Patents

Literature

32results about How to "Release thermal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

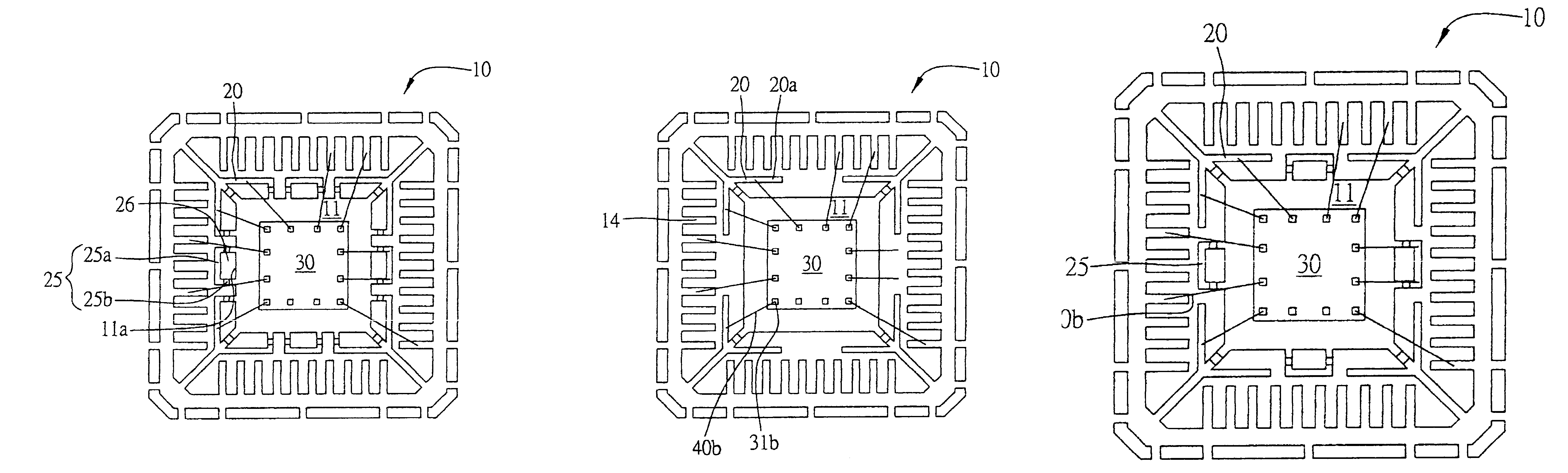

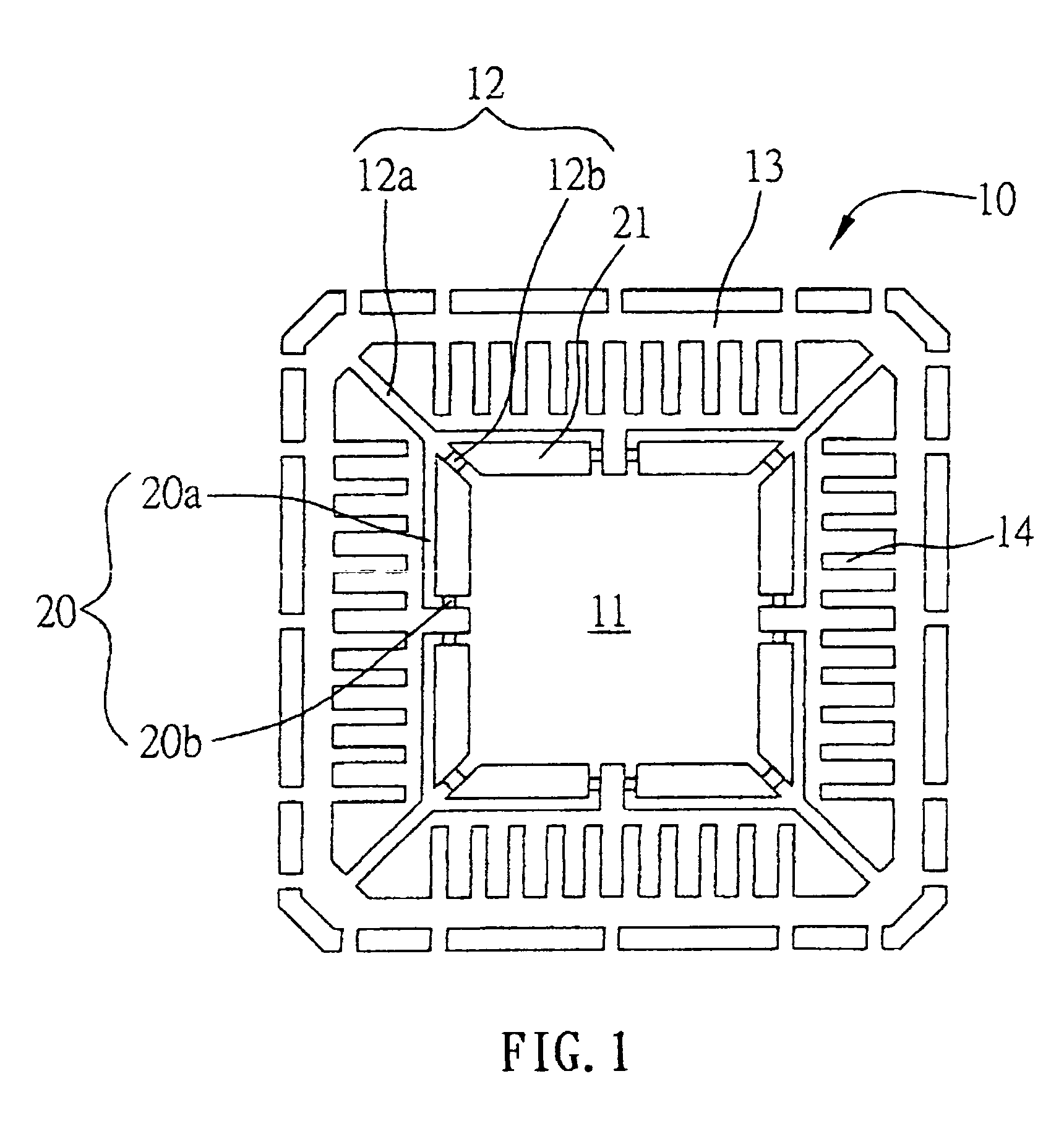

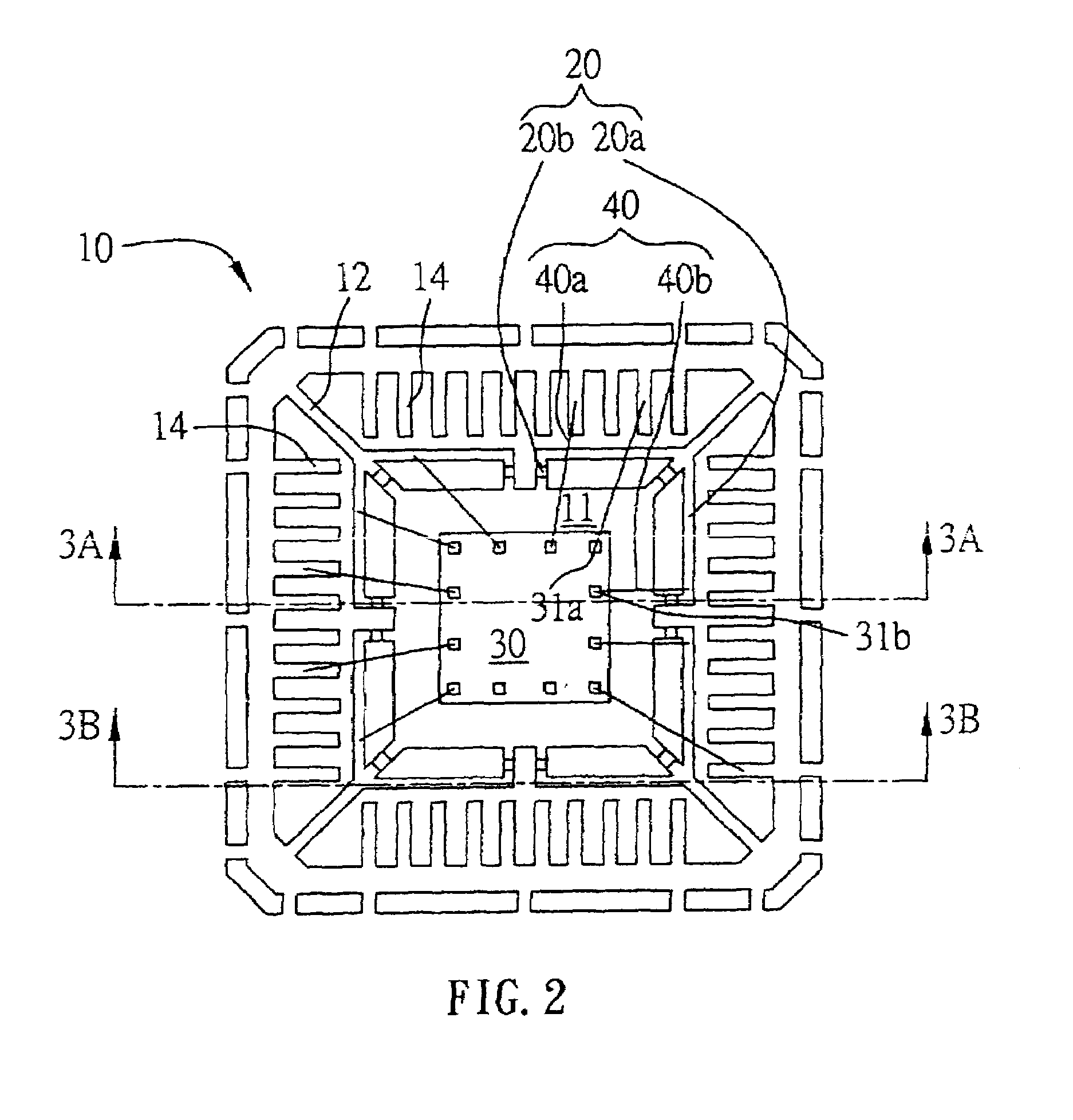

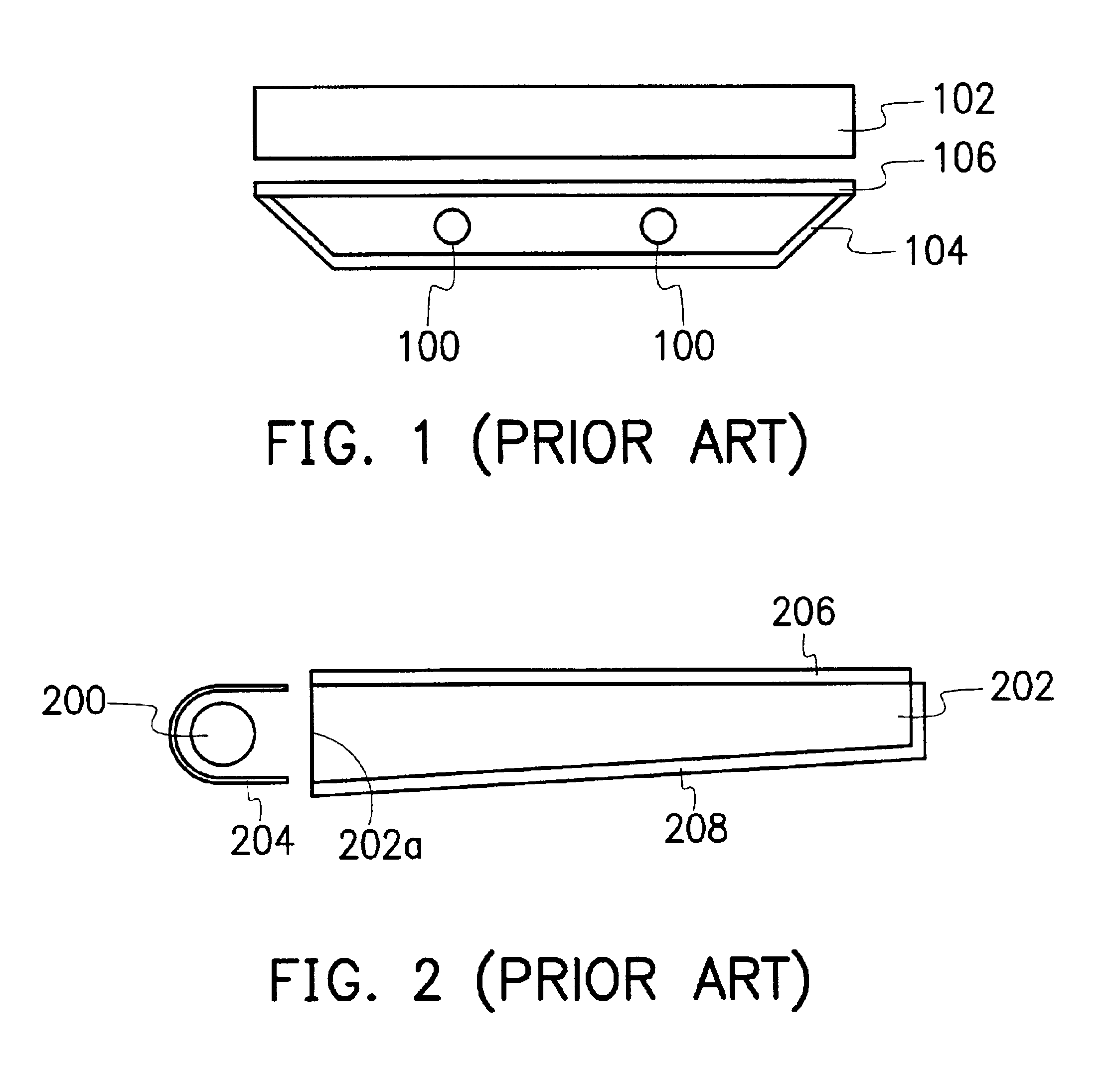

Ground-enhanced semiconductor package and lead frame for the same

ActiveUS7230323B2Avoid deformationEliminate difficult bondingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

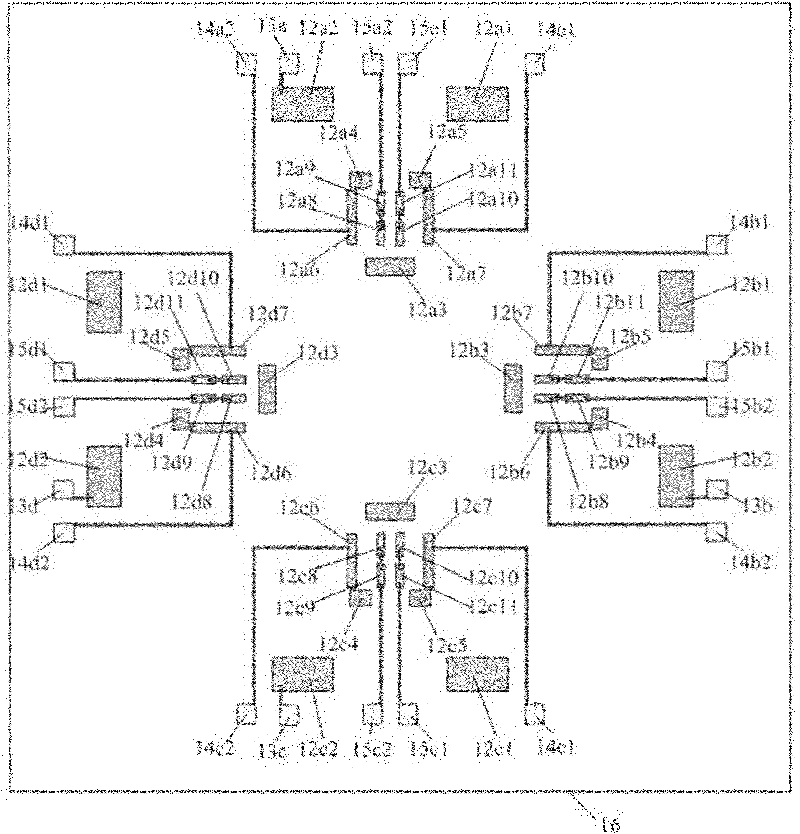

A ground-enhanced semiconductor package and a lead frame used in the package are provided. The semiconductor package includes a lead frame having a die pad, a plurality of tie bars connected with and supporting the die pad, a plurality of leads surrounding the die pad, and a ground structure, wherein the ground structure comprises at least one of first ground portions connected to the tie bars, and / or at least one of second ground portions connected to the die pad, and wherein the first ground portions are separate from each other, and the second ground portions are separate from each other; at least one chip mounted on the die pad and electrically connected to the leads and the ground structure; and an encapsulation body for encapsulating the chip and the lead frame. The separately-arranged ground portions allow thermal stresses to be released from the ground structure without rendering deformation issues.

