A secondary charging system for a single crystal furnace

A technology of secondary feeding and single crystal furnace, which is applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems that single crystal silicon rods are not involved, so as to improve the effective quality, release thermal stress, The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

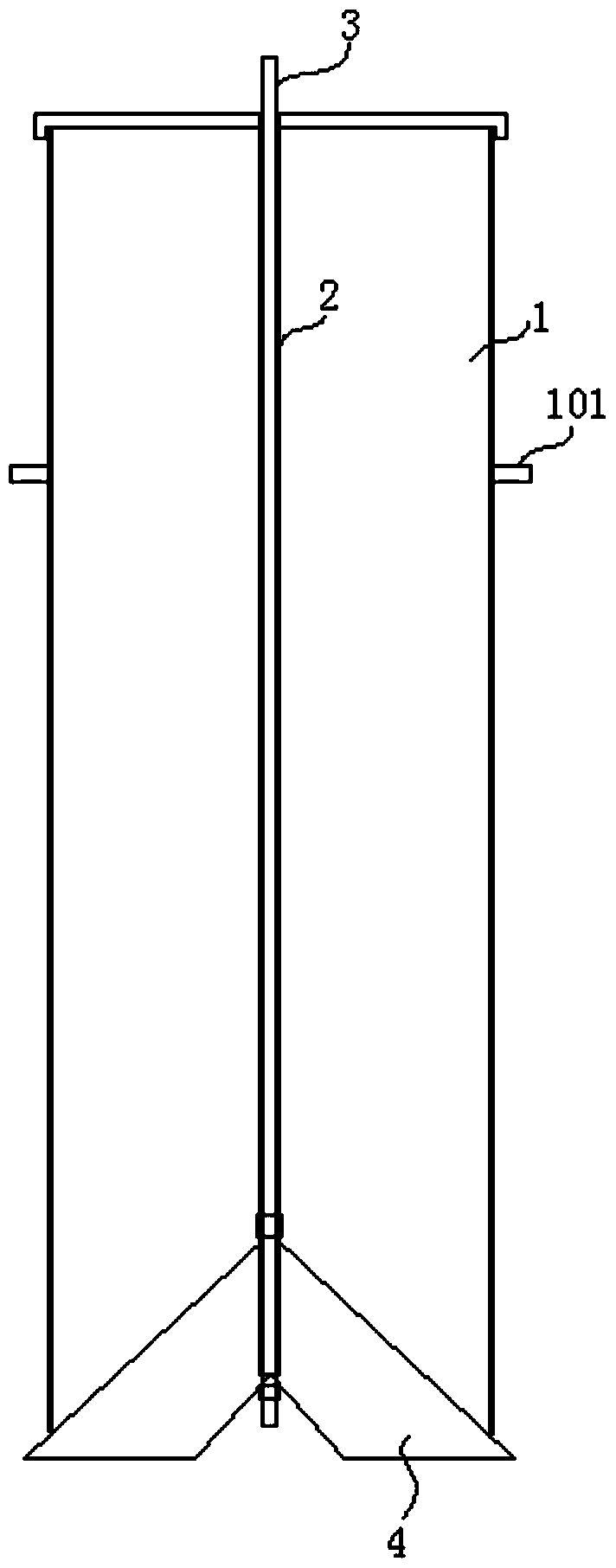

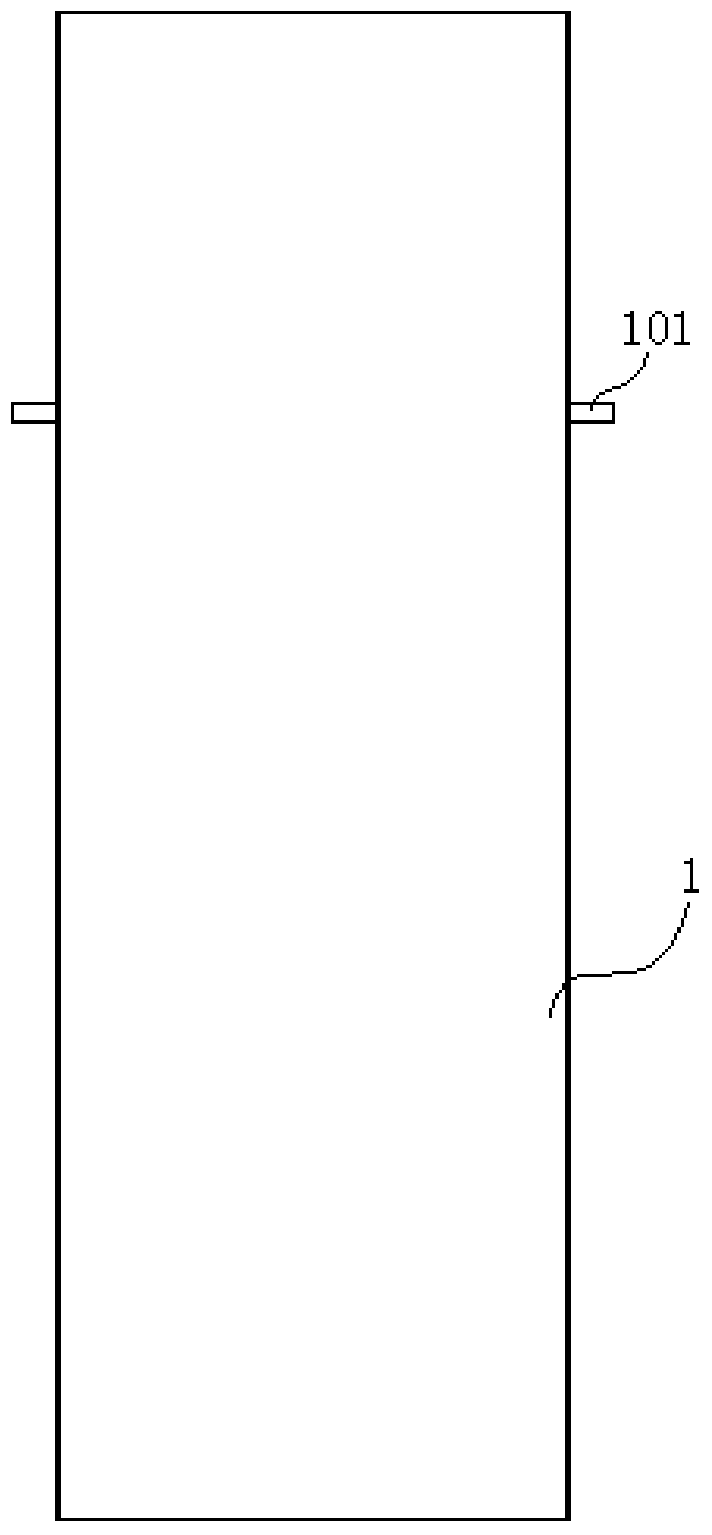

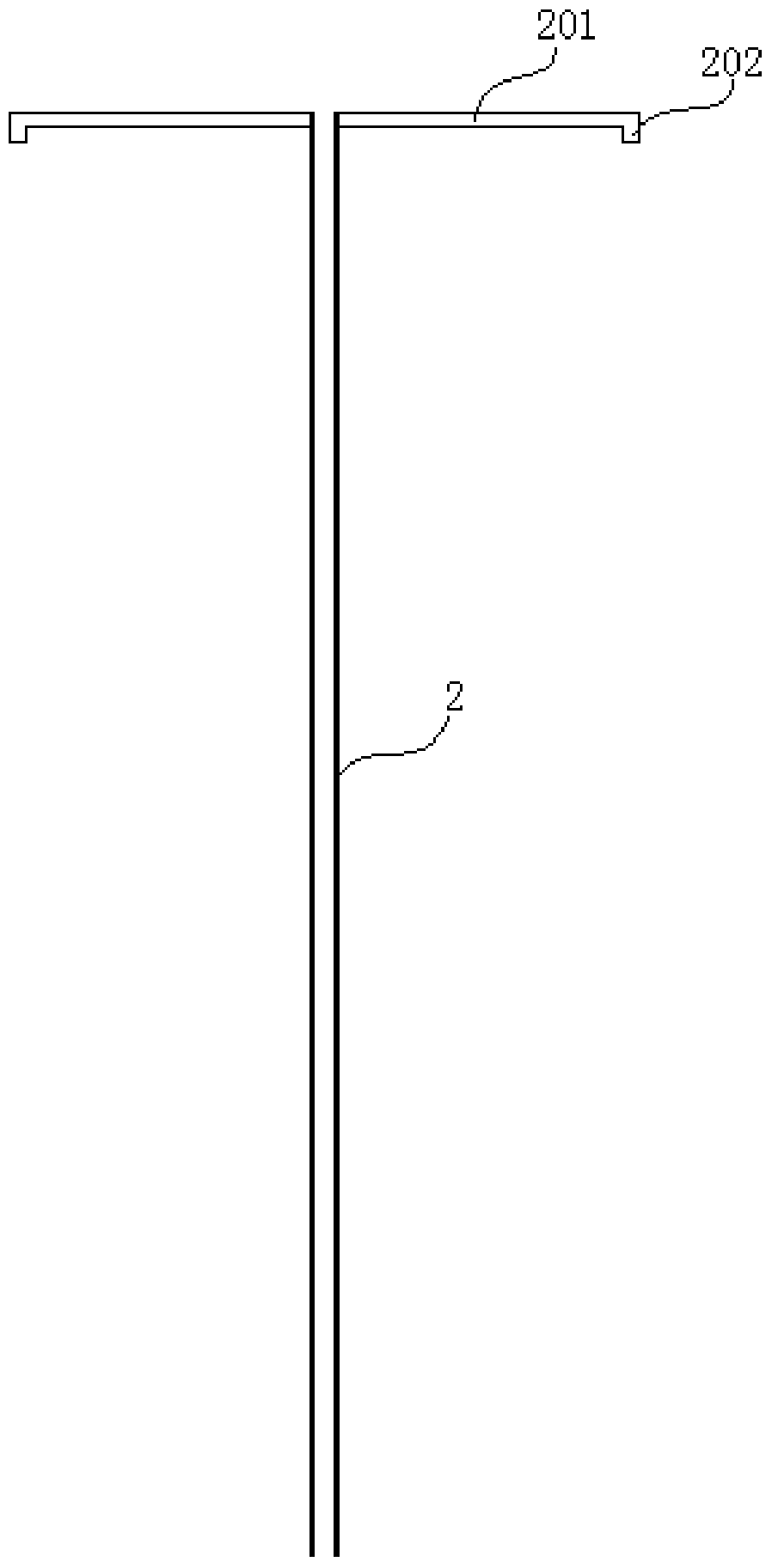

[0054] combine Figure 1~5 , the single crystal furnace secondary charging system of the present embodiment comprises a single crystal furnace main body and a secondary charging device, the single crystal furnace main body includes a furnace cylinder 11, an isolation chamber 7 and an auxiliary chamber 6, and the upper part of the furnace cylinder 11 is a furnace cylinder neck mouth 9, the furnace cylinder neck 9 communicates with the auxiliary chamber 6 above through the isolation bin 7, and the