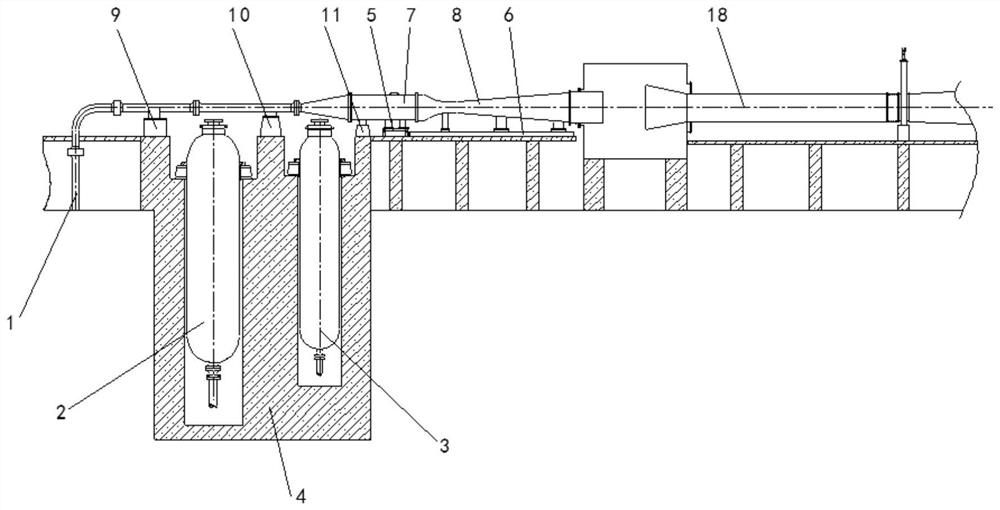

The invention discloses an overall structure of a hypersonic wind tunnel with three branches connected in series, comprising branches that divide the Mach number simulation range of the hypersonic wind tunnel from 3 to 10 into three intervals, and the three branches are respectively large flow The low-pressure cold air branch, the large-flow medium-temperature and medium-pressure branch, and the medium-small flow high-temperature and high-pressure branch, the Mach number operating range of the large-flow low-pressure cold air branch is less than or equal to Mach number 4, and the high-flow medium-temperature and medium-pressure branch The Mach number operating range is greater than 4 and less than or equal to 7, and the Mach number operating range of the small and medium flow high temperature and high pressure branch is greater than 7 and less than or equal to 10; the overall structure of a three-branch series hypersonic wind tunnel provided by the present invention can be Through the method of step-by-step implementation, the requirements of advanced hypersonic wind tunnel for wide parameter simulation are realized; the operation status of the wind tunnel is convenient to switch, and the layout of the wind tunnel is simple, which is conducive to the safe operation and standardized management of the wind tunnel.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

