Patents

Literature

128 results about "Flat interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

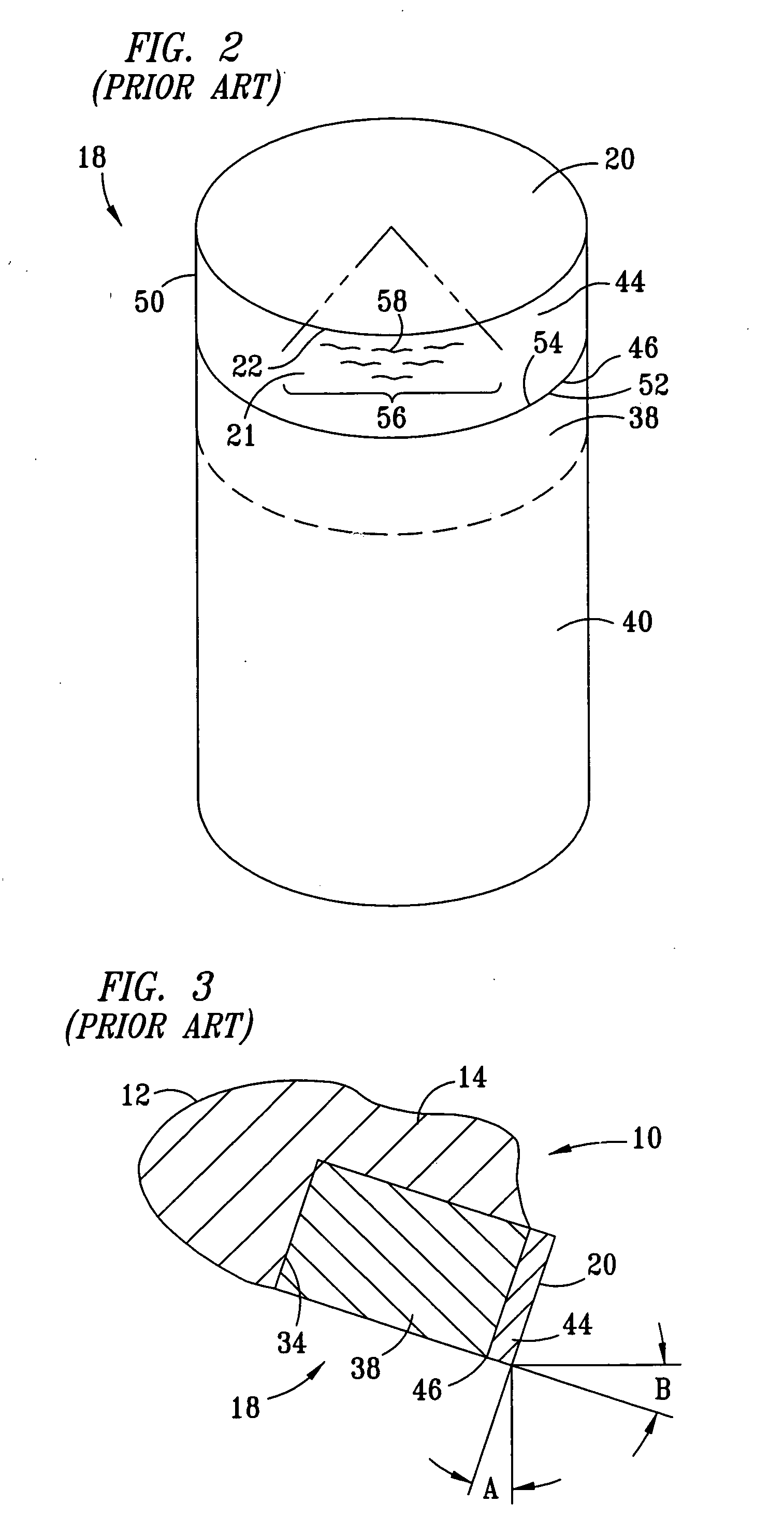

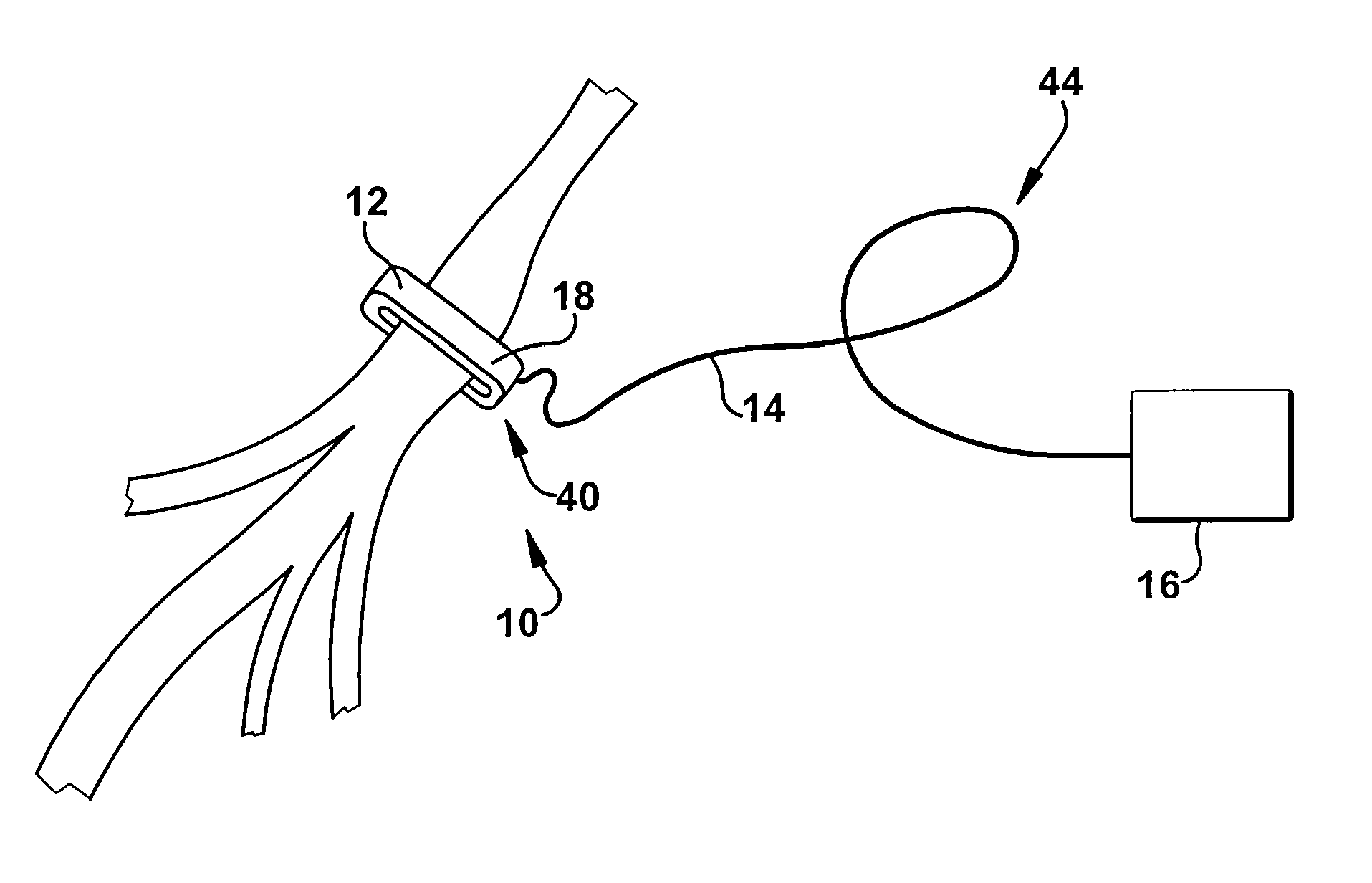

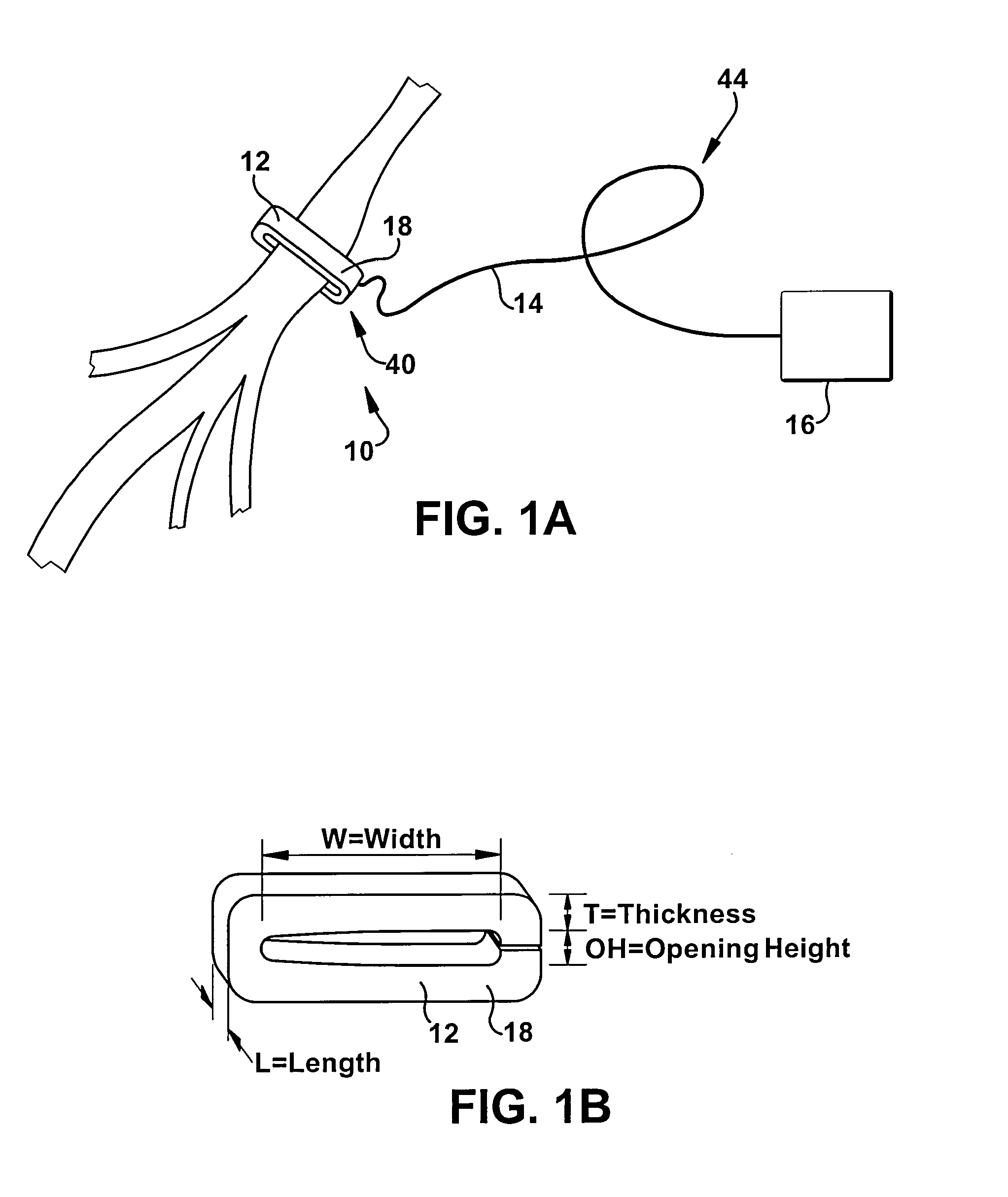

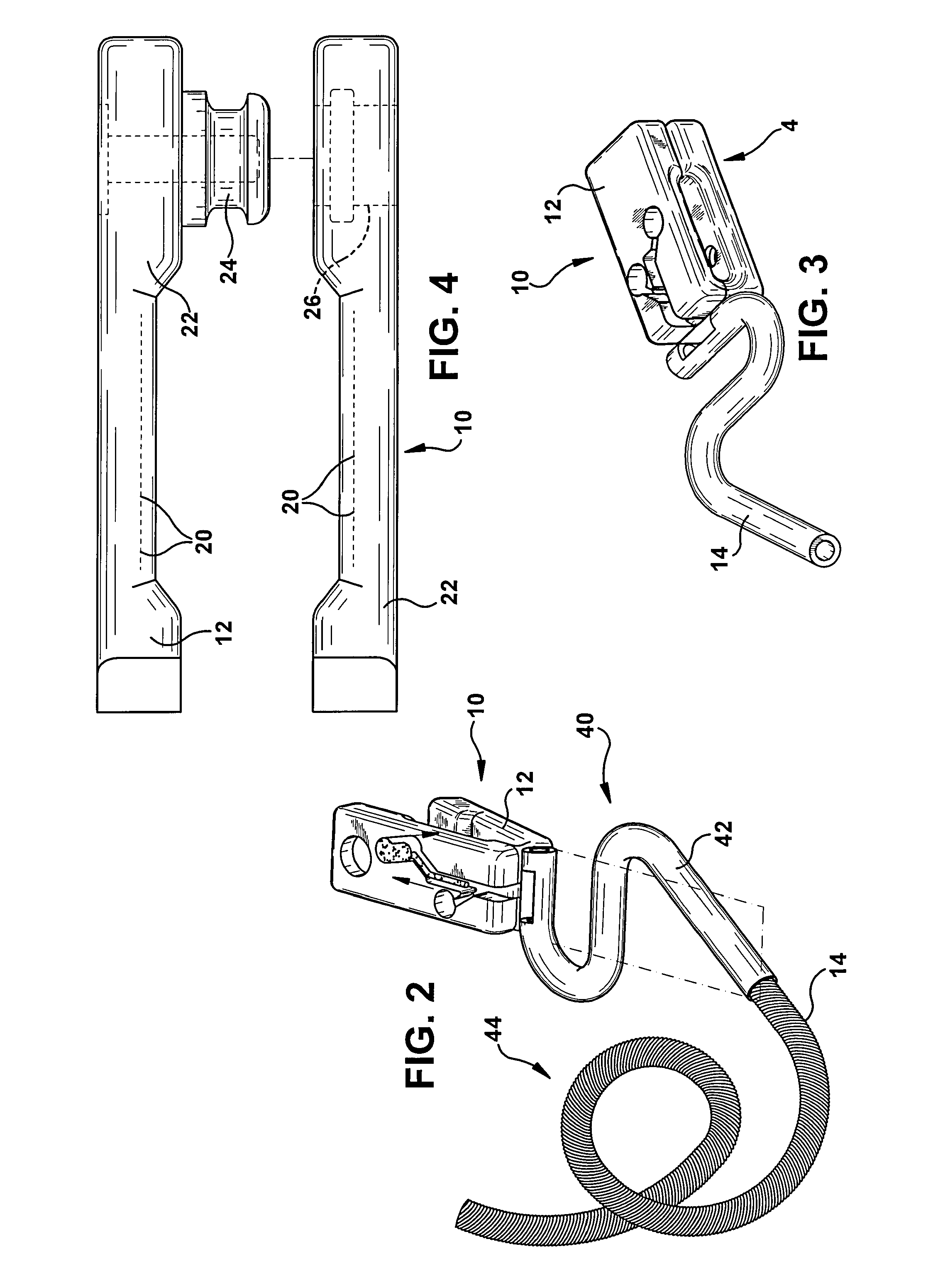

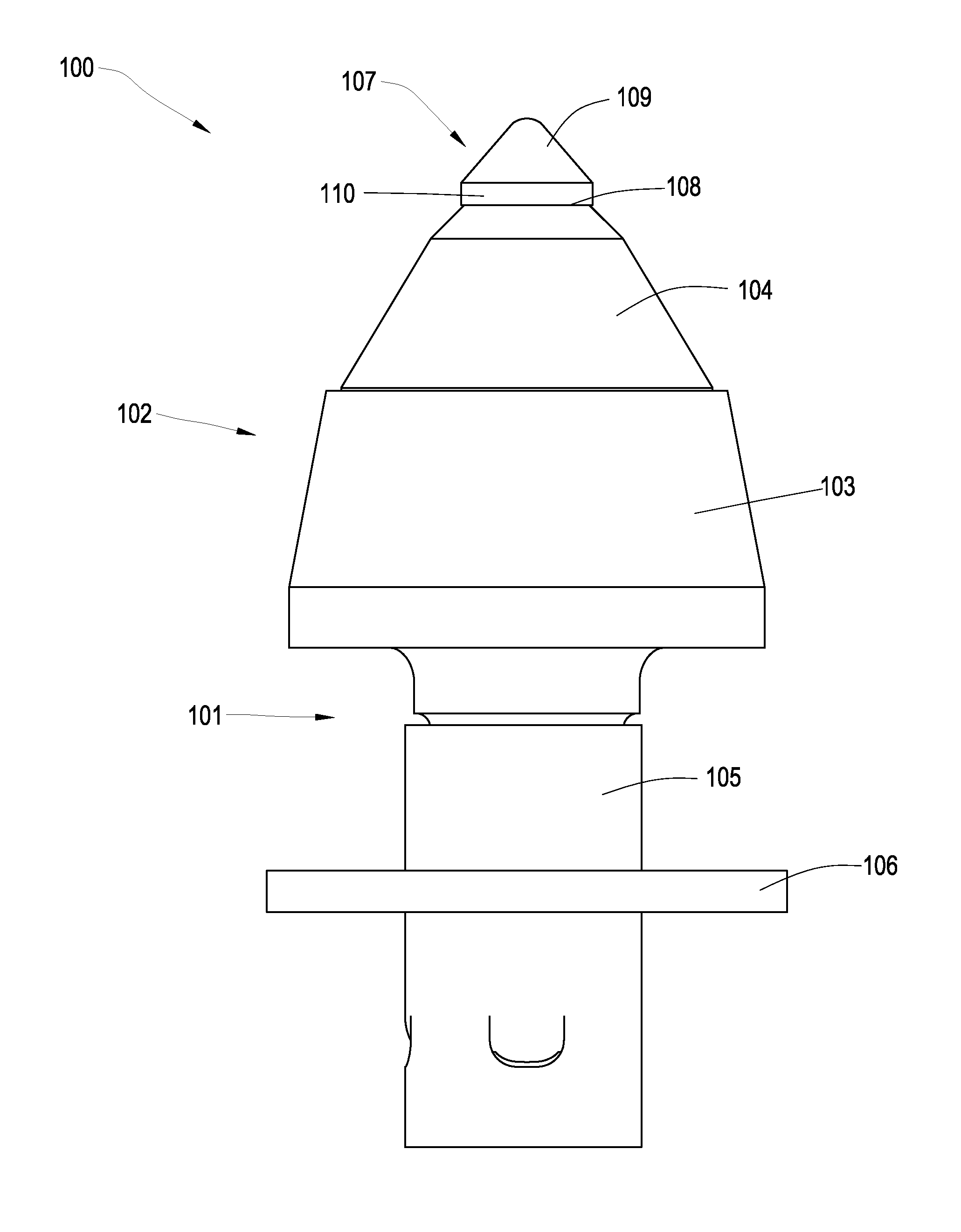

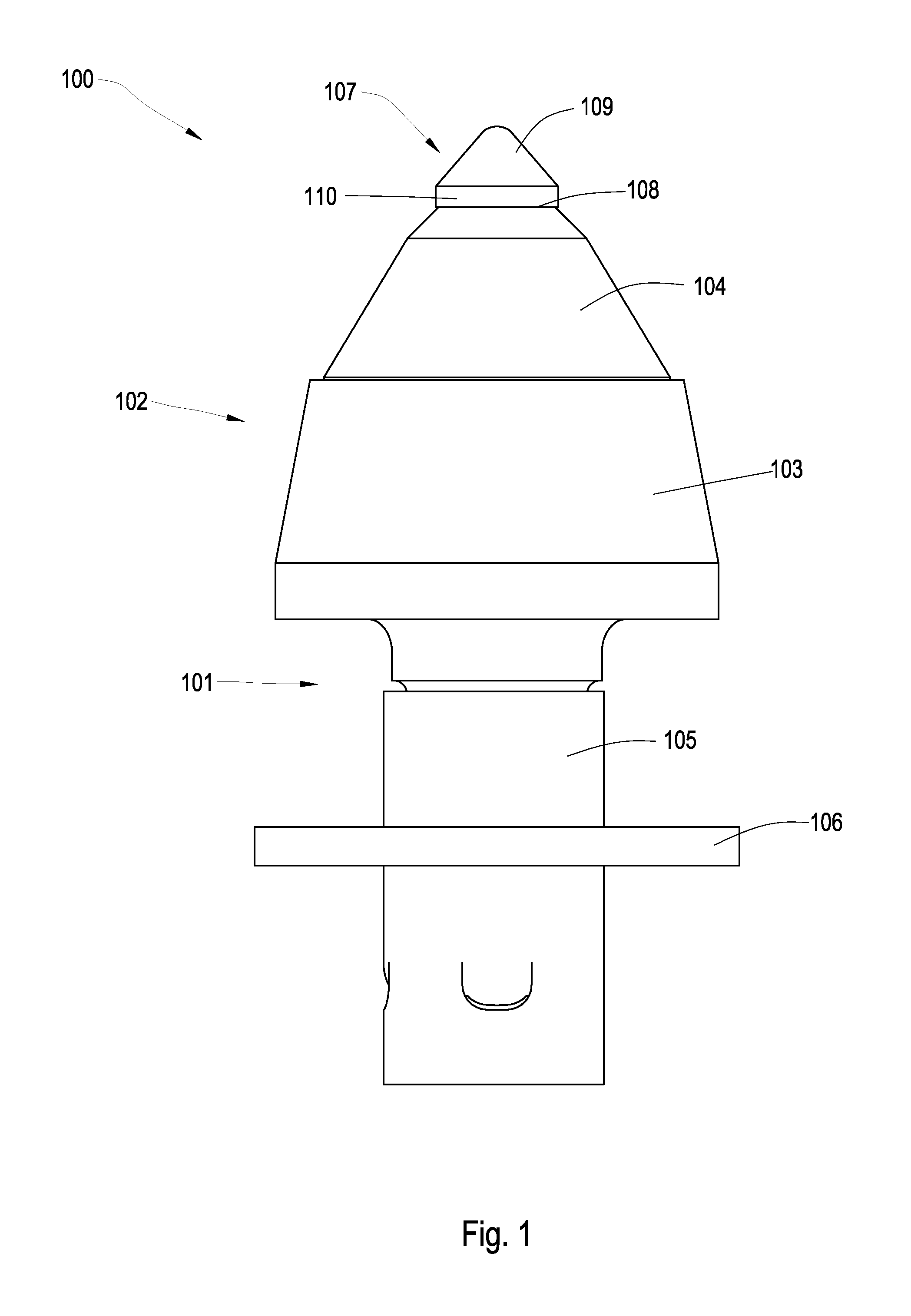

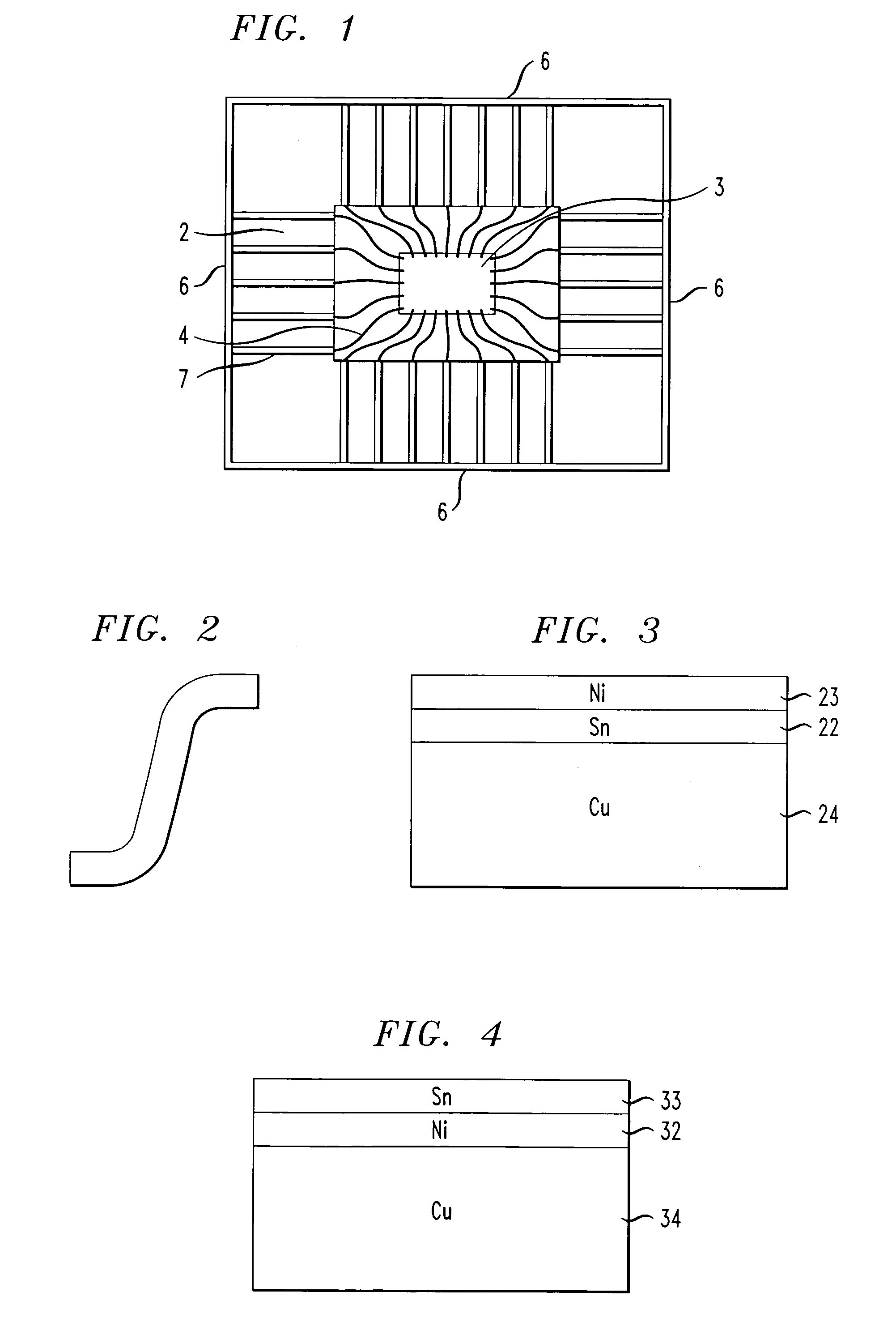

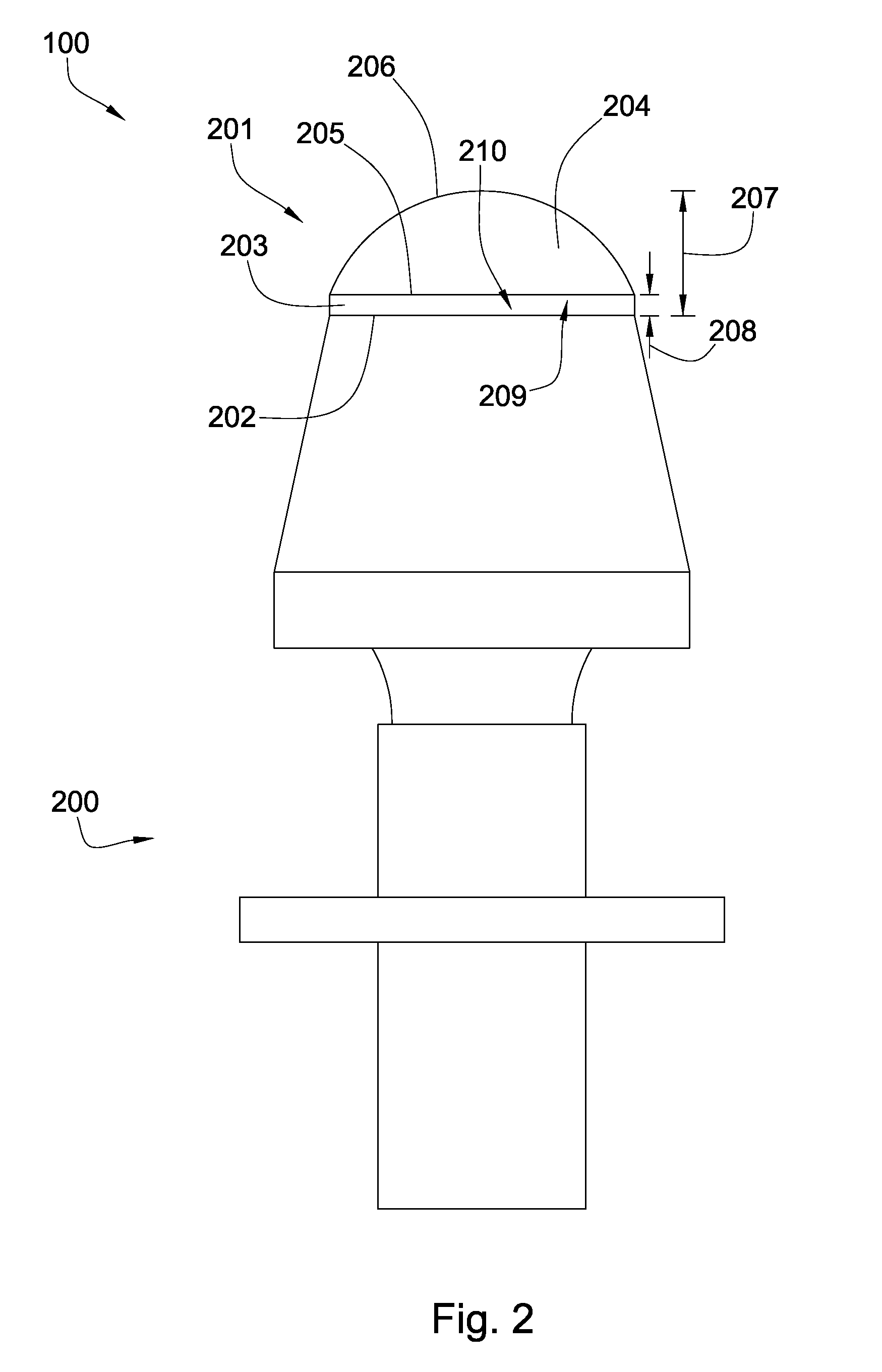

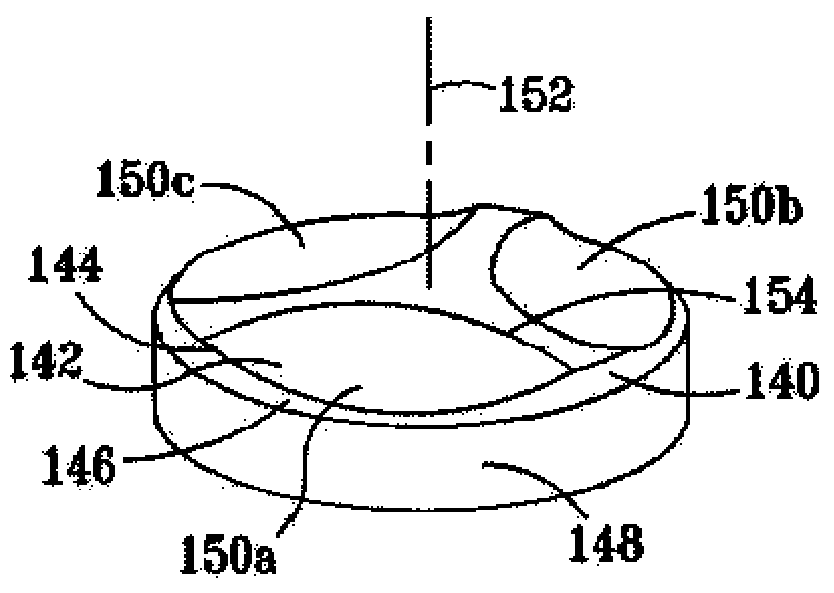

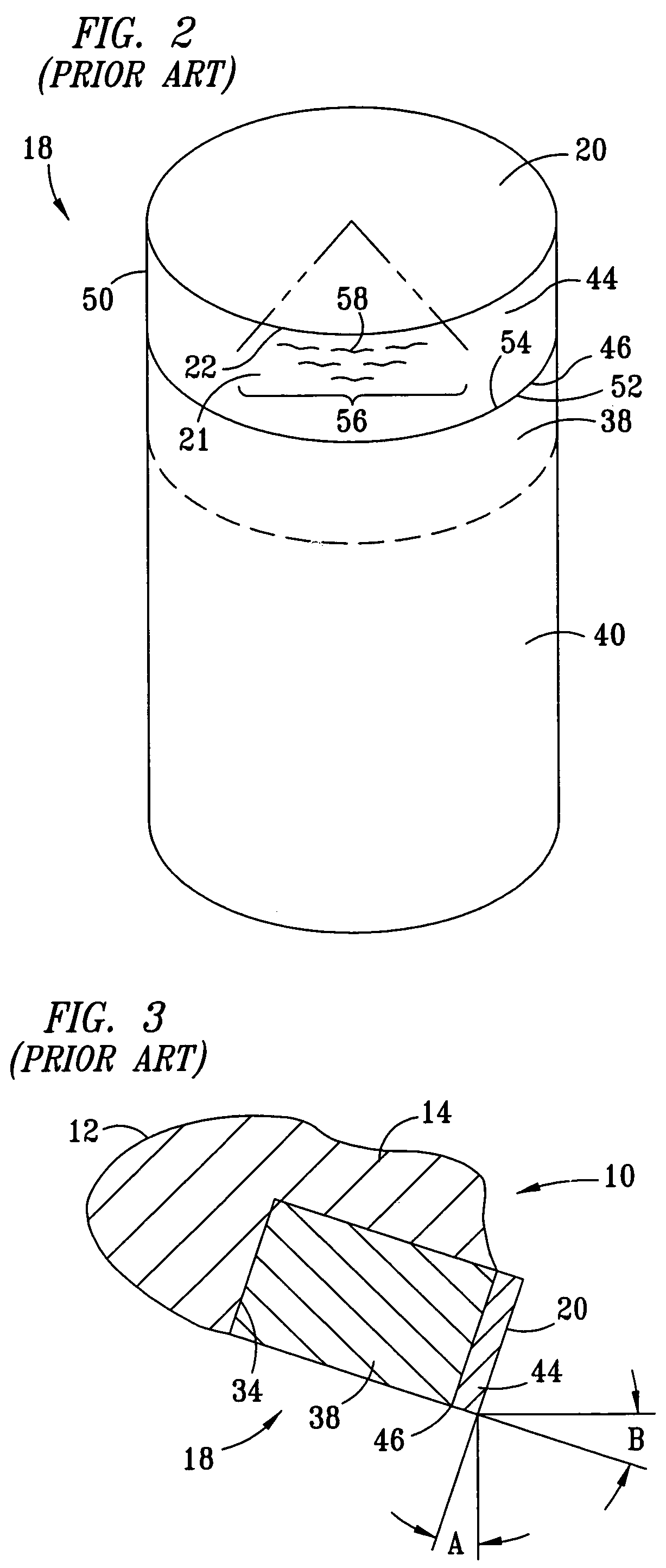

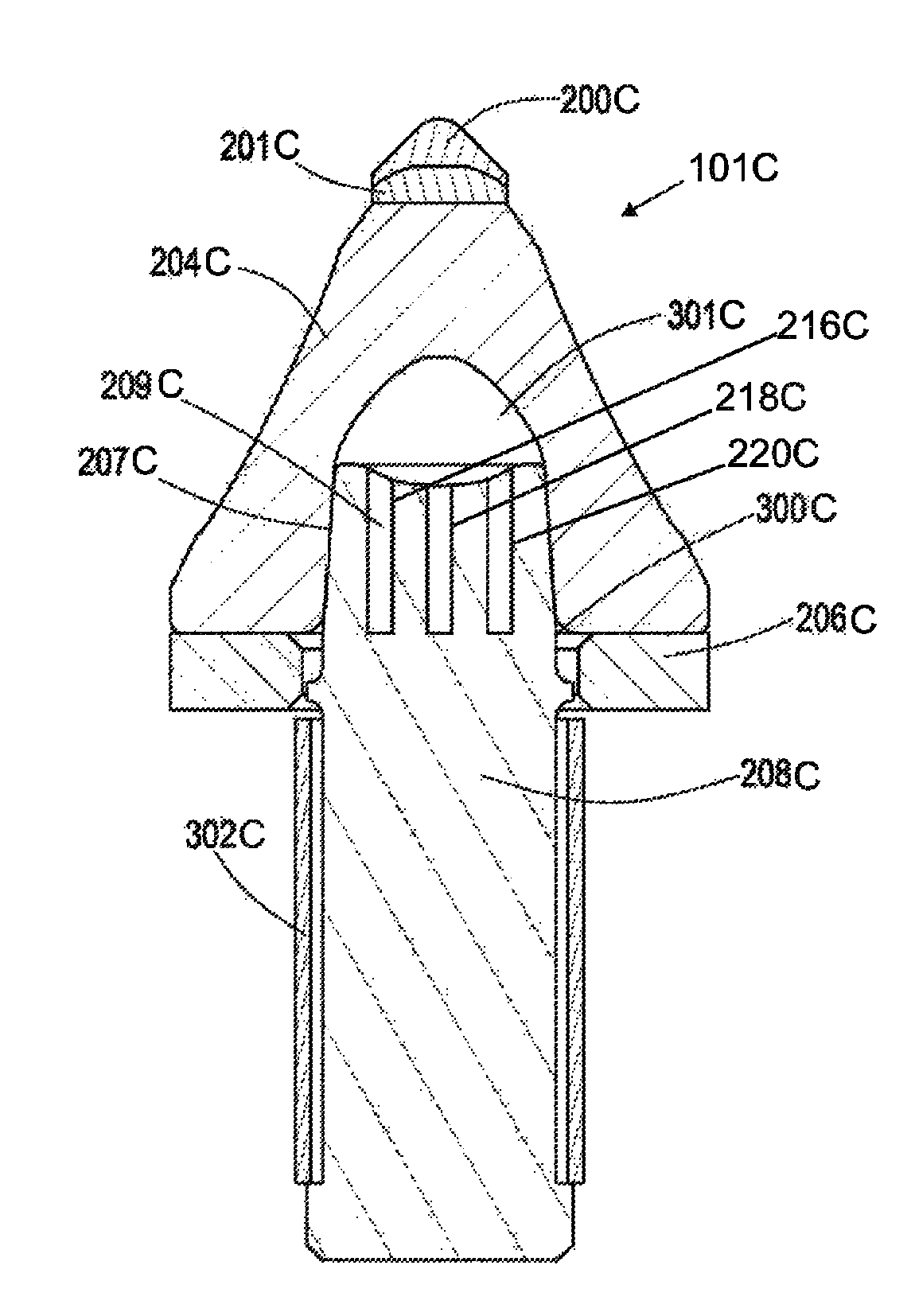

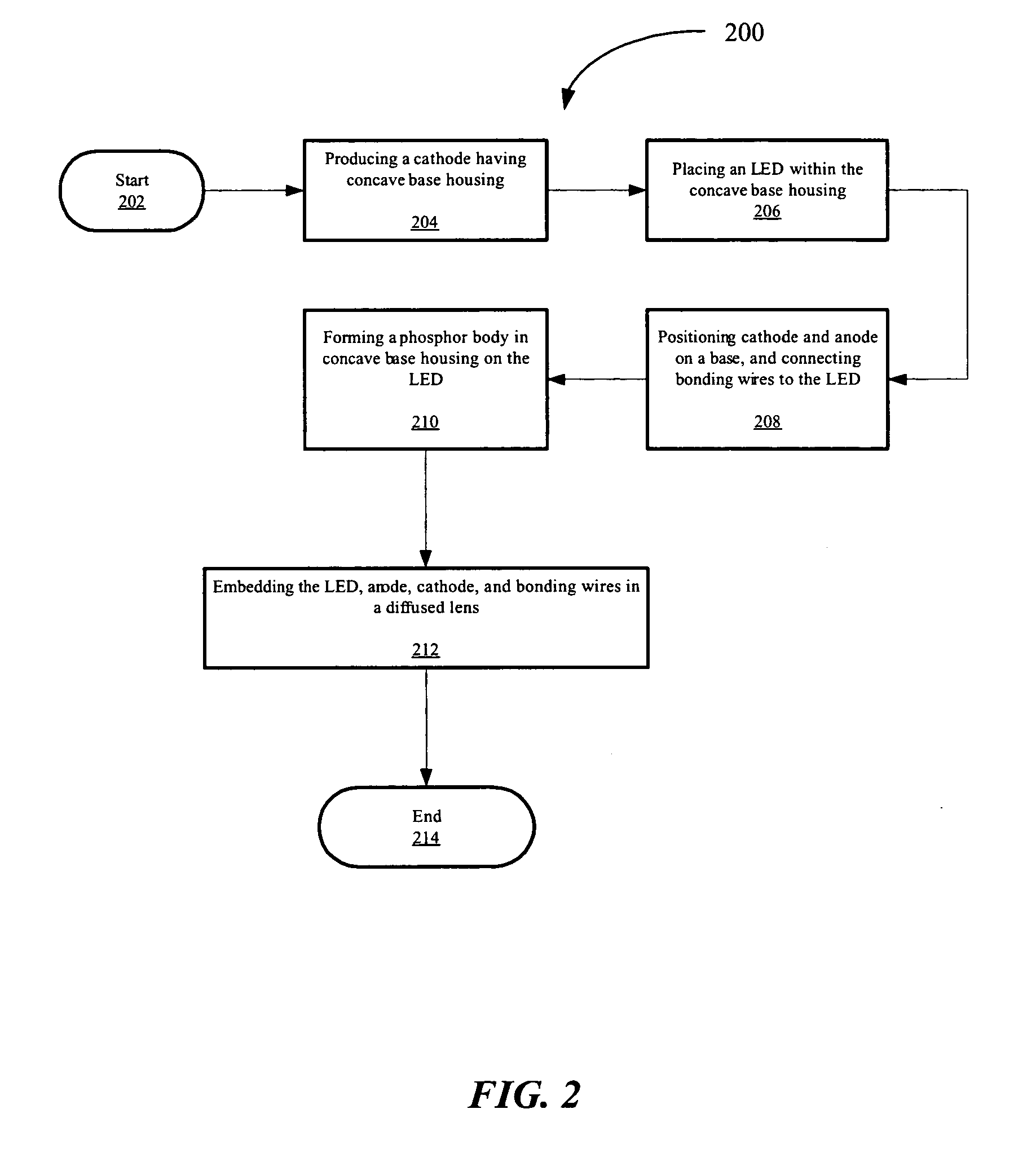

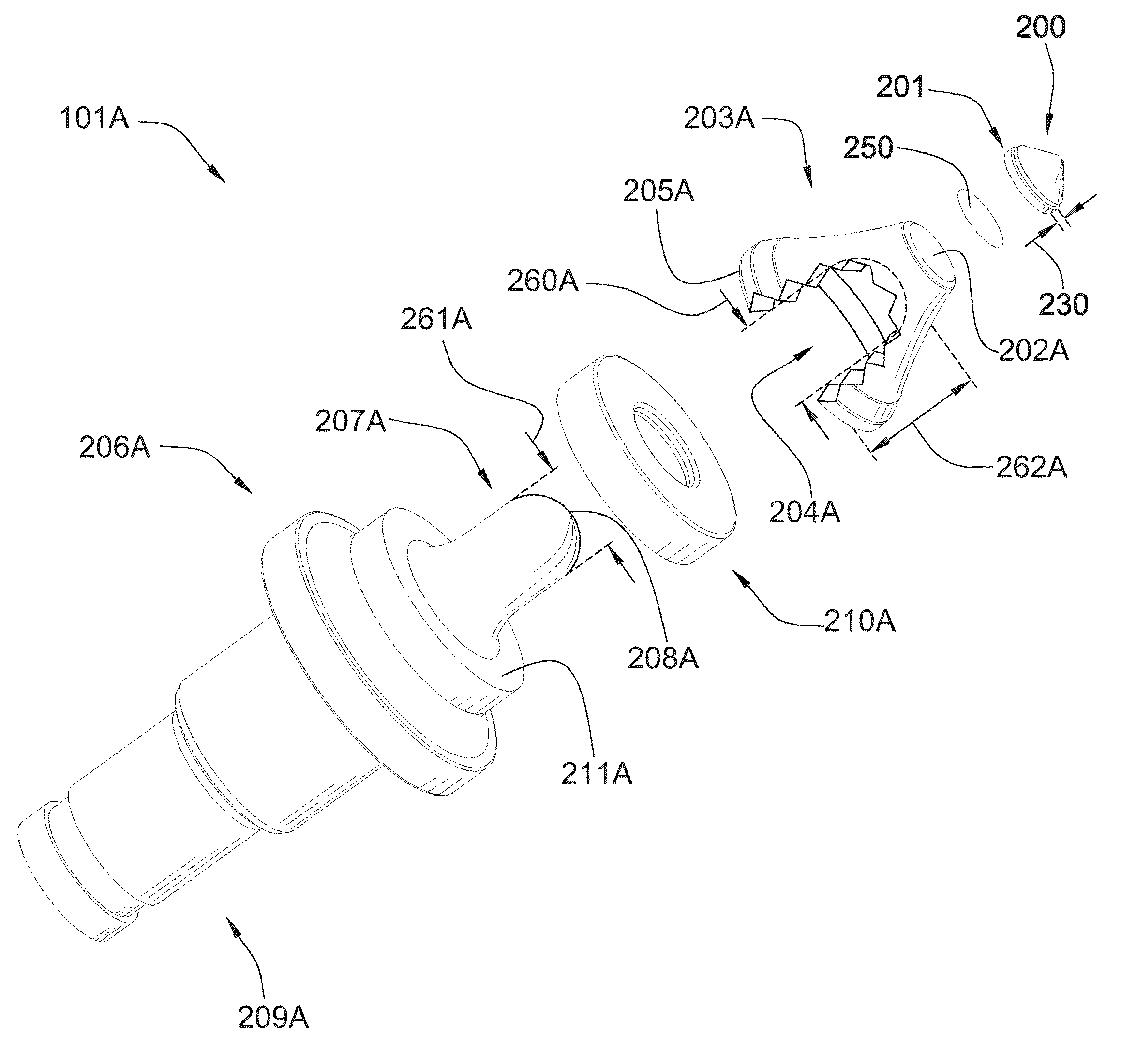

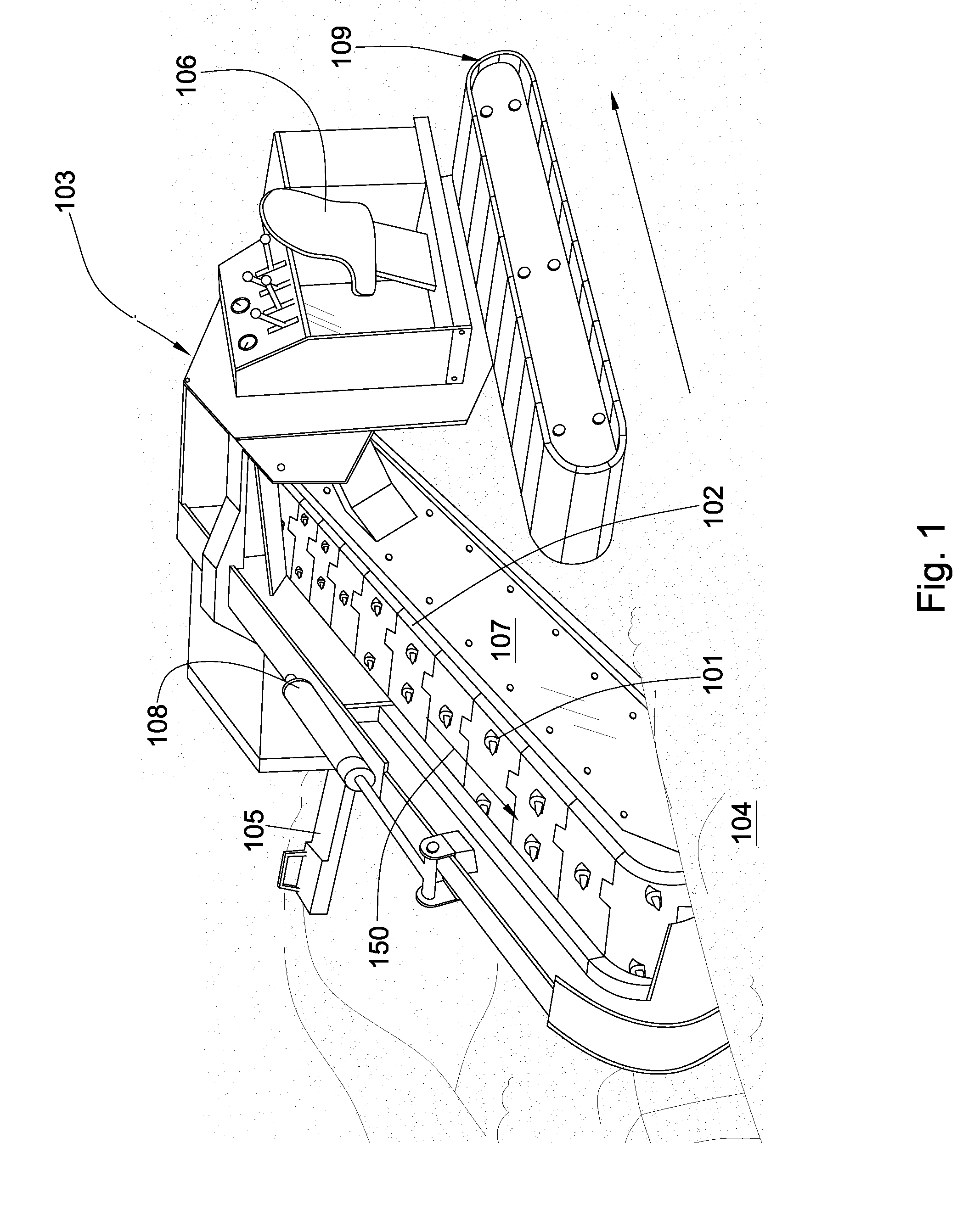

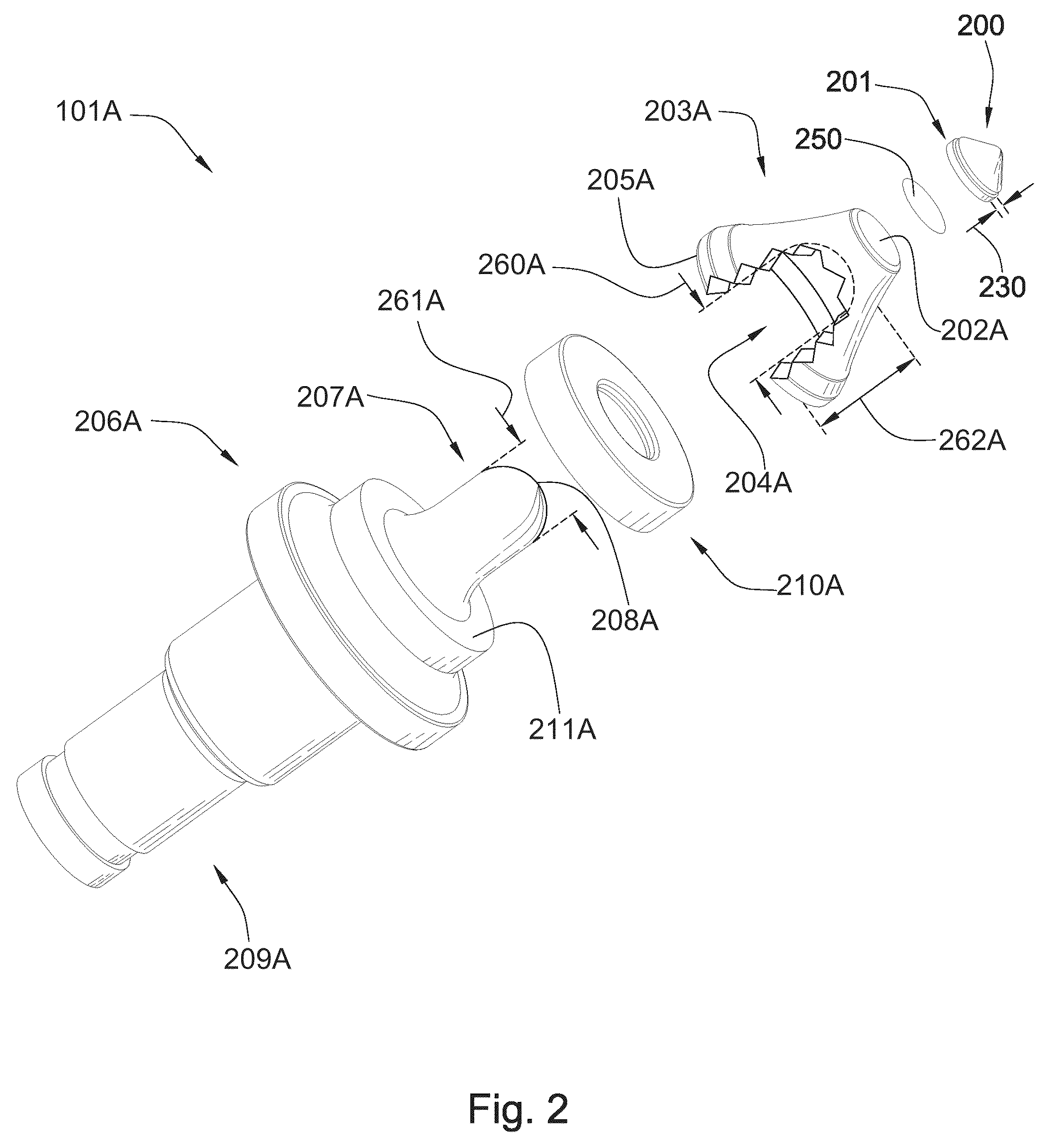

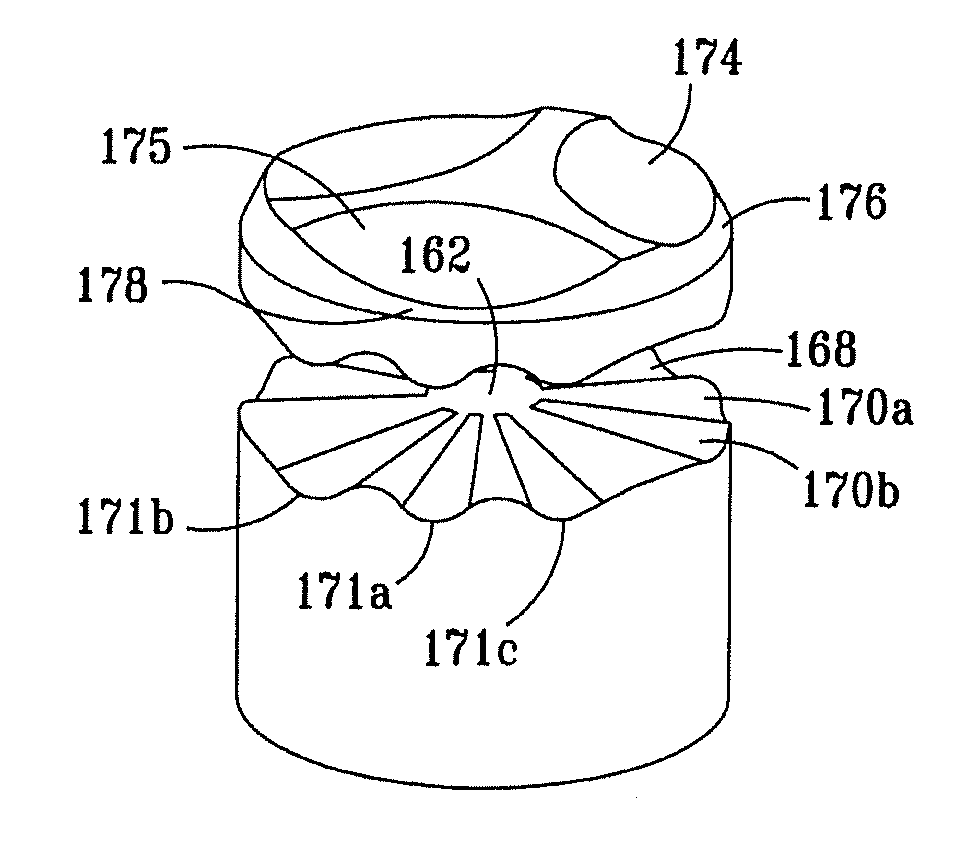

Flat interface nerve electrode and a method for use

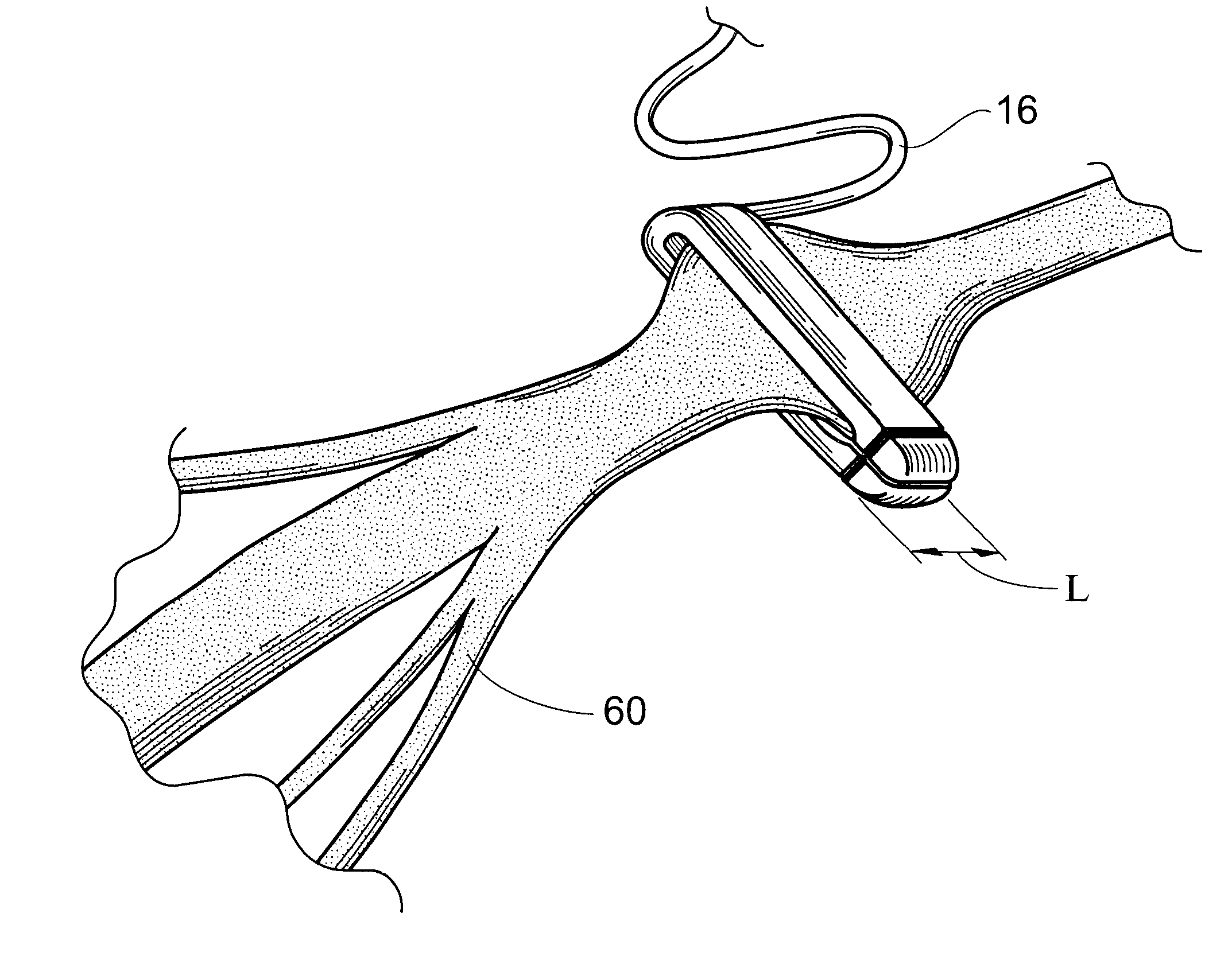

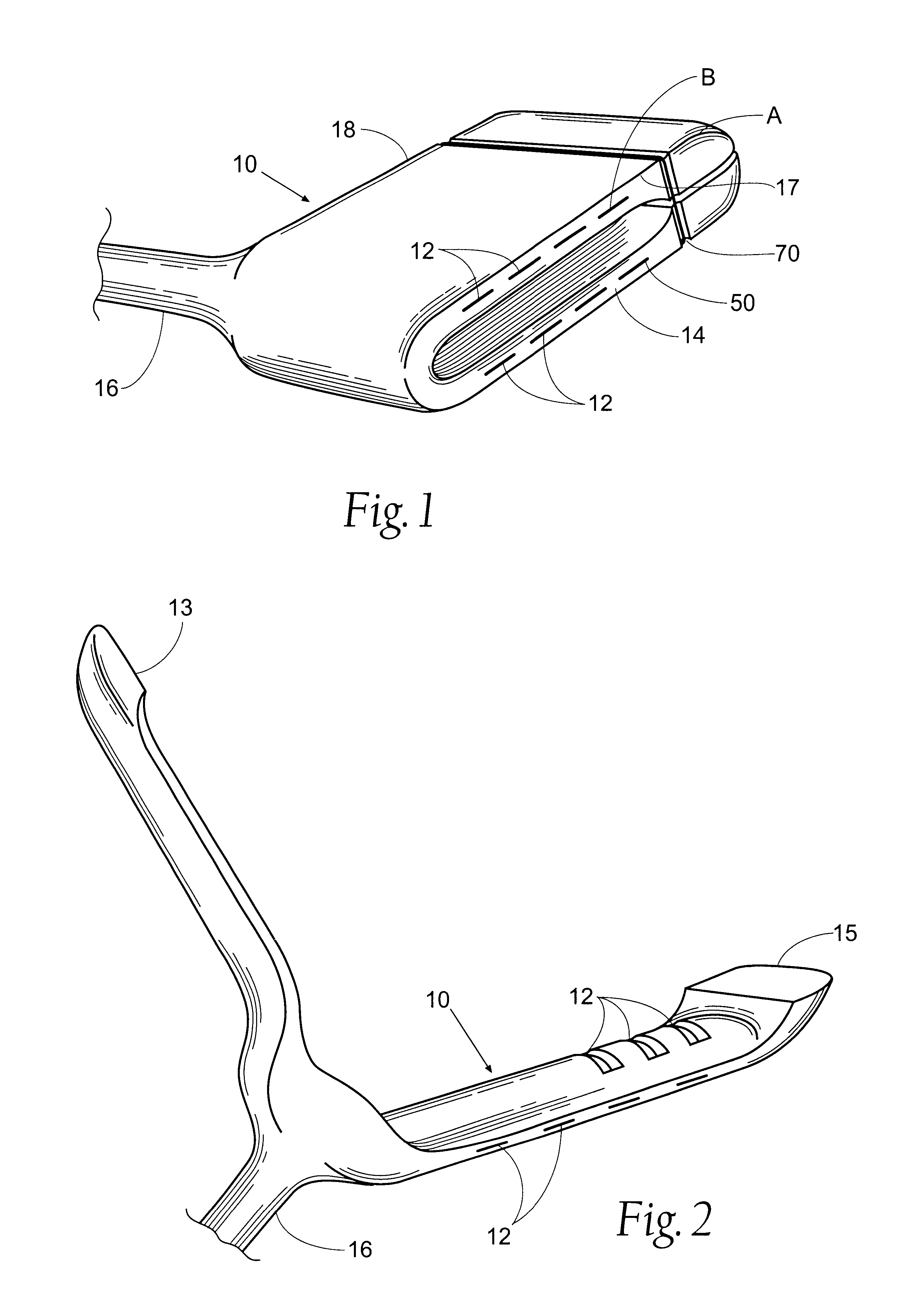

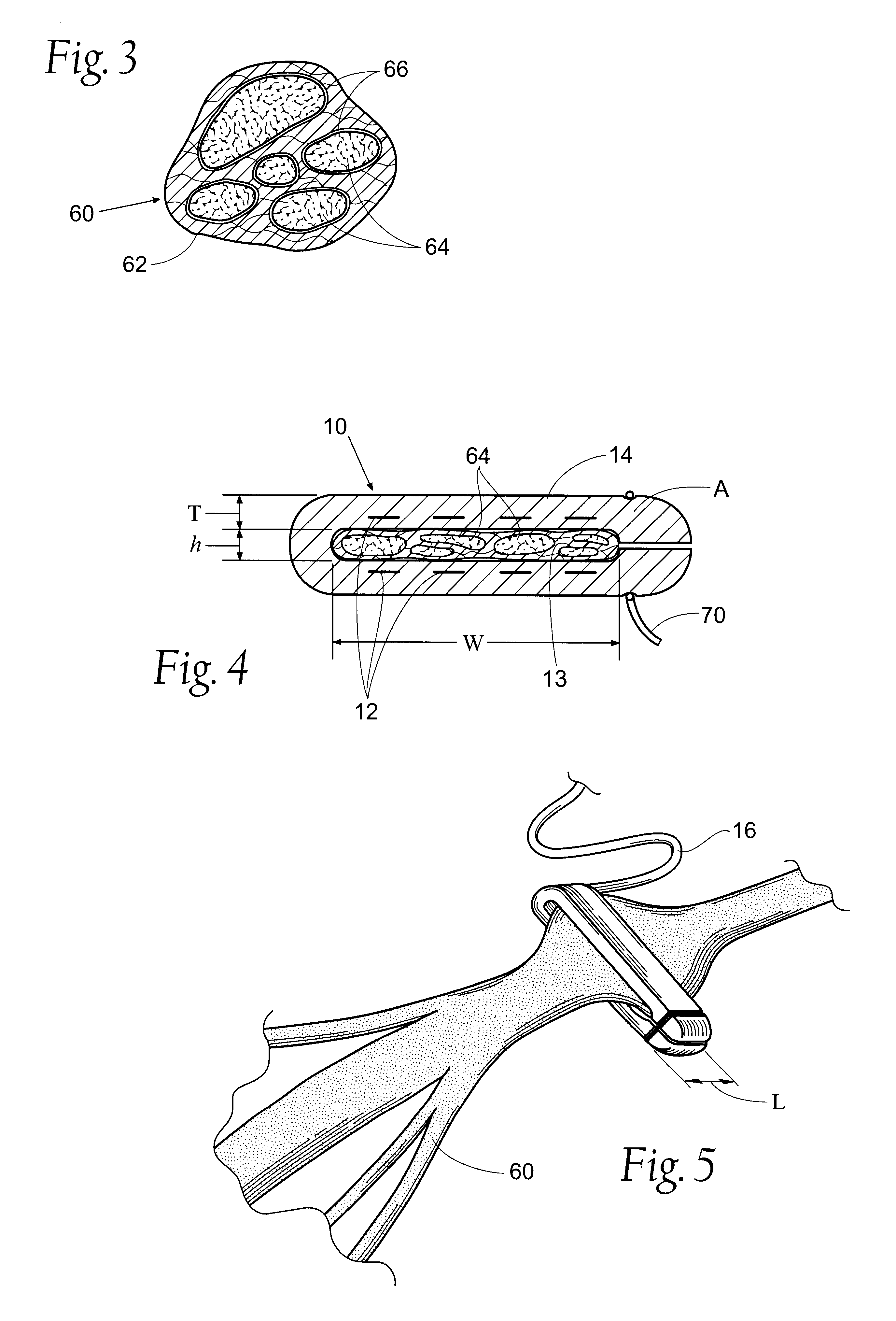

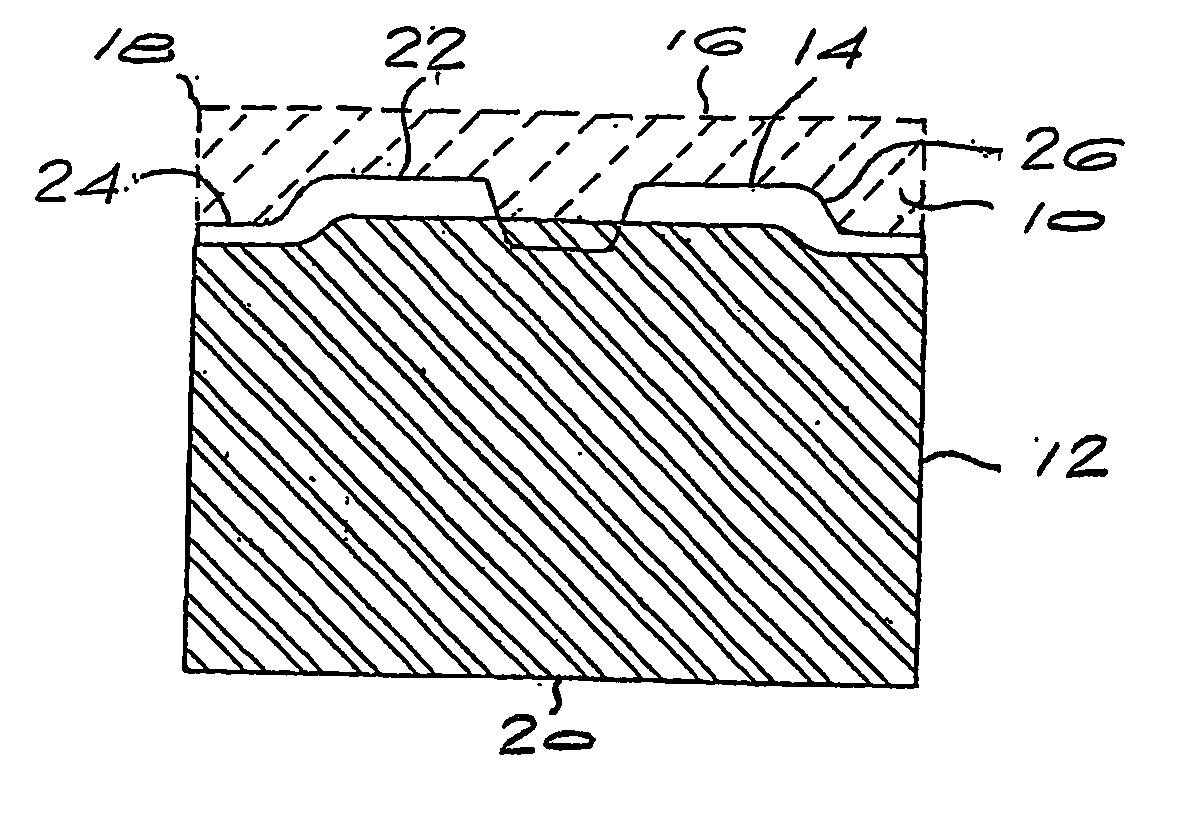

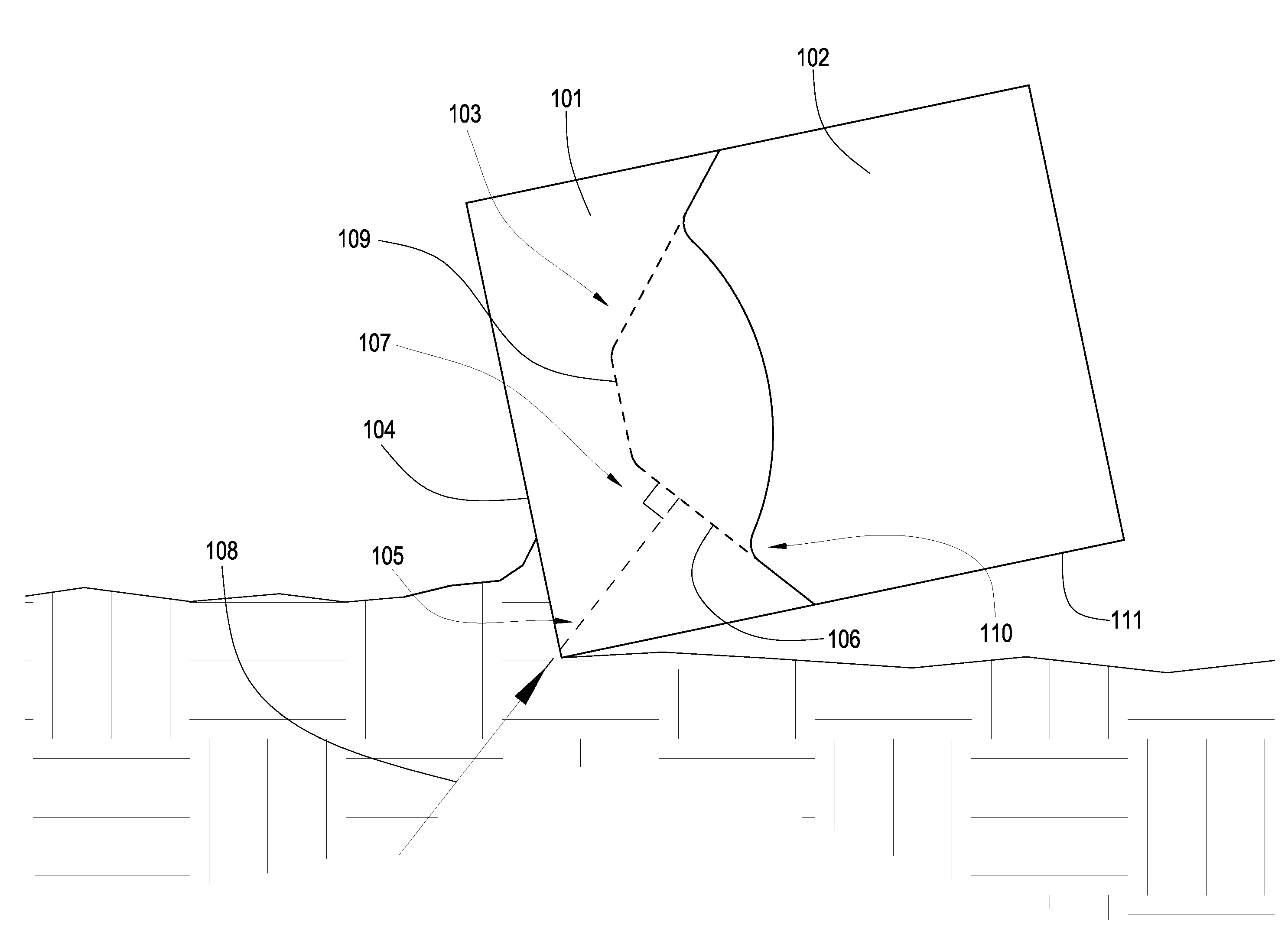

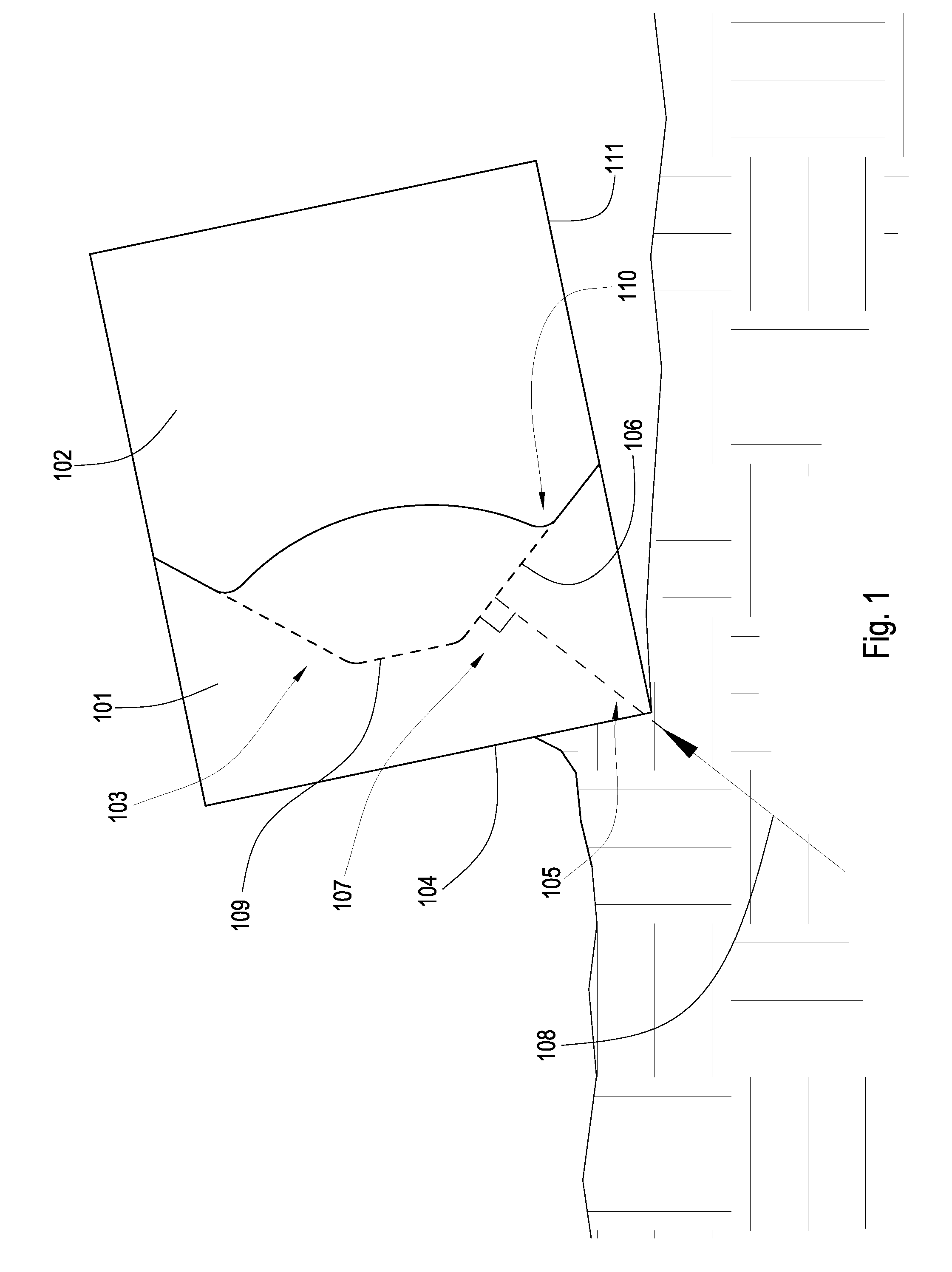

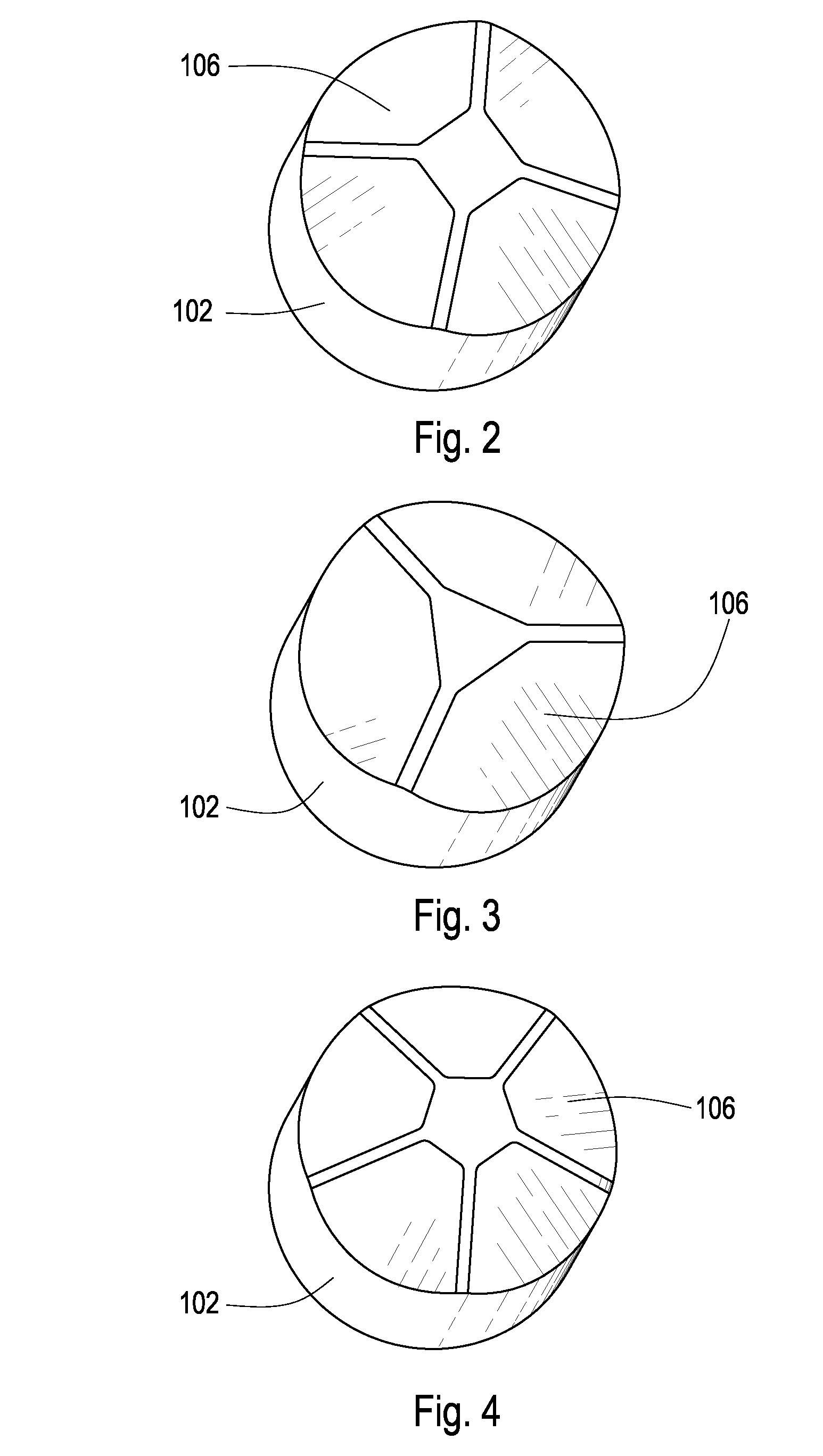

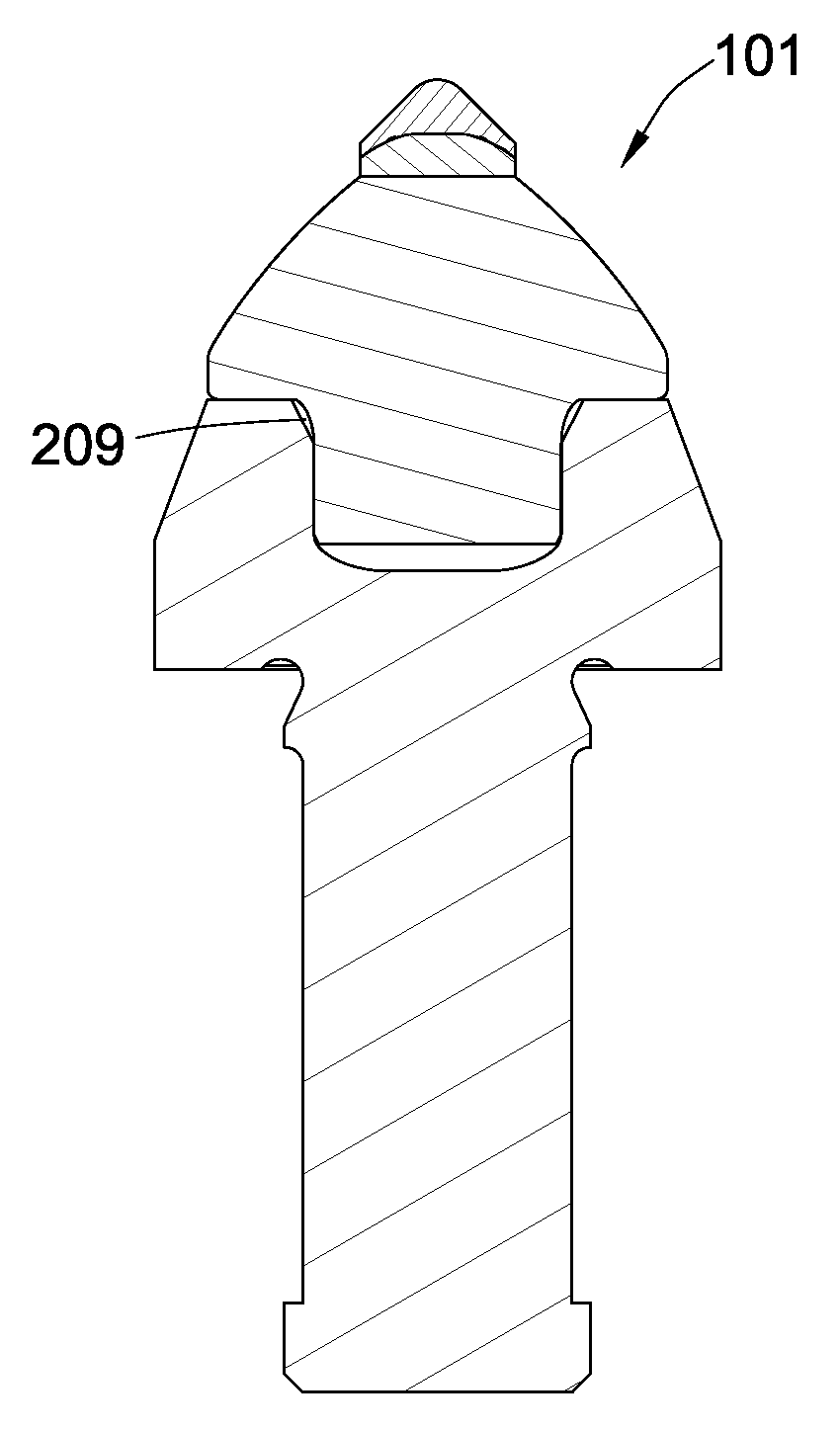

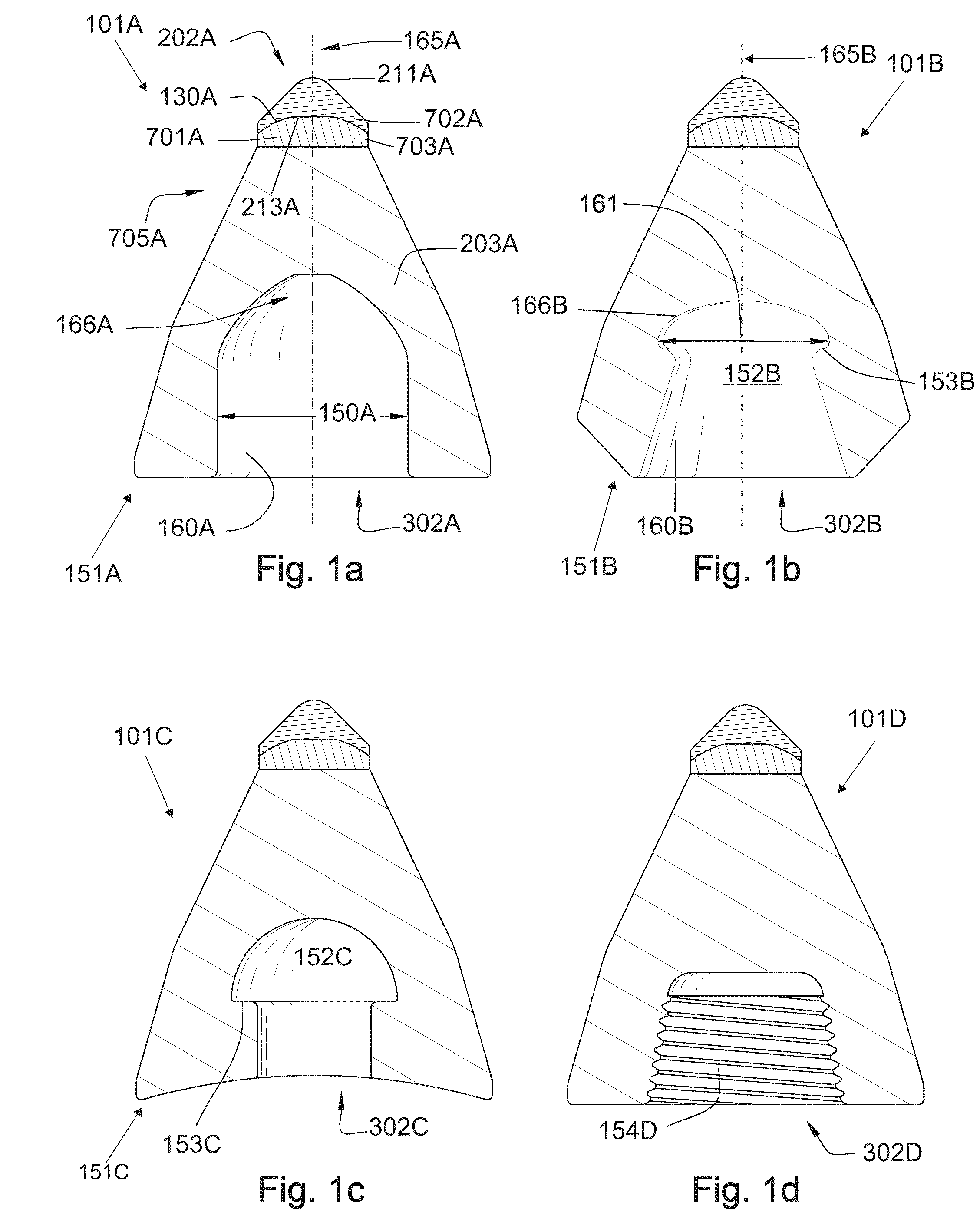

A flat interface nerve electrode is provided along with a method for its use. The electrode provides a plurality of conductive elements embedded in a non-conductive cuff structure, which acts to gently and non-evasively redefine the geometry of a nerve through the application of a force so as to apply pressure to a nerve in a defined range, namely from 2 to 40 mmHG and more preferably from 15 to 30 mmHG and most preferably from 15 mmHG to 20 MMHG. This range is selected to minimize the reduction of blood flow within the tissue, which preferably is at least 70% of the initial value, more preferably 90% of the initial value. The cuff has an opening, which is elongated relative to the diameter of the nerve to which it is applied. Preferably, the cuff is constructed from an elastic bio-compatible material having top and bottom beam members configured to define a nerve opening. The cuff is open at one side and has a connection at the other side which results in a spring force being applied through the surfaces of the nerve opening to the subject nerve. During implantation the open sides of the cuff are closed so as to capture the nerve in the cuff. As the nerve is reshaped, specific nerve axons become more easily addressed through the epineurium by the embedded conductive elements.

