Patents

Literature

65results about How to "Transfer delay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

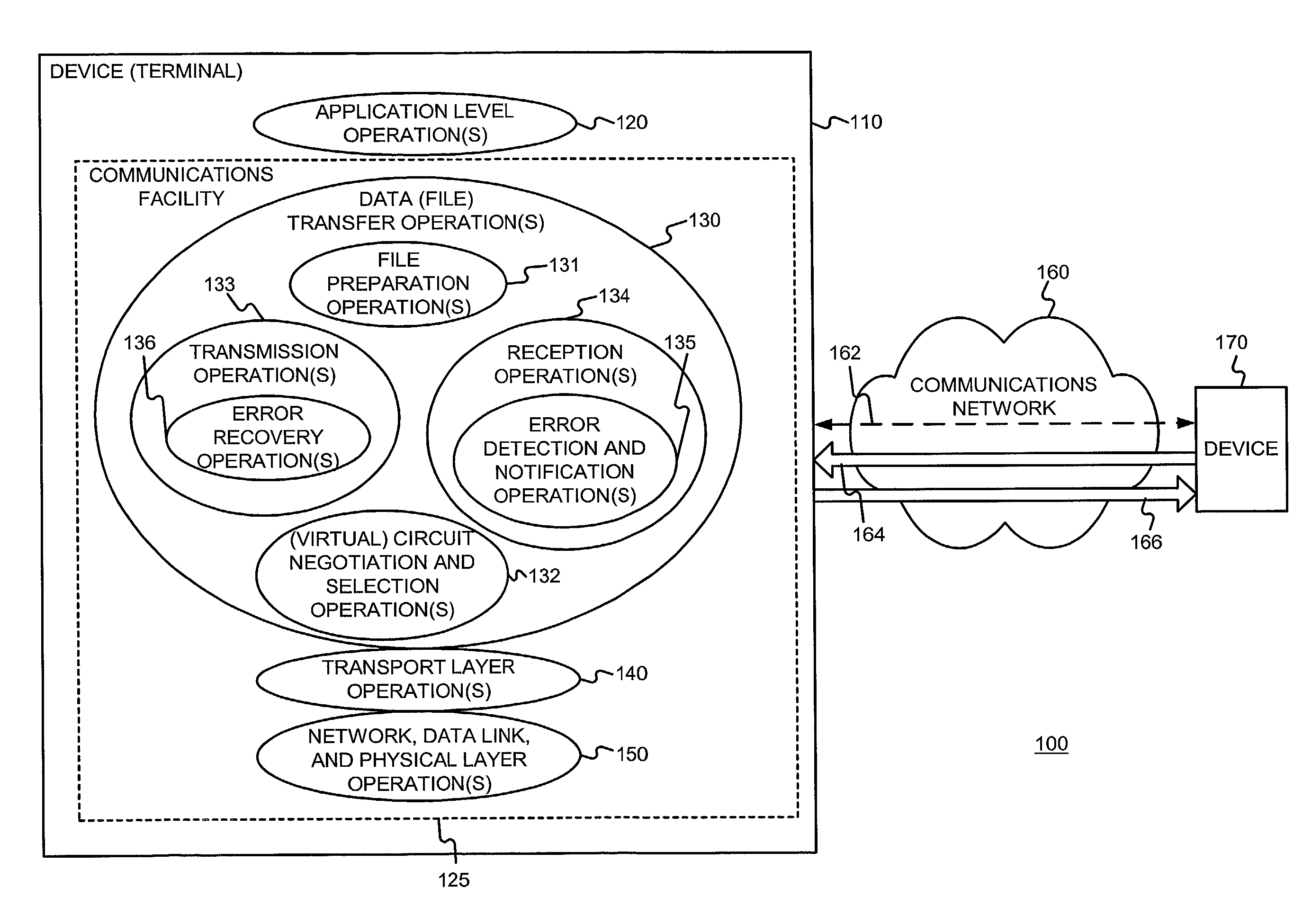

Transferring data such as files

ActiveUS20030053475A1Easy to useAvoid complex processError prevention/detection by using return channelData switching by path configurationComputer hardwareNetwork connection

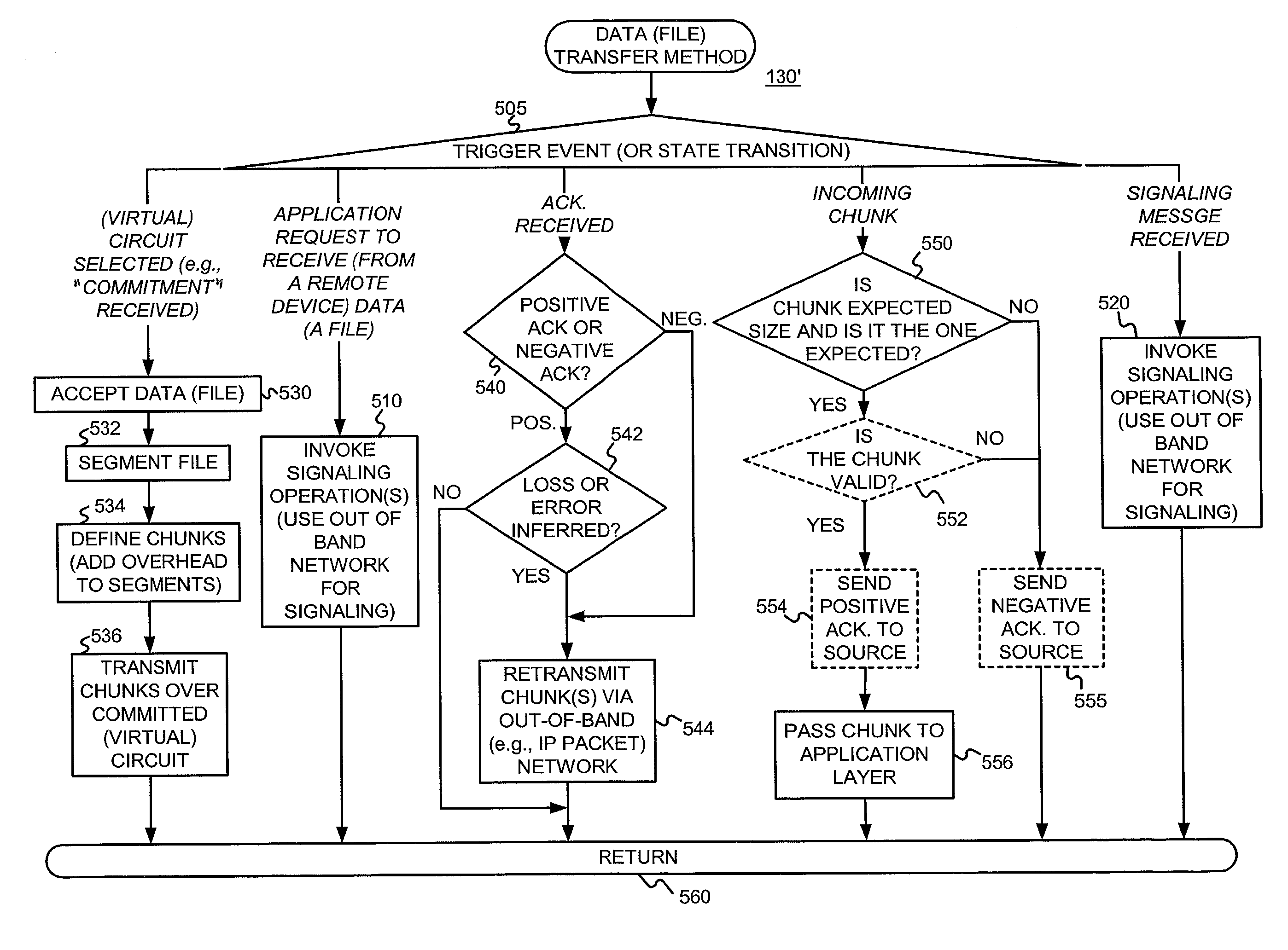

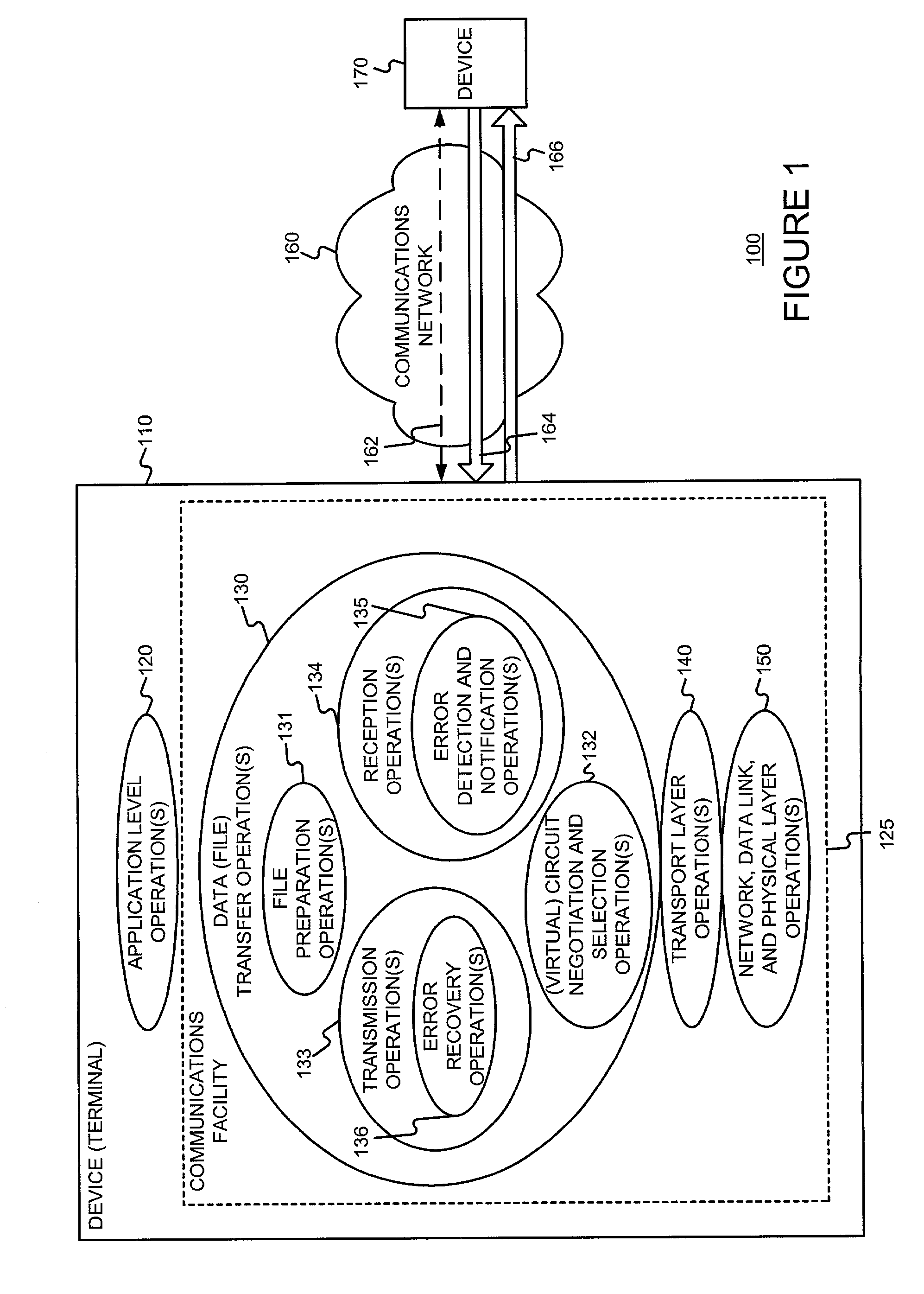

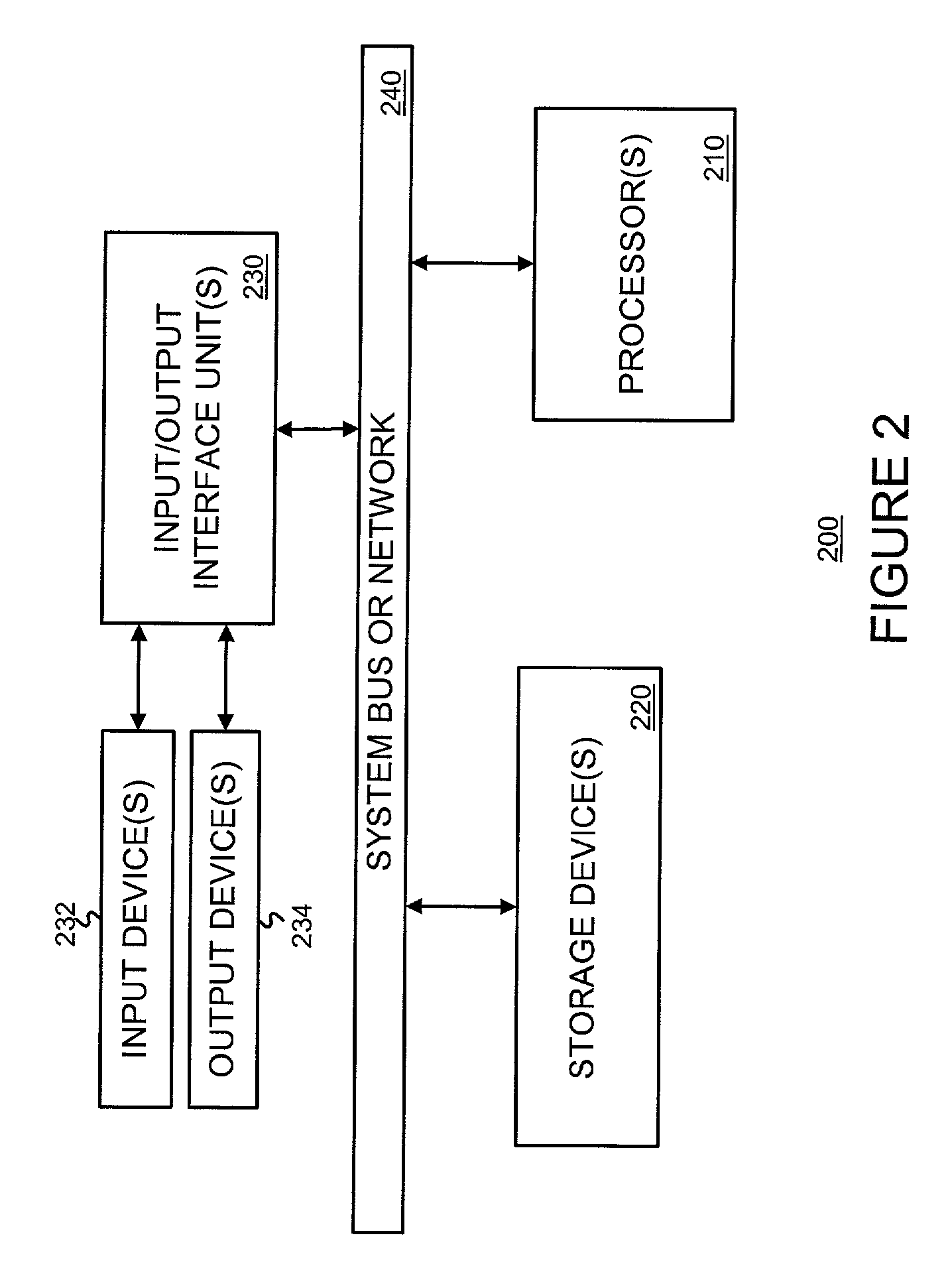

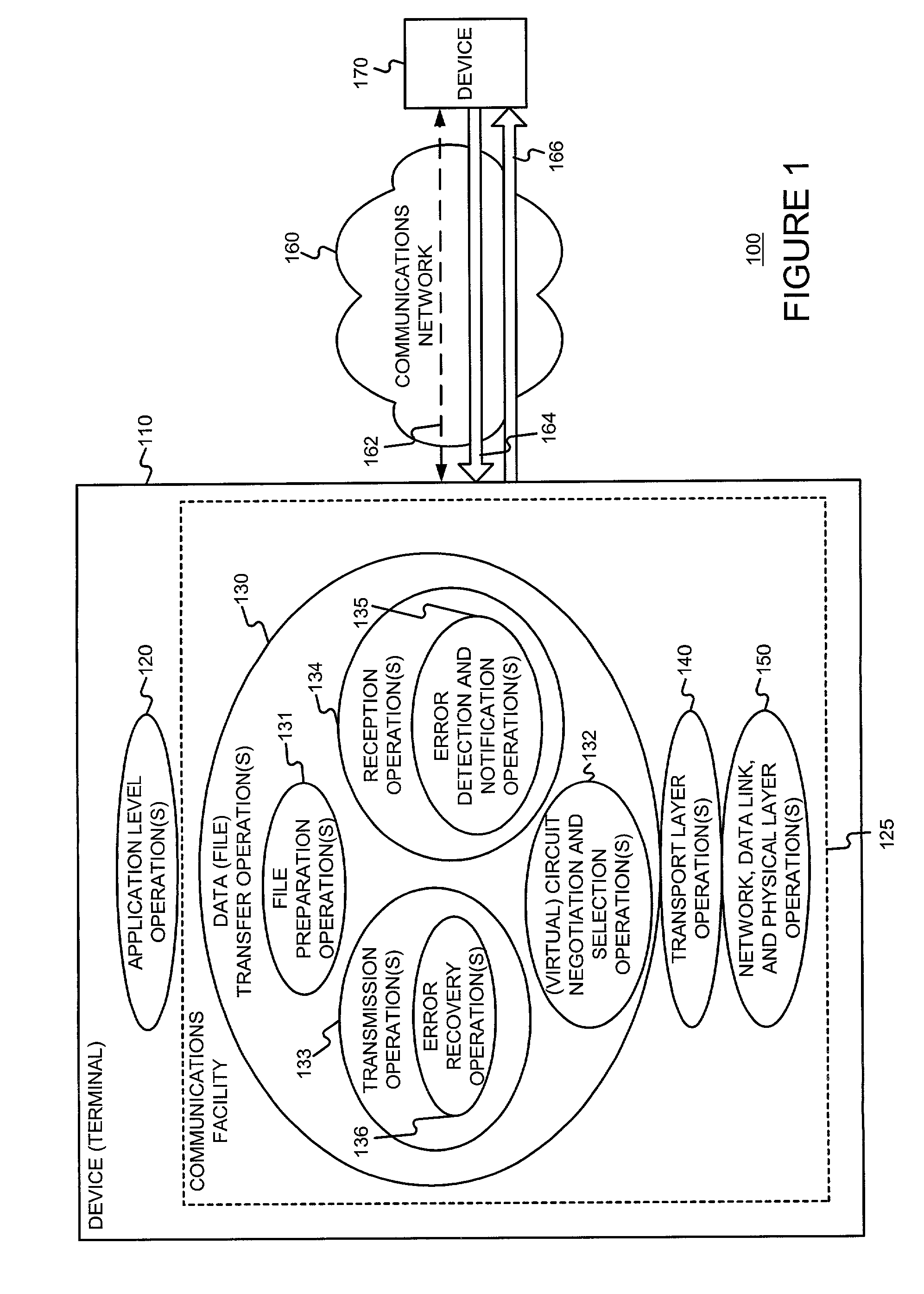

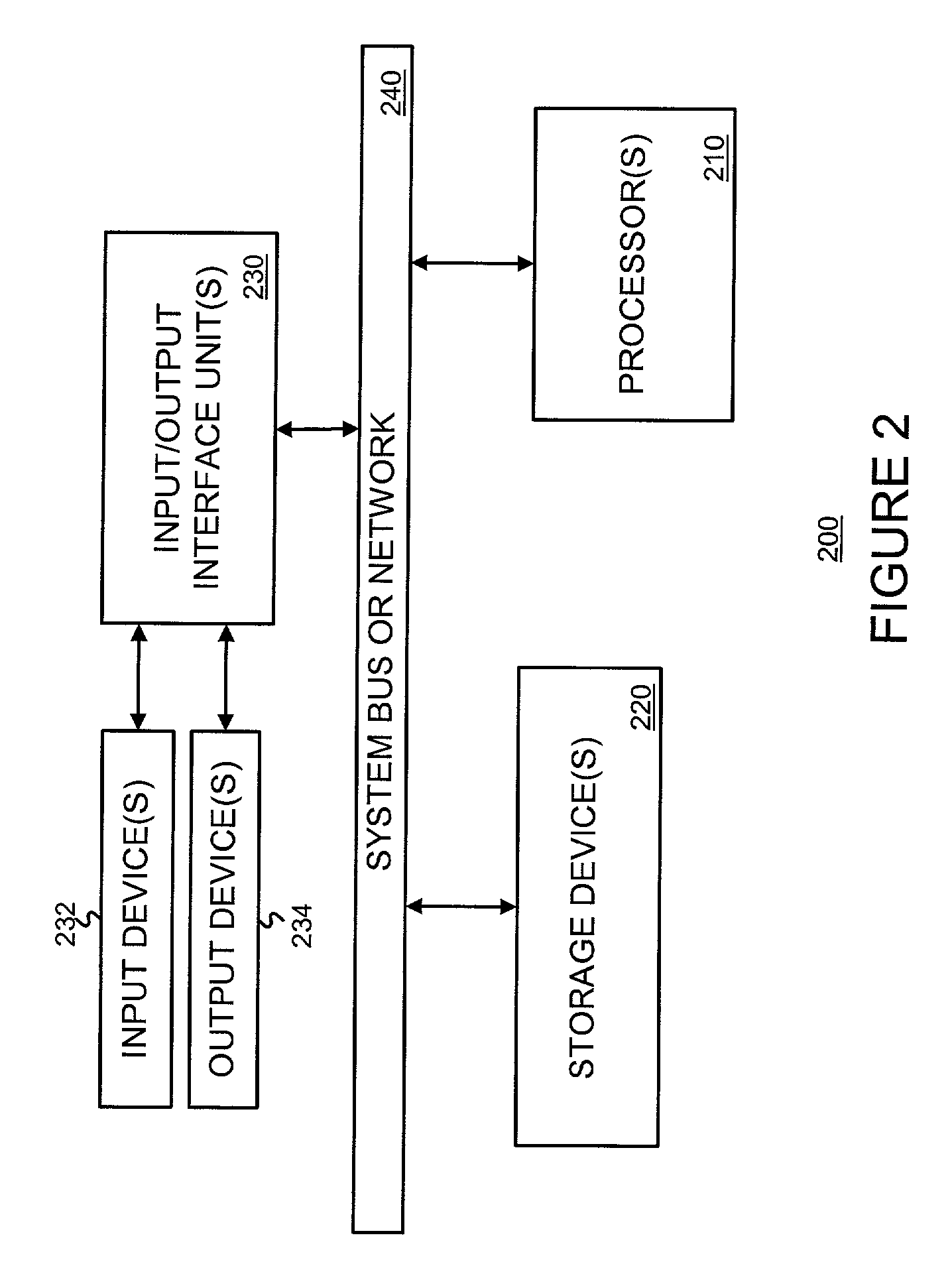

Transferring data (such as files) on an end-to-end, high-speed packet-switched network connection (a "virtual circuit") or on a circuit. An out-of-band path is used for signaling and status messages (control). The same, or a separate, out-of-band path may be used to retransmit chunks of data that were received with errors or that were not received at all. By simplifying the data being sent over the high-speed (virtual) circuit, the resources of the (virtual) circuit are used efficiently since less overhead is required. Further, since the size of the file to be transferred can be predetermined, and since any retransmissions can be made over a path other than the (virtual) circuit, the (virtual) circuit that best meets the needs of the data transfer can be selected, thereby further increasing the efficiency with which the (virtual) circuit is used.

Owner:POLYTECHNIC INST OF NEW YORK

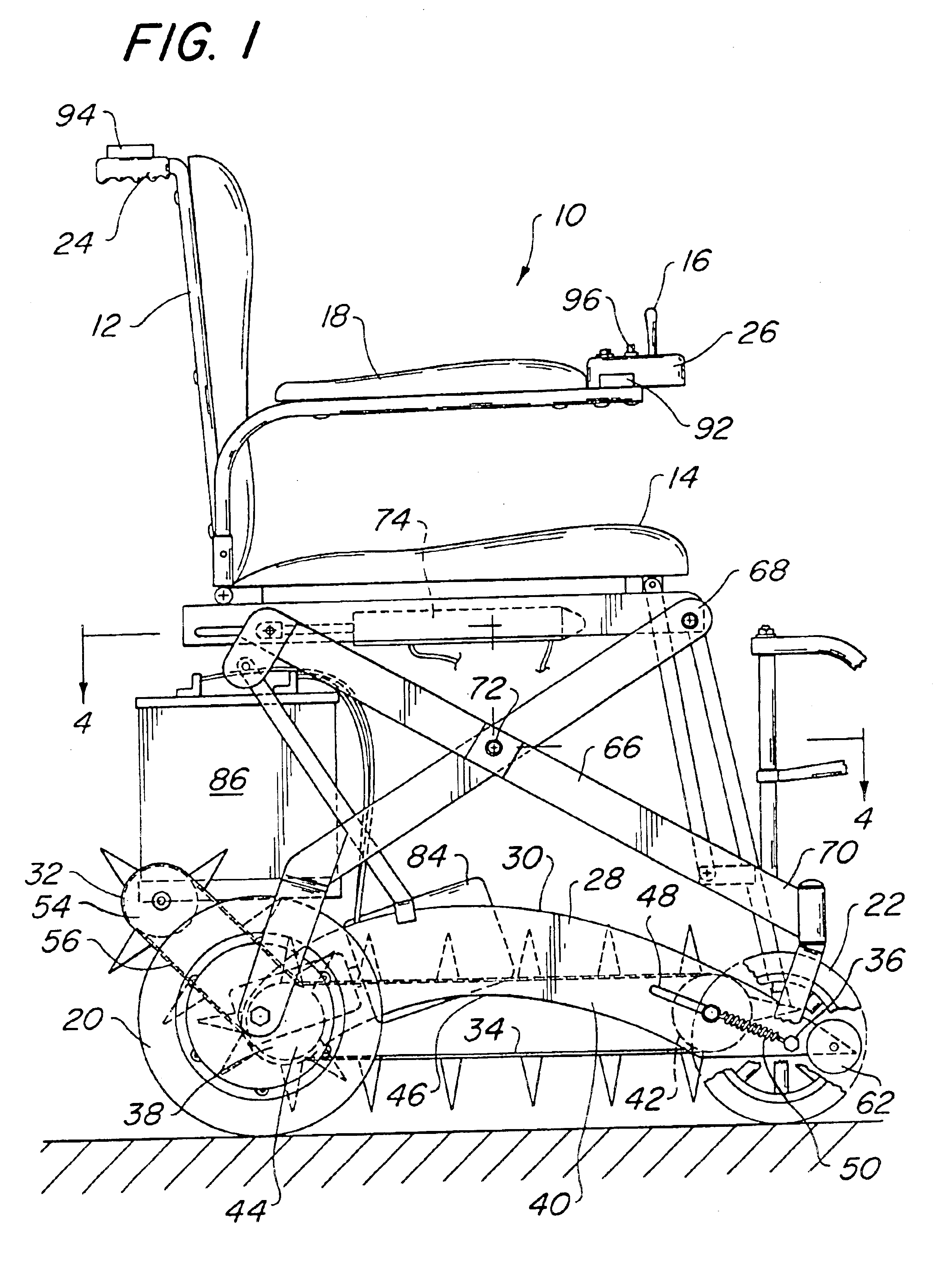

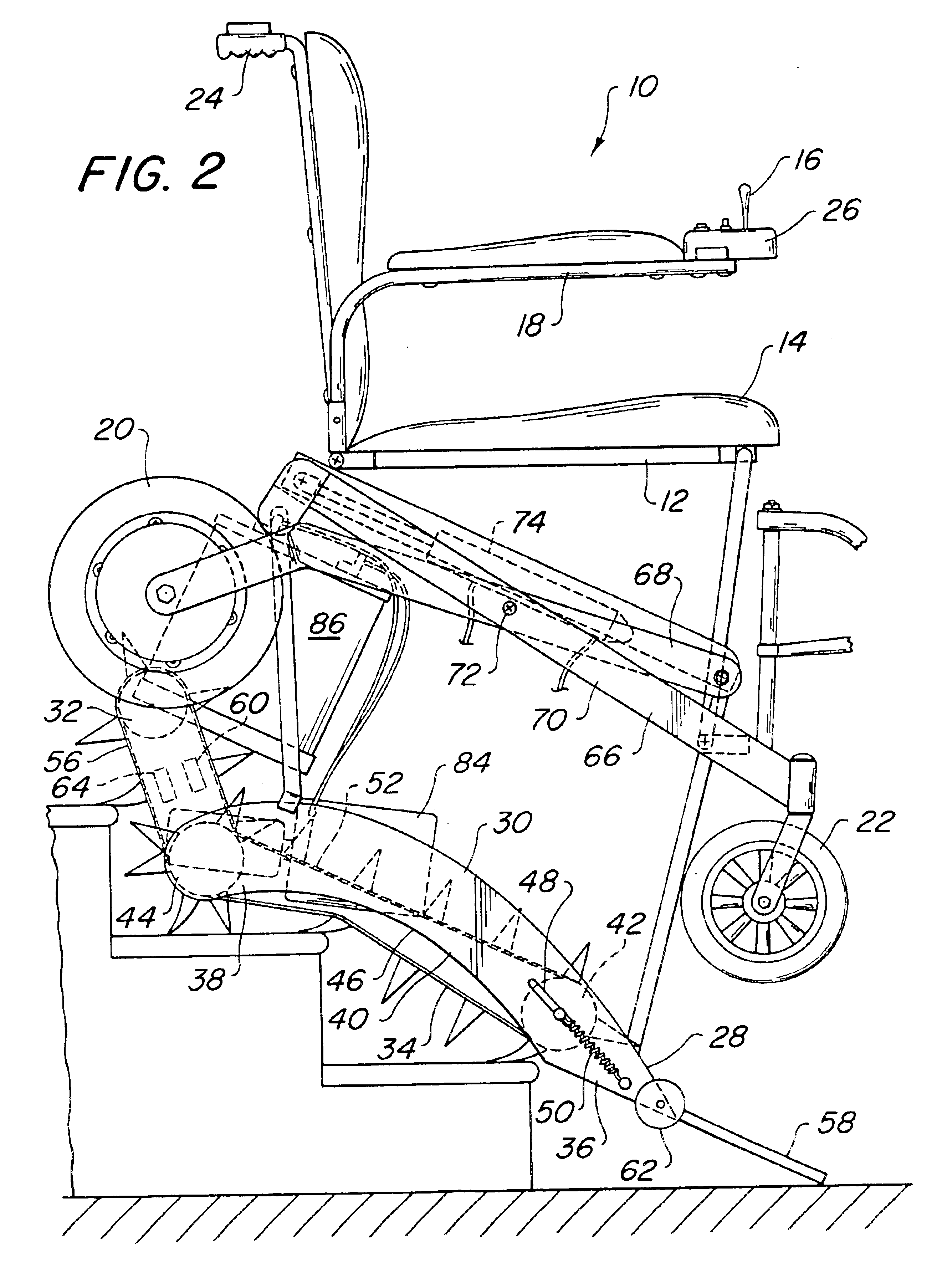

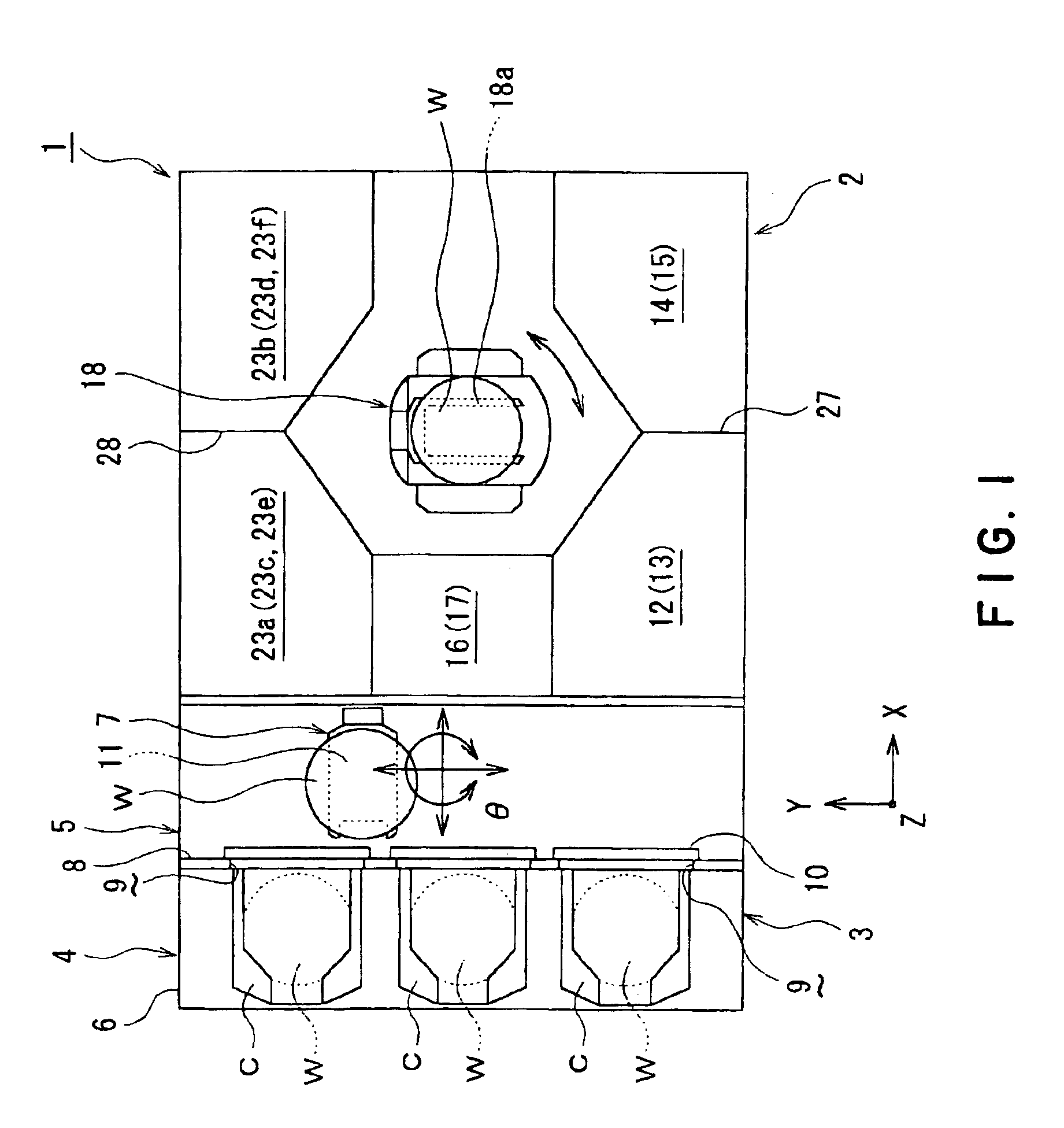

Stair-climbing wheelchair

InactiveUS6857490B2Smooth transitionProvides safety featuresCarriage/perambulator accessoriesWheelchairs/patient conveyanceRemote controlEngineering

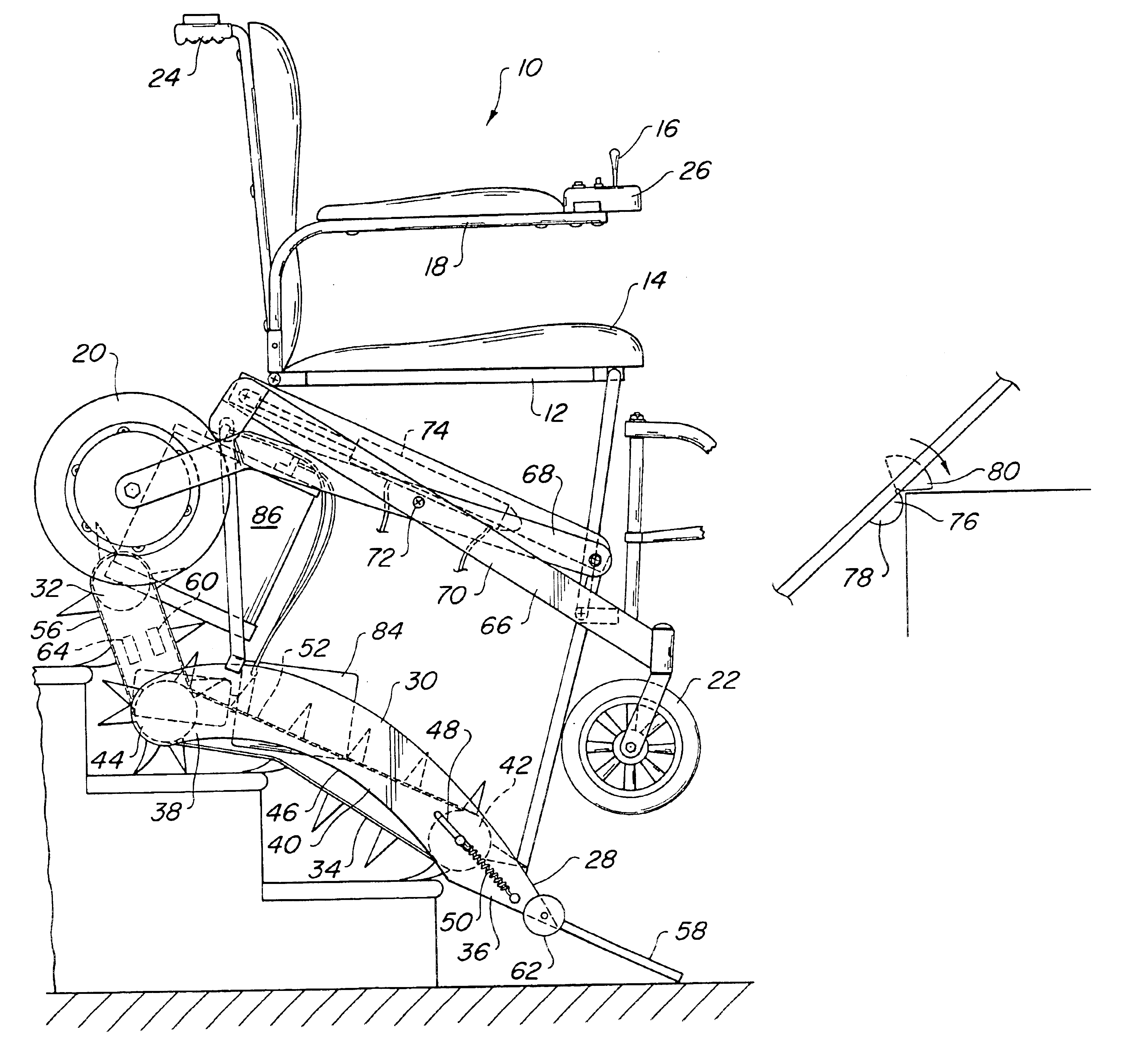

A stair-climbing wheelchair has a pair of track assemblies that can be placed in an operative drive mode to propel the wheelchair along ascending and descending paths of travel relative to an obstacle such as a stairway, curb, or the like. Each track assembly includes a guide member with rollers at opposite ends thereof carrying an endless cleated belt. The guide member is arched between its end sections thereby permitting the endless belt to deflect upwardly between the rollers when the endless belt engages an obstacle such as a step, curb or the like. This permits a smooth gradual transition of the wheelchair onto and / or off the top step of a staircase. Preferably, each track assembly also includes an inclined tail section having a separate endless cleated belt. The track assemblies can also be utilized in connection with remote control and / or unmanned motorized vehicles.

