Patents

Literature

38results about How to "High copying accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

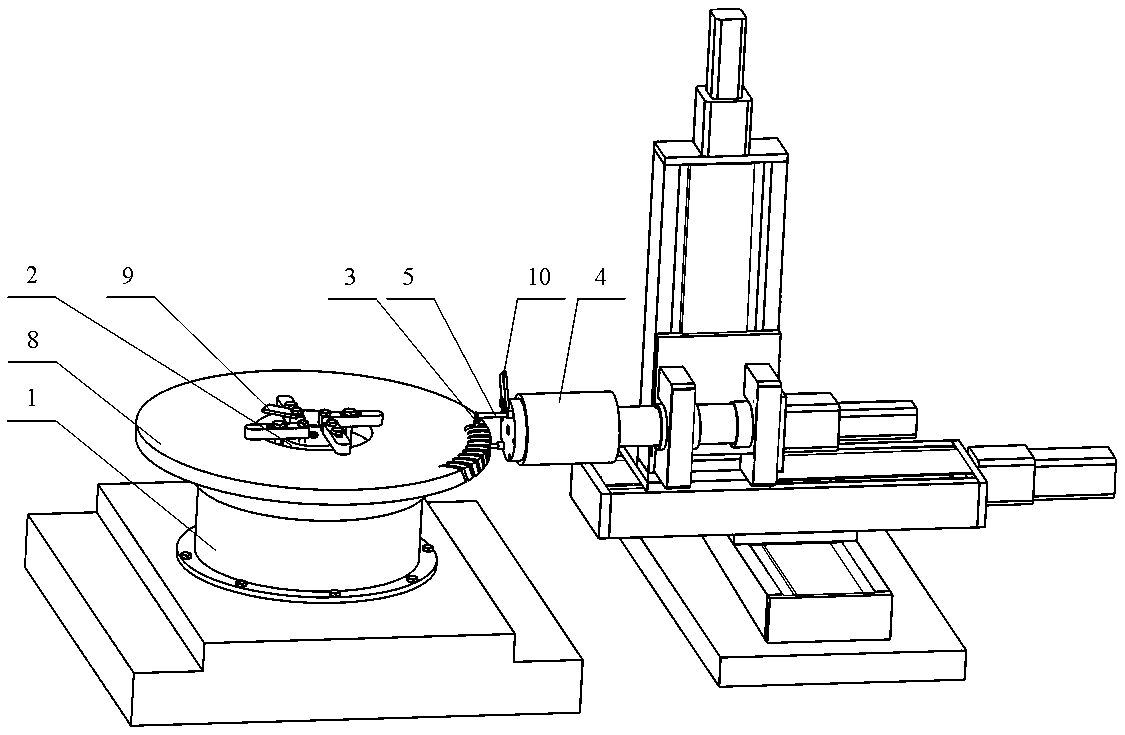

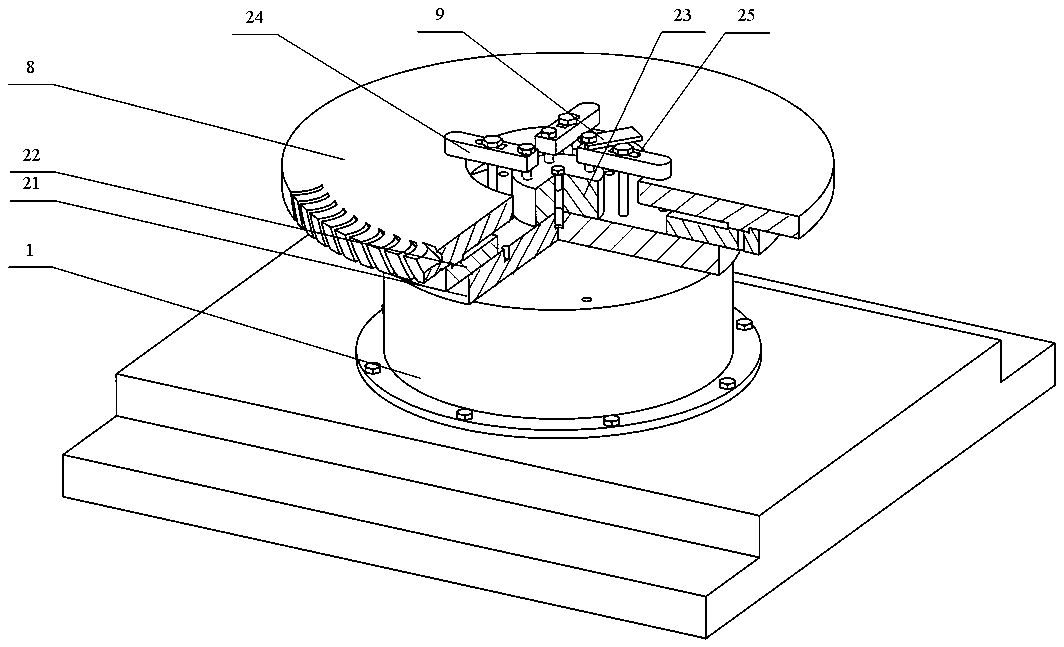

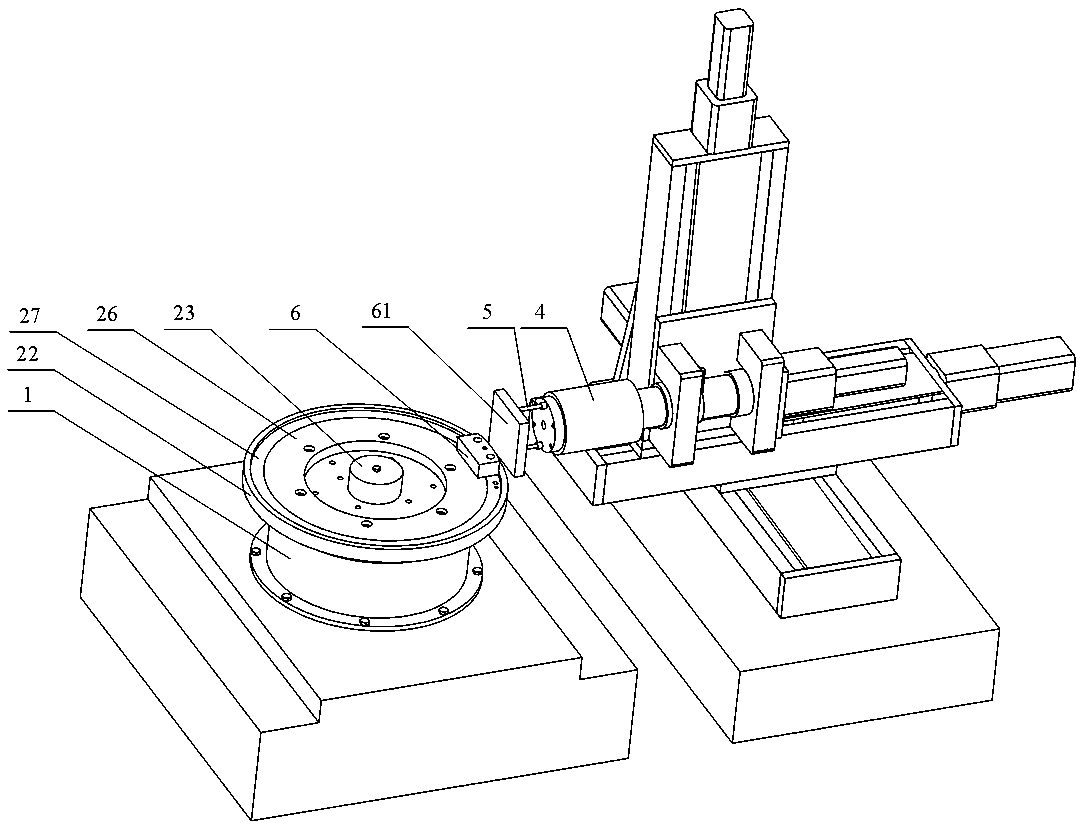

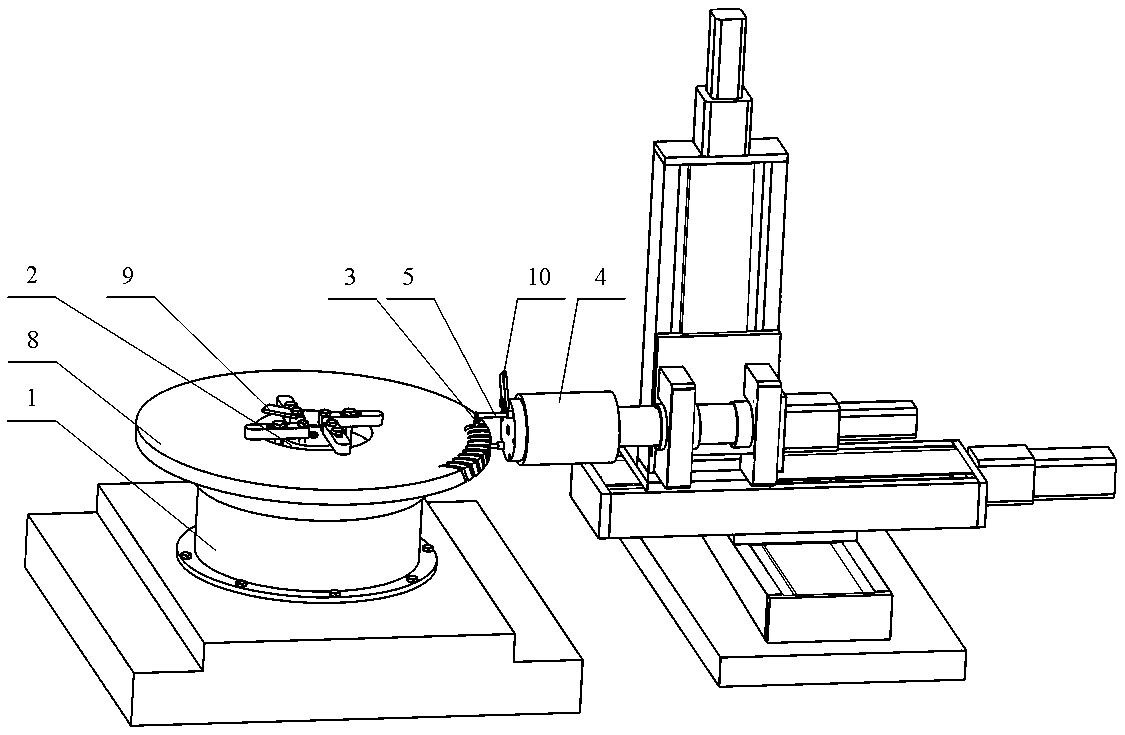

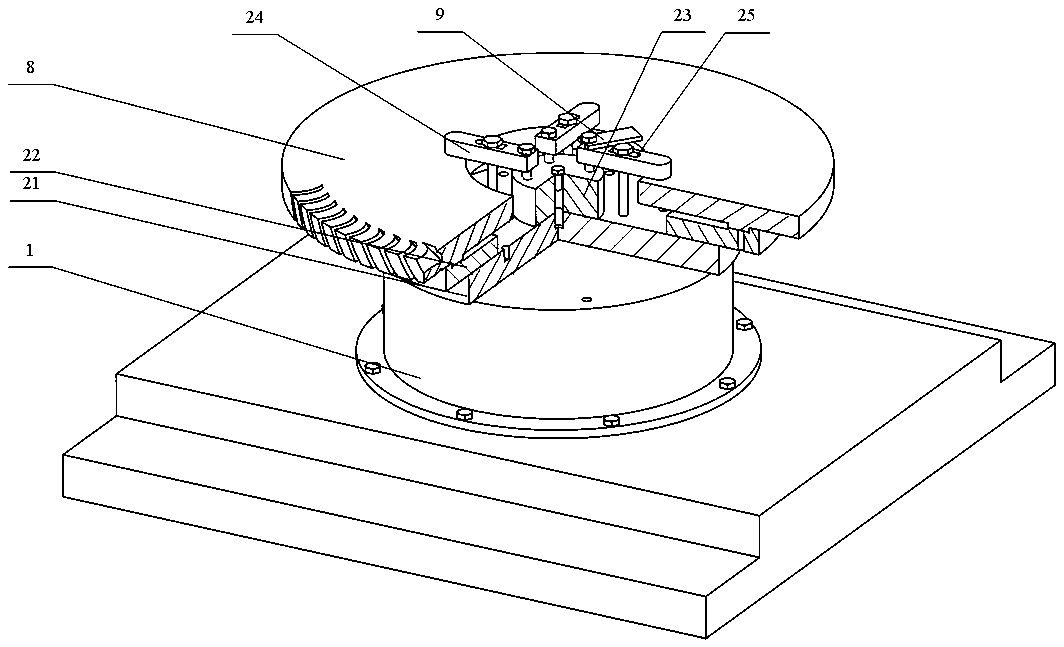

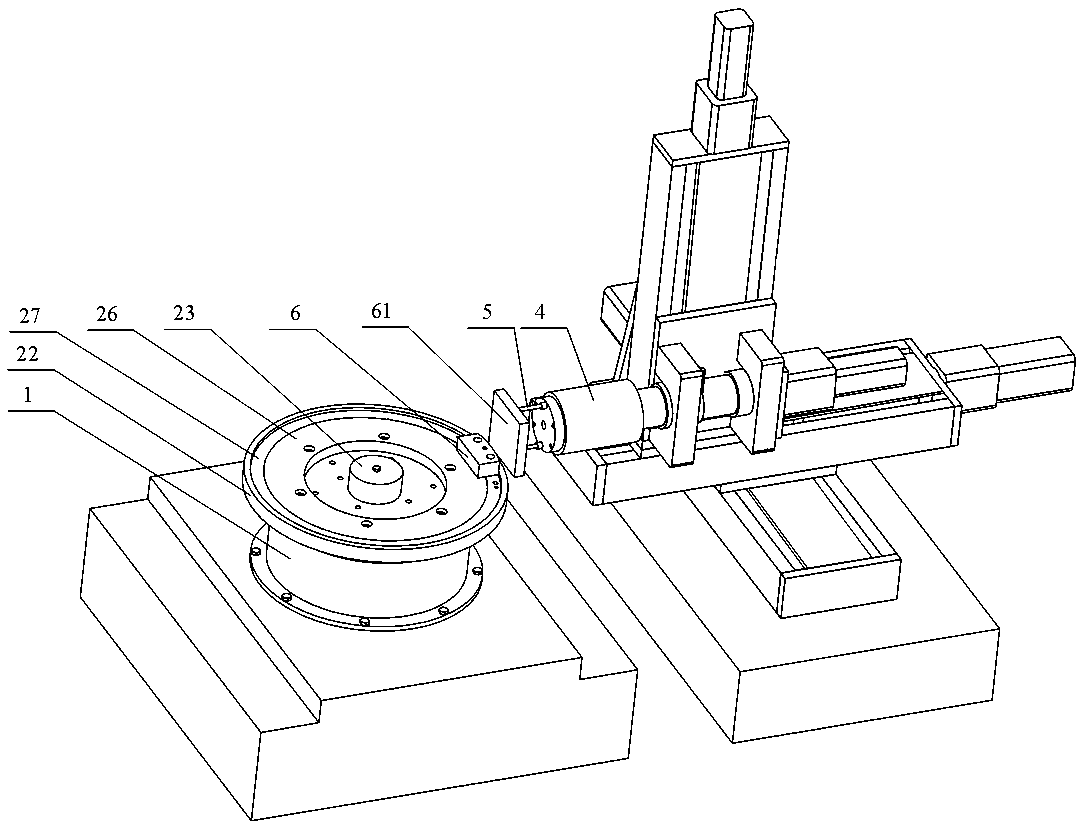

Blisk integrated electrolytic machining method and electrolysis tool

ActiveCN110935968AHigh precisionQuality improvementElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisEngineering

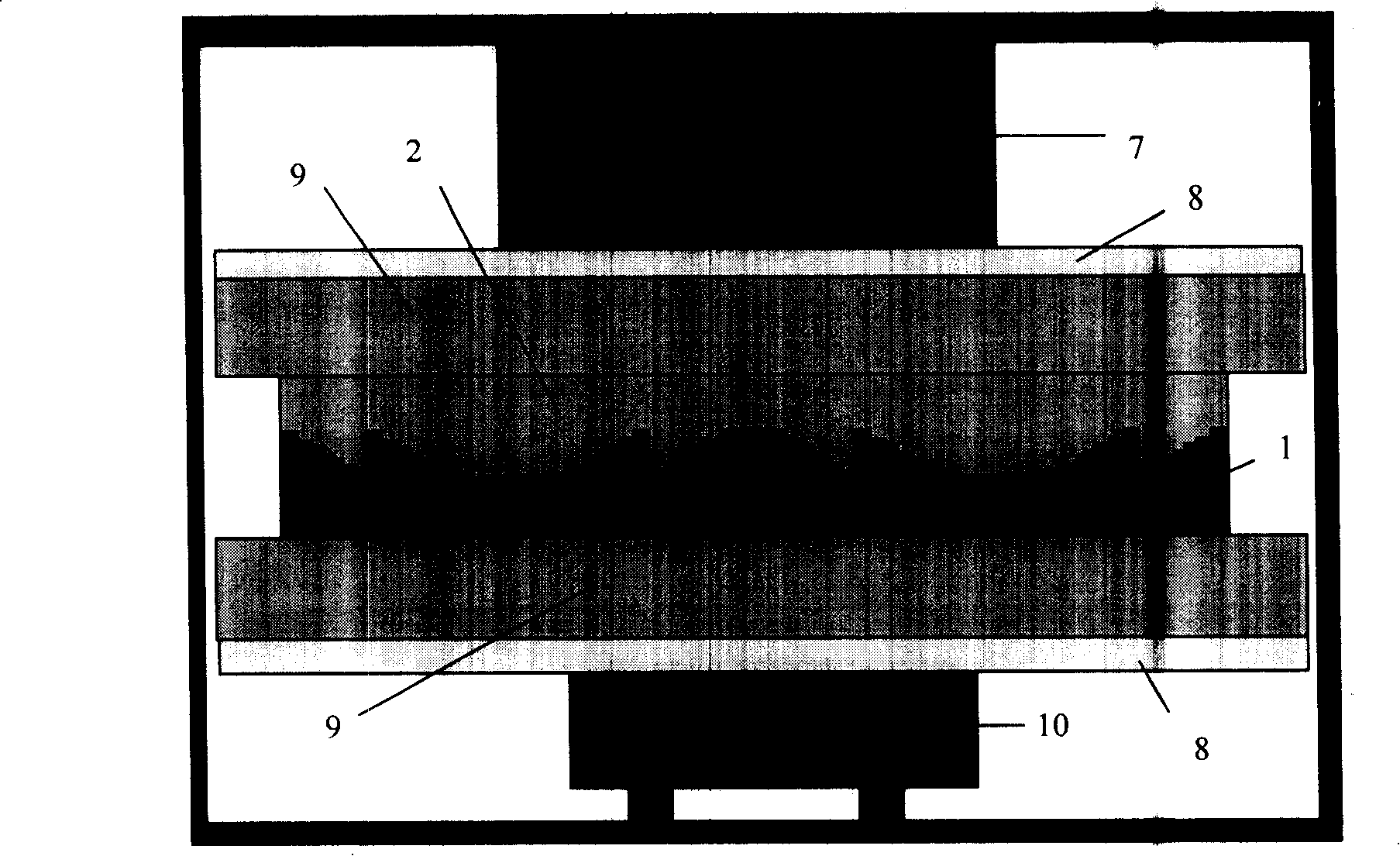

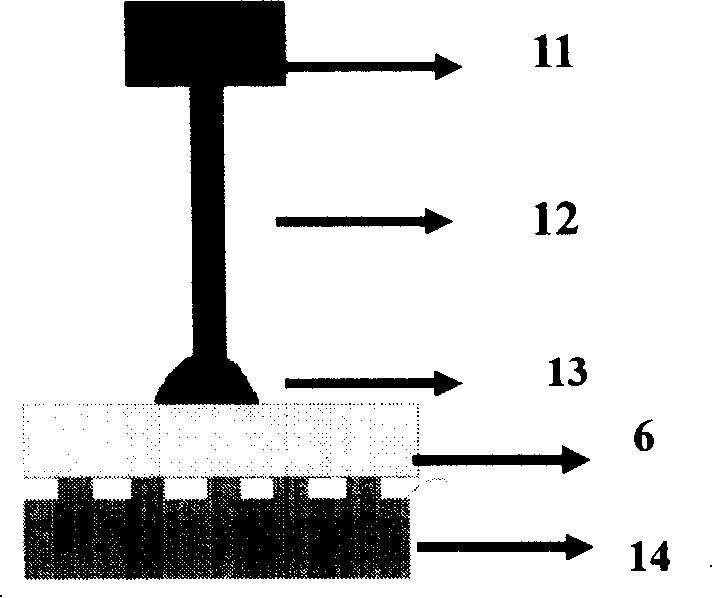

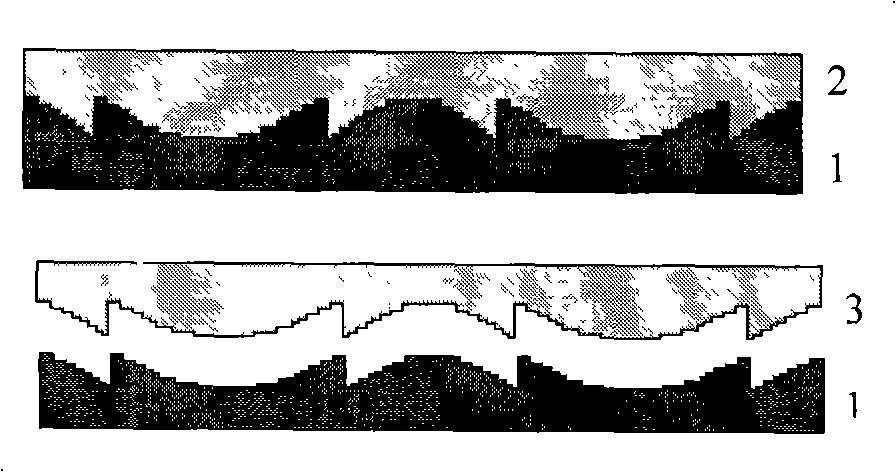

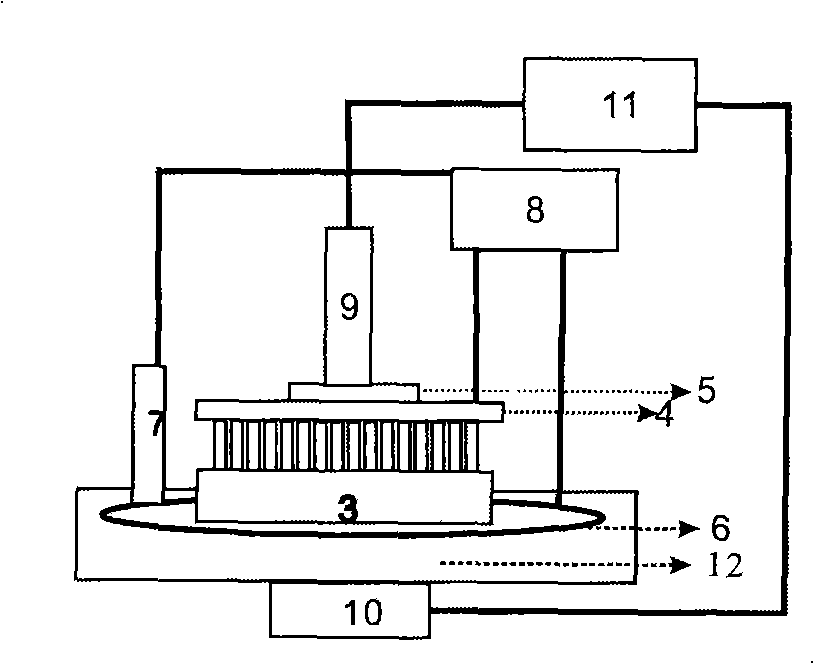

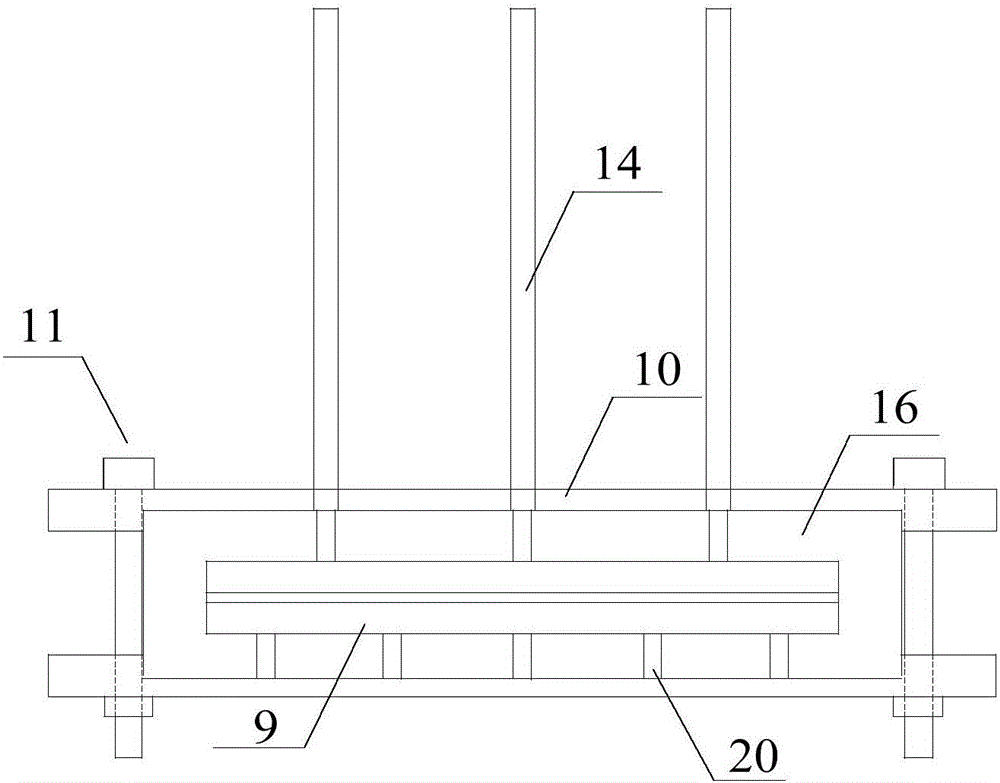

The invention discloses a tool for achieving integrated electrolysis machining of a complex profile blisk, a blade basin, a blade back and a hub by means of multi-axis linkage of a curved cathode, andrelates to the technical field of electrolytic machining. The tool comprises a rotary workbench, a workpiece clamp mounted on the rotary workbench, a cathode body located at workpiece grid channels,a feeding mechanism capable of performing multi-axis action, a connecting rod for connecting the curved cathode with a machining main shaft and a tool-setting block. The cathode body is of a hollow thin-wall structure, and the geometry of the cathode body is designed according to the grid channels and the hub profile. During machining, the rotary workbench drives a workpiece to do rotary action, the machining main shaft of the feeding mechanism drives the cathode body to move, rotate and the like to form multi-axis linkage, and a blisk workpiece with a complex twisted shape is obtained. The machining method has wide applicability, and the blisk workpiece with high dimensional precision and high surface quality for an aerospace engine can be obtained through one-time machining.

