Tube electrode for electrolytic and electric spark composite cutting and machining method

A technology of cutting processing and electric spark, which is applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of poor surface quality and low efficiency of electrolytic wire cutting, achieve good strength and rigidity, and improve processing efficiency and processing quality, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

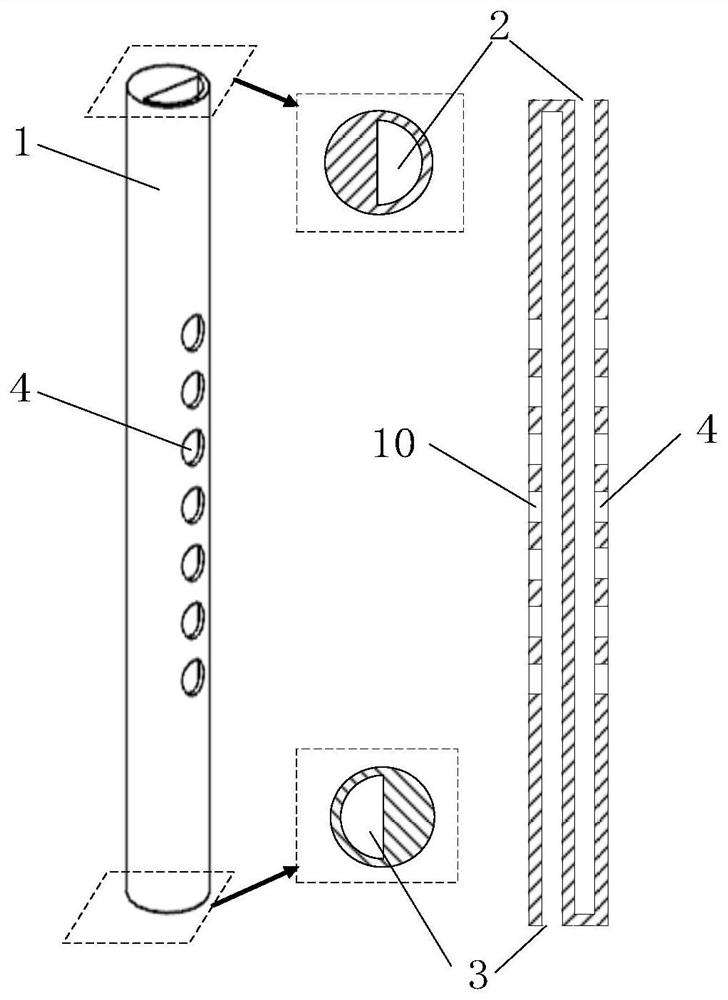

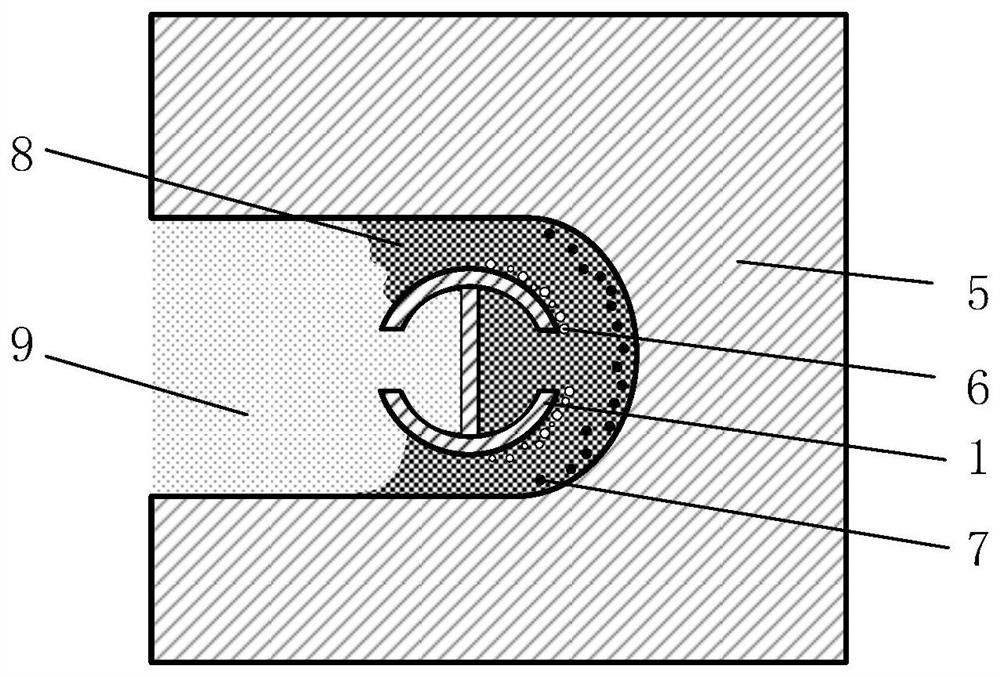

[0022] according to figure 1 As shown, the tube electrode 1 for electrolytic EDM composite cutting is a hollow copper-tungsten alloy tube, and its inner cavity is divided into two parts: the liquid flow channel 2 and the ventilation flow channel 3 by a longitudinal partition, and