Owner:QUIGG ROBERT T

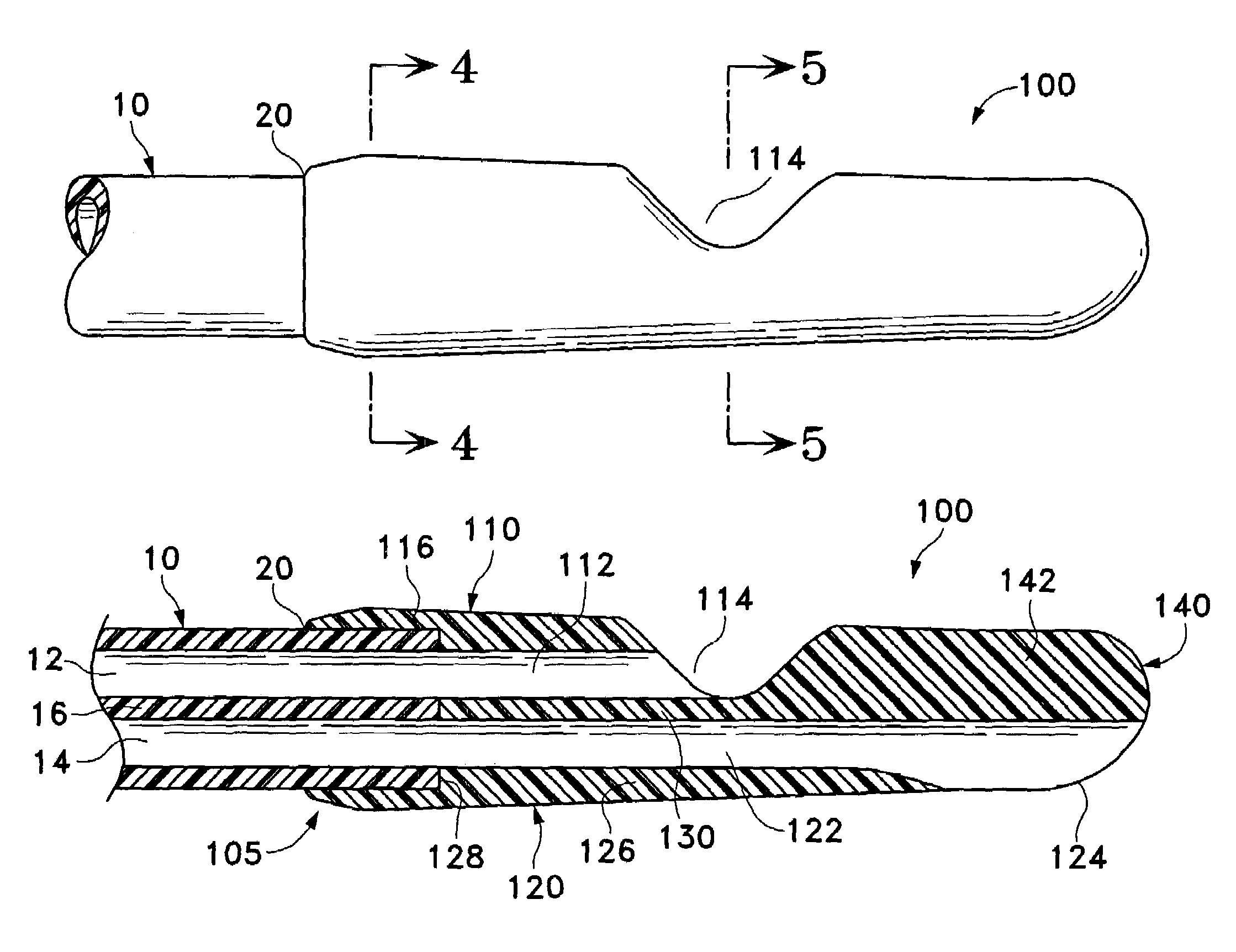

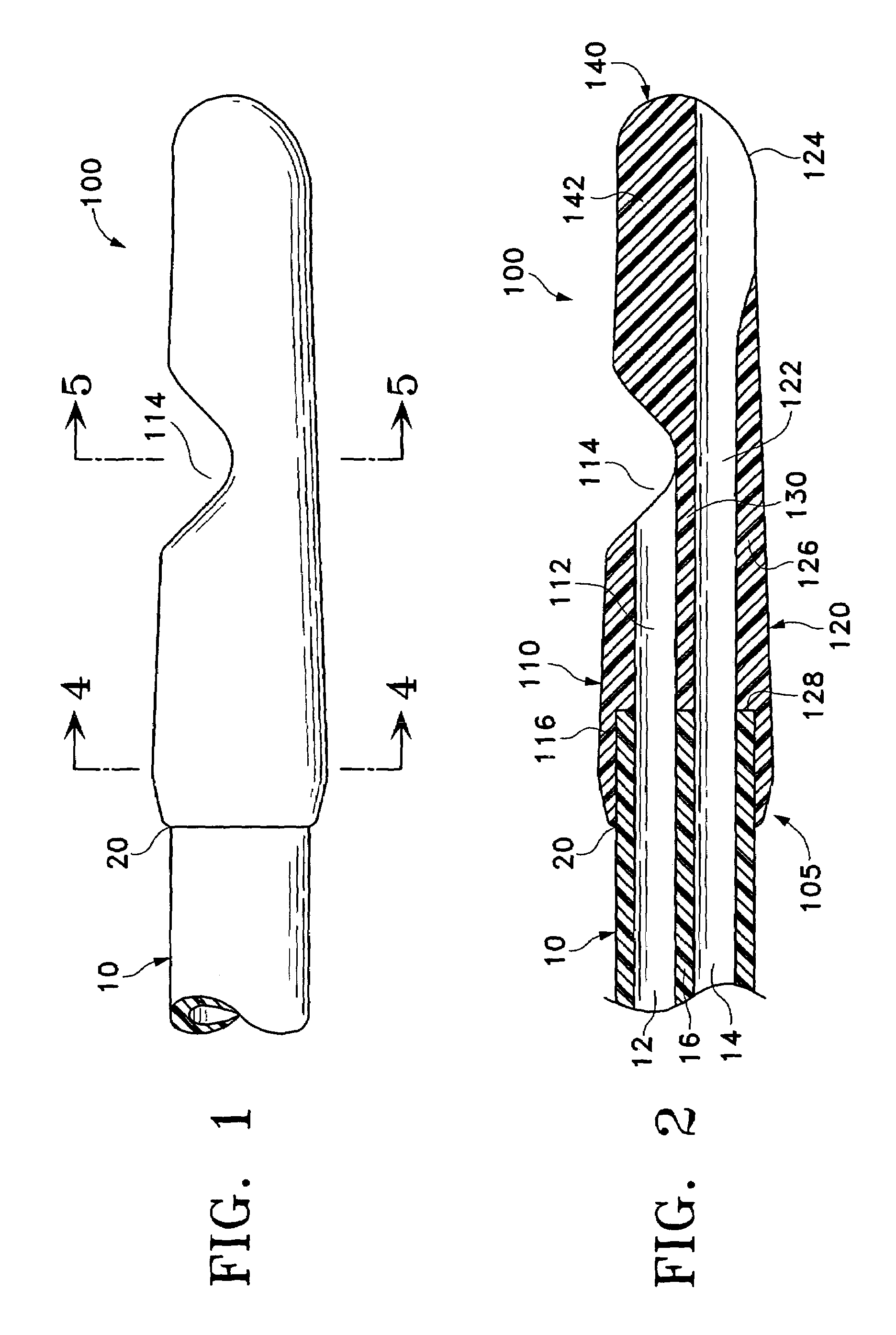

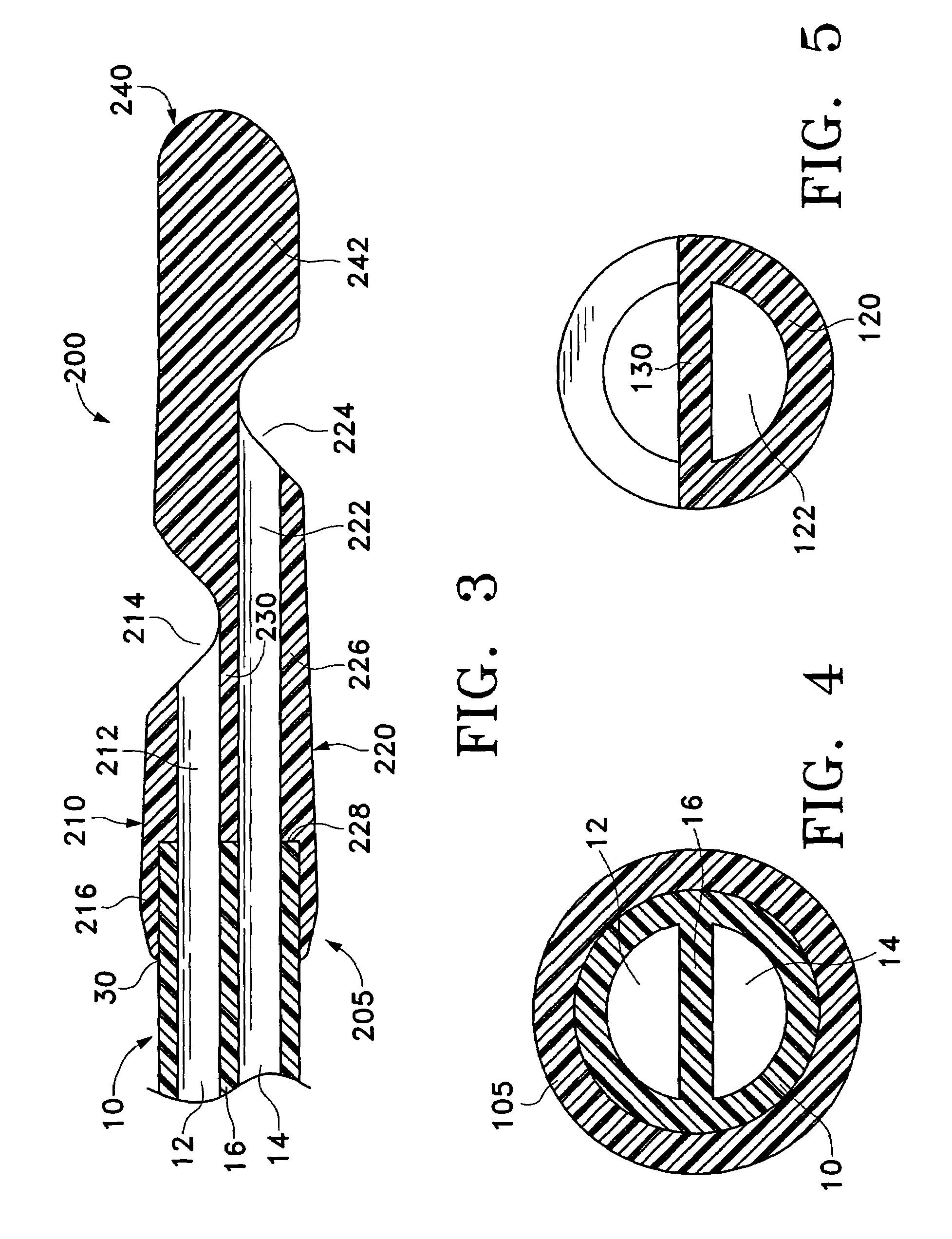

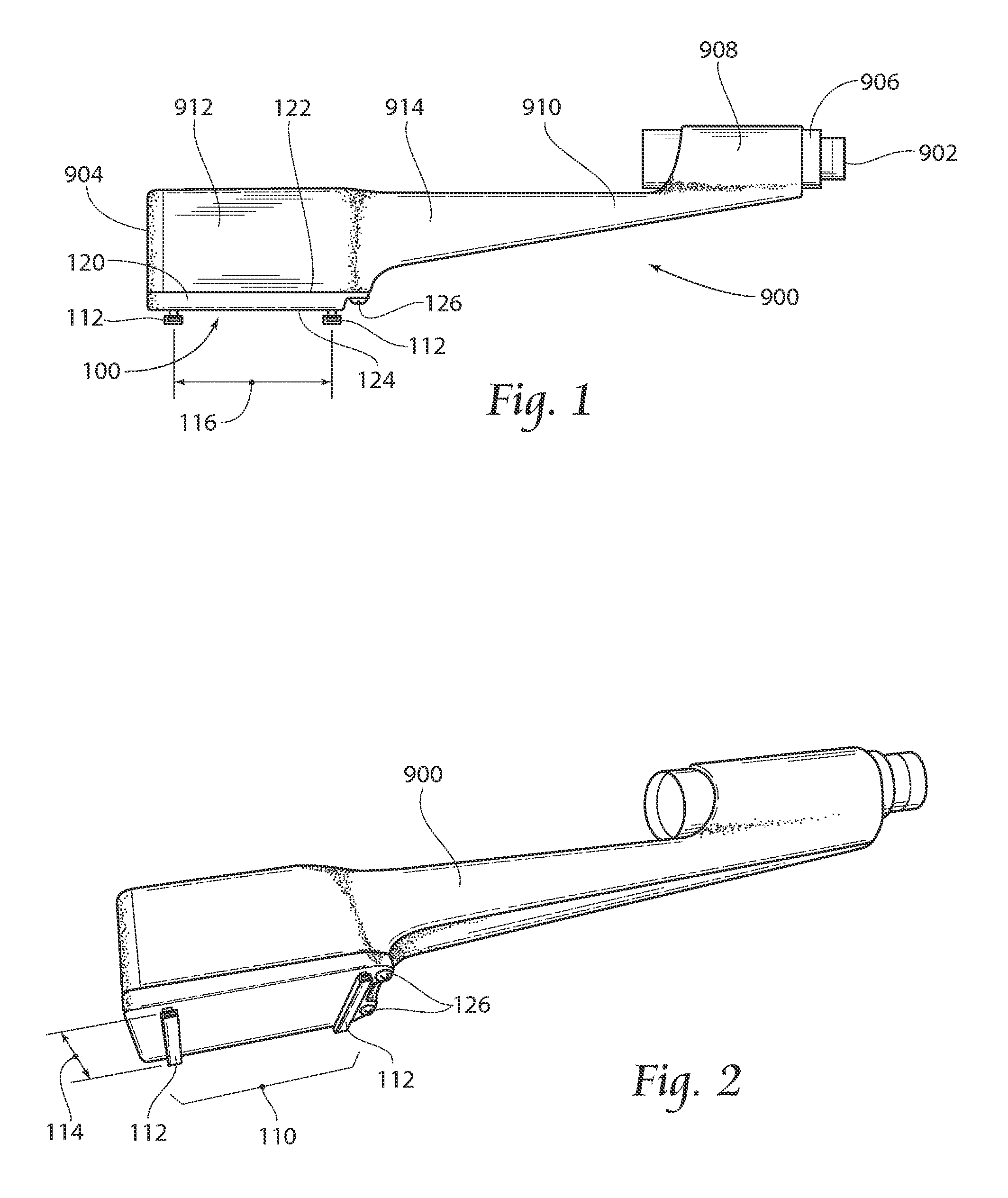

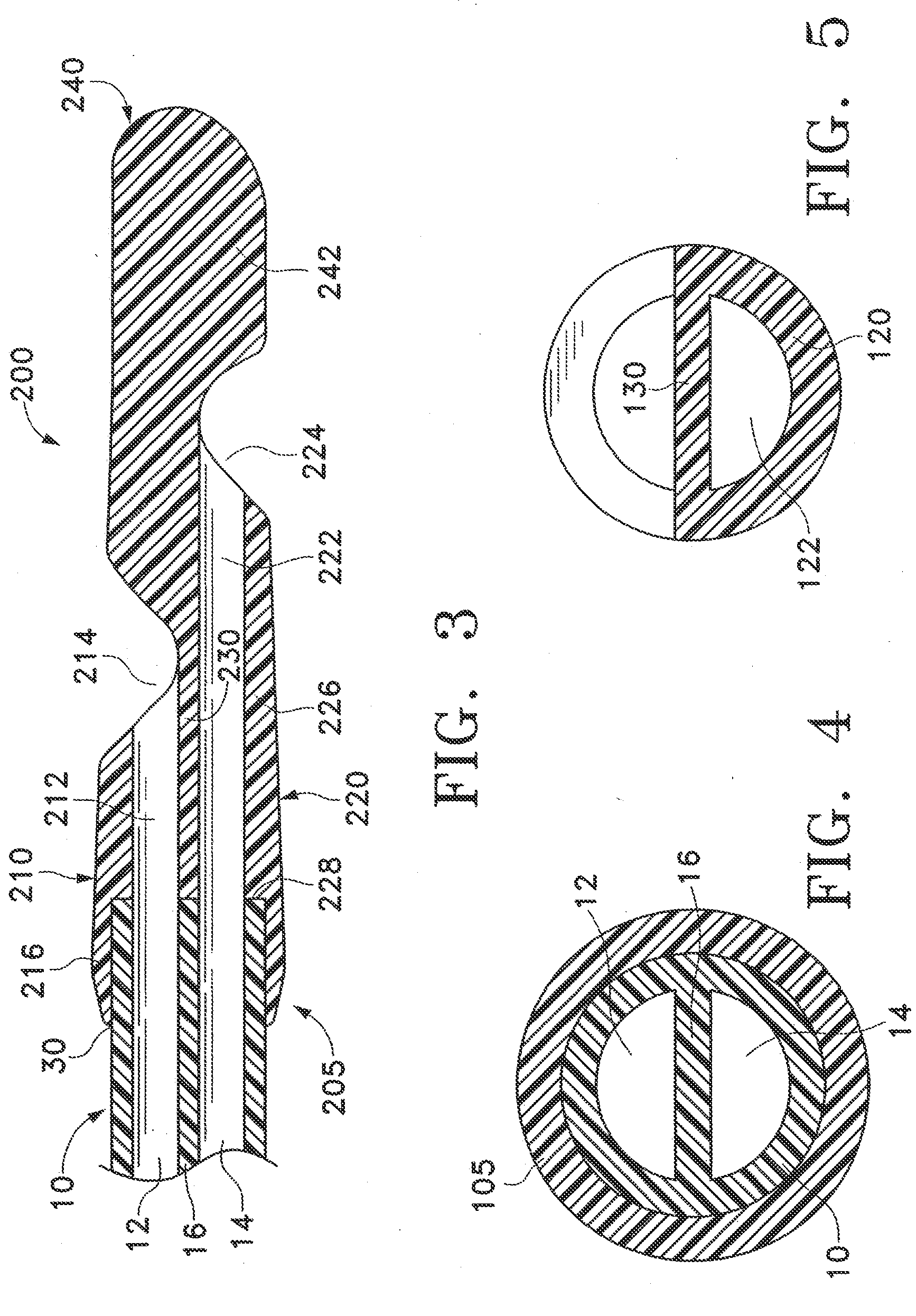

Bolus tip design for a multi-lumen catheter

InactiveUS7485107B2Prevent unnecessary traumaSimple designMulti-lumen catheterOther blood circulation devicesCatheter deviceGeneral surgery

A bolus tip for a multi-lumen catheter includes a first channel terminating distally in a first opening, and a second channel terminating distally in a second opening. The first opening may be positioned proximal the second opening along a longitudinal axis of the bolus tip and may be positioned on a side of the bolus tip opposite that of the second opening. The first and second openings may extend through an outer wall of the bolus tip to a dividing section. The bolus tip may also include a third channel sized for accommodating a guidewire.

Owner:BARD ACCESS SYST INC A SUBSIDIARY OF C R BARD

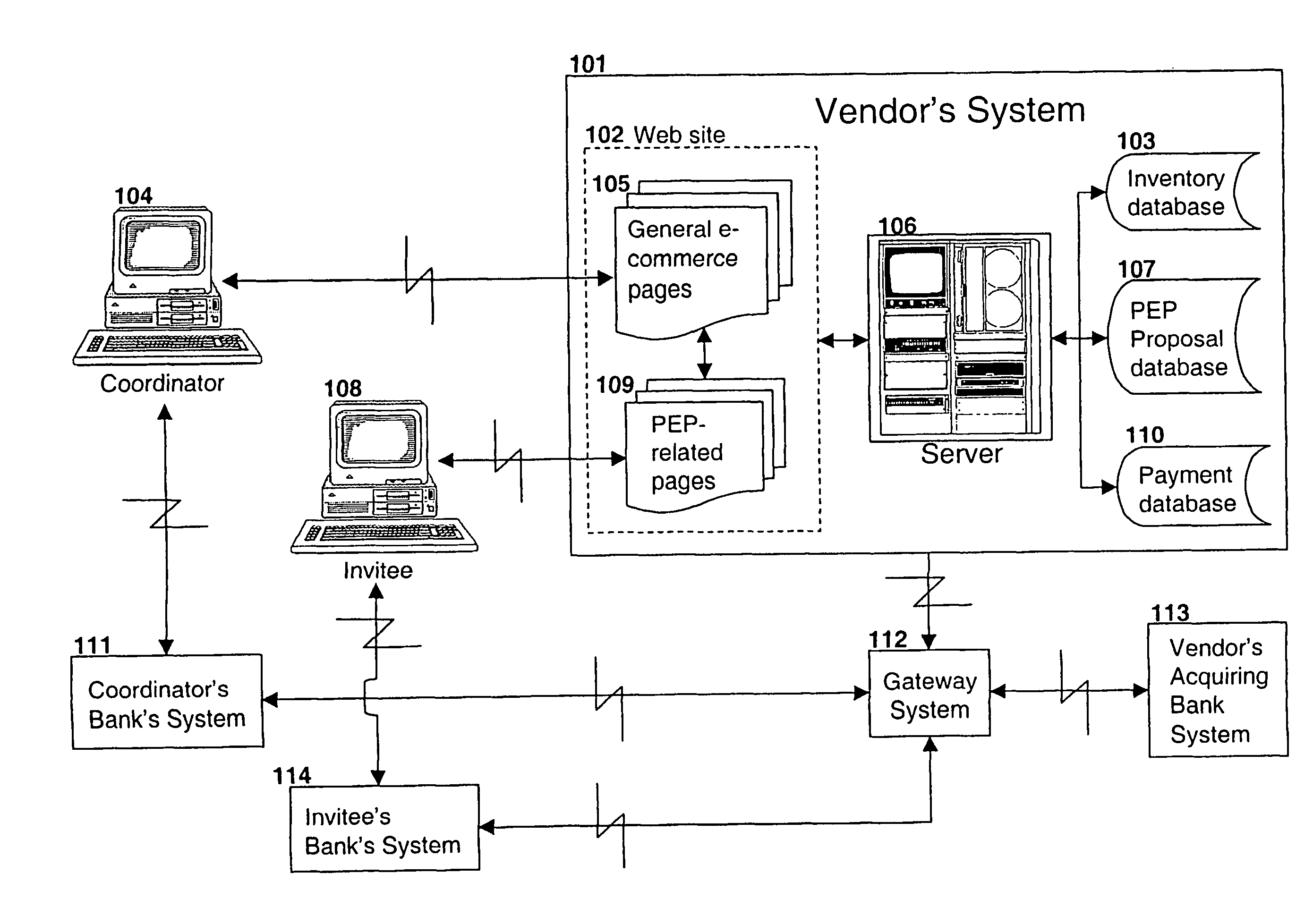

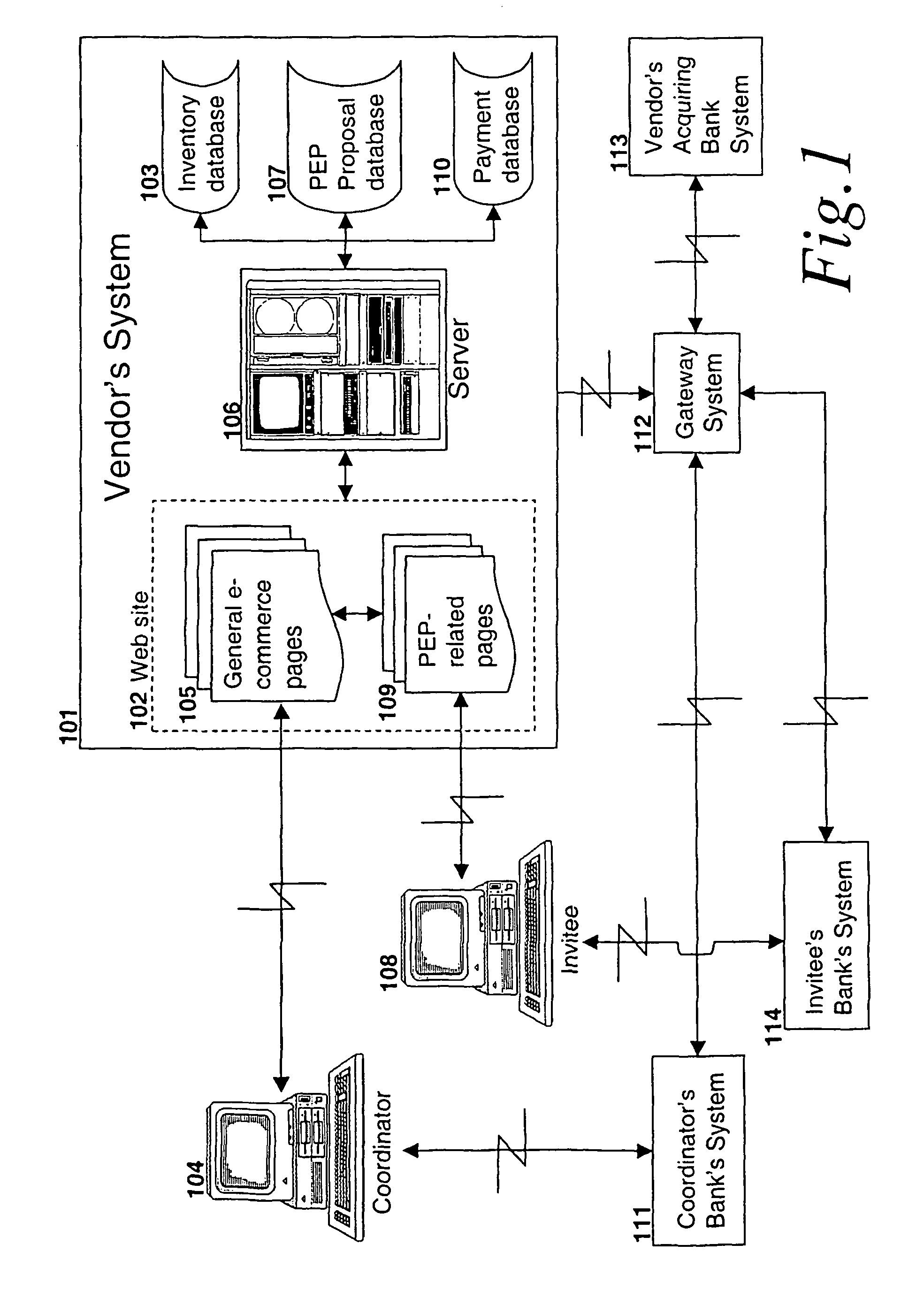

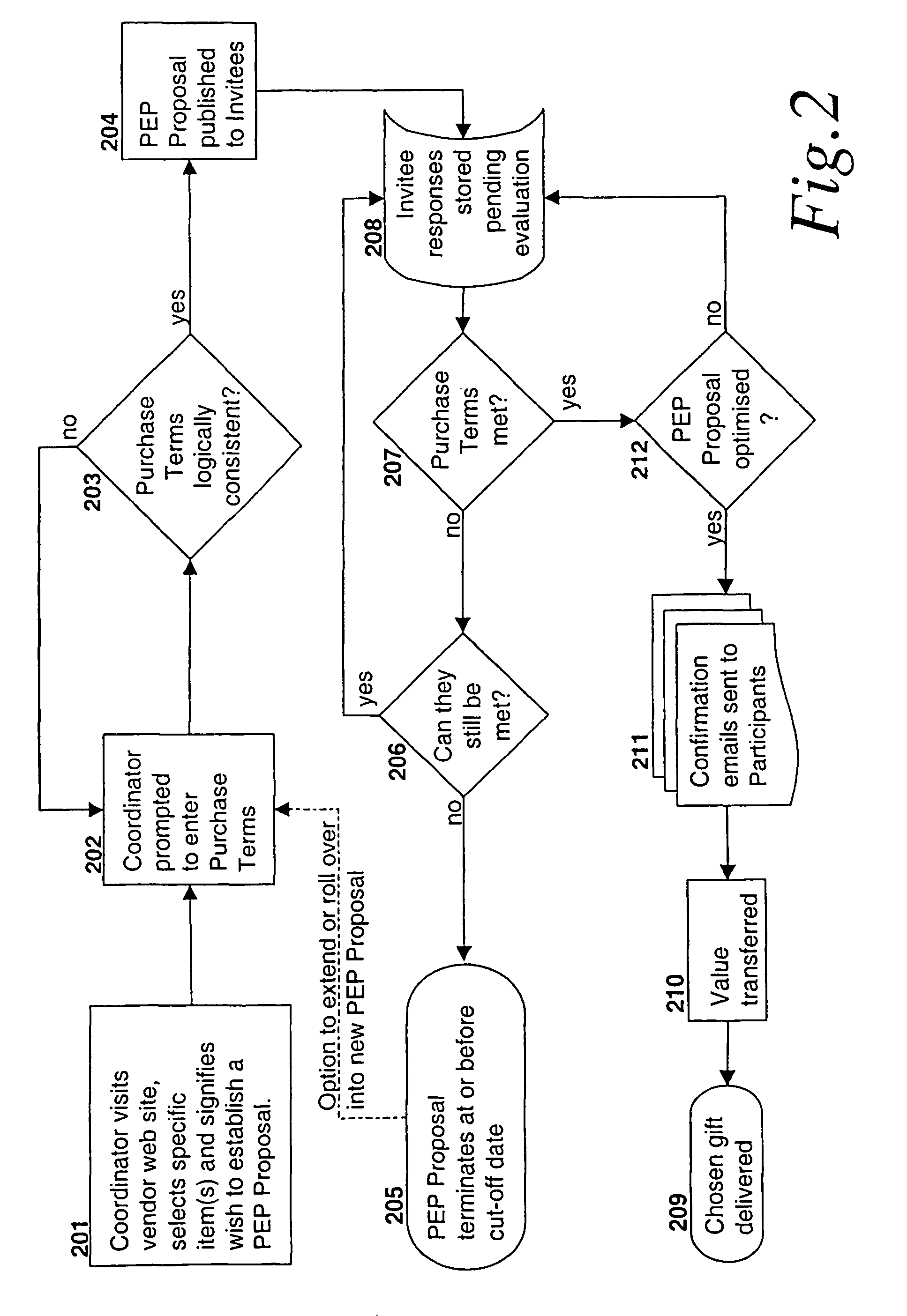

System and method for pooled electronic purchasing

InactiveUS7792699B2Transfer delayBuying/selling/leasing transactionsComputerized systemLibrary science

A retailing method executable by a computer system, includes sending a page to a prospective purchaser in response to a request, the page being associated with a specific product; receiving a purchase proposal from the prospective purchaser for direct purchase of the product at a fixed price, the purchase proposal including identifier information of persons nominated by the prospective and purchase term information selected at least in part by the prospective purchaser, the nominated persons being nominated to contribute to purchase of the product at the fixed price.

Owner:CASSIA GROUP HLDG

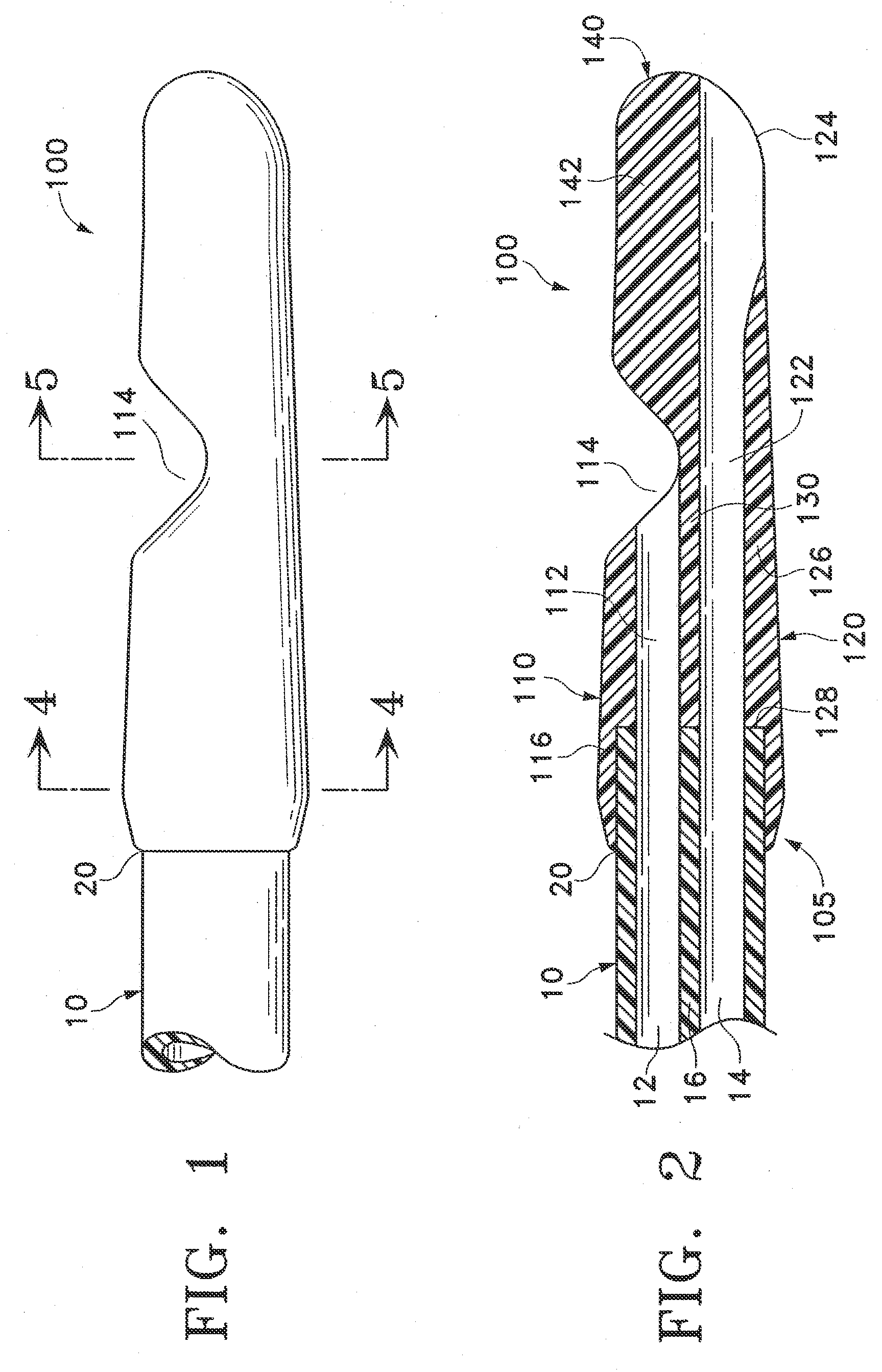

Ultra thin graphics and methods

InactiveUS20060246266A1Reduce shipping costsQuality improvementDecorative surface effectsDuplicating/marking methodsColor effectGraphics

A transferable image for water-slidable application to surfaces is provided comprising a water-absorbing Porous Backing Sheet; a water-soluble Resin Coating coated on the water-absorbing Porous Backing Sheet; a base layer on the water-soluble Resin Coating; and a plurality of ink layers on the base layer, at least one of the ink layers being translucent or transparent and applied in overlapping fashion in a manner to provide a color effect. In preferred embodiments, a transfer premask is provided wherein the transfer premask is substantially no wider than about 0.25 inches than the perimeter of the image shape.

Owner:MODERNISTIC

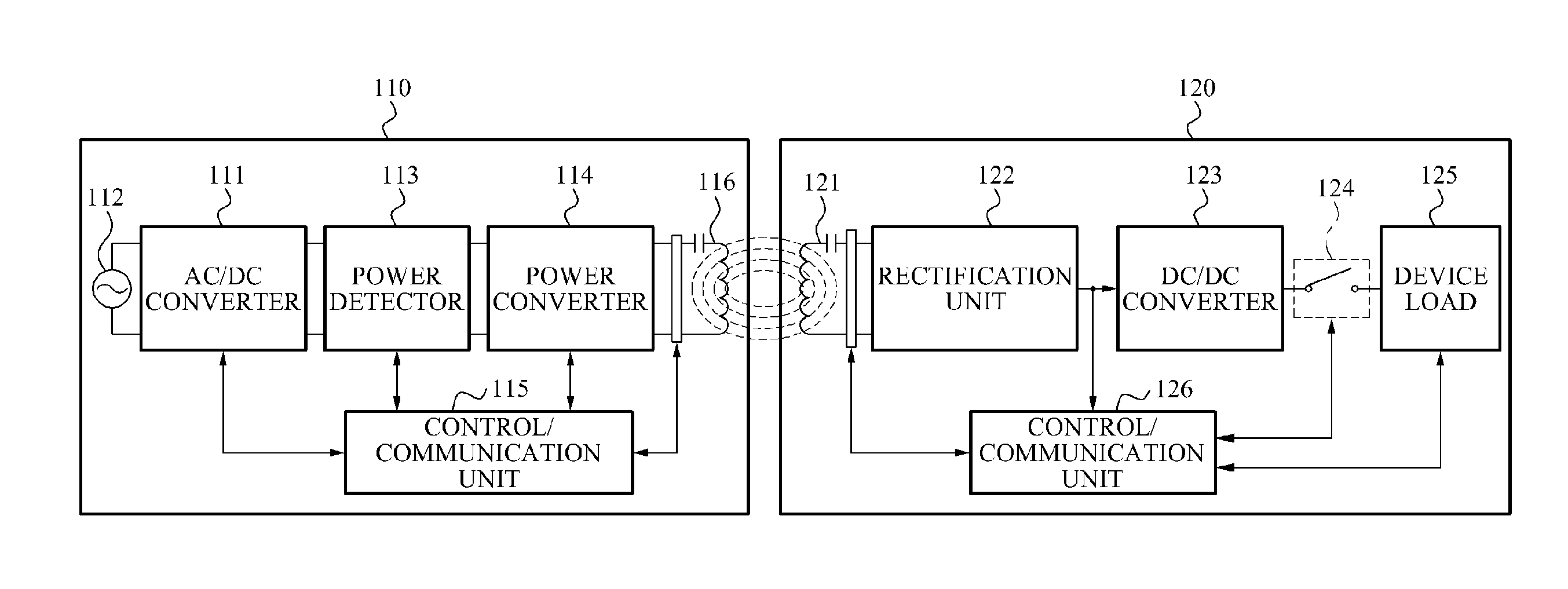

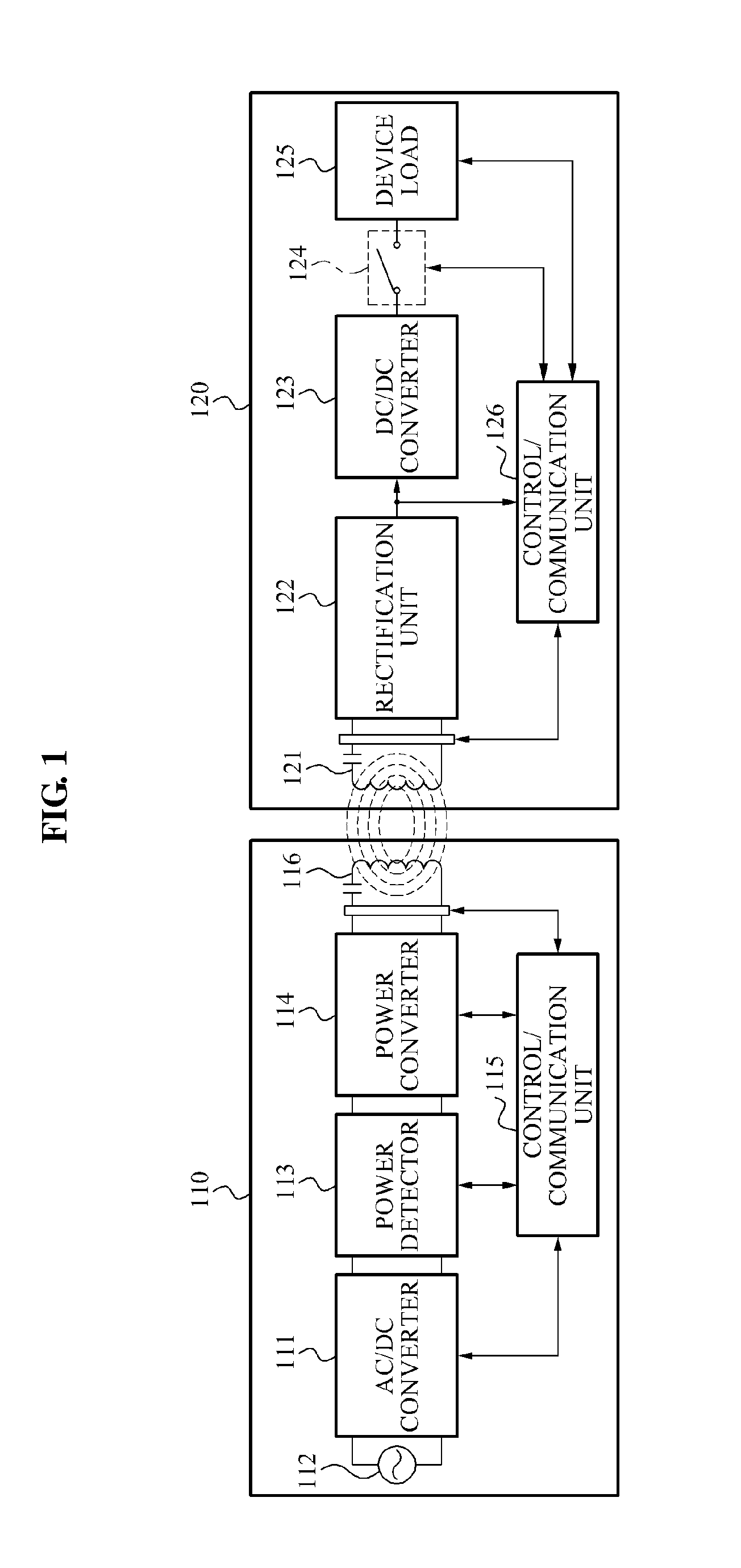

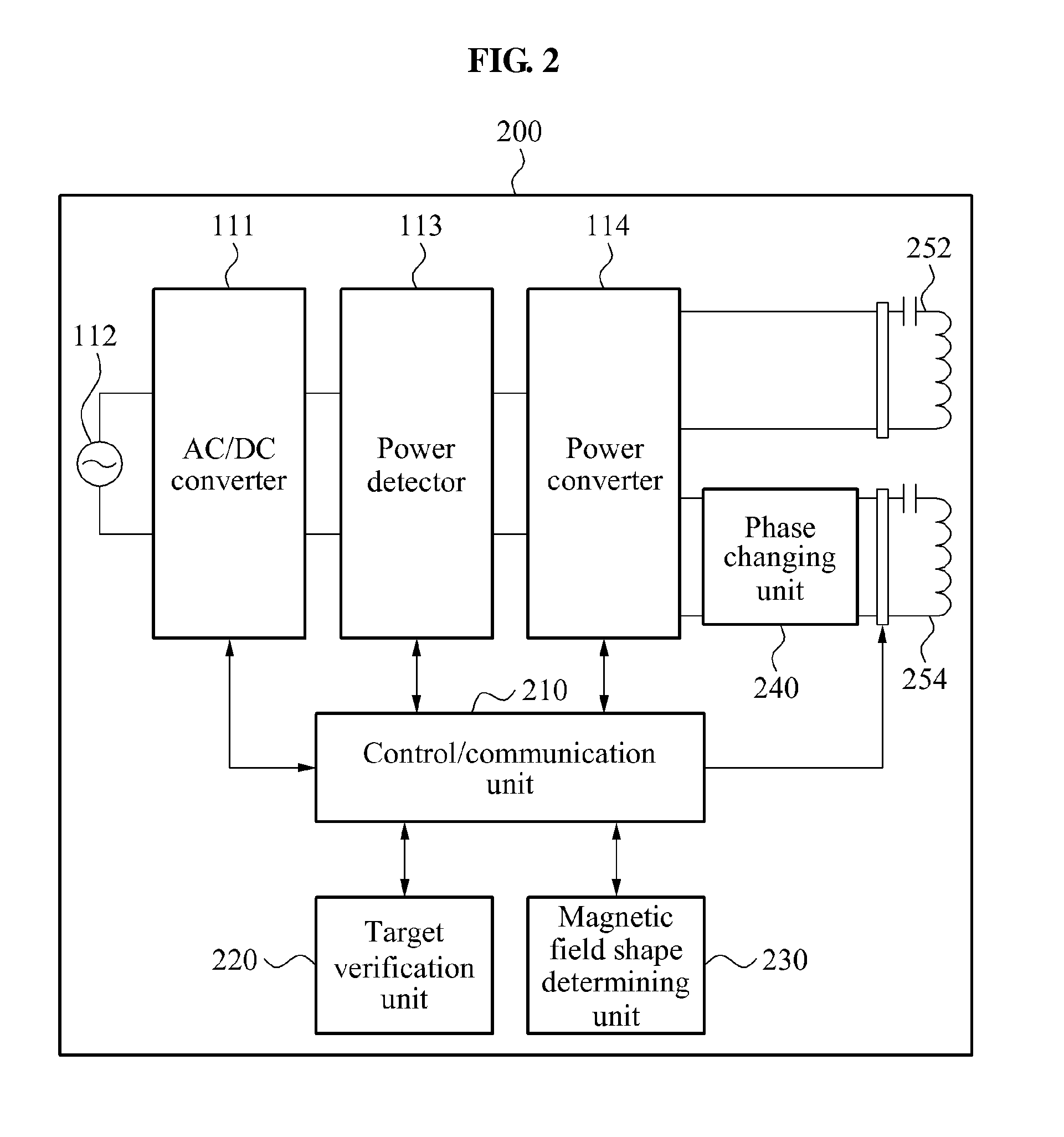

Source device and method for controlling magnetic field using two source resonators in wireless power transmission system

ActiveUS20130049456A1Transfer delayElectromagnetic wave systemVehicular energy storageElectric power transmissionTransmitted power

A source device and a method for controlling a magnetic field using two source resonators in a wireless power transmission system are provided. A device configured to control a magnetic field, includes resonators configured to form the magnetic field to transmit power to another device. The device further includes a magnetic field shape determining unit configured to determine a shape of the magnetic field. The device further includes a phase changing unit configured to change a phase of at least one of the resonators to form the magnetic field in the determined shape.

