Method and electrolytic tool for integral blisk integrated electrolytic machining

A technology of integral blisk and processing method, which is applied in electric machining equipment, electrochemical machining equipment, manufacturing tools, etc., to achieve the effects of reducing stray corrosion, improving processing localization, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The workpiece to be processed is an integral blisk of radial blades, with a diameter of 600mm, a thickness of 40mm, the number of blades is 69, and the material is titanium alloy; the cascade channel is narrow, and the blade surface is twisted and easily deformed; the processing accuracy is high, and the blade surface accuracy requires 0.1-0.5mm, the surface roughness of the hub is required to be less than 1.0μm, and the surface roughness of the cascade channel is required to be less than or equal to 1.6μm.

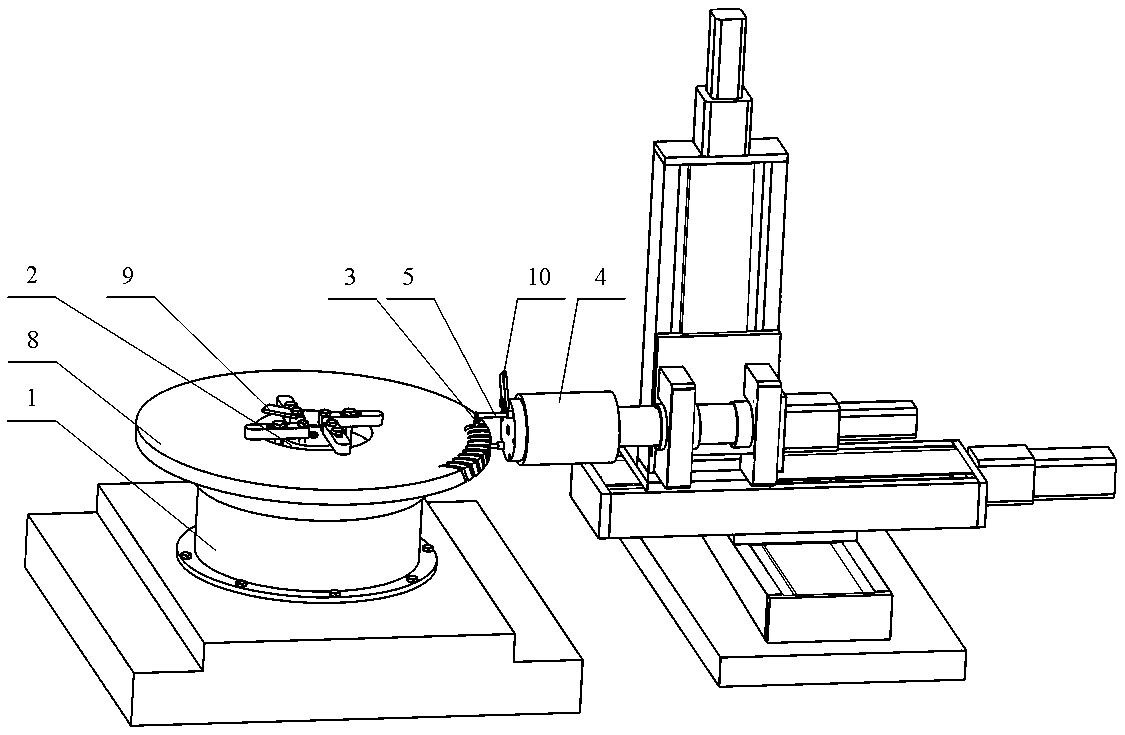

[0051] see figure 1 and image 3 The processing equipment includes a rotary table 1, a workpiece fixture 2 installed on the rotary table, a cathode body 3 located at the passage of the workpiece cascade, a processing spindle of the feed mechanism 4, a connecting rod 5 connecting the curved cathode and the processing spindle, and Tool setting block 6.

