Patents

Literature

100results about How to "Reduce taper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

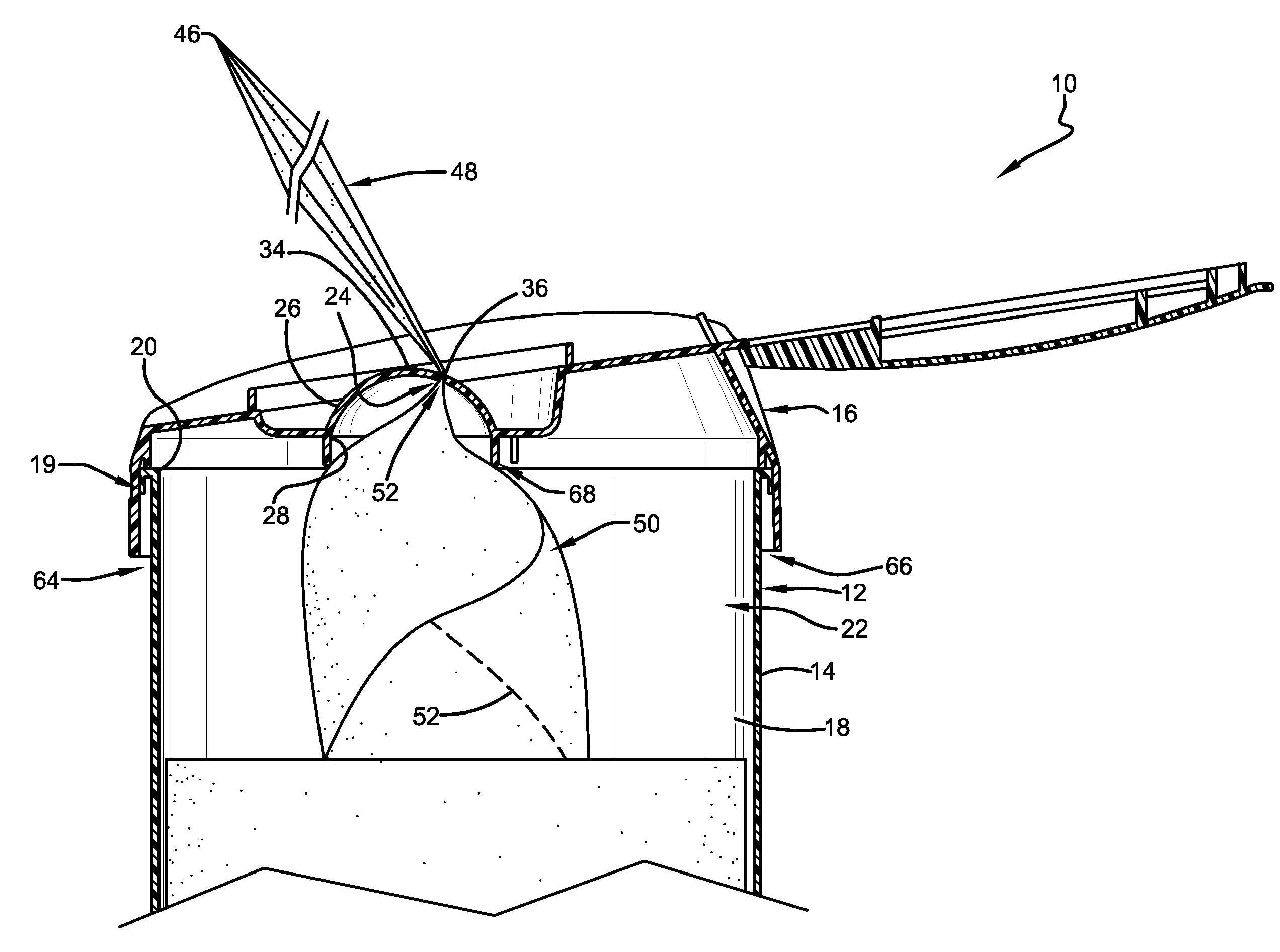

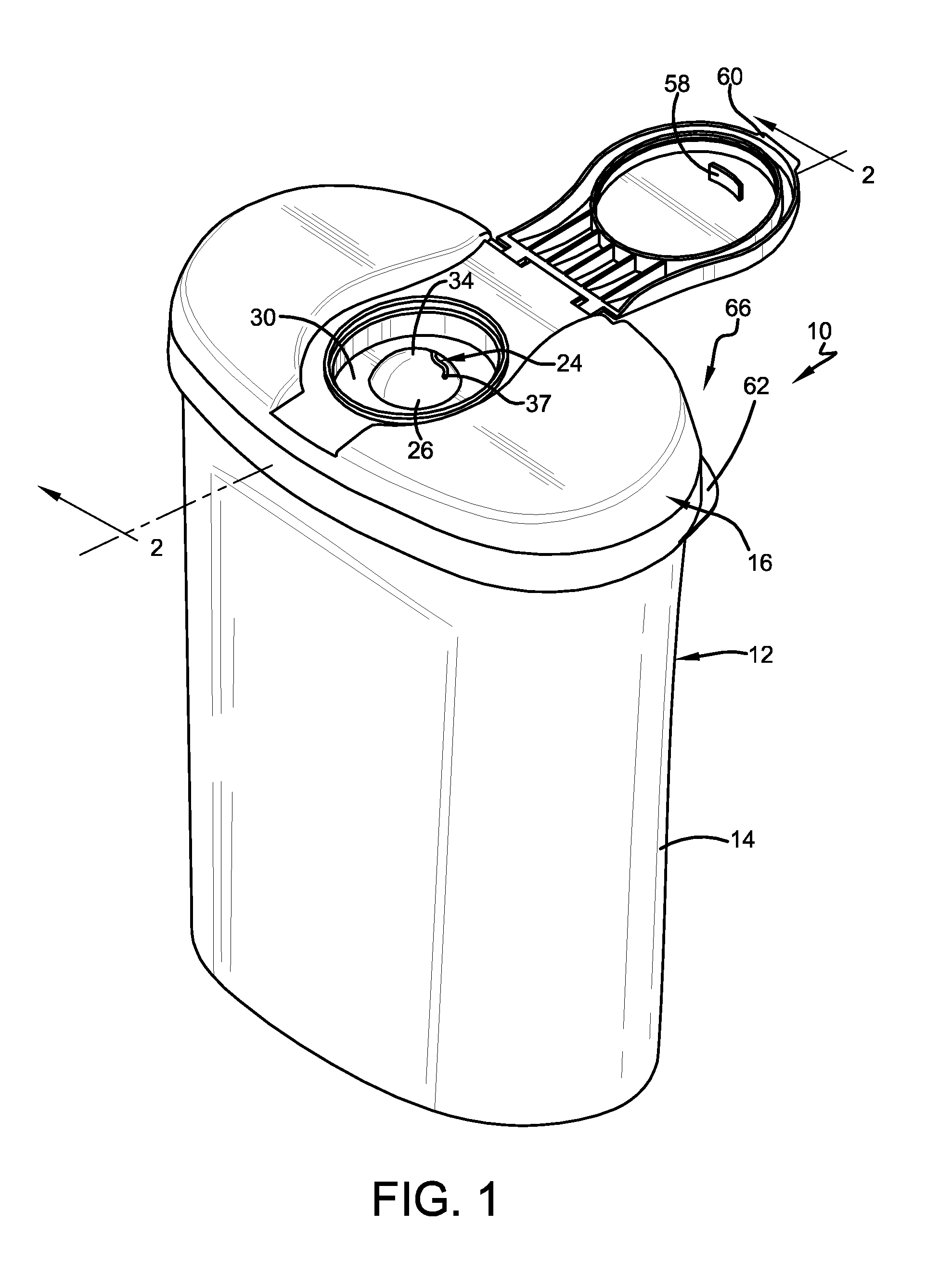

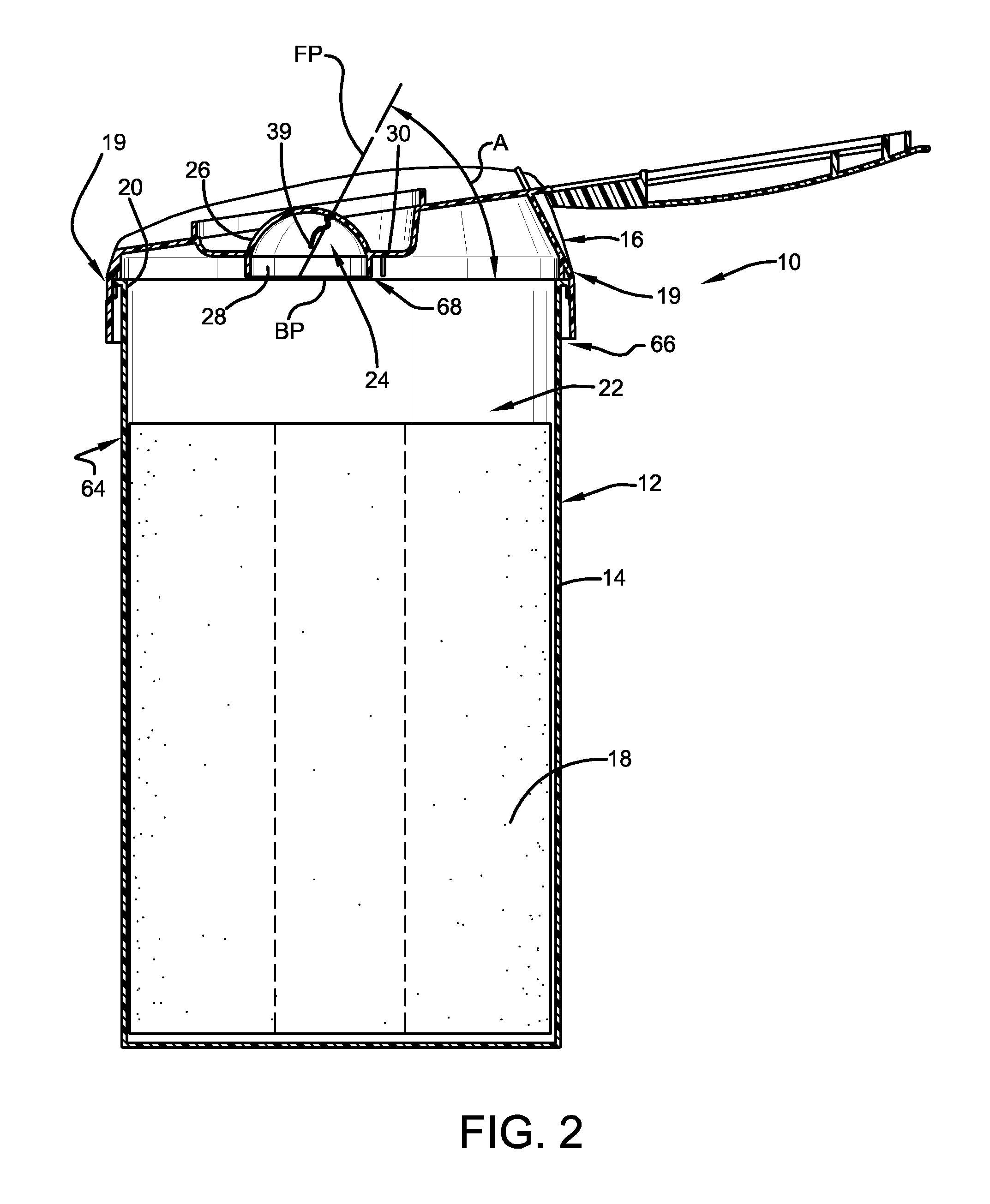

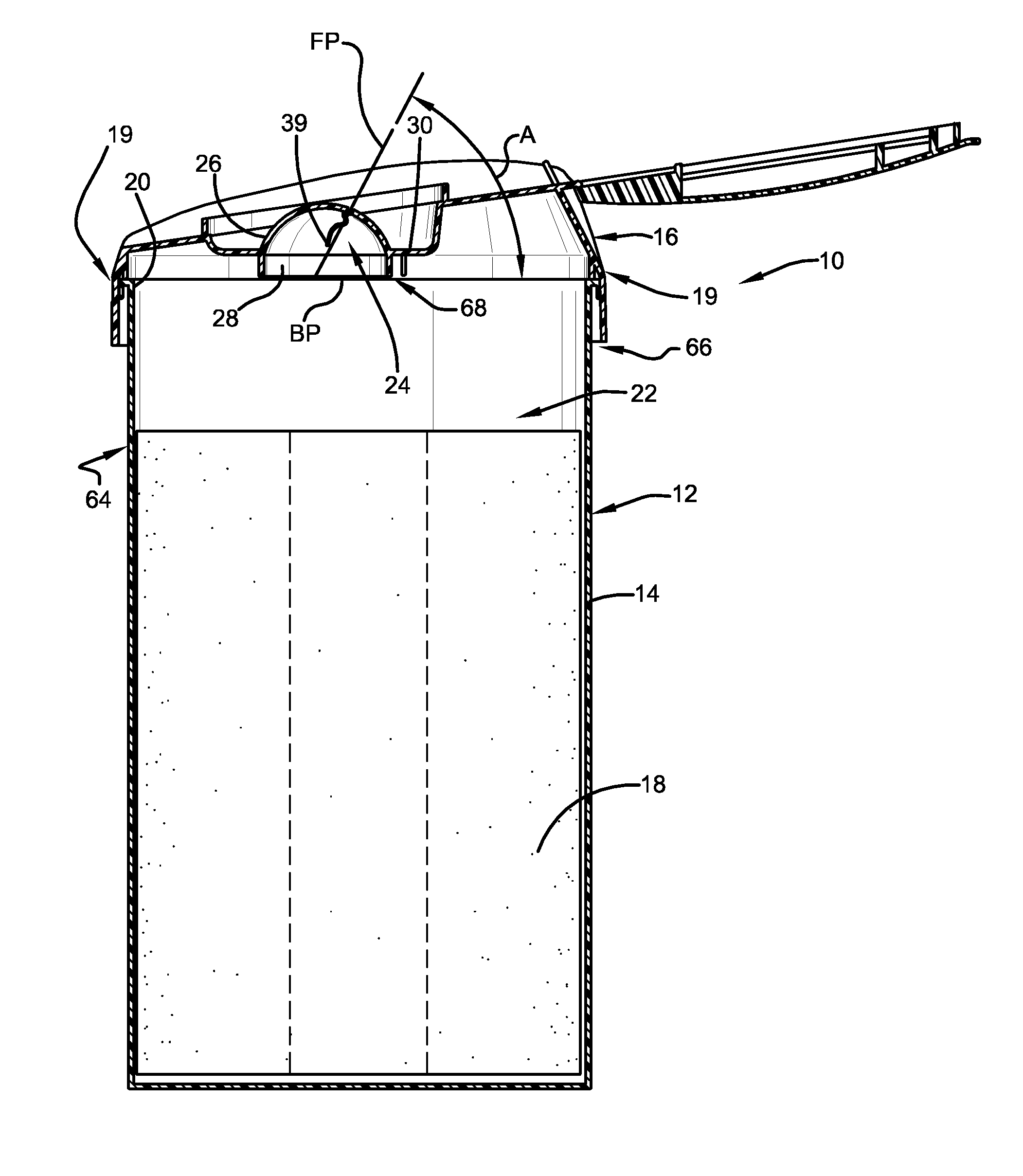

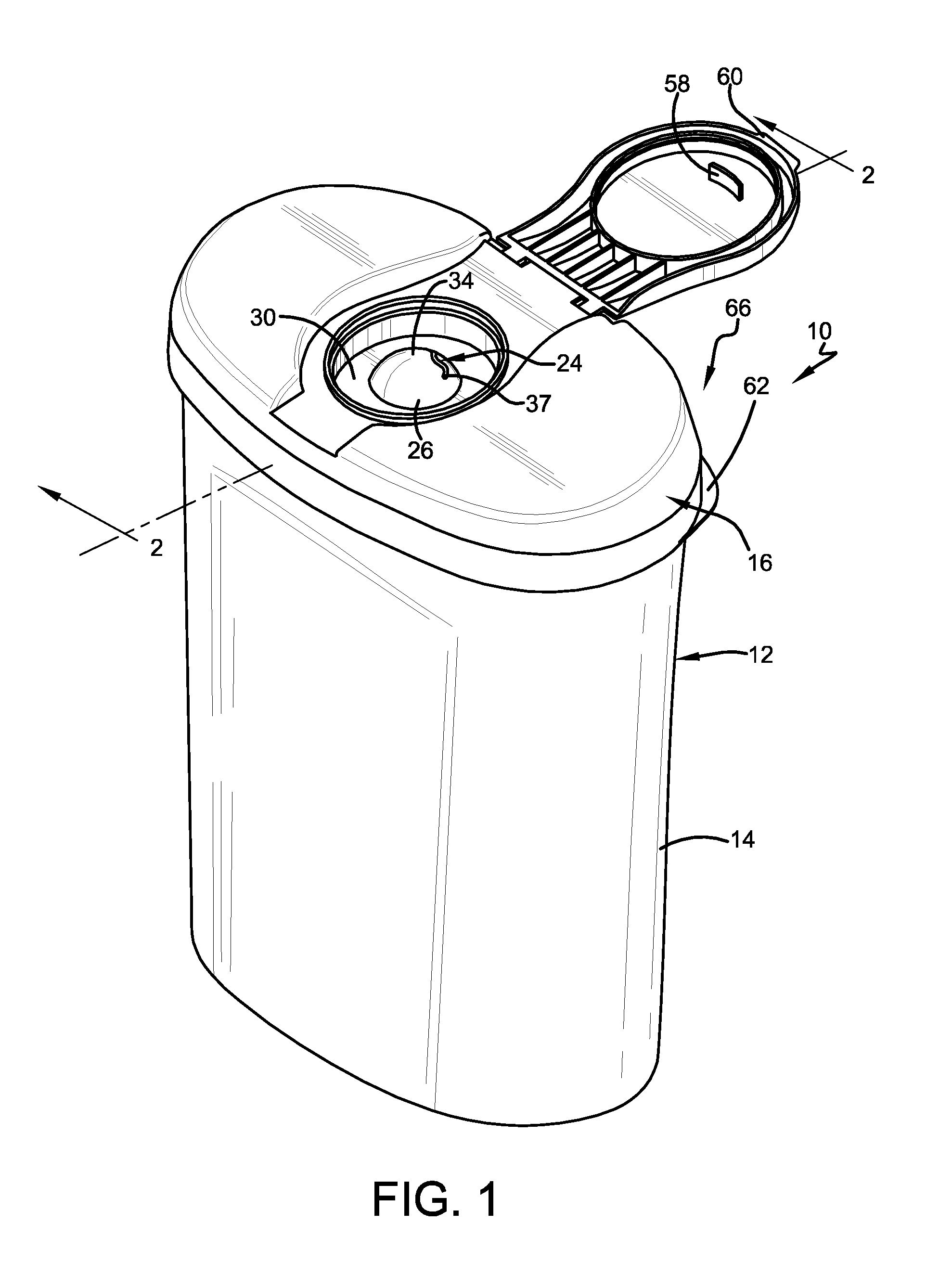

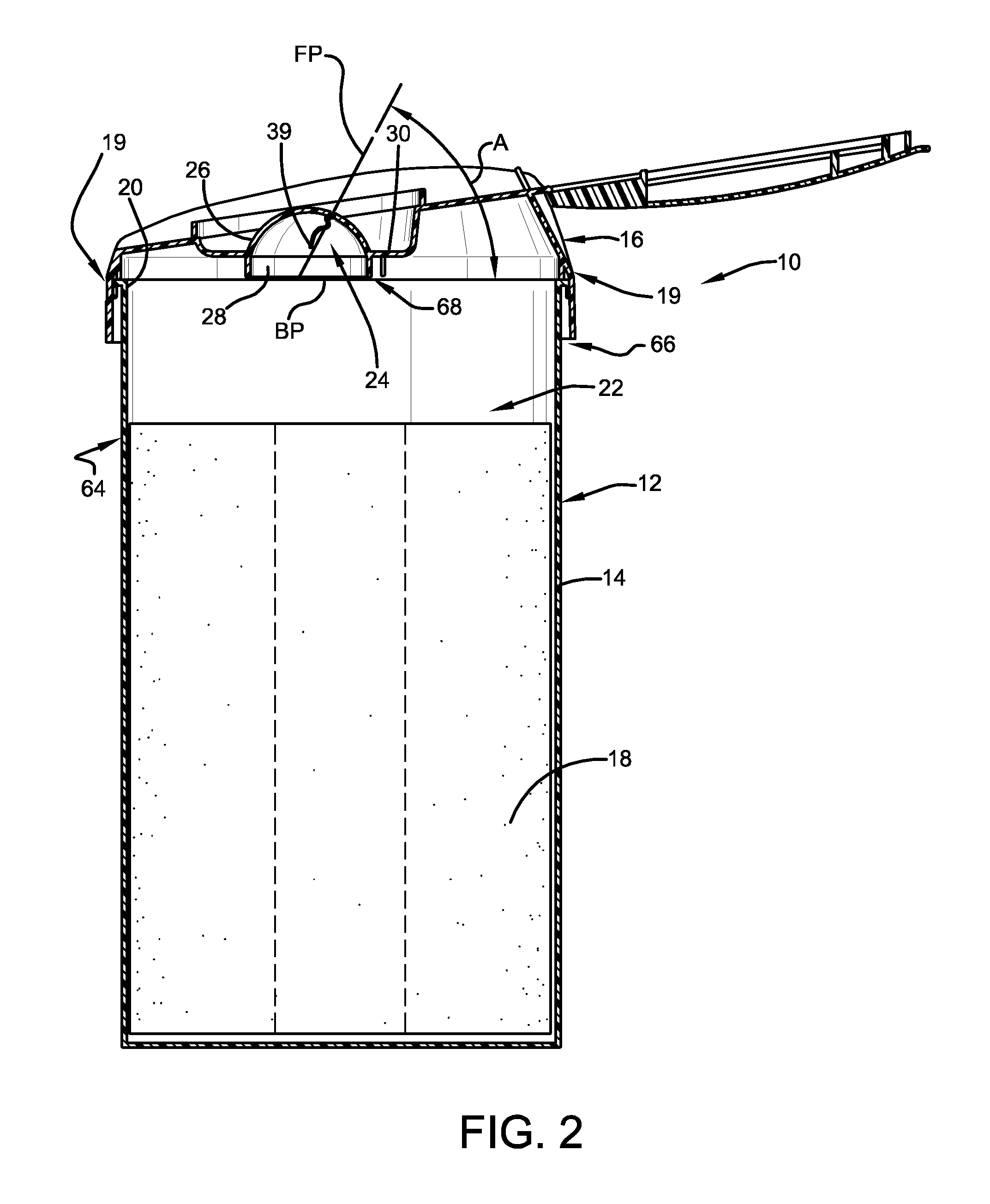

Wipes dispenser

ActiveUS20120145737A1Reduce taperAvoid problemsFlat article dispensingDomestic applicationsEngineeringMechanical engineering

