Factory prefabricated elevator well foundation pit and mounting method thereof

A factory prefabricated, elevator shaft technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of large influence of on-site construction weather factors, lack of appearance of concrete finish surface, high noise of cutting board, etc., and it is easy to achieve construction quality. Guarantee, inspection process perfect, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings.

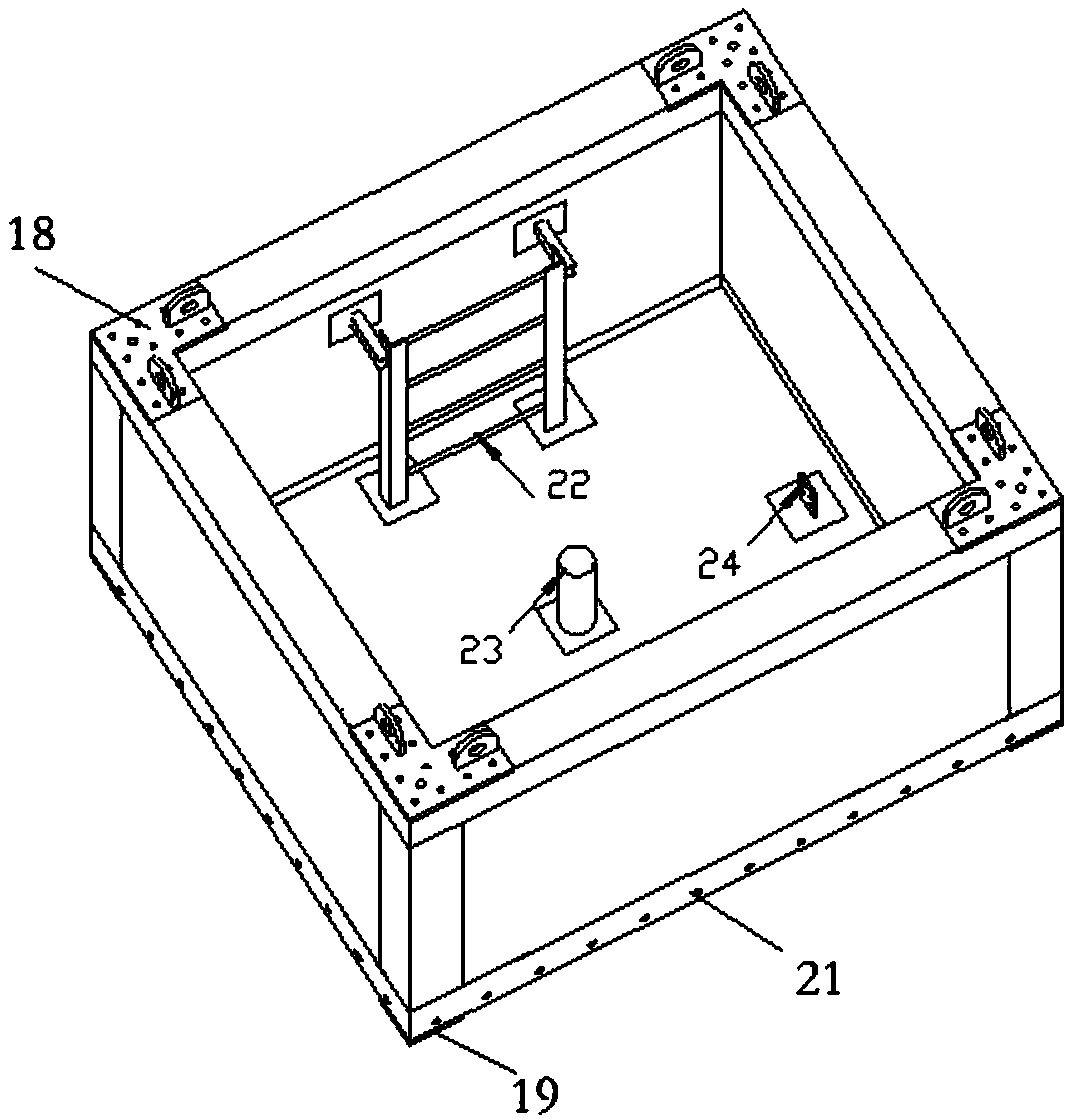

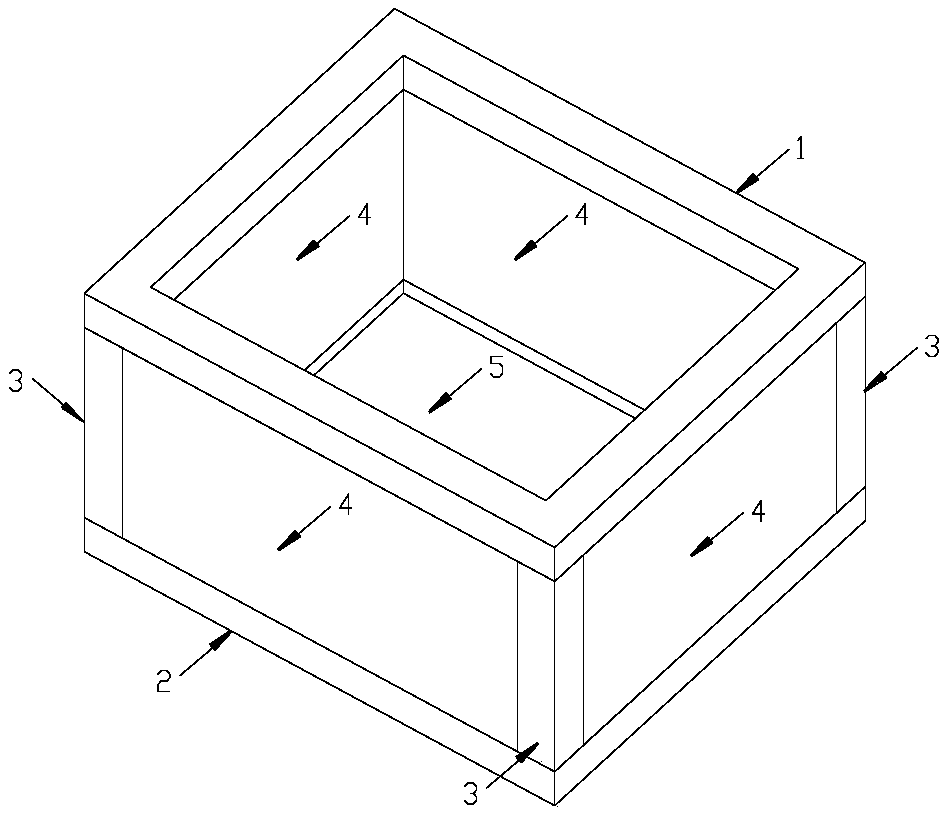

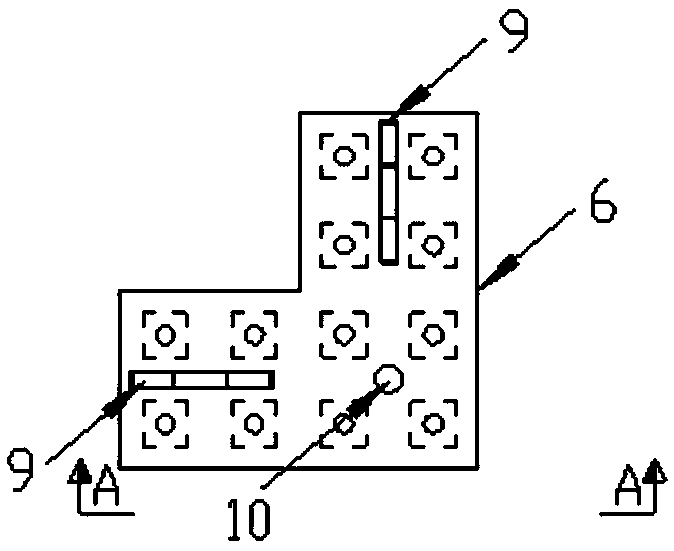

[0058] Such as figure 1 As shown, the present invention includes individual concrete hoistway components and embeddings.

[0059] (1) Separate concrete shaft components

[0060] Such as figure 2 As shown, it consists of five parts: top ring beam 1, bottom ring beam 2, corner column 3, wall body 4, and bottom plate 5. Among them, the section of the top ring beam 1 is 200 mm * 200 mm; the section of the bottom ring beam 2 is 200 mm * 200 mm; the section of the corner column 3 is 200 mm * 200 mm; the thickness of the wall 4 is 200 mm; the thickness of the bottom plate 5 is 150 mm. The concrete strength grade is C30, and the impermeability grade is greater than or equal to P6.

[0061] The inner dimension of the shaft is 2100*1750mm, and the depth is 1500mm.

[0062] Due to the difference in the model of the elevator, the height of the shaft, and the external decorat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com