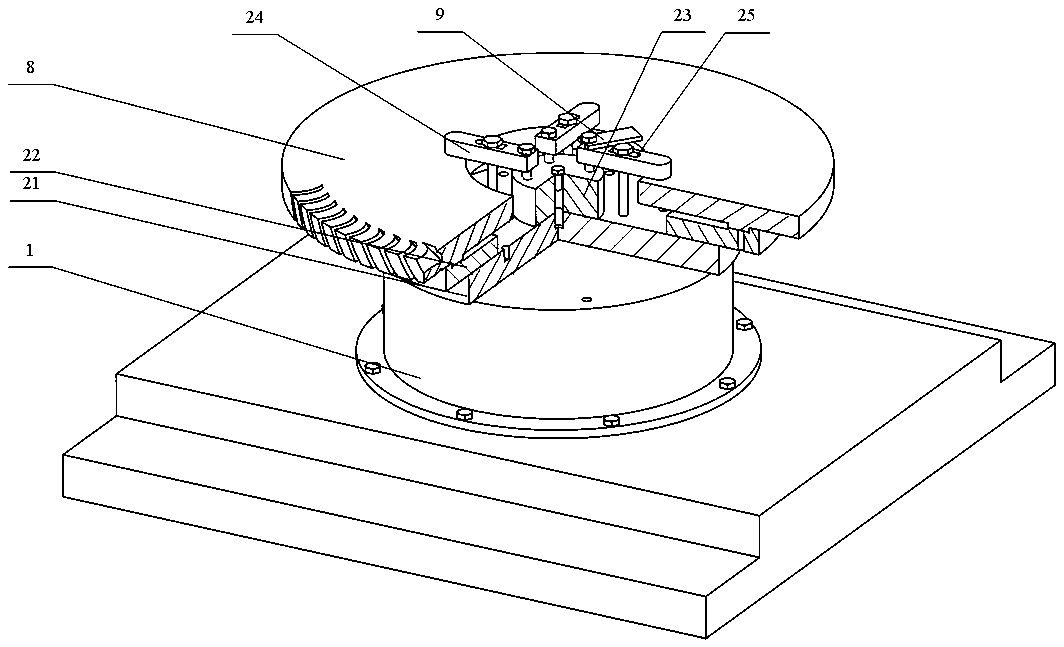

[0052] see figure 2 , The workpiece fixture for electrolytic machining includes an insulating mounting plate ...

Embodiment 2

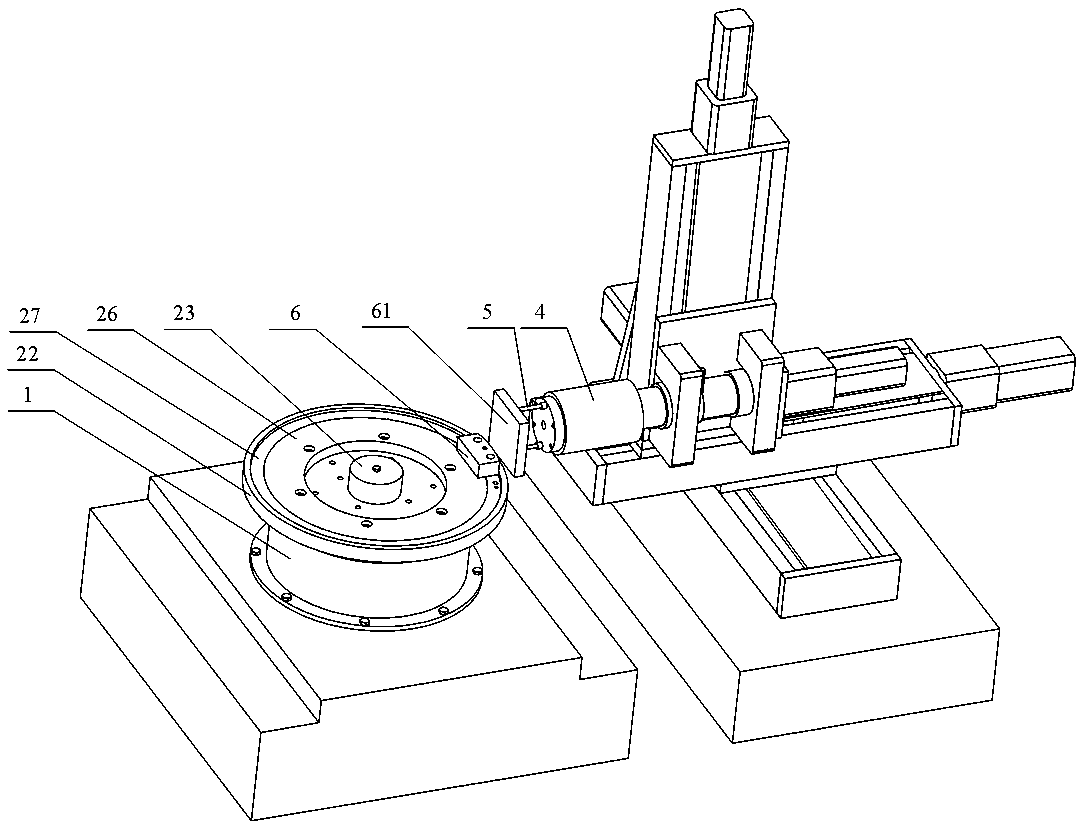

[0073] see Figure 7 , the workpiece to be processed is an integral blisk of axial blades, with a diameter of 450 mm, a thickness of 30 mm, the number of blades is 90, and the material is superalloy; the accuracy of the blade surface is required to be less than 0.5 mm, and the surface roughness of the cascade channel is required to be Ra less than or equal to 1.6 μm .

[0074] The rotary table is a horizontal structure,

[0075] The specific electrolytic machining operation steps are as follows:

[0076] (1) Tool setting

[0077] Install the workpiece pallet on the horizontal rotary table 1, install the tool setting block 6 on the workpiece pallet; install the electrolytic tool setting block 61 on the front end of the processing spindle of the feed mechanism 4; implement the rotary table 1 and the feed mechanism 4. For the tool setting of the spindle, remove the tool setting block and the electrolytic tool setting block after the tool setting is completed.

[0078] (2) Ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com