Owner:GOJO IND INC

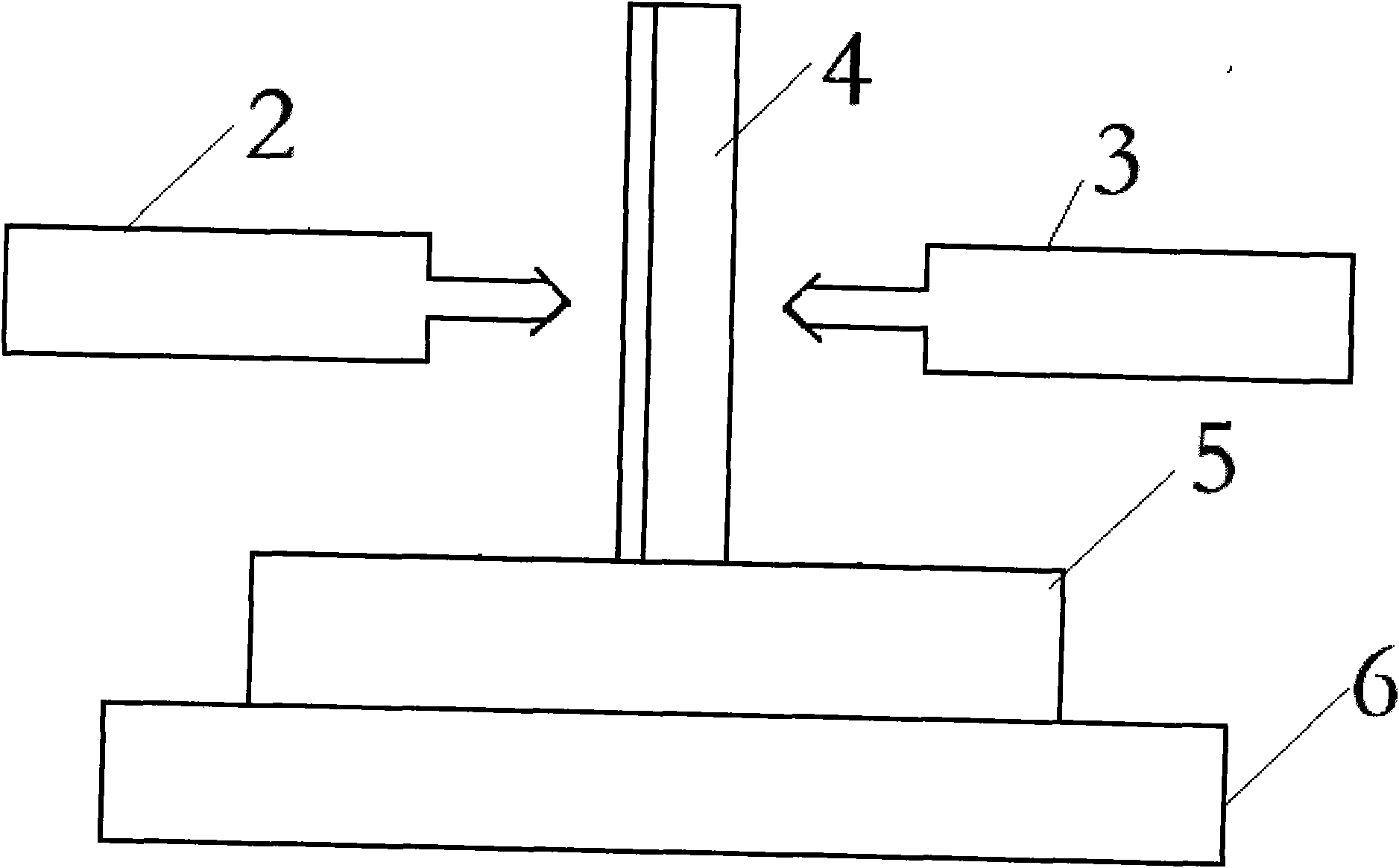

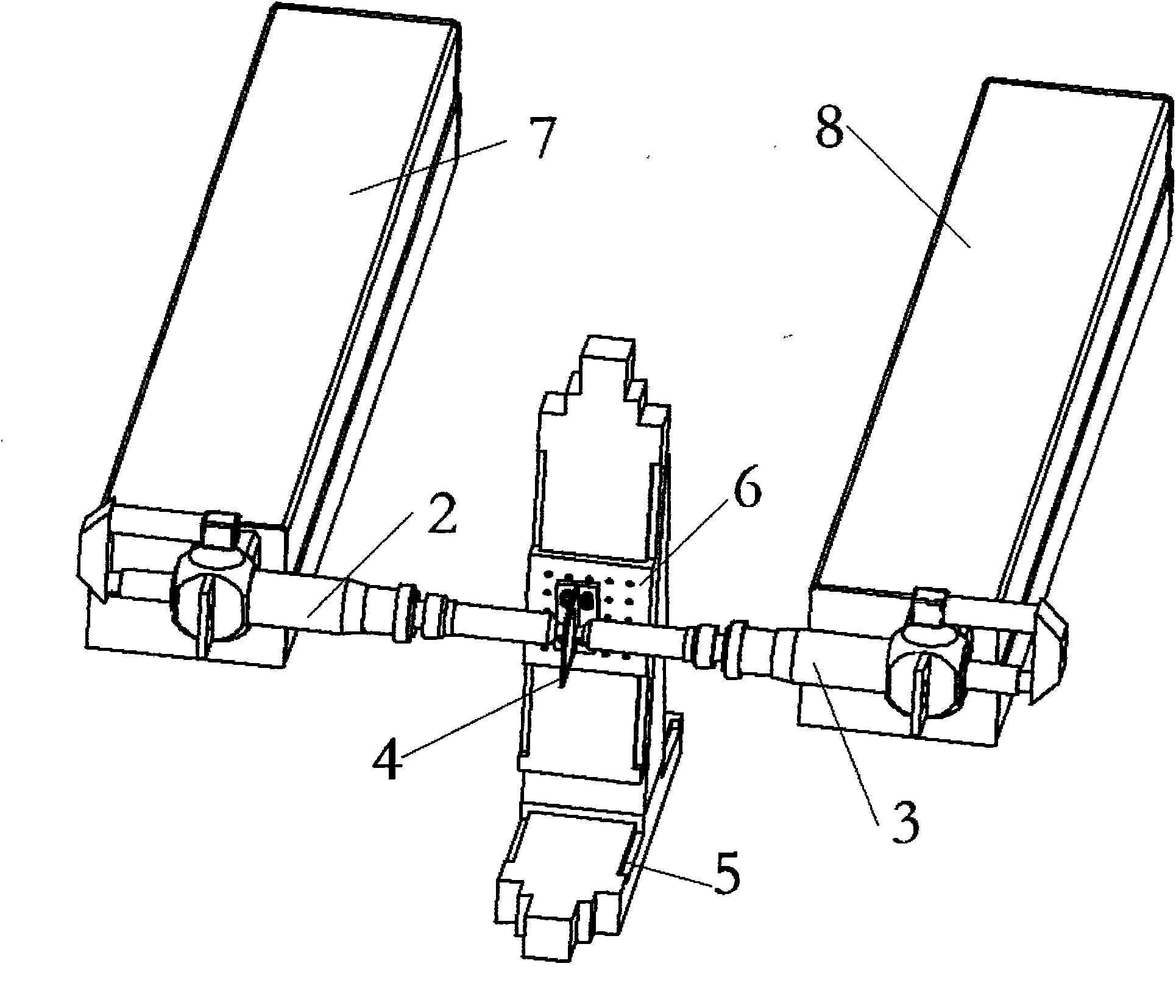

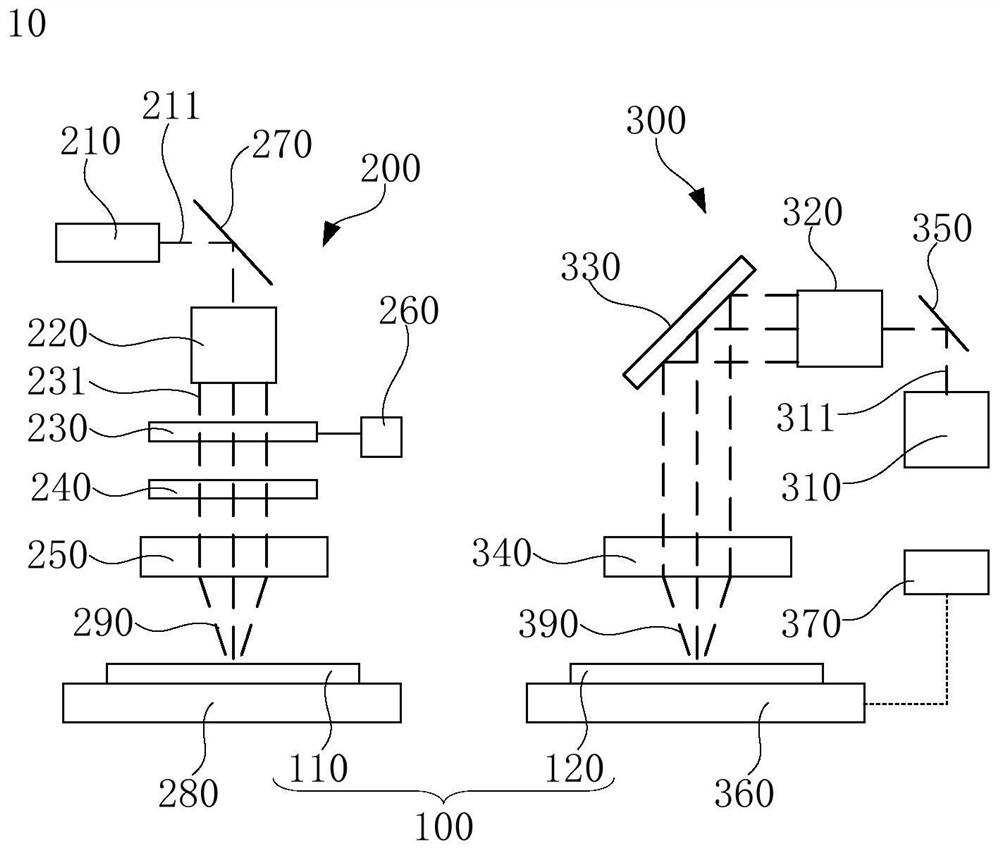

Laser double-faced synchronous machining system and machining method thereof

InactiveCN101658979ASmall thermal damage areaNarrow kerfLaser beam welding apparatusSuperhard materialBeam splitter

The invention discloses a laser double-faced synchronous machining system and a machining method thereof. The system comprises a laser, a middle displacement platform and a machined work piece. The two sides of the machined work piece are two laser beams which are respectively acted on the two side faces of the machined work piece. The laser beams at the two sides of the machined work piece are onthe same straight line or intersectant in the work piece. The two laser beams can be respectively generated by two lasers or generated by one laser with a beam splitter. The method comprises the steps: inputting cut graph into a computer, and controlling the middle displacement platform to move according to a track by software, to complete the cutting machining. By laser double-faced synchronousmachining, the machining depth at one time is more than 1 times of that of the single-faced machining. Compared with traditional double-faced machining, the invention does not need adjust a clamping tool in an overturning way, can complete the machining by clamping at one time, has balanced heat action applied to the two faces of the work piece, has low remnant stress and heat deformation after cutting, improves the cutting quality, and realizes the double-faced synchronous cutting to various superhard materials such as PDC, PCB and composite sheet thereof, ceramics, etc.

Owner:LANGFANG HAOBO DIAMOND

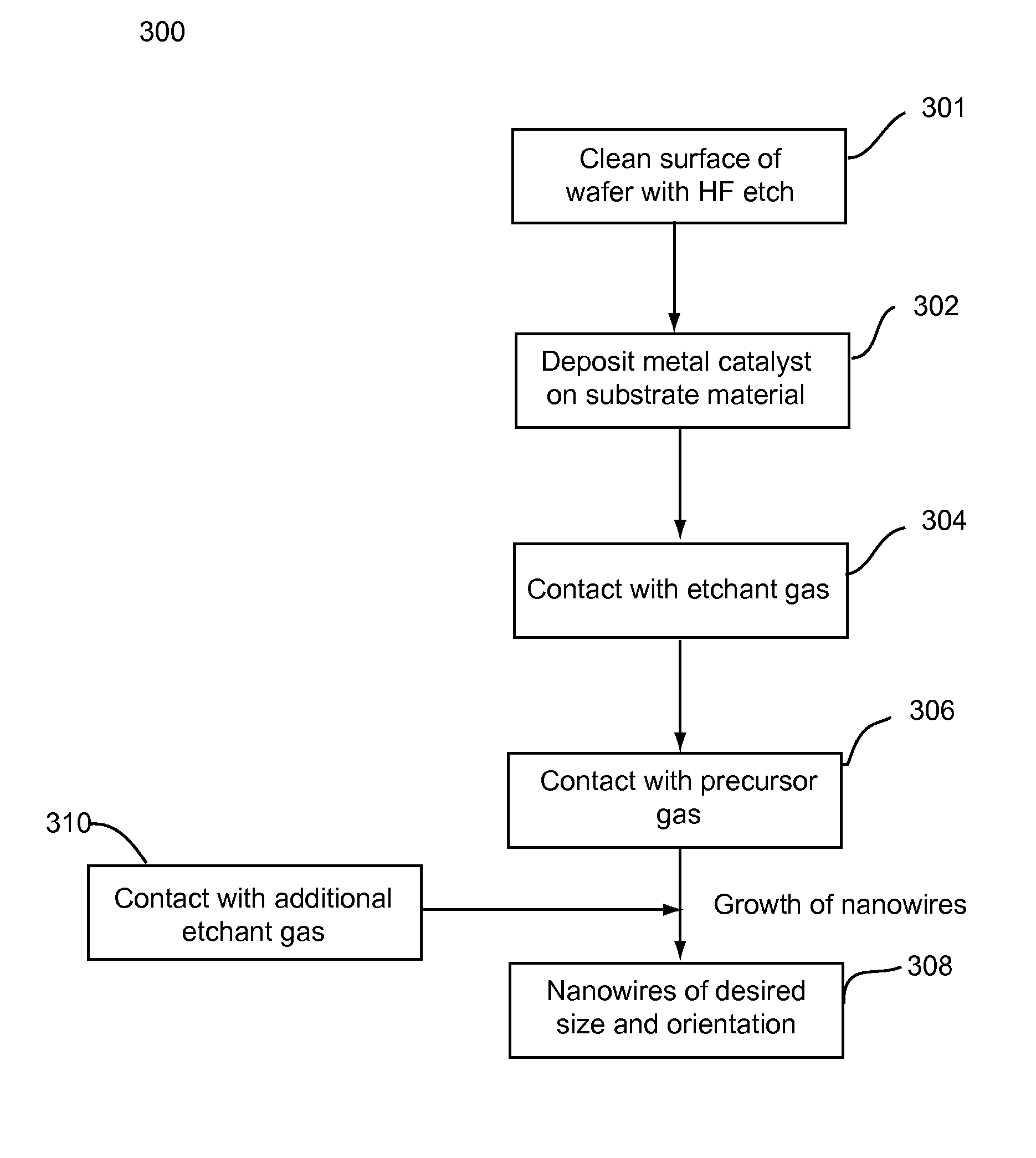

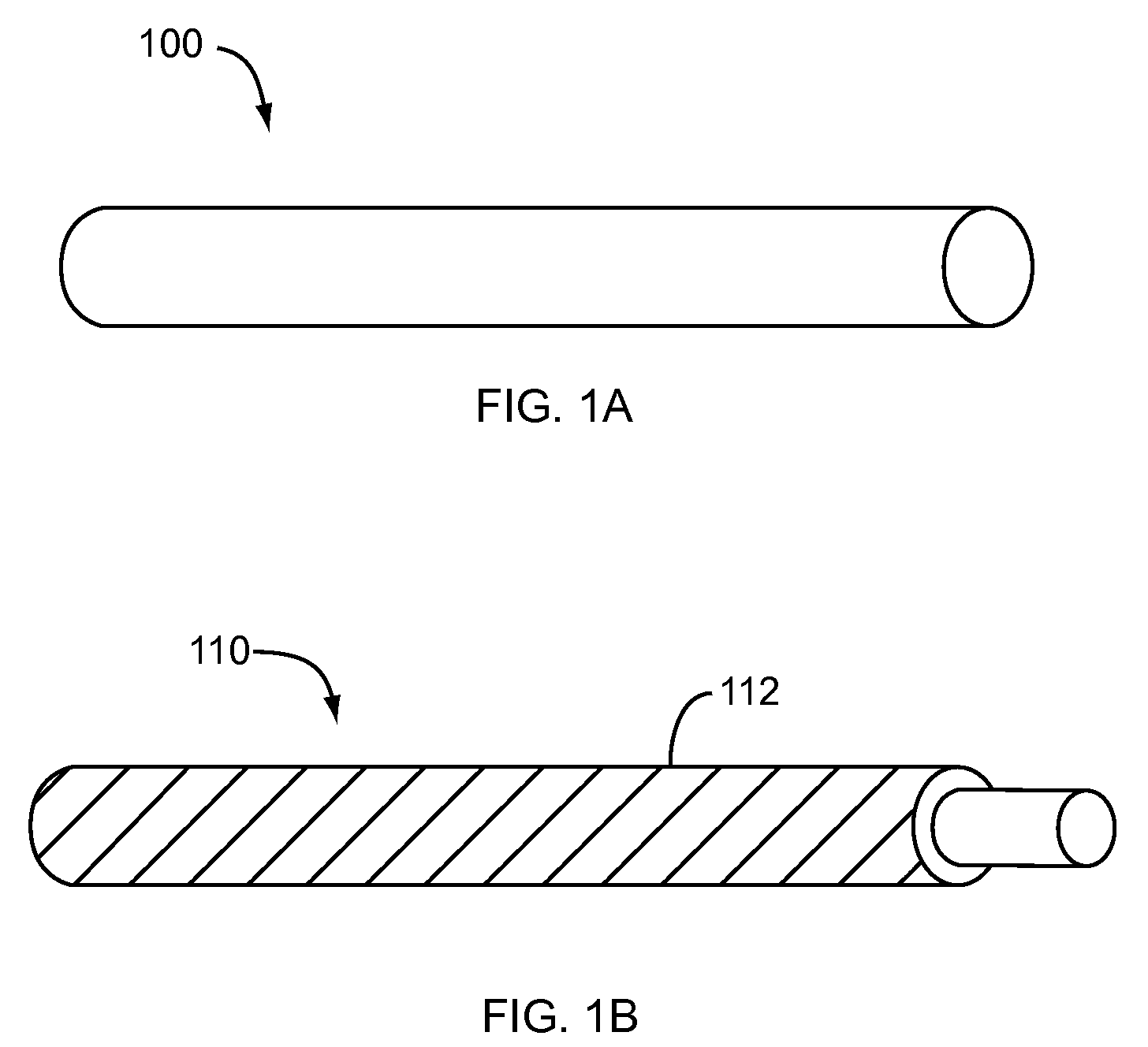

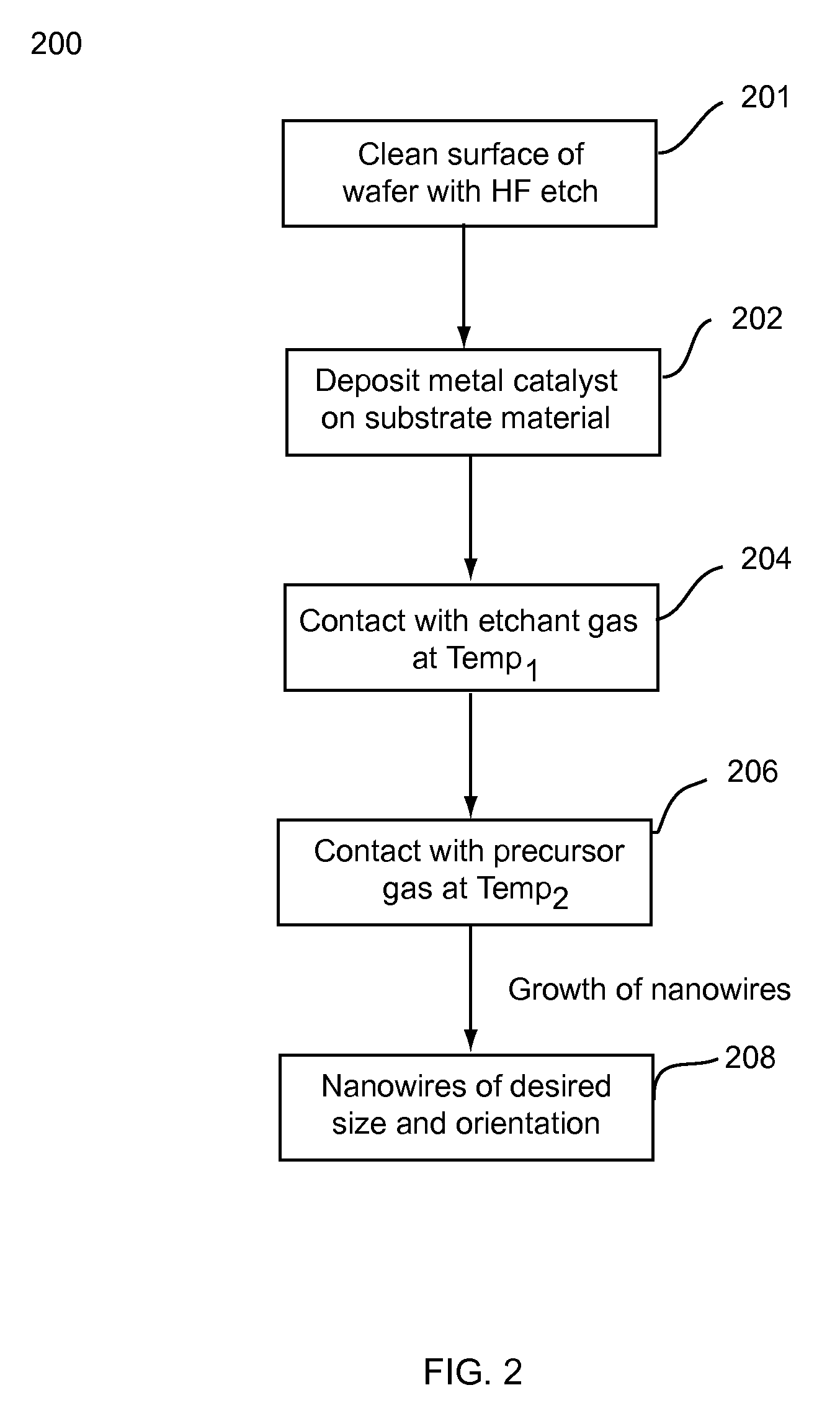

Systems and methods for nanowire growth

ActiveUS7776760B2Good ohmic contactReduce decomposition ratePolycrystalline material growthIndividual molecule manipulationNanowireAlloy

Owner:ONED MATERIAL INC

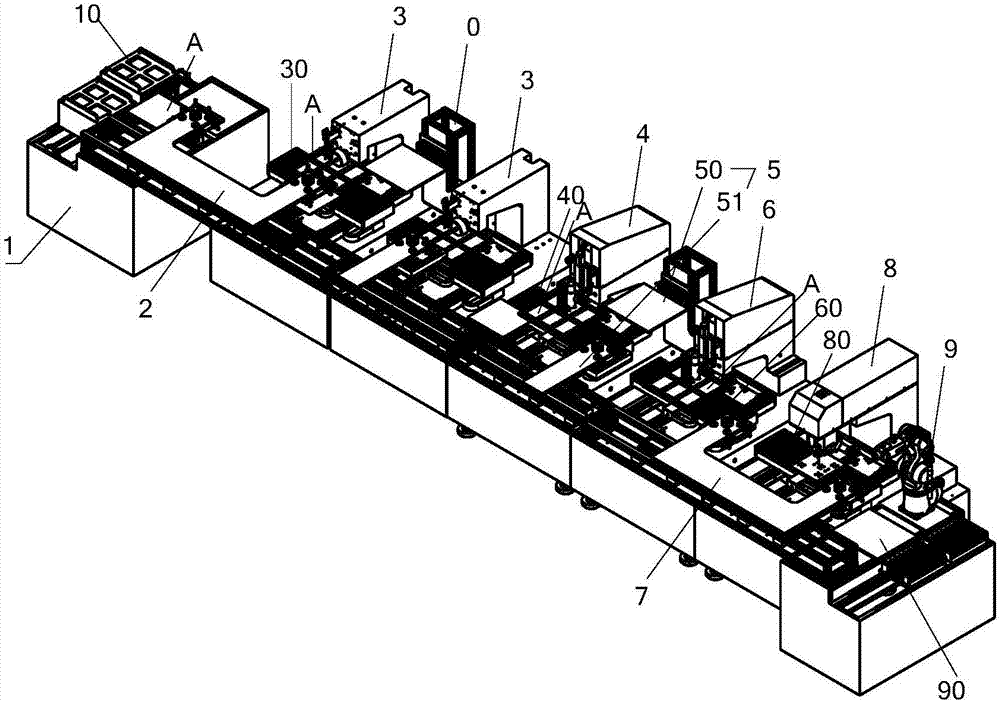

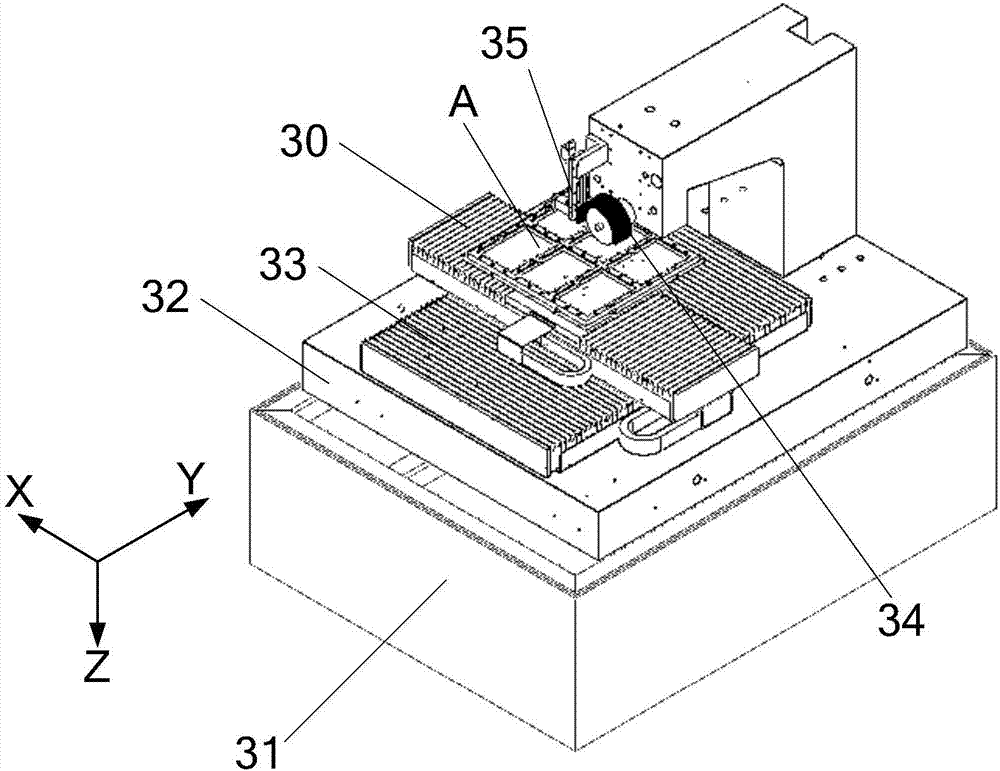

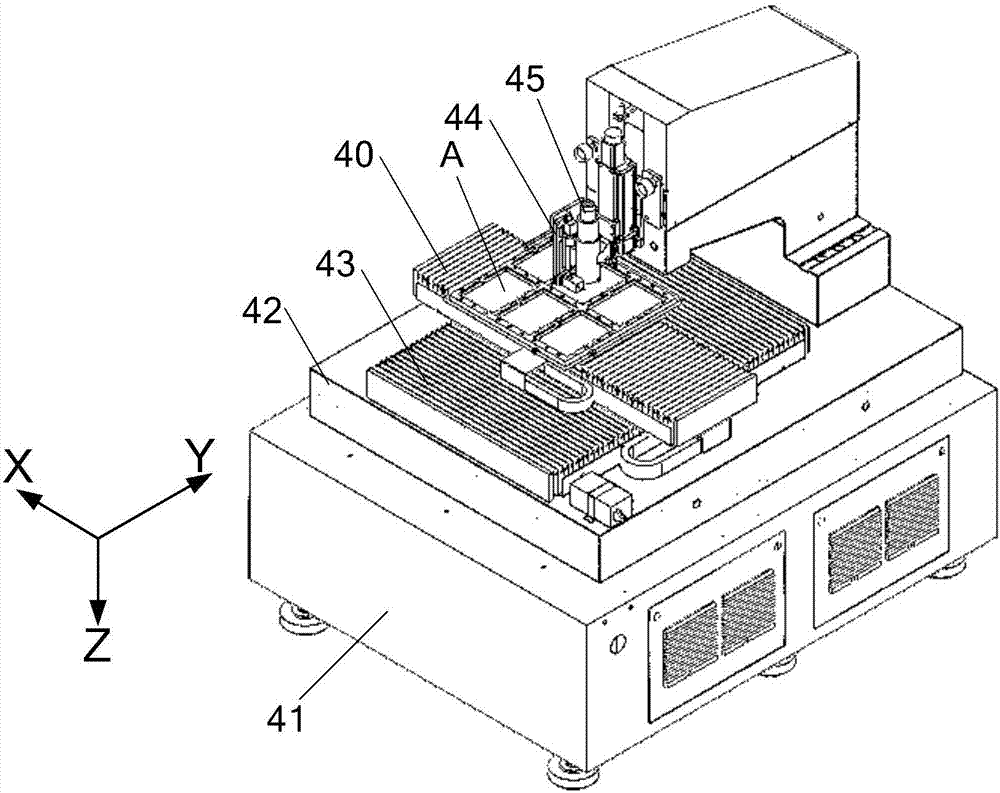

Laser cutting equipment and method

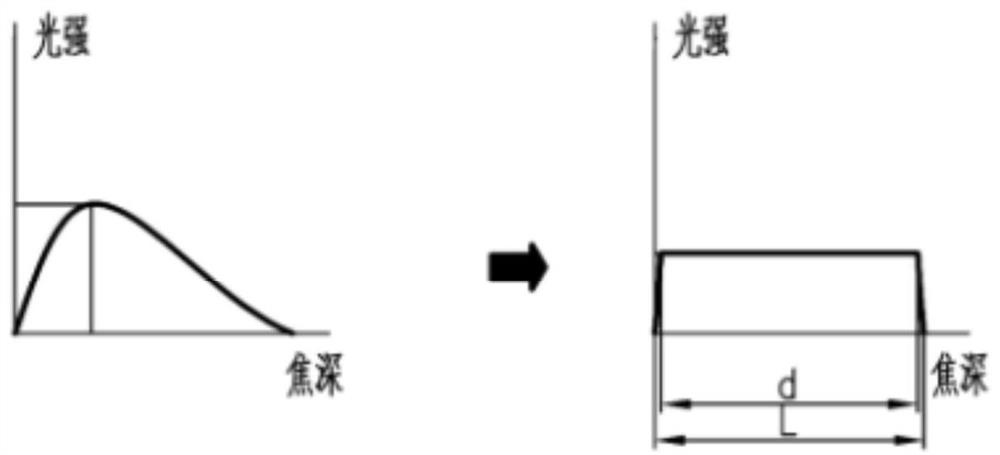

ActiveCN107199410AEfficient cuttingImprove static strengthGlass severing apparatusWelding/soldering/cutting articlesGaussian beamLight beam

The invention provides laser cutting equipment and method. The laser cutting equipment comprises a feeding assembly, a first dual-linkage mechanical arm, a cutter wheel cutting assembly, a front laser cutting assembly, a turning-over assembly, a reverse laser cutting assembly, a second dual-linkage mechanical arm, a laser broken piece assembly and a sorting assembly. The front laser cutting assembly and the reverse laser cutting assembly perform laser cutting on a sample through bessel beams, and the focused bessel beams are focused light beams with a large focal depth, so that compared with gauss beams, the thick sample to be cut can be cut effectively, and thus the application range of the laser cutting equipment is broadened. Besides, the laser cutting assemblies and the laser broken piece assembly are adopted to cut the sample twice correspondingly, a finished product can be separated from waste, and cutting efficiency is high. In addition, the laser cutting equipment has the advantages that the cutting path is narrow, edge breakage of the surface of the cut product is small, the conical degree is small, the static pressure strength is high, an abnormally-shaped product can be cut, and the like.