Owner:SILICONWARE PRECISION IND CO LTD

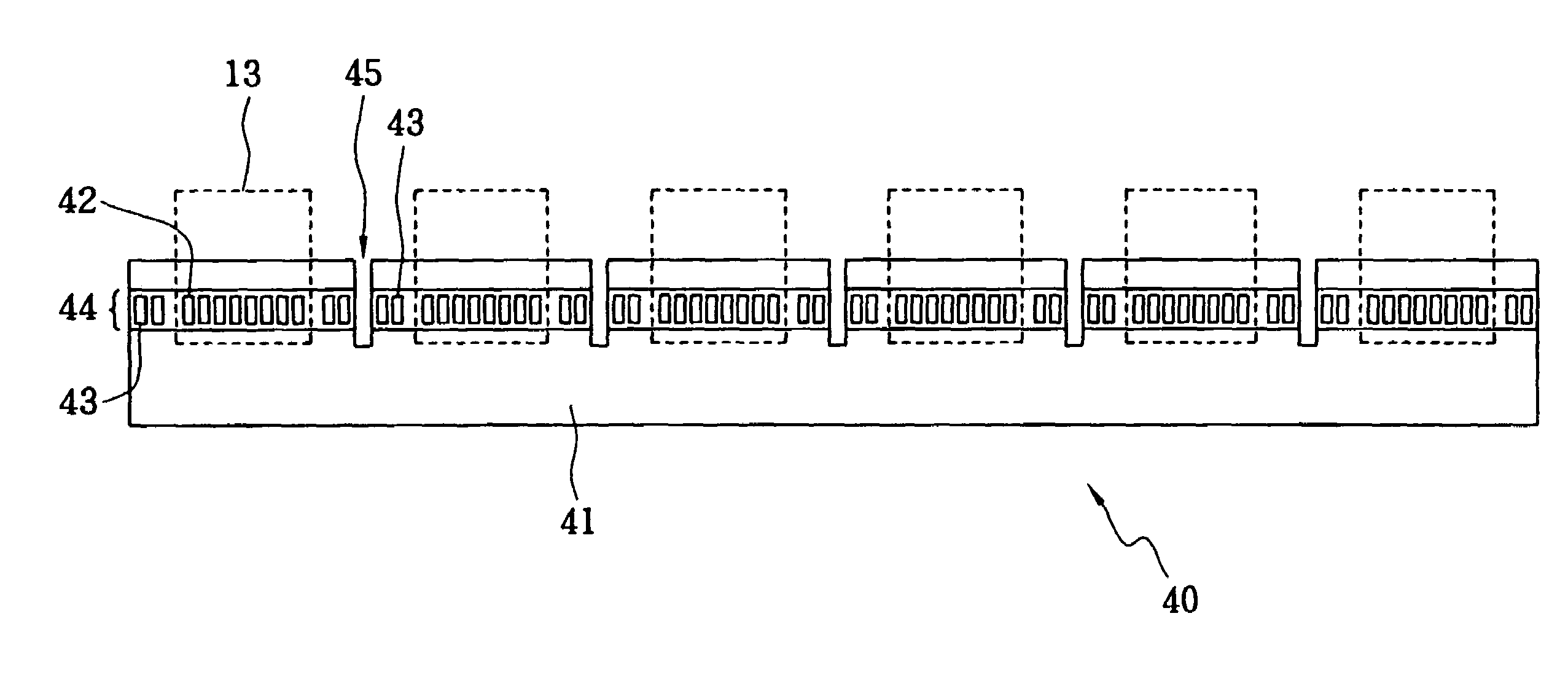

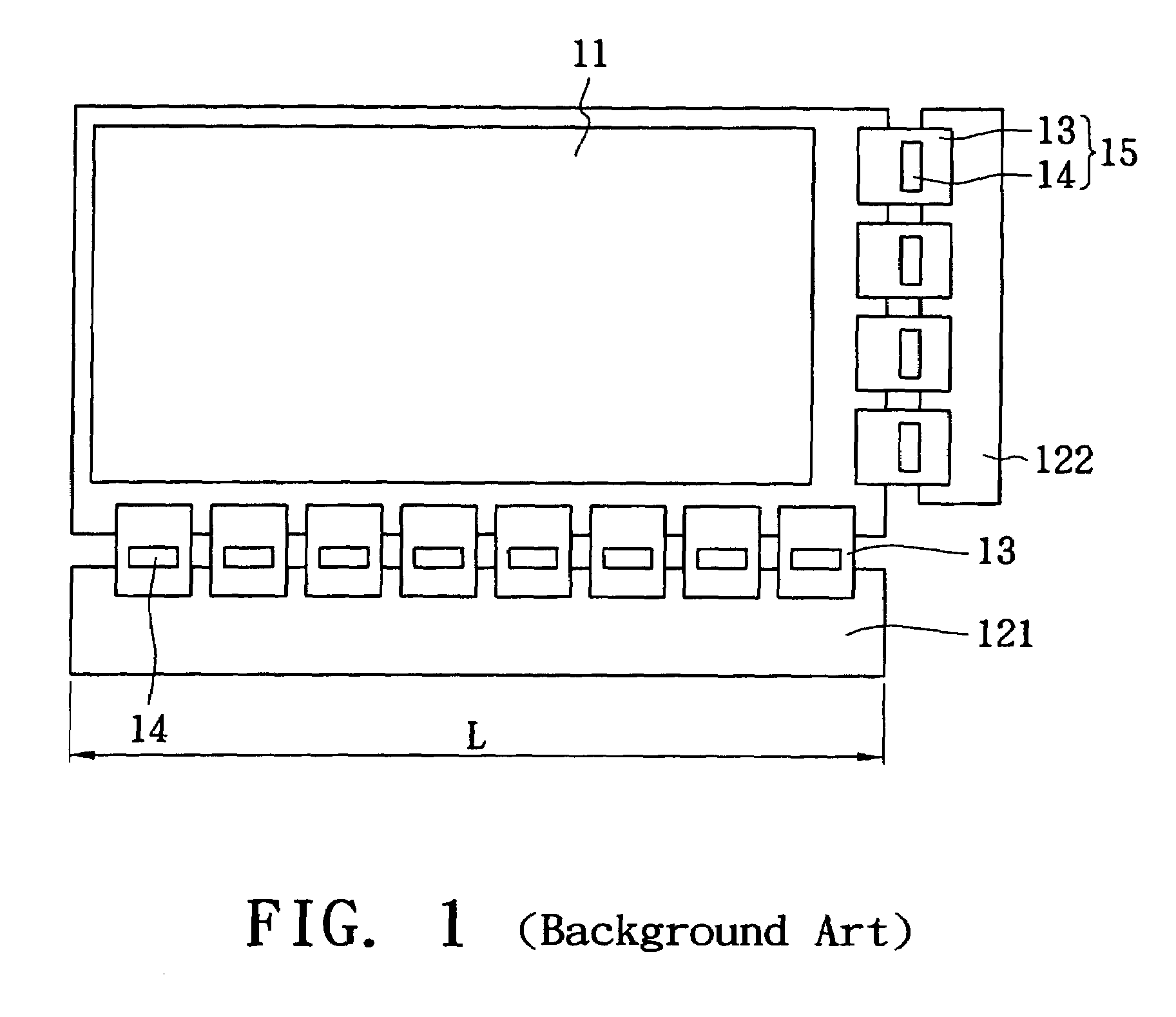

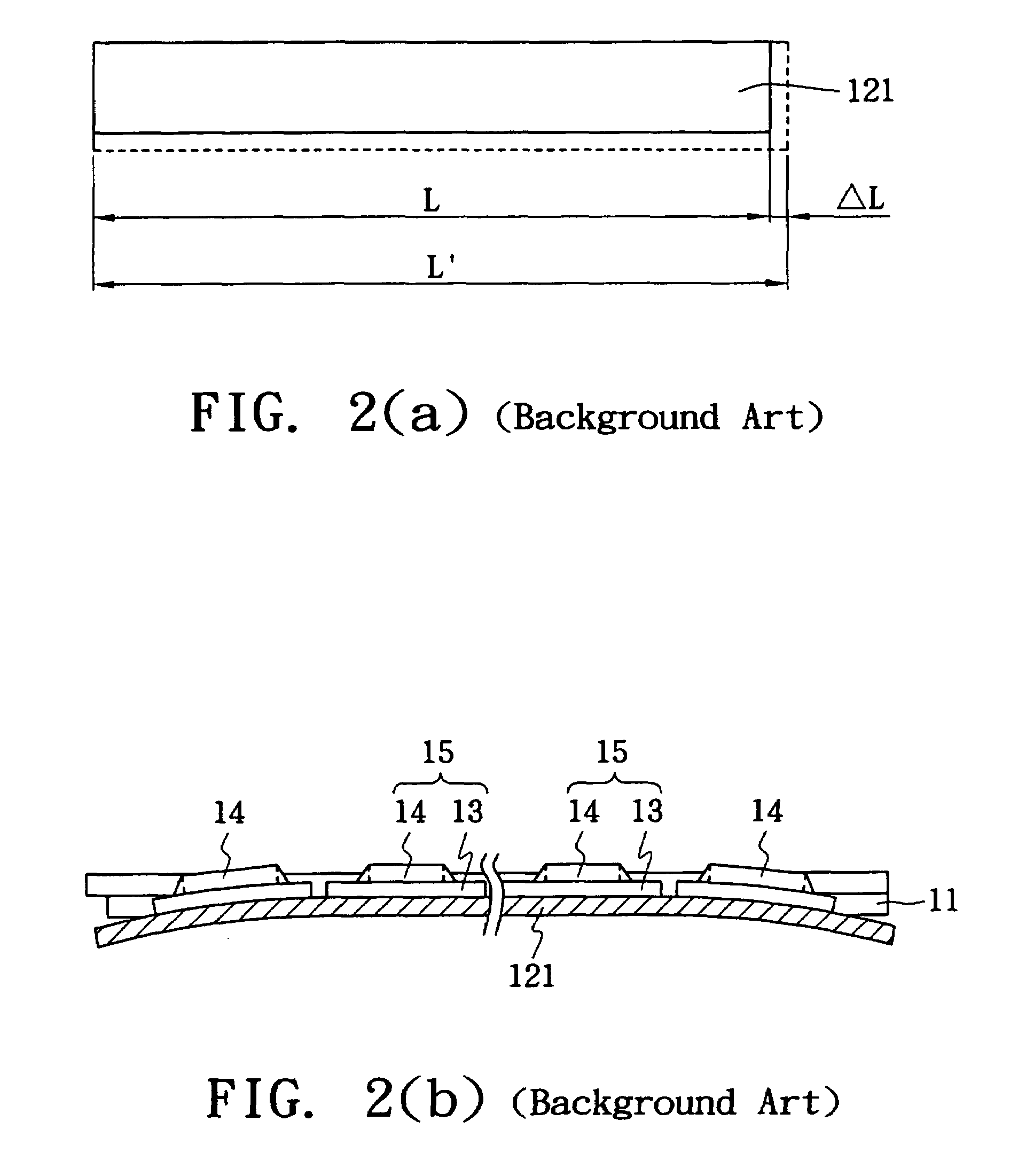

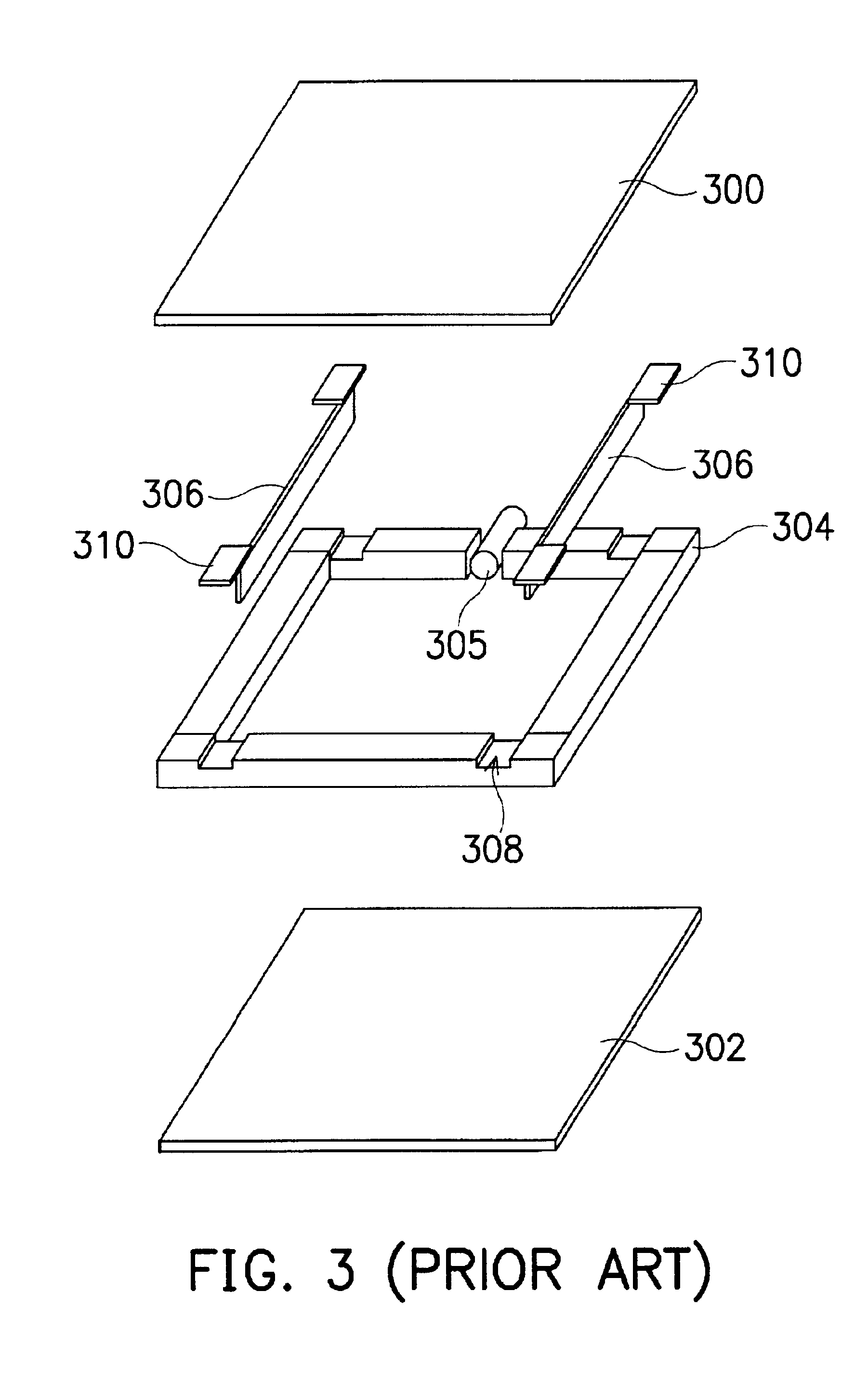

PCB capable of releasing thermal stress

ActiveUS7223923B2Release thermal stressPrinted circuit aspectsPrinted circuits stress/warp reductionThermal compressionEngineering

A PCB comprises a slender substrate, a thermal compression area and at least a slit. The thermal compression area, placed on the slender substrate, has a plurality of bonding pads for a plurality of TCPs to be mounted thereon and a plurality of dummy pads placed between the TCPs. The slit transversely crosses the thermal compression area and slices some of the dummy pads. When the TCPs are connected to the bonding pads of the PCB, the thermal compression area is heated to around 150° C. to 200° C. Therefore, the slit can block the thermal expansion to be accumulated along the longitudinal direction of the thermal compression area.

