Patents

Literature

44results about How to "Avoid cut quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

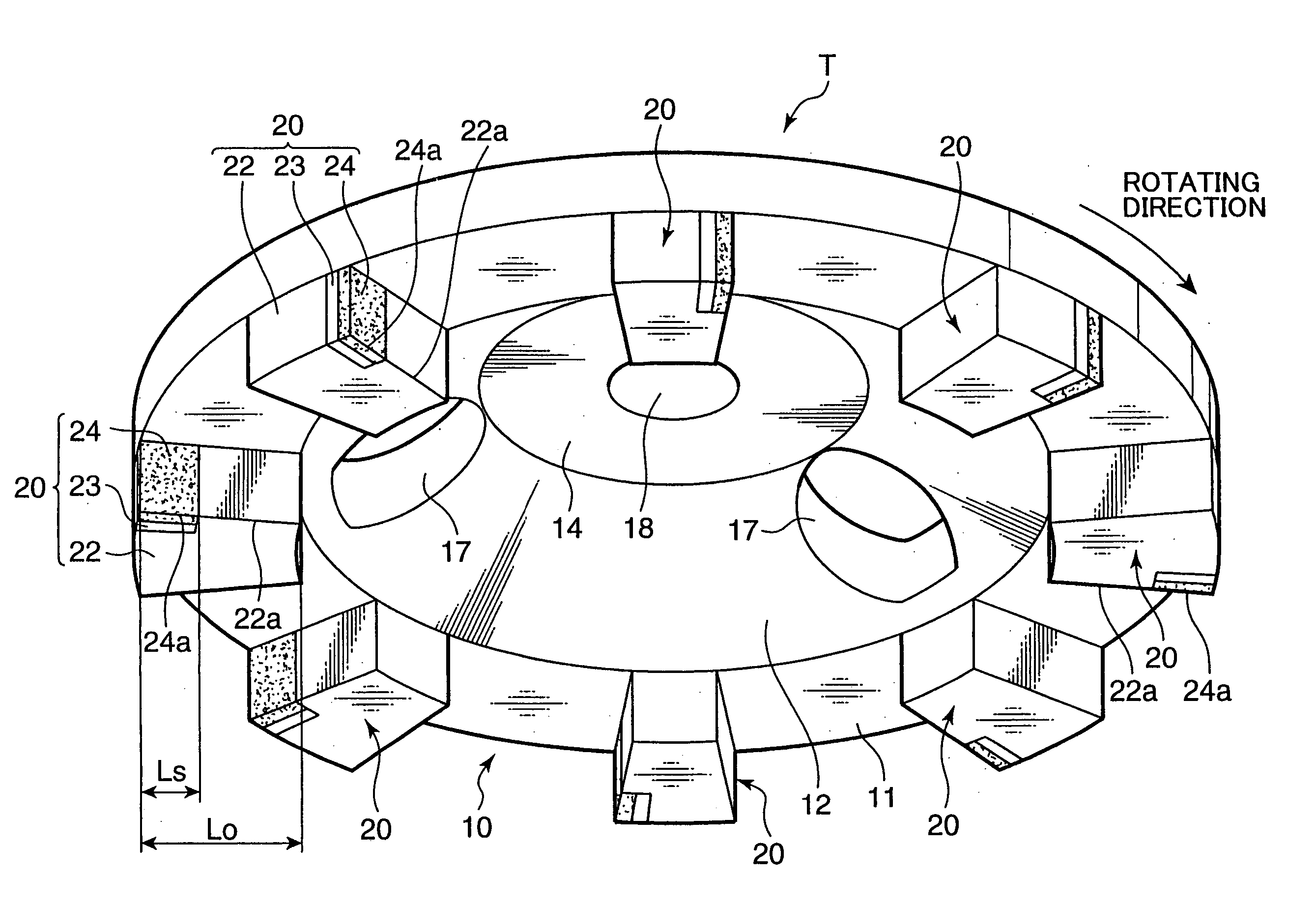

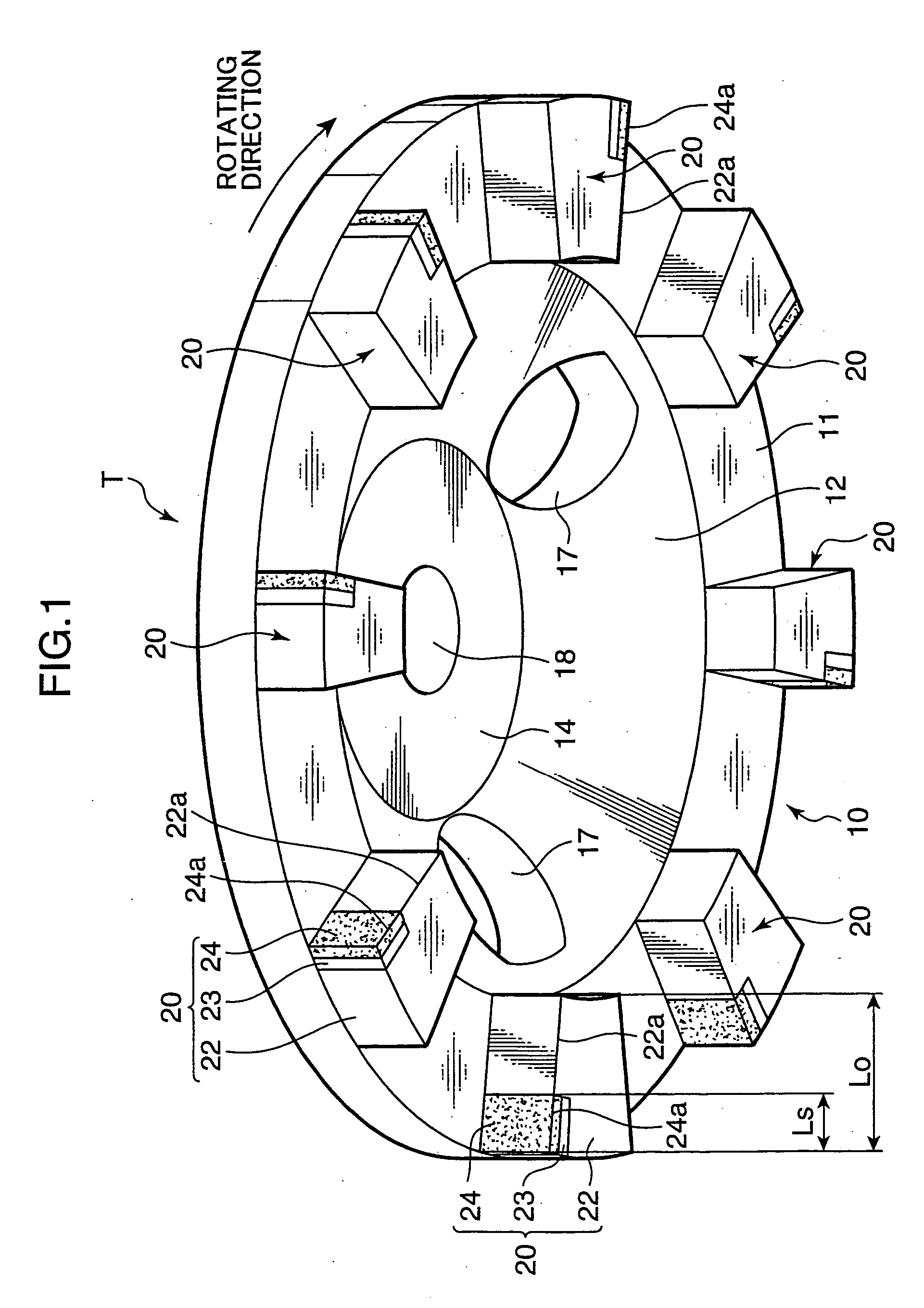

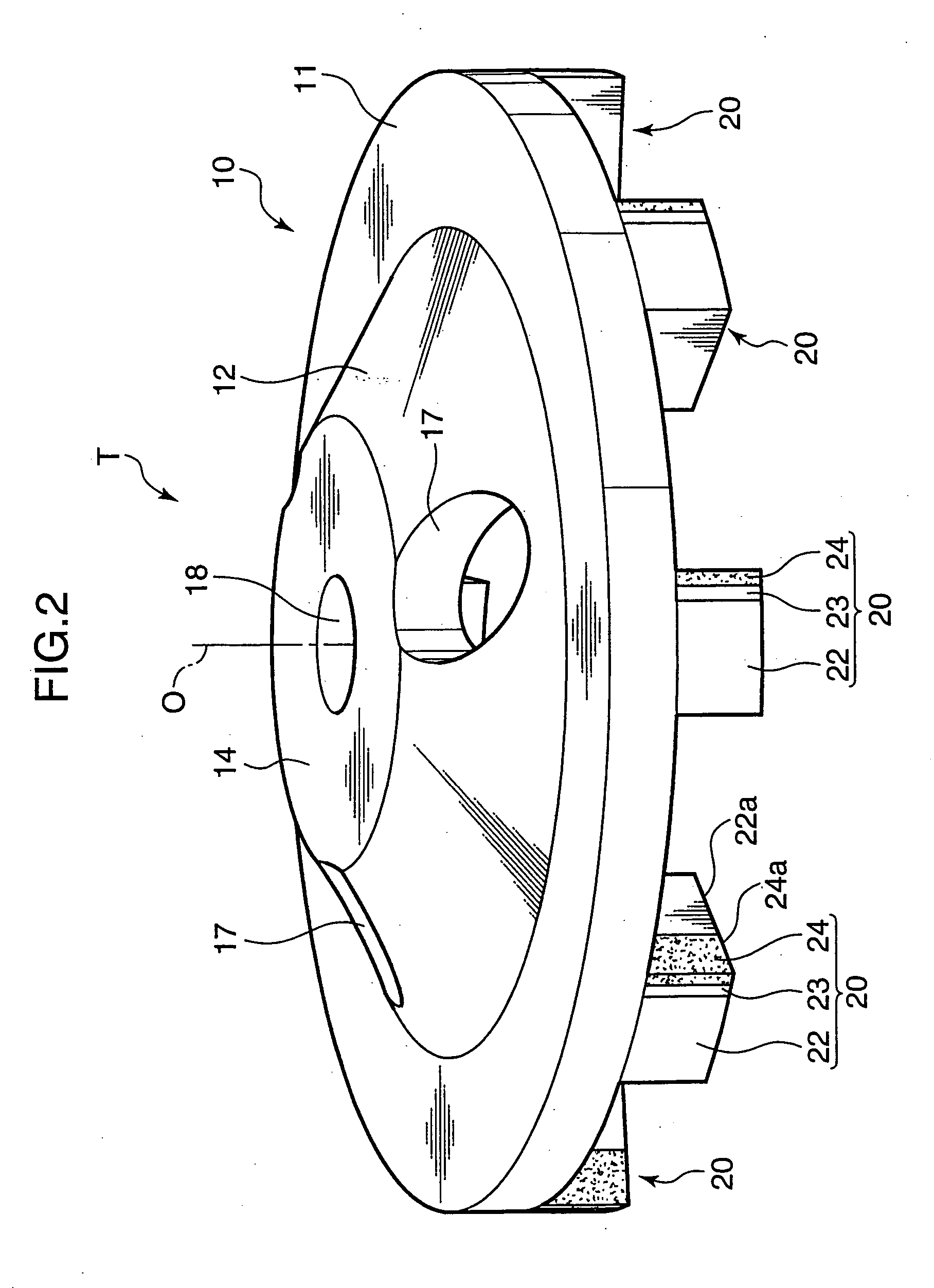

Rotary tool and its cutting part

InactiveUS20050164620A1Few or no effectsSharp cutting qualityRevolution surface grinding machinesMilling cuttersMetallurgy

A rotary tool (T) has a rotary segment (10) with an opposed surface opposed to a work surface and a plurality of cutting parts (20) arranged on the opposed surface. Some cutting parts (20) include tips (22a) made of a grinding tool segment obtained by binding abrasive grains by a metal binder and the other cutting parts (20) include tips (24a) made of a sintered material harder than the grinding tool segment, and the respective cutting parts (20) are arranged such that the tips (24a) are located at positions more outward than the tips (22a) with respect to radial directions of the rotary segment.