Owner:HEFEI UNIV OF TECH

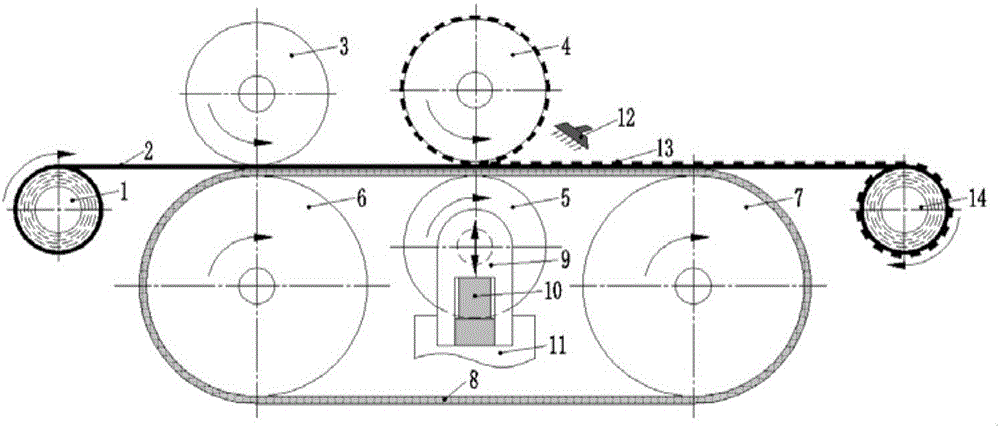

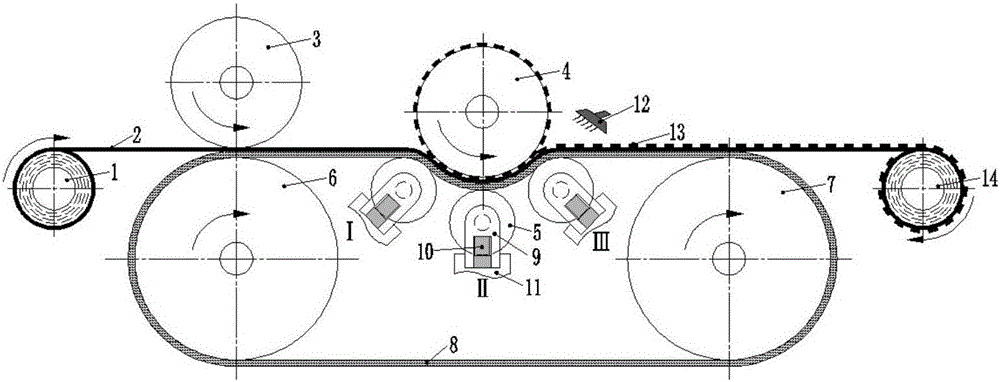

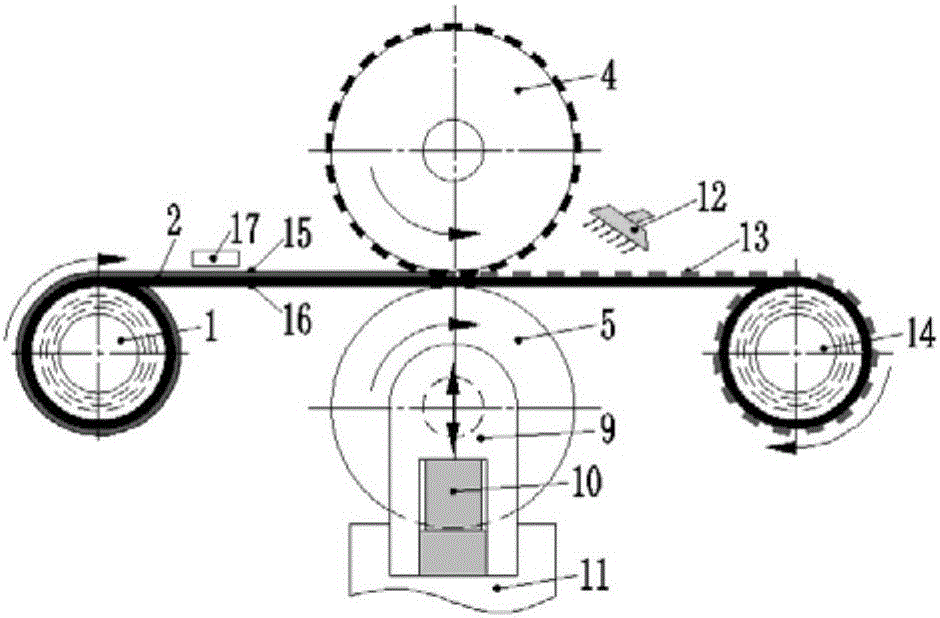

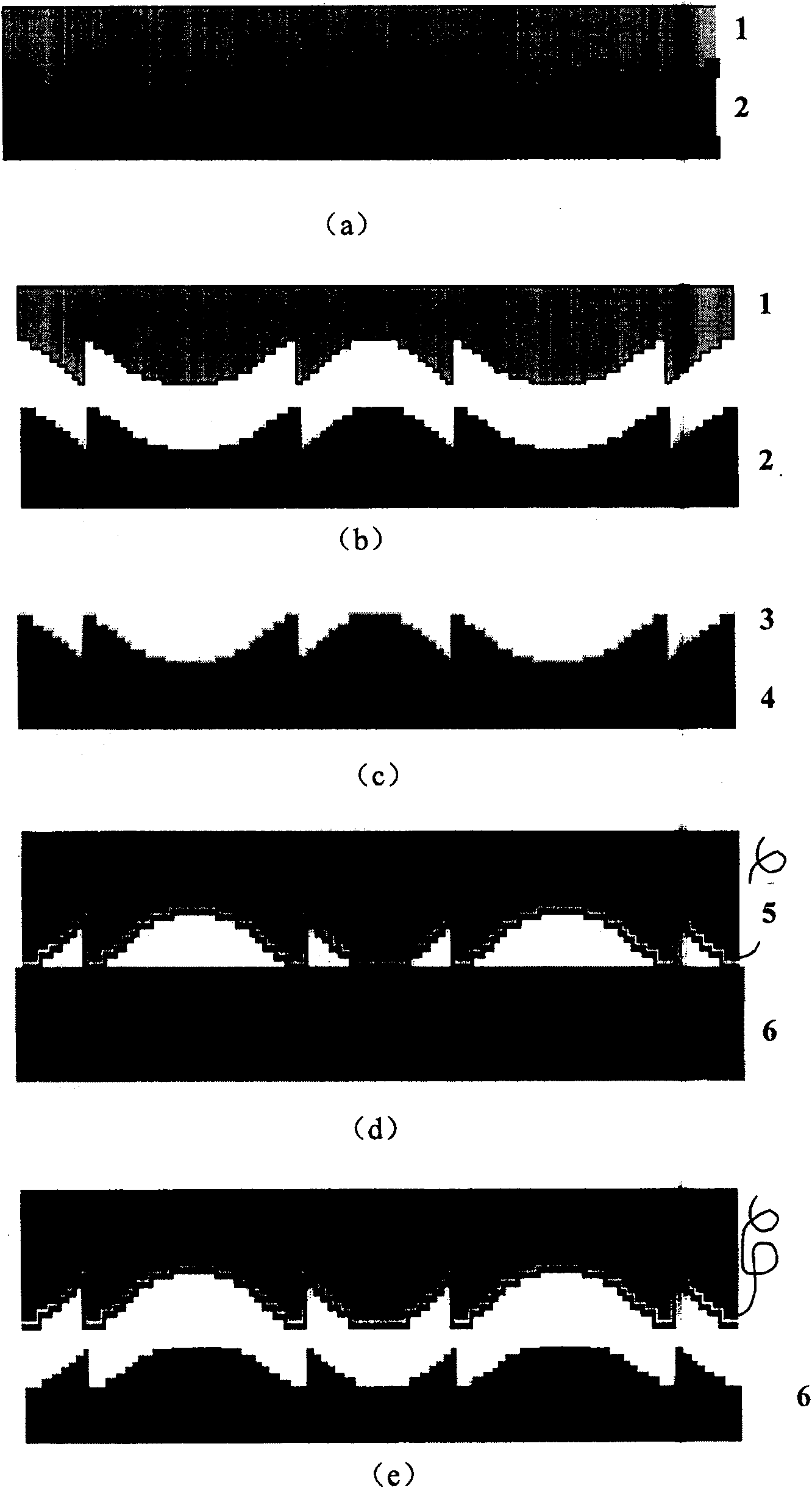

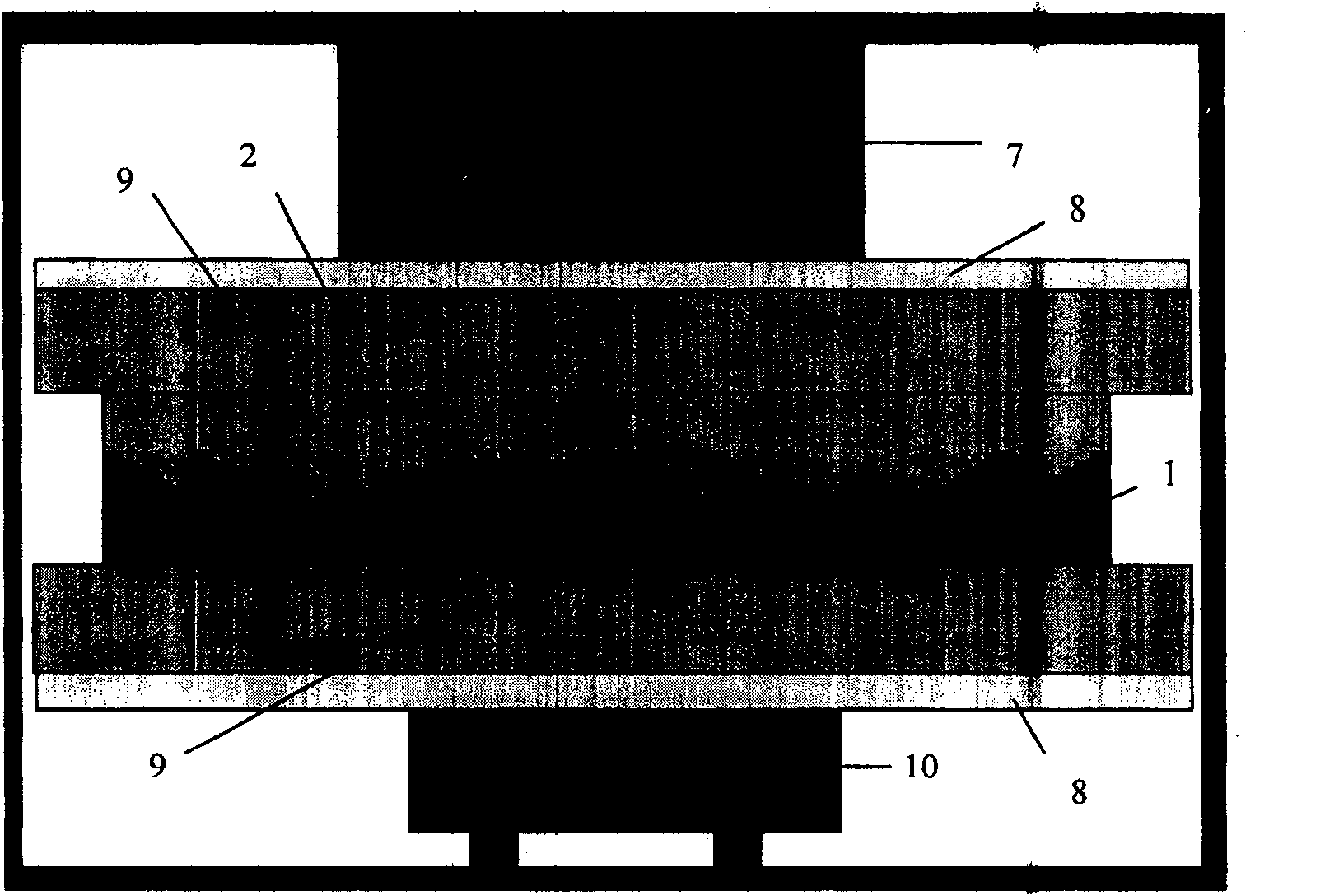

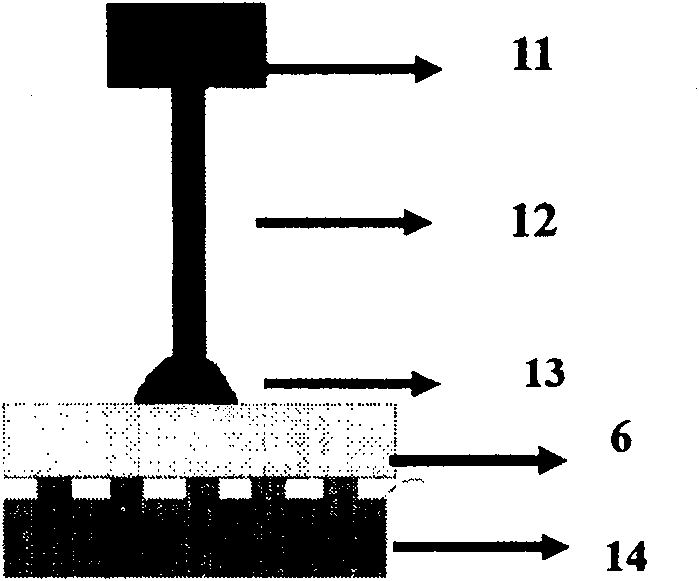

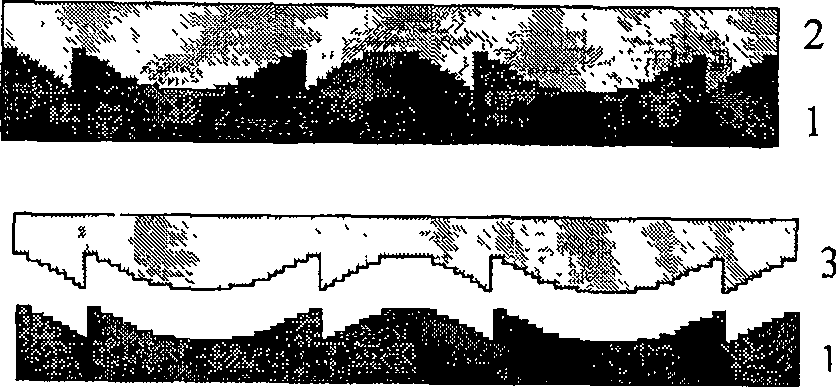

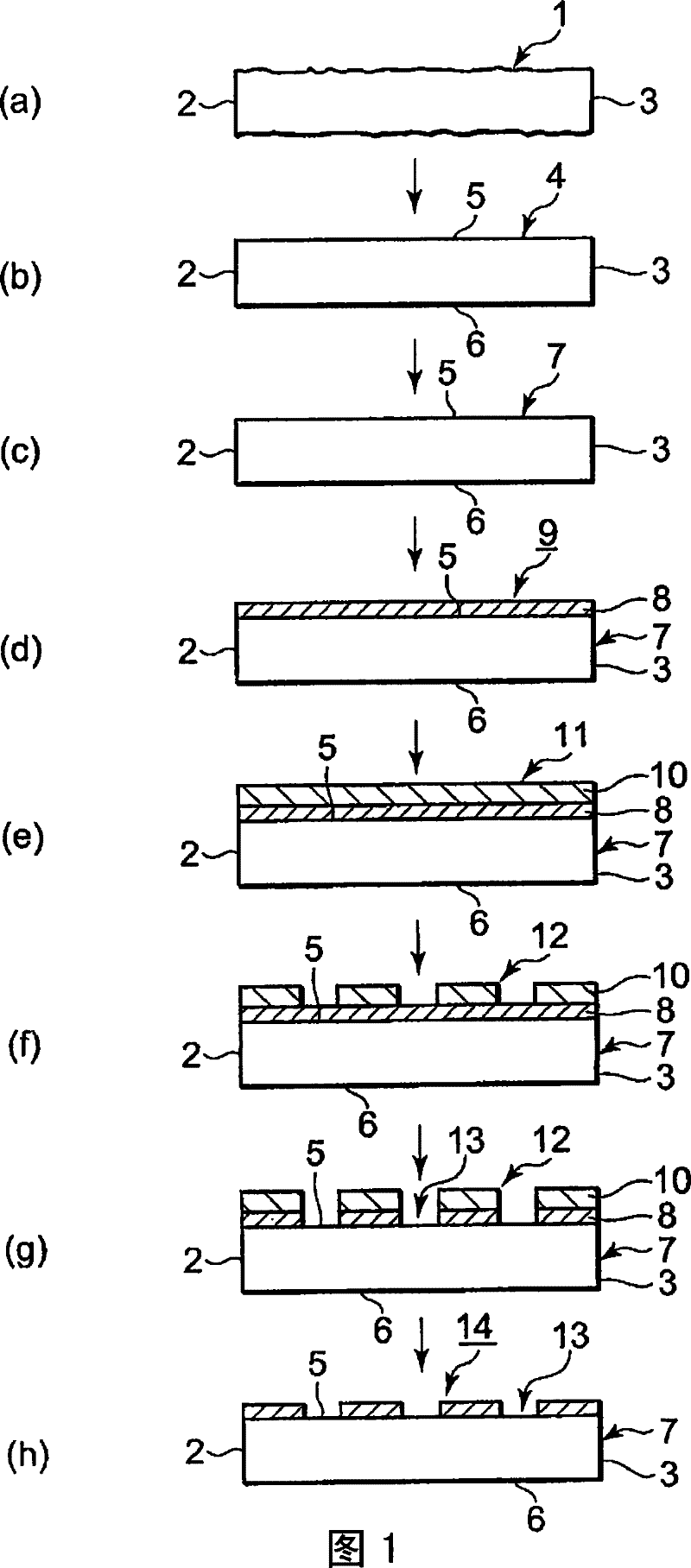

Reel-to-reel hot roller coining forming method for micro-nano structure on surface of polymer

The invention relates to a reel-to-reel hot roller coining forming method for a micro-nano structure on the surface of polymer. The reel-to-reel hot roller coining forming method comprises the steps that a polymer material is conveyed to a preheat roller from an unreeling device, preheated to the attaching temperature and attached to a base band in a hot pressing mode; the polymer material attached to the base band is conveyed to the position between a mold roller and a pressure roller and heated to the coining temperature through the mold roller heated in advance, and then a mold cavity is filled with the polymer material through the action of the pressure roller; mold filling and supersonic vibration assembly starting are conducted at the same time, and the reel-to-reel hot roller coining process is completed with assistance of supersonic vibration; the polymer material is conveyed out from the position between the mold roller and the pressure roller, and then cooled and separated from the position inside the mold roller; and after demolding is completed, a polymer product is continuously cooled, separation of the polymer product and the base band is achieved, and finally reeling is conducted. According to the reel-to-reel hot roller coining forming method for the micro-nano structure on the surface of the polymer, the reel-to-reel hot roller coining process is improved through supersonic vibration, the mold filling process is accelerated, the duplication precision is improved, and the demolding force and demolding deformation are reduced; and the reel-to-reel hot roller coining forming method is advanced.

Owner:SHANGHAI JIAO TONG UNIV

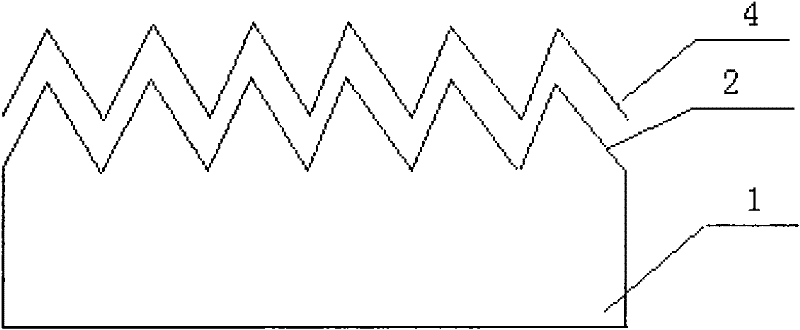

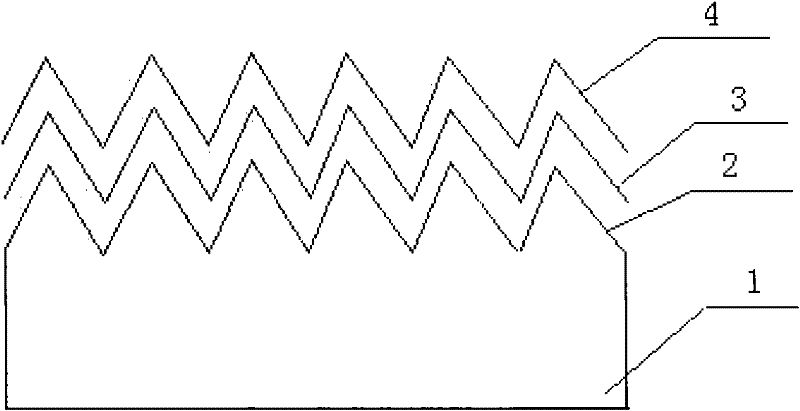

Oral porcelain tooth 3D gel printing preparation method

InactiveCN106045503AHigh copying accuracyIncrease profitImpression capsAdditive manufacturing apparatusCeramic compositeSprayer

The invention provides an oral porcelain tooth 3D gel printing preparation method, and belongs to the technical field of quick forming of precise porcelain composite materials. The oral porcelain tooth 3D gel printing preparation method comprises the following steps: firstly, acquiring an actual three-dimensional virtual model of oral teeth of a patient by using a medical digital scanning technology, processing with medical model analyzing and processing software, and then generating a formatted file required by 3D printing; secondly, preparing required non-toxic biomedical porcelain slurry, controlling a 3D printer to extrude the slurry along a sprayer with a specific size through computer 3D printing software, and then stacking layer by layer to form a three-dimensional blank body of the oral porcelain teeth; and finally, after drying the blank body, sintering the blank body at high temperature to obtain the final product. By the method, the oral porcelain teeth can be produced quickly and highly precisely, the material utilization rate is high, the printed porcelain teeth are safe and non-toxic and are good in biological compatibility, and in the aspect of the mechanical property, teeth can be matched well. In addition, by the method, production cost is reduced, a technical process of product is simplified, operability is high, and private customization is easy to implement.