Owner:HANNSTAR DISPLAY CORPORATION

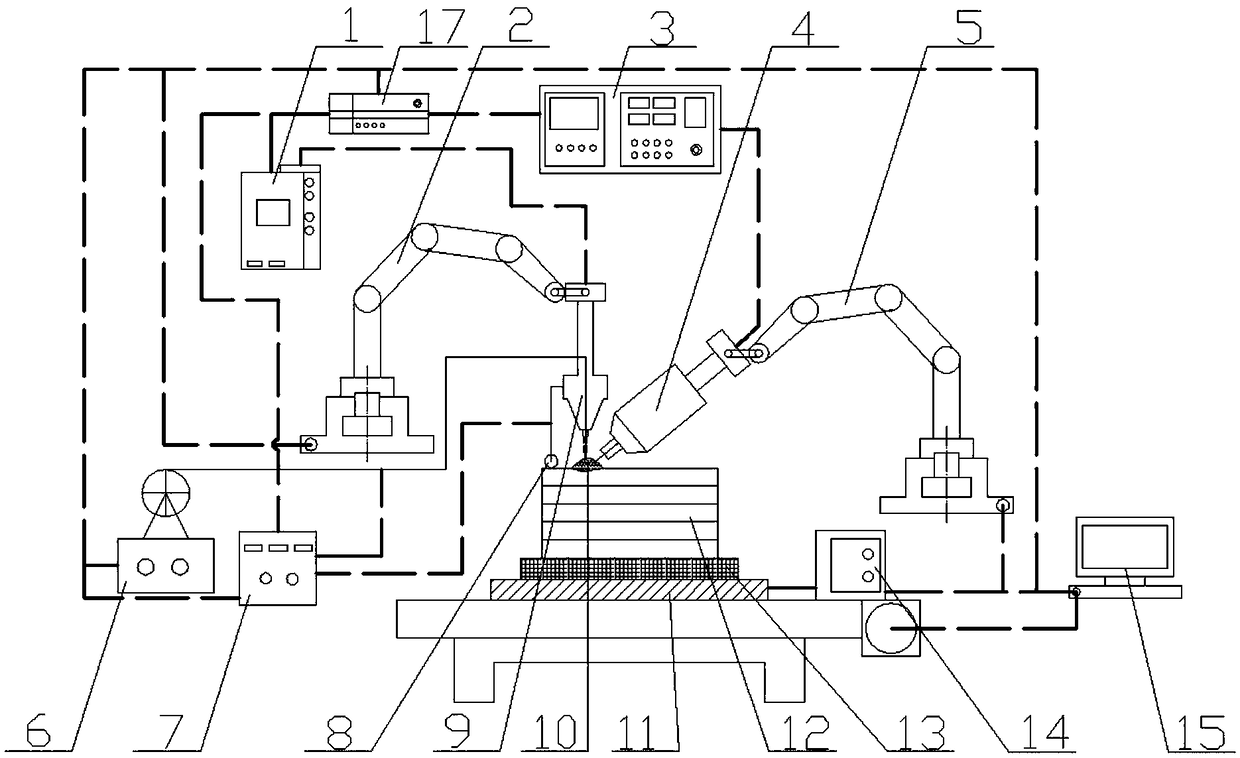

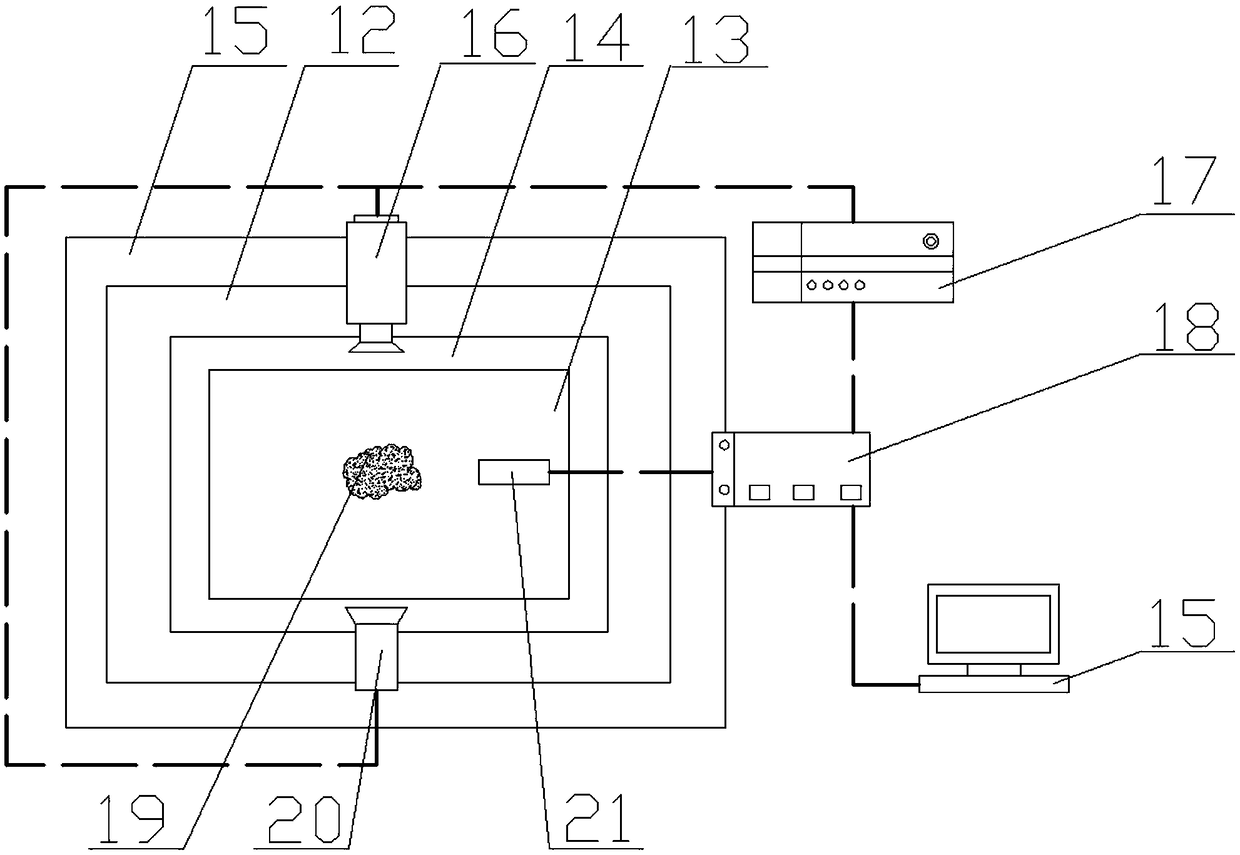

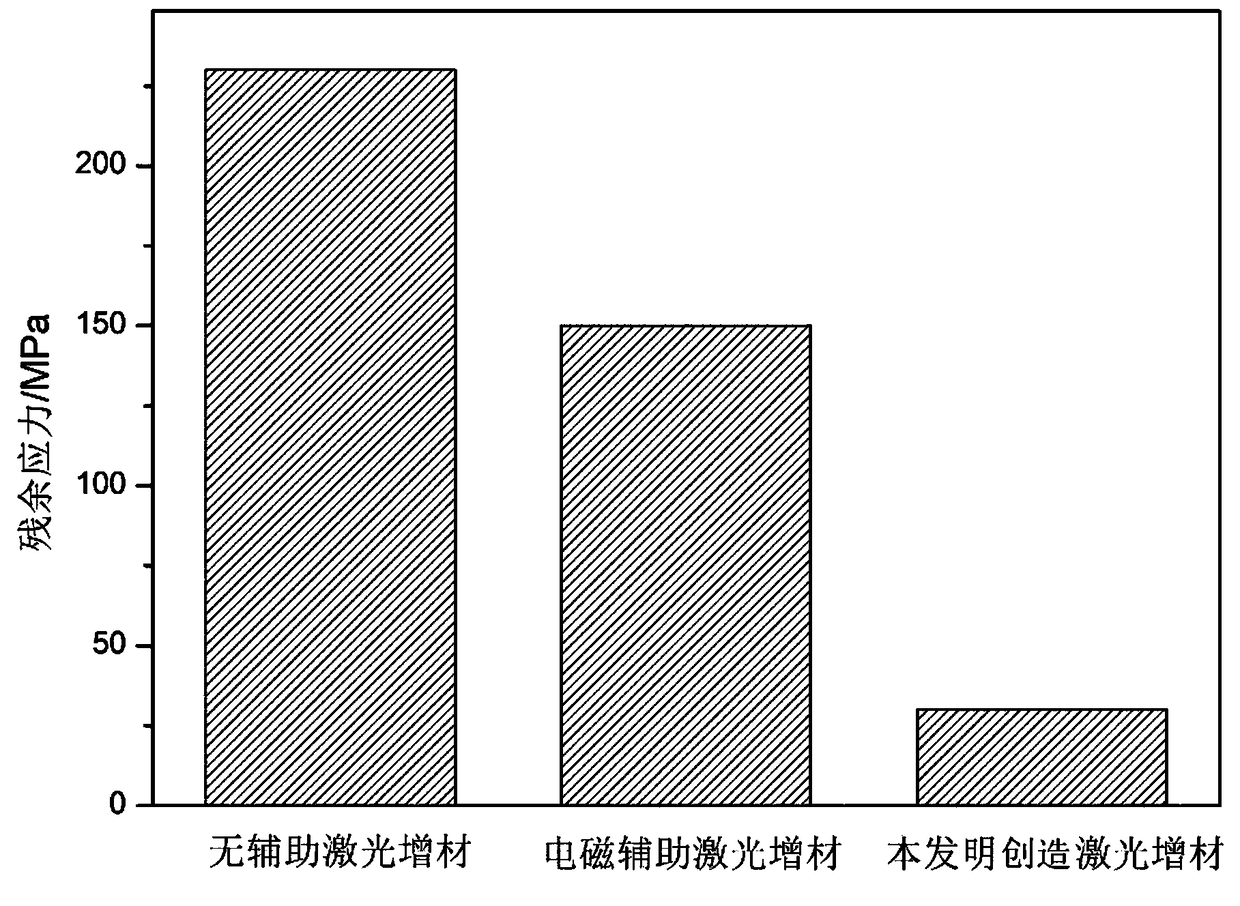

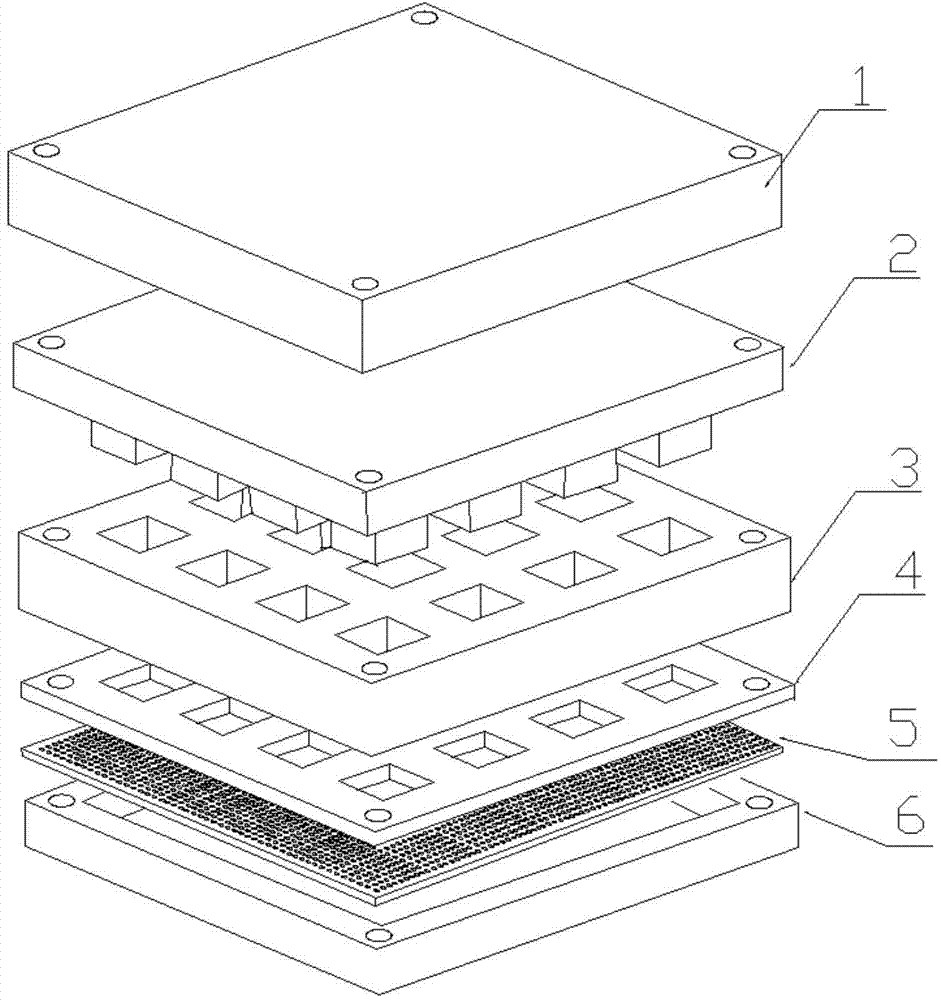

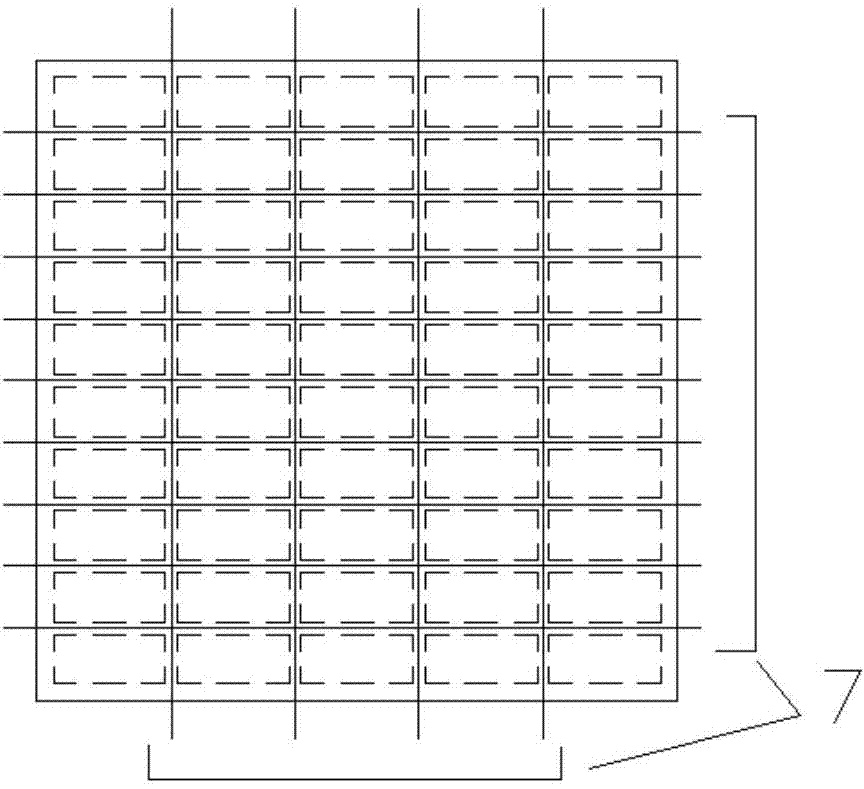

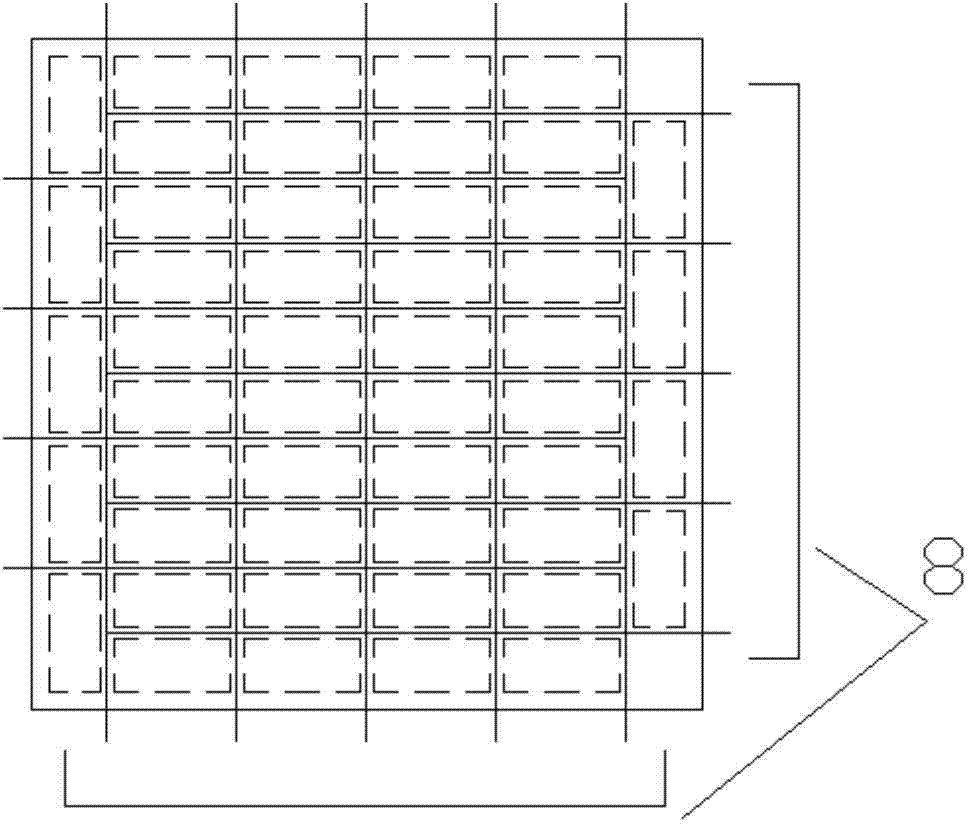

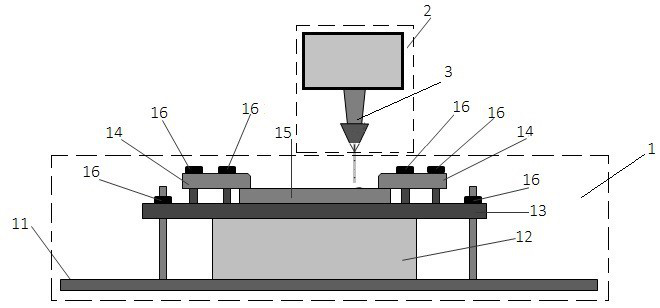

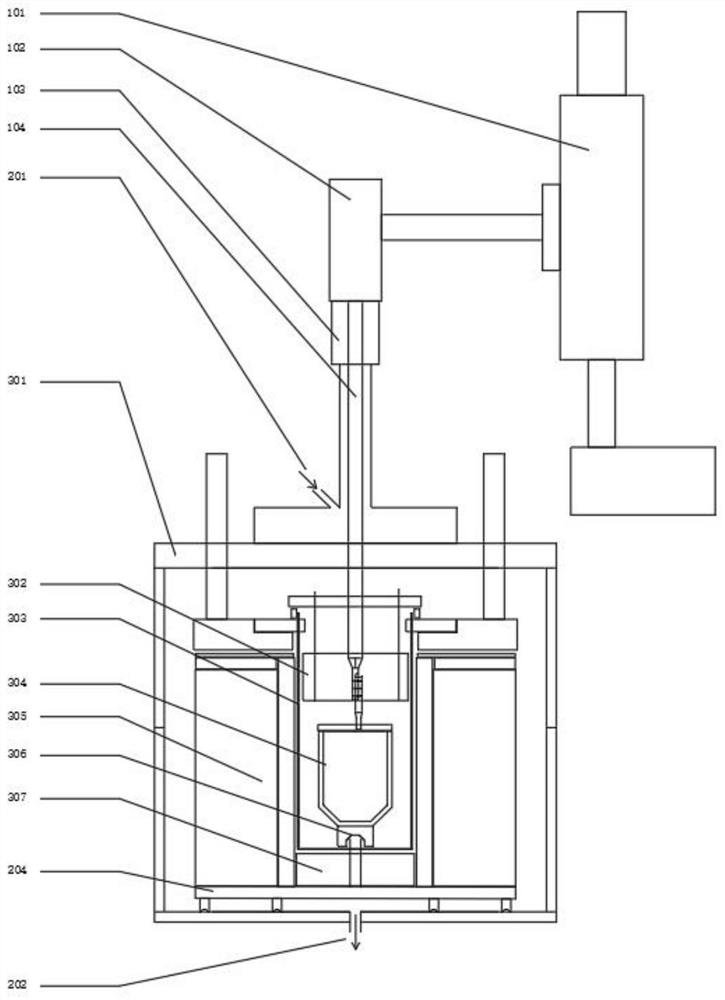

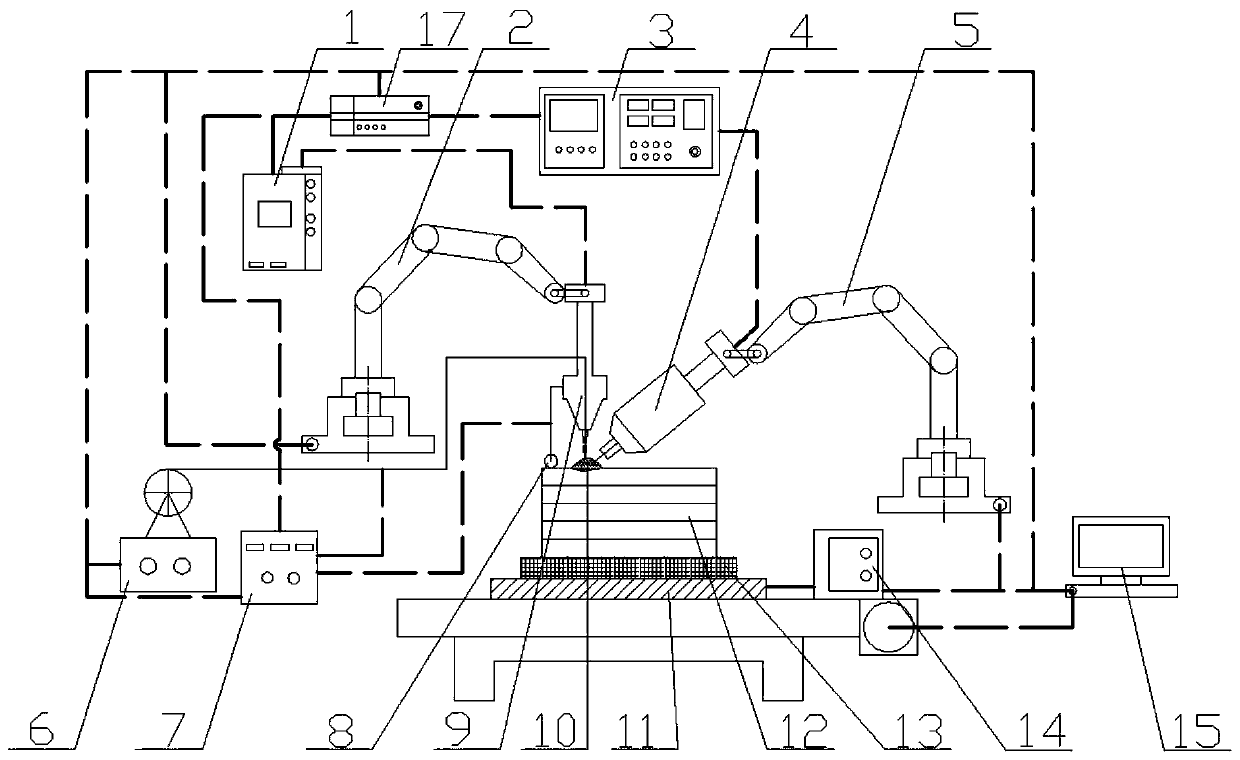

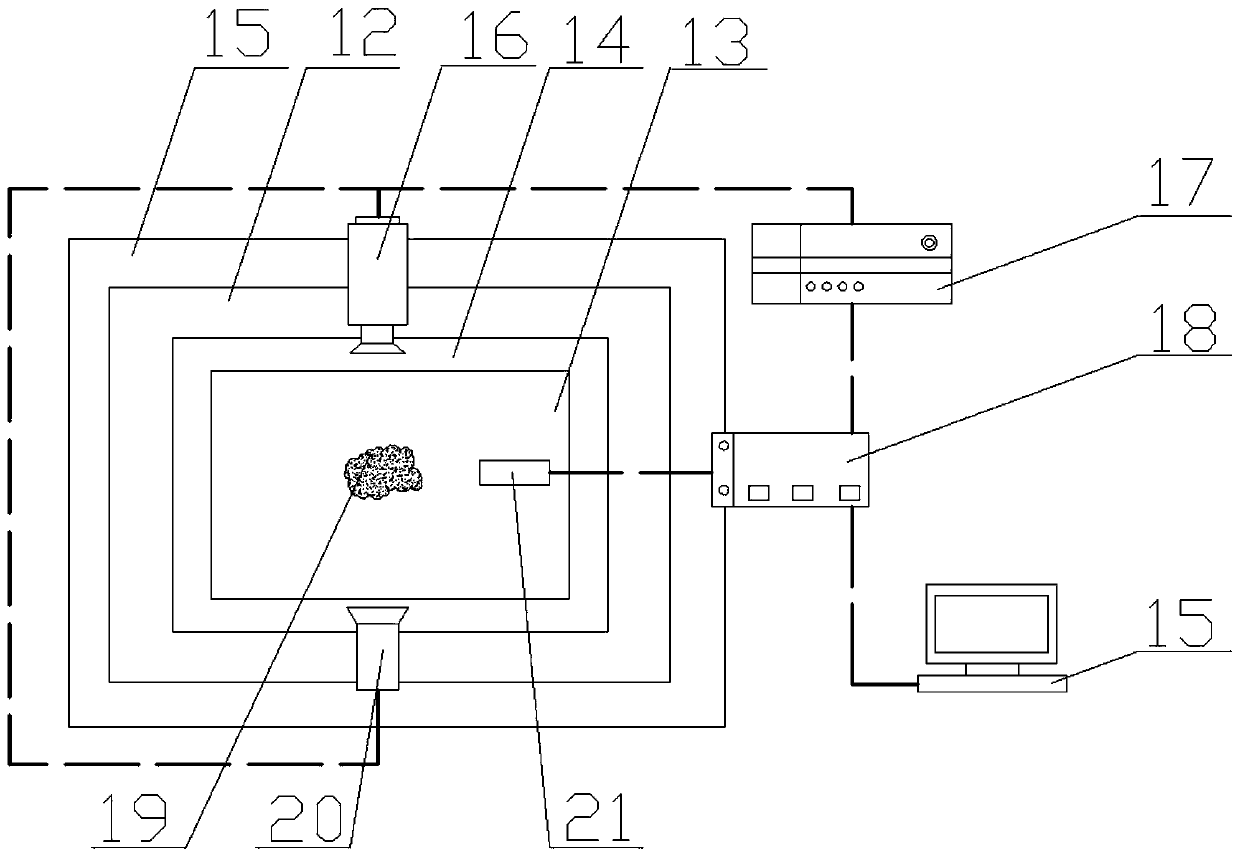

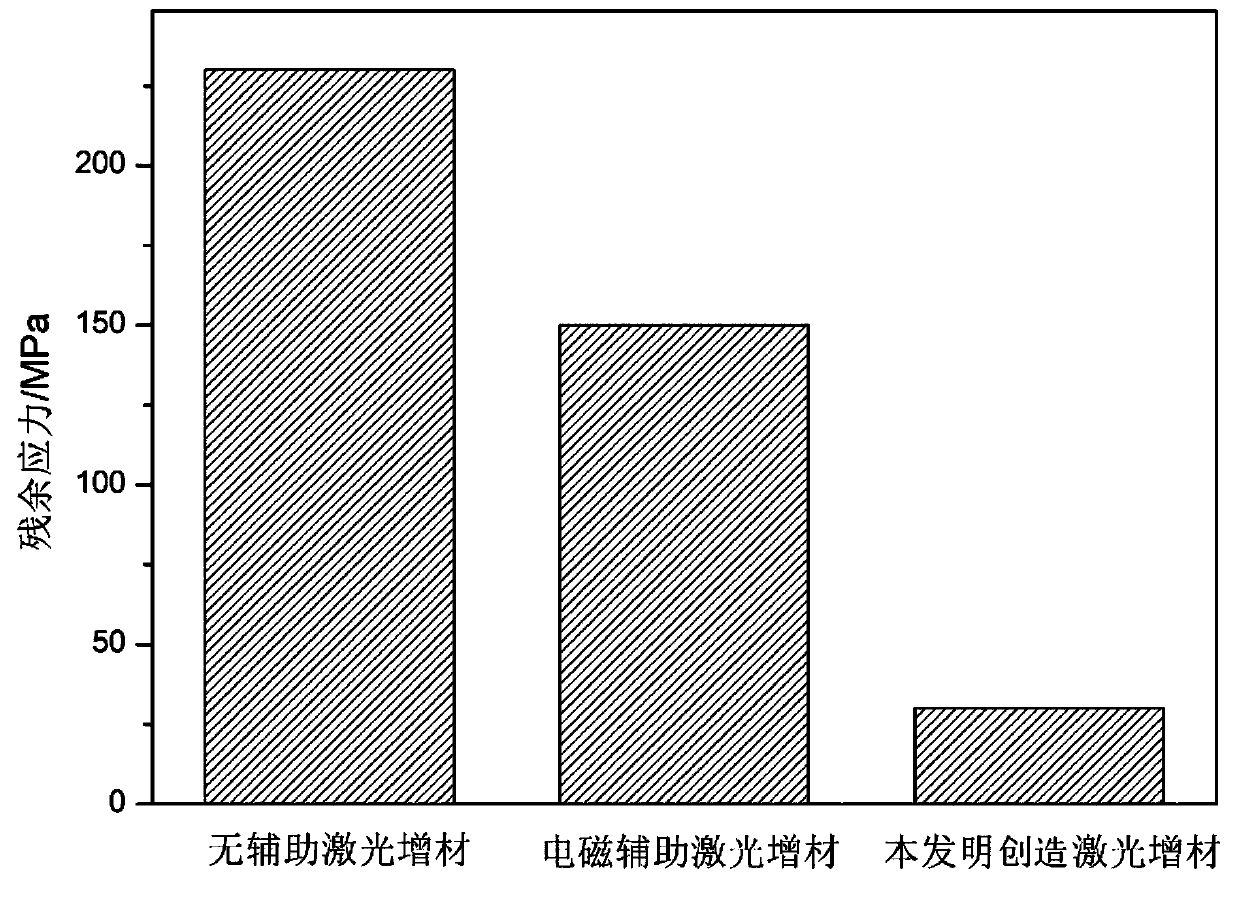

Laser additive device and additive manufacturing method thereof

InactiveCN109175364AUniform distribution of energy and temperature fieldsStir wellAdditive manufacturing apparatusIncreasing energy efficiencyPower flowHigh frequency

The invention provides a laser additive device which comprises a rotary light beam laser system, a high-frequency short pulse laser system and an auxiliary current system. The rotary light beam lasersystem outputs rotary continuous laser light, and the continuous laser light is used for melting and depositing wires to the surface of a base material; the high-frequency short pulse laser system outputs high-frequency short pulse laser light, and the high-frequency short pulse laser light is used for inputting a pulse laser beam into a molten bath. The auxiliary current system is used for enabling the wires and the molten bath to form a current loop, and therefore strong electromagnetic force is directly produced in the molten bath. The rotary light beam laser system comprises a continuous laser generator, a first high precision mechanical arm and a continuous laser device laser head. The high-frequency short pulse laser system comprises a high-frequency short pulse laser generator, a high-frequency short pulse laser head and a second high precision mechanical arm. The defects that element segregation is likely to be caused in the molten bath, gas cannot be exhausted, the structure is uneven, and heat stress is concentrated can be overcome.

Owner:JIANGSU UNIV

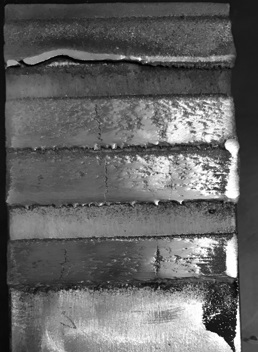

Impact-resistant and high-wear-resistant surfacing alloy material

ActiveCN101870046AImprove wear resistanceImprove impact resistanceWelding/cutting media/materialsSoldering mediaCrazingWear resistant

The invention relates to an impact-resistant and high-wear-resistant surfacing alloy material, which belongs to the technical field of materials, and comprises the following components by weight percent: 55-68% of chrome iron, 5-13% of boron iron, 0.5-1.5% boron carbide, 8-15% of sodium and potassium water glass, 1-4.5% of silicon-manganese alloy powder, 0.5-6.5% of nickel powder, 0.2-5% vanadium iron, 0.5-7.5% of molybdenum iron, 1.5-6% of niobium iron, 1.5-5% of rare earth magnesium alloy, 0.1-2.8% of graphite and the balance of iron, and the particle size of each component is 70-140 meshes, wherein the weight content of magnesium of the rare earth magnesium alloy is 20-26%, and the balance is lanthanum or cerium; and the weight percent of silicon of the silicon-manganese alloy powder is 25-50%, and the balance is manganese. The surfacing alloy material designed by the invention can be applied to the preparation of wear-resistant piece surface composite materials and the repair of workpiece surfaces, and the alloy has high macro hardness and strong shock resistance, produces few cracks in the process of use, and has very strong abrasive wear resistance and very wide range of application.

Owner:LIAONING TECHNICAL UNIVERSITY +1

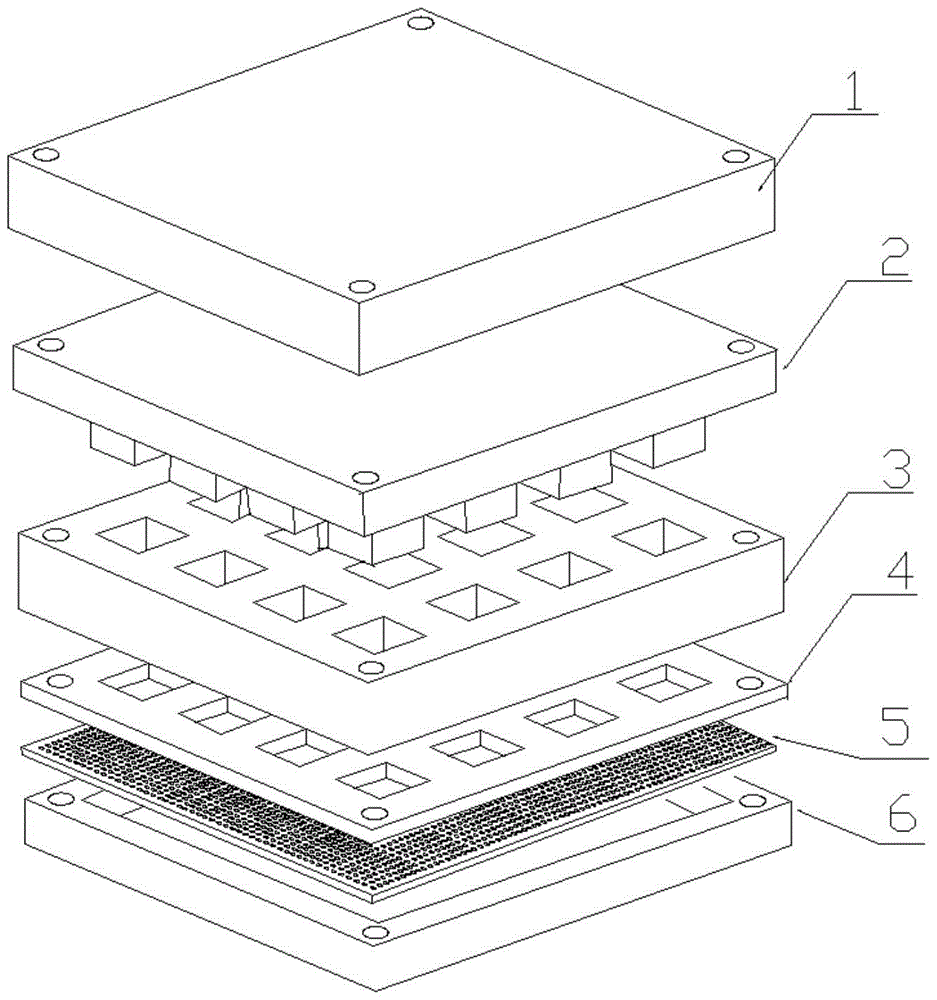

Manufacturing method of flexible thermo-electric device and manufactured flexible thermo-electric device

ActiveCN104766922ANo impact ingredientsRelease thermal stressThermoelectric device manufacture/treatmentSemiconductor materialsCopper wire

The invention relates to a manufacturing method of a flexible thermo-electric device and the manufactured flexible thermo-electric device. The method comprises the steps that a red copper wire mesh with high electric conduction performance is adopted as an electrode material, the red copper wire mesh is directly fixed to a die substrate, high-temperature-resisting silica gel is adopted as a flexible substrate to replace a traditional ceramic substrate, P-N thermo-electric particles alternately fall into a grid die device, on the basis of achieving overall welding, line cutting of design patterns is carried out on cold and hot end faces, and each pair of P-N semiconductor thermo-electric particles is of a parallel-connection independent structure in electrology and series-connection thermology; basic curing operation of high-temperature-resisting flexile insulation is carried out on a device achieving adjustable gluing thickness, and the flexible device is obtained. The flexible device can be bent by a large angle, a semiconductor material body is not changed, semiconductor material components obtained after doping modification are not influenced, the application occasion of the thermo-electric device is widened, the device is not restricted to plane occasions any more, and heat stress generated in the work process of the thermo-electric device is released.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Crewel vibrating silicon micro-gyroscopes

InactiveCN101135560AHigh sensitivityReduce error signalTelevision system detailsImpedence networksGyroscopeShaped beam

The invention comprises an upper layer and a lower layer. On the upper layer there is a gyroscope mechanical structure made on a monocrystalline silicon plate; on the lower layer there are signal leads made on the glass substrate. The inner frame of the gyroscope upper layer mechanism structure is connected to the outer frame of the detection support beam; on the gyroscope lower layer glass substrate there are grounding lines, driving input leads, sensitive output signal lines; the upper layer mechanical structure is mounted on the linkage point of the fixed base on the glass substrate through the fixed base in order to make the upper layer mechanical structure hang above the lower layer glass substrate. The invention features U-shaped beam structure used by both the driving sport beam and detection support beam.

Owner:NANJING UNIV OF SCI & TECH

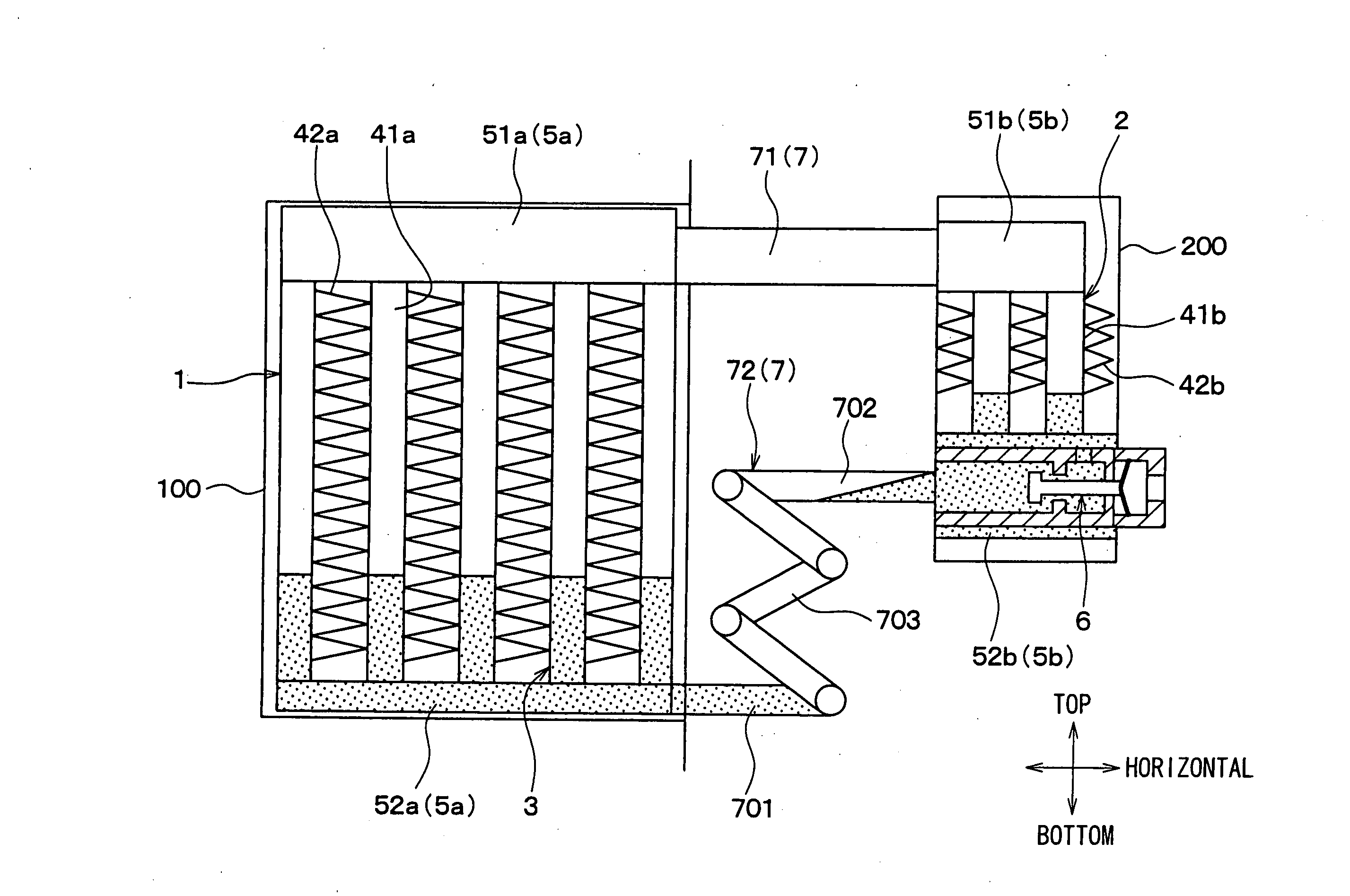

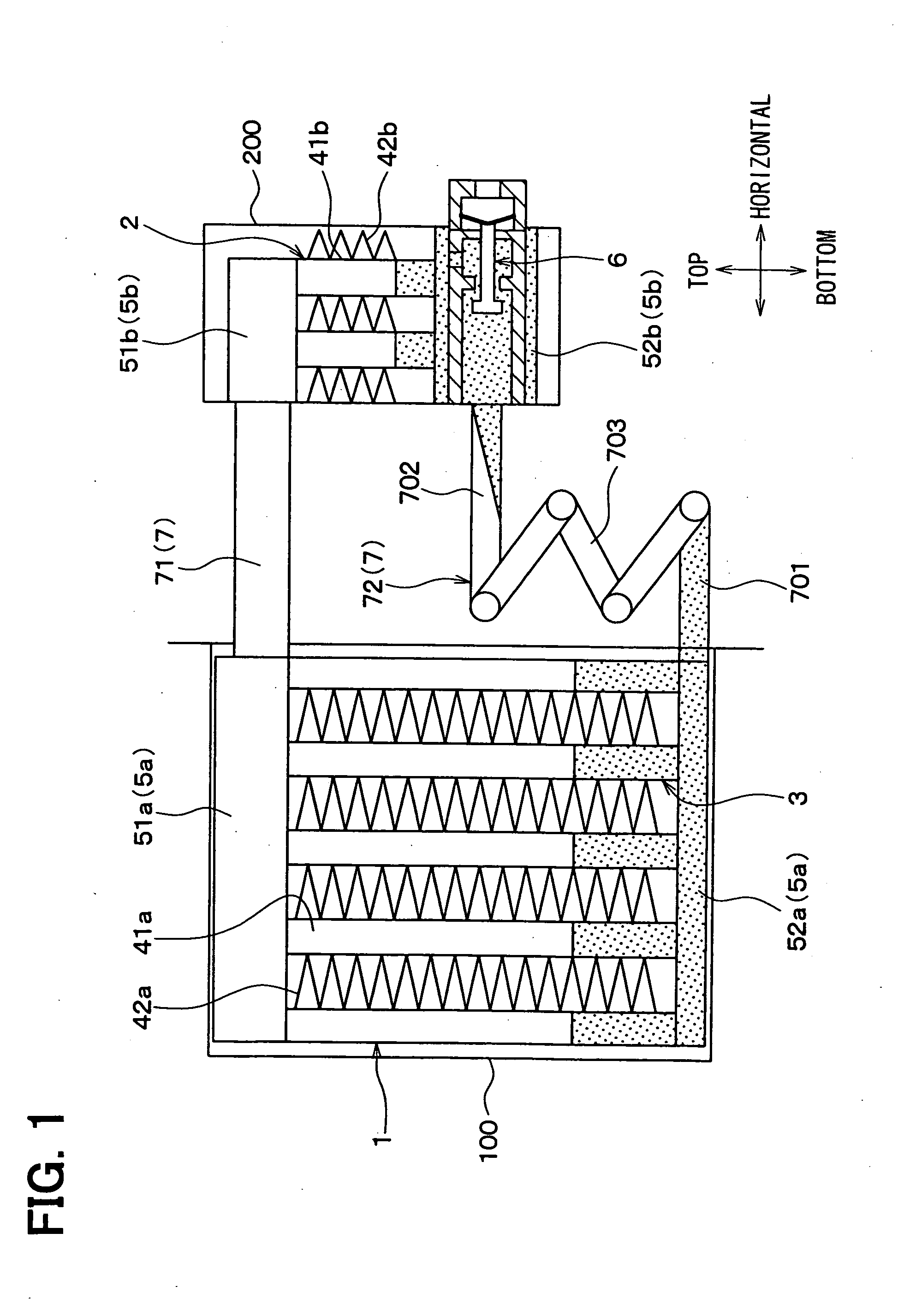

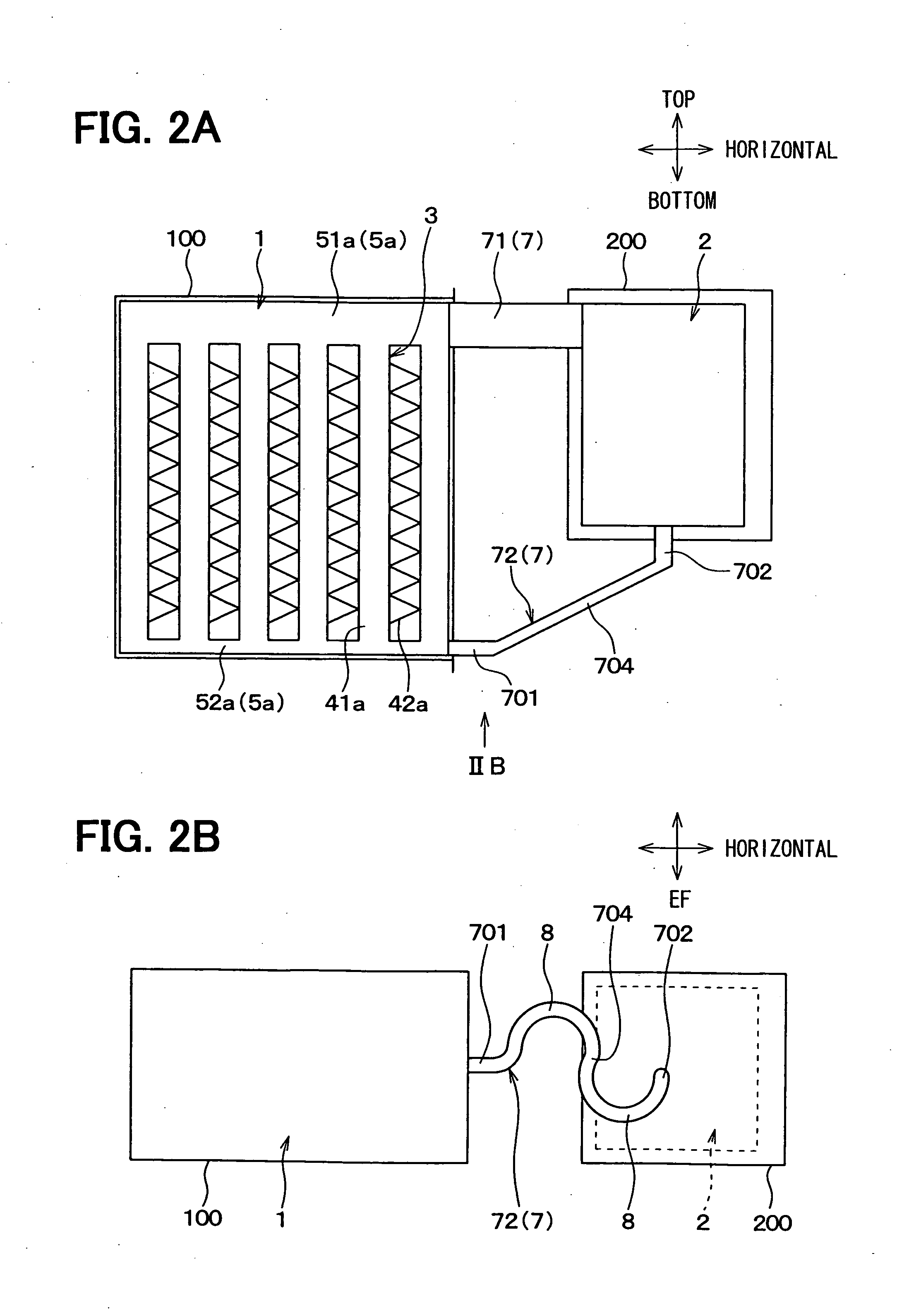

Exhaust heat recovery device

InactiveUS20090000285A1Simple structureAvoid it happening againInternal combustion piston enginesRecuperative heat exchangersWorking fluidEvaporation

An exhaust heat recovery device includes an evaporator disposed to evaporate a working fluid by exchanging heat between a heating fluid and the working fluid, a condenser disposed to cool and condense the working fluid by exchanging heat between a fluid to be heated and the working fluid evaporated by the evaporator, an evaporation side connection portion for guiding the working fluid evaporated by the evaporator to the condenser, and a condensation side connection portion for guiding the working fluid condensed by the condenser to the evaporator. Furthermore, at least one of the evaporation side connection portion and the condensation side connection portion has a curved portion.