Owner:SAMSUNG ELECTRONICS CO LTD

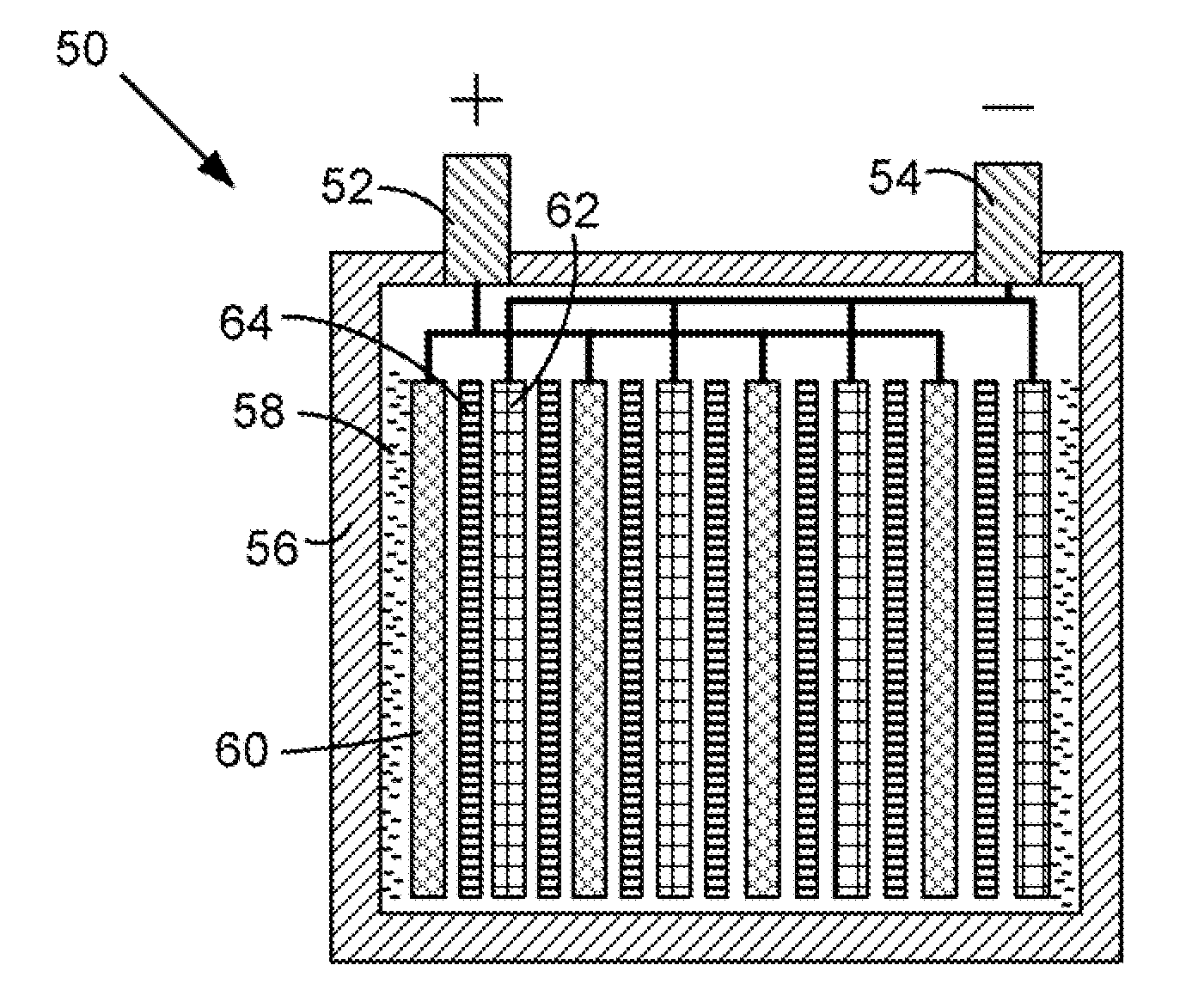

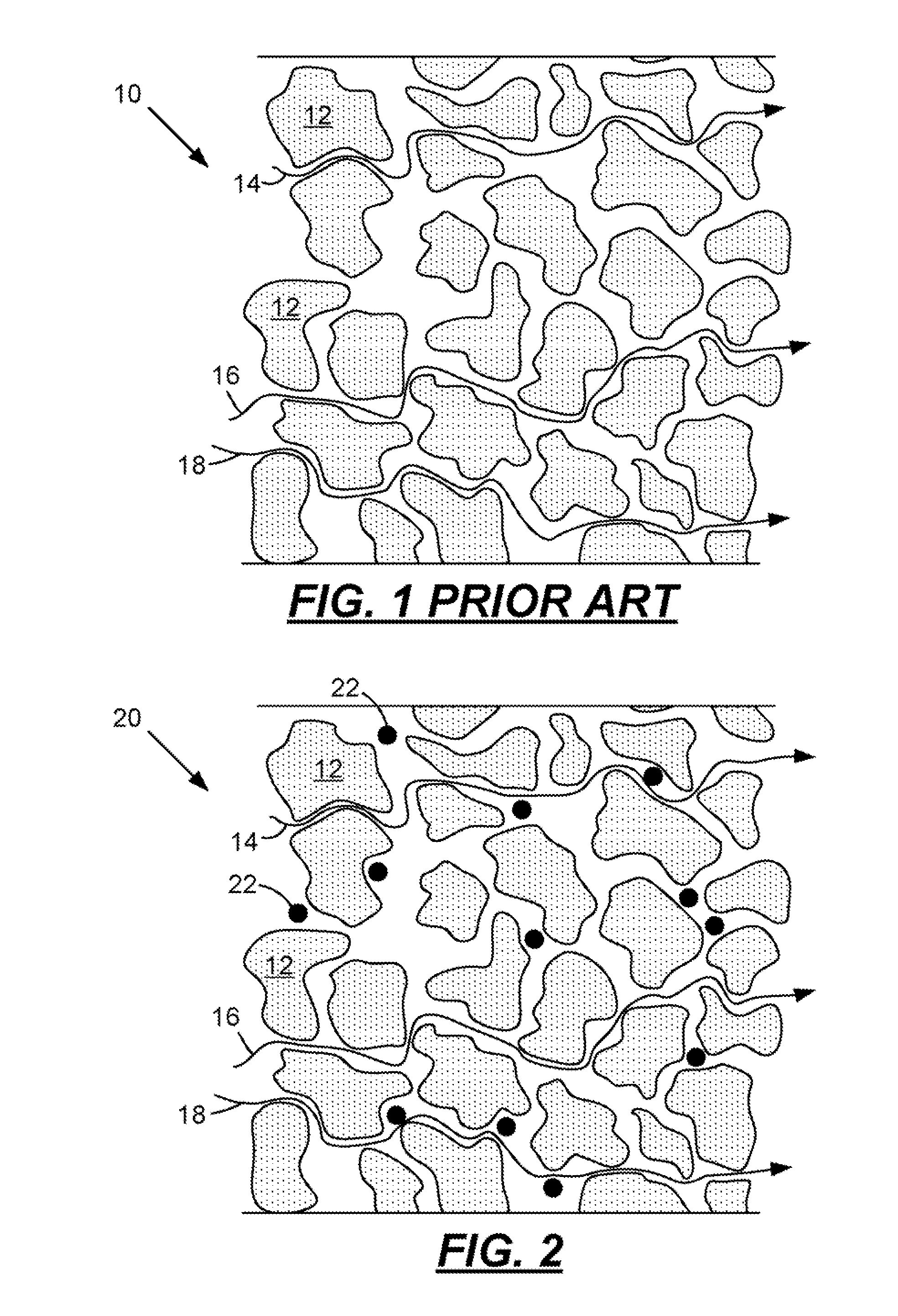

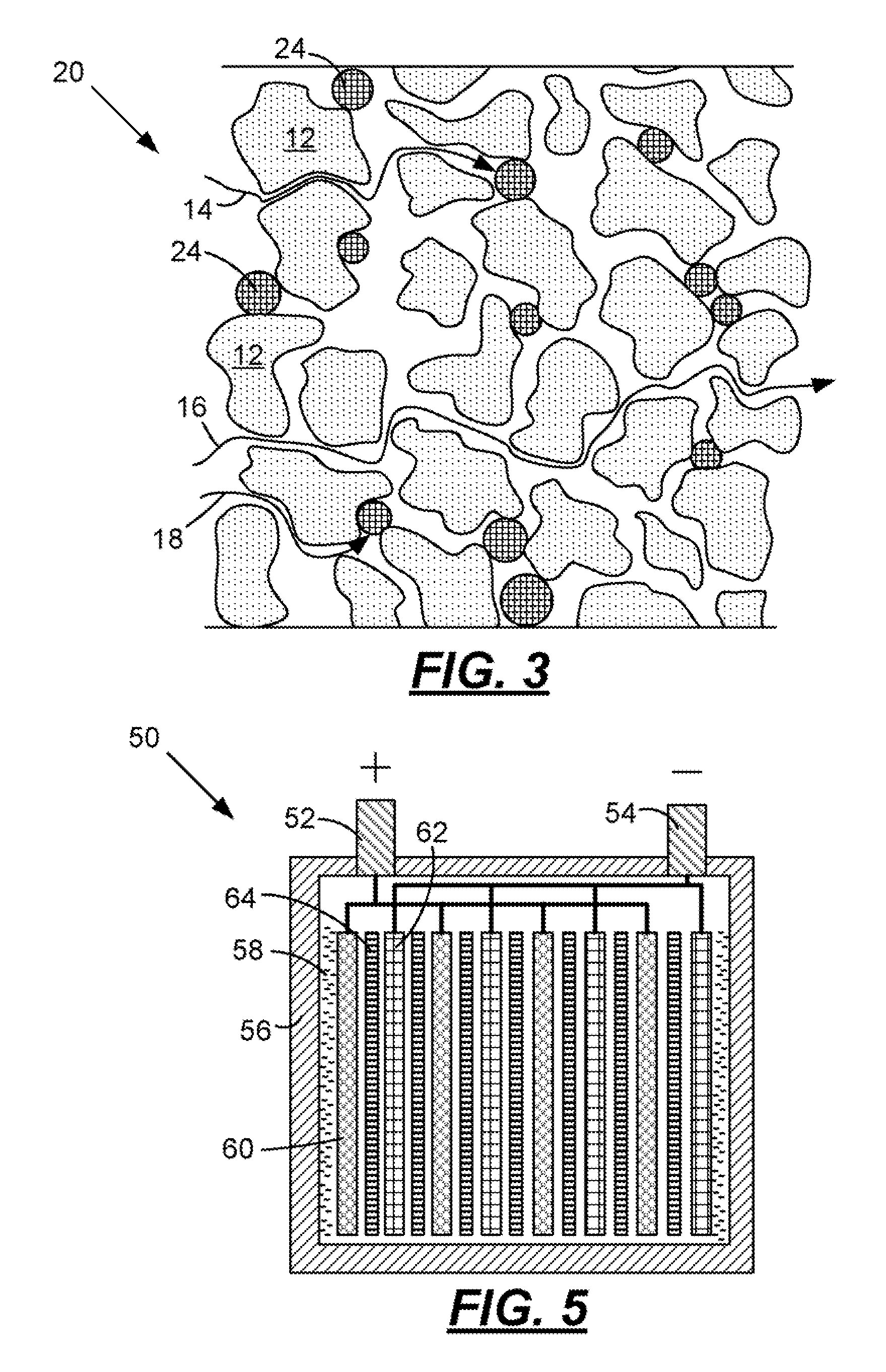

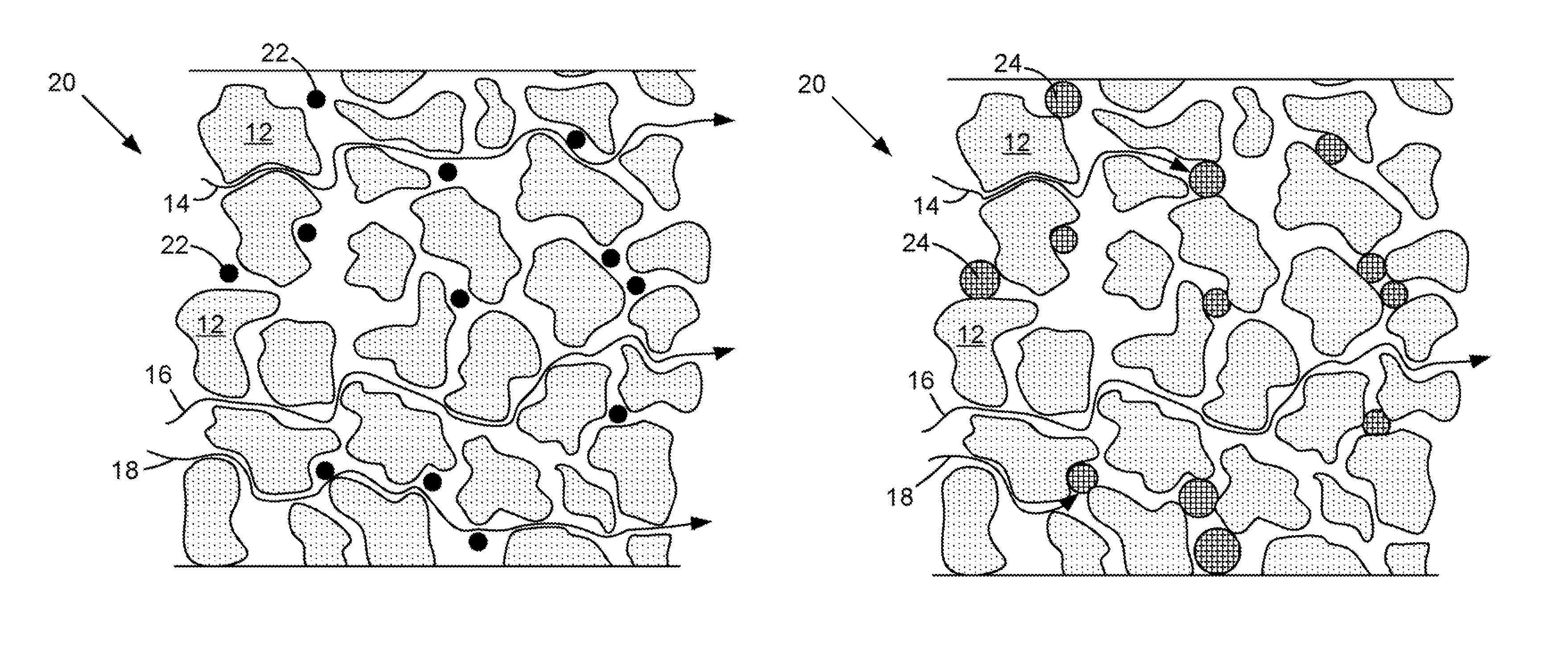

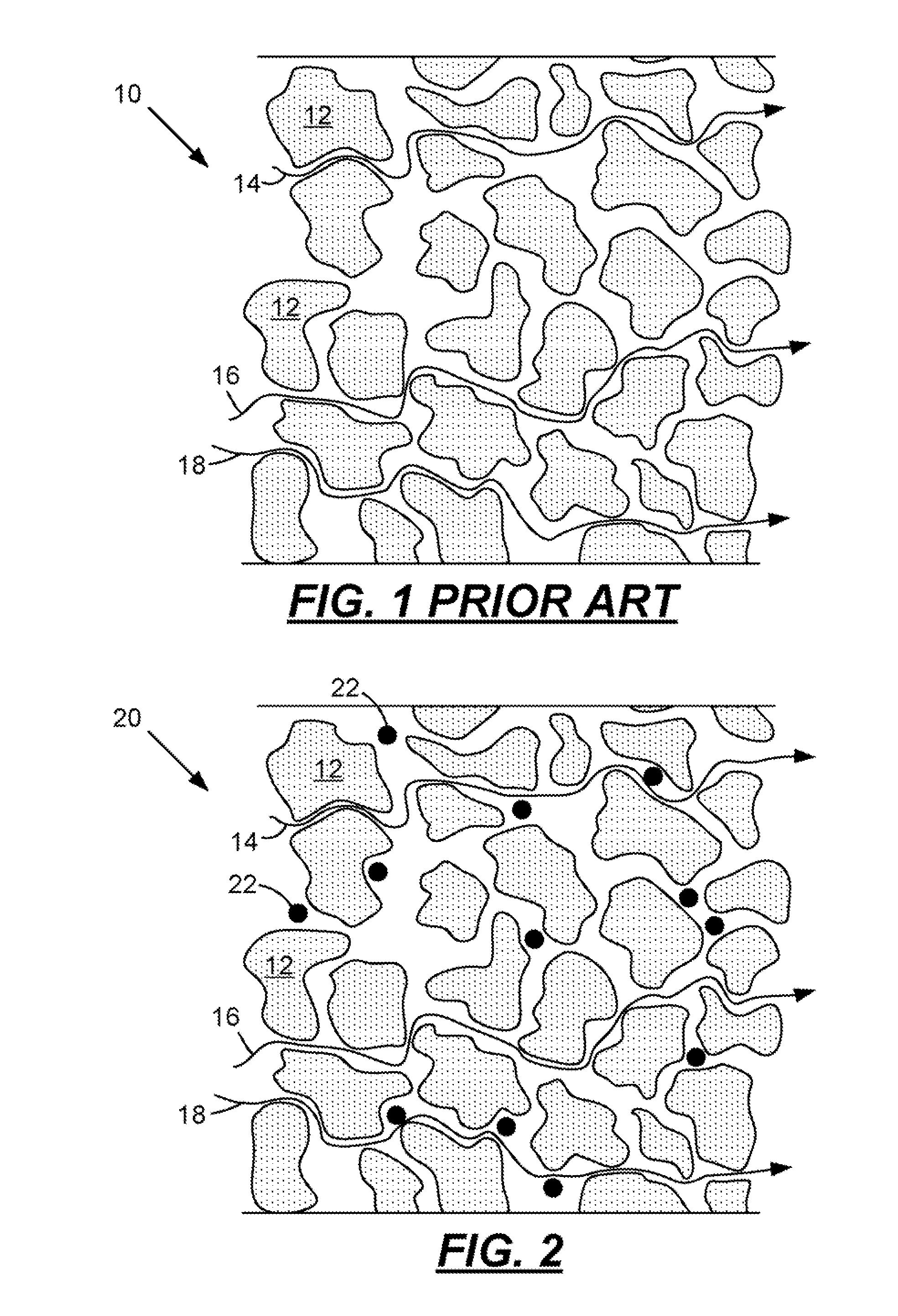

Smart battery separators

InactiveUS20080113259A1Improve energy performanceElectrical resistance increasePrimary cellsSecondary cells charging/dischargingElectrolyteEnergy storage

A separator for an energy storage cell having a microporous matrix including a reversible porosity-controlling agent. The porosity-controlling agent is selected from the group consisting of agents that change size as a function of temperature, agents that change size as a function of electrolyte concentration, and agents that change size as a function of temperature and electrolyte concentration to provide a change in an overall porosity of the separator.

Owner:MP ASSETAB CORP

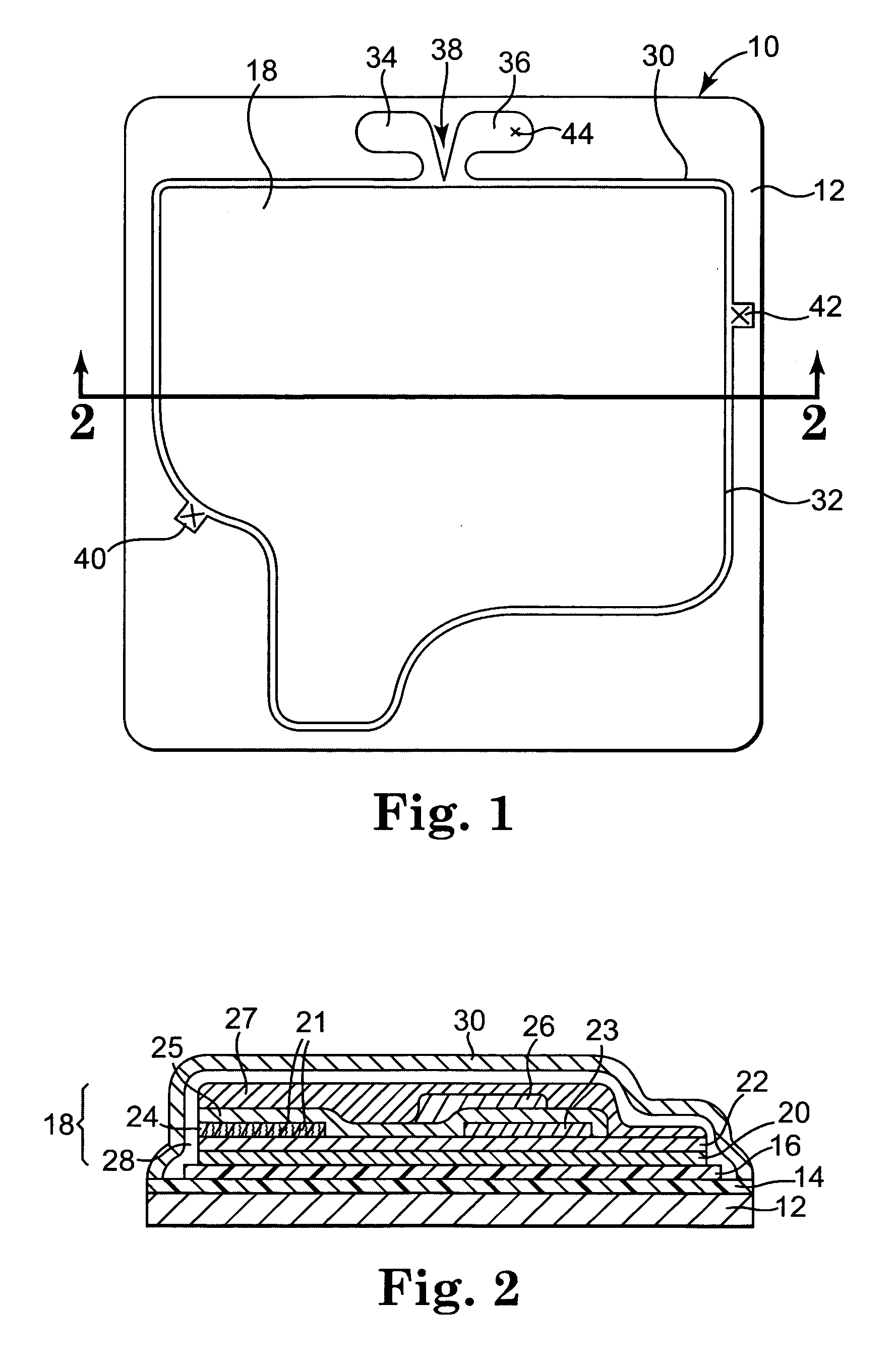

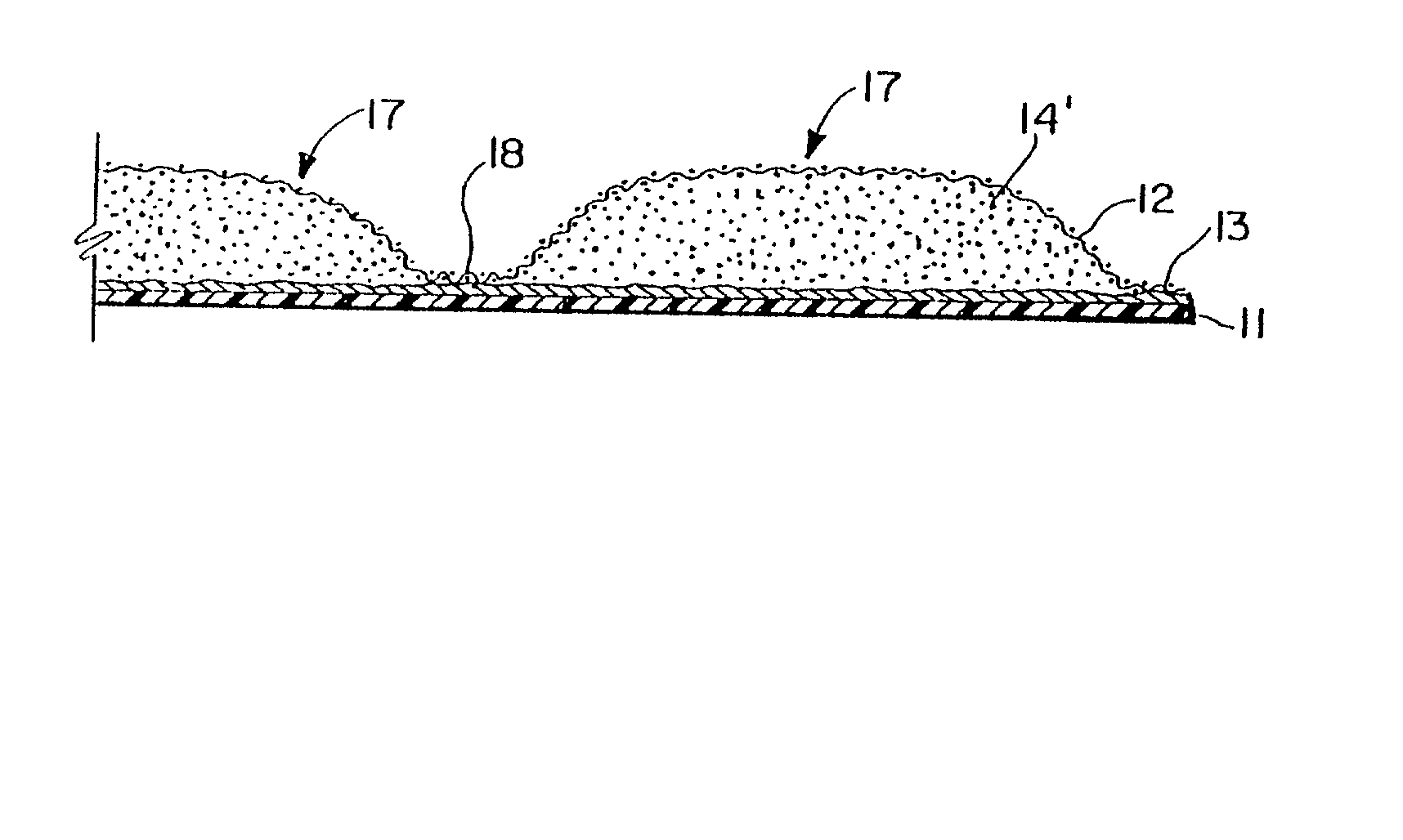

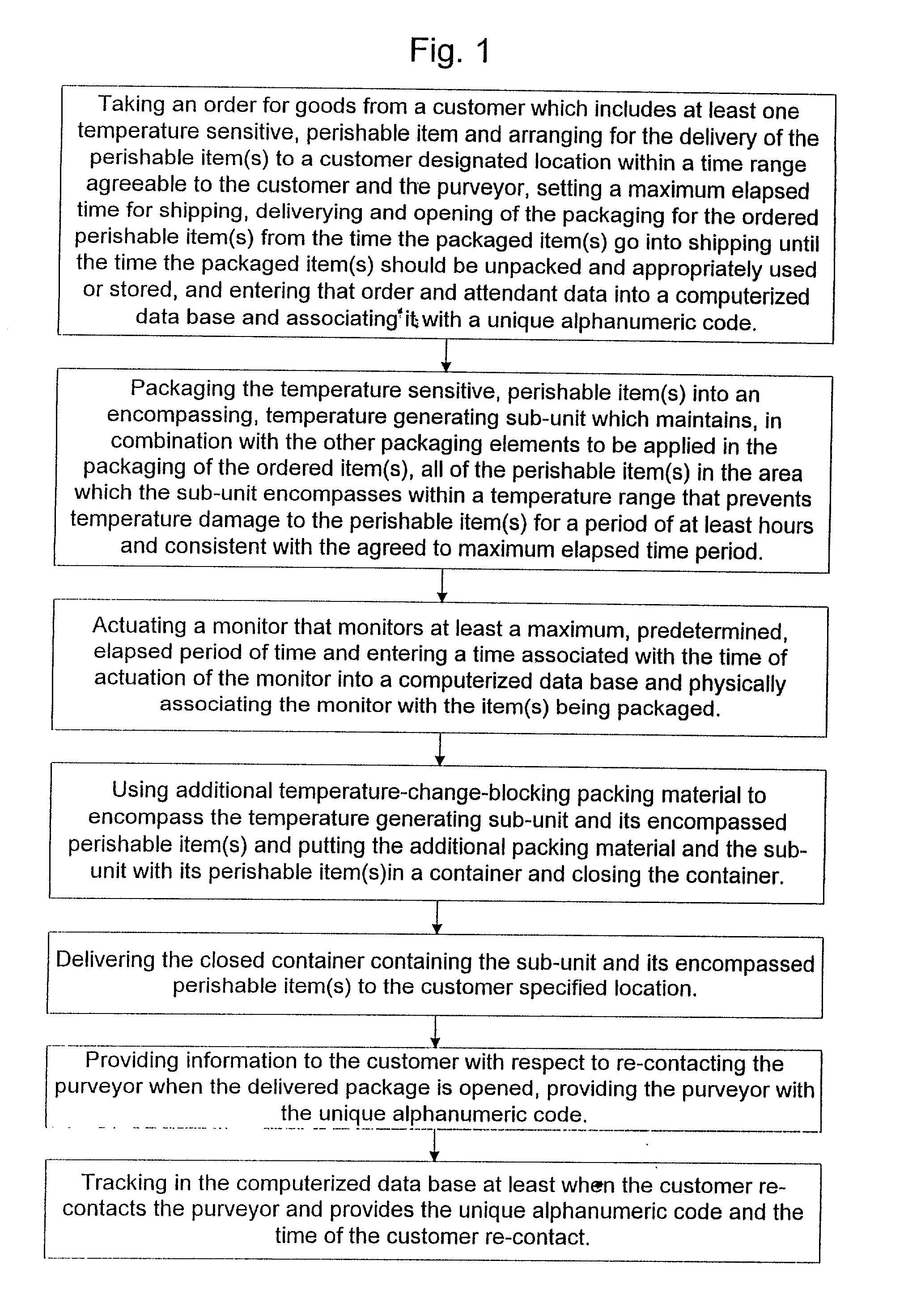

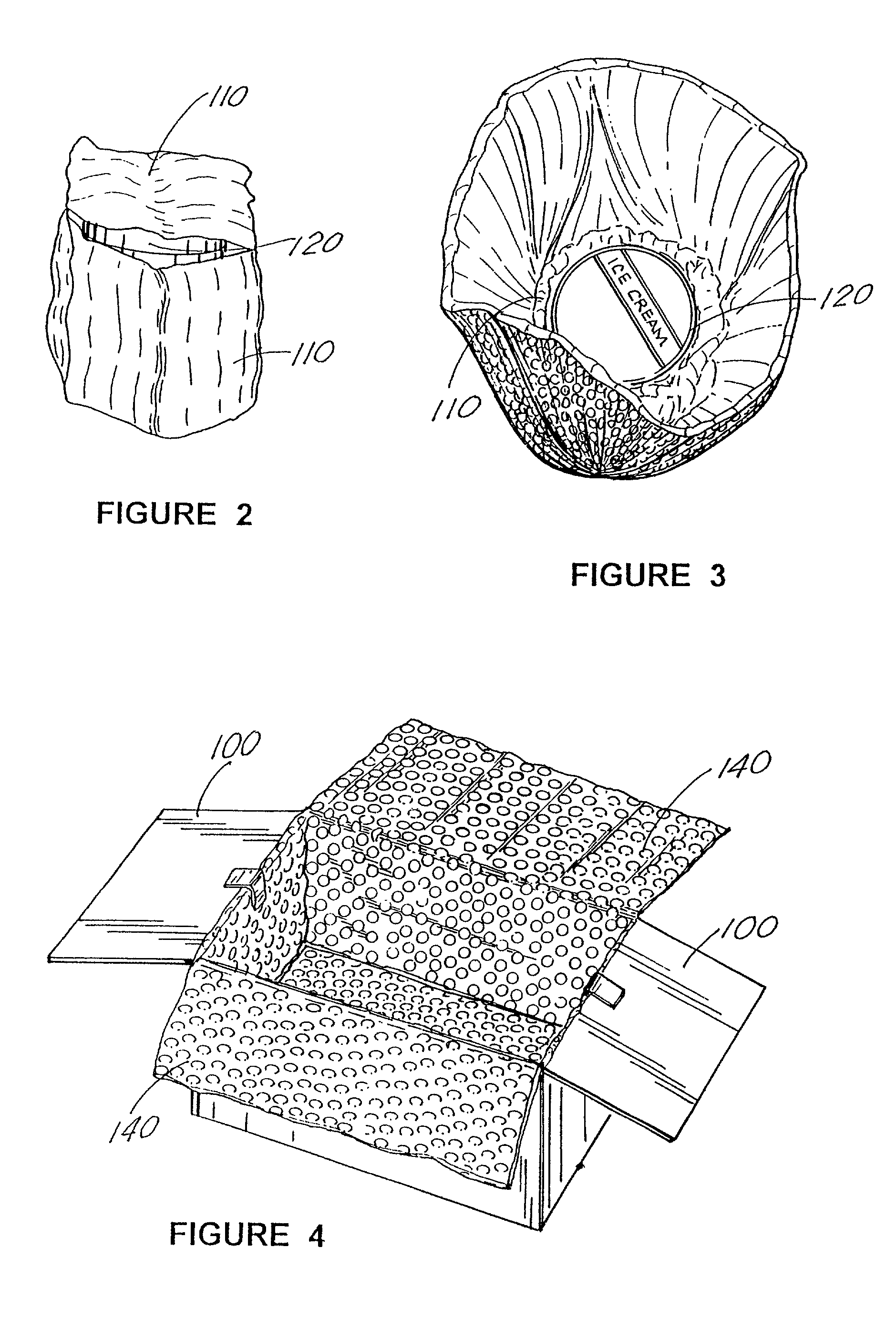

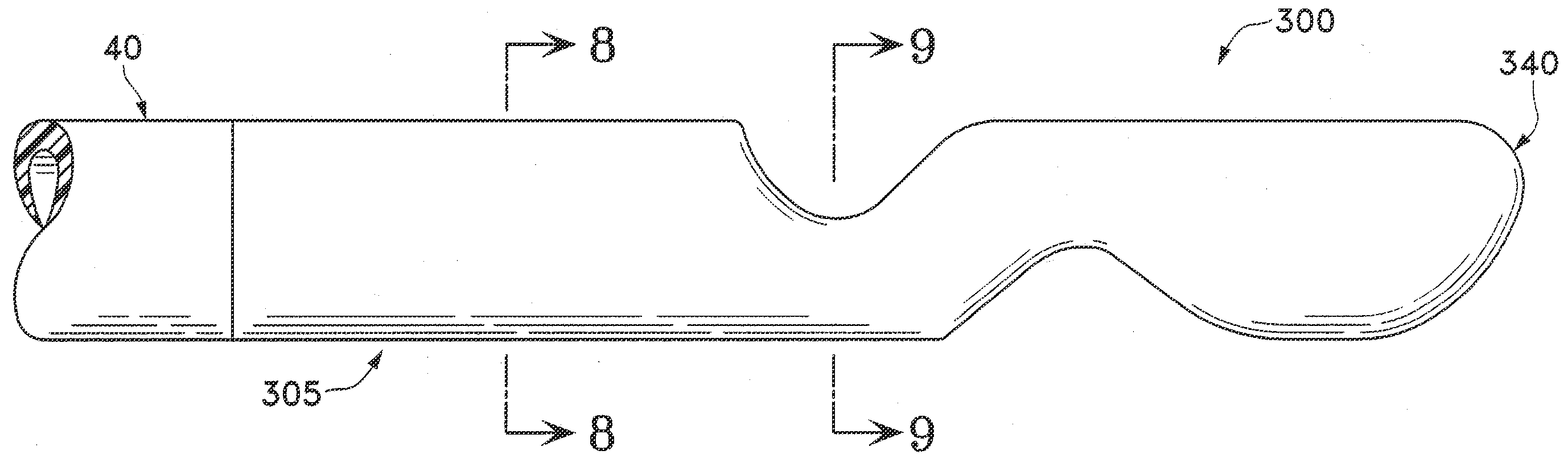

Insulating packaging material and related packaging system

InactiveUS20030087051A1Easy entryTransfer delaySynthetic resin layered productsPackaging foodstuffsCardboardNatural state

Insulating packaging material is wrapped or otherwise positioned around the typically temperature sensitive product, with the packing material including, alternatively, 1 ply (FIG. 22; metallized plastic film), 2 ply (FIGS. 23 & 24) and 3 ply (FIG. 25) material, in which some of the 2 ply & 3 ply embodiments include a layer of bubble wrap material having its bubble side placed or laminated against the flat side of the adjacent ply, which adjacent ply can be, for example, a mettalized plastic film or a foam layer or both layers can be included. With such a bubble side arrangement, multitudinous air pockets are formed between the bubbles of the bubble wrap and the other ply's typically flat interfacing surface. A separate layer of bubble wrap also preferably is placed about the interior of the box with its bubble side placed against the interior flat surfaces of the box, with the bubbles forming air pockets with the flat sides, further enhancing the insulating properties of the packaging for the goods. An exemplary system for delivering perishable groceries (120 / 120'), including a corrugated cardboard or other type box (100); a source of cold (or heat as needed) maintaining the temperature inside the box within a desired temperature range for hours or days, using an all encompassing pouch of packet material (110 / 10), used individually (FIGS. 2 & 3) or collectively (FIGS. 5 & 6), with each packet (17) containing a super-absorbent polymer (14, FIG. 12) which is hydrated (14', FIG. 12A) and then either frozen (e.g., in a freezer) or heated (e.g., in a microwave), without producing moisture as the polymer returns to its natural state; a protective cover (130) protecting the box and its contents from heat radiation (e.g., sunlight).

