Patents

Literature

57results about How to "Reduction of stray corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

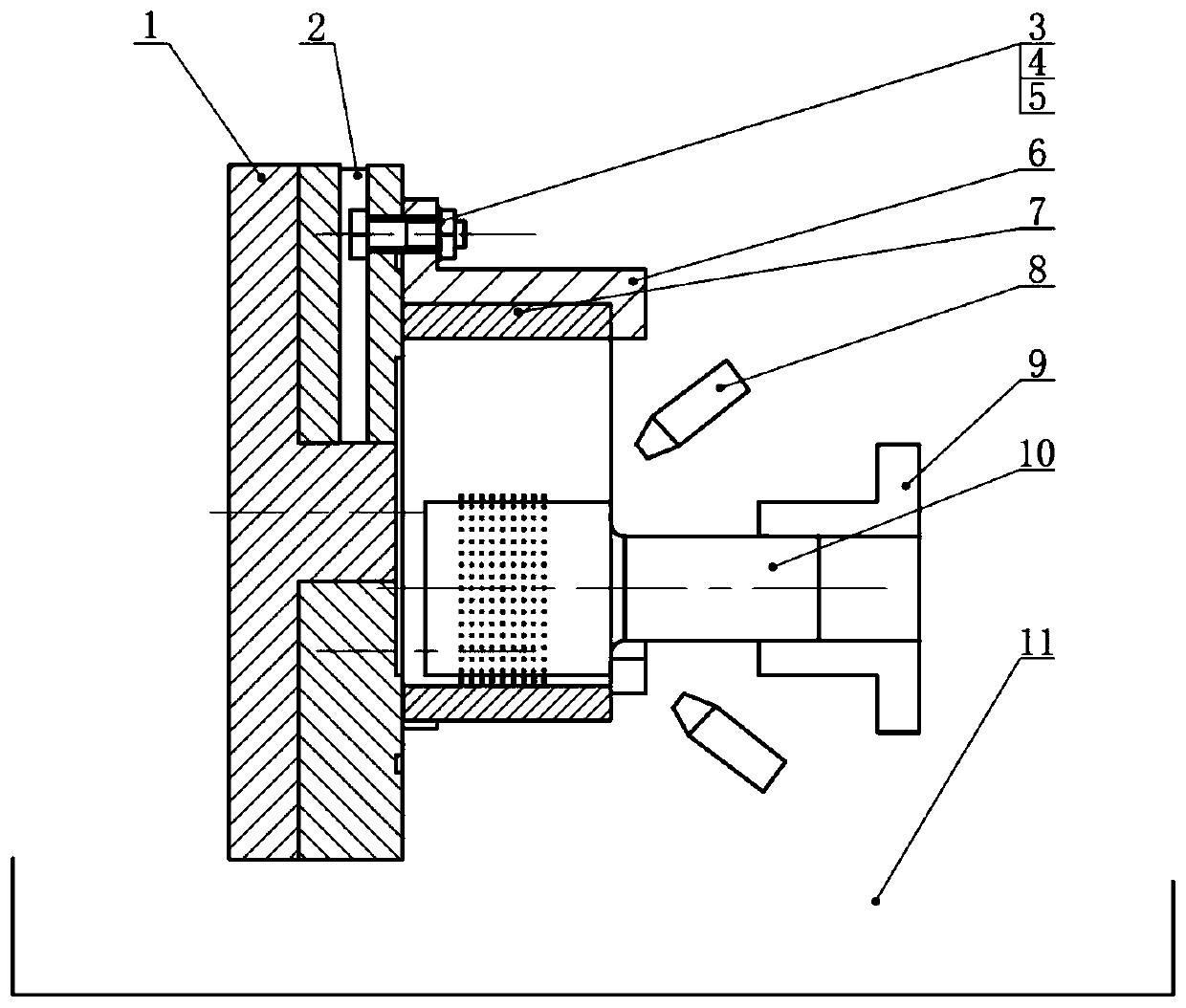

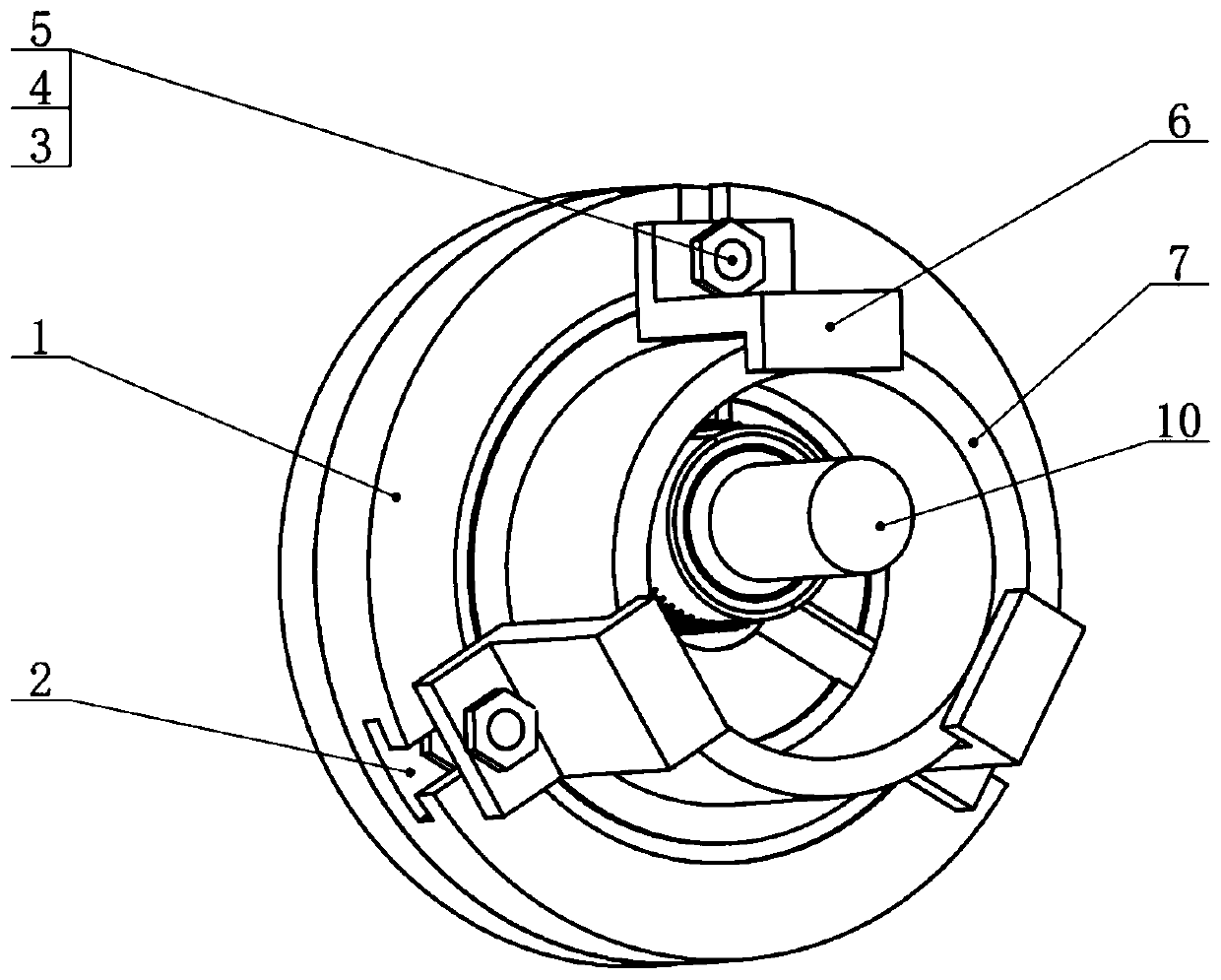

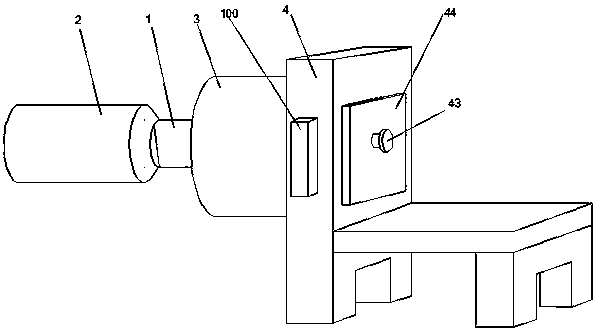

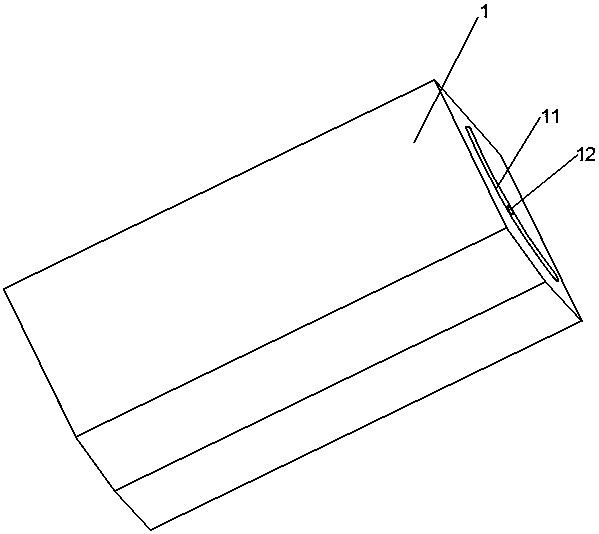

Electrolytic machining method for micro-pit group using bipolar electrode and bipolar electrode thereof

ActiveCN101327535AReduction of stray corrosionImprove localizationMachining electrodesMachining working media supply/regenerationOptoelectronicsAnode

