Furnace drying method for new intermediate-frequency furnace during pre-alloyed powder smelting

A furnace method and pre-alloyed powder technology, applied in the direction of furnaces, crucible furnaces, furnace components, etc., can solve the problems of poor baking effect of furnace lining materials, short service life of furnace lining, affecting production rhythm, etc., and achieve the expansion of sintered layer thickness , improve service life, good melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

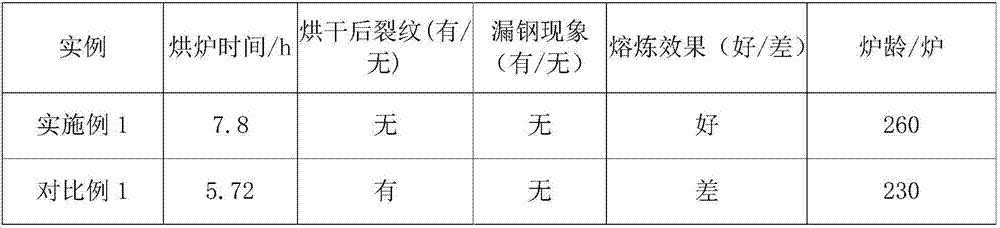

Examples

Embodiment 1

[0022] A method for baking a new intermediate frequency furnace for pre-alloyed powder smelting, comprising the following process steps:

[0023] (1) Use an electric oven to raise the temperature of the new furnace from room temperature to 100°C, the heating rate is controlled at 2.5 / min, and the time is 0.5 hours;

[0024] (2) Use an electric oven to raise the furnace temperature from 100°C to 400°C, and control the heating rate at 1.25°C / min for 4 hours;

[0025] (3) Use an electric oven to raise the furnace temperature from 400°C to 900°C, and control the heating rate at 4.15°C / min for 2 hours;

[0026] (4) After the furnace temperature reaches 900°C, add 80Kg of pure iron rods into the new furnace. Be careful not to collide with the furnace lining when feeding. The lower layer is compact and the upper layer is loose to avoid bridging;

[0027] (5) Power on the intermediate frequency furnace, raise the temperature from 900°C to 1200°C, and control the heating rate at 10°C / ...

Embodiment 2

[0031] A method for baking a new intermediate frequency furnace for pre-alloyed powder smelting, comprising the following process steps:

[0032] (1) Use an electric oven to raise the temperature of the new furnace from room temperature to 100°C, the heating rate is controlled at 2.5 / min, and the time is 0.5 hours;

[0033] (2) Use an electric oven to raise the furnace temperature from 100°C to 400°C, the heating rate is controlled at 1.5°C / min, and the time is 3.33 hours;

[0034] (3) Use an electric oven to raise the furnace temperature from 400°C to 900°C, the heating rate is controlled at 5.0°C / min, and the time is 1.67 hours;

[0035] (4) After the furnace temperature reaches 900°C, add 85Kg of pure iron rods into the new furnace. Be careful not to collide with the furnace lining when adding materials. The lower layer is compact and the upper layer is loose to avoid bridging;

[0036] (5) Then power on the intermediate frequency furnace, raise the temperature from 900°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com