Owner:SANWA KENMA

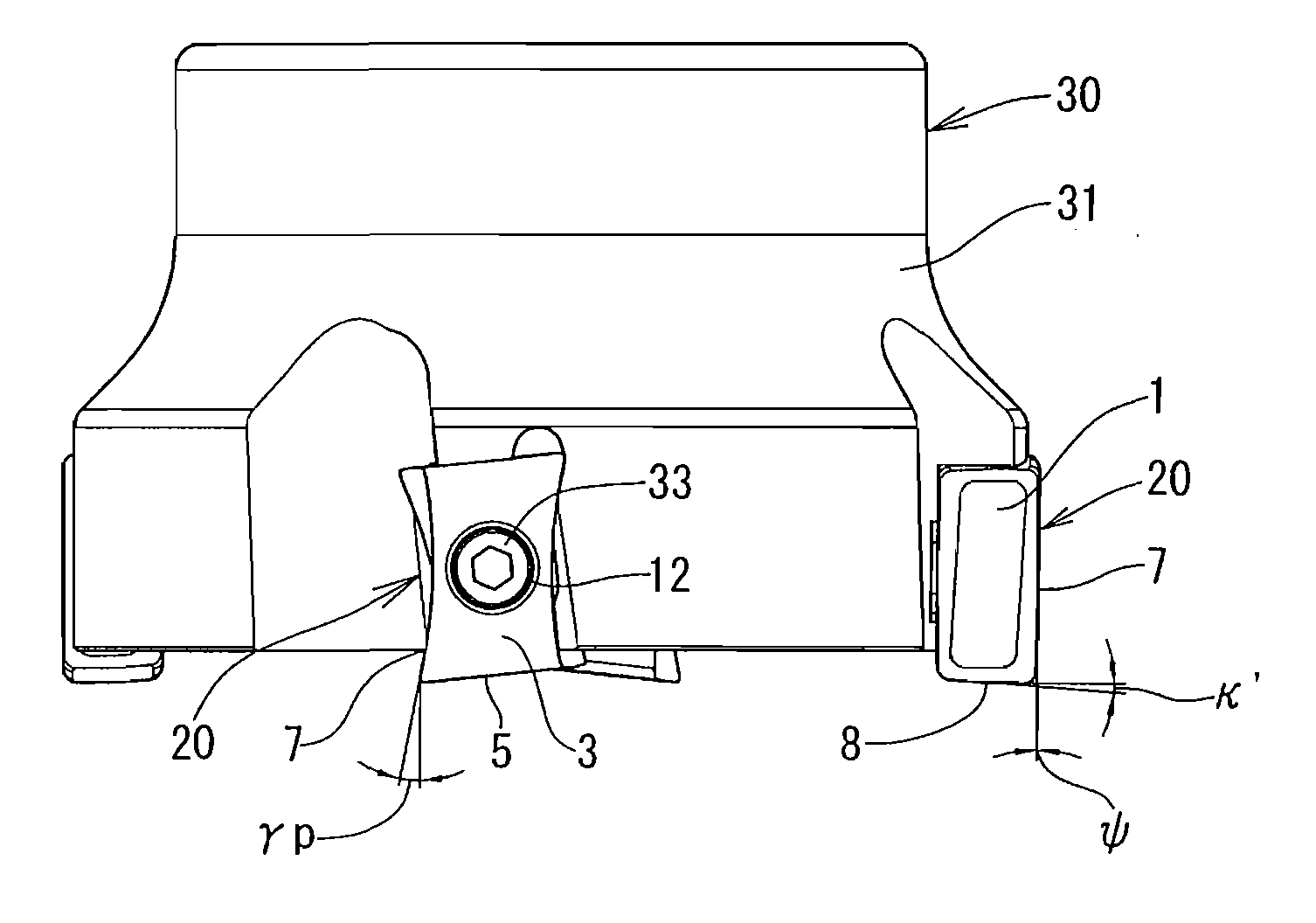

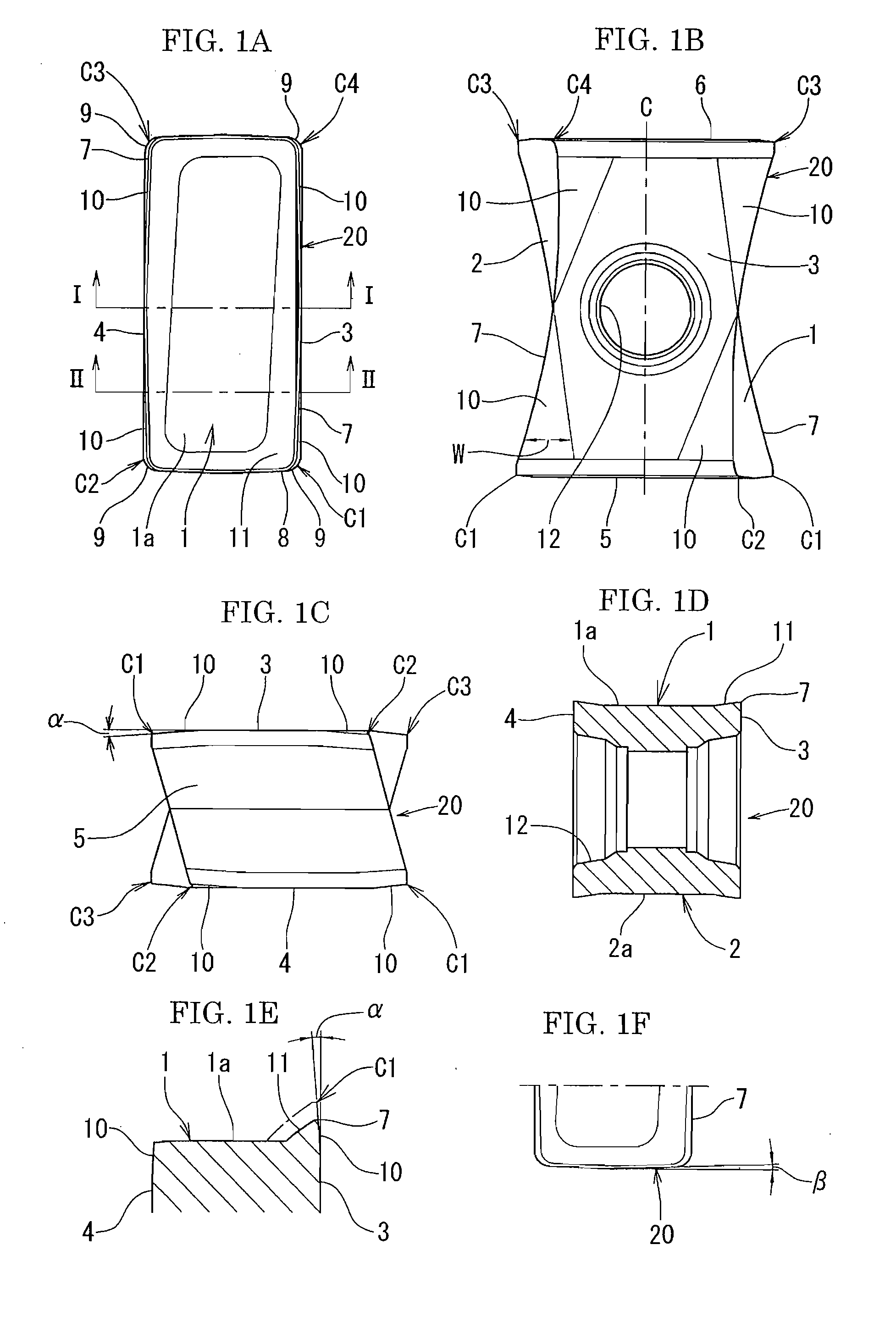

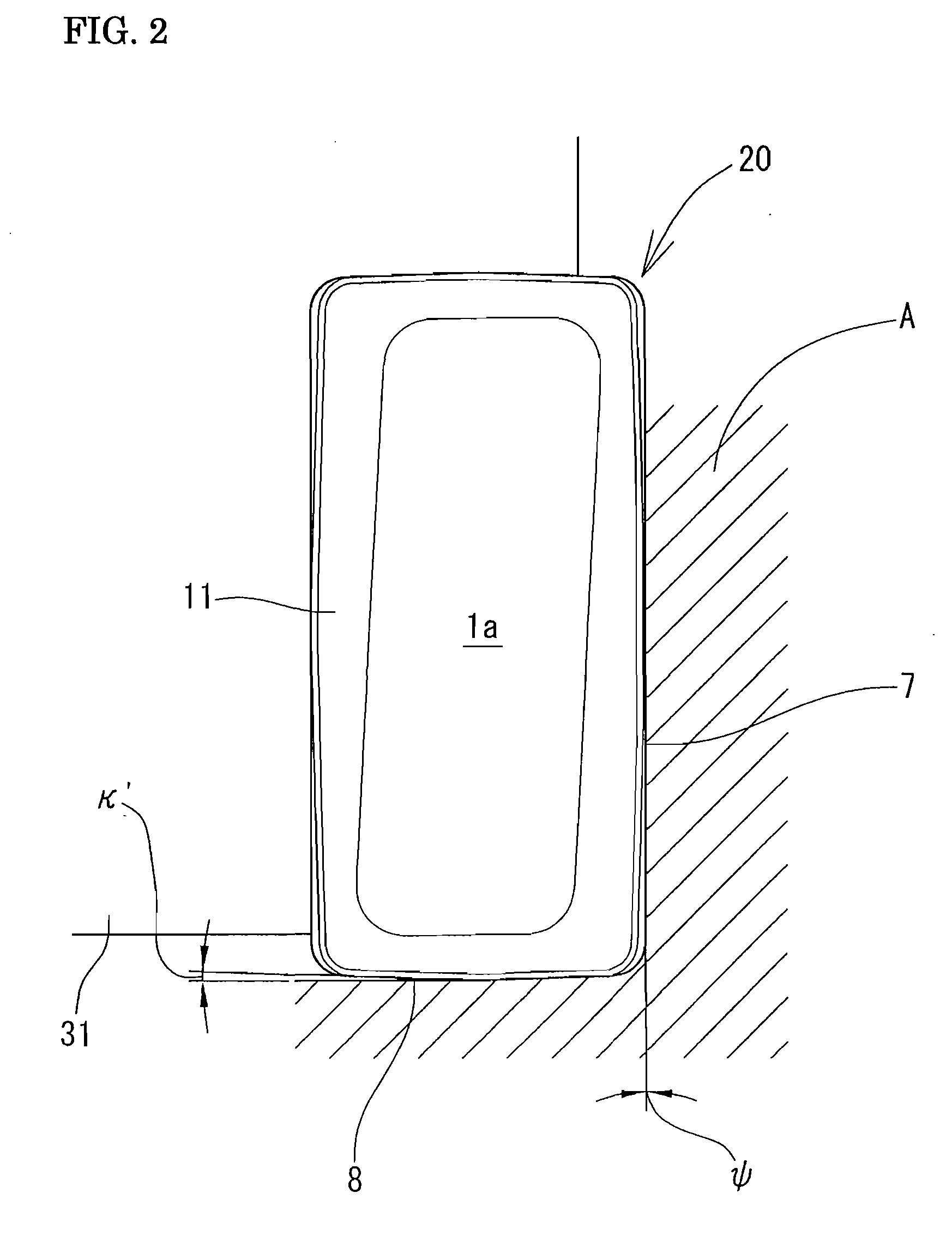

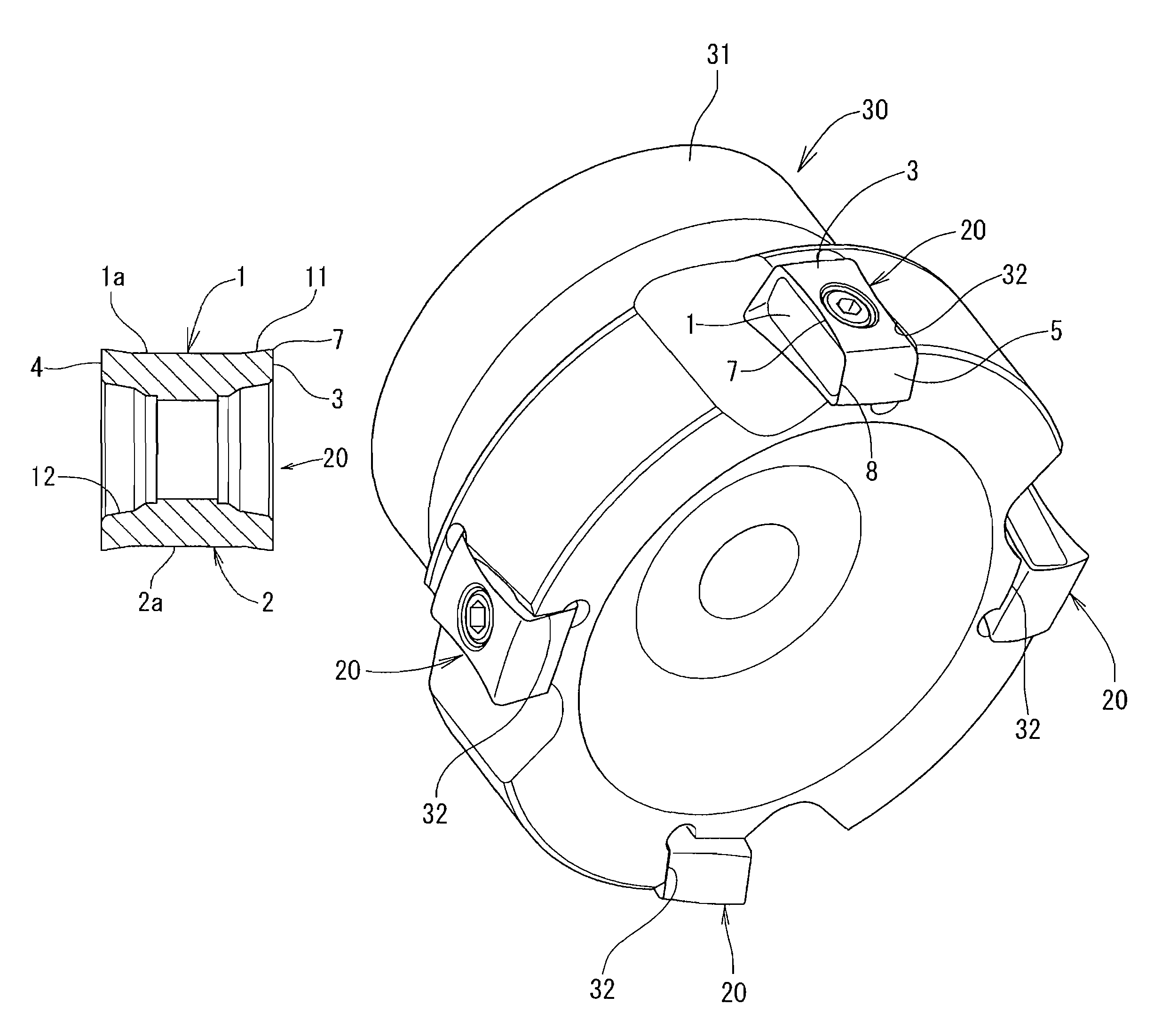

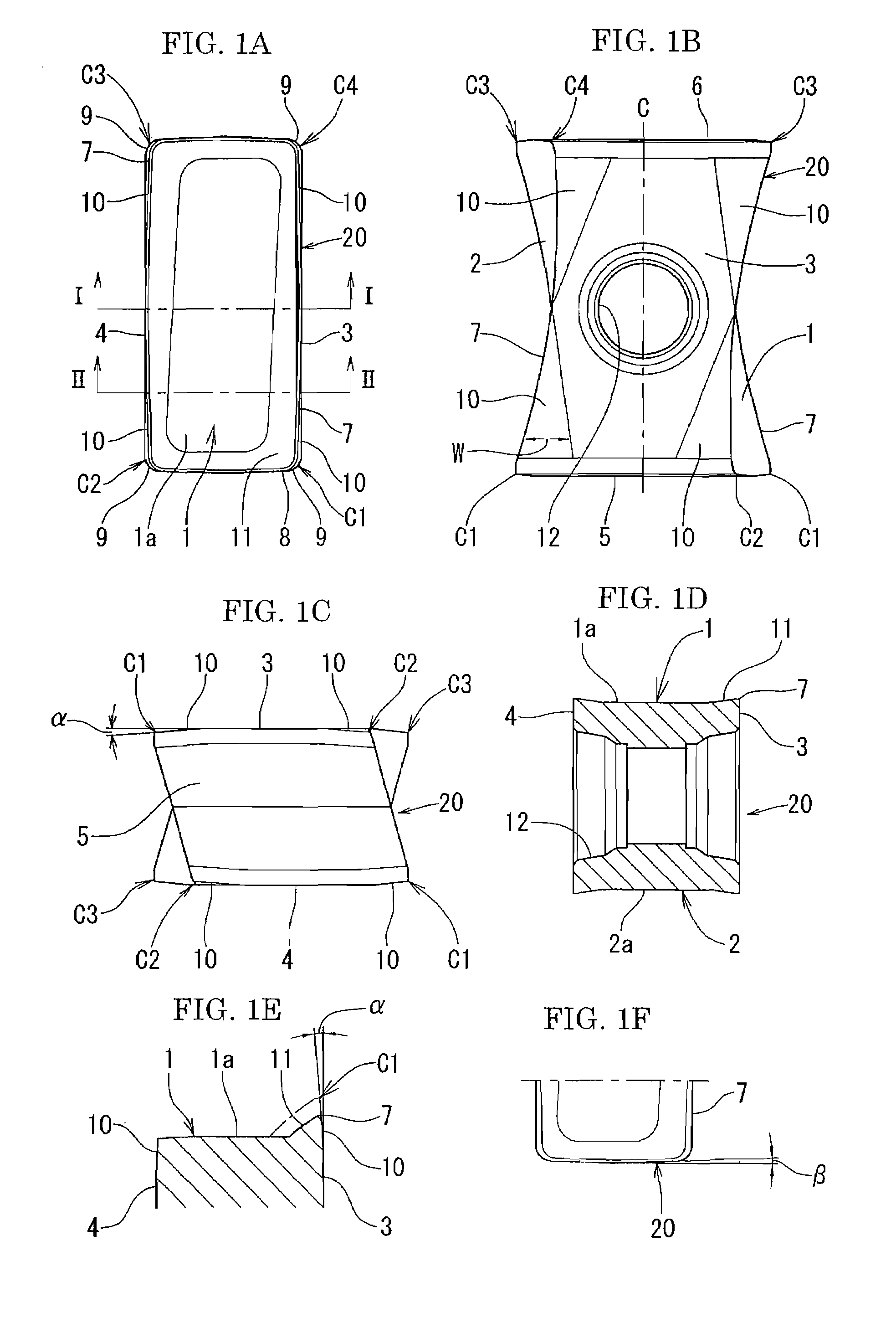

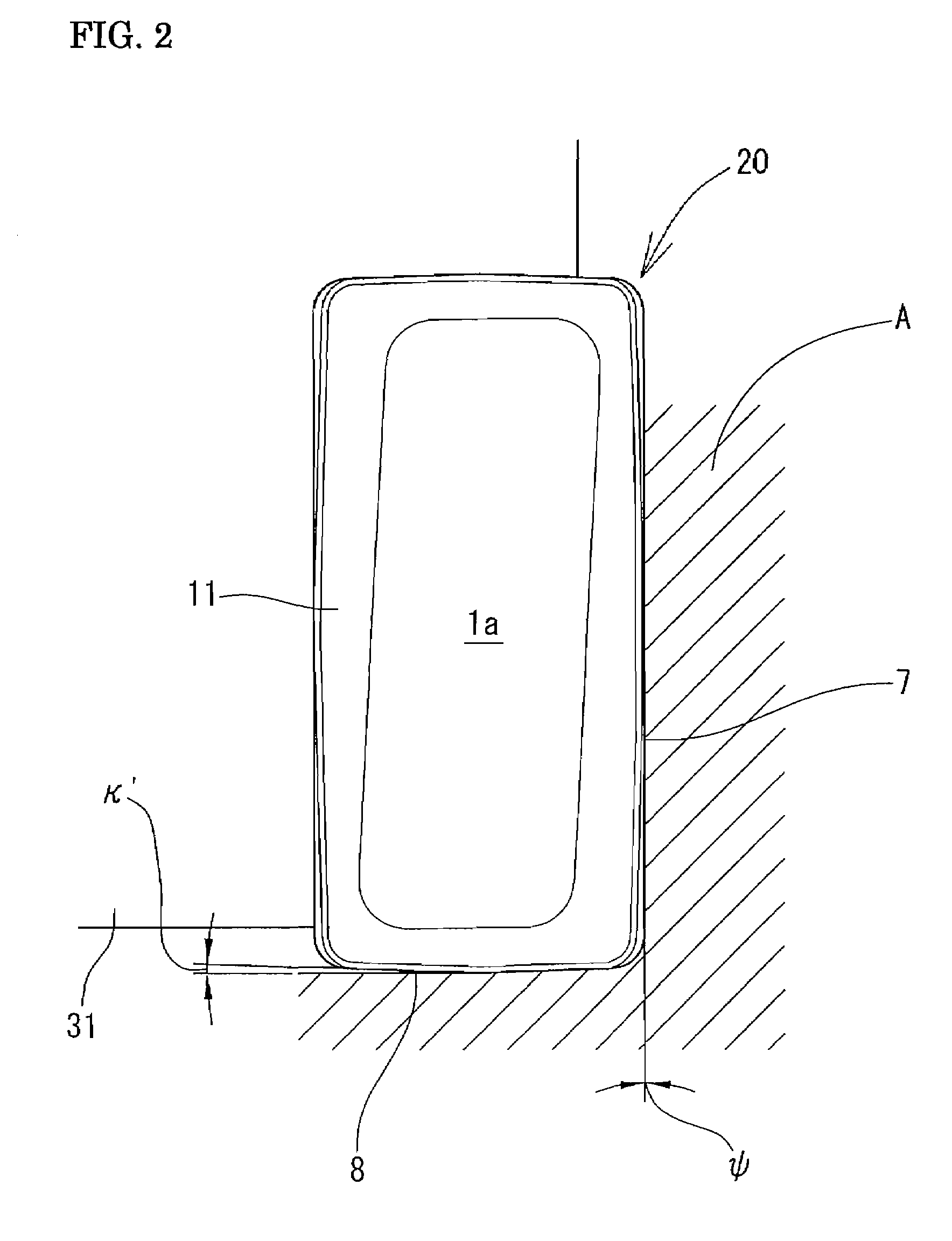

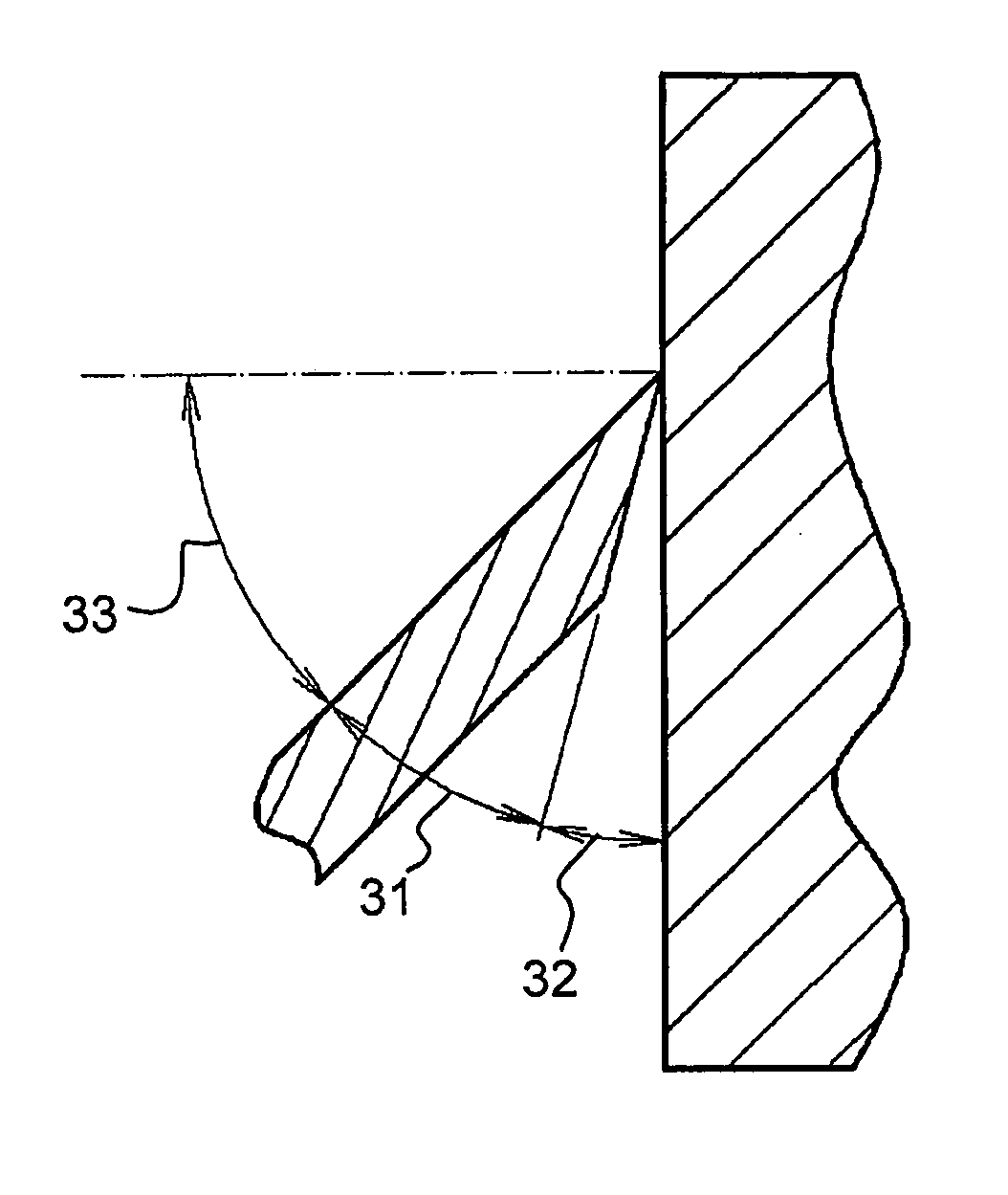

Insert with replaceable cutting edge and corner milling cutter with replaceable cutting edge

ActiveUS20070104546A1Added economic advantageEasy to shapeMilling cuttersShaping cuttersMilling cutterEngineering

A replaceable-blade cutting insert for corner milling cutters has a first and second surface; a third and fourth surface connected to a first side edge and a second side edge thereof respectively; and a fifth and sixth surface connected to a first edge and a second edge of the first surface and the second surface respectively. The first surface is used as rake face, the third surface is used as an outer perimeter flank face, and the fifth surface is used as a forward flank face. A twisted surface is disposed on a section of the third surface, forming a ridge line that acts as a main cutting edge intersecting with the first surface and interposed between the third and first surface. The first and second surface can be positioned with a height offset relative to each other so that at least one set of diagonal corners are projected.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