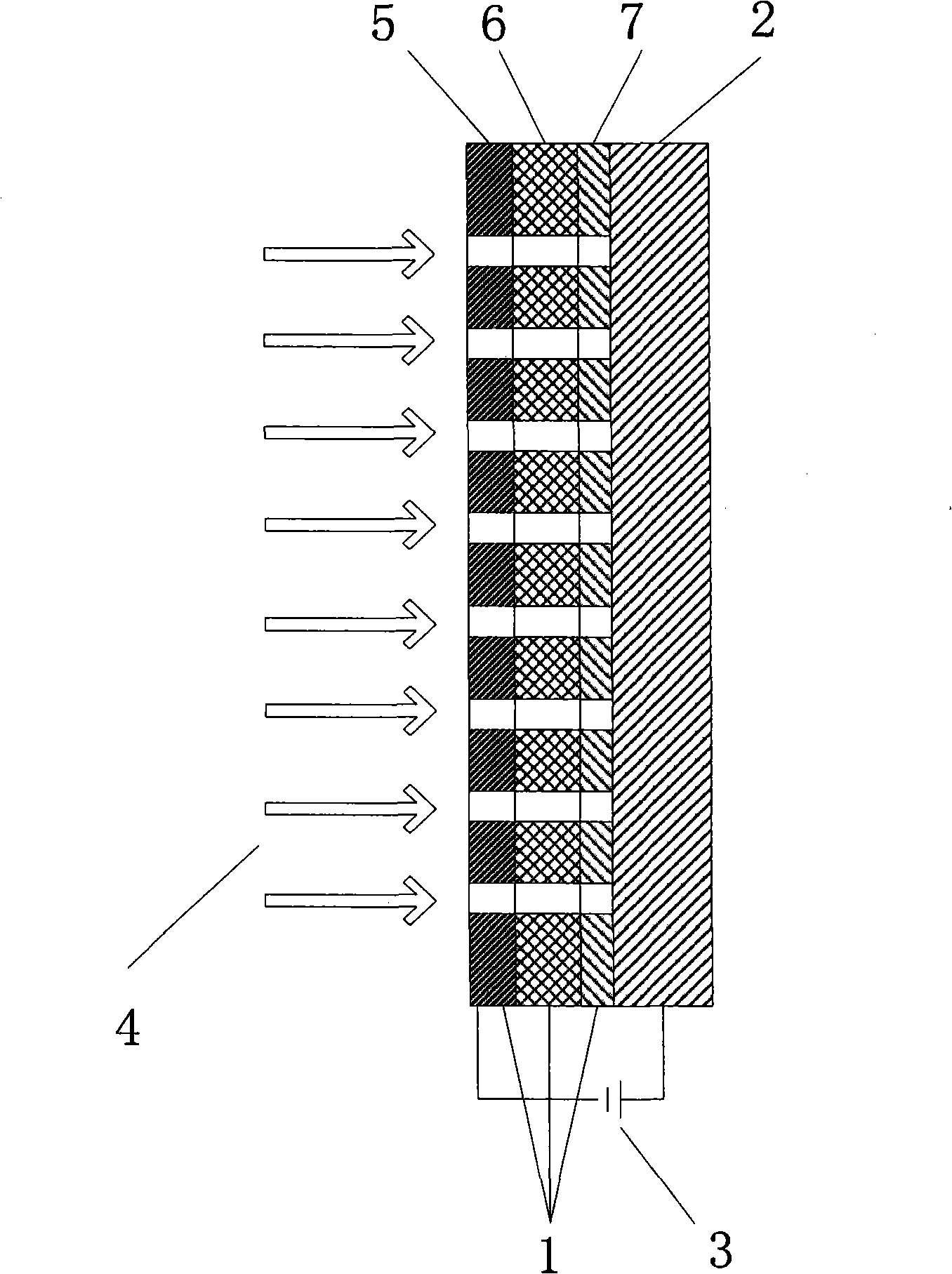

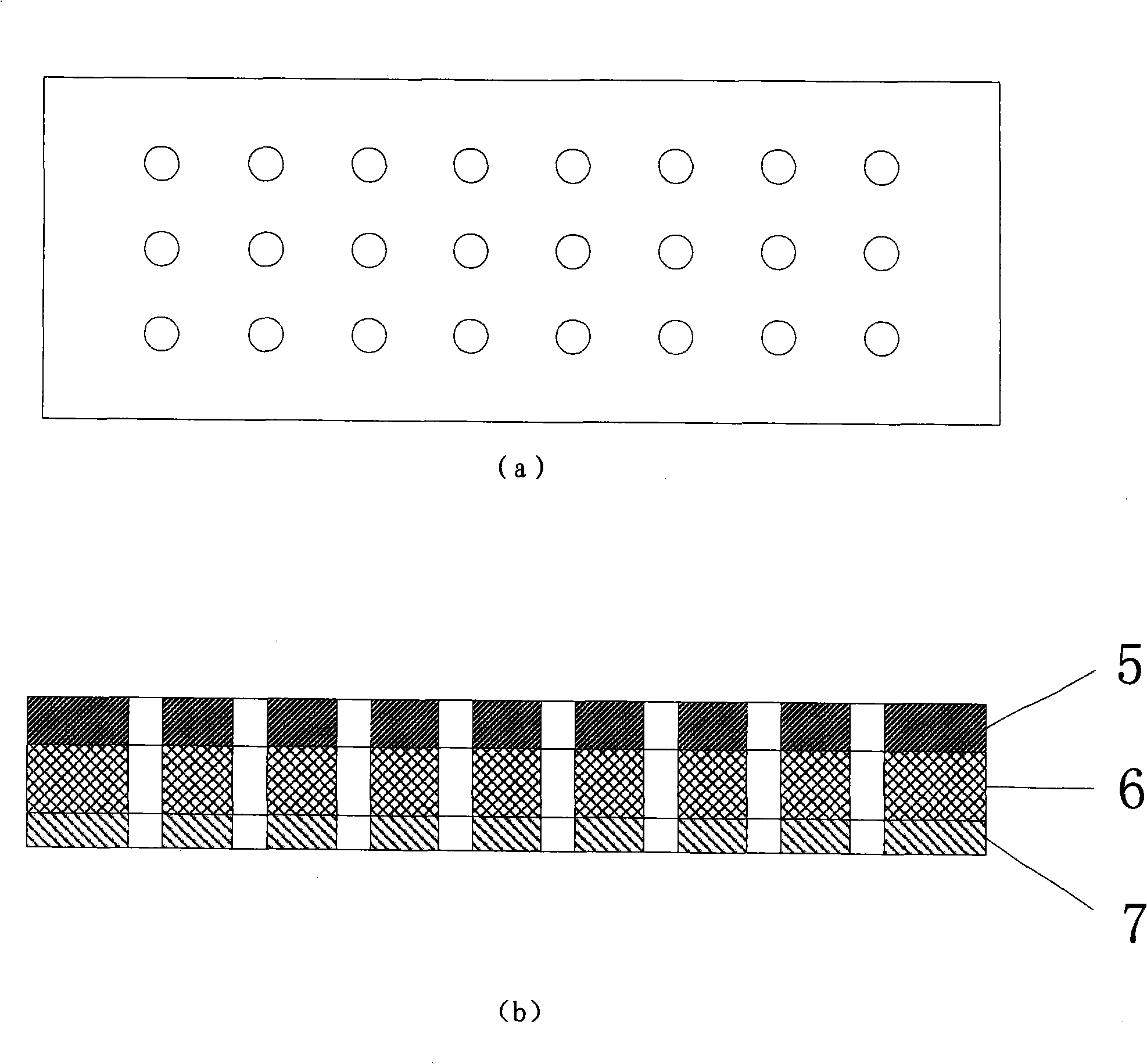

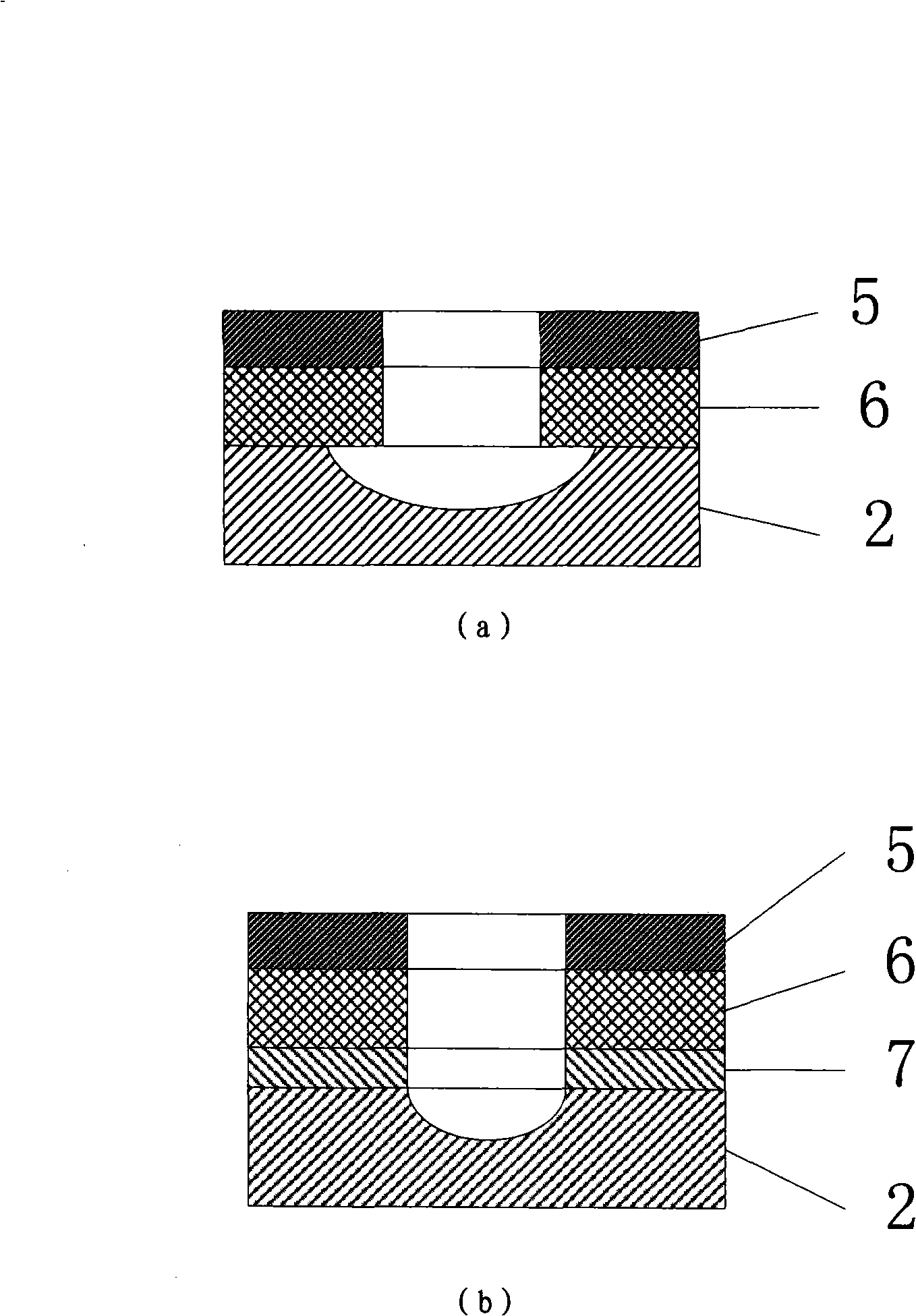

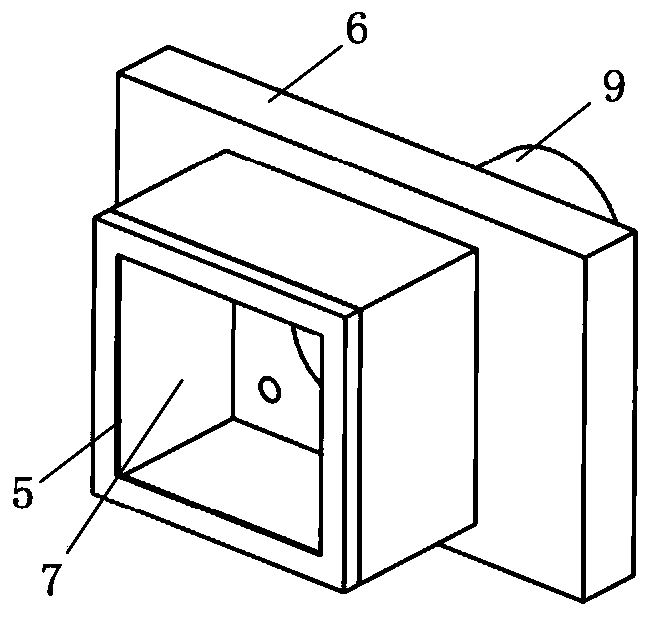

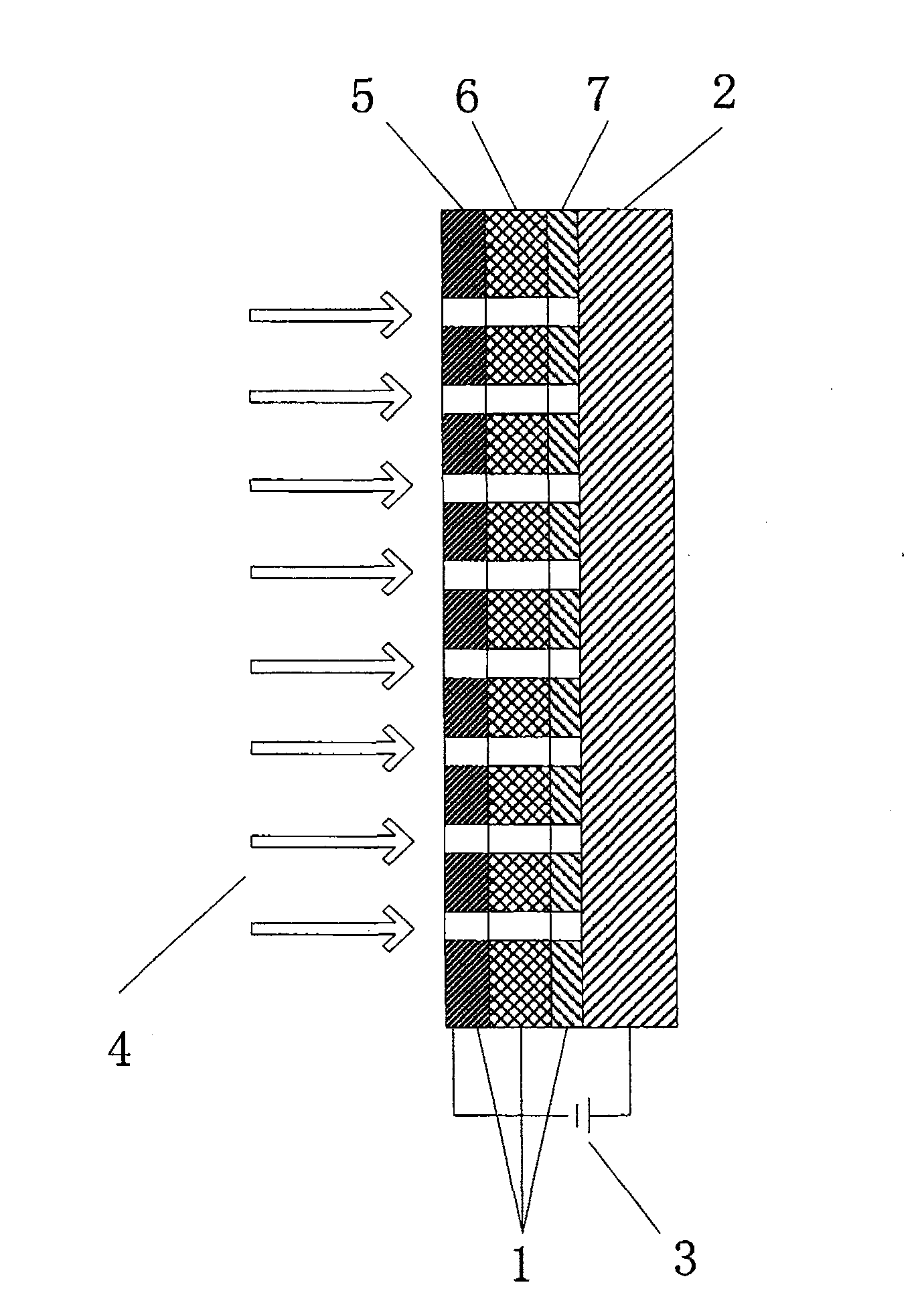

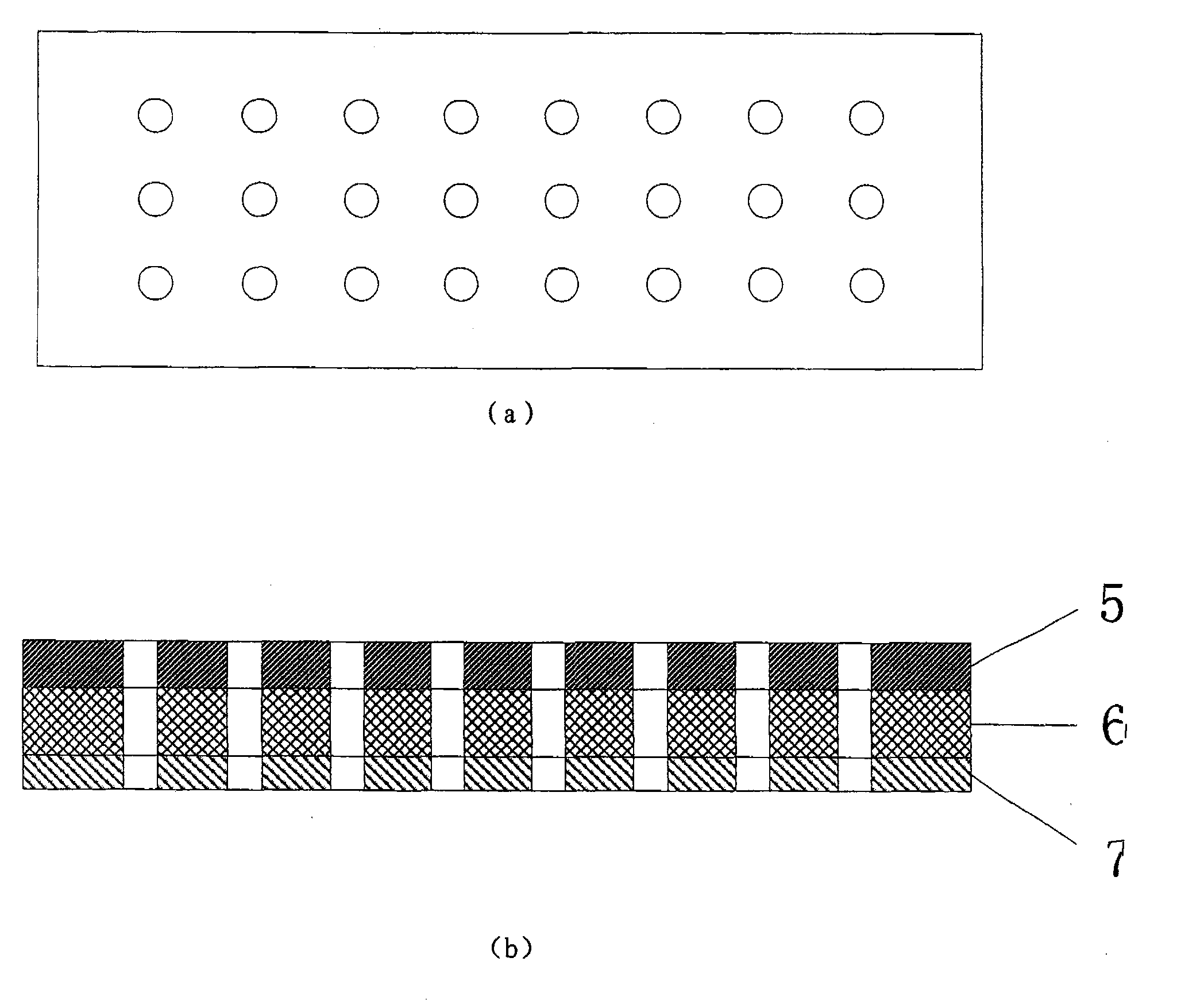

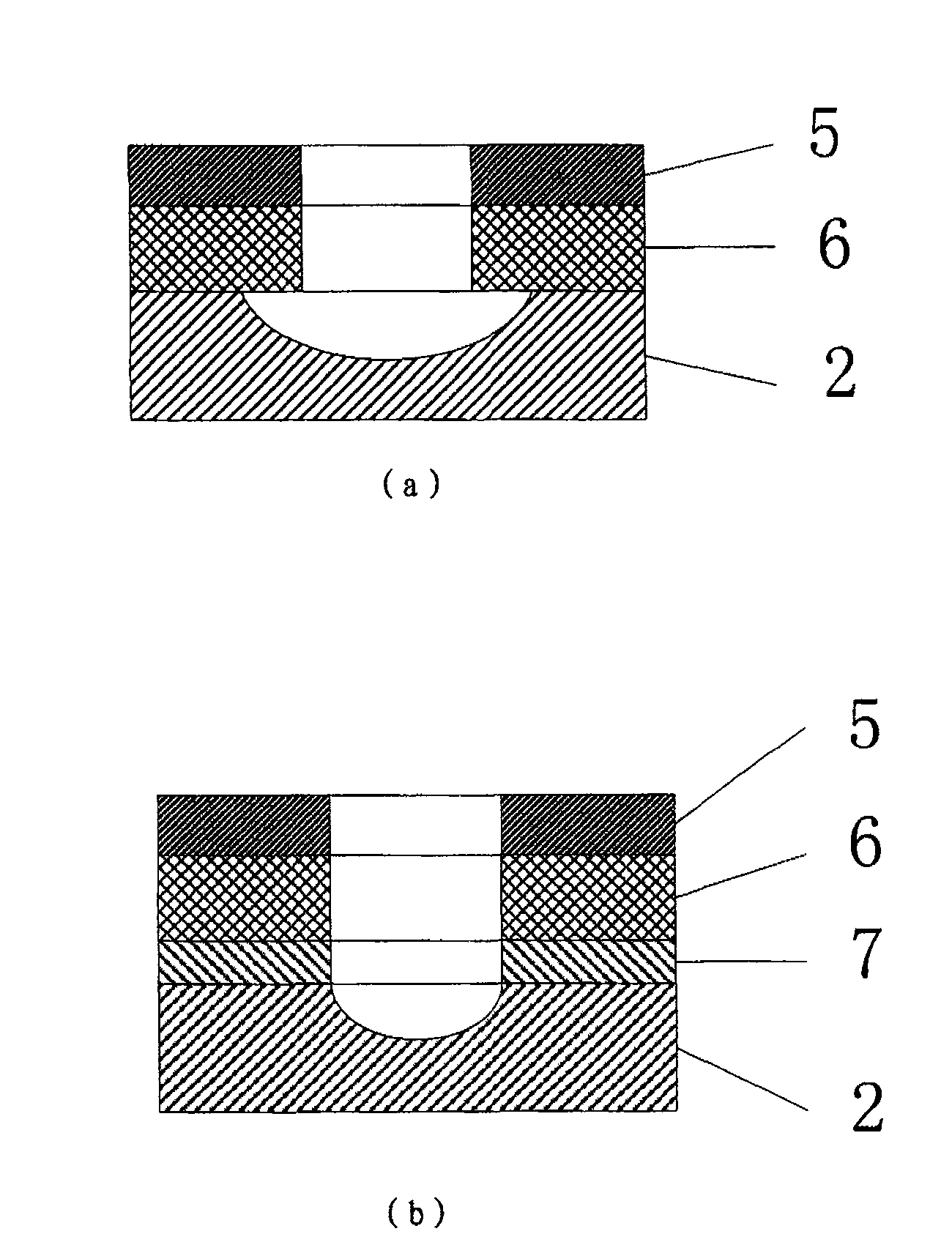

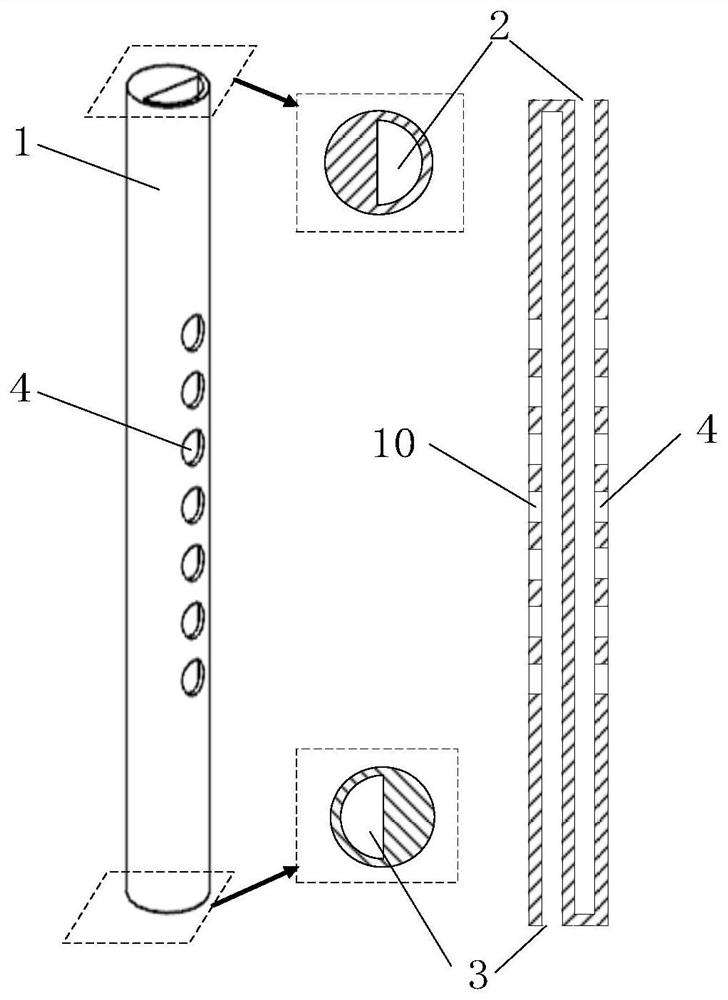

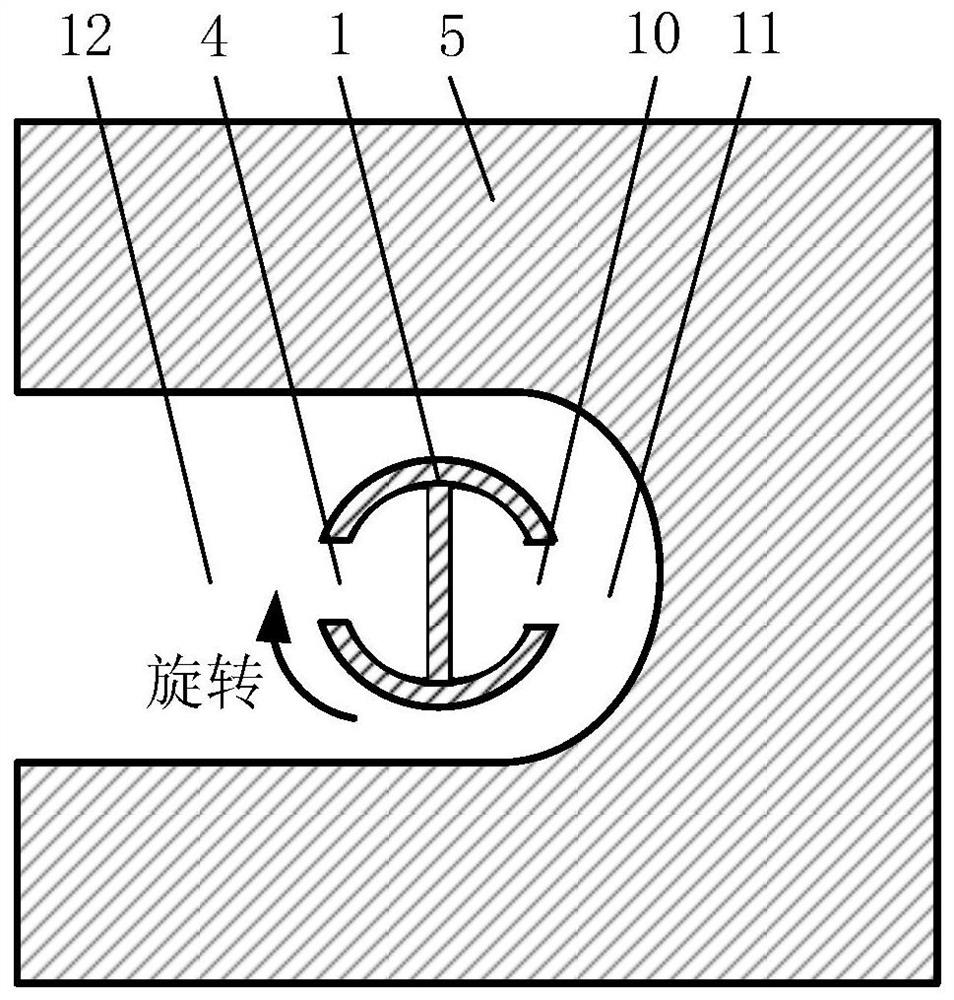

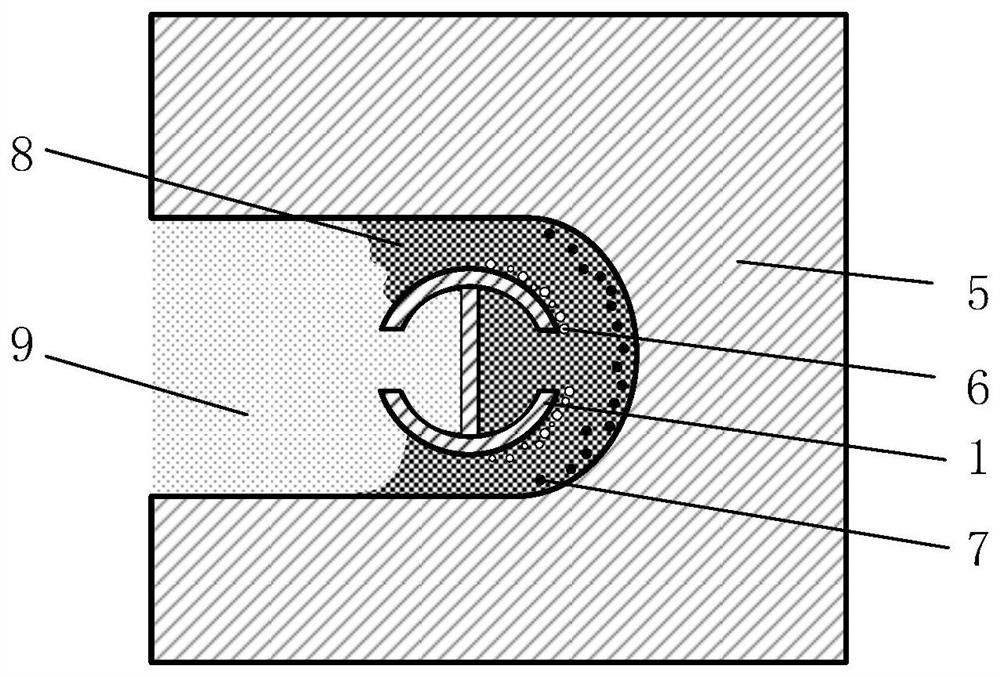

The invention relates to a micro-hole group electrolytic machining method and a bipolar electrode thereof, which adopts a bipolar electrode and belongs to the technical field of electrolytic machining. The invention is characterized in that the method includes the following steps: (a) manufacturing a bipolar electrode (1) provided with a through hole group structure and consists of an auxiliary anode (7), an insulated layer (6) and a tool cathode (5); (b) tightly binding the auxiliary anode (7) with a workpiece anode (2) on the bipolar electrode; (c) connecting the workpiece anode (2) and the tool cathode (5) with the anode and the cathode of the electrical source (3) respectively; (d) spraying electrolyte (4) on the surface of the tool cathode (5) in the way that the electrolyte runs through the through hole group of the bipolar electrode (1) to reach the surface of the workpiece anode (2); (e) connecting the electrical source (3) for electrolytic machining. The invention can significantly improve the localization and micro-scale processing capacity of electrolytic machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

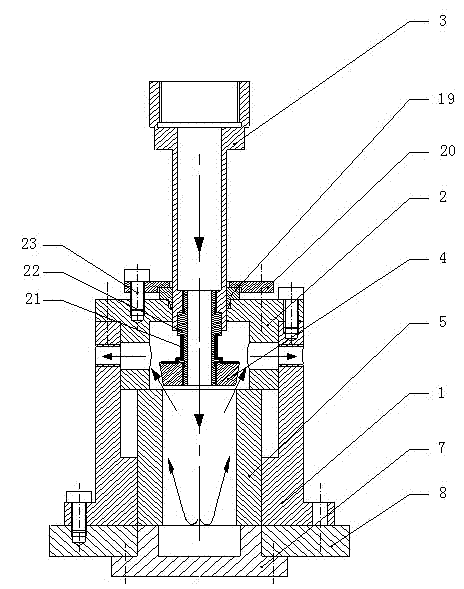

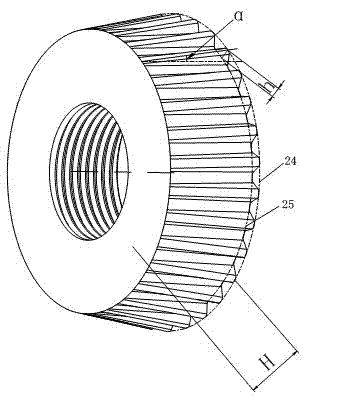

Electrolytic machining method of difficult-to-cut material, fine-module internal gear and device

InactiveCN102896383AIncrease feed rateImprove processing efficiencyMachining electrodesElectrical-based machining electrodesElectrolytic agentEngineering

The invention discloses an electrolytic machining method of a difficult-to-cut material, a fine-module internal gear and a device. The method comprises the following steps that a tool cathode with a top-bottom different shape structure is adopted; the surface of the small end of the tool cathode is circular, and a gap between the tool cathode and a work piece pre-hole is served as an initial machining gap which can ensure that a flow field is stable; the large end of the tool cathode is served as a cathode tooth; a part from the small end to the large end of the tool cathode is smoothly transited to a cathode tooth shape from a circular; a forward flow and backpressure electrolyte flowing mode is adopted; and electrolyte flows into a hollow channel of a cathode system, further an organic glass cavity with organic pieces is filled with the electrolyte, and then the electrolyte flows out off the gap between the tool cathode and the work piece. The tool cathode adopts a top-bottom different shape structure, can realize three-dimensional feeding, a pre-hole is arranged in a work piece blank, so that a feeding speed of the tool cathode is improved by 5 to 10 times relative to the feeding speed of an end surface during electrolytic machining, a machining process is stable, and the method is beneficial to improvement of machining efficiency and forming accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

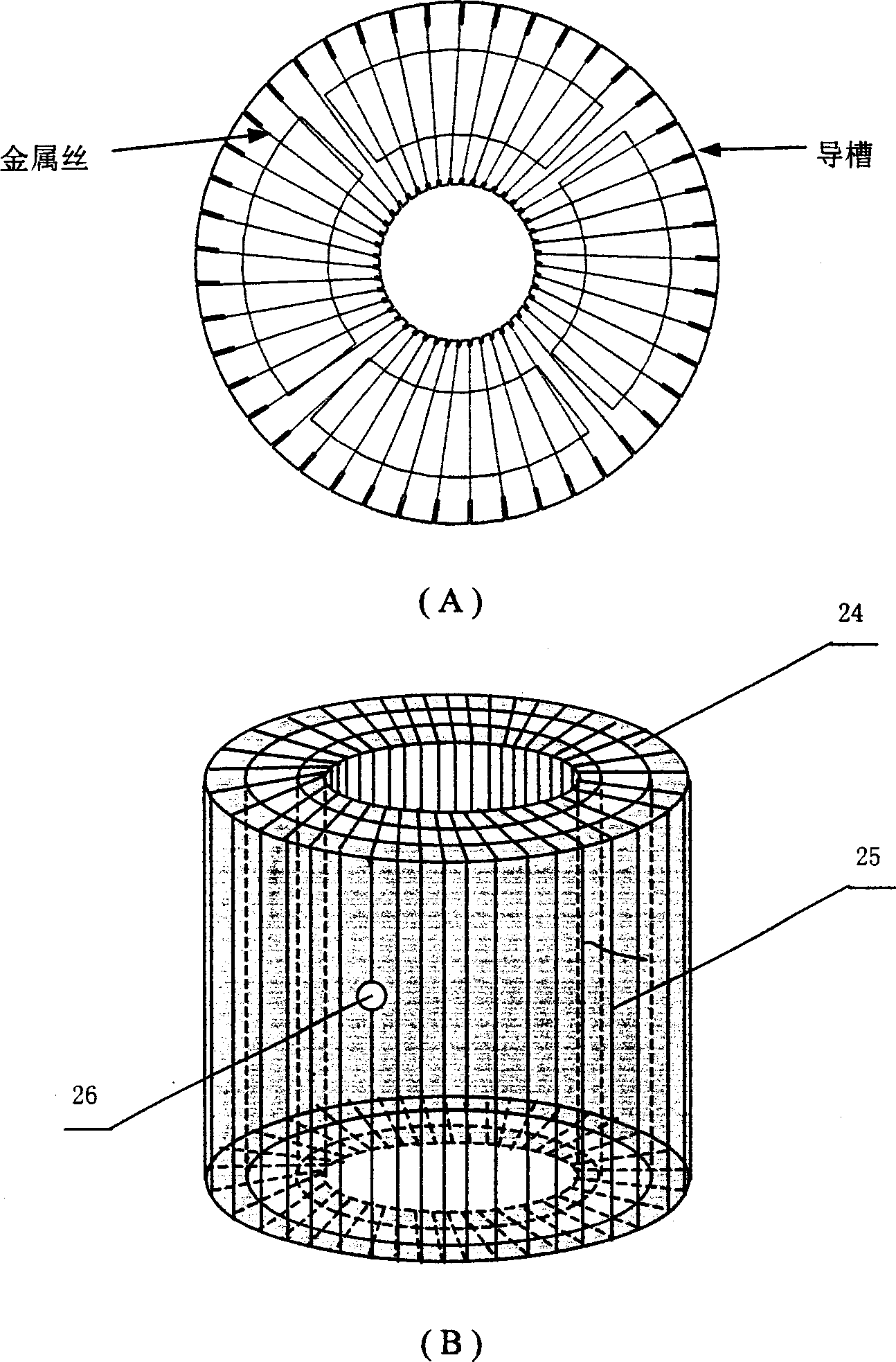

Technique for electrolysis processing fine slits and its devices

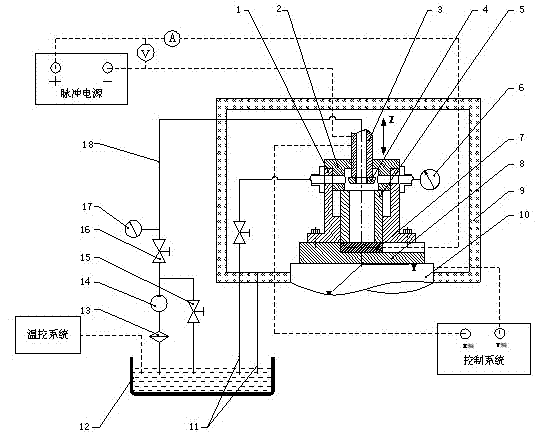

InactiveCN1445040AReduce manufacturing difficultyReduction of stray corrosionElectrical-based machining electrodesElectrochemical machining apparatusBall valveEngineering

An electrolysis technology for machining fine (0.2 mm) slit or seam features that the fine metal wire is wound on particular frame to form an electrode and the liquid is fastly flushed in the radial and axial directions of electrode wire to ensure high stability and uniformity of flow field. Its apparatus is composed of liquid tank, pump, filter, overflow valve, ball valve, working cavity, temp controller, heater, controller, power supply driver, and machining unit. Its advantage is high precision (+ / -0.02 mm).