Owner:CASE WESTERN RESERVE UNIV

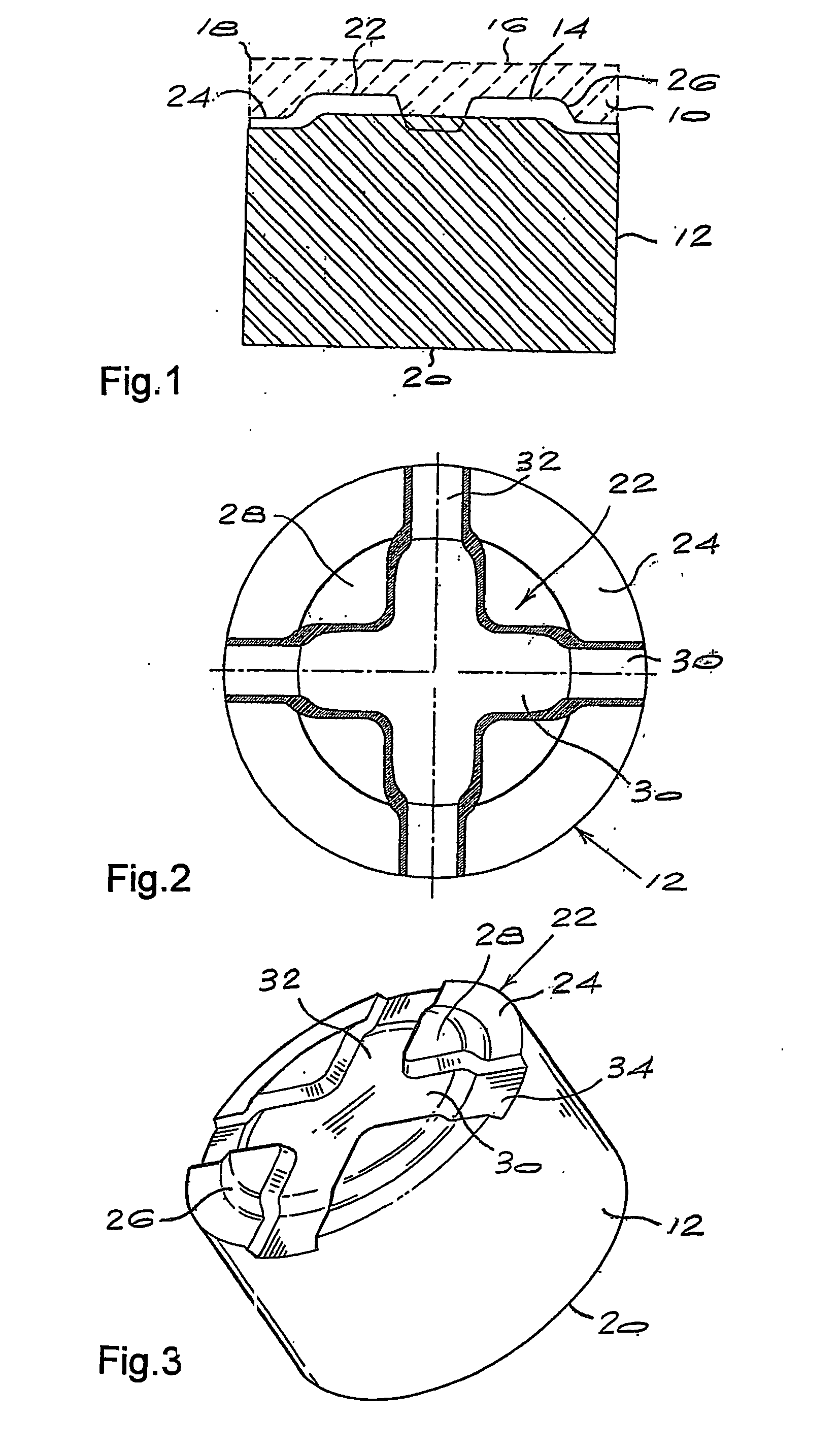

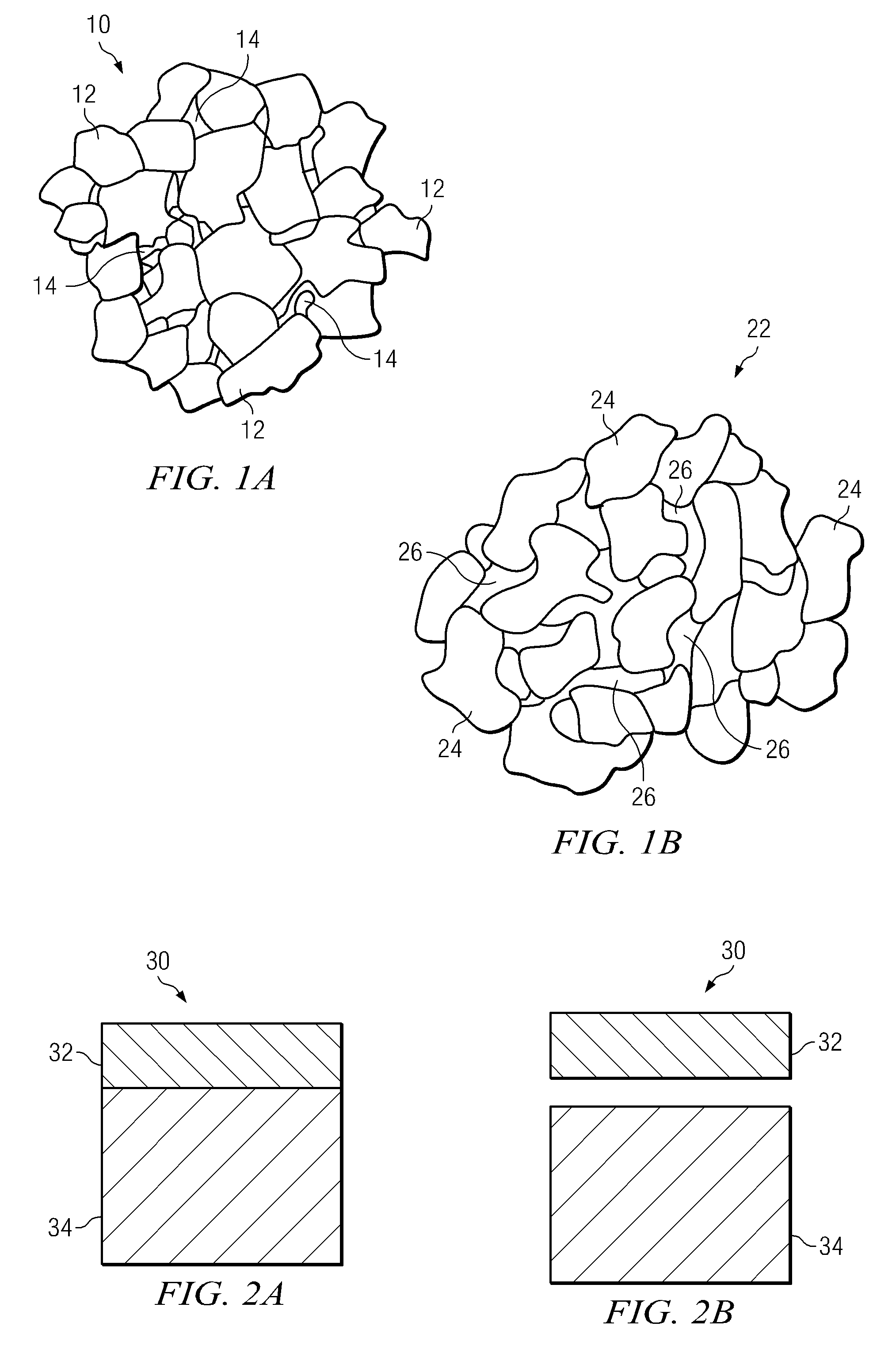

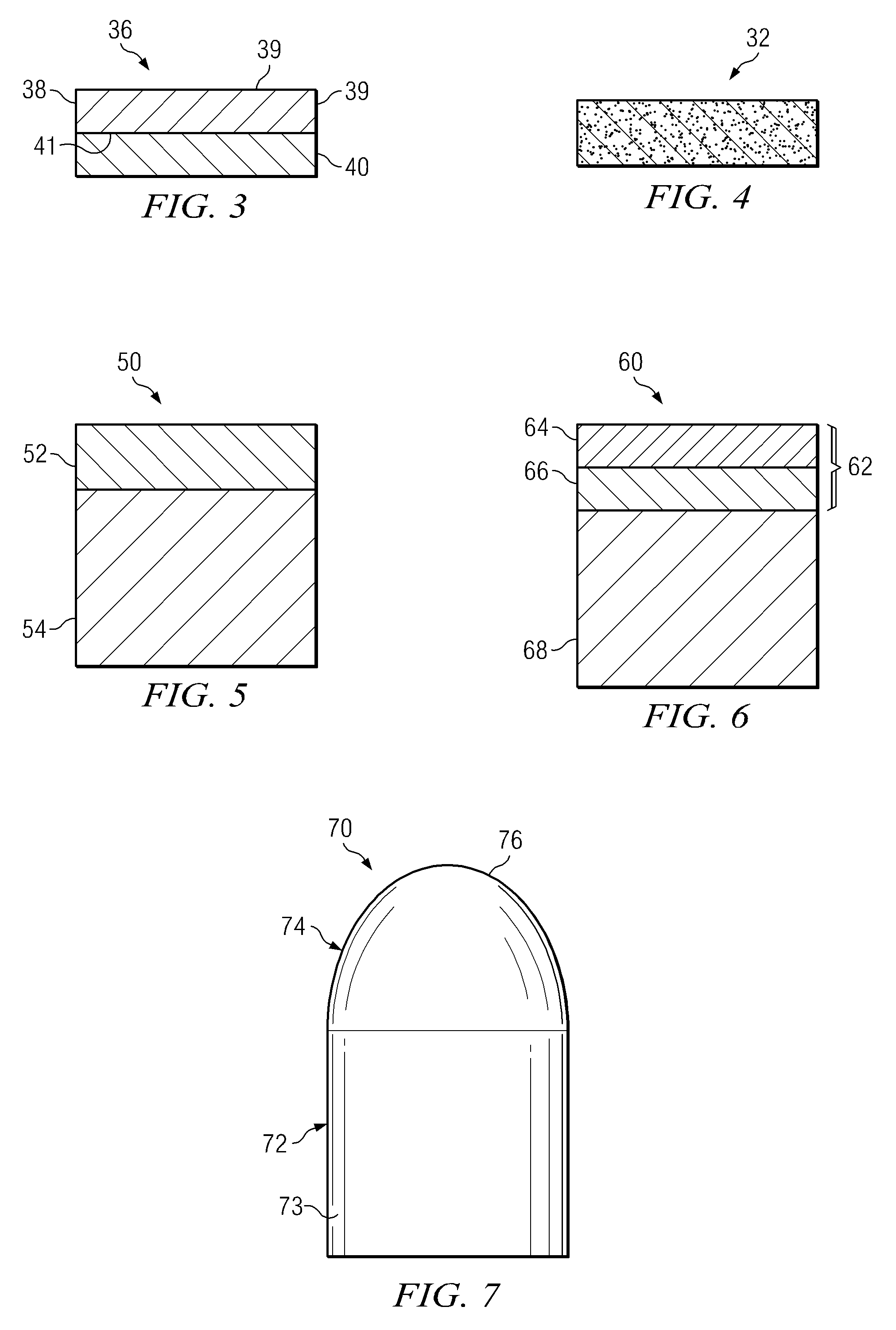

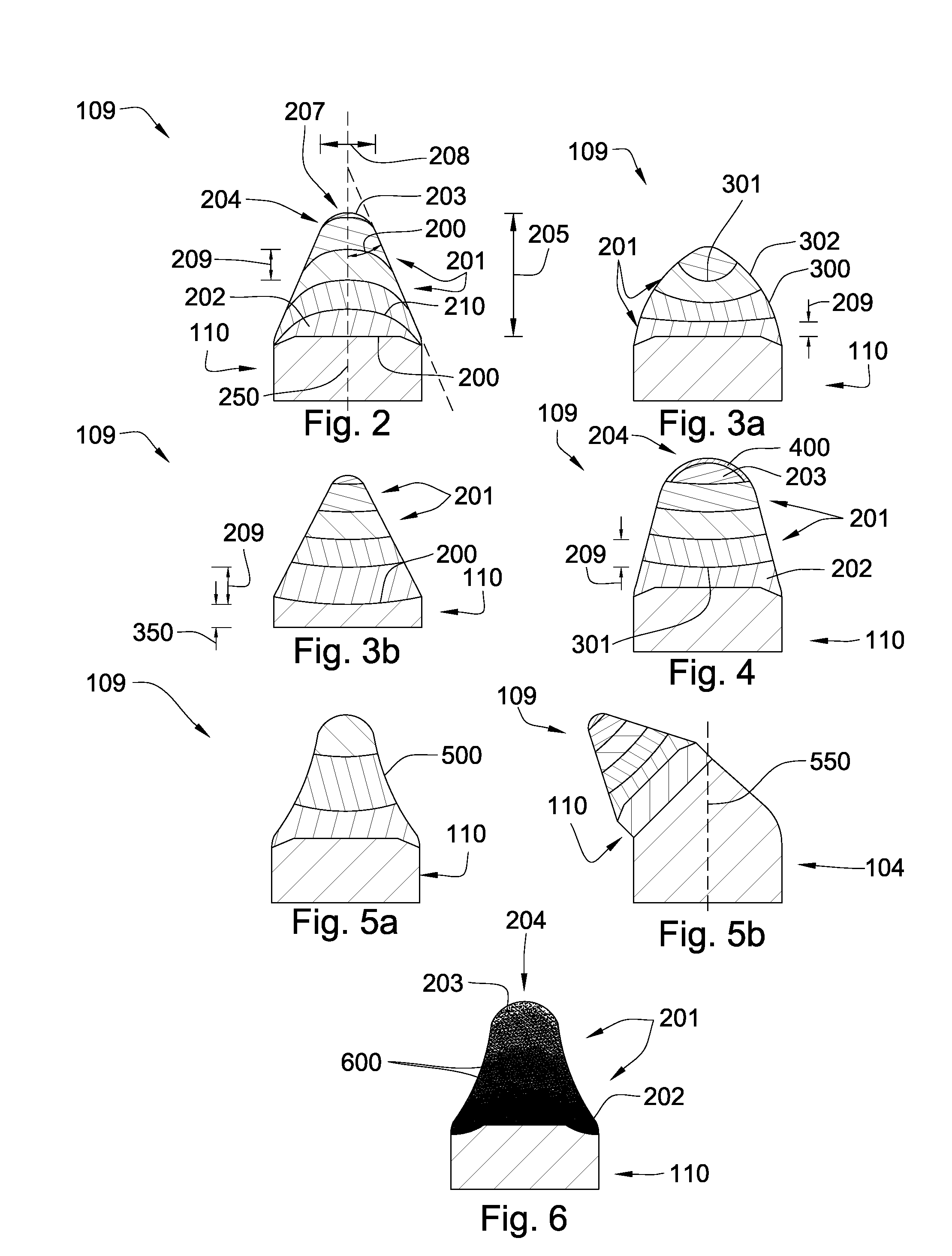

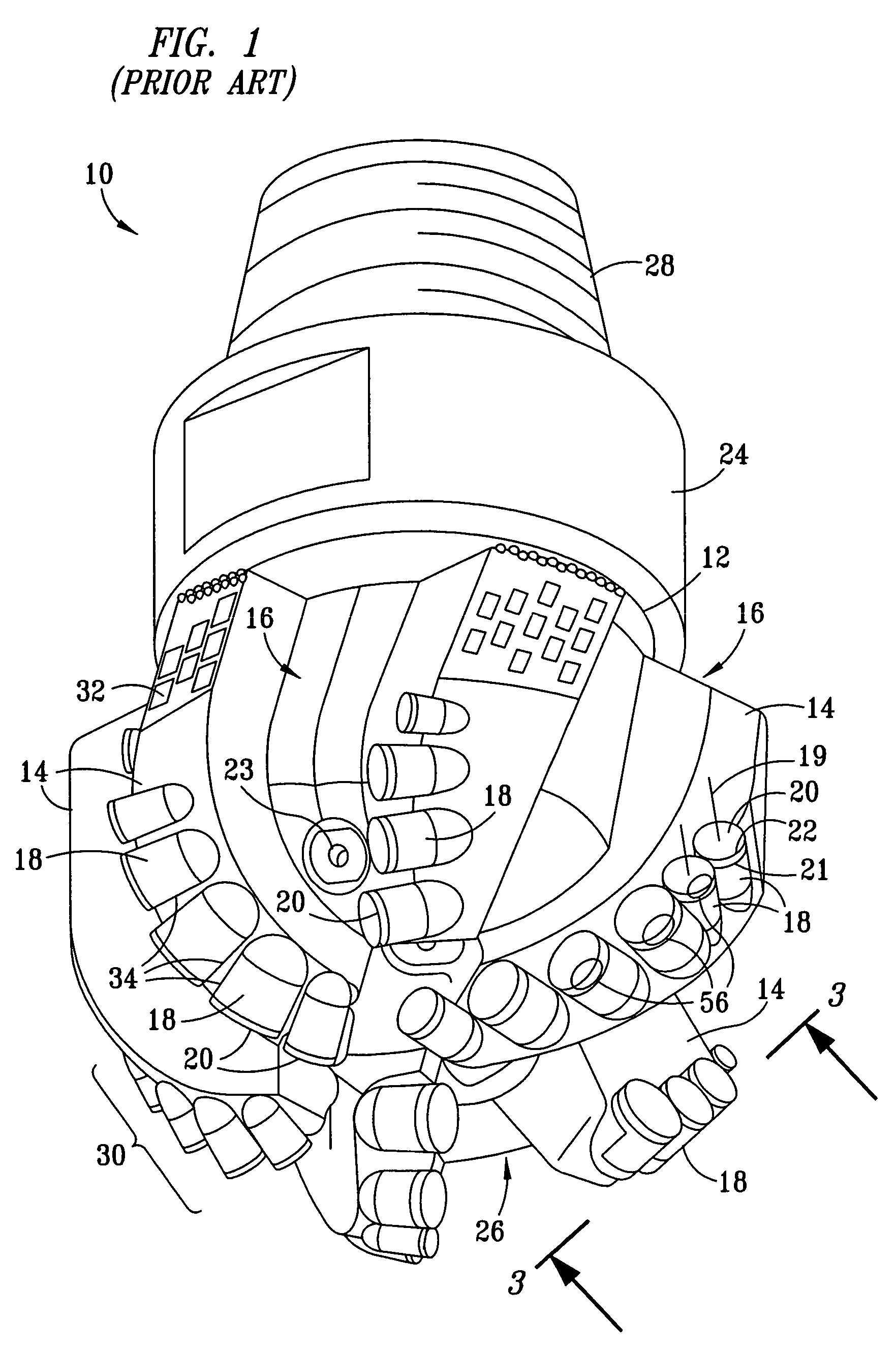

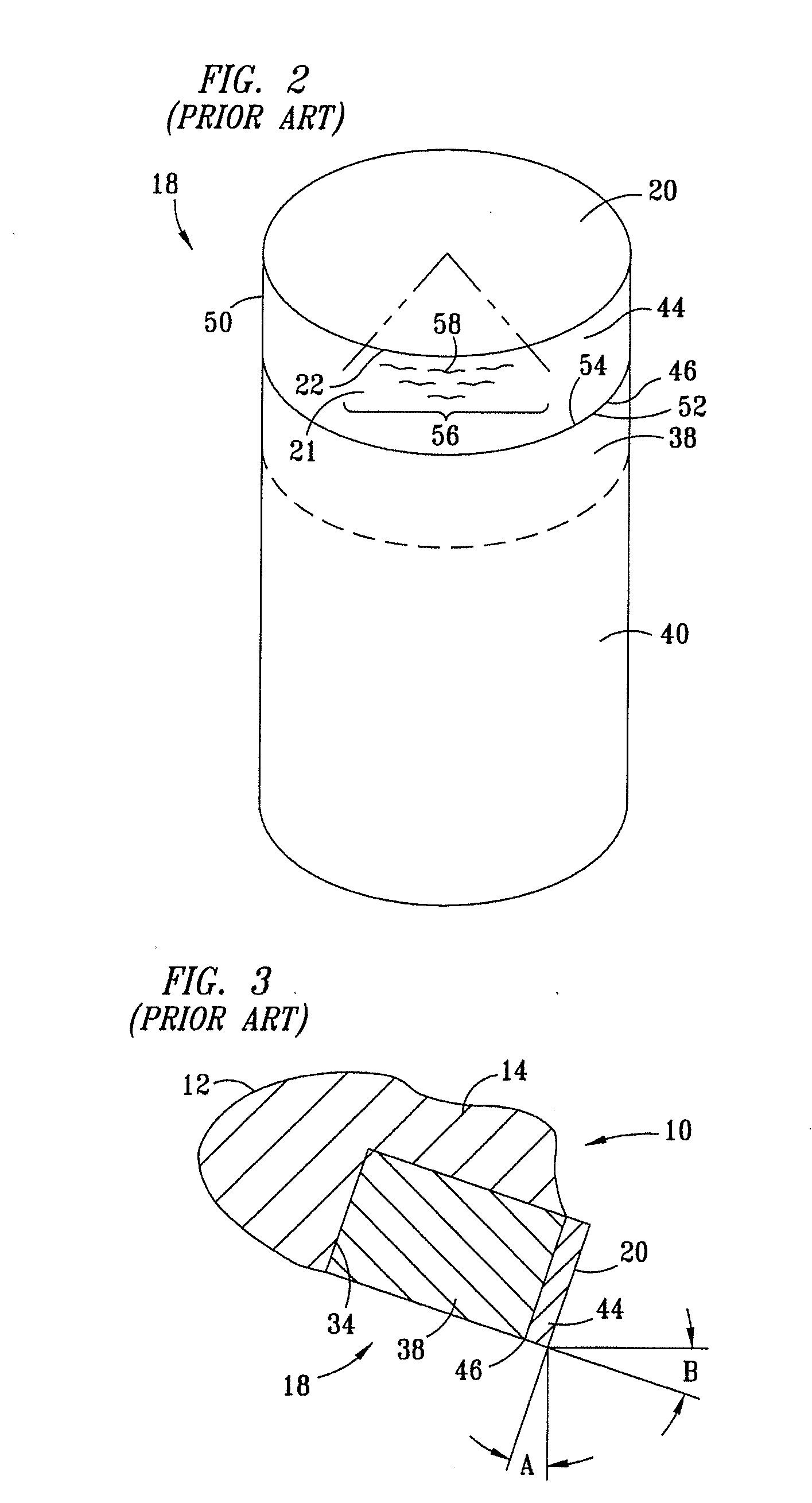

Polycrystalline diamond abrasive elements

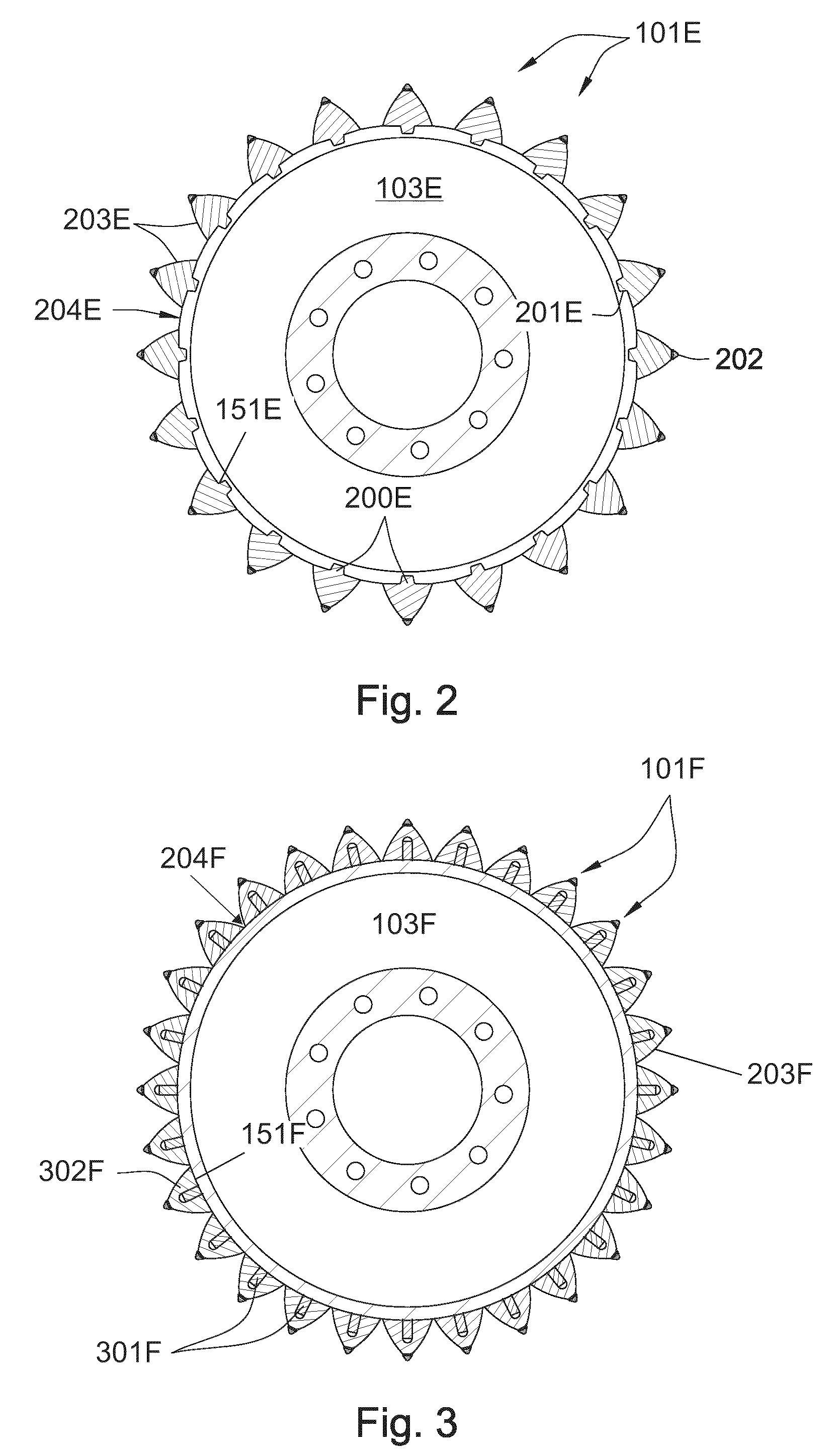

A polycrystalline diamond abrasive element, particularly a cutting element, comprises a table of polycrystalline diamond bonded to a substrate, particularly a cemented carbide substrate, along a non-planar interface. The non-planar interface typically has a cruciform configuration. The polycrystalline diamond has a high wear-resistance, and has a region adjacent the working surface lean in catalysing material and a region rich in catalysing material. The region lean in catalysing material extends to a depth of 40 to 90 microns, which is much shallower than in the prior art. Notwithstanding the shallow region lean in catalysing material, the polycrystalline diamond cutters have a wear resistance, impact strength and cutter life comparable to that of prior art cutter, but requiring only 20% of the treatment times of the prior art cutters.

Owner:BAKER HUGHES INC

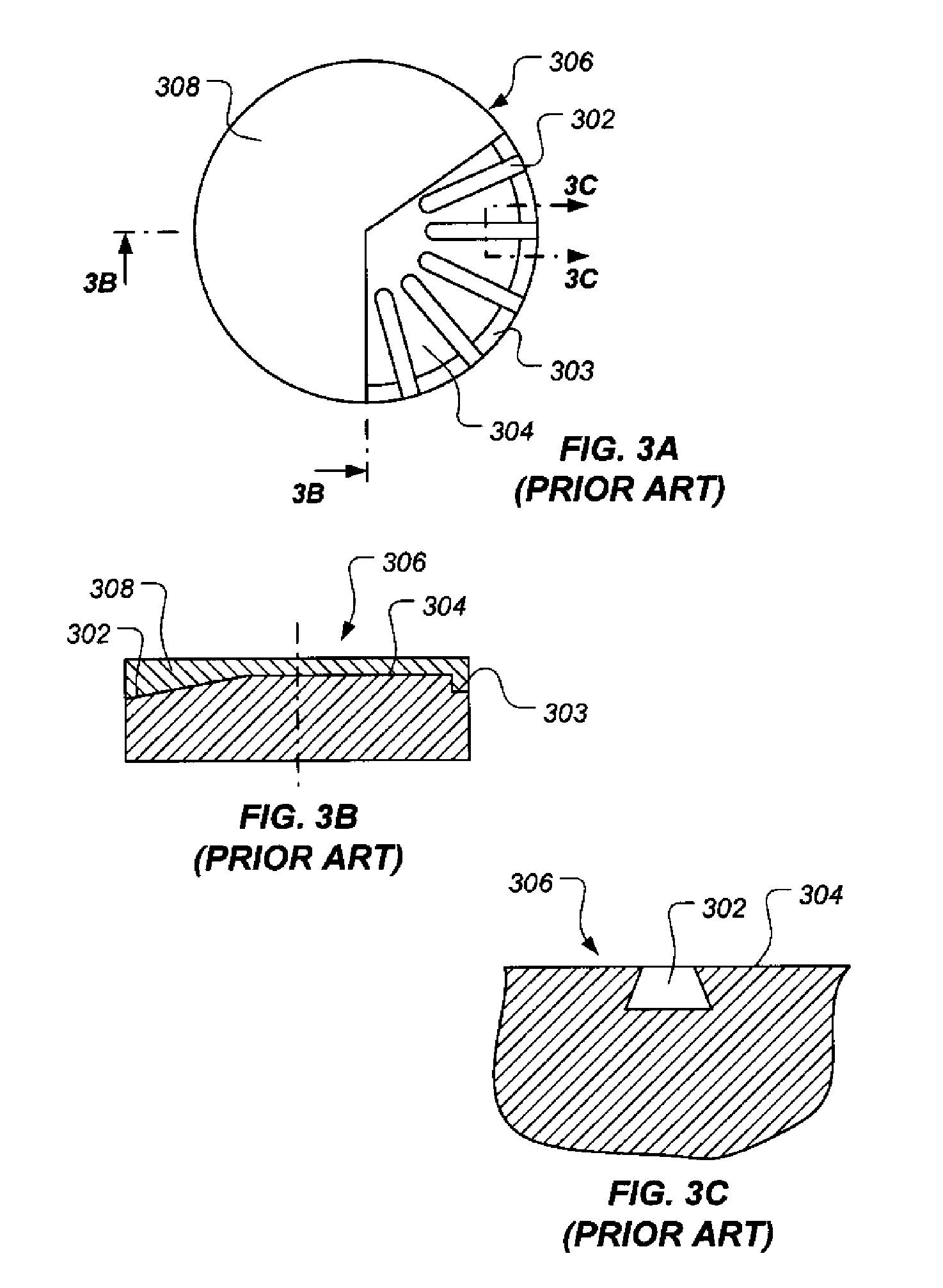

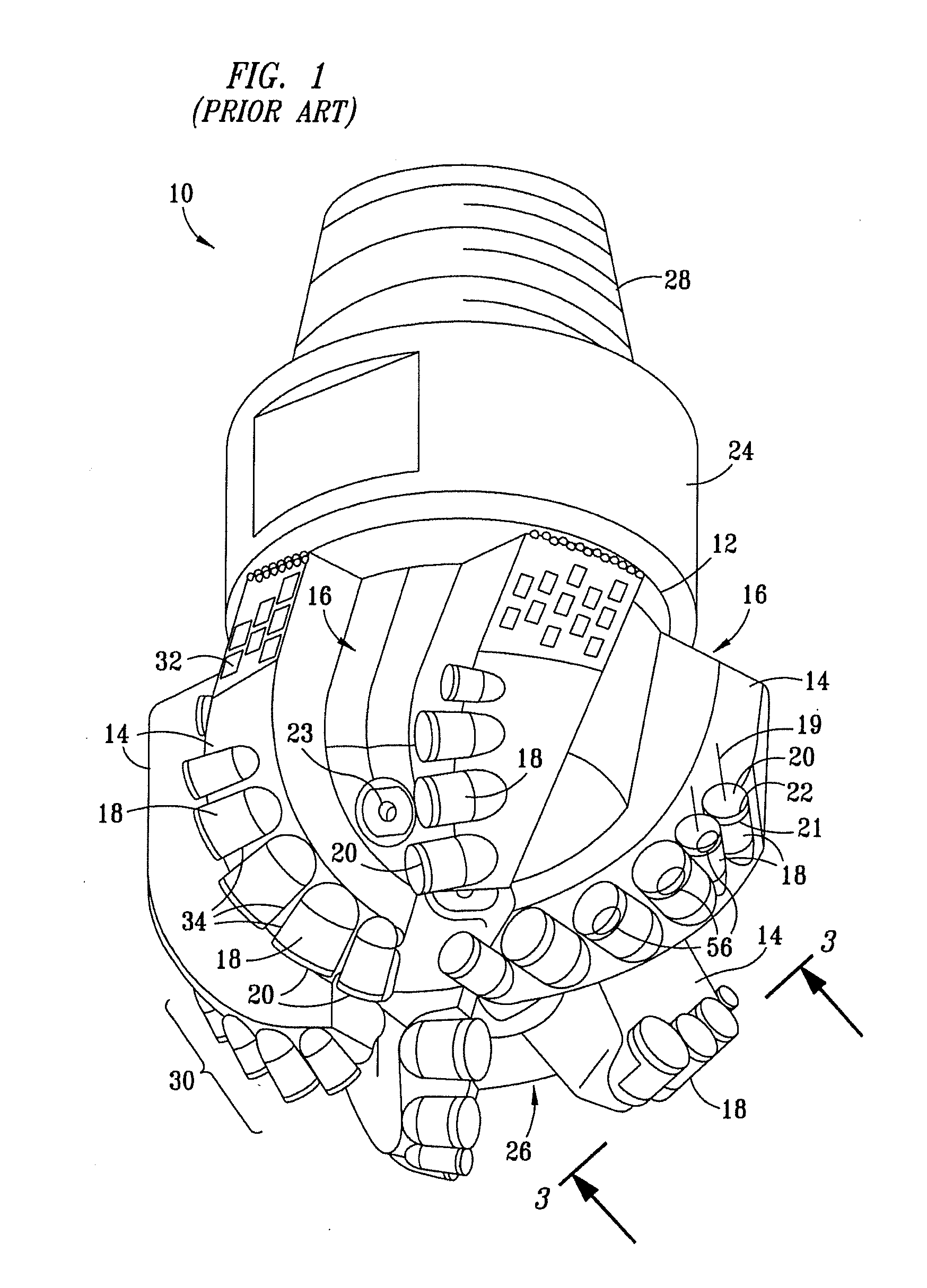

Cutter having shaped working surface with varying edge chamber

ActiveUS20050247492A1Reduce certain adverse consequenceDrill bitsConstructionsEngineeringMechanical engineering

Owner:SMITH INT INC

Composite structure having a non-planar interface and method of making same

A composite structure includes a first portion comprising a first metallic material, a monolayer of particles extending into and bonded with the first portion, and a second portion comprising a second material, the second portion bonded with the monolayer of particles and extending into interstices between the particles. A method for fabricating a composite structure includes bonding a monolayer of particles to a first portion comprising a first metallic material, such that the monolayer of particles extends into the first portion and bonding a second portion comprising a second material to the monolayer of particles, such that the second portion extends into interstices between the particles.

Owner:REEDHYCALOG LP

Nerve cuff for implantable electrode

A flat interface nerve electrode provides a plurality of electrical contacts embedded in a non-conductive cuff structure, which acts to gently and non-evasively redefine the geometry of a nerve through the application of a force acting on the nerve without causing damage to the nerve. The cuff is open at one side and has a connection to a lead at the other side. During implantation the open sides of the cuff are closed so as to capture the nerve in the cuff in a single motion.

Owner:CASE WESTERN RESERVE UNIV

Thermally stable polycrystalline diamond constructions

InactiveUS20110036643A1Improve thermal characteristicsReduces and eliminates crack formationPigmenting treatmentDrill bitsNon solventSized small

Thermally stable polycrystalline constructions comprise a diamond body joined with a substrate, and may have a nonplanar interface. The construction may include an interlayer interposed between the diamond body and substrate. The diamond body preferably has a thickness greater than about 1.5 mm, and comprises a matrix phase of bonded together diamond crystals and interstitial regions disposed therebetween that are substantially free of a catalyst material used to sinter the diamond body. A replacement material is disposed within the interstitial regions. A population of the interstitial regions may include non-solvent catalyst material and / or an infiltrant aid disposed therein. The diamond body comprises two regions; namely, a first region comprising diamond grains that may be sized smaller than diamond grains in a second region, and / or the first region may comprise a diamond volume that is greater than that in the second region.