Owner:THERMAFREEZE PRODS CORP

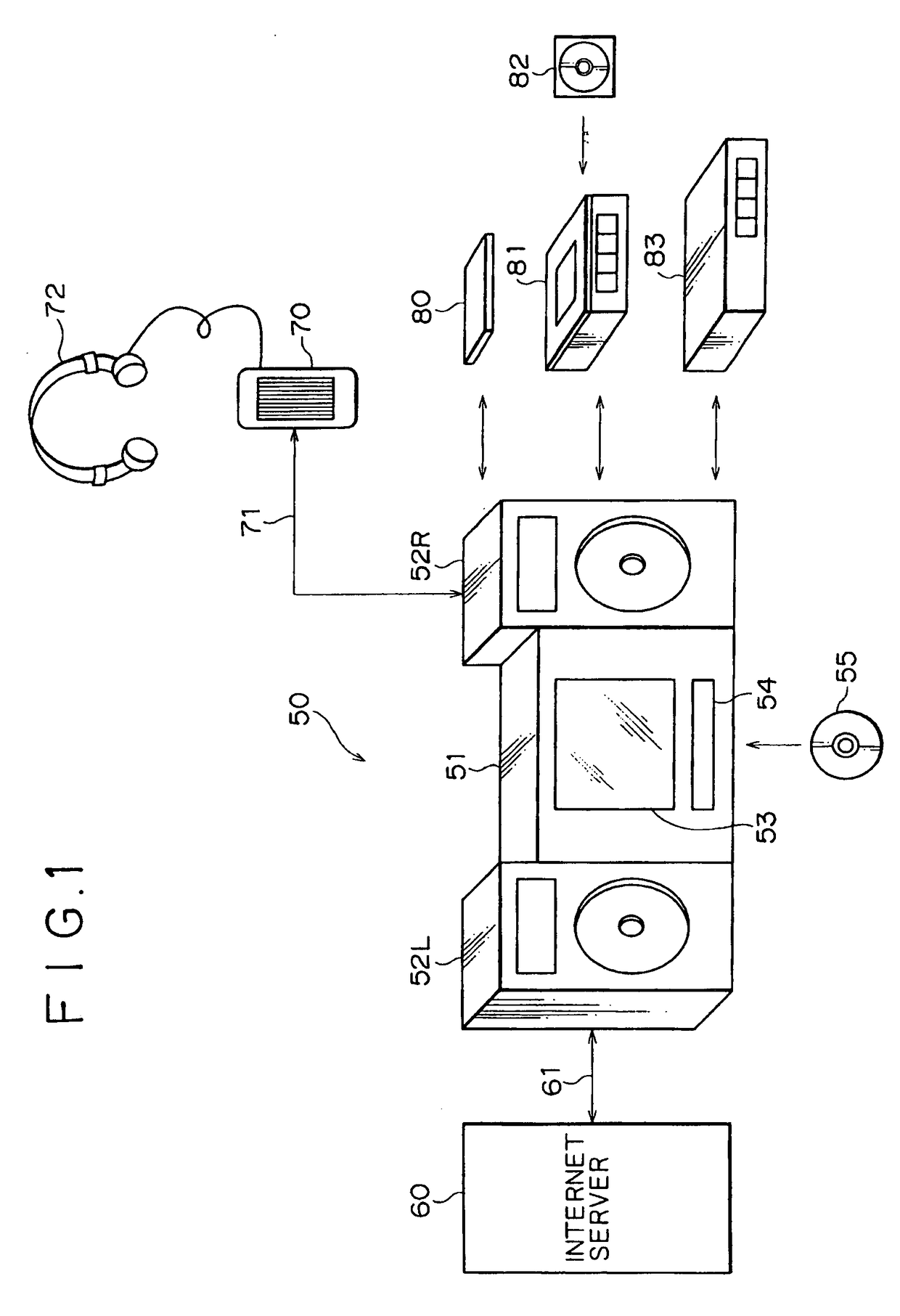

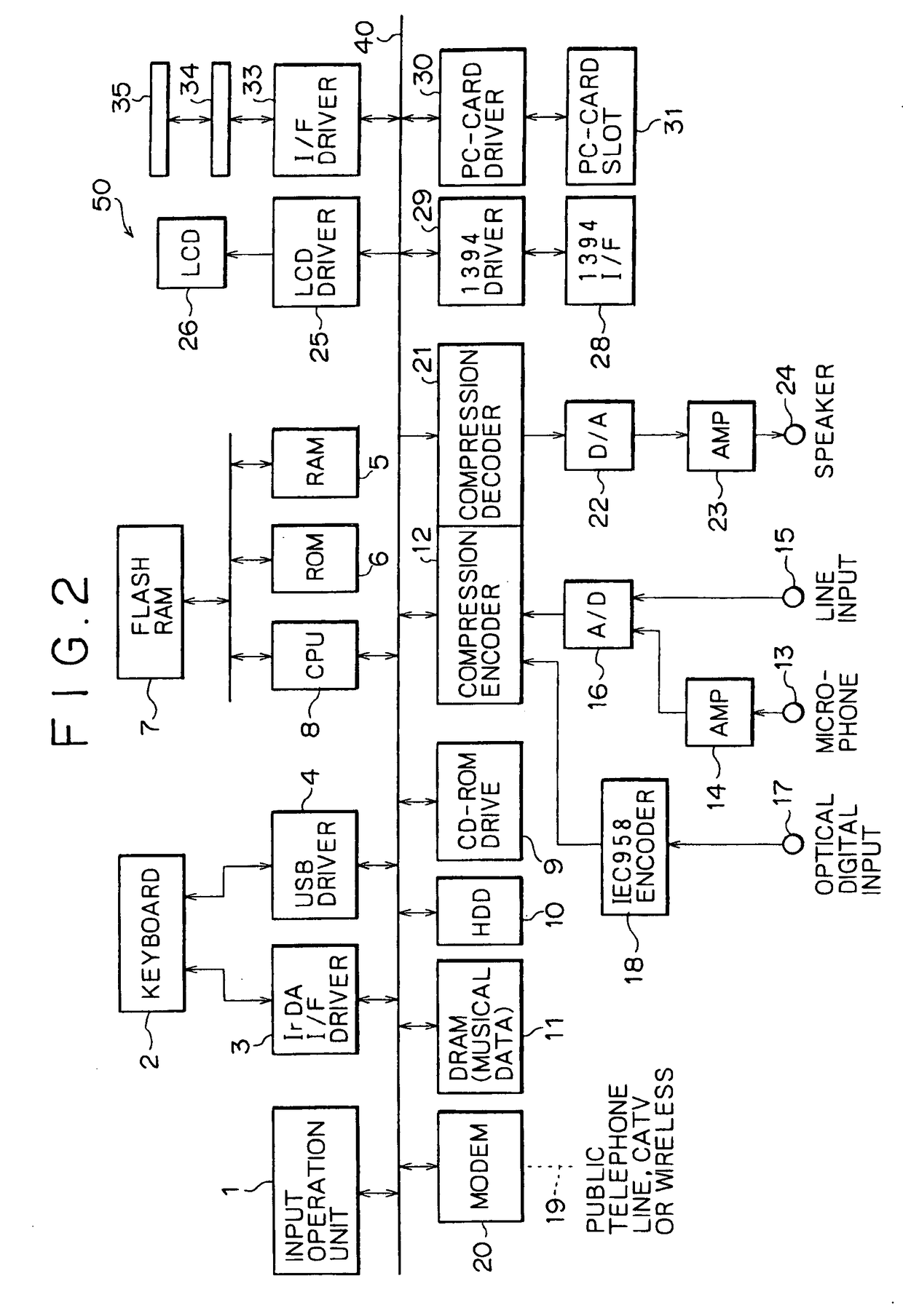

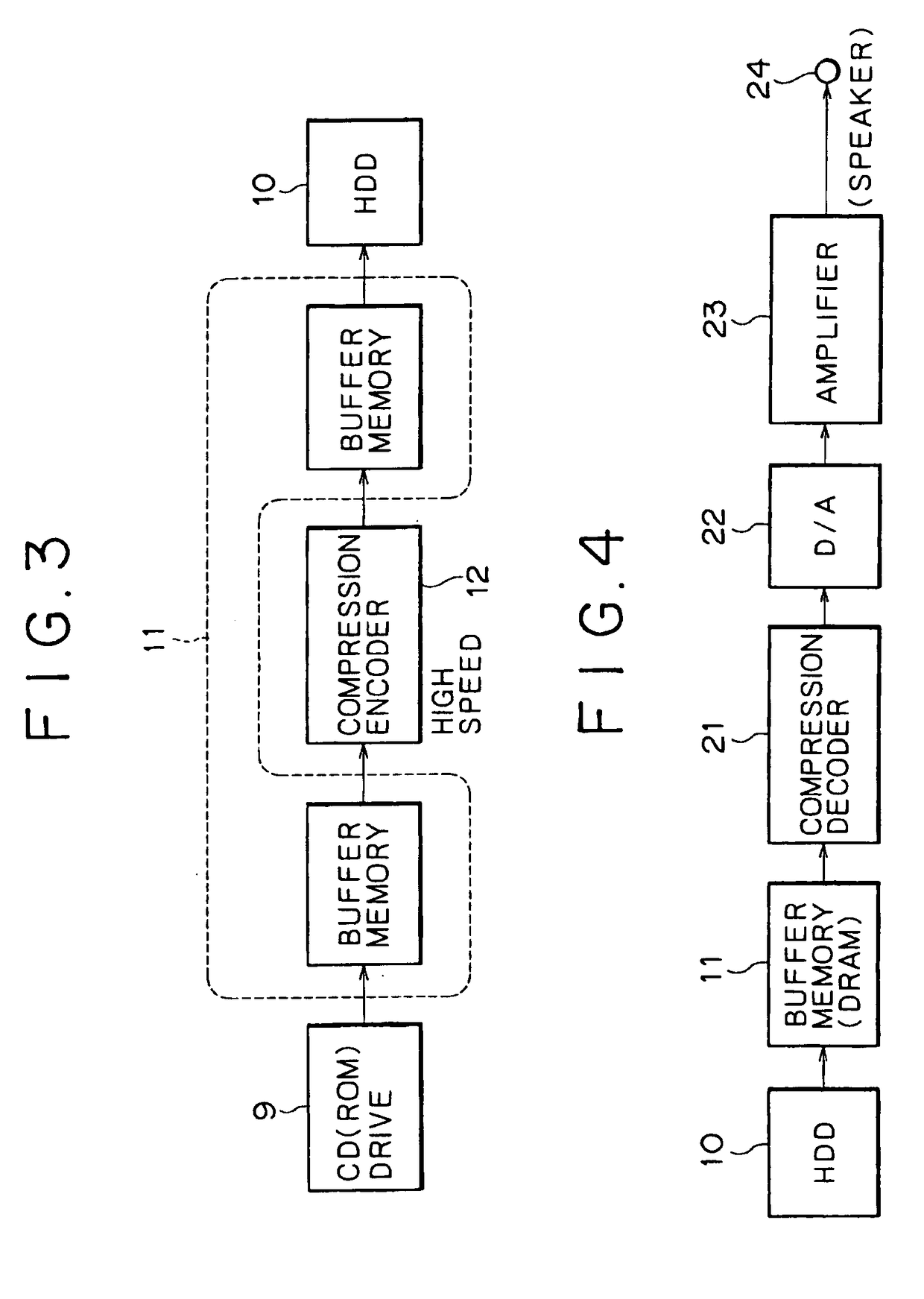

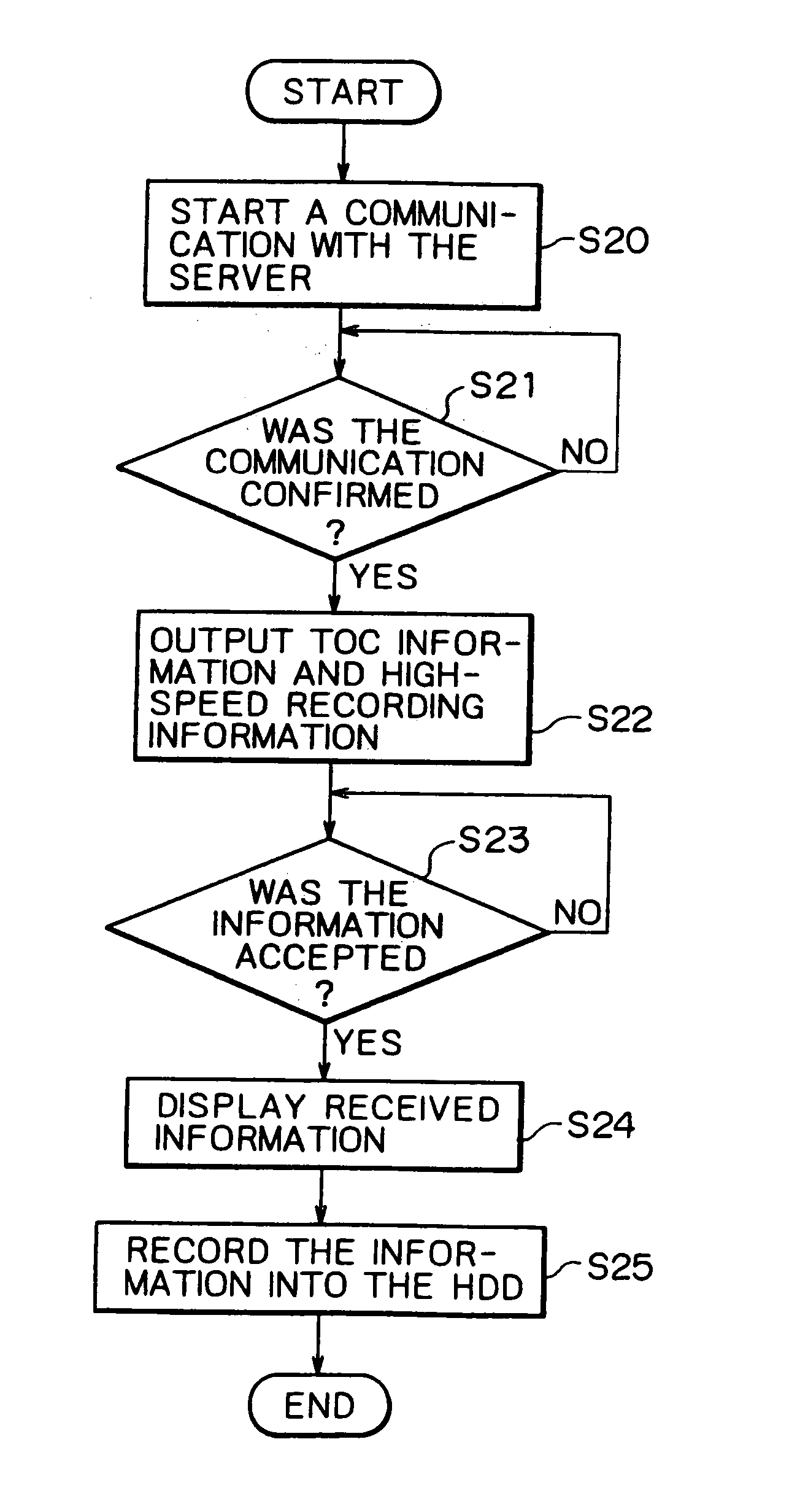

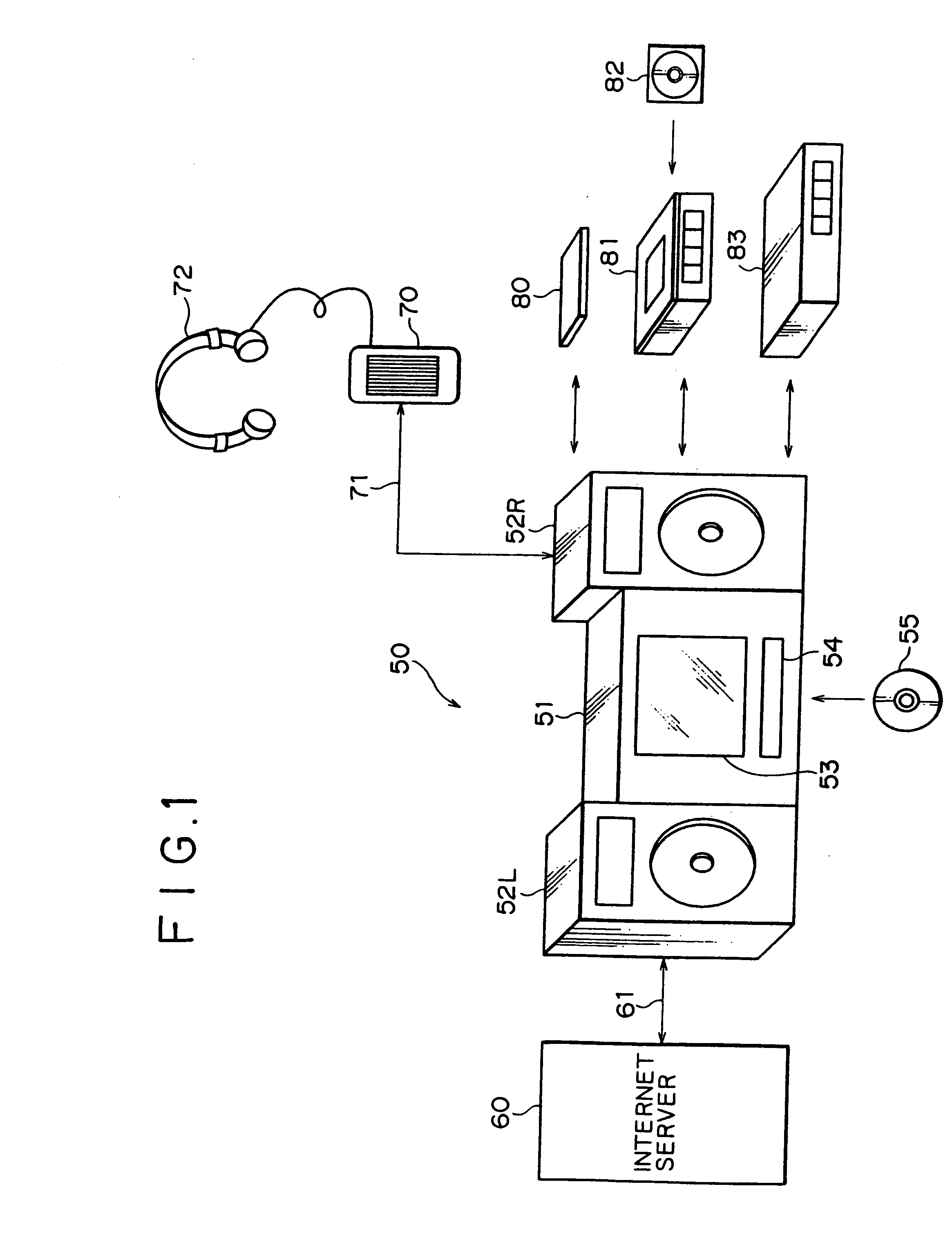

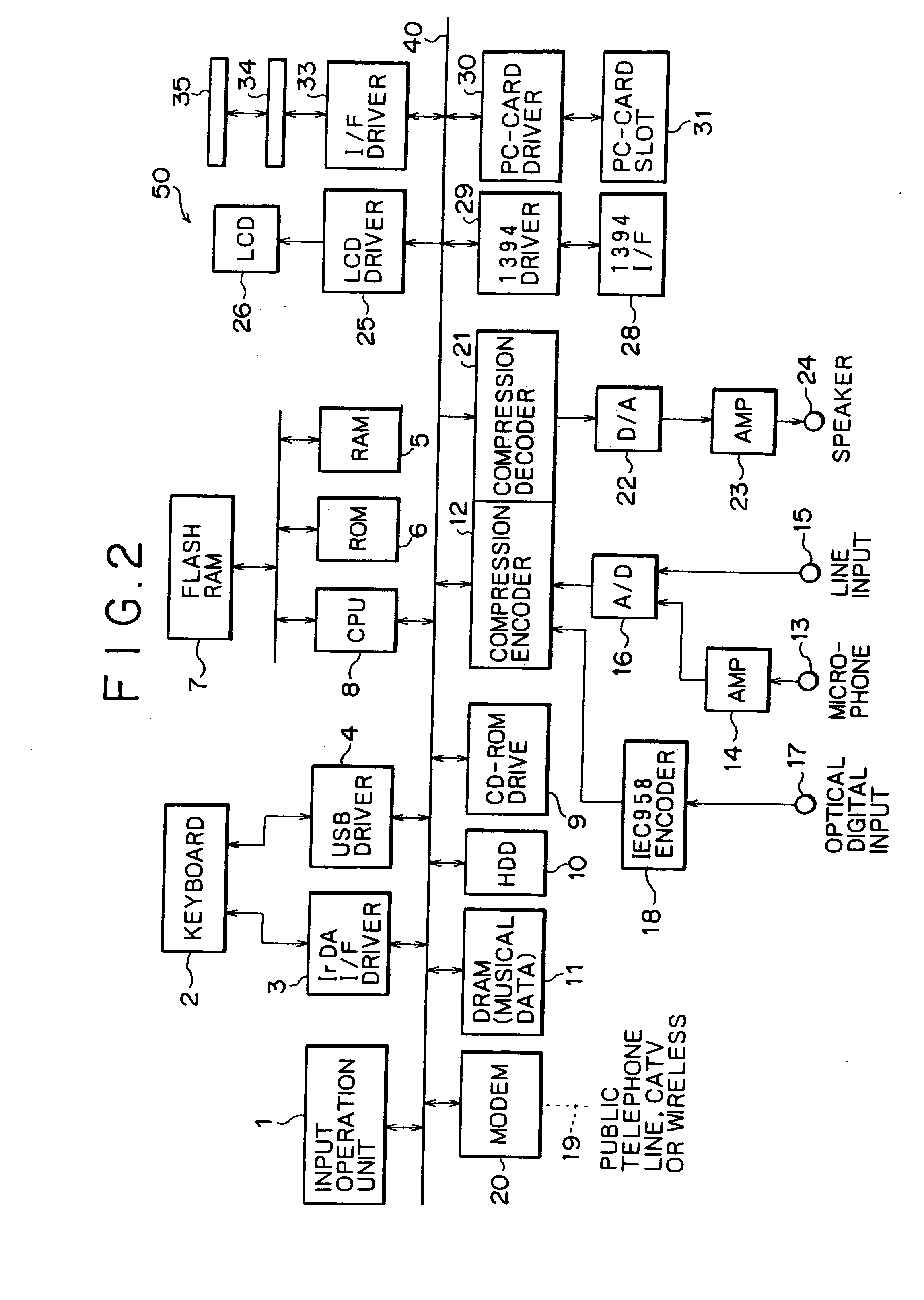

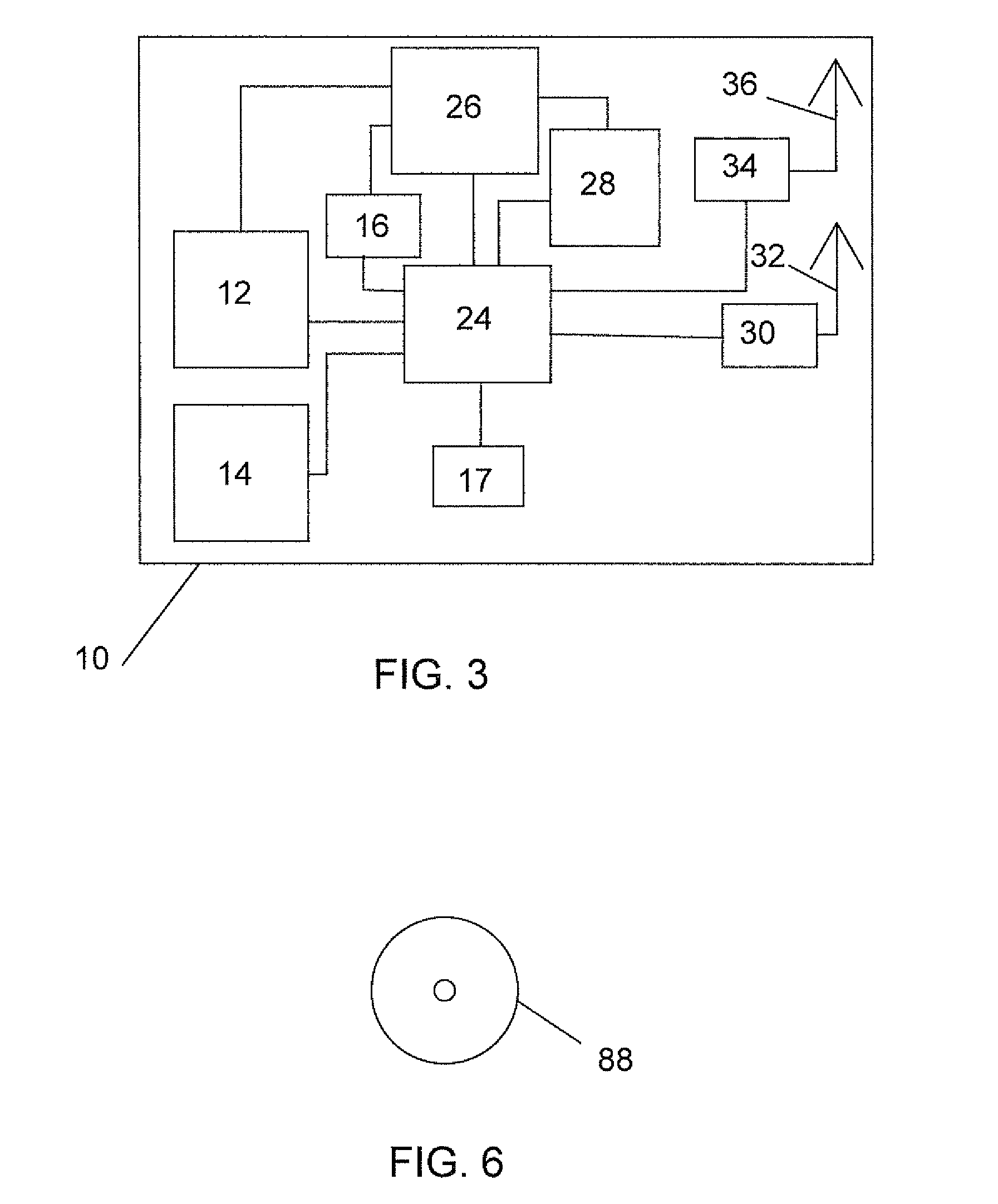

Communication system and its method and communication apparatus and its method

InactiveUS7130251B1Transfer delayFilamentary/web record carriersMechanical recordingCommunications systemData storing

A communication system including a first apparatus having a first storage medium, and a second apparatus for transmitting data to the first apparatus. The second apparatus has a second storage medium for storing management information of data to be transferred to the first storage medium, a communicator for communicating data with the first apparatus, an editor capable of editing the management information and a controller for making a control to transfer data stored in the second storage medium to the first storage medium by way of the communicator based on the management information edited by the editor.

Owner:DATA SCAPE LTD

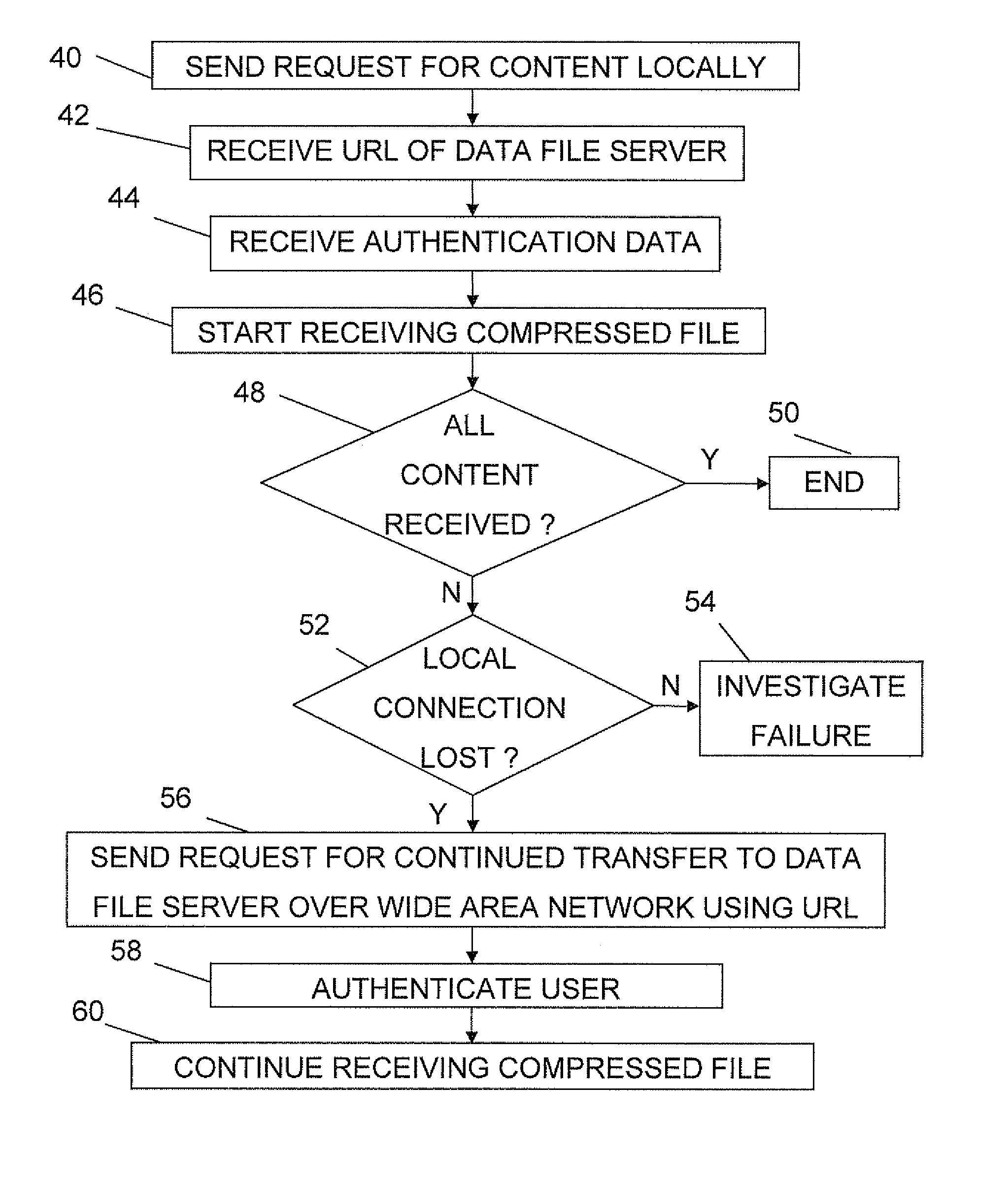

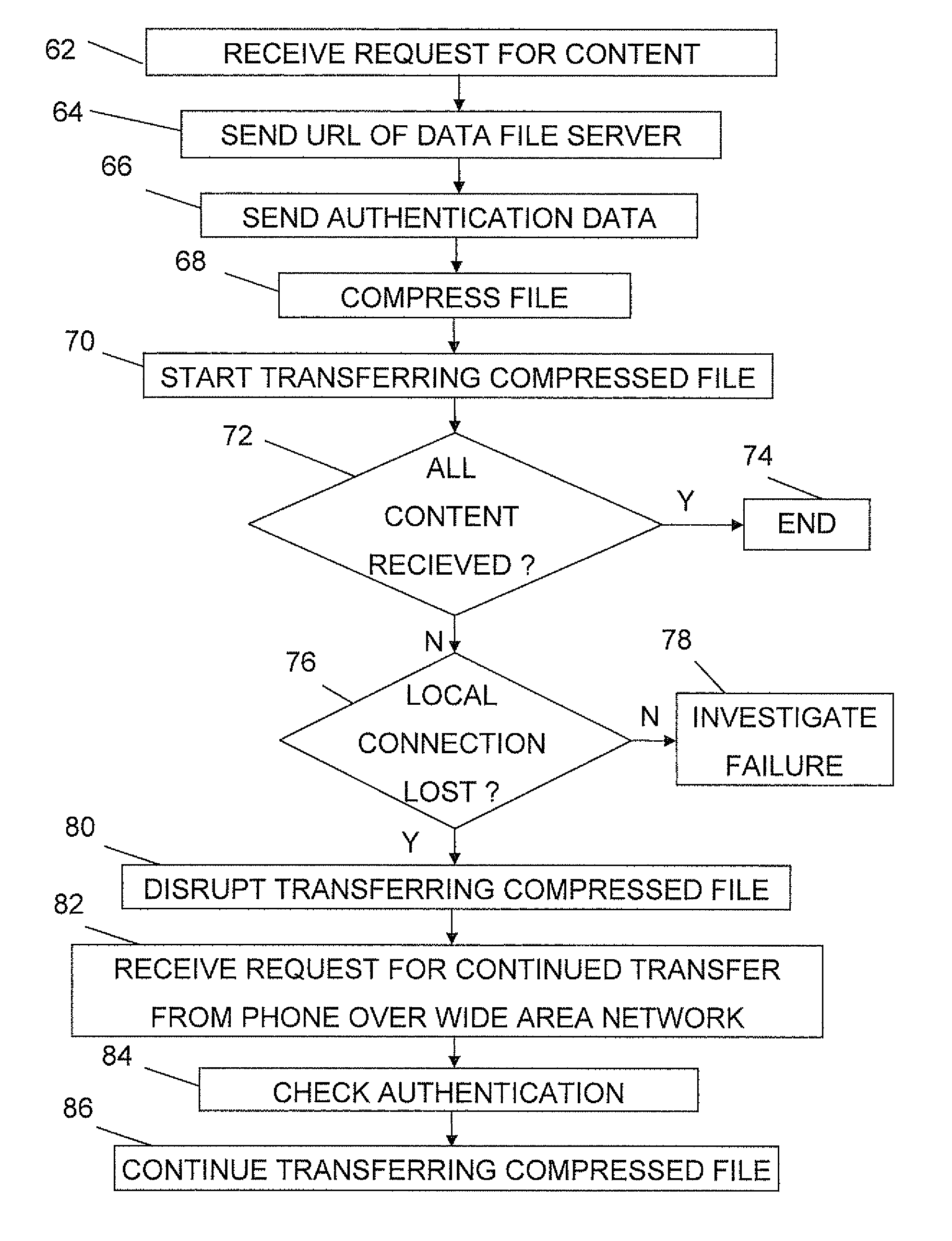

Continued transfer or streaming of a data file after loss of a local connection

InactiveUS20070299930A1Transfer delayNetwork topologiesMultiple digital computer combinationsData fileWide area network

A server receives a request for transfer or streaming of a data file sent in the local network from a portable communication device. The server provides the portable communication device with an identifier allowing the data file to be located on the server via a wide area network and transfers or streams the file over the local network to the portable communication device.

Owner:SONY CORP

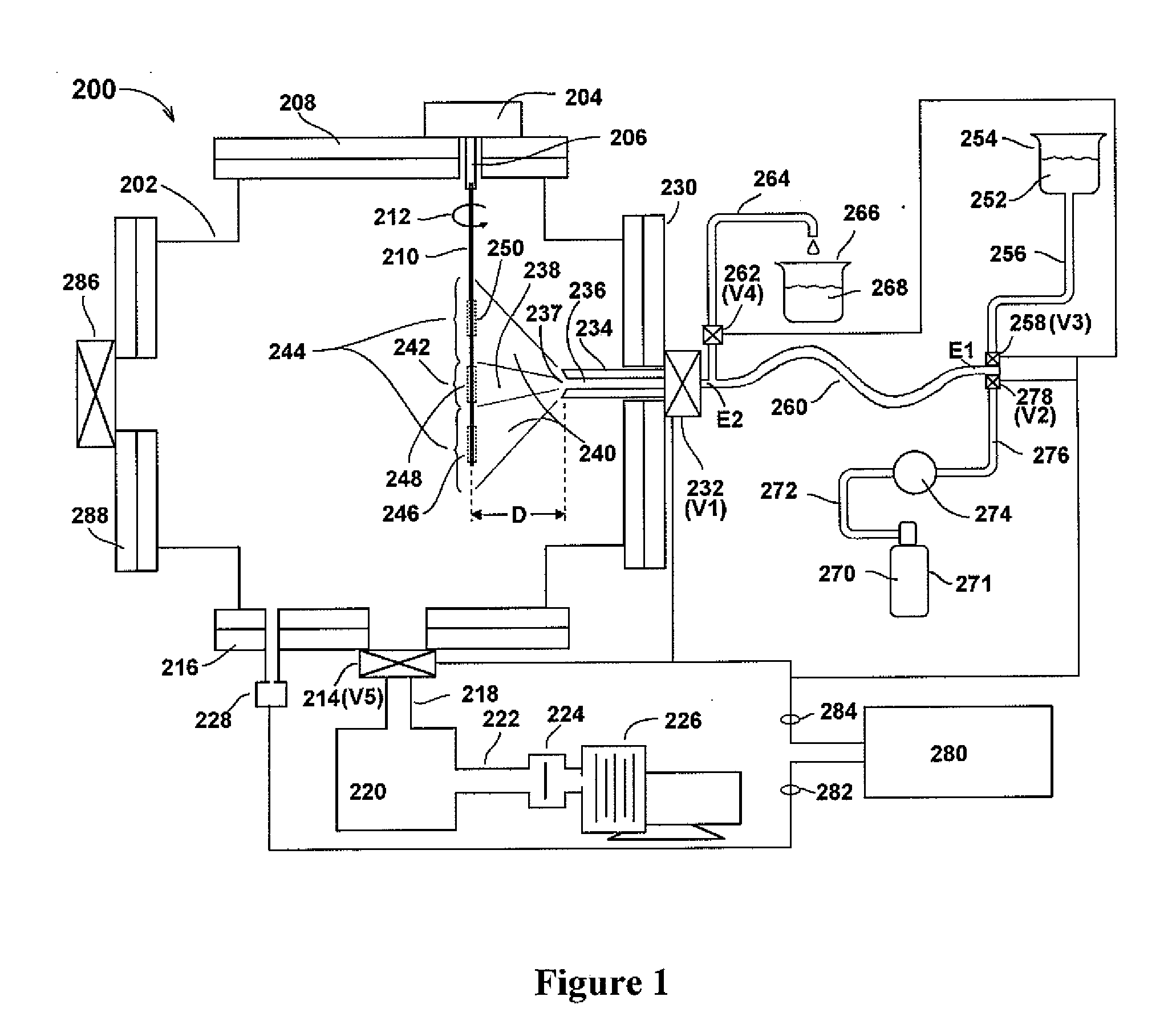

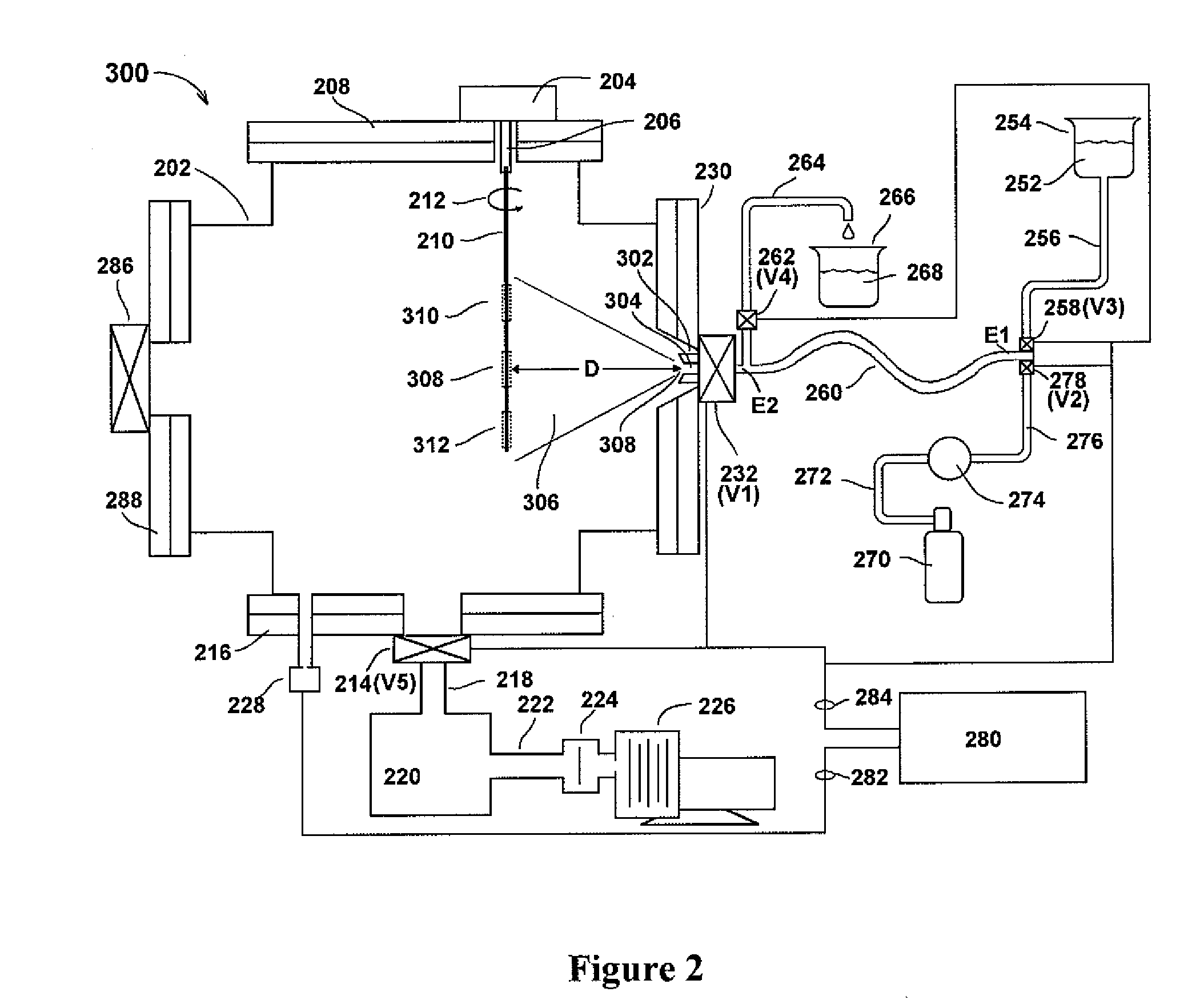

Method and system for coating a surface of a medical device with a therapeutic agent and drug eluting medical devices made thereby

ActiveUS20090098186A1Use be knowImprove coatingVacuum evaporation coatingPretreated surfacesDrug-eluting stentDrug coating

A multi-layer drug coated medical device such as for example an expandable vascular drug eluting stent is formed by vacuum pulse spray techniques wherein each layer is irradiated to improve adhesion and / or drug elution properties prior to formation of subsequent layers. Layers may be homogeneous or of diverse drugs. Layers may incorporate a non-polymer elution-retarding material. Layers may alternate with one or more layers of non-polymer elution-retarding materials. Polymer binders and / or matrices are not used in the formation of the coatings, yet the pure drug coatings have good mechanical and elution rate properties. Systems, methods and medical device articles are disclosed.