Owner:东莞市盛雄激光先进装备股份有限公司

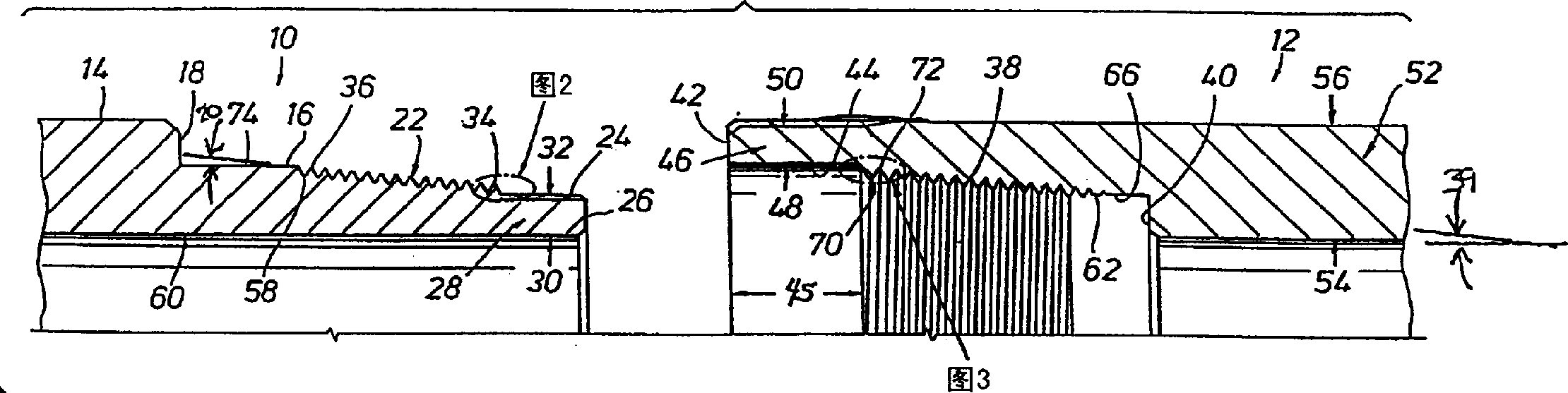

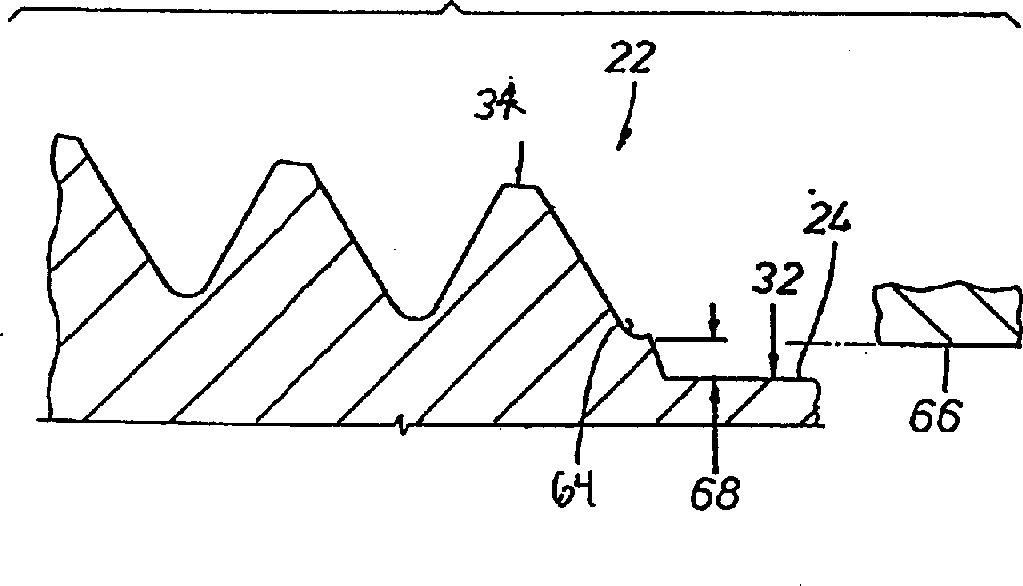

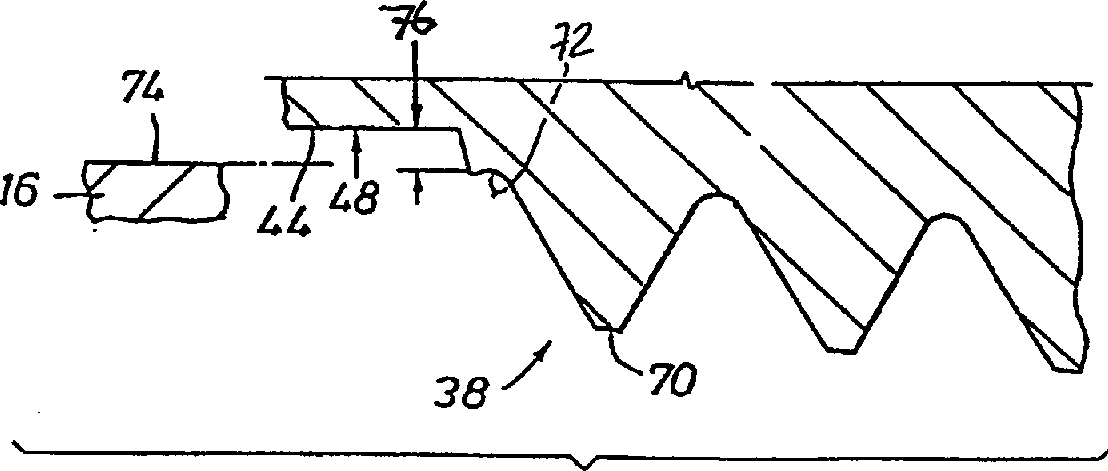

Ultra high torque double shoulder tool joint

InactiveCN1261948AIncrease the cross-sectional areaWide front section with large cross-sectional areaDrilling rodsDrilling casingsNoseTorsional strength

An ultra high torque double shoulder tool joint for maximizing the torsional strength of a threaded connection by correlating a transverse cross-sectional counter-bore area of the box (12) and pin (10). The pin (10) includes a base section (74) and a nose section (24). The nose section (24) defines a cross-sectional nose area (28). The pin external threads (22) include a taper no greater than 1 / 12. The box (12) include a cross-sectional counterbore area (46) and a cross-sectional box area (52). The overall strength of the tool joint is dependent upon the torsional strength of the threaded connection, the cross-sectional nose area (28) and the cross-sectional counter-bore area (46).

Owner:GRANT PRIDECO LP

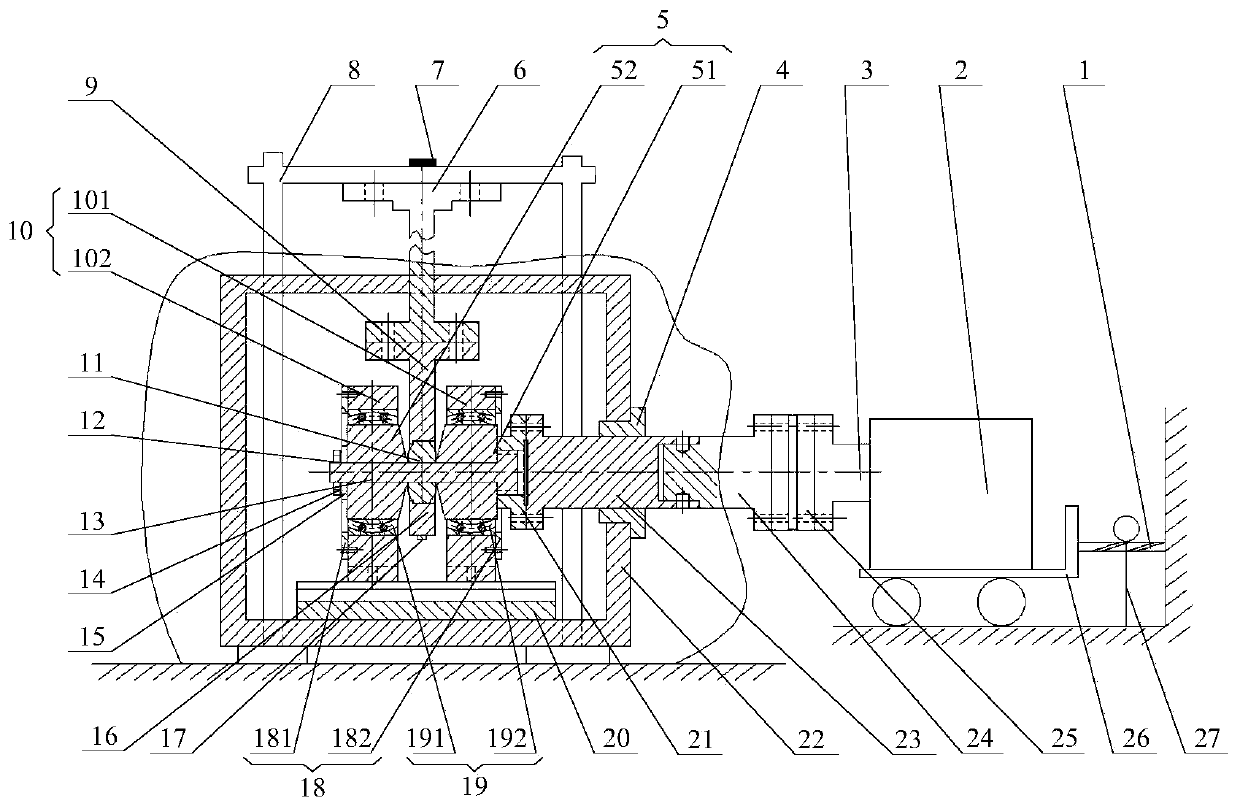

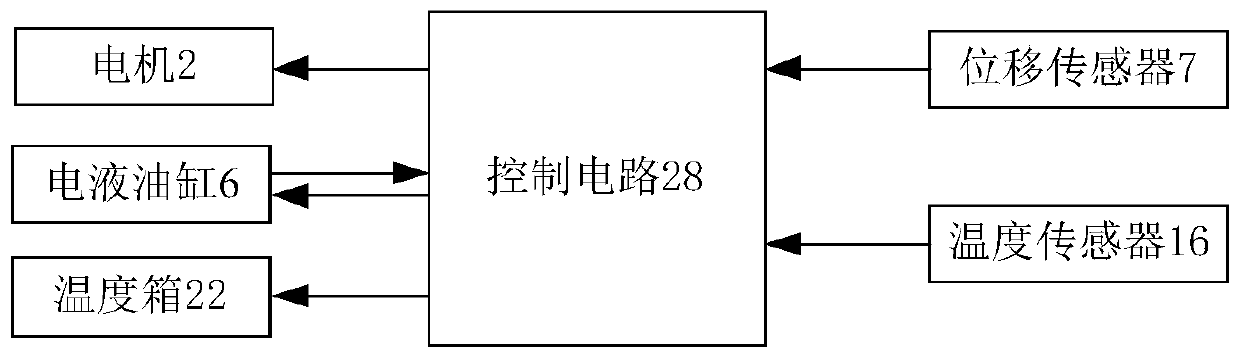

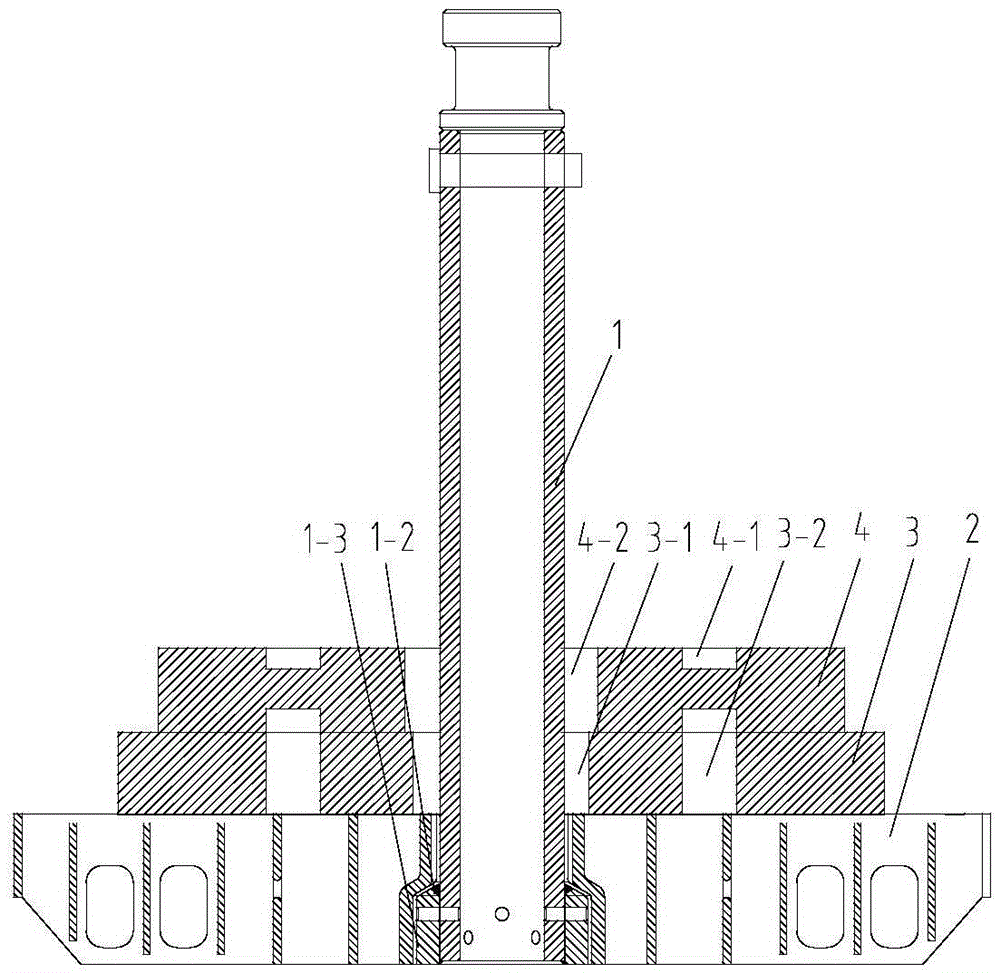

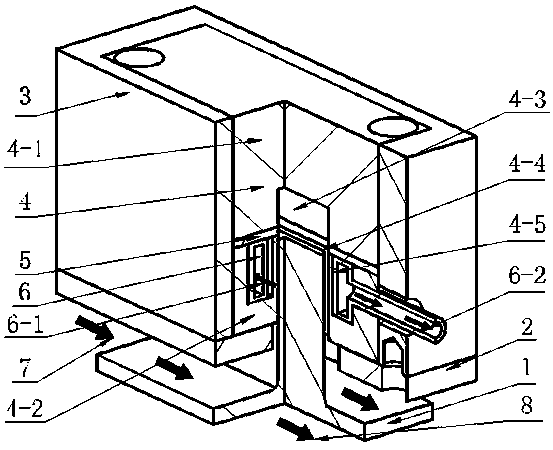

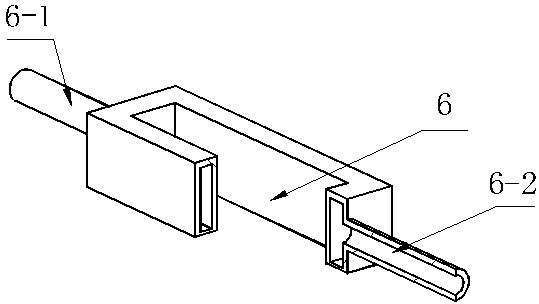

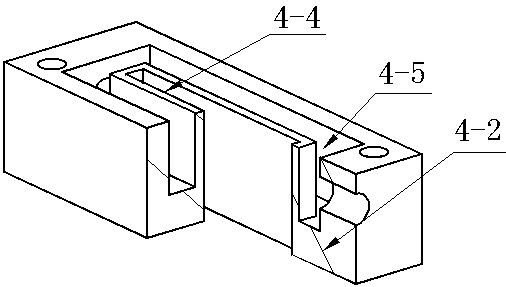

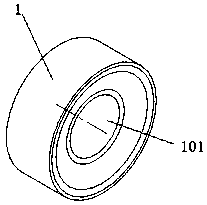

Joint bearing low-temperature wear test system and assembly method thereof

ActiveCN110243602AEasy to disassembleImprove general performanceMachine bearings testingInvestigating abrasion/wear resistanceTemperature controlRadial stress

The invention provides a joint bearing low-temperature wear test system. The system comprises a base, a temperature box, a radial stress subsystem, a power subsystem, a temperature control subsystem, a wear measurement subsystem and a clamp subsystem. The clamp subsystem comprises a pushing block, a loading plate, an accompanying test bearing seat, a mandrel, an accompanying test bearing, an end cover and a locking part, which are independent detachable parts; the mandrel, the pushing block or the loading plate can be replaced to realize clamping in a life test of joint bearings with different diameters, so that the utilization rate and the universality of a test clamp are improved; and in addition, the clamp subsystem adopts the structural design improvement that a single-side flange is added to an inner hole of the loading plate, the thickness of the pushing block is reduced, the flange and the end cover cooperatively fix the accompanying test bearing, and the like, so that the mandrel deformation or breakage easily caused in the joint bearing wear test process is effectively avoided.

Owner:CHINA AERO POLYTECH ESTAB

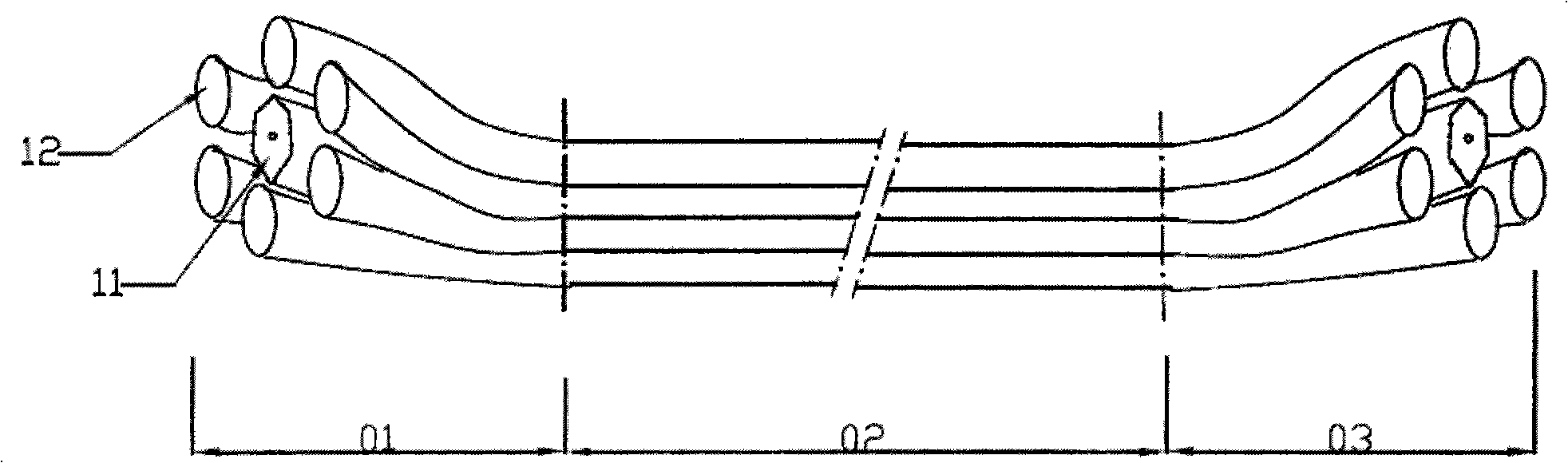

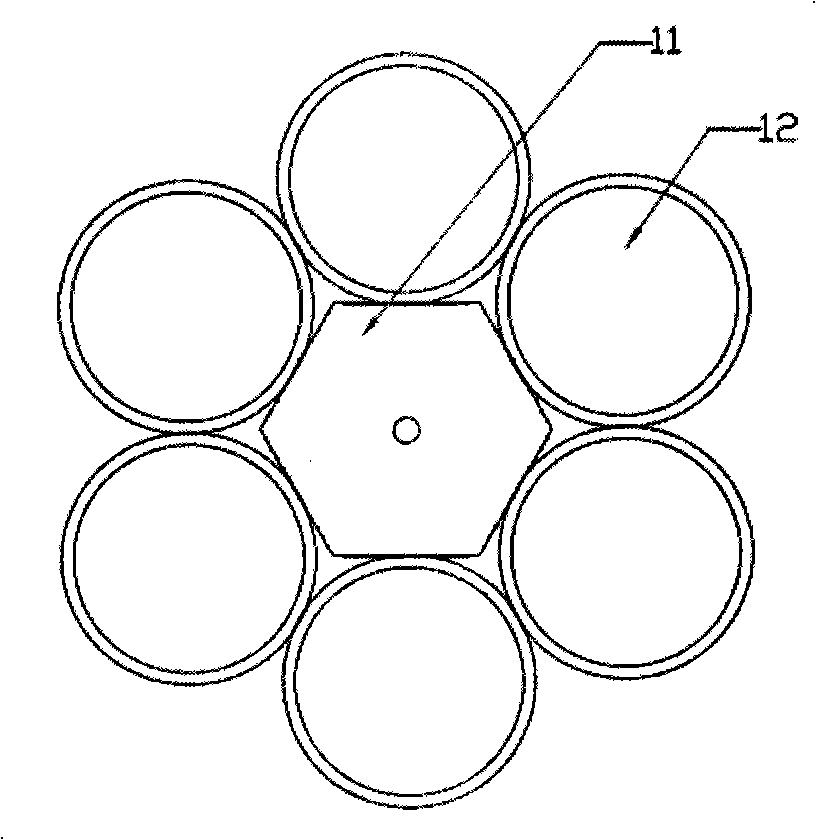

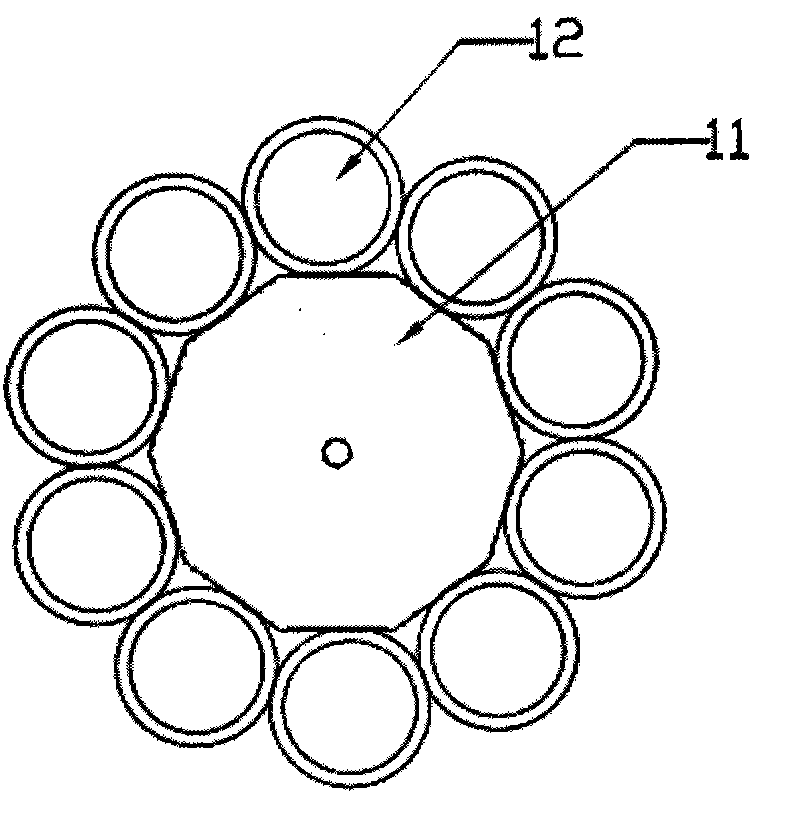

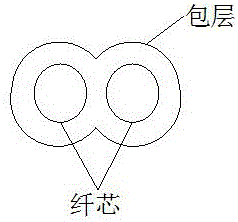

Full optical fiber laser synthesizer and preparation method thereof

The invention discloses a novel all optical fiber laser synthesizer which is used for high-power optical fiber lasers and amplifiers and a preparation method thereof. The novel full optical fiber laser synthesizer is composed of an optical fiber bundle consisting of a plurality of optical fibers with a certain diameter, wherein the optical fiber bundle comprises a rare earth doped fiber 11 in the middle and a plurality of multimode optical fibres 12, the shape of the rare earth doped fiber 11 the coating of which is removed is regular polygon, and the shape of the multimode optical fibre the coating of which is removed is round; all optical fibers in a middle position 02 are tight and close, and the outer surface of the optical fiber bundle is coated with a coating with the refractive index lower than that of pure quartz; and all optical fibers on two end parts 01 and 03 of the optical fiber bundle can be separated, and each optical fiber is independently coated with a coating. The fiber bundle is formed by carrying out wiredrawing on the corresponding optical fiber preform bunch on an optical fiber wire drawer tower in the mode of designed arrangement. The full optical fiber laser synthesizer of the invention has simple preparation process, is suitable to be produced in large batch and has the characteristics of high reliability and low insertion loss.