Owner:DENSO CORP

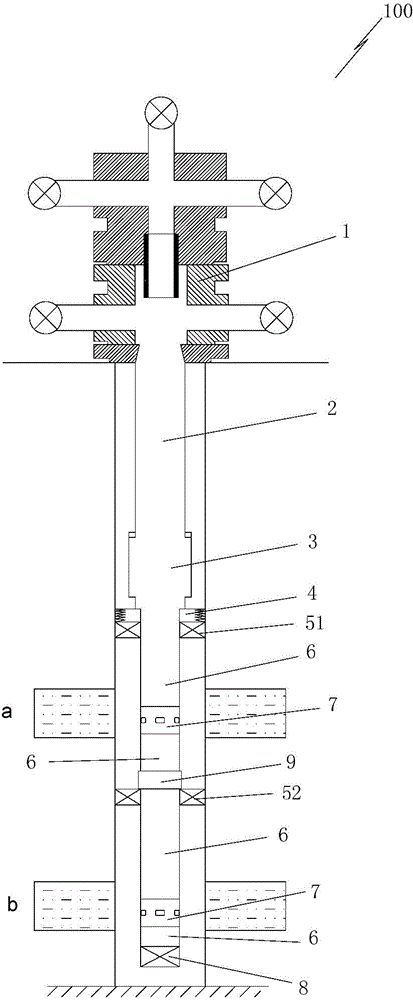

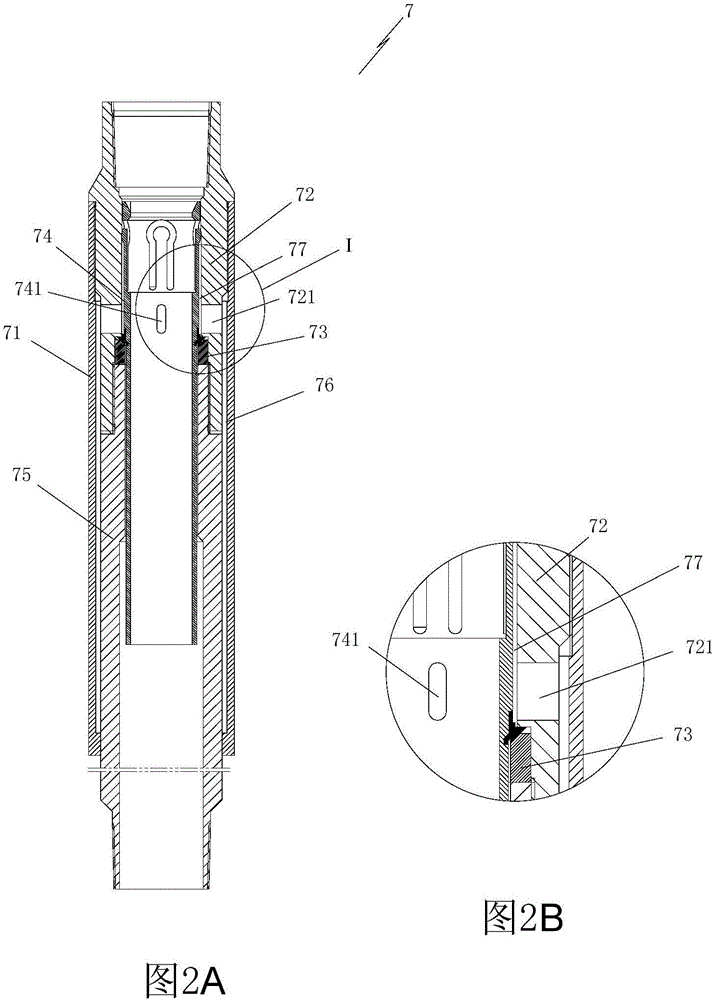

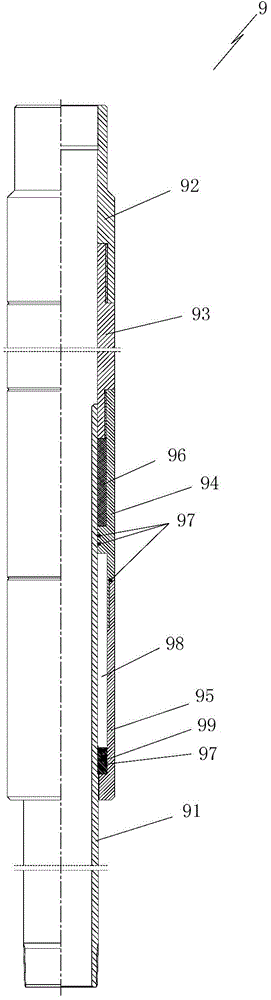

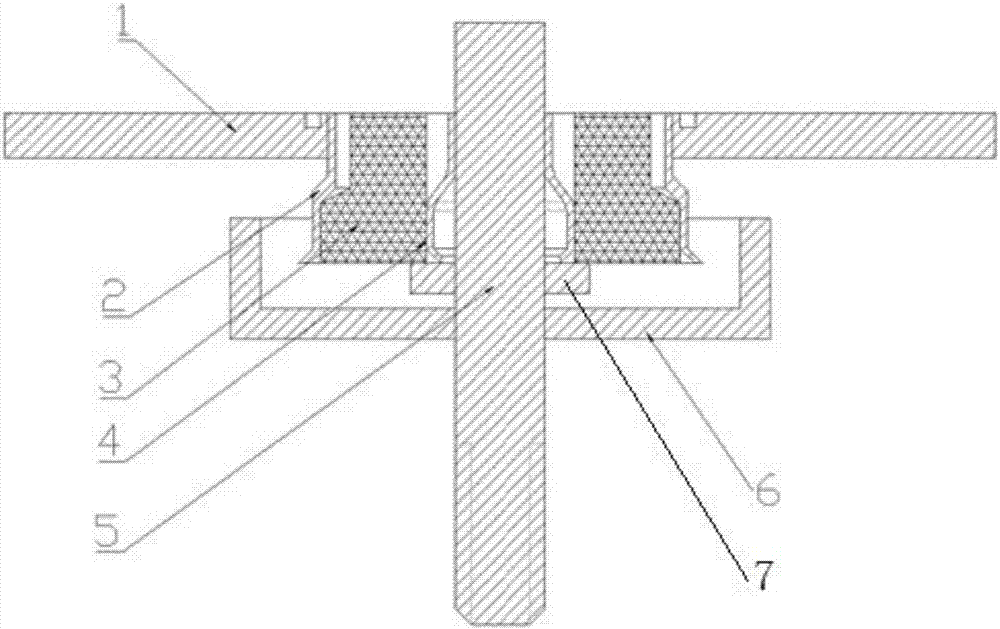

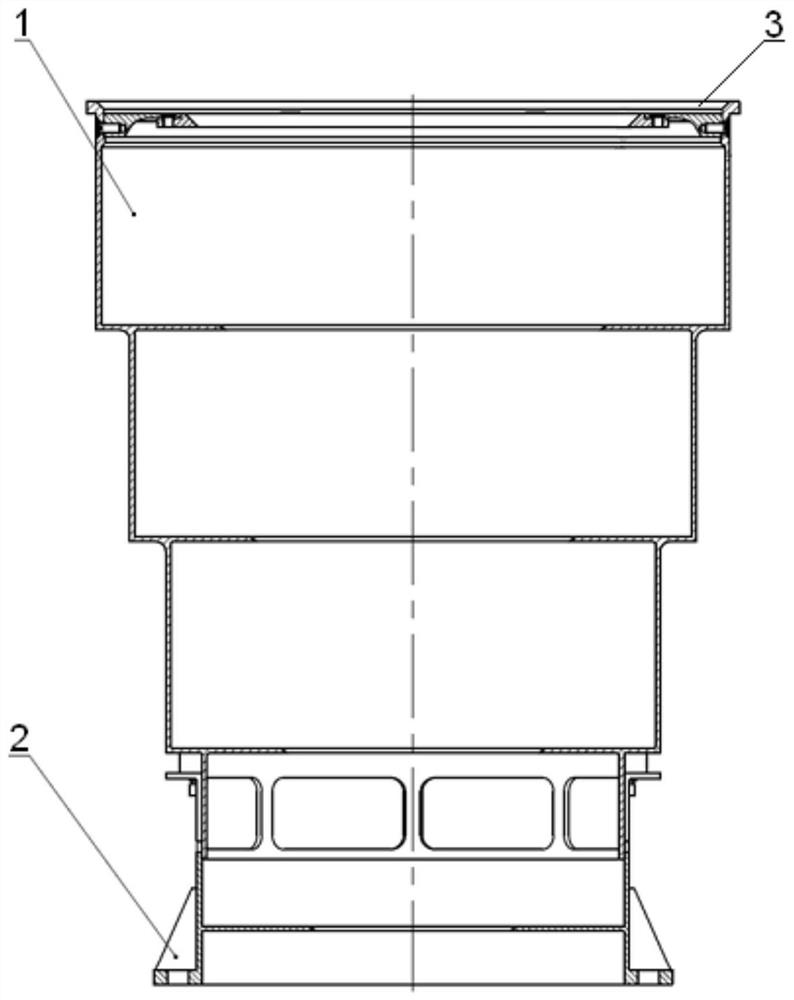

Hollow layering steam injecting system

The invention discloses a hollow layering steam injecting system. An heat preservation oil pipe is connected below a well head device; the lower end of the heat preservation oil pipe is connected with a telescopic pipe; the lower end of the telescopic pipe is connected with a steam distributing pipe column part; the steam distributing pipe column part comprises an anchor, an oil pipe, packers, an oil pipe releaser and a hollow steam injecting valve; the anchor is positioned at the uppermost end of the steam distributing pipe column part; the lower end of the telescopic pipe is connected with the anchor; in the steam distributing pipe column part, a top packer is arranged above a top oil layer, and is connected to the lower end of the anchor; a middle packer is arranged in a gap of adjacent two oil layers; the oil pipe, the hollow steam injecting valve and the oil pipe releaser are connected between adjacent two packers; and the lower end of the middle packer above a lowermost oil layer is connected with the oil pipe, the hollow steam injecting valve, the oil pipe and a plug. The hollow layering steam injecting system can preferably release thermal stress of a pipe column, is more accurate and effective in steam injecting effect, prevents the steam injecting valve from scaling to block a steam injecting channel, and increases the inner diameter of the pipe column for convenient dropping and fishing.

Owner:PETROCHINA CO LTD

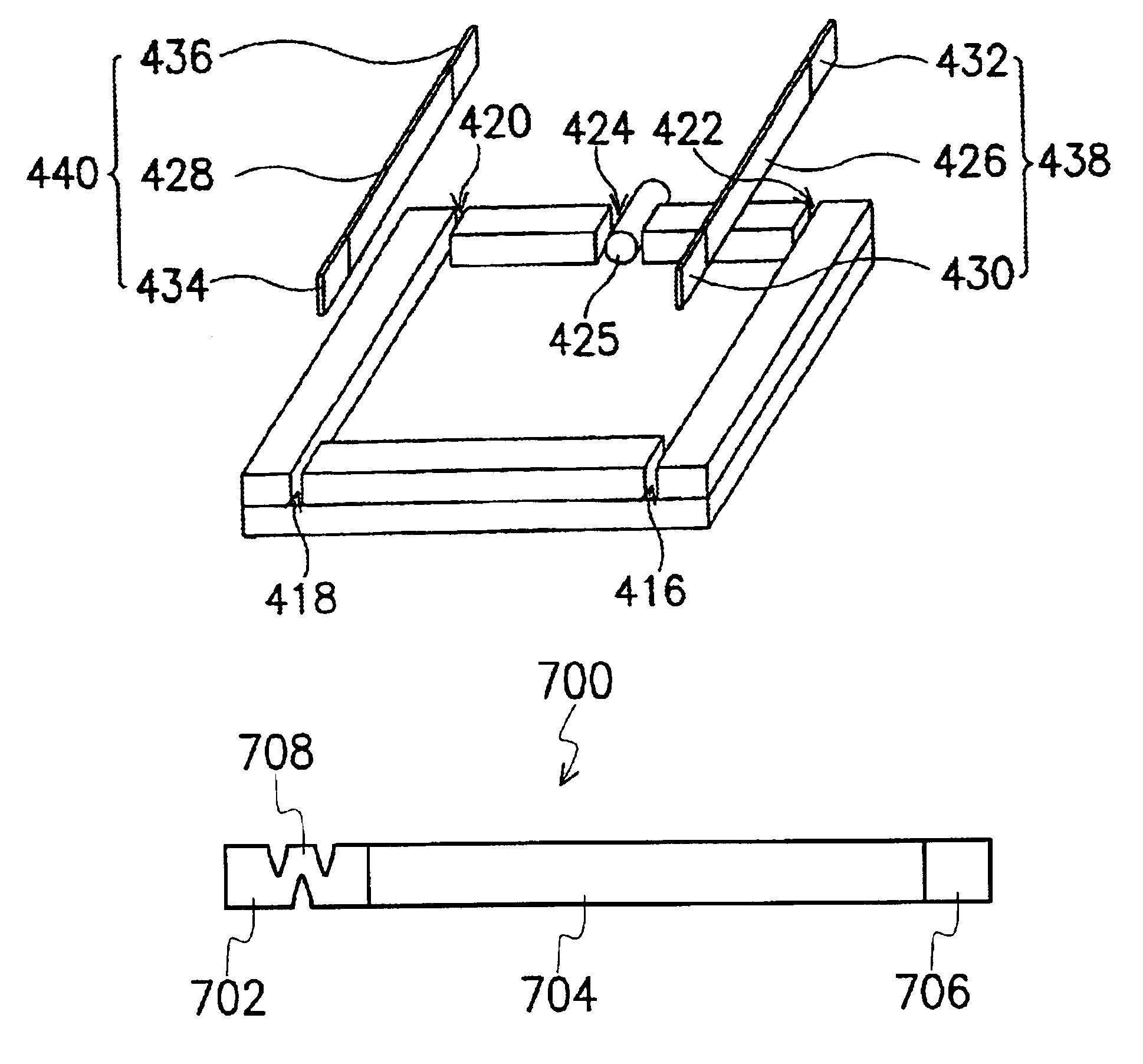

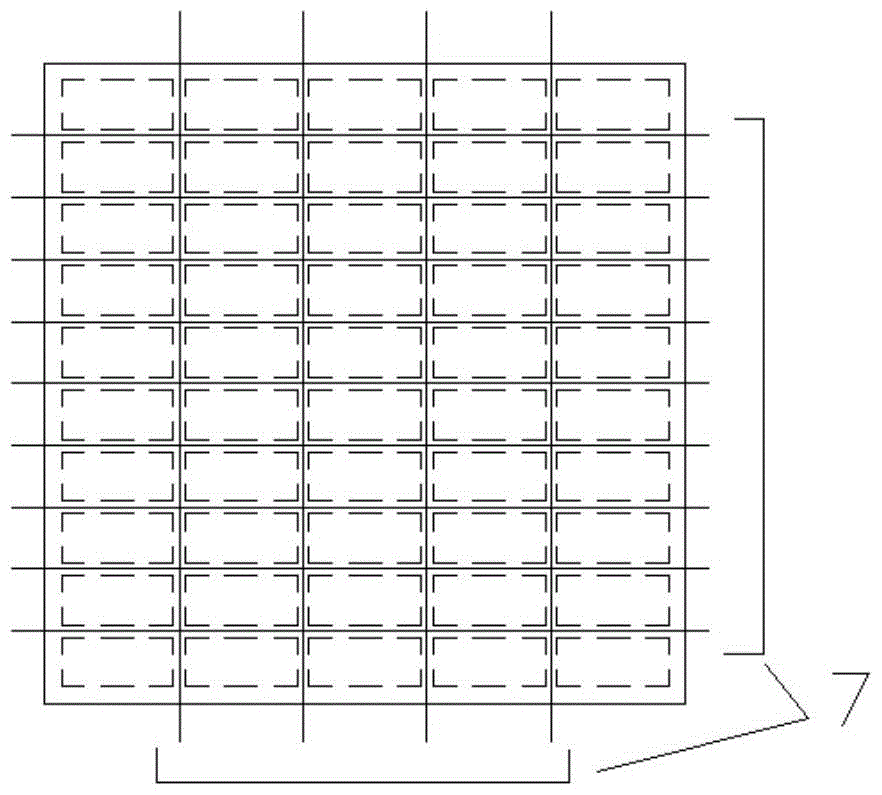

Planar fluorescent lamp having particular electrode structure

InactiveUS6933669B2Luminescent area be increaseIncrease brightnessDischarge tube luminescnet screensLamp detailsMercury vaporsSurface plate

A planar fluorescent lamp having a first panel, a second panel, a glass rim, a venting tube, and a set of electrodes. Fluorescent layers are formed on both the first panel and the second panel. The glass rim is mounted on edges of the first and second panels. A recess and a gap are formed in the glass rim; the recess is used for placing the electrodes while the gap is reserved for installing the venting tube. The first panel, the second panel, and the glass rim are so arranged so that a cavity is formed thereby. The cavity is vacuumed via the venting tube and mercury vapor and inert gas are then introduced into the cavity.

Owner:DELTA ELECTRONICS INC

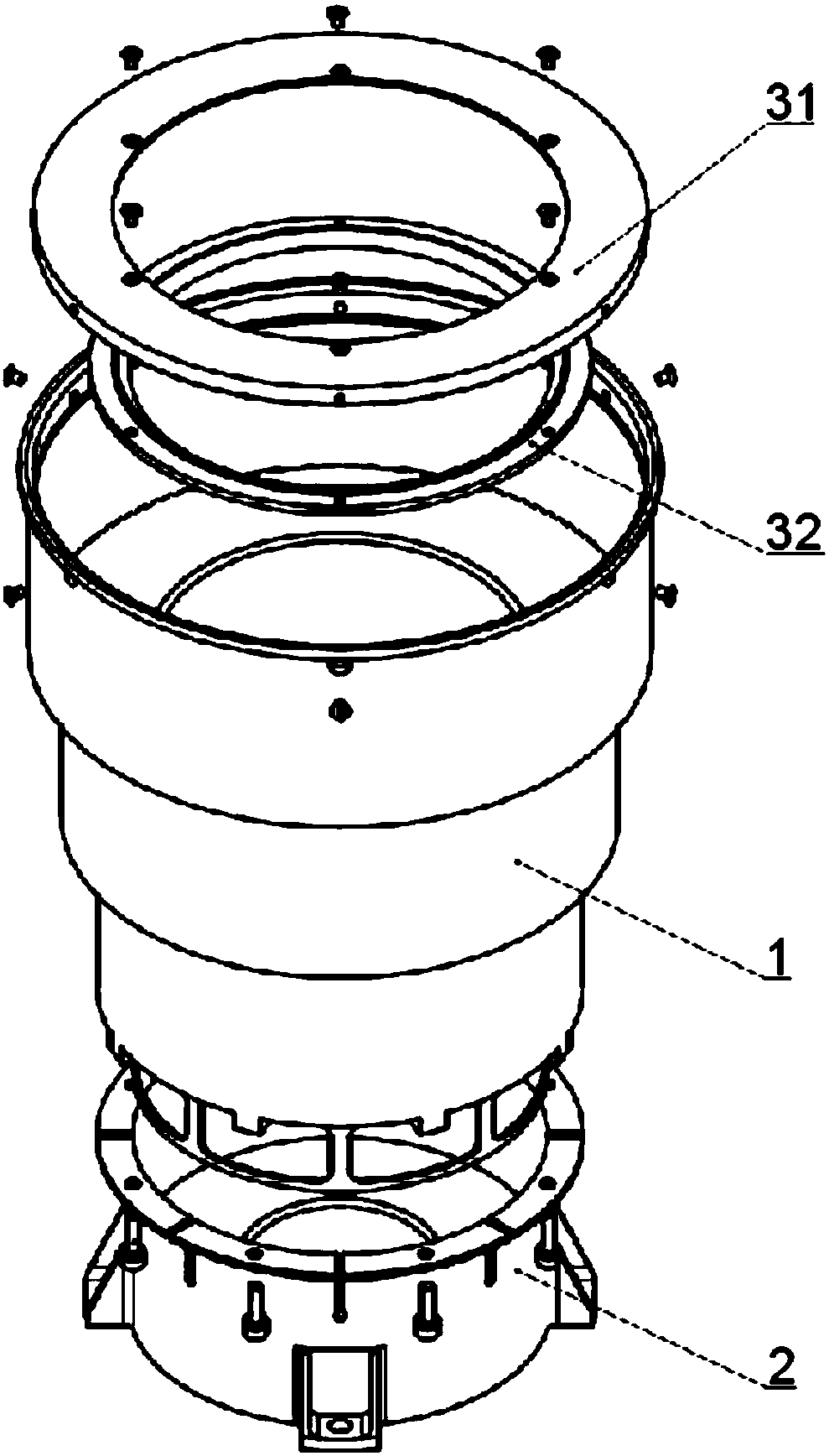

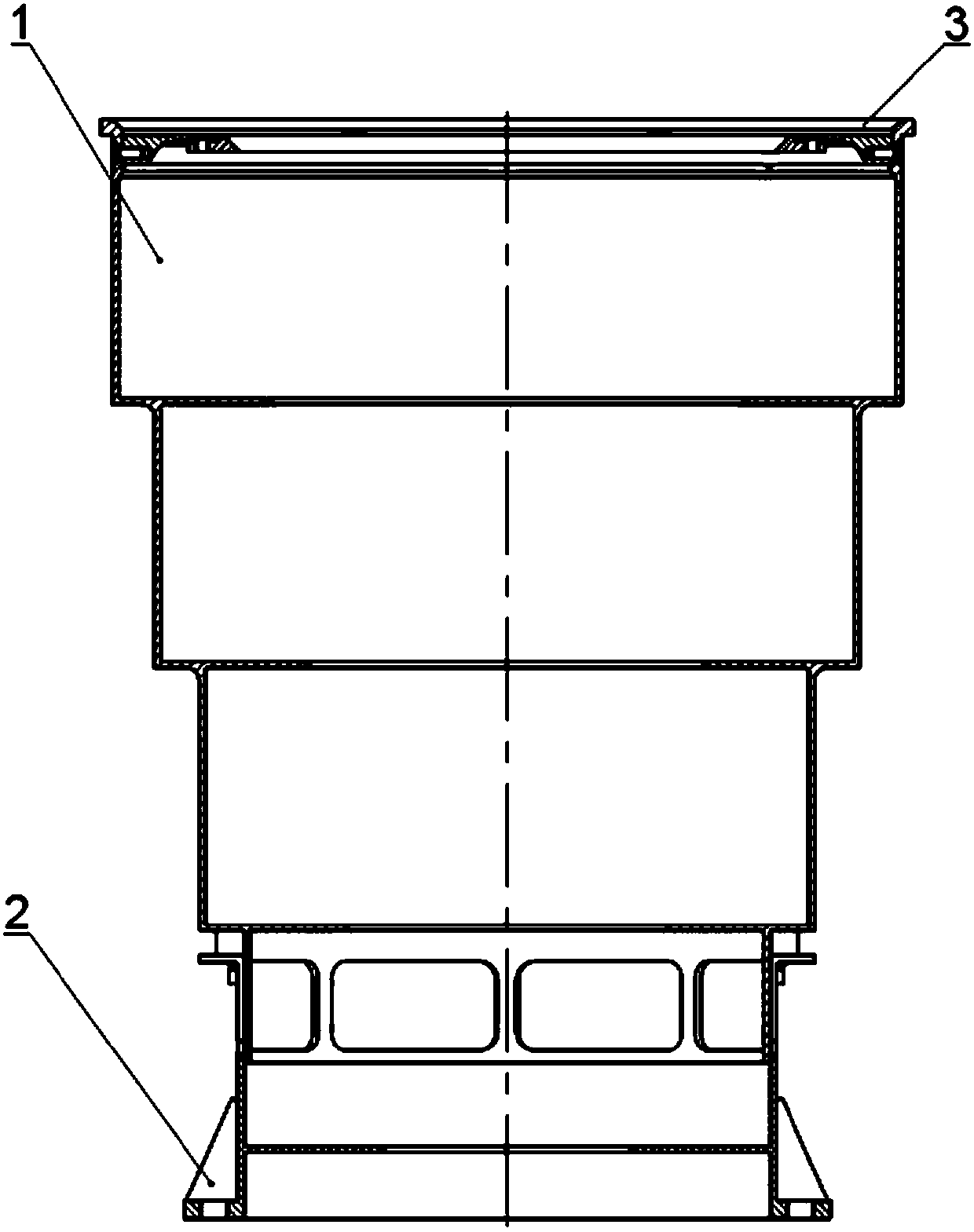

Combined heat insulation light shielding cover structure for star sensor

The invention discloses a combined heat insulation light shielding cover structure for a star sensor. The structure comprises a cover body, a support seat and a light shielding ring. Each of the coverbody and the support seat is a hollow cylinder. The light shielding ring is a split type hollow circular ring. The light shielding ring used for heat dissipation and light elimination is installed onone end of the cover body. The support seat where a start sensor optical machine circuit box is assembled sleeves the other end of the cover body. According to the invention, by combining the cover body and the support seat, the structure of the star sensor light shielding cover is optimized; defects of complex structure, big weight, tedious assembly and disassembly and excessive heat transmission of the traditional star sensor are overcome; and by designing the light shielding ring, stray light and heat flows of spatial tracks are inhibited and difficulty that the traditional star sensor light shielding cover absorbs too much heat is overcome.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