Owner:EXOGENESIS CORP

Content management system and associated methodology

InactiveUS20060212564A1Transfer delayRecord information storageCommerceCommunications systemData transmission

Owner:SONY CORP

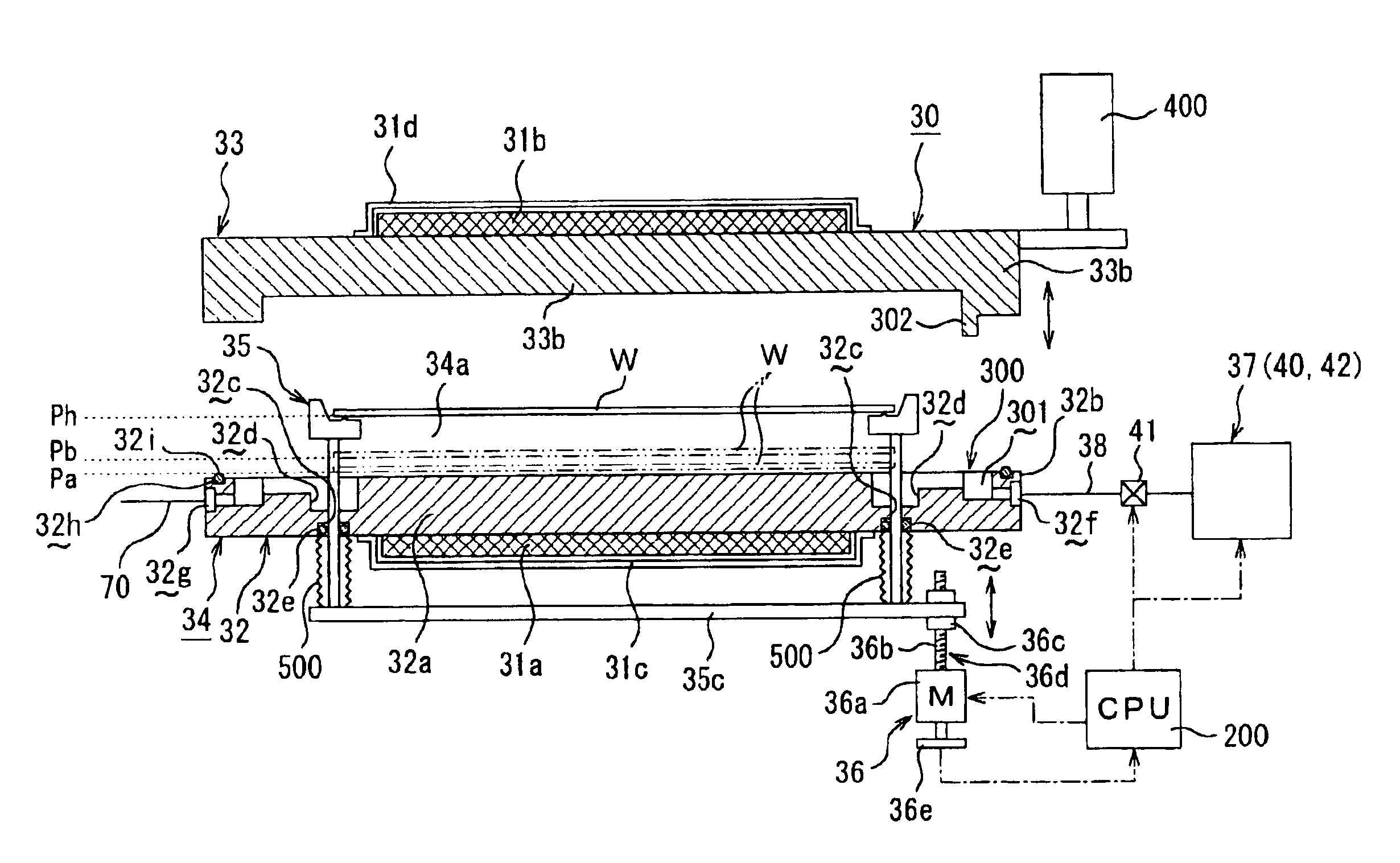

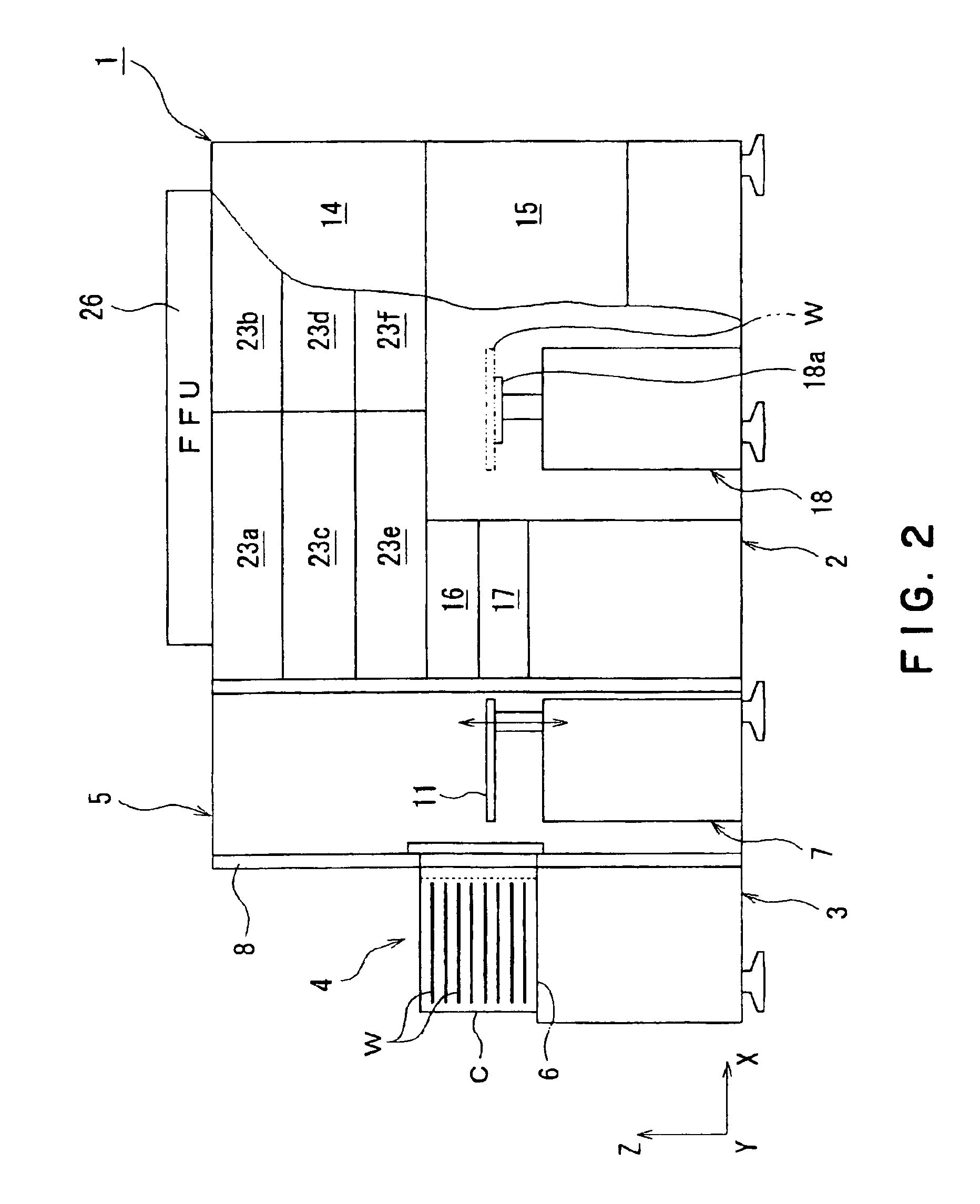

Substrate processing method and apparatus

ActiveUS6954585B2Uniform processingUniform supplyDrying solid materials with heatMuffle furnacesEngineering

A method for heating a wafer to a predetermined temperature, the wafer being held by a holding unit and being accommodated in a processing container equipped with a heater. The wafer is heated to a processing temperature while positioning the wafer at an adjacent position that results form making the wafer approach the heating surface of the heater. After heating the wafer to the predetermined temperature, the wafer is separated from the flat bottom surface of the container body to a processing position. In this state, a processing chamber of the processing container is supplied with a processing fluid, while the holding unit and the heater are relatively moved close to and apart from each other intermittently or continuously. Accordingly, it is possible to quickly heat the substrate to a processing temperature while supplying the substrate with the processing fluid uniformly. This improves throughout and the homogenization in processing.

Owner:TOKYO ELECTRON LTD

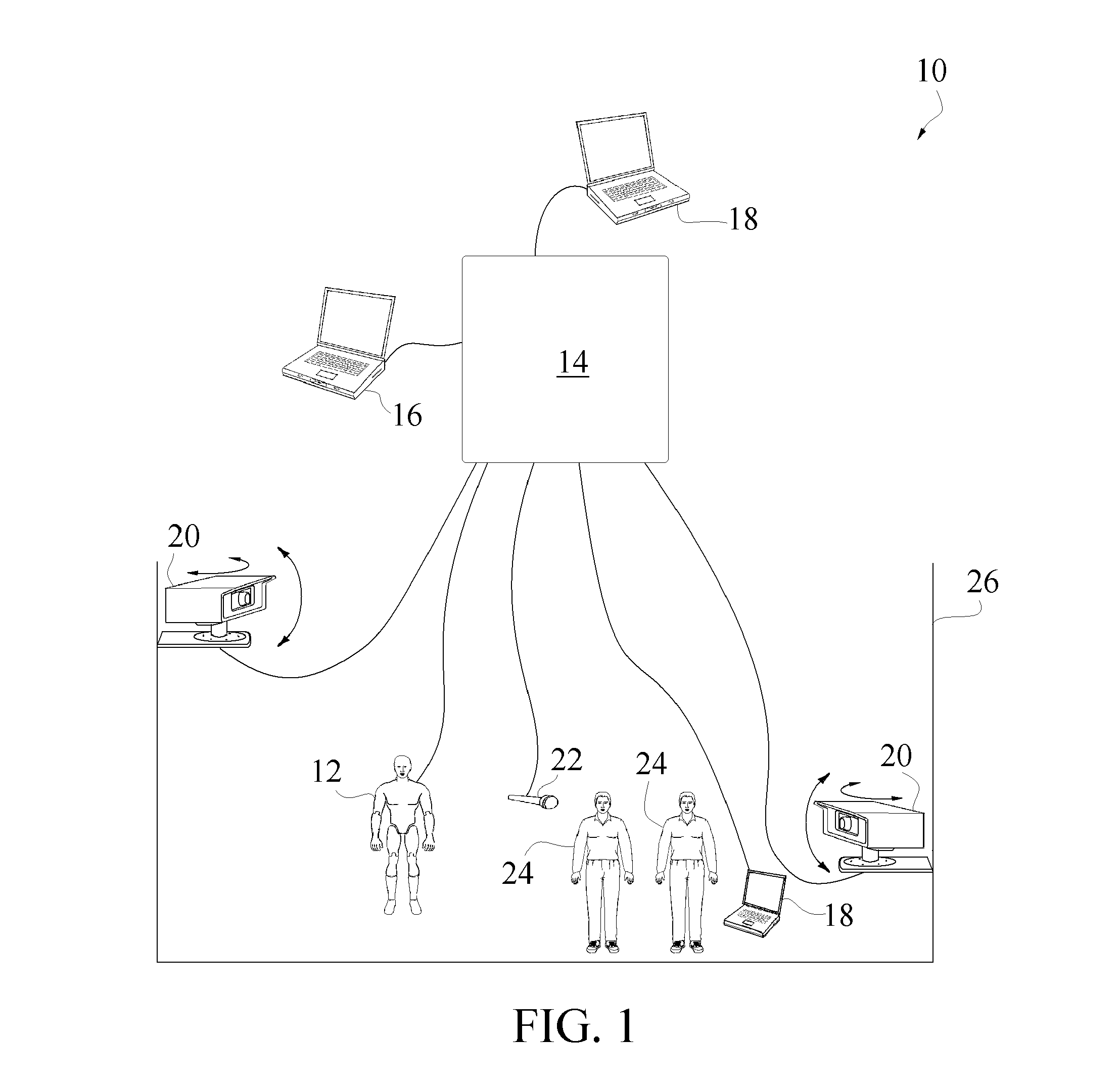

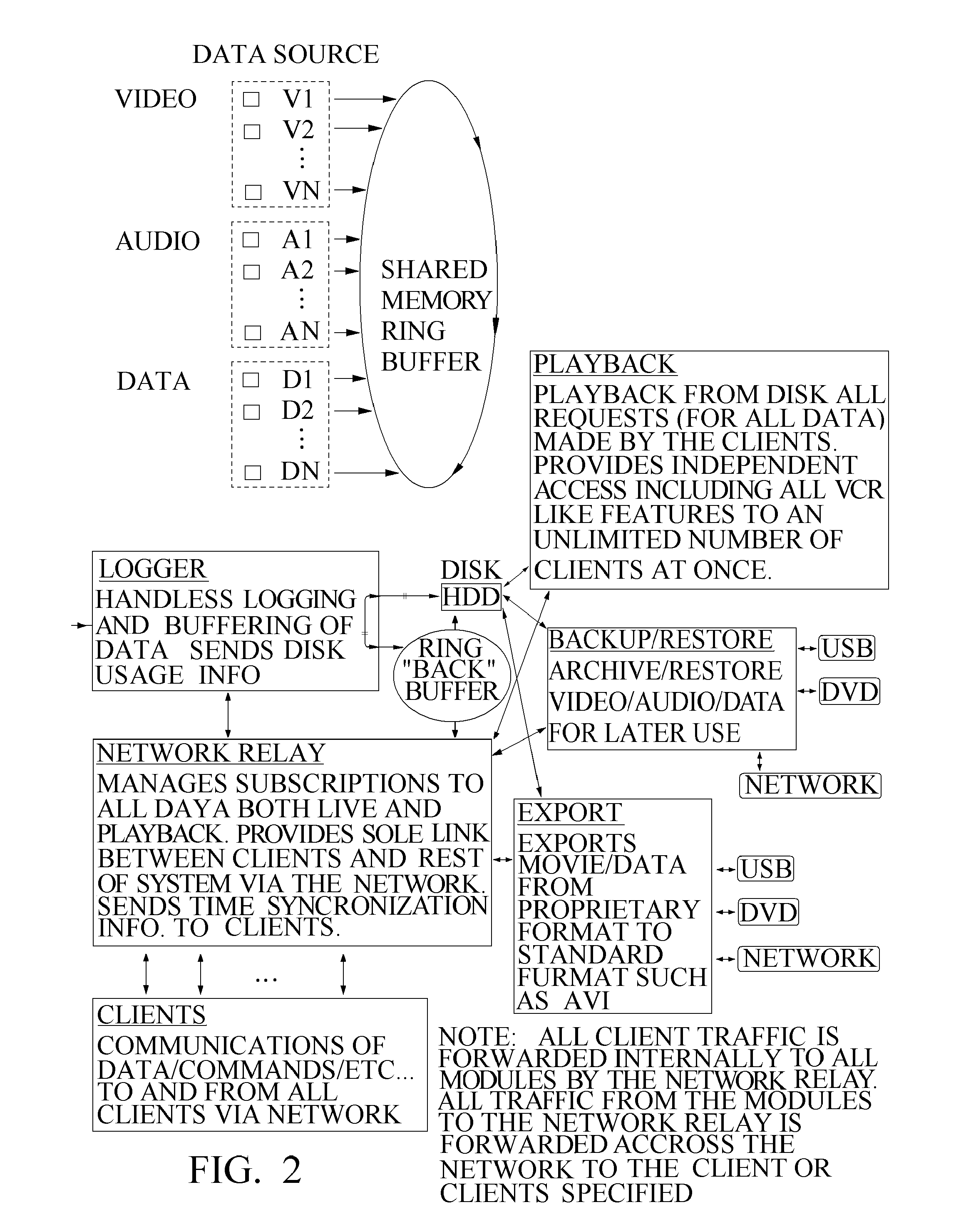

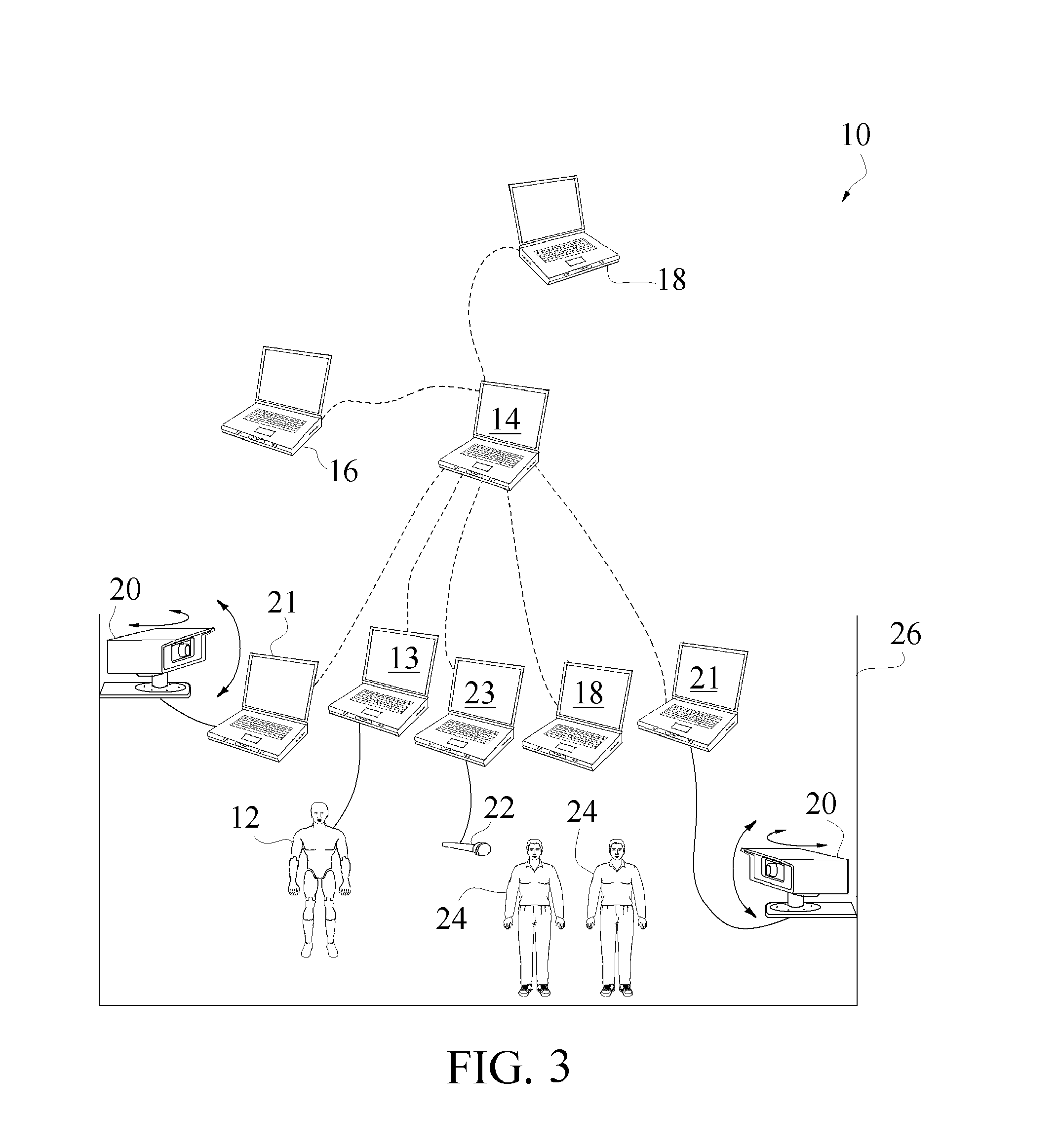

Method and apparatus for integrated recording and playback of video audio and data inputs

ActiveUS20080124694A1Transfer delayEasy transferEducational modelsElectrical appliancesWireless controlVideo record

A method for the integrated recording and playback of video, audio and data inputs using training simulators comprises the step of simultaneously receiving at least one data source input, audio input and video input into a common digital memory buffer in a time stamped manner for at least a given training event, wherein at least one of the data source inputs is a data record throughout the event of at least one simulated parameter of the training simulator, wherein at least one audio input is an audio record of the training event and at least one video input is a video record of the training event, and wherein the common memory buffer allows independent, simultaneous, synchronized, user controlled playback of the individual inputs received within the memory buffer. The system provides for contemporaneously flagging the common memory buffer during the event through a wireless controller.

Owner:PORT

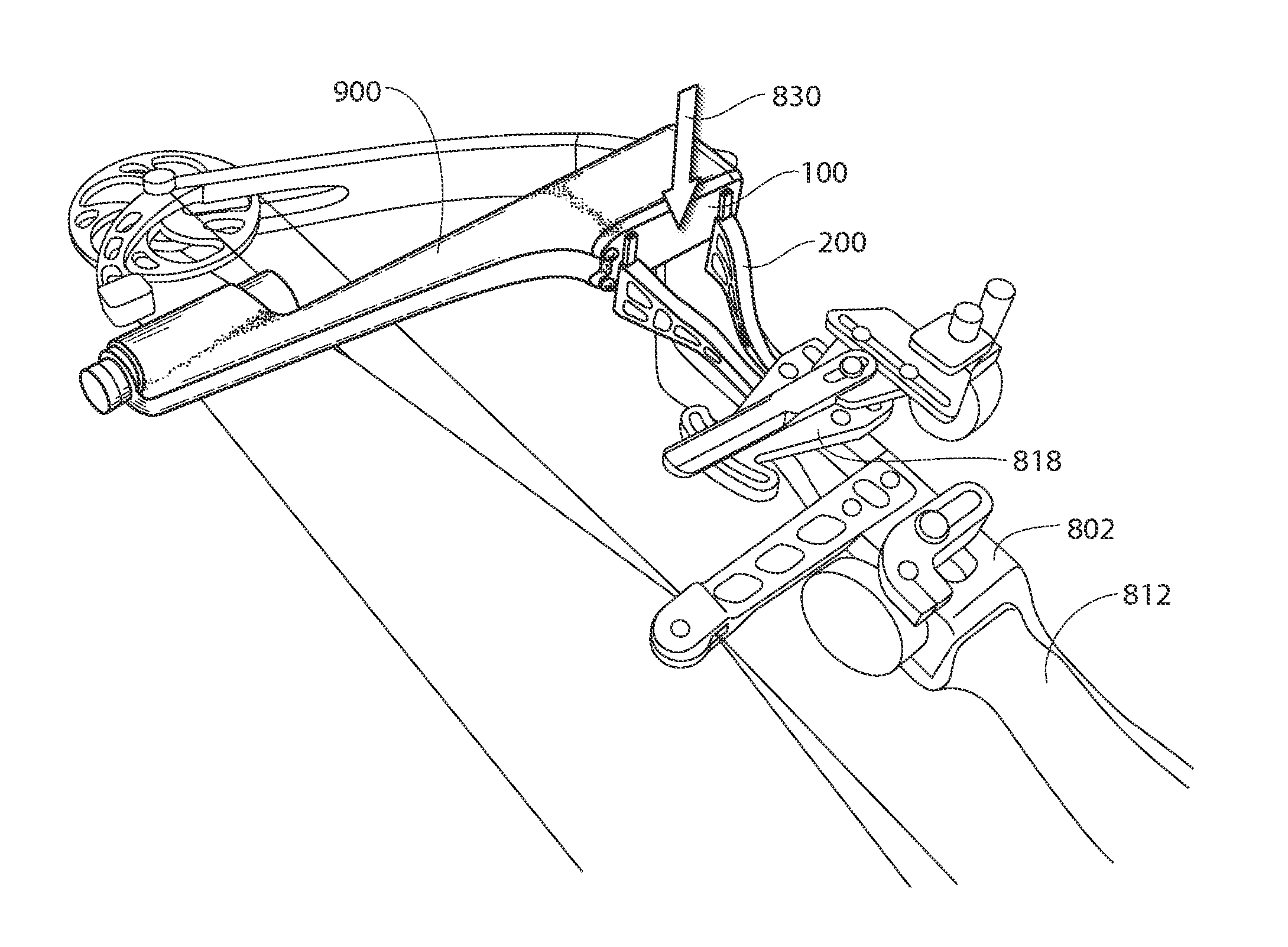

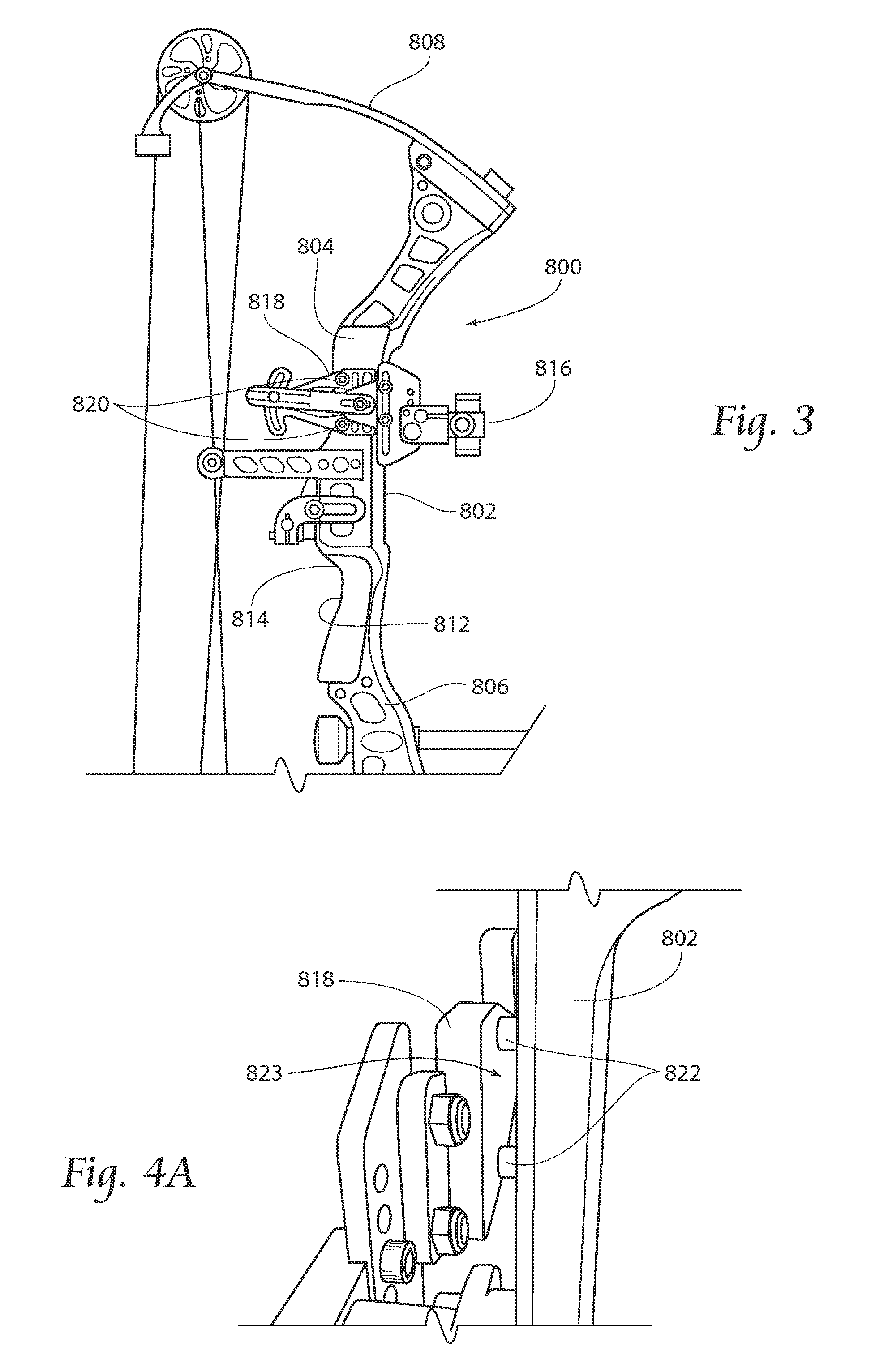

Systems and methods of accessory mounting

InactiveUS20120085331A1Uniform structurePrecise positioningBows/crossbowsSighting devicesEngineering

Embodiments according to the present invention provide improved systems and methods for mounting accessories, such as a rangefinder, to supporting structure, such as an archery bow or firearm. The improved accessory mount includes one or more brackets adapted to interface to the accessory and to the supporting structure. Preferred brackets provide universal adaptability between and amongst a variety of supporting structures.

Owner:LANG RUSSELL W

Bolus tip design for a multi-lumen catheter

InactiveUS20090126867A1Prevent unnecessary traumaEase and efficiency and reduced traumaMulti-lumen catheterOther blood circulation devicesCatheter device

A method of making a multi-lumen catheter includes forming a catheter body including a first lumen and a second lumen, and forming a catheter tip having a first channel terminating distally in a first opening on a first side of the catheter tip, and a second channel terminating distally in a second opening on a second side of the catheter tip opposite of the first side. The first and second openings of the catheter tip extend through an outer wall of the catheter tip to a dividing section. The catheter tip is affixed to the catheter body such that the first channel is aligned with the first lumen and the second channel is aligned with the second lumen.

Owner:CR BARD INC

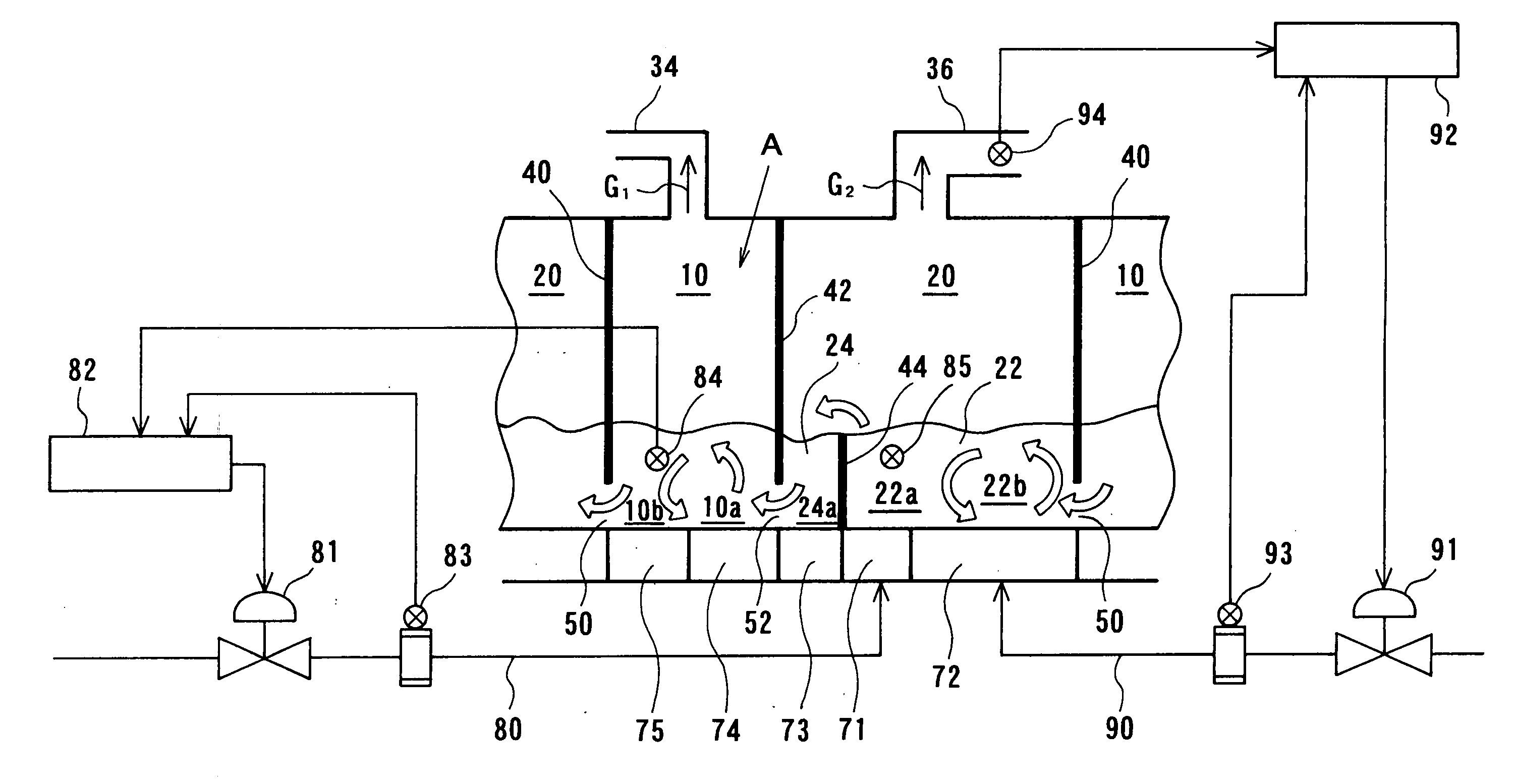

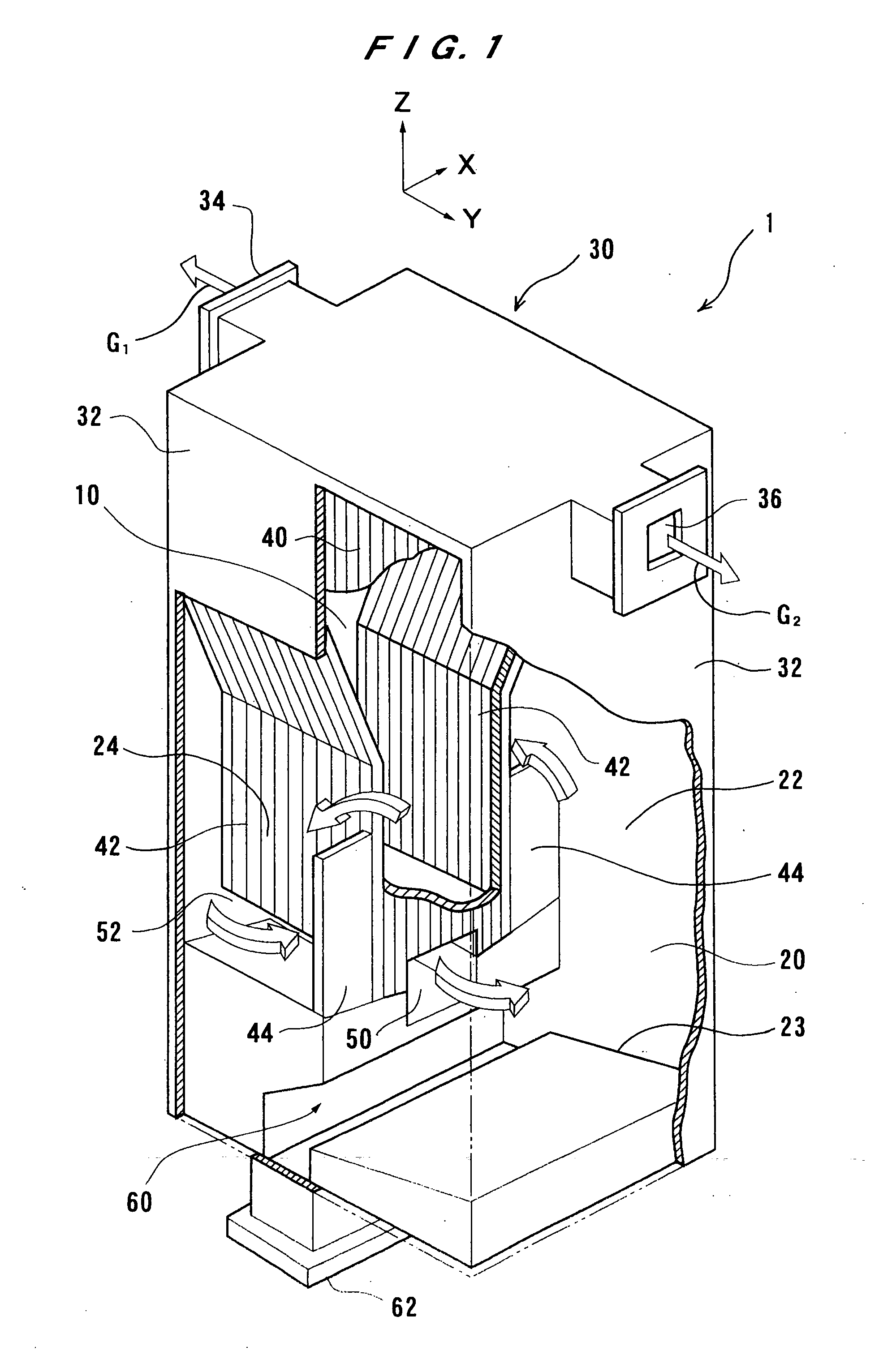

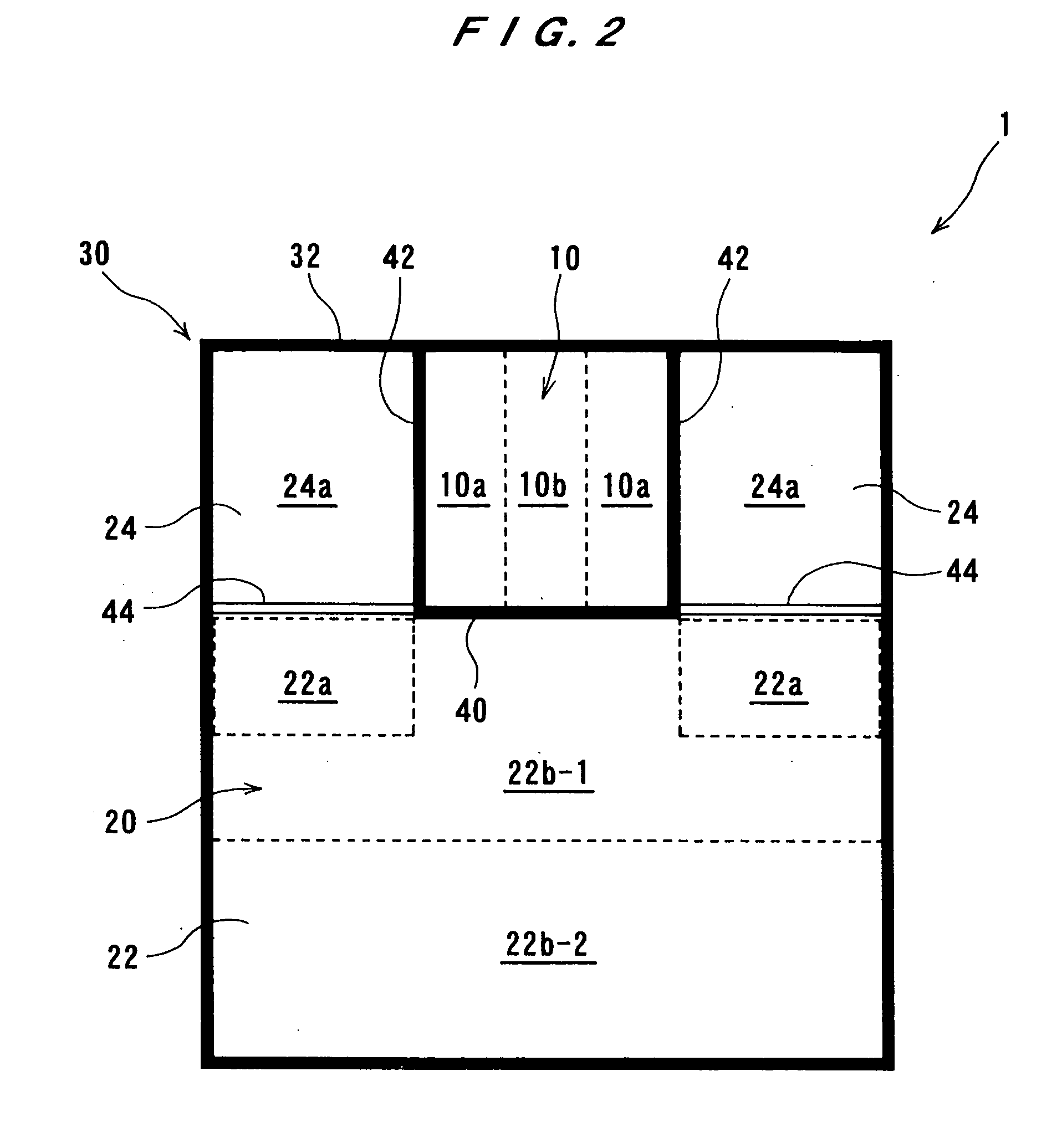

Fluidized-bed gasification furnace

InactiveUS20070014704A1Easy to controlHeat stableWaste based fuelCrucible furnacesProcess engineeringCombustion chamber

A fluidized-bed gasification furnace has a gasification chamber for fluidizing a fluidized medium therein and pyrolyzing a material in the fluidized medium to produce a pyrolysis gas and a pyrolysis residue. The fluidized-bed gasification furnace also has a combustion chamber having a combustion portion for fluidizing a fluidized medium therein and combusting the pyrolysis residue to heat the fluidized medium and a settling portion disposed adjacent to the combustion portion and the gasification chamber for settling the heated fluidized medium therein. The fluidized-bed gasification furnace includes a first passage for introducing the pyrolysis residue from the gasification chamber to the combustion chamber together with the fluidized medium, a second passage for introducing the heated fluidized medium in the combustion chamber from the settling portion of the combustion chamber to the gasification chamber, and a first diffusion device for supplying a fluidizing gas to a first region in the combustion portion adjacent to the settling portion of the combustion chamber to move the fluidized medium from the combustion portion to the settling portion. The fluidized-bed gasification furnace also includes a circulation controller operable to adjust a flow rate of the fluidizing gas supplied from the first diffusion device to control a circulation amount of the fluidized medium.