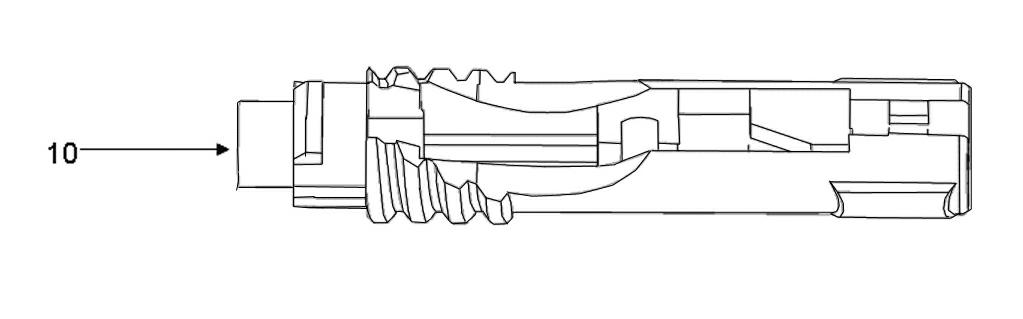

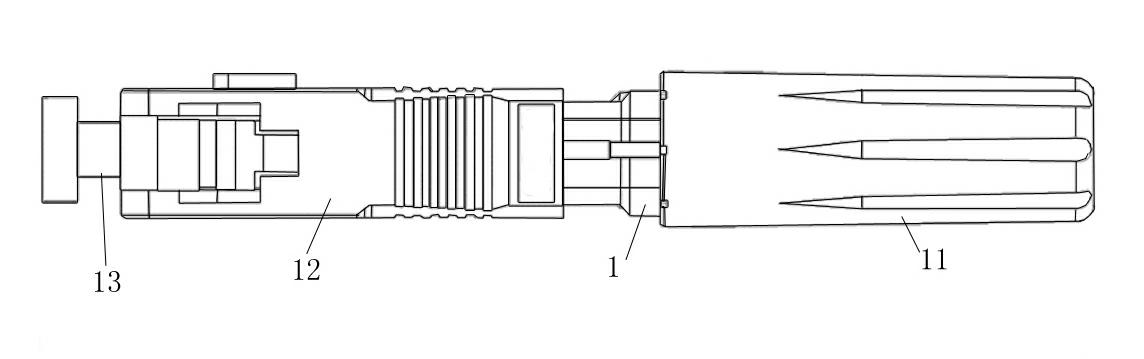

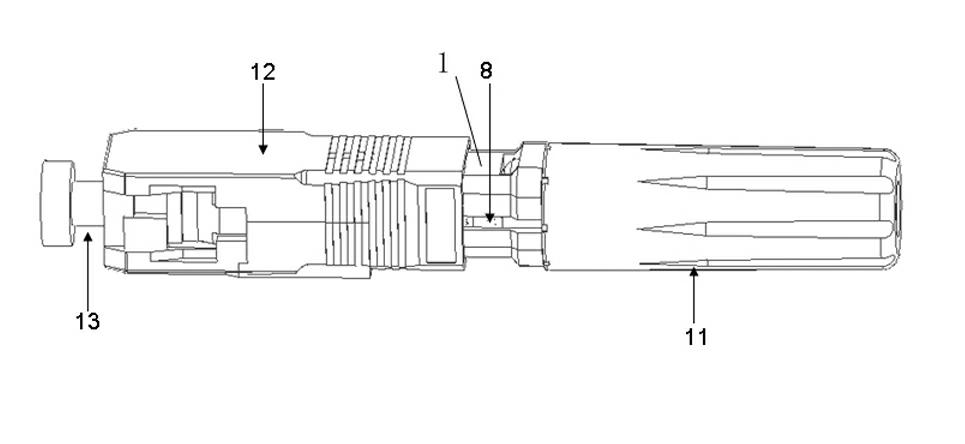

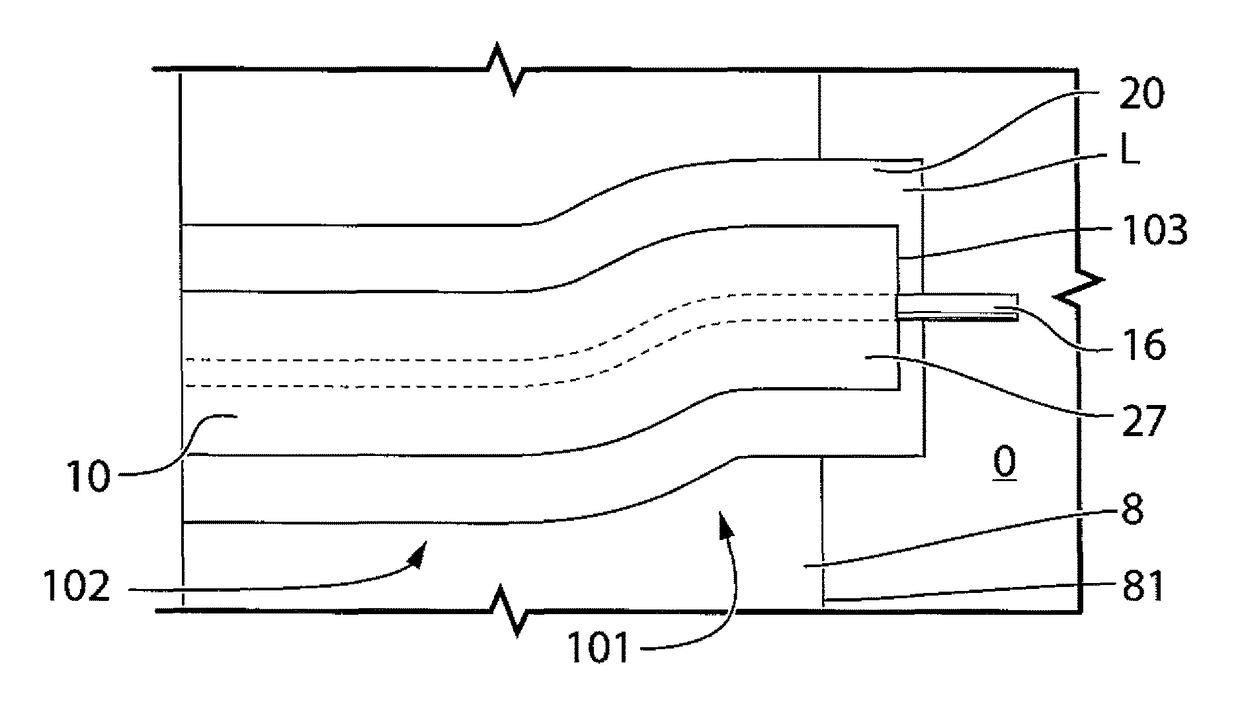

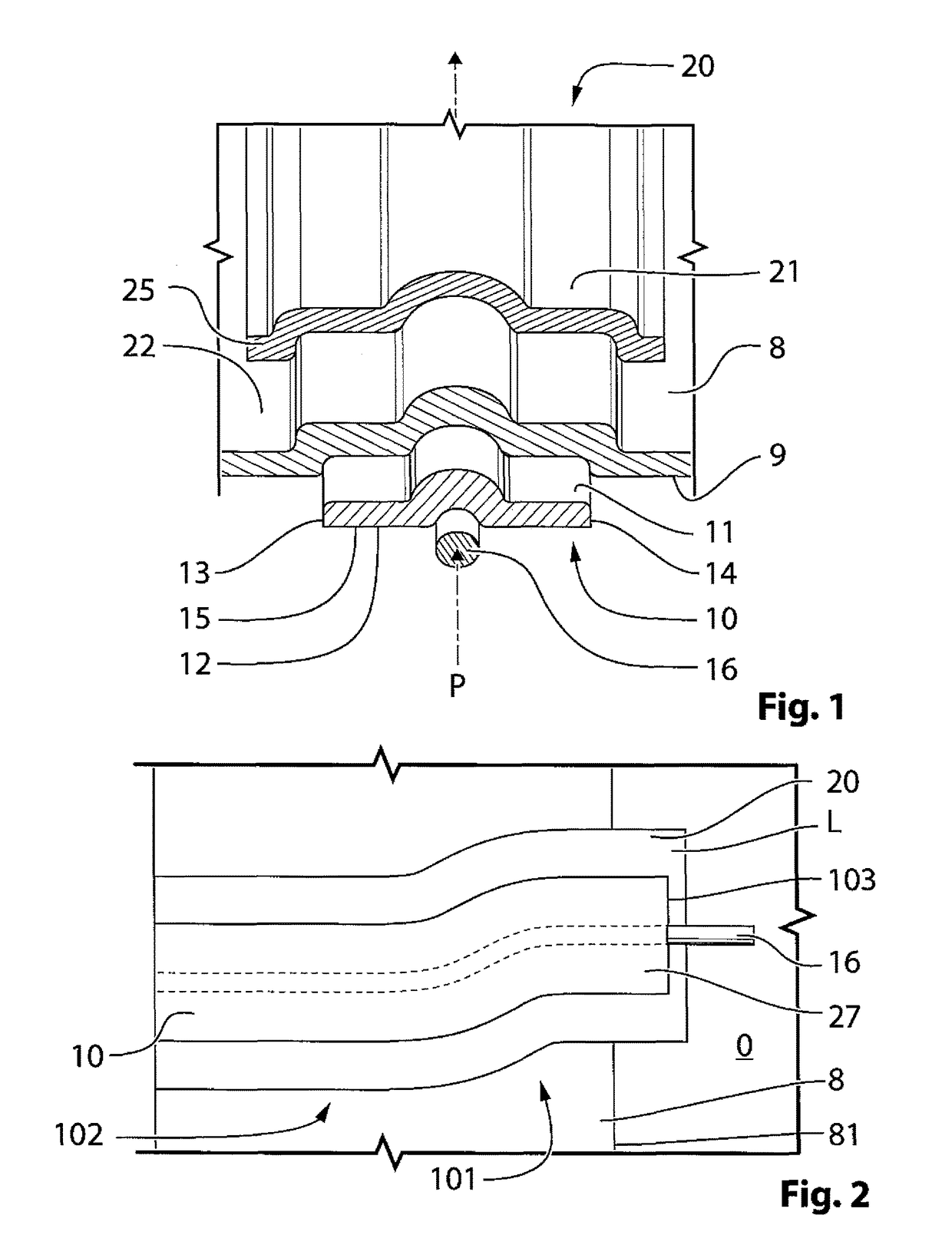

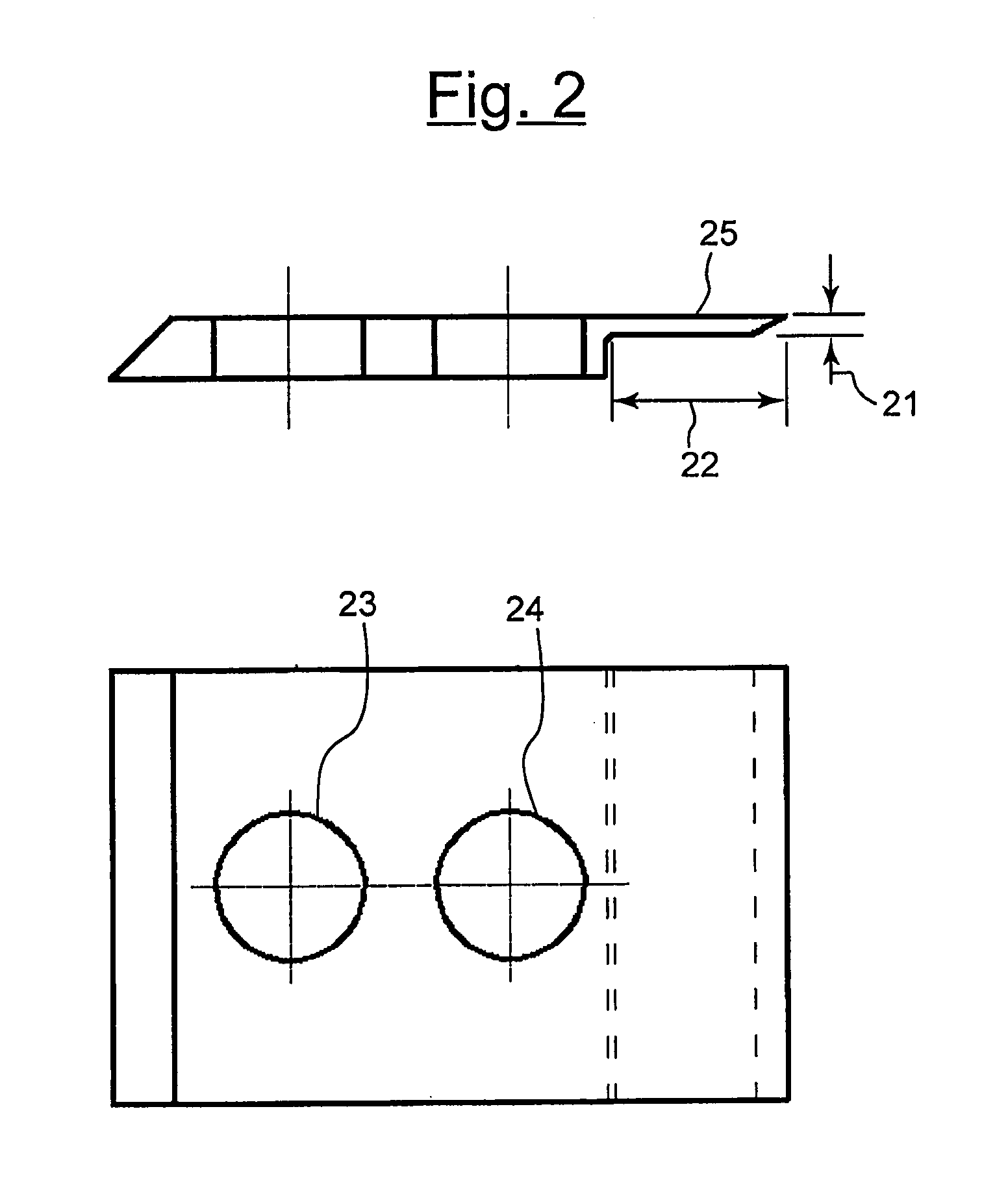

Fibre-embedded optical fibre fast connector

ActiveCN102156331AAvoid cut qualityLower requirementCoupling light guidesOptical fiber connectorMaterials science

The invention discloses a fibre-embedded optical fibre fast connector and relates to a passive optical device for field fast-forming of an optical fibre and an optical cable. The fibre-embedded optical fibre fast connector comprises an embedded optical fibre alignment and clamping device, an optical fibre guide and optical cable clamping piece, a tail sleeve, a joint outer cover of a subscriber connector (SC) optical fibre connector and a joint end-face dust-proof cap, wherein the embedded optical fibre alignment and clamping device comprises an integrated shell, a ceramic ferrule, an embedded optical fibre, a gradually-variable diameter optical fibre guiding piece, a V-shaped slot butting integrated piece, a clamping pressure connection piece, a spring and an optical fibre clamping opening piece; the embedded optical fibre is inserted into the ceramic ferrule; the joint end-face dust-proof cap is arranged on one side of an end face of the ceramic ferrule; the other side of the ceramic ferrule is fixed at the front end of the V-shaped slot butting integrated piece; the gradually-variable diameter optical fibre guiding piece is fixed at the rear end of the V-shaped slot butting integrated piece; the V-shaped slot butting integrated piece and the gradually-variable diameter optical fibre guiding piece are fixed by the integrated shell; the optical fibre clamping opening piece issuspended and clamped at a corresponding opening of the integrated shell; and the optical fibre guide and optical cable clamping piece is in pressure connection with the integrated shell.

