Crewel vibrating silicon micro-gyroscopes

A silicon micro-gyroscope, line vibration technology, applied in the direction of speed measurement, instruments, generators/motors, etc. with gyro effect, can solve problems such as thermal stress and orthogonal coupling errors, large motion nonlinearity, and large gyroscope errors. , to achieve the effect of releasing thermal stress, reducing nonlinearity, and reducing error signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

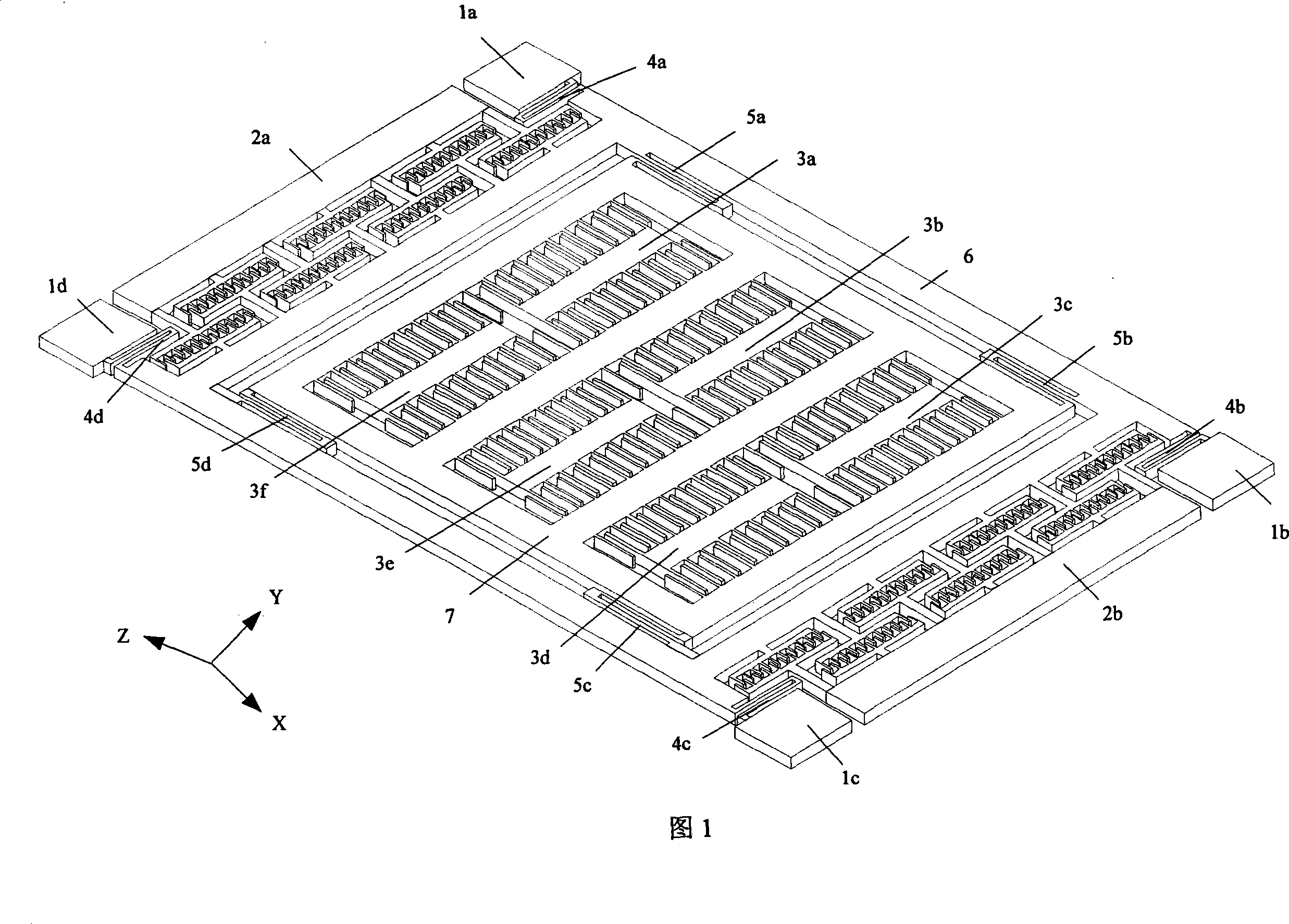

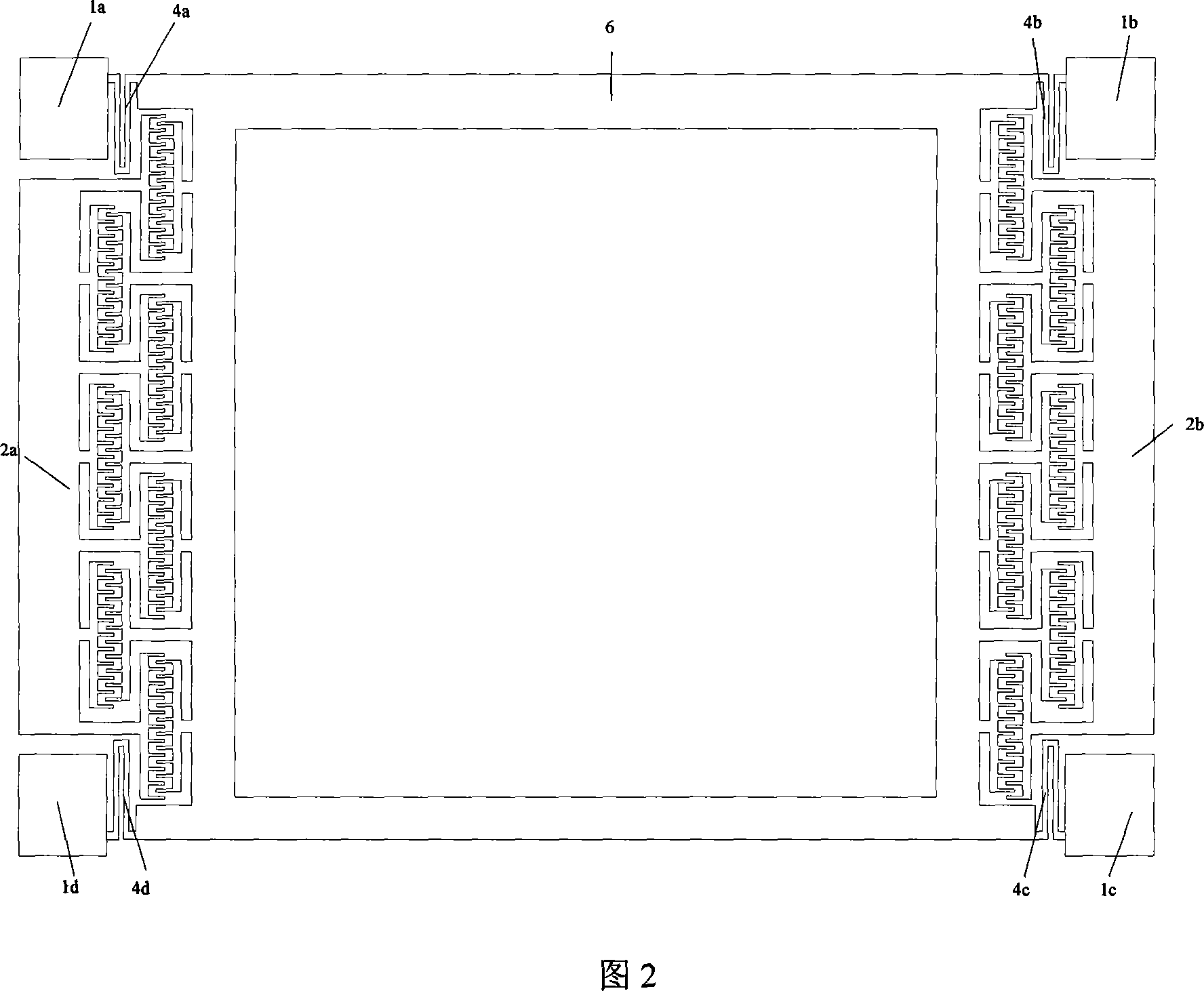