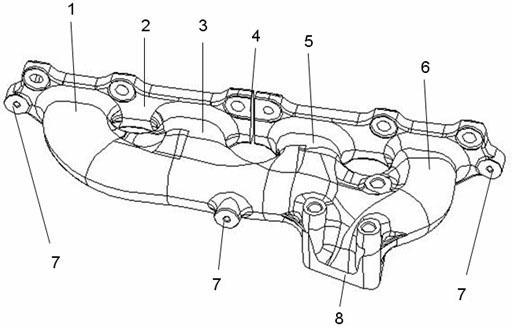

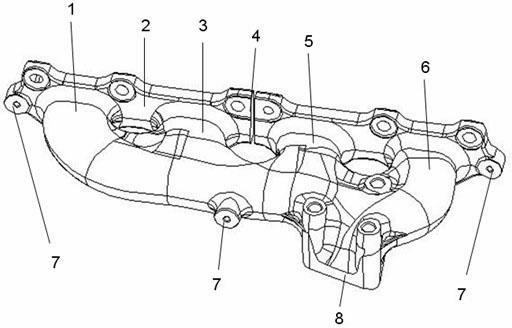

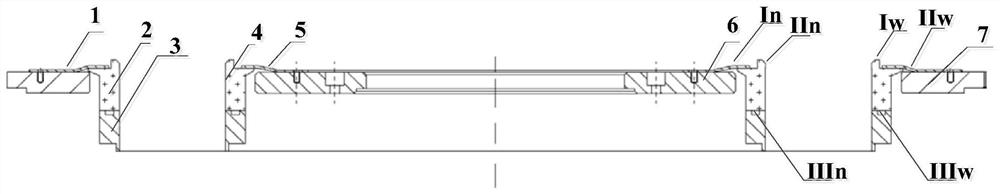

Cast iron exhaust manifold for supercharged gasoline engine

InactiveCN102146834ASmall thermal deformationRelease thermal stressExhaust apparatusSilencing apparatusGasolineEngineering

The invention discloses a cast iron exhaust manifold for a supercharged gasoline engine, comprising a plurality of air passages, wherein an inlet flange is molded at the inlet end of each air passage in an integrated casting way, and an outlet flange is molded at the outlet end of each air passage in an integrated casting way. The middle position of each inlet flange is machined with a notch to separate the inlet flange into a left section and a right section so as to release heat stress of a flange plate of the cast iron exhaust manifold, and thus the heat deformation of the cast iron exhaust manifold is reduced; and heat shield mounting lugs are arranged at two ends of each inlet flange close to the first air passage and the fourth passage, the mounting points are arranged on the inlet flange with lower temperature as possible, and thus the arrangement of heat shield mounting points at an area with higher temperature is avoided, the quantity of high-temperature-resistance bolts is reduced, and the cost is lowered.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Secondary charging method of mono-crystal furnace

ActiveCN108166053AIncrease usageReduce manufacturing costPolycrystalline material growthBy pulling from meltPolymer scienceRaw material

The invention discloses a secondary charging method of a mono-crystal furnace and belongs to the field of preparation of monocrystalline silicon. The secondary charging method disclosed by the invention comprises the following steps: step ST1, a preparation phase; step ST2, a positioning phase of a secondary charging device; step ST3, a jog charging phase; step ST4, a secondary charging device taking-out phase. By adopting the secondary charging method of the mono-crystal furnace, a function of adding raw materials at any time in a process of drawing a monocrystalline silicon rod by the mono-crystal furnace is mainly realized.

Owner:ANHUI HUAXIN SEMICON CO LTD

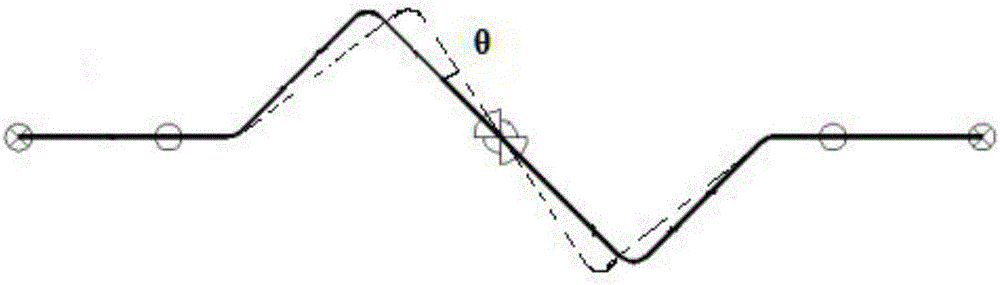

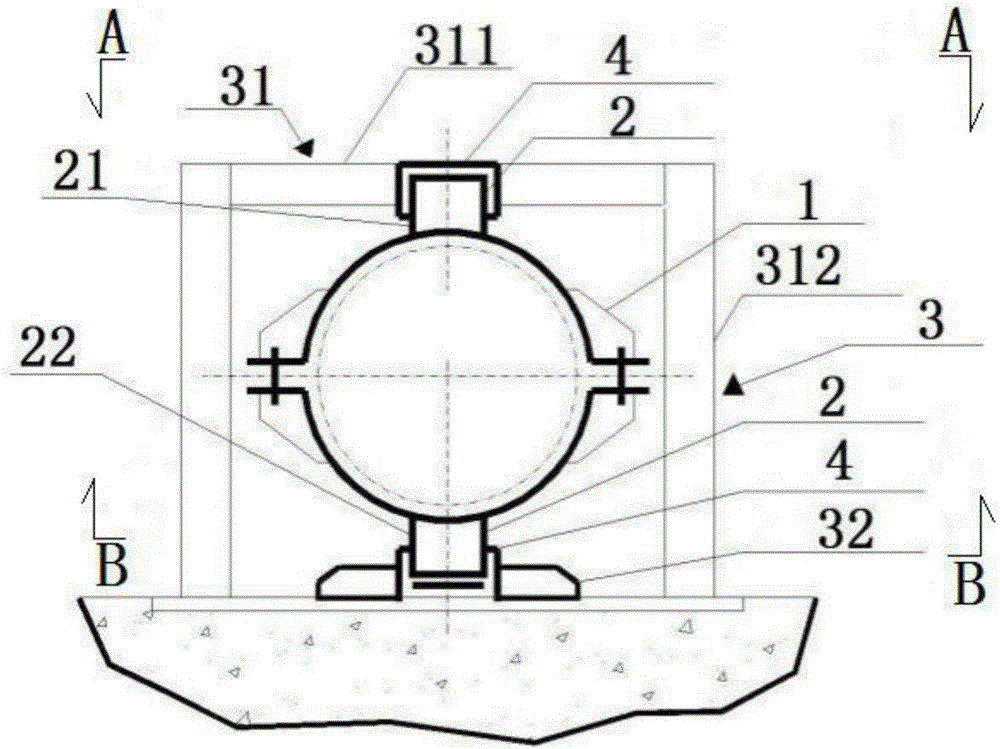

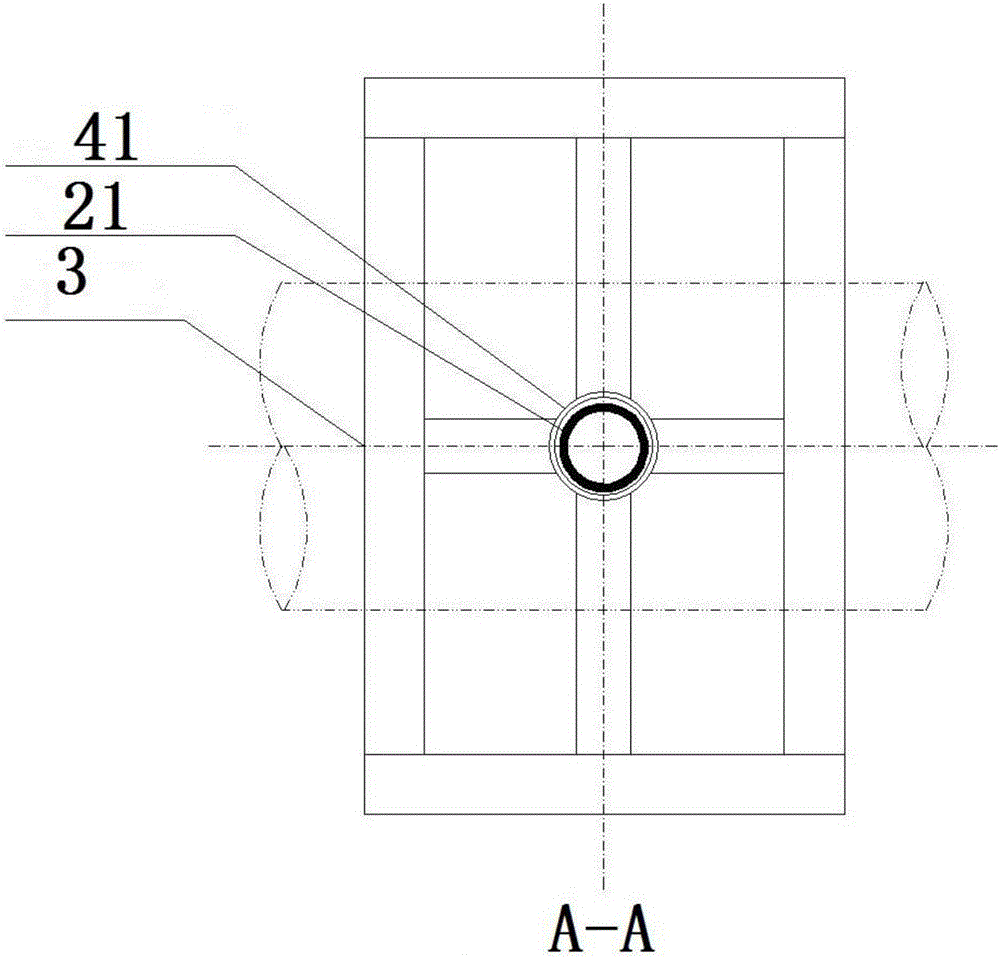

Rotating limiting support for thermal pipe and rotating limiting method of support

InactiveCN106151686AReduce thrustAllowable free angular displacementPipe supportsSupporting systemEngineering

The invention discloses a rotating limiting support for a thermal pipe. The support comprises a pipe clamp, rotating shafts and a supporting system, wherein the supporting system comprises a supporting frame and a supporting plate; the supporting frame comprises a transverse supporting frame and longitudinal supporting frames; the rotating shafts comprise an upper rotating shaft and a lower rotating shaft, the lower end of the upper rotating shaft is welded at the upper end of the pipe, and the upper end of the lower rotating shaft is welded at the lower end of the pipe; rotating shaft grooves are located in the supporting system; and the rotating shafts are sleeved with the rotating shaft grooves. The support overcome defects that only linear displacement in one or two directions can be limited and angular displacement is limited on the premise that the linear displacement of the position of a supporting point is limited in the prior art are overcome; and the rotating limiting support has the advantages that the rotating shafts are increased on the pipe clamp, and limiting supporting is designed, so that the linear displacement of the pipe in a heated state is limited, the angular displacement is allowed on a certain plane, and partial swelling stress is released. The invention further discloses a rotating limiting method of the rotating limiting support for the thermal pipe.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

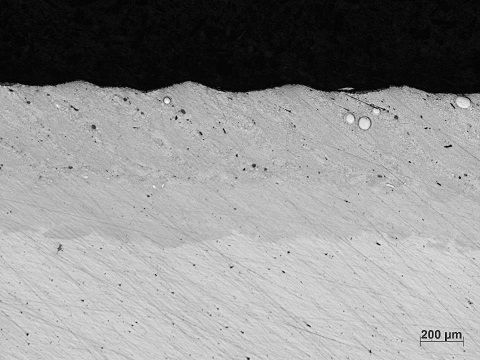

Method for high-speed laser cladding of Mo-Cu alloy layer on copper substrate

PendingCN112708882AImprove bindingHigh strengthMetallic material coating processesAlloyUltimate tensile strength

The invention discloses a method for laser cladding of a Mo-Cu alloy layer on a copper substrate. The method comprises the following steps: 1) drying Mo powder and Cu powder in vacuum; 2) polishing and cleaning a cladding substrate; (3) performing cladding with a high-speed laser cladding device, during cladding, adopting double-cylinder powder feeding, and controlling the powder feeding amount of the Mo powder and Cu powder respectively to achieve the purpose of gradient cladding, wherein the mass ratio of Mo to Cu of the cladding alloy layer is sequentially increased in a gradient mode, in addition, the cladding substrate is loaded on a high-frequency vibration platform, and the high-frequency vibration platform generates platform type vibration during cladding. Gradient cladding is adopted, the binding force between a cladding layer and a base body and the strength of the cladding layer are improved, and the uniformity of Mo and Cu components and structures in the cladding layer is improved through double-cylinder powder feeding. High-frequency vibration in cladding effectively releases thermal stress in the cladding layer, improves the strength of the cladding layer, improves the fluidity of a molten pool, reduces air hole shrinkage in the cladding layer, improves the strength of the cladding layer and the like.

Owner:ZHEJIANG UNIV

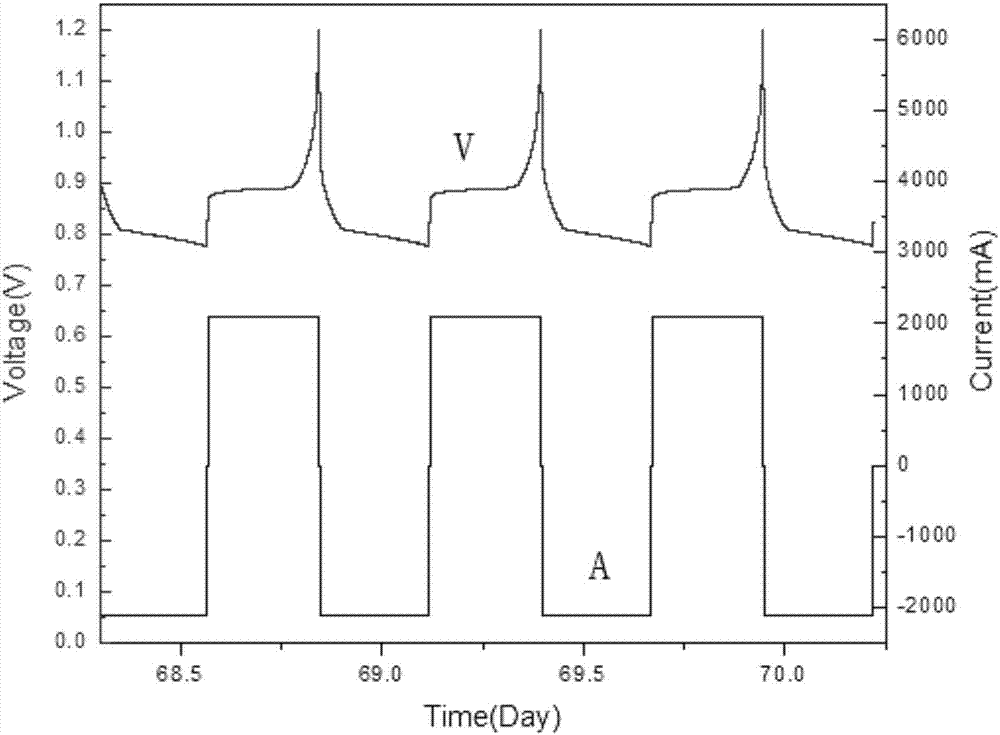

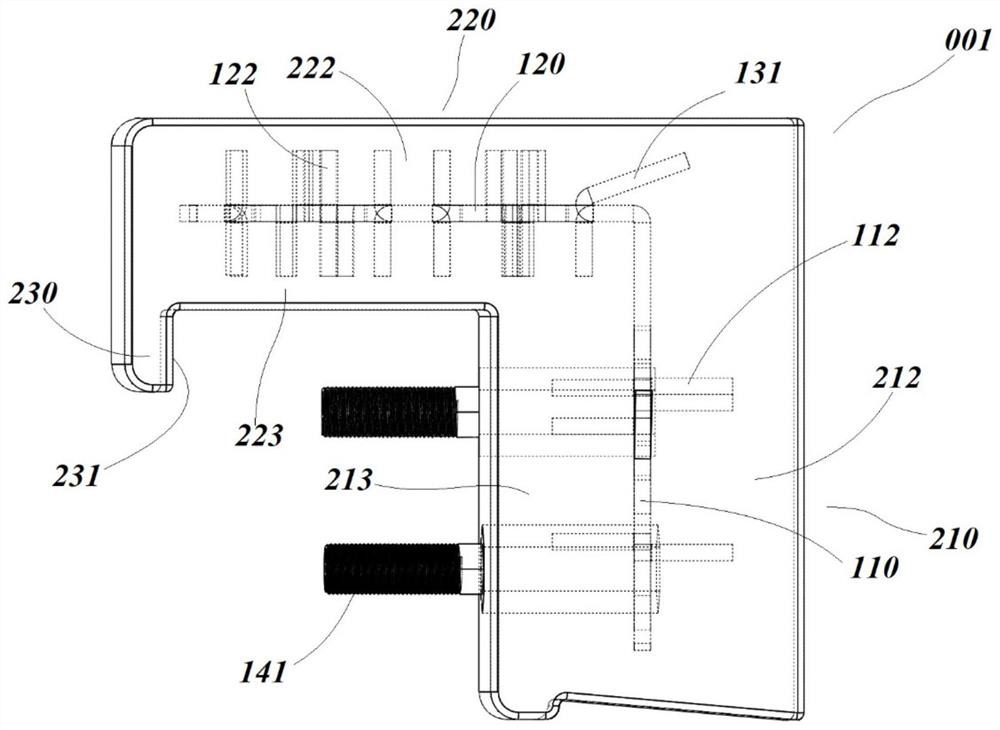

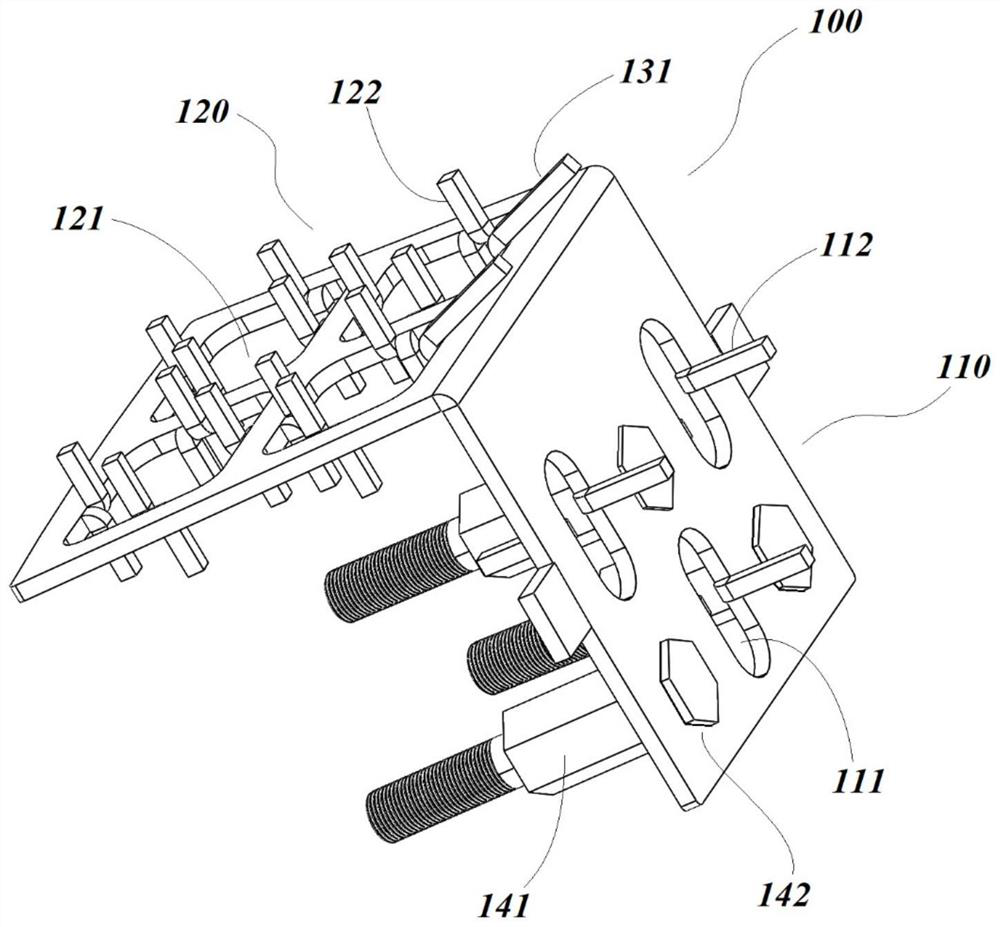

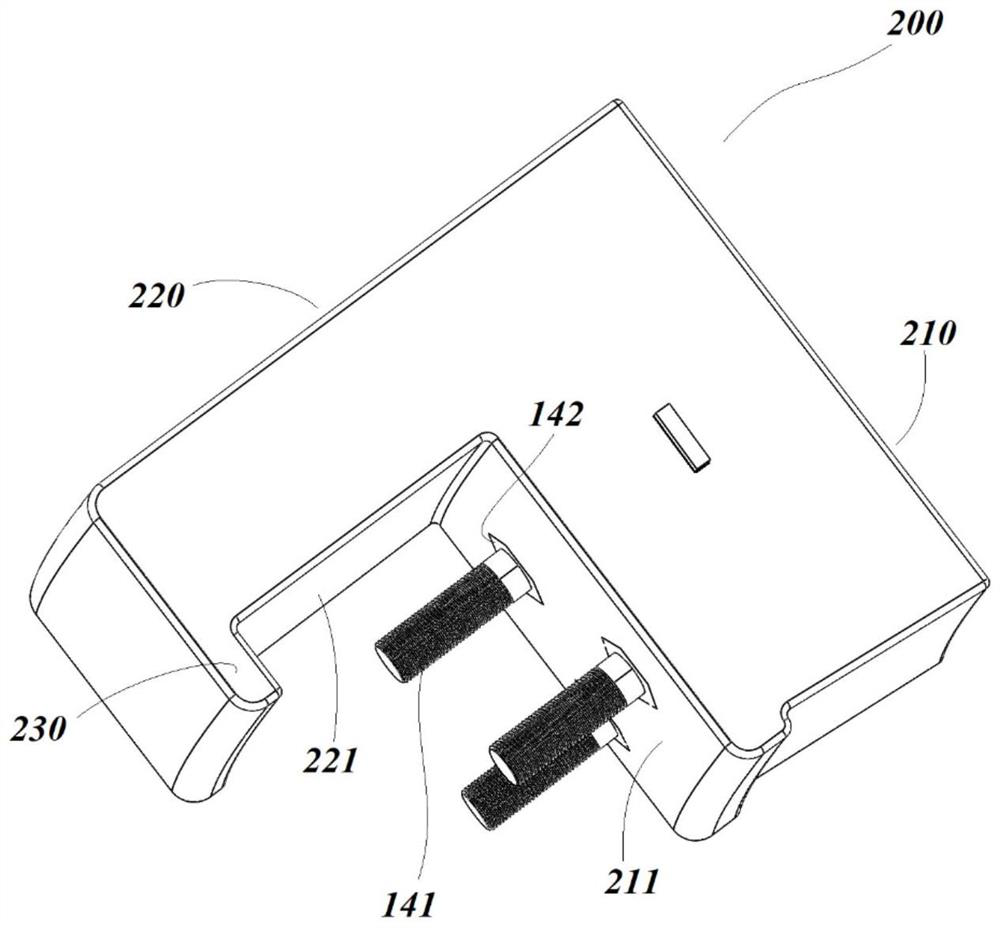

Parallel structure sealing electrode and assembly method thereof

ActiveCN107394067AExtend your lifeGuaranteed distanceFinal product manufactureSecondary cellsLiquid metalEngineering

The invention is a parallel structure sealing electrode and an assembly method thereof. The parallel structure sealing electrode saves space and realizes good sealing of a liquid metal battery for long term working under a high temperature environment. The electrode includes a battery cover plate, an external transition ring, an insulation structure, an internal transition ring, an electrode core and a liquid sealing bowl holder that are disposed coaxially. Sealing insulation connection of the battery cover plate, the insulation material and the electrode core is achieved through the external transition ring and the internal transition ring, the setting of the internal transition ring increases a stress release structure, and the battery cover plate upper end face is adopted as the positioning end face, a positioning clamp stand disposed on the electrode core is utilized to position the electrode core, the distance from the positioning clamp stand lower surface to the electrode core lower surface ensures the distances from the electrode core to a battery internal active material, the liquid sealing bowl holder is utilized to realize isolation of the battery internal active material, and the connection of the external transition ring, the insulation structure and the internal transition ring is protected by means of liquid sealing, thereby avoiding corrosion to the sealing electrode, and guaranteeing a lasting battery life.

Owner:CHINA XD ELECTRIC CO LTD

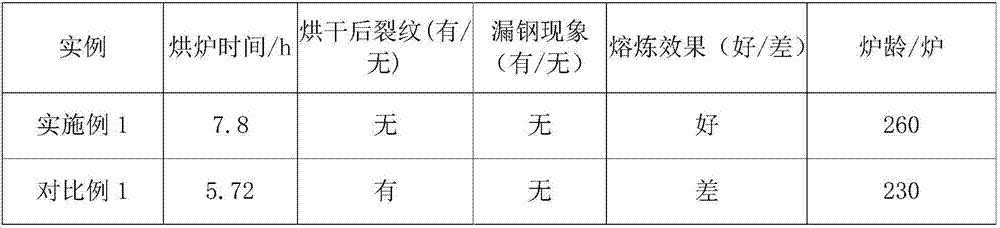

Furnace drying method for new intermediate-frequency furnace during pre-alloyed powder smelting

ActiveCN107326201AExtended sintered layer thicknessExtended service lifeLinings repairCrucible furnacesIntermediate frequencyMoisture

The invention discloses a furnace drying method for a new intermediate-frequency furnace during pre-alloyed powder smelting. According to the furnace drying method for the new intermediate-frequency furnace during pre-alloyed powder smelting, scientific and reasonable design is adopted, moisture in brickwork is dissipated slowly and reasonably by controlling the heating rate, so that sudden stress changes are avoided, and the influence of disordered and arbitrary operation on furnace drying is avoided; and compared with a traditional technique, the furnace drying method has the advantages that a furnace drying temperature curve of the new furnace is designed scientifically and reasonably, the furnace drying time is short, the production efficiency is high, the service life of the new furnace is long, and the smelting effect is good.