Owner:ZHONGTIAN BROADBAND TECH +1

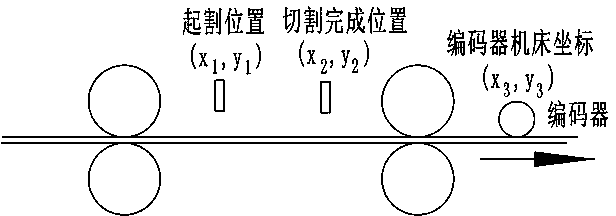

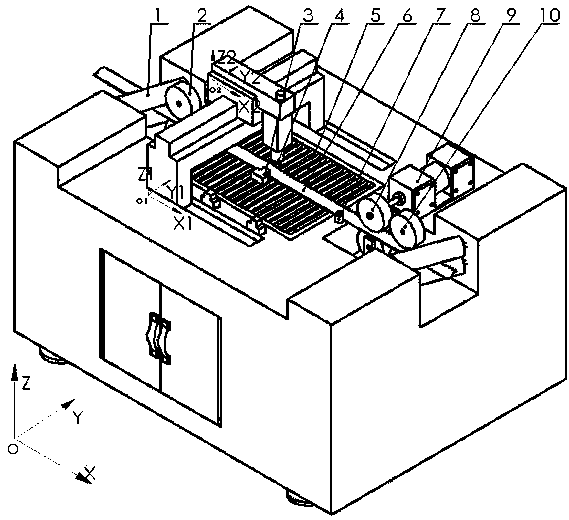

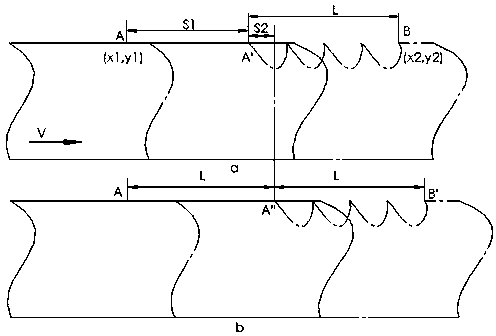

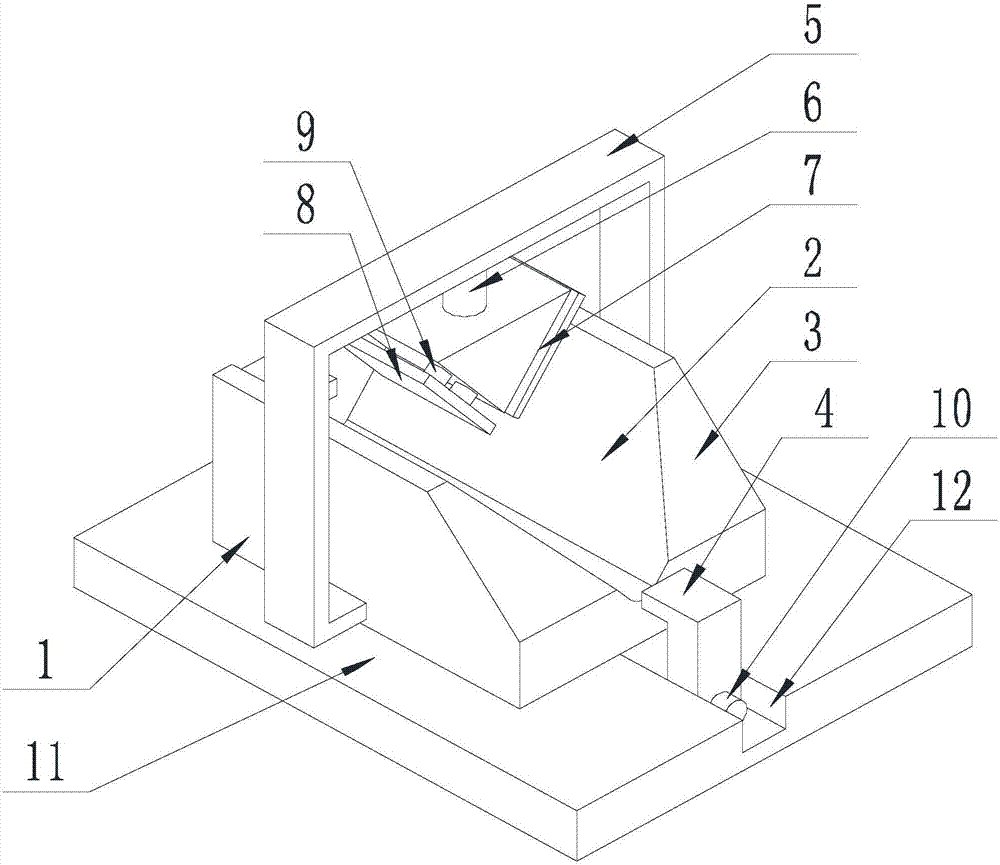

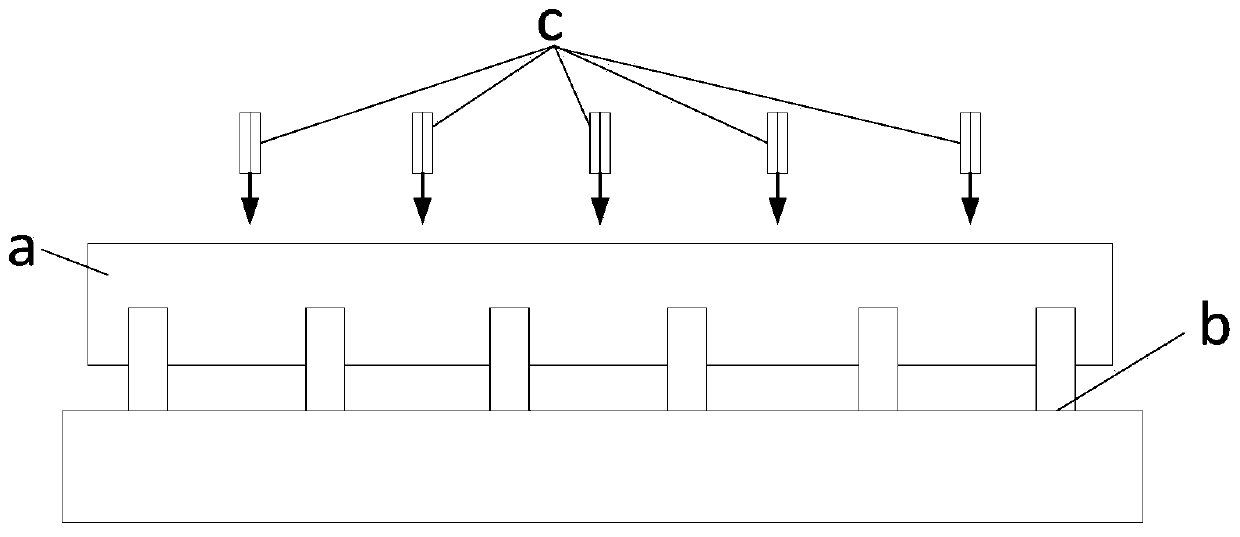

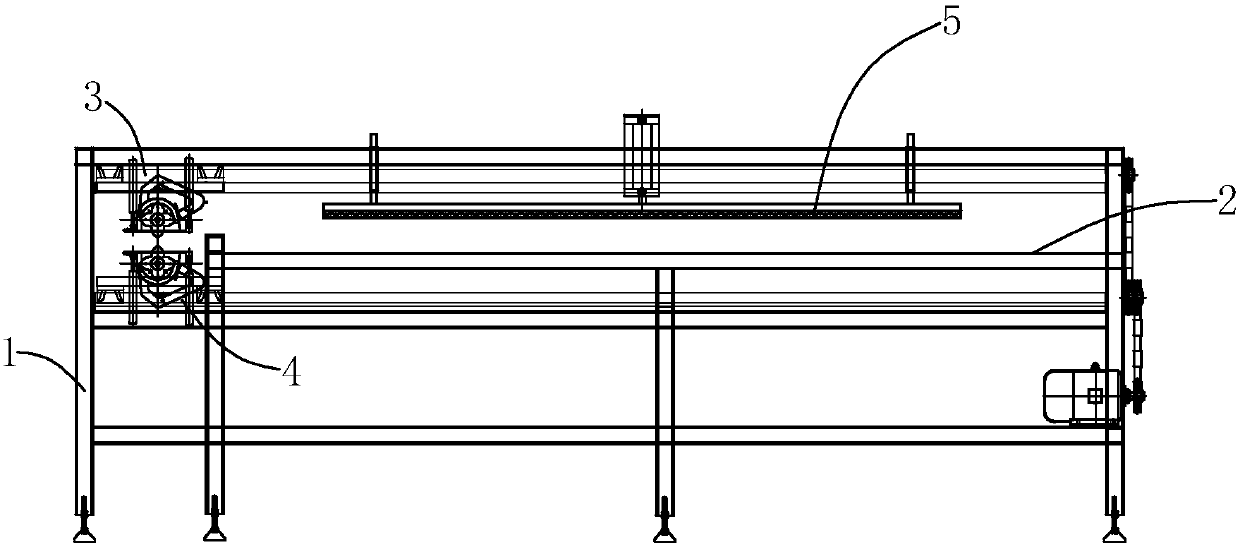

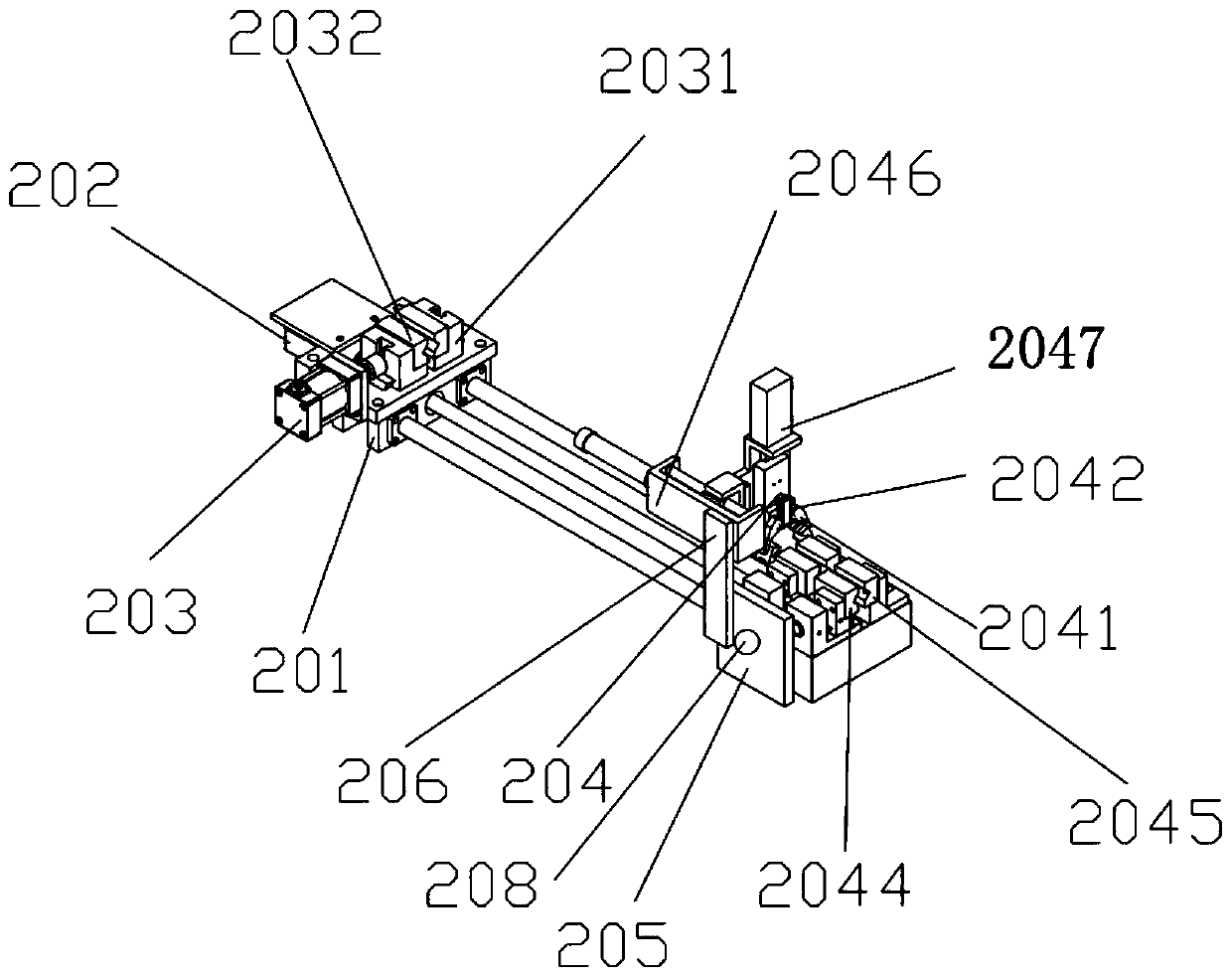

Laser continuous cutting device used for cutting saw belt and cutting method

ActiveCN104014938ANo thermal deformationNo damageWelding/soldering/cutting articlesMetal working apparatusMilling cutterLaser cutting

The invention discloses a laser continuous cutting device used for cutting a saw belt and a cutting method. The laser continuous cutting device aims to solve the problems that continuous cutting and forming of sawteeth can not be achieved, tool auxiliary time accounts for a high percentage, and cutting efficiency is low in the prior art. The laser continuous cutting device comprises a base which is sequentially provided with a driving friction roller used for regulating feeding speed of the saw belt, a pressing wheel set used for pressing the saw belt, a work platform and a driving wheel set driven by a driving device; a laser head which is arranged on a Z shaft for cutting the saw belt is arranged above the work platform; the work platform is provided with a feeler block and a transverse locating mechanism used for locating the saw belt; during cutting work, the speed of a sliding platform X1 is the same as the feeding speed of the saw belt. The laser cutting sawtooth continuous forming technique does not need a milling cutter, and the sawteeth in any two-dimensional shapes can be correspondingly manufactured very rapidly.

