Reel-to-reel hot roller coining forming method for micro-nano structure on surface of polymer

A technology of micro-nano structure and forming method, which is applied in the field of roll-to-roll hot roller embossing processing, can solve the problems of low rolling speed and replication accuracy, unfavorable high-efficiency production, etc., to enhance process adaptability, promote discharge, and improve replication. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

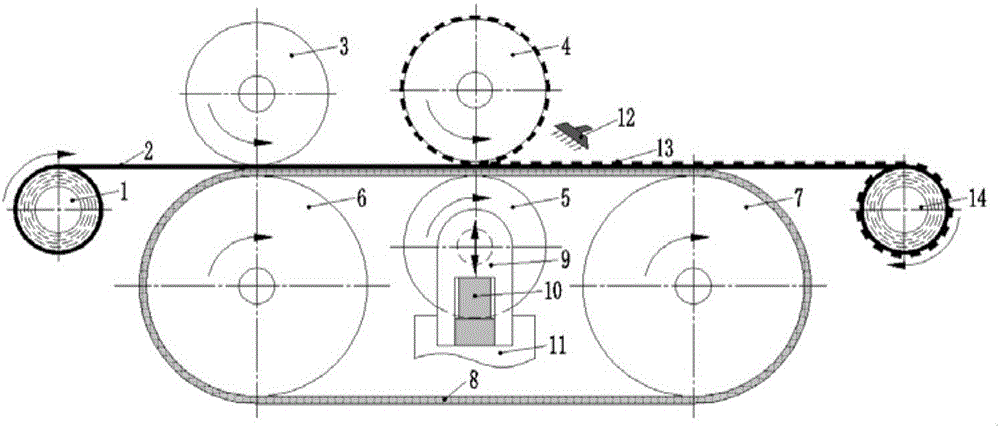

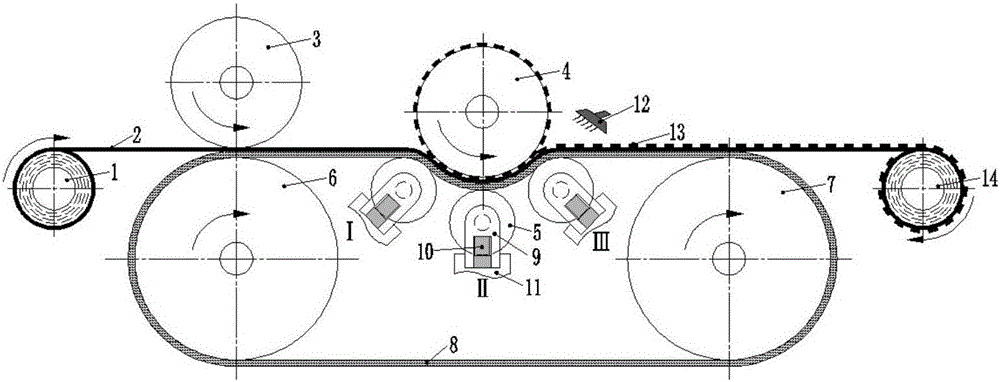

[0032] In this embodiment, the polymer material used is a single-layer material, and thermoplastic polymer PC (polycarbonate) is selected for use, and its schematic diagram of the device used is as follows figure 1 As shown, the rotation of the unwinding roller 1, the preheating roller 3, the mold roller 4, the second base belt transmission wheel 7 and the winding roller 14 is driven by a motor, and they are used as the driving roller in the roll-to-roll transmission, and the second base belt transmission The rotation of the wheel 7 drives the transmission movement of the base belt 8 and the rotation of the first base belt transfer wheel 6, and the rotation of the pressure roller 5 is jointly driven by the movement of the mold roller 4 and the base belt 8; the hydraulic cylinder connected with the preheating roller 3 can promote preheating The roller 3 presses against the first base belt transmission wheel 6 , and the hydraulic cylinder connected with the pressure roller 5 can ...

Embodiment 2

[0041] In this embodiment, the polymer material used is a double-layer material, and a double-layer material composed of PET (polyethylene terephthalate) and PVC (polyvinyl chloride) is selected.

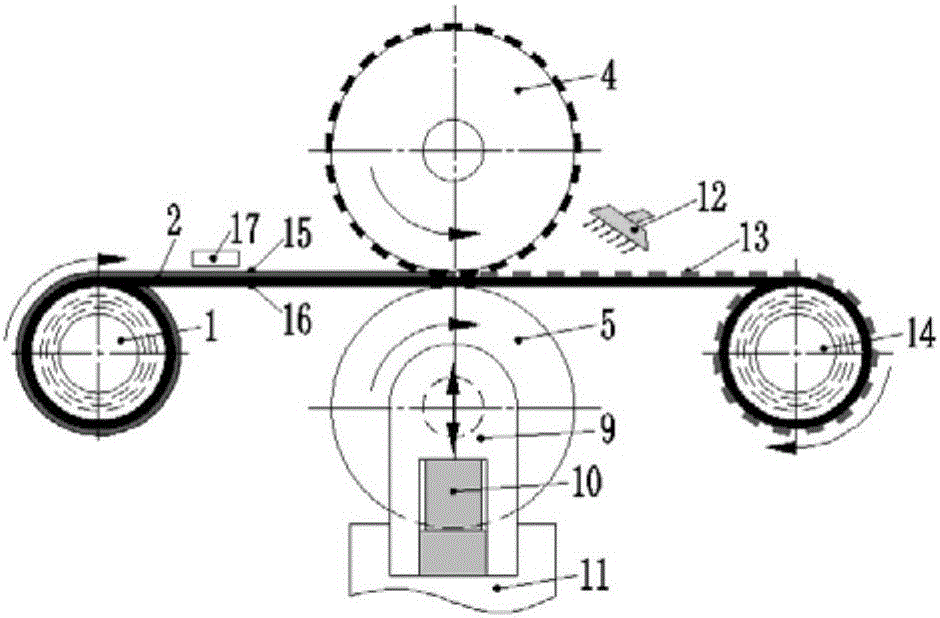

[0042] The schematic diagram of the device used is shown in image 3 As shown, the rotation of the unwinding roller 1, the mold roller 4 and the winding roller 13 is driven by a motor, as the driving roller in the roll-to-roll transmission, the rotation of the pressure roller is driven by the movement of the mold roller 4, and is connected with the pressure roller 5 The hydraulic cylinder can push the pressure roller 5 to press the mold roller 4.

[0043] The polymer material 2 is formed by bonding a PVC layer 15 (glass transition temperature 81°C, viscous flow temperature 160°C) and a PET layer 16 (glass transition temperature 69°C, viscous flow temperature 250°C), wherein the PVC layer 15 The thickness is 50 μm, which is the forming layer of the micro-nano structure, and the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com