Owner:SMITH INT INC

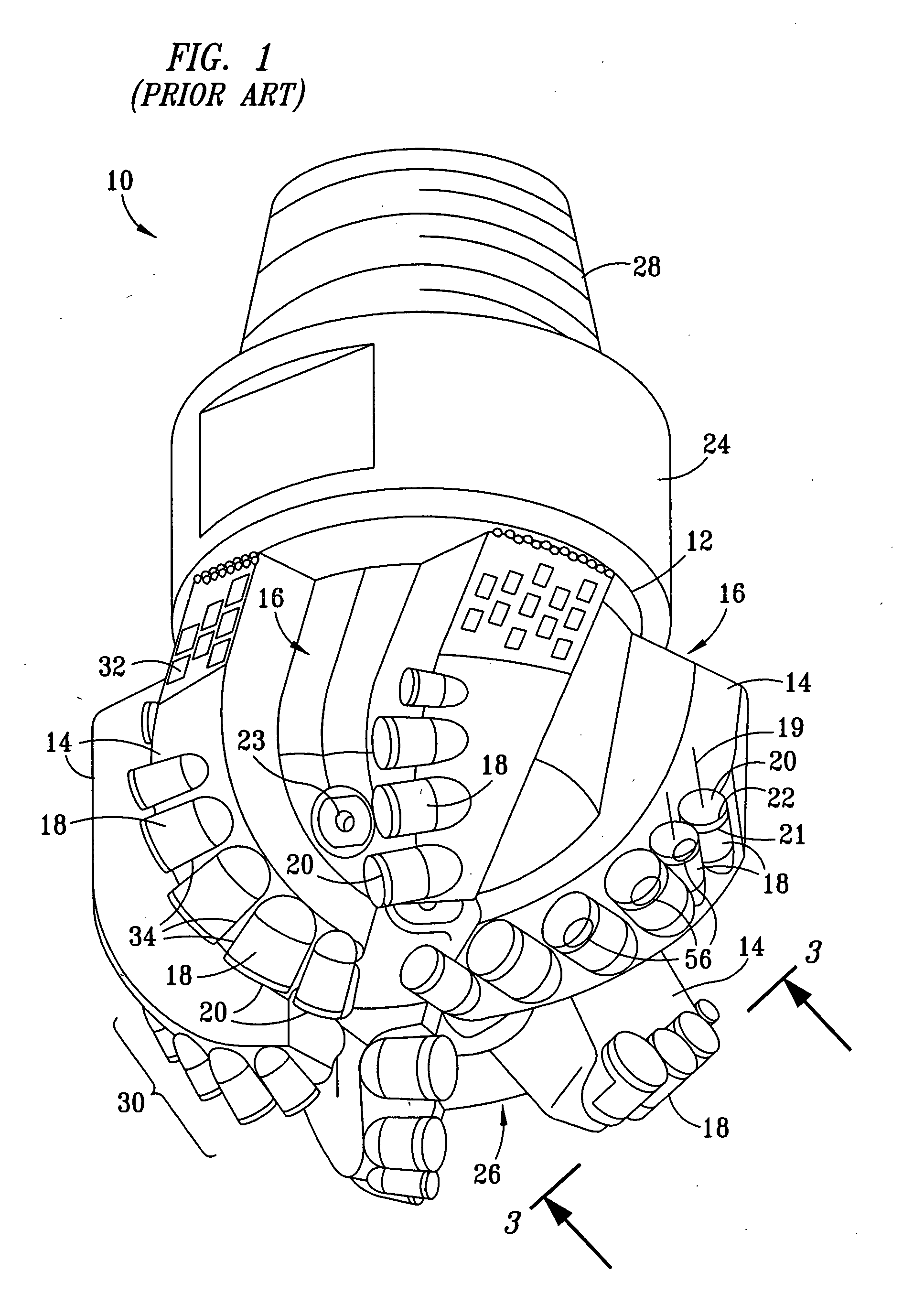

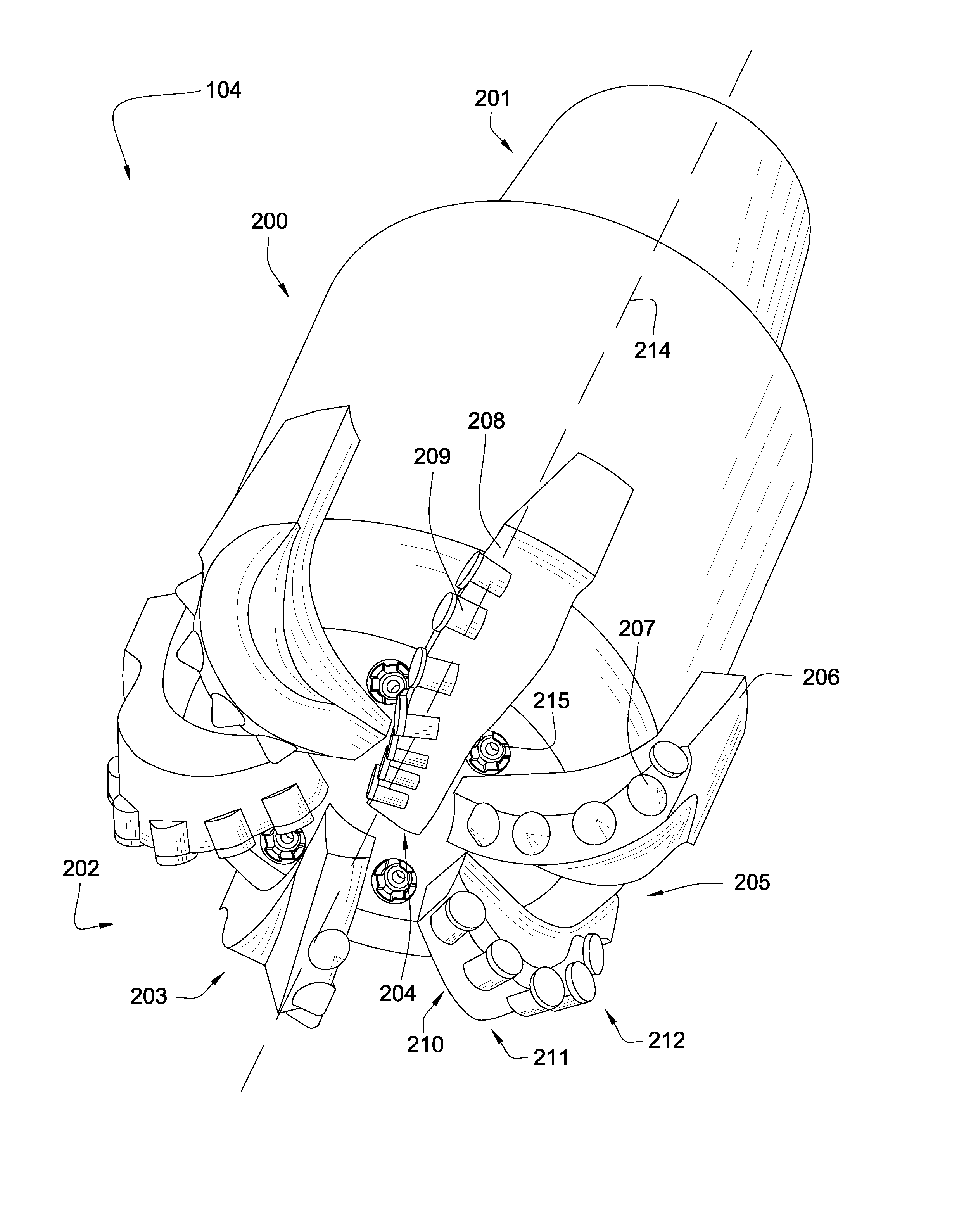

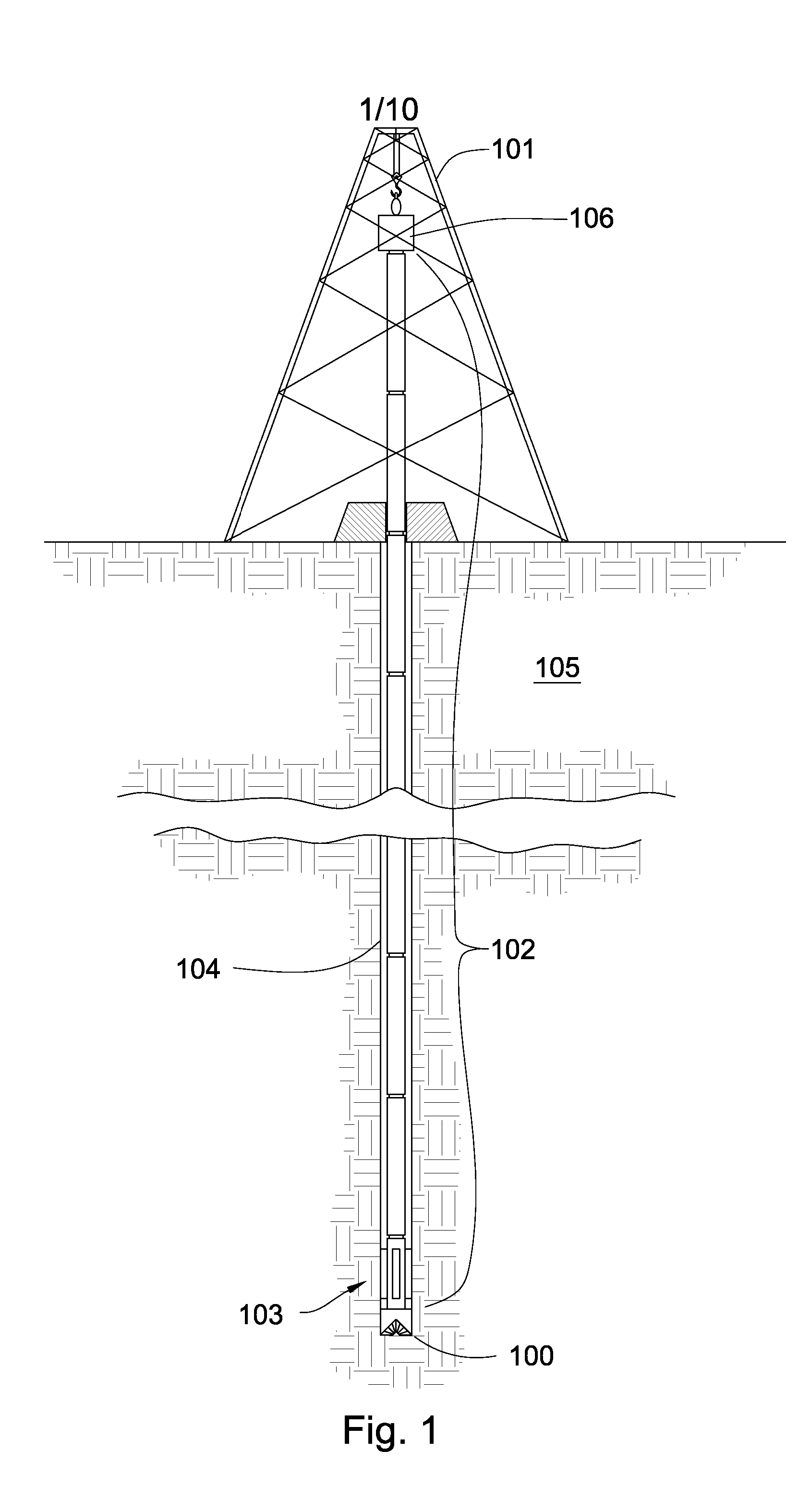

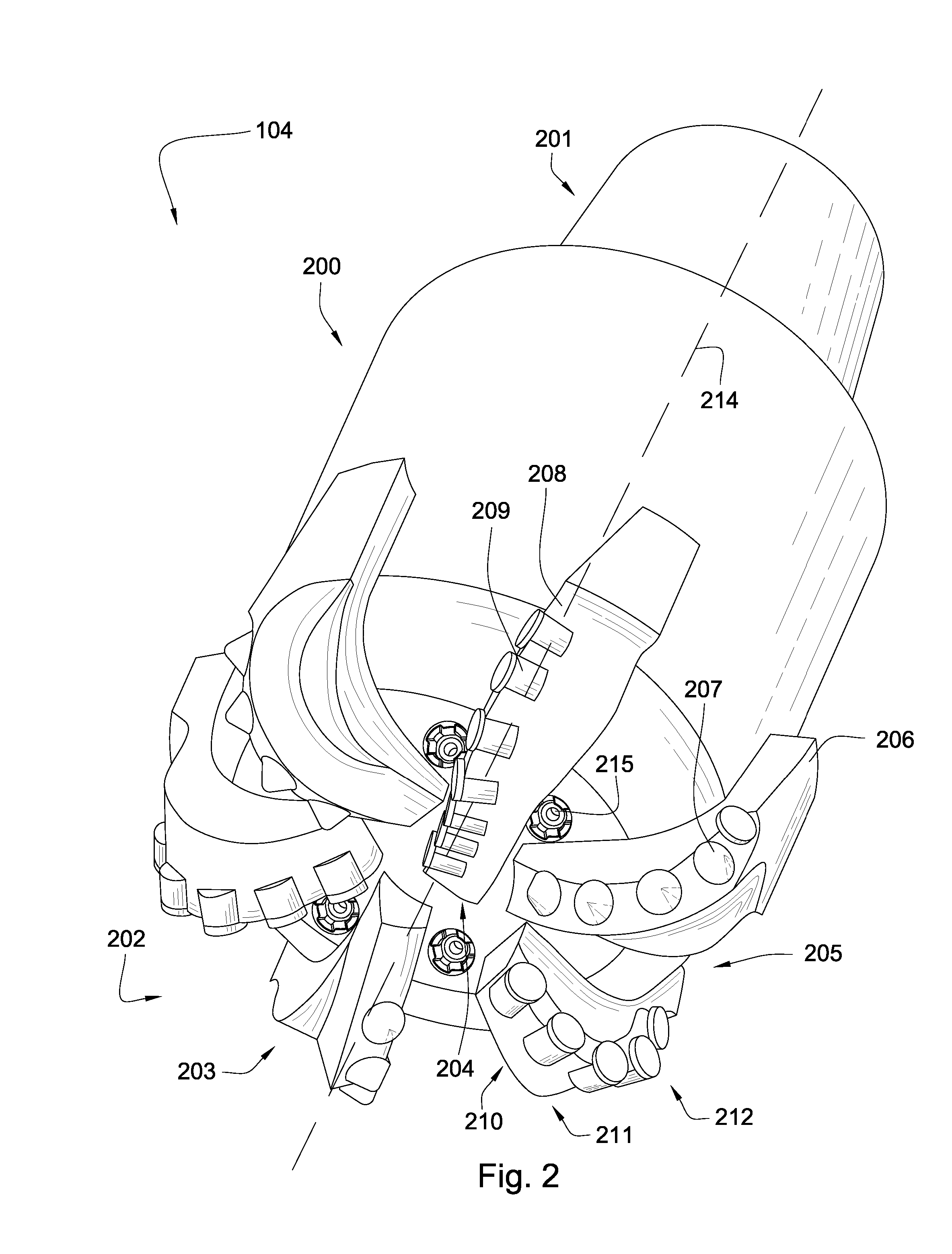

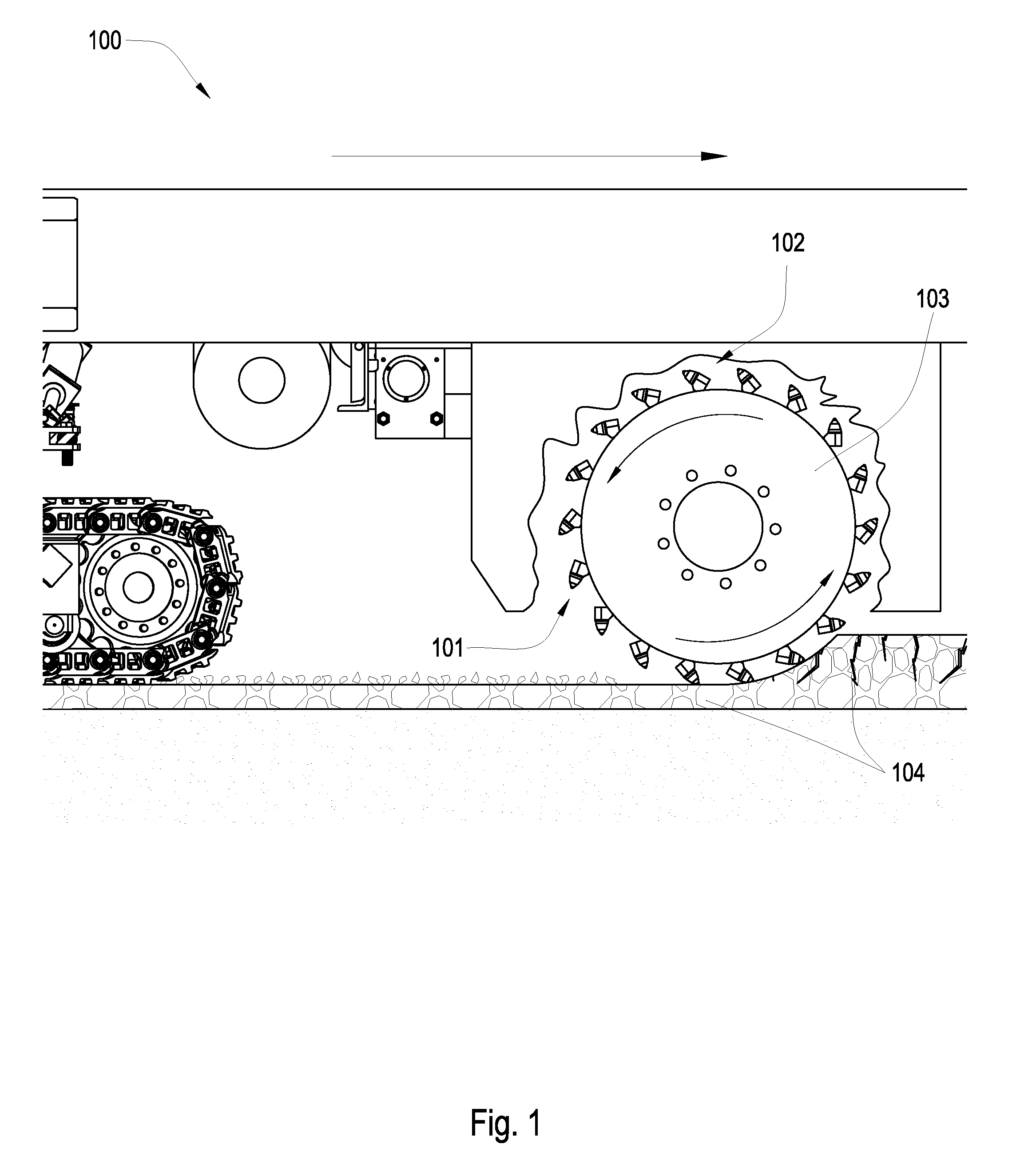

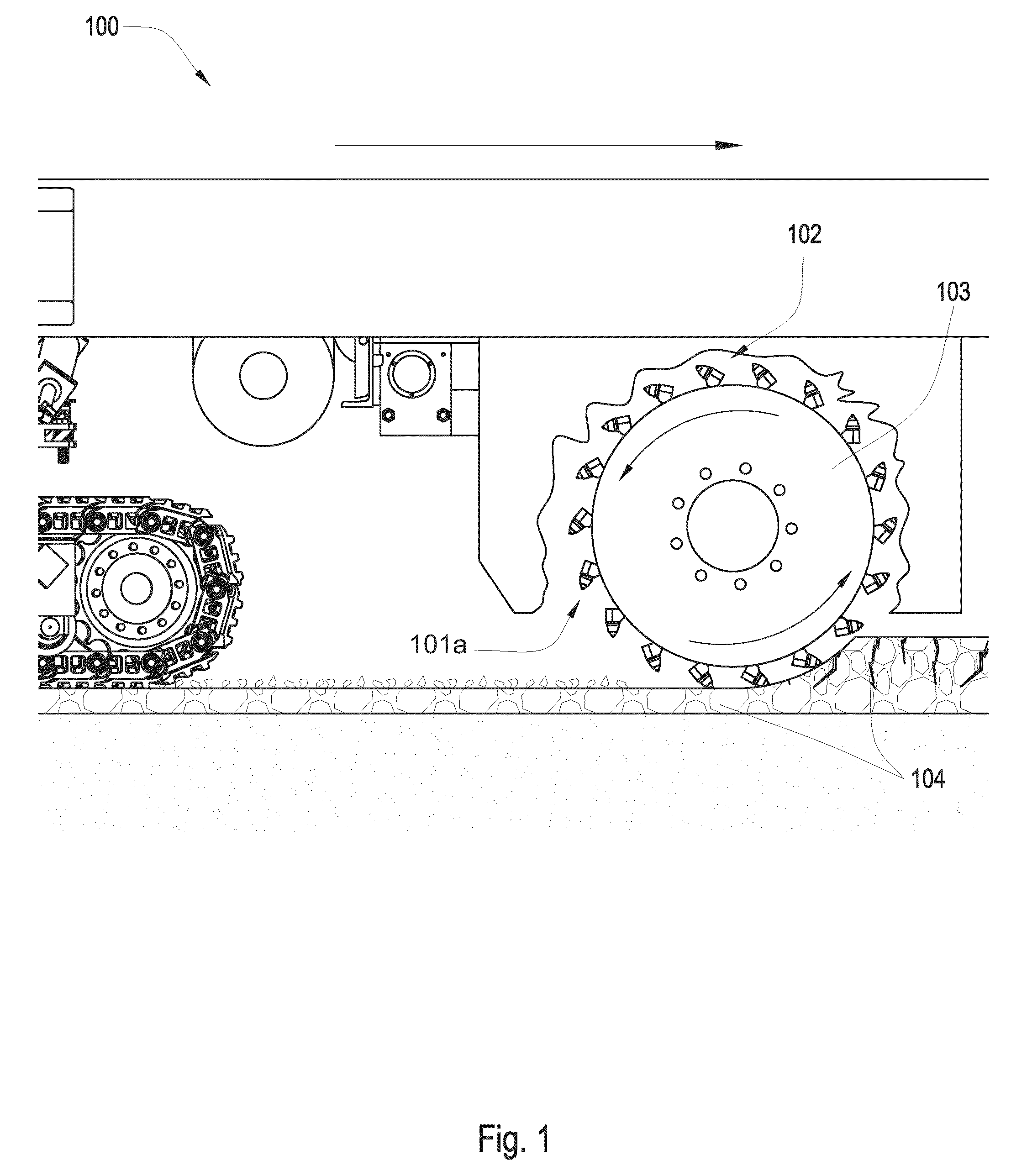

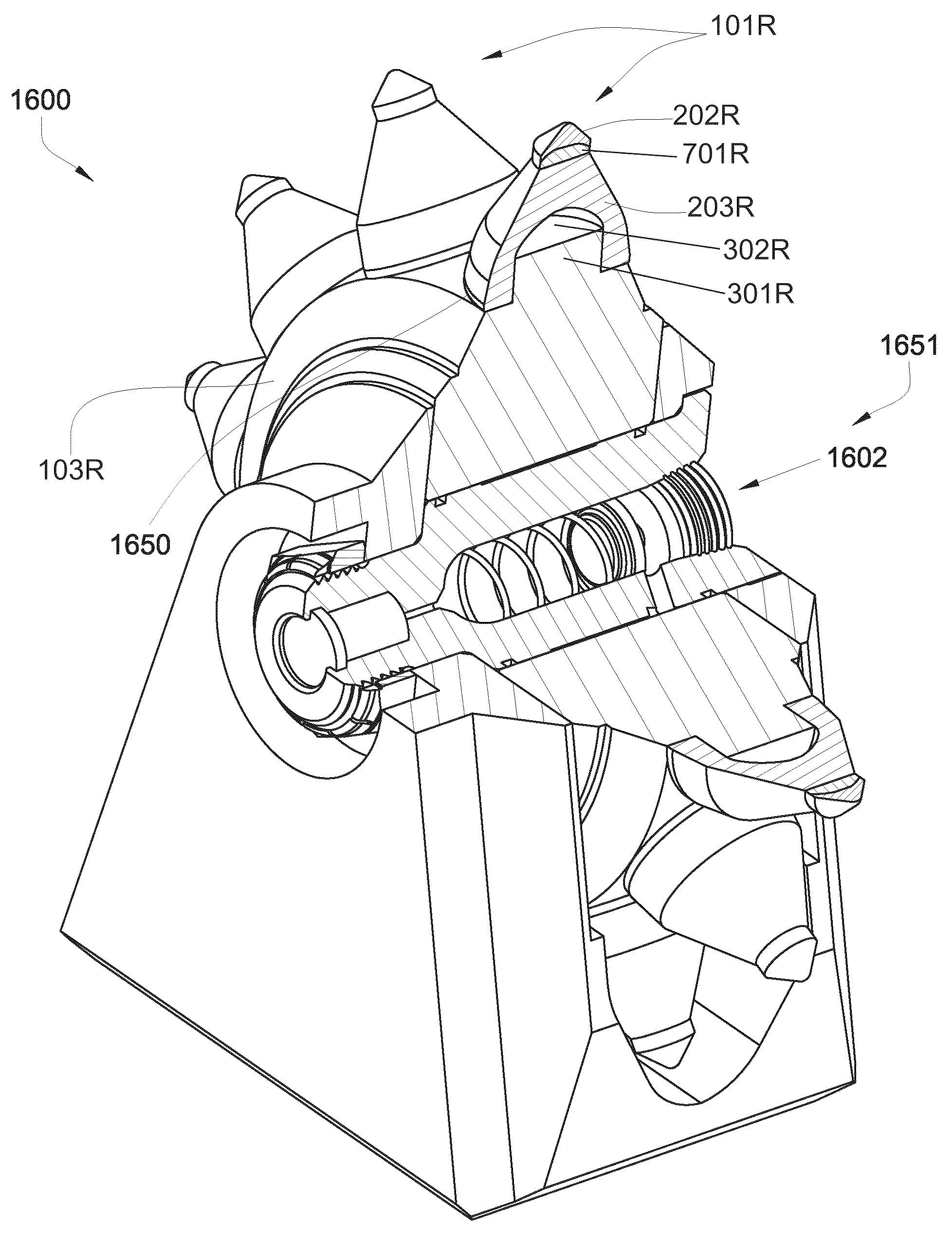

Downhole Drill Bit

In one aspect of the present invention, a drill bit has a body intermediate a shank and a working face. The working face has a plurality of blades converging towards a center of the working face and diverging towards a gauge of the working face. A first blade has at least one pointed cutting element with a carbide substrate bonded to a diamond working end with a pointed geometry at a non-planar interface and a second blade has at least one shear cutting element with a carbide substrate bonded to a diamond working end with a flat geometry.

Owner:SCHLUMBERGER TECH CORP

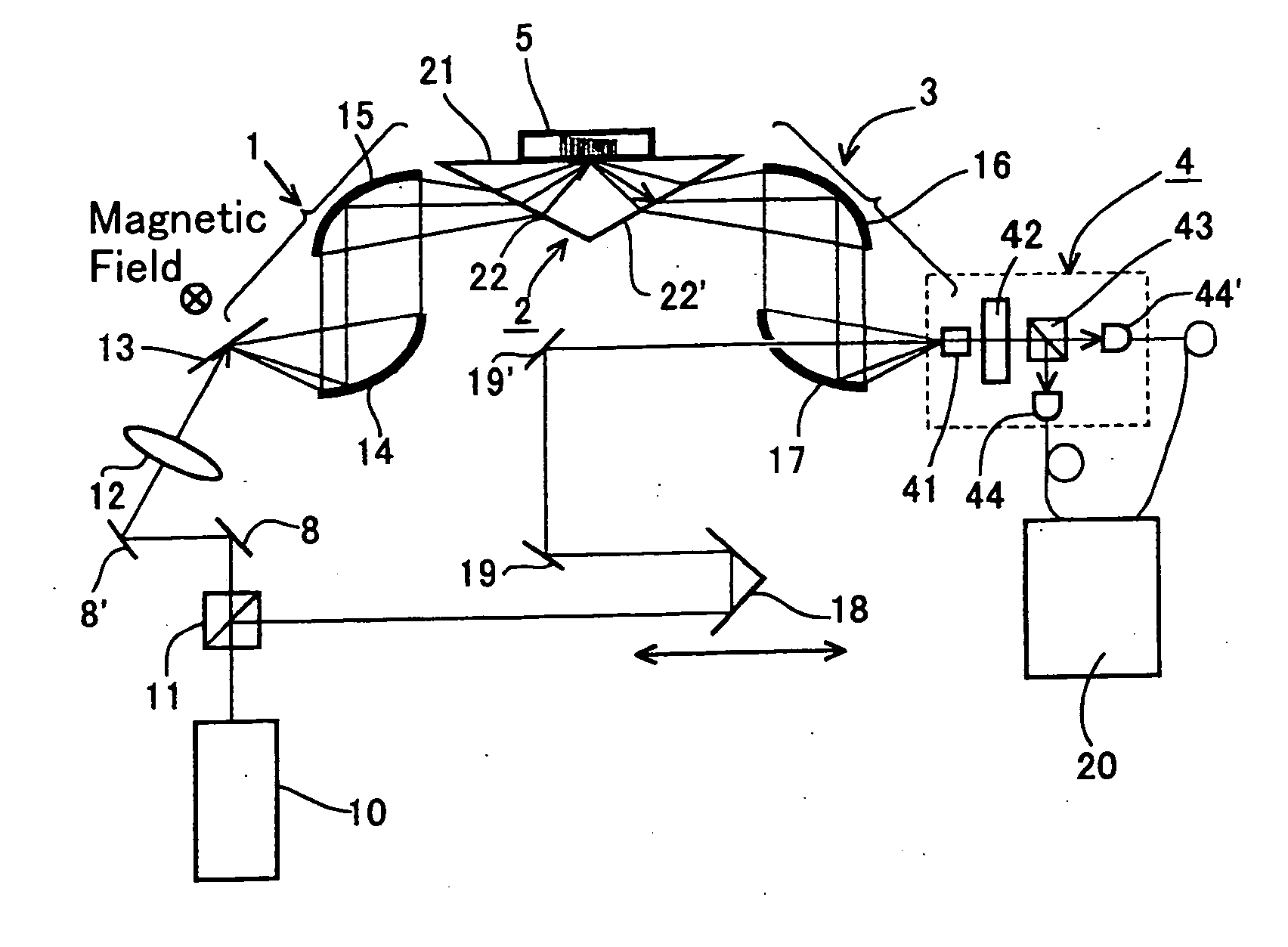

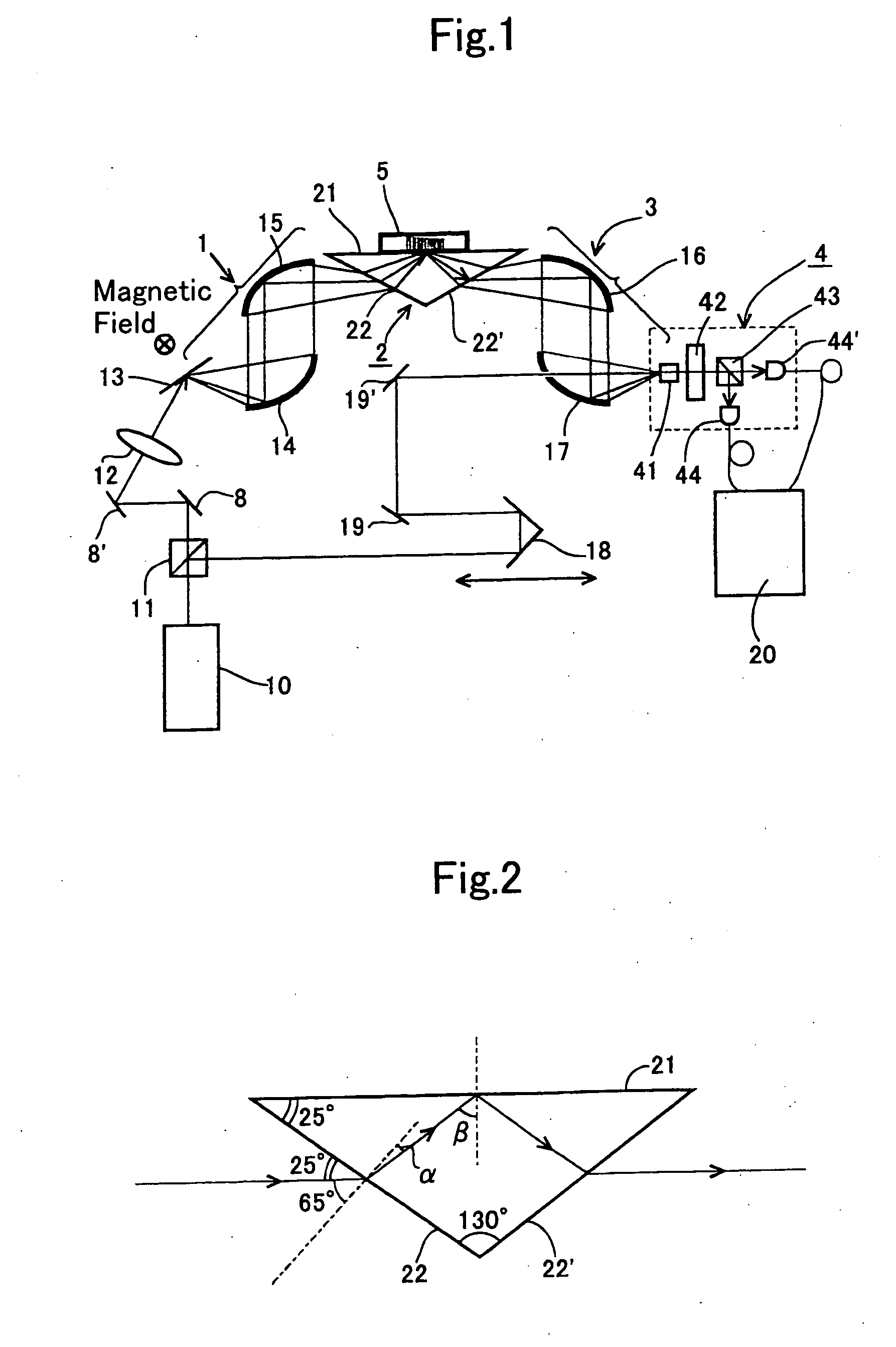

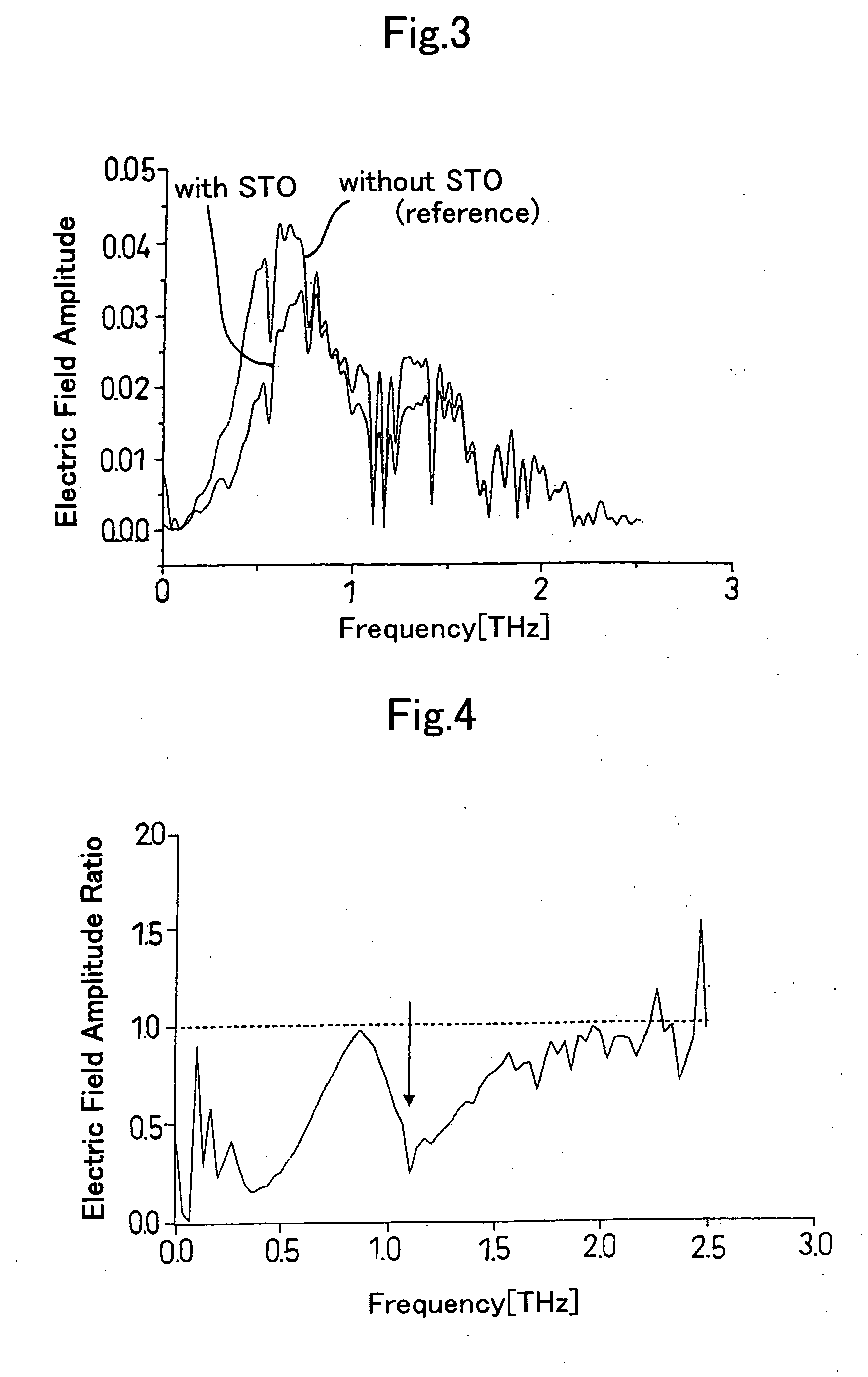

Reflection type terahertz spectrometer and spectrometric method

InactiveUS20060231762A1Avoid absorptionReduce absorptionRadiation pyrometryPolarisation spectroscopyTotal internal reflectionRefractive index

A reflection-type terahertz spectrometer includes an input optical path through which terahertz waves are propagated, an irradiating mechanism that irradiates a sample with terahertz waves propagated through the input optical path, an output optical path through which terahertz waves exiting from the irradiating mechanism are propagated, and a detector that receives and detects the terahertz waves propagated through the output optical path. The irradiating mechanism has at least one planar interface and a refractive index greater than that of a peripheral region contacting the planar interface and is disposed between the input optical path and the output optical path such that the terahertz waves propagated through the input optical path to be incident on the planar interface undergo total internal reflection at the planar interface, and the sample is disposed in the peripheral region contacting the planar interface of the irradiating mechanism. When the terahertz waves undergo the total internal reflection at the planar interface, the sample is irradiated with evanescent waves scattering from the planar interface to the peripheral region contacting the planar interface, so as to measure a spectrum.

Owner:AISIN SEIKI KK

High impact resistant tool

A tool has a sintered body of diamond or diamond-like particles in a metal matrix bonded to a cemented metal carbide substrate at a non-planar interface. A working surface has at least one region fir enough away from the non-planar interface that during high pressure, high temperature processing a restricted amount of metal from the substrate reaches the region, the amount comprising 5 to 0.1 percent of the region by volume, resulting in the region having a high density of superhard particles.

