Titanium alloy special-shaped electrolytic machining fixture

A tooling fixture and titanium alloy technology, applied in the field of titanium alloy special-shaped cavity electrolytic machining fixtures, can solve the problems of poor processability of titanium alloy materials, low cavity removal efficiency, affecting surface roughness, etc., and achieve low cost and reduce impurities. The effect of dispersing corrosion and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

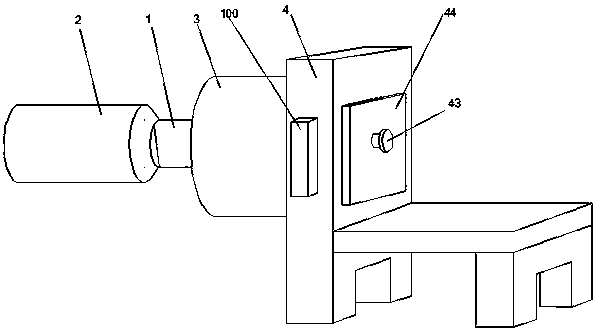

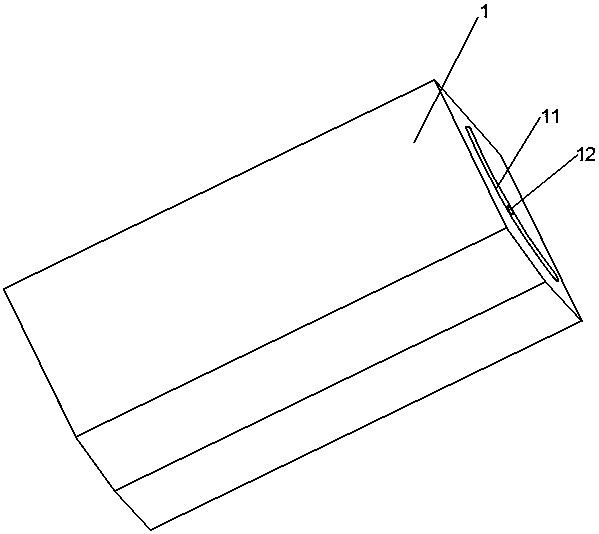

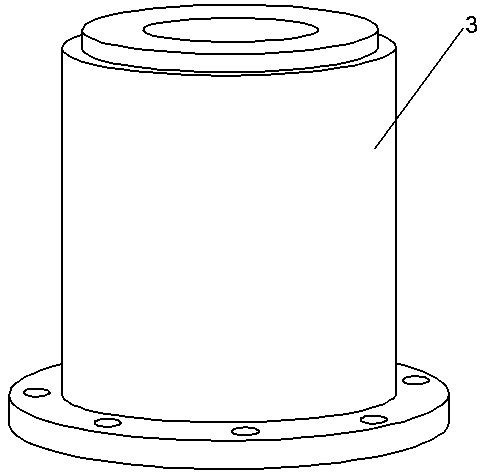

[0031] Such as Figure 1~Figure 7 As shown, a titanium alloy special-shaped cavity electrolytic machining tooling fixture includes a cathode 1, a cathode rod 2, a back pressure cylinder 3 and a fixture base 4 arranged in sequence; one end of the cathode rod 2 extends into the back pressure cylinder 3 Inner and interference fit with the back pressure cylinder 3, the end of the back pressure cylinder 3 away from the cathode rod 2 is sealed with the clamp base 4, and the end of the cathode 1 is fixedly connected with the end of the cathode rod 2 extending into the back pressure cylinder 3 , and the cathode 1 extends toward the fixture base 4; the fixture base 4 is provided with a workpiece positioning hole 41 and a circular hole 42 horizontally intersecting the workpiece positioning hole 41, and the diameter of the circular hole 42 is not larger than the cathode cavity 33 The inner diameter of the circular hole 42, the workpiece positioning hole 41 communicates with the back pres...

Embodiment 2

[0049] This embodiment is improved on the basis of Embodiment 1, and the improvement is that: the side of the clamp base 4 away from the back pressure cylinder 3 is provided with a plurality of set screws 43 threadedly connected with the clamp base 4, so The set screw 43 extends into the workpiece positioning hole 41, and the diameter of the circular hole 42 is not greater than the inner diameter of the cathode chamber 33.

[0050] The set screw 43 compresses the titanium alloy workpiece 100 so that the titanium alloy workpiece 100 will not move during the machining process, and at the same time prevent the electrolyte from seeping out along the workpiece positioning hole 41 during the electrolytic machining process.

[0051] Other parts in this embodiment are basically the same as those in Embodiment 1, so details will not be repeated one by one.

Embodiment 3

[0053] This embodiment is improved on the basis of Embodiment 2, and the improvement is that: the side of the clamp base 4 away from the back pressure cylinder 3 is provided with a pressure plate 44, and the circular hole 42 is formed through the clamp base 4 Circular through hole, the area of described pressing plate 44 is greater than the area of circular hole 42 so that pressing plate 44 can cover circular hole 42 completely, and described set screw 43 is threadedly connected with pressing plate 44 and stretches into workpiece positioning hole 41, for The titanium alloy workpiece 100 is pressed. A plurality of threaded holes are also provided around the pressing plate 44 , and the pressing plate 44 is fixedly connected to the fixture base 4 through screws or screw rods passing through the threaded holes.

[0054] Other parts in this embodiment are basically the same as those in Embodiment 2, so details will not be repeated one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com