Owner:湖南泰嘉智能科技有限公司

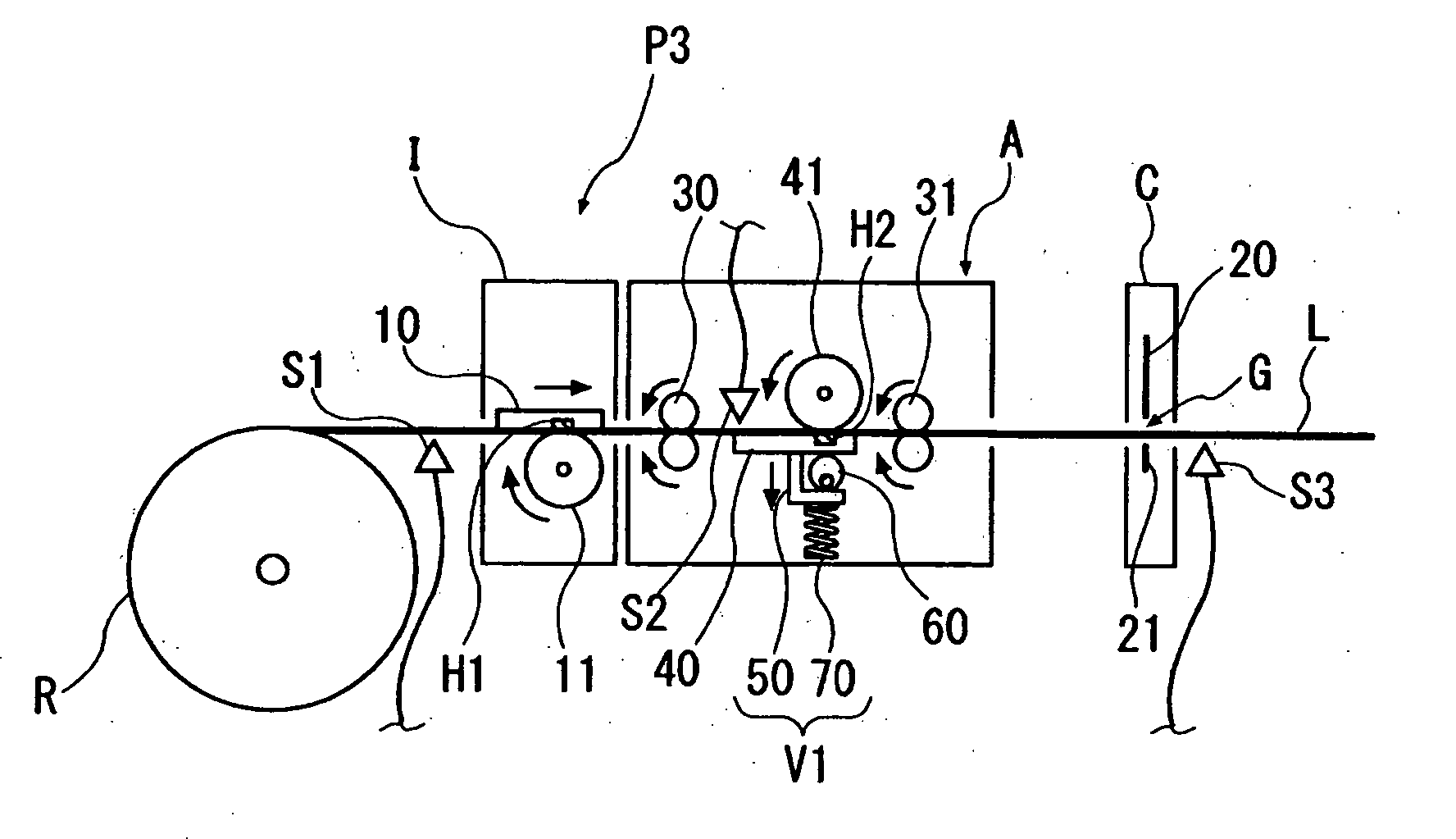

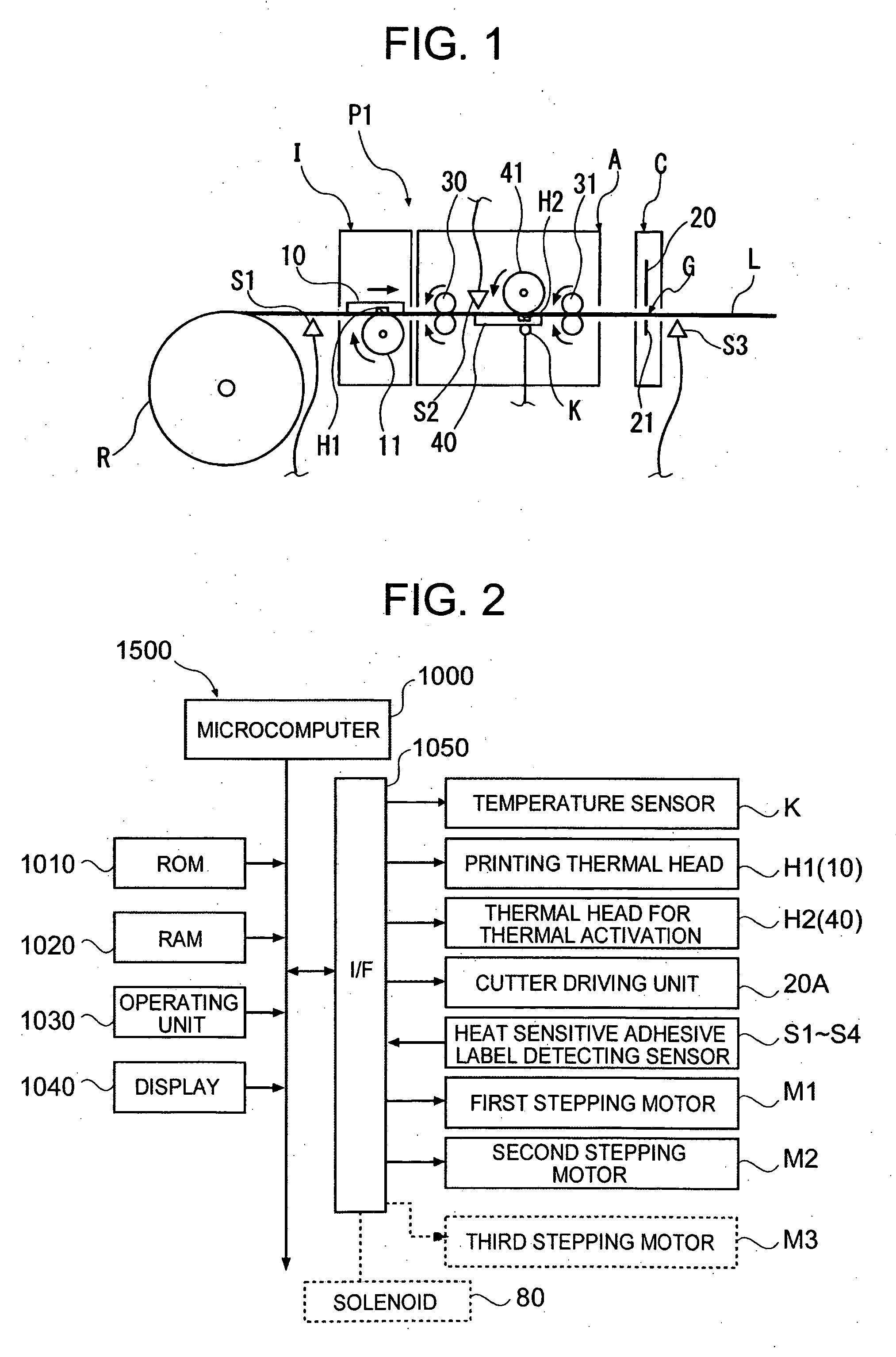

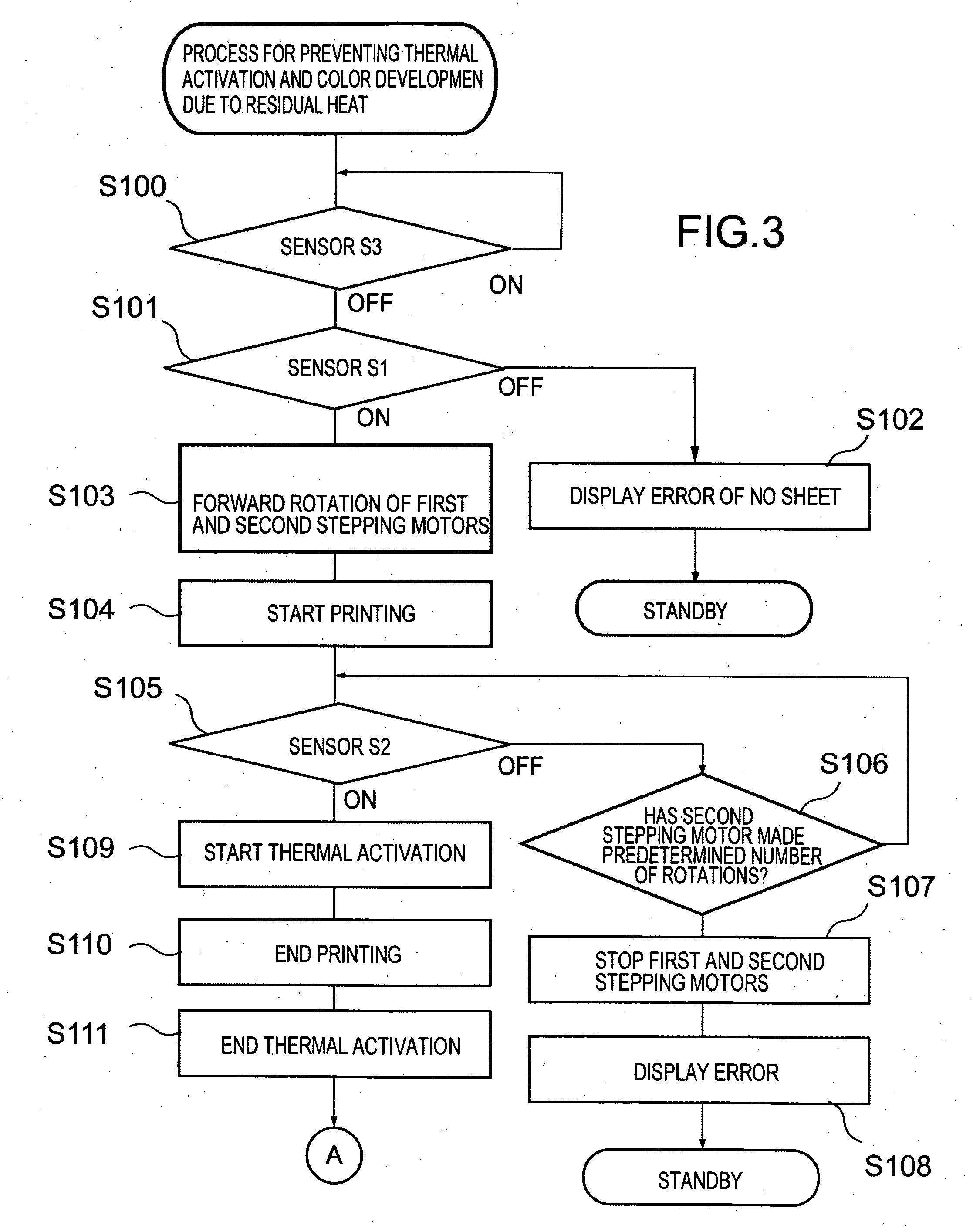

Printer apparatus

InactiveUS20060083570A1Reliably avoidedAvoid performanceRecording apparatusPrinting mechanismsLeading edgeAdhesive

Provided is a printer apparatus, including: a thermal print head that performs printing by contacting a heat-sensitive color-developing layer of a heat-sensitive adhesive sheet that includes a printable surface made from the heat-sensitive color-developing layer on one surface of a sheet-like base material, and a heat-sensitive adhesive layer on another surface of the sheet-like base material; a thermal-activation thermal head that activates the heat-sensitive adhesive layer by heating; a cutter device that cuts the heat-sensitive adhesive sheet; a transporting unit that transports the heat-sensitive adhesive sheet; and a controlling unit that controls the thermal print head, the thermal-activation thermal head, and the cutter device. The controlling unit controls the transporting unit to transport the heat-sensitive adhesive sheet so as to pass through the thermal print head, the thermal head used for activation, and the cutter device, in order; and to transport a leading edge of a remainder portion of the heat-sensitive adhesive sheet, after the cutter device cuts the heat-sensitive adhesive sheet, to return to a printing position of the thermal print head or to a heating position of the thermal-activation thermal head.

Owner:SEIKO INSTR INC

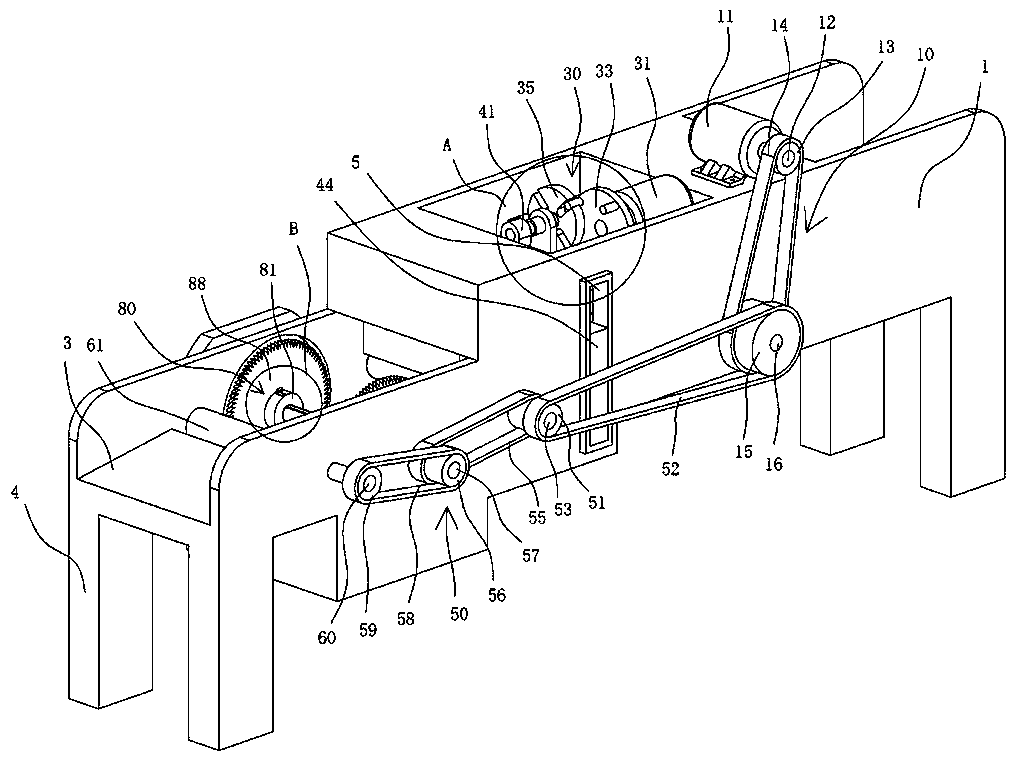

Board edge cutting device with automatic alignment function

ActiveCN110788934AReduce labor intensityEliminate manual alignment stepsFeeding devicesCircular sawsMechanical engineeringWood plank

The invention discloses a board edge cutting device with an automatic alignment function. The board edge cutting device with the automatic alignment function comprises a device body. A feed inlet is formed in one end of the device body, and a discharge outlet is formed in the other end of the device body. The board edge cutting device with the automatic alignment function is characterized in thata first transport mechanism is arranged at one end of the device body, a power mechanism used for providing intermittent rotational force is arranged at one end of the device body, a stop mechanism which can rise and fall is arranged at one end of the power mechanism and is located on one side of the first transport mechanism, a second transport mechanism is arranged at one end of the first transport mechanism, a stabilizing mechanism used for preventing board from jumping is arranged on one side of the second transport mechanism, a plurality of movable edge cutting mechanisms are arranged inthe middle of the second transport mechanism, and a pressing mechanism used for board alignment is arranged on the other side of the first transport mechanism. The board edge cutting device has the beneficial effects automatic alignment and fixation of to-be-cut boards can be achieved, the working efficiency is effectively improved, and the labor intensity of users is relieved.

Owner:江西奥瑞森新材料科技有限公司

Tape System with a Longitudinal Filament For Slitting Film

ActiveUS20150367524A1Improve adhesionTrend downDecorative surface effectsAdhesive articlesEngineeringMechanical engineering

A vehicle is wrapped by an adhesive film which is then slit by applying first tape to the vehicle having a longitudinally extending filament carried by the tape at a position spaced from the side edges. A second tape is applied over the film at the first tape body so as to bridge to each side of the filament and pulling the filament so as to tear through the film and the first ad second tapes body with the second tape applying a force to the film acting to reduce tendency of the film to pull away from the object during the cutting by the filament as the filament is pulled.

Owner:3M INNOVATIVE PROPERTIES CO

Cutting system and cutting method

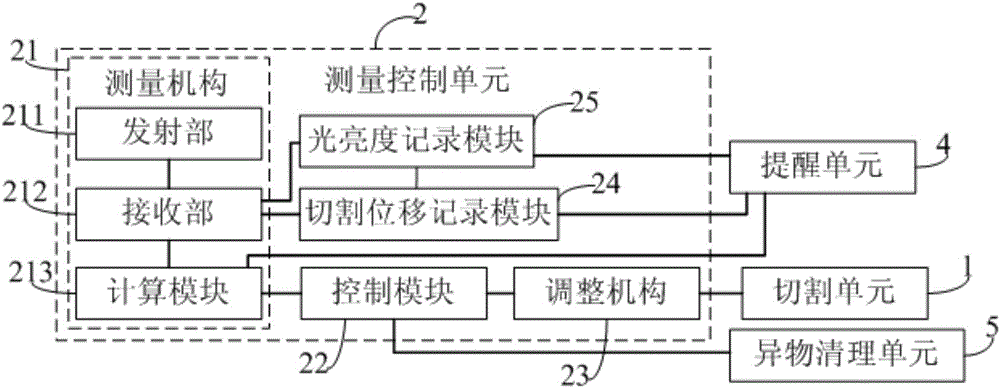

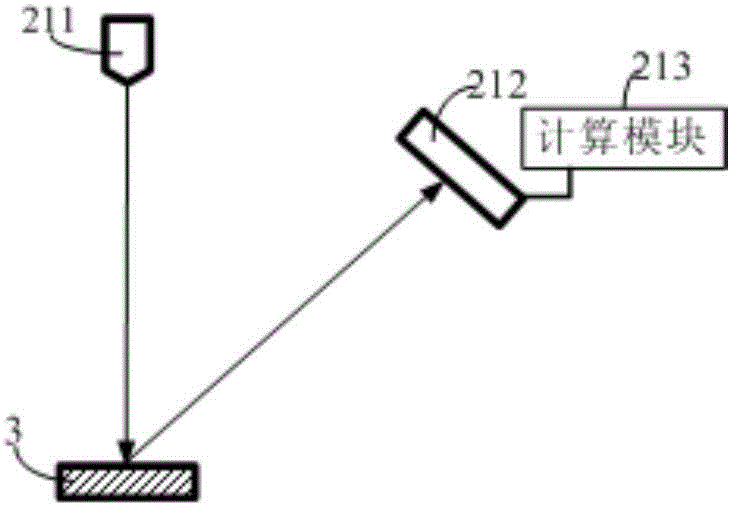

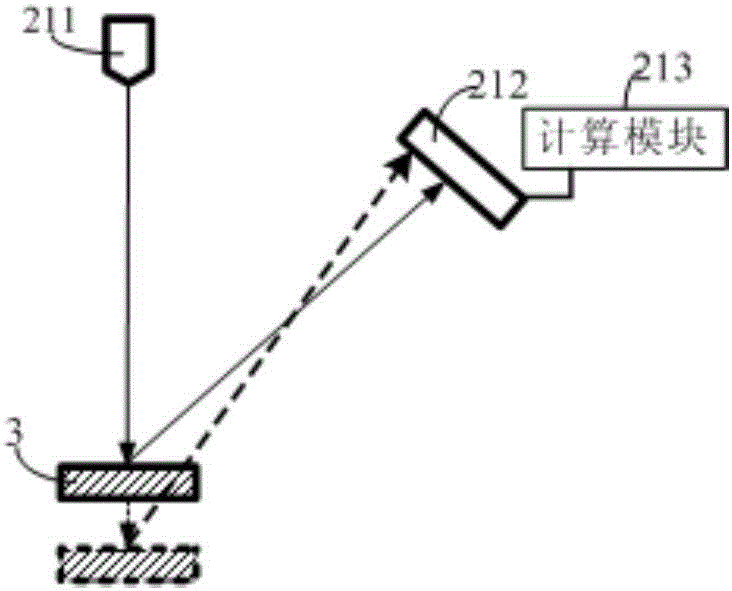

ActiveCN106746557ALow costImprove cutting accuracyGlass severing apparatusGlass productionAbutmentBiomedical engineering

The invention provides a cutting system and a cutting method. The cutting system comprises a cutting unit and a measurement control unit, wherein the cutting unit is used for cutting a display substrate with laser; and the measurement control unit is used for measuring the distance between a laser focus of the cutting unit and the surface of the display substrate in real time, and when the measurement result is not zero, adjusting the distance between the laser focus and the surface of the display substrate to zero in real time. The cutting system not only avoids the influence of flatness of an abutment for supporting the display substrate on cutting precision and cutting quality, but also avoids the influence of flatness of the display substrate on cutting precision and cutting quality, particularly avoids the influence of warpage difference caused by thickness difference of different positions of the display substrate along a cutting line on cutting precision and cutting quality, effectively improves the cutting compatibility on various display substrates having different sizes and thicknesses, reduces the cost, and simultaneously improves the cutting precision and the cutting yield.