Owner:HUBEI EXIN DIAMOND TECH

Improved device and method for growing high-temperature oxide crystals through heat exchange method with seed crystals arranged on top

InactiveCN114150383AGood for taking awayImprove cleanlinessAfter-treatment apparatusPolycrystalline material growthChemical physicsCzochralski method

The invention discloses a device and a method for growing a high-temperature oxide crystal by an improved heat exchange method with a seed crystal arranged on the top, which are characterized in that a kyropoulos method, a Czochralski method (CZ), a heat exchange method (HEM), a temperature gradient method (TGT), a Bridgman-Stockbarger method and a kyropoulos method (KY method) are combined together; according to the special high-temperature vacuum crystal furnace, gas flows in from the center of the top of a hearth from top to bottom, absolute uniform and symmetrical flow out from the center of the bottom is ensured through flow planning, and gradients of all parts in different growth stages are achieved by adjusting the gas flow in different stages and the pumping speed of a vacuum pump. The method comprises the following steps: charging a furnace, vacuumizing, introducing flowing protective gas, heating and melting materials, washing seed crystals, changing the gas inlet and outlet proportion, carrying out real-time gradient adjustment, seeding by a pulling method, carrying out a hole shrinkage process, increasing the shouldering process of a heat exchange method for increasing the gas flow, controlling a crystal growth interface (adjusting a convex interface to be slightly convex or close to a flat interface), and carrying out equal-diameter growth by combining HEM heat exchange with a KY technology (namely carrying out equal-diameter growth by combining HEM heat exchange with a KY technology). A weighing diameter control technology is optimized; amp is ended through a KY method; and removing the crucible, and performing in-situ annealing by gradually increasing the pressure of the protective gas. According to the invention, the existing method is combined to produce the large-size high-temperature oxide crystal.

Owner:黄鼎雯 +2

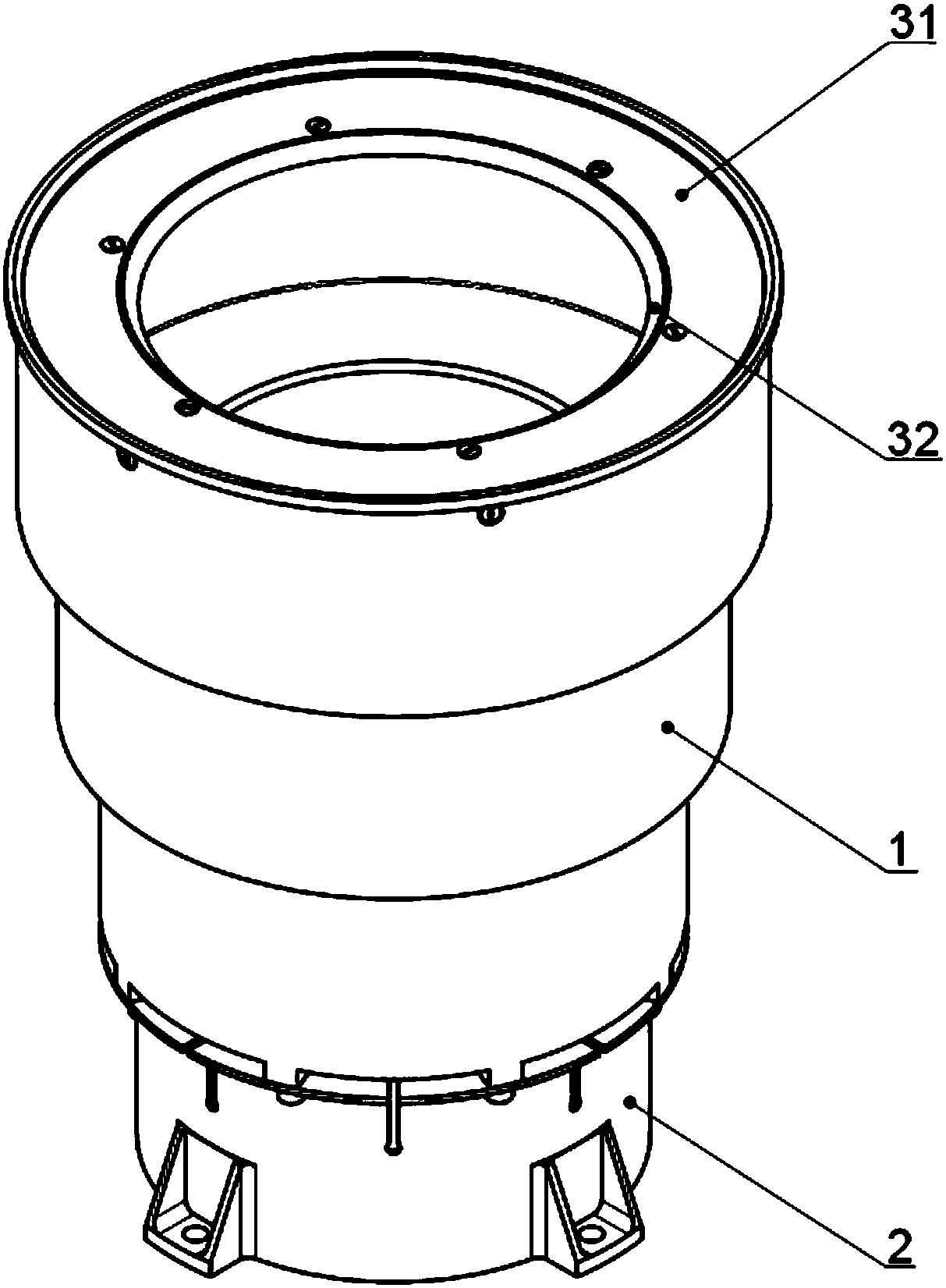

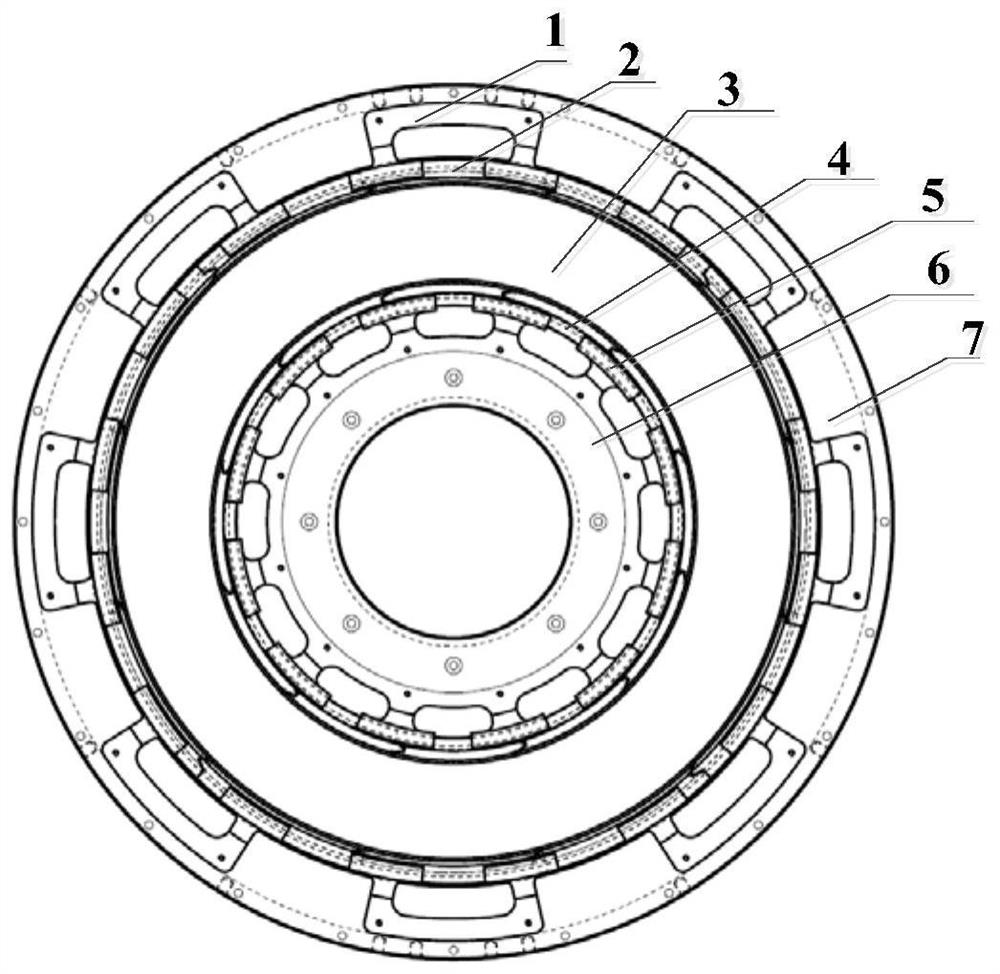

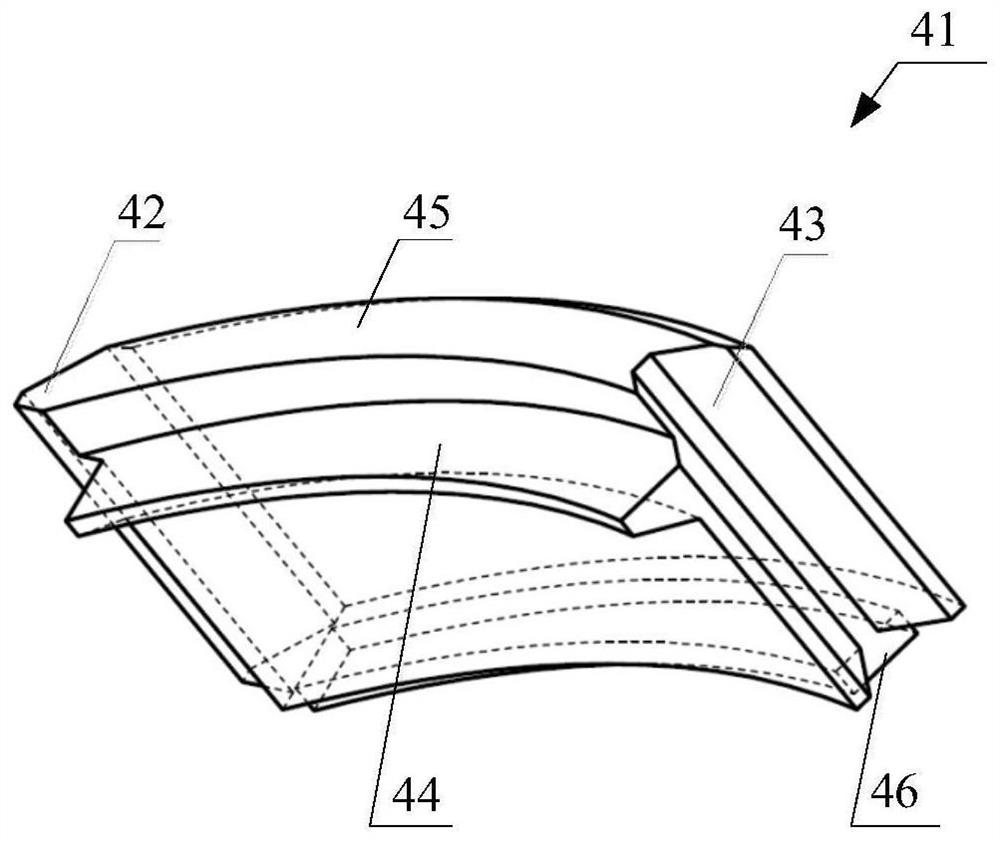

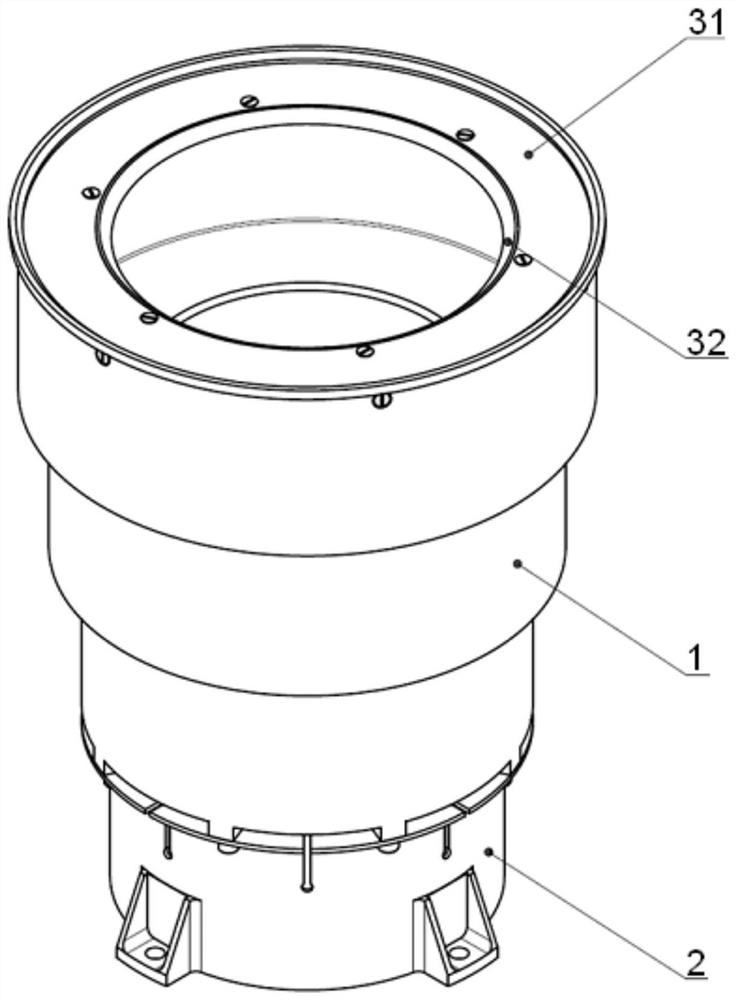

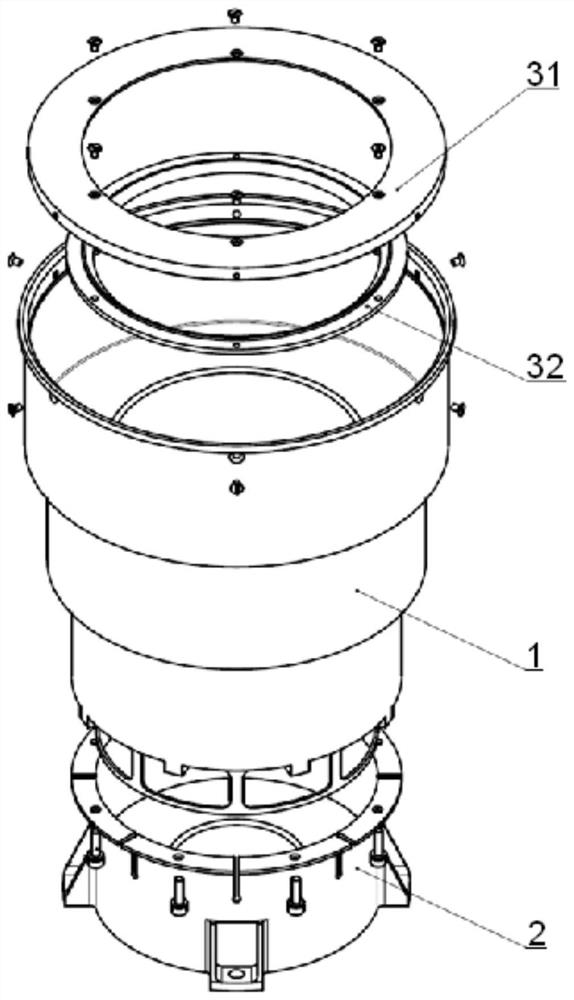

A high-power Hall thruster discharge chamber assembly based on flexible connection

ActiveCN111140449BOvercoming the risk of damageImprove reliabilityMachines/enginesUsing plasmaMagnetic polesMechanical engineering

The invention discloses a high-power Hall thruster discharge chamber assembly based on flexible connection, which is composed of a hand-in-hand inner ceramic ring, a hand-in-hand outer ceramic ring, an outer pressure ring, an inner pressure ring and an anode with grooves; Both the insert-type inner ceramic ring and the outer ceramic ring are closed-loop rings composed of multiple ceramic pieces connected end to end; each ceramic piece is an arc-shaped structure with a matching head protrusion and tail depression; the insert-type inner ceramic ring The lower end surfaces of the inner and outer ceramic rings of the inserting type have protrusions, which are embedded in the inner and outer annular grooves provided by the anode; the upper end surfaces of the inner and outer ceramic rings of the inserting type are pressed by the inner and outer pressure rings; the inner and outer pressure rings The other end is fixed on the inner and outer magnetic pole plates; the pressing of the inner pressure ring and the outer pressure ring is elastic. The invention can realize the release of thermal stress under the condition of high-power discharge, ensures the stable and reliable operation of the thruster, and avoids the technical difficulty of one-time forming under large size.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

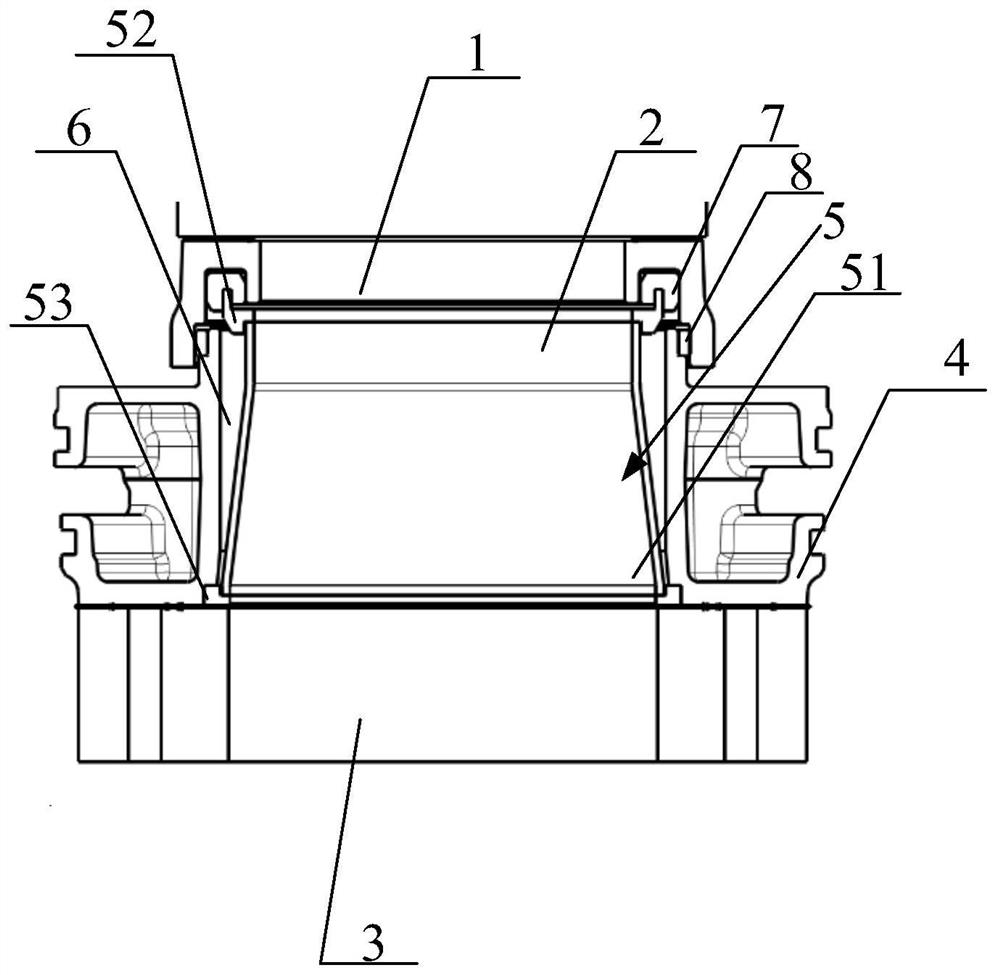

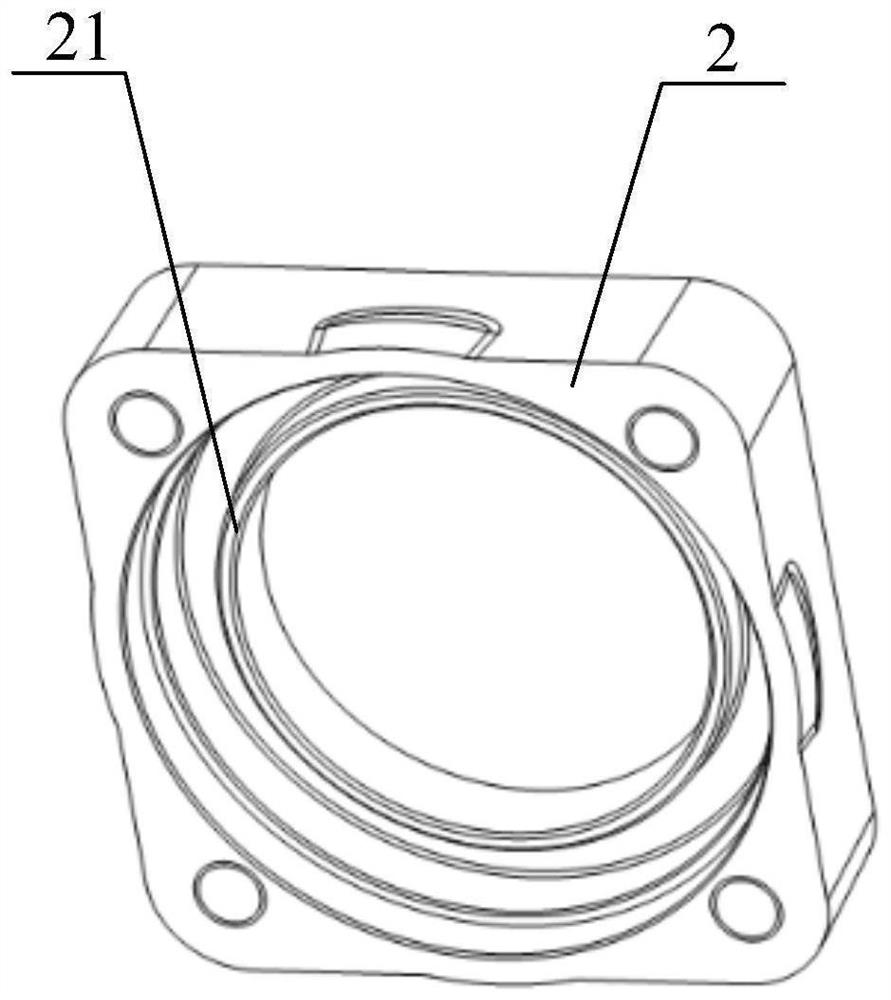

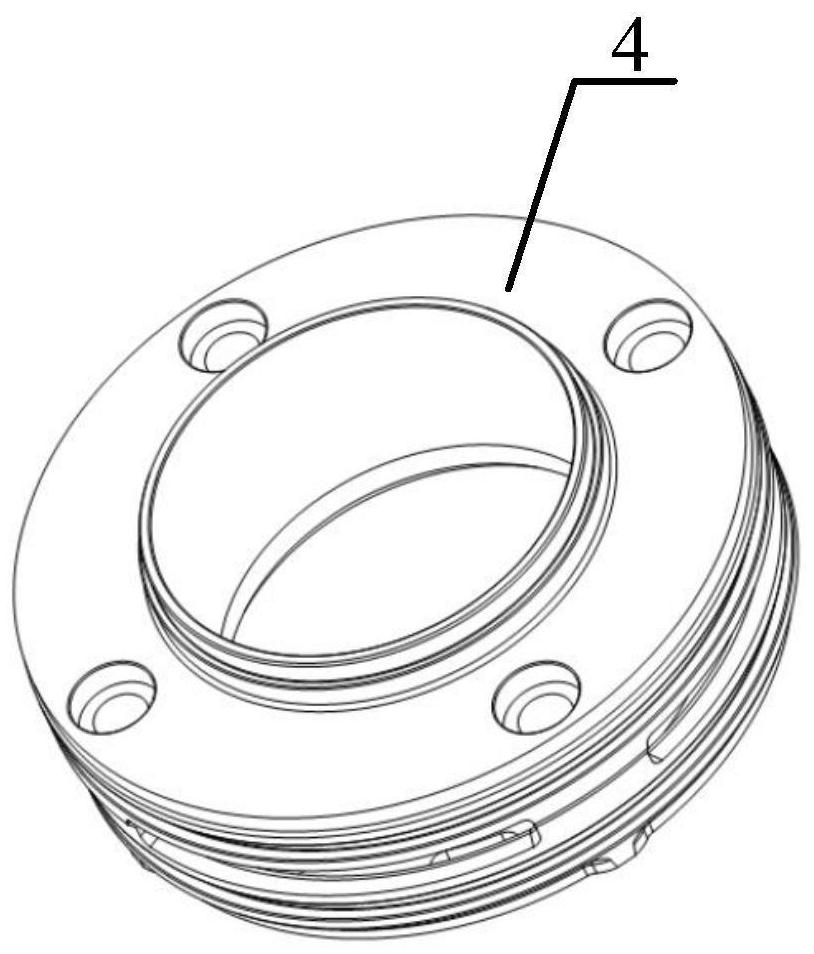

Connecting device and engine for supercharger and exhaust pipe

ActiveCN111997728BSolve the phenomenon of air leakageImprove reliabilityInternal combustion piston enginesExhaust apparatusThermal dilatationThermodynamics

The invention discloses a connection device between a supercharger and an exhaust pipe and an engine, wherein the connection device between the supercharger and the exhaust pipe comprises: a first flange used to connect with the supercharger; The second flange connected with the pipe; the liner arranged in the center hole of the second flange, and there is also a gap between the outer wall of the liner and the inner wall of the second flange; between the liner and the first flange There is also a first metal superimposed net through which high-temperature gas passes. Because the high-temperature gas generated when the engine is working can enter the gap formed between the outer wall of the liner and the inner wall of the second flange from the first metal superimposed mesh, thereby effectively releasing the high-temperature gas to the exhaust pipe and turbocharger. The thermal expansion of the compressor releases the thermal stress, solves the phenomenon of engine leakage caused by the expansion joint rupture, and improves the reliability of the engine.