furnace cylinder neck 9 is provided with an isolation valve 8; the furnace cylinder 11 is provided with a quartz crucible 12, and the bottom of the quartz crucible 12 is connected The supporting part 14 with lifting and rotating functions is connected, a heater 13 is provided around the quartz crucible 12, and a guide tube 16 is provided above the quartz crucible 12, and the guide tube 16 is a tube whose diameter gradually decreases from top to bottom. body; the upper part of the furna...

Embodiment 2

[0062] The single crystal furnace secondary charging system of the present embodiment, its structure and embodiment 1 are basically the same, and its difference is: the top 2mm of the molybdenum nut 301 of quartz cone 4 upper side apart from quartz cone 4, the quartz cone 4 Its bottom of the molybdenum nut 301 on the lower side is apart from the bottom 4mm of the molybdenum connecting rod 3; The included angle is 55°.

Embodiment 3

[0064] combine Figure 6-10 , a secondary charging method of the present embodiment using the single crystal furnace secondary charging system described in Example 1, comprising the following steps,

[0065] Step ST1, preparation stage;

[0066] Use absolute ethanol to wipe the charging cart, molybdenum feeding cylinder 1, stainless steel sleeve 2, molybdenum connecting rod 3 and quartz cone 4;

[0067]Assemble the secondary feeding device, wherein the quartz cone 4 is first clamped on the molybdenum connecting rod 3 through the molybdenum nuts 301 on the upper and lower sides of the quartz cone 4, and then the molybdenum nuts on the lower side of the quartz cone 4 are loosened 301, so that the bottom of the molybdenum nut 301 on the lower side of the quartz cone 4 is apart from the bottom 3~4mm of the molybdenum connecting rod 3 (3mm is taken in this embodiment), the molybdenum nut 301 on the upper side of the quartz cone 4 is loosened, so that the quartz cone The bottom of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com