Owner:EBARA CORP

Smart battery separators

Owner:MP ASSETAB CORP

Transferring data such as files

ActiveUS7965729B2Avoid complex processTransfer delayError prevention/detection by using return channelTime-division multiplexComputer hardwareNetwork connection

Owner:POLYTECHNIC INST OF NEW YORK

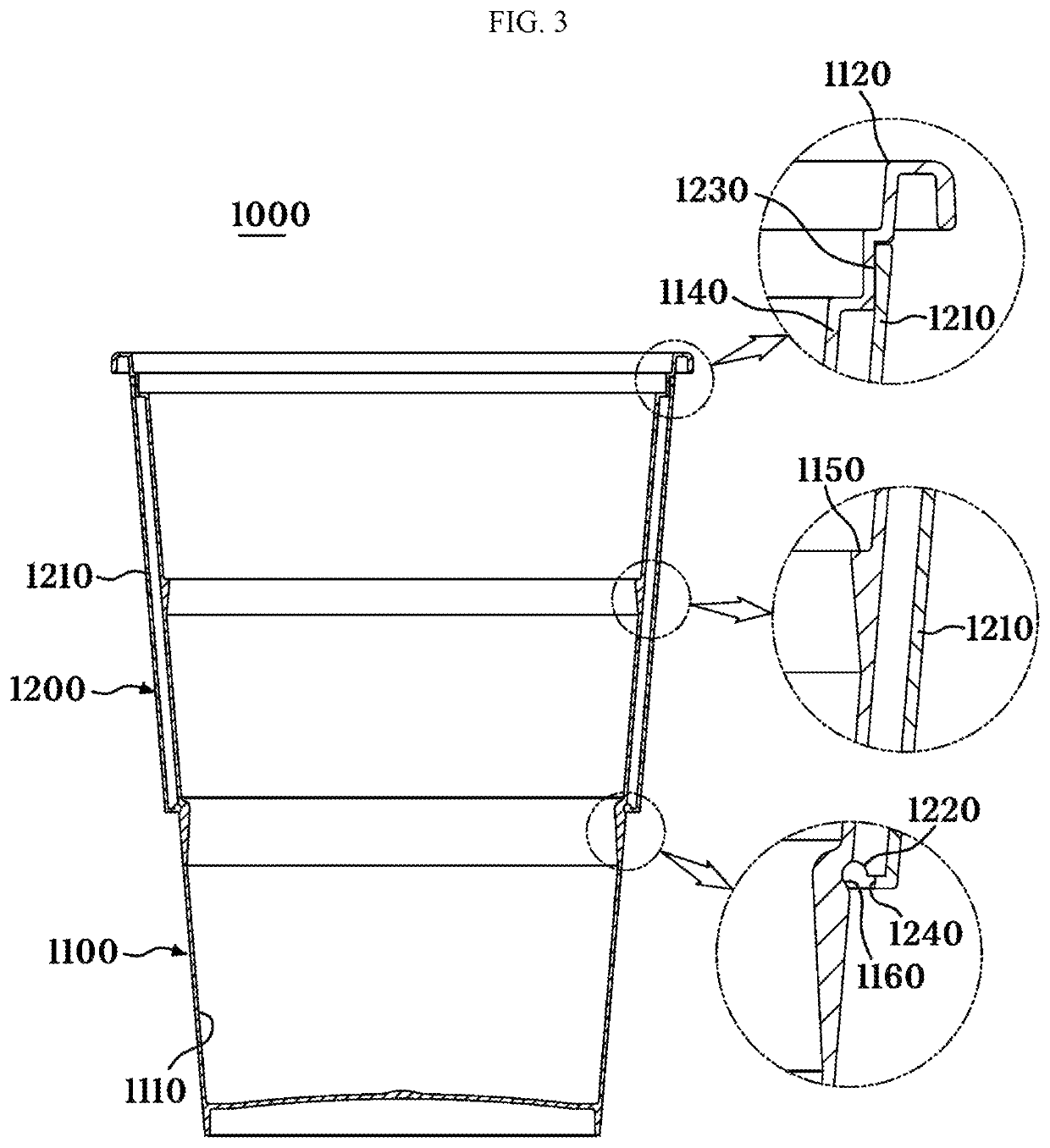

Insulated cup with double wall construction

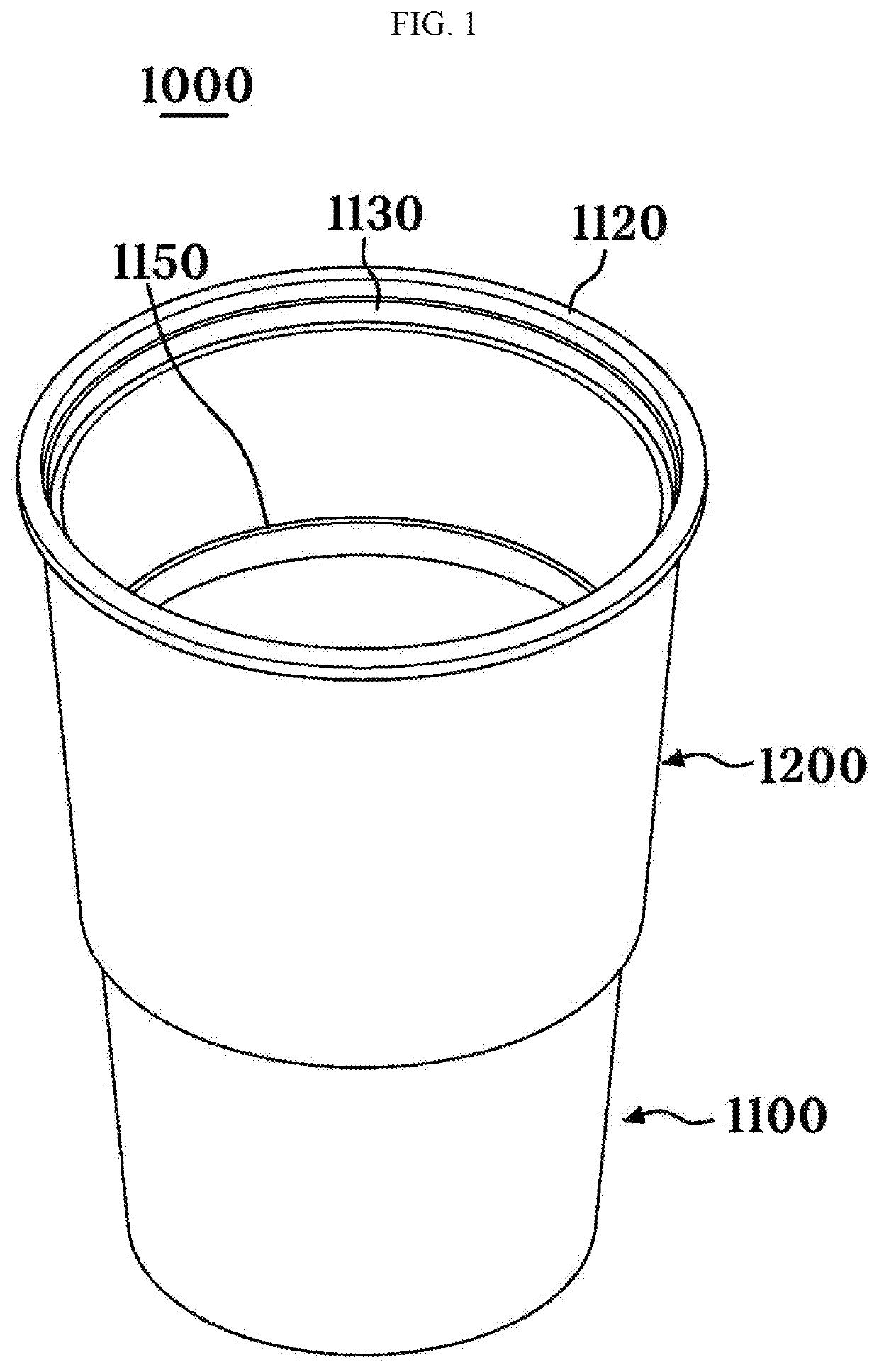

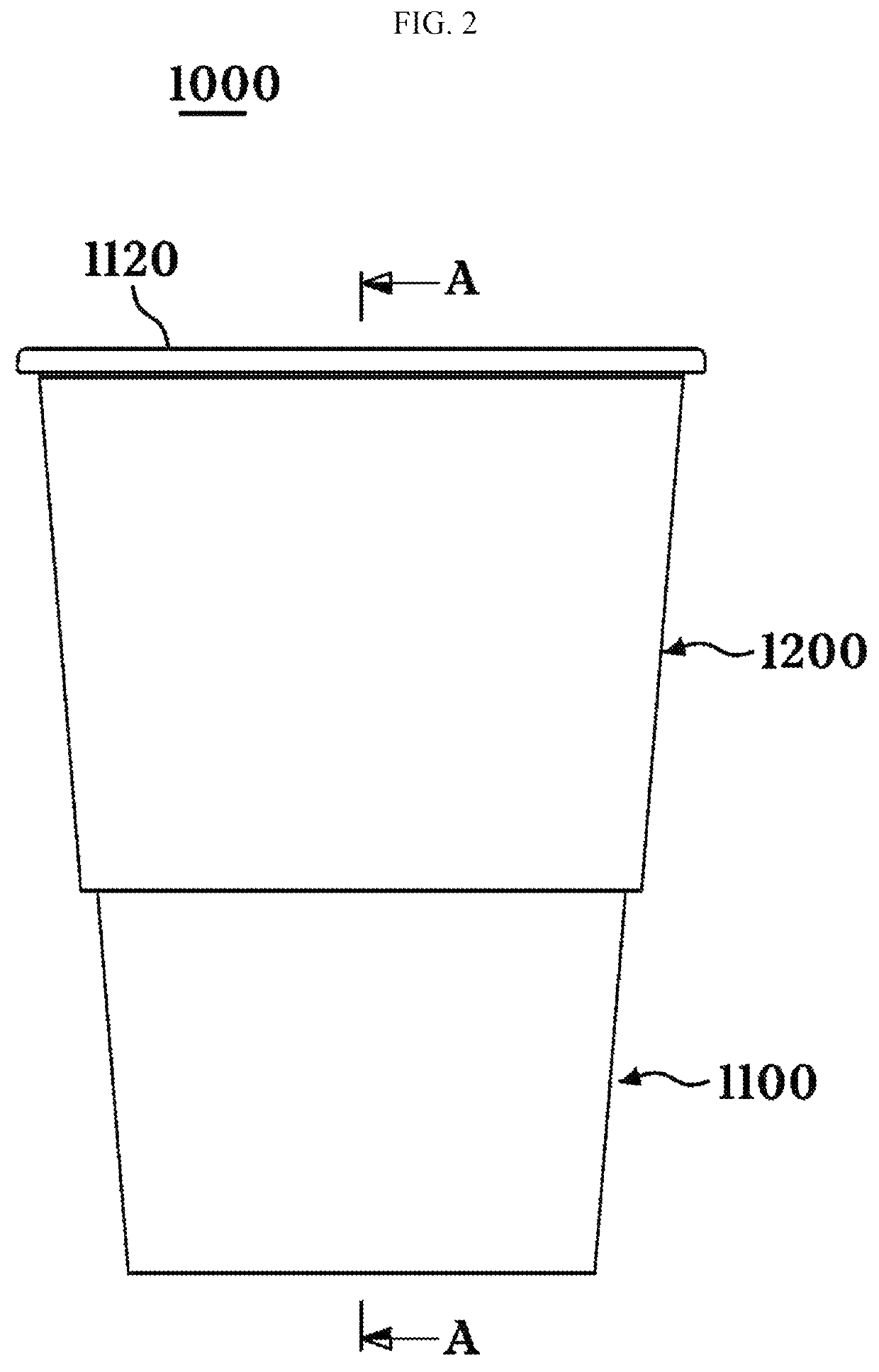

ActiveUS10478000B2Well formedPrevented from feelingDomestic cooling apparatusLighting and heating apparatusDouble wallEngineering

Owner:SEUNG HWA PNP CO LTD

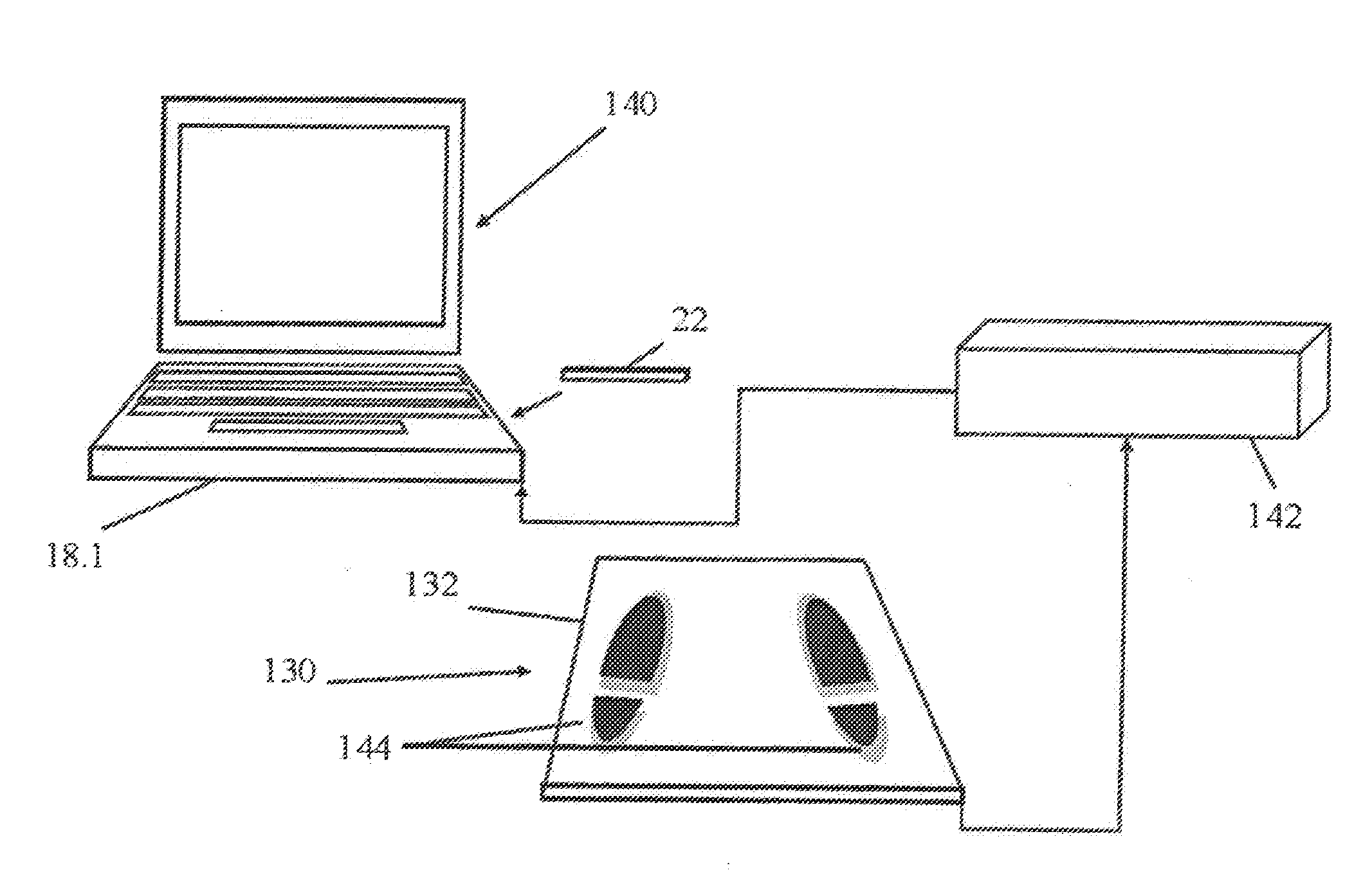

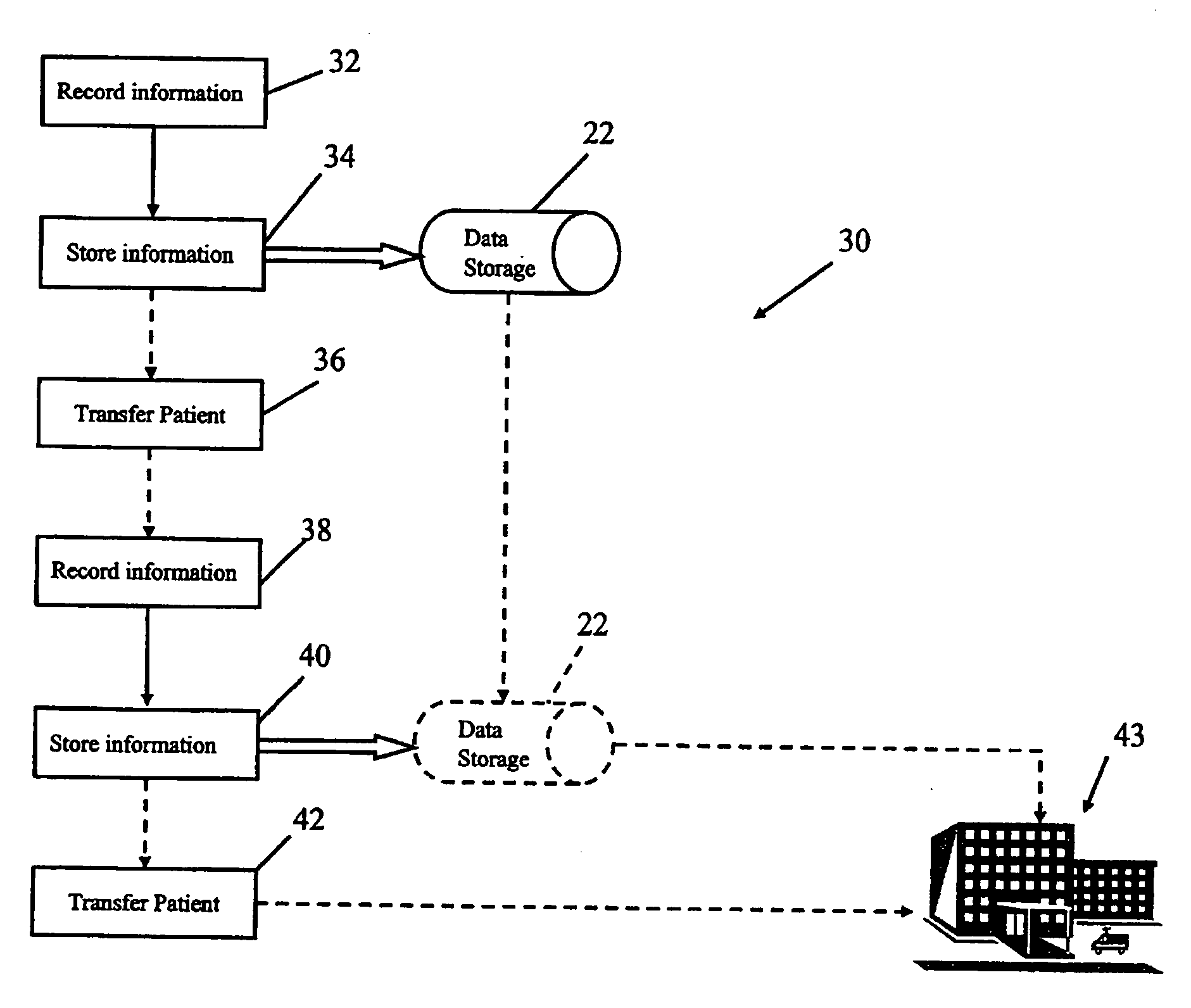

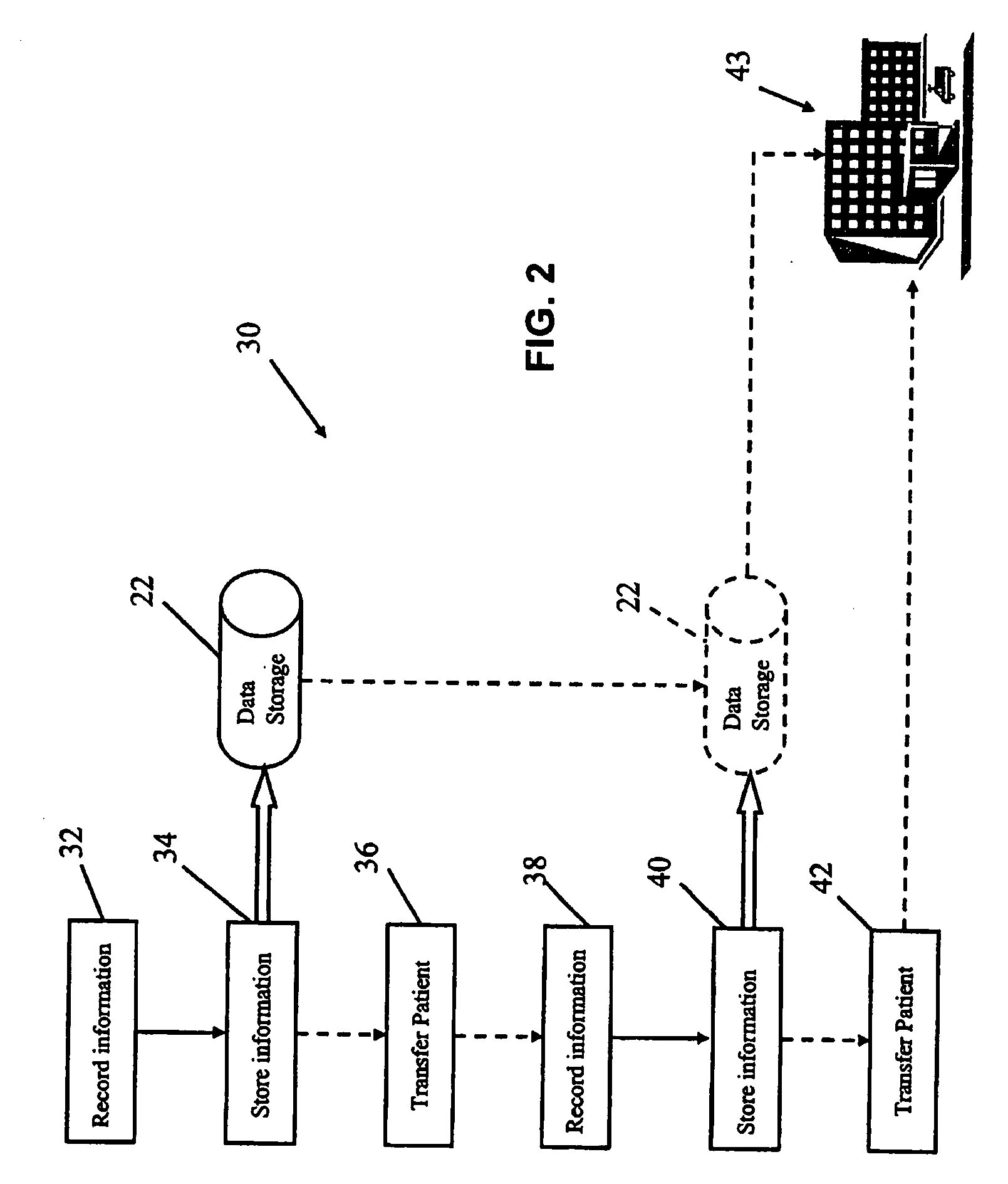

The collection of medical data

ActiveUS20160007904A1Fine-tune treatmentImprove data securityPerson identificationMedical automated diagnosisFine motor skillImpaired fine motor skills

A system and method for assessing a patient's balancing ability in order to facilitate ascertaining the patient's current medical status. The system includes a balance plate for measuring the center of gravity dynamic weight distribution in combination with a sensor for measuring the patient's fine motor skills.

Owner:ISOTECH

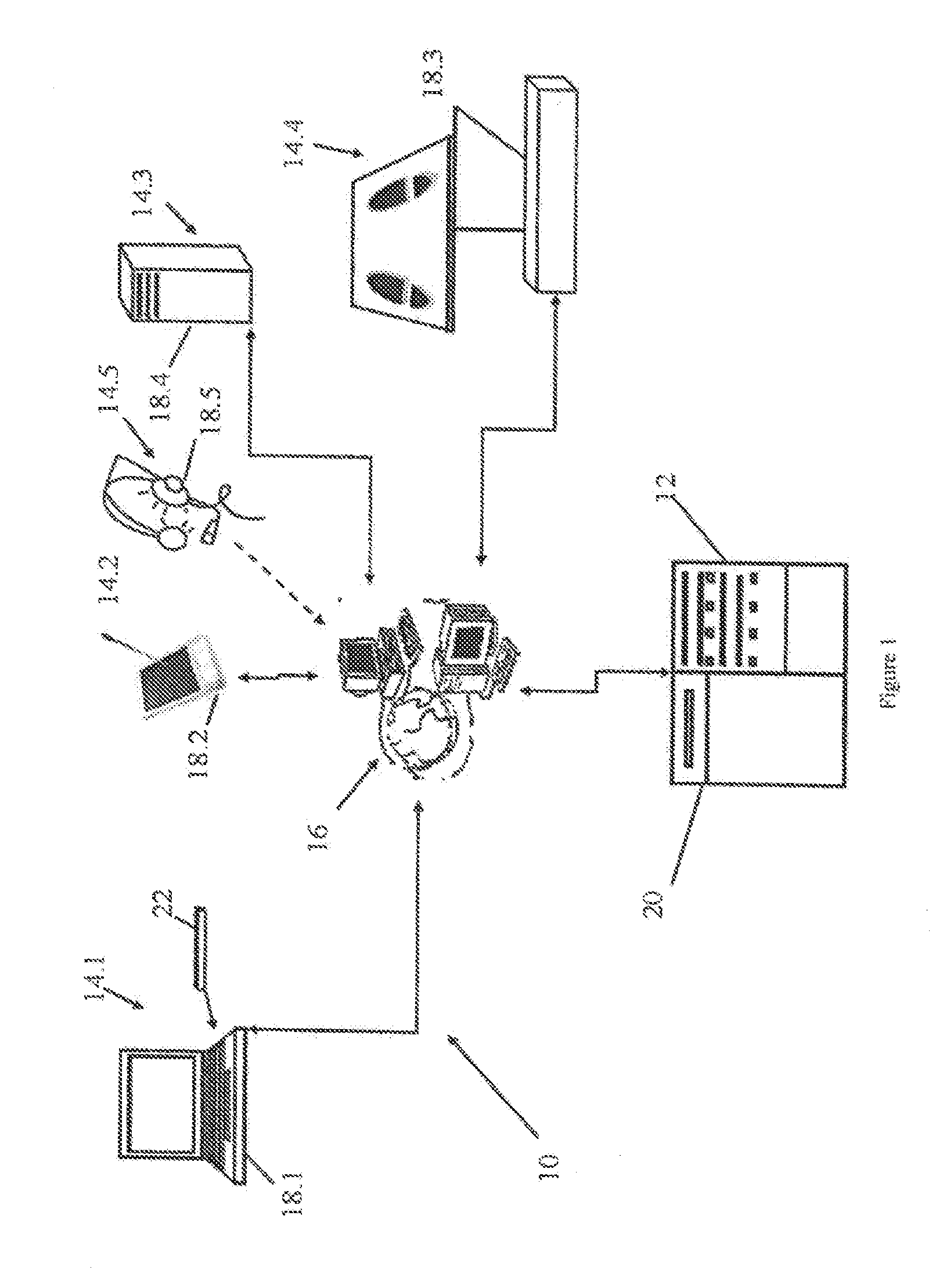

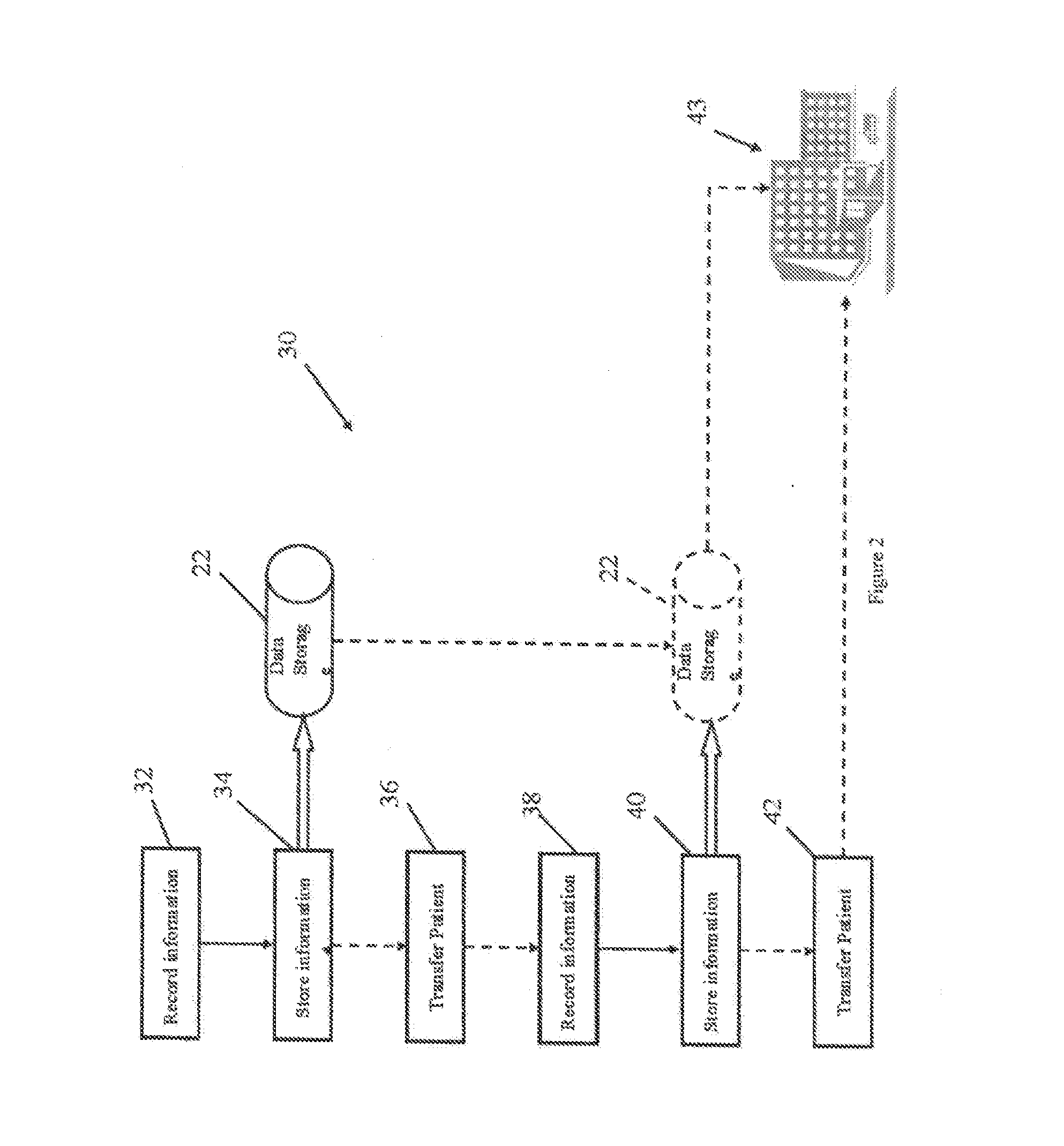

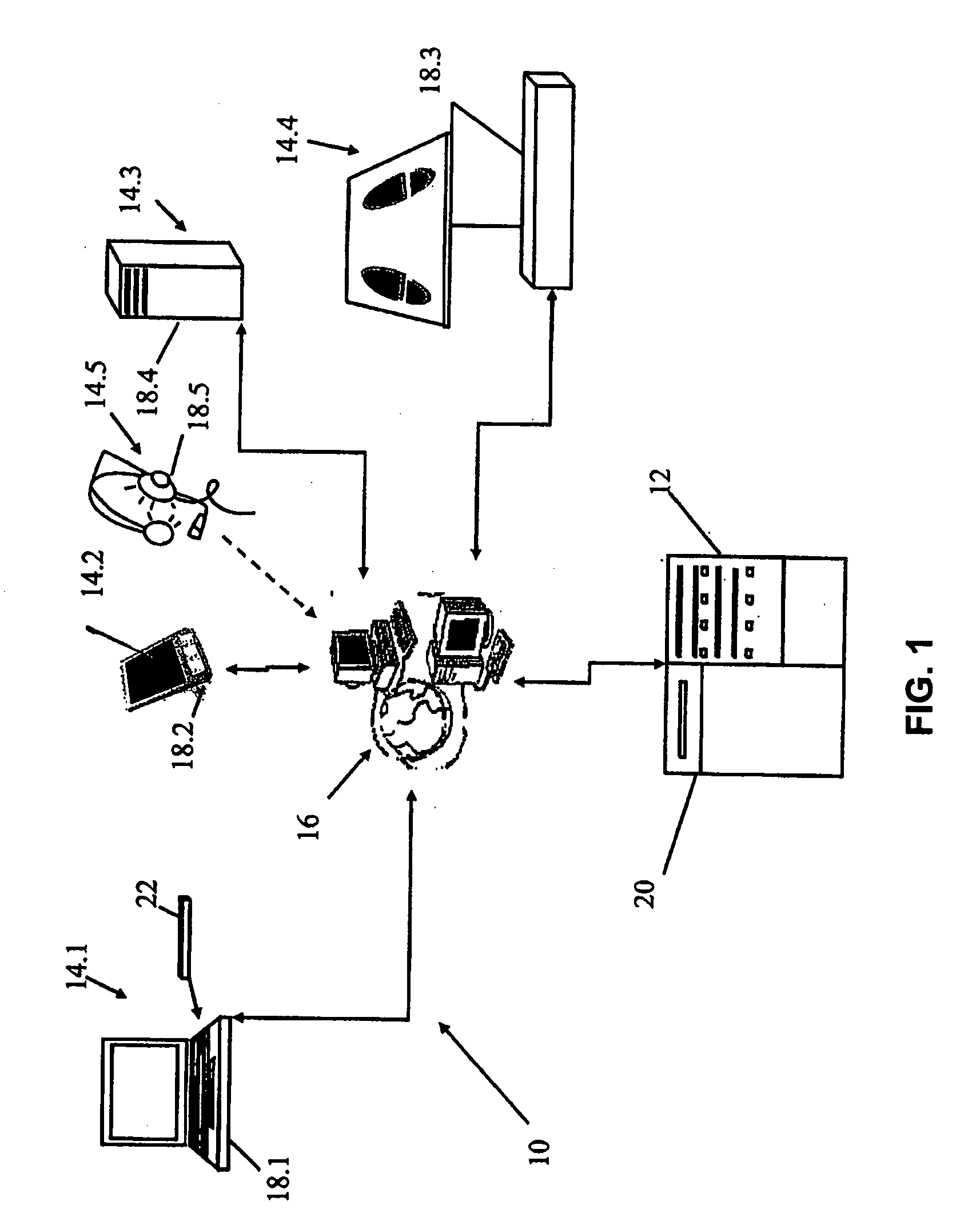

Collection of medical data

InactiveUS20090144092A1Fine-tune treatmentImprove data securityPatient personal data managementOffice automationDatabase serverData source

A system for collecting medical data includes a database server programmed to receive data in a number of different formats from respective different data sources. The database server is connectable to a communications network. A number of remote data collection arrangements are associated with respective medical operators and each is configured to permit said respective medical operators to input medical data relating to a medical condition of a patient into the data collection arrangement and to write the medical data to the database server via the communications network. The database server is configured to receive the medical data and to generate an electronic record representing a compilation of different items of the medical data.