Owner:WEICHAI POWER CO LTD

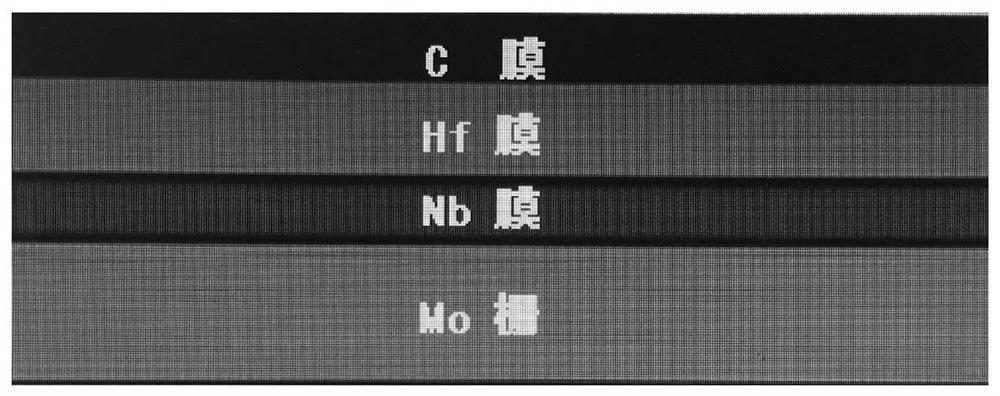

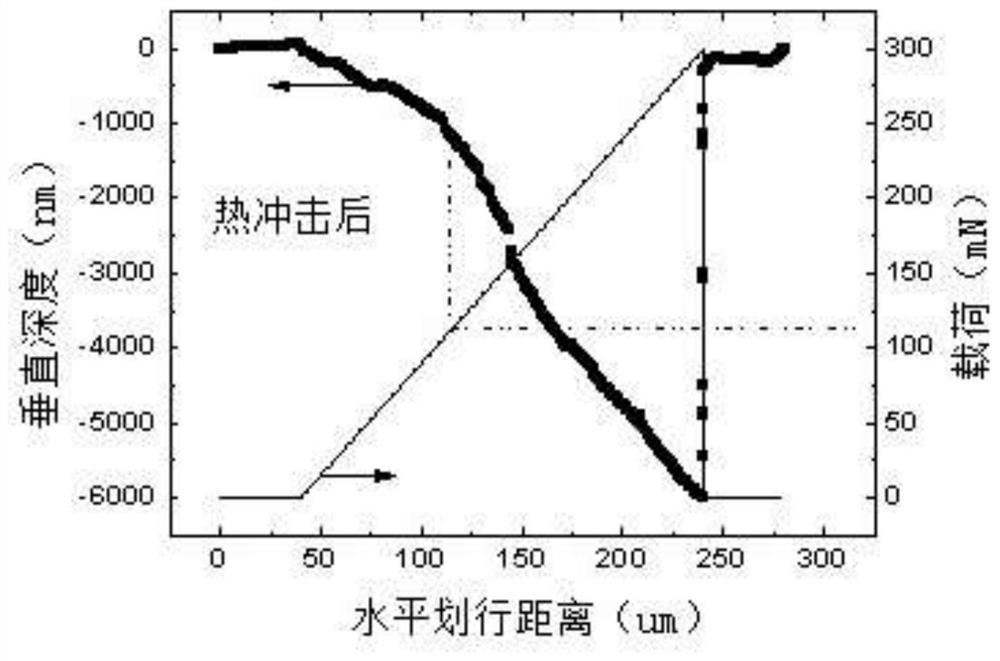

A grid used in a grid-controlled pulse traveling wave tube electron gun and its manufacturing process

ActiveCN109961994BImprove bindingReduce thermal stressTransit-tube electron/ion gunsNon-emitting electrodes manufactureParticle physicsIon implantation

The invention discloses a grid used in a grid-controlled pulse traveling wave tube electron gun and a manufacturing process thereof. The grid includes a grid substrate made of molybdenum, a gradient functional layer formed on the grid substrate, and a composite anti-grid electron emission film formed on the gradient functional layer; wherein the gradient functional layer is made of Nb or Ta, and the composite The anti-grid electron emission film is made of high melting point material with a work function greater than 4eV. The manufacturing process includes the following steps: (1) degassing the formed molybdenum grid substrate at 700-1000°C in high-temperature vacuum; (2) preparing a gradient function on the grid substrate by ion implantation and vacuum deposition coating method (3) Prepare a composite anti-grid electron emission film on the gradient functional layer by ion implantation and vacuum deposition coating method; (4) Perform high-temperature heat treatment on the prepared grid. The grid net of the invention can suppress the grid electron emission of the grid-controlled pulse traveling wave tube, and improve the working reliability and service life of the grid-controlled pulse traveling wave tube.

Owner:GRIMAT ENG INST CO LTD

A kind of high heat-resistant wear-resistant ball for ball mill

ActiveCN104087866BImprove performancePrevent precipitationFurnace typesMetallic material coating processesWear resistantOptoelectronics

The invention discloses a high-heat-resistant and wear-resistant ball for a ball mill. The high-heat-resistant and wear-resistant ball comprises the following components: C, Mn, Si, Ni, Cr, Mo, V, W, Nb, Ca, Zr, Mg, Zn, Cu, S, P, Fe and impurities. Different temperature rise rates are adopted in the heat treatment process, and the surface of the wear-resistant ball is modified by using a laser cladding method. Laser cladding powder comprises the following components: Cr, C, Si, B, Re, Al2O3, Ni, nano CeO2 and nano SiC; the process parameters of laser cladding are that in single-channel scanning, a laser pool is protected by argon, the laser power is set to be 1.5-2.0KW, the light panel diameter is 1-2.5mm, and the cladding speed is 2-4mm / s. The high-heat-resistant and wear-resistant ball for the ball mill, which is disclosed by the invention, has excellent heat-resistant performance, and also has good wear-resistant performance, hardness and toughness.

Owner:宁国市宁武新材料科技有限公司

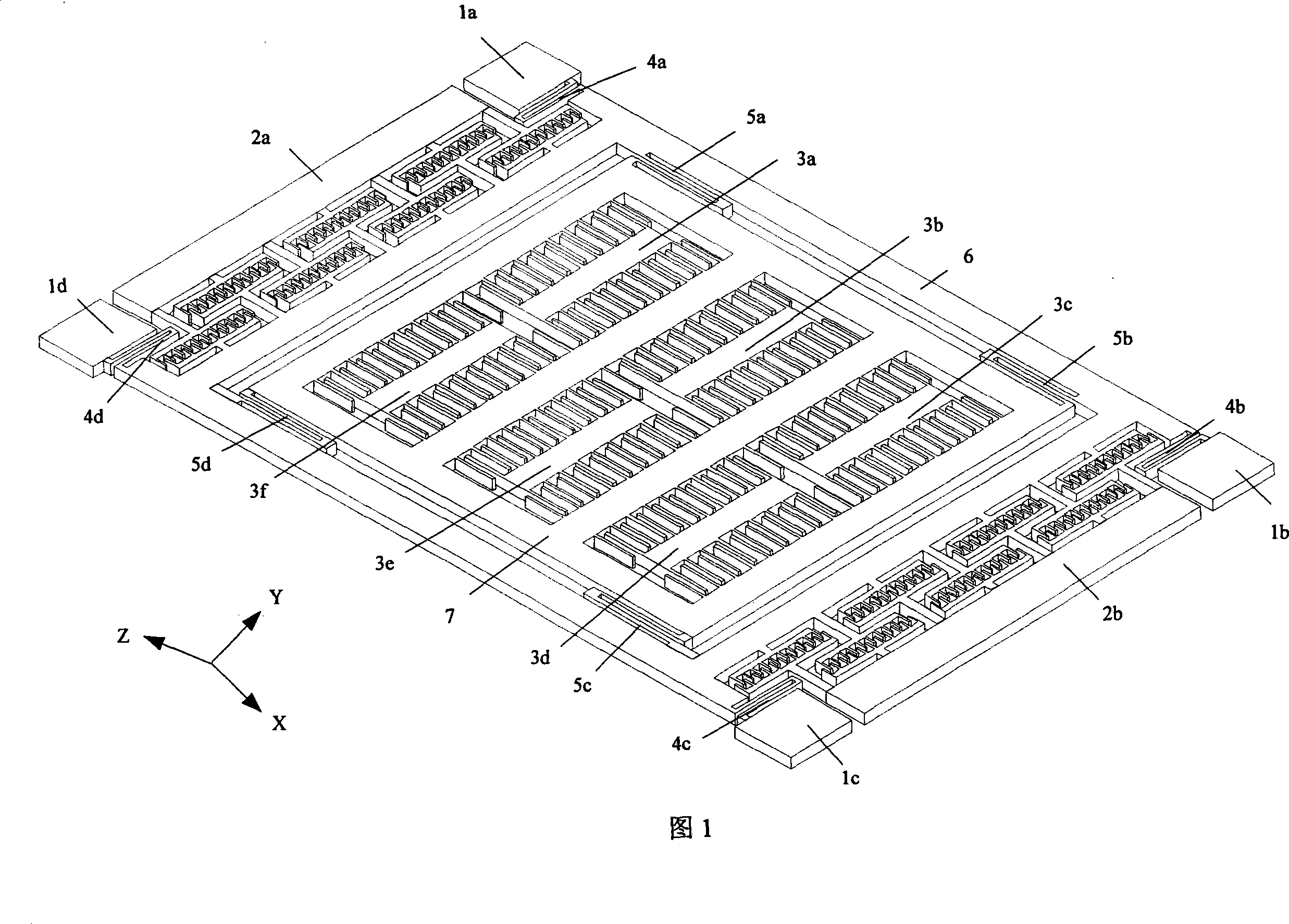

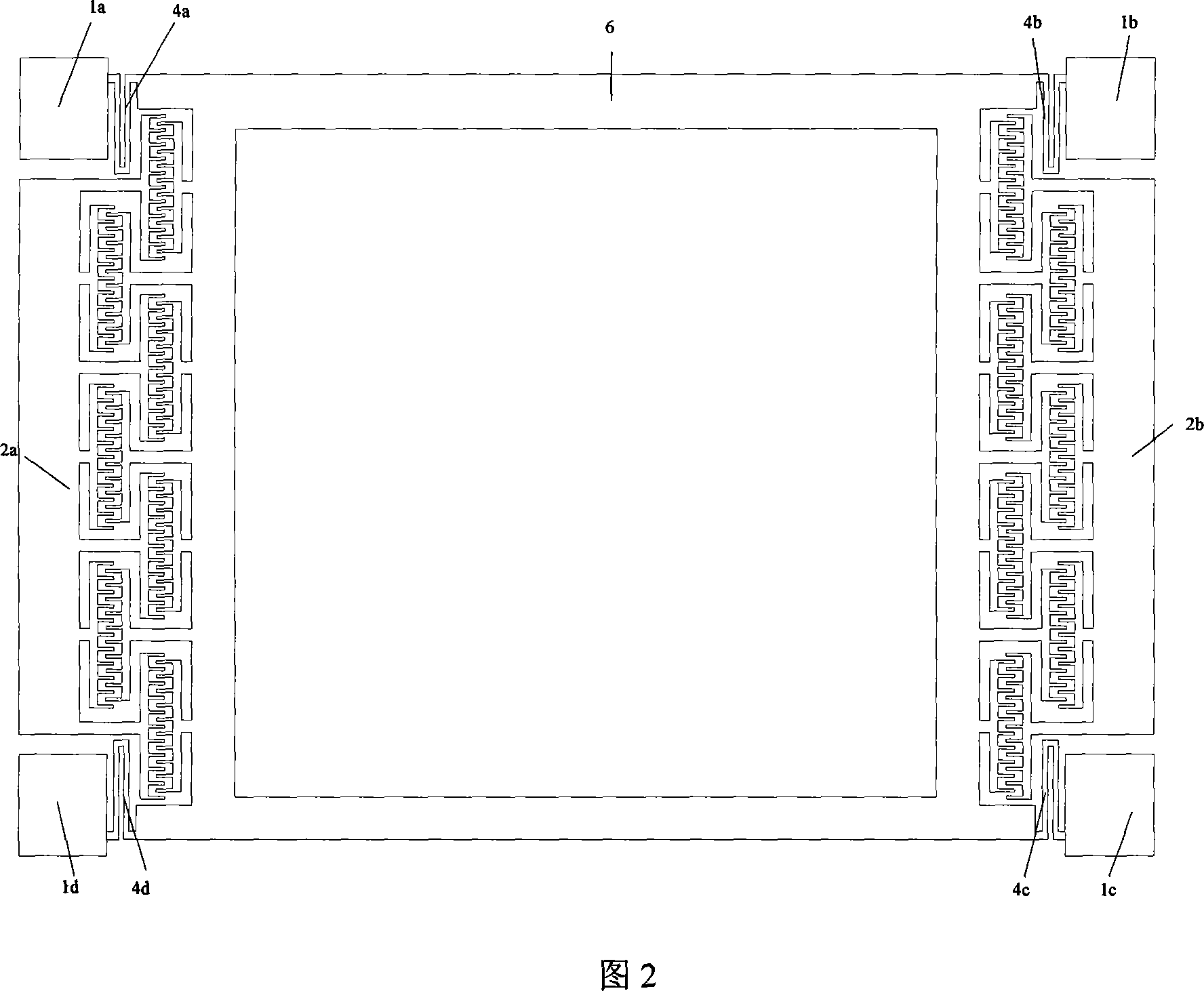

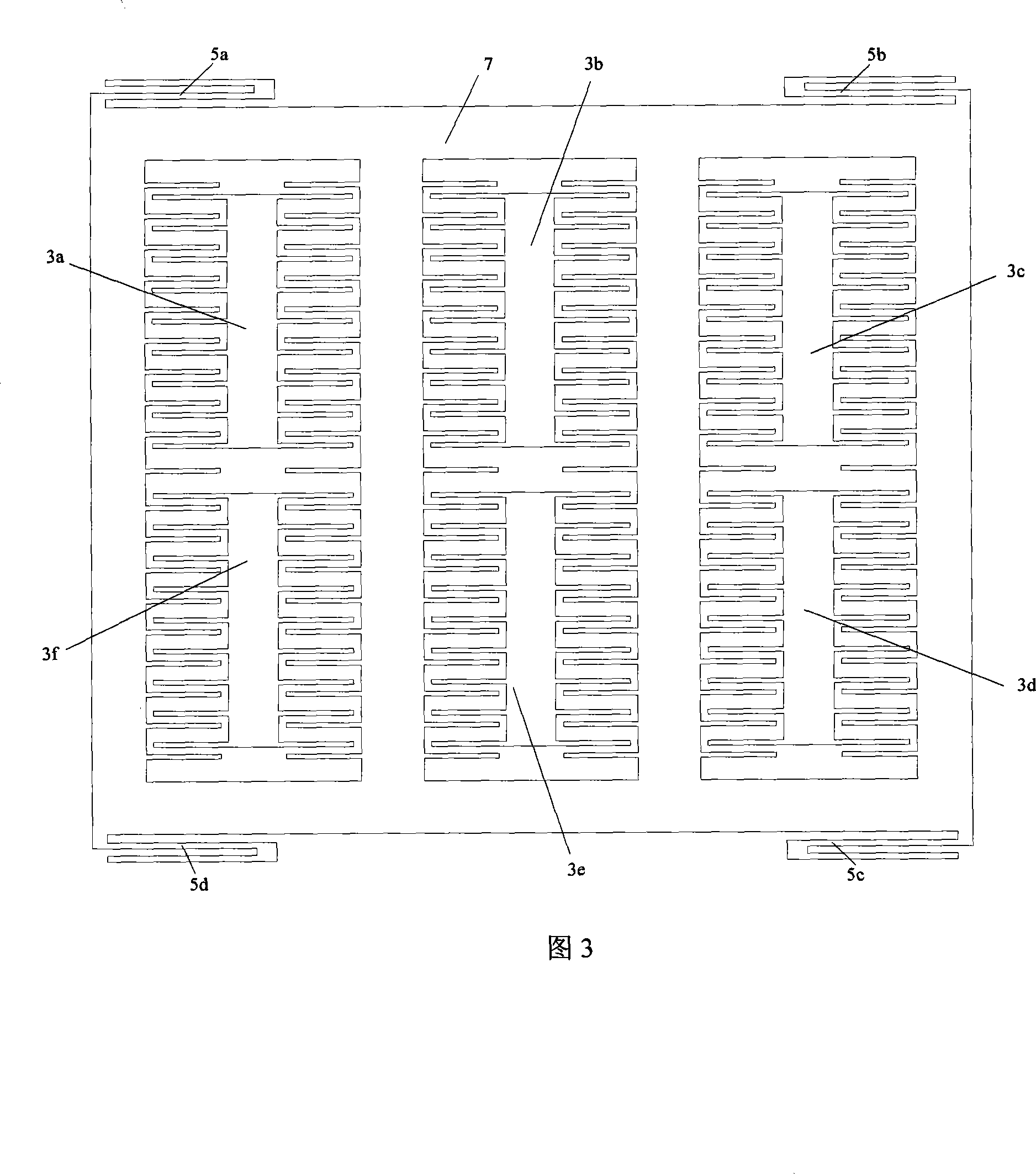

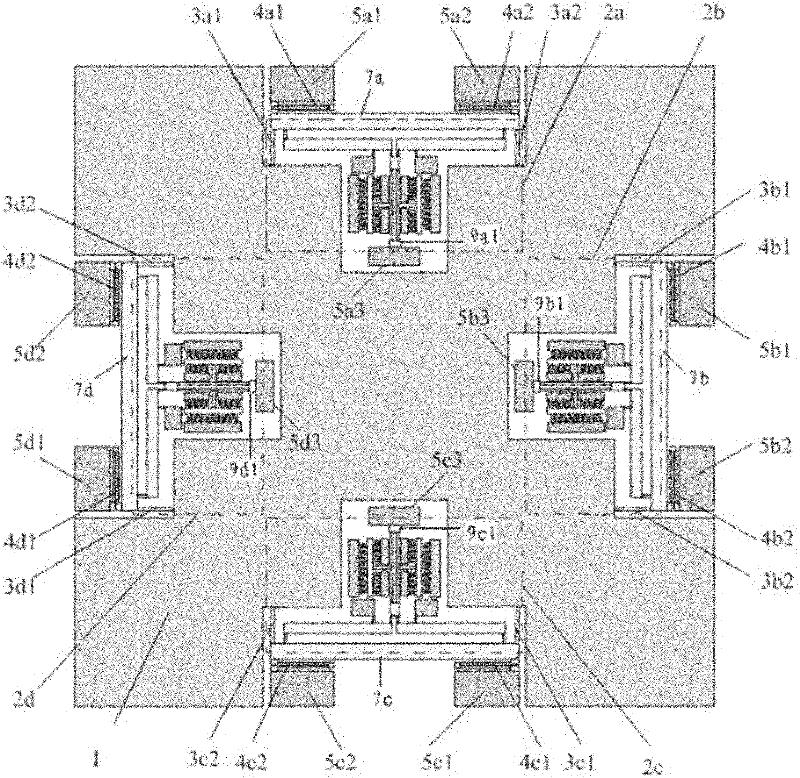

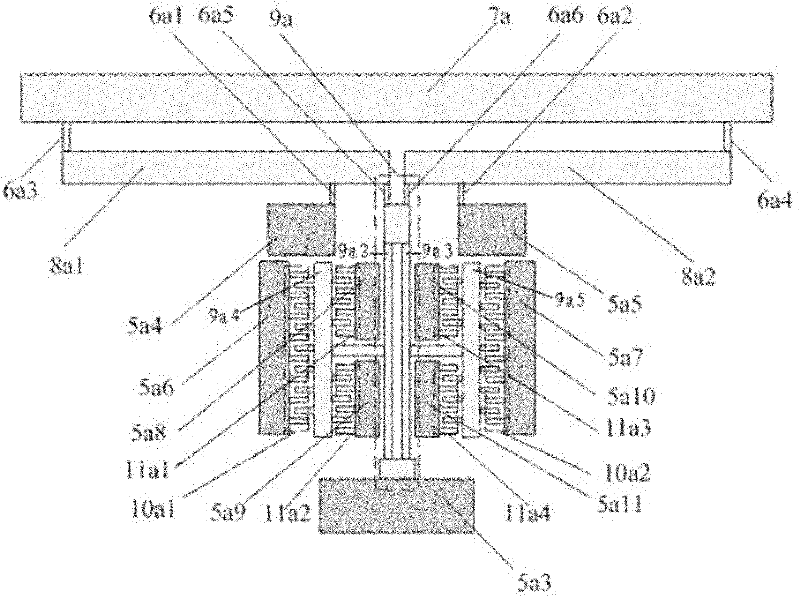

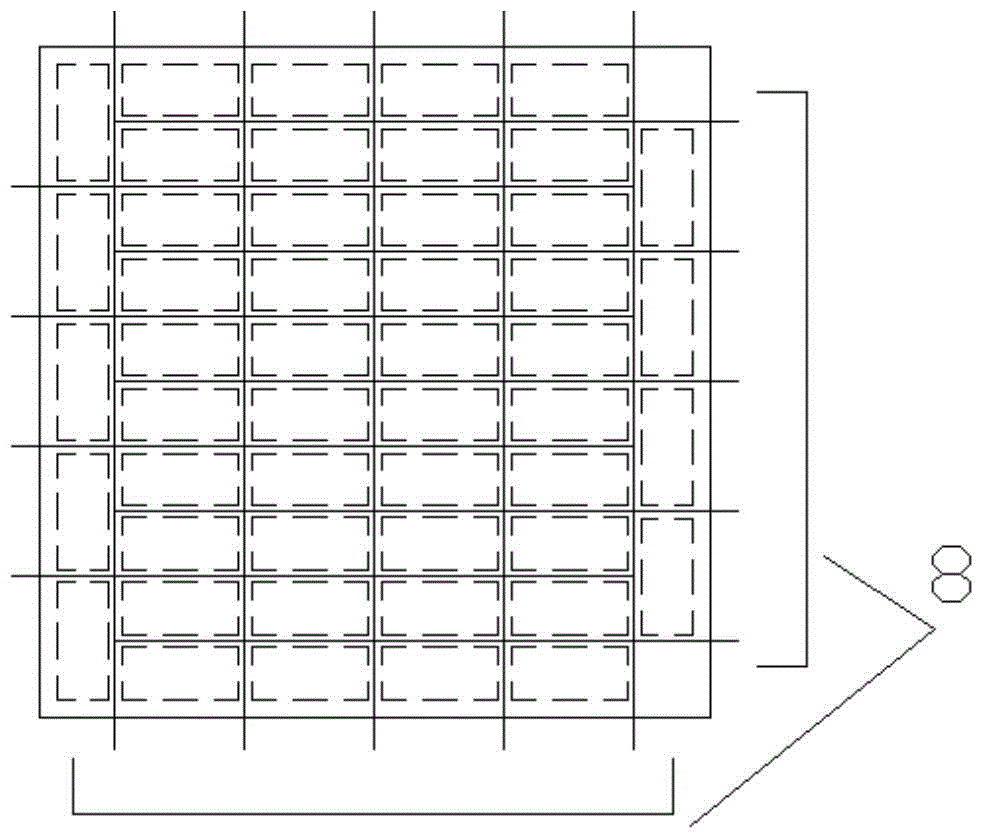

Dual-axle integrated fully-coupled silicon micro-resonance type accelerometer

InactiveCN102147423BReduce coupling effectReduce non-linearityAcceleration measurement using interia forcesPiezoelectric/electrostrictive devicesFully coupledAccelerometer

The invention discloses a dual-axle integrated fully-coupled silicon micro-resonance type accelerometer which comprises an upper-layer micro accelerometer structure and a lower-layer glass base, wherein the micro accelerometer structure is bonded on the glass base, the glass base is provided with a signal lead, an electrode of the micro accelerometer structure is connected with a corresponding signal lead, and the micro accelerometer structure comprises a mass block and four completely same resonator substructures. The dual-axle integrated fully-coupled silicon micro-resonance type accelerometer adopts frequency detection, and two detecting axles are fully coupled and arranged symmetrically; and the dual-axle integrated fully-coupled silicon micro-resonance type accelerometer has the advantages of simple and compact structure, small volume and high accuracy.

Owner:SOUTHEAST UNIV

A laser additive device and method for additive manufacturing thereof

InactiveCN109175364BUniform energyUniform temperatureAdditive manufacturing apparatusIncreasing energy efficiencyRobotic armEngineering

The invention provides a device for adding materials by laser, which includes a rotating beam laser system, a high-frequency short pulse laser system and an auxiliary current system; Melted and deposited on the surface of the substrate; the high-frequency short-pulse laser system outputs a high-frequency short-pulse laser, and the high-frequency short-pulse laser is used to input pulsed laser beams into the molten pool; the auxiliary current system is used to make the filament It forms a current loop with the molten pool, which is used to directly generate strong electromagnetic force inside the molten pool. The rotating beam laser system includes a continuous laser generator, a first high-precision mechanical arm and a continuous laser laser head; the high-frequency short-pulse laser system includes a high-frequency short-pulse laser generator, a high-frequency short-pulse laser head and a second High-precision mechanical arm. The invention can solve defects such as element segregation easily occurring inside the molten pool, gas cannot be discharged, uneven structure, thermal stress concentration and the like.

Owner:JIANGSU UNIV

Kiln mouth protection reinforcing mechanism, protection device and rotary kiln

PendingCN114812160AImprove thermal shock resistanceRelease thermal stressRotary drum furnacesRotary kilnStructural engineering

The invention discloses a kilneye protection reinforcing mechanism, a protection device and a rotary kiln, and belongs to the technical field of rotary kiln protection. According to the kilneye protection reinforcing mechanism, through connection of the cylinder wall reinforcing piece and the end opening reinforcing piece, the whole kilneye protection reinforcing mechanism has high strength, in addition, the cylinder wall reinforcing piece and the end opening reinforcing piece can be used in a cylinder wall castable in the kilneye cylinder wall and an end opening castable at the kilneye end opening, and the castable locally has good strength; and in addition, the kiln mouth protection reinforcing mechanism and the castable form a whole, so that the occurrence of structural damage caused by high-temperature thermal expansion due to higher working condition temperature in the use process is reduced.