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

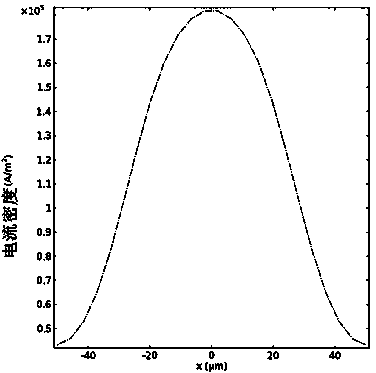

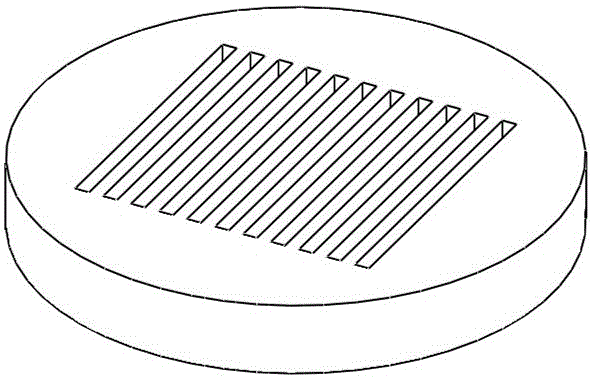

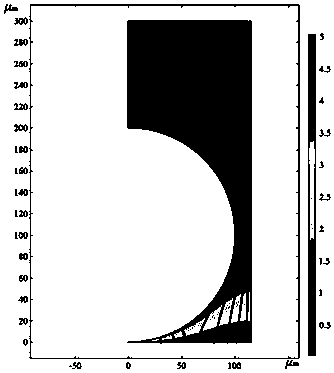

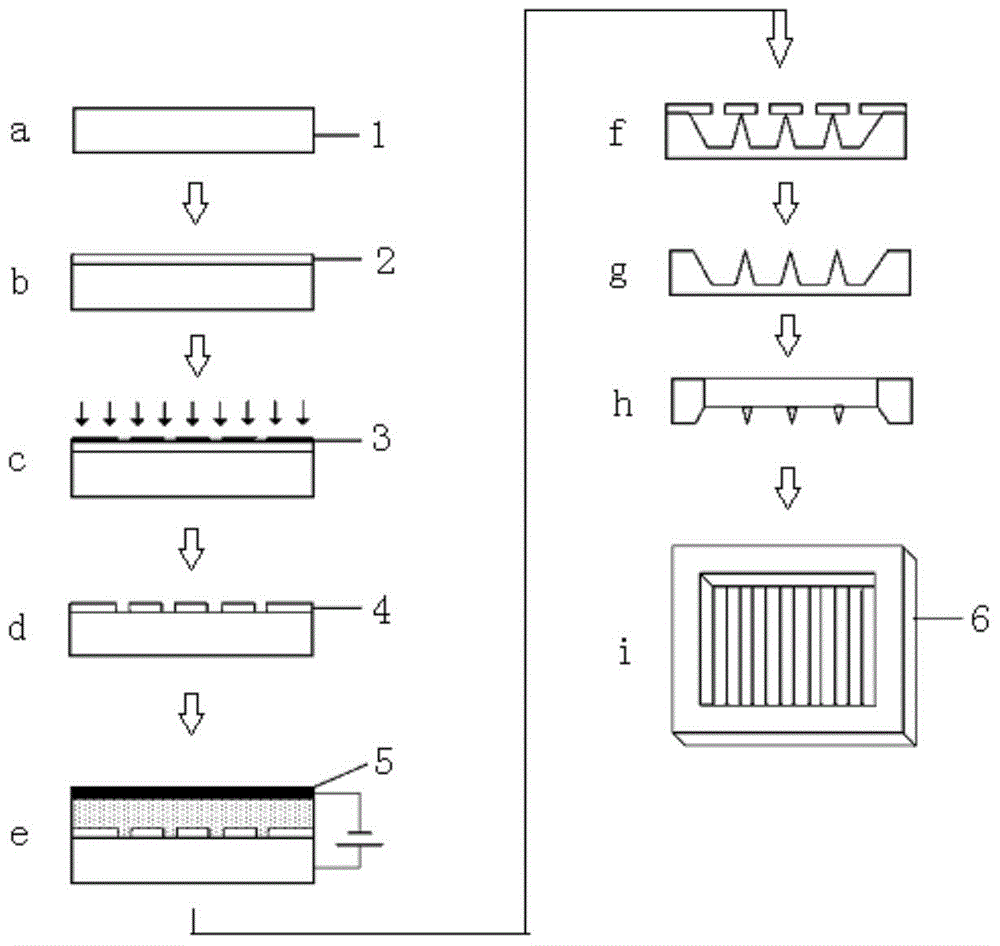

Wire electrode array structure preparation method for micro-electrochemical machining

ActiveCN103706899AEfficient preparationReduce the impactMachining electrodesElectrical-based machining electrodesElectrolysisElectrode array

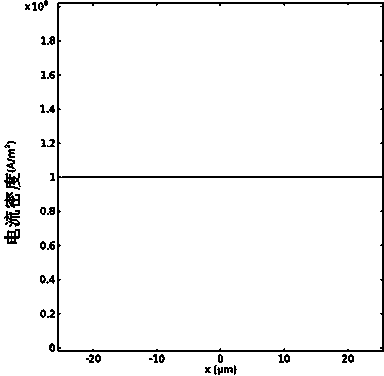

The invention discloses a wire electrode array structure preparation method for micro-electrochemical machining. The wire electrode array structure preparation method includes the steps of 1), pretreating a metal base; 2), manufacturing a graphical masking film; 3), subjecting the masking film to profound electrolytic corrosion, namely taking the metal base with the graphical surface as a positive electrode for electrolytic machining to obtain a tool negative electrode in a wire electrode template machined and manufactured in the profound electrolytic corrosion, and determining electrolytic corrosion time according to photoresist pattern width and electrolysis current density till to obtain a metal gate line array pattern with the point top; 4), removing back materials, namely removing the back materials corresponding to the manufactured metal gate lines to obtain a wire electrode array integrated with a frame. By means of the method, the metal microstructure array with cross sections different in shapes like square, rectangle and rhombus can be manufactured, so that the metal microstructure array with large depth-to-width ratio, high density and high machining quality can be efficiently realized.

Owner:江苏蔚之领域智能科技有限公司

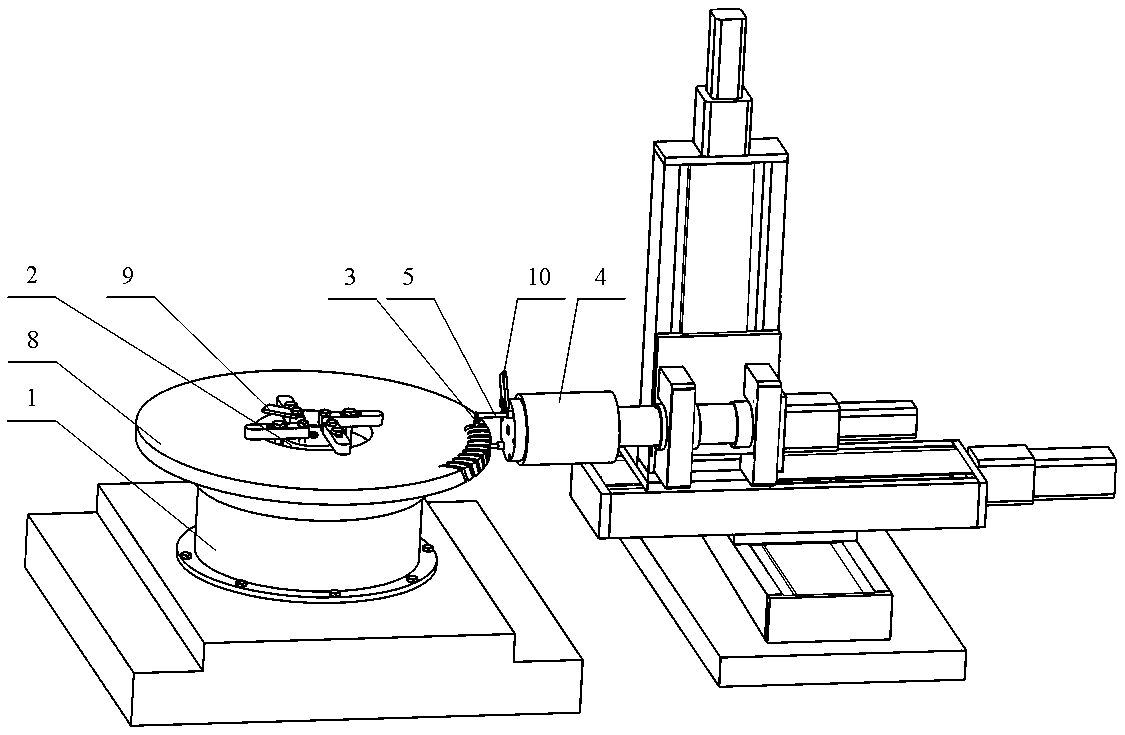

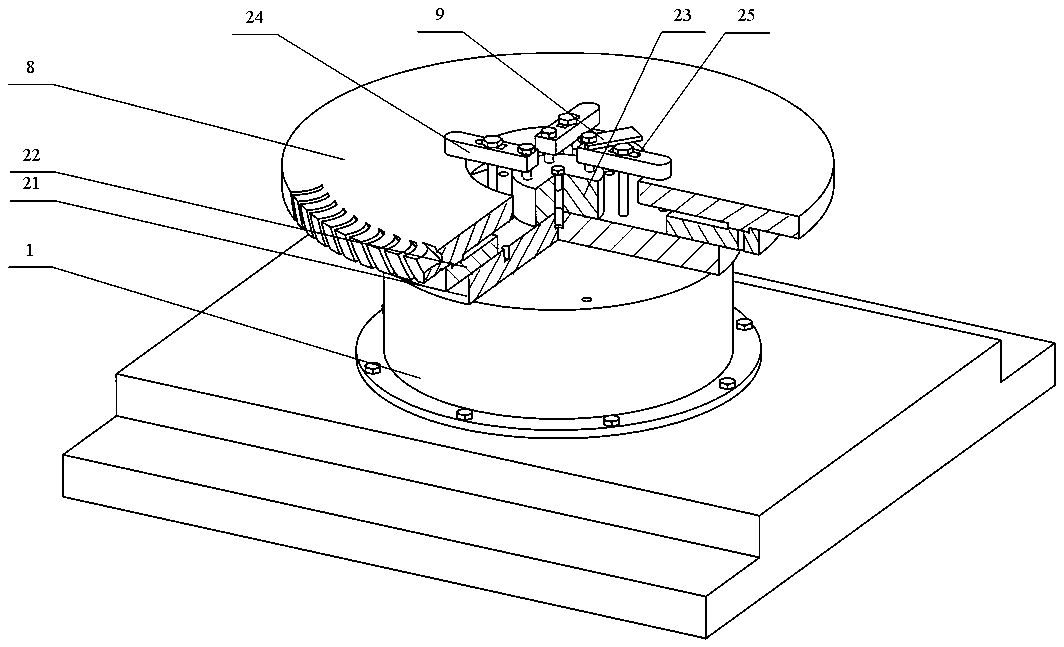

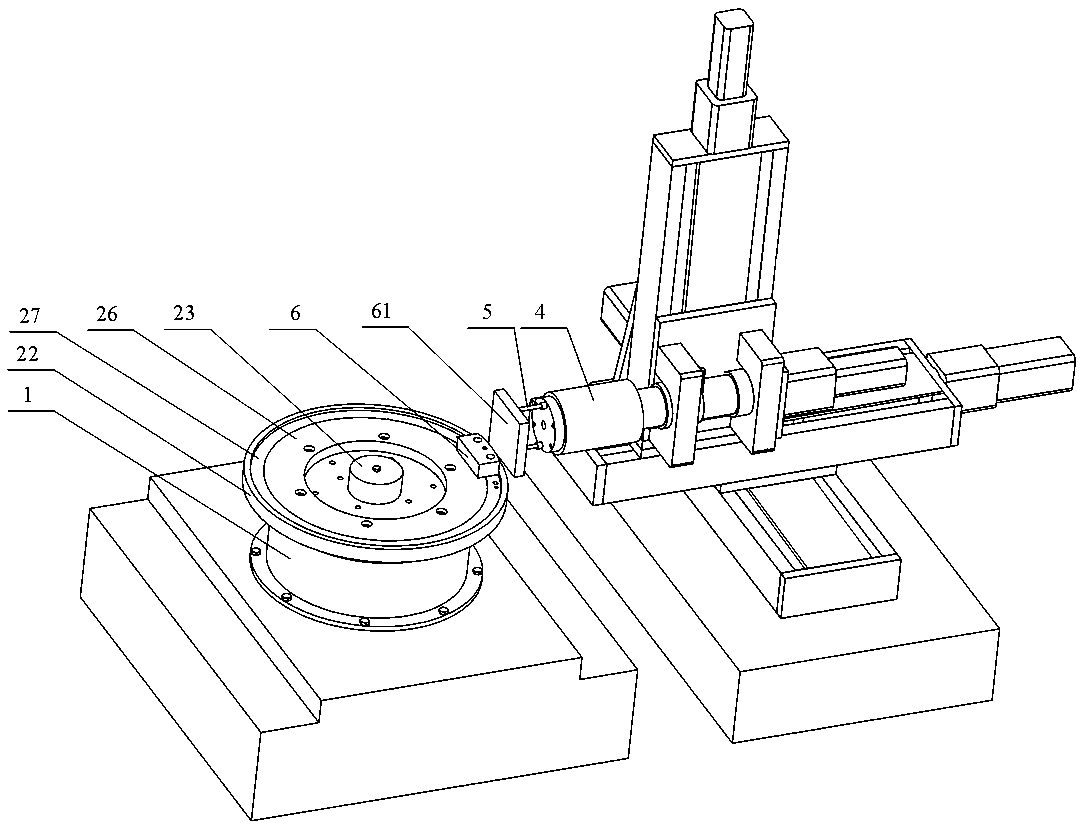

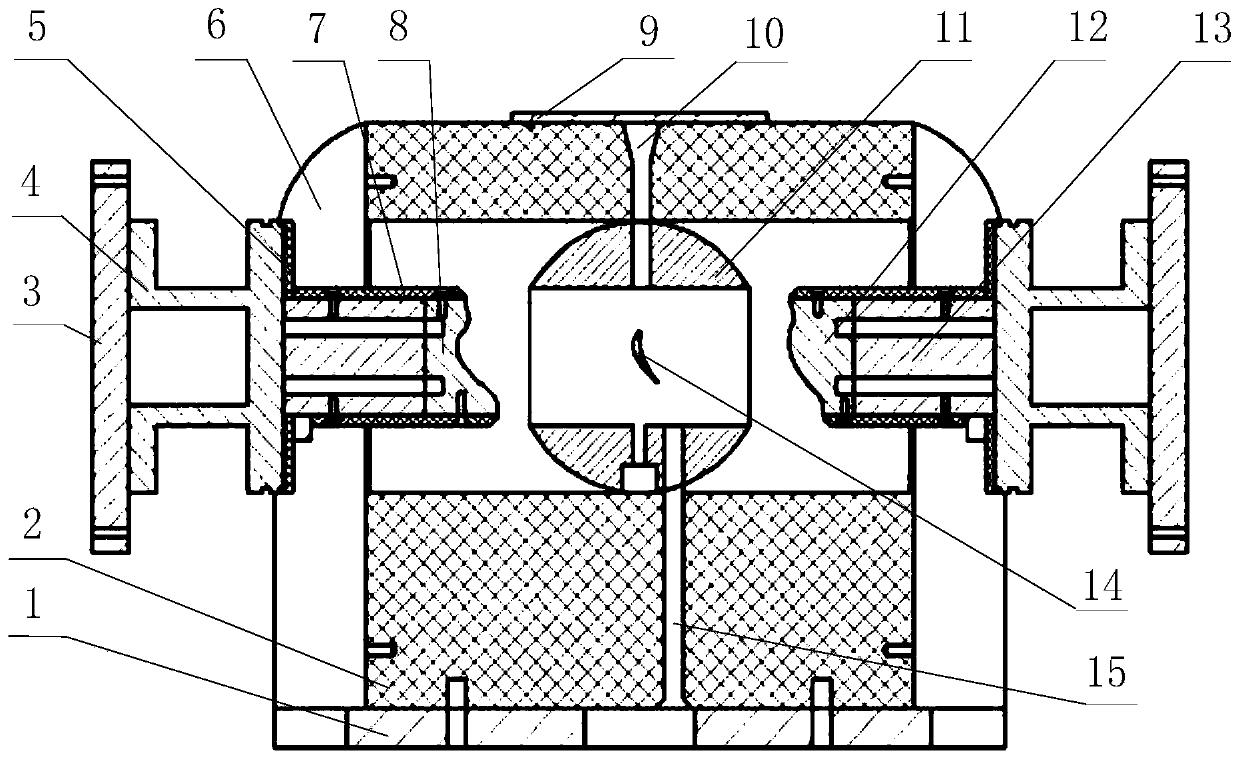

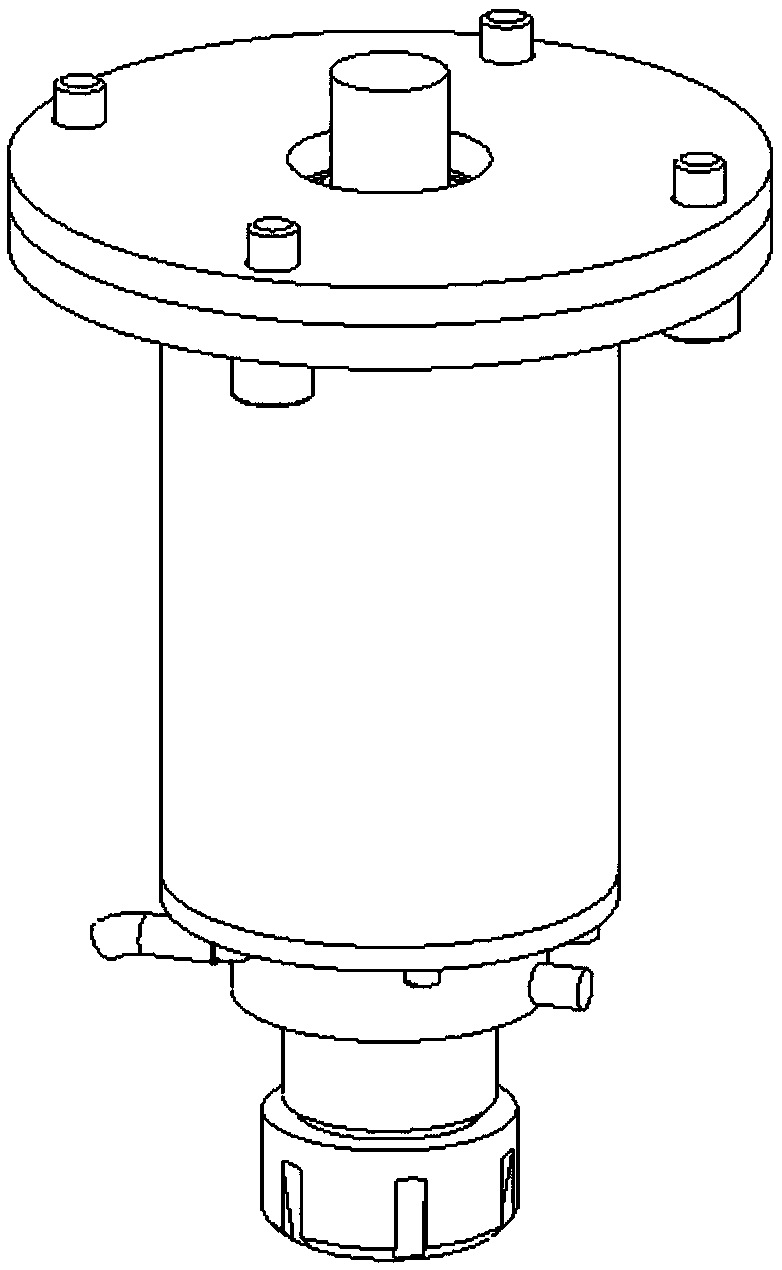

Blisk integrated electrolytic machining method and electrolysis tool

ActiveCN110935968AHigh precisionQuality improvementElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisEngineering

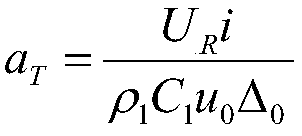

The invention discloses a tool for achieving integrated electrolysis machining of a complex profile blisk, a blade basin, a blade back and a hub by means of multi-axis linkage of a curved cathode, andrelates to the technical field of electrolytic machining. The tool comprises a rotary workbench, a workpiece clamp mounted on the rotary workbench, a cathode body located at workpiece grid channels,a feeding mechanism capable of performing multi-axis action, a connecting rod for connecting the curved cathode with a machining main shaft and a tool-setting block. The cathode body is of a hollow thin-wall structure, and the geometry of the cathode body is designed according to the grid channels and the hub profile. During machining, the rotary workbench drives a workpiece to do rotary action, the machining main shaft of the feeding mechanism drives the cathode body to move, rotate and the like to form multi-axis linkage, and a blisk workpiece with a complex twisted shape is obtained. The machining method has wide applicability, and the blisk workpiece with high dimensional precision and high surface quality for an aerospace engine can be obtained through one-time machining.

Owner:HEFEI UNIV OF TECH

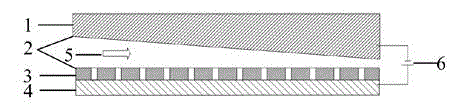

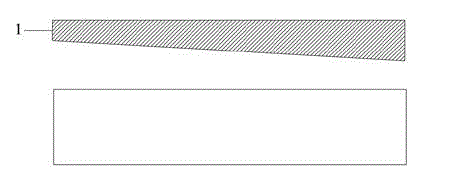

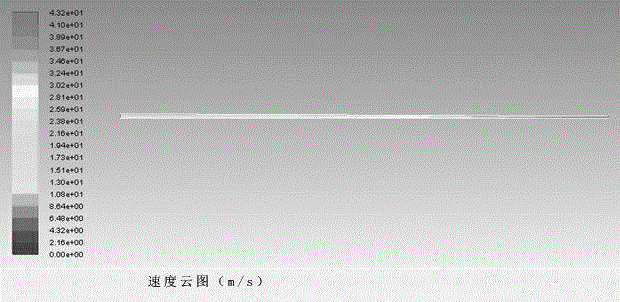

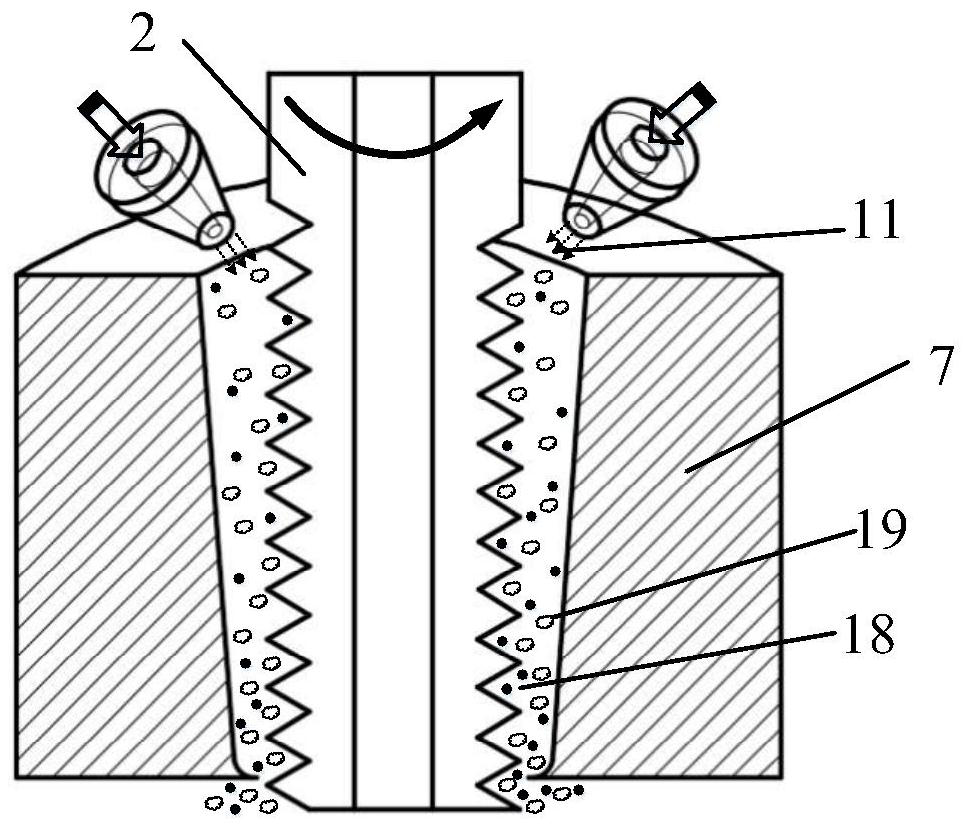

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144AImprove uniformity and machining accuracyHigh bonding strengthMachining electrodesElectrical-based machining electrodesElectric fieldCorrosion

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

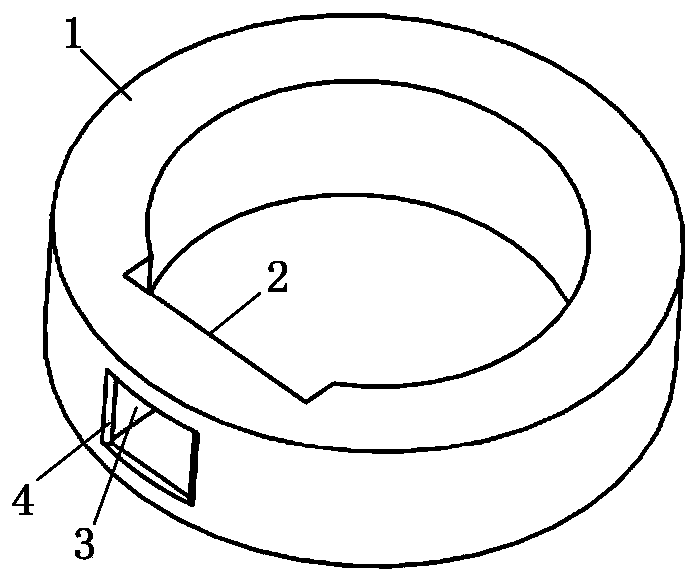

Micro-texture radial vibration auxiliary electrolytic machining method and device for inner wall of rotary body of thin-wall part

PendingCN110102846ASimple structureShort preparation cycleElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisEngineering

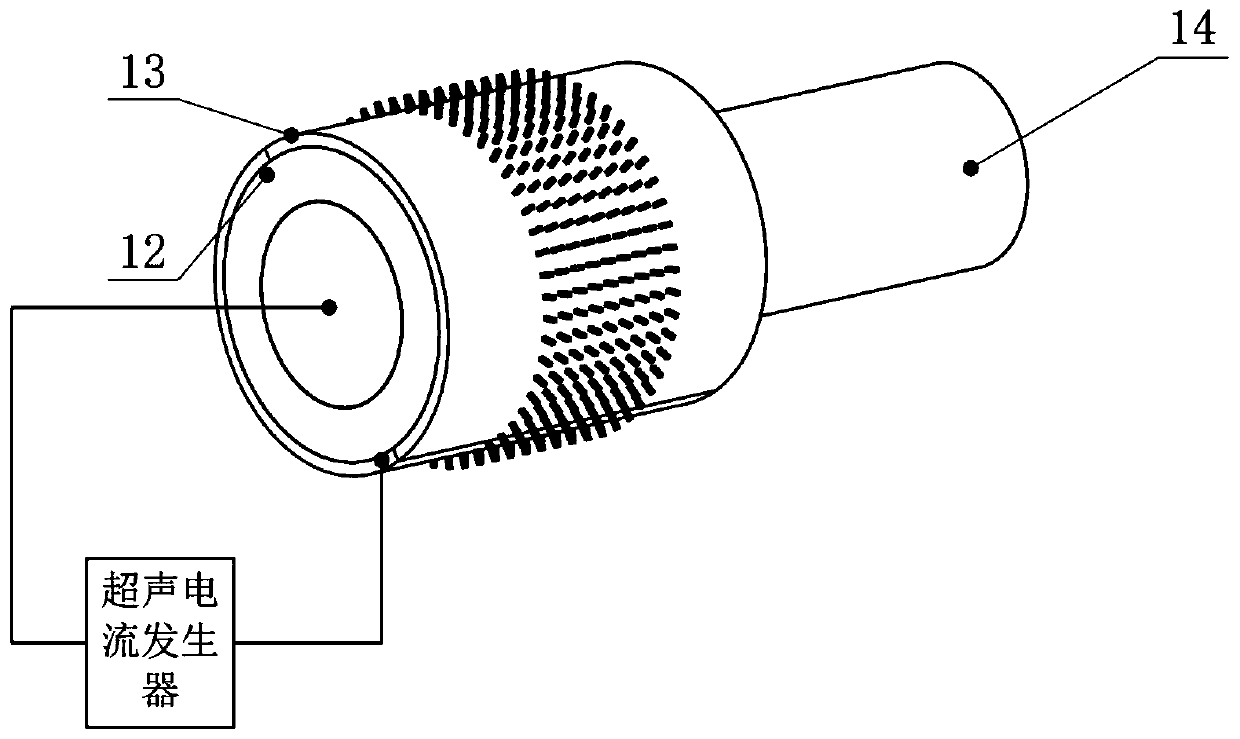

The invention relates to a micro-texture radial vibration auxiliary electrolytic machining method for the inner wall of a rotary body of a thin-wall part. The method is characterized in that a tool cathode with a micro-boss texture on the surface and capable of doing radial vibration is connected with a negative electrode of the power supply, the tool cathode is connected with an ultrasonic current generator, a thin-wall rotary body workpiece is connected with a positive electrode of the power supply, and the columnar electrode on the tool cathode is arranged in a linear array mode; an electrolyte enters a reaction area between the tool cathode and the workpiece through a liquid supply pipe; a machine tool spindle drives the tool cathode to horizontally move in the peripheral direction according to a preset trajectory, a certain machining gap is reserved between the workpiece and the columnar electrodes on the tool cathode, the machine tool spindle drives the tool cathode to do autorotation motion, and the tool cathode connected with the ultrasonic current generator is used for constructing an ultrasonic energy field; the electrolyte flowing out at a high speed is sprayed onto theworkpiece to obtain the required machining morphology. The invention further provides an micro-texture radial vibration auxiliary electrolytic machining device for the inner wall of the rotary body ofthe thin-wall part. According to the method and the device, the centering property, the stability, the precision and the efficiency for machining the micro-texture of the inner wall of the rotary body are improved.

Owner:ZHEJIANG UNIV OF TECH

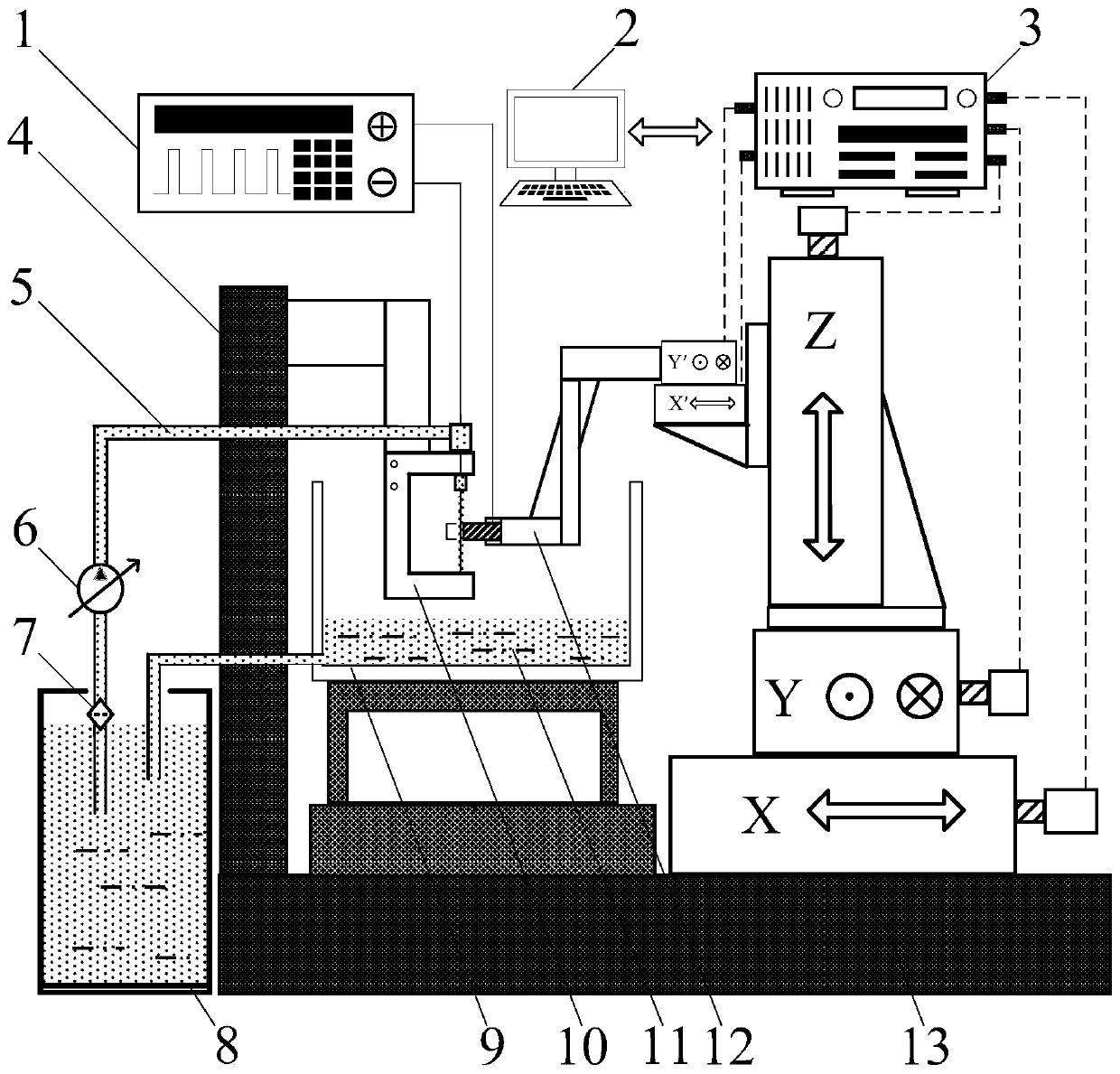

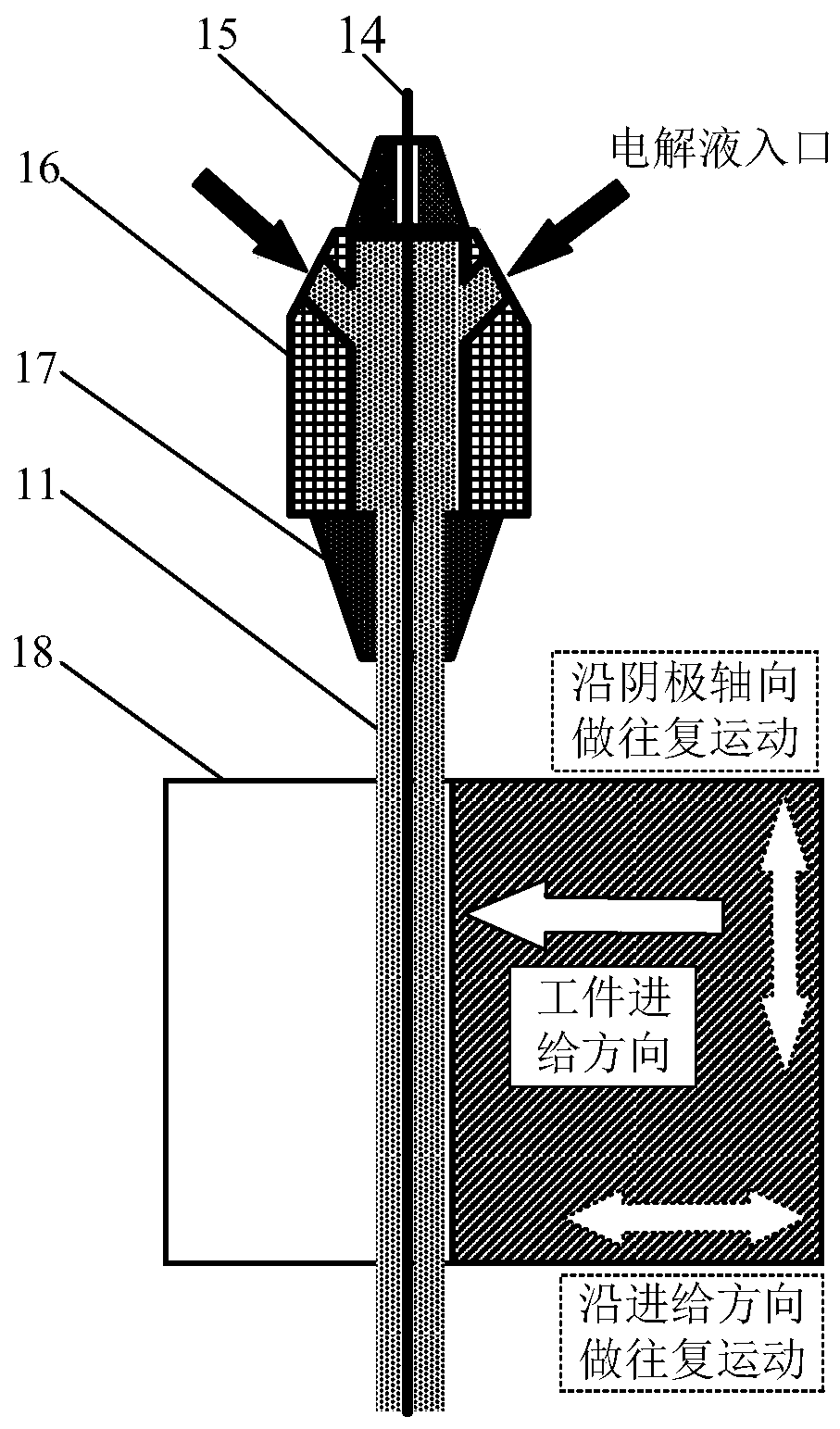

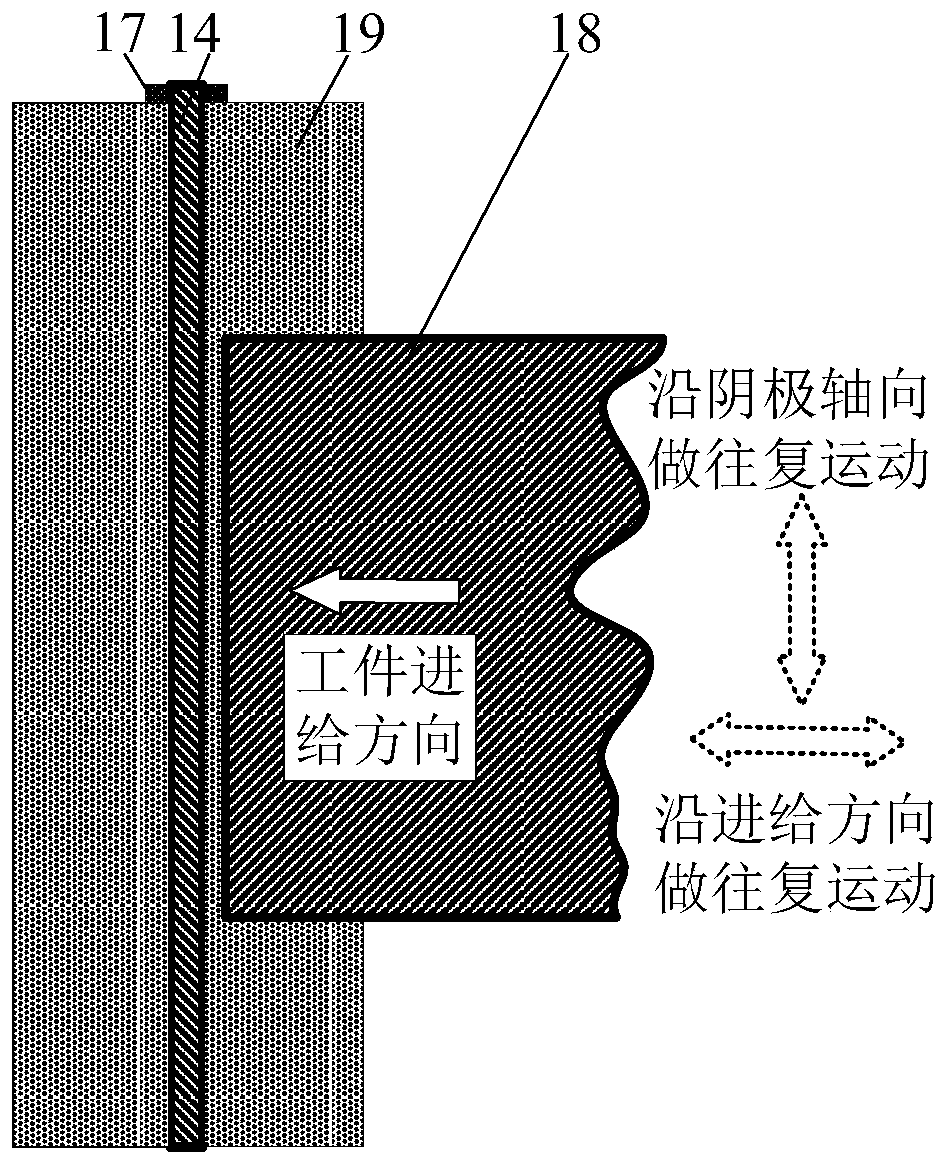

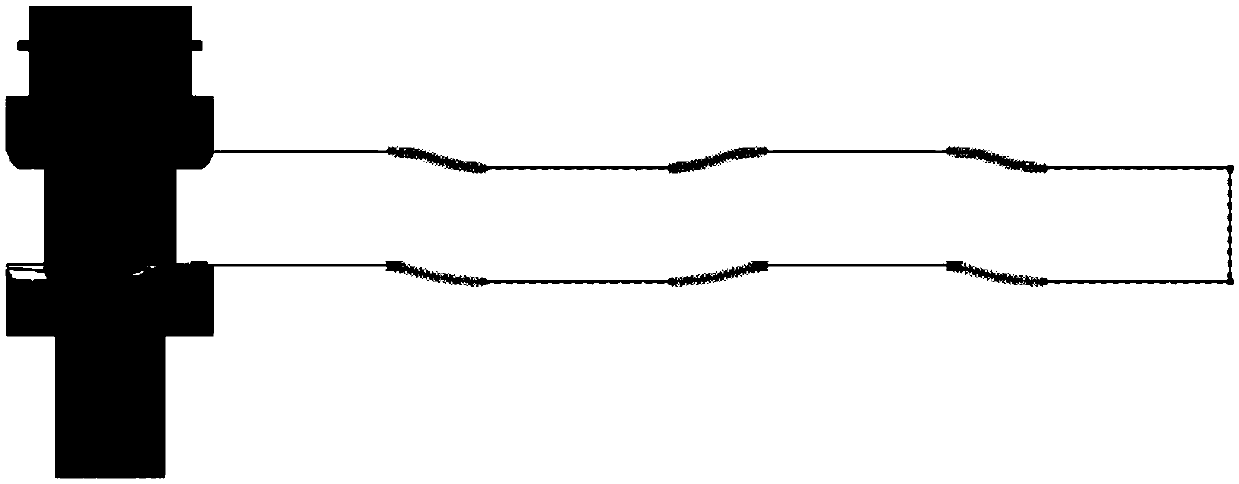

Machining method and device for axial purge electrolytic wire cutting assisted by workpiece reciprocating motion

The invention relates to a machining method and device for axial purge electrolytic wire cutting assisted by workpiece reciprocating motion, and belongs to the technical field of electrochemical machining. The machining method and device for the axial purge electrolytic wire cutting assisted by the workpiece reciprocating motion is mainly characterized in that a workpiece with large thickness is cut and machined by adopting the axial purge electrolytic wire, and cutting motion is conducted on wire electrode by a workpiece while the reciprocating motion is conducted on the workpiece by the workpiece along the feeding direction and the wire electrode axis direction. The method of the workpiece reciprocating motion is adopted to change the distance between the workpiece and the wire electrode, and the distance between the workpiece and a nozzle, fast flowing of an electrolytic solution in a long and narrow feeding end surface machining clearance is facilitated, renewal of the electrolyticsolution and removal of electrolysate are accelerated, the difference of the electrolytic solution flow velocity is shortened, and the machining efficiency and machining accuracy of electrolytic cutting are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electromachining method for preventing electrochemical dispersion corrosion

InactiveCN105033371AReduce movementReduction of stray corrosionElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisPower flow

The invention relates to an electromachining method for preventing electrochemical dispersion corrosion. The method includes the following steps that firstly, a tool electrode is fixed to a machine tool spindle, a workpiece is fixed into an electrolytic tank of a machine tool workbench, the tool electrode and the workpiece are connected with the negative electrode and the positive electrode of a power source respectively for forming a circuit, a current sensor is arranged in the circuit, and collected current values are sent to a controller by the current sensor in real time; secondly, the tool electrode reaches an initial position; thirdly, the tool electrode continues to move to the workpiece, and switch of the power source is controlled by the controller so that an alternating-current auxiliary power source with the positive electrode and the negative electrode symmetrical can be applied between the tool electrode and the workpiece; fourthly, the pulse width and the frequency of the alternating-current auxiliary power source are adjusted so that ions and electrons between the tool electrode and the workpiece can move back and forth along the initial position; fifthly, as the tool electrode gets close to the workpiece gradually, the current value is gradually increased, and when the current value does not change, the gap between the tool electrode and the workpiece is a balance gap; and sixthly, the controller controls the power source to be switched to an electrolysis machining main power source so that the workpiece can be machined.

Owner:TSINGHUA UNIV

Revolving body surface high boss electrolytic machining tool electrode assembly and electrolytic machining method

ActiveCN110605444AAvoid electric field concentrationReduction of stray corrosionMachining electrodesMachining working media supply/regenerationElectrolysisEngineering

The invention provides a revolving body surface high boss electrolytic machining tool electrode assembly and an electrolytic machining method, and belongs to the technical field of electrolytic machining. The method is characterized in that the tool electrode assembly comprises a tool cathode, a first insulating cavity and a second insulating cavity; and the tool cathode is of a revolving body structure, the surface of the tool cathode is provided with a hollowed-out groove structure, and an opening of the groove structure is of a protruding guide circle structure; the outer side of the firstinsulating cavity is fixedly attached to the inner wall of the protruding guide circular structure, the side wall of the groove structure and the inner side plane of the tool cathode, and the other end of the first insulating cavity is of a tubular structure; the outer side corner of the second insulating cavity is in an arc transition, and the second insulating cavity is fixed in the first insulating cavity through a bottom mounting seat and forms an electrolyte flow channel with the first insulating cavity. According to the method, the electrolyte flowing from the side surface through a first electrolyte inlet can provide a stable flow field for the processing region at the revolving surface, and the electrolyte flowing from the inner side of the groove structure through a second electrolyte inlet can ensure the uniformity of the flow field of the machining region at the side wall of the boss, so that the electrolytic machining stability of the high boss on the surface of the revolving body is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