Owner:UNIV OF SCI & TECH BEIJING

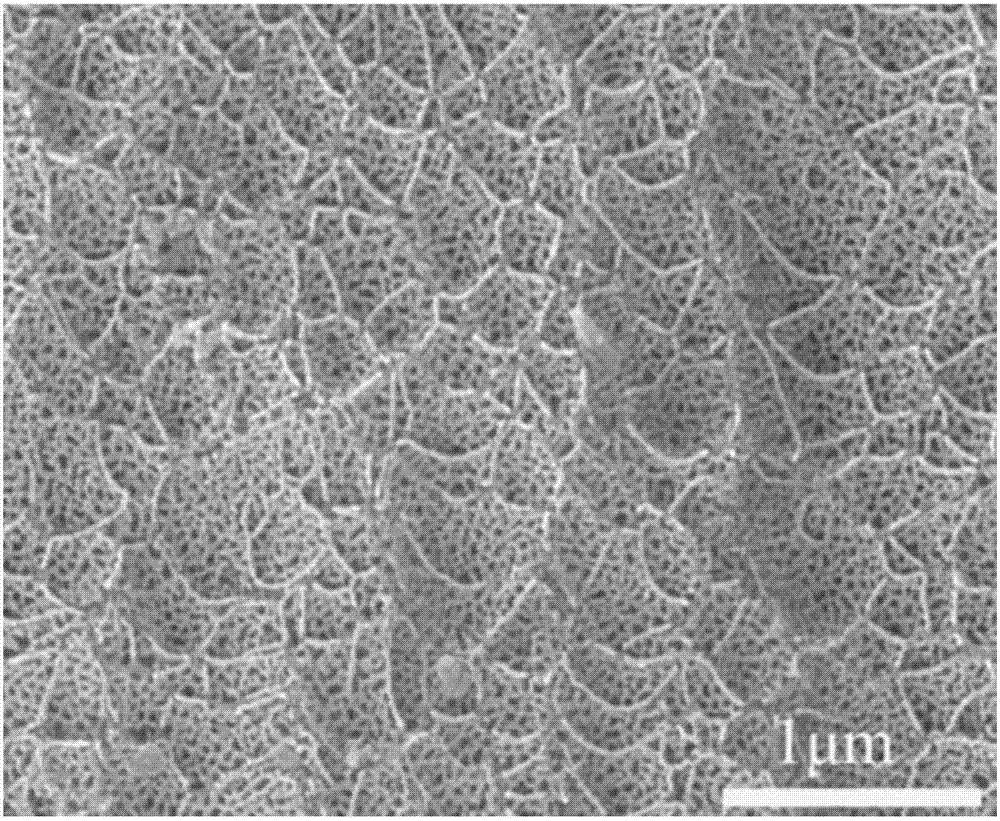

Method for processing surface of multi-scale bionic structure

InactiveCN102094222ASimple processing technologyRaw materials are easy to getVacuum evaporation coatingSputtering coatingNano structuringEngineering

The invention discloses a method for processing the surface of a multi-scale bionic structure. The method combines a surface replica method and an electro-deposition method and sequentially comprises the following steps of: (1) replicating a biological prototype surface structure by using active carbon (AC) paper by using a soft sealing technique, and then evaporating a gold film on the AC paper to increase the electric conductivity; and (2) depositing a metal coating on the conductive treated AC paper by adopting the electro-deposition method in metal electrolyte, and finally, micro-processing the bionic structure with biological surface and high precision on the metal surface, wherein the shape and the size of the bionic structure are consistent with those of a micro / nano structure on the biological prototype surface.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

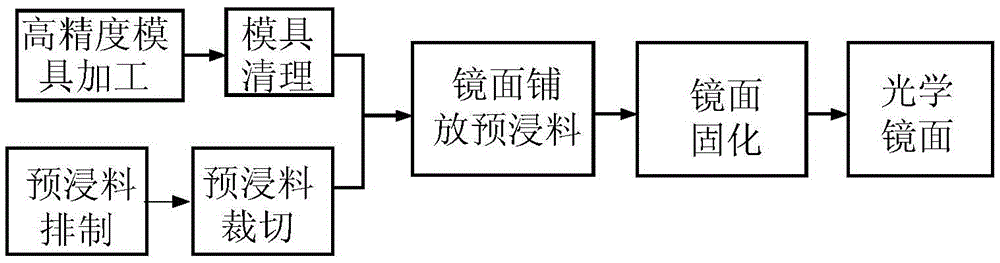

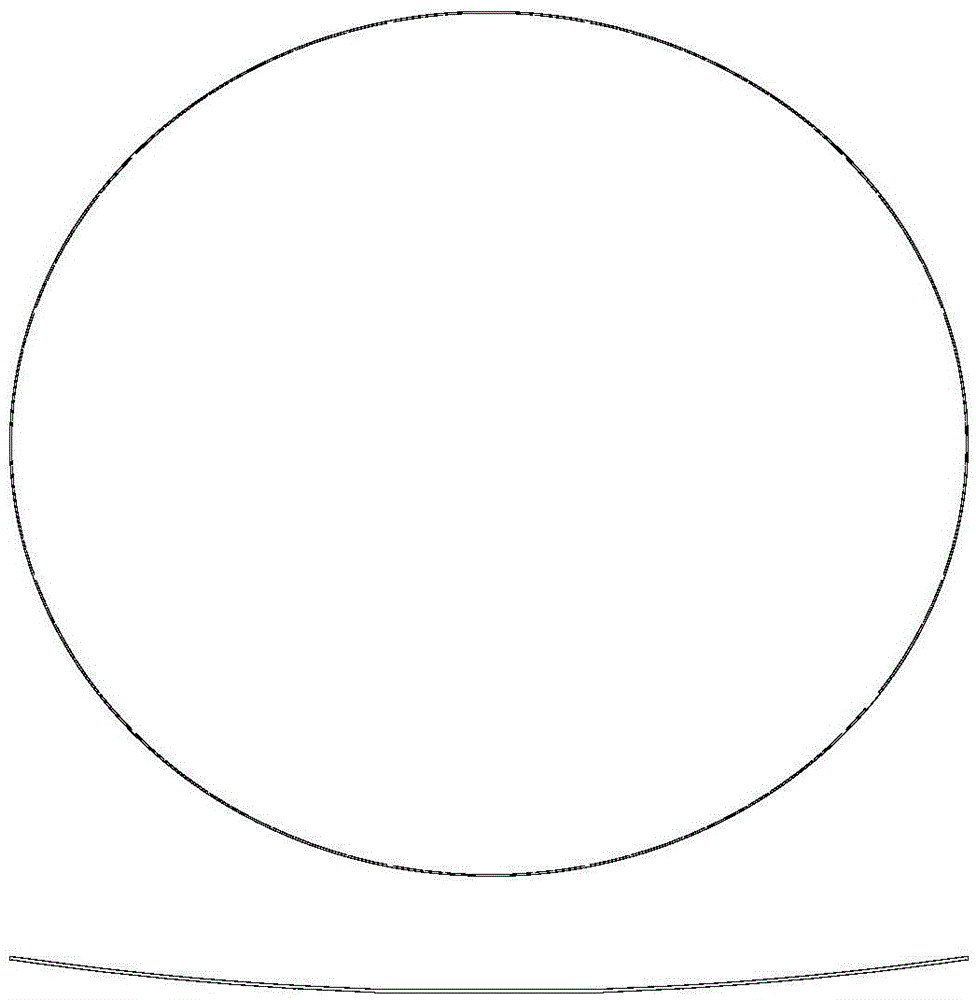

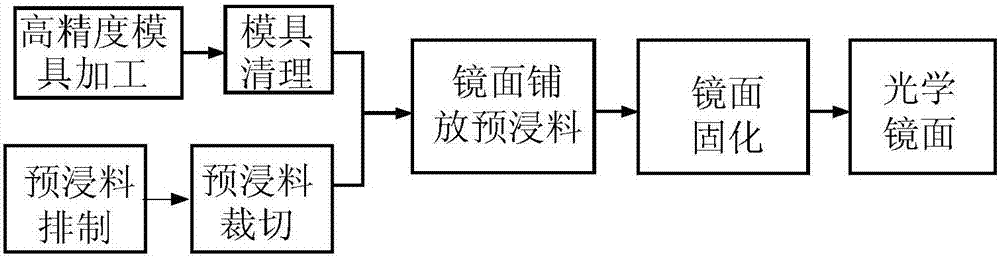

High-precision copying method of carbon fiber composite space optical mirror plane

ActiveCN105643955APrecisely control the laying angle of prepregHigh copying accuracyOptical articlesCoatingsFiberOptoelectronics

The invention relates to a high-precision copying method of a carbon fiber composite space optical mirror plane, particularly relates to an optical mirror plane product which is a spherical-crown or spherical-crown-like curved surface structure and is made of a carbon fiber enhanced cyanic acid composite, and belongs to the technical field of advanced composites. The optical mirror plane is a large-aperture spherical-crown concave surface structure. The mirror plane copying technology comprises the following steps: carrying out technological simulation analysis and experimental confirmation according to surface precision and performance requirements, and determining a suitable cyanate / carbon fiber prepreg system and a prepreg laying sequence; laying prepreg wires of a large-size optical mirror plane with a curved surface structure by using an automatic wire laying technology, accurately controlling a laying angle of the prepreg wires, and guaranteeing high-quality copying at a full laid angle; and curing the laid prepreg by using an autoclave to obtain the copied high-precision optical mirror plane. The copied mirror plane is high in surface precision and high in repeatability and consistency; and compared with manufacturing of the traditional optical mirror plane, the copying technology is short in manufacturing cycle and low in manufacturing cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

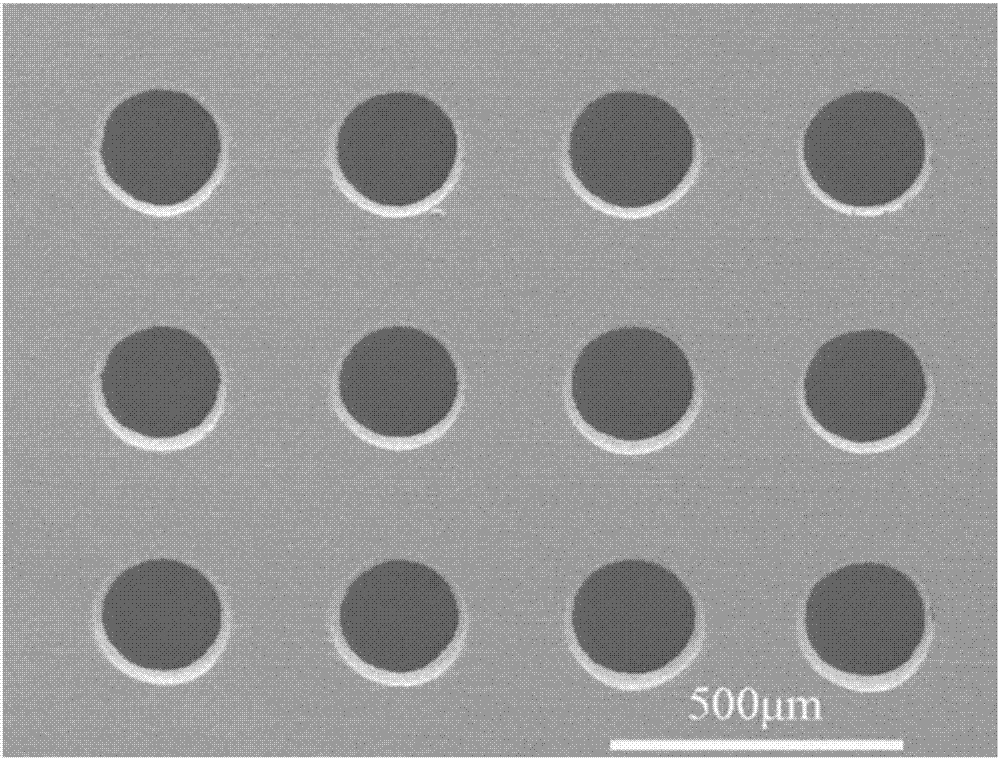

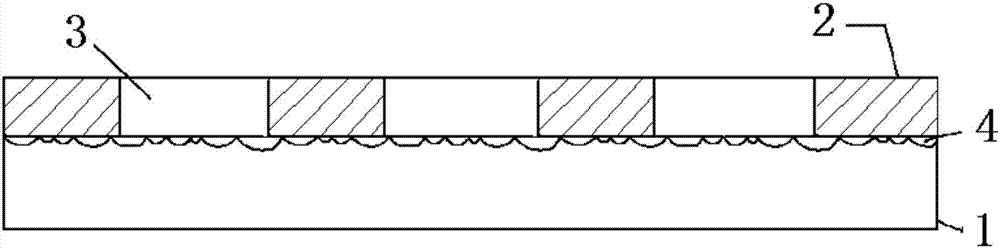

Micro-injection molding mould with super-hydrophobic surface of micro-nano composite structure and micro-injection molding method

ActiveCN107199671AEasy and flexible installationEasy to disassemble flexiblyElectrochemical machining apparatusCleaning using liquidsMicro structureMicro nano

The invention discloses a micro-injection molding mould with a super-hydrophobic surface of a micro-nano composite structure and a micro-injection molding method. The mould comprises a fixed template. A movable template which can move up and down is arranged below the fixed template, an injection molding cavity is formed between the fixed template and the movable template, and a mould core is mounted in the injection molding cavity; the mould cover comprises a stainless steel made micro punched-plate and a nano aluminum alloy plate. And a micro-structure surface of the micro punched-plate and a nano structure surface of the nano aluminum alloy plate are laminated and overlaid. The mould disclosed by the invention is simple and practical. The prepared super-hydrophobic surface is good in hydrophobic property, surface treatment steps in a later period are reduced, and the problem that in the prior art, the processing difficulty of the super-hydrophobic surface is great, the mould core is poor in tolerance and the prepared super-hydrophobic surface is poor in hydrophobic property.

Owner:CENT SOUTH UNIV

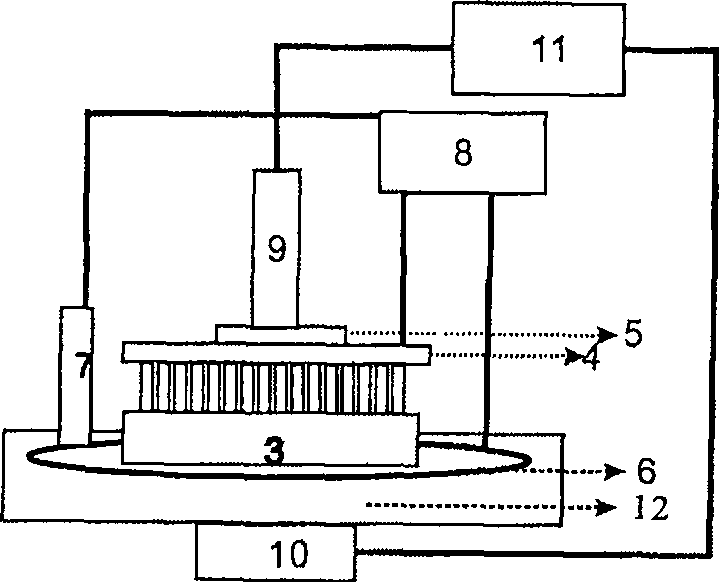

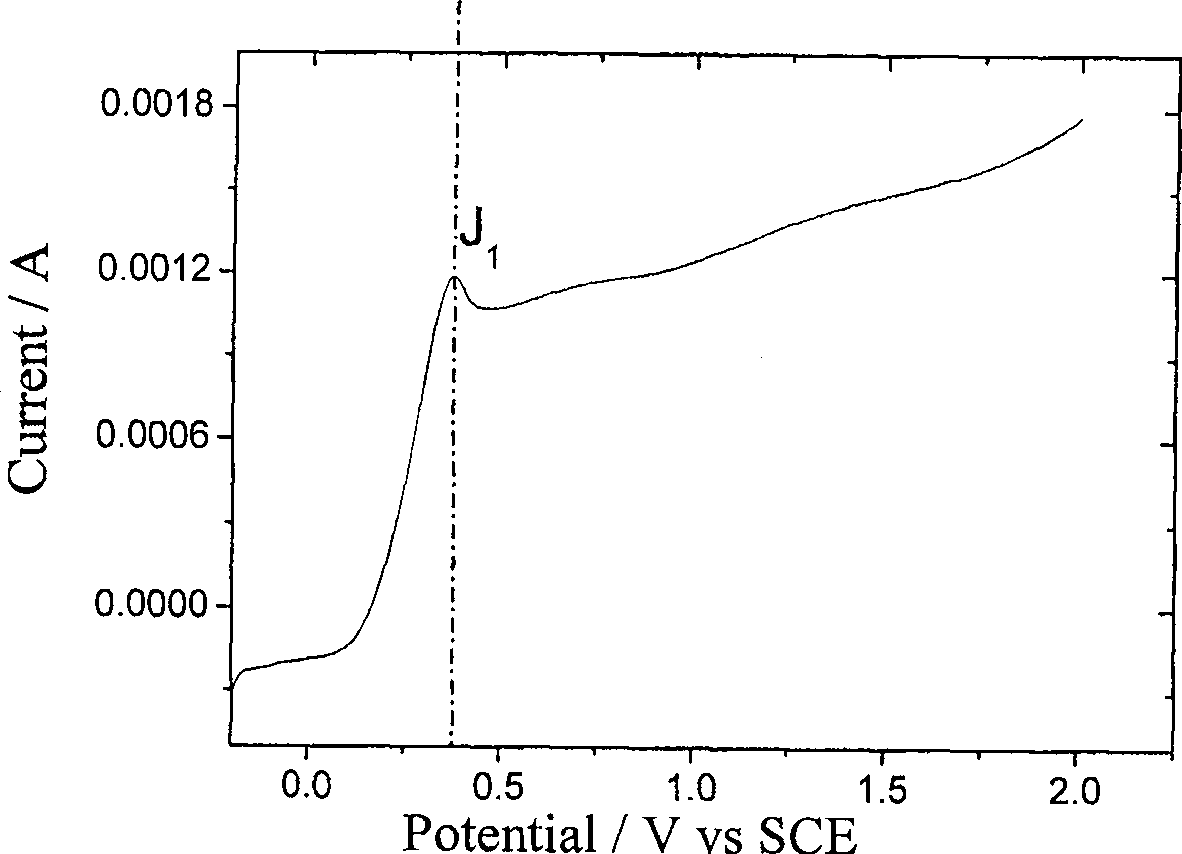

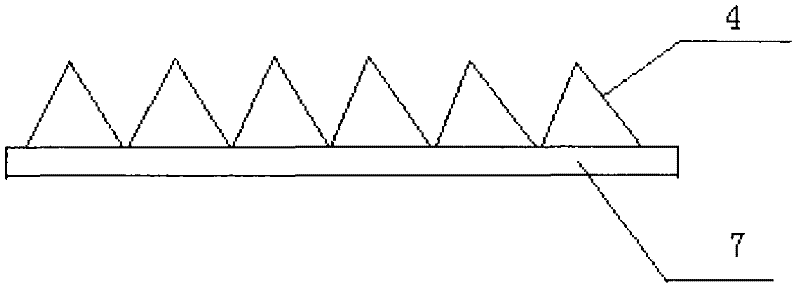

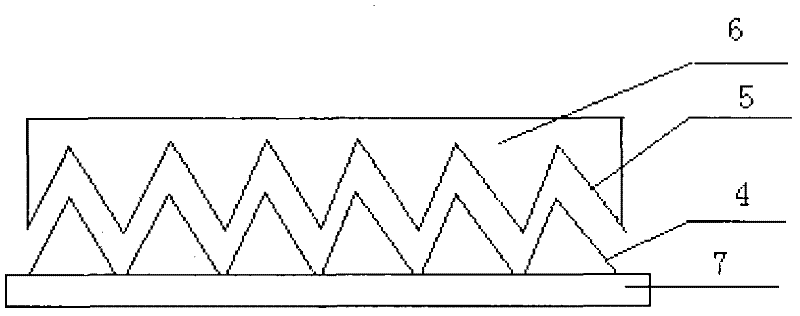

Method for preparing GaAs micro/nono optical element

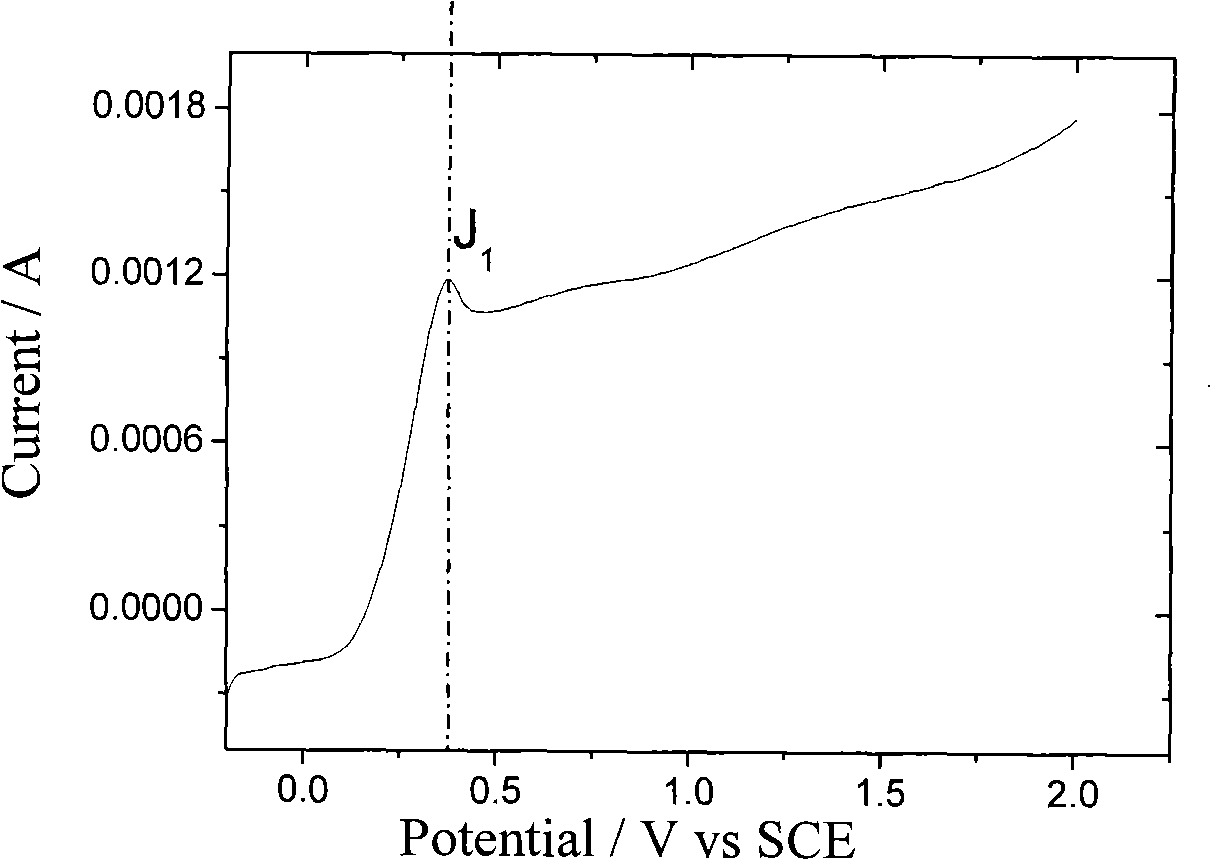

InactiveCN101234744AHigh copying accuracyReduce processing costsDecorative surface effectsChemical vapor deposition coatingOptical arraysWorking electrode

The invention relates to a method for preparing a micron / nanometer optical element on GaAs and a micron / nanometer optical element thereof, in particular to a preparation method in which the micron / nanometer optical array element is directly etched on the surface of semiconductor GaAs material at one time with low cost, simple method and no complex processes such as mask lithography and so on. The quartz with the micron / nanometer optical array element is taken as an original mother blank; a relief structure on the quartz micron / nanometer optical array element is accurately replicated on the surface of polymer material and then a Ti layer and a Pt layer are sputtered in sequence; the surface is then metallized to obtain a template electrode. The template electrode is used as a working electrode and is adjusted to be parallel to a processed workpiece GaAs; an electrochemical etching solution is added into an electrolytic cell and an etching agent is generated on the template electrode; a restraint agent in the etching solution is used for compressing the thickness of an etching agent layer to the thickness of a micron or a nanometer level; GaAs sheets are controlled to move to the surface of the template electrode until the structure on the template electrode is completely replicated on the surface of the processed workpiece and the separation of the GaAs sheets and the template electrode is controlled.