Owner:SCHLUMBERGER TECH CORP

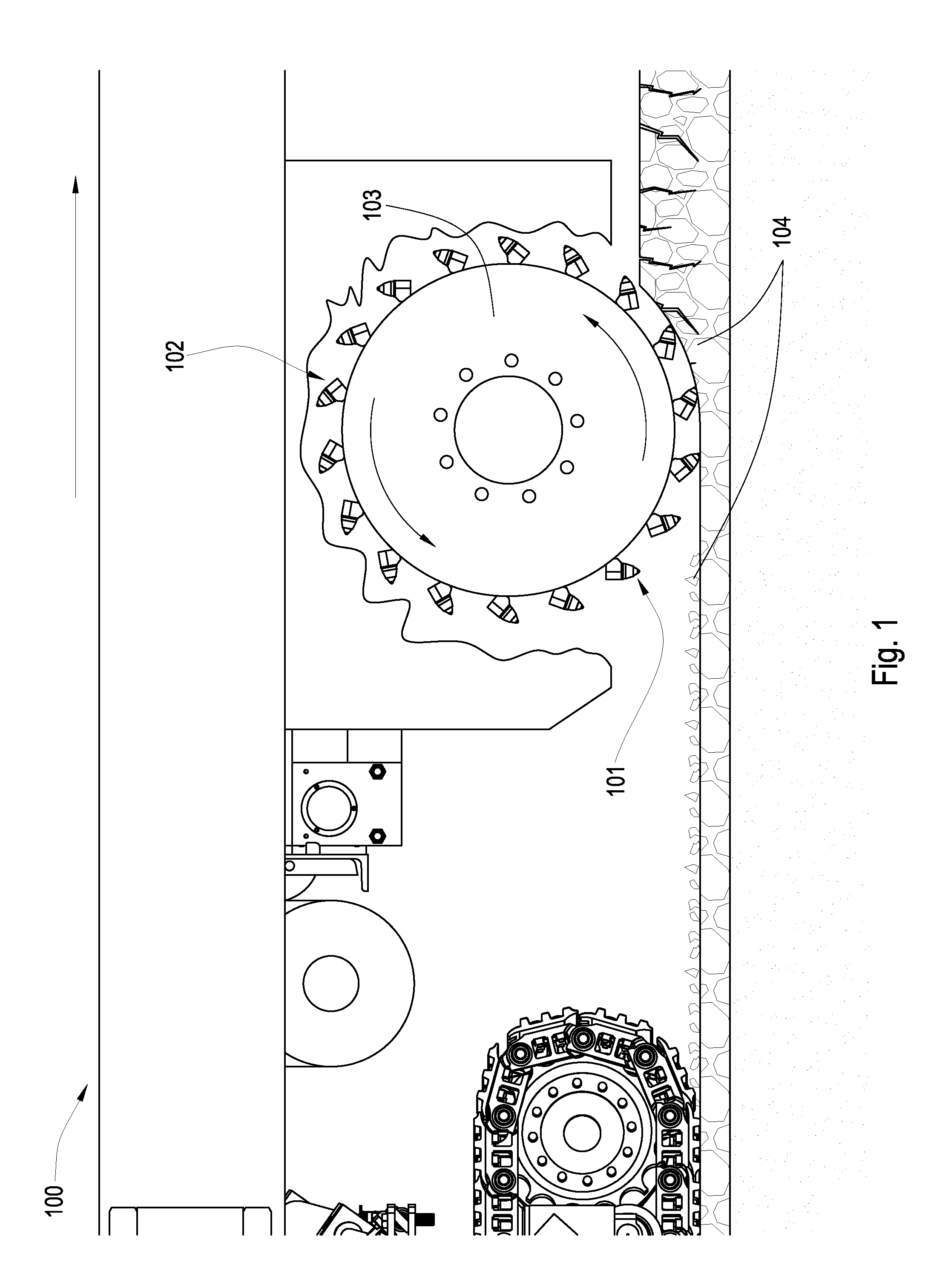

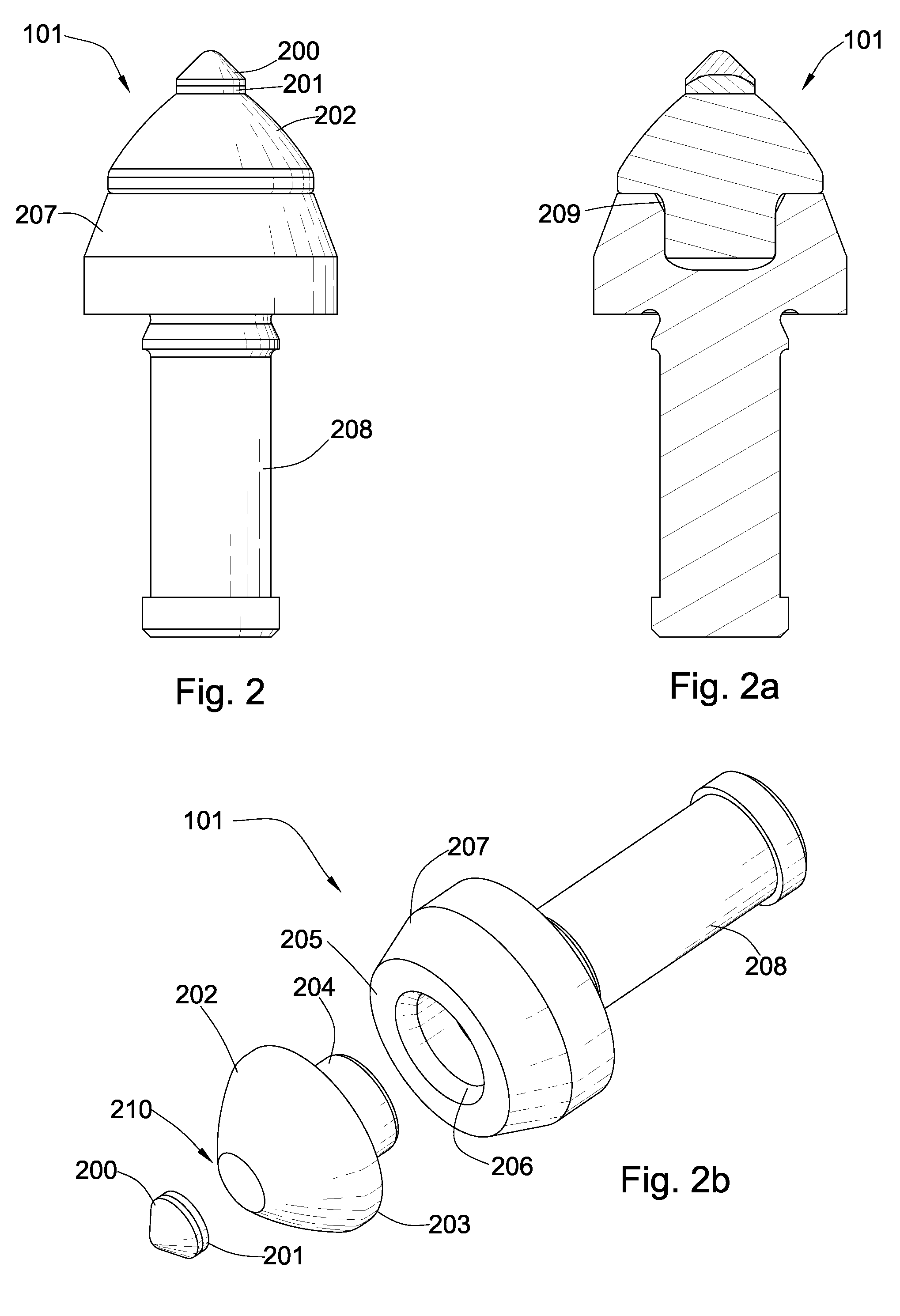

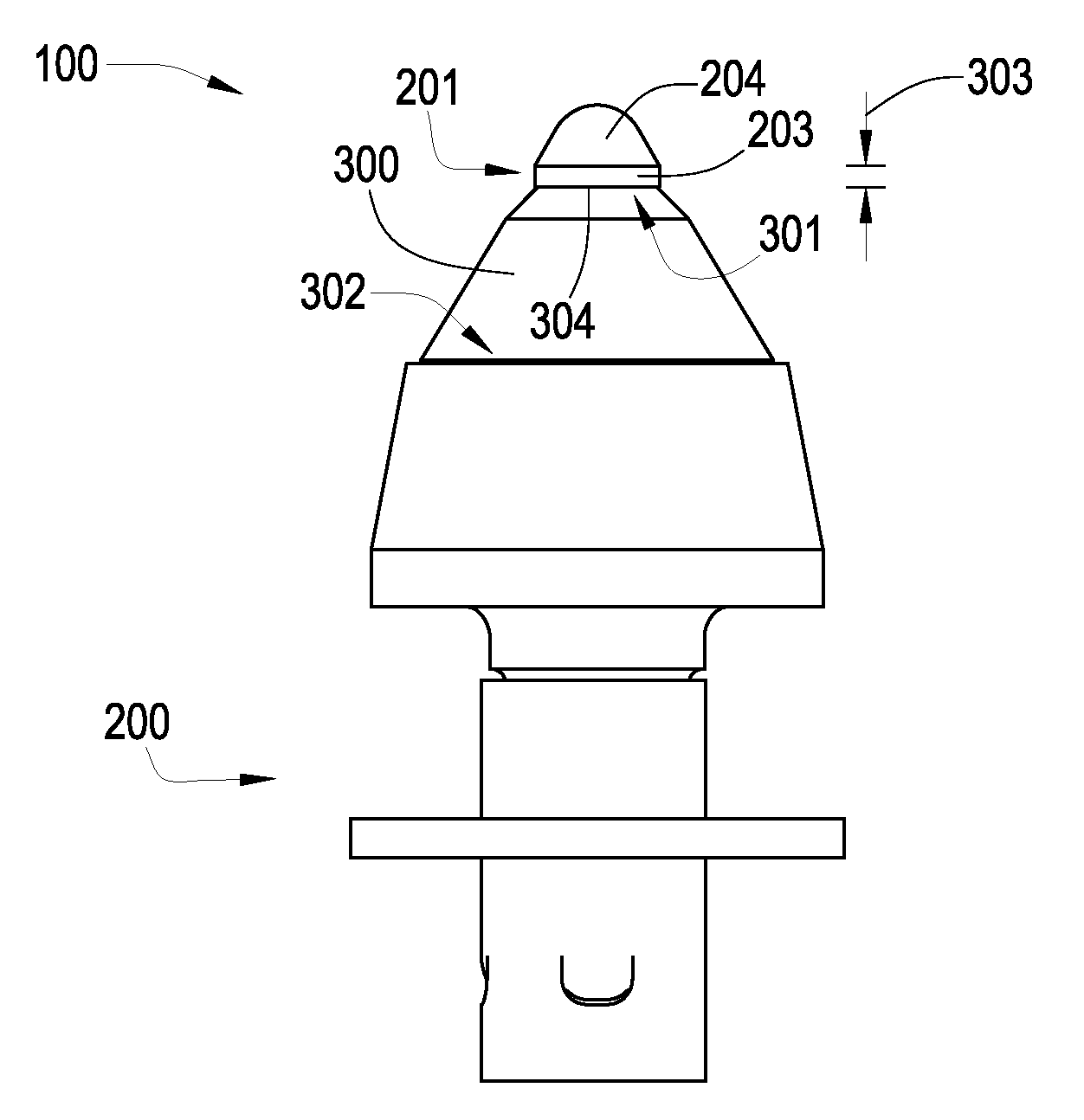

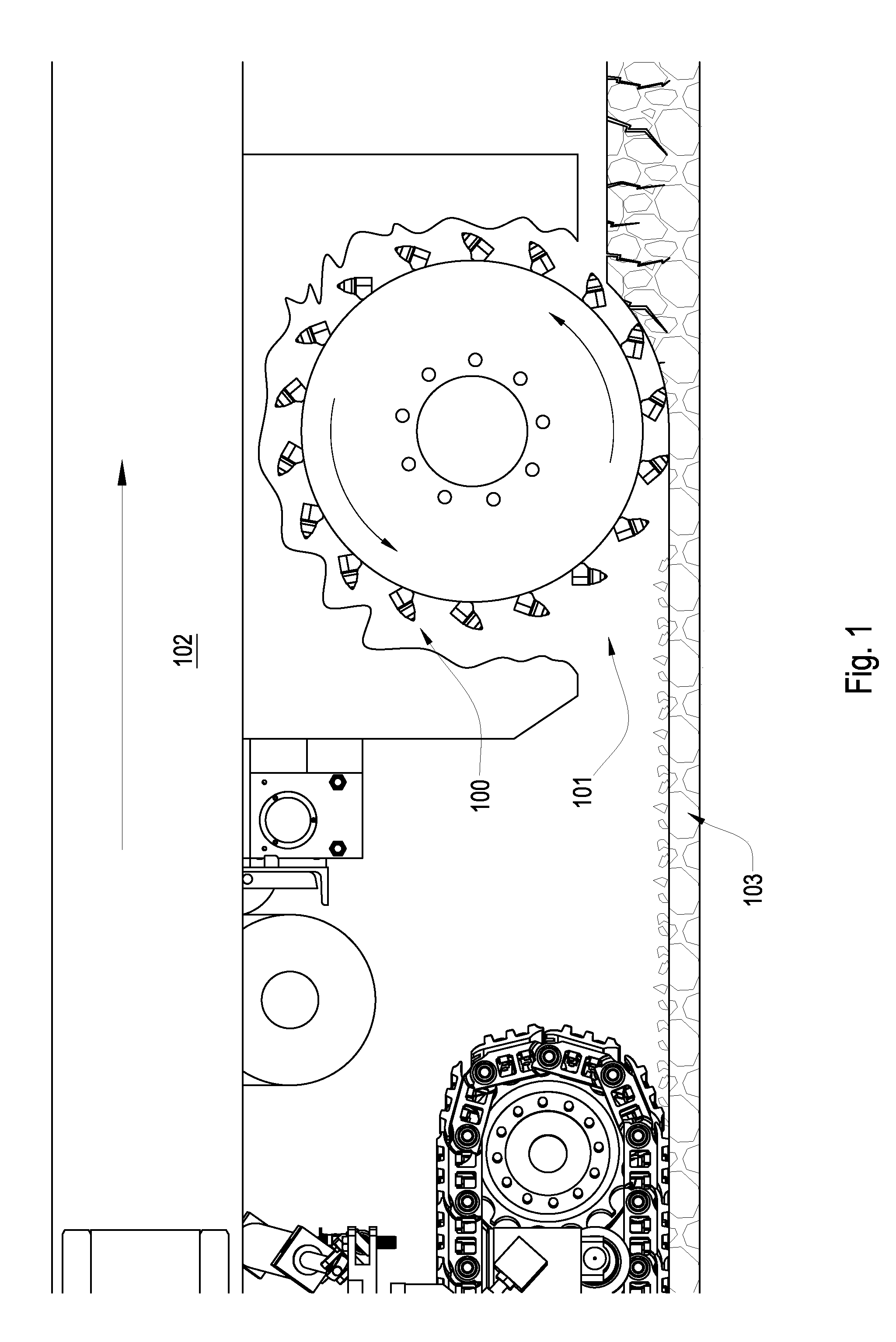

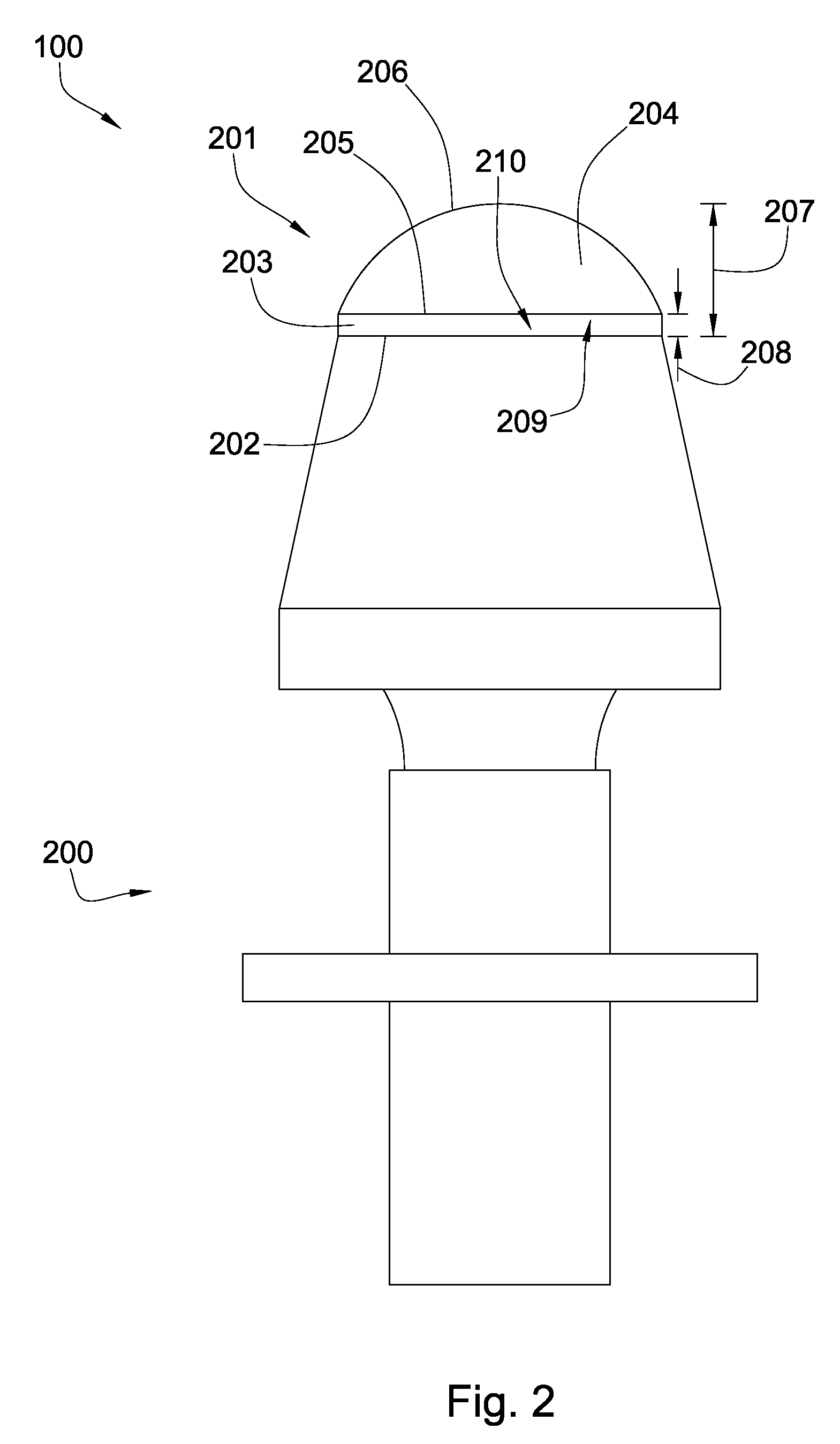

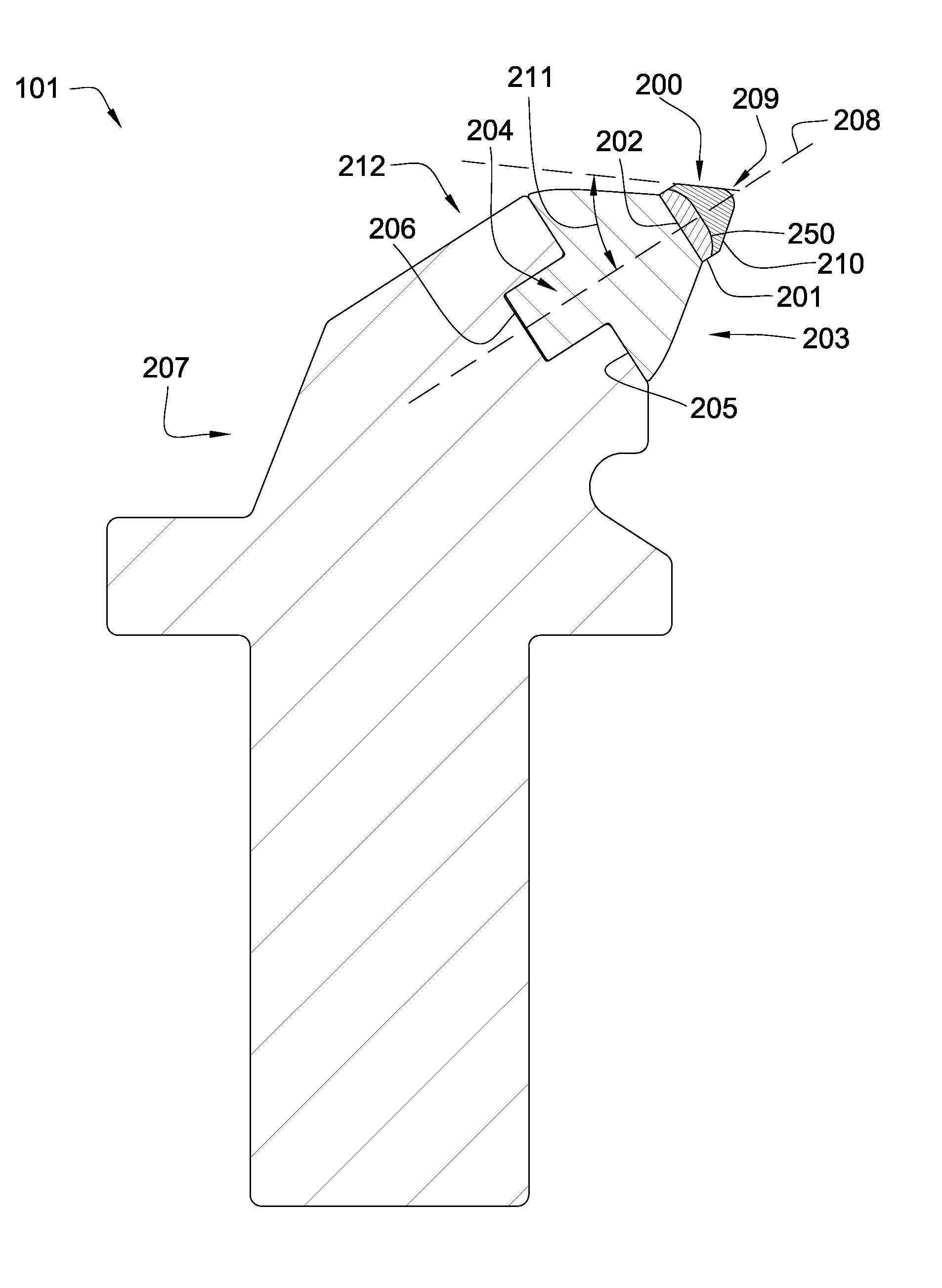

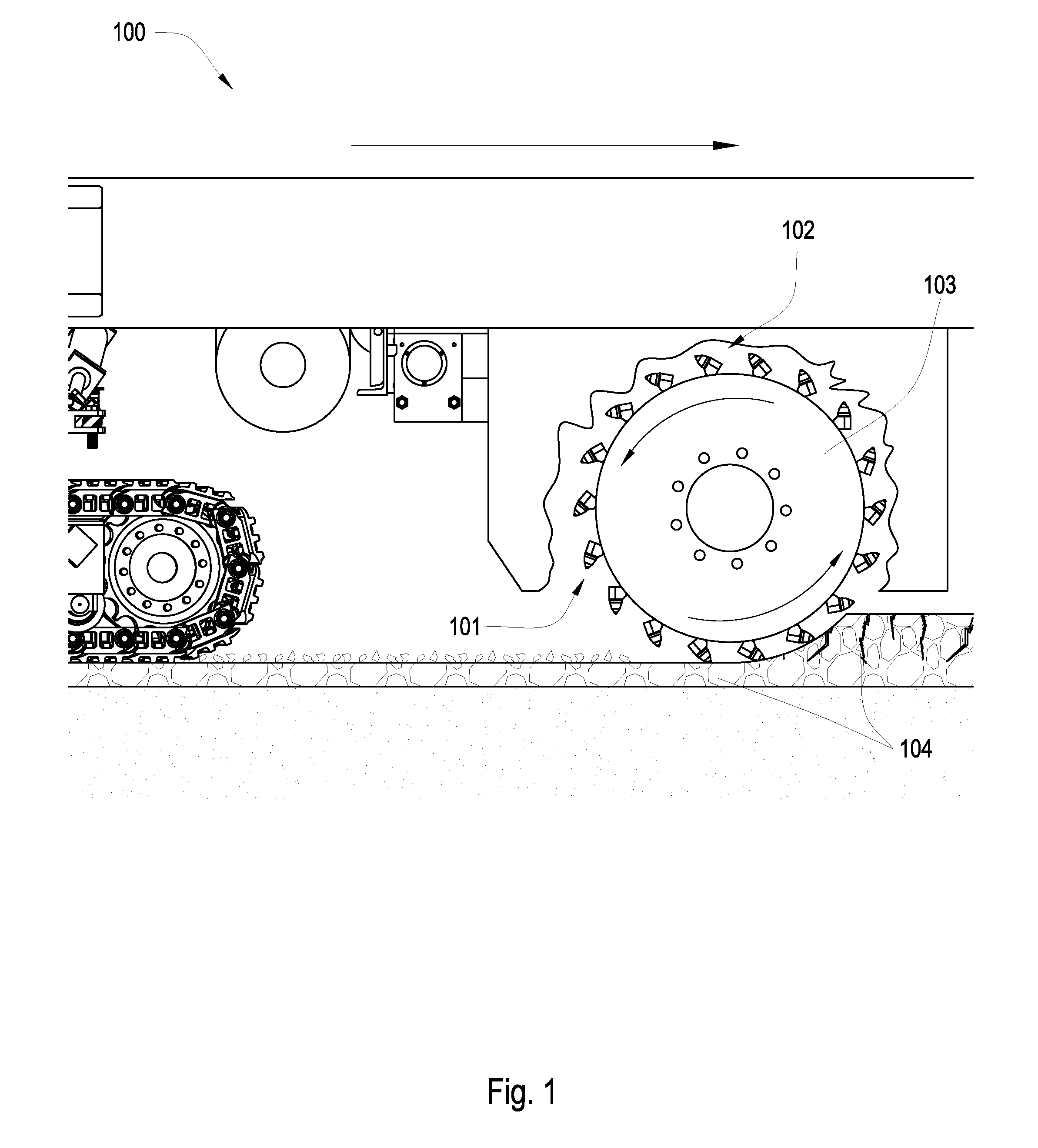

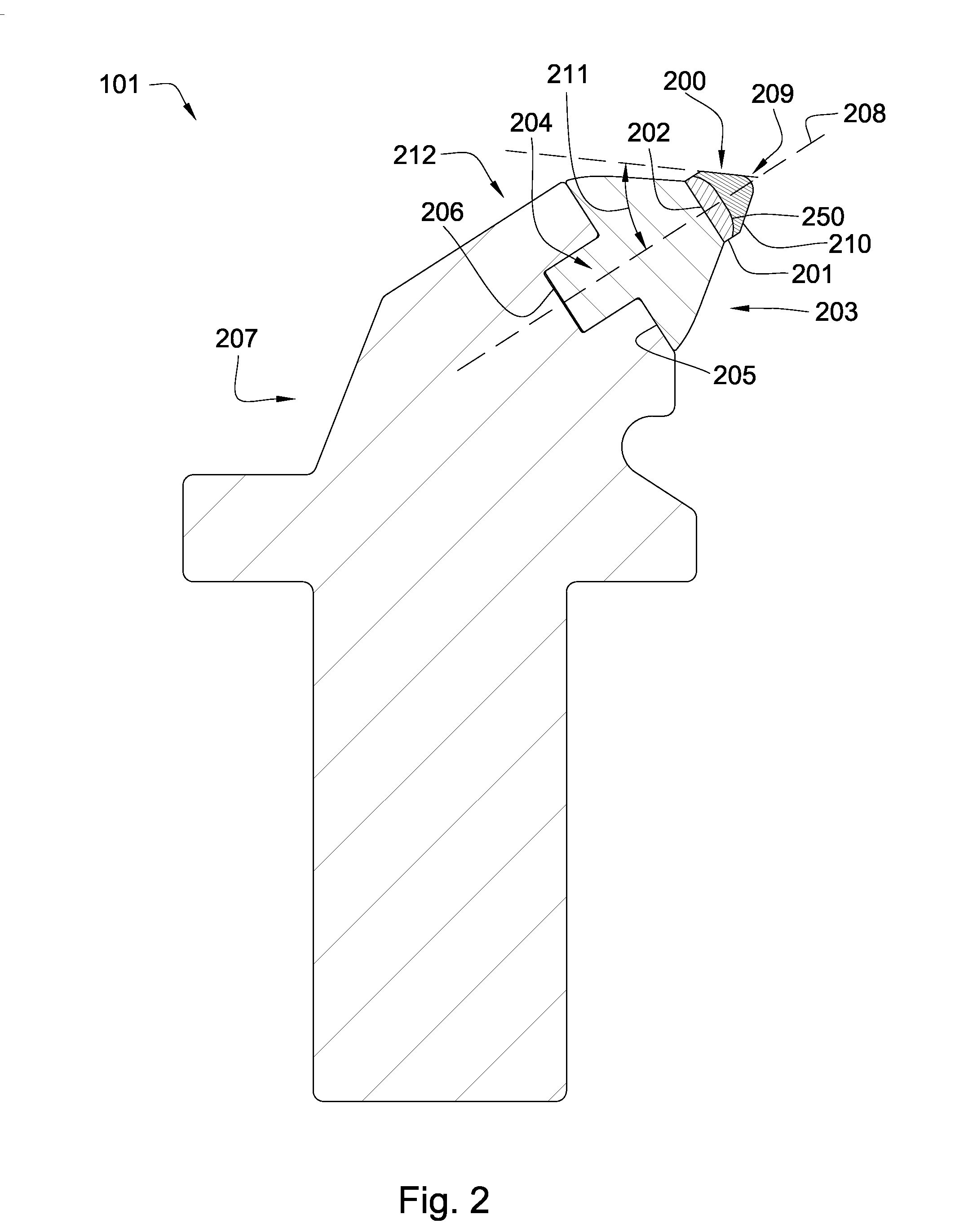

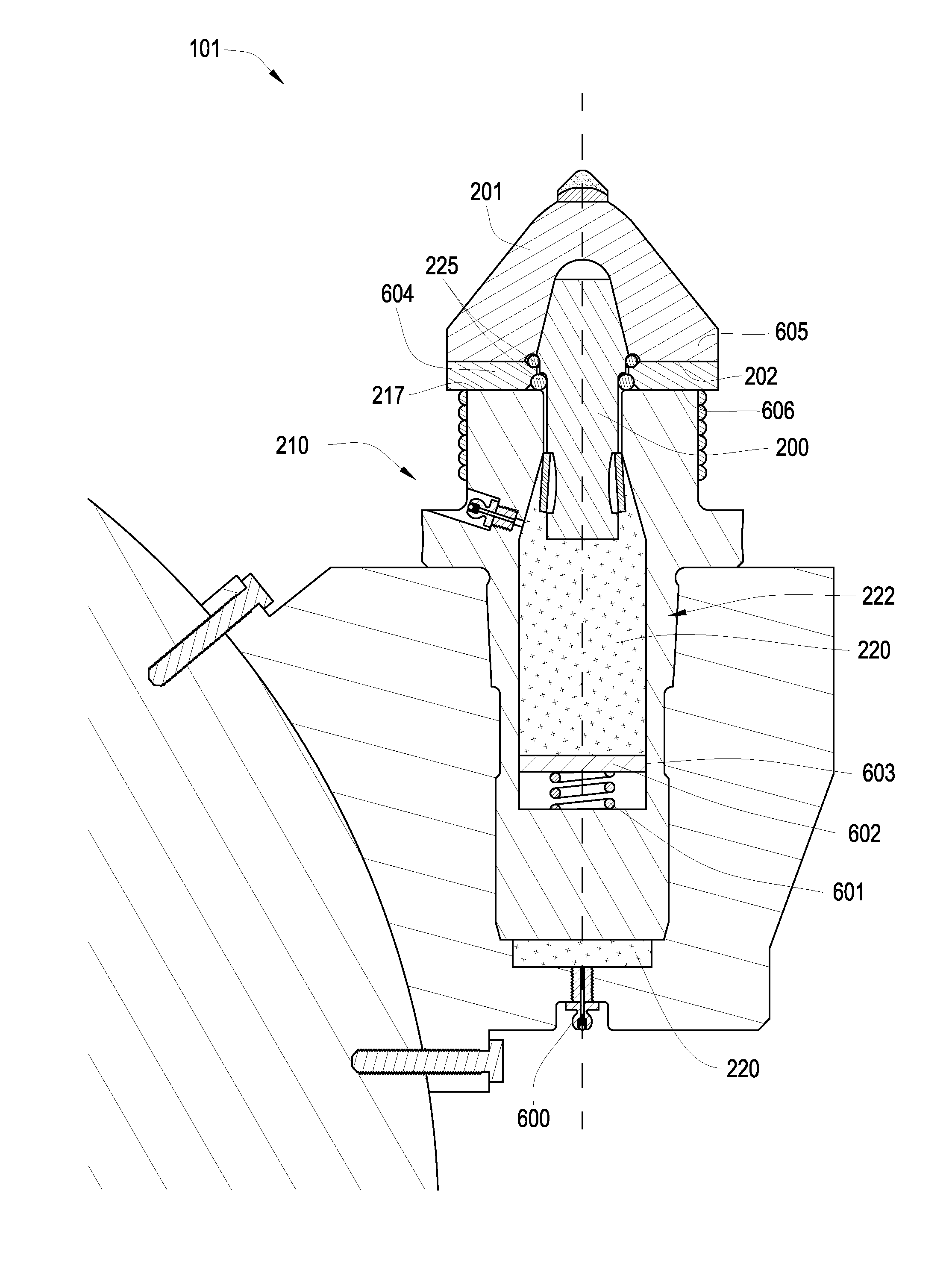

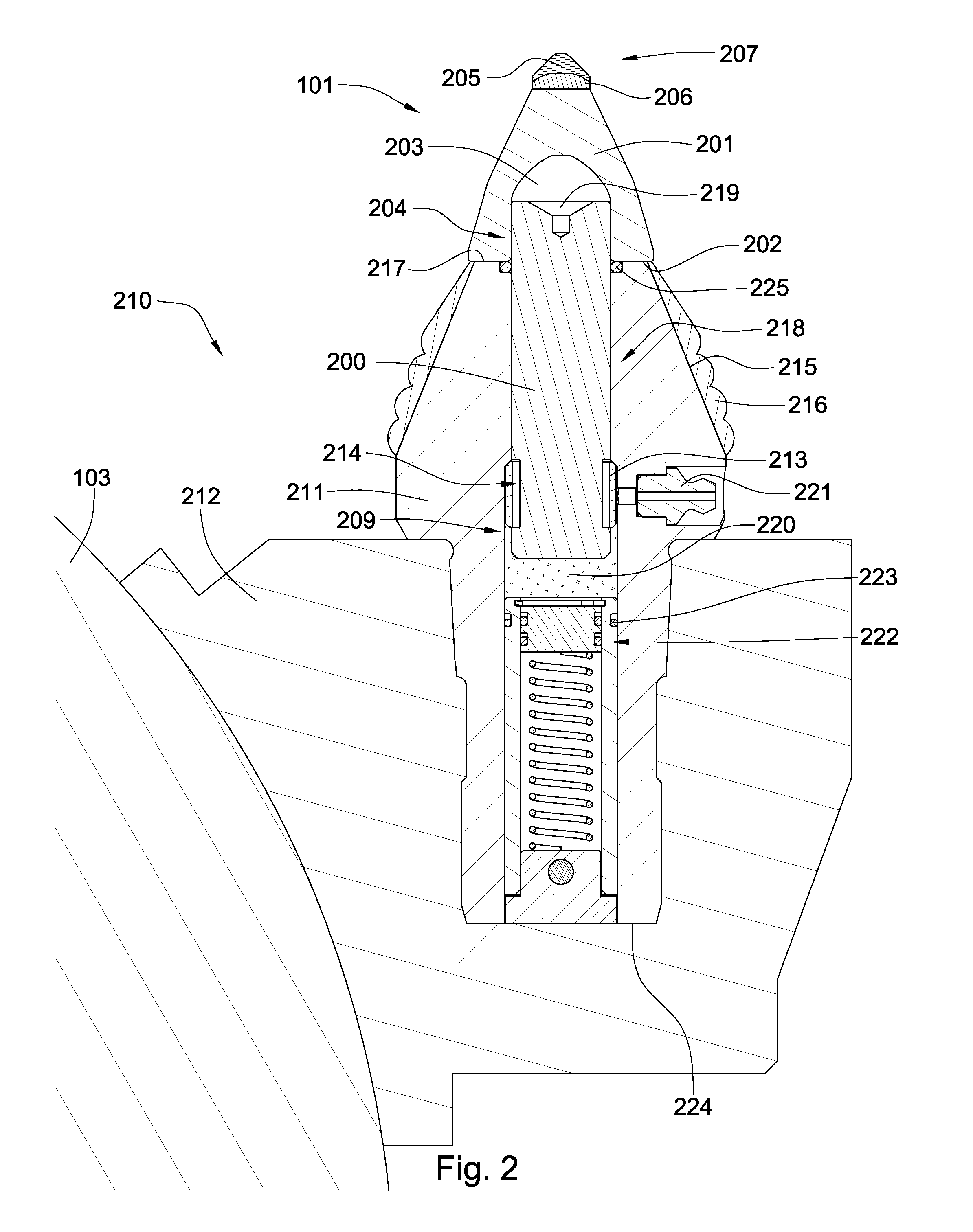

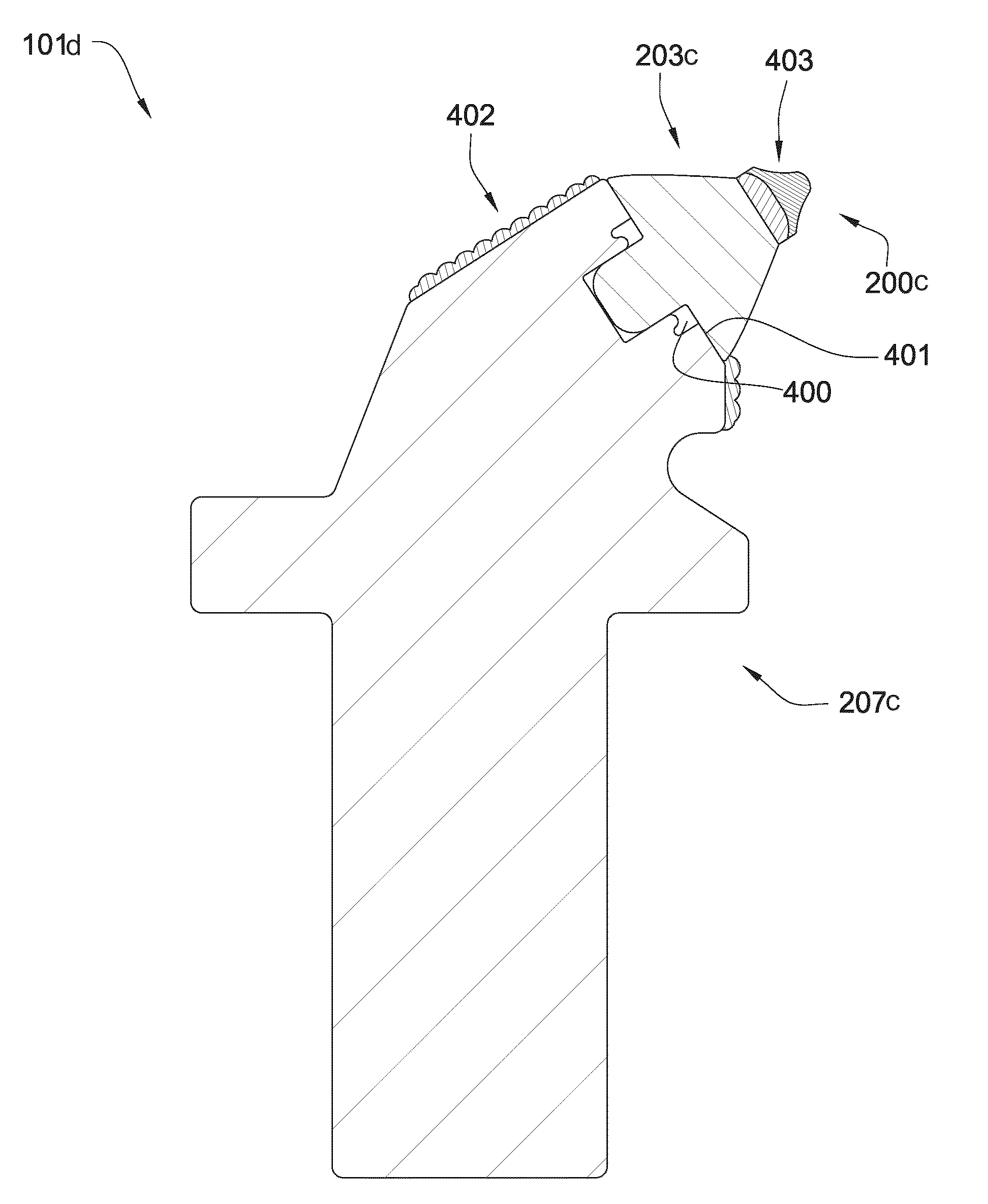

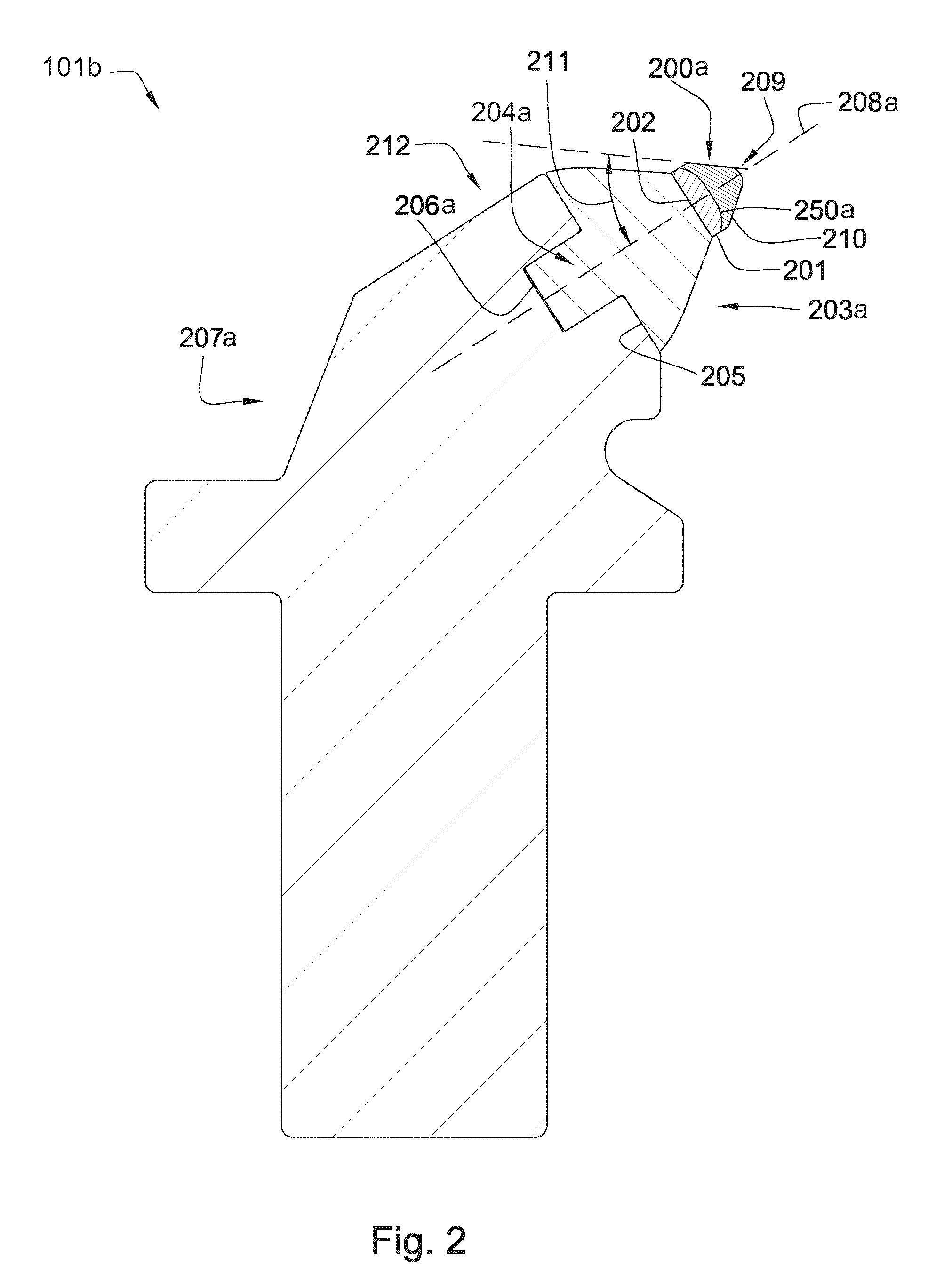

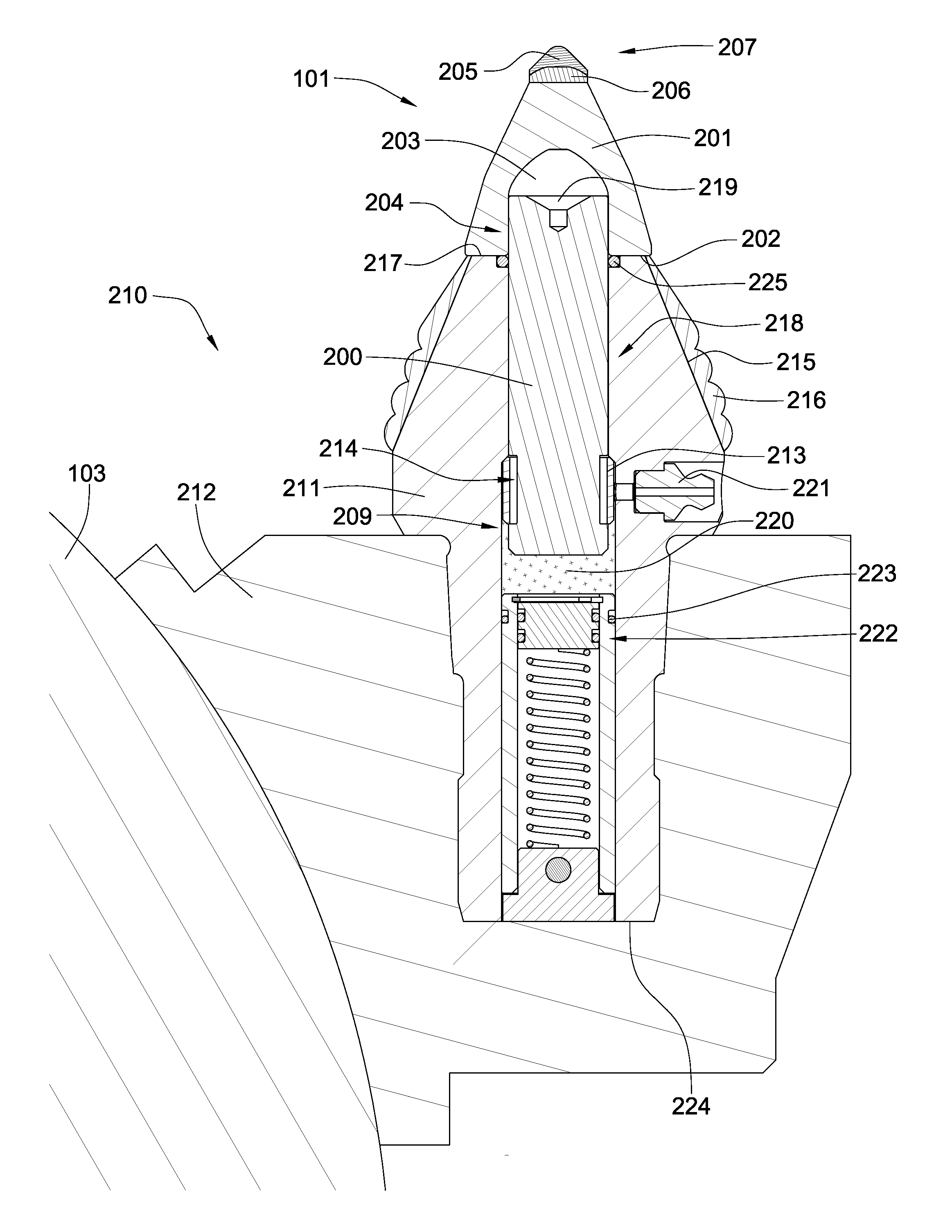

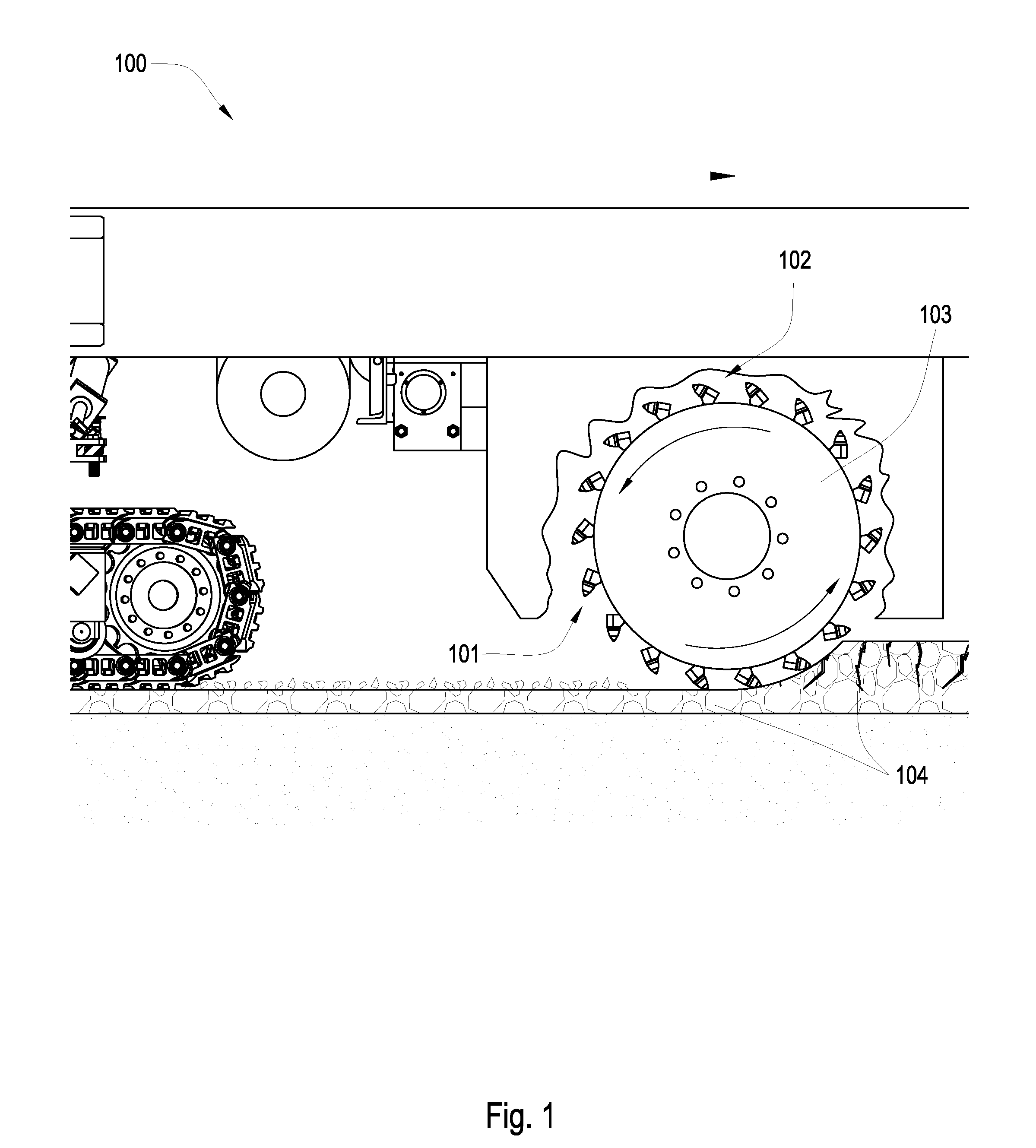

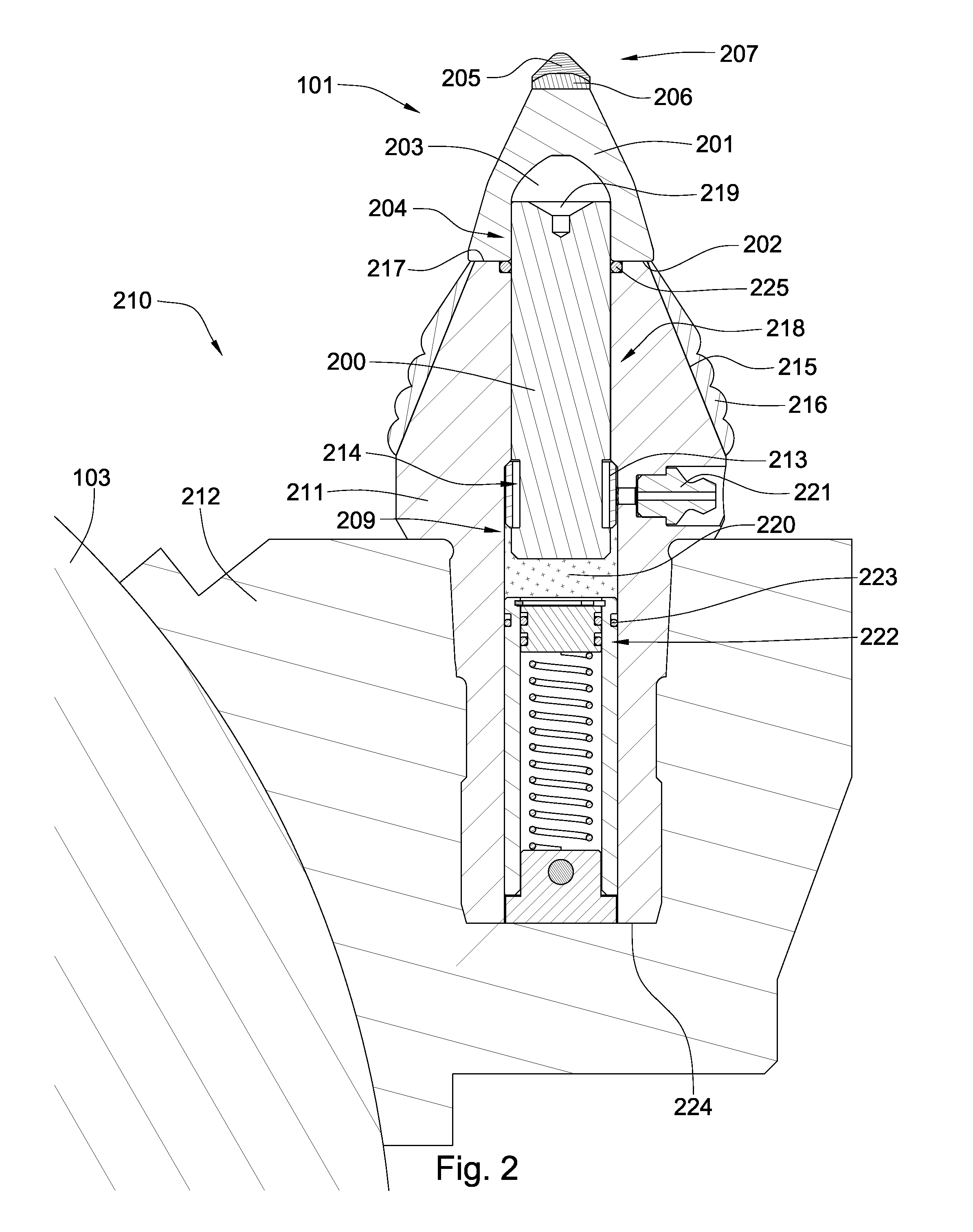

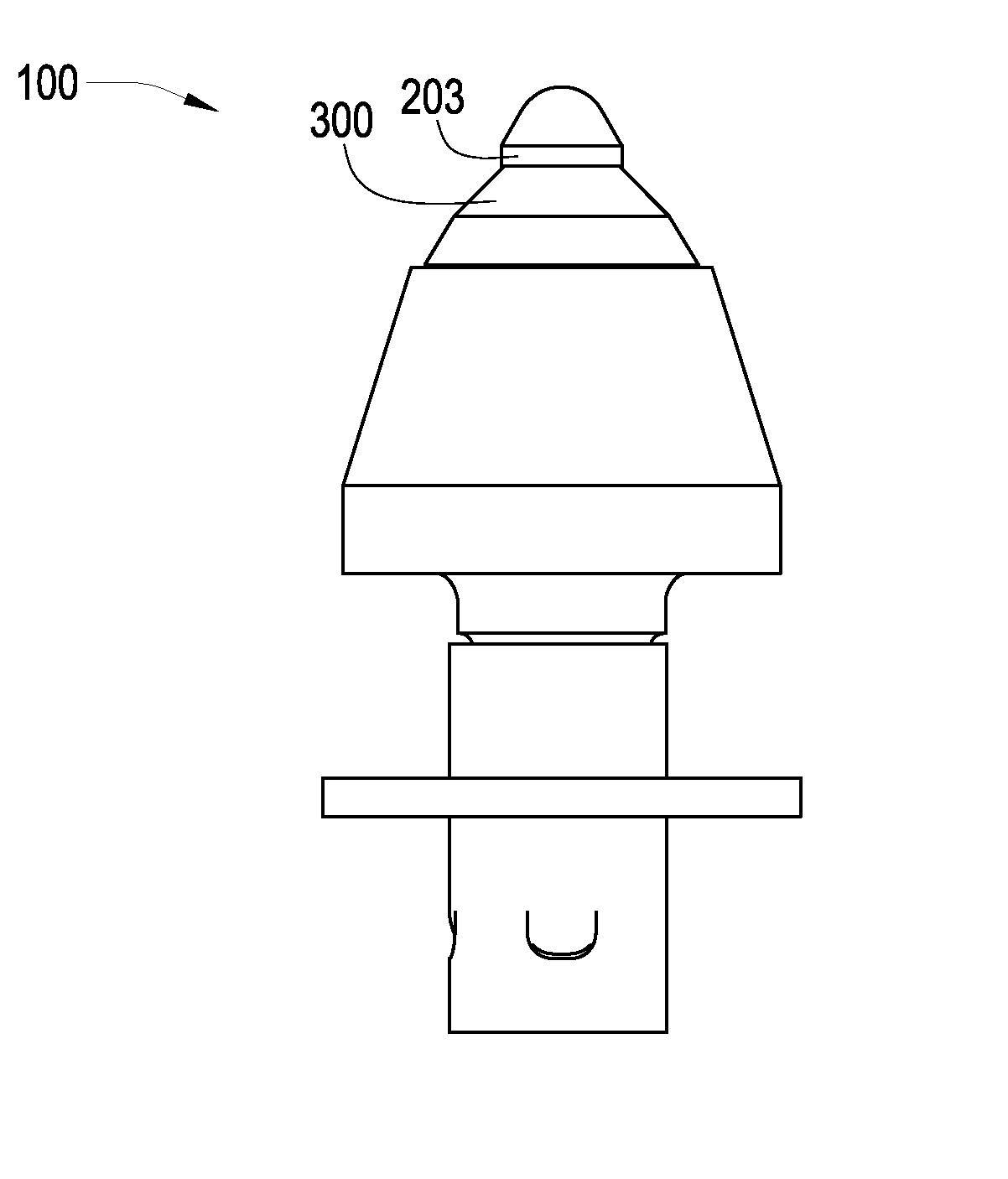

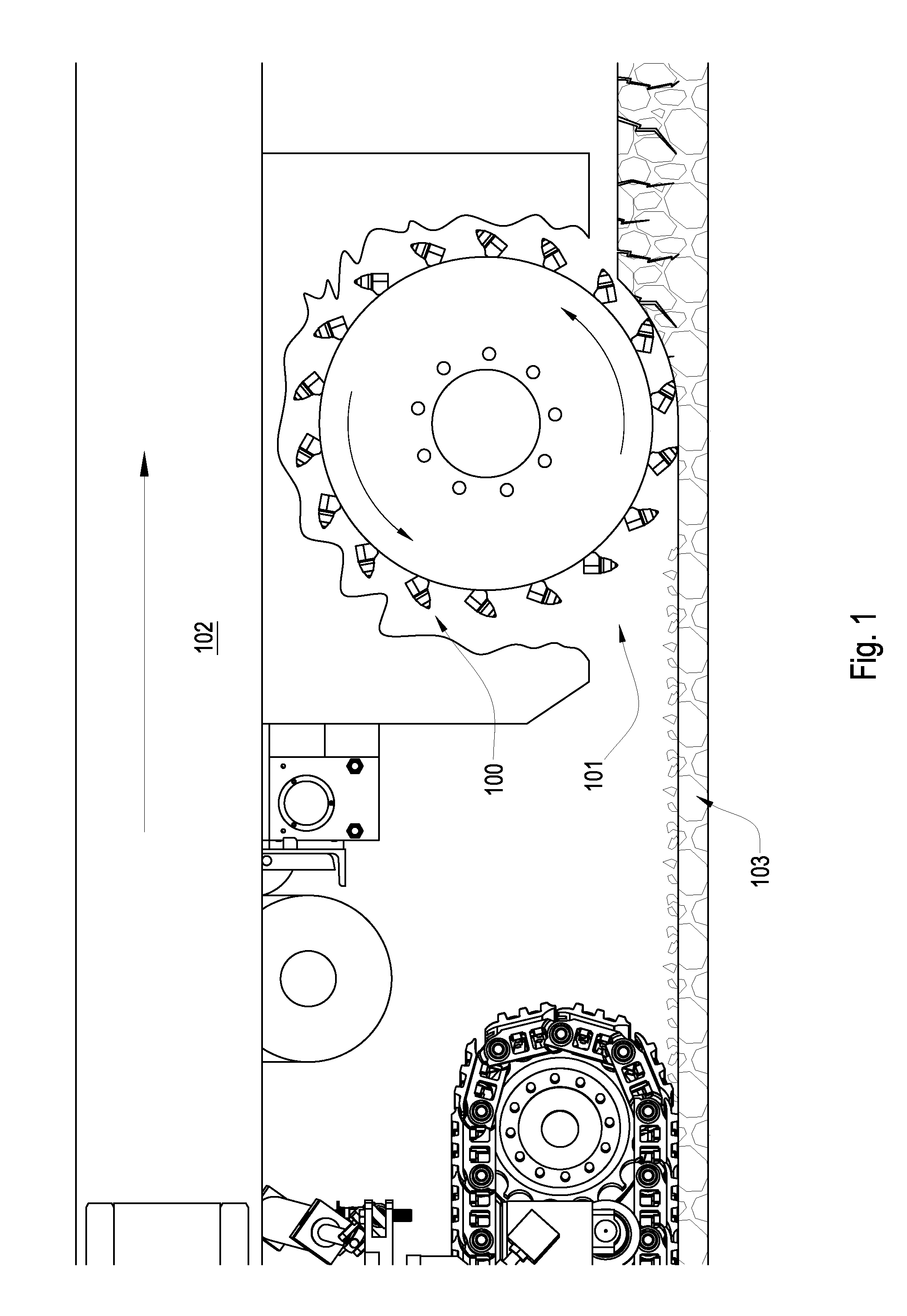

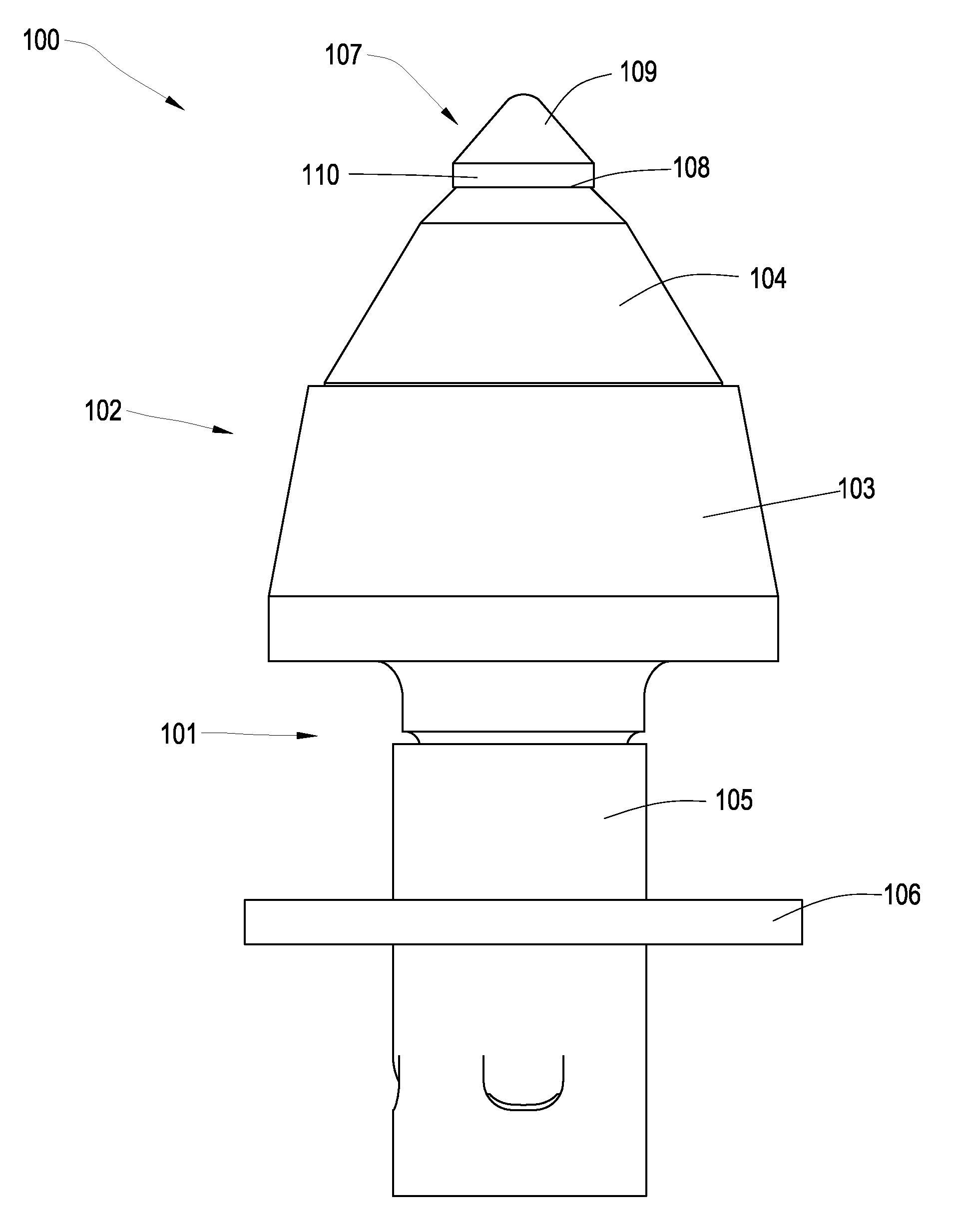

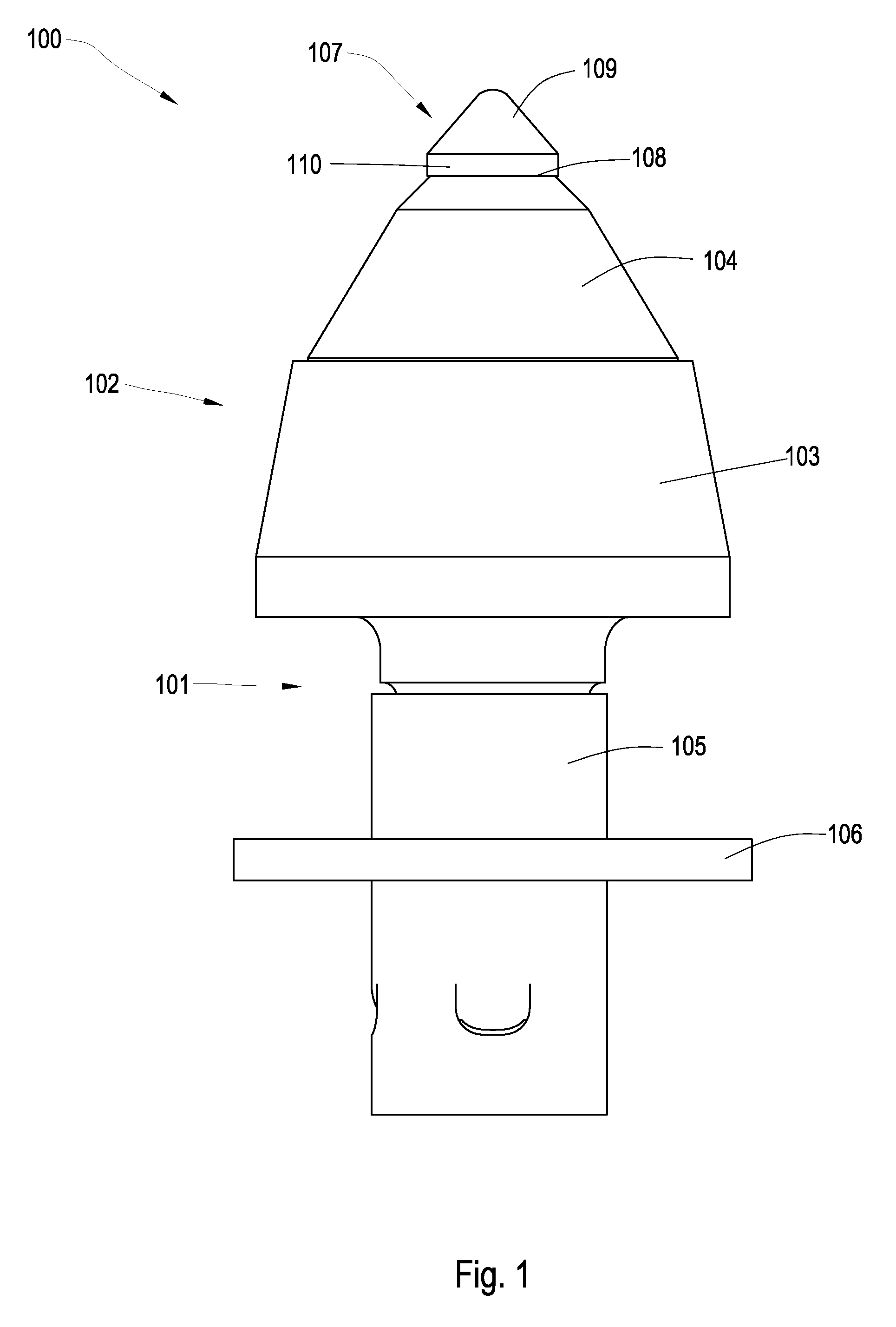

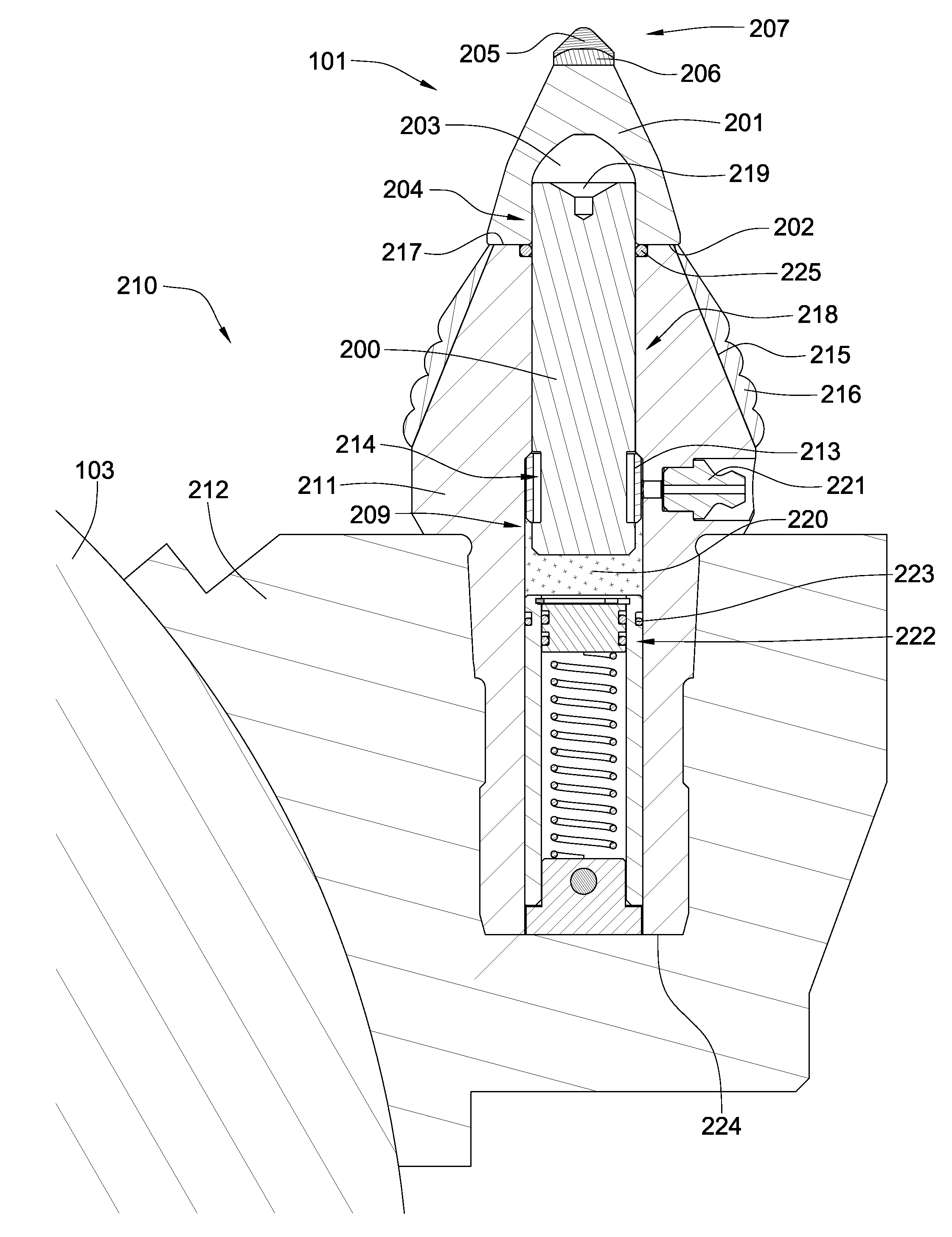

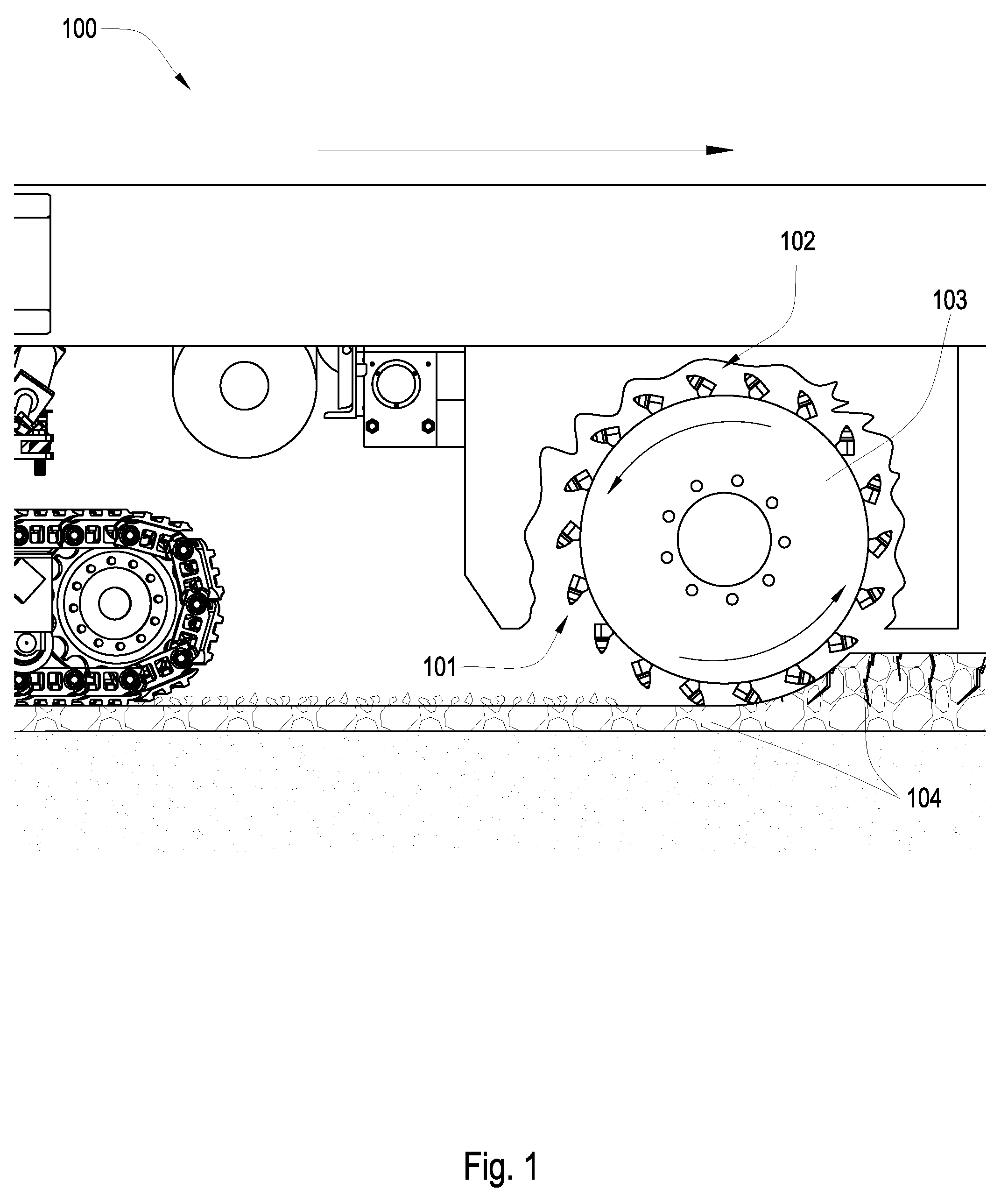

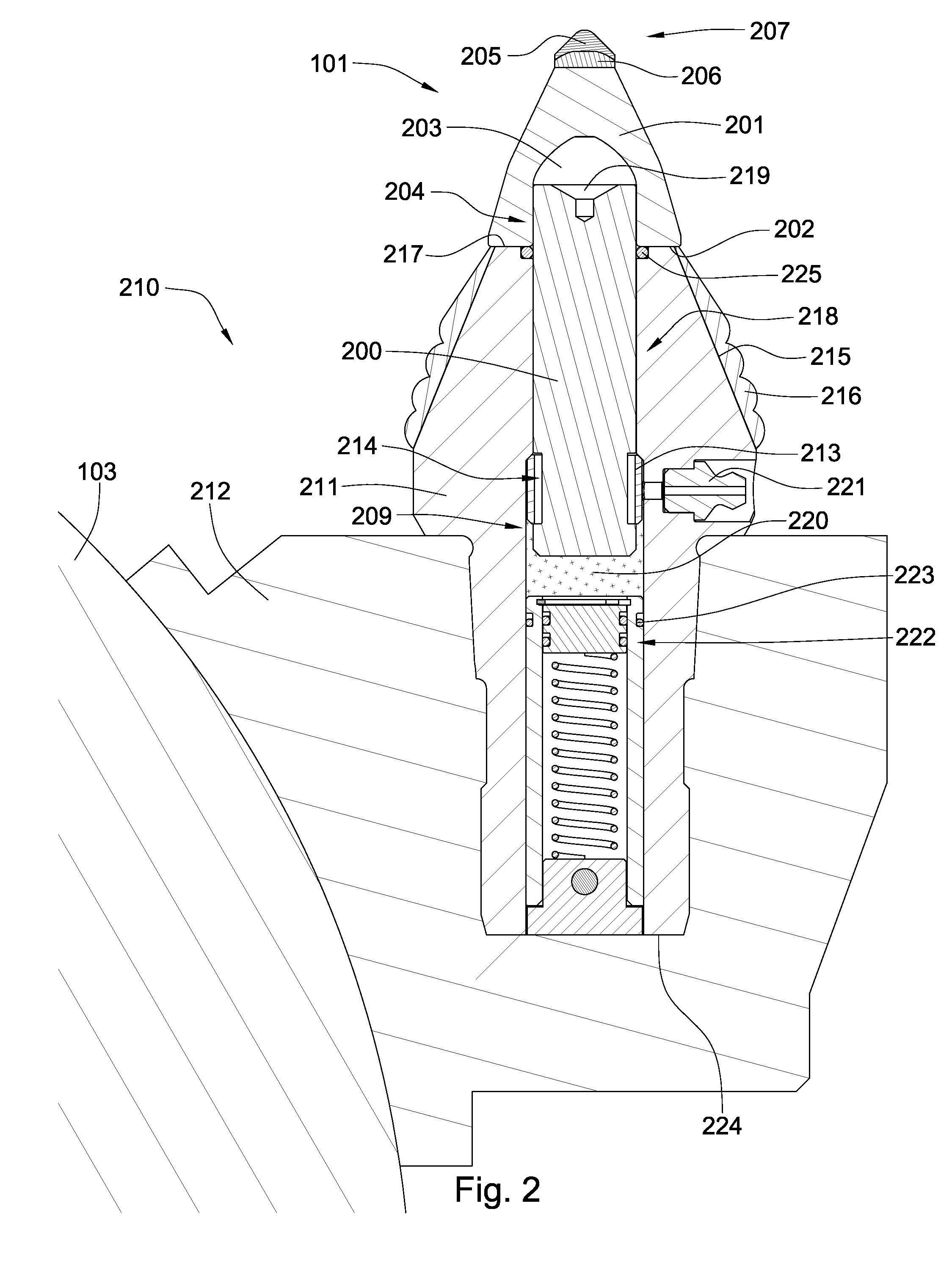

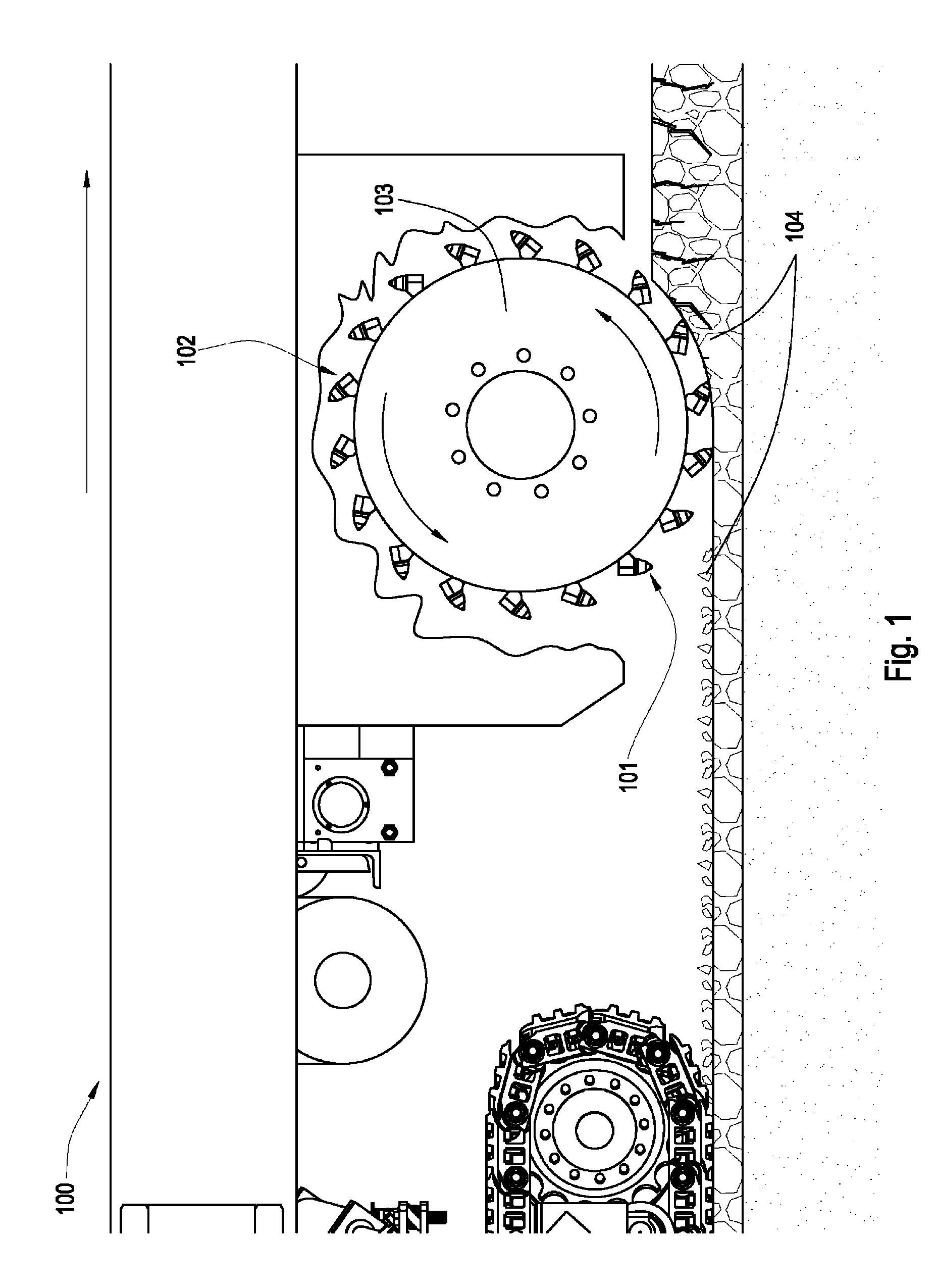

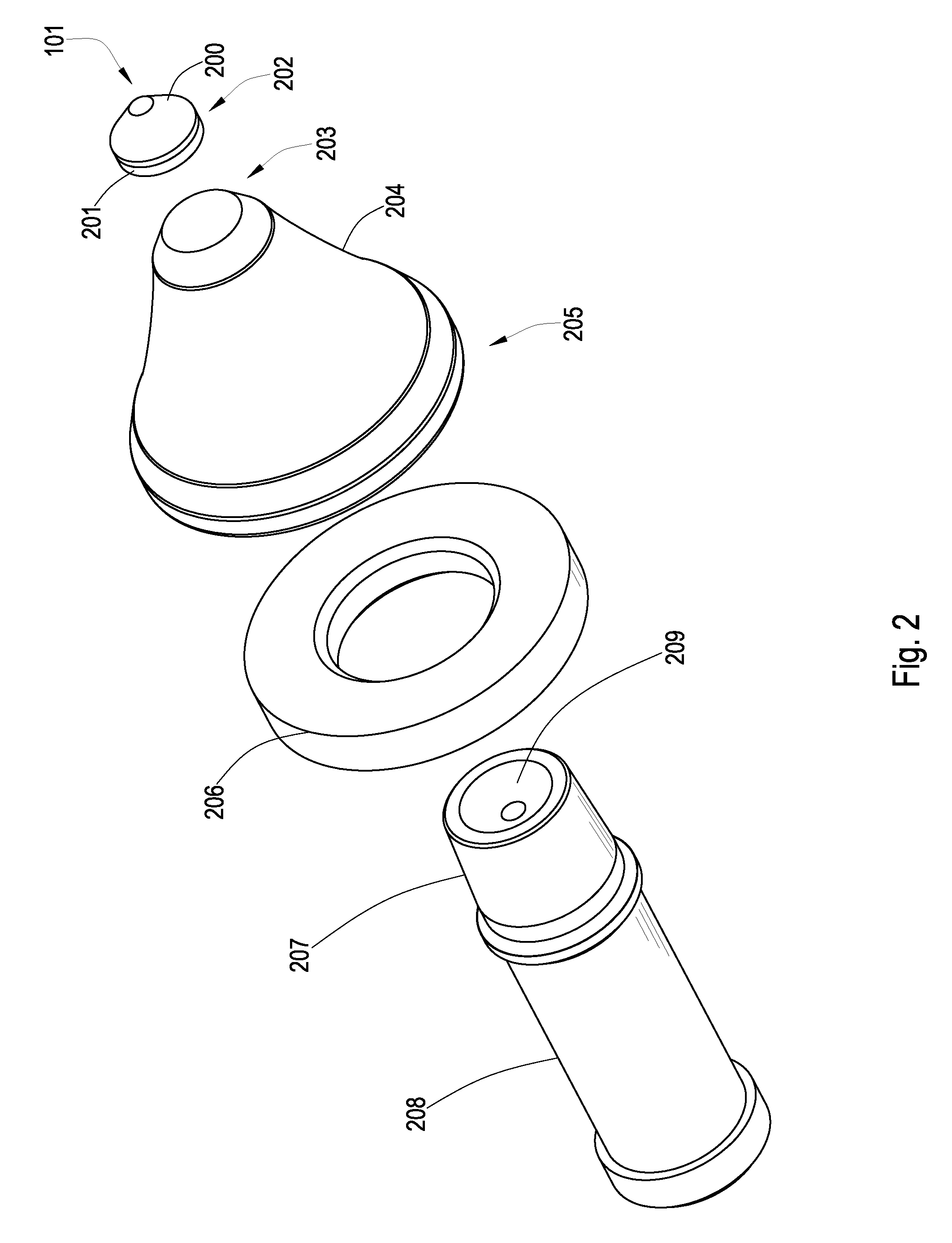

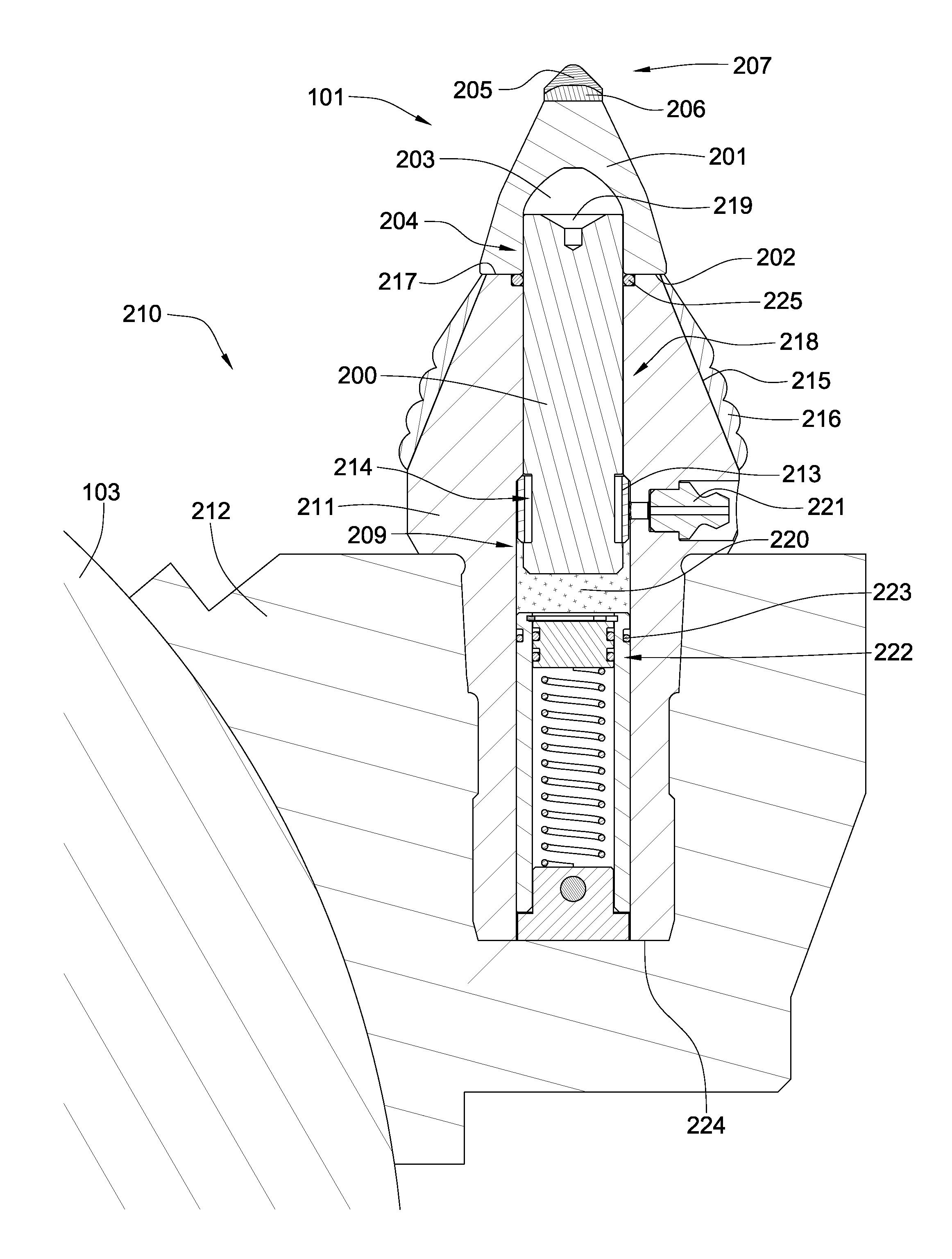

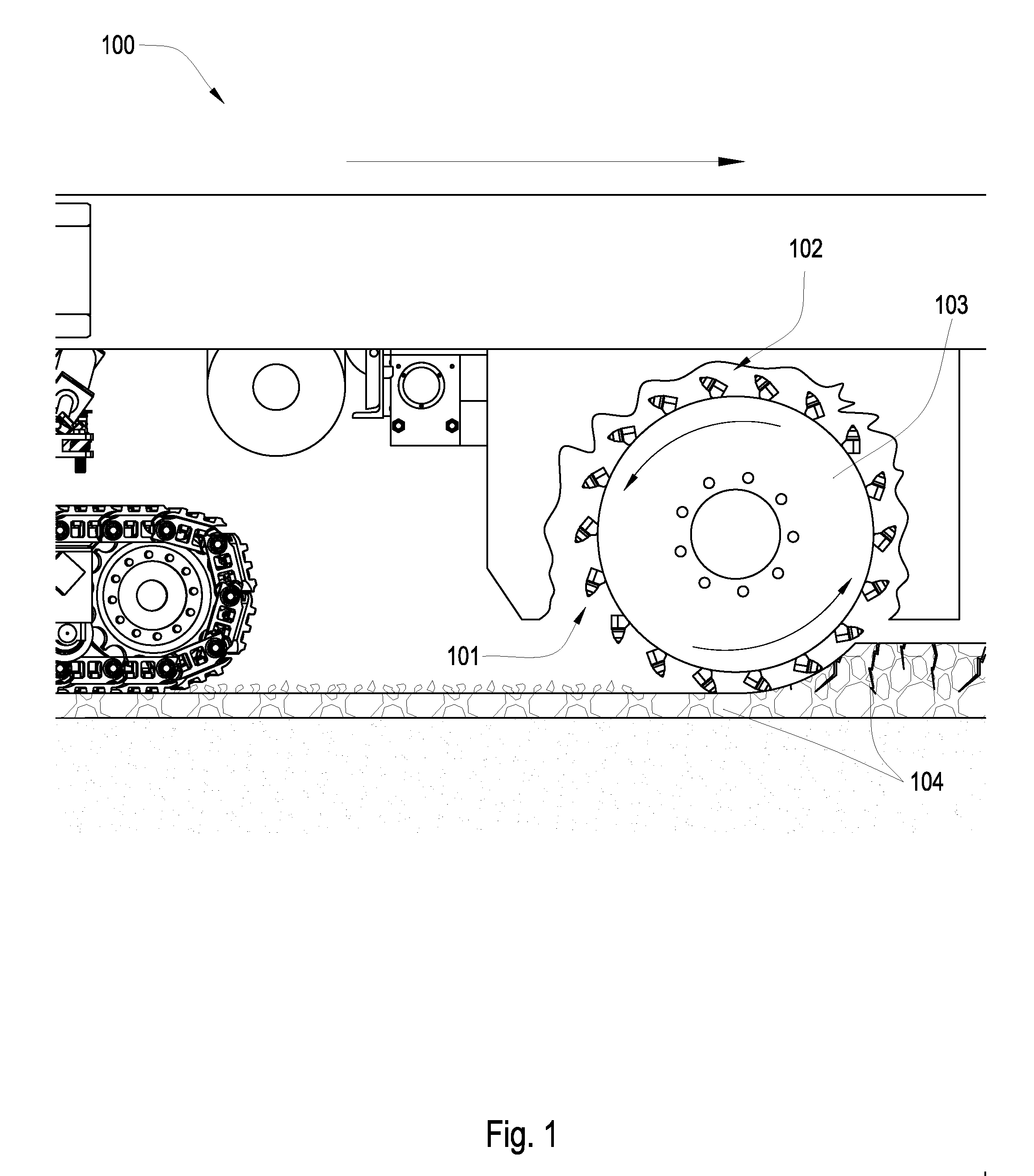

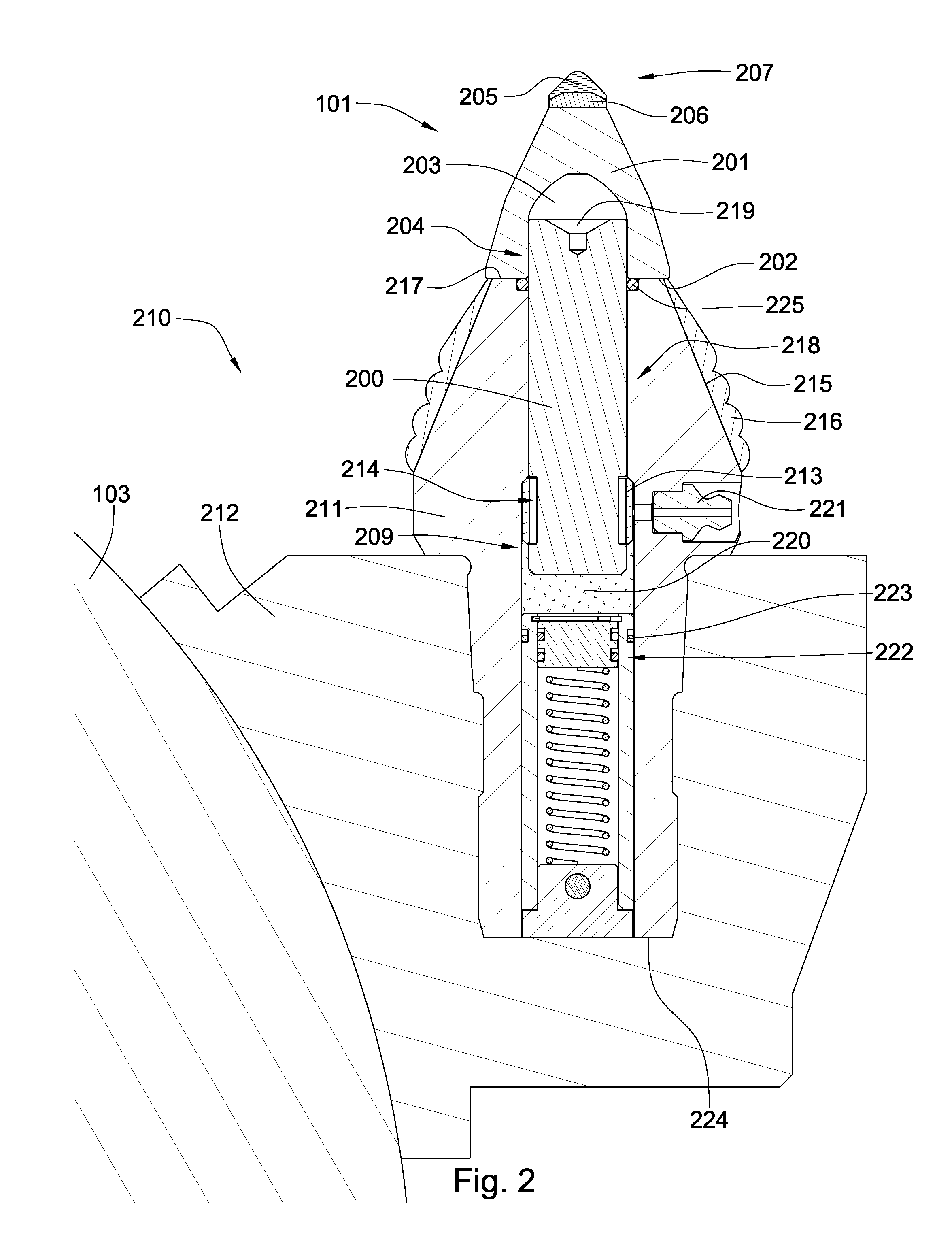

Carbide stem press fit into a steel body of a pick

In one aspect of the present invention, a high impact resistant tool, having a super hard material is bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide segment. A stem is formed in the base end of the carbide segment opposite the front end and the carbide stem is press fitted into bore of a steel body.

Owner:SCHLUMBERGER TECH CORP

Tool with a large volume of a superhard material

In one aspect of the invention, a tool has a wear-resistant base suitable for attachment to a driving mechanism and also a hard tip attached to an interfacial surface of the base. The tip has a first cemented metal carbide segment bonded to a superhard material at a non-planar interface. The tip has a height between 4 and 10 mm and also has a curved working surface opposite the interfacial surface. A volume of the superhard material is about 75% to 150% of a volume of the first cemented metal carbide segment.

Owner:SCHLUMBERGER TECH CORP

Non-rotating Pick with a Pressed in Carbide Segment

ActiveUS20080035383A1Improve impact resistanceDrill bitsSlitting machinesSuperhard materialCemented carbide

In one aspect of the present invention, a high impact resistant tool has a superhard material bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide segment. A stem formed in the base end of the carbide segment opposite the front end is press fit into a bore of a steel body. The steel body is rotationally fixed to a drum adapted to rotate about its axis.

Owner:SCHLUMBERGER TECH CORP

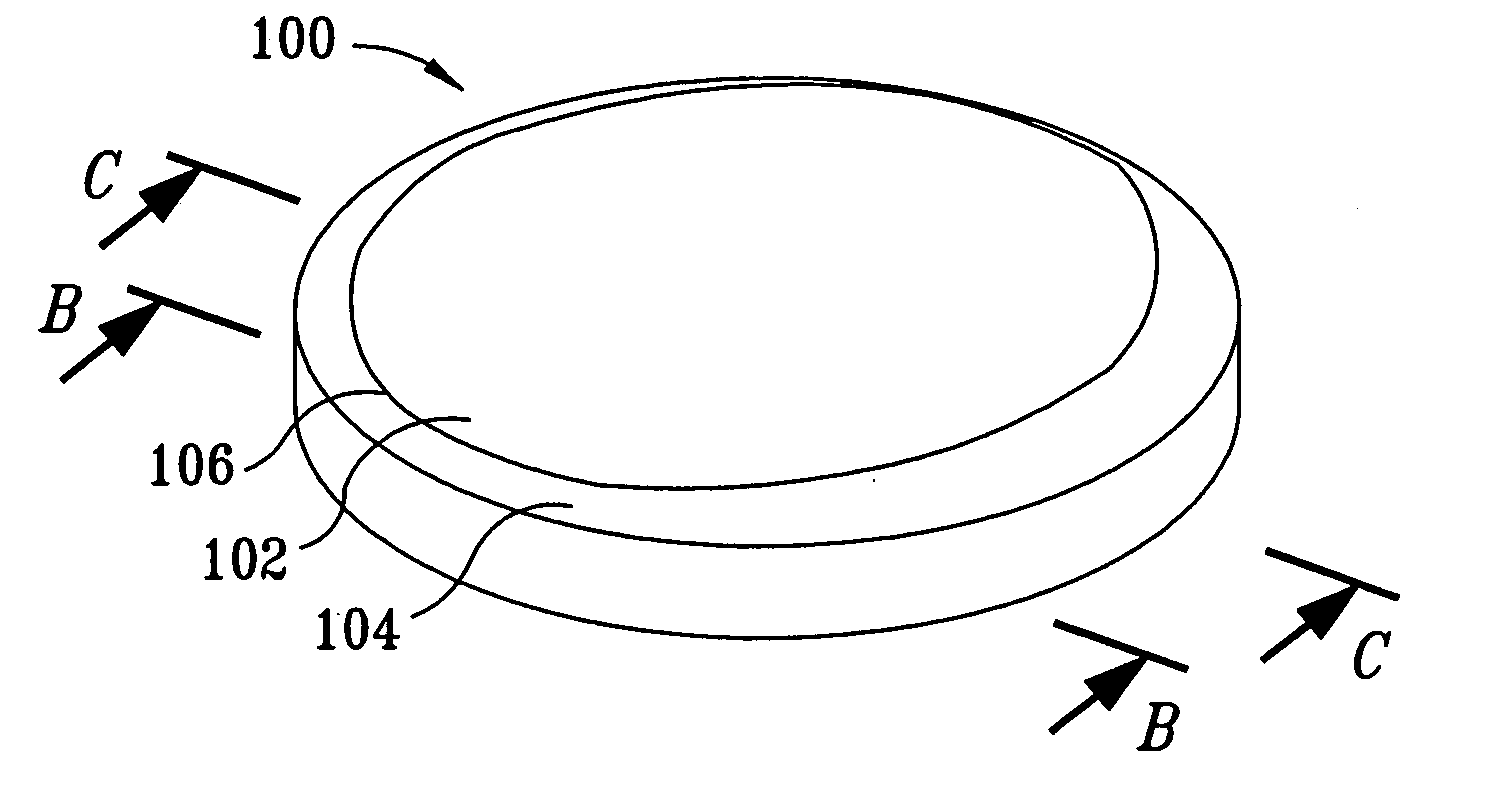

Layered polycrystalline diamond