the partition is located in the tube electrode 1 In the middle of the cavity, the upper end of the liquid flow channel 2 is opened and the lower end is sealed, and the upper end of the flow channel 3 is sealed and the lower end is opened. The sides of the two flow channels are symmetrically provided with the same array of liquid injection holes 4 and array of air injection holes 10 . Electrolyte 8 is ejected from the array of spray holes 4 through the liquid flow channel 2 ; air is ejected from the array of air spray holes 10 through the flow channel 3 .

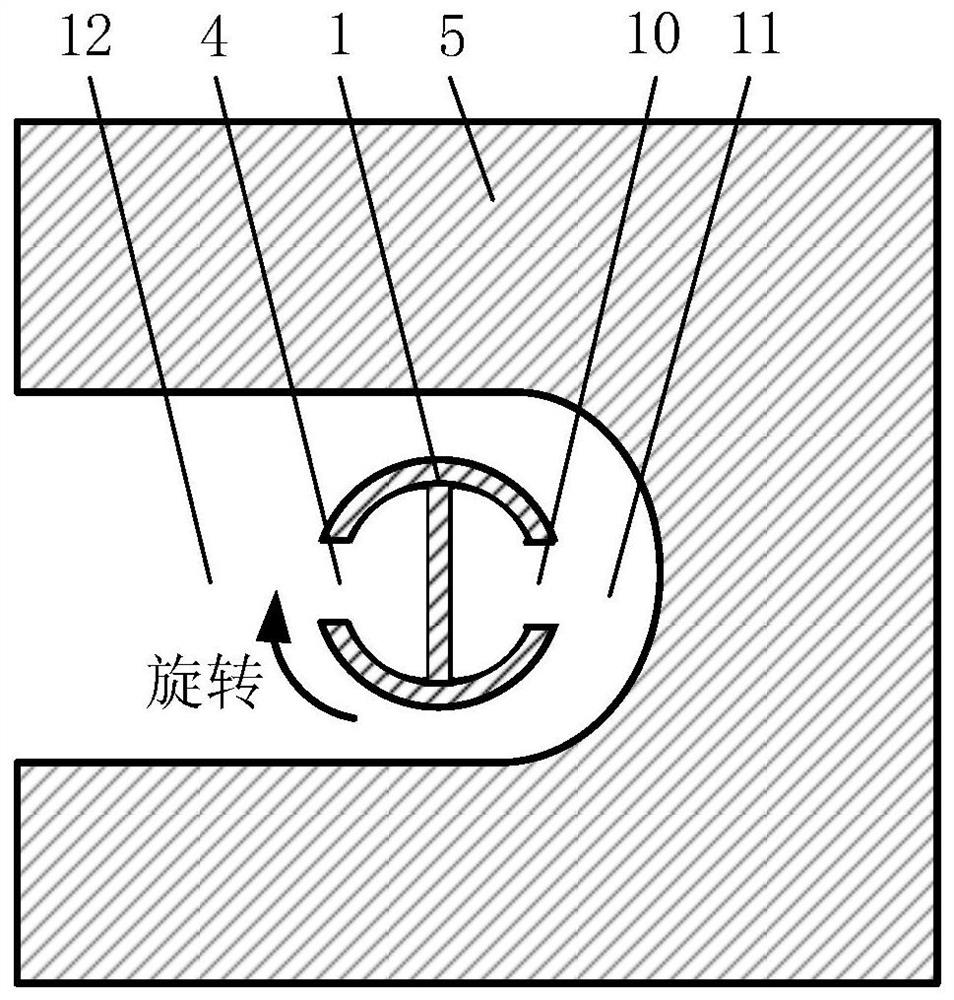

[0023] according to figure 2 As shown, during the cutting process, the tube electrode 1 rotates, so that the array liquid injection holes 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com