Method for high-speed laser cladding of Mo-Cu alloy layer on copper substrate

A technology of laser cladding and alloy layer, applied in metal material coating process, coating and other directions, can solve problems such as low mutual solubility, finished product strength, electrical conductivity and performance uniformity can not meet the requirements, cumbersome process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

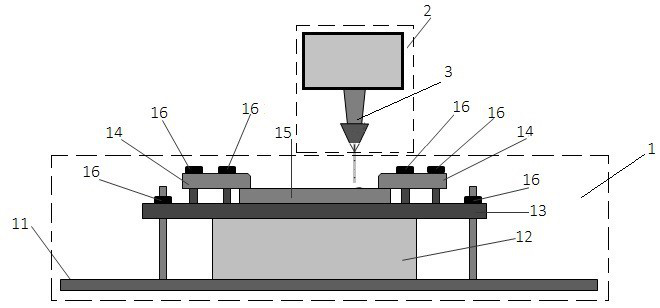

Method used

Image

Examples

Embodiment 1

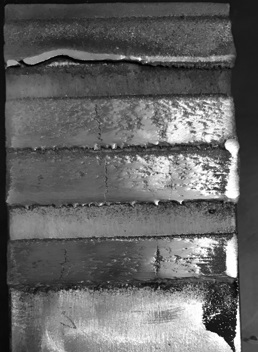

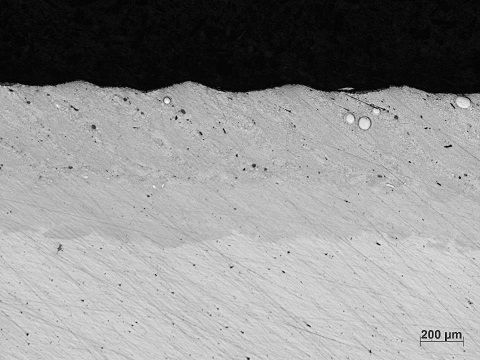

[0041] Prepare a copper plate with a size of 6mm×150mm×100mm, grind and clean it until the surface is smooth and clean, the cladding powder is 300 mesh Mo powder and Cu powder, use a platform-type high-frequency vibration platform to apply high-frequency vibration, and perform double-tube layered gradient cladding The specific parameters are the first layer: Mo powder feeder speed 0.2rpm, Cu powder feeder speed 0.3rpm, power 3500W, cladding distance 15.5mm, protective gas (argon) 14L / min, cladding head moving speed 0.05mm / s, preheating temperature 200°C. The second layer: Mo powder feeder speed 0.3rpm, Cu powder feeder speed 0.4rpm, power 3300W, cladding distance 15.5mm, protective gas (argon) 14L / min, cladding head moving speed 0.05mm / s, preheating temperature 200°C. The third layer: Mo powder feeder speed 0.4rpm, Cu powder feeder speed 0.4rpm, power 3000W, cladding distance 15.5mm, protective gas (argon) 14L / min, cladding head moving speed 0.05mm / s, preheating temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com