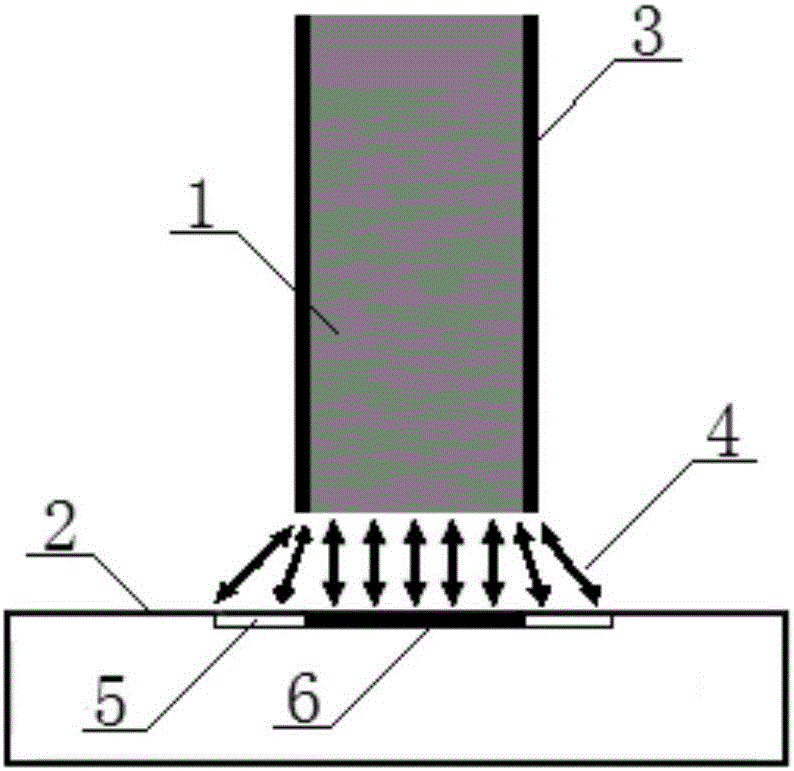

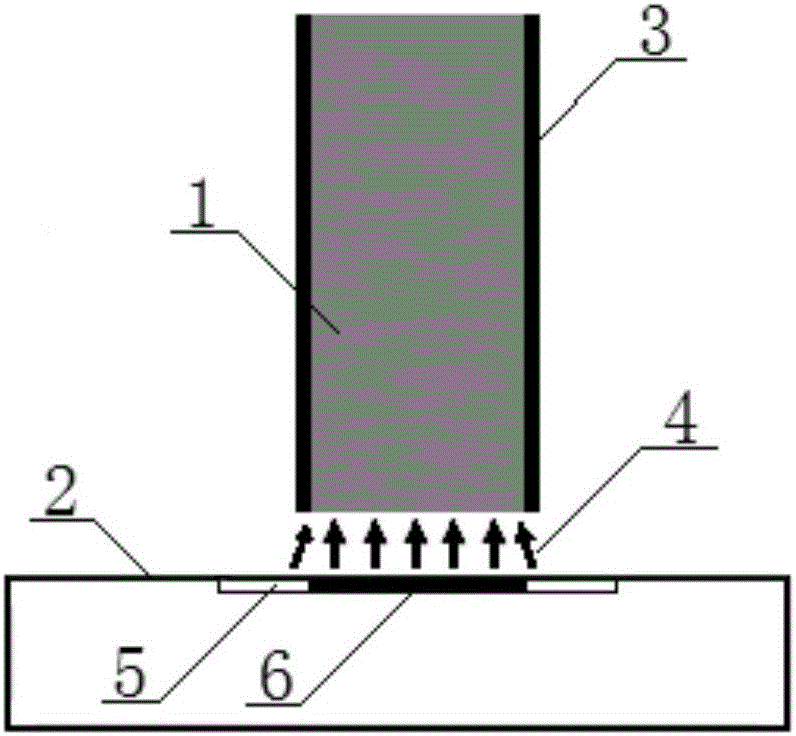

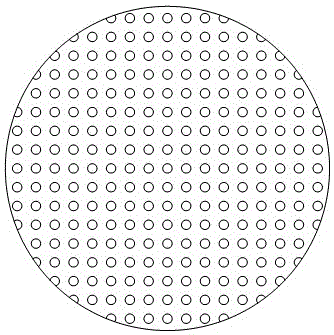

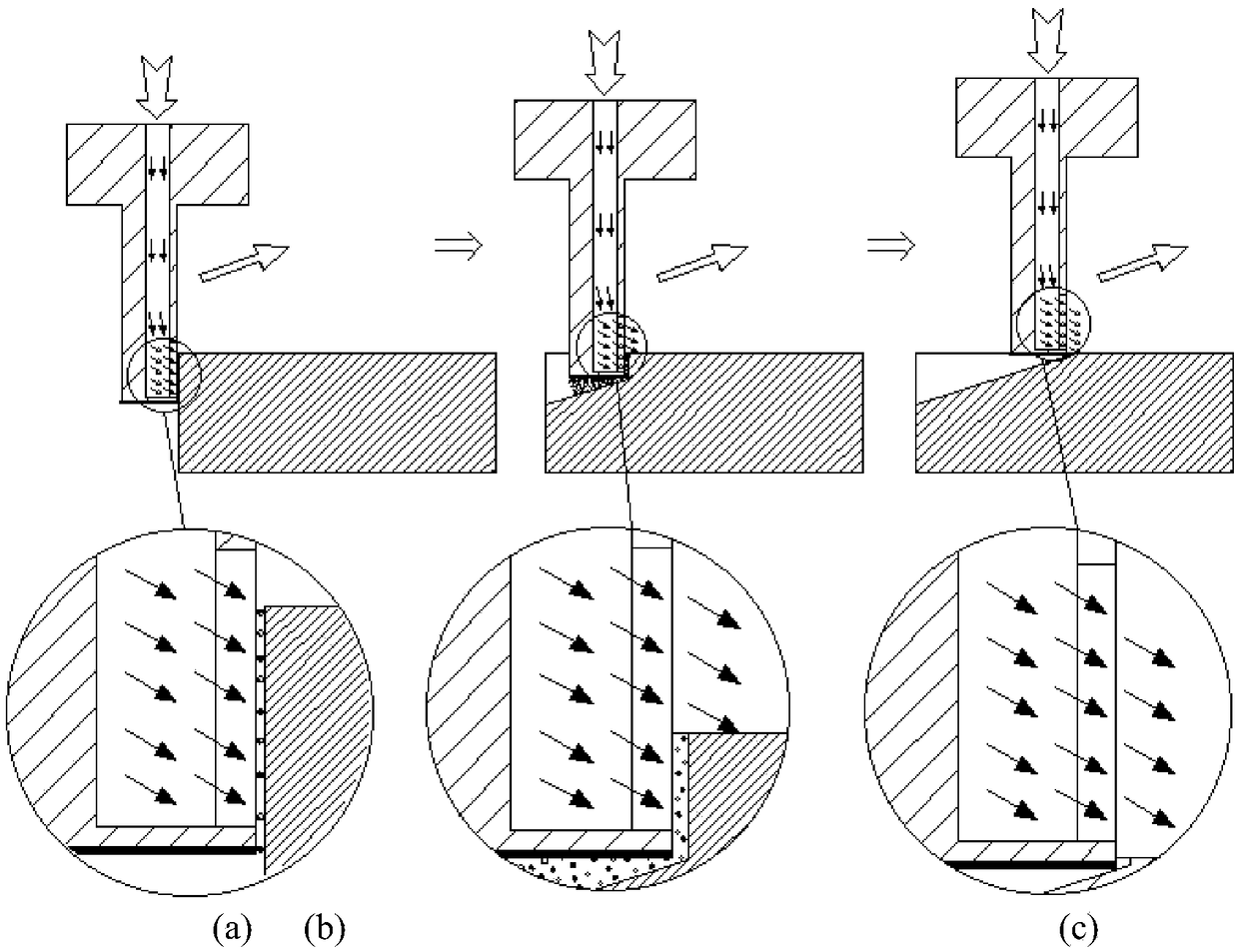

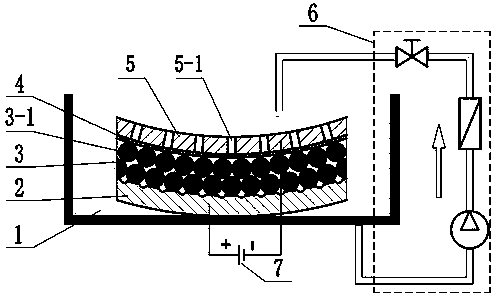

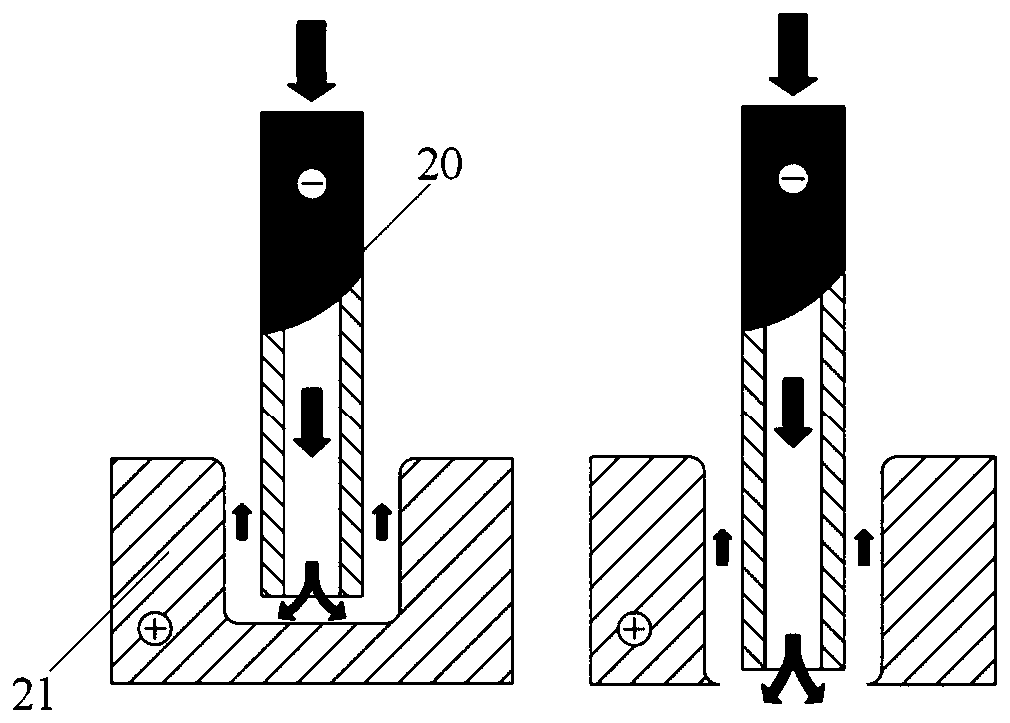

Slave type array micro pit electrolytic machining method

ActiveCN104014879AFast removalIncrease the electric field strengthElectrochemical machining apparatusElectrolysisCold cathode

The invention provides a slave type array micro pit electrolytic machining method, and belongs to the technical field of electrolytic machining. The method includes the steps that a tool cathode is manufactured and composed of a metal tool and a mask plate provided with a through hole group structure, a workpiece anode and the tool cathode are connected with the positive pole and the negative pole of a power supply respectively, the workpiece anode is immersed in electrolyte, the surface of the tool cathode and the surface of the workpiece anode are tightly attached, and electrolytic machining is carried out after the power supply is turned on; after primary electrolytic machining, the power supply is cut off, the tool cathode is lifted, the electrolyte on the surface of the workpiece anode is replaced, then the surface of the tool cathode and the surface of the workpiece anode are tightly attached, and the power supply is turned on for electrolytic machining. The tool cathode is lifted and falls periodically, and electrolytic machining is carried out. Due to the fact that the tool cathode and the workpiece anode are tightly attached, generated bubbles are accumulated on the side wall of a micro pit, stray corrosion around a machining area can be effectively reduced, and locality of electrolytic machining and micro machining are remarkably improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electrolytic machining cathode device for freezing protection sleeve material and processing method

ActiveCN109909565AReduce taperReduce ion concentrationMachining electrodesElectrical-based machining electrodesElectrolysisMachine parts

The invention provides an electrolytic machining cathode device for freezing protection sleeve material and a processing method, and belongs to the technical field of electrolytic machining. The cathode device is mainly composed of a cathode head, a cathode block, a freezing block and a coolant bag body. In the sleeve material electrolytic machining method, the coolant bag body surrounds the periphery of a protection cavity in the middle of the freezing block, the machined part of the workpiece gradually extends into the protection cavity in the middle of the freezing block, a coolant is fed from the inlet end of the coolant bag body and flows out from the outlet end of the freezing block, and the stray electrolyte in the middle protection cavity of the freezing block is frozen. Accordingto the electrolytic machining cathode device, stray corrosion caused by stray electrolyte on the machined surface of the workpiece is reduced, the taper of the workpiece is reduced, and the surface quality of the workpiece is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

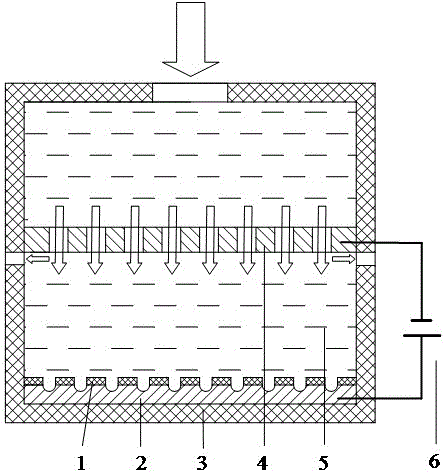

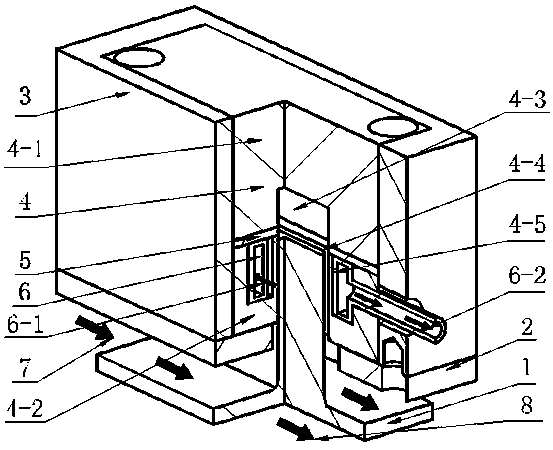

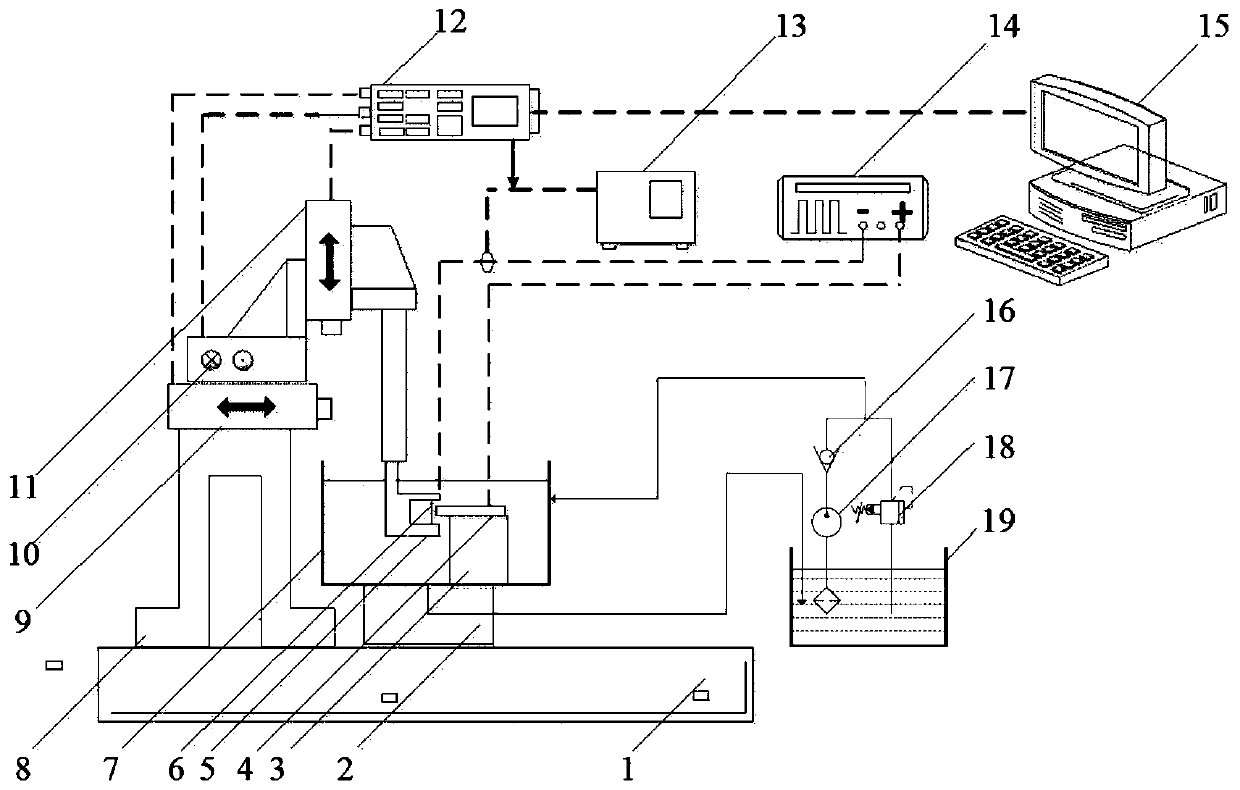

System and method applied to high-accuracy electrolytic machining of large-area micro-pit arrays

ActiveCN106001806AUniform seam structureEasy to manufactureMachining working media supply/regenerationElectricityElectrolysis

The invention relates to a system and a method applied to high-accuracy electrolytic machining of large-area micro-pit arrays and belongs to the field of micro electrolytic machining. The method comprises the following steps: manufacturing a cathode tool and a clamp and forming liquid outlets in the lower surface of the cathode tool, wherein the total section area ratio of a liquid inlet and the liquid outlets is 50 to 200; attaching a flexible template onto an anode workpiece, clamping the cathode tool and the anode workpiece, wherein the distance between the cathode tool and the flexible template is 10mm to 50mm; and connecting the anode workpiece and the cathode tool to a positive electrode and a negative electrode of a power supply respectively, filling electrolyte, then switching on the power supply and carrying out electrolytic machining. When the method is applied to electrolytic machining, the flexible template is closely attached onto the surface of the workpiece due to pressure and gravity of the electrolyte; meanwhile, electrolytic products in micro pits slowly flow away from a machining area; the conductivity in machining clearance is reduced; the sensitivity of the machining size to the electrical parameter is reduced; and the influence of electric field marginal effect on the machining size of the large-area micro-pit arrays is suppressed. The method is capable of effectively improving the machining accuracy of the large-area micro-pit arrays.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

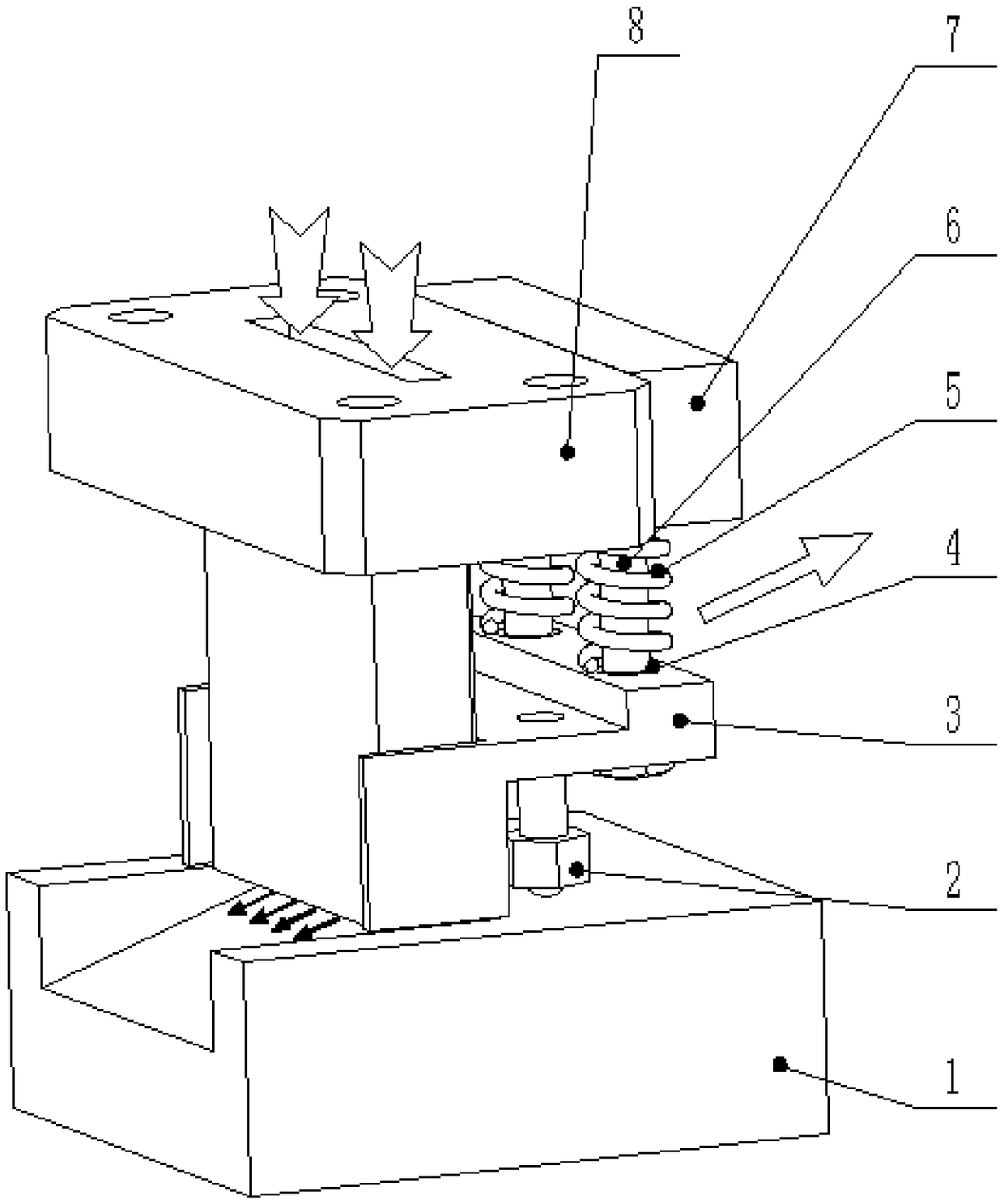

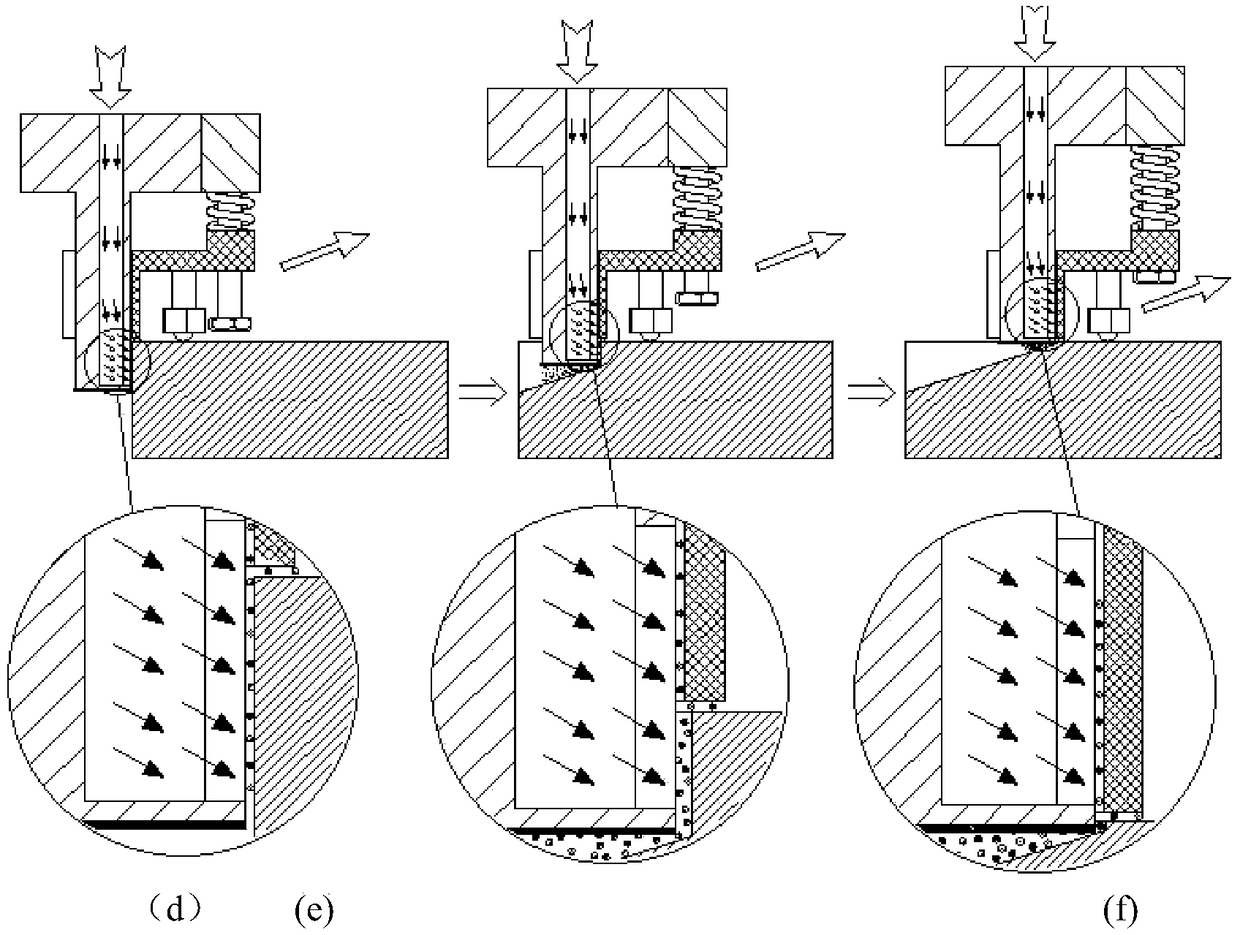

Device and method for processing inclined surface through follow-up sealing liquid cutting-in type electrolytic milling machining

ActiveCN109226913AGuaranteed flowReal-time change the size of the cross-sectional area of the waterElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisEngineering

The invention relates to a device and method for processing an inclined surface through follow-up sealing liquid cutting-in type electrolytic milling machining, and belongs to the field of electrolytic processing technology. The device mainly comprises a tool cathode, an upper supporting plate, guide rods, a spring, a linear bearing, a universal ball and a water blocking block. The upper supporting plate is fixed on the front of the tool cathode; the two guide rods are fastened on the upper supporting plate through threads; the guide rods are sequentially sleeved with the spring and the waterblocking block, the water blocking block can slide up and down along the axis direction of the guide rod through the linear bearing, the universal ball is arranged below the water blocking block and is contact with a work piece in real time, and the universal ball is pressed on a surface of the work piece under the action of the spring compression elasticity. When the tool cathode processes the inclined surface by using a cutting-in type electrolytic machining method, the follow-up sealing liquid device can float up and down according to the up-and-down movement of the tool cathode, so as to change the cross-sectional area, out of water, of the tool cathode, the spraying of the electrolyte liquid from a liquid outlet to a processing area is limited in real time, and the processing precision, the stability and the efficiency are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for making holes through electric spark-electrolysis combination via matching of thread pipe electrode with inner and outer liquid flushing

The invention provides a method for making holes through electric spark-electrolysis combination via matching of thread pipe electrode with inner and outer liquid flushing. At the electric spark high-speed hole making machining stage, an electric spark pulse power source is connected, the inner liquid flushing manner is adopted for leading in of deionized water, in cooperation with rotation of thethread pipe electrode, meanwhile, downward feeding is carried out, when the interpolar distance is up to the electric spark discharge gap, a pulse electric spark is generated, a workpiece material issubjected to corrosion removing, through thread rotation disturbance and upward action force of a thread groove on electric corrosion solid small particles, the electric corrosion solid small particles can be rapidly and upwards discharged, when a workpiece is subjected to breakdown, the electrode station is kept unchangeable, an electrolysis power source is connected, outer liquid flushing is replaced, an outer nozzle is aligned with the gap to spray an electrolyte, in cooperation with reverse rotation of the thread pipe electrode, the thread groove can contain more electrolyte to enter thenarrow and small gap, the workpiece has the anodic dissolution reaction, electrolytic flocs can be rapidly and downwards discharged under extrusion of the thread groove, micro hole manufacturing highprecision and high efficiency can be ensured, and the hole wall non-micro-crack and non-recast-layer machining needs can be achieved.