Owner:XIAMEN UNIV

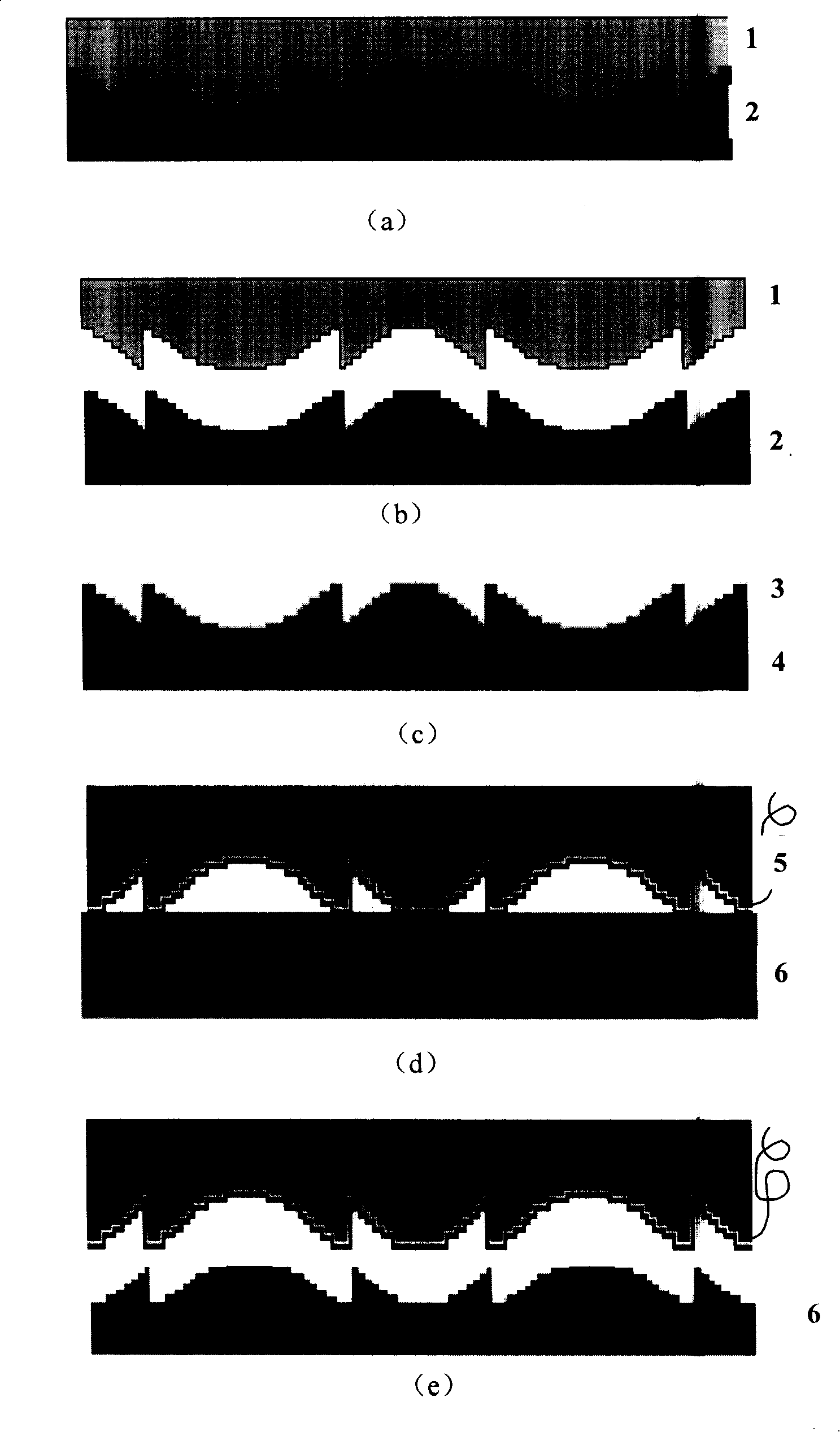

Electrochemical processing method for micro-structure of P type silicon surface

InactiveCN101271842APrecision Processing ApproachHigh copying accuracyDecorative surface effectsSemiconductor/solid-state device manufacturingMicro structureLithographic artist

The invention provides an electro-chemical processing method of a P-typed silicon surface micro-structure, relating to the processing of silicon surface. The invention provides a novel electro-chemical processing method which has low cost and simple processing steps, does not have complex processes such as mask lithography, etc., and with micro-structure etched and is processed on the surface of the P-typed silicon in one-step. The electro-chemical processing method comprises the steps that: the micro-structure on an original mother blank is transferred onto a gelose surface and then dipped in electrolyte, so as to gain the gelose gel template with the stored electrolyte; the gelose gel template is then arranged in an electrolytic cell, the micro-structure part of which is exposed on the liquid surface; a Pt layer is splashed on the back surface by the P-typed silicon through a front disposal to form an ohm contact; a polished surface is then arranged on the surface of the gelose gel template; the P-typed silicon sheet is taken as a working electrode and the electro-chemical polishing micro-processing is carried out to the P-typed silicon sheet; the micro-structure on the gelose gel template is transferred on the surface of the P-typed silicon by the electro-chemical polishing micro-processing to gain the P-typed silicon sheet with the micro-structure and the P-typed silicon sheet with the micro-structure is separated from the gelose.

Owner:XIAMEN UNIV

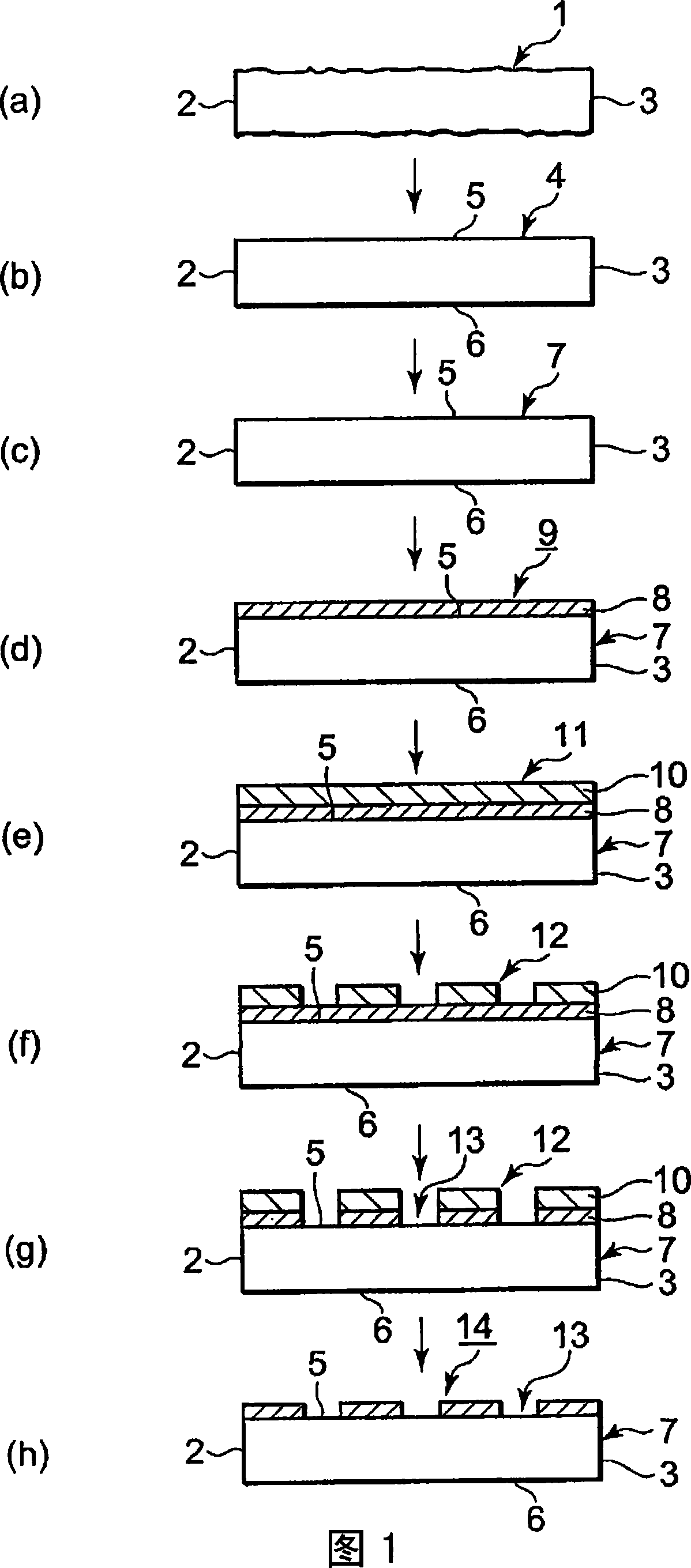

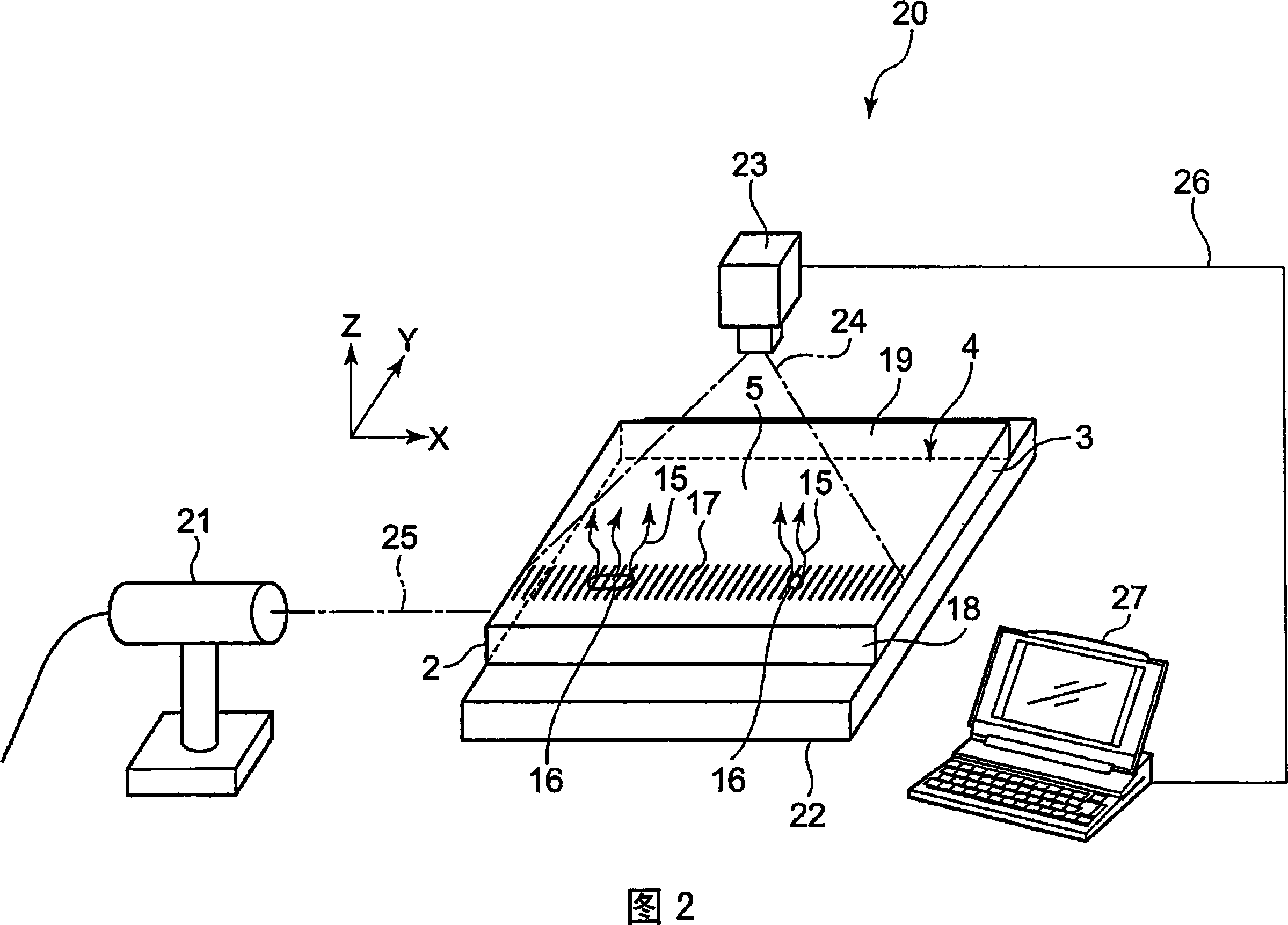

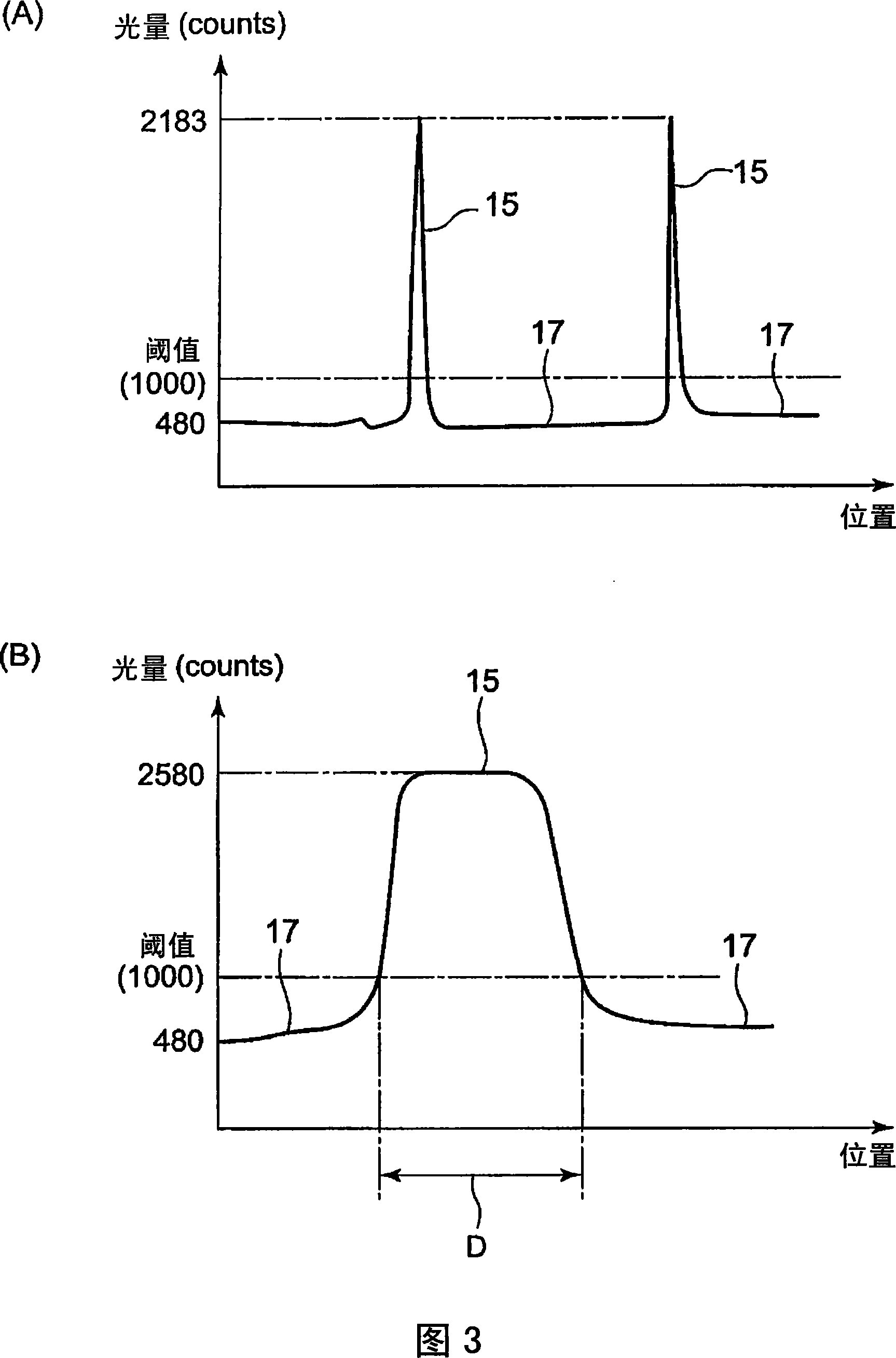

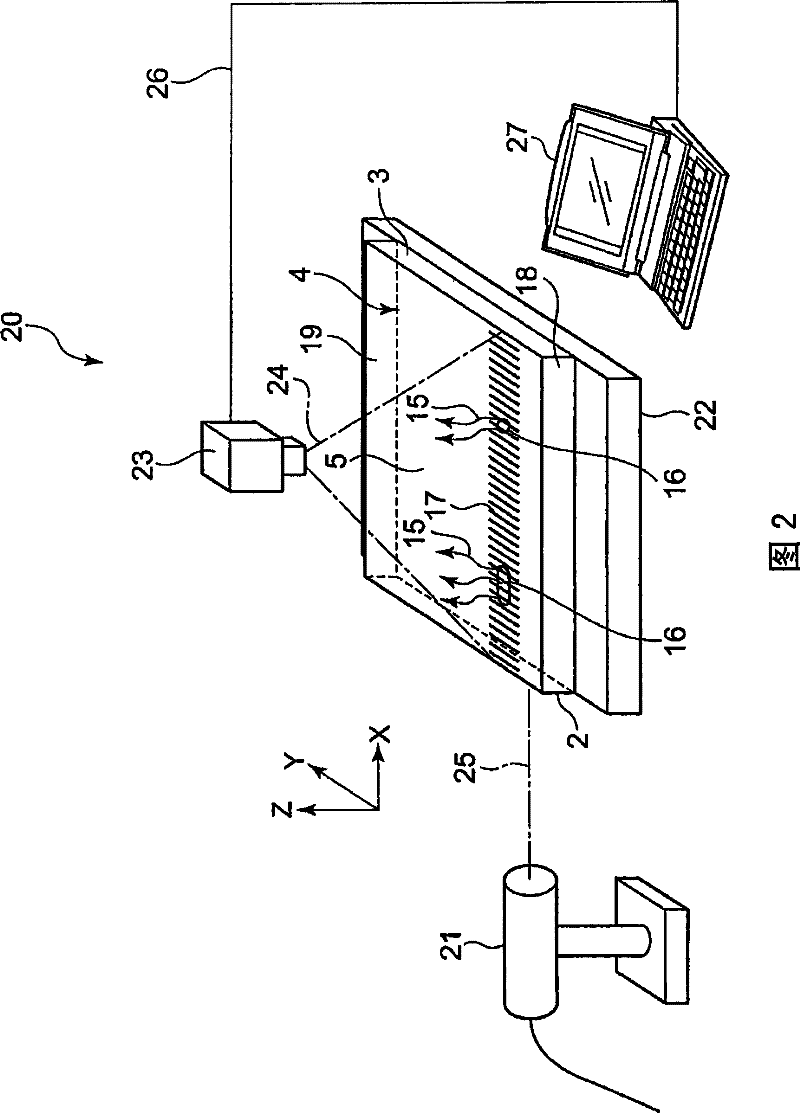

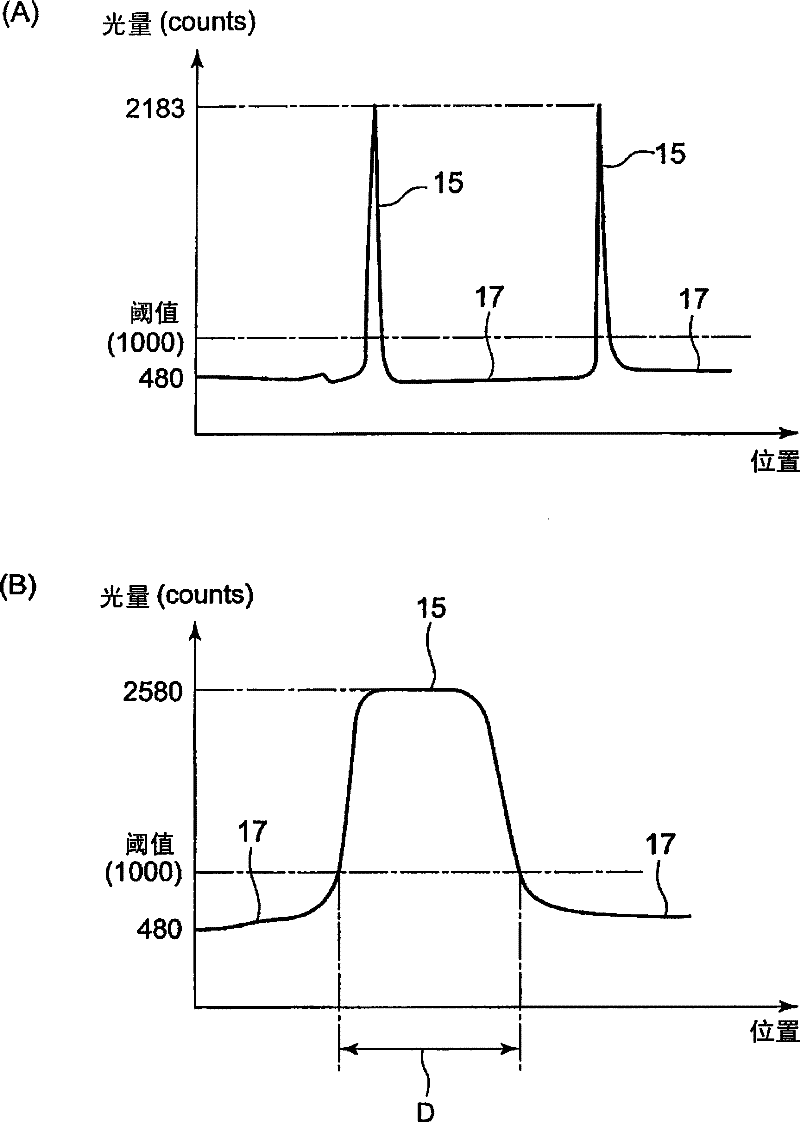

Method for inspecting translucent article

ActiveCN101120245AAvoid damageGuaranteed StrengthMaterial analysis by optical meansGlass shaping apparatusOptical propertyEngineering

The present invention provides an inspection method of a light-transmitting article capable of accurately inspecting the presence or absence of optical inhomogeneity inside the light-transmitting article. A method for inspecting a light-transmitting article, which is used in photolithography, and inspects whether there is a partial or partial change in the light-transmitting article (4) made of a light-transmitting material in response to exposure light. Uniformity (specifically, internal defects (16)), wherein inspection light having a wavelength of 200 nm or less is introduced into the light-transmitting article, and the inspection light is detected by passing the inspection light on an optical path through which the inspection light propagates inside the light-transmitting article. The presence or absence of optical inhomogeneity in the light-transmitting article is inspected by partially or locally generating light (15) having a wavelength longer than that of the inspection light.