Owner:HUAZHONG UNIV OF SCI & TECH

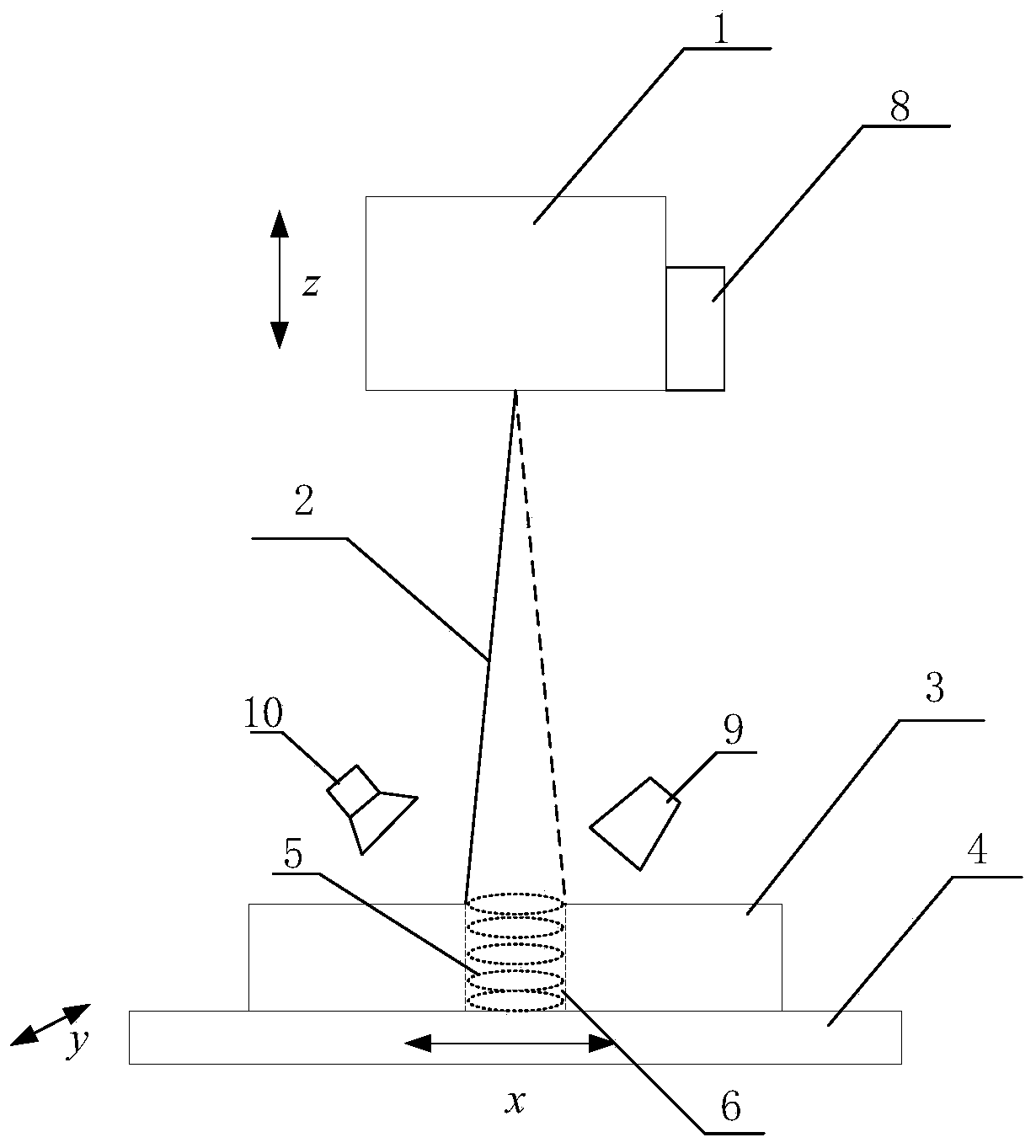

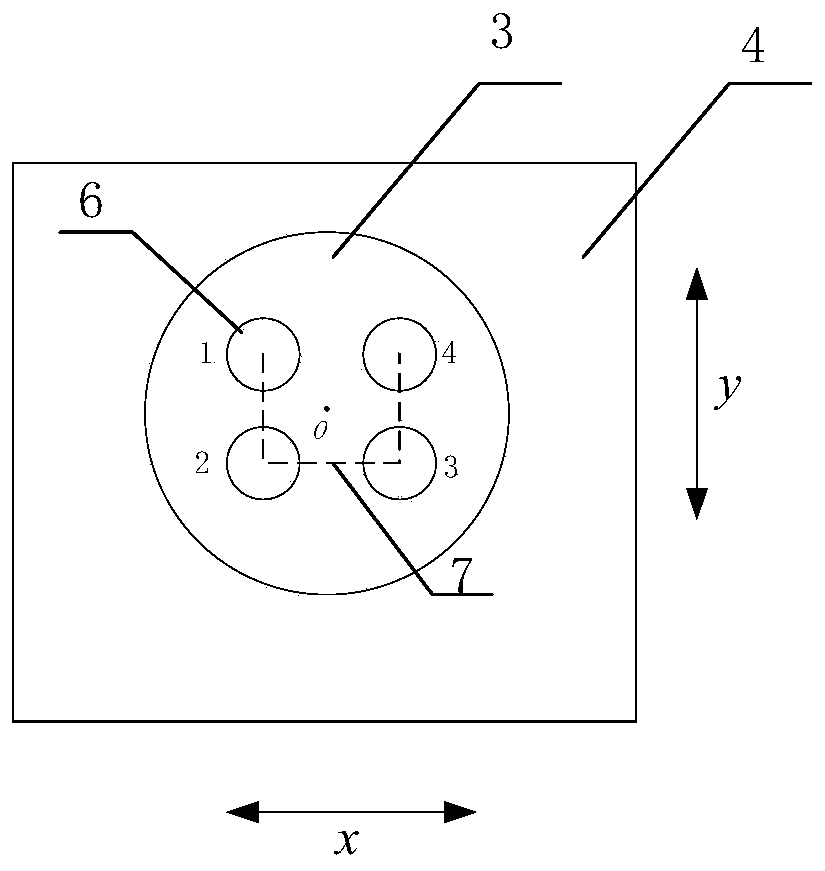

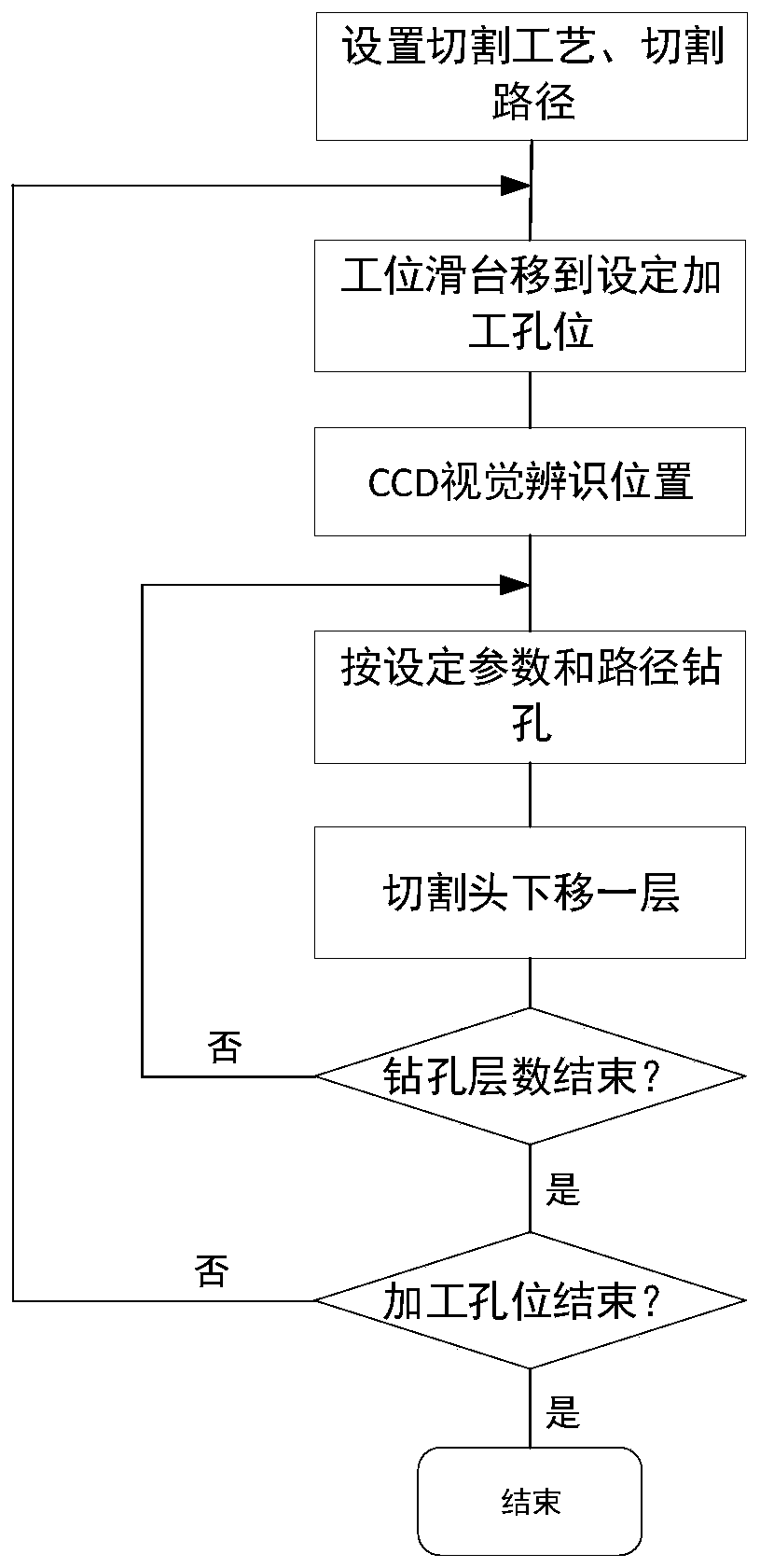

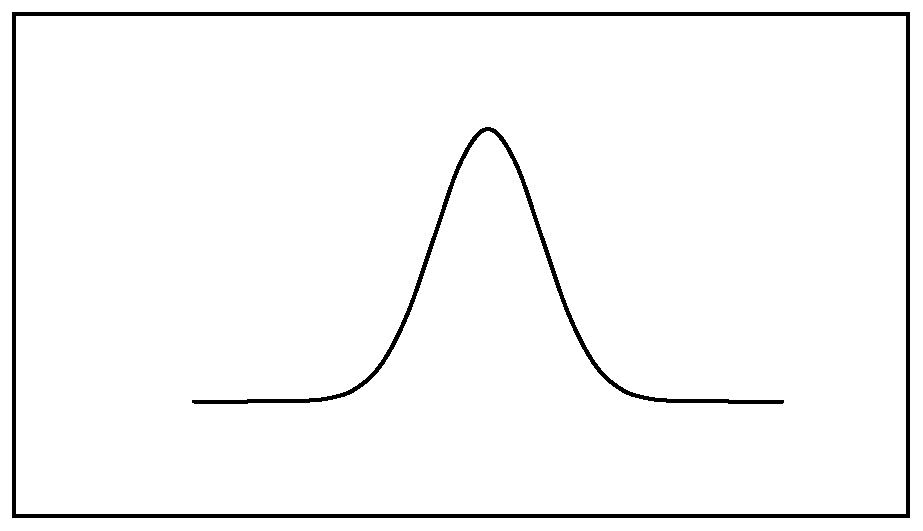

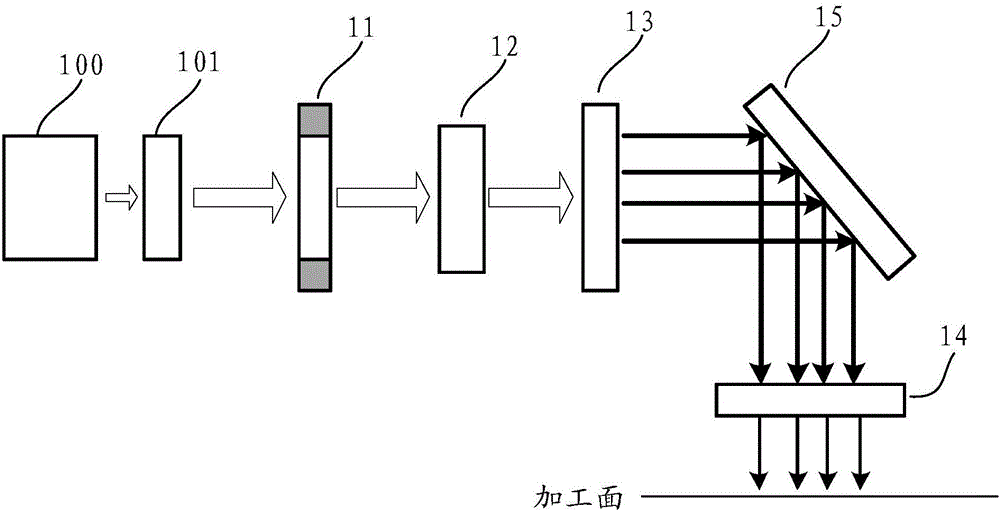

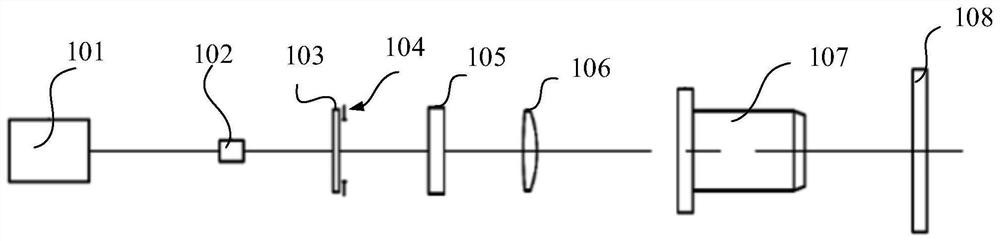

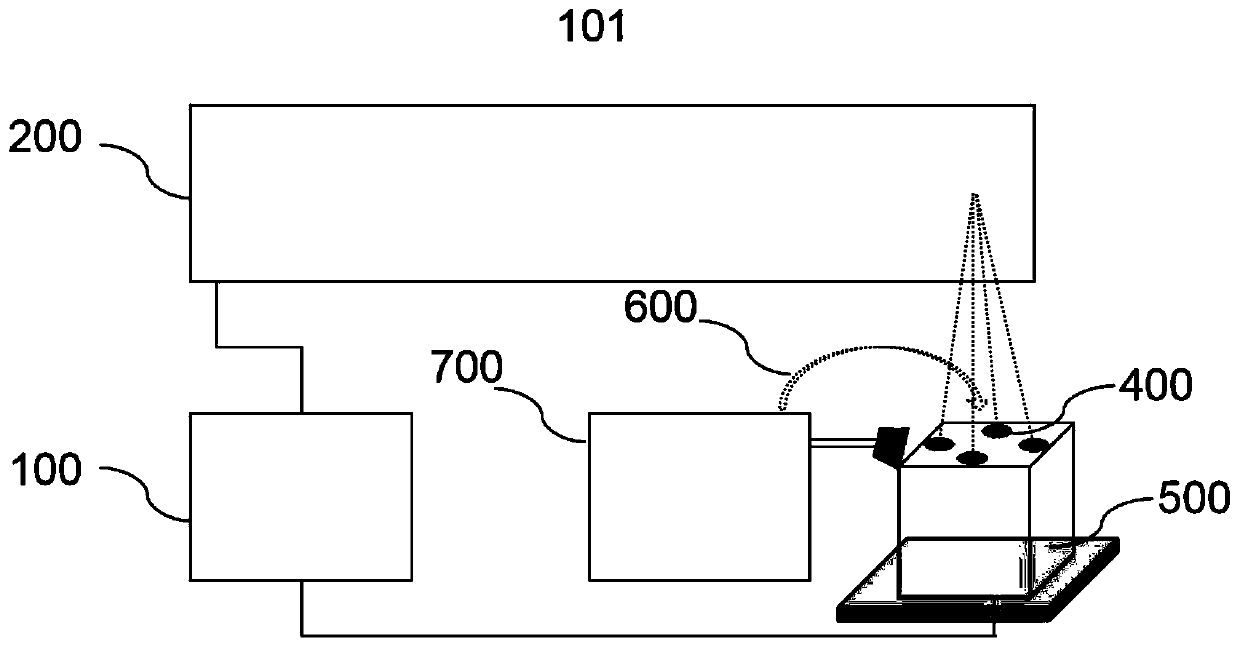

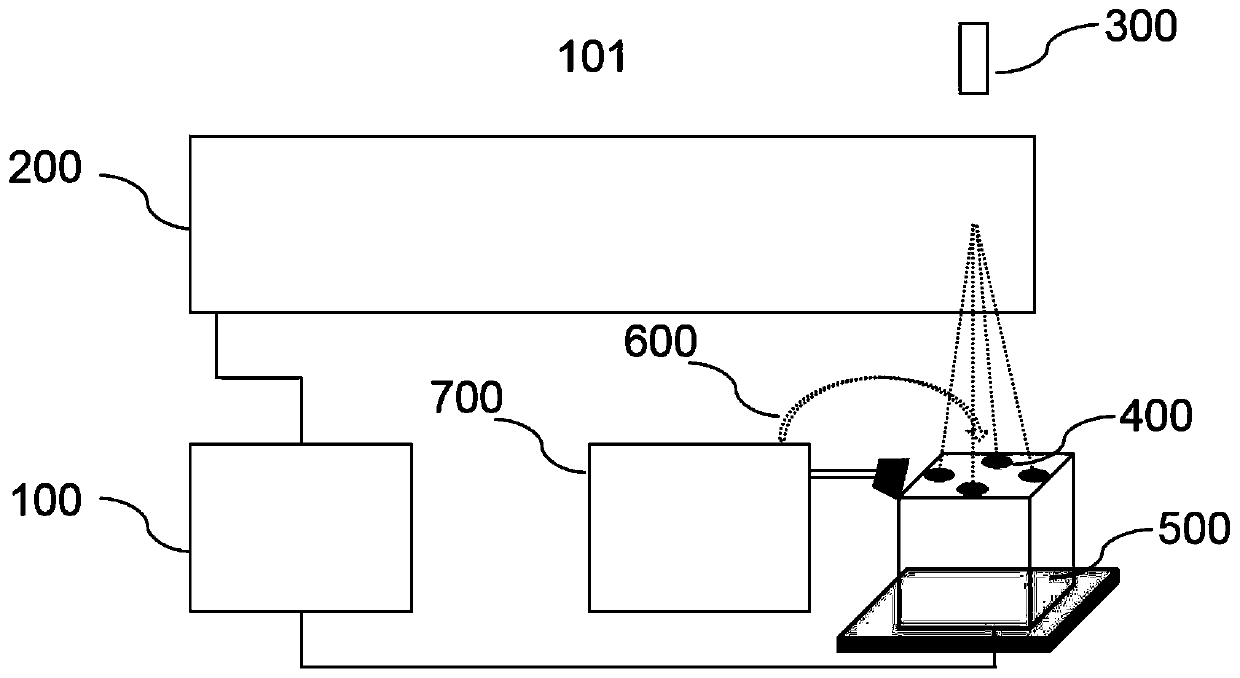

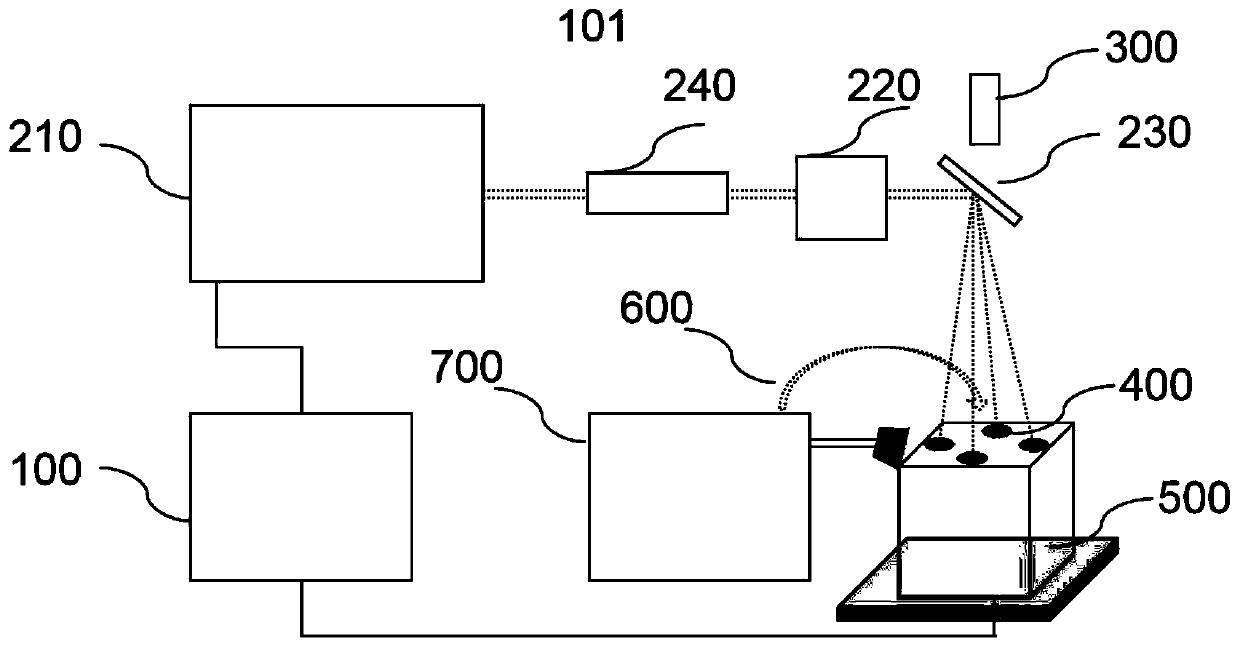

Ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method

InactiveCN111590197ANo damageSmooth edgesLaser beam welding apparatusPicosecond laserHeat-affected zone

The invention provides a ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method. The method comprises the steps that firstly a laser drilling route and a laser drilling technological parameter are arranged, during drilling, a station sliding table moves a hole to be drilled of a ceramic substrate to a drilling position, CCD vision identifies and positionsthe drilling position, and a galvanometer laser beam precisely drills the ceramic substrate layer by layer; meanwhile, smoke suction and protective gas are started, a cutting head automatically movesdown one layer of machining thickness for each layer machining until all the layers are machined; and then the station sliding table moves a workpiece to the next drilling position, repetition is carried out until all the holes in the ceramic substrate are drilled. According to the ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method, cutting edges of the ceramic substrate are smooth, the roundness is good, the taper is small, the fragmentation probability is low, nearly no heat affected zone exists, the edges are not yellowed, nearly no damage is caused to the ceramic substrate, and the yield is greatly improved.