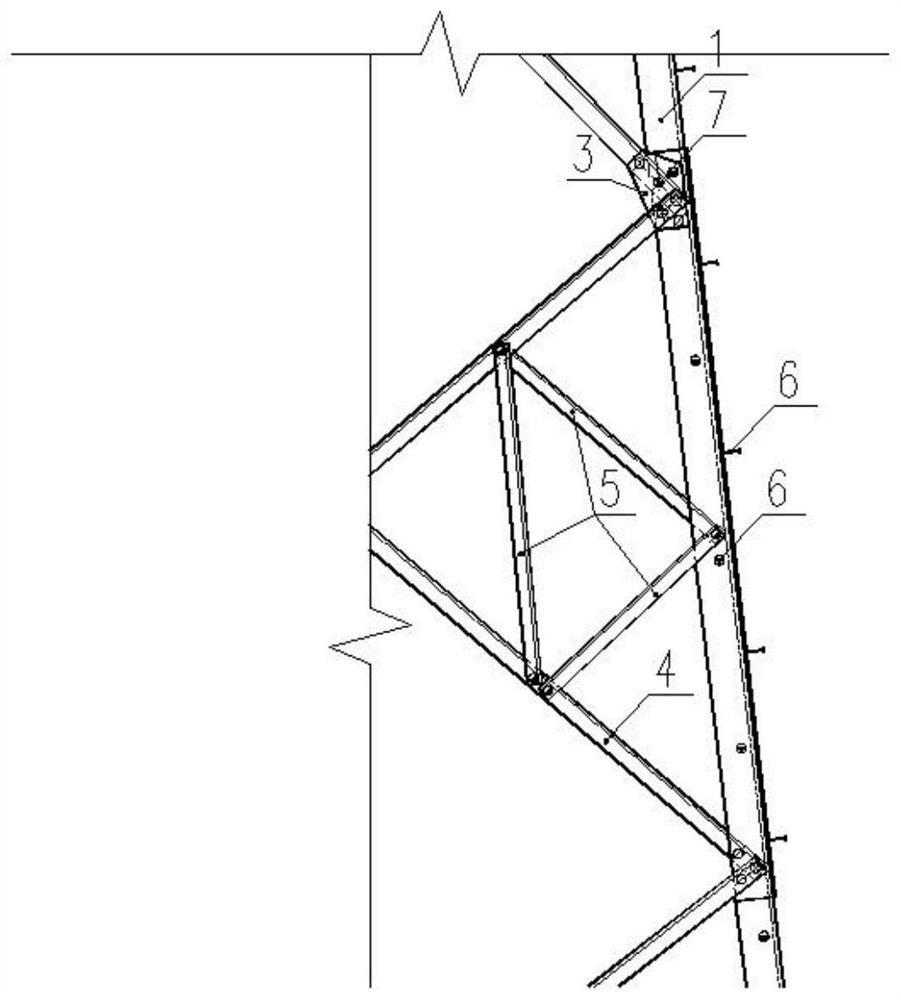

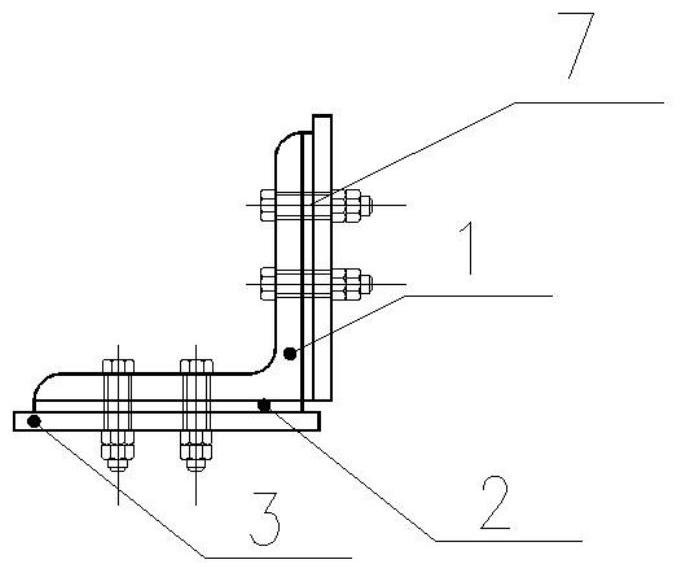

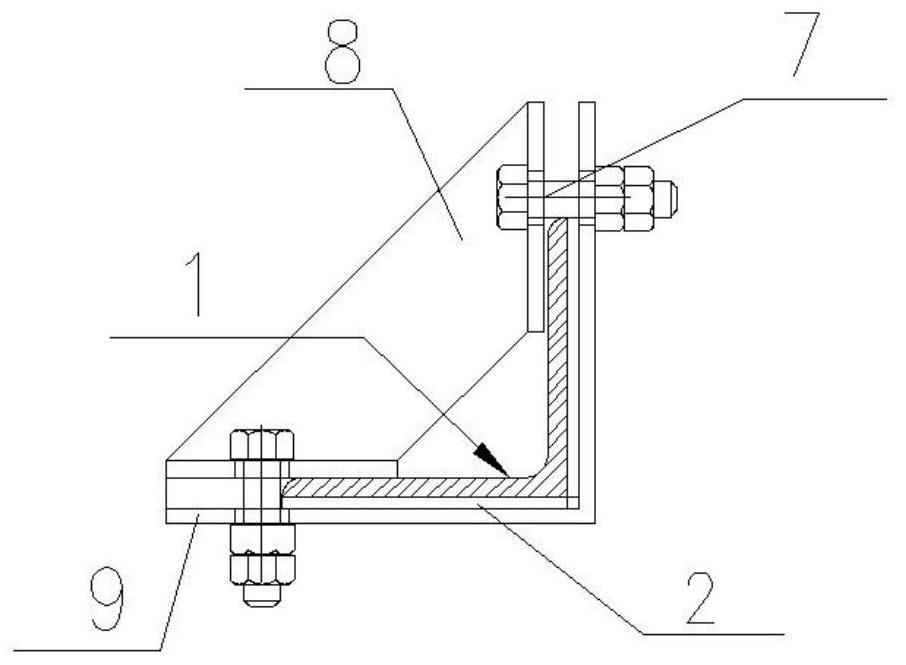

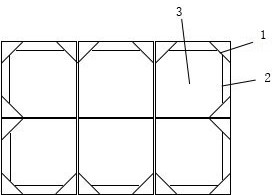

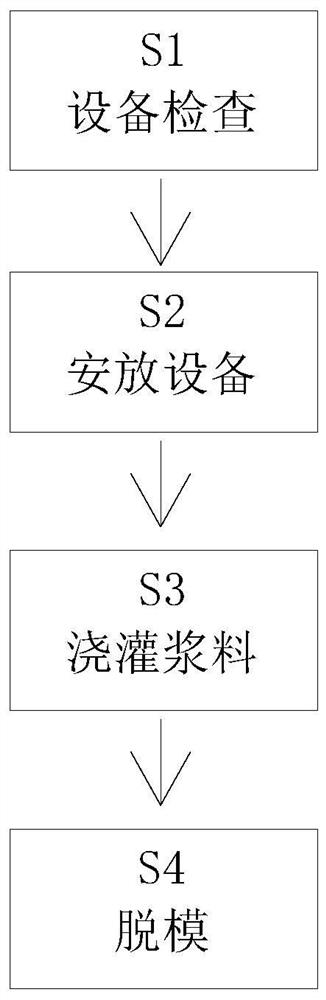

Construction method of a prefabricated assembly cornice

ActiveCN107190983BReduce the difficulty of construction workReduce intensityBuilding material handlingSurface finishHydrophile

The invention discloses a construction method for a prefabricated cornice. The construction method specifically comprises the following steps of making preparations before construction; pre-burying main structural iron pieces; fabricating cornice components; constructing an operating platform; welding and mounting the cornice; specifically, prefabricating of the cornice components includes the steps of determining the sizes of components with different specifications according to prepared models, determining the sizes of the pre-buried iron pieces in the components at the same time, and determining the length and the welding sizes of internal pre-buried bars; preparing the corresponding pre-buried iron pieces according to the sizes of the pre-buried iron pieces; manufacturing mounting formworks and brushing a mold releasing agent; mounting the pre-buried bars and the corresponding pre-buried iron pieces in the mounting formworks; pouring ceramsite concrete and conducting vibration; using an iron trowel to conduct trowelling and surface finishing to ensure the surface achieve hydrophile effect; conducting demoulding after maintenance and conducting numbering; and conducting stacking according to the corresponding specifications.

Owner:康博达建设科技集团有限公司

Construction method of built-in diagonal steel truss deep coupling beams in superimposed shear walls with openings

