A high-power Hall thruster discharge chamber assembly based on flexible connection

A Hall thruster and flexible connection technology, applied in the direction of thrust reverser, machine/engine, and plasma utilization, can solve problems such as large thermal stress, ceramic wall damage, high technical difficulty, etc., to avoid technical difficulties, Ease of processing, ensuring airtightness and insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

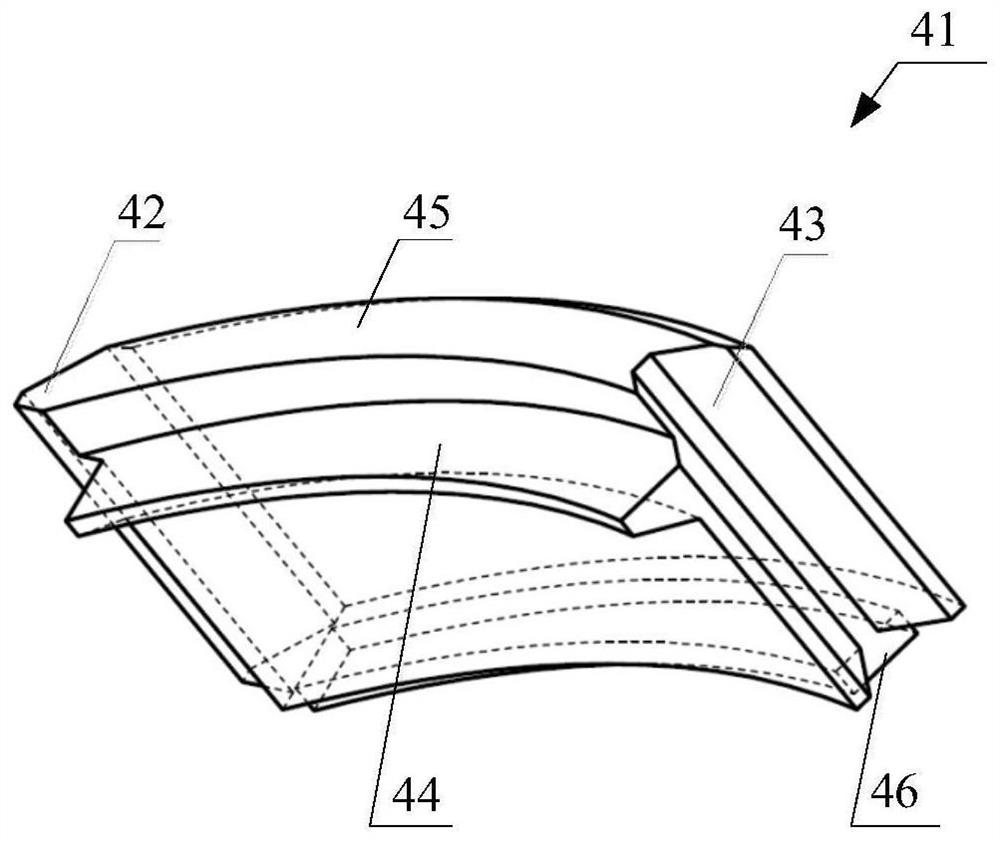

[0031] The present invention proposes a high-power Hall thruster discharge chamber assembly based on flexible connection. The solution is based on the concept of flexible connection, and a corresponding plug-in ceramic ring, elastic pressure ring and anode with annular groove are designed to form A flexible connection ceramic discharge chamber component device with the characteristics of simplicity, stability, reliability, and ease of processing, while maintaining the stable operation of the discharge chamber, avoids the risk of damage to the discharge chamber caused by the thermal stress caused by the discharge of a high-power thruster .

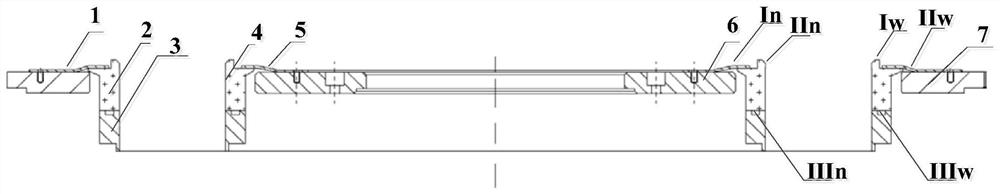

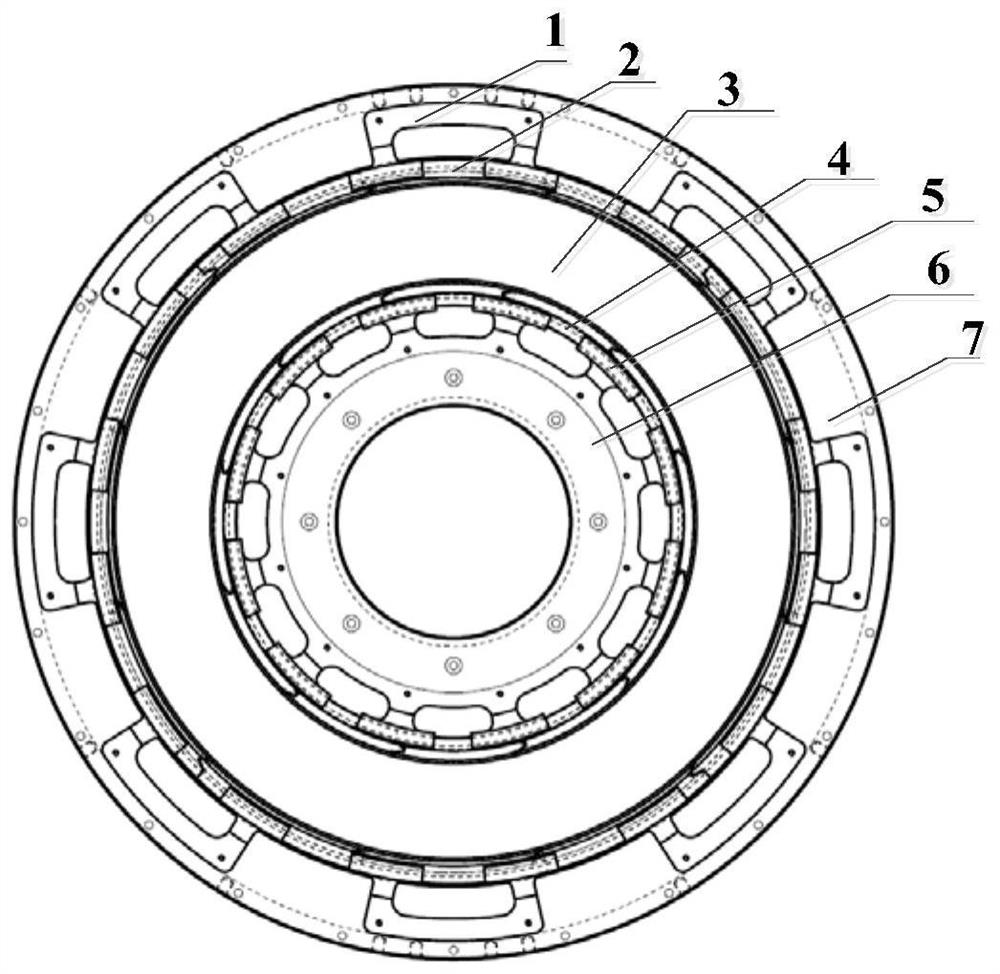

[0032] As shown in Figure 1(a) and Figure 1(b), the high-power Hall thruster discharge chamber assembly consists of a plug-in inner ceramic ring 4, a plug-in outer ceramic ring 2, an outer pressure ring 1, an inner pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com