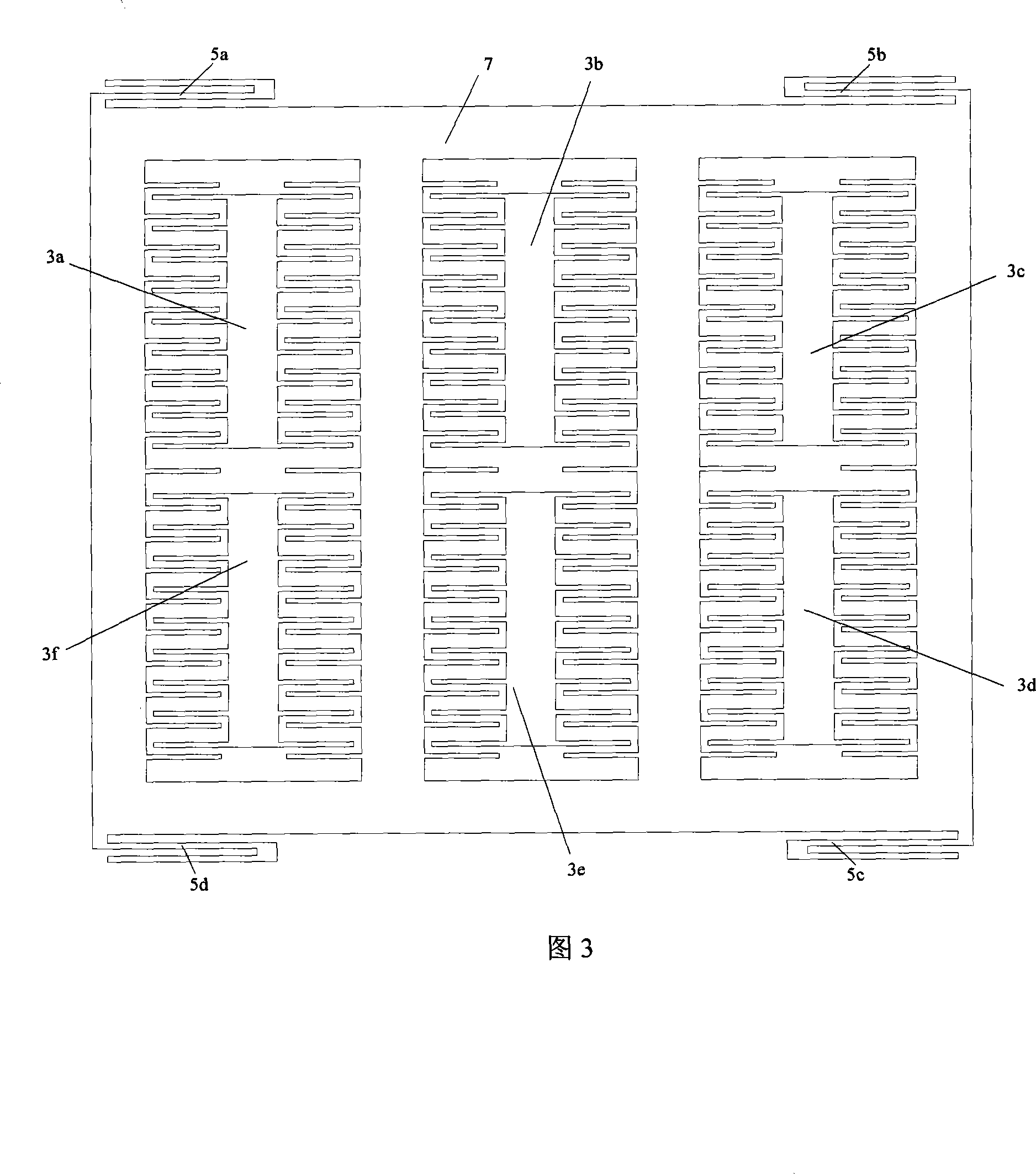

[0017] In conjunction with Fig. 1 and Fig. 4, the double-wire vibrating silicon micro-gyroscope of the present invention is used to measure the measuring instrument perpendicular to the base level, and consists of upper and lower layers, and the upper layer is a gyroscope machine made on a single crystal silicon wafer. Structure, the lower layer is the signal leads made on the glass substrate, the inner frame 7 of the upper mechanical structure of the gyroscope is connected with the outer frame 6 through the detection support beams 5a, 5b, 5c, 5d, and the lower layer of the gyroscope is made on the glass substrate. Line 8, drive input leads 9a, 9b, sensitive output signal leads 10a, 10b, the upper mechanical structure is installed on the glass substrate through the fixed bases 1a, 1b, 1c, 1d corresponding to the fixed base bonding points 11a, 11b, 11c , 11d, the upper mechanical structure part is suspended above the lower glass substrate part, and the driving support beams 4a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com