Cast iron exhaust manifold for supercharged gasoline engine

A gasoline engine and exhaust manifold technology, which is applied to engine components, machines/engines, exhaust devices, etc., can solve the problems of large thermal deformation of the exhaust manifold, reduce the cost of the whole machine, and be easy to crack, and achieve reduction Effects of thermal deformation, optimized position, reduced amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

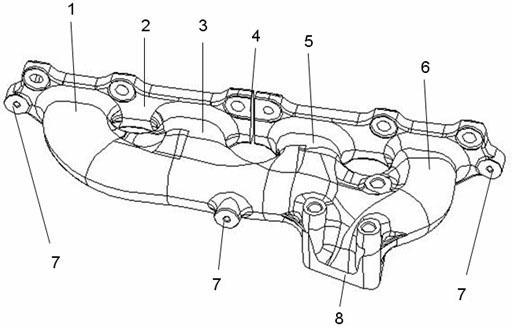

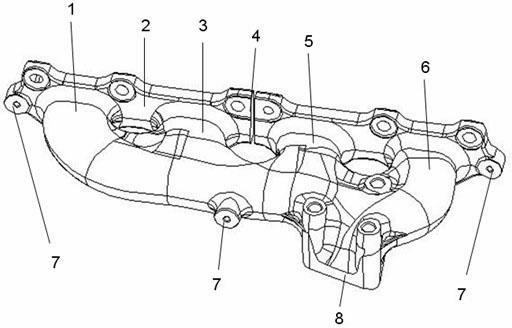

[0012] Taking the exhaust manifold of four air passages as an example below, the present invention will be further described in conjunction with the accompanying drawings and examples:

[0013] see figure 1 , the structure of the cast iron exhaust manifold for the supercharged gasoline engine of the present invention includes an inlet flange 2, a first air passage 1, a second air passage 3, a third air passage 5 and a fourth air passage 6, and a heat shield is installed. Sub 7, outlet flange 8. In the middle of the inlet flange 2, that is, between the second air passage 3 and the third air passage 5, there is a cutout 4 with a width of about 3 mm, which cuts the inlet flange 2 into left and right sections. , this structure can effectively release the thermal stress of the exhaust manifold under the repeated action of exhaust temperature changes, reduce the risk of airway cracking, and the area of each section of the split flange becomes smaller, making the inlet flange 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com