A grid used in a grid-controlled pulse traveling wave tube electron gun and its manufacturing process

A technology of gate-controlled pulse and manufacturing process, which is applied in the direction of electron/ion gun and non-luminescent electrode manufacturing of time-of-flight electron tubes, and can solve the problem of reducing the working reliability and service life of grid-controlled pulse traveling wave tubes The normal operation of the tube, the reduction of the work function of the grid surface, etc., to improve the reliability and service life of the work, the stability of the repeatability, and the effect of reducing the thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

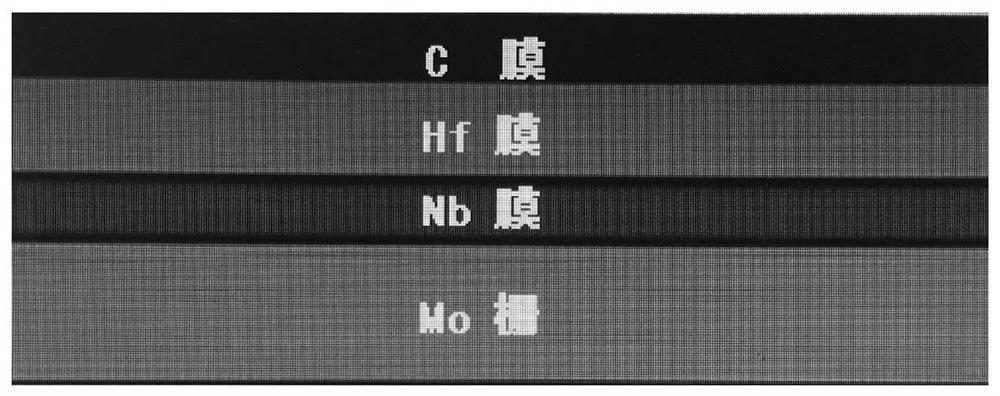

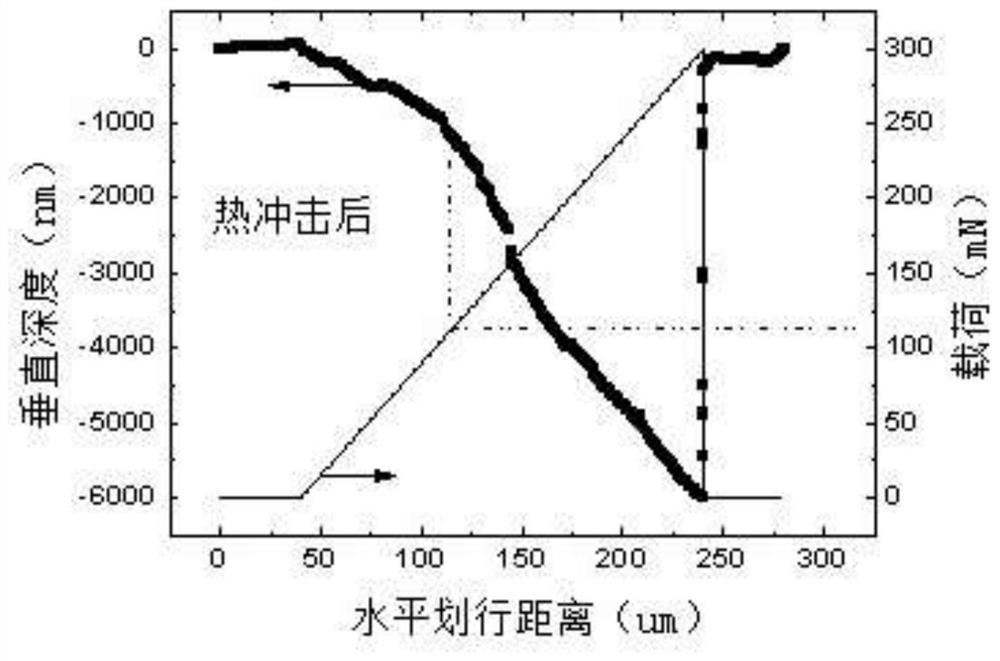

[0026] Such as figure 1 As shown, the grid of the present invention is used in the grid-controlled pulsed traveling wave tube electron gun to suppress the grid electron emission of the grid-controlled pulsed traveling wave tube. The substrate is cleaned and degassed in high temperature vacuum; the ion beam assisted deposition method is used to ion implant Nb and deposit Nb thin film on the molybdenum grid substrate, the ion beam (Ar+) energy is 850eV, and the background vacuum is better than 1×10 -4 Pa, the working pressure is 2.4×10 -2 Pa, to prepare a gradient functional layer, the thickness of the gradient functional layer is 1.1um; the ion beam assisted deposition method is used to implant Hf and deposit Hf coating on the Nb film layer, and then deposit C coating on it, ion beam (Ar+ ) energy is 800eV, the background vacuum is better than 1×10 -4 Pa, the working pressure is 5×10 -1 Pa, prepare the Hf / C composite anti-grid electron emission film layer, the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com