In one aspect of the present invention, a high impact wear resistant tool has a superhard material bonded to a cemented metal carbide substrate at a non-planar interface. The superhard material has a thickness of at least 0.100 inch and forms an included angle of 35 to 55 degrees. The superhard material has a plurality of substantially distinct diamond layers. Each layer of the plurality of layers has a different catalyzing material concentration. A diamond layer adjacent the substrate of the superhard material has a higher catalyzing material concentration than a diamond layer at a distal end of the superhard material.

Owner:SCHLUMBERGER TECH CORP

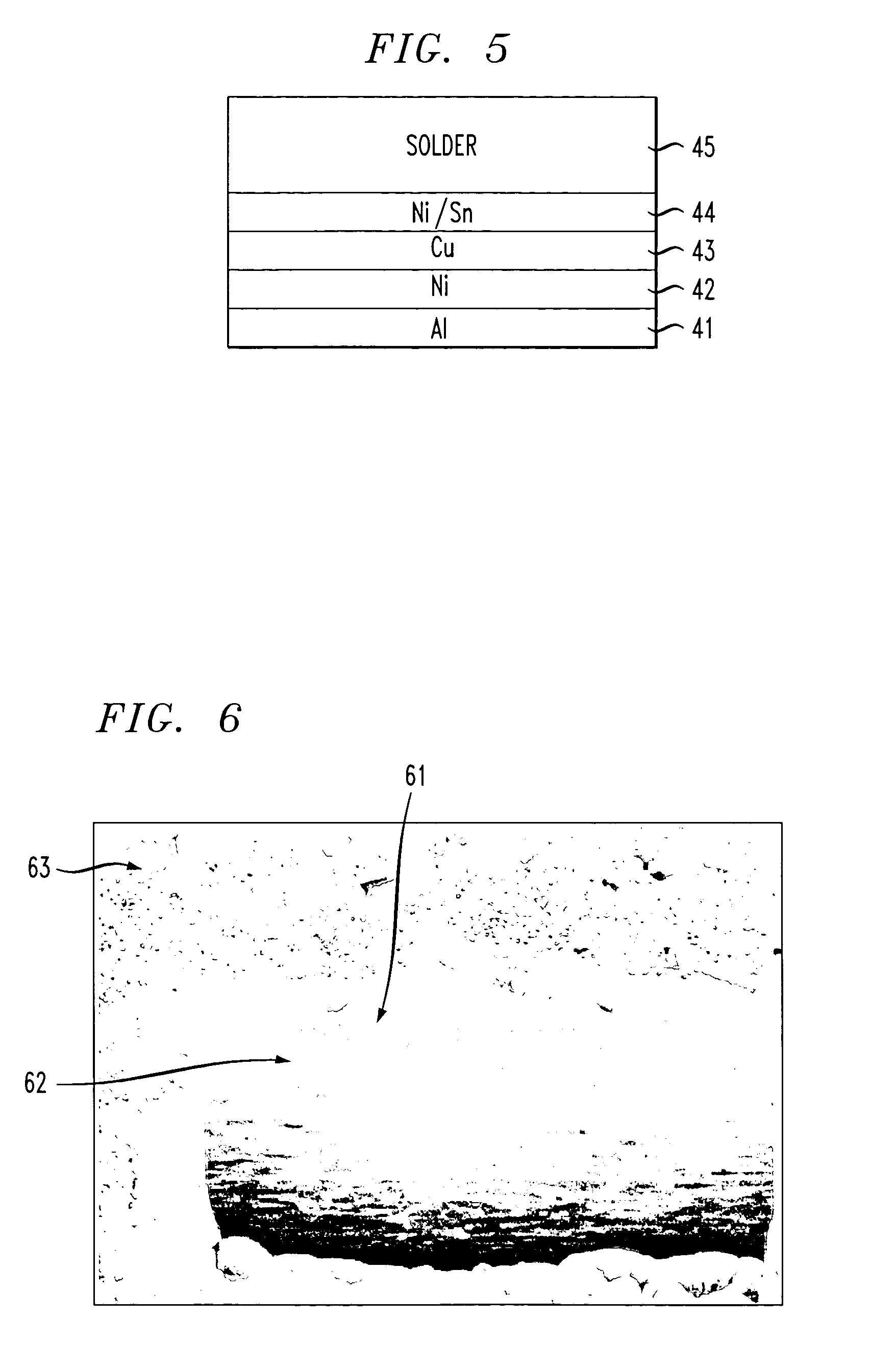

Whisker-free lead frames

InactiveUS20060068218A1Reduction tendencyStable mechanical propertiesMetallic material coating processesPrinted circuit manufactureCopperLead frame

The electrical and mechanical properties of structures such as lead frames and other electrical / electronic devices containing, during processing, copper / tin interfaces are improved by introduction of nickel to such interface. Typically, a weight percentage of nickel to tin in the range 1 to 12 weight percent yields upon melting of the tin, an intermetallic compound with essentially no occluded, unbound tin. Thus undesirable anomalous structures such as tin needles and substantially non-planar interface compositions are avoided. Advantageously a nickel / tin / copper intermetallic interface that is substantially planar is formed in the substantial absence of needle-like tin structures.

Owner:AGERE SYST INC +1

Pick assembly

A high impact resistant pick in a holder having a super hard material bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide bolster. A bore is formed in a base end of the carbide bolster generally opposed to the front end. A steel shank being fitted into the bore of the bolster at a bolster end of the shank, and a portion of the shank is disposed within a bore of the holder at a holder end of the shank.

Owner:SCHLUMBERGER TECH CORP

Non-rotating pick with a pressed in carbide segment

Owner:SCHLUMBERGER TECH CORP

Pick Assembly

A high impact resistant pick in a holder having a super hard material bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide bolster. A bore is formed in a base end of the carbide bolster generally opposed to the front end. A steel shank being fitted into the bore of the bolster at a bolster end of the shank, and a portion of the shank is disposed within a bore of the holder at a holder end of the shank.

Owner:SCHLUMBERGER TECH CORP

Braze material for an attack tool

In one aspect of the invention, a tool has a wear-resistant base suitable for attachment to a driving mechanism and also a hard tip attached to an interfacial surface of the base. The tip has a first cemented metal carbide segment bonded to a superhard material at a non-planar interface. The tip has a height between 4 and 10 mm and also has a curved working surface opposite the interfacial surface. A volume of the superhard material is about 75% to 150% of a volume of the first cemented metal carbide segment.