Owner:NANJING UNIV OF TECH

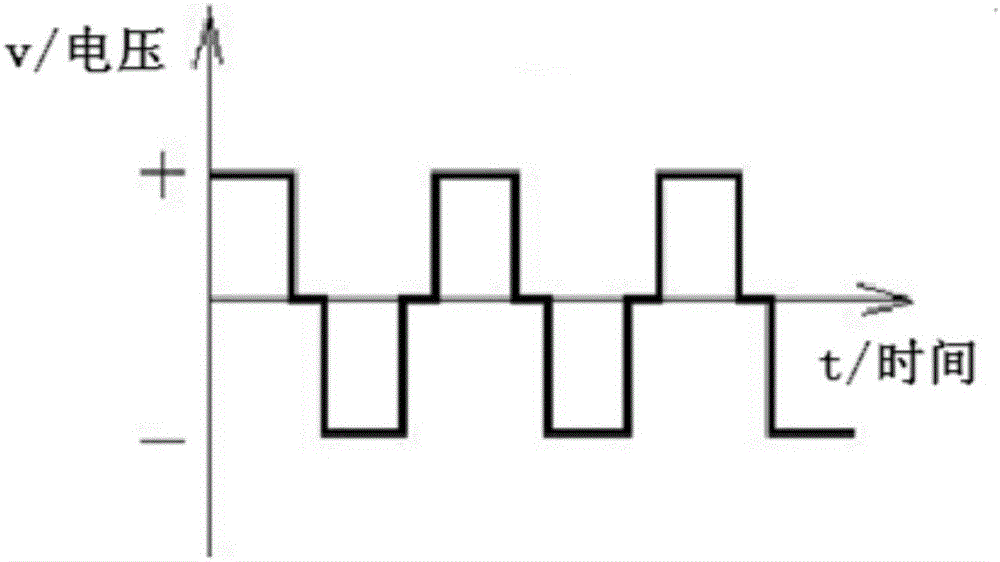

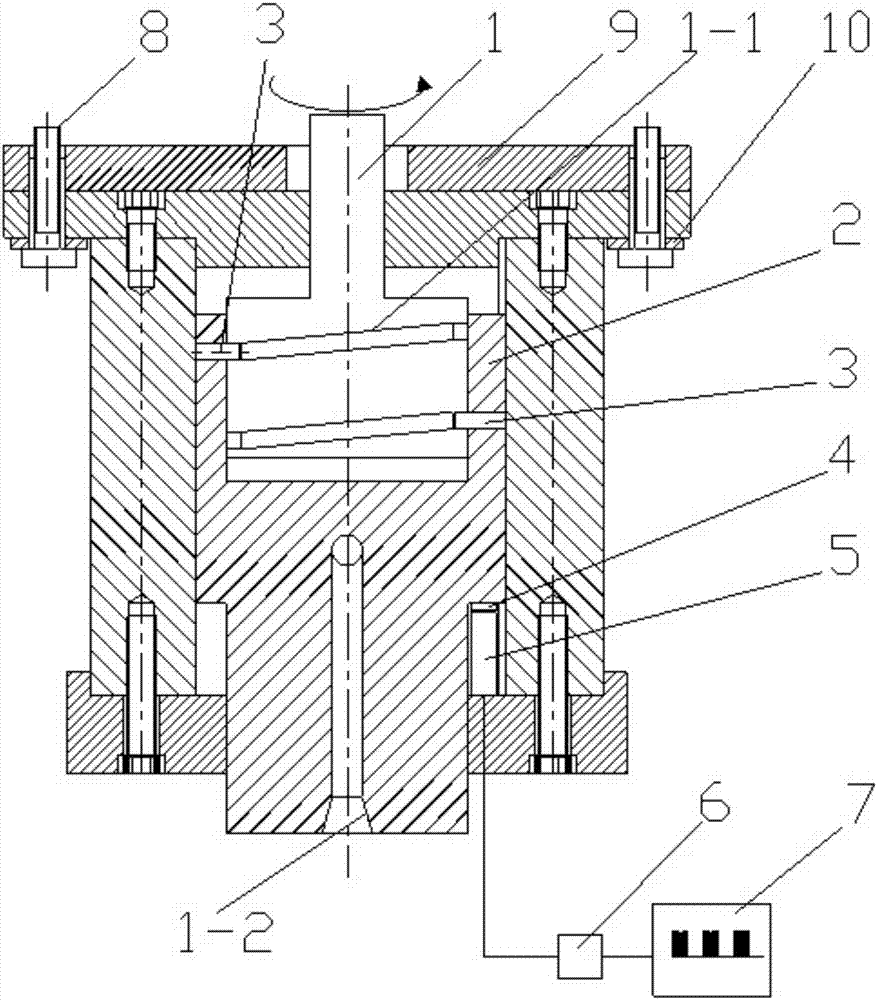

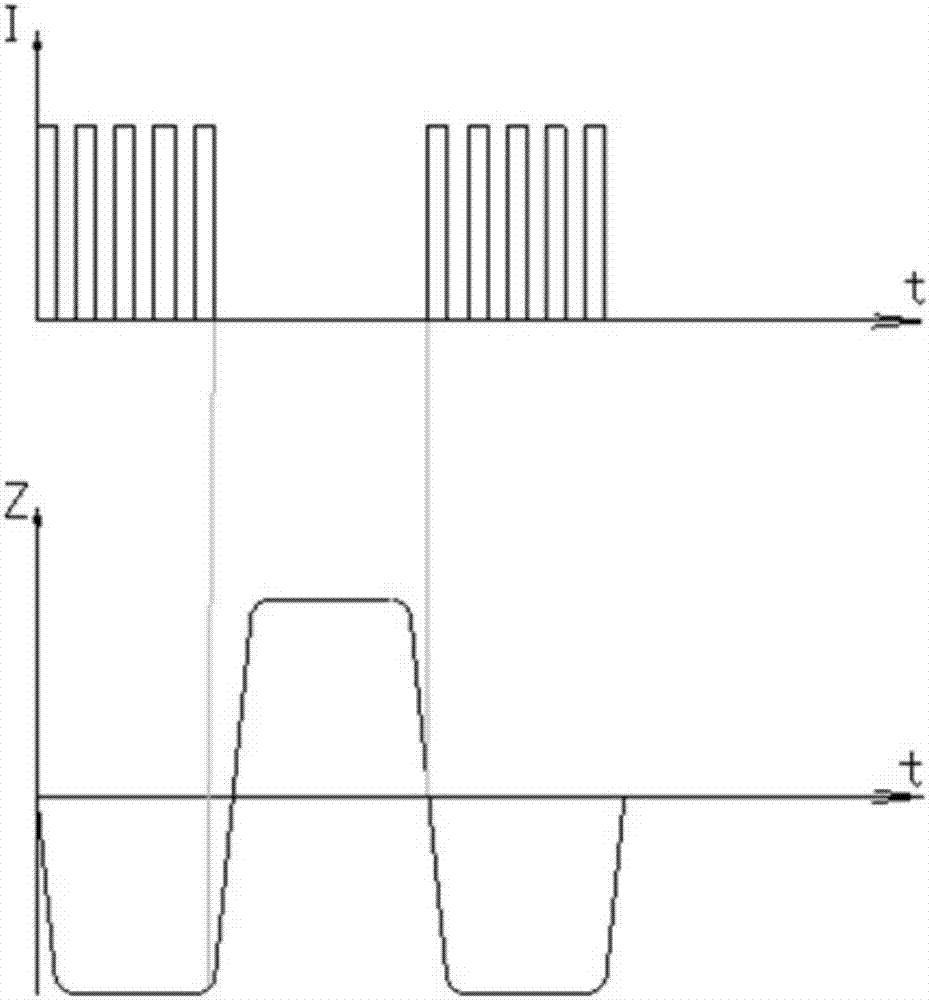

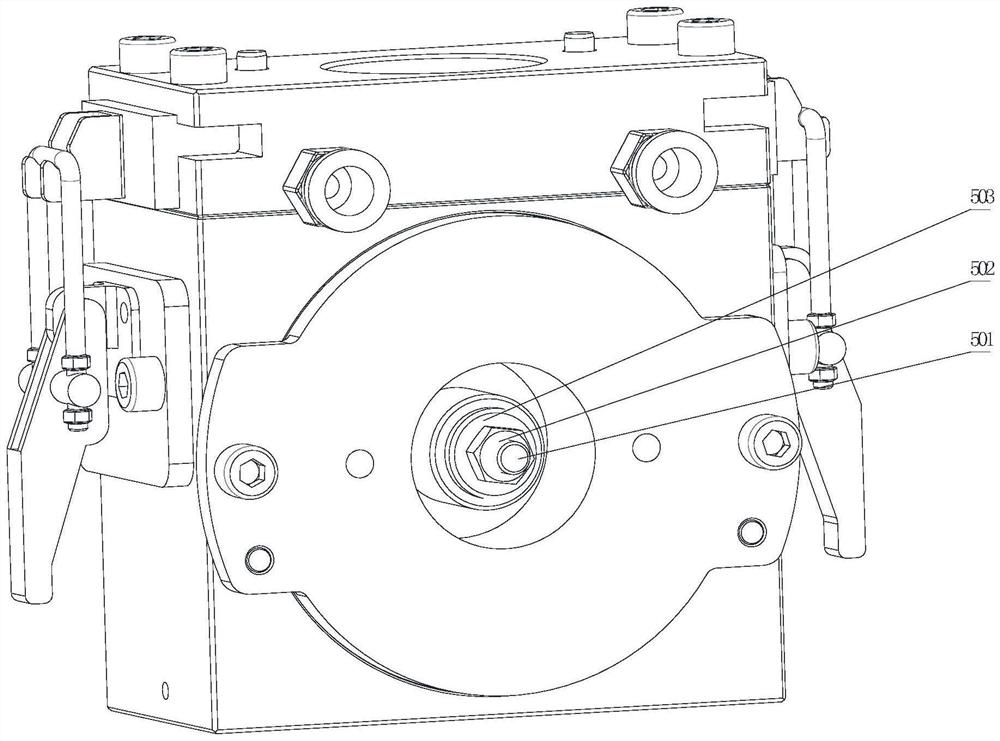

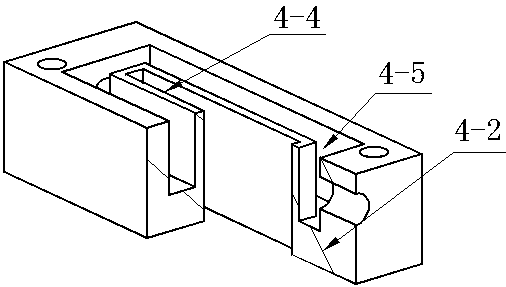

Pulse current and vibration matched feeding device

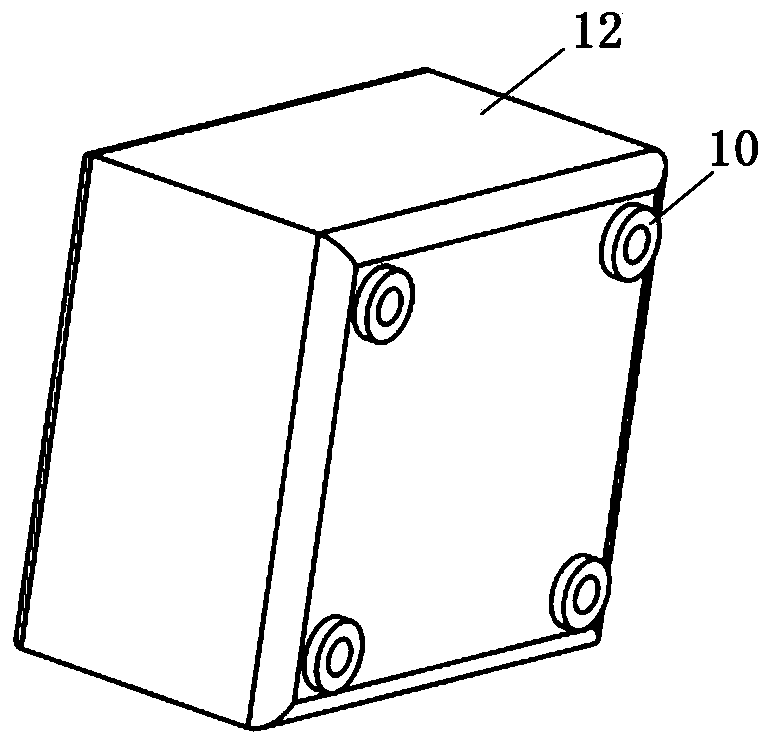

InactiveCN107322112AQuick updateReduce consumptionElectrochemical machining apparatusElectrical-based auxillary apparatusEngineeringPulse power supply

The invention discloses a pulse current and vibration matched feeding device which comprises a housing, and a cam and a sliding block that are arranged in the housing; the upper part of the cam is connected with a motor; a groove is formed in the upper part of the sliding block; the lower part of the cam is movably sleeved in the groove in the upper part of the sliding block; profile curves are formed in the cam; cylindrical pins are arranged on the sliding block, and are limited in the profile curves of the cam, and thus rotary motion of the cam is converted to up-down vibration of the sliding block; a permanent magnet is arranged on the sliding block; a hall switch is arranged at the place where the sliding block is in the lowest position after the sliding block vibrates downwards, in the housing; and when the sliding block is in the lowest position after the sliding block vibrates downwards, the hall switch sends out a voltage signal to a driving module, and thus a pulse power source sends out a packet high frequency pulse. An electrolytic solution in a machining gap can be renewed effectively; pulse current and vibration are matched for feeding, a cathode is vibrated to be fed to a place closest to an anode and the pulse power source sends out pulse, thus dispersion corrosion is reduced, energy consumption is reduced, and the precision of electrolytic machining is improved.

Owner:CHANGZHOU INST OF TECH

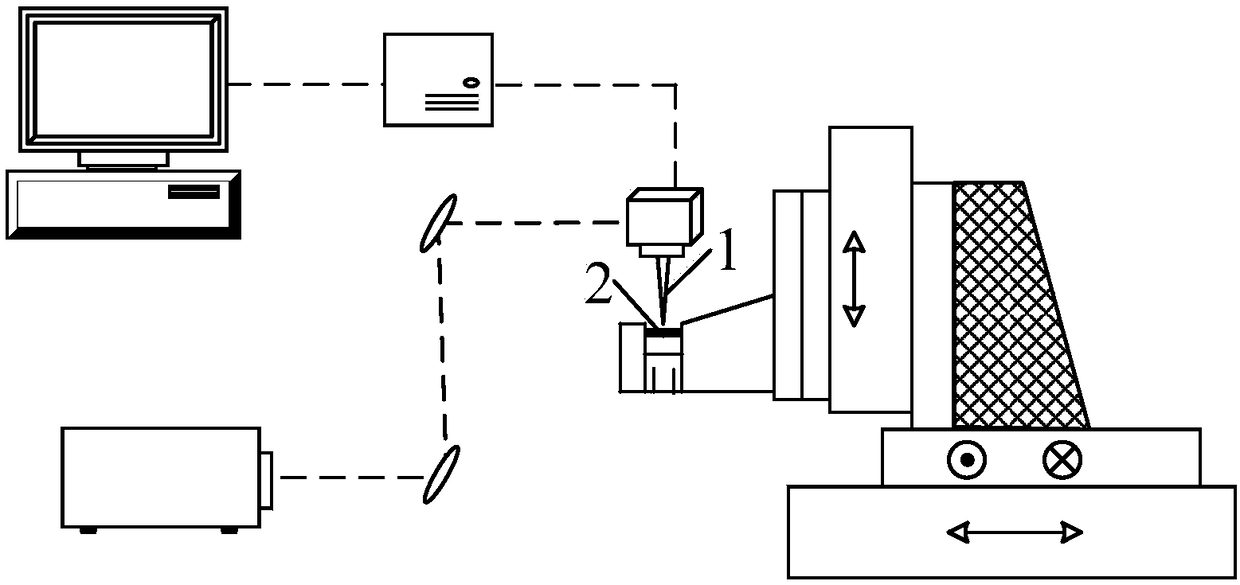

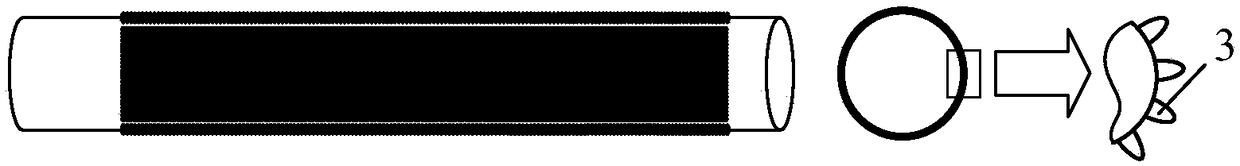

Side wall insulation method of micro hole electrolytic machining electrode and application

ActiveCN108080782AGuaranteed validityGood adhesionLaser beam welding apparatusInsulation layerOptoelectronics

The invention relates to a side wall insulation method of a micro hole electrolytic machining electrode, and belongs to the field of micro hole electrolytic machining. The method comprises following processes that a focal point of a laser beam (1) is located on the side wall of the electrode (2), laser machining parameters are controlled, the electrode is not burnt out, and the side wall of the electrode is provided with oxide protrusions (3); the oxide protrusions (3) have the insulation effect, and when the electrode is used for serving as a cathode to carry out micro hole electrolytic machining, electric fields are distributed between the untreated electrode end face and the workpiece in a concentrated manner. The insulation layer on the surface of the insulated electrode is good in adhesion, stripping is difficult, and insulation effectiveness is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

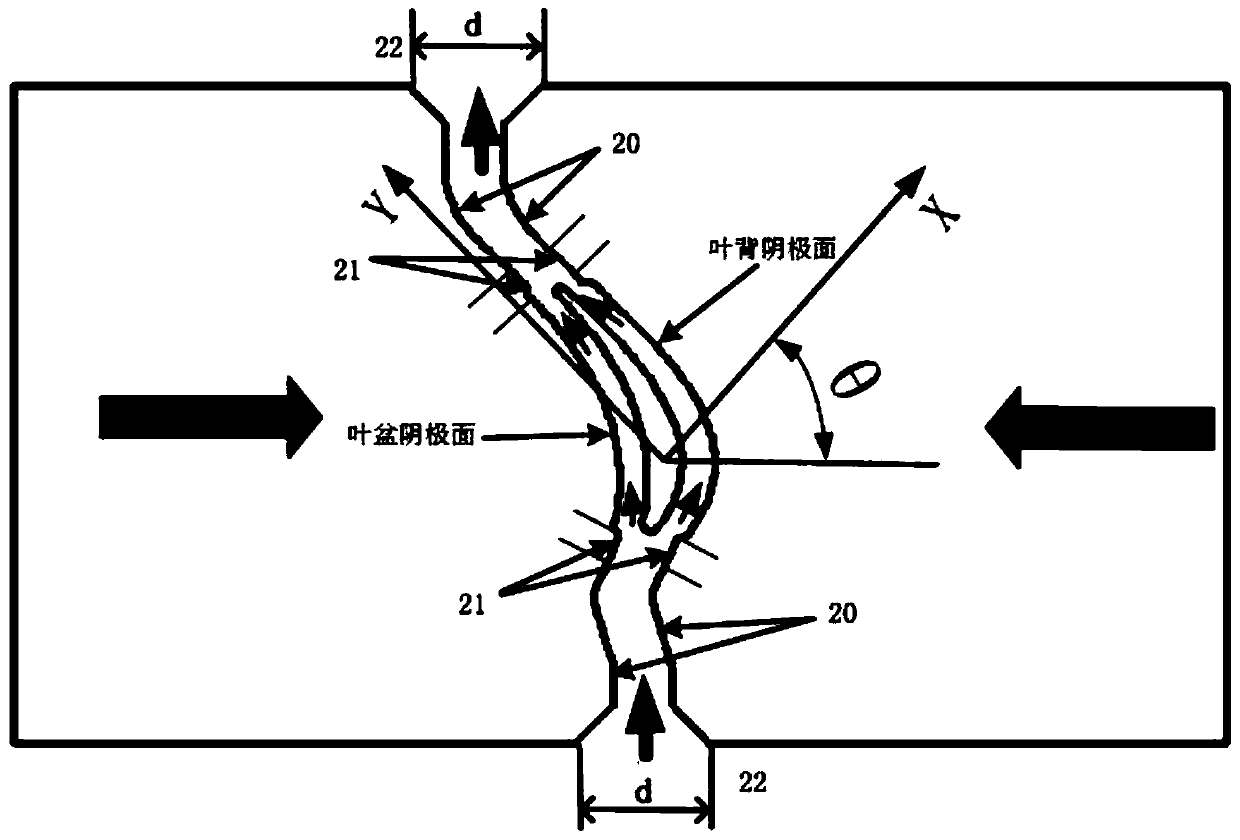

Large-distortion blade precise electrolytic machining device and process method

PendingCN110605447AFlow field stabilityReduction of stray corrosionMachining working media supply/regenerationElectrical-based auxillary apparatusDistortionEngineering

The invention relates to a large-distortion blade precise electrolytic machining device and a process method. The device comprises a cathode positioning and clamping device, a workpiece quick-changingdevice and an electrolyte flow guiding device. According to the large-distortion blade precise electrolytic machining device and the process method, a fully-closed electrolytic machining tool clamp is adopted, the cathode design is integrated, and a composite flow guiding segment combined with a metal segment and an insulating segment arranged on a blade basin cathode and a blade rear cathode arecombined, so that a flow field in the machining process is stable; the workpeice space pose is optimized through a particle swarm algorithm, and the optimal feeding angle can be achieved only feedingthe blade basin cathode and the blade rear cathode in an opposite-linear mode, so that the electrolytic forming precision is improved. According to the method, the high-precision of blade space positioning can be ensured; and meanwhile, quick workpiece changing can be realized by means of a quick-change reference element arranged on a fully-closed tool, and one-time clamping can be achieved to complete the integral forming of a blade basin surface, a blade rear surface and inlet and exhaust edges, and the purpose of improving the machining precision and machining efficiency of a blade can beachieved.

Owner:JITRI INST OF PRECISION MFG

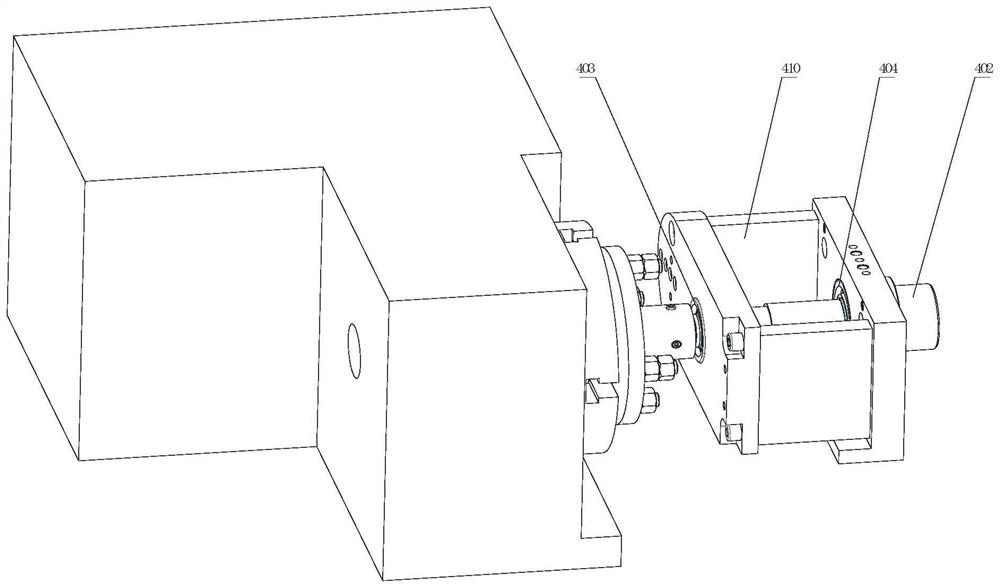

Cathode vibration device for electrolytic machining

InactiveCN109570661ASymmetrical forceQuick updateMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a cathode vibration device for electrolytic machining. The cathode vibration device comprises a cam shaft, wherein the cam shaft and a machine tool spindle rotate synchronously, a vibration shaft is arranged on the cam shaft, the end of a rotating shaft is connected with a chuck, a cam groove profile curve is arranged on the cam shaft, sliding blocks which protrude inwardsare arranged on the vibration shaft, the sliding blocks cooperate with the cam groove profile curve, so that the up-down movement of the vibration shaft is realized, and the cam shaft and the vibration shaft are provided with a photoelectric door which is consistent with the up-down movement direction of the vibration shaft. According to the cathode vibration device for electrolytic machining, twopairs of sliding block shafts and the sliding blocks are symmetrically installed, so that the stress of the vibration shaft is symmetrical; and the pulse current and vibration feeding of the cathodevibration device for electrolytic machining are synchronous, when the cathode vibration is fed to the position closest to an anode, a pulse power supply sends pulses, when the cathode vibration is away from the anode, machining gaps start to increase, the dissolution speed of the anode starts to be slowed, an electrolyte can be quickly updated, the pulse power supply does not generate the pulses,thus, stray corrosion can be reduced, energy consumption can be reduced, and the precision of electrolytic machining can be improved.