Owner:BOE TECH GRP CO LTD +1

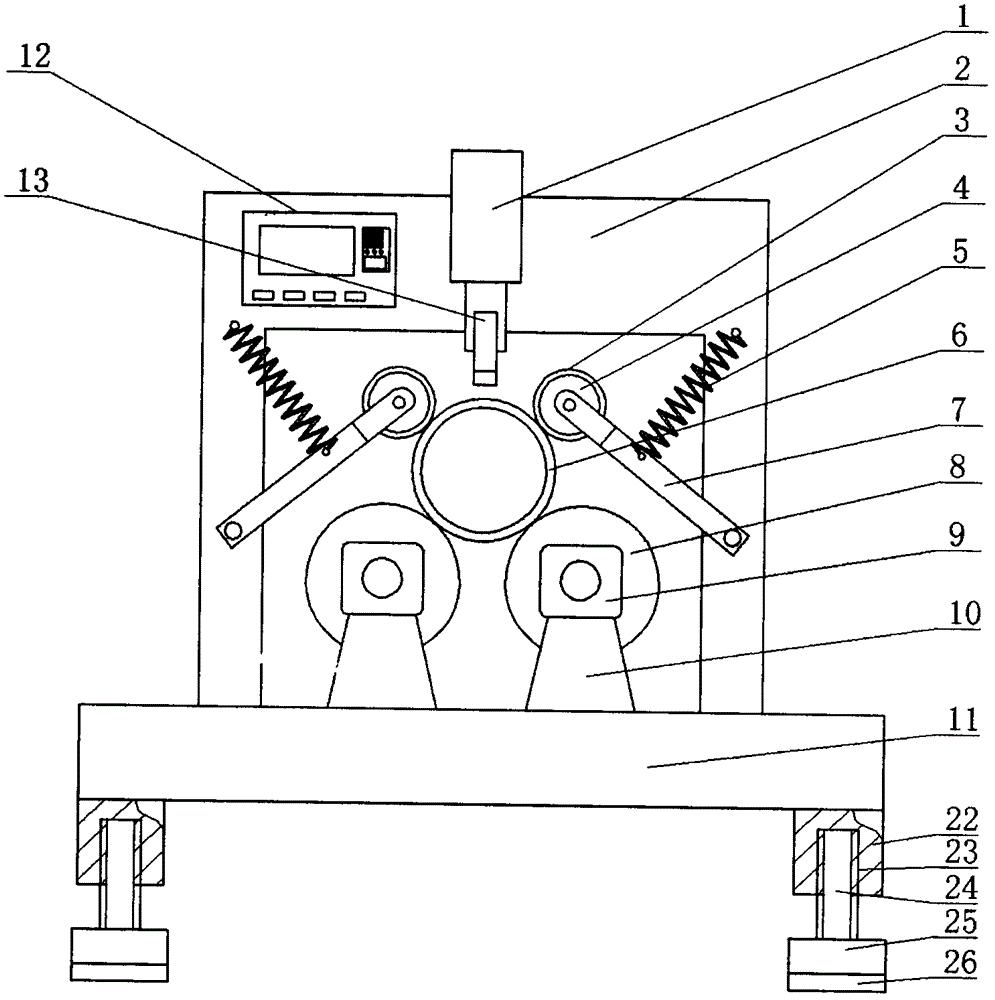

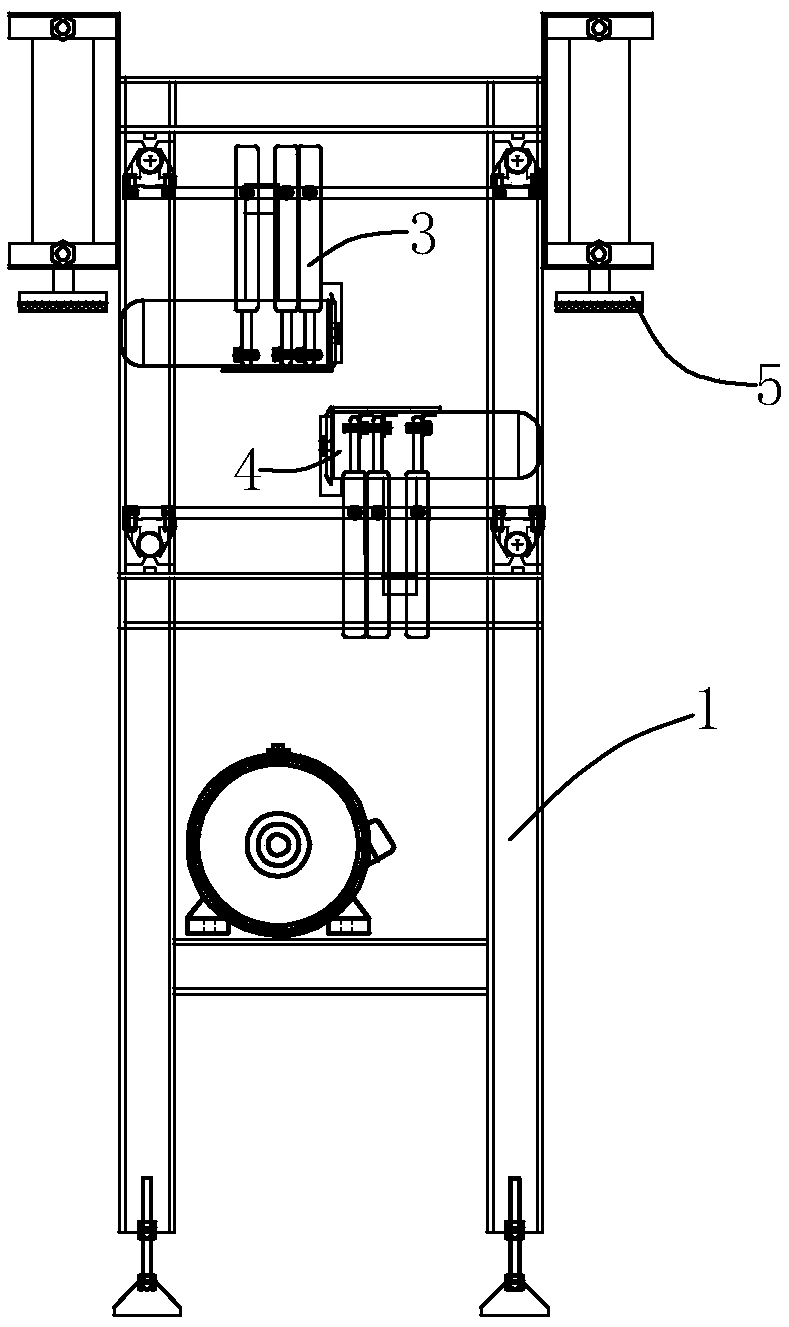

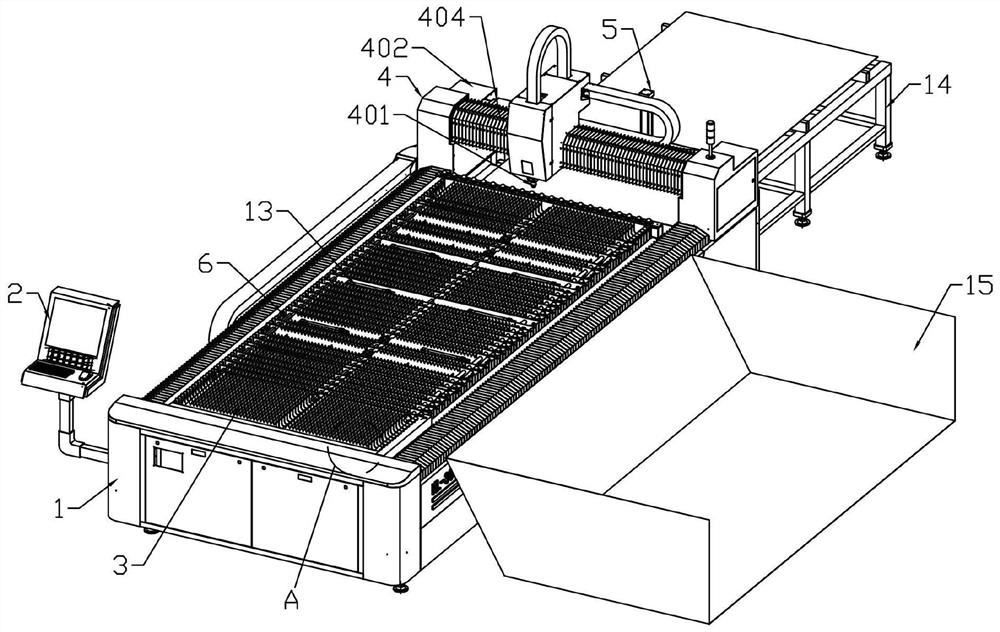

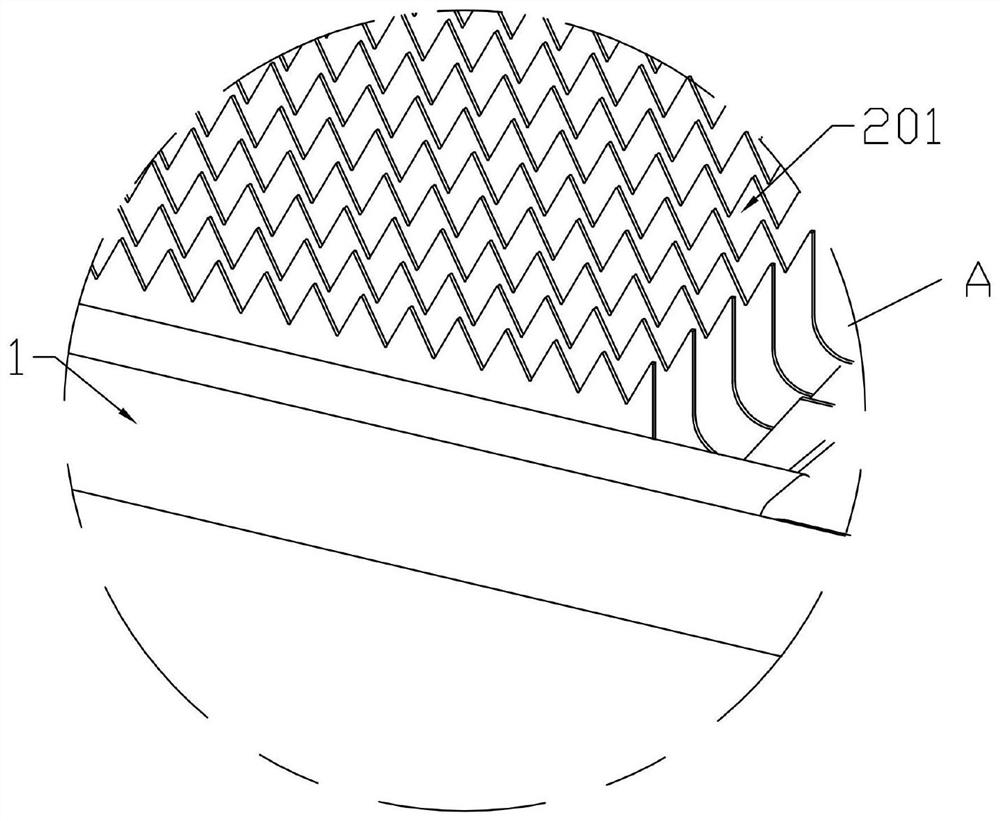

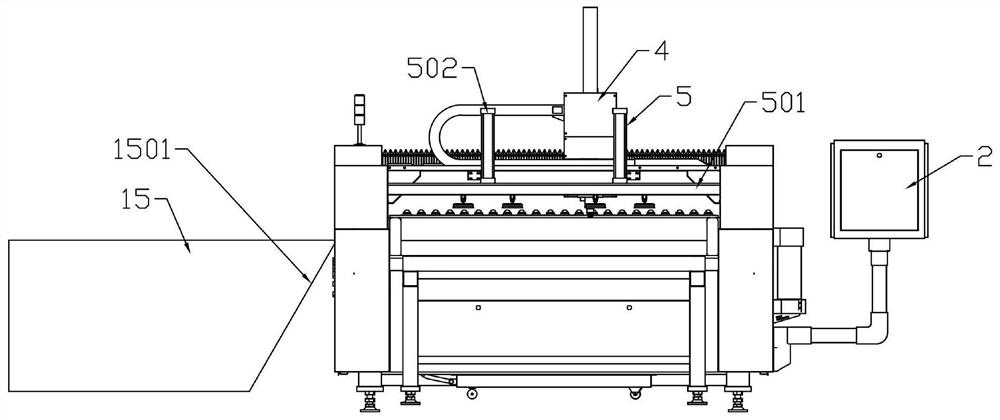

Laser cutting machine for single-wall corrugated pipe

InactiveCN105880840AEasy to cutAvoid cut qualityLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a single-wall bellows laser cutting machine, which comprises a base, a fixing frame is installed on one side of the upper part of the base, an industrial control instrument is installed on one side of the upper part of the fixing frame, a push rod motor is installed in the upper middle part of the fixing frame, and a push rod motor is installed on the upper side of the fixing frame. The push rod is vertically downward, the end of the push rod motor is installed with a laser module, the upper middle of the base is installed with two roller frames, and the roller and stepper motor are installed on the roller frame, and the output shaft of the stepper motor is connected Wheel shaft connection. The invention provides a cutting machine for cutting a single-wall corrugated pipe by using a laser. The invention cuts the single-wall corrugated pipe with the laser emitted by the laser mode, and the single-wall corrugated pipe does not need to be in contact with the cutting parts, thus avoiding the vibration during mechanical cutting and greatly reducing the cutting quality of the single-wall corrugated pipe. The cutting surface of the single-wall corrugated pipe after die cutting is smooth and smooth without burrs.