Owner:VARDY TERENCE

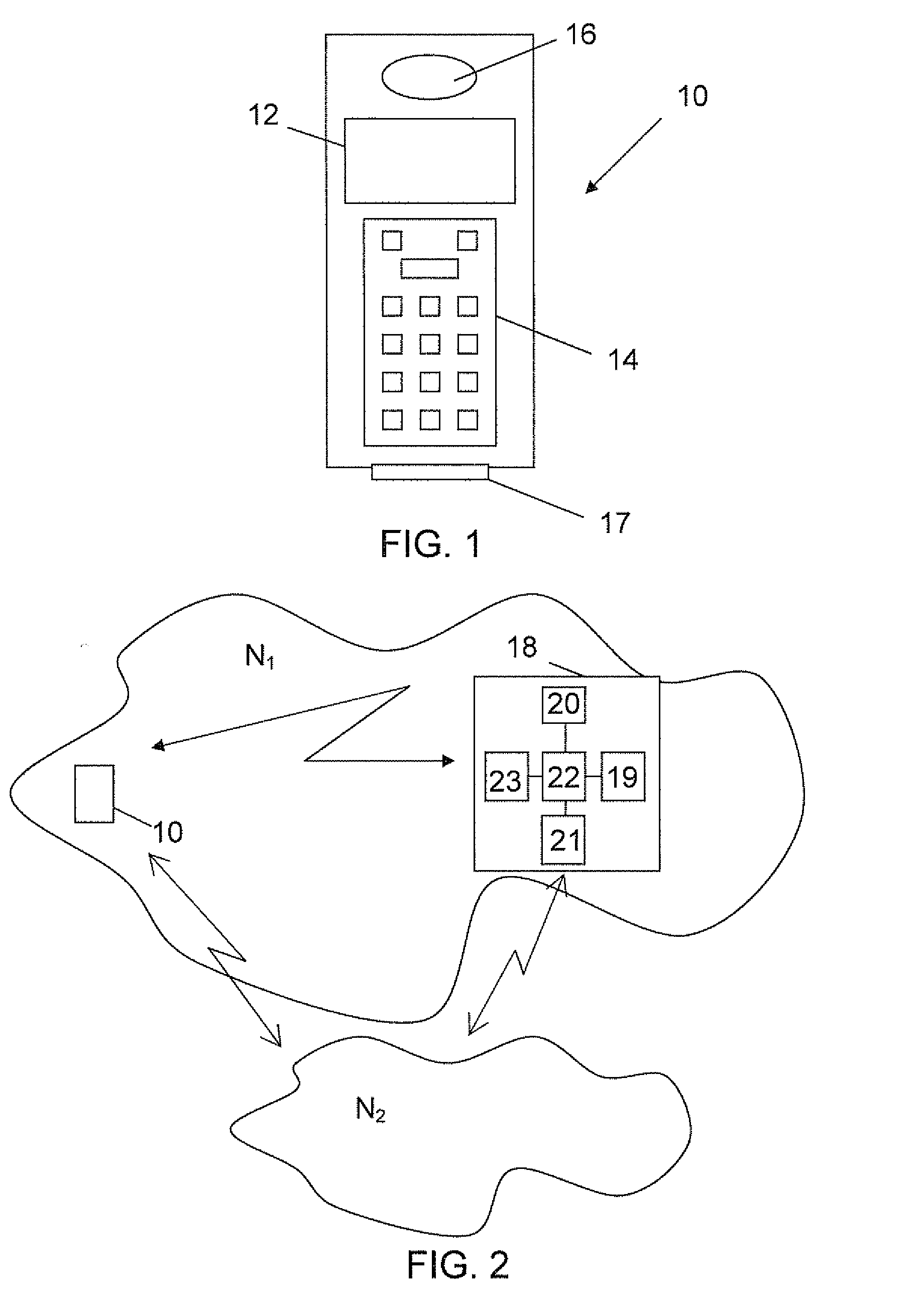

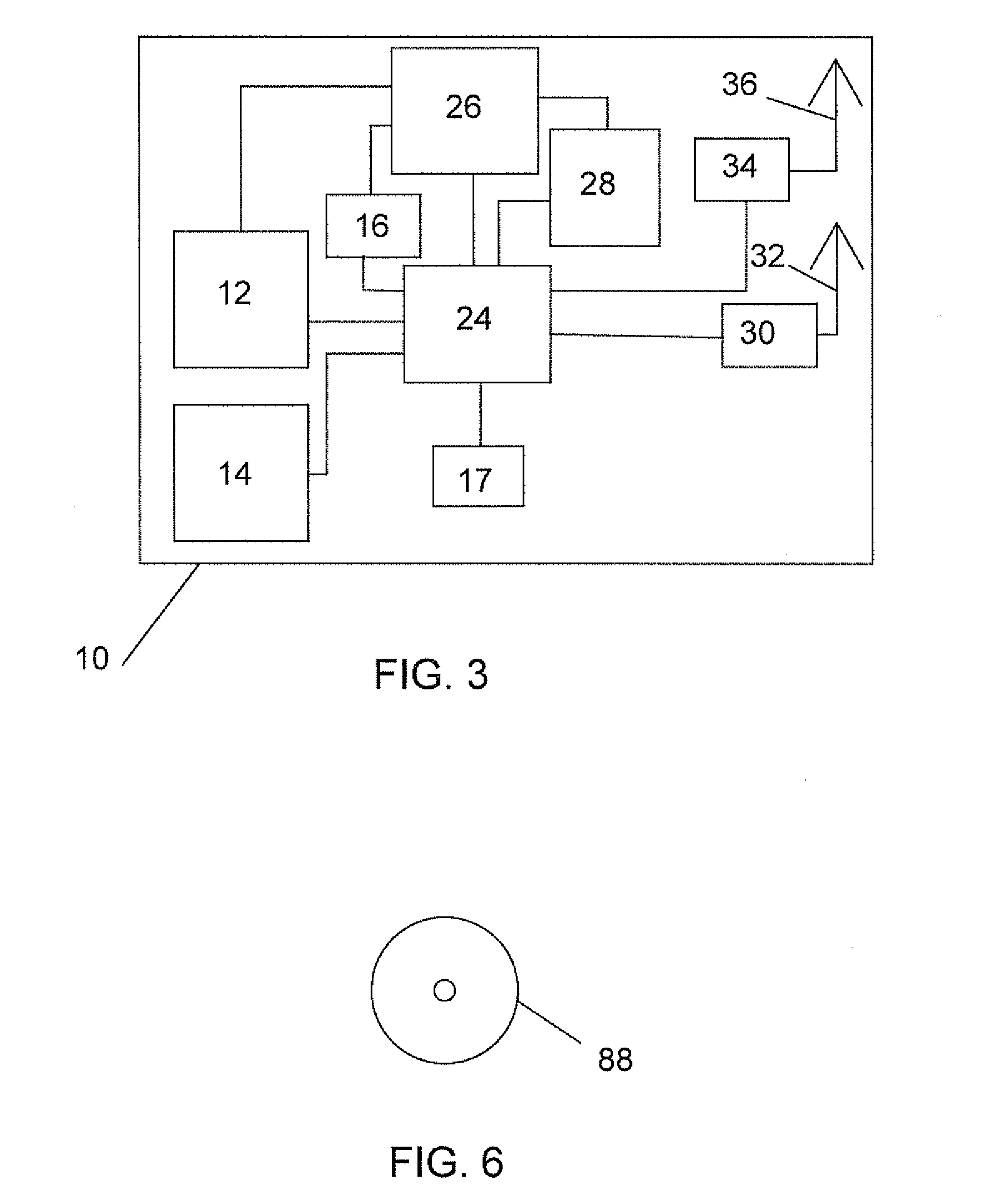

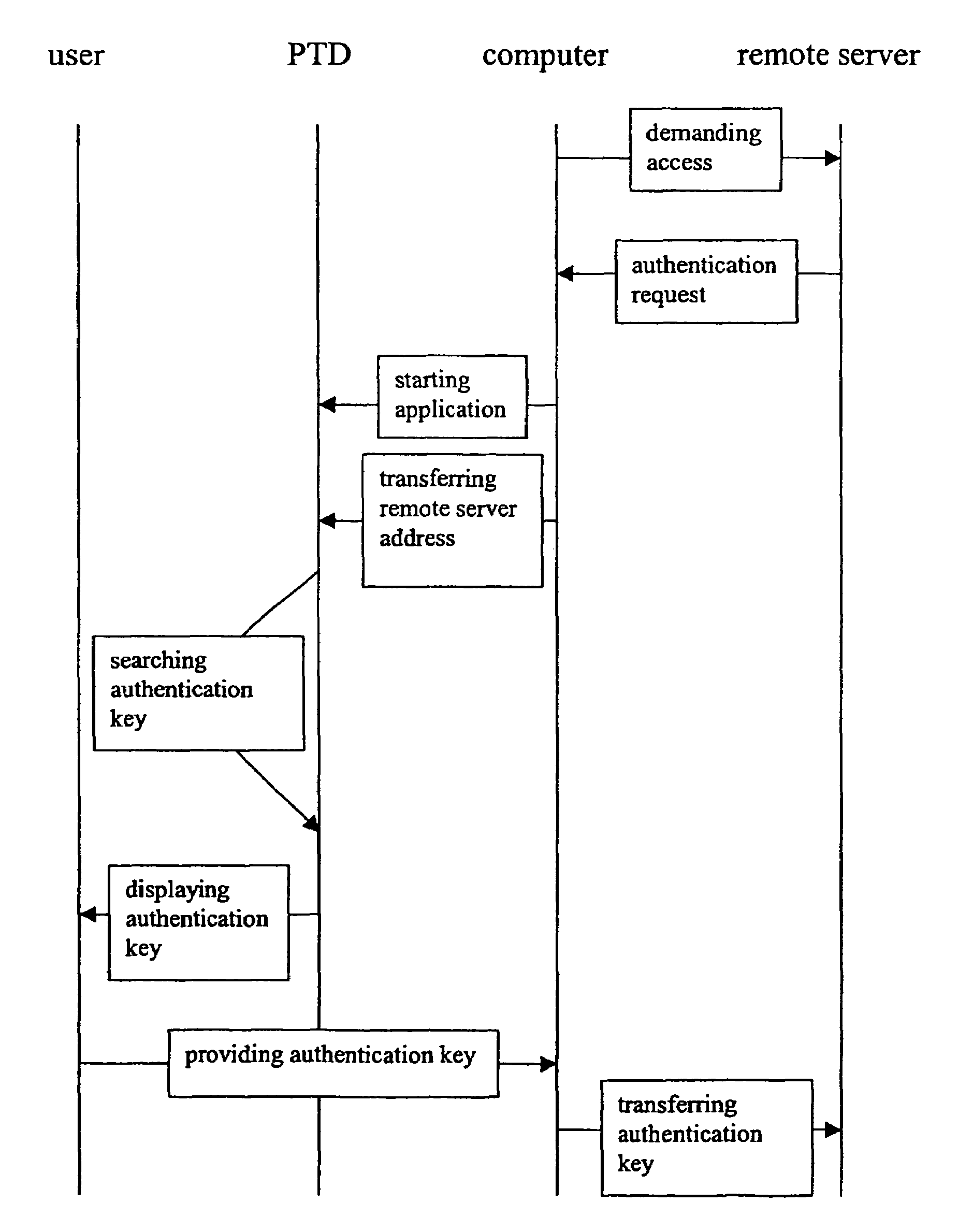

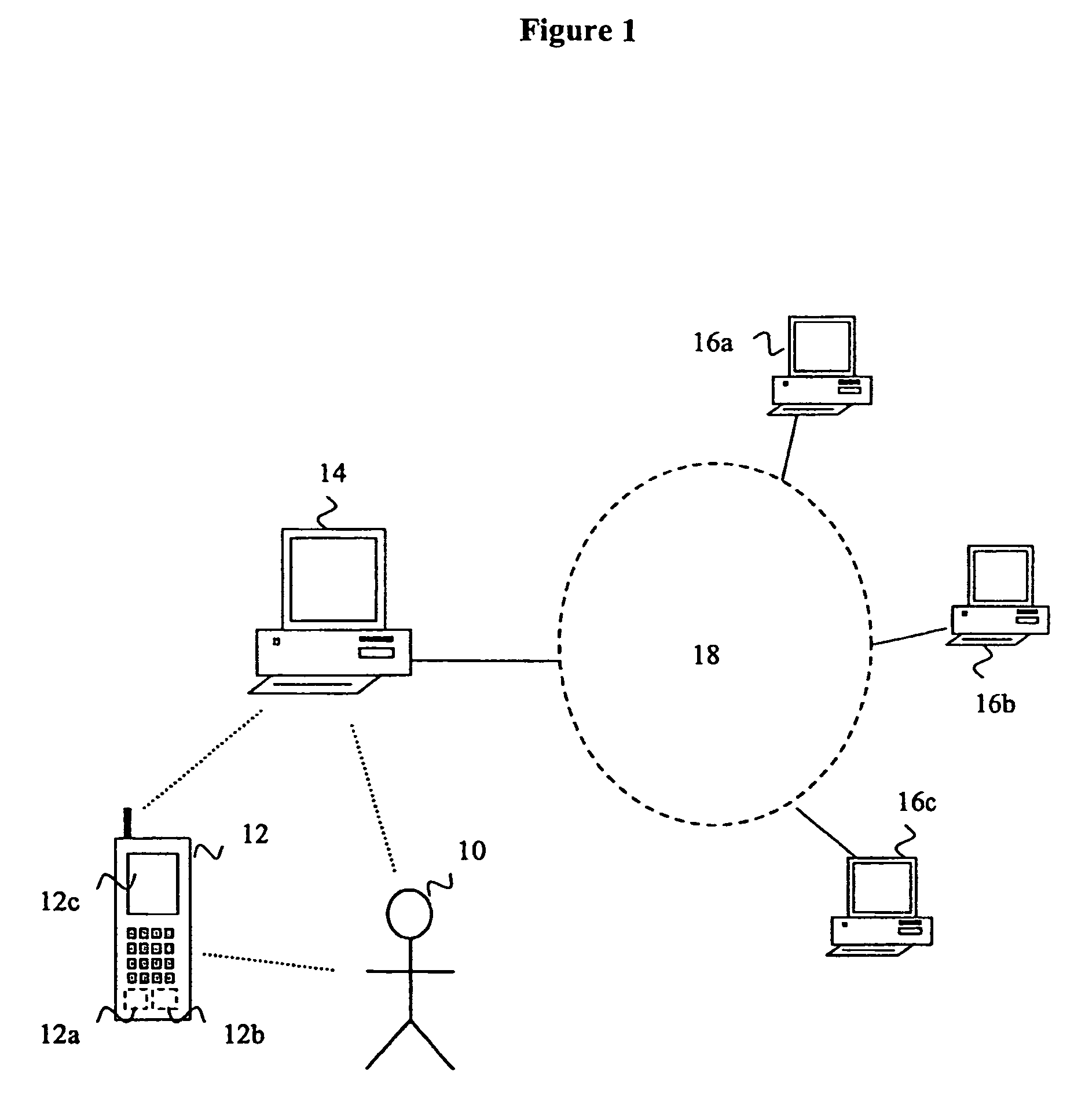

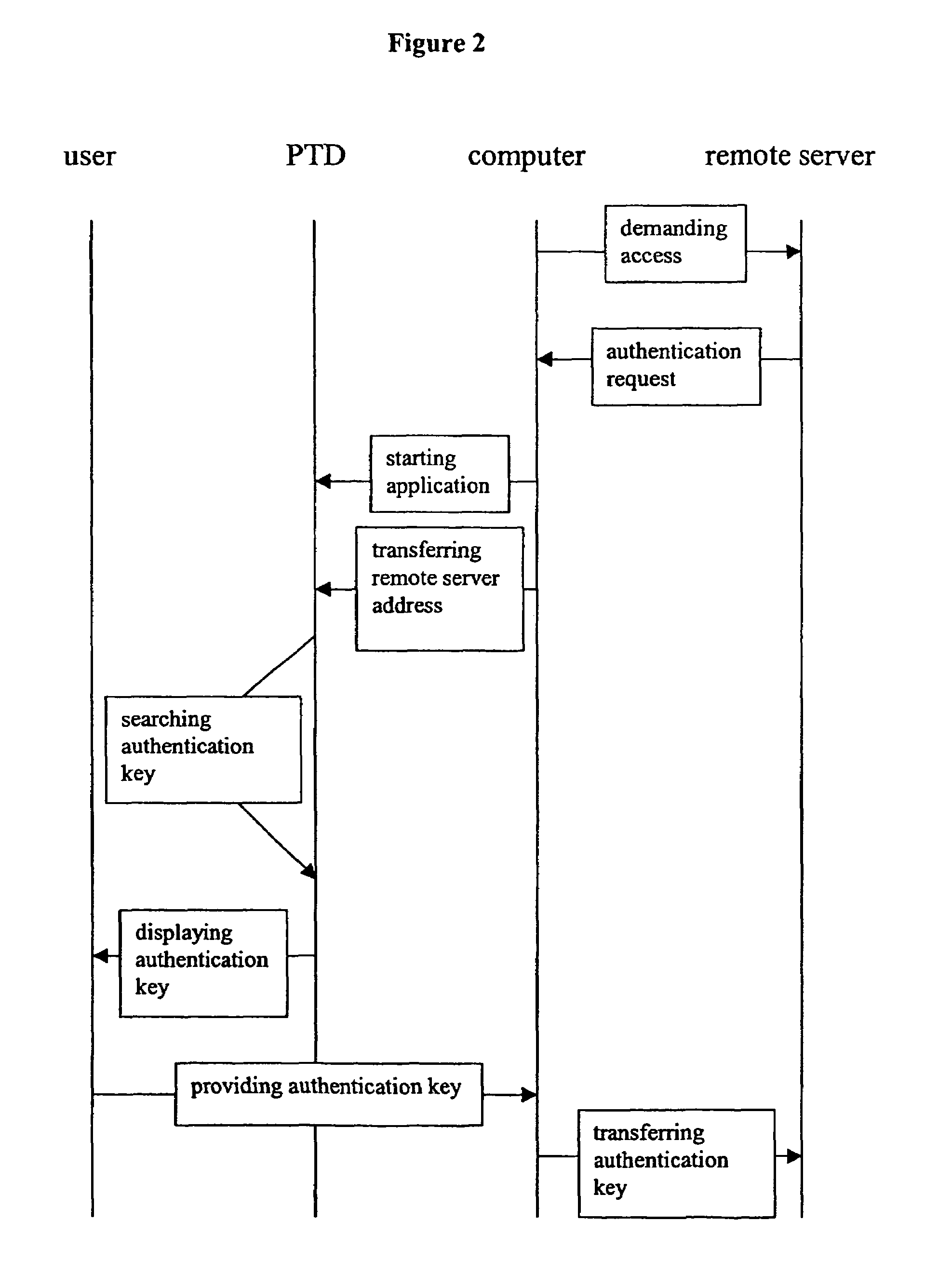

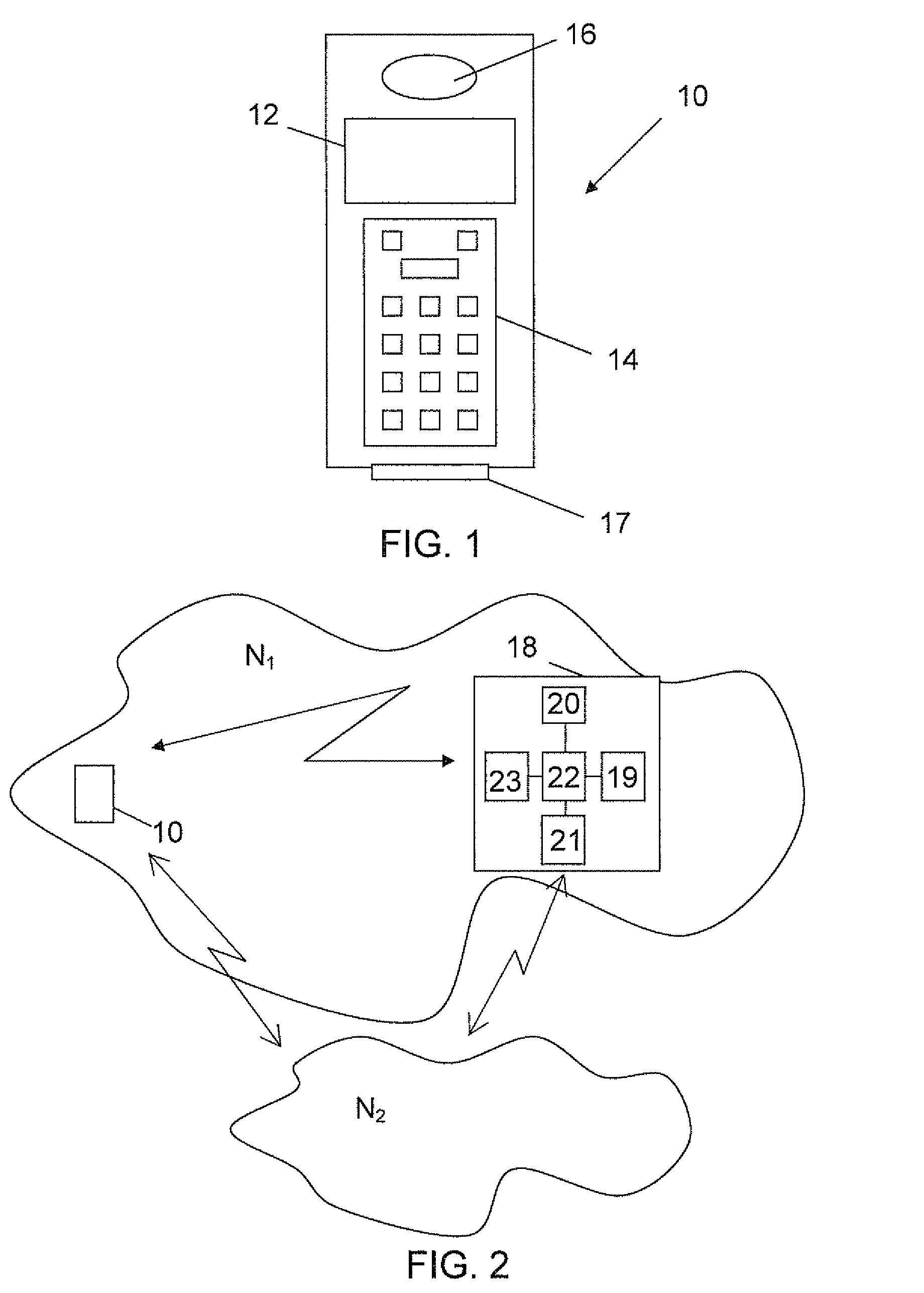

Method and device for authenticating a user on a remote server

InactiveUS7502931B2None of methods is secureImprove securityDigital data processing detailsUser identity/authority verificationTerminal equipmentNetwork addressing

A method is provided for authenticating a user (10) on a remote server 16a, 16b, 16c of a network 18, comprising the steps of receiving an authentication request from said remote server 16a, 16b, 16c of said network 18 by a terminal device 14, retrieving a respective authentication key from a personal trusted device 12 in which a plurality of network addresses of remote servers 16a, 16b, 16c and corresponding authentication keys are stored in a database, and displaying said authentication key to the user 10 on said personal trusted device 12.

Owner:NOKIA TECHNOLOGLES OY

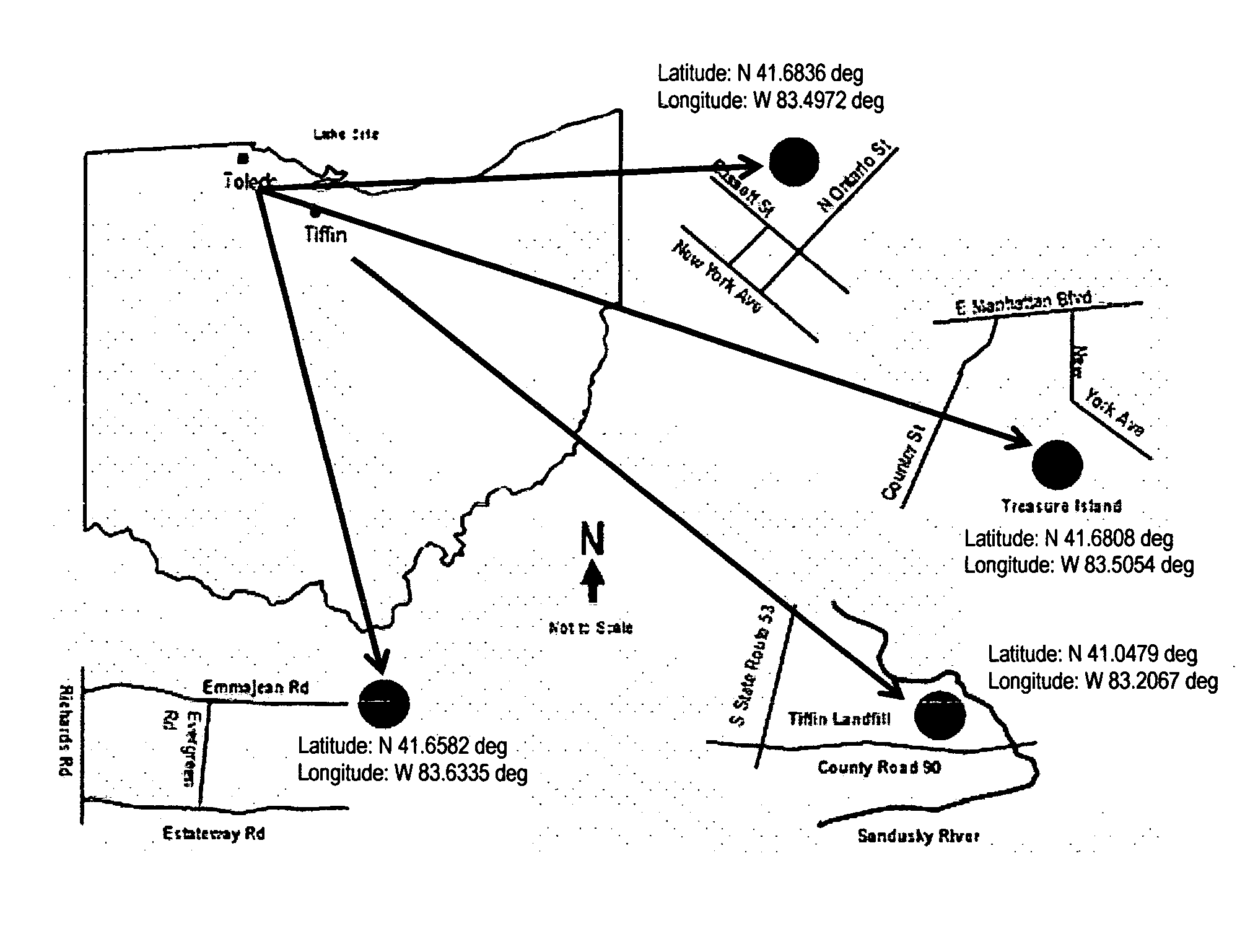

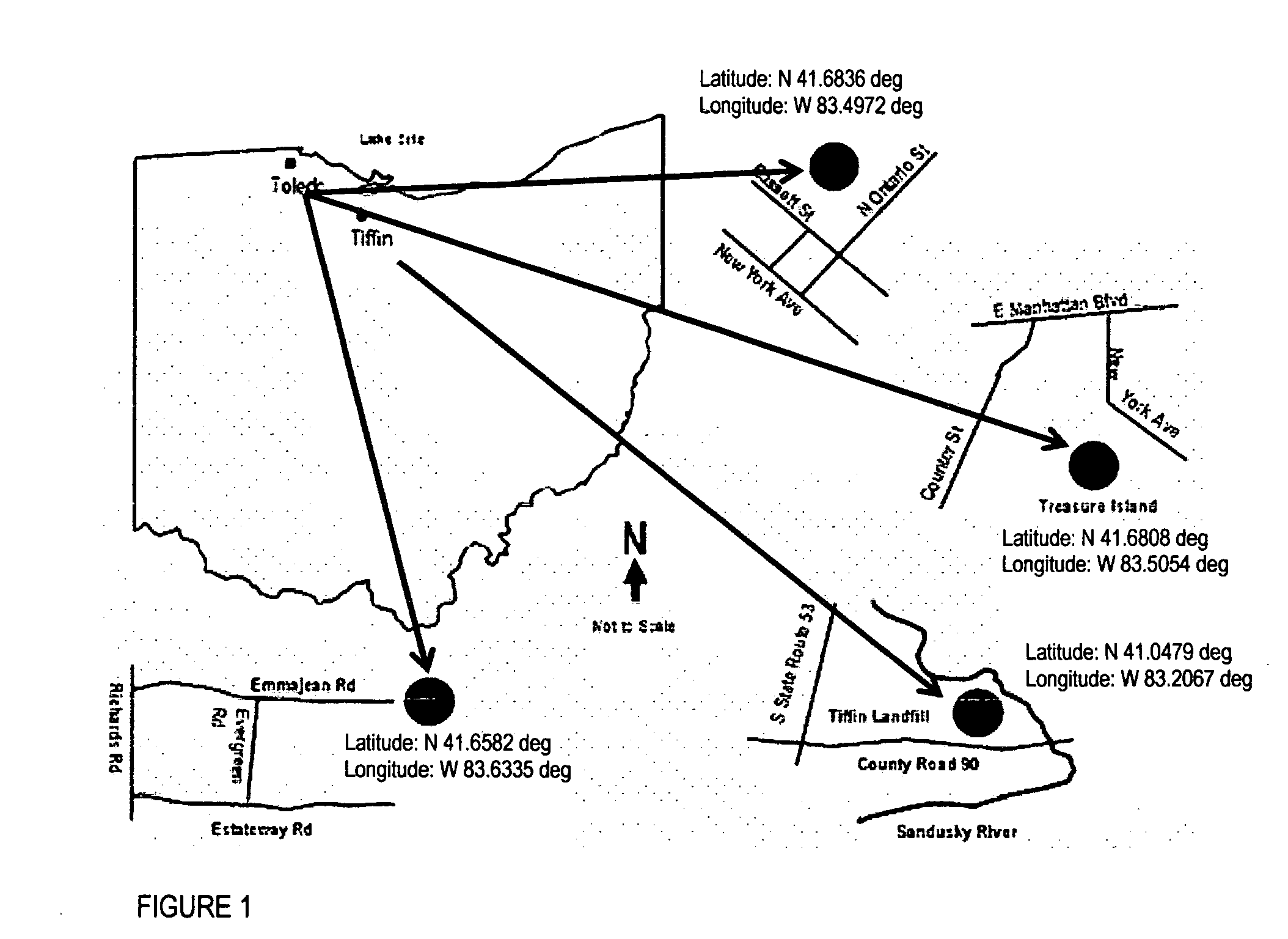

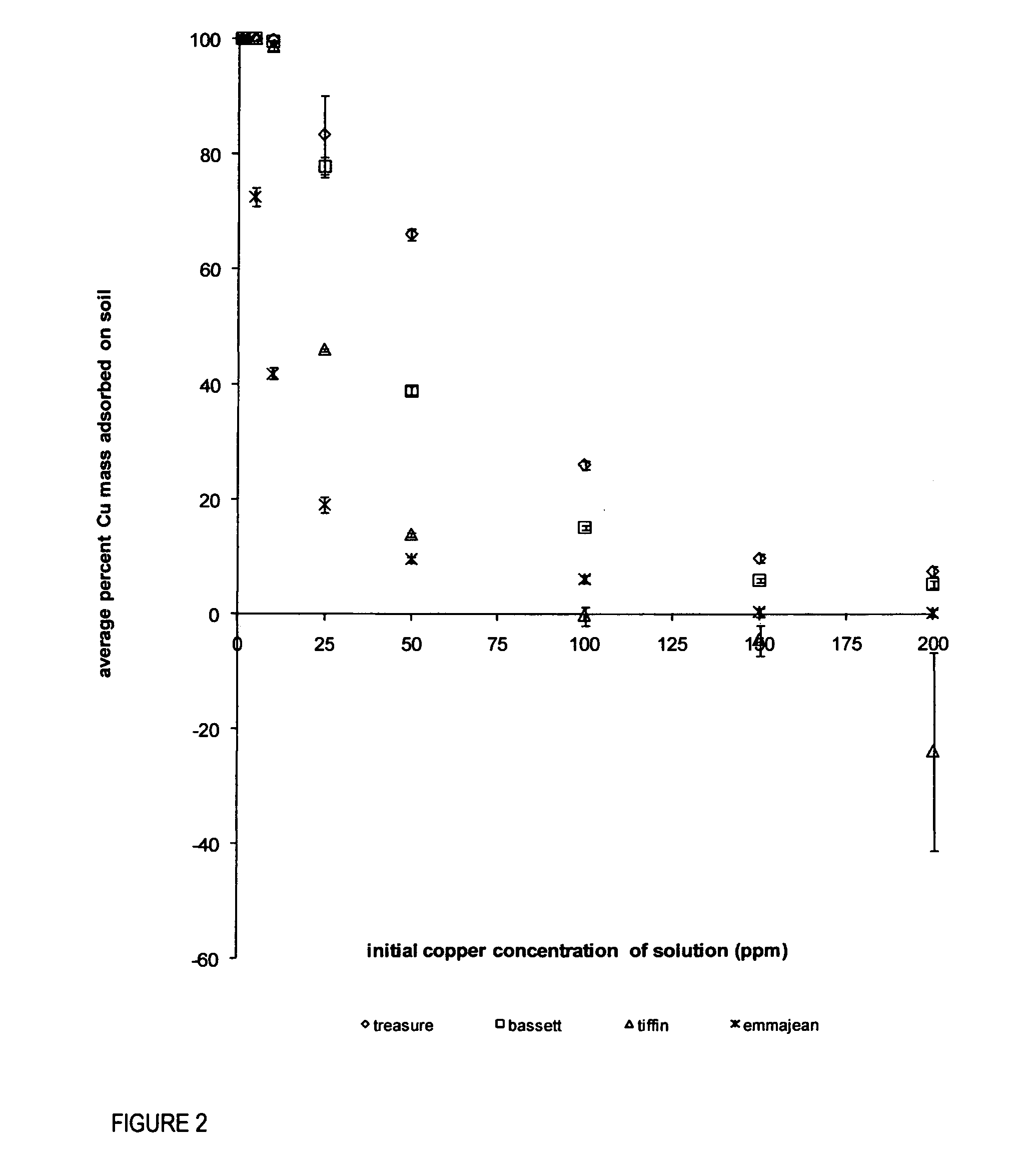

Method to evaluate plants and soils to optimize conditions for phytoremediation

InactiveUS20110153213A1Effective recoverySave resourcesContaminated soil reclamationComputation using non-denominational number representationSoil scienceOrganic matter

Phytoremediation is an economical method to remove contaminants from soils. Understanding the mechanisms that control adsorption of a contaminant to a soil particle is the first step in designing a phytoremediation project in order to optimize removal of said contaminant. To characterize soil conditions, the following data were collected: a) historical land use information, b) evaluating on-site soils and plants for contaminant identity and concentrations, c) particle size analysis of soil samples, d) estimate total organic matter of soil samples, e) conducting batch adsorption experiments to determine Kd values, varying pH levels and concentrations of standard solutions, g) testing on-site pH of soils, h) testing pH levels of standard solutions prior to and after contact with soils used for batch adsorption experiments, i) conducting alkalinity / hardness tests. Once the conditions are known, experiments can be designed manipulating conditions to find optimal conditions to maximize the removal of a contaminant.