Owner:CHANGZHOU INST OF TECH

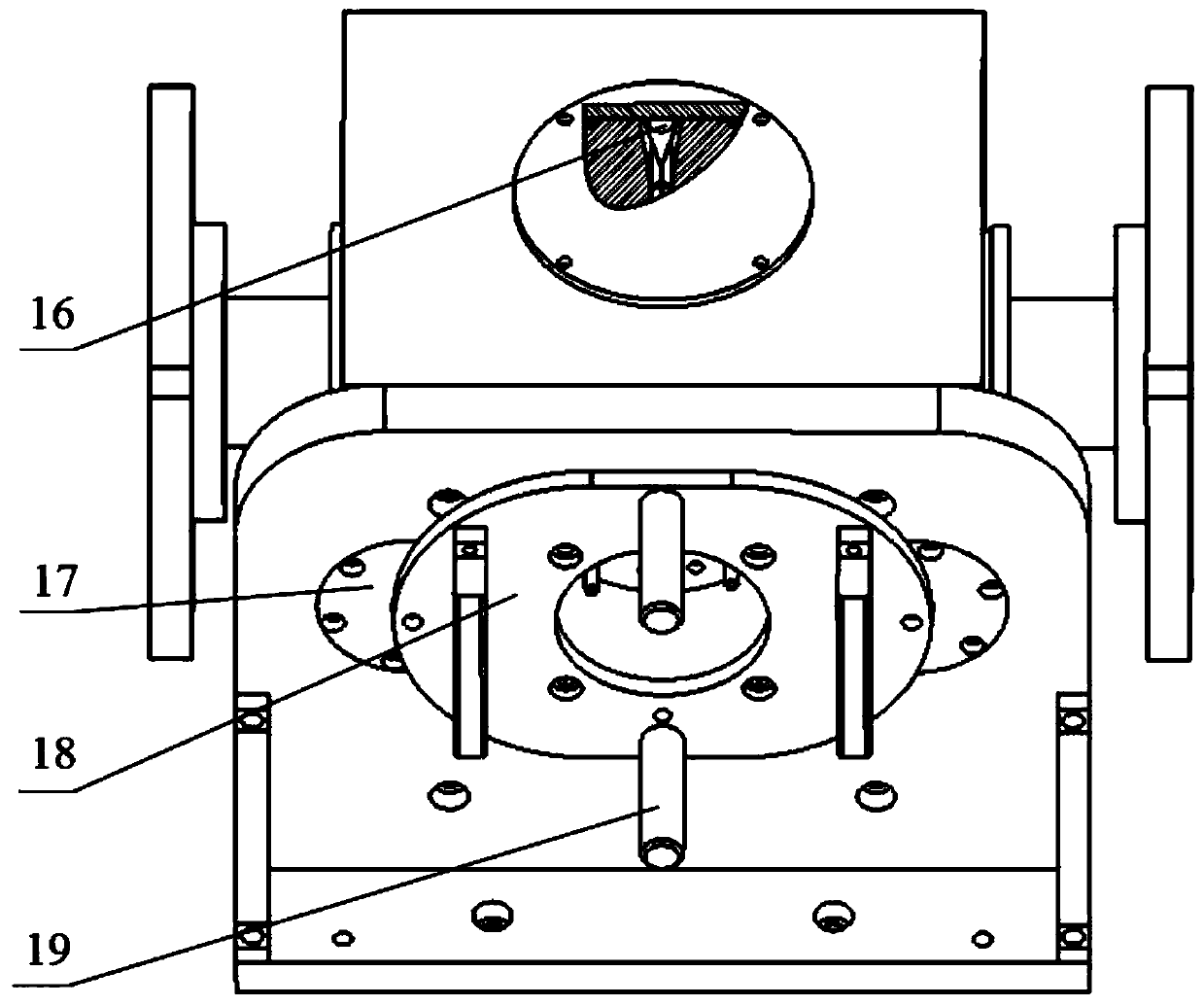

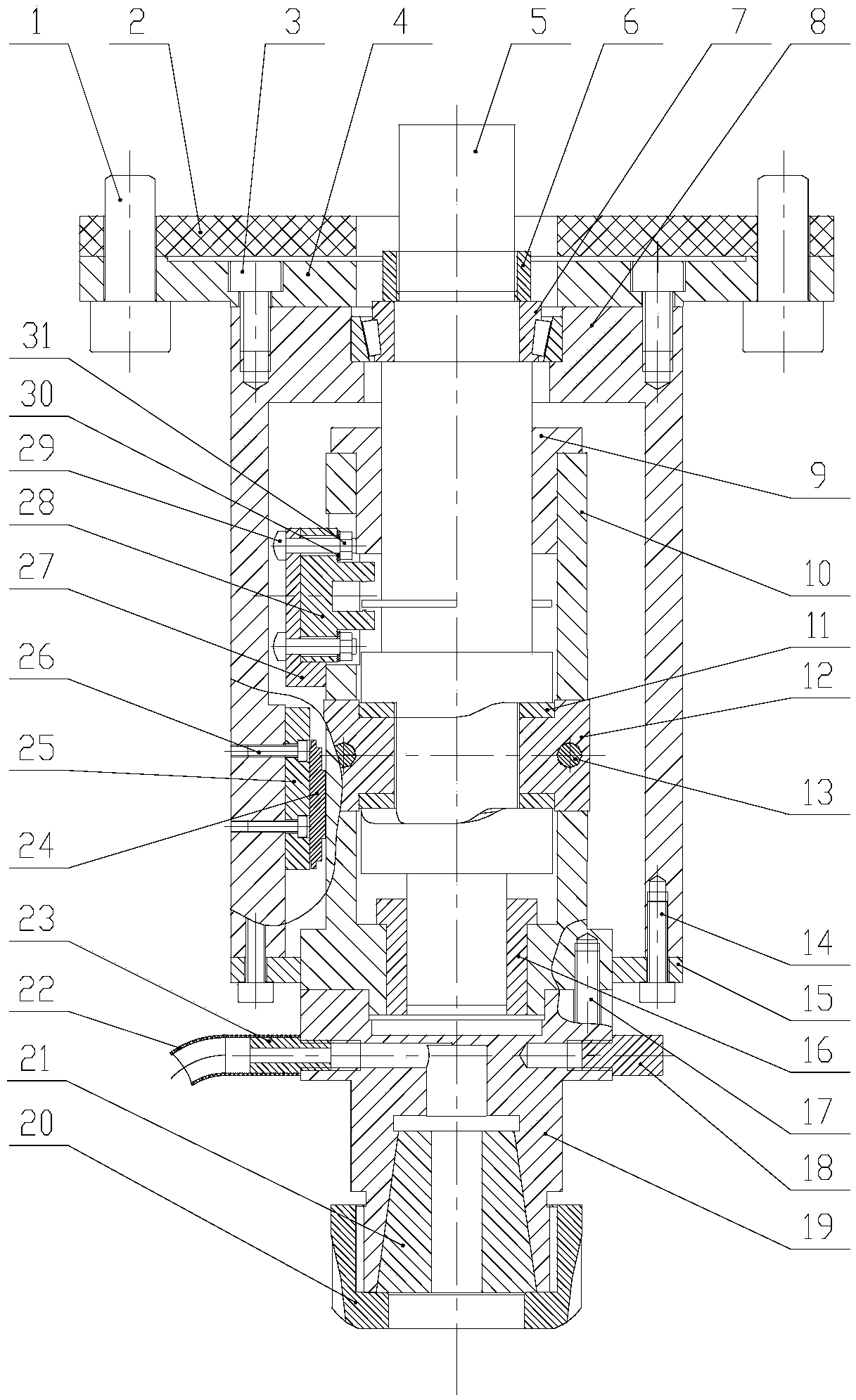

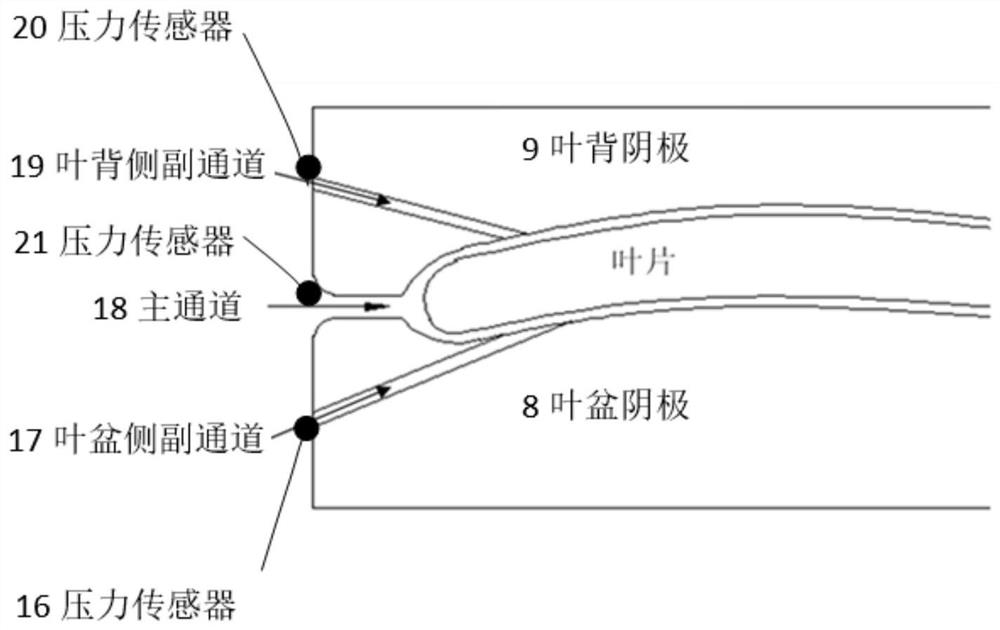

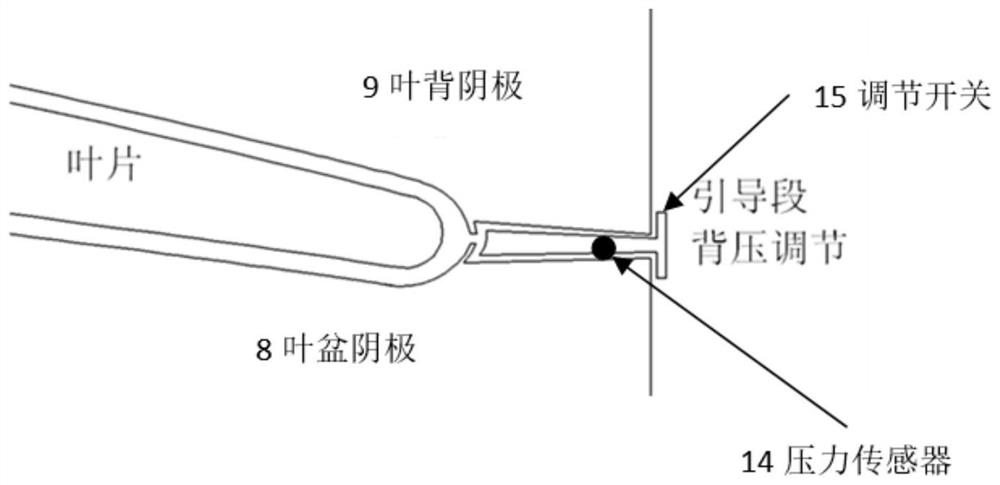

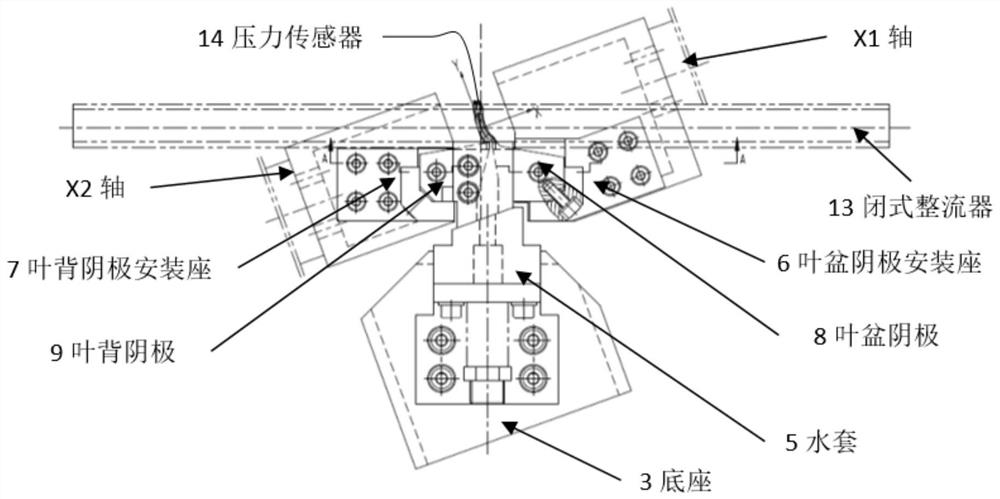

Precise regulating and controlling device for electrolytic machining flow field of closed structure blade

ActiveCN113333882AReduce flow rate differenceAvoid free flightMachining working mediaMachining working media supply/regenerationElectrolysisEngineering

The embodiment of the invention provides a precise regulating and controlling device for an electrolytic machining flow field of a closed structure blade. The device comprises an electrolytic machining device used for conducting electrolytic machining on the closed structure blade and an assembling device used for assembling the electrolytic machining device; the electrolytic machining device comprises a blade back cathode provided with a blade back side auxiliary channel, a blade basin cathode provided with a blade basin side auxiliary channel and a main channel in the same direction as the blade back side auxiliary channel and the blade basin side auxiliary channel; and the blade back cathode and the blade basin cathode are structurally symmetrical. According to the precise regulating and controlling device, the blade back side auxiliary channel is arranged on the blade back cathode, the blade basin side auxiliary channel is arranged on the blade basin cathode, after liquid supply on the two sides and the main channel are combined, a certain back pressure effect is achieved on the front section of the flow field of the main channel, the vortex and hole phenomena caused by shock waves of a liquid inlet are eliminated, and furthermore, through the pressure adjusting effect of auxiliary liquid, the stability of the flowing state of the liquid inlet section is effectively improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Method for electrolytic machining of microtexture

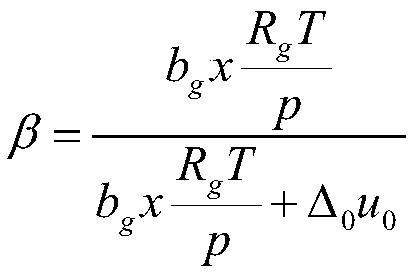

InactiveCN110369815AFast decayImprove processing efficiencyElectrochemical machining apparatusElectrical-based auxillary apparatusElectricityElectrolysis

The invention discloses a method for electrolytic machining of a microtexture. The method mainly includes the following steps that S1, a workpiece anode is immersed in electrolytes, and metal particles are laid flatly on the surface of the workpiece anode to form an equivalent thickness metal particle layer; S2, a tool cathode attached with electric insulation cloth is tightly attached to the metal particle layer, and the electric insulation cloth is disposed between the tool cathode and the metal particle layer; S3, the workpiece anode is connected with the positive pole of a power supply, and the tool cathode is connected with the negative pole of the power supply; S4, the electrolytes are supplied into the metal particle layer through an electrolyte circulating system and flow circularly in a machining gap formed between the workpiece anode and the tool cathode; and S5, the power supply is switched on for electrolytic machining, when machining requirements are met, the power supplyis disconnected, electrolyte supply stops, the workpiece anode is taken out, and machining is completed. The method has the advantages that mask preparation is simple, the application range is wide, and microtextures with uniform sizes and good profiles can be prepared on planes and curved surfaces.

Owner:HENAN POLYTECHNIC UNIV

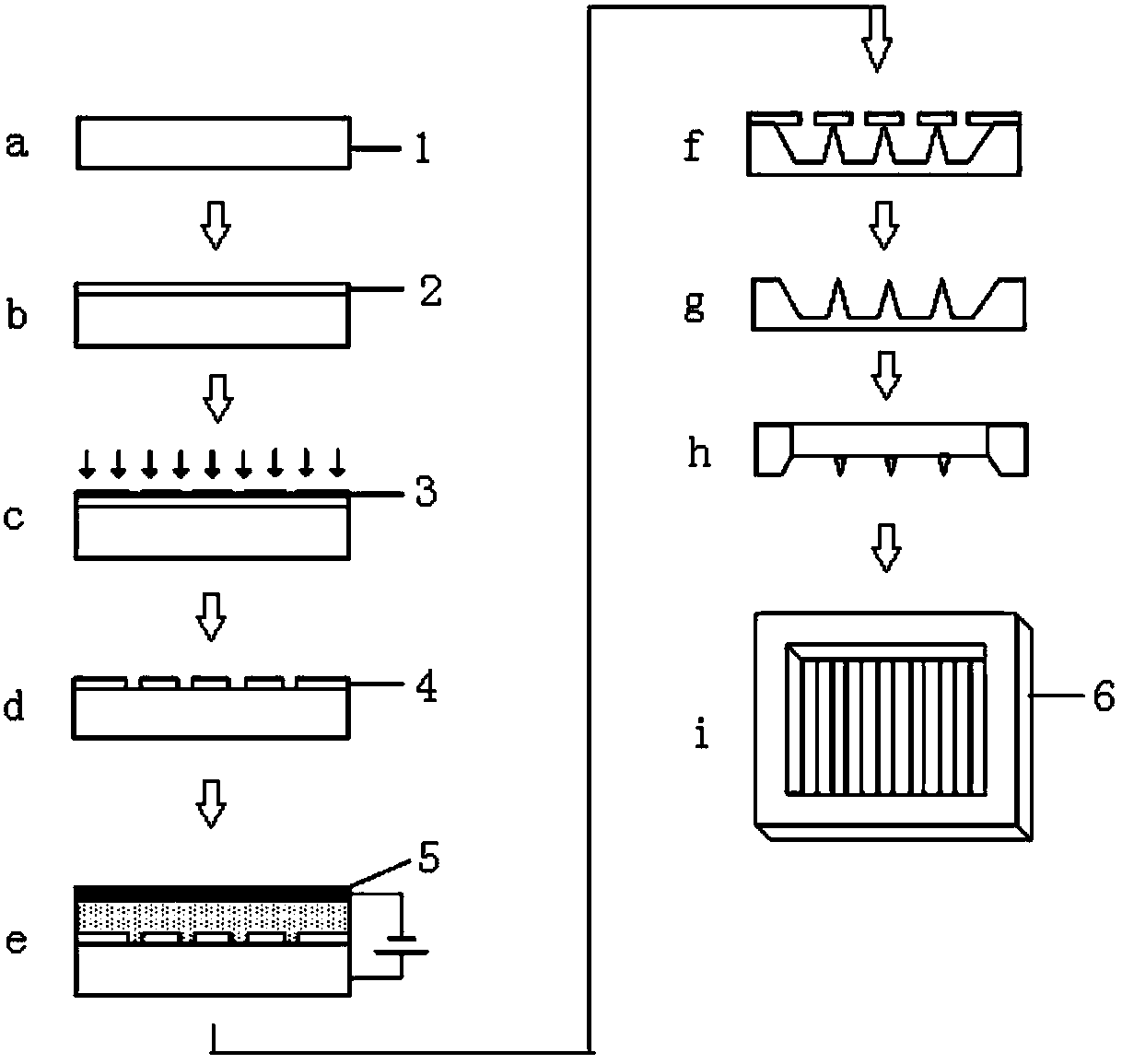

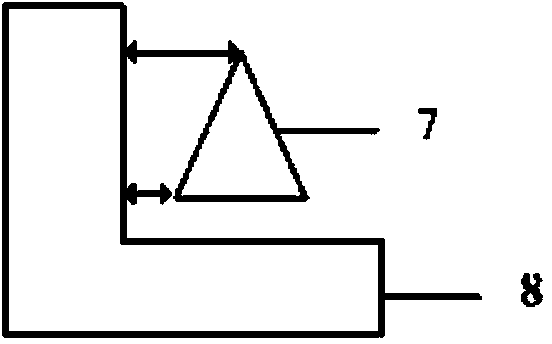

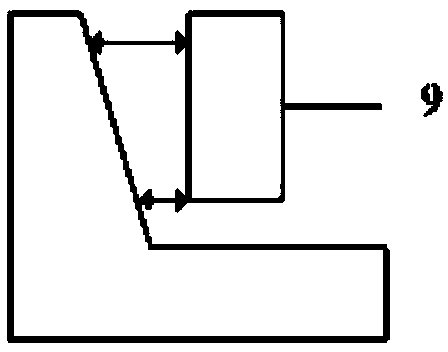

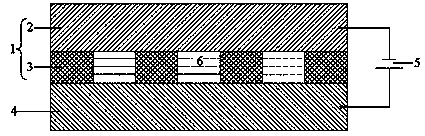

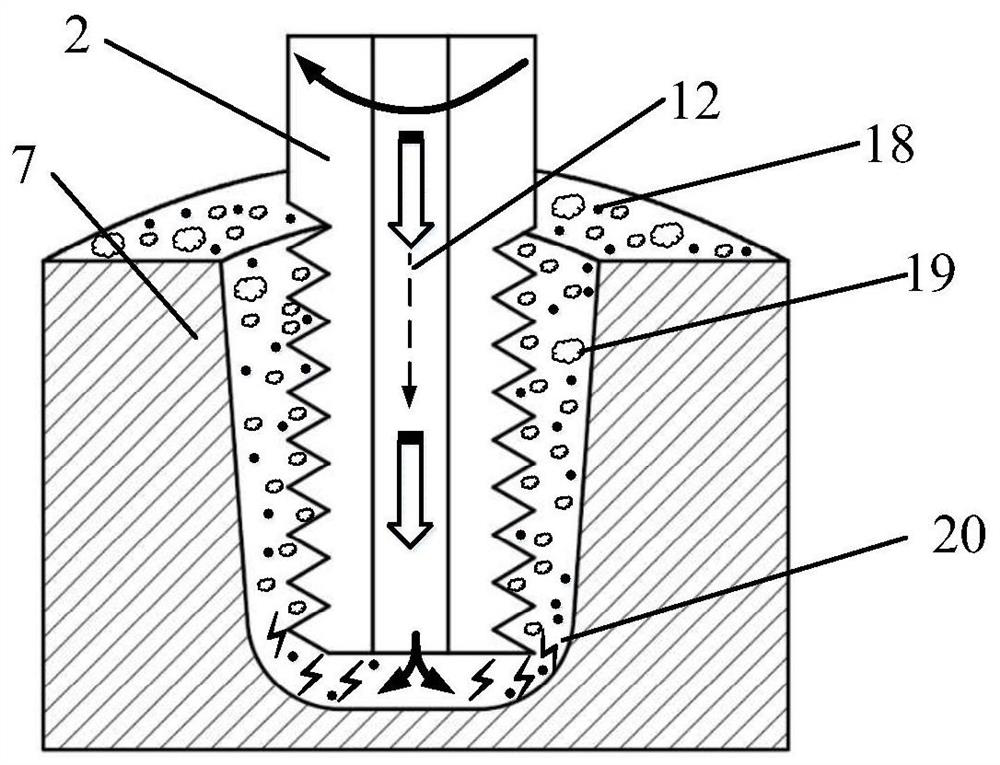

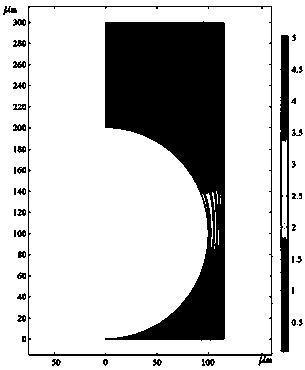

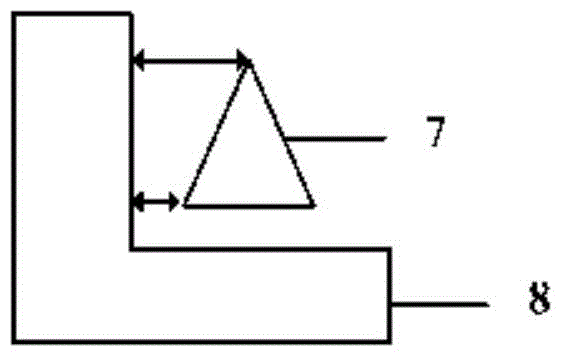

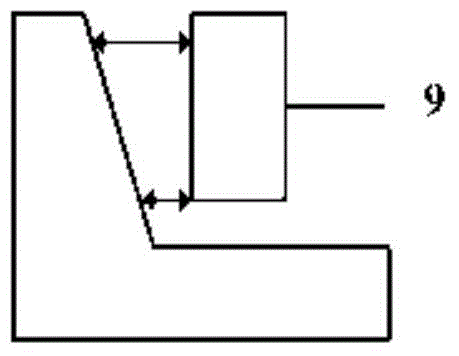

Electrolytic machining method for micro-pit group using bipolar electrode and bipolar electrode thereof

ActiveCN100544872CReduction of stray corrosionImprove localizationMachining electrodesMachining working media supply/regenerationElectrolysisOptoelectronics

The invention discloses a method for electrolytic machining of fine group pits using bipolar electrodes and the bipolar electrodes, belonging to the technical field of electrolytic processing. The method is characterized in that it includes the following steps: (a) making a bipolar electrode (1) with a penetrating group hole structure and sequentially composed of an auxiliary anode (7), an insulating layer (6) and a tool cathode (5) ; (b) The auxiliary anode (7) on the bipolar electrode is closely attached to the workpiece anode (2); (c) The workpiece anode (2) and the tool cathode (5) are respectively connected to the positive and negative poles of the power supply (3) (d) spray electrolyte (4) to the surface of the tool cathode (5), so that the electrolyte reaches the surface of the workpiece anode (2) through the through holes on the bipolar electrode (1); (e) switch on the power supply ( 3) Perform electrolytic machining. The invention can significantly improve the localization and micro-scale processing ability of electrolytic machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Low-temperature precision electrolytic machining method

InactiveCN110394519APromote localizationAdd nonlinearityMachining working media supply/regenerationElectrolysisMachining

The invention discloses a low-temperature precision electrolytic machining method, and belongs to the field of special machining. The method is characterized in that a machining area is in a low-temperature environment, and the temperature can be as low as zero DEG C or lower; a specific electrolyte is prepared, the freezing point of the specific electrolyte is lower than zero DEG C, and thus thefluidity can still be kept in the low-temperature environment; during machining, a workpiece and a tool can be placed in the low-temperature environment, meanwhile, in order to strengthen the freezingeffect, the workpiece can be placed on a specially-made low-temperature clamp, and an inner cooling device can be installed in the tool, so that further cooling of the workpiece and the tool is realized; or an auxiliary conductive ice layer or an auxiliary non-conductive ice layer is frozen in the machining area or a non-machining area of the workpiece, and low-temperature electrolytic machiningassisted with the ice layer is carried out. Under a low-temperature condition, the ion movement capacity in a solution is weakened, the non-linearity of the electrolyte is remarkably enhanced, the electrolytic machining defects such as stray corrosion and pitting corrosion can be reduced or eliminated, and the machining locality is improved, so that precise and ultra-precise electrolytic machiningis realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gas-assisted protection integral impeller trepanning electrolytic machining process and device

ActiveCN114247943AAchieve precise indexingRealize automatic compressionElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentImpeller

The invention discloses an integral impeller trepanning electrolytic machining process and device with a gas-assisted protection function, and belongs to the field of electrolytic machining. The upper part of the device is provided with a cylindrical cathode seat which is in clamping connection with a main shaft, and the bottom of the cylindrical cathode seat is provided with a pin hole so as to realize the positioning of a cathode; a vent hole is formed in the middle of the device and used for conducting gas-assisted insulation on a machined blade and a blade to be machined. An insulation sealing device is arranged on the lower portion of the device, and the insulation sealing device and the front blade insulation sleeve and the rear blade insulation sleeve inside the device form a closed machining area to achieve closing of an electrolytic machining flow field. In the machining process, the blade sleeved with the blade insulation sleeve is always in the gas auxiliary insulation state, and the stray corrosion degree of the machined blade is effectively reduced. The method solves the problems that the machined blade is subjected to stray corrosion and the flow field open type electrolyte remains in a non-machining area during the trepanning electrolytic machining of the uniform-section blade type integral impeller, and is beneficial to improving the machining precision of the blade and enhancing the stability of the machining process.