ActiveCN111576881BImprove seismic performanceSolve the construction problem of difficult arrangement of oblique reinforcementConstruction materialWallsMesh reinforcementArchitectural engineering

The invention relates to a construction method for a composite shear wall with an opening and a built-in diagonal steel truss deep connecting beam, which comprises the following steps: a prefabricated processing plant manufactures a prefabricated composite shear wall, which is used to manufacture the overall reinforced skeleton of the composite shear wall , two obliquely arranged steel bar trusses are placed crosswise between the longitudinally stressed steel bars of the coupling beams, and then the steel bar skeletons of the coupling beams are effectively connected with the steel mesh pieces in the prefabricated wall panels of the inner and outer leaves, and finally the concrete of the wall panels is poured to form a prefabricated Composite shear wall: transport the prepared prefabricated composite shear wall to the construction site, pour the core concrete and wait for the core concrete to reach a certain strength, then carry out the construction of the superstructure to complete the construction of the entire shear wall structure. The present invention utilizes obliquely arranged steel bar trusses to improve the shear resistance of the laminated deep connecting beams, endows the structural steel bar trusses connected to the laminated wall pieces with a new function of bearing structural internal forces, and makes the laminated deep connecting beams without additional reinforcement Under the circumstances, it can meet the structural force and seismic requirements.

Owner:WUHAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com