Owner:BUCHANAN CATHERINE LYNN

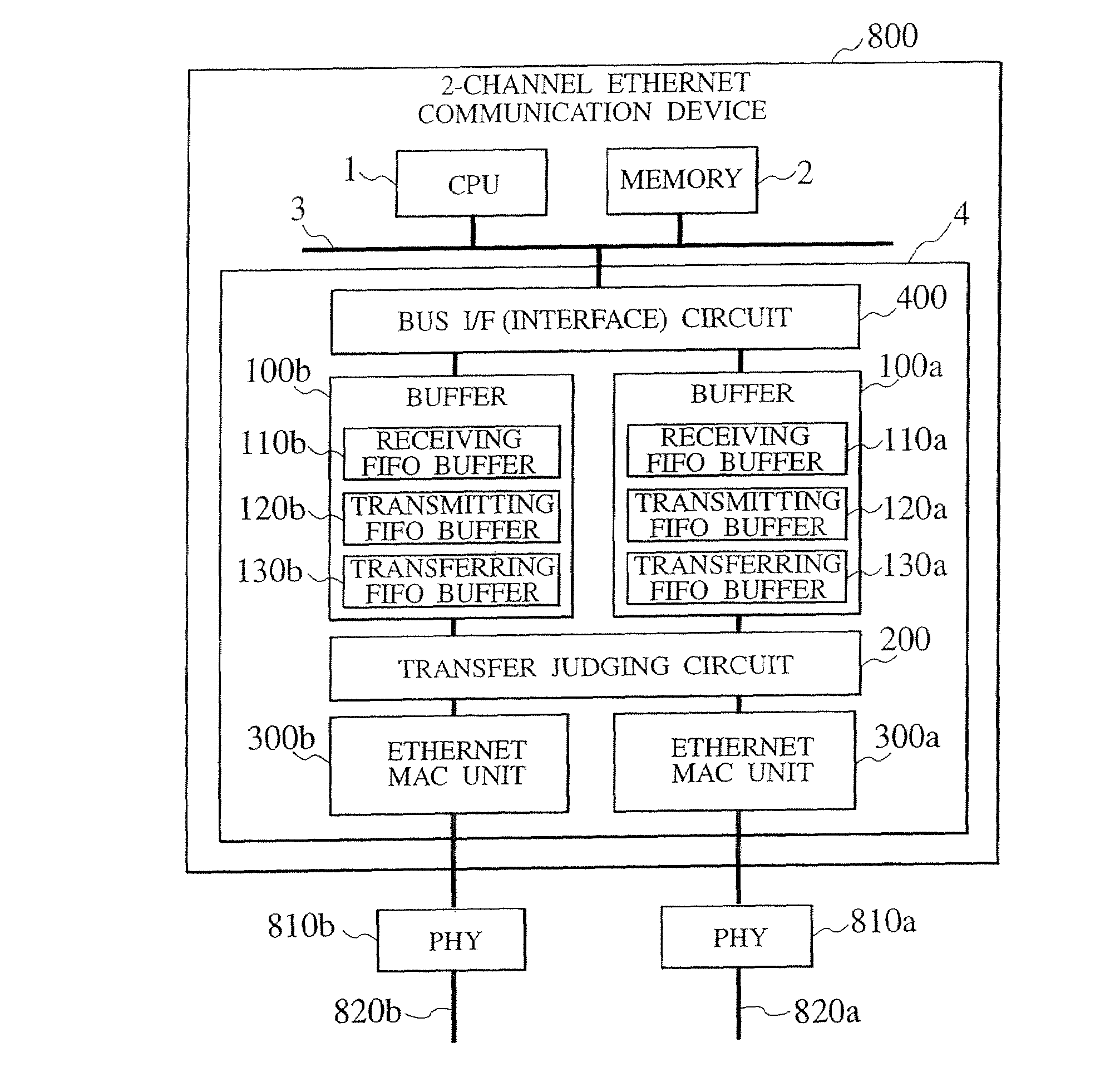

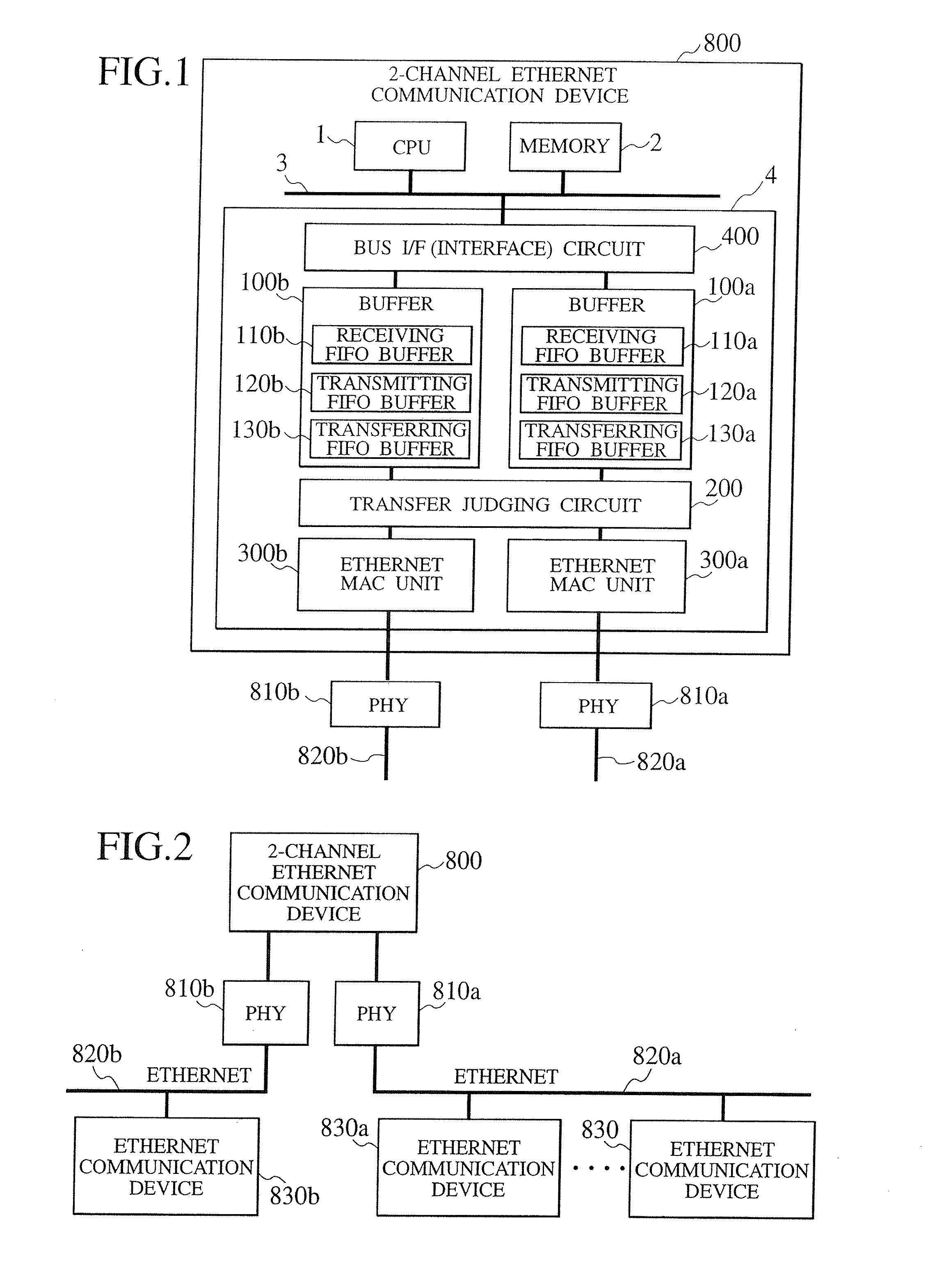

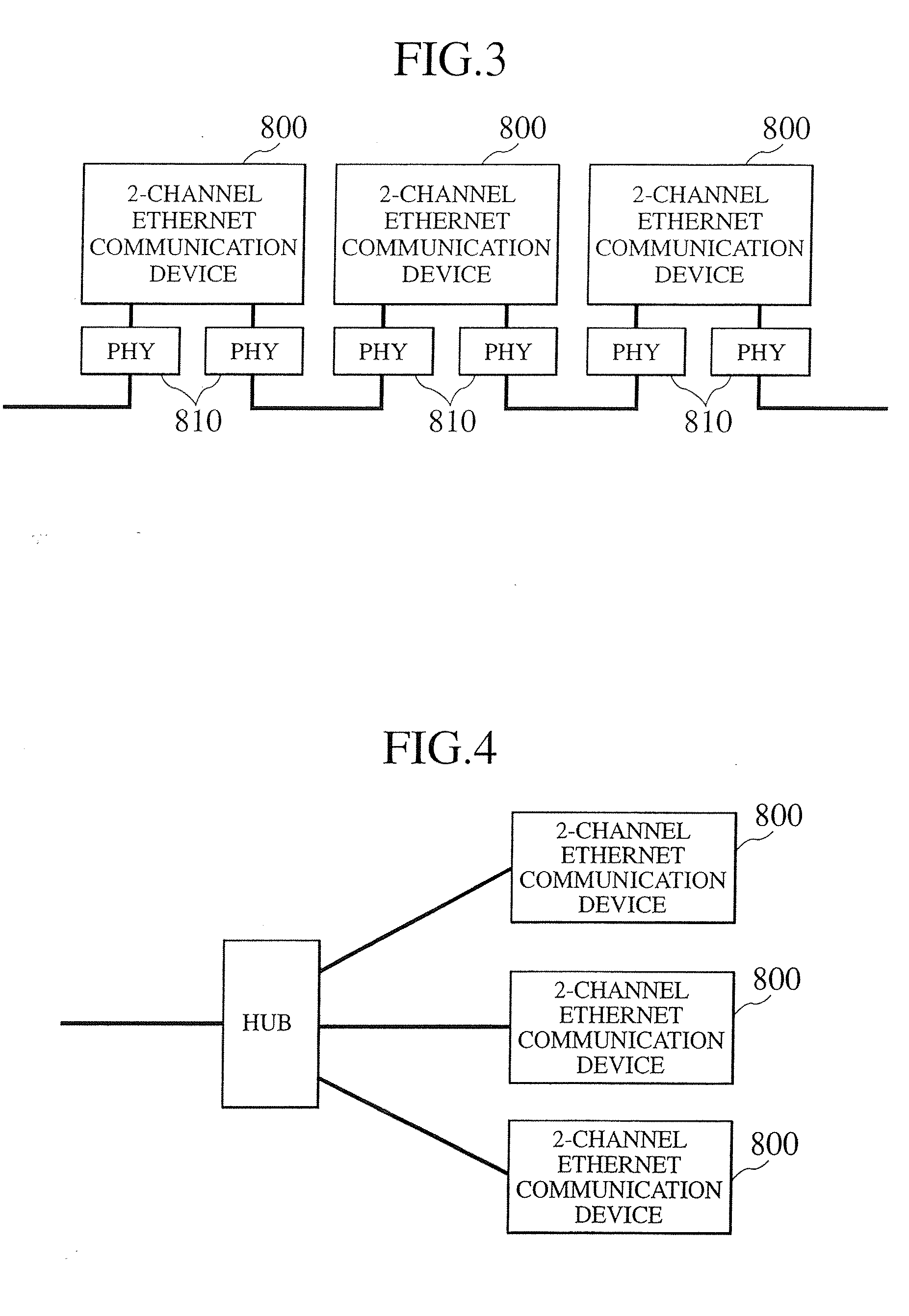

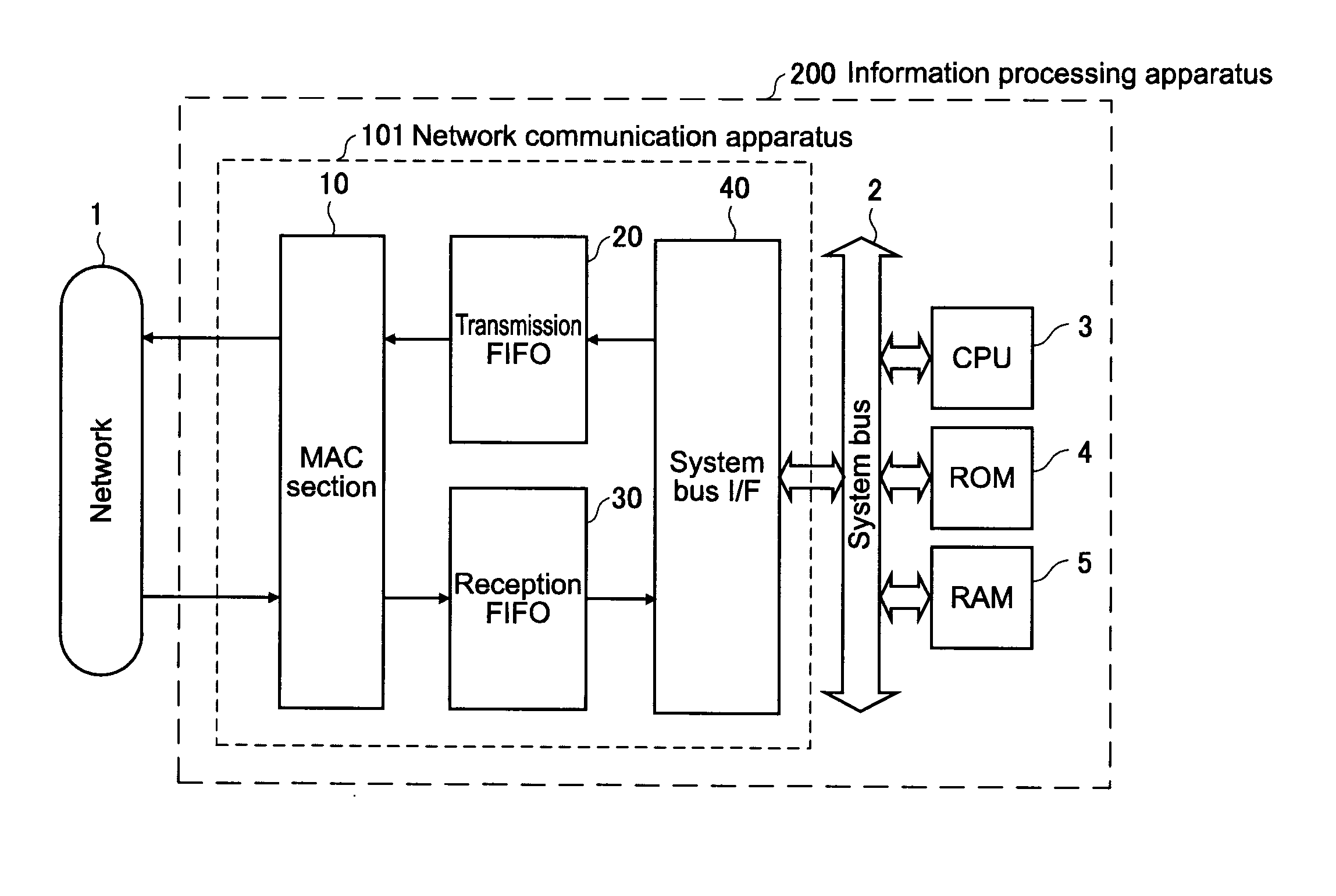

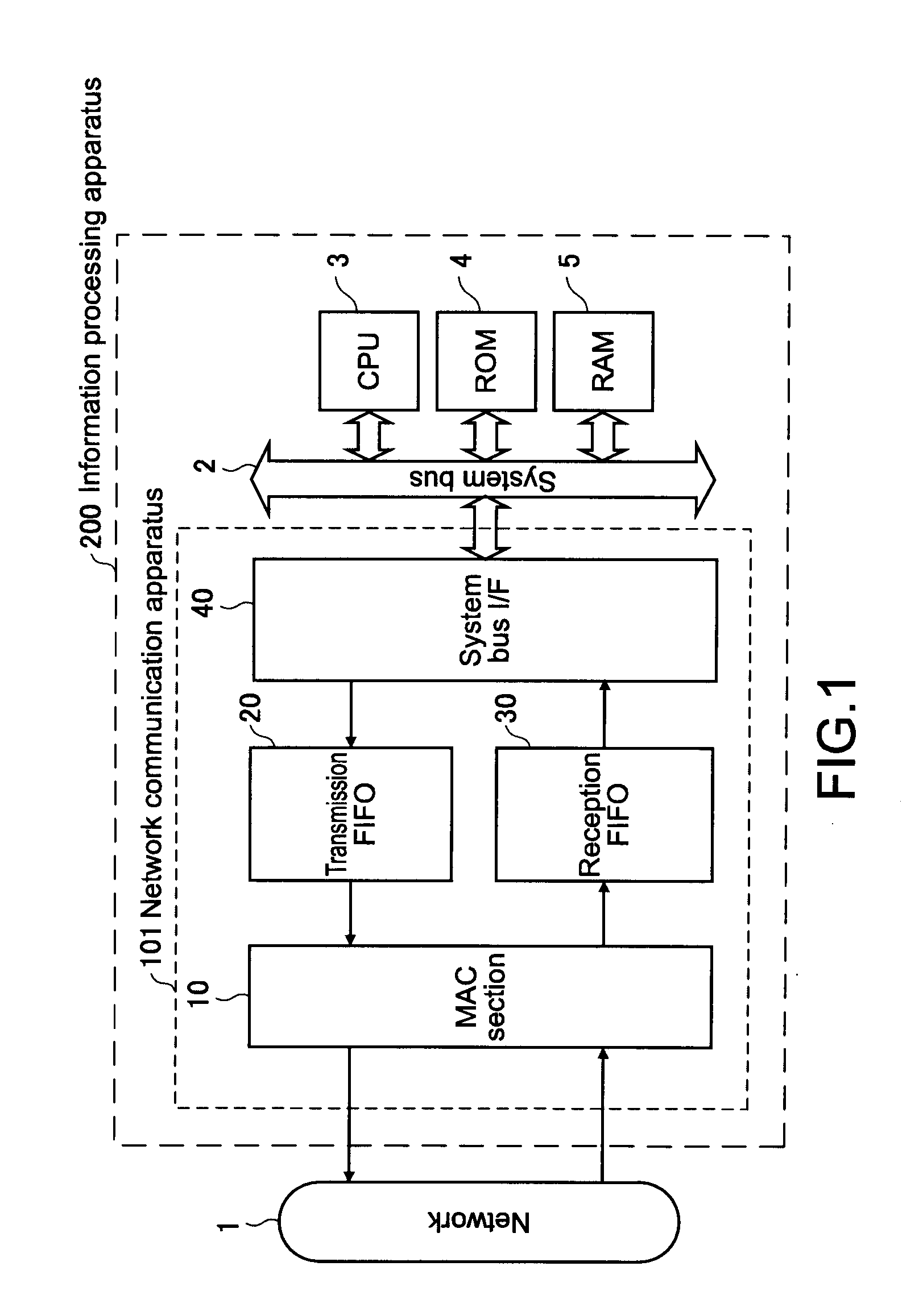

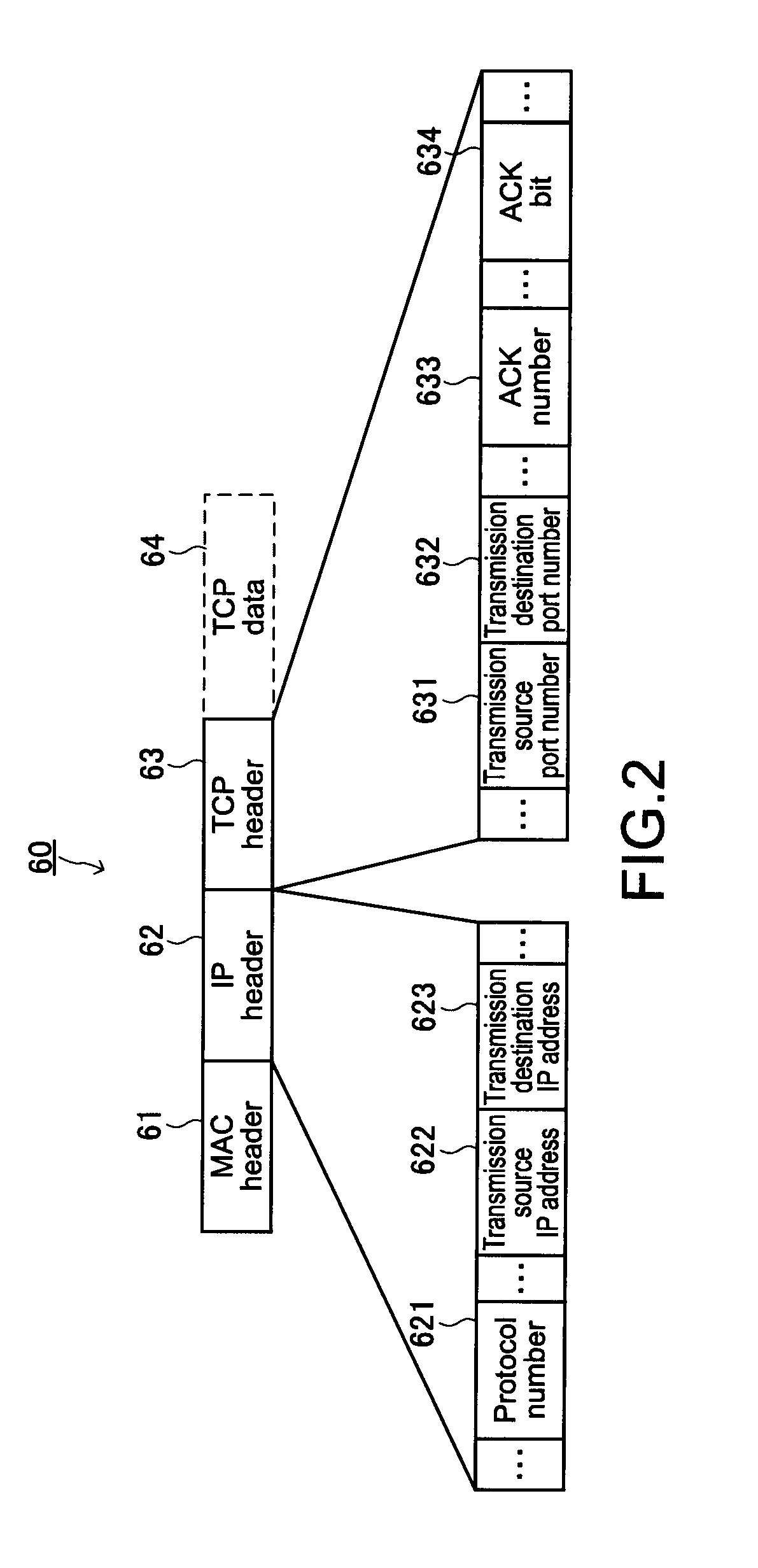

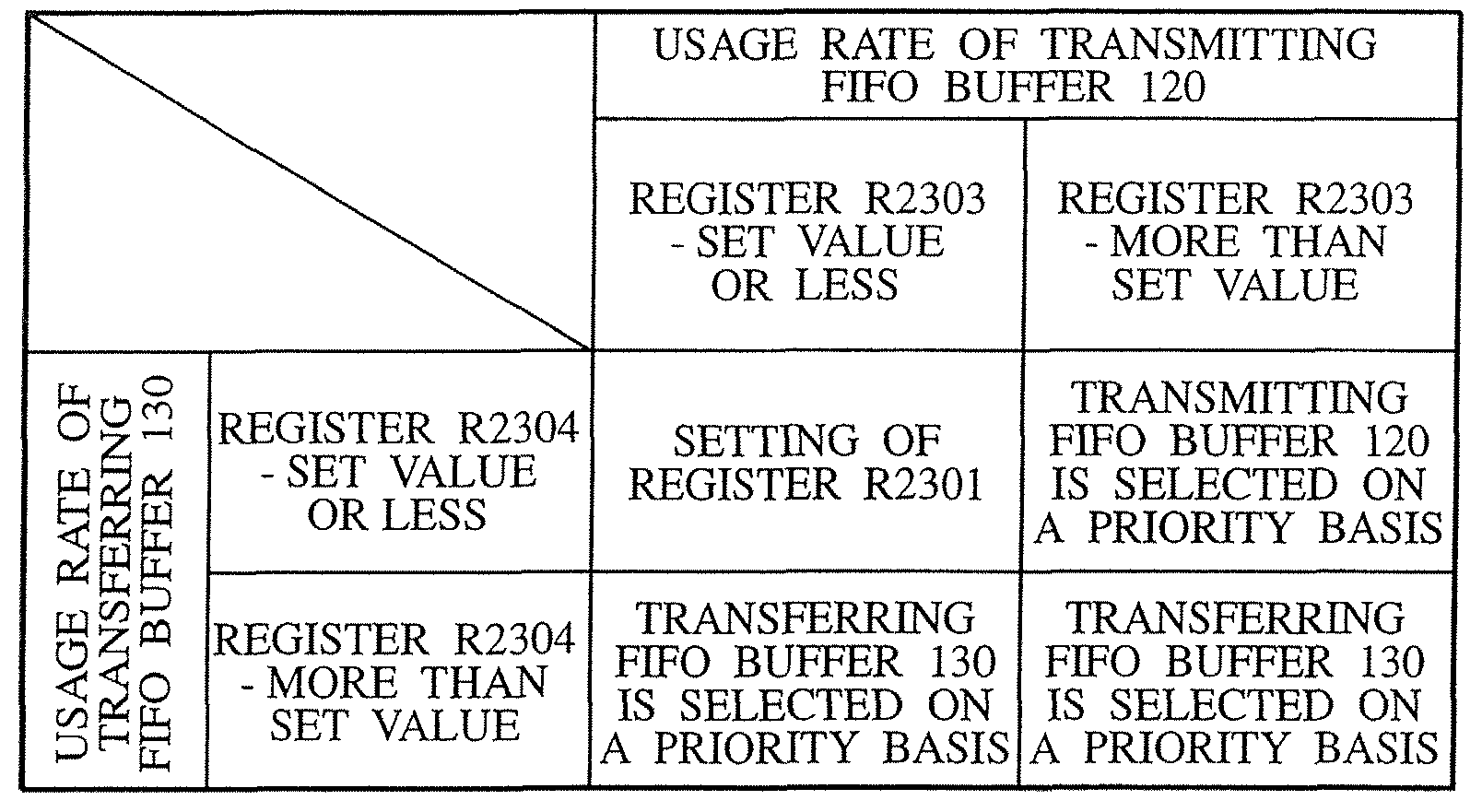

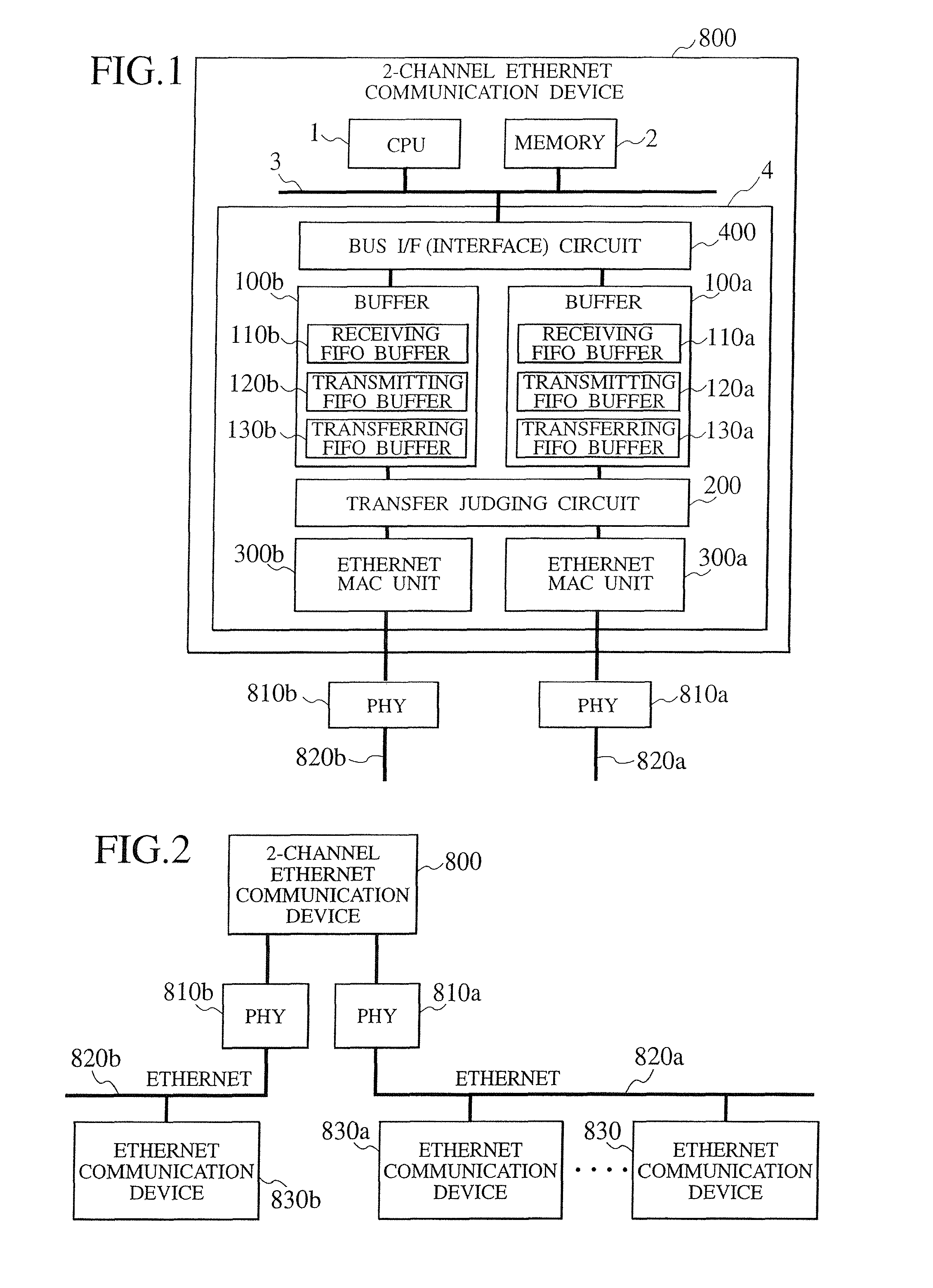

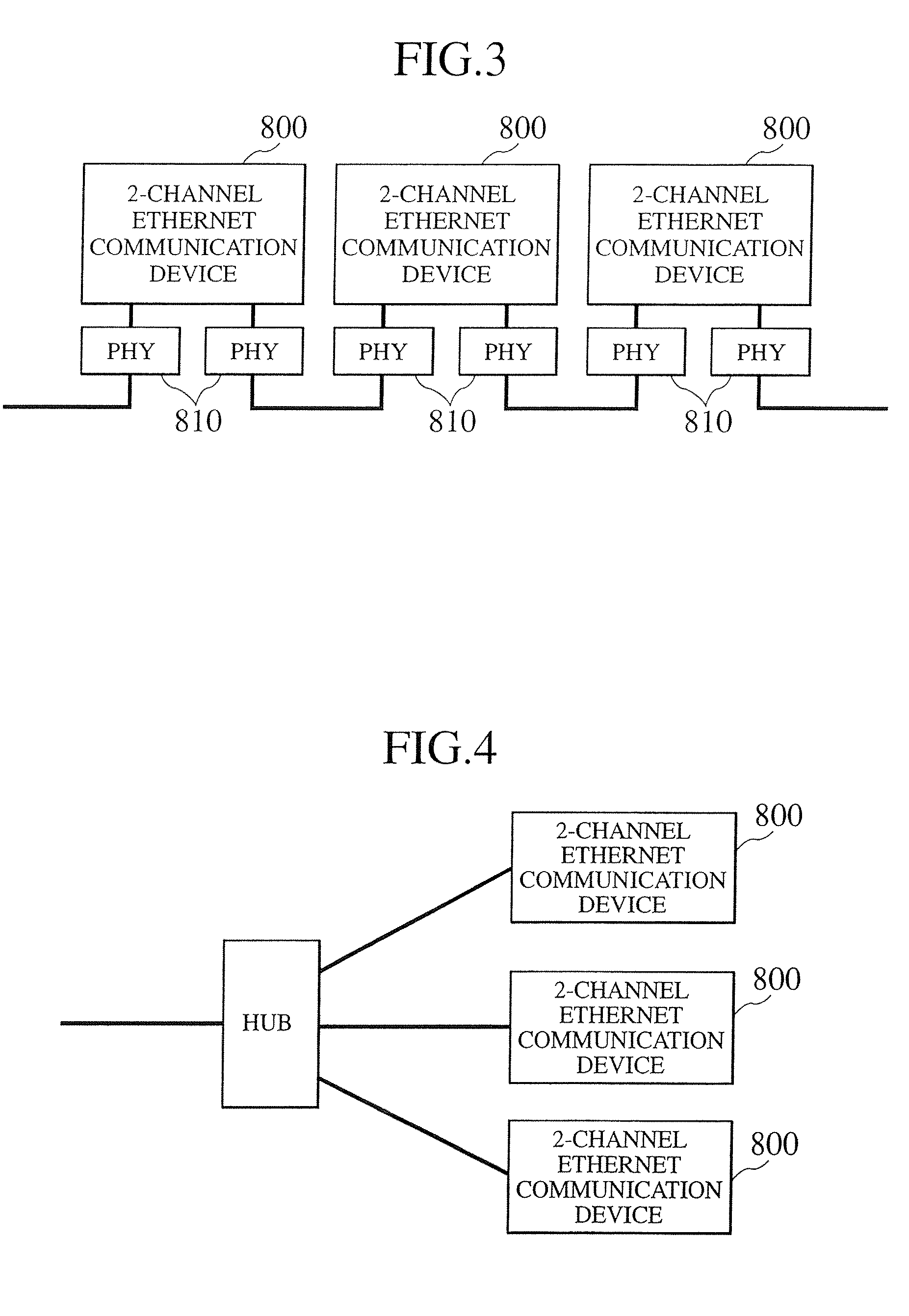

Packet communication device, packet communication system, packet communication system, packet communication module, data processor, and data transfer system

InactiveUS20090092147A1Increase the number ofLow efficiencyStar/tree networksGroup communication systemsTransfer system

A transmit packet generated by a CPU 1 is held in a buffer 100a (100b). From among packets received from Ethernet 820a (820b), a packet, a destination of which is a communication device 800, is held in the buffer 100a (100b). A packet which should be transmitted is transmitted from a transfer judging circuit 200 to Ethernet 820a or 820b through a MAC unit 300a or 300b. If a transfer judging circuit 200 judges a packet from the Ethernet 820a to be a packet, a destination of which is another communication device, with reference to a destination MAC address, this packet is transferred to the Ethernet 820b through MAC 300b. If a usage rate of a transferring FIFO buffer 130a (130b) exceeds a threshold value in the process of transmitting a packet held in a transmitting FIFO buffer 120a (130b) on a priority basis, the priority order of a transfer packet is made higher than that of a transmit packet so that the transfer packet is transferred to the Ethernet 820a or 820b in preference to the transmit packet. This prevents a transfer buffer means from overflowing.

Owner:RENESAS ELECTRONICS CORP

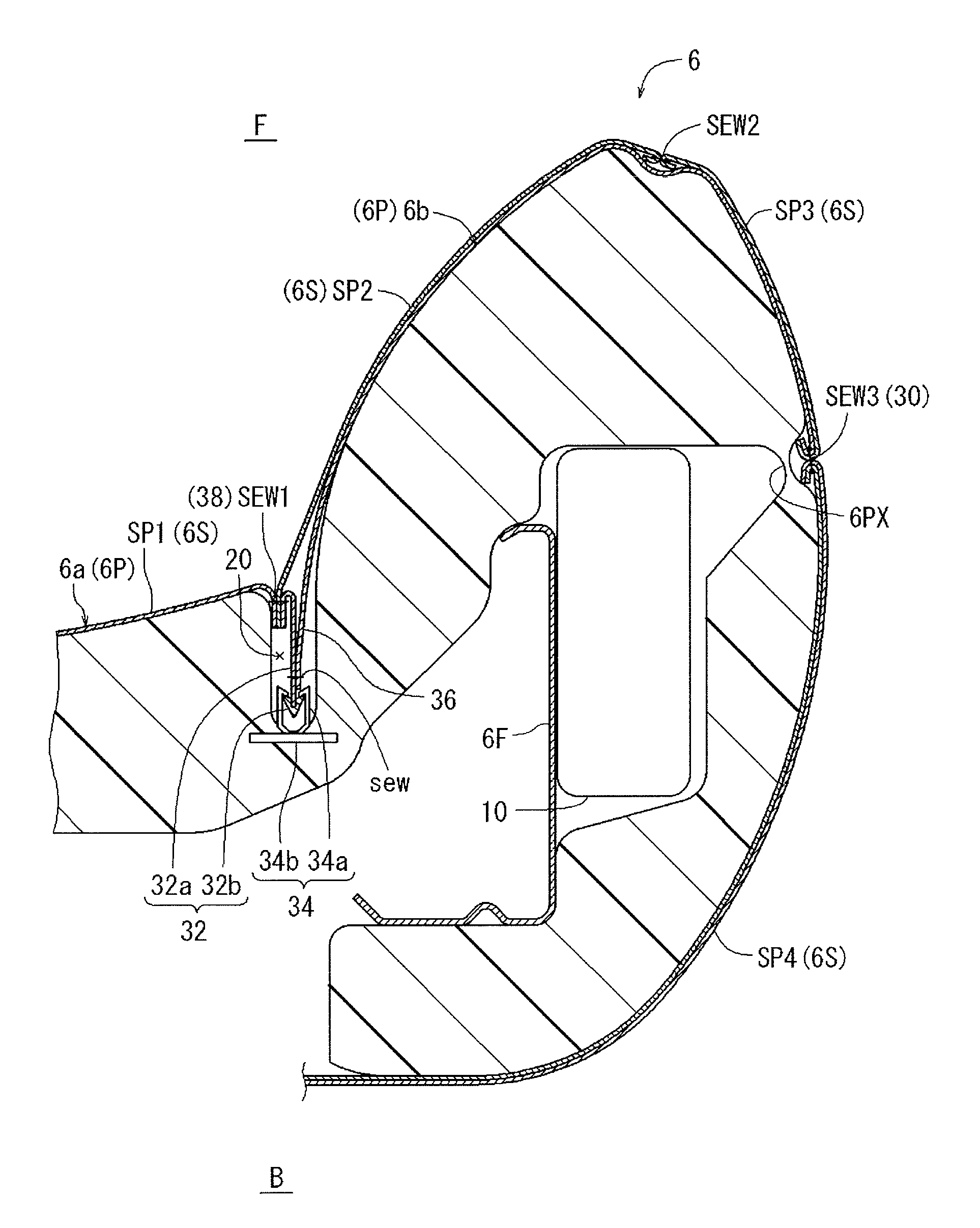

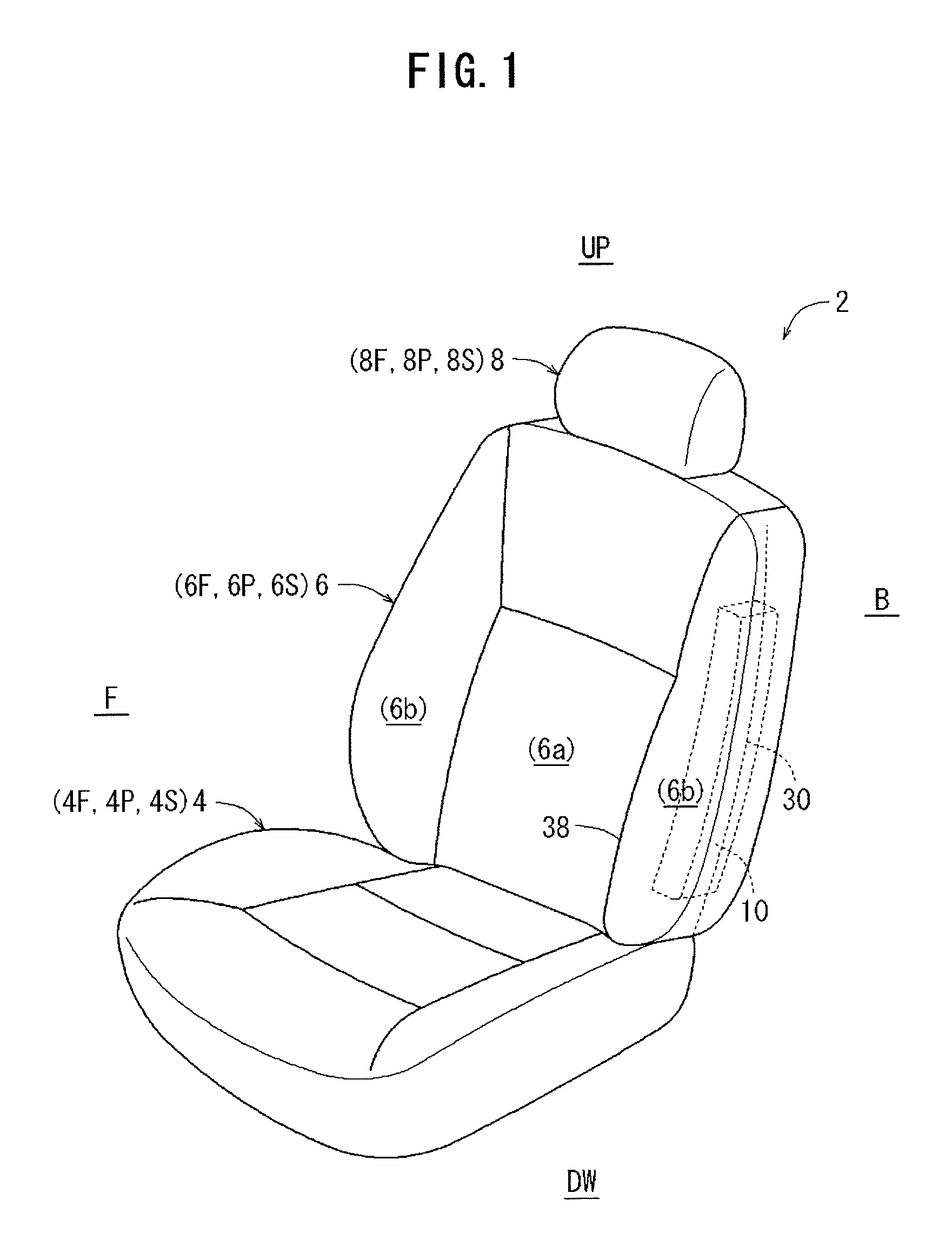

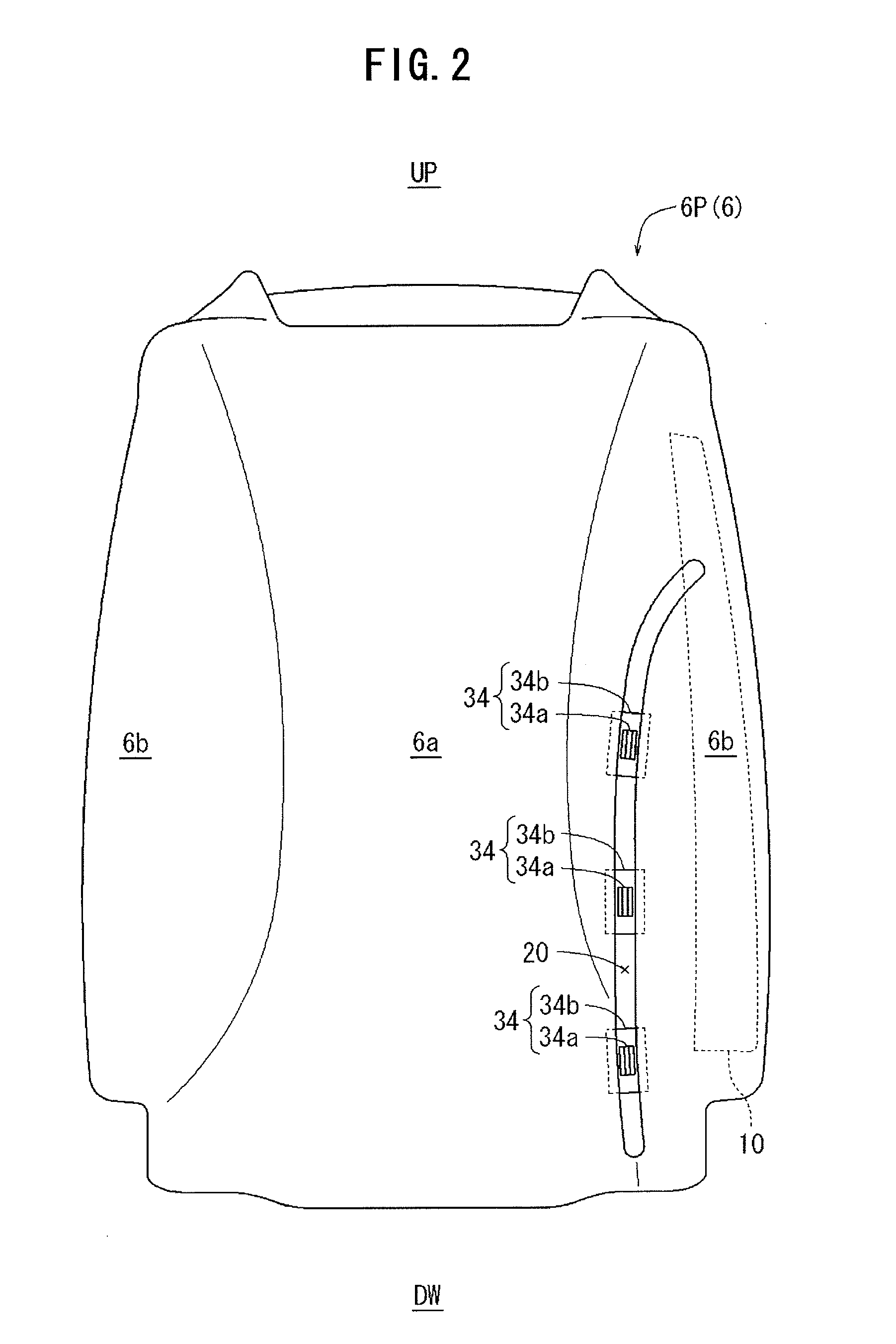

Vehicle seat

Owner:TOYOTA BOSHOKU KK

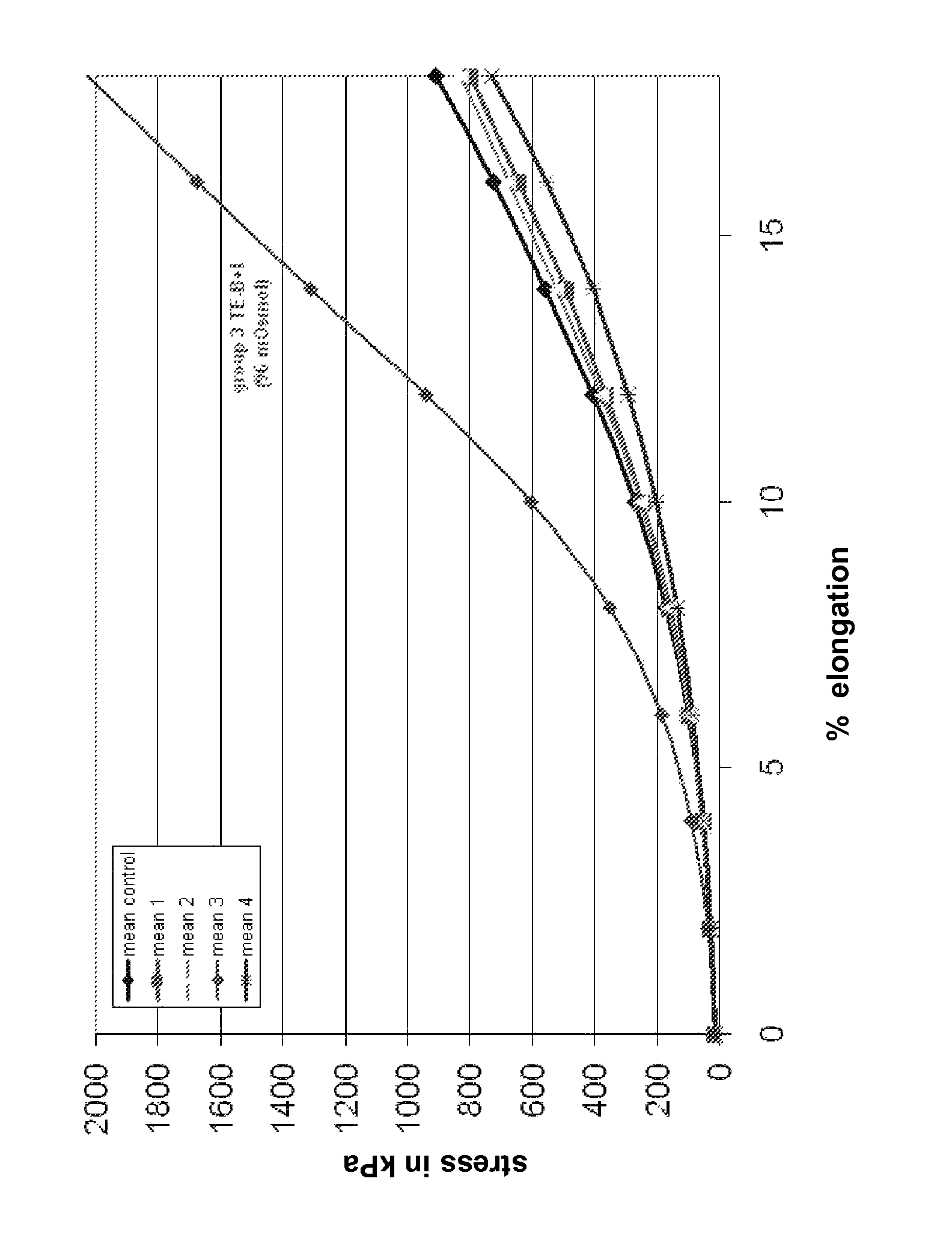

Cross-linking composition delivered by iontophoresis, useful for the treatment of keratoconus

ActiveUS9439908B2Transfer delayProtection from damageOrganic active ingredientsSenses disorderTreatment effectKeratoconus

An improved formulation of an ophthalmic composition contains riboflavin, as cross-linking agent of corneal collagen, administered by corneal iontophoresis, able to guarantee an increased capacity of permeation of riboflavin of the corneal stroma and therefore greater therapeutic efficacy in the treatment of keratoconus.

Owner:SOOFT ITAL SPA

Network communication apparatus

InactiveUS20100246402A1Improve communication qualityQuality improvementError preventionFrequency-division multiplex detailsNetwork communicationComputer science

A network communication apparatus transmitting a first acknowledgment from a higher-level layer to a transmission source of a predetermined number of first segments and a second segment from the higher-level layer to a transmission source of a second acknowledgment, includes: a first condition setting section in which a first condition for specifying a connection to delay the first acknowledgment is set; a first judgment section to judge whether the first acknowledgment is to be delayed; a transmission processing section to delay the to-be-delayed first acknowledgment and transmit it to the transmission source of the first segments; a second condition setting section in which a second condition for specifying a connection to delay the second acknowledgment is set; a second judgment section to judge whether the second acknowledgment is to be delayed; and a reception processing section to delay the to-be-delayed second acknowledgment and transfer it to the higher-level layer.

Owner:SONY CORP

Packet communication device, packet communication system, packet communication system, packet communication module, data processor, and data transfer system

InactiveUS7814223B2Increase the number ofLow efficiencyMultiple digital computer combinationsStar/tree networksPacket communicationGroup communication systems

A transmit packet generated by a CPU 1 is held in a buffer 100a (100b). From among packets received from Ethernet 820a (820b), a packet, a destination of which is a communication device 800, is held in the buffer 100a (100b). A packet which should be transmitted is transmitted from a transfer judging circuit 200 to Ethernet 820a or 820b through a MAC unit 300a or 300b. If a transfer judging circuit 200 judges a packet from the Ethernet 820a to be a packet, a destination of which is another communication device, with reference to a destination MAC address, this packet is transferred to the Ethernet 820b through MAC 300b. If a usage rate of a transferring FIFO buffer 130a (130b) exceeds a threshold value in the process of transmitting a packet held in a transmitting FIFO buffer 120a (130b) on a priority basis, the priority order of a transfer packet is made higher than that of a transmit packet so that the transfer packet is transferred to the Ethernet 820a or 820b in preference to the transmit packet. This prevents a transfer buffer means from overflowing.

Owner:RENESAS ELECTRONICS CORP

Continued transfer or streaming of a data file after loss of a local connection

InactiveUS8209434B2Transfer delayNetwork topologiesMultiple digital computer combinationsData fileComputer science

A server receives a request for transfer or streaming of a data file sent in the local network from a portable communication device. The server provides the portable communication device with an identifier allowing the data file to be located on the server via a wide area network and transfers or streams the file over the local network to the portable communication device.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com