Owner:HOYA CORP

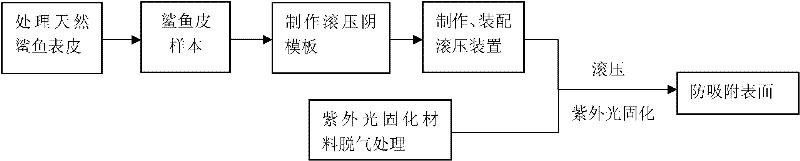

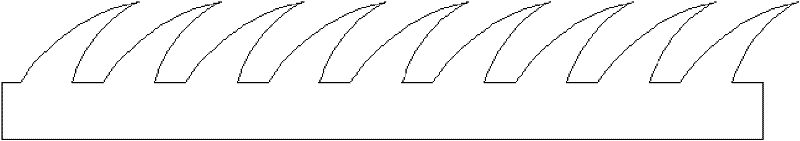

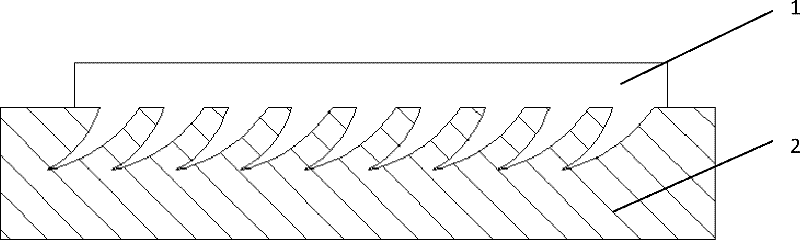

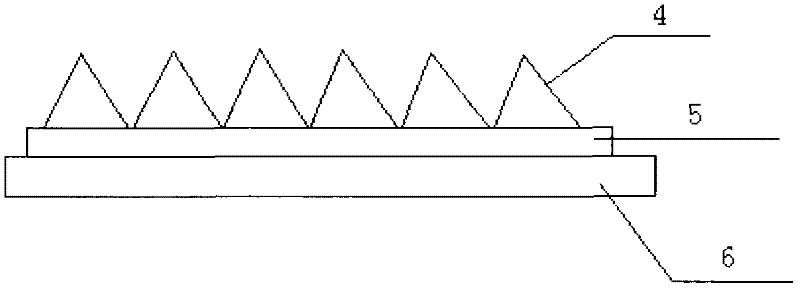

Method for manufacturing larger-area anti-adsorption surface with emulational shark skin appearance

The invention relates to a method for manufacturing larger-area anti-adsorption surface with an emulational shark skin appearance, comprising two steps: (1) manufacturing a rolling female template device; and (2) manufacturing the anti-adsorption surface by adopting the ultraviolet-light curing technology. The ultraviolet-light curing technology is used for curing material rapidly to form the surface in a needed structure by using the sensitivity of the material to ultraviolet light. The micro embossing moulding method is used for rapidly carrying out micro-replication and nano-replication to structural patterns under the micro-nano scale with low cost. The method uses the ultraviolet-light curing technology and the micro embossing moulding technology to manufacture the larger-area anti-adsorption surface with the emulational shark skin appearance. The method has good practical value and wide application prospect in the technical field of biomimetic manufacturing.

Owner:BEIHANG UNIV

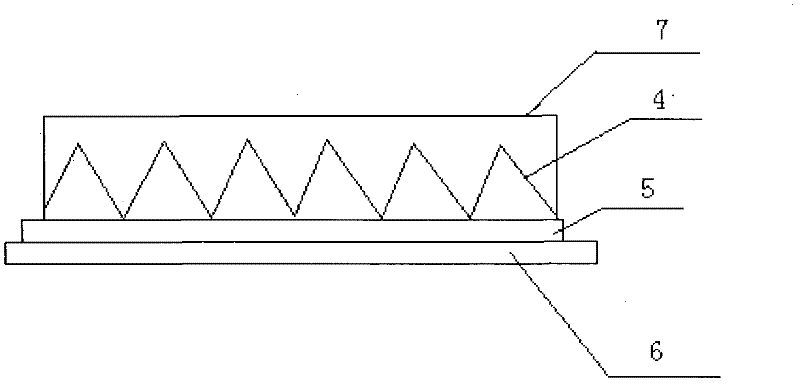

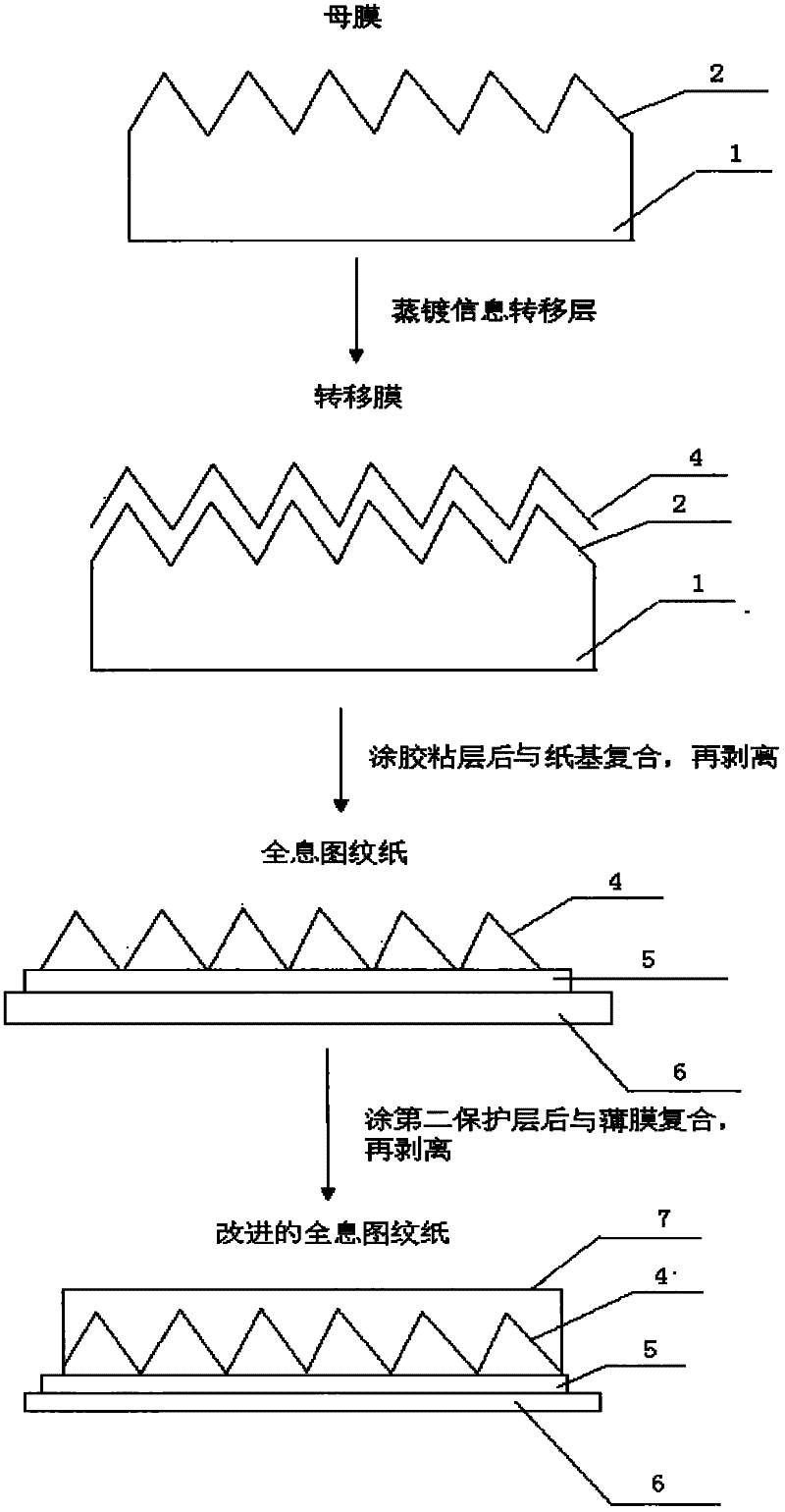

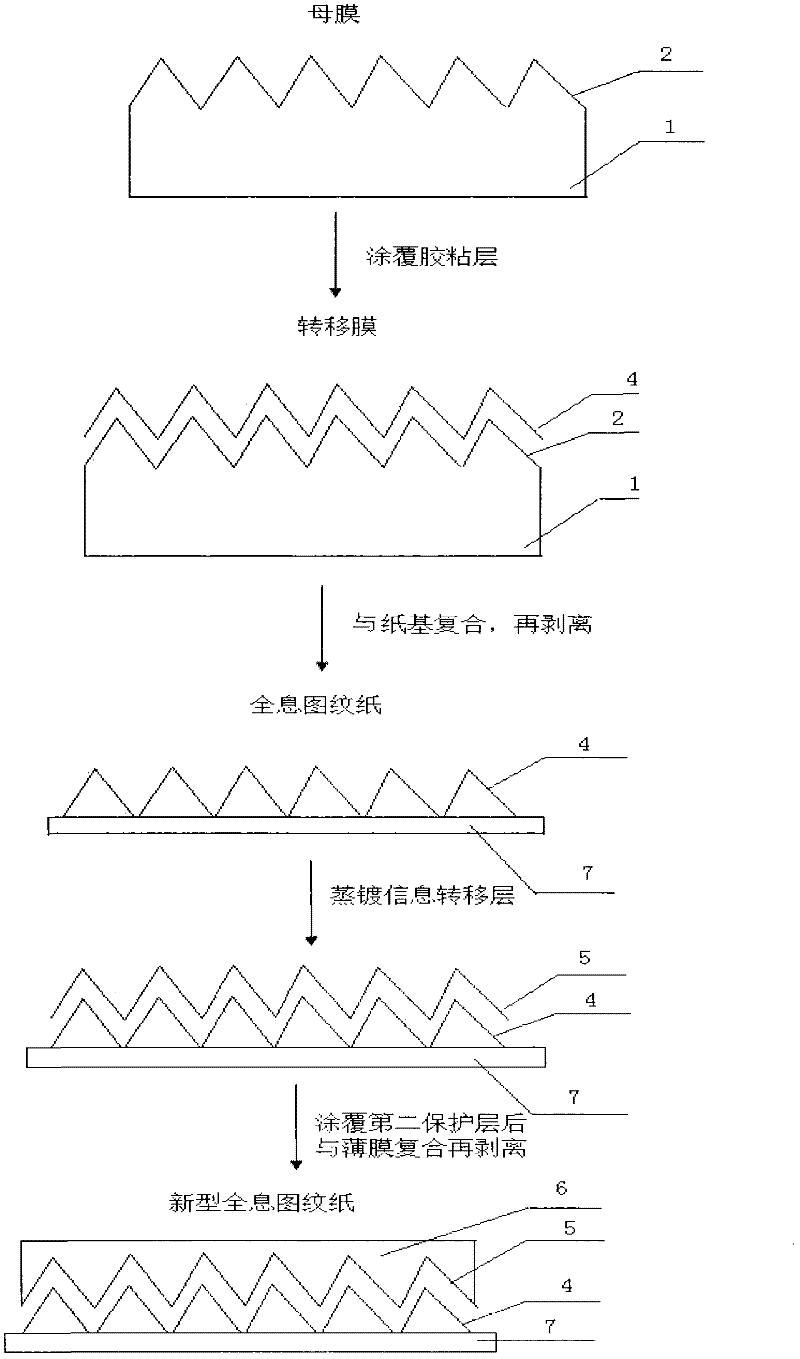

Production process for reel type hologram pattern paper, hologram pattern paper and system

ActiveCN102230307AExact copyHigh copying accuracySurface covering paperSynthetic resin layered productsBiochemical engineeringPaper based

The invention relates to a production process for a reel type hologram pattern paper and a hologram pattern paper and a system thereof. The process comprises the following steps: 1.1 carrying out vapor plating on an information transfer layer on the surface of a mother membrane having a hologram pattern so as to obtain a transfer membrane; 1.2 applying an adhesive layer on the information transfer layer and then combining the adhesive layer with a paper base, wherein the adhesive layer is UV resin; 1.3 peeling the mother membrane so as to obtain a hologram pattern paper. The process is characterized in that: groove structure of hologram pattern on the surface of the mother membrane is duplicated and transferred onto the transfer layer. According to the invention, the fact that the hologram pattern groove structure on the mother membrane surface can be precisely duplicated is used creatively to improve the prior art, and duplication of the hologram pattern groove structure on the mother membrane surface and a coating process are used for the production of a reel type hologram pattern paper, thereby substantially reducing production cost and increasing production efficiency.

Owner:蔡旭楠

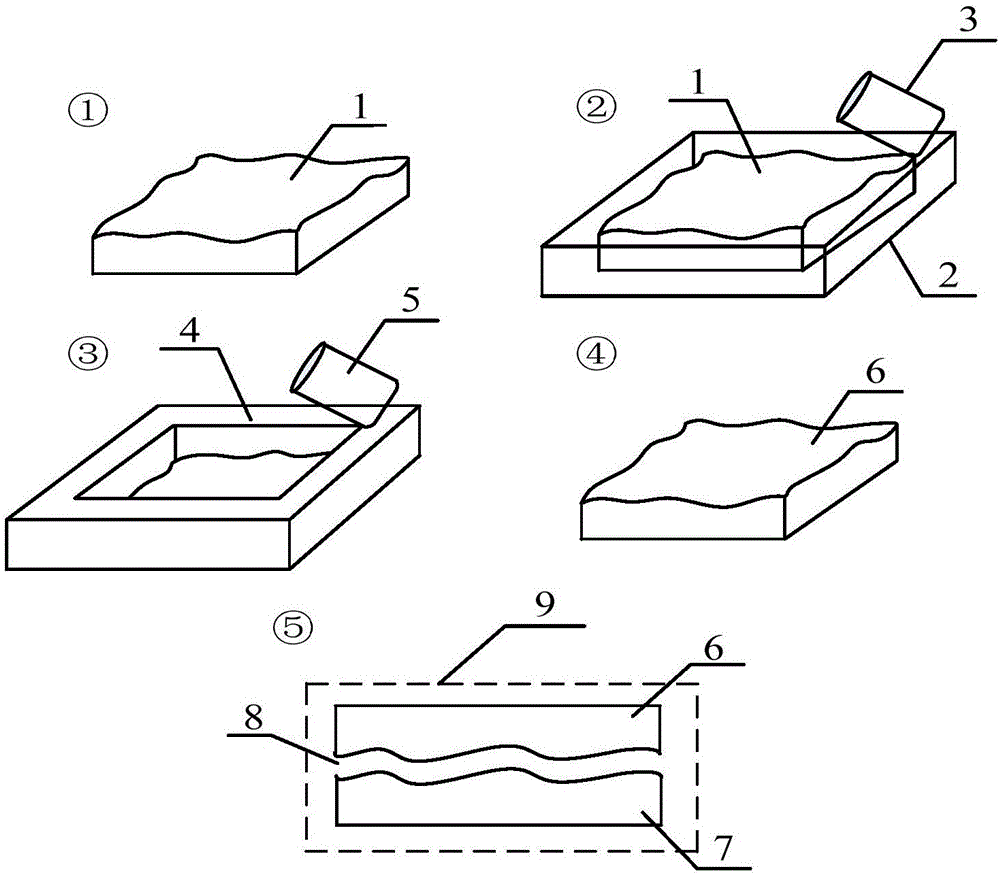

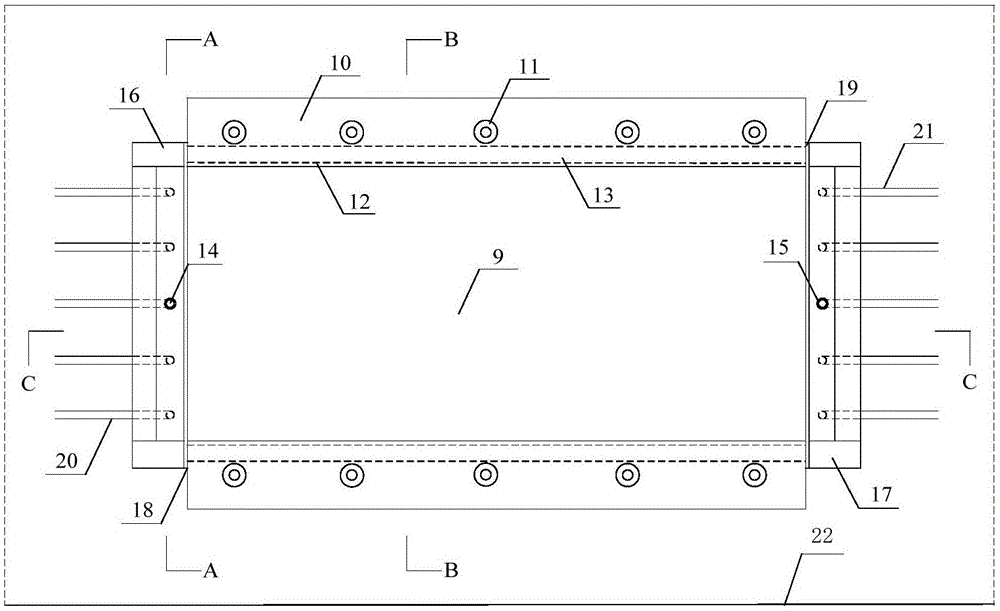

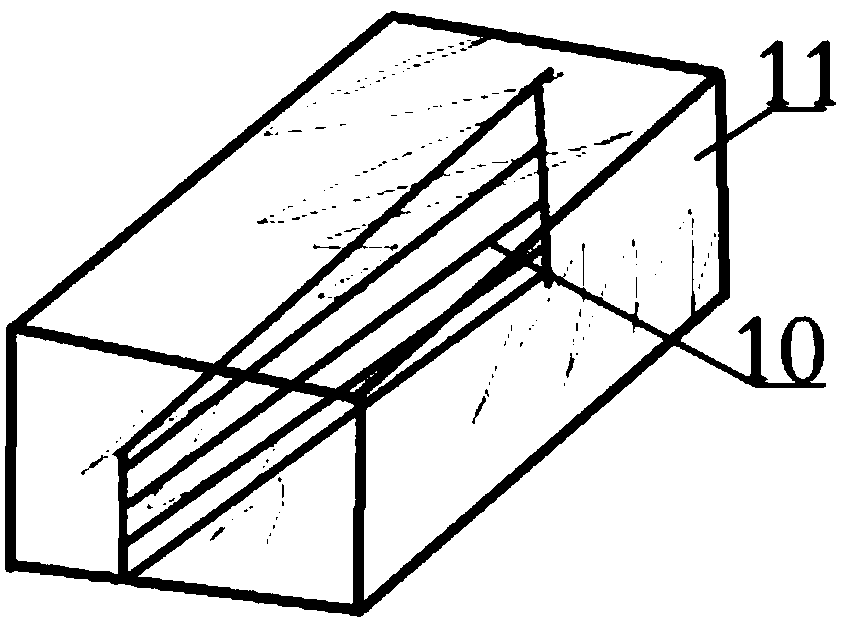

Solute transport process optical measuring device based on rock joint transparent copy

PendingCN106680154AHigh copying accuracyGuaranteed similaritySurface/boundary effectMeasurement deviceWater flow

The invention discloses a solute transport process optical measuring device based on a rock joint transparent copy. The device is characterized by comprising a transparent joint overcurrent device, an optical monitoring system, a water flow controlling and measuring system and a data acquiring and analyzing system. A to-be-tested and detected transparent rock joint copy is placed on the transparent joint overcurrent device, and the transparent joint overcurrent device provides a stable water flow which is precise in flow through the water flow controlling and measuring system; and the data acquiring and analyzing system is connected to the optical monitoring system and the water flow controlling and measuring system, and the data acquiring and analyzing system is used for acquiring the flow rate data of the water flow controlling and measuring system and transparent rock joint copy photographing data by the optical monitoring system. The measuring device can realize solute transport processes of the joints with different spatial morphological characteristics at different flow rates. The testing process is simple to operate, the device is low in cost, the repeatability is strong, a result can be intuitively displayed, and the reliability is strong.