Owner:JITRI INST OF PRECISION MFG

Electrolytic Machining Cathode Device and Processing Method for Freeze Protection Sheath Material

ActiveCN109909565BReduce taperReduce ion concentrationMachining electrodesElectrical-based machining electrodesElectrolytic agentMachine parts

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fabrication method of wire electrode array structure for micro electrolytic machining

ActiveCN103706899BEfficient preparationRealize integrated manufacturingMachining electrodesElectrical-based machining electrodesElectrolysisElectrode array

The invention discloses a method for preparing a wire electrode array structure for micro-electrolytic processing. The steps include: step 1, pretreatment of a metal substrate; step 2, making a patterned masking film; step 3, electrolytic deep etching of the mask, and The surface-patterned metal substrate is used as the anode for electrolytic processing, and the mask is obtained by electrolytic deep etching to manufacture the tool cathode in the wire electrode template. The electrolytic etching time is determined according to the width of the photoresist pattern and the electrolytic current density until the metal with a sharp top is obtained. Grid line array pattern; step 4, remove the back material, remove the back material corresponding to the fabricated metal grid lines to obtain a line electrode array integrated with the frame, and it is ready. The method of the present invention can produce metal microstructure arrays with different shapes such as square, rectangle, rhombus, etc., and efficiently realize the metal microstructure arrays with large aspect ratio, high density and high processing quality.

Owner:江苏蔚之领域智能科技有限公司

Tube electrode for electrolytic and electric spark composite cutting and machining method

ActiveCN112059340AReduction of stray corrosionImprove processing qualityElectrical-based machining electrodesElectrolytic agentMachined surface

The invention relates to a tube electrode for electrolytic and electric spark composite cutting and a machining method, and belongs to the technical field of electro-machining. The tube electrode is mainly characterized in that the tube electrode for electrolytic and electric spark composite cutting is a double-flow-channel copper-tungsten alloy tube with a liquid flow channel and an air flow channel, and the outer side faces of the two flow channels are symmetrically provided with same array small holes. When the liquid spraying holes of the liquid flow channel are rotated into an end face machining gap, an electrolytic reaction occurs between the tube electrode and a machined face. Air is jetted into a kerf from the air jet holes through the air flow channel, waste electrolyte in the kerf is blown away, and stray corrosion is reduced. When the air jet holes of the air flow channel rotate into the end face machining gap, spark discharge occurs between the tube electrode and the machined face. Electrolyte is sprayed into the kerf from the liquid spraying holes through the liquid flow channel, and electrolytic reaction occurs between the tube electrode and the side wall of the workpiece. In the cutting process, the tube electrode rotates, electrolyte and air are alternately sprayed into the end face machining gap, electrolytic machining and electric spark machining are alternately conducted between the tube electrode and the workpiece, and the machining efficiency and the machining quality are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

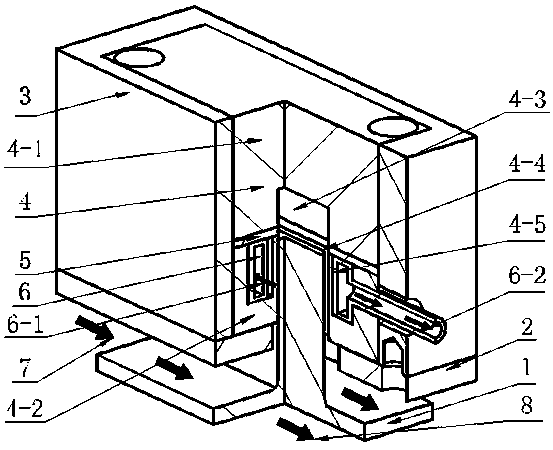

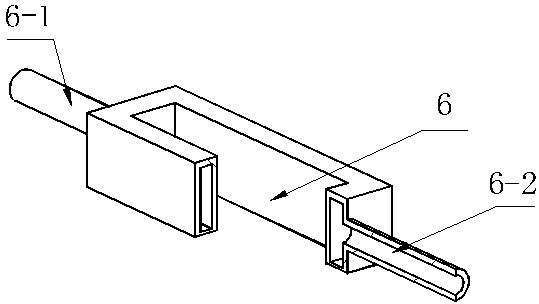

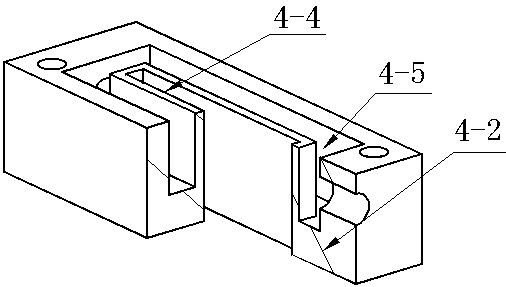

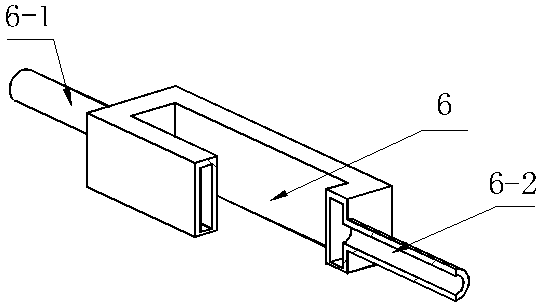

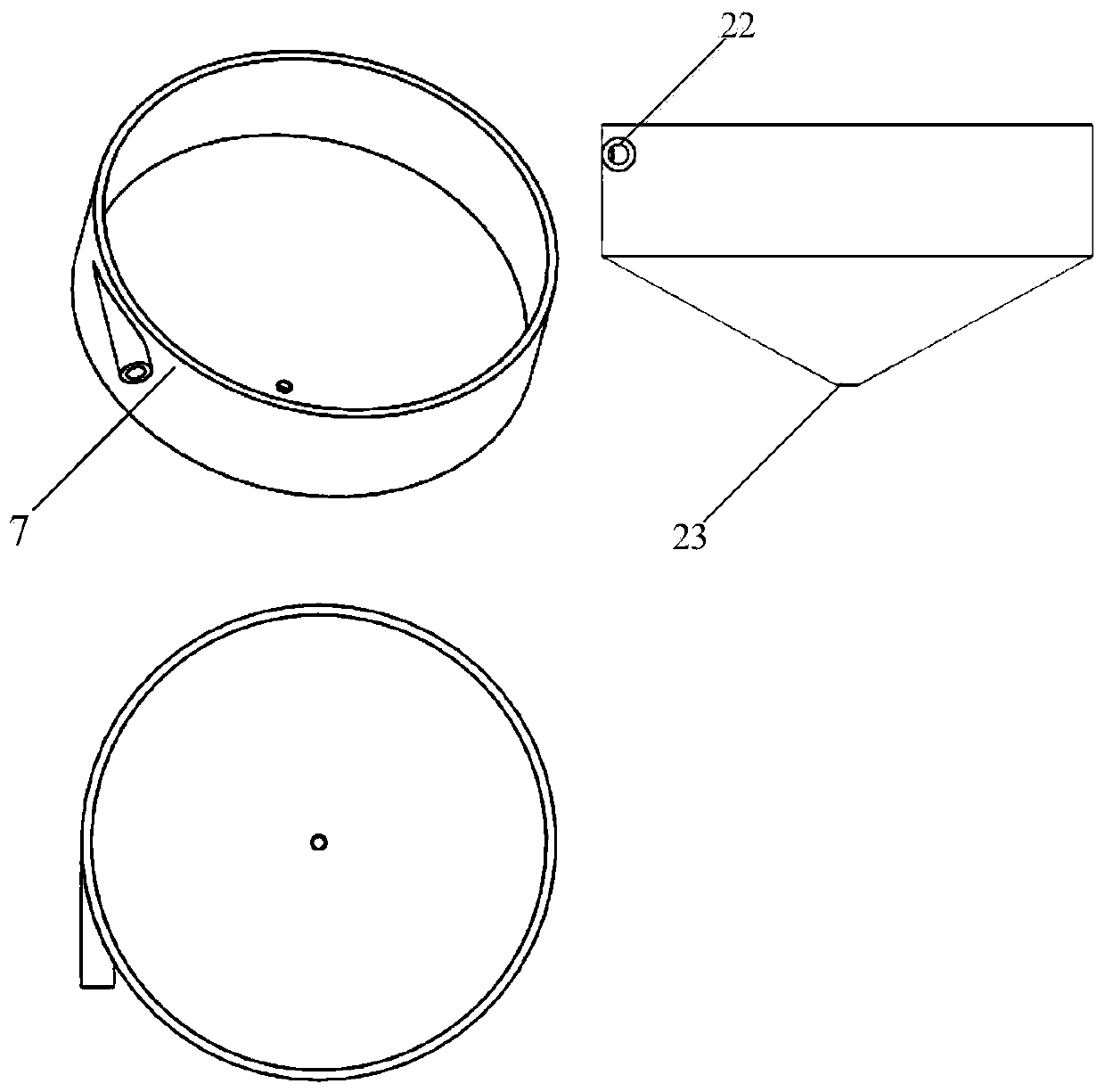

Conical electrolyte groove and micro electrolytic wire cutting and piercing processing method

The invention relates to a conical electrolyte groove and a micro electrolytic wire cutting and piercing processing method, and belongs to the field of micro electrolytic processing. The micro electrolytic wire cutting and piercing processing method is characterized in that the conical electrolyte groove (7) is used. The upper end of the conical electrolyte groove is provided with a cylindrical groove body (7-1), and the lower end of the conical electrolyte groove is provided with a conical groove body (7-2); and a liquid inlet (22) is formed in the side surface of the upper cylindrical groovebody, and a liquid outlet (23) is formed in the bottom of the lower conical groove body. The cylindrical groove body (7-1) part makes an electrolyte flowing in a direct current mode move rotatably, and products around a processing channel are discharged fully; and the conical groove body (7-2) part makes a flowing fluid generate a flow rate in the vertical direction, the processed products in thechannel are further taken away, and the effect of electrolysis is enhanced. The conical electrolyte groove and the micro electrolytic wire cutting and piercing processing method can be applied to micro electrolytic wire cutting and piercing processing, the processing efficiency is high, and the processing quality is good.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Titanium alloy special-shaped electrolytic machining fixture

InactiveCN109262093AEnsure stabilityReduce short circuitMachining working media supply/regenerationElectrical-based auxillary apparatusInterference fitElectrolysis

The invention discloses a titanium alloy special-shaped electrolytic machining fixture, which comprises a cathode, a cathode rod, a back pressure barrel and a fixture base in sequential arrangement. One end of the cathode rod extends into the back pressure barrel and is in interference fit with the back pressure barrel, and one end, away from the cathode rod, of the back pressure barrel is in hermetical connection with the fixture base. The tail end of the cathode is fixedly connected with one end, extending into the back pressure barrel, of the cathode rod, and the cathode extends towards thefixture base. The fixture base is provided with a workpiece positioning hole communicated with the back pressure barrel. The cathode rod is internally provided with a liquid inlet hole, the middle ofthe cathode is provided with a liquid outlet hole communicated with the workpiece positioning hole, and the liquid inlet hole is communicated with the liquid outlet hole. The titanium alloy special-shaped electrolytic machining fixture is simple in structure and stable and efficient in processing process.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

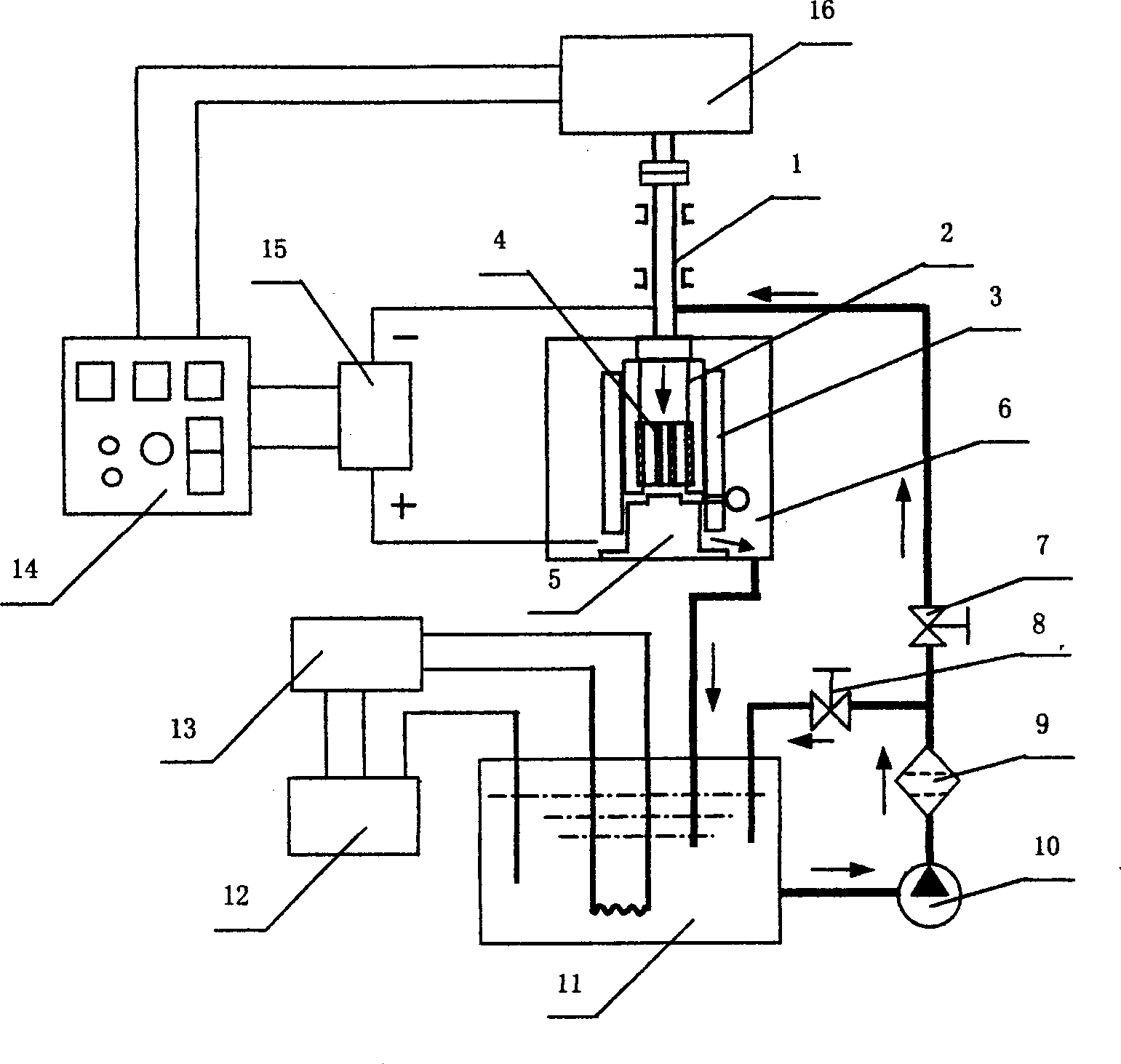

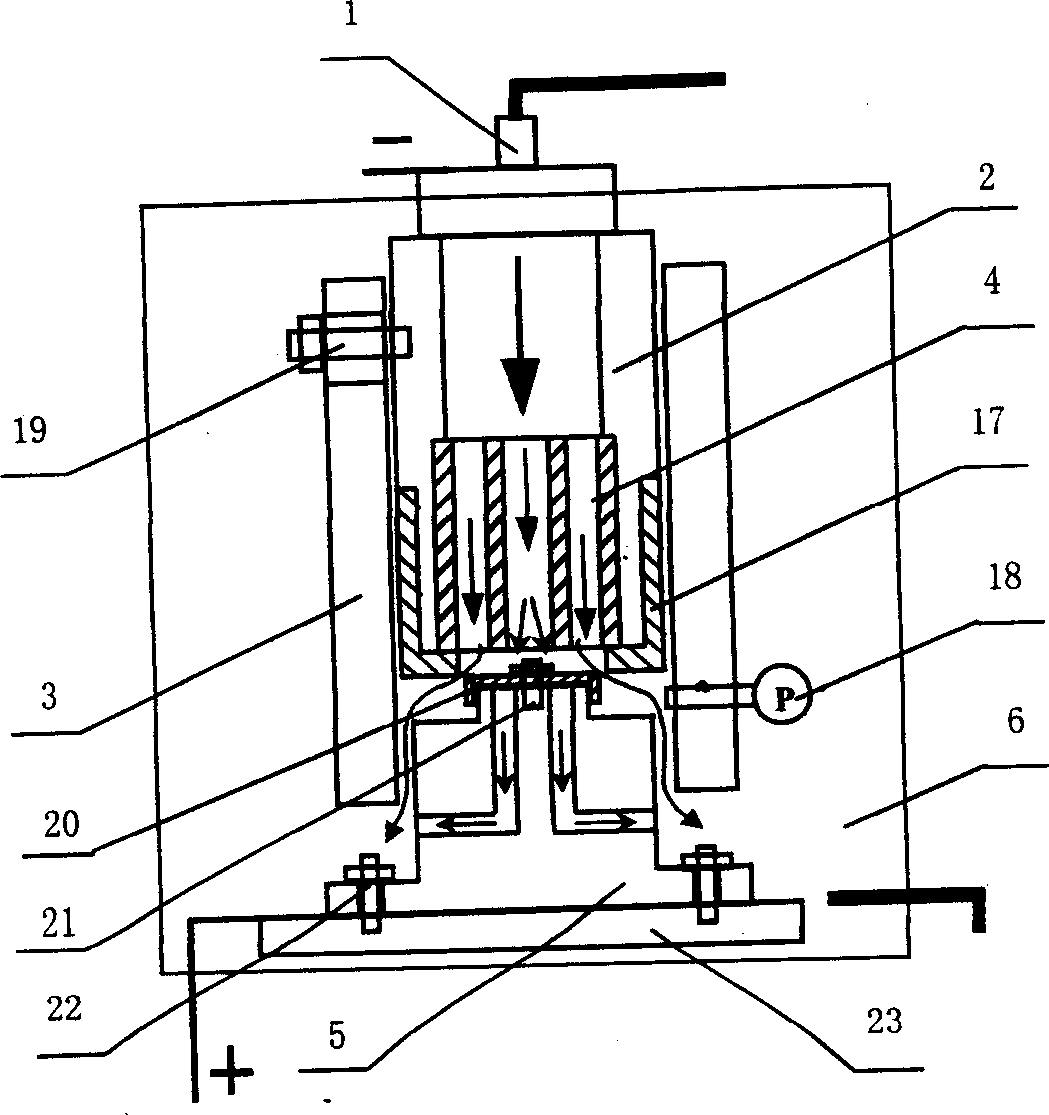

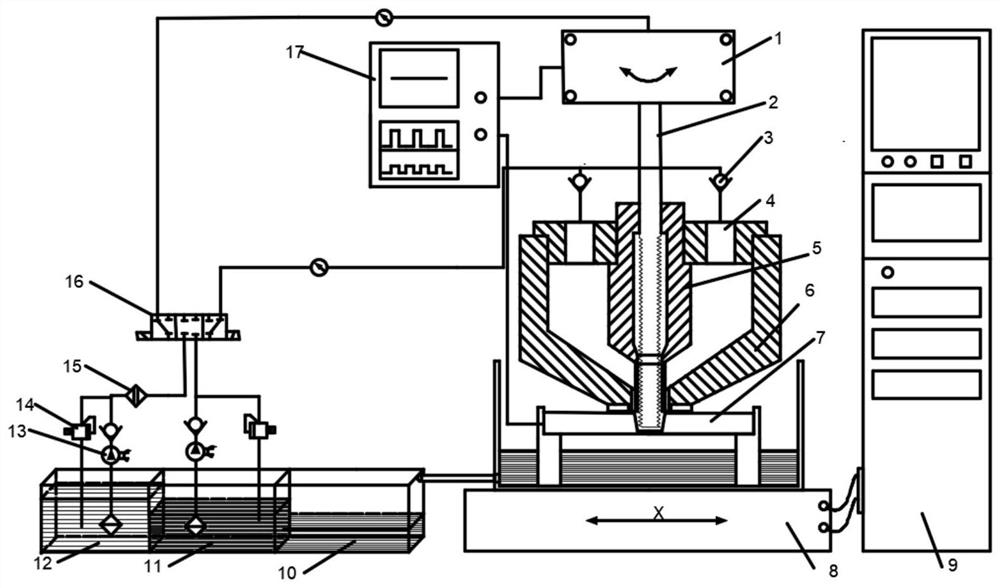

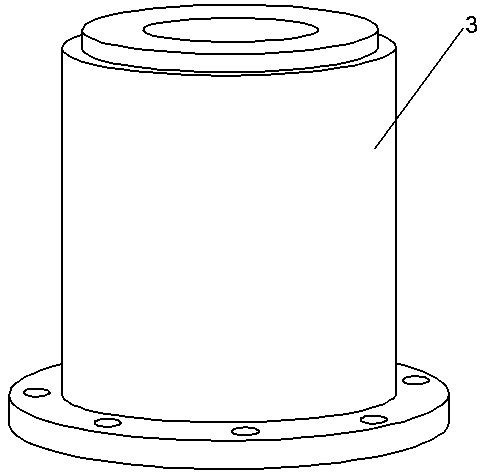

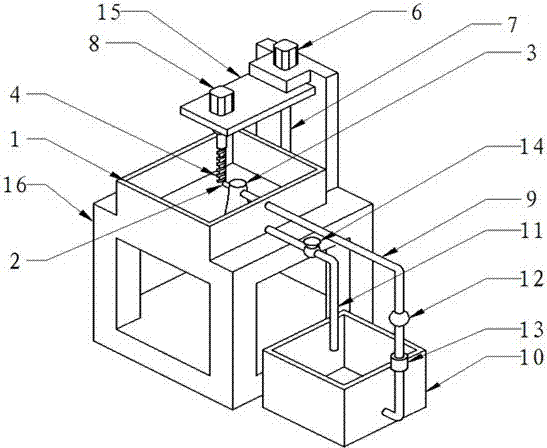

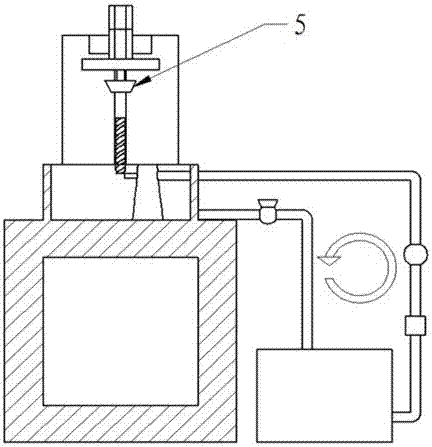

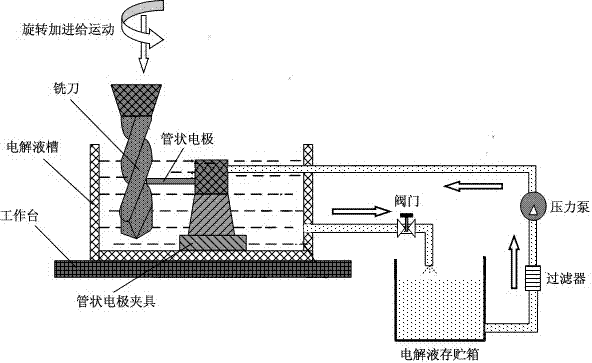

A device for preparing helical carbide micro milling cutter

InactiveCN103817388BGood dissolution and localizationExcellent surface quality control abilityElectrochemical machining apparatusElectrolysisSodium chlorate

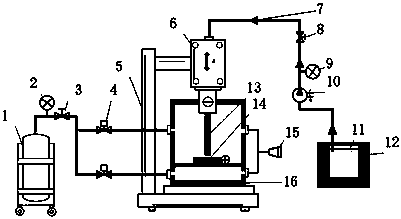

The invention provides a device for preparing helical carbide micro milling cutters using micro electrolysis technology, which is characterized in that it includes: electrolyte tank (1), tubular electrode (2), tubular electrode fixture (3), spiral hard alloy Quality alloy micro milling cutter (4), tool holder (5), motor one (6), lead screw (7), motor two (8), electrolyte tank inlet pipe (9), electrolyte storage box (10 ), electrolyte tank drain pipe (11), pressure pump (12), filter (13), valve (14), motion platform (15), workbench (16), using the good dissolution localization of fine electrolysis And surface quality control ability, using the electric field concentrated distribution near the end face of the electrode in electrolytic machining of tubular electrodes, taking advantage of the relatively small stray corrosion of sodium nitrate solution, sodium chlorate solution or their mixed solution, can achieve high precision and high efficiency , low-cost preparation of spiral carbide micro milling cutter.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com