Owner:WUXI LONGSHUN IND

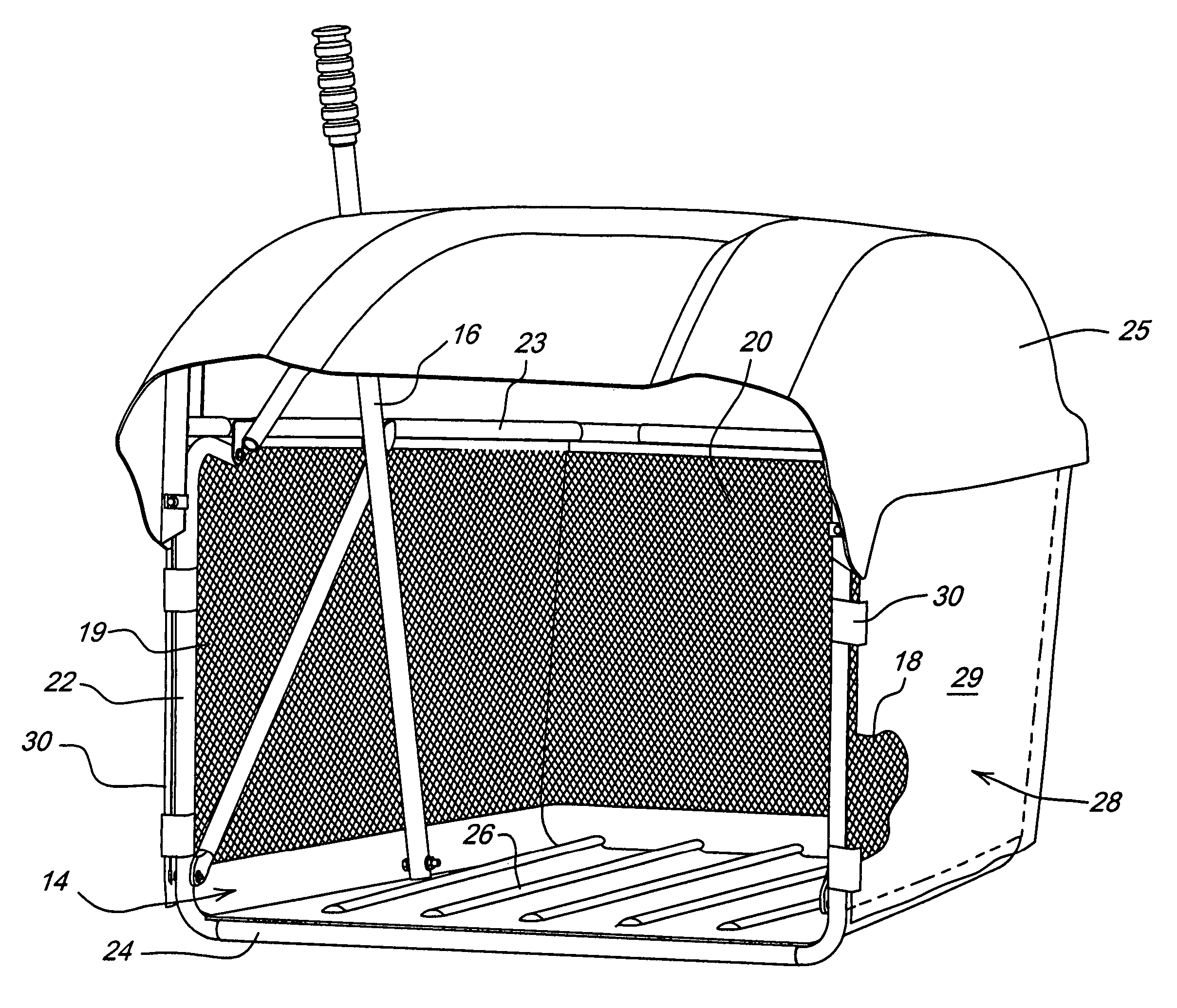

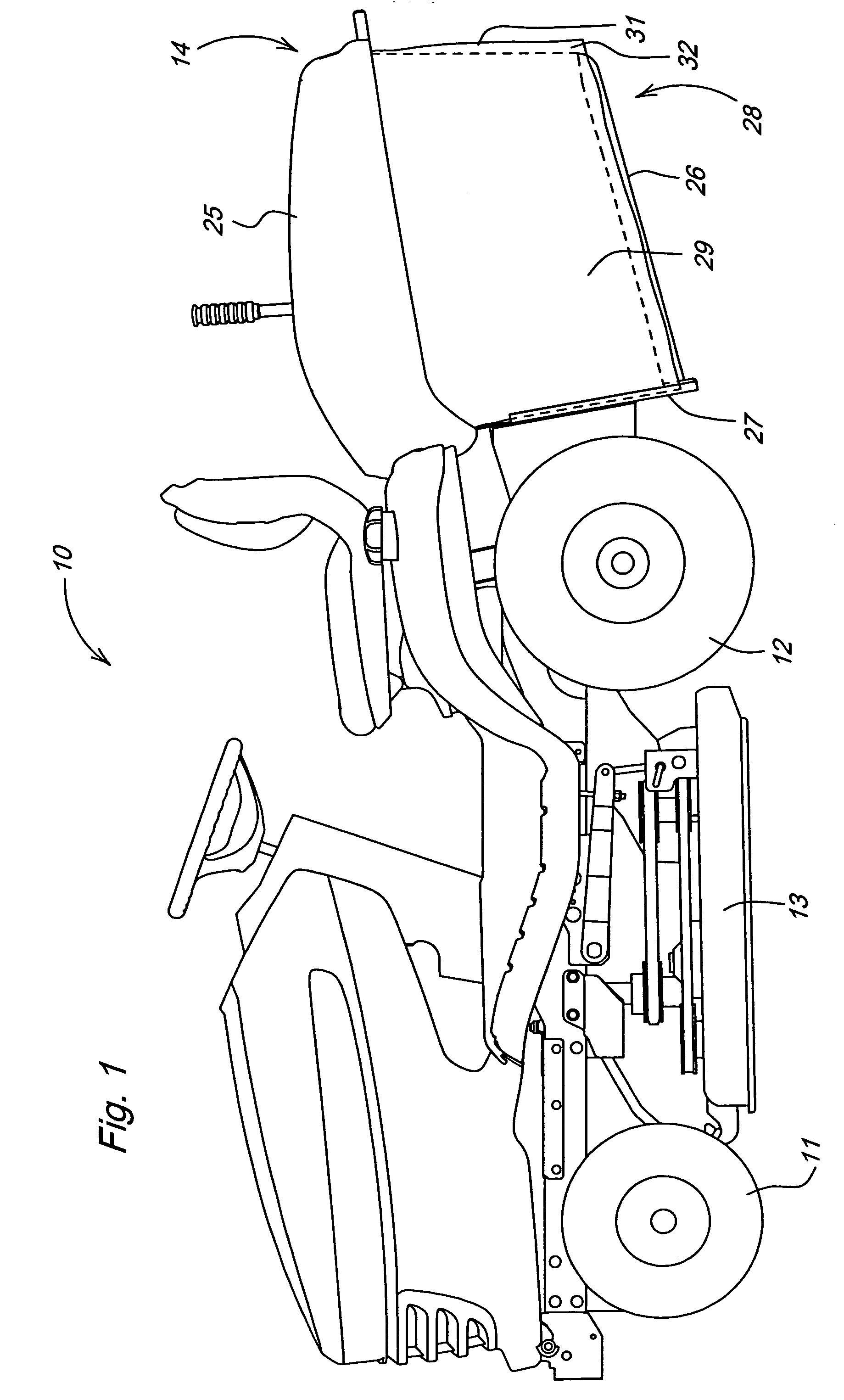

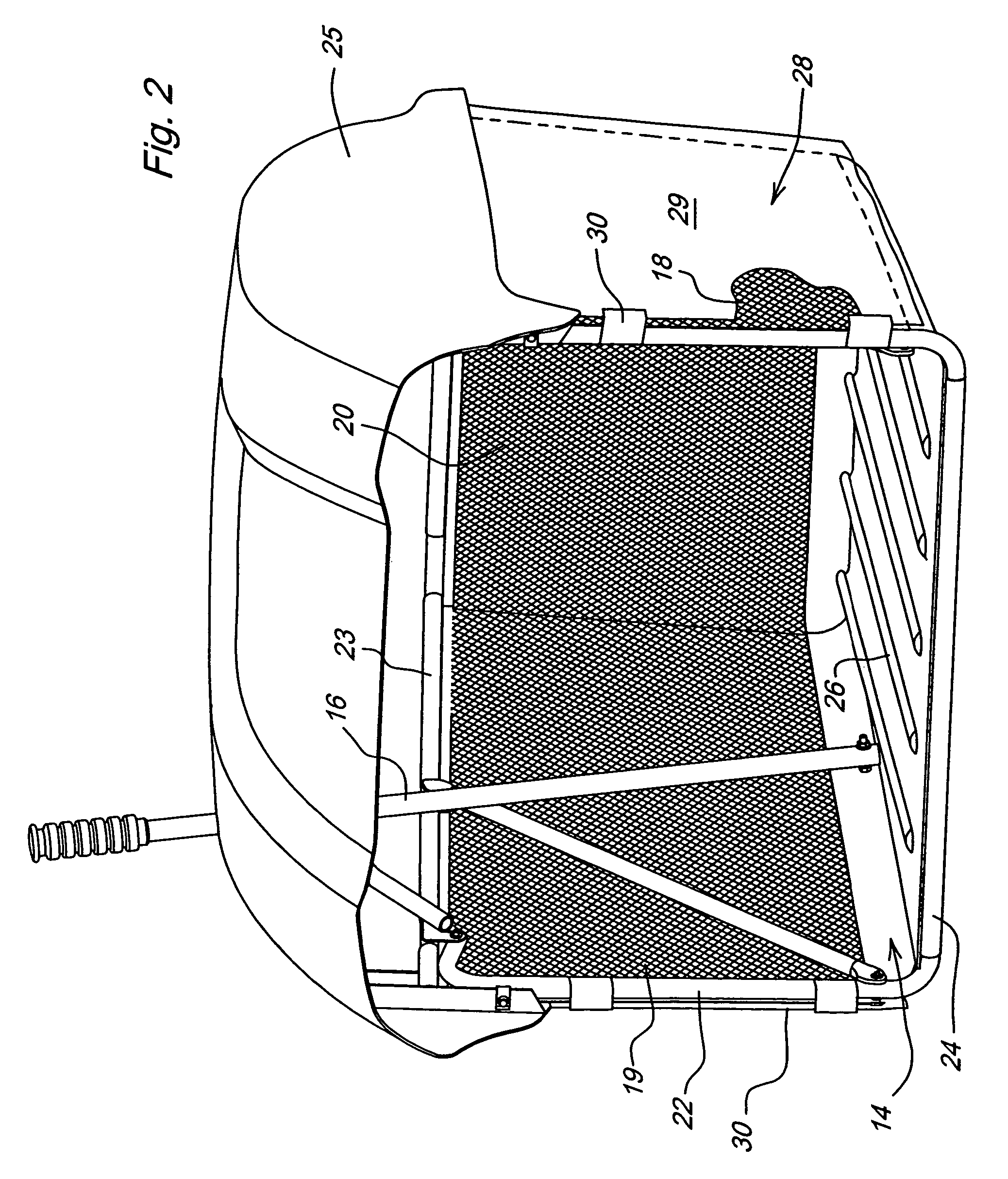

Flexible sound barrier curtain for grass collection container

ActiveUS7322176B2Reduces and limits noiseAvoid cut qualityMowersAgricultural undercarriagesSound barrierBraced frame

A grass collection container for a grass mowing machine includes a bag or hopper attached to a support frame under the plastic top cover with air permeable panels, and a flexible sound barrier curtain attached to the support frame over the air permeable panels. The flexible sound barrier curtain has a thickness of between about 1 mm and about 5 mm. An air passage is provided between the bag or hopper and the flexible sound barrier curtain.

Owner:DEERE & CO

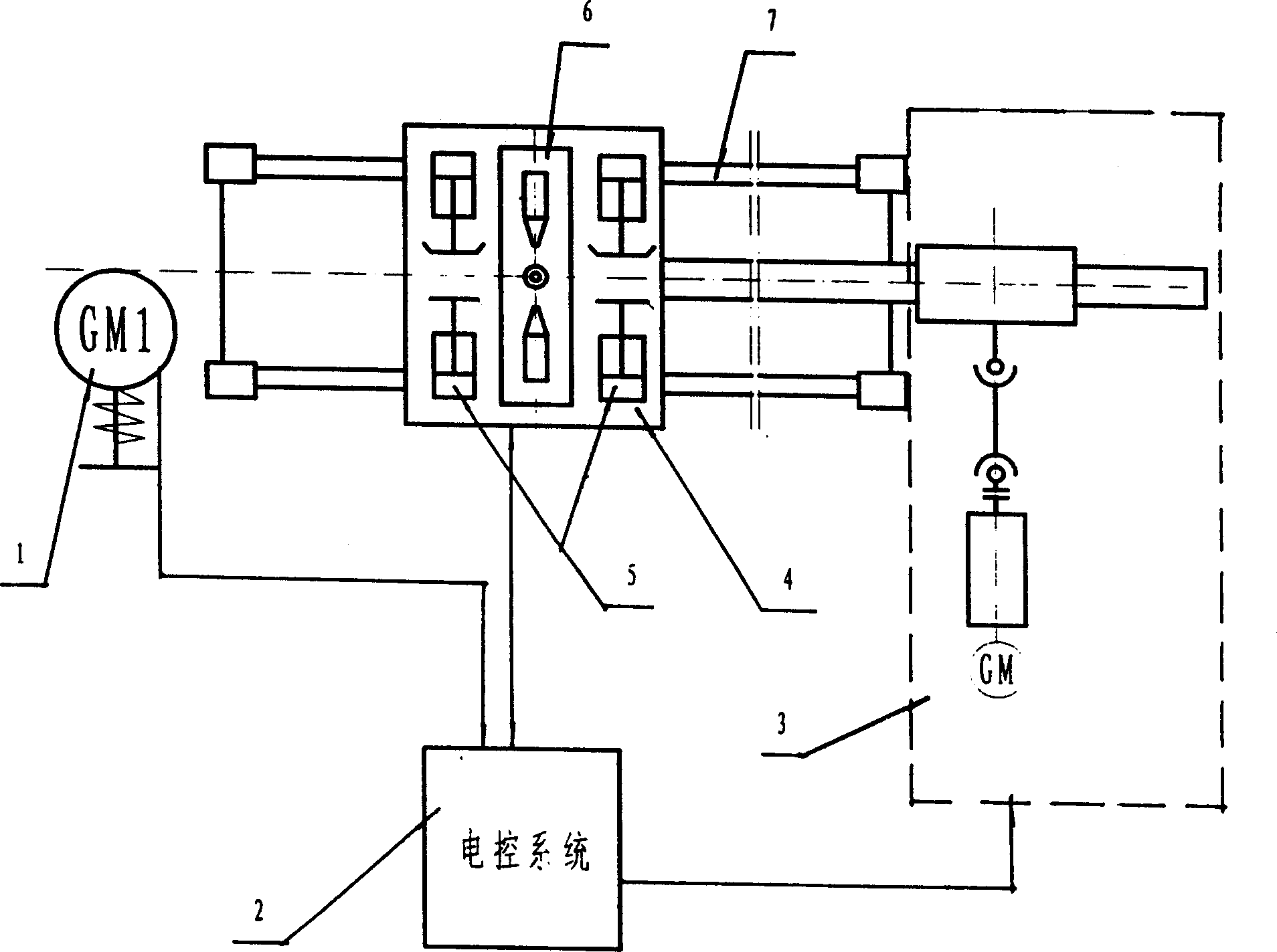

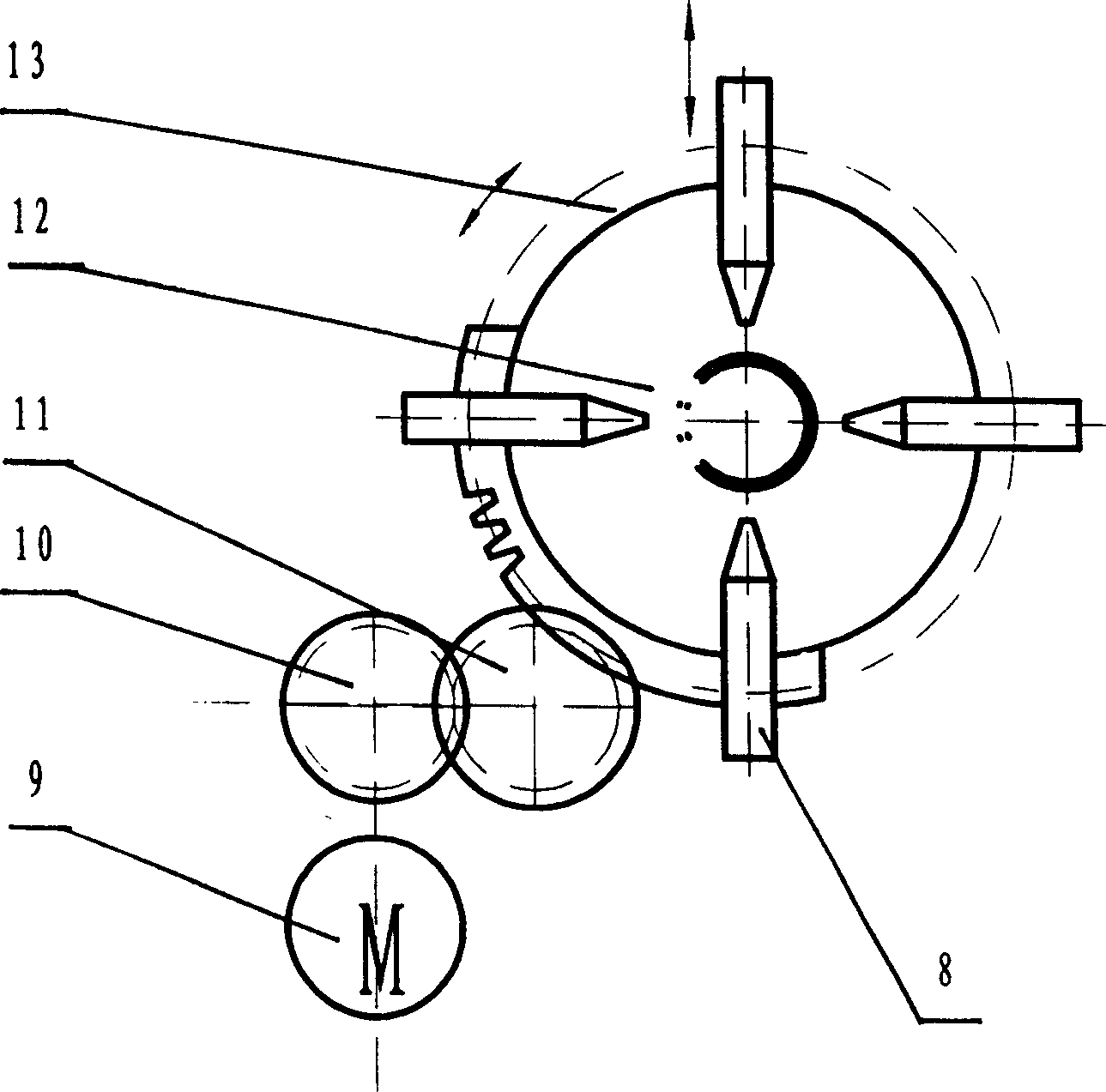