Owner:WUHAN UNIV

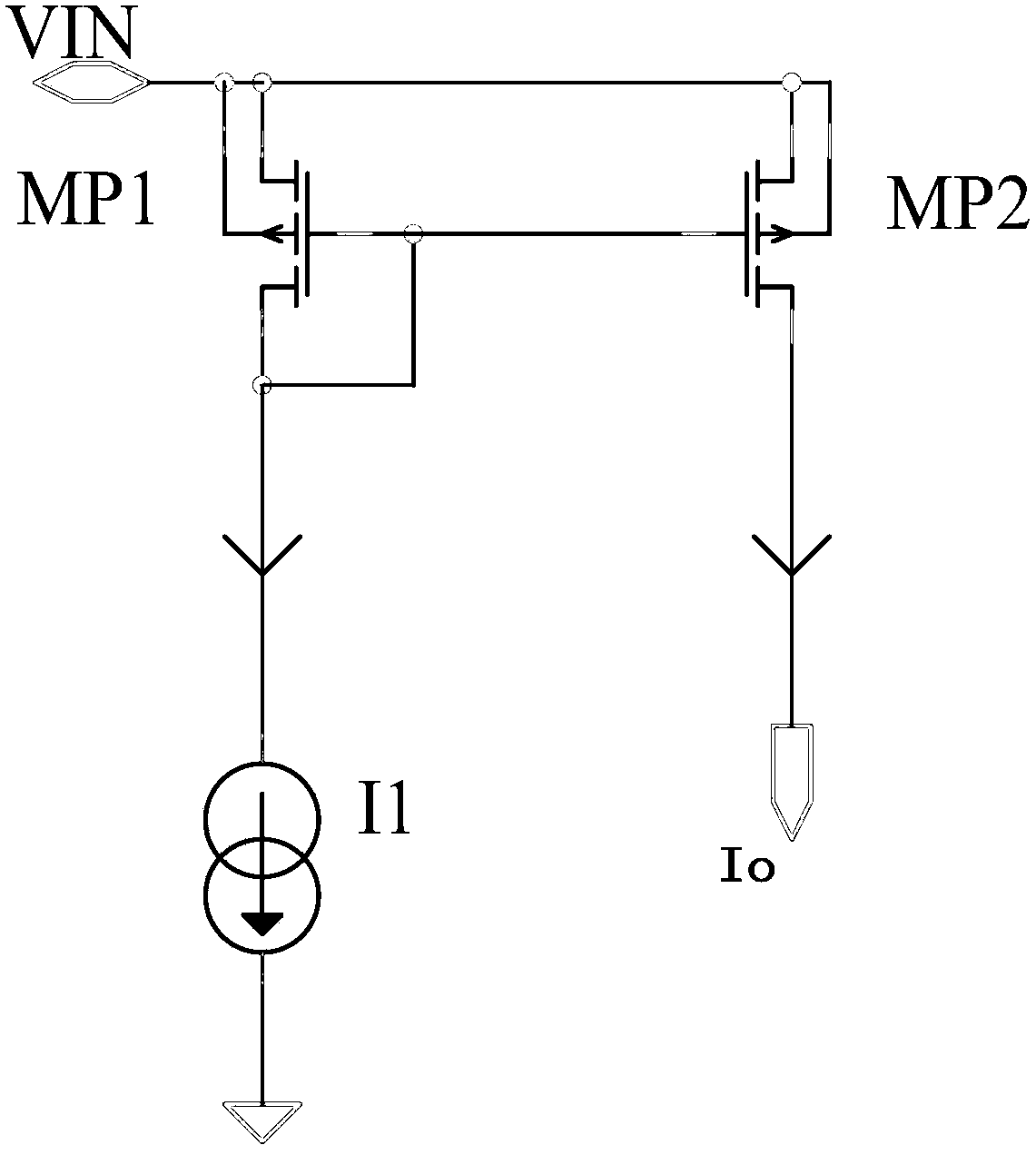

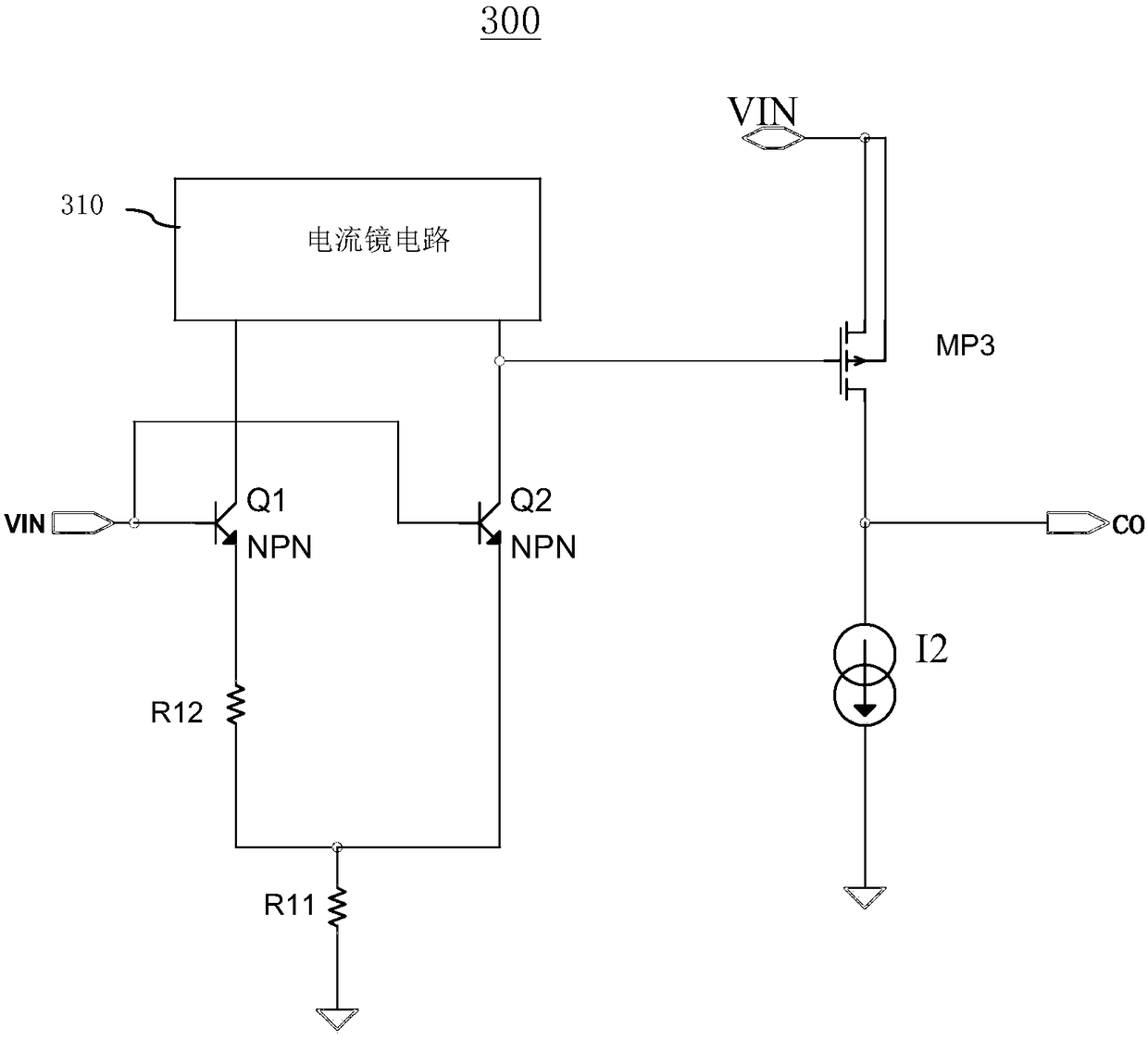

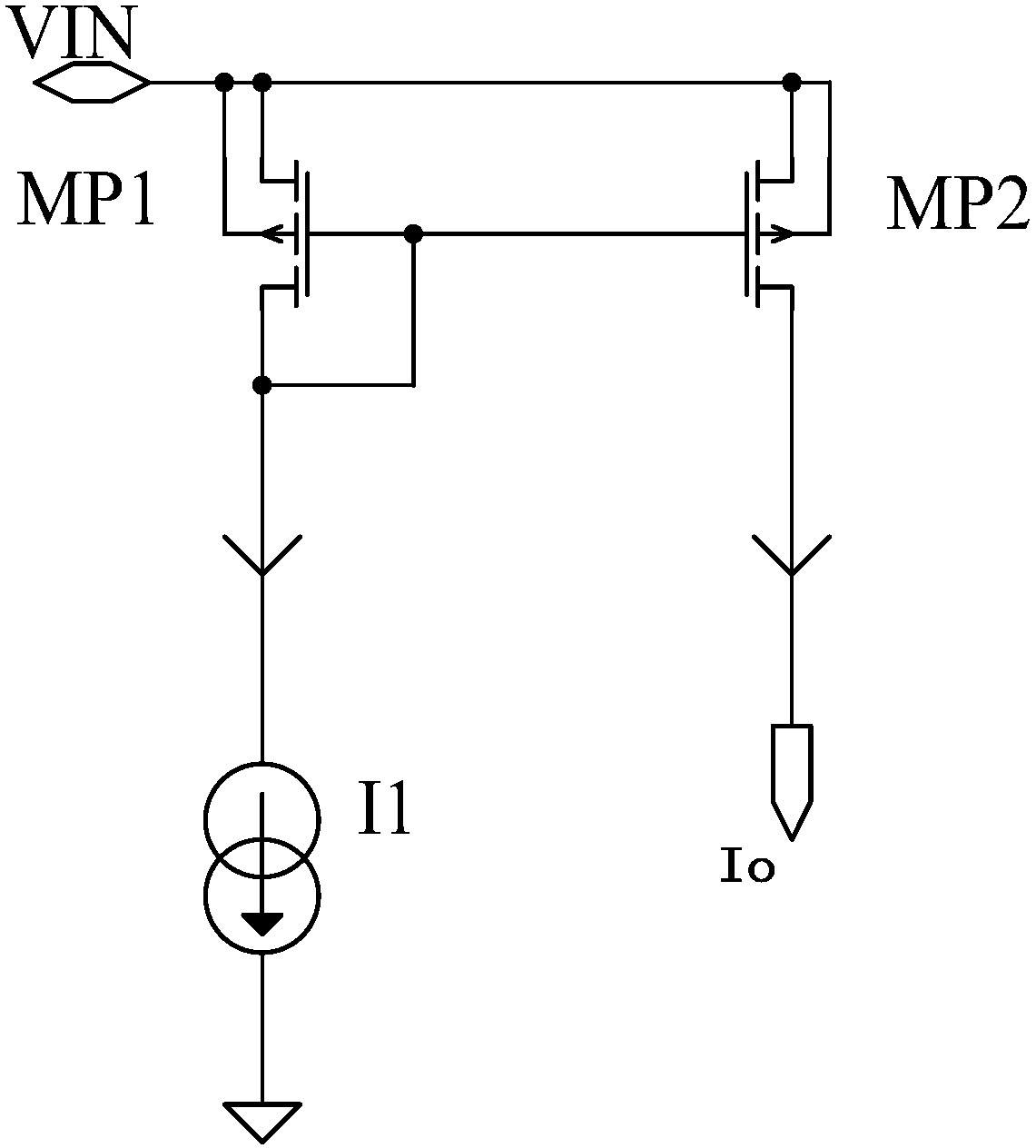

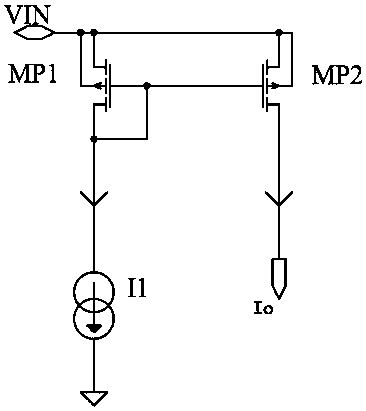

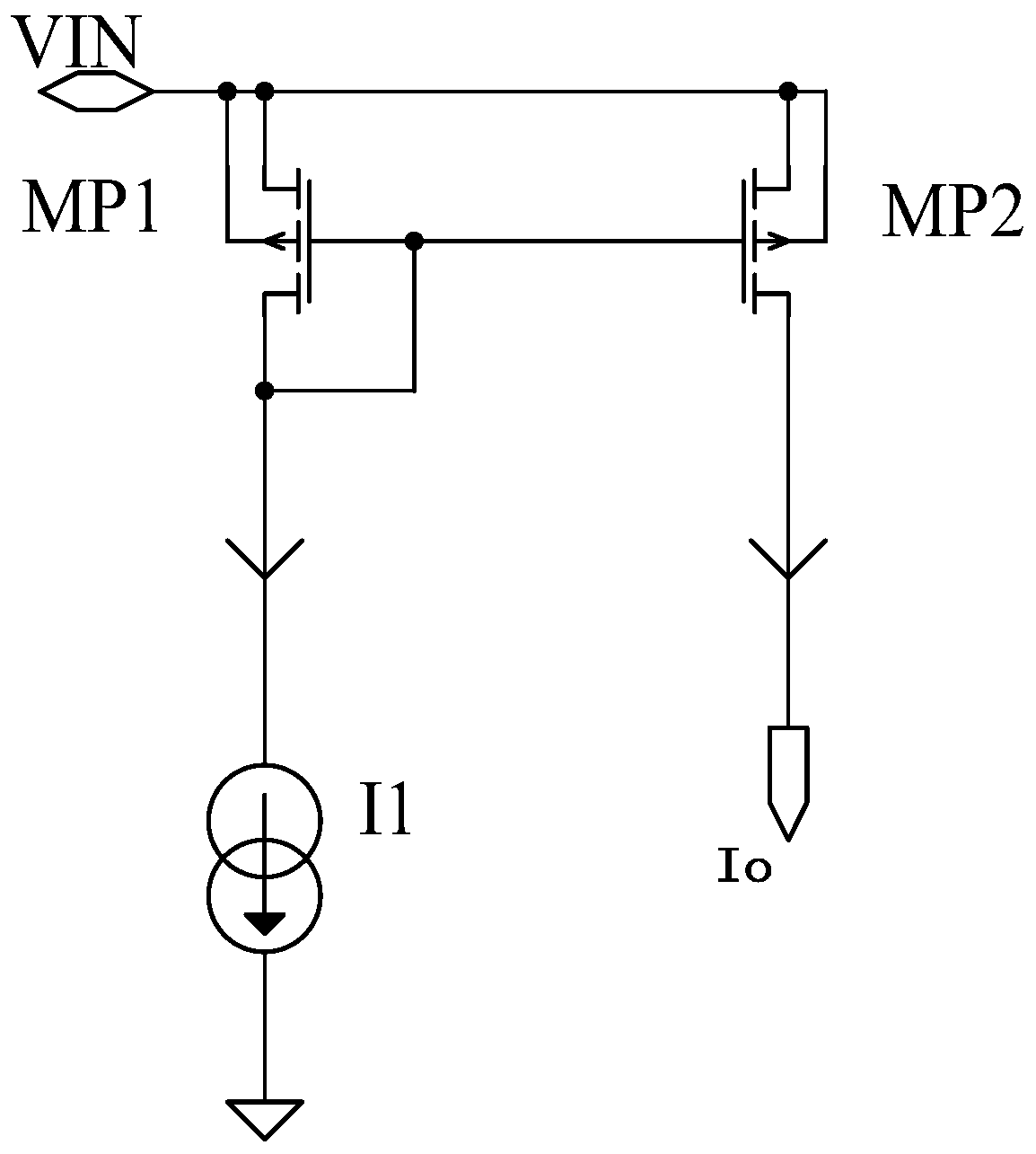

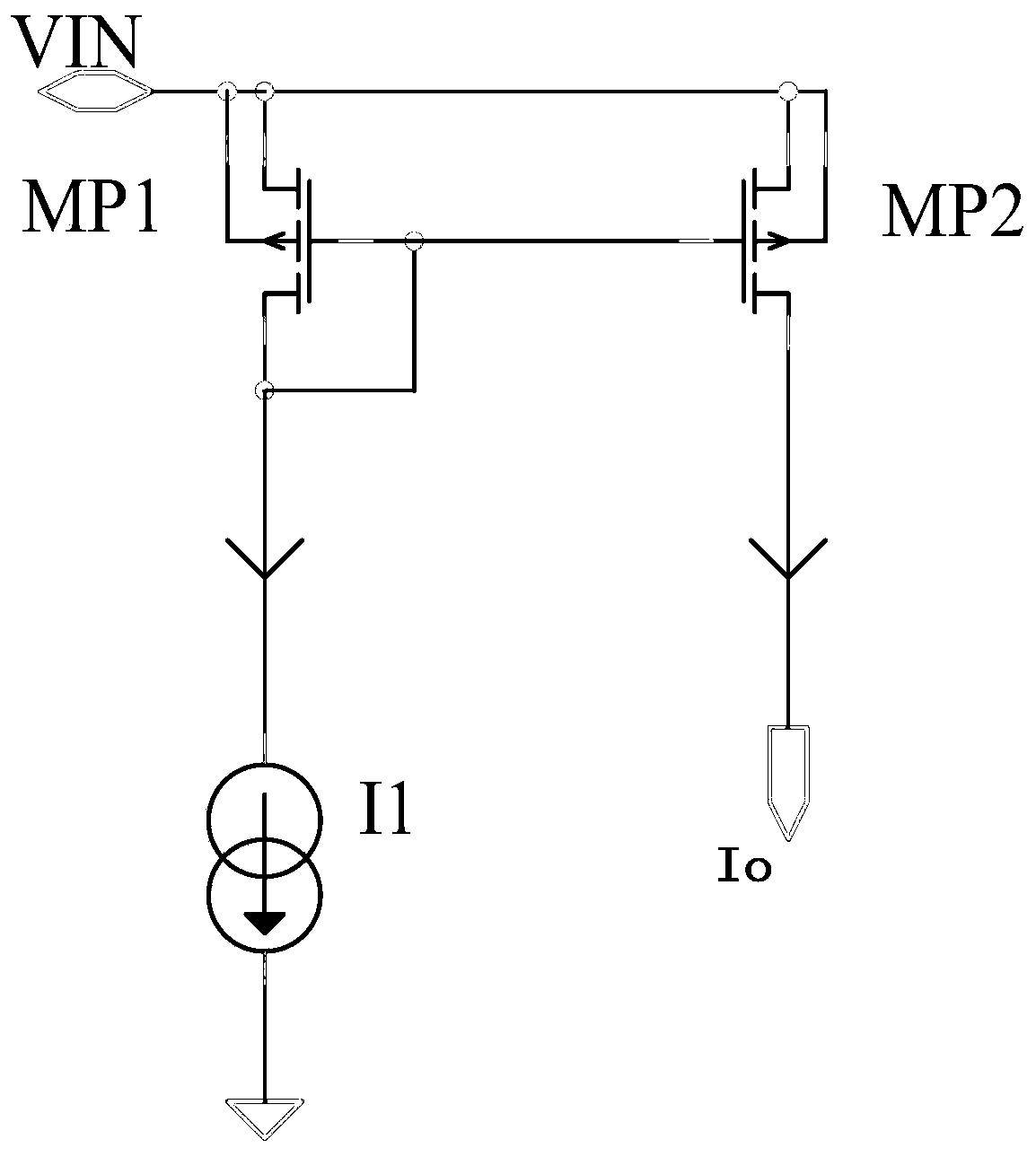

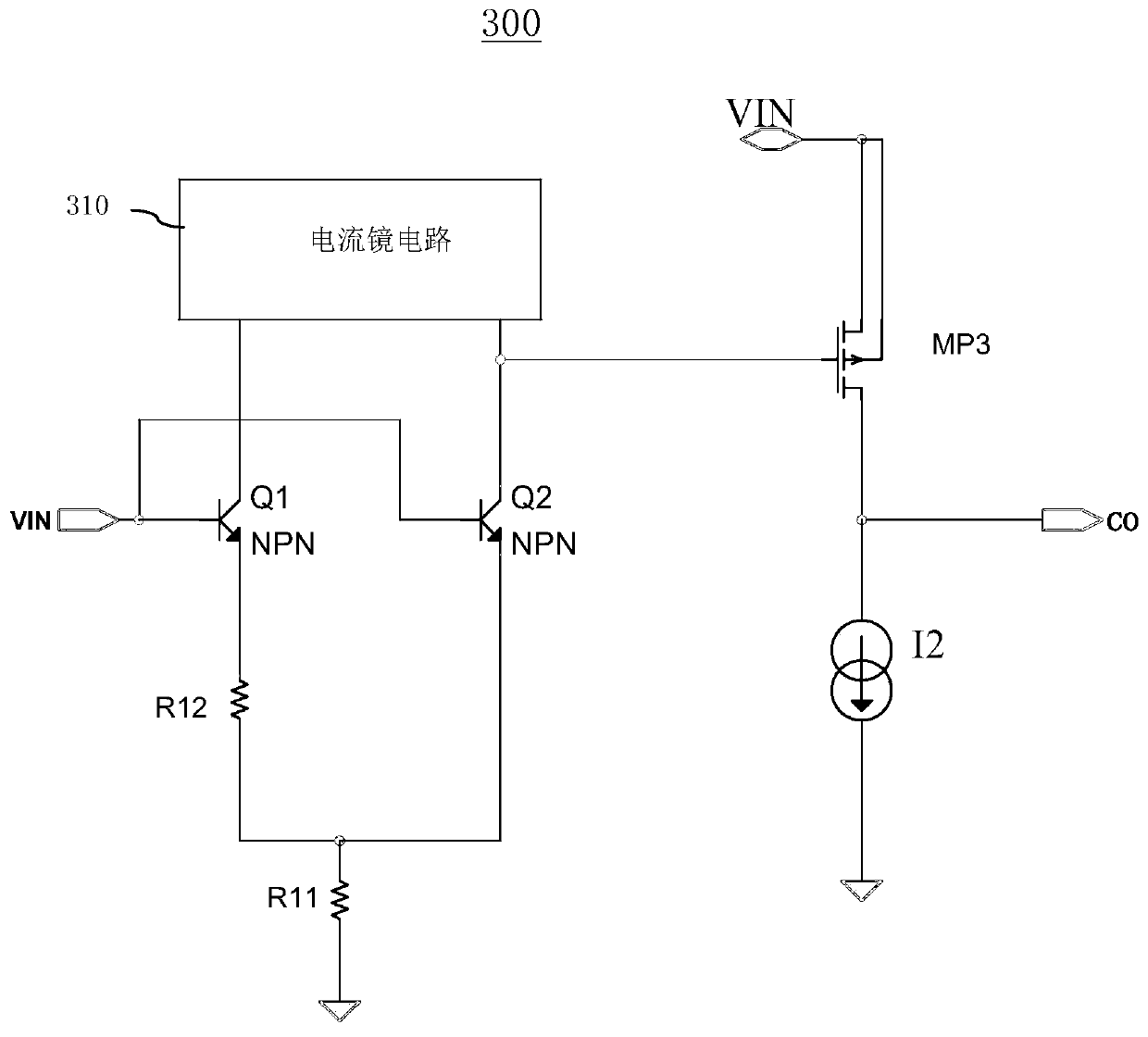

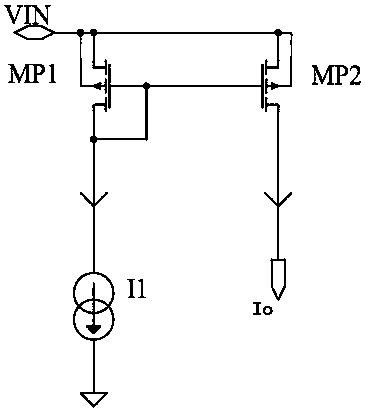

Improved voltage comparator

ActiveCN108233900AReduce mismatchHigh copying accuracyMultiple input and output pulse circuitsOxide semiconductorBipolar junction transistor

The invention provides a voltage comparator. The voltage comparator comprises a current mirror circuit, a third resistor, a fourth resistor, a first bipolar transistor, a second bipolar transistor, asecond current source and a third MOS (Metal Oxide Semiconductor) transistor. The current mirror circuit has very small current mirror current duplication mismatch, and very high current duplication precision, so that the precision of an internal reference voltage threshold of the voltage comparator can be increased.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

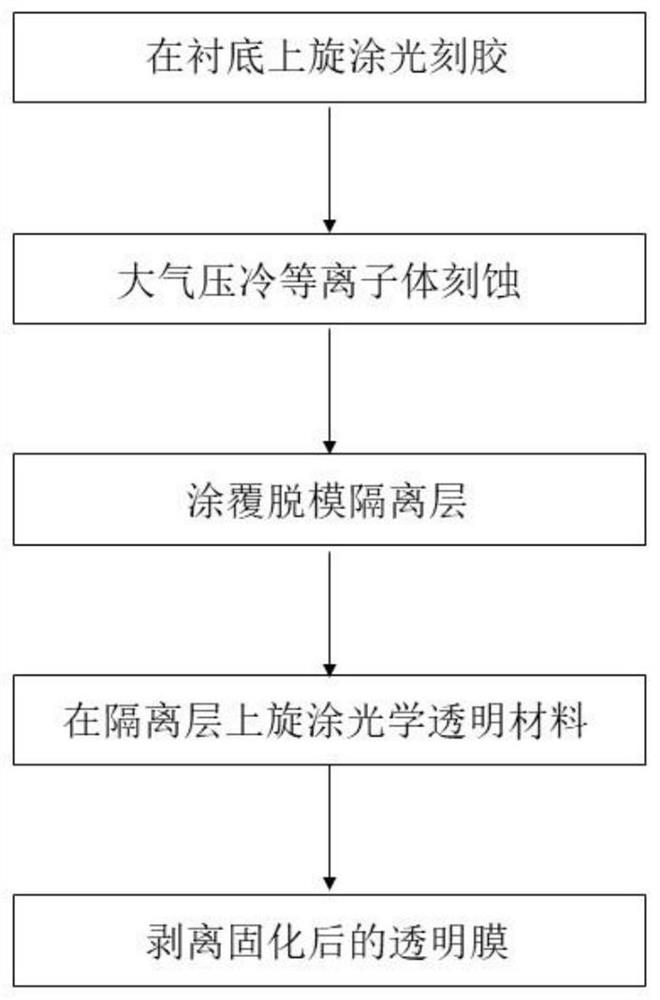

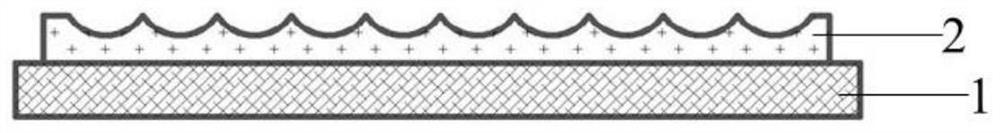

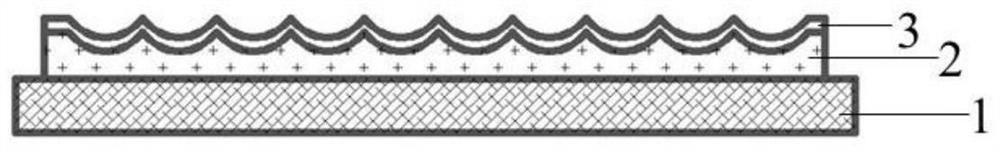

Artificial bionic compound eye preparation method based on atmospheric pressure cold plasma micromachining

The invention provides an artificial bionic compound eye preparation method based on atmospheric pressure cold plasma micromachining. The artificial bionic compound eye preparation method comprises the following steps of spin-coating a layer of photoresist on a substrate, etching the photoresist by adopting atmospheric pressure cold plasma jet, and obtaining a planar concave array structure on thephotoresist after etching, preparing a demolding isolation layer on the upper surface of the planar concave array structure obtained after etching, spin-coating a layer of optical transparent material on the isolation layer, and curing the optical transparent material to form a transparent film, and stripping the cured transparent film to obtain the compound eye lens with the planar convex arraystructure. According to the method, a mask plate is not needed, and the artificial bionic compound eye structure can be obtained through hot-pressing deformation after one-time mold reversing; compared with a traditional micro-lens machining process, the method has the advantages of simple process, low cost, high copying precision and the like.