Owner:苏州优快激光科技有限公司

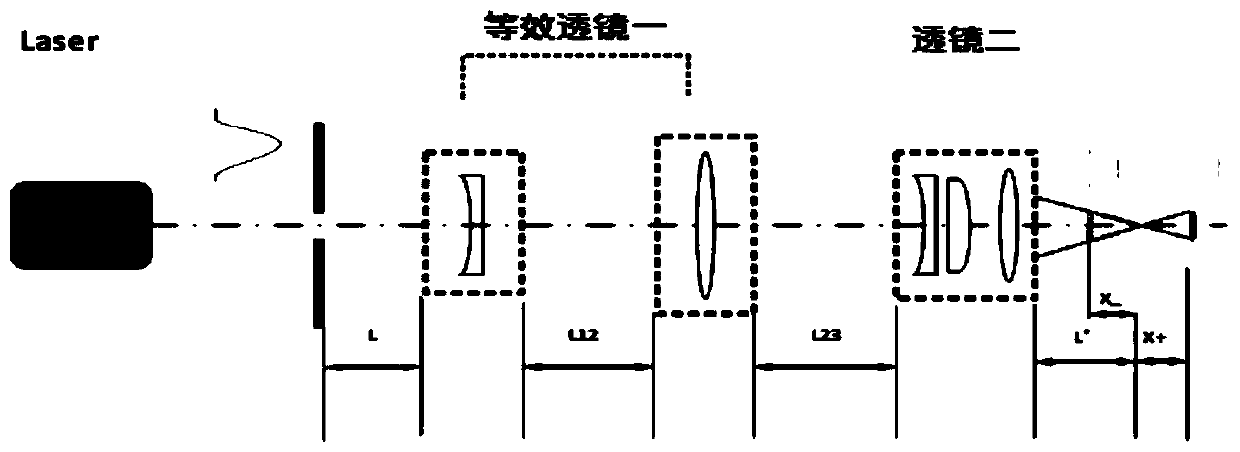

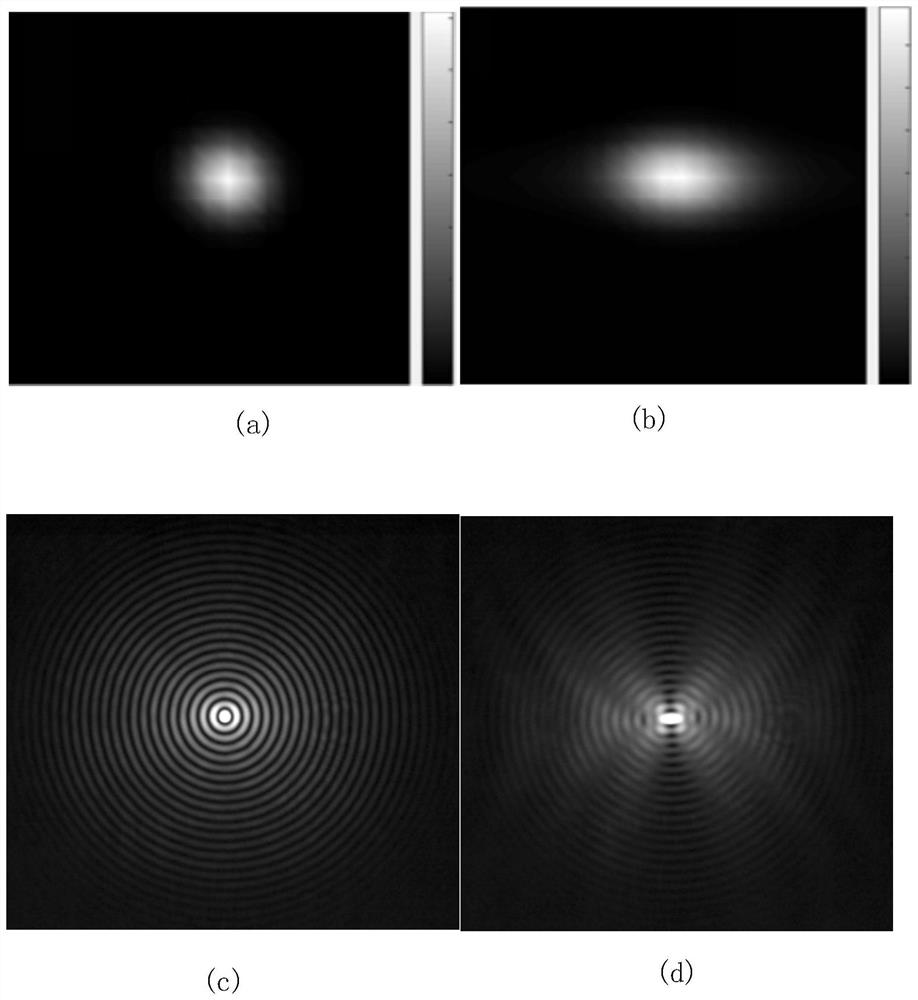

Laser processing device and method for film material removal

ActiveCN110125536ASolve the melting phenomenonEasy to adjustLaser beam welding apparatusLaser processingDiffraction order

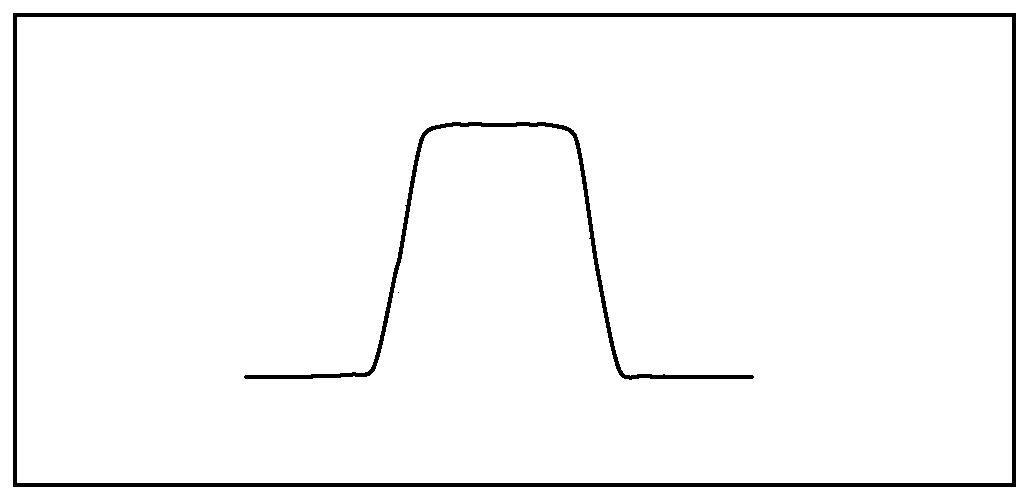

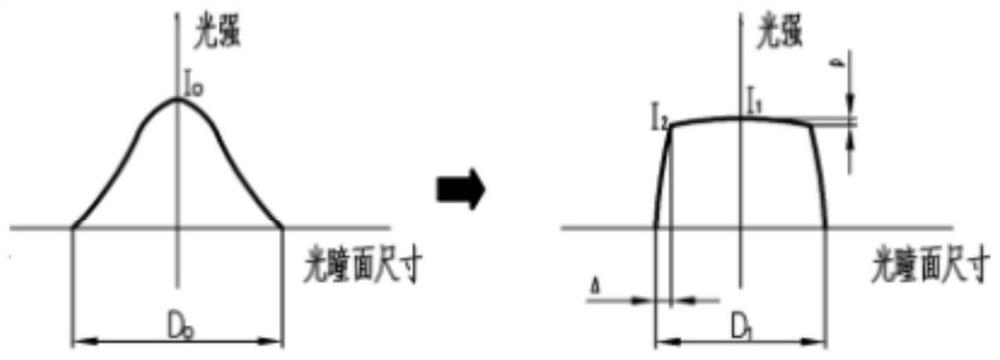

The invention discloses a laser processing device for film material removal. A laser, a small aperture diaphragm and a lens system are arranged in sequence along a laser light propagation path. The lens system comprises a first equivalent lens and a second lens. Gaussian beam emitted by the laser passes through the small aperture diaphragm and the lens system and then forms an image with sharp edges, meanwhile, after the Gaussian beam passes through the small aperture diaphragm, diffraction orders with unobvious edges occur due to the diffraction phenomenon, and light spots of Gaussian beam are imaged into sharp-edged and flat-topped light after different diffraction orders are gathered and superimposed through the lens system. The invention further discloses a laser processing method forfilm material removal. Through the device and method disclosed by the invention, the problems that a flat-topped light spot shaping technology is complicated, and application to film materials is difficult are solved.

Owner:WUHAN HGLASER ENG CO LTD

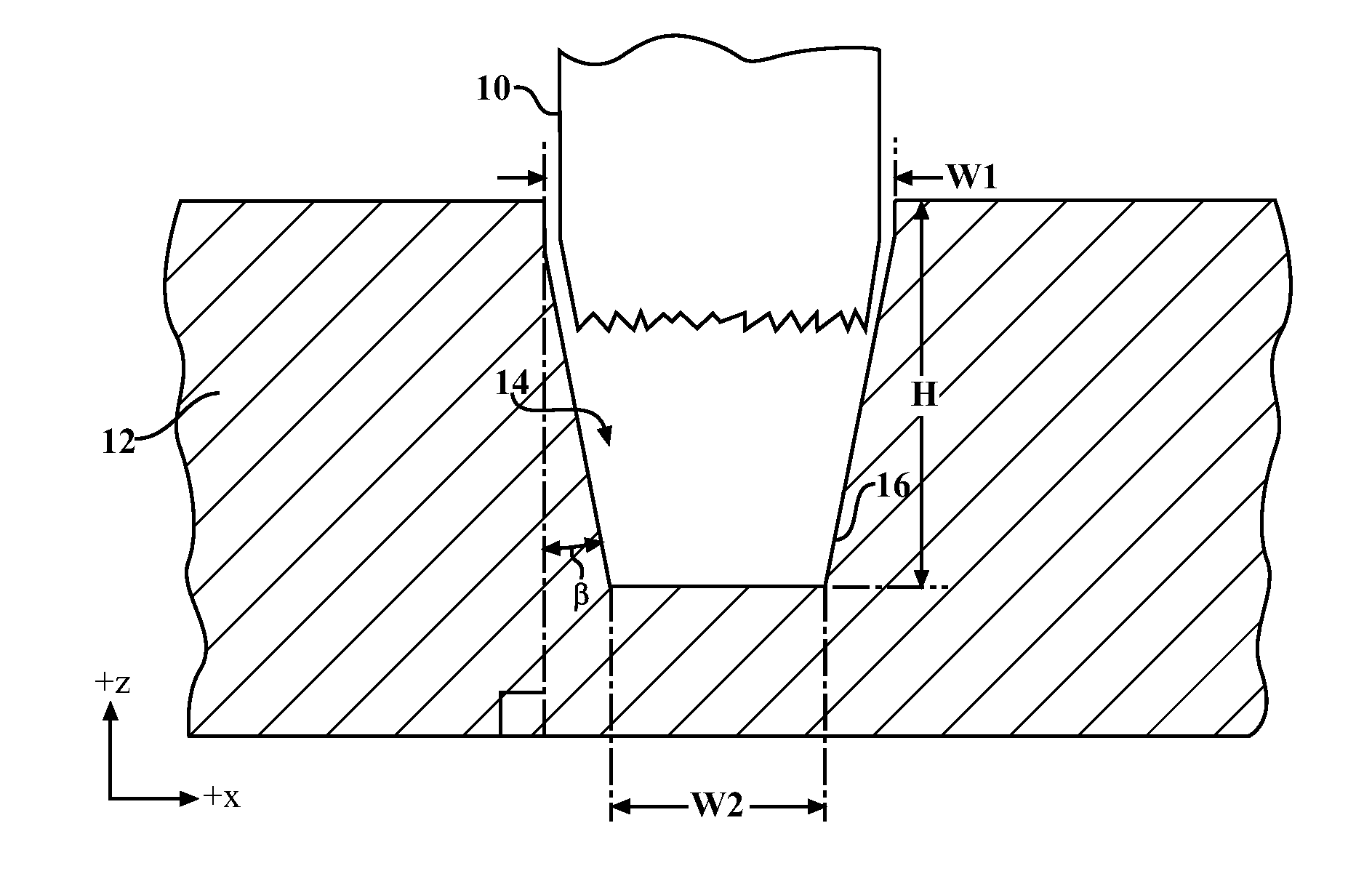

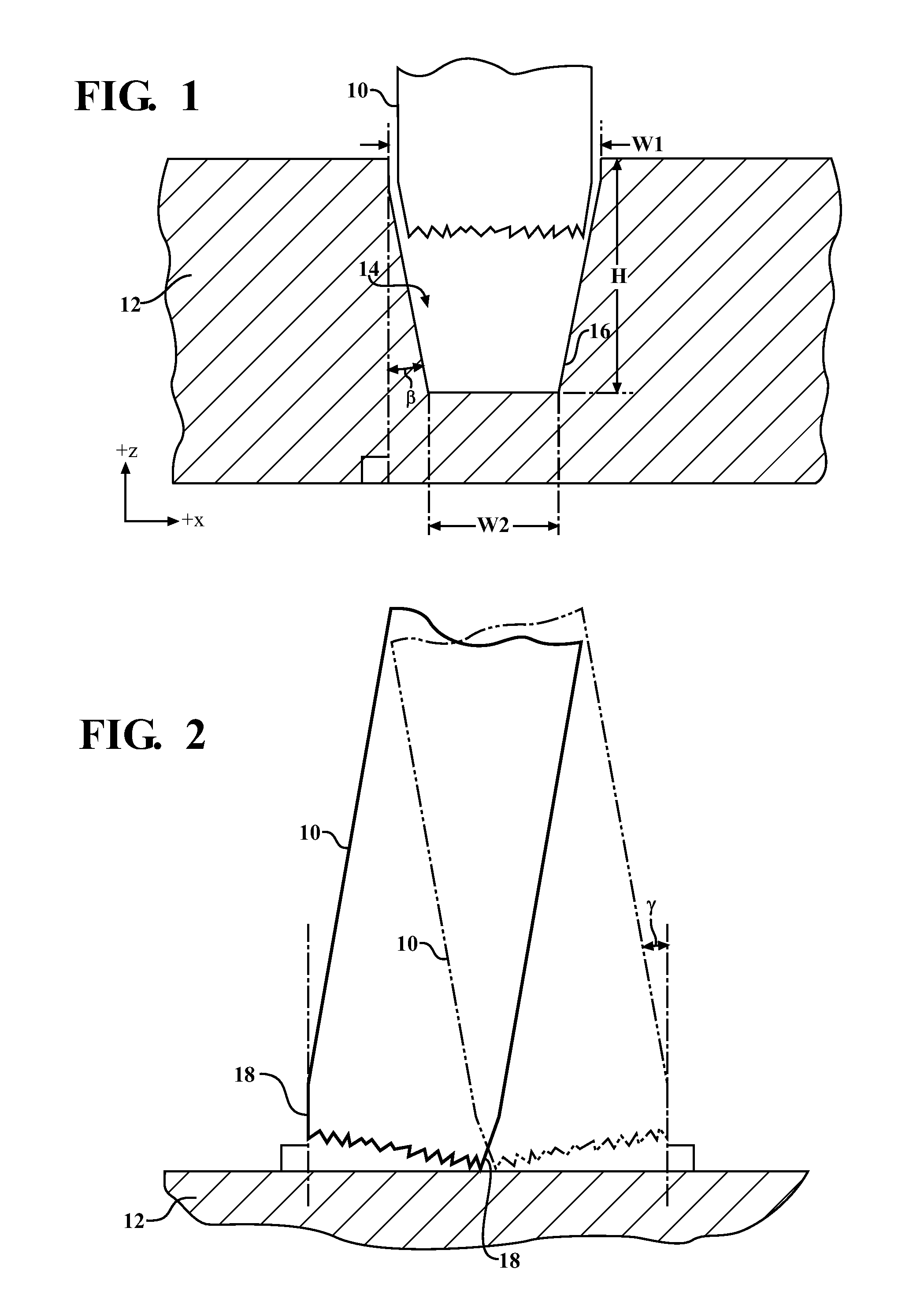

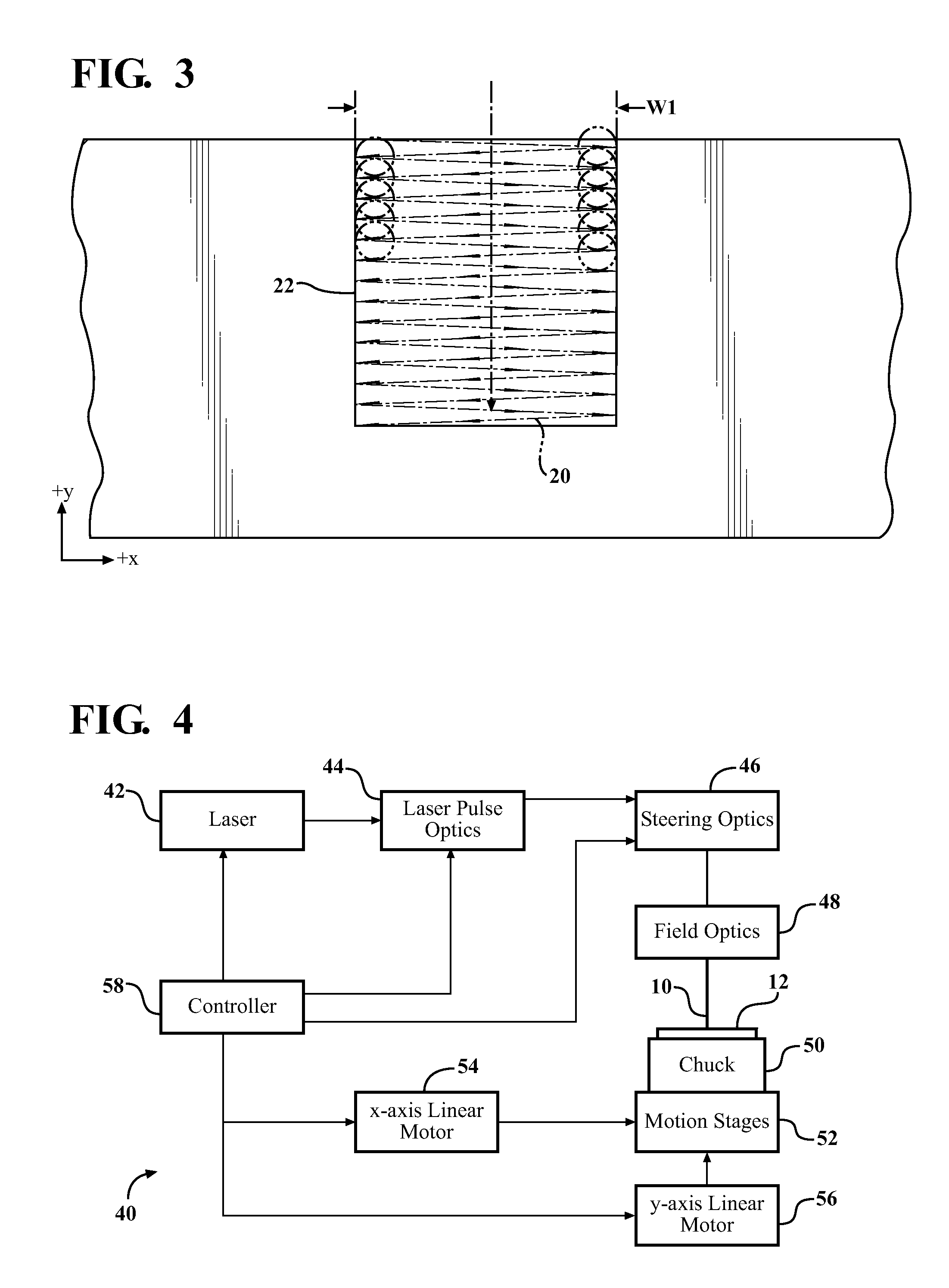

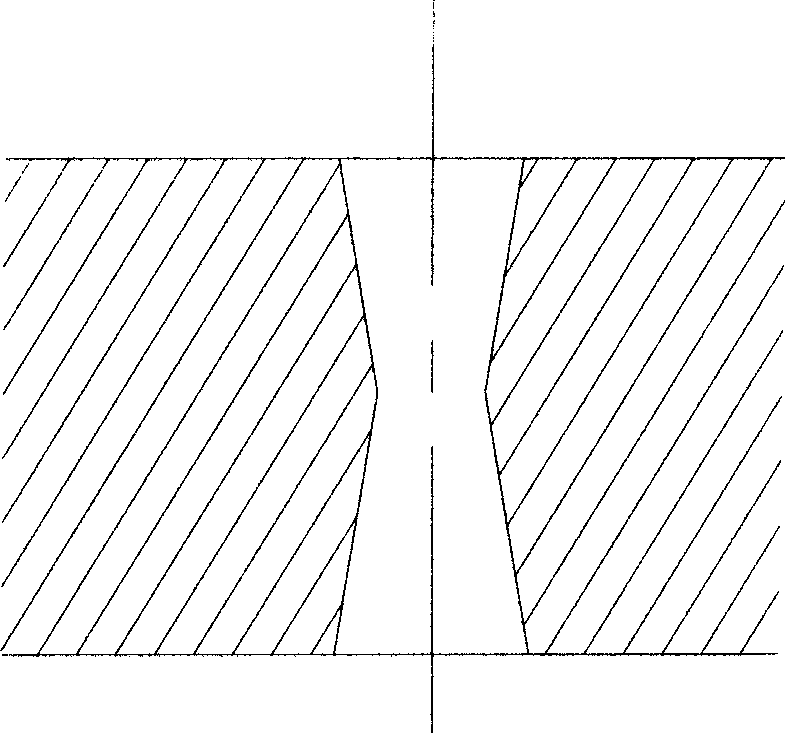

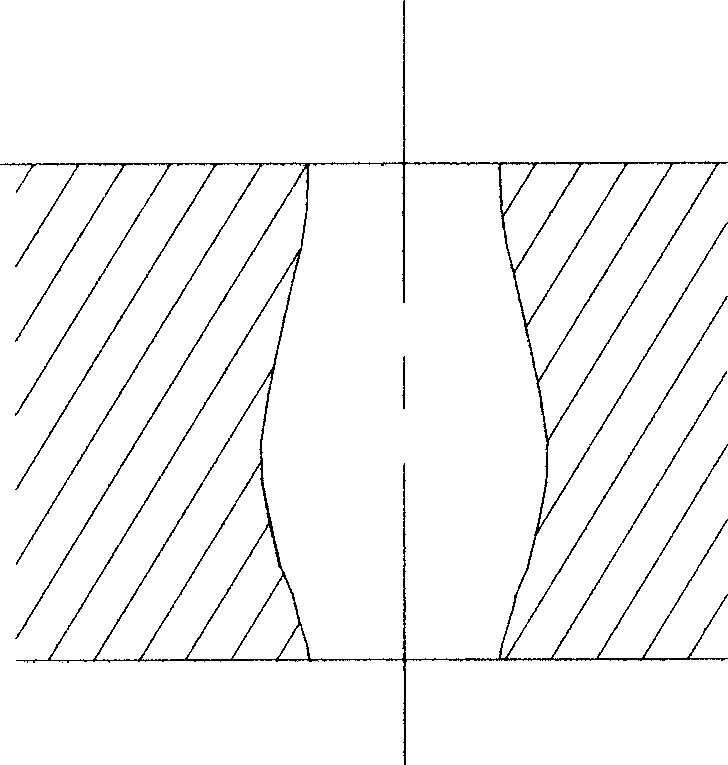

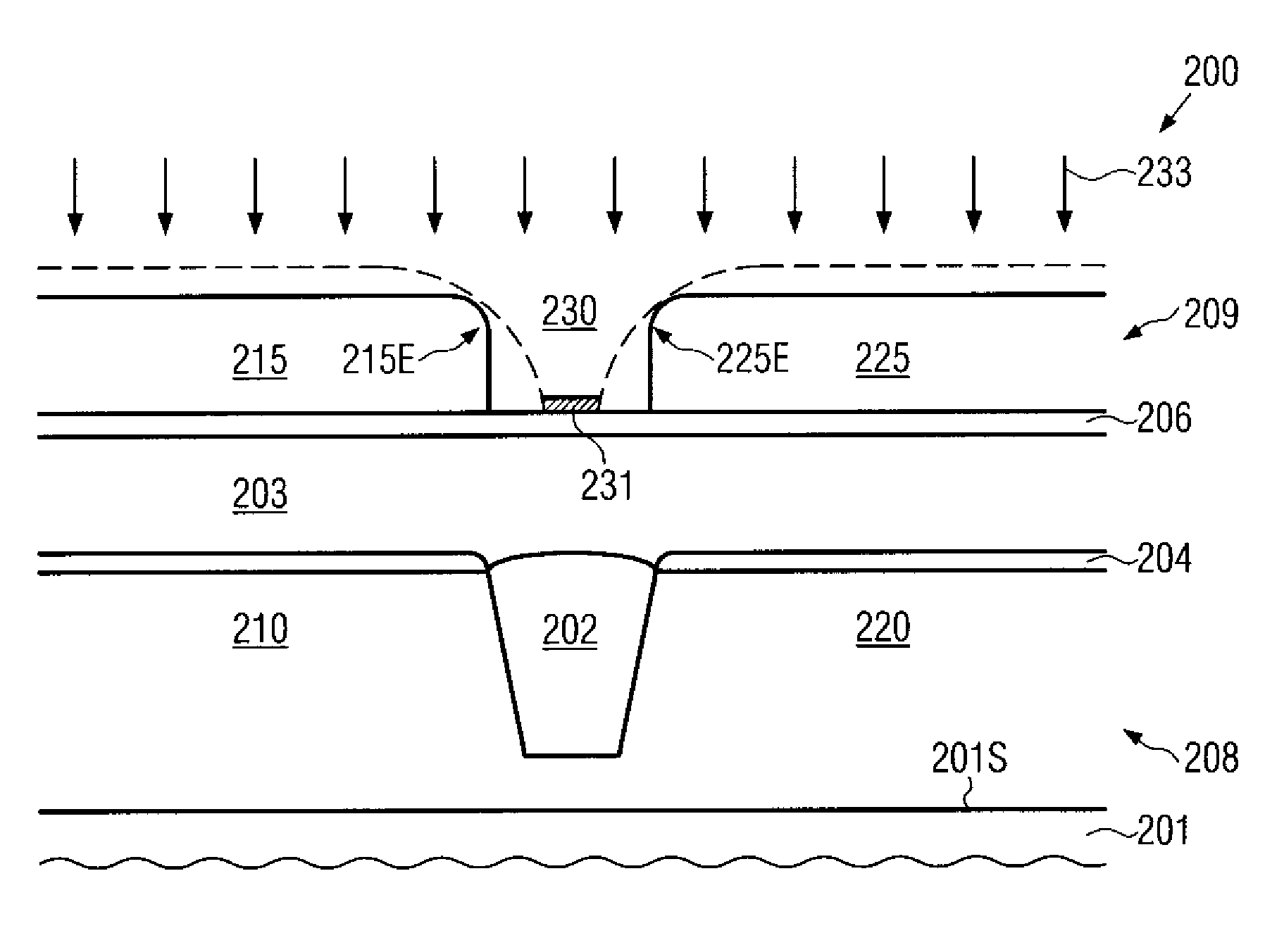

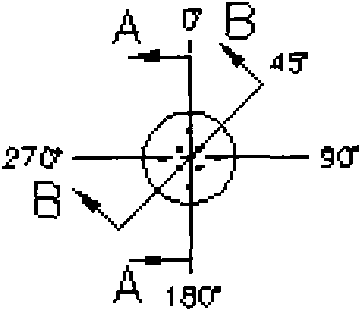

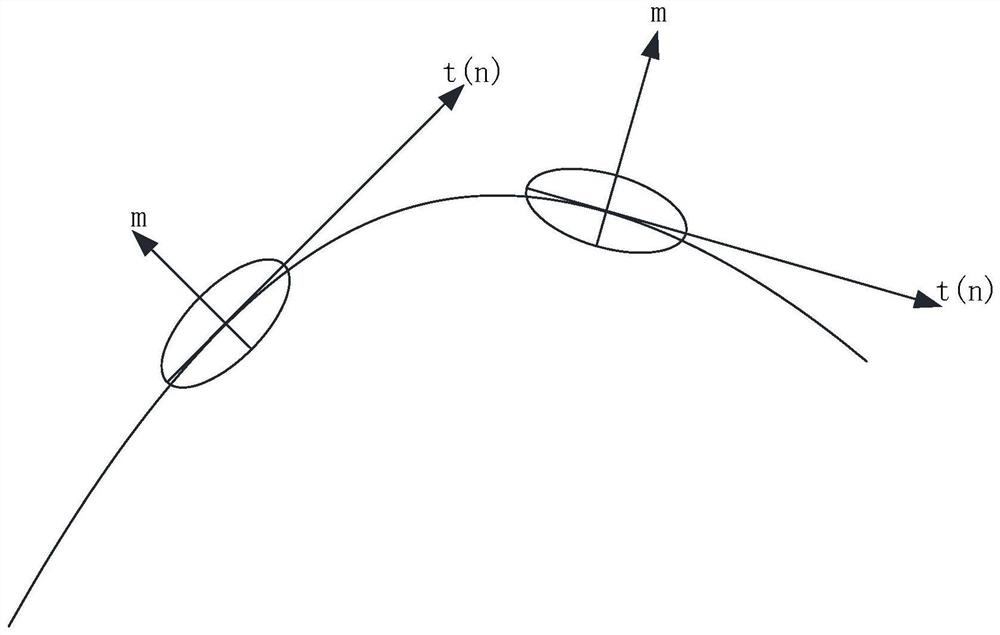

Method and apparatus for reducing taper of laser scribes

Methods and apparatuses for reducing taper of a laser scribe in a substrate are described. One method includes aiming a laser beam at a surface of the substrate in a first direction perpendicular to a first cutting direction of the beam and aiming it at the surface in a second direction perpendicular to the first cutting direction. In each position, the laser beam is tilted at a beam tilt angle with respect to a line perpendicular to the surface. A single scribe line is formed in the surface by applying the laser beam to the surface while aiming the laser beam in the first direction and cutting in the first cutting direction and applying the laser beam to the surface while aiming the laser beam in the second direction and cutting in one of the first cutting direction and a second cutting direction opposite the first cutting direction.