Owner:SCHLUMBERGER TECH CORP

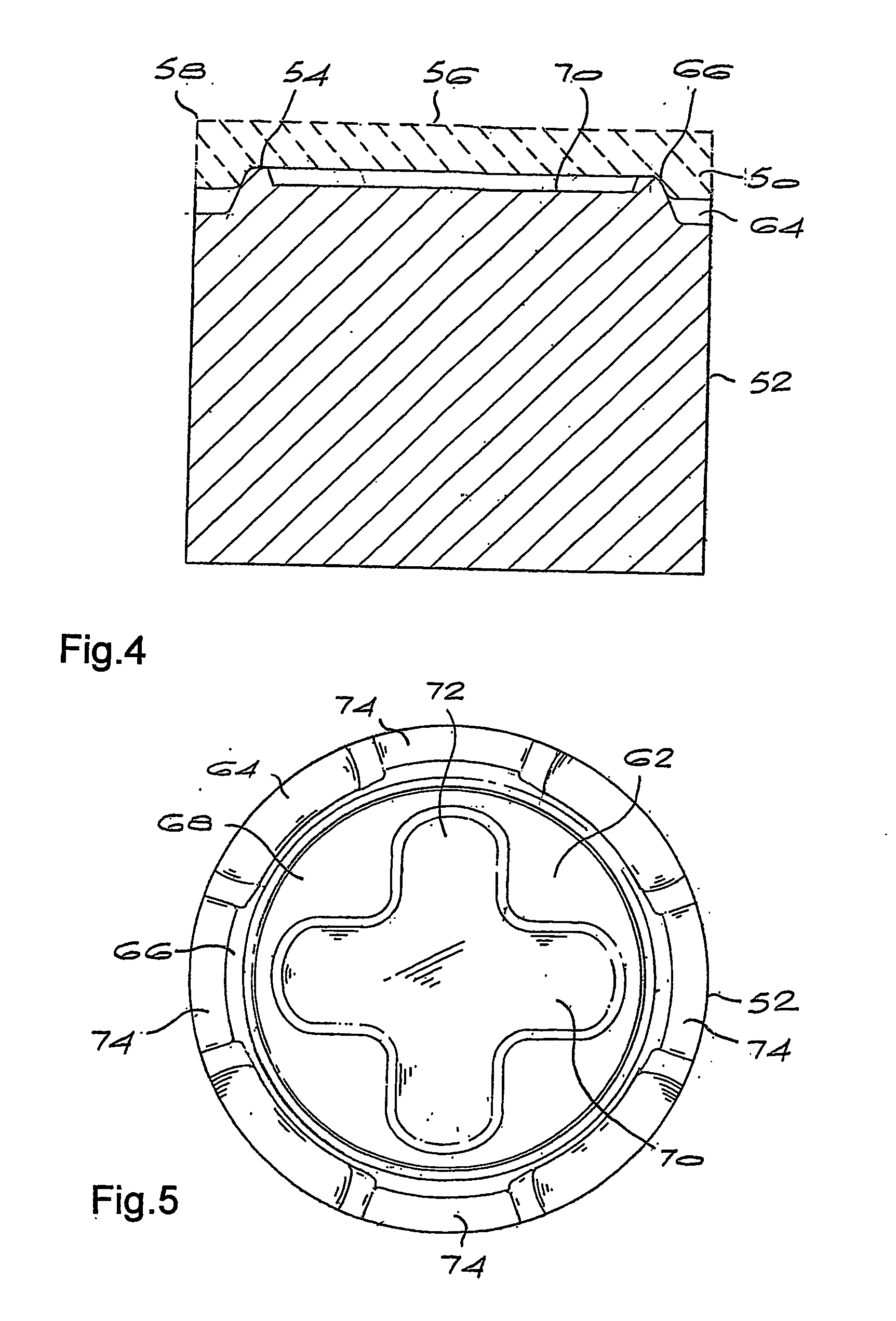

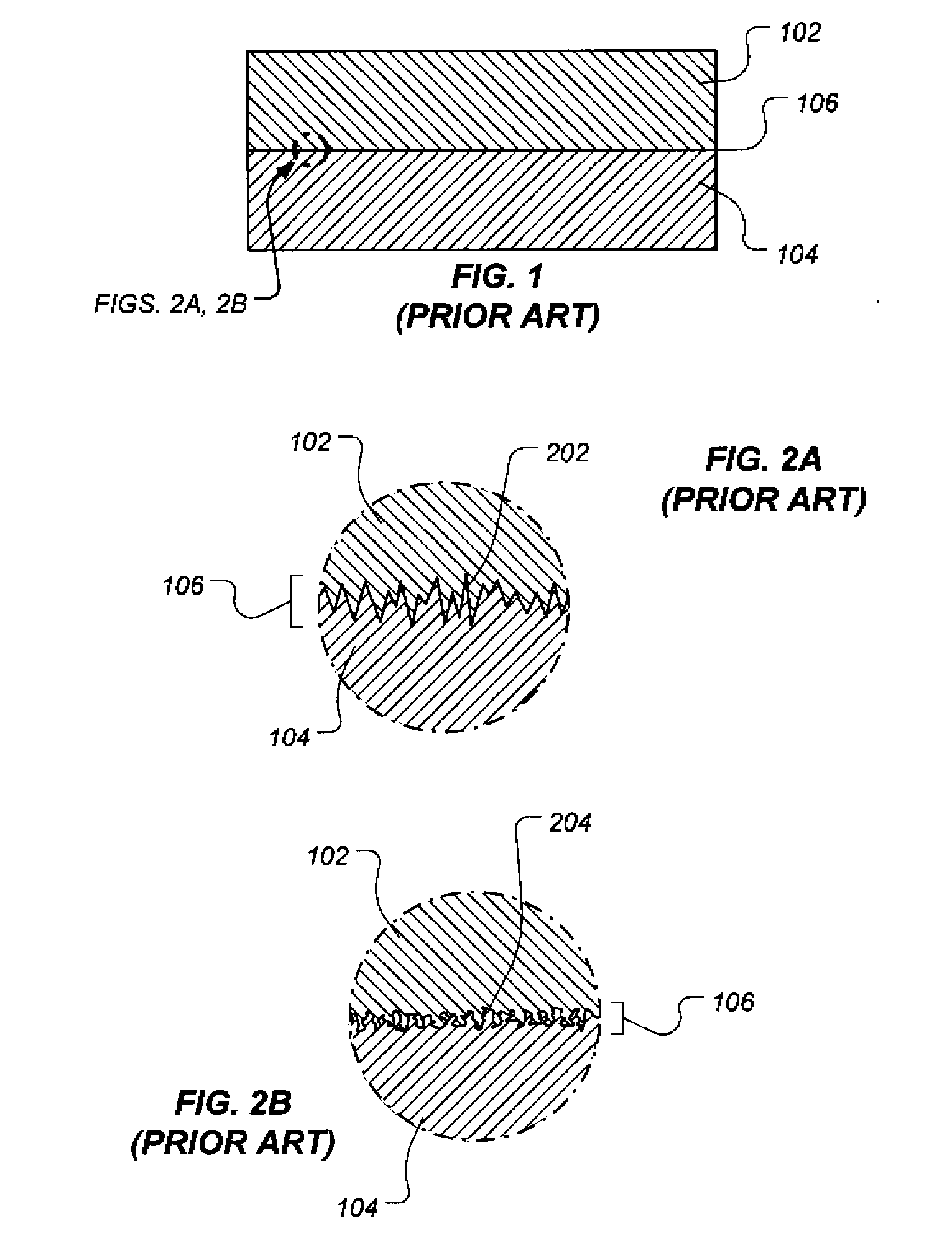

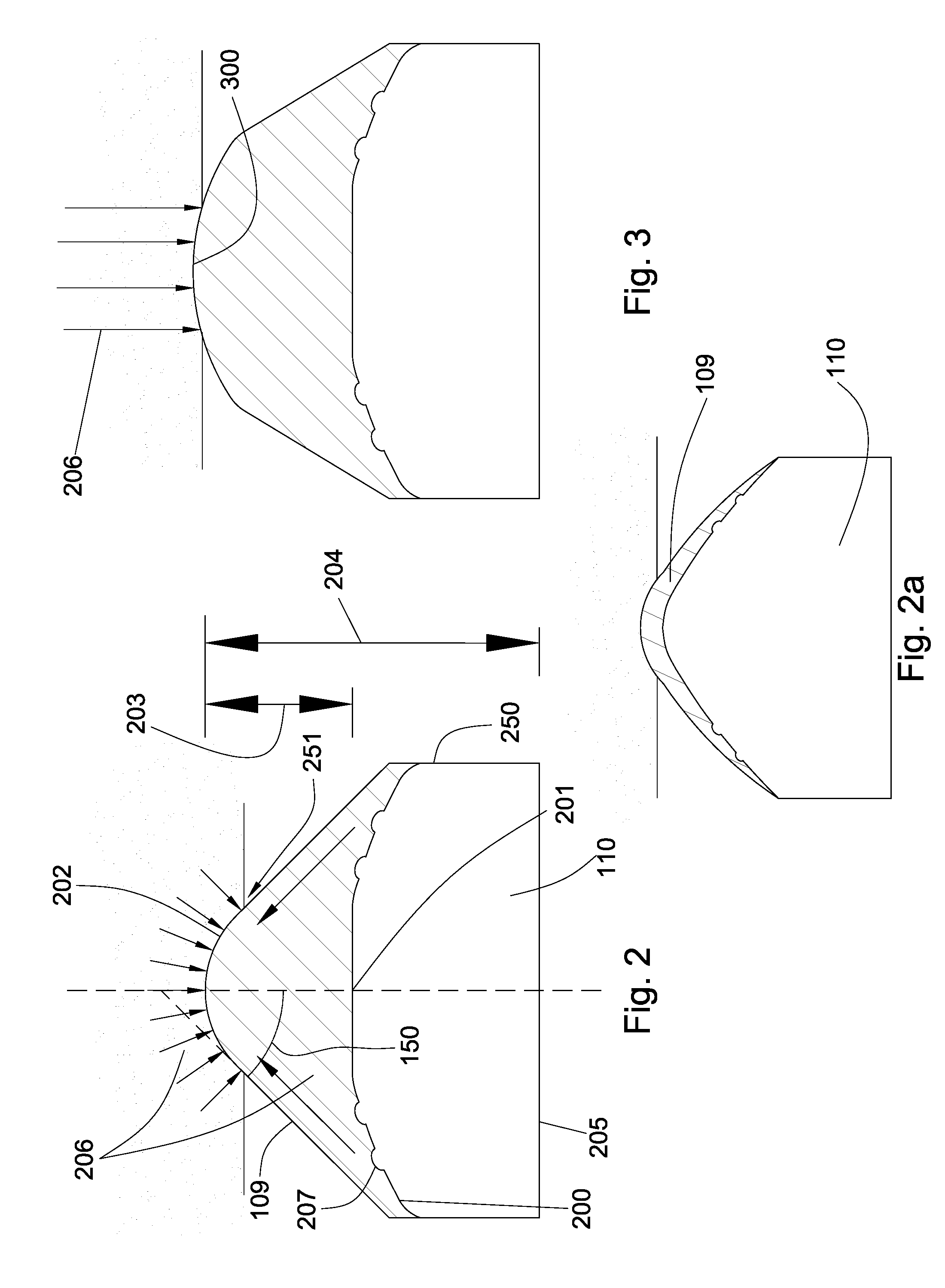

Cutter having shaped working surface with varying edge chamfer

ActiveUS7726420B2Reduce certain adverse consequenceIncreasing the thicknessDrill bitsConstructionsWell drillingEngineering

A cutter for a drill bit used for drilling wells in a geological formation includes an ultra hard working surface and a chamfer along an edge of the working surface, wherein the chamfer has a varied geometry along the edge. The average geometry of the chamfer varies with cutting depth. A depression in the shaped working surface is oriented with the varied chamfer and facilitates forming the varied chamfer. A non-planar interface has depressions oriented with depressions in the shaped working surface to provide support to loads on the working surface of the cutter when used.

Owner:SMITH INT INC

Thick Pointed Superhard Material

In one aspect of the invention, a high impact resistant tool having a superhard bonded to a cemented metal carbide substrate at a non-planar interface. The superhard material has a substantially pointed geometry with a sharp apex having 0.050 to 0.125 inch radius. The superhard material also has a 0.100 to 0.500 inch thickness from the apex to the non-planar interface.

Owner:SCHLUMBERGER TECH CORP

Pick assembly

Owner:SCHLUMBERGER TECH CORP

Tapered bore in a pick

In one aspect of the present invention, a high impact resistant excavation pick having a super hard material is bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide frustum. A tapered bore is formed in the base end of the carbide frustum opposite the front end and a steel shank with a tapered interface is fitted into the tapered bore.

Owner:SCHLUMBERGER TECH CORP

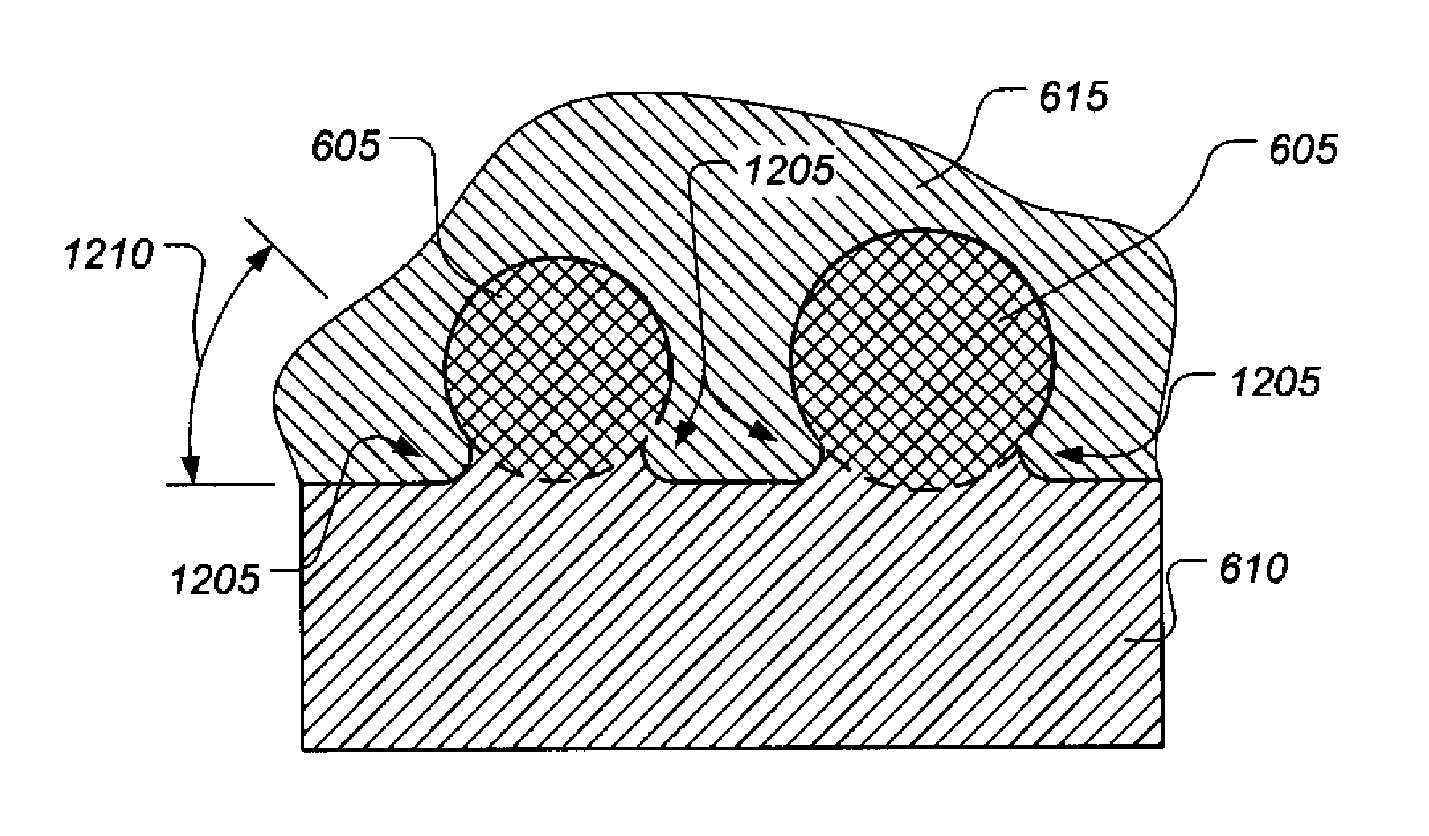

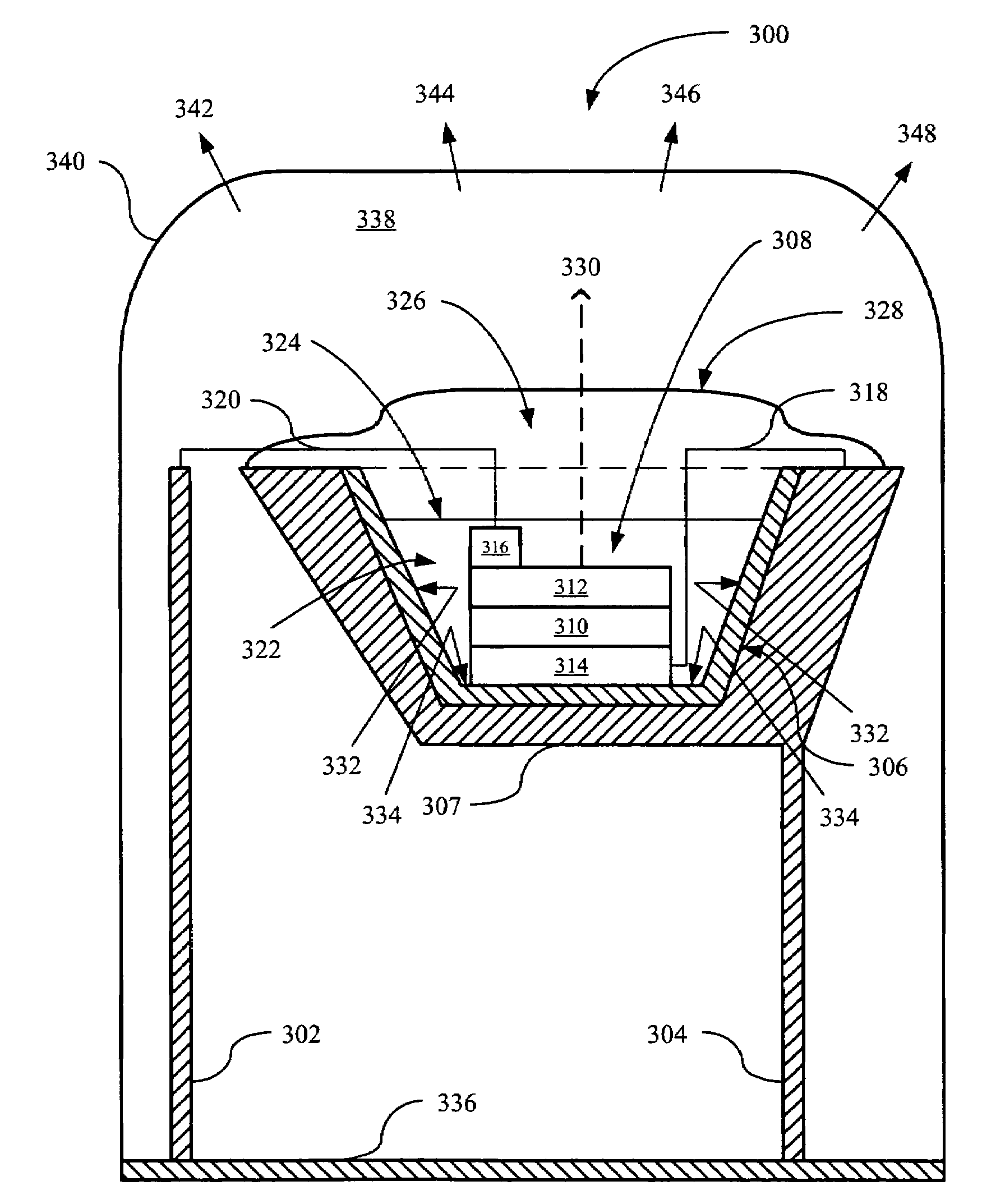

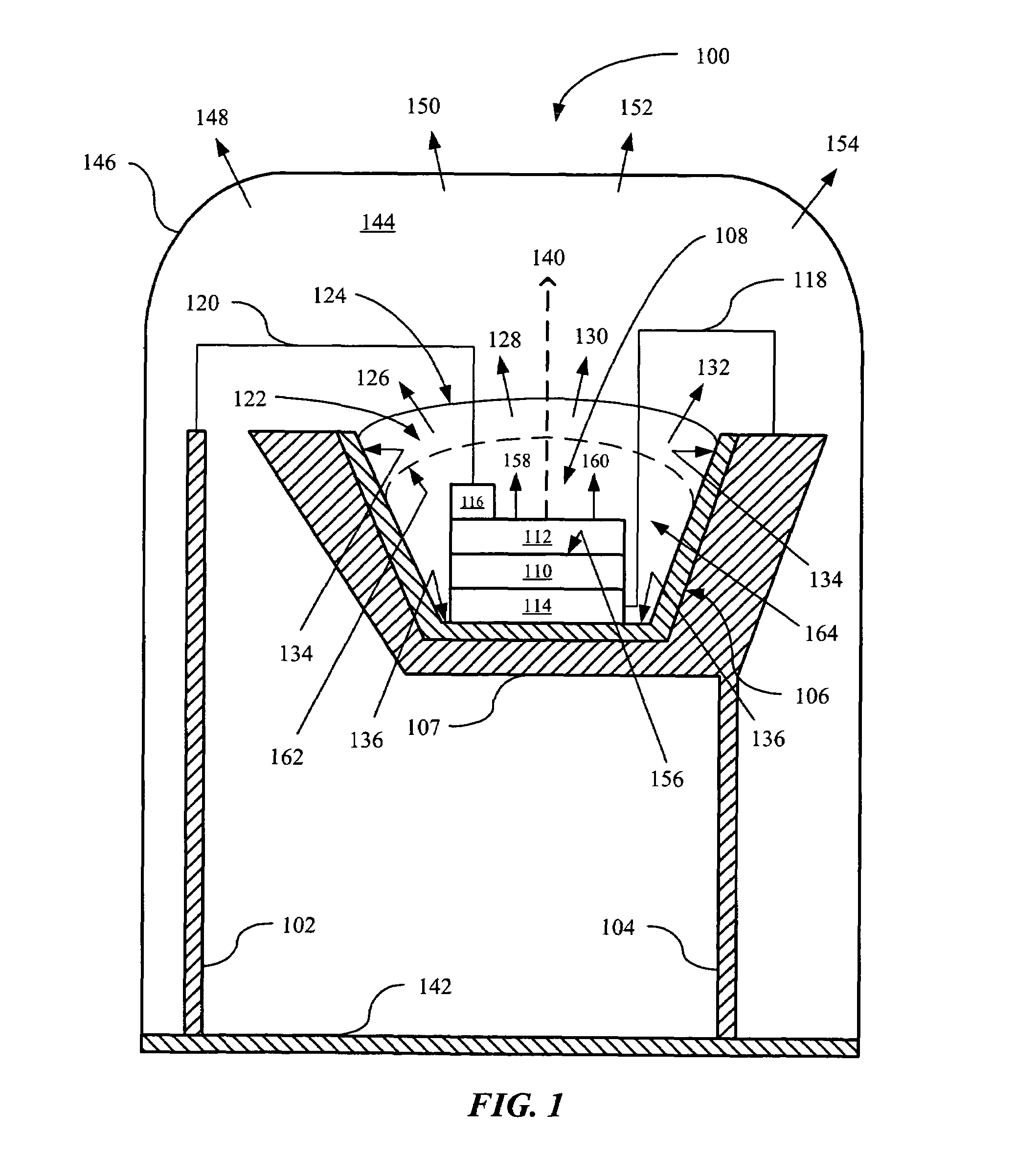

Phosphor-converted LED devices having improved light distribution uniformity

ActiveUS7329907B2Semiconductor/solid-state device detailsSolid-state devicesPhosphorDistribution uniformity

Owner:DOCUMENT SECURITY SYST

Pick with carbide cap

A high-impact resistant pick having a superhard material bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide bolster. A bore formed in a base end of the carbide bolster is generally opposed to the front end. A steel body has a shaft extending distally from a shelf, and which shaft is fitted into the bore of the bolster at an interface. A shank adapted for connection to a driving mechanism extends proximally from the steel body opposite the shaft. A washer is disposed intermediate the base end of the carbide bolster and the shelf of the steel body.

