Parallel structure sealing electrode and assembly method thereof

A technology for sealing electrodes and assembly methods, which is applied to structural parts, battery pack parts, circuits, etc., can solve the problems of large sealing structure size, poor space utilization, and difficult sealing, so as to reduce welding deformation and ensure Long-lasting, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

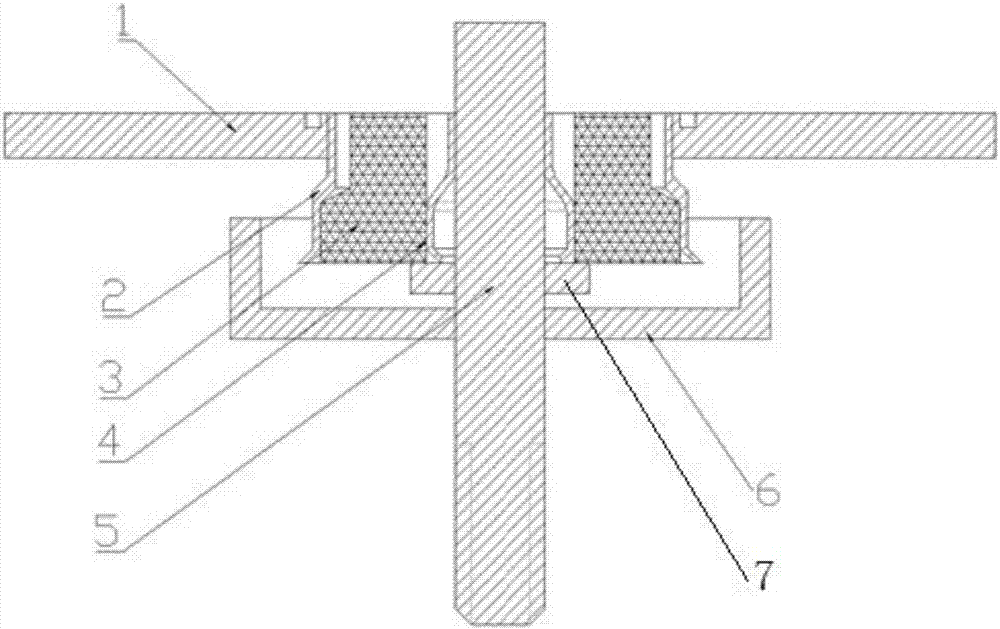

[0041] A kind of parallel structure sealing electrode of the present invention, such as figure 1 As shown, it includes a battery cover plate 1 , an outer transition ring 2 , an insulating structure 3 , an inner transition ring 4 , an electrode core 5 and a liquid-sealed bowl holder 6 .

[0042] Among them, the battery cover 1 and the liquid-sealed bowl holder 6 are made of stainless steel or 4J33 ceramic sealing alloy; the outer transition ring 2 and the inner transition ring 4 are made of 4J33 ceramic sealing alloy; the insulating structure 3 is made of alumina ceramics, quartz glass and other materials ; The electrode core 5 is made of stainless steel, oxygen-free copper or 4J33 ceramic sealing alloy material.

[0043] When the electrode core 5 of oxygen-free copper is used, it needs to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com