Owner:ELECTRO SCI IND INC

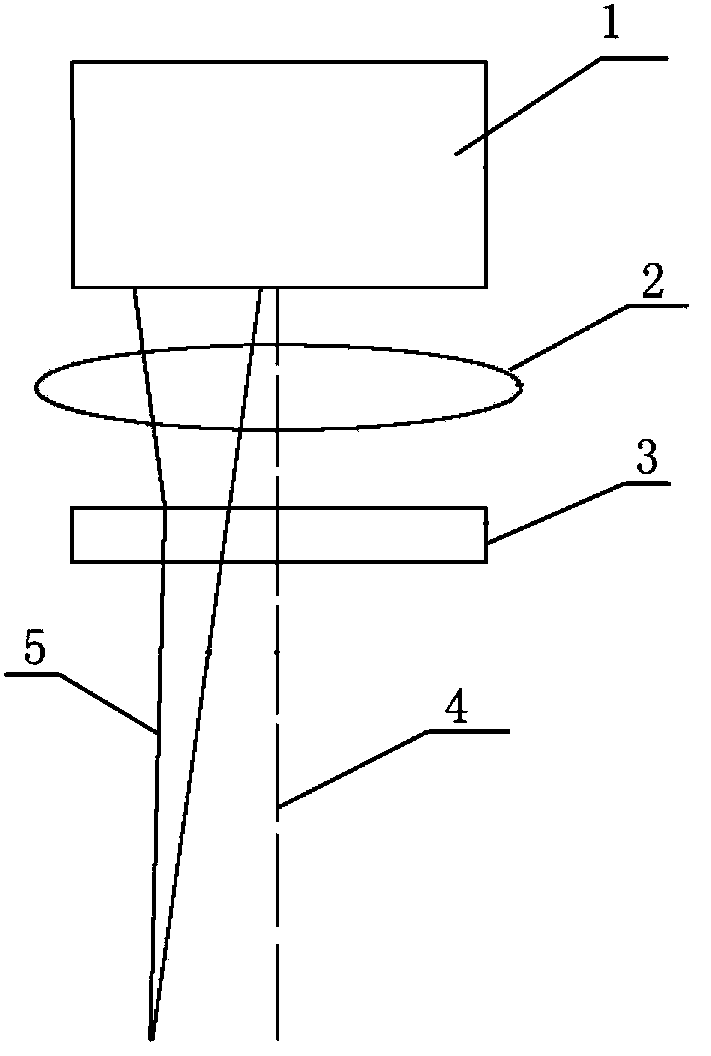

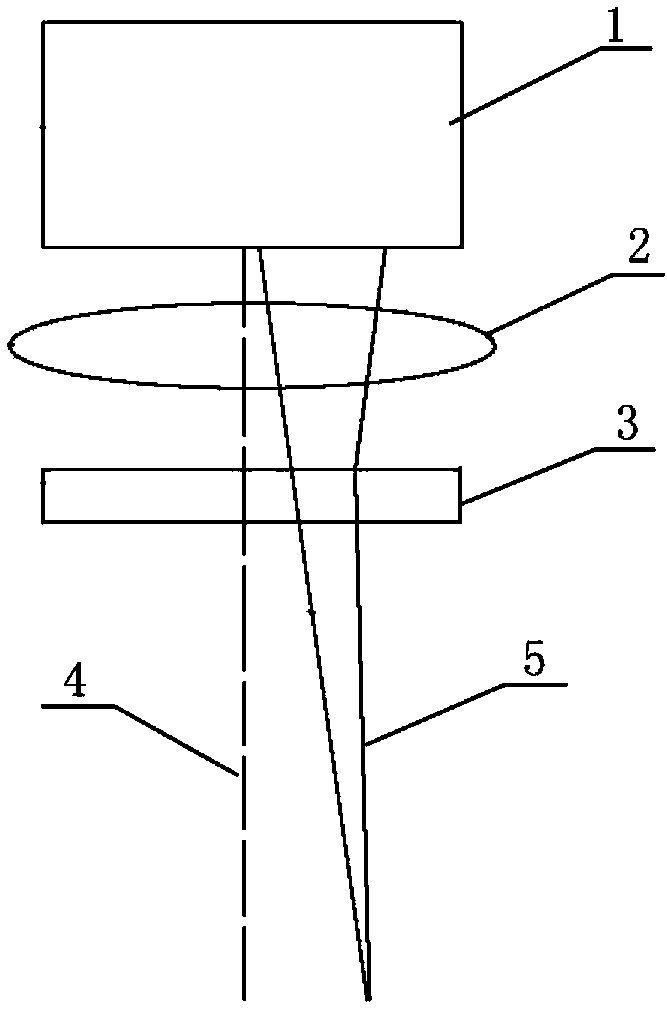

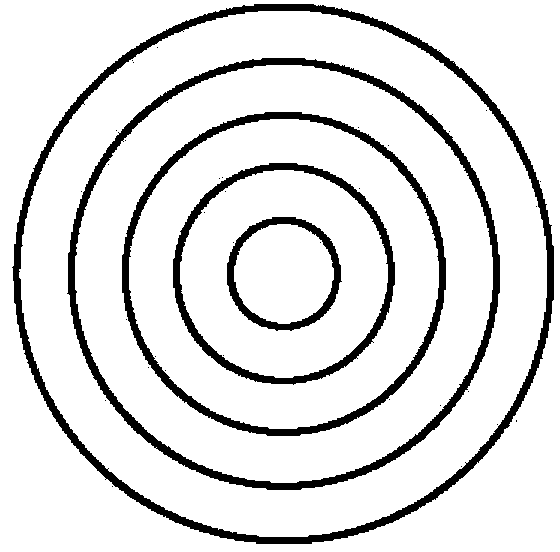

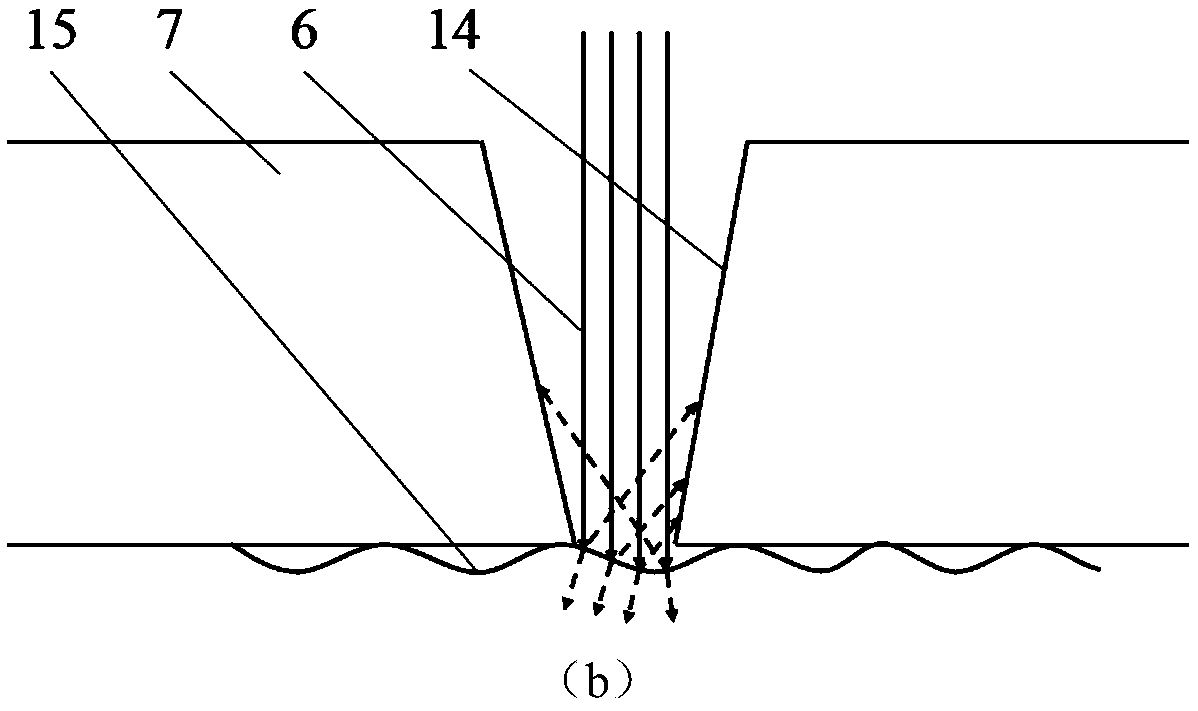

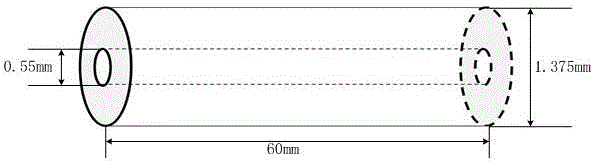

Device for machining small hole by using ultrashort pulse laser and small hole machining method

The invention provides a device for machining small holes by using ultrashort pulse laser and a small hole machining method. The device comprises a scanning galvanometer, a laser scanning focus lens and a wedge lens. The scanning galvanometer, the laser scanning focus lens and the wedge lens are arranged on the same central axis. A laser beam rotates around the central axis along a concentric circle track through the scanning galvanometer, is focused through the laser scanning focus lens and is deflected far away from the central axis through the wedge lens. The wedge lens and the laser beam rotate synchronously to keep the inclination angle of the laser beams to be the same. The device for machining small holes by using ultrashort pulse laser and the small hole machining method have the advantages that the small hole machining depth is increased and the machining quality and stability of the small holes are improved.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Novel nuclear pore membrane

InactiveCN101380547AIncreased etch sensitivityReduce taperSemi-permeable membranesMass numberMembrane surface

The invention relates to a novel nuclear pore membrane (or nuclear track membrane), generally the nuclear track always has conicity after etching, the millipore of the nuclear pore membrane is single-cone or double-cone, the center aperture of the millipore of the double cone is less than the aperture on both surfaces of the membrane. Particles are blocked in the millipore easily when filtering, and the membrane is blocked easily. Meanwhile, the ions with lower mass number are utilized for irradiating the electrolyte membranes, for the nuclear track etching sensitivity is lower, conicity is larger, the nuclear pore membrane with small aperture is made hard. The center aperture of the millipore of the nuclear pore membrane made by the invention is larger than the diameters of both surfaces of the membrane or is of column form capillary tube shape. The shape of the millipore causes the particles larger than the membrane surface aperture to be trapped on the membrane surface, and the nuclear pore membrane is not blocked easily. Meanwhile, a new method is provided for making nuclear pore membranes by utilizing the ions with lower mass number.

Owner:毕明光

Array hole machining device

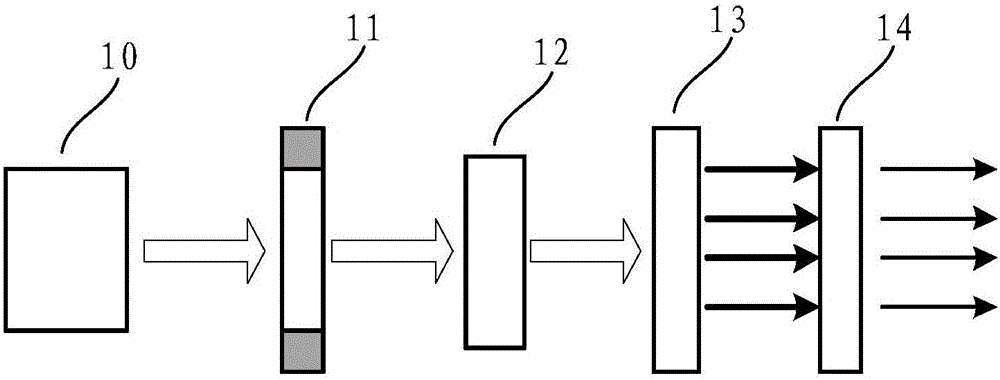

PendingCN106842589AEvenly distributedReduce taperLaser beam welding apparatusOptical elementsBeam splittingHigh energy

The invention discloses an array hole machining device which comprises a laser generation device, a light beam selector, a light beam shaper, a beam splitting component and a focusing component. The laser generation device, the light beam selector, the light beam shaper, the beam splitting component and the focusing component are sequentially arranged in the light path direction, the laser generation device is used for generating laser and achieving light beam expansion and alignment, the light beam selector is used for grating a light beam central region and intercepting a light beam edge region, the light beam shape is used for adjusting energy of light beams emitted from the light beam selector to be uniformly distributed, the beam splitting component is used for splitting the light beams output by the light beam shaper into array light beams broadcast in parallel, the beam splitting component is provided with a plurality of micro-optical structures arranged in an array mode, and the focusing component is used for gathering the array light beams to the same plane to form array laser beams applied to machining. According to the array hole machining device, the portion, with the high energy, of the light beam central region is gated at first before laser beam splitting, light beams are shaped so that energy of the light beams is uniformly distributed, the energy of the laser beams for machining is uniformly distributed, tape generated by micropores can be decreased during machining, and the micropore machining quality can be improved.

Owner:GUANGDONG UNIV OF TECH +1

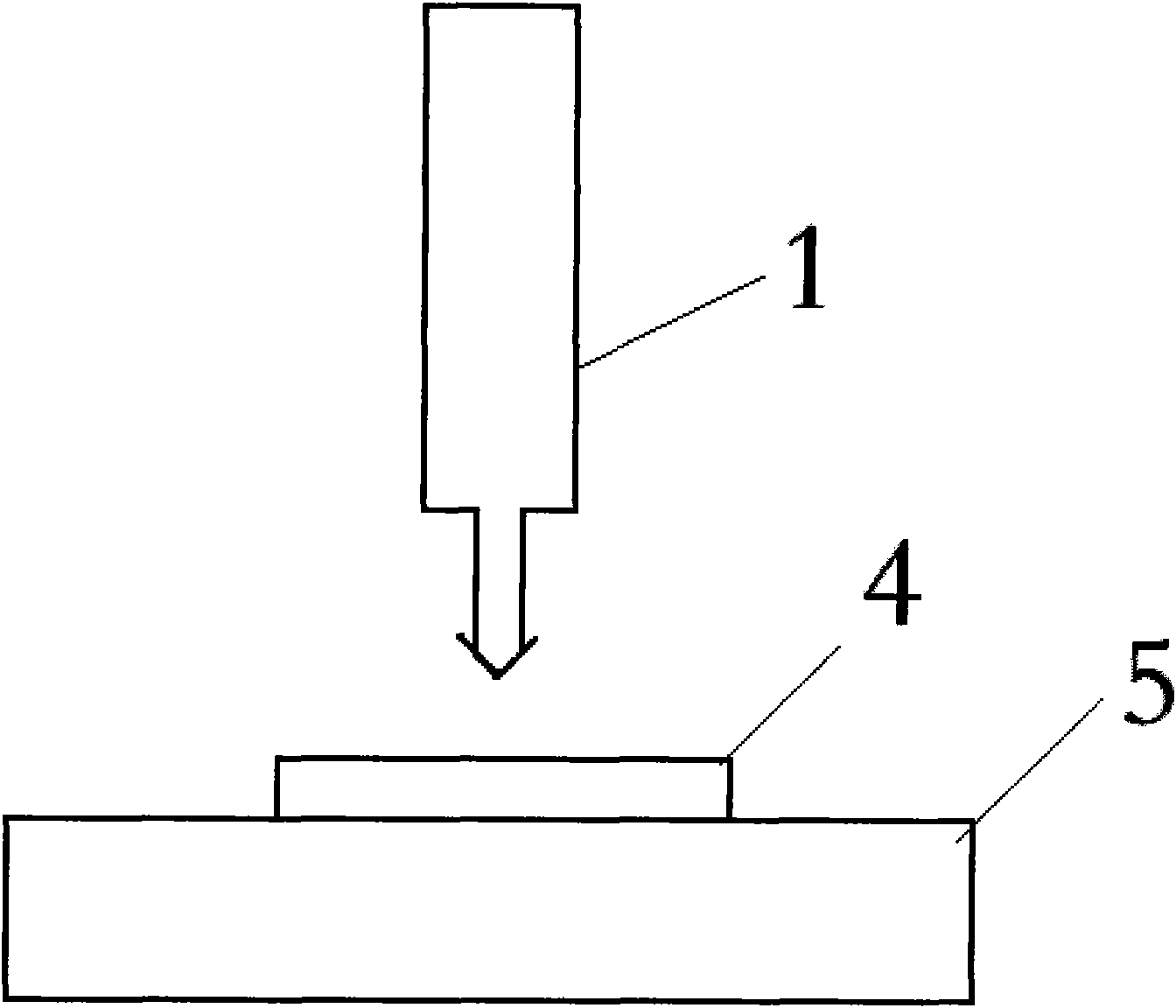

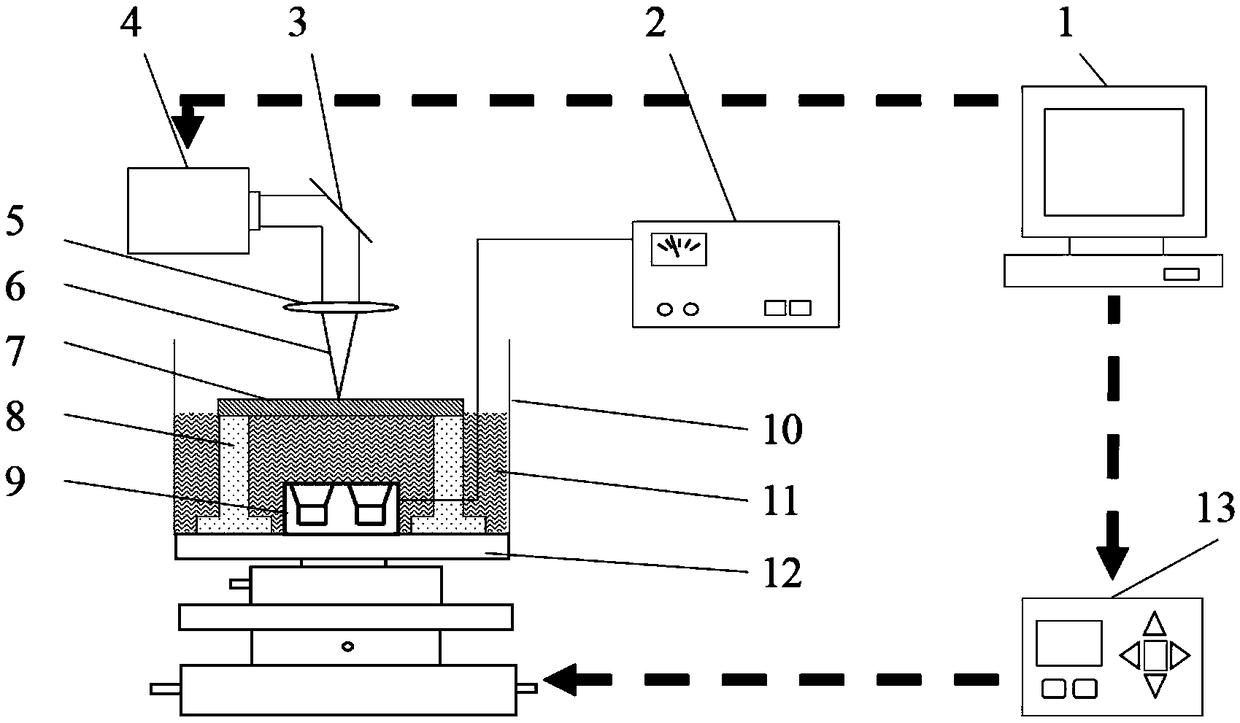

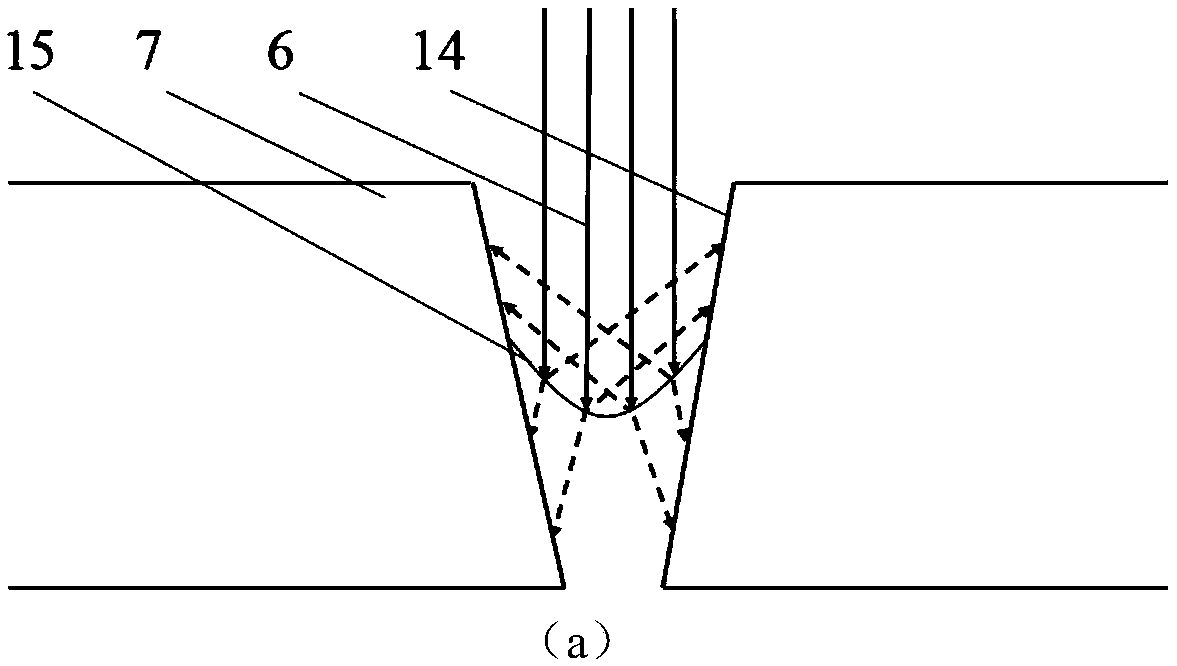

Laser punching device and method for improving hole taper and hole wall quality

InactiveCN109158775AUniform and stable fluctuationReduce taperLaser beam welding apparatusPunchingLaser processing

The invention relates to a laser punching device and method for improving the hole taper and the hole wall quality, relates to the field of laser processing in non-traditional machining, and belongs to the field of laser processing in non-traditional machining. A workpiece machining system and a control system are included. The workpiece machining system comprises a laser device, a water trough, aclamp and a workpiece. Laser beams emitted by the laser device irradiate the workpiece after being focused through a focus lens. The workpiece is horizontally placed and fixed to the clamp. The clampis arranged at the bottom of the water trough. The liquid level of the liquid in the water trough immerses the lower surface of the workpiece. The control system comprises a computer and a motion control card, the computer controls the laser device and the motion control card, and the motion control card controls an x-y-z three-coordinate workbench. Compared with machining in which only a laser device is adopted, the small hole taper can be obviously reduced, heat damage is reduced, the small hole machining quality is improved, and the laser energy utilization rate is increased. The device issimple, and operation is convenient.

Owner:JIANGSU UNIV

Laser cutting system

InactiveCN112496529AReduce taperImprove uniformityLaser beam welding apparatusLaser processingOptical axis

The embodiment of the invention discloses a laser cutting system. The laser cutting system sequentially comprises a laser unit, a laser receiving unit, a beam expanding unit, a dodging unit, a shielding unit, a light beam conversion unit and a collimating and focusing assembly in the light path direction, wherein the laser unit is used for providing a laser beam; the beam expanding unit is used for expanding the laser beam into an expanded laser beam; the dodging unit is used for modulating the expanded laser beam into a uniform laser beam with uniformly distributed light intensity flat top; the shielding unit is used for shielding the edge part of the uniform laser beam and stray light outside the uniform laser beam; the light beam conversion unit is used for modulating the uniform laserbeam into a hollow annular laser beam and forming a Bessel laser beam along the optical axis direction; and the collimating and focusing assembly is used for collimating and focusing the Bessel laserbeam. According to the laser cutting system, the problems of large taper, poor section uniformity and the like of the section of the cut material caused by Gaussian distribution of light intensity distribution of the existing laser processing system are solved.

Owner:SHENZHEN INTE LASER TECH

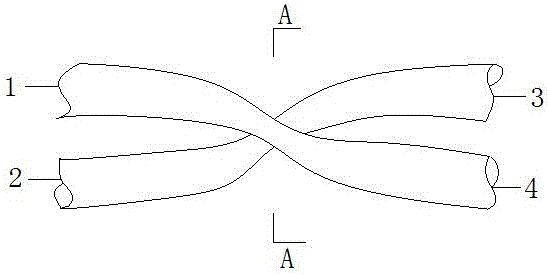

Multimode fiber beam splitter and production method thereof

ActiveCN106772803AReduce stretch lengthReduce taperCoupling light guidesBeam splitterDivergence angle

The invention provides a multimode fiber beam splitter and a production method thereof. The multimode fiber beam splitter comprises an input optical fiber and multiple output optical fibers, wherein the input optical fiber and the multiple output optical fibers are fixedly connected, the input optical fiber is a multimode fiber, and the output optical fibers are single-mode fibers. According to the multimode fiber beam splitter, the optical fiber at an input end is the multimode fiber, so that laser with higher power strength, larger M<2> factor and larger waist diameter is coupled into the optical fiber at the input end conveniently, and higher input-end laser coupling efficiency is realized; the optical fibers at an output end are single-mode fibers, so that output laser with small divergence angle, small waist diameter and uniform power distribution can be obtained. Further, in the production method of the multimode fiber beam splitter, a flow for removing part of an outer cladding layer is set for the single-mode fibers at the output end, the tapering difficulty of the late tapering process can be reduced, the stretched length of cores of the optical fibers at the output end is reduced, and taper is small, so that fiber core size and numerical aperture change are small, butt joint with the optical fiber at the input end is facilitated, and the coupling efficiency is increased.