Owner:SHANGHAI JIAO TONG UNIV

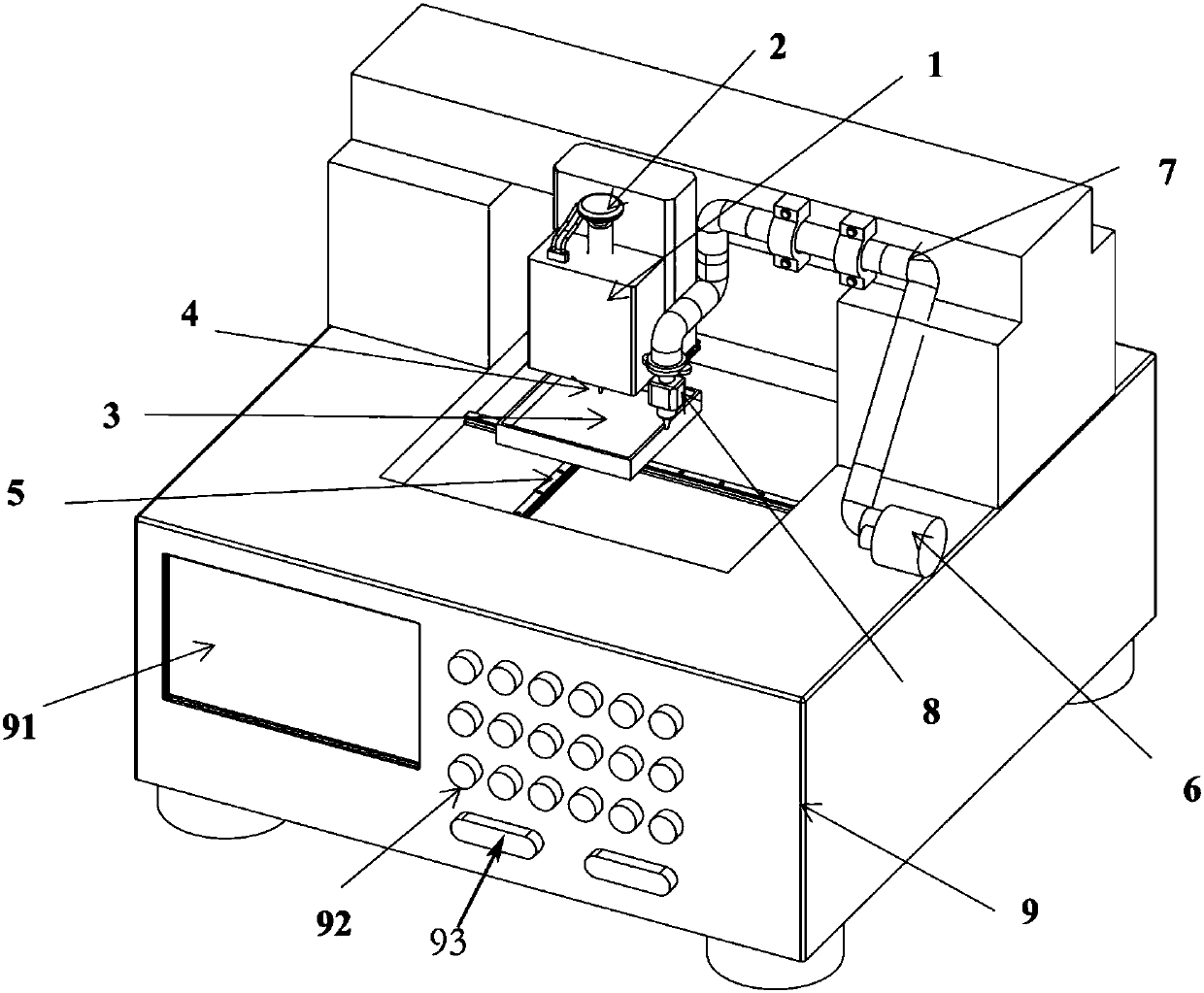

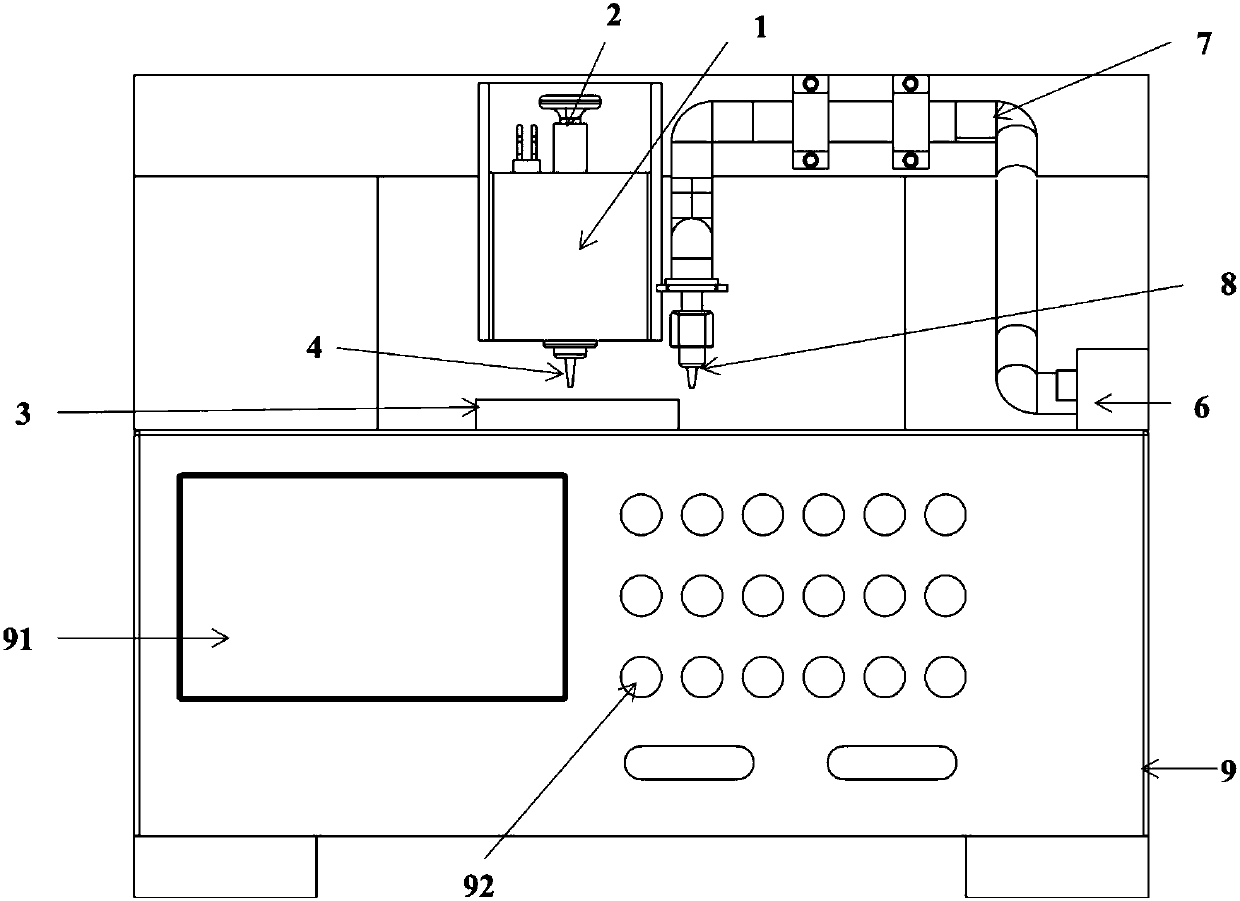

Melt direct writing process based micro-channel chip manufacturing processing system and processing method

The invention provides a melt direct writing process based micro-channel chip manufacturing processing system. The system comprises a melt direct writing deposition device, a curing agent liquid adding device and a control device. The control device comprises a microprocessor, the melt direct writing deposition device comprises a heating module, an injector, a metal needle, a motion platform, a collection plate and a high-voltage power source. The injector comprises a liquid storage chamber which is internally provided with a polymer material, the lower end of the liquid storage chamber is connected with the metal needle while the upper end is connected with a pneumatic pump, and the pneumatic pump is connected with the microprocessor. The heating module is arranged on the outer side of the liquid storage chamber, the metal needle is arranged above the collection plate, a plane of the metal needle is perpendicularly intersected with a plane of the collection plate, the metal needle isconnected with a high-voltage output terminal of the high-voltage power source, and the collection plate has a zero potential. By means of melt direct writing for manufacturing a micro-channel main mould, the main mould width is reduced, the main mould depth is increased, and a depth-to-width ratio of a micro-channel chip after copying and curing of a curing agent is increased.

Owner:GUANGDONG UNIV OF TECH

Reel type holographic pattern paper, manufacturing process and system of reel holographic pattern paper and transfer film

ActiveCN102225668ARealize holographic pattern paper technologyExact copySynthetic resin layered productsStampingBiochemical engineeringPaper based

The invention relates to reel type holographic pattern paper, a manufacturing process and system of the reel holographic pattern paper and a transfer film used in the process. The process comprises the following steps: 1.1 depositing an information transfer layer on the surface of a mother film to form the transfer film; 1.2 coating an adhesive layer on the information transfer layer and then compounding the information transfer layer with a paper base; and 1.3 stripping the mother film, thus obtaining the holographic pattern paper. The process is characterized in that the mother film is in reel type; the surface of the mother film is provided with a groove structure of the holographic pattern; and the groove structure is duplicated to the information transfer layer. The invention also discloses the transfer film used in the process, the holographic pattern paper and the manufacturing system. The holographic pattern paper, the process, the system and the transfer film have the following beneficial effects: the coating procedure is utilized to manufacture the reel type holographic pattern paper, thus greatly lowering the production cost and improving the production efficiency by atleast above 3 times.

Owner:蔡旭楠

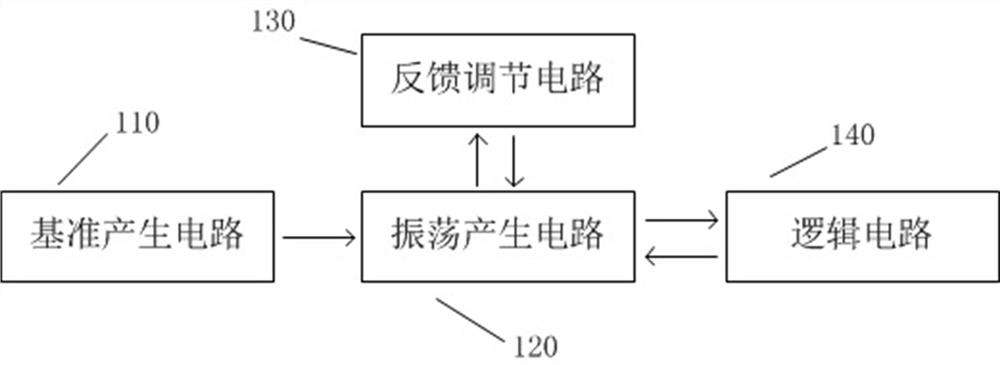

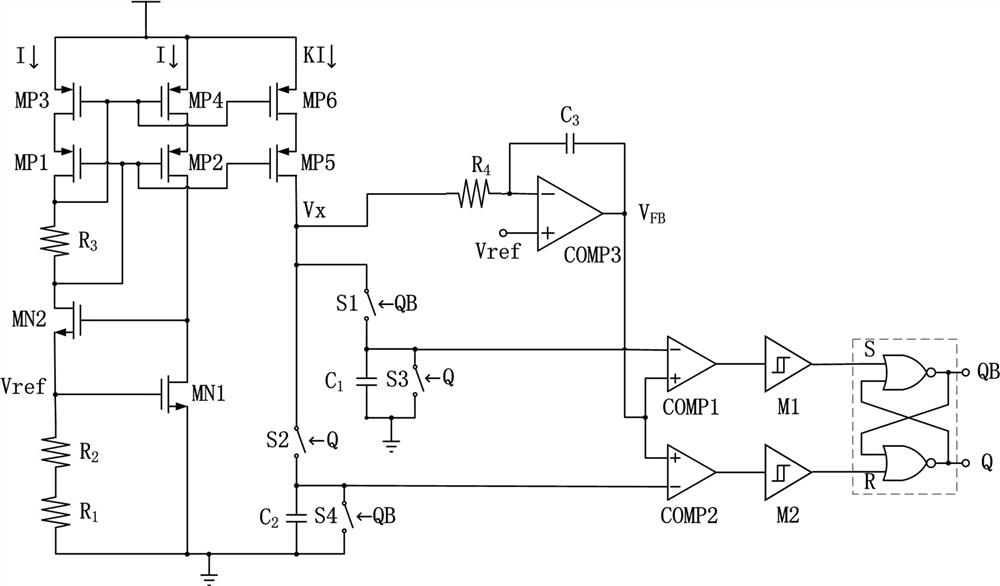

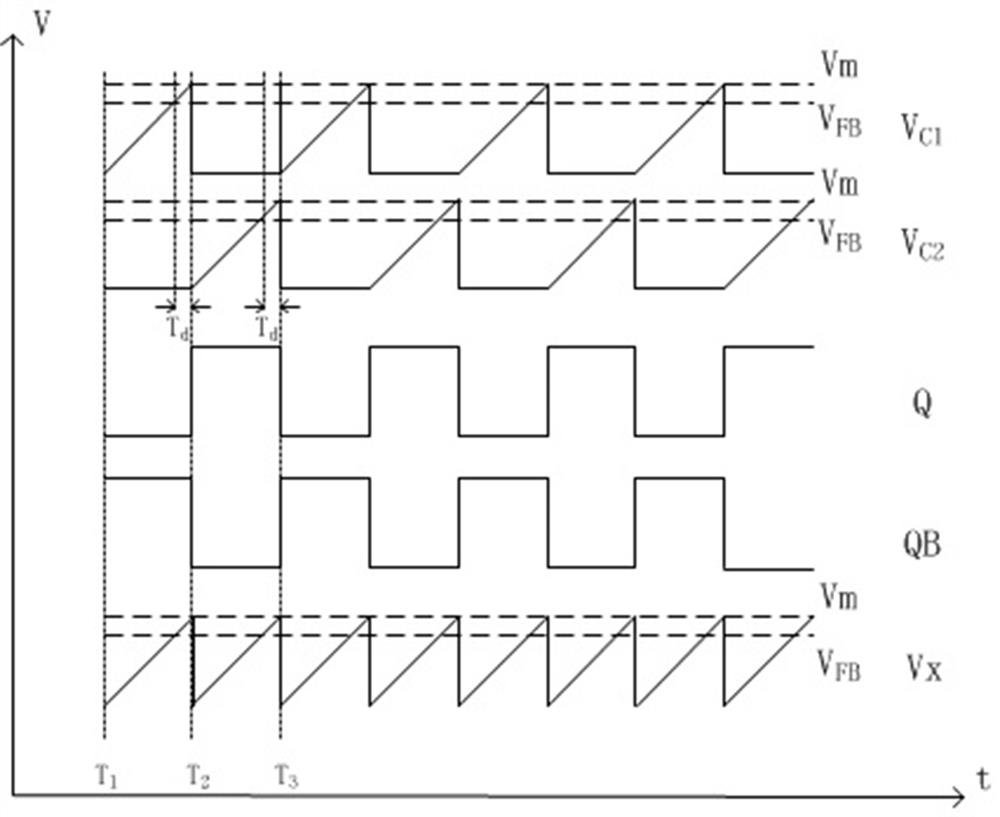

RC oscillator with stable frequency

ActiveCN113949344AStable output frequencyReduce the impactOscillations generatorsHigh level techniquesCapacitanceFrequency stabilization

The invention discloses an RC oscillator with stable frequency, which is an RC oscillator with low temperature drift and high power supply rejection ratio, has the characteristics of simple structure, small influence by temperature and power supply voltage and stable frequency, and comprises a reference generation circuit used for generating fixed bias current and bias voltage, and the bias voltage is generated by the bias current flowing through a bias resistor; an oscillation generating circuit is used for generating a periodic signal of which the frequency is only related to the resistance and the capacitance by utilizing the reference of the reference generating circuit; a feedback adjustment circuit is used for adjusting the comparison reference voltage of the comparator according to the time delay change of the comparator in the oscillation generation circuit and eliminating the influence of the time delay of the comparator; a logic circuit is used for receiving a signal of the oscillation generation circuit and controlling switching of a switch in the oscillation generation circuit to generate a periodic clock signal; a reference generation circuit is connected with the oscillation generation circuit, the oscillation generation circuit is connected with the logic circuit, and the feedback adjustment circuit is connected with the oscillation generation circuit.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing GaAs micro/nono optical element

InactiveCN100564241CPrecision Processing ApproachHigh copying accuracyDecorative surface effectsChemical vapor deposition coatingArray elementEngineering

The invention relates to a method for preparing a micron / nanometer optical element on GaAs and a micron / nanometer optical element thereof, in particular to a preparation method in which the micron / nanometer optical array element is directly etched on the surface of semiconductor GaAs material at one time with low cost, simple method and no complex processes such as mask lithography and so on. The quartz with the micron / nanometer optical array element is taken as an original mother blank; a relief structure on the quartz micron / nanometer optical array element is accurately replicated on the surface of polymer material and then a Ti layer and a Pt layer are sputtered in sequence; the surface is then metallized to obtain a template electrode. The template electrode is used as a working electrode and is adjusted to be parallel to a processed workpiece GaAs; an electrochemical etching solution is added into an electrolytic cell and an etching agent is generated on the template electrode; a restraint agent in the etching solution is used for compressing the thickness of an etching agent layer to the thickness of a micron or a nanometer level; GaAs sheets are controlled to move to the surface of the template electrode until the structure on the template electrode is completely replicated on the surface of the processed workpiece and the separation of the GaAs sheets and the template electrode is controlled.

Owner:XIAMEN UNIV

Electrochemical processing method for micro-structure of P type silicon surface

InactiveCN100501936CPrecision Processing ApproachHigh copying accuracyDecorative surface effectsSemiconductor/solid-state device manufacturingMicro structureLithographic artist

The invention provides an electro-chemical processing method of a P-typed silicon surface micro-structure, relating to the processing of silicon surface. The invention provides a novel electro-chemical processing method which has low cost and simple processing steps, does not have complex processes such as mask lithography, etc., and with micro-structure etched and is processed on the surface of the P-typed silicon in one-step. The electro-chemical processing method comprises the steps that: the micro-structure on an original mother blank is transferred onto a gelose surface and then dipped in electrolyte, so as to gain the gelose gel template with the stored electrolyte; the gelose gel template is then arranged in an electrolytic cell, the micro-structure part of which is exposed on the liquid surface; a Pt layer is splashed on the back surface by the P-typed silicon through a front disposal to form an ohm contact; a polished surface is then arranged on the surface of the gelose gel template; the P-typed silicon sheet is taken as a working electrode and the electro-chemical polishing micro-processing is carried out to the P-typed silicon sheet; the micro-structure on the gelose gel template is transferred on the surface of the P-typed silicon by the electro-chemical polishing micro-processing to gain the P-typed silicon sheet with the micro-structure and the P-typed silicon sheet with the micro-structure is separated from the gelose.

Owner:XIAMEN UNIV

Roll-type hologram paper manufacturing process, hologram paper and system

ActiveCN102285157AExact copyHigh copying accuracySynthetic resin layered productsPaper basedPaper manufacturing

The invention relates to a roll-type hologram paper manufacturing process, a transfer film, hologram paper and a system. The roll-type hologram paper manufacturing process provided by the invention comprises the following steps of: 1.1, coating an adhesive layer on the surface of a master film which comprises a hologram and then compounding the master film with a paper base, wherein the adhesive layer is a UV (ultraviolet) resin; 1.2, stripping the master film to obtain the hologram paper; and the roll-type hologram paper manufacturing process is characterized in that: a groove structure of the hologram on the surface the master film is copied on the adhesive layer. In the invention, the characteristic that the hologram groove structure on the surface the master film can be accurately copied is creatively utilized, the prior art is changed into copying of the hologram groove structure on the surface the master film, and a coating process is utilized for manufacturing the roll-type hologram paper, thus the production cost is greatly lowered and the production efficiency is increased.

