Laser processing device and method for ceramic special-shaped groove

A technology of laser processing and laser devices, which is applied in the field of ceramic processing to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

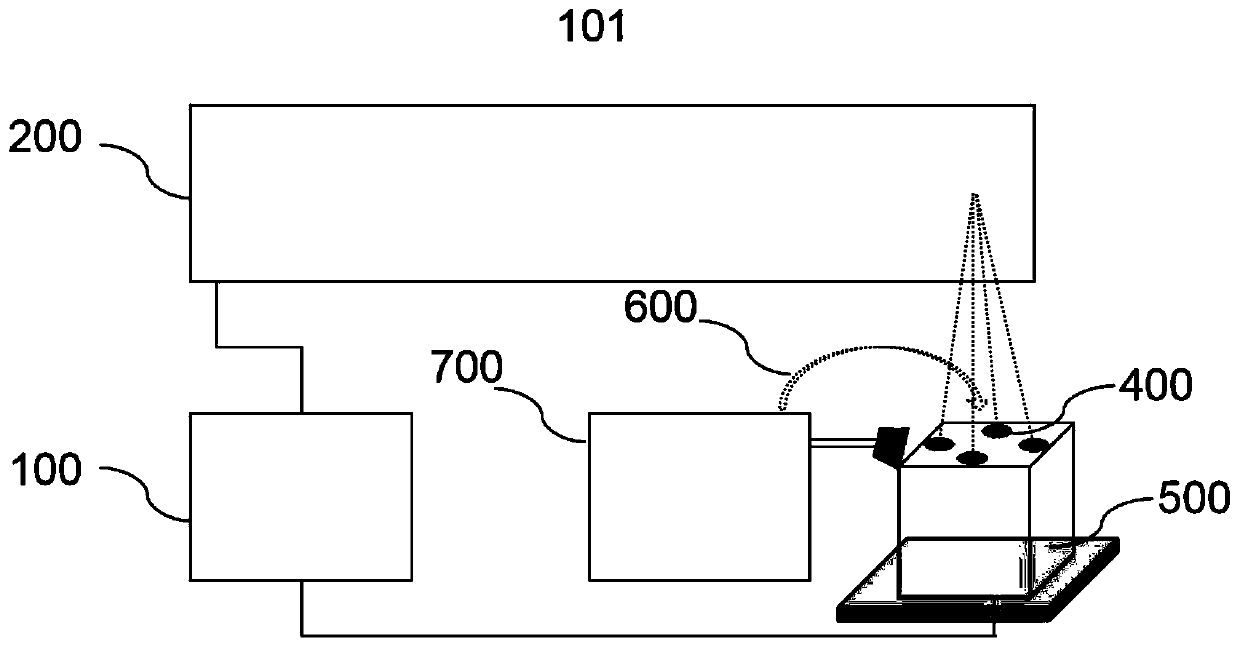

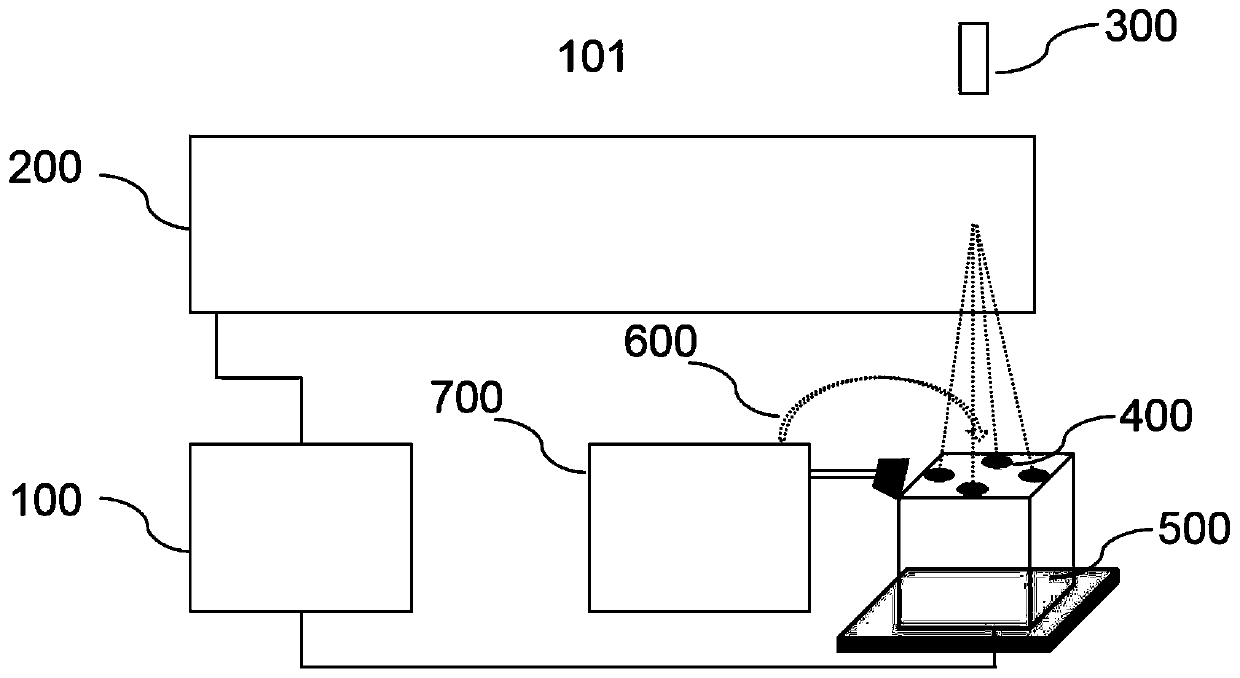

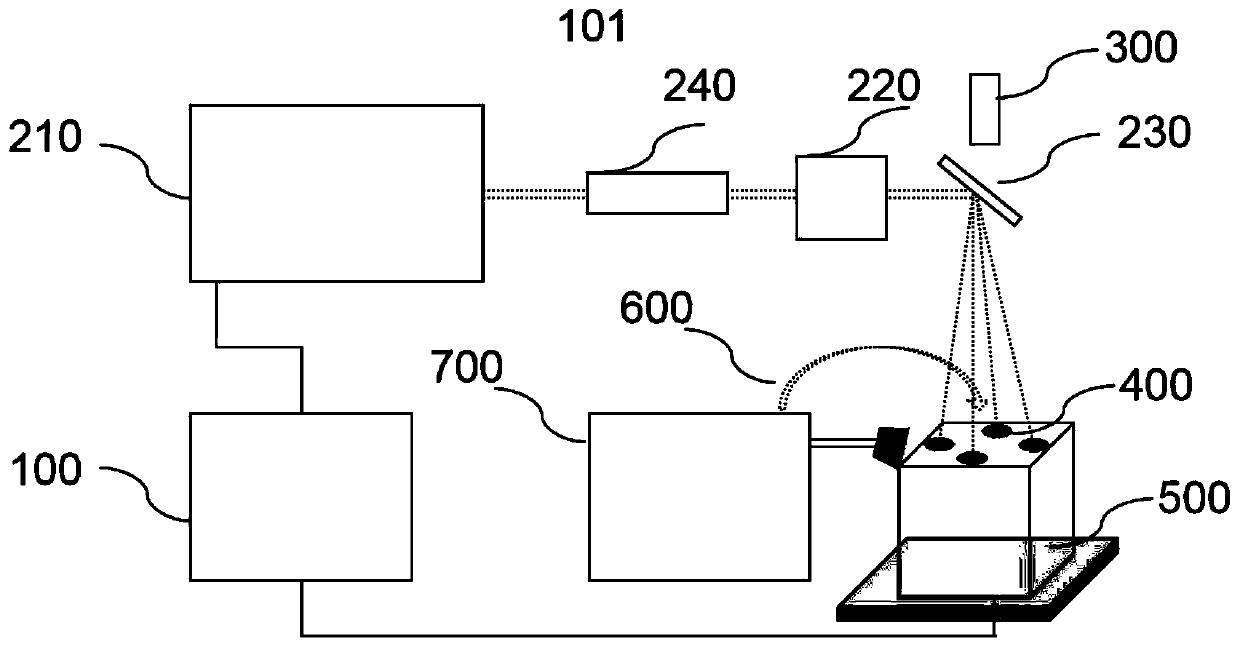

[0039] See figure 1 , figure 1 It shows a schematic view of the first view structure of the device for laser machining irregular-shaped ceramic grooves provided by the embodiment of the present application. The present application provides a device 101 for laser processing irregular-shaped ceramic grooves. The device 101 for laser processing irregular-shaped ceramic grooves includes: a control device 100, a laser device 200 and a motion device 500; the control device 100 is electrically connected to the laser device 200 and the motion device 500 respectively Sexually connected, the movement device 500 is arranged at the laser irradiation place emitted by the laser device 200 .

[0040] The control device 100 is used for simultaneously or separately sending control signals to the laser device 200 and the motion device 500 . The control signal includes a laser control signal sent to the laser device 200 and a motion control signal sent to the movement device 500 .

[0041] Th...

no. 2 example

[0059] See Figure 6 , Figure 6 A schematic flow chart of the method for laser machining irregular-shaped ceramic grooves provided by the embodiment of the present application is shown. The present application also provides a method of laser machining irregular-shaped ceramic grooves, the laser machining method comprising:

[0060] Step S11: According to the required taper value of the sample to be processed, calculate the distance of the rotating fixture from the center of the lens;

[0061] Step S12: the control device controls the rotary fixture to move to a designated position;

[0062] Step S13: The control device draws a processing layer of the sample to be processed according to the data of the sample to be processed, and the data includes the depth, taper size and rotation angle of the special-shaped groove of the sample to be processed.

[0063] Step S14: Calculate the number of layers according to the depth of the special-shaped groove of the sample to be process...

Embodiment approach

[0068] See Figure 7 , Figure 7 It shows a schematic flow chart of another implementation of the method for laser machining irregular-shaped ceramic grooves provided by the embodiment of the present application. Another embodiment of the method for laser machining irregular-shaped ceramic grooves provided by the present application is a processing method for laser-machining irregular-shaped ceramic grooves with a small taper. The steps of the processing method are as follows:

[0069] Step S21: According to the depth and taper of the required groove on the annular ceramic sample to be processed, the required processing layer is established through the control software in the computer.

[0070] Step S22: Calculate the required number of layers according to the required depth D of the groove to be processed and the processing depth d of each layer.

[0071] Step S23: Turn on the laser in the processing device, and set required parameters.

[0072] Step S24: Install the ring-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com