Owner:南通北外滩建设工程有限公司

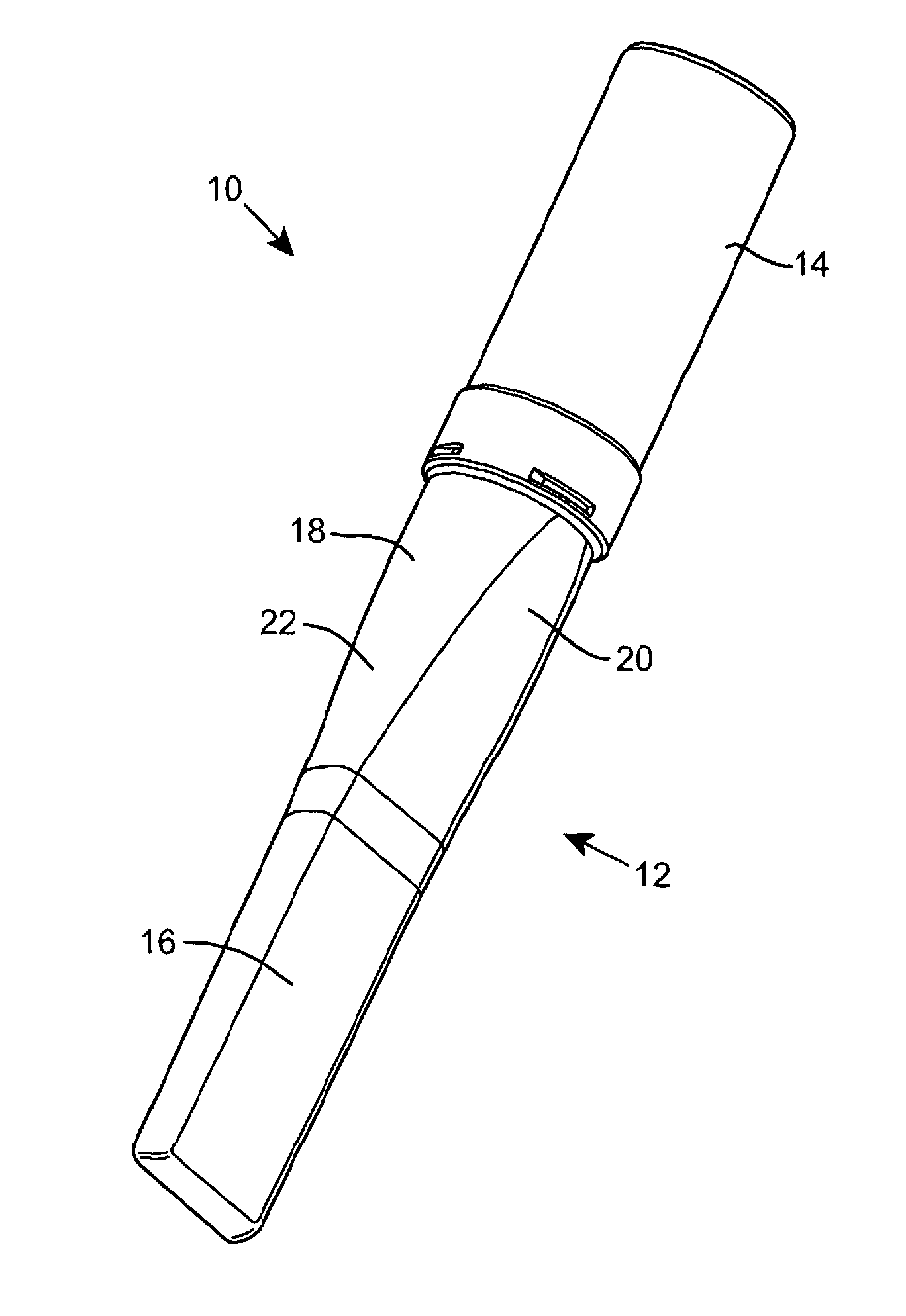

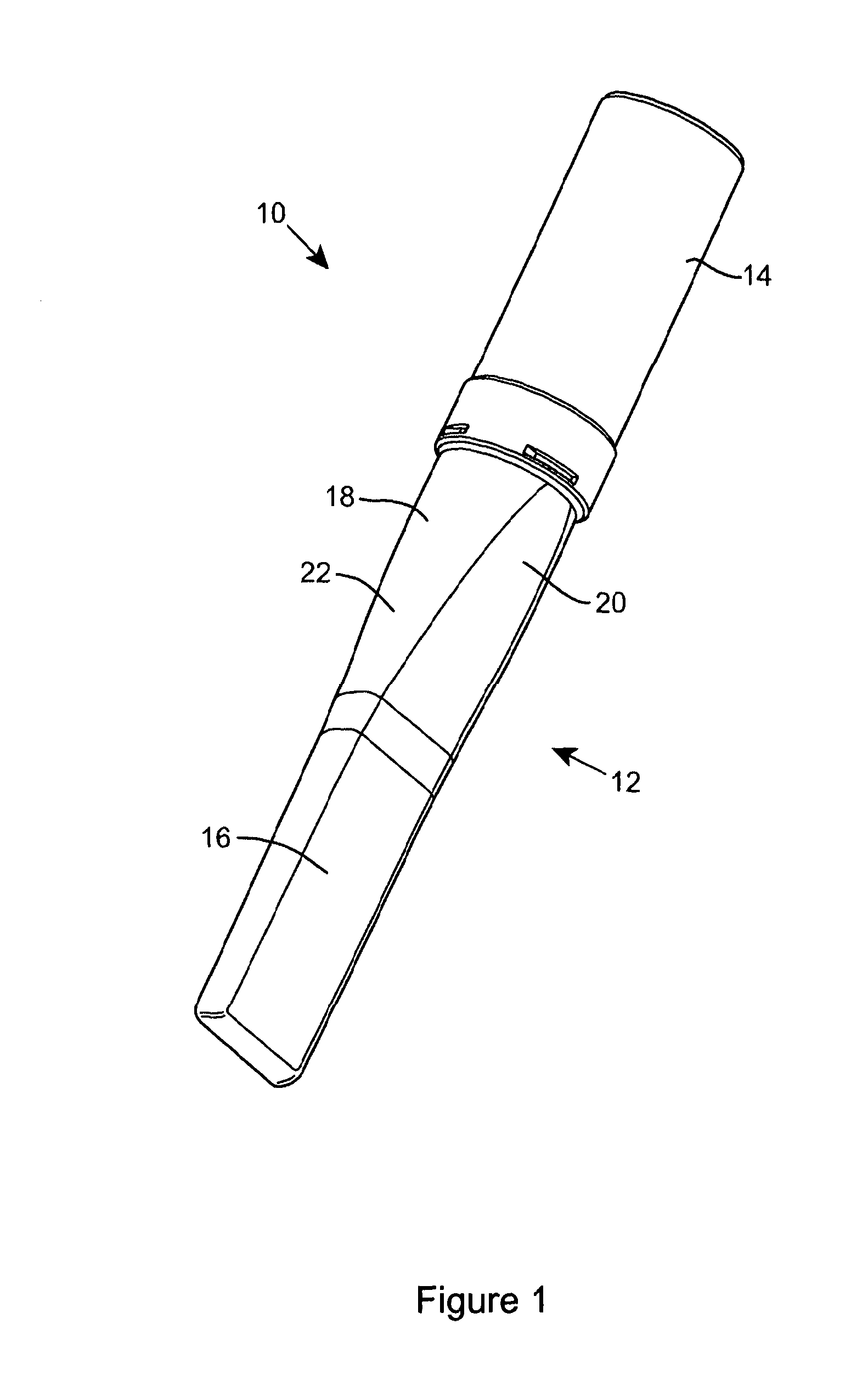

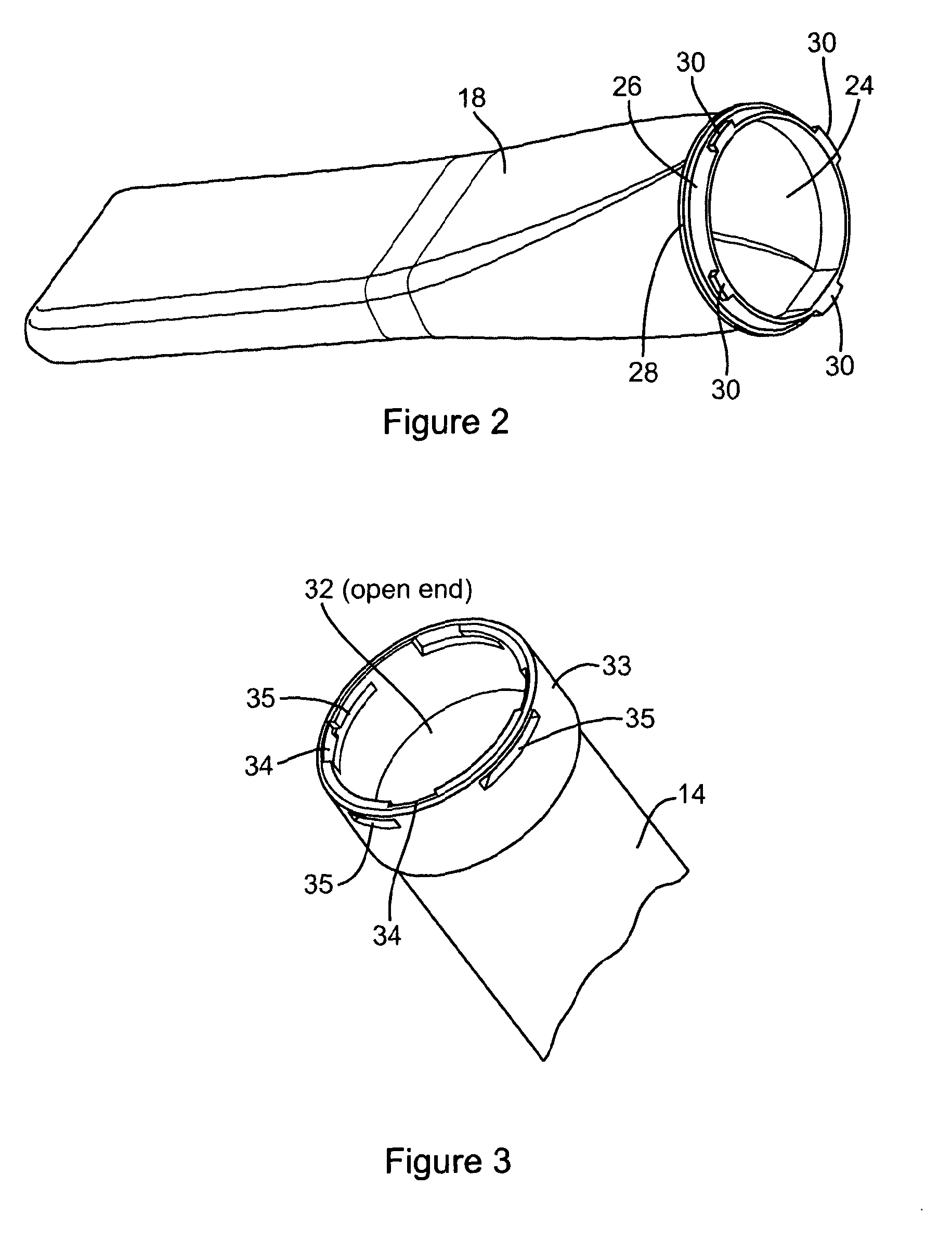

Wipes dispenser

ActiveUS9549646B2Reduce taperAvoid problemsFlat article dispensingDomestic applicationsEngineeringMechanical engineering

Owner:GOJO IND INC

Polishing process for high-flatness 8-inch silicon wafer

The invention provides a polishing process for a high-flatness 8-inch silicon wafer. The polishing process comprises the following steps: step I, testing a surface flatness previous value of the silicon wafer, coating polishing wax on the surface of the silicon wafer, uniformly throwing the polishing wax, roasting the polishing wax for enabling the wax to have viscidity, pasting one surface coated with the polishing wax onto a high-temperature ceramic plate, and cooling the ceramic plate pasted with the silicon wafer; step II, performing rough polishing, intermediate polishing and fine polishing on the cooled ceramic plate to obtain bright flat silicon wafer; and step III, chipping off the silicon wafer obtained in step II, and performing ADE9600 to test the surface flatness. Mechanical action and chemical action are balanced by improving rough polishing process parameters in a polishing process, the surface flatness of the polished wafer is improved, and TTV, TIR, STIR and TAPER of a polished product can be reduced in comparison with an existing process.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

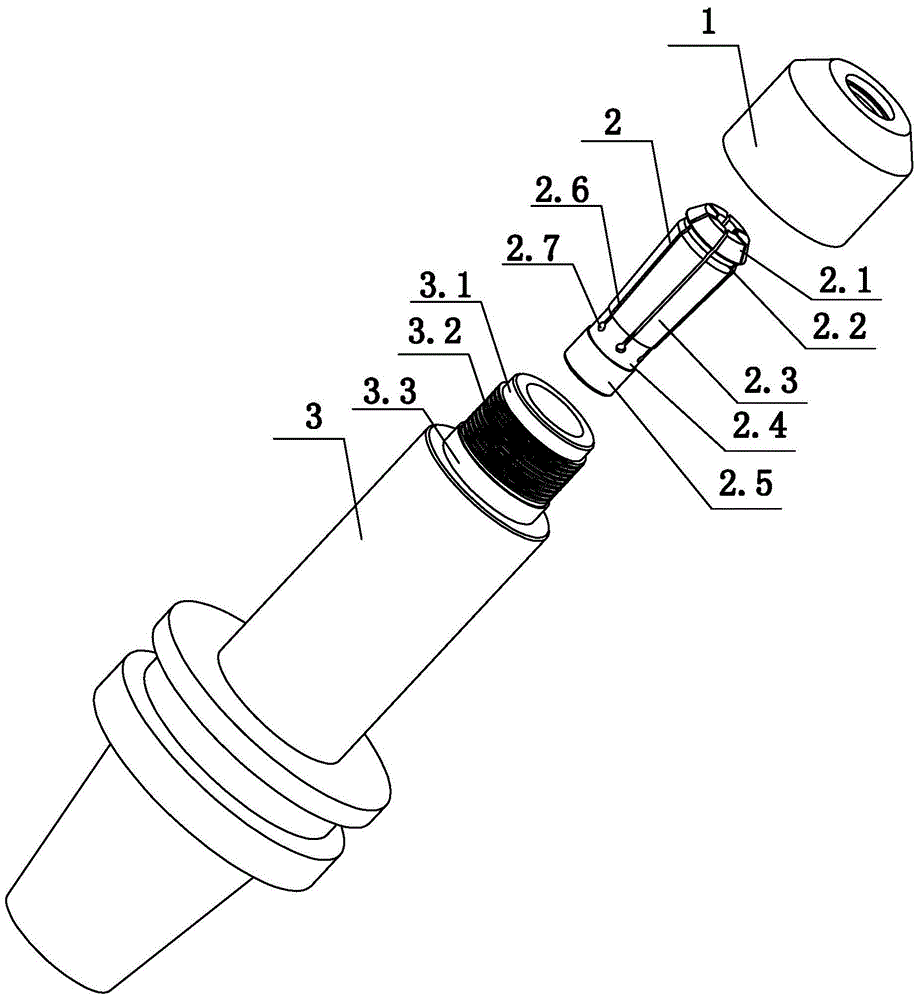

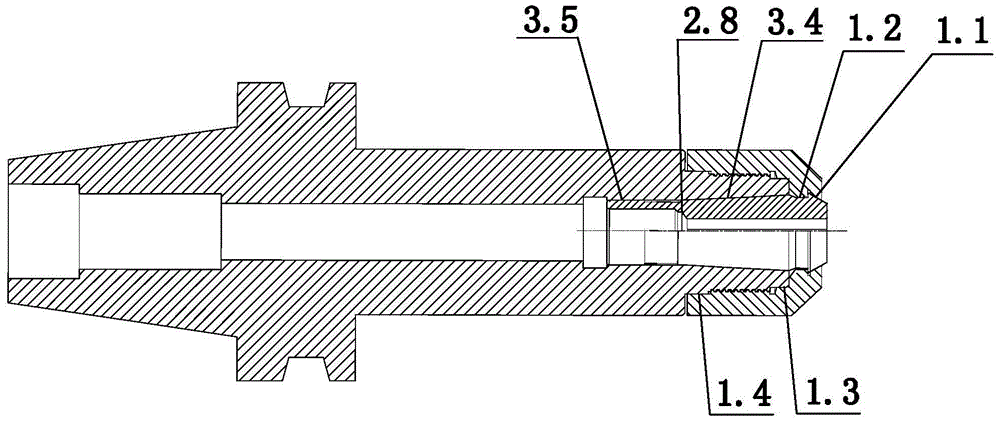

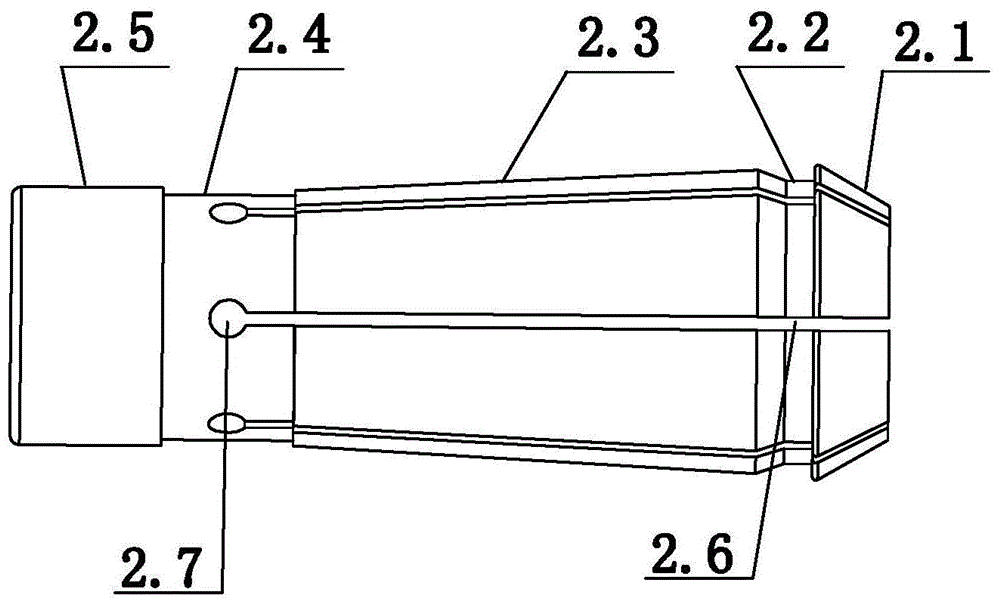

Shank structure for cutter clamping

The invention discloses a shank structure for cutter clamping. The shank structure comprises a shank body (3), a cylinder clamp (2) and a screw cap (1), wherein tapers of an outer taper section (2.3) of the cylinder clamp (2) and an inner taper section (3.4) of the shank body (3) are both 3 degrees; a straight positioning section (2.5) is arranged at the tail section of the cylinder clamp (2); a straight transition section (2.4) is arranged between the positioning section (2.5) and the outer taper section (2.3); a diameter of the straight transition section (2.4) is smaller than a diameter of the positioning section (2.5); a closing end of a spit groove (2.6) is positioned on the transition section (2.4); a positioning surface (3.5) fitting the positioning section (2.5) is arranged in a shaft hole of the shank body (3); and the outer peripheral surface of the positioning section (2.5) is bonded with the positioning surface (3.5). The cylinder clamp of the shank structure for cutter clamping is positioned by three surfaces, so that the positioning effect is good; the precision is high; the clamping force is strong; the pull is easy; and the use cost is low.

Owner:NINGBO CHUANJINGYU MECHANICAL TECH DEV

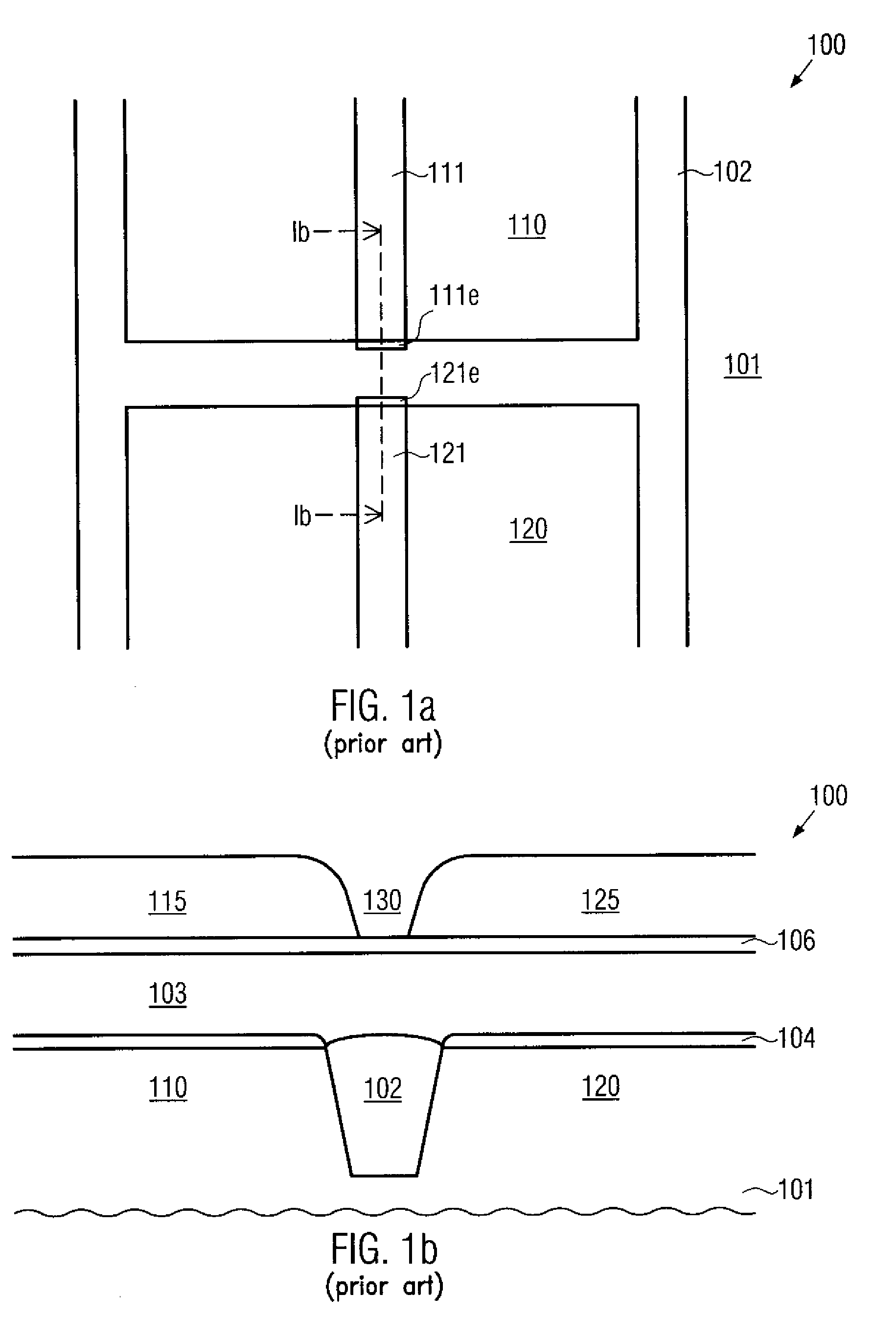

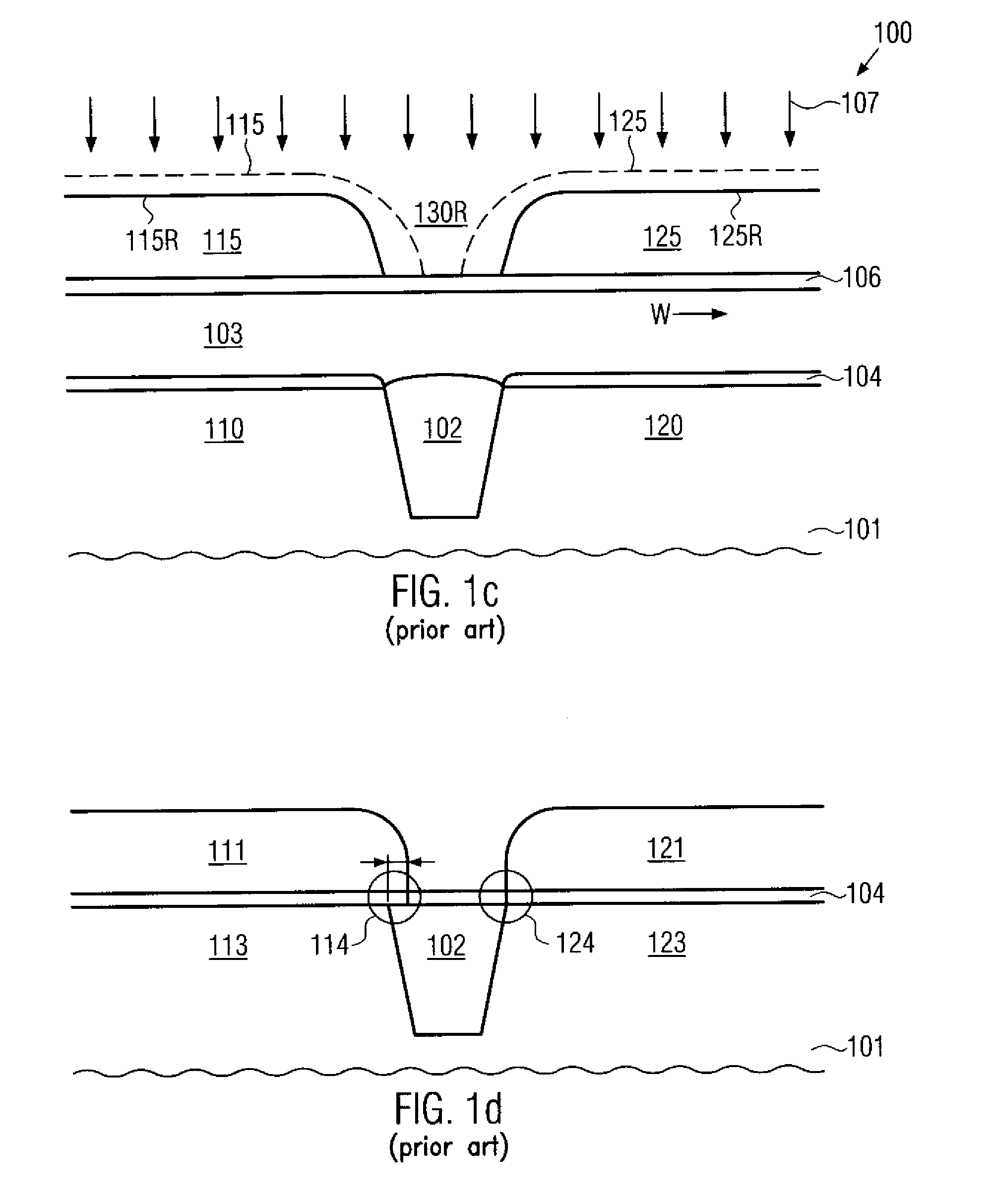

Method of patterning gate electrodes by reducing sidewall angles of a mask layer

ActiveUS20080003825A1Enhance the imageLower performance requirementsDecorative surface effectsSemiconductor/solid-state device manufacturingResistEngineering

By performing an anisotropic resist modification prior to the actual resist trimming process, the profile of the end portions of the resist features may be significantly enhanced, for instance by providing substantially vertical sidewall portions. Consequently, an overlap of gate electrodes with the respective isolation structures may be obtained, while nevertheless the probability for a short circuit between opposing end portions of the gate electrodes may be significantly reduced, thereby providing the potential for further scaling down device dimensions.