Owner:JIANGSU SHUANGFA MACHINERY CO LTD

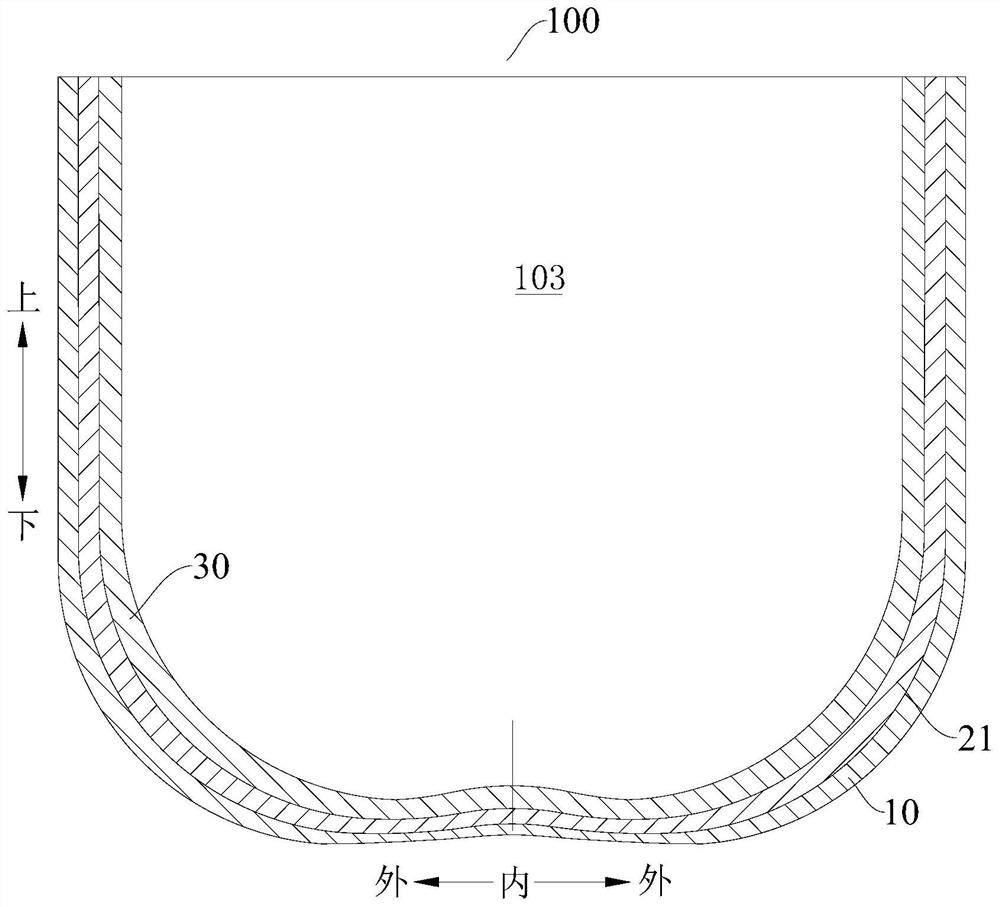

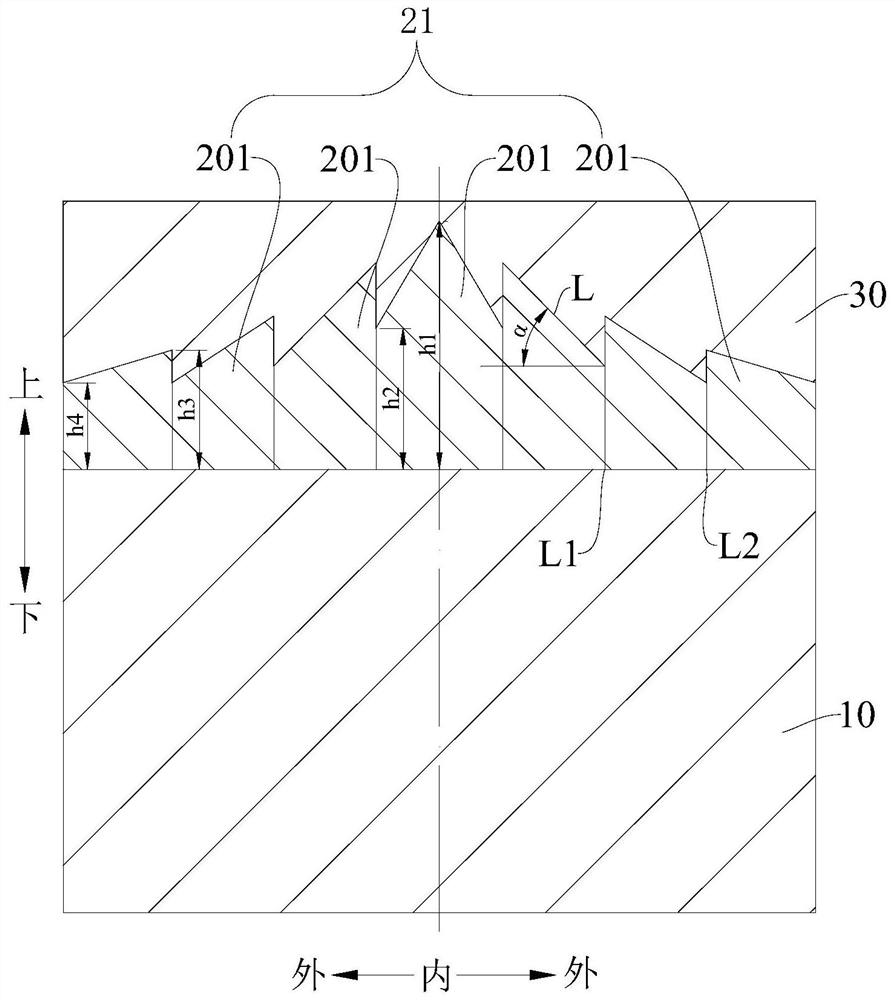

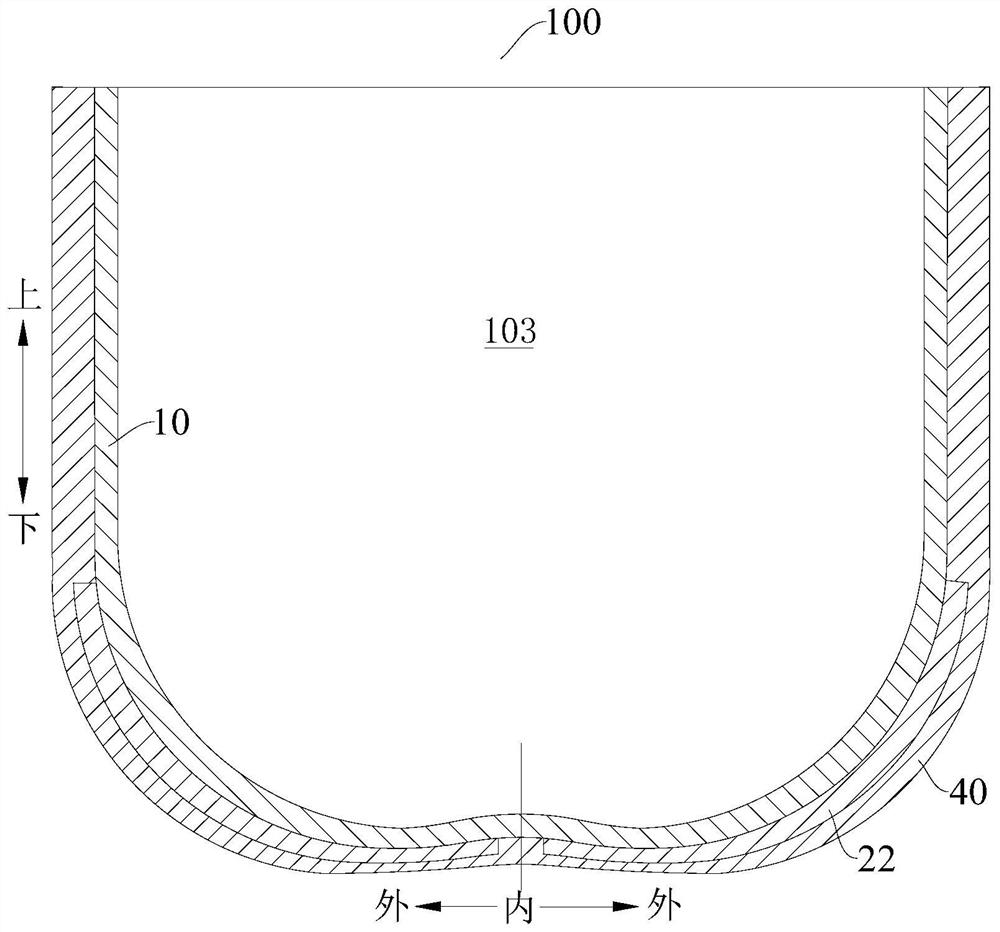

Container and cooking utensil

ActiveCN113116118AImprove corrosion resistanceInhibit sheddingCooking-vessel materialsPressure inorganic powder coatingMechanical engineeringSurface coating

The invention discloses a container and a cooking utensil. The container comprises a container body and a coating, the container body defines a cavity with a top opening, the coating is arranged on the surface of the container body, and the thickness of at least one part of the coating is gradually increased in the radial direction of the container body towards the direction close to the center of the bottom of the container body. According to the container disclosed by the embodiment of the invention, the coating is sprayed on the surface of the container body so that the thickness of the coating is gradually increased along the radial direction of the container body towards the direction close to the center of the bottom of the container body, and therefore, a thermal stress is effectively released, the coating is prevented from falling off, and the reliability of the coating is ensured.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Impact-resistant and high-wear-resistant surfacing alloy material

ActiveCN101870046BImprove wear resistanceImprove impact resistanceWelding/cutting media/materialsSoldering mediaWear resistantNiobium

The invention relates to an impact-resistant and high-wear-resistant surfacing alloy material, which belongs to the technical field of materials, and comprises the following components by weight percent: 55-68% of chrome iron, 5-13% of boron iron, 0.5-1.5% boron carbide, 8-15% of sodium and potassium water glass, 1-4.5% of silicon-manganese alloy powder, 0.5-6.5% of nickel powder, 0.2-5% vanadiumiron, 0.5-7.5% of molybdenum iron, 1.5-6% of niobium iron, 1.5-5% of rare earth magnesium alloy, 0.1-2.8% of graphite and the balance of iron, and the particle size of each component is 70-140 meshes, wherein the weight content of magnesium of the rare earth magnesium alloy is 20-26%, and the balance is lanthanum or cerium; and the weight percent of silicon of the silicon-manganese alloy powder is 25-50%, and the balance is manganese. The surfacing alloy material designed by the invention can be applied to the preparation of wear-resistant piece surface composite materials and the repair of workpiece surfaces, and the alloy has high macro hardness and strong shock resistance, produces few cracks in the process of use, and has very strong abrasive wear resistance and very wide range of application.

Owner:LIAONING TECHNICAL UNIVERSITY +1

A method for drying a new intermediate frequency furnace for pre-alloyed powder smelting

ActiveCN107326201BGuaranteed high temperature performanceReduce bond strengthLinings repairCrucible furnacesTemperature curveIntermediate frequency

Owner:HUBEI EXIN DIAMOND TECH

A combined heat-insulating shading structure for a star sensor

The invention discloses a combined heat-insulating shading cover structure for a star sensor, which comprises a cover body, a support and a light-blocking ring; the cover body and the support are both hollow cylinders, the light-blocking ring is a split hollow ring, and the cover body One end is equipped with a light blocking ring for heat dissipation and light extinction, and the other end of the cover is equipped with a support for assembling the optical machine circuit box of the star sensor. The invention optimizes the structure of the star sensor shading cover through the combination of the cover body and the support, and makes up for the defects of the traditional star sensor such as complex structure, excessive weight, complicated disassembly and assembly, and excessive heat transfer; The configuration suppresses space orbit stray light and space orbit heat flow, and overcomes the problem of excessive heat absorption of traditional star sensor shading.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

A preparation method of a flexible thermoelectric device and the prepared flexible thermoelectric device

ActiveCN104766922BNo impact ingredientsRelease thermal stressThermoelectric device manufacture/treatmentSemiconductor materialsCopper wire

The invention relates to a preparation method of a flexible thermoelectric device and the prepared flexible thermoelectric device. The method uses a copper mesh with high conductivity as the electrode material, directly fixes the copper mesh on the mold substrate, uses high-temperature resistant silica gel as a flexible substrate to replace the traditional ceramic substrate, and alternately drops P-N thermoelectric particles into the grid. On the basis of overall welding in the lattice mold device, the designed pattern is cut on the hot and cold end faces, so that each pair of P‑N semiconductor thermoelectric particles are electrically connected in series and thermally in parallel to form independent structures; and the thickness of the glue can be adjusted The basic curing operation of high-temperature-resistant flexible insulation is performed on the adjustable device to obtain a flexible device. The flexible device of the present invention can be bent at a large angle without changing the body of the semiconductor material and without affecting the composition of the doped and modified semiconductor material. It broadens the application scenarios of thermoelectric devices and is no longer limited to flat applications, releasing Thermal stress generated by the working process of thermoelectric devices.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

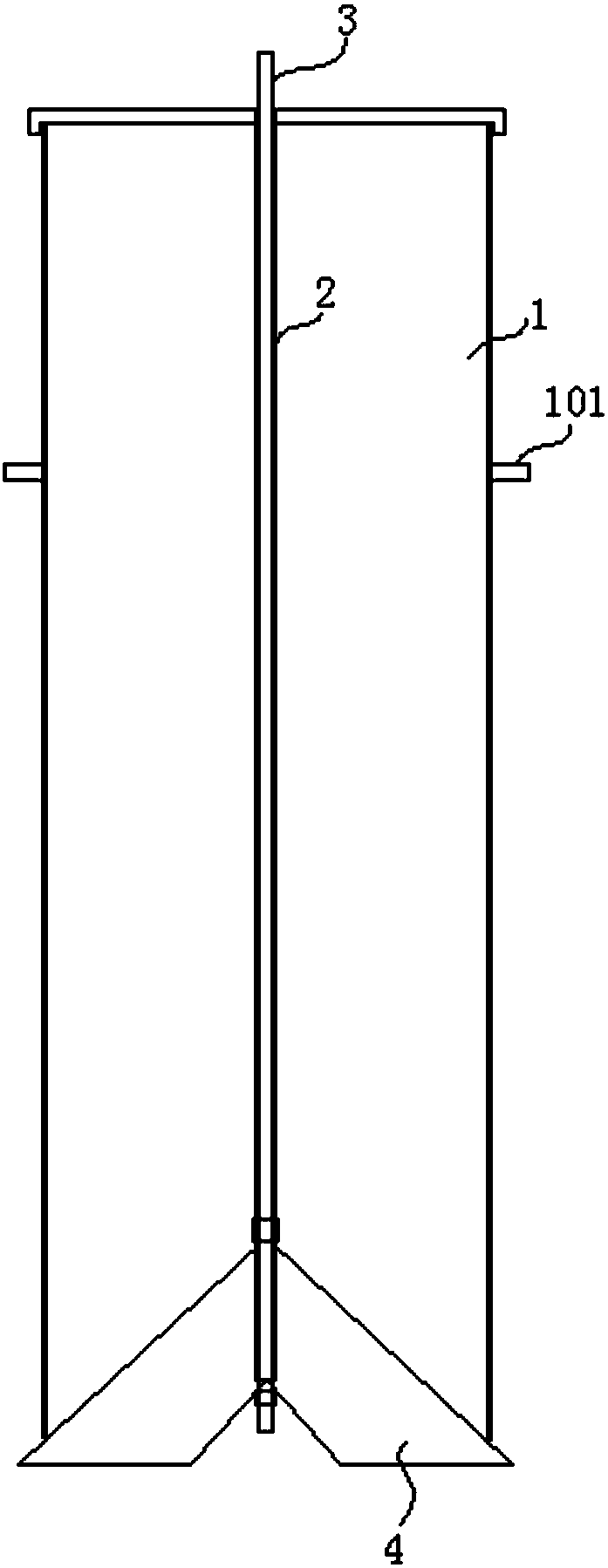

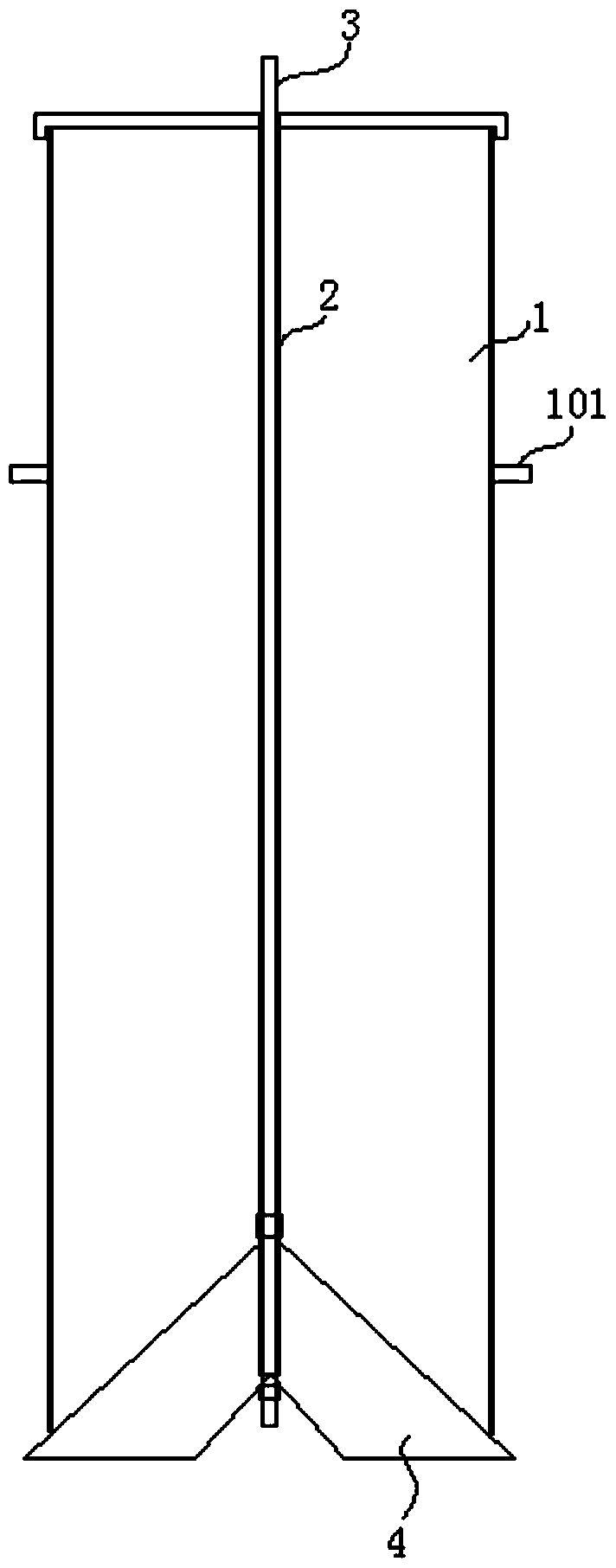

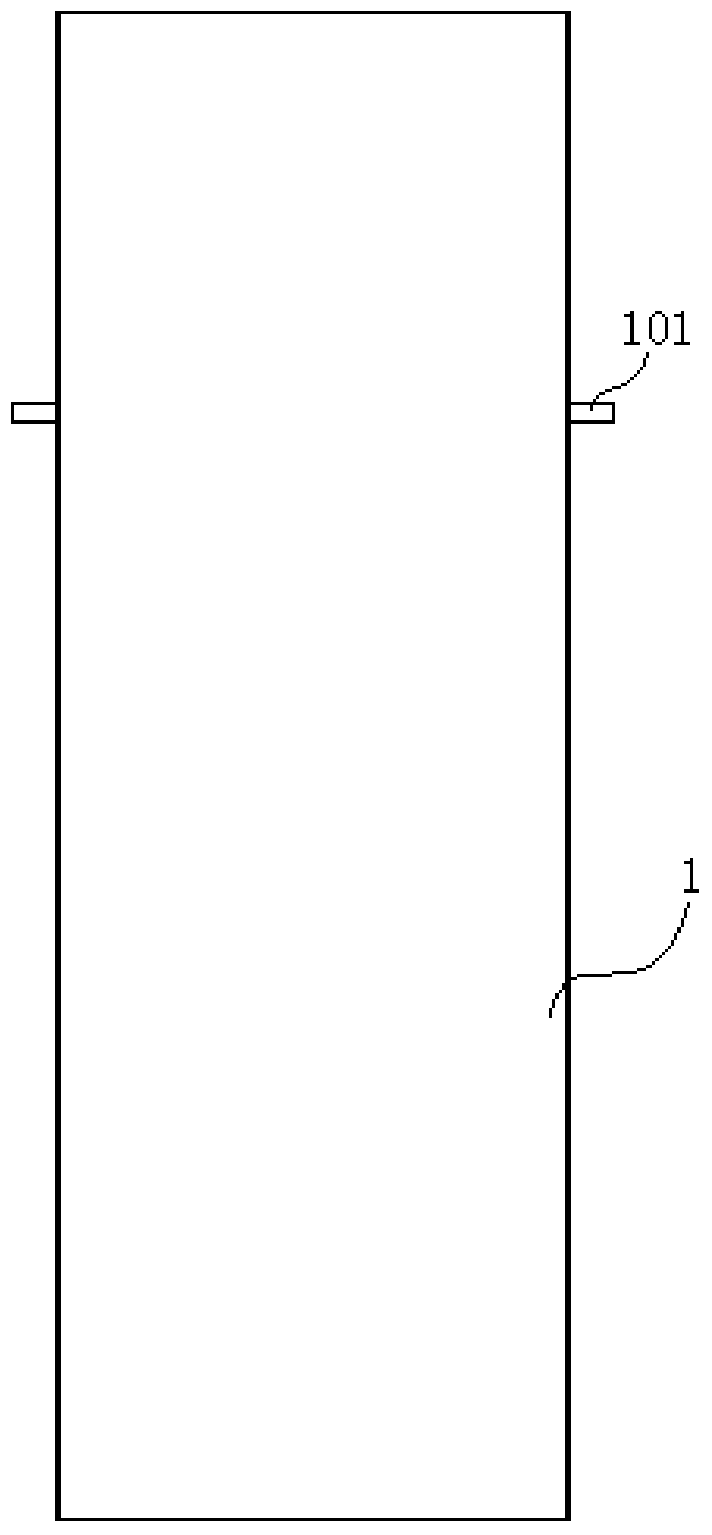

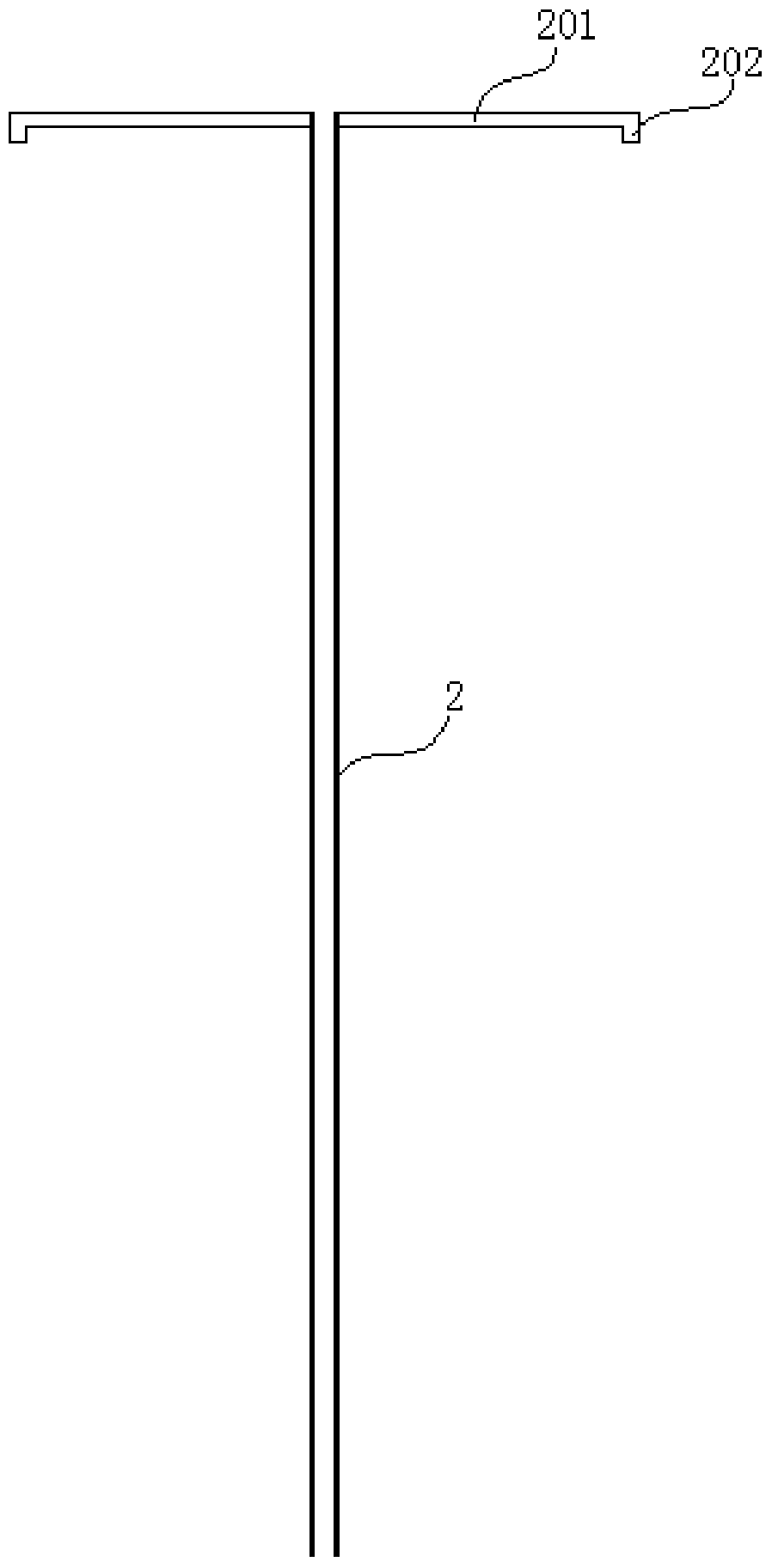

A secondary charging system for a single crystal furnace

ActiveCN105420806BIncrease usageReduce manufacturing costPolycrystalline material growthBy pulling from meltSingle crystalQuartz

The invention discloses a single crystal furnace secondary charging system and a charging method thereof, which belong to the field of monocrystalline silicon preparation. The single crystal furnace secondary charging system comprises a single crystal furnace main body and a secondary charging device, the secondary charging device comprises a molybdenum charging cylinder, a stainless steel sleeve, a molybdenum connecting rod and a quartz pyramid, the stainless steel sleeve is erected on a center position in the molybdenum feeding cylinder; a shape of the quartz pyramid is an equilateral triangular pyramid, an equilateral triangular pyramid groove is arranged at bottom of the quartz pyramid; an included angle of the side surface and the bottom of the quartz pyramid is alpha, the included angle of the side surface and the bottom of the equilateral triangular pyramid groove is beta, and beta is less than alpha by 5 DEG. The secondary charging method comprises the following steps: 1) preparing; 2) positioning of the secondary charging device; 3) charging; and 4) taking the secondary charging device. The charging system mainly realizes a function for adding the raw materials at any time during a monocrystalline silicon rod drawing process by the single crystal furnace.

Owner:安徽华芯半导体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com