Owner:SCHLUMBERGER TECH CORP

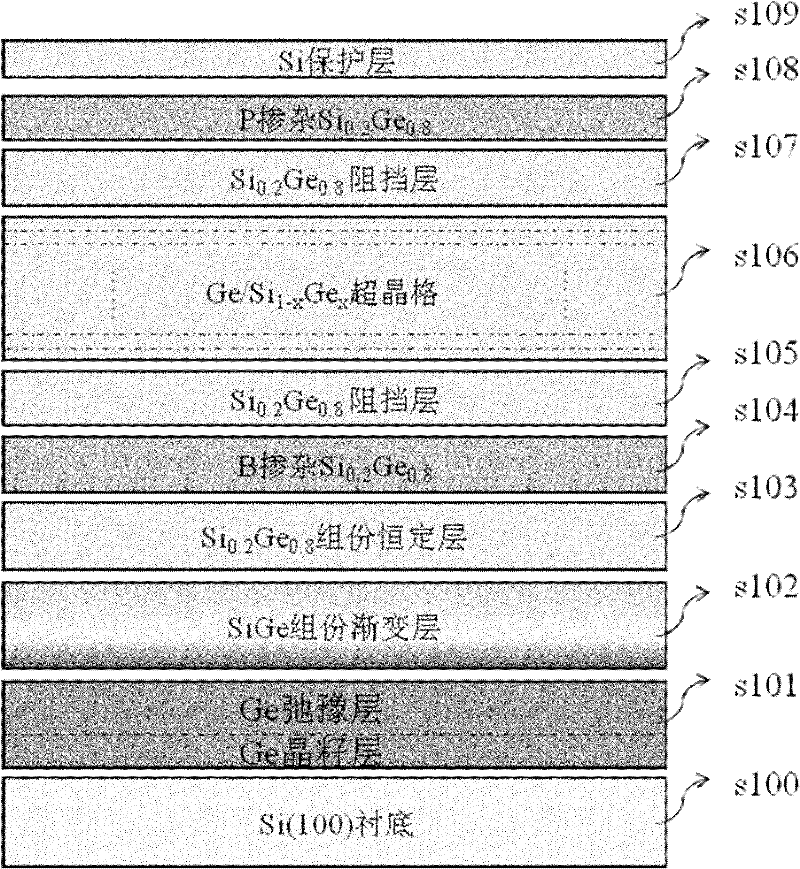

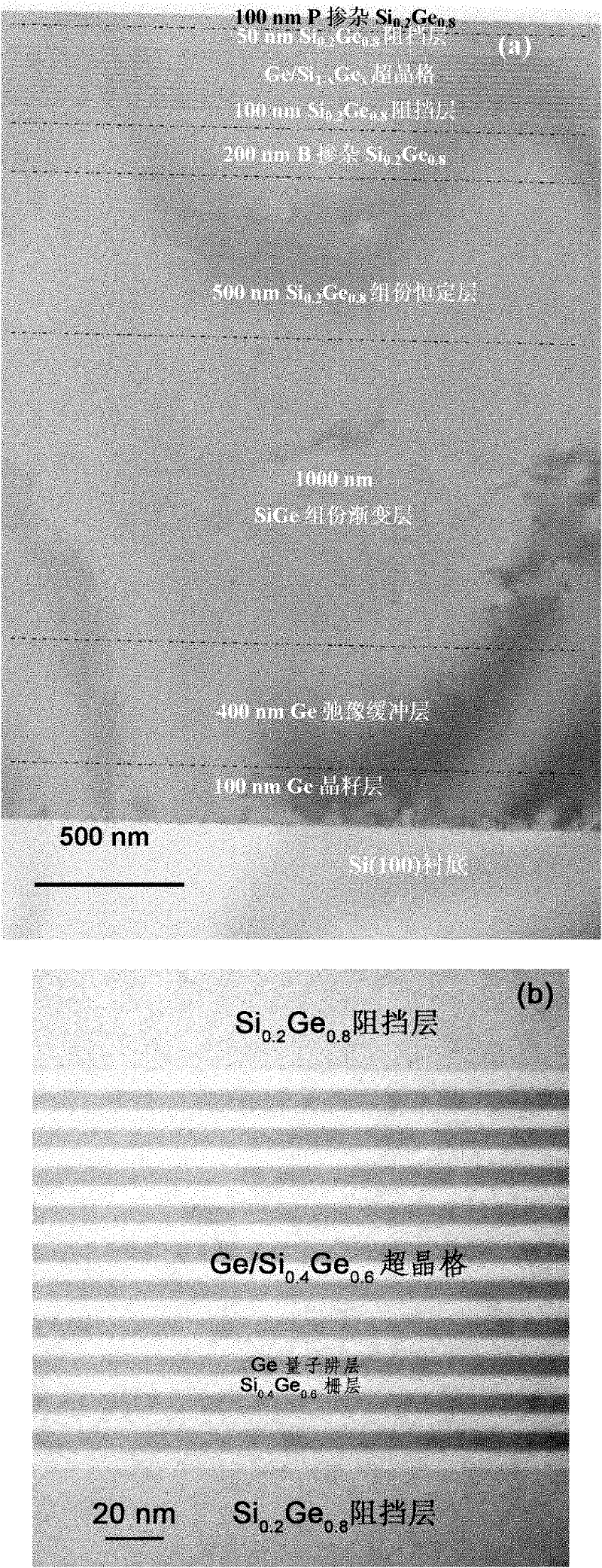

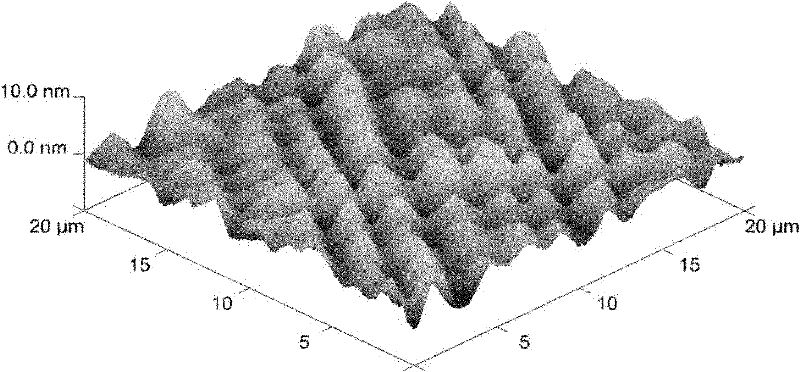

High quality strain Ge/SiGe super-lattice structure and preparation method thereof

InactiveCN102162137AHigh Ge contentReduce dislocation densityPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsReduced pressure chemical vapor deposition

The invention belongs to the technical field of semiconductor materials, and relates to a Ge / Si1-xGex super-lattice structure and preparation thereof. The high quality strain Ge / Si1-xGex super-lattice structure comprises a Si substrate, and a Si0.2Ge0.8 virtual substrate layer, a B-doped Si0.2Ge0.8 epitaxial layer, a Si0.2Ge0.8 blocking layer, a Ge / Si1-xGex super-lattice layer, a P-doped Si0.2Ge0.8 epitaxial layer, a Si0.2Ge0.8 blocking layer and a Si protective layer sequentially and epitaxially grown on the Si substrate, wherein x is more than or equal to 0.6 and less than or equal to 0.7. The epitaxial layers are sequentially grown on the Si substrate by adopting a reduced pressure chemical vapor deposition method; the obtained super-lattice structure has the properties of low dislocation defect density, low thickness and flat interface / surface, and the Ge / Si1-xGex super-lattice is in a strain state; and the super-lattice structure has high quality and is particularly suitable for manufacturing silicon-based laser devices and waveguide modulators.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Impact tool

Owner:SCHLUMBERGER TECH CORP

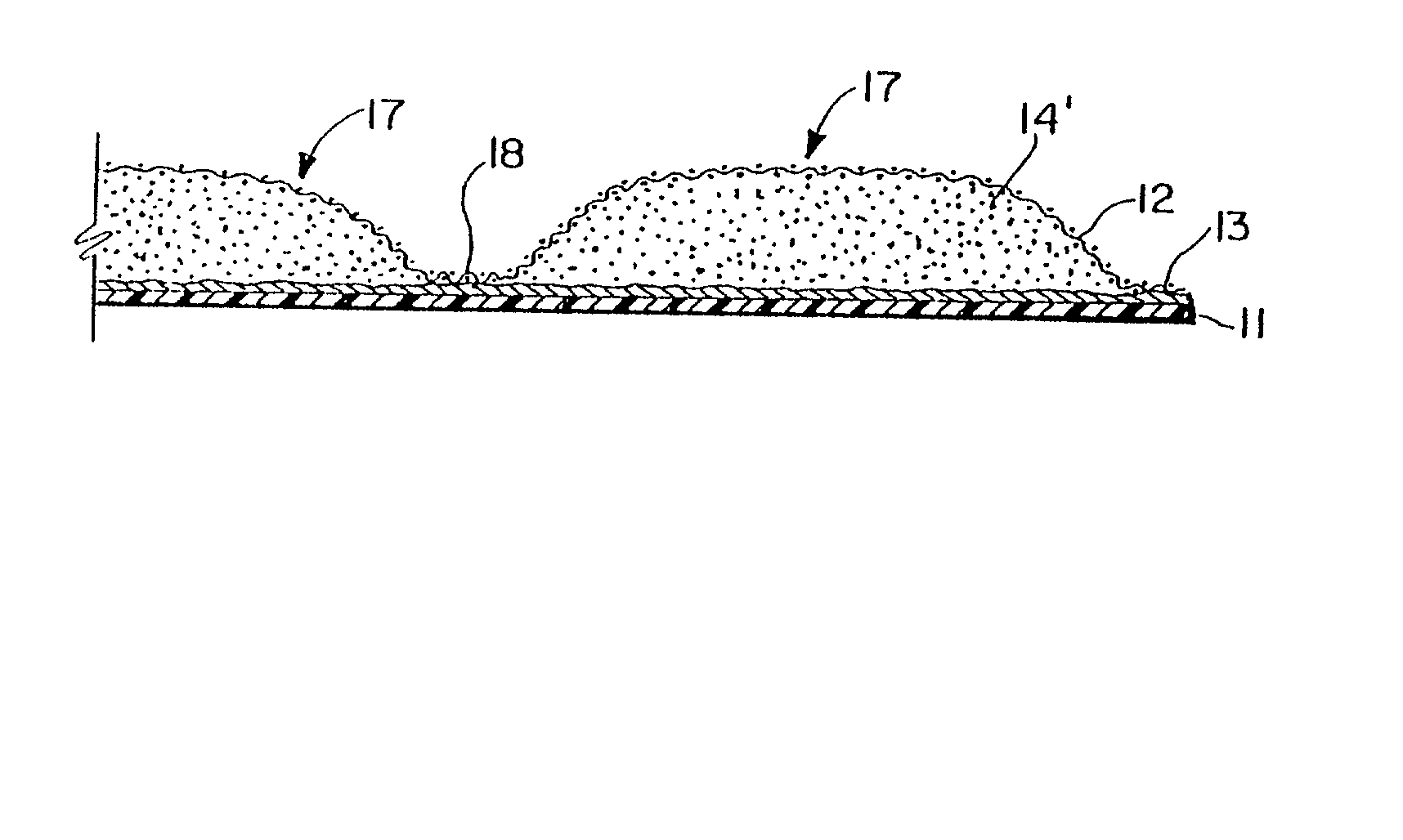

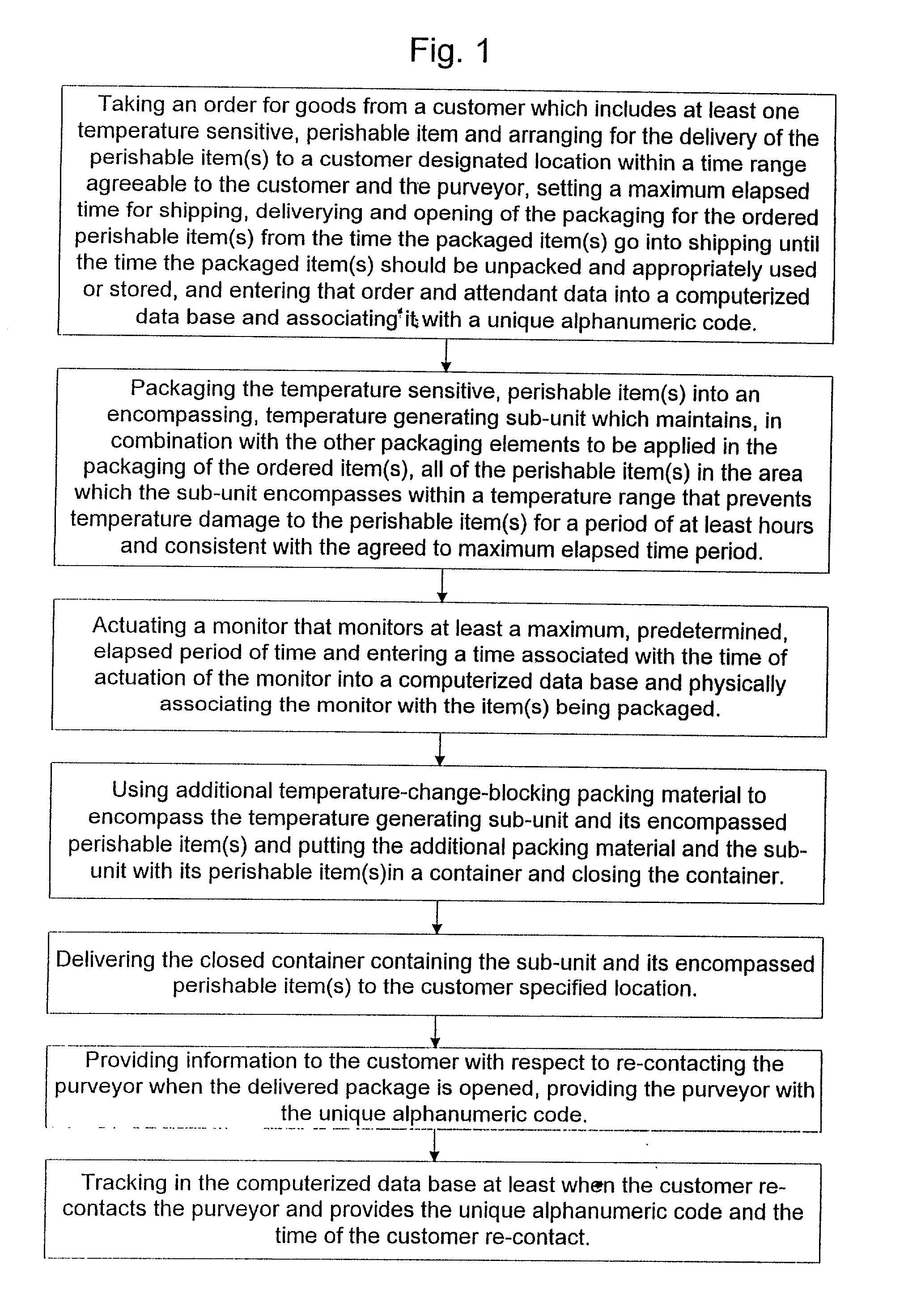

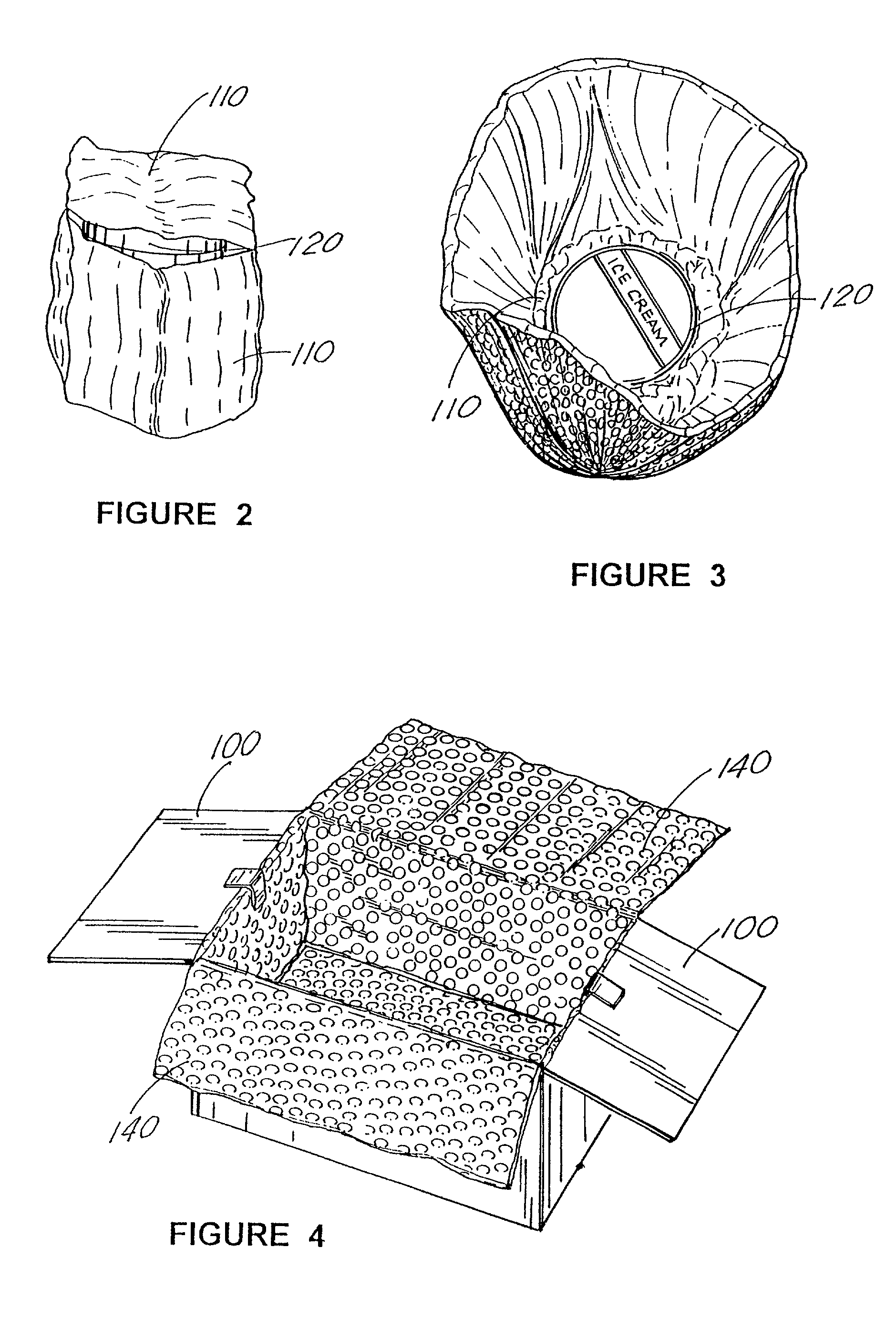

Insulating packaging material and related packaging system

InactiveUS20030087051A1Easy entryTransfer delaySynthetic resin layered productsPackaging foodstuffsCardboardNatural state

Insulating packaging material is wrapped or otherwise positioned around the typically temperature sensitive product, with the packing material including, alternatively, 1 ply (FIG. 22; metallized plastic film), 2 ply (FIGS. 23 & 24) and 3 ply (FIG. 25) material, in which some of the 2 ply & 3 ply embodiments include a layer of bubble wrap material having its bubble side placed or laminated against the flat side of the adjacent ply, which adjacent ply can be, for example, a mettalized plastic film or a foam layer or both layers can be included. With such a bubble side arrangement, multitudinous air pockets are formed between the bubbles of the bubble wrap and the other ply's typically flat interfacing surface. A separate layer of bubble wrap also preferably is placed about the interior of the box with its bubble side placed against the interior flat surfaces of the box, with the bubbles forming air pockets with the flat sides, further enhancing the insulating properties of the packaging for the goods. An exemplary system for delivering perishable groceries (120 / 120'), including a corrugated cardboard or other type box (100); a source of cold (or heat as needed) maintaining the temperature inside the box within a desired temperature range for hours or days, using an all encompassing pouch of packet material (110 / 10), used individually (FIGS. 2 & 3) or collectively (FIGS. 5 & 6), with each packet (17) containing a super-absorbent polymer (14, FIG. 12) which is hydrated (14', FIG. 12A) and then either frozen (e.g., in a freezer) or heated (e.g., in a microwave), without producing moisture as the polymer returns to its natural state; a protective cover (130) protecting the box and its contents from heat radiation (e.g., sunlight).

Owner:THERMAFREEZE PRODS CORP

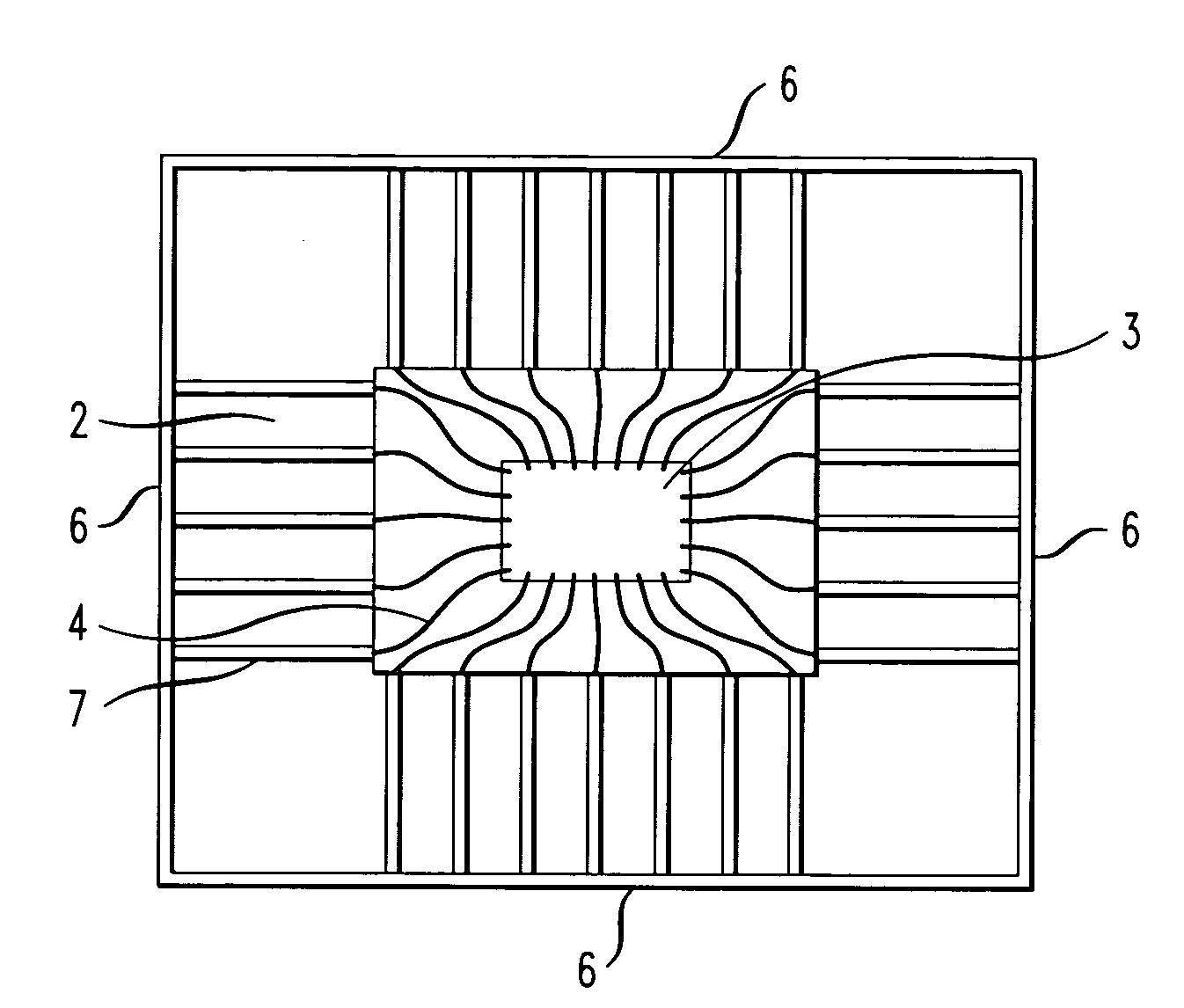

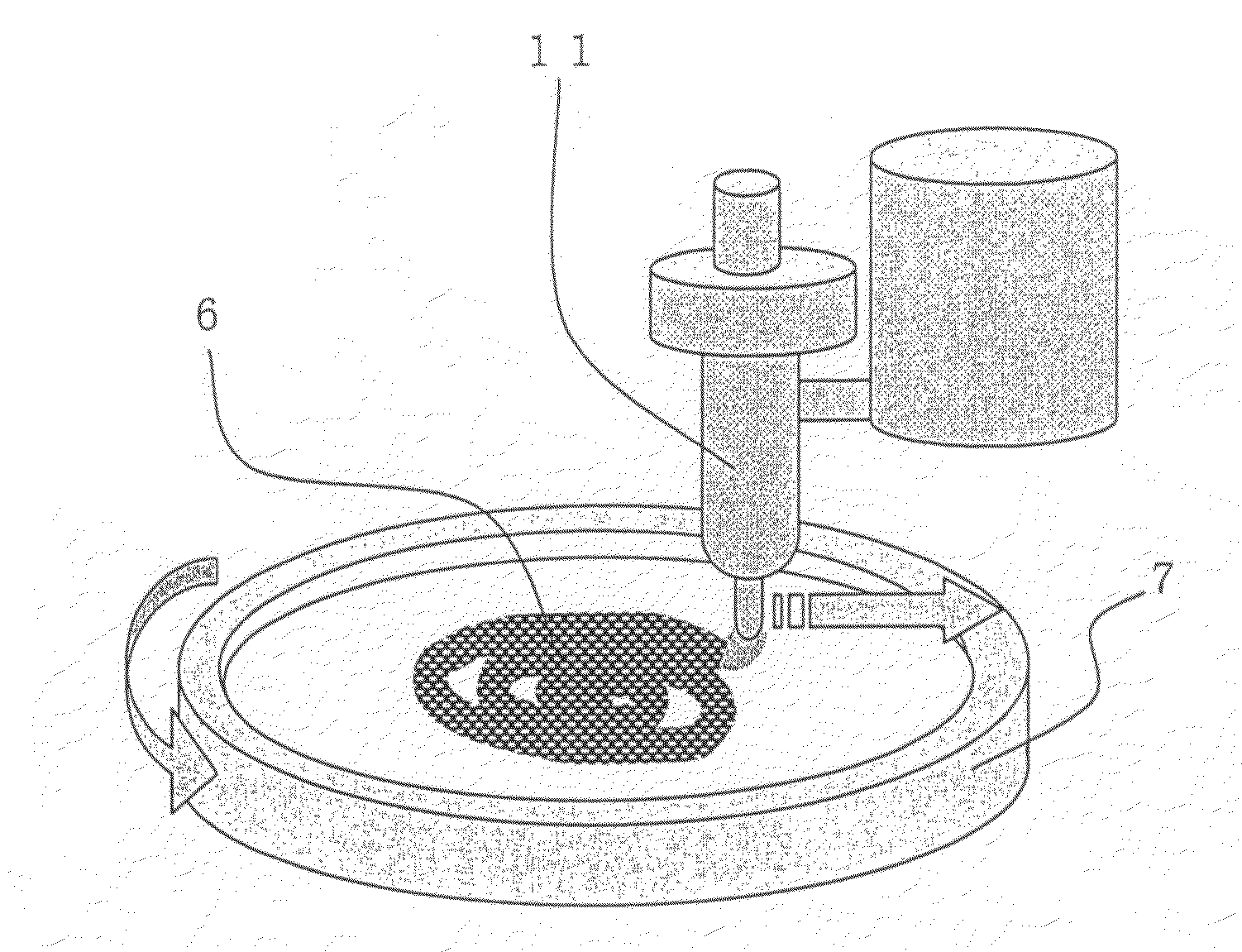

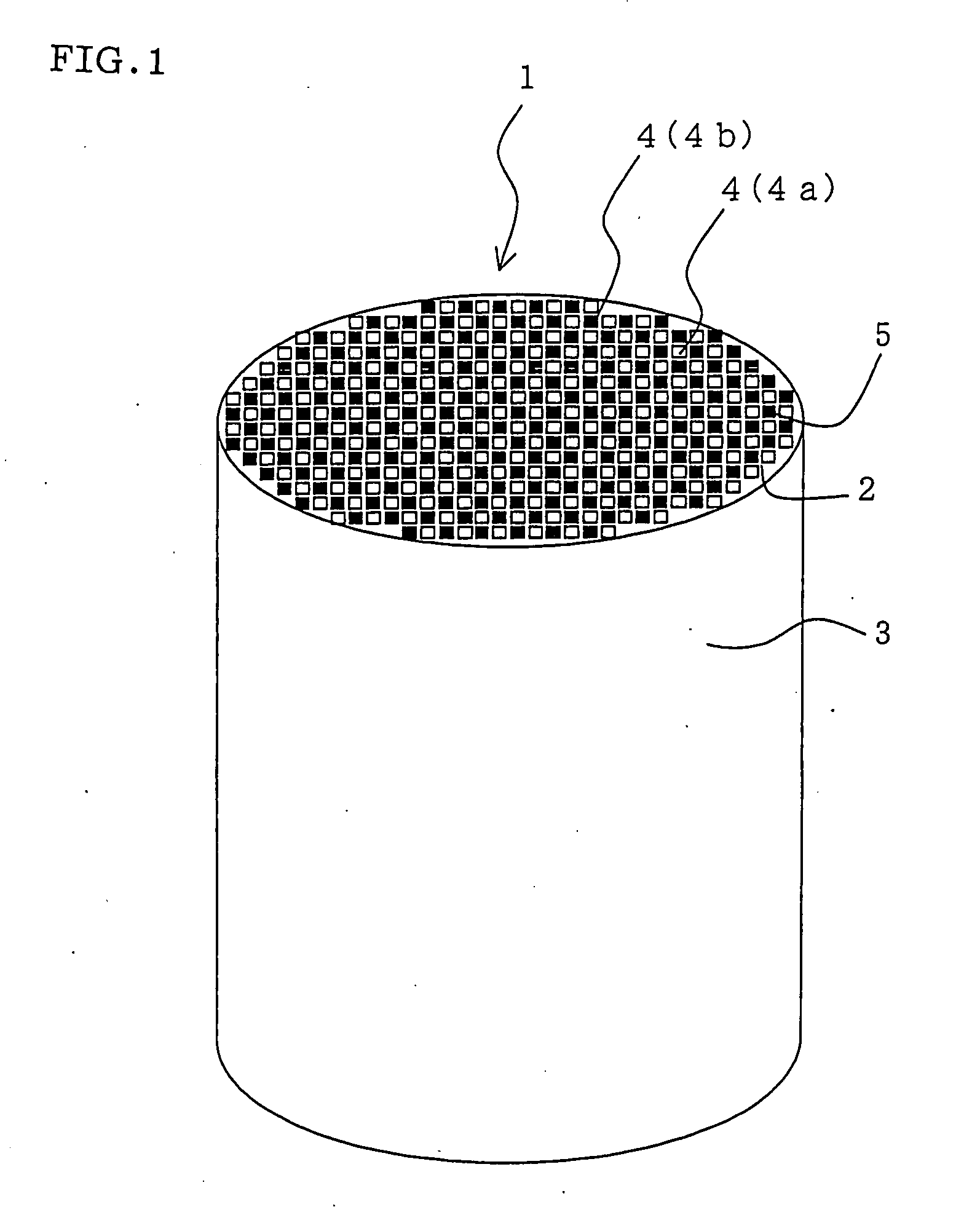

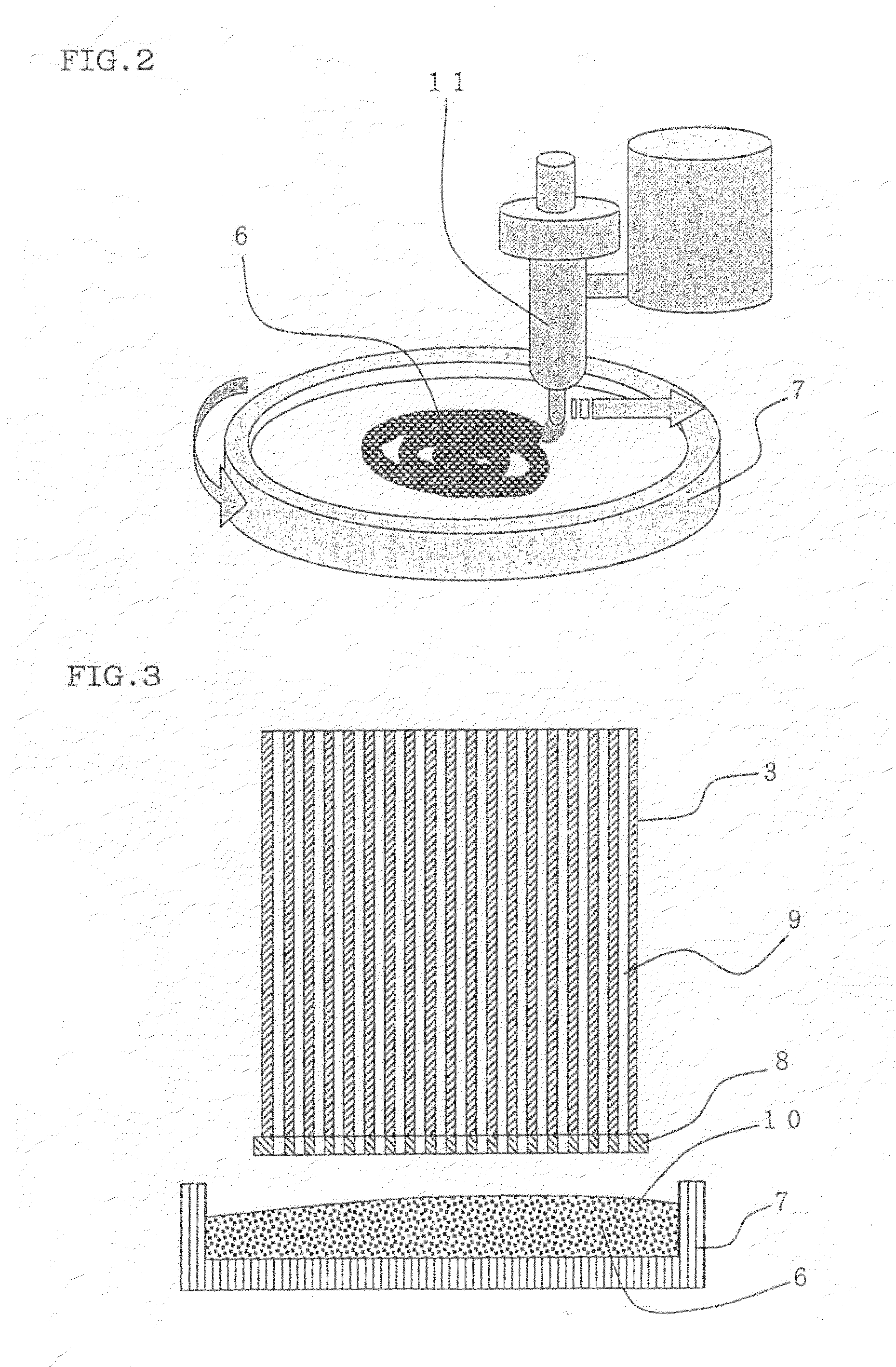

Method for Manufacturing Plugged Honeycomb Structure

InactiveUS20080128082A1Improve trapping efficiencyReduce total pressure lossGas treatmentDispersed particle filtrationEngineeringSlurry

There is provided a method for manufacturing a plugged honeycomb structure, where slurry 6 functioning as a raw material for the plugged portions is stored in a storage container 7 so that the slurry 6 may have a flat interface, and the plugged portions are formed by pressing an end face of the honeycomb structure 3 having a mask 8 for forming plugged portions disposed so as to cover open end portions of the cells other than the cells 9 to be plugged of the honeycomb structure 3 against the slurry 6 stored in the storage container 7 to introduce the slurry 6 into the inside of the cells 9 to be plugged.

Owner:NGK INSULATORS LTD

Pick Assembly

A high impact resistant pick in a holder having a super hard material bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide bolster. A bore is formed in a base end of the carbide bolster generally opposed to the front end. A steel shank being fitted into the bore of the bolster at a bolster end of the shank, and a portion of the shank is disposed within a bore of the holder at a holder end of the shank.

Owner:SCHLUMBERGER TECH CORP

Cutter having shaped working surface with varying edge chamfer

ActiveUS20110031030A1Reduce certain adverse consequenceIncreasing the thicknessDrill bitsConstructionsWell drillingMechanical engineering

A cutter for a drill bit used for drilling wells in a geological formation includes an ultra hard working surface and a chamfer along an edge of the working surface, wherein the chamfer has a varied geometry along the edge. The average geometry of the chamfer varies with cutting depth. A depression in the shaped working surface is oriented with the varied chamfer and facilitates forming the varied chamfer. A non-planar interface has depressions oriented with depressions in the shaped working surface to provide support to loads on the working surface of the cutter when used.

Owner:SMITH INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com