Owner:ADVANCED MICRO DEVICES INC

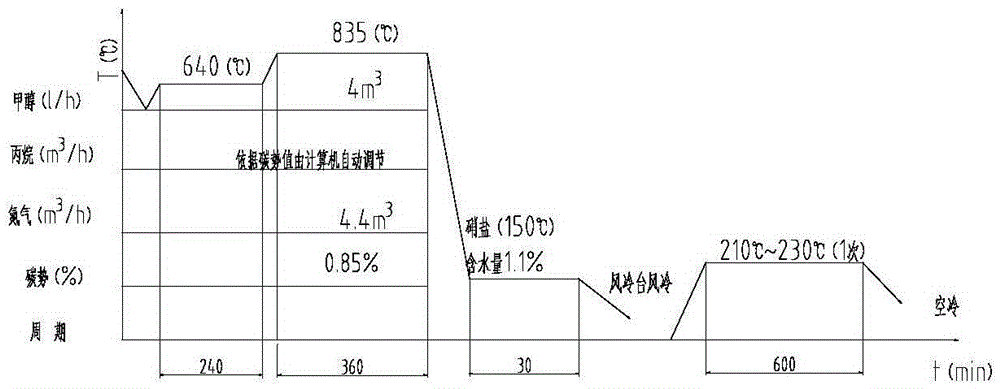

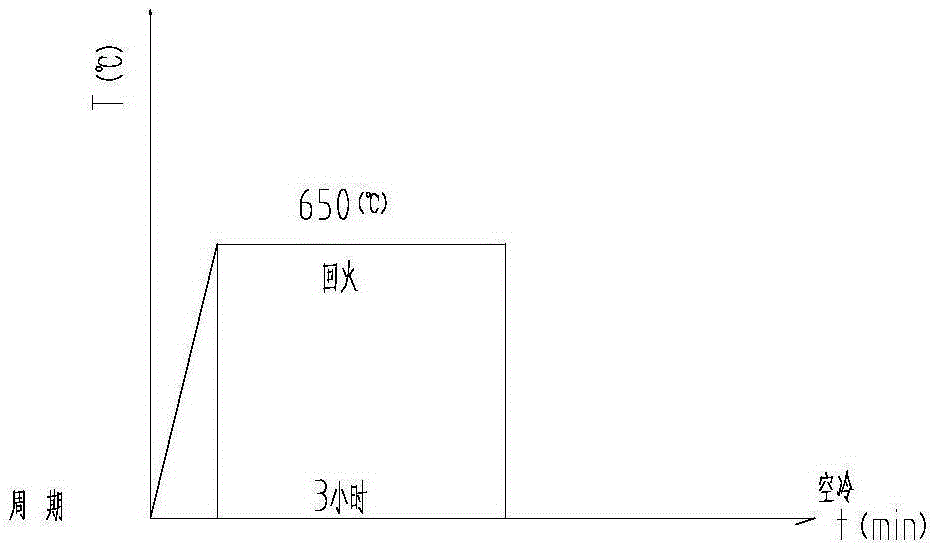

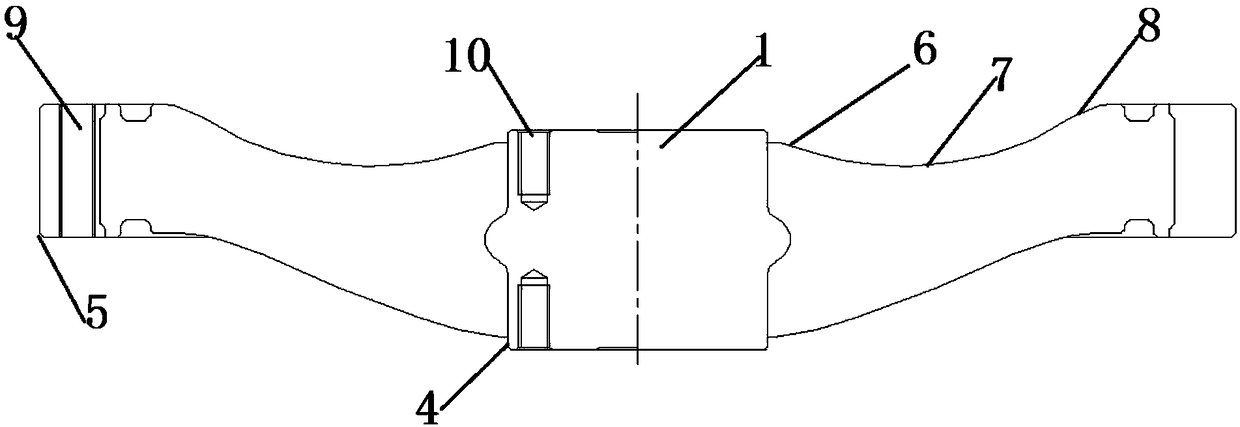

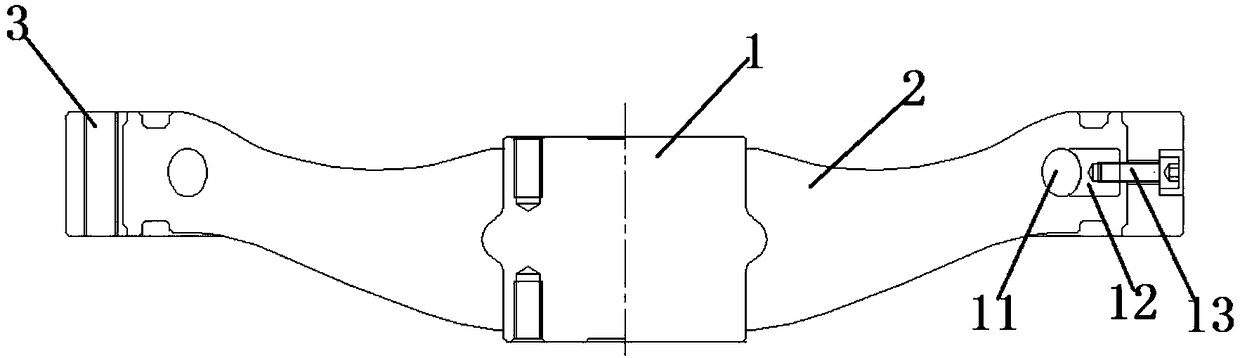

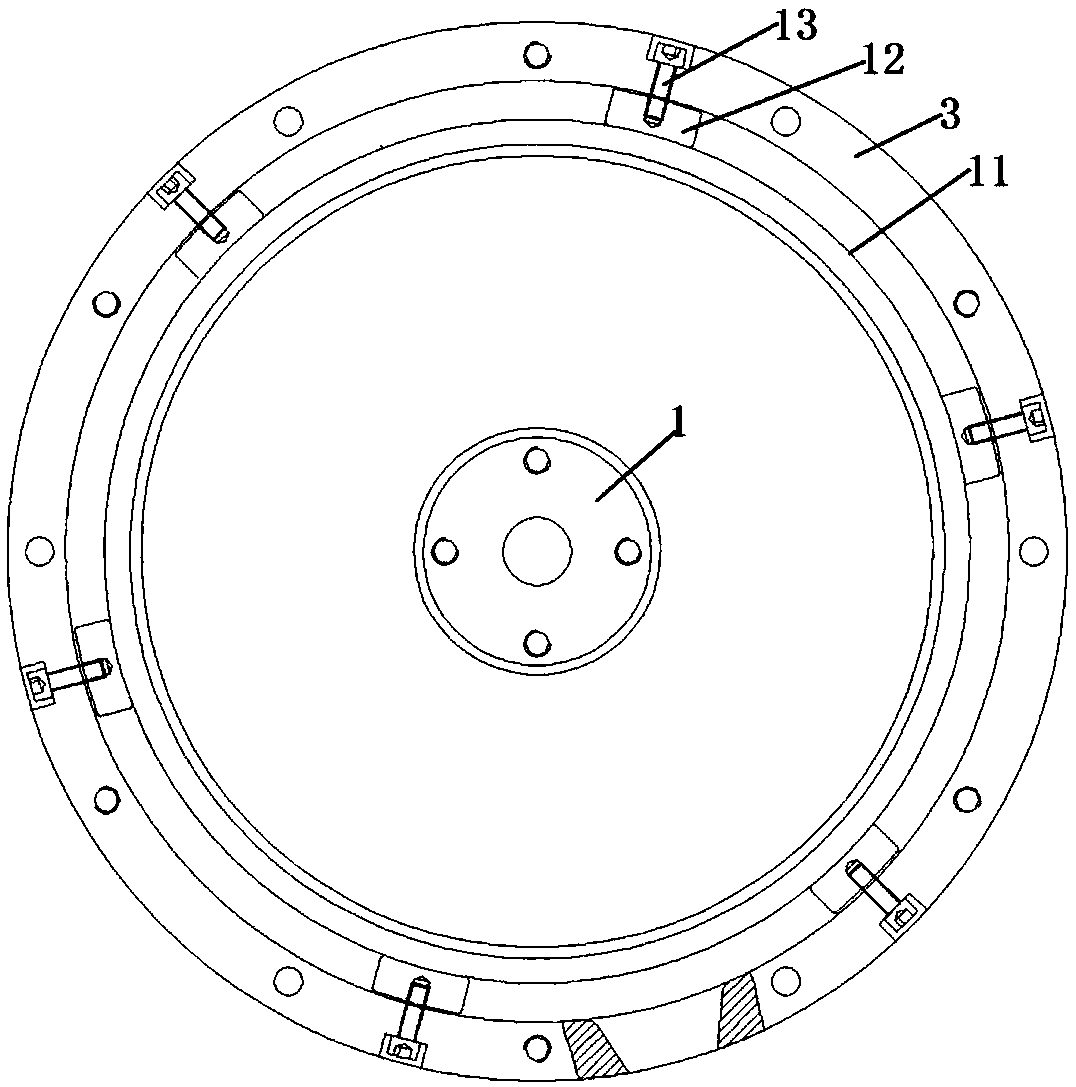

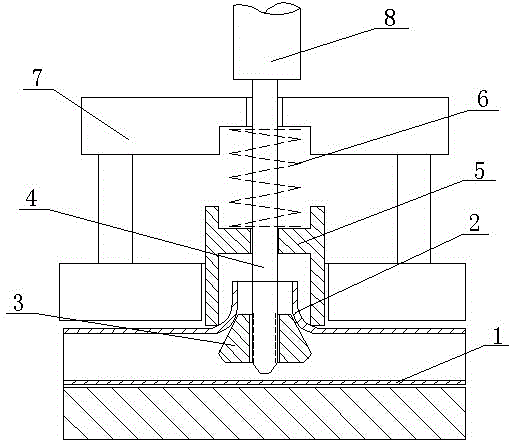

Deformation rectifying method for plate carburizing and quenching gears and special tool for deformation rectifying method

ActiveCN105525252AReduce cooling rateCompensation for smaller size defectsSolid state diffusion coatingFurnace typesCarburizingThermal treatment

The invention relates to a deformation rectifying method for plate carburizing and quenching gears, and belongs to the technical field of metal thermal treatment. The method comprises steps of measuring and selecting, pre-moving stress, preparing a tool, mounting a workpiece, re-quenching, tempering and the like. By adopting the deformation rectifying method, the large end of a common normal line of a to-be-rectified gear faces downwards and is in direct contact with a tray higher than the gear, so that the cooling speed of the part of the gear can be reduced, thermal treatment expansion of the part is relatively small, and the phenomena of a relatively shallow carburized layer and a gear root step caused by too great follow-up milling amount due to secondary quenching are avoided; and meanwhile, the cooling speed for the upper end of the gear is relatively high, and the thermal treatment expansion is greater, so that the defect of a relatively small size of the common normal line after primary carburizing and quenching is compensated.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Electrolytic machining cathode device for freezing protection sleeve material and processing method

ActiveCN109909565AReduce taperReduce ion concentrationMachining electrodesElectrical-based machining electrodesElectrolysisMachine parts

The invention provides an electrolytic machining cathode device for freezing protection sleeve material and a processing method, and belongs to the technical field of electrolytic machining. The cathode device is mainly composed of a cathode head, a cathode block, a freezing block and a coolant bag body. In the sleeve material electrolytic machining method, the coolant bag body surrounds the periphery of a protection cavity in the middle of the freezing block, the machined part of the workpiece gradually extends into the protection cavity in the middle of the freezing block, a coolant is fed from the inlet end of the coolant bag body and flows out from the outlet end of the freezing block, and the stray electrolyte in the middle protection cavity of the freezing block is frozen. Accordingto the electrolytic machining cathode device, stray corrosion caused by stray electrolyte on the machined surface of the workpiece is reduced, the taper of the workpiece is reduced, and the surface quality of the workpiece is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Direct-current basin type insulator

InactiveCN108320869AReduce taperImprove running stabilityBus-bar installationInsulatorsEpoxyManufacturing technology

The present invention belongs to the power technology equipment manufacture technical field and relates to a direct-current basin type insulator. The environmental insulation property of an SF6 gas under a direct-current voltage are very different from the environmental insulation property of the SF6 gas under alternating current, and controlling charge accumulation and reducing surface charges during the long-term operation of an insulator have become key technologies and difficulties in the study of direct-current GIL (Gas-insulated transmission line) insulators. The direct-current basin type insulator provided by the invention comprises a central insert; the outer side of the central insert is provided with an epoxy aluminum oxide composite member; one end of the epoxy aluminum oxide composite member is connected with the central insert; the other end of the epoxy aluminum oxide composite member is connected with a flange; the central insert comprises a first intersection point; theflange comprises a second intersection point; and an included angle between a connection line between the first intersection point and the second intersection point and a horizontal plane is not larger than 20 degrees. Therefore, a normal electric field component can be greatly reduced under a premise that a horizontal electric field component is not increased, and therefore, surface charge accumulation can be suppressed, and the operational stability of the direct-current basin type insulator under direct current can be improved.

Owner:TSINGHUA UNIV

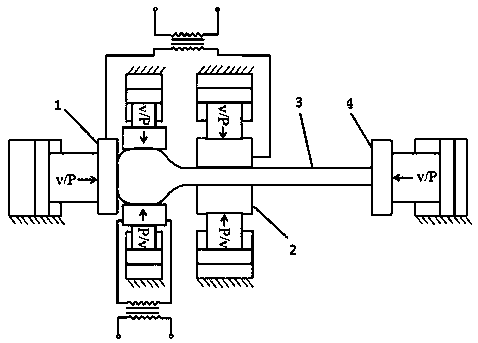

Spinning and cold drawing process of three-way pipe

The invention relates to a spinning and cold drawing process of a three-way pipe. The spinning and cold drawing process is characterized by comprising the steps of drilling a preprocessed hole, screwing a spinning body, connecting a machine tool, spinning and drawing. When a connection rod is pulled outwards along the axial direction of the preprocessed hole, a pipe body is pressed downwards by a spinning sleeve under the effect of a spring, a rising position of a pipe orifice of a new pipeline is limited, so that the new pipeline extends upwards along the inner wall of the spinning sleeve, the produced pipe body is small in taper, the pipe orifice is smooth, the crack is unlikely to occur, fewer reject products are produced, simplicity and convenience in operation can be realized, and the production cost can be effectively reduced.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Laser processing device and method for ceramic special-shaped groove

PendingCN110181172ASolve the problem of excessive taperControl the manufacturing cycleLaser beam welding apparatusLaser processingIrradiation

The invention discloses a laser processing device for a ceramic special-shaped groove. The laser processing device comprises a control device, a laser device and a motion device, wherein the control device is electrically connected with the laser device and the motion device respectively; the motion device is arranged at a laser irradiation position emitted by the laser device; the motion device comprises rotary clamps and a three-dimensional platform; a support frame body is fixed on the three-dimensional platform; a plurality of rotary clamps are installed on the upper surface of the supportframe body; the bottom parts of the rotary clamps are connected with rotary motors; the top parts of the rotary clamps are fixedly connected with to-be-machined samples; the rotary motors are electrically connected with the control device, and to-be-machined samples clamped on the rotary clamps are controlled to rotate to a to-be-machined position; the three-dimensional platform is electrically connected with the control device, and to-be-machined samples clamped by the rotary clamps on the three-dimensional platform are controlled to move to a to-be-machined position. According to the laserprocessing device, the problem that taper of a special-shaped groove of a ceramic inner wall is too large after machining can be effectively solved under a common configuration; and machining efficiency is improved.

Owner:WUHAN HGLASER ENG CO LTD

Efficient gun barrel bore chromium plating additive and plating solution thereof

The invention discloses an efficient gun barrel bore chromium plating additive and a plating solution thereof. The additive mainly comprises methyl sulfonic salt, sodium bromide and magnesium sulfate, and the plating solution mainly comprises CrO3, H2SO4, Fe3+ and Cr3+. By applying the additive and the plating solution to gun barrel bore chromium plating, qualified rate of gun barrel bore chromium coatings can be improved significantly, current efficiency is improved and can reach 20%-27%, chromium coating deposition velocity is increased and is 2-3 times of that of traditional hard chromium plating, gun barrel bore chromium plating time is shortened, and energy consumption in the chromium plating process is reduced. In the aspect of chromium coating performances, chromium coating hardness is enhanced beneficially, chromium loss rate after shooting of a gun barrel is decreased, chromium coating quality is improved remarkably, the chromium coatings are fine, and bright and uniform in thickness, throwing power of the plating solution is high, cone difference is reduced, inner wall chromium plating of deep-barrel parts can be completed only one-time plating to enable cone difference thereof to meet process standards, reversing chromium plating is not needed, chromium plating efficiency is improved greatly, time is saved, and cost of deep-barrel inner wall chromium plating is lowered. The additive is fluoride-free, small in anodic corrosion and capable of effectively protecting anodes.

Owner:欧忠文 +1

Method for improving large-specification electrically-upset end face concave and promoting grain refining

ActiveCN111085644AReduced sinking depthReduce radial pressureForging/hammering/pressing machinesForging press detailsReduction treatmentMetallurgy

The invention discloses a method for improving large-specification electrically-upset end face concave and promoting grain refining, the sinking depth can be reduced, and grain refining can be promoted. The method comprises the following steps that rod material pretreatment is conducted; material reduction treatment is conducted on the edge areas on the two end faces of a rod material, and the contact area between the two end faces of the rod material, an anvil electrode and an upsetting cylinder can be reduced; the concave face type anvil electrode is adopted for conducting electric upsettingon the rod material on an electric upsetting device, pre-contact is provided for the peripheral face of a garlic head through the concave face type anvil electrode, plastic deformation happens to thepre-contact part, and accordingly sinking depth increasing is hindered; meanwhile, due to material reduction treatment, axial upsetting force is transmitted to the center of the garlic head in a centralized manner, and accordingly the concave of the end face of the garlic head is corrected; and along with improvement of the concave degree, garlic head grains are evenly refined.

Owner:NANJING INT MARINE EQUIP & SPARES

Chisel Case

InactiveUS20120118775A1Prevents unnecessary abrasionRestrict movementOther accessoriesContainer/bottle contructionEngineeringMechanical engineering

A chisel case 50 includes a hollow unitary body portion 52 and a removable cap portion 54. The body portion 52 has a substantially cylindrical section 56 for receiving a chisel handle 70. A substantially elongate box section 58 adjoins and is integrally formed with the body portion 52 and in use receives a chisel blade 66. A chisel 62 is contained within the chisel case 50 and is supported by a deformable blade supporting means 64 disposed at the end of the elongate box section 58 and a deformable handle supporting means 68 disposed within the cap portion 54.

Owner:WEBB JOHN

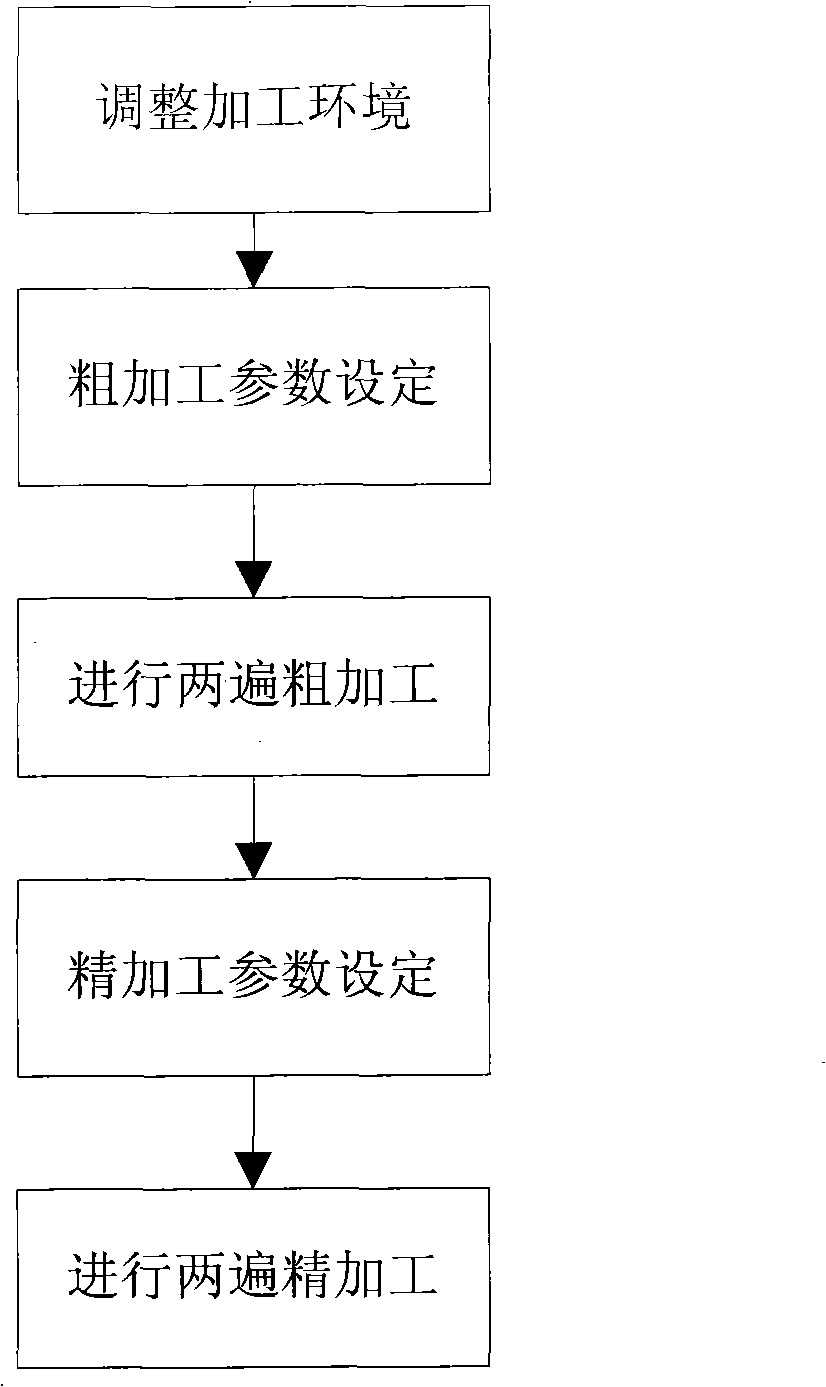

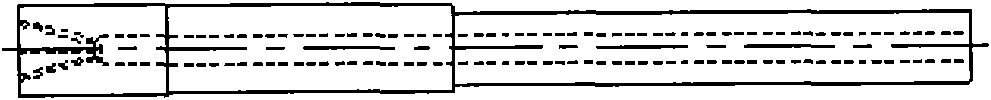

Underwater high-precision hole forming method based on electrical discharge machining

The invention belongs to the technical field of electrical discharge machining, in particular to an underwater high-precision hole forming method based on electrical discharge machining, and aims to provide a method for forming a high-precision hole underwater under high irradiation conditions by electrical discharge machining, which can meet both requirements of the processing precision and processing speed. The method comprises the following steps: adjusting the process environment, setting rough processing parameters, performing rough processing twice, setting fine processing parameters, and performing fine processing twice. The invention has the advantages that: the rapid and high-precision hole processing is achieved by adopting the optimized electrical discharge machining parameters and the special design of the electrode scour hole, performing the rough processing twice and performing the fine processing twice. The processing depth of the threaded bottom hole is ensured, the degree of taper of the threaded bottom hole is reduced, and the risk that the screw tap is broken during the long-distance underwater tapping process is reduced. The smoothness of the processed surface is improved and a certain over-cut amount is provided, so that the processed threaded bottom hole can fully meet the requirement for engineering applications. The working current is increased to increase the speed of the electrical discharge machining.

Owner:QINSHAN NUCLEAR POWER

Laser processing system, laser processing method and method of obtaining oval light spot

PendingCN113770548ANot prone to edge collapseReduce taperWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingLight spot

The invention relates to a laser processing system, a laser processing method and a method of obtaining an oval light spot. In the laser processing system, by arranging a first phase modulation element and a second phase modulation element to modulate a phase of a light beam, after the light beam is focused by a first focusing unit, the light beam irradiates a to-be-processed workpiece to form the oval light spot with a large focal depth, a crack is more easily formed in a long axis direction of the oval light spot, and a direction of the crack can be controlled only by reasonably controlling the long axis direction of the oval light spot, so that the crack develops in a direction beneficial to cutting the to-be-processed workpiece , and the edge breakage phenomenon of the to-be-workpiece is not prone to occurring; and in addition, a first cutting light beam is in penetrative energy distribution in the to-be-processed workpiece in a light propagation direction, so that a cutting channel is more uniform, the taper is relatively small, and the cutting section is smoother.

Owner:深圳市大族半导体装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com