Owner:广东东南薄膜科技股份有限公司

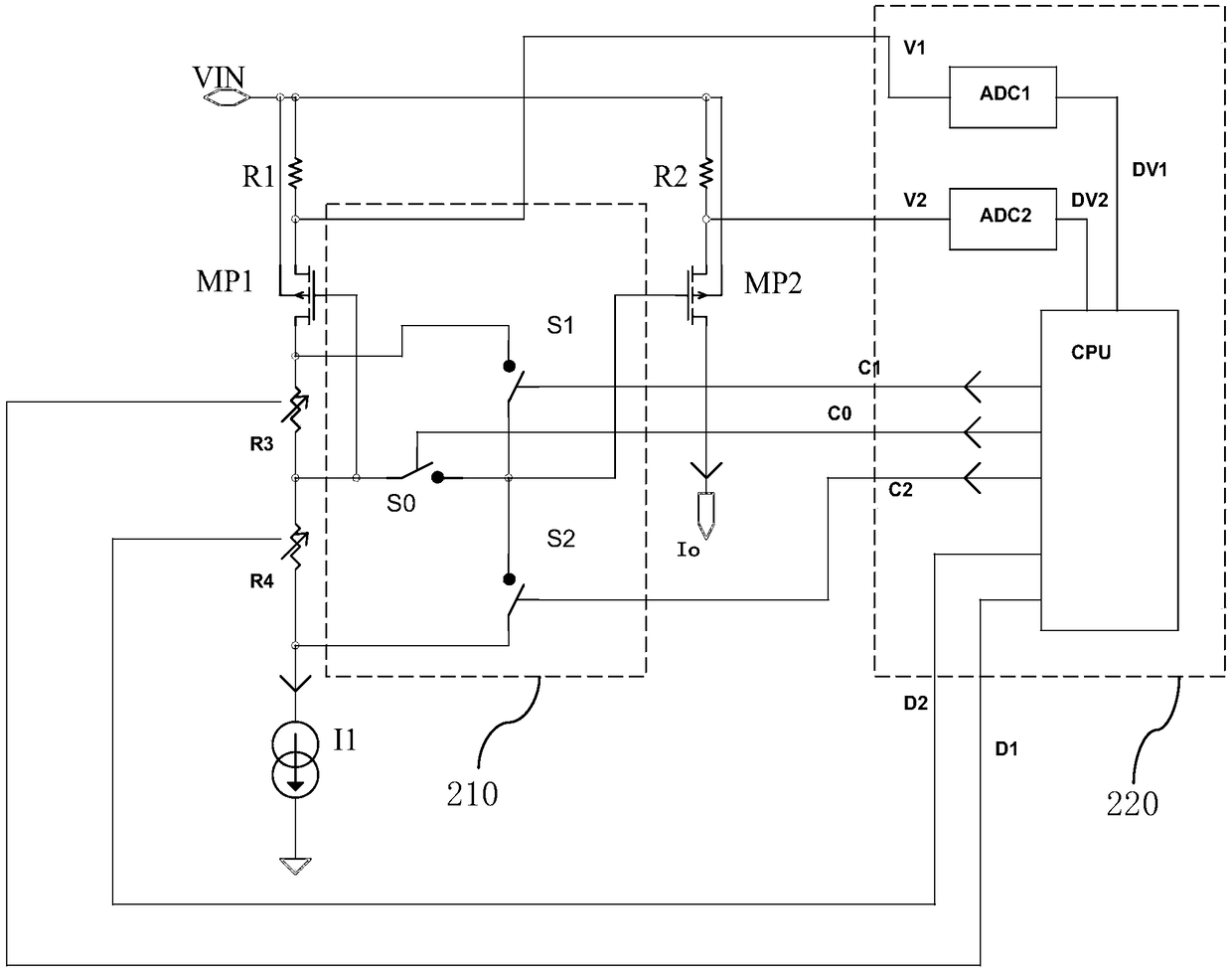

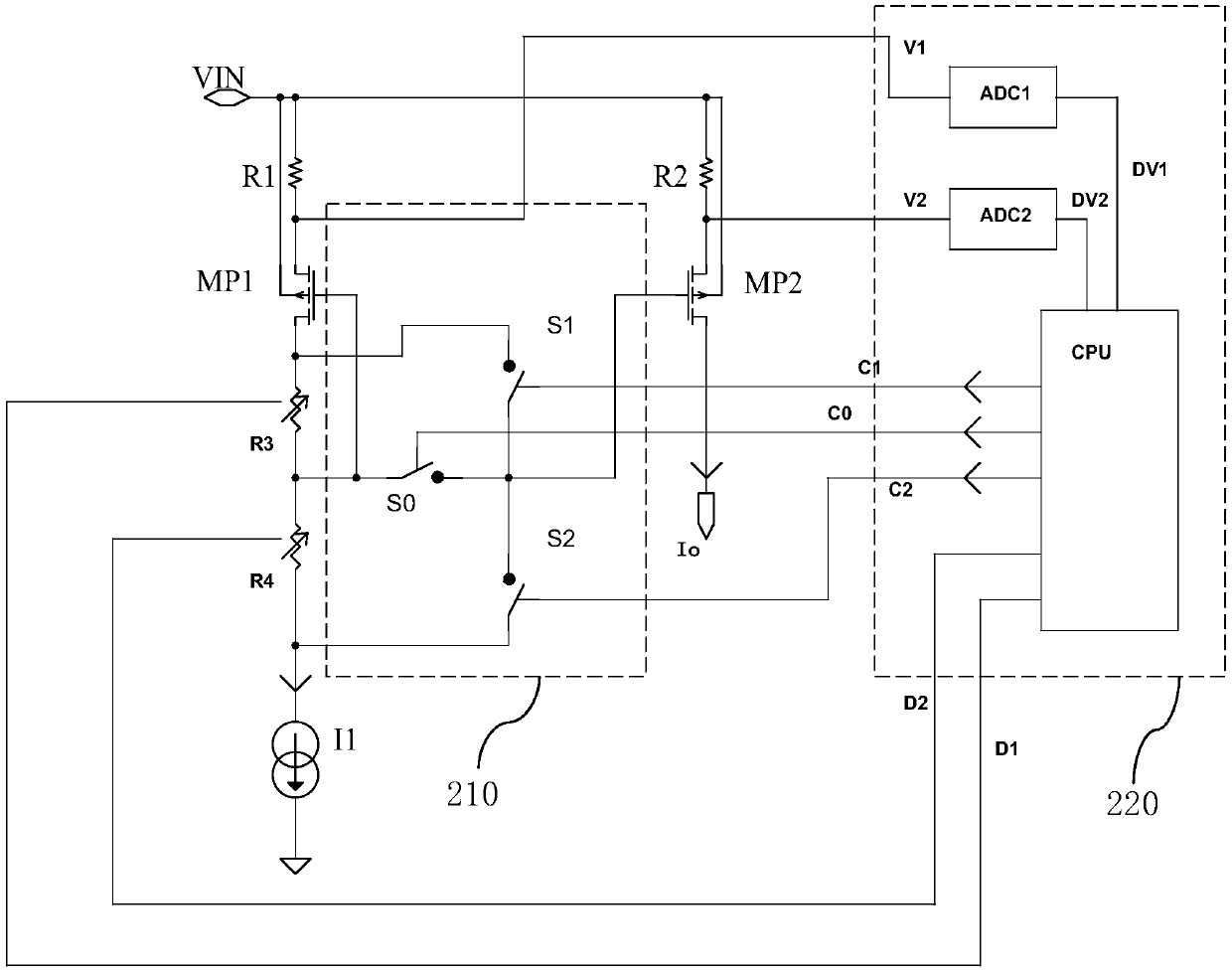

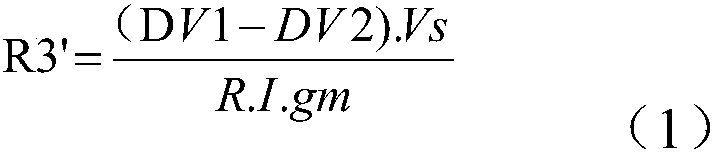

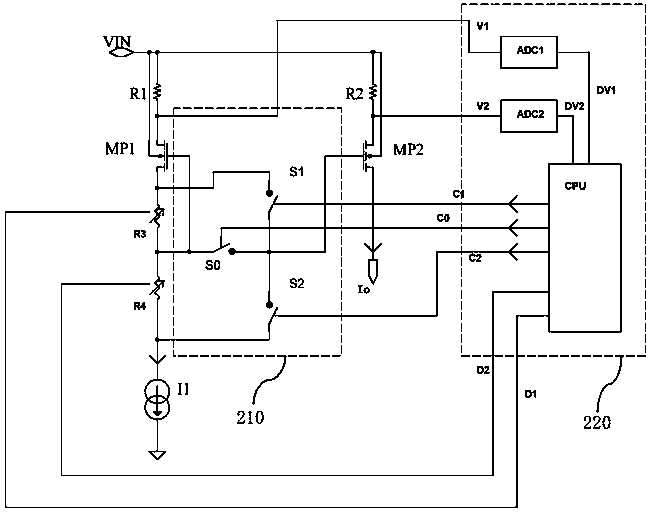

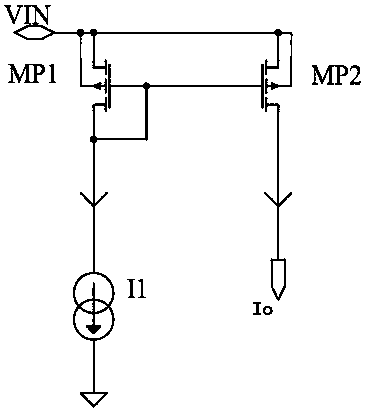

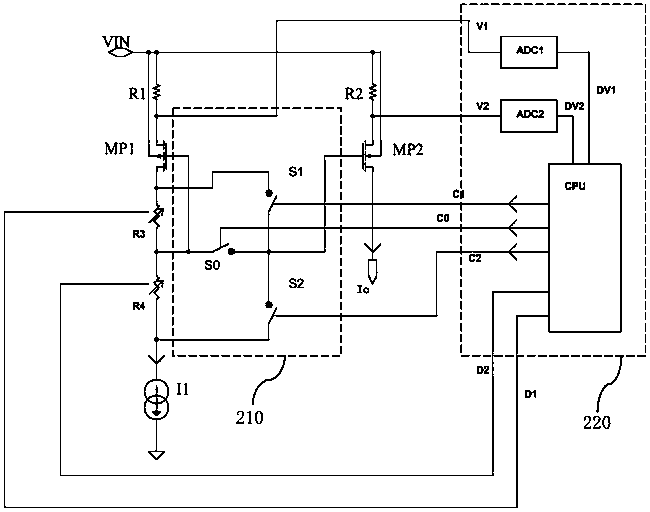

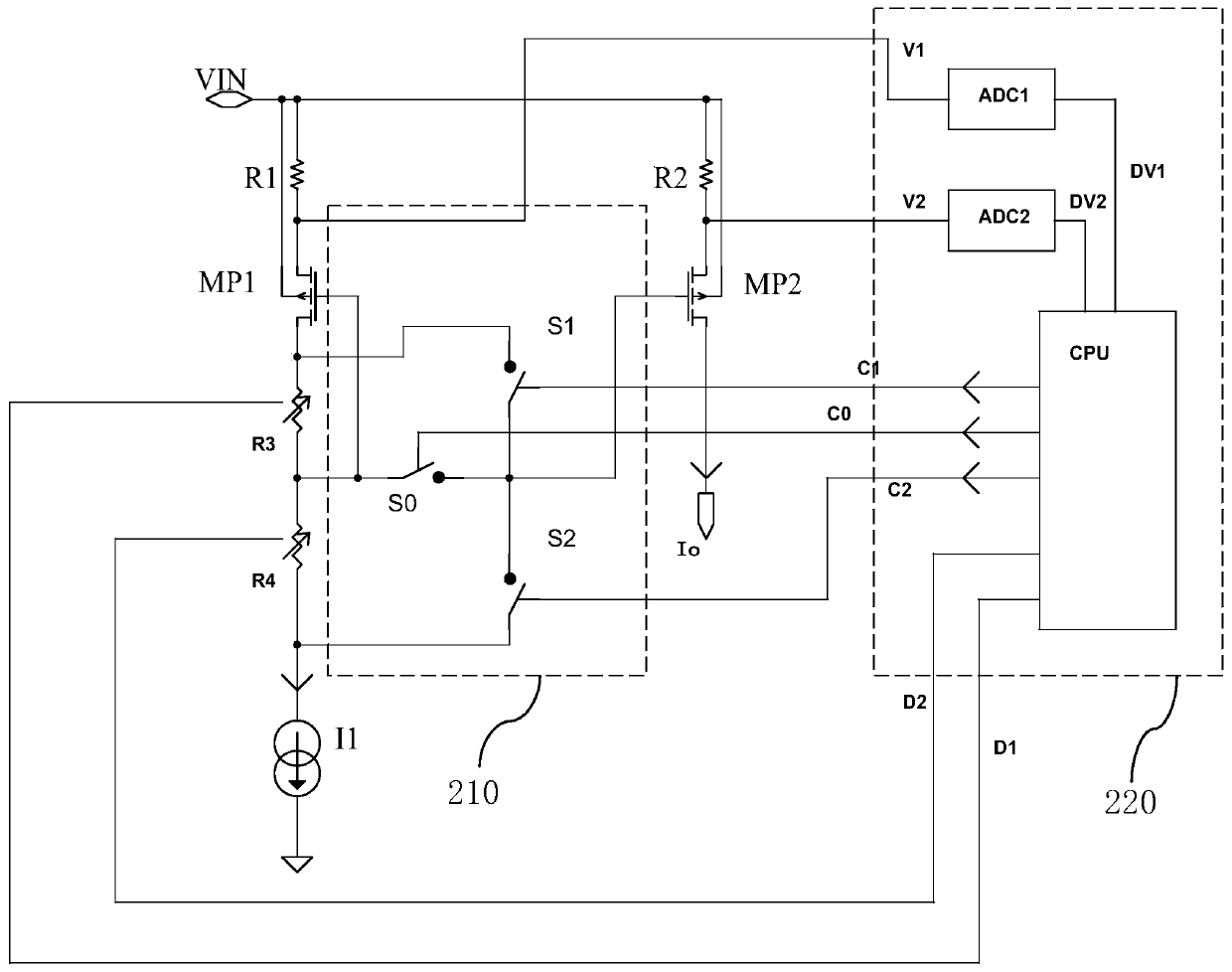

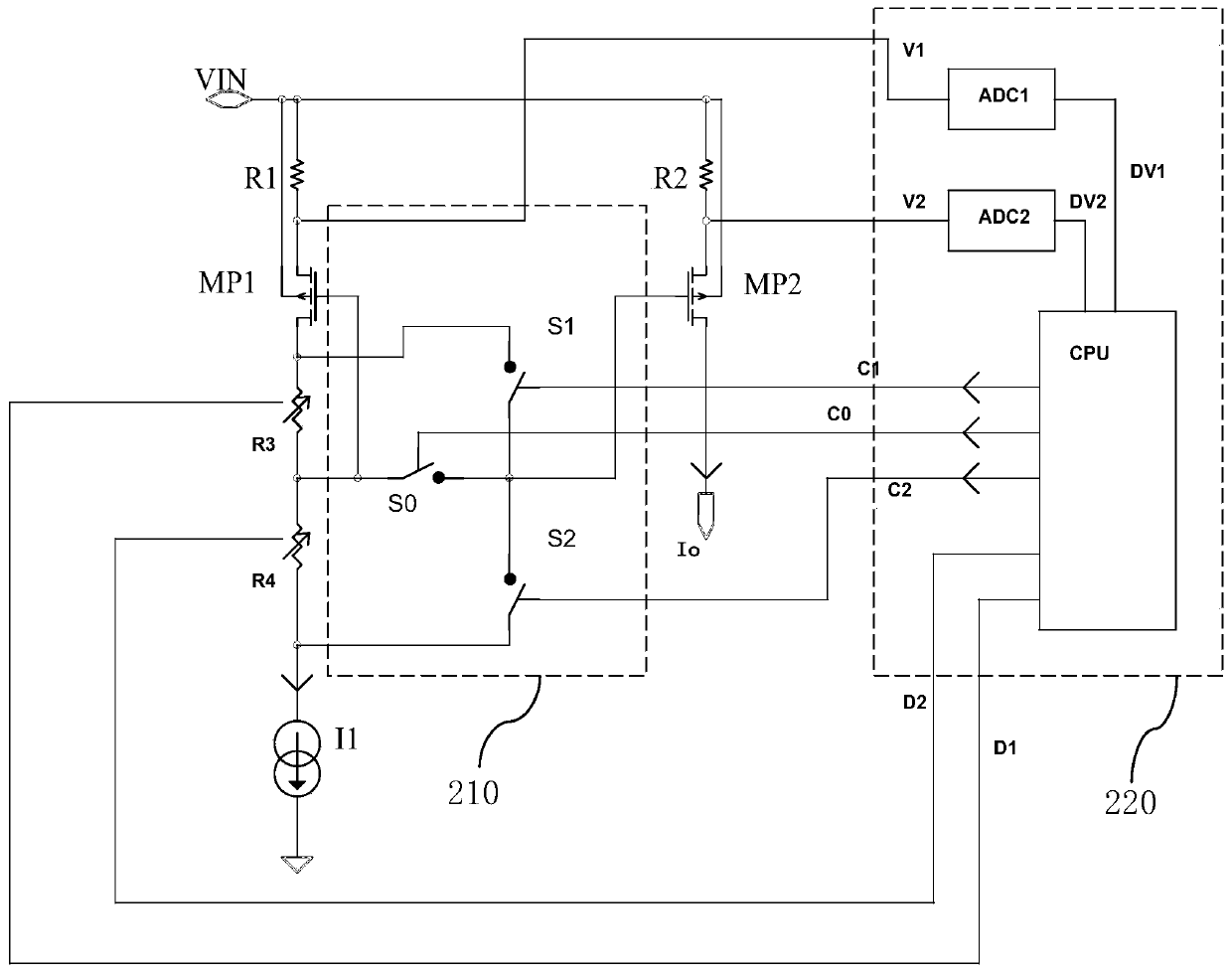

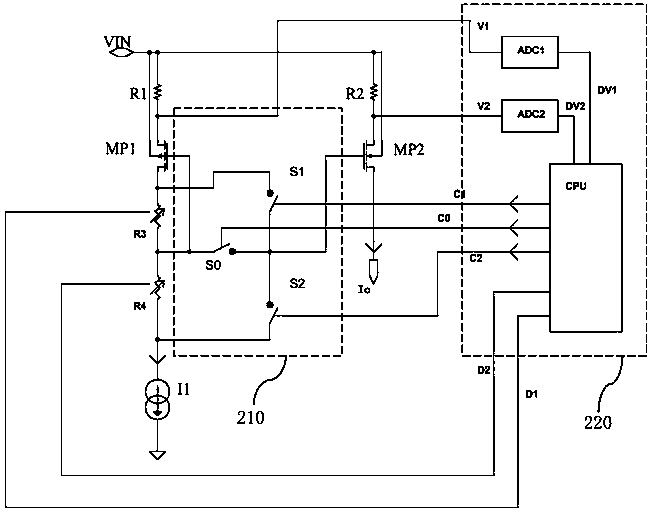

Current mirror circuit provided with calibrating circuit

ActiveCN107817868AHigh copying accuracyReduce mismatchElectric variable regulationEngineeringElectrical current

The invention provides a current mirror circuit which comprises a first MOS tube, a second MOS tube, a first resistor, a second resistor, a first adjustable resistor, a second adjustable resistor, a switch circuit and a calibrating circuit. The calibrating circuit controls a first switch to be on first and then controls a second switch and a third switch to be off; at the moment, the calibrating circuit samples and compares the voltage at the other end of the first resistor with that of the other end of the second resistor; when the first sampling voltage is greater than the second sampling voltage, the calibrating circuit adjusts the first regulatable resistor to a first effective resistance value and controls the second switch of the switch circuit to be on and the first switch and the third switch to be off; when the first sampling voltage is lower than the second sampling voltage, the calibrating circuit adjusts the second adjustable resistor to a second effective resistance value,and controls the third switch of the switch circuit to be on and the first and second switches to be off. Compared with the prior art, mismatch of current copy of the current mirror can be reduced, and the copy precision of the current mirror can be increased.

Owner:NANJING ZGMICRO CO LTD

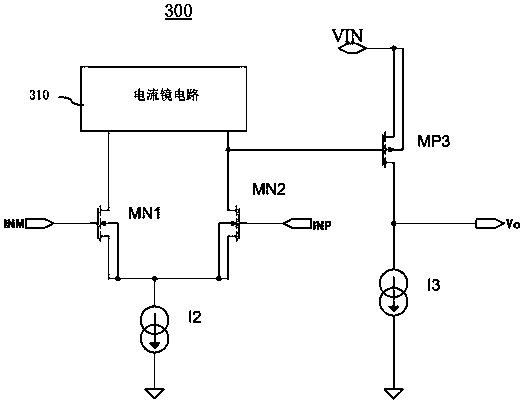

Improved Op Amp

ActiveCN108259010BHigh control precisionHigh copying accuracyAmplifier modifications to reduce temperature/voltage variationDifferential amplifiersAudio power amplifierOperational amplifier

The present invention provides an operational amplifier comprising: a current mirror circuit, a first differential transistor, a second differential transistor, a second current source, a third current source, and a third MOS transistor. The current mirror current replica of the current mirror circuit has a very small mismatch and has a high current mirror replica accuracy, which improves the control precision of the operational amplifier.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

A carbon fiber composite material space optical mirror surface high-precision replication method

ActiveCN105643955BPrecisely control the laying angle of prepregHigh copying accuracyOptical articlesCoatingsFiberOptoelectronics

The invention relates to a high-precision copying method of a carbon fiber composite space optical mirror plane, particularly relates to an optical mirror plane product which is a spherical-crown or spherical-crown-like curved surface structure and is made of a carbon fiber enhanced cyanic acid composite, and belongs to the technical field of advanced composites. The optical mirror plane is a large-aperture spherical-crown concave surface structure. The mirror plane copying technology comprises the following steps: carrying out technological simulation analysis and experimental confirmation according to surface precision and performance requirements, and determining a suitable cyanate / carbon fiber prepreg system and a prepreg laying sequence; laying prepreg wires of a large-size optical mirror plane with a curved surface structure by using an automatic wire laying technology, accurately controlling a laying angle of the prepreg wires, and guaranteeing high-quality copying at a full laid angle; and curing the laid prepreg by using an autoclave to obtain the copied high-precision optical mirror plane. The copied mirror plane is high in surface precision and high in repeatability and consistency; and compared with manufacturing of the traditional optical mirror plane, the copying technology is short in manufacturing cycle and low in manufacturing cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

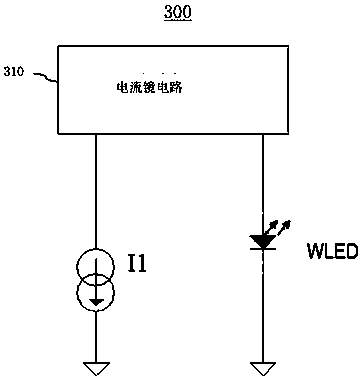

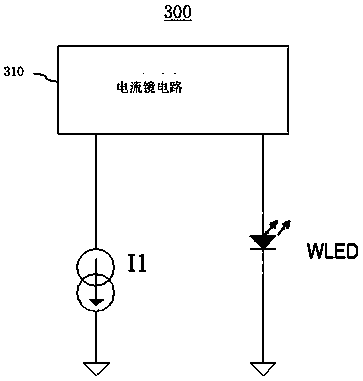

Improved LED circuit

ActiveCN108207057AImprove brightness control precisionHigh copying accuracyElectrical apparatusElectroluminescent light sourcesPower flowEngineering

The invention provides an improved LED circuit, which comprises a current mirror circuit, an LED and a first current source, wherein the current mirror circuit has very small mismatch of current replication of a current mirror and has very high current replication accuracy, so that the brightness control accuracy of the LED of the LED circuit can be improved.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

A current mirror circuit provided with a calibration circuit

ActiveCN107817868BHigh copying accuracyReduce mismatchElectric variable regulationElectrical currentResistor

The invention provides a current mirror circuit which comprises a first MOS tube, a second MOS tube, a first resistor, a second resistor, a first adjustable resistor, a second adjustable resistor, a switch circuit and a calibrating circuit. The calibrating circuit controls a first switch to be on first and then controls a second switch and a third switch to be off; at the moment, the calibrating circuit samples and compares the voltage at the other end of the first resistor with that of the other end of the second resistor; when the first sampling voltage is greater than the second sampling voltage, the calibrating circuit adjusts the first regulatable resistor to a first effective resistance value and controls the second switch of the switch circuit to be on and the first switch and the third switch to be off; when the first sampling voltage is lower than the second sampling voltage, the calibrating circuit adjusts the second adjustable resistor to a second effective resistance value,and controls the third switch of the switch circuit to be on and the first and second switches to be off. Compared with the prior art, mismatch of current copy of the current mirror can be reduced, and the copy precision of the current mirror can be increased.

Owner:NANJING ZGMICRO CO LTD

Method for inspecting translucent article

ActiveCN101120245BAvoid damageGuaranteed StrengthMaterial analysis by optical meansGlass shaping apparatusOptical propertyLength wave

A light-transmitting object examining method enables an accurate examination whether optical nonuniformity is present or not inside a light-transmitting object. The light-transmitting object examining method examines whether nonuniformity (specifically an internal defect (16)) causing an optical characteristic to an exposure light to change locally or at local portion is present or not inside a light-transmitting object (4) that is made of a light-transmitting material and used for photolithography. An examining light having a wavelength of less than 200 nm is made to enter the light-transmitting object and a light (15) having a wavelength longer than that of the examining light and emitted locally or at a local portion is sensed in an optical path along which the examining light propagates inside the light-transmitting object, thus presence / absence of an optical nonuniformity of a light-transmitting object is examined.

Owner:HOYA CORP

Improved Voltage Comparator

ActiveCN108233900BHigh precisionHigh copying accuracyMultiple input and output pulse circuitsPower flowVoltage reference

The present invention provides a voltage comparator comprising: a current mirror circuit, a third resistor, a fourth resistor, a first bipolar transistor, a second bipolar transistor, a second current source, and a third MOS transistor. The current mirror circuit has a small current mirror current replica mismatch with high current replica accuracy, which improves the accuracy of the voltage comparator's internal reference voltage threshold.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

Method and electrolytic tool for integral blisk integrated electrolytic machining

ActiveCN110935968BHigh precisionQuality improvementElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisEngineering

The invention discloses a tool for achieving integrated electrolysis machining of a complex profile blisk, a blade basin, a blade back and a hub by means of multi-axis linkage of a curved cathode, andrelates to the technical field of electrolytic machining. The tool comprises a rotary workbench, a workpiece clamp mounted on the rotary workbench, a cathode body located at workpiece grid channels,a feeding mechanism capable of performing multi-axis action, a connecting rod for connecting the curved cathode with a machining main shaft and a tool-setting block. The cathode body is of a hollow thin-wall structure, and the geometry of the cathode body is designed according to the grid channels and the hub profile. During machining, the rotary workbench drives a workpiece to do rotary action, the machining main shaft of the feeding mechanism drives the cathode body to move, rotate and the like to form multi-axis linkage, and a blisk workpiece with a complex twisted shape is obtained. The machining method has wide applicability, and the blisk workpiece with high dimensional precision and high surface quality for an aerospace engine can be obtained through one-time machining.

Owner:HEFEI UNIV OF TECH

Improved led circuit

ActiveCN108207057BImprove brightness control precisionHigh copying accuracyElectrical apparatusElectroluminescent light sourcesEngineeringLED circuit

The invention provides an LED circuit, which includes: a current mirror circuit, an LED and a first current source. The current mirror circuit has very small mismatch of current mirror current replication and high current replication accuracy, which can improve the brightness control accuracy of LEDs in the LED circuit.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

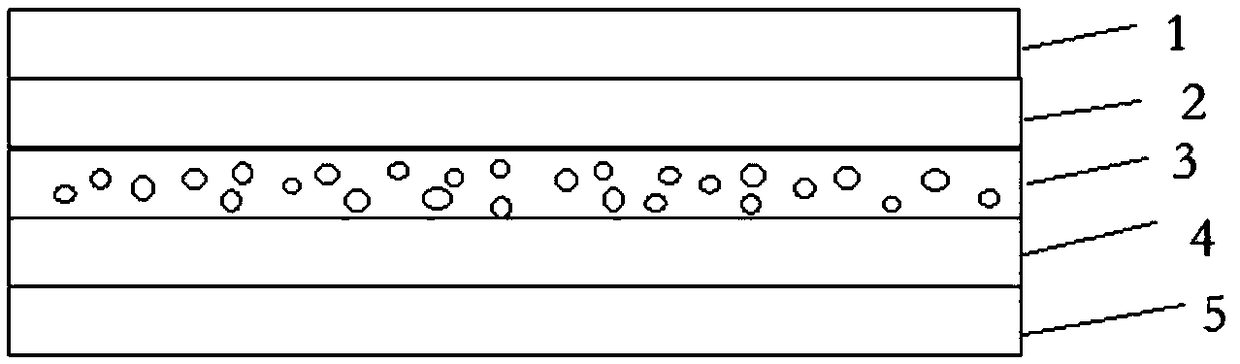

A laser holographic anti-counterfeiting film

ActiveCN106739629BNo fogging phenomenonGood high precision effectInformation cardsInformation layerEpoxy

The invention belongs to the field related to preparation of holography anti-fake materials, and discloses a laser holography anti-fake film. The laser holography anti-fake film comprises a base film, a release layer, an information layer, a reflection layer and a hot melt adhesive layer laminated in sequence, wherein the information layer consists of such as substrates as epoxy resins and a lot of micro capsules dispersed in the substrates; capsule cores of the micro capsules consist of heating curing agents for generating a cross linking reaction with the epoxy resins in the mold pressing process to cure holography relief patterns; and capsule walls are used for stopping contact between the capsule cores and the substrates before mold pressing. The laser holography anti-fake film can effectively solve multiple defects in a thermoplastic holography anti-fake film; and a laser holography film product with nearly 100% of high-precision copy information, not influenced by the heat transfer working conditions, convenient to preserve for a long time and maintaining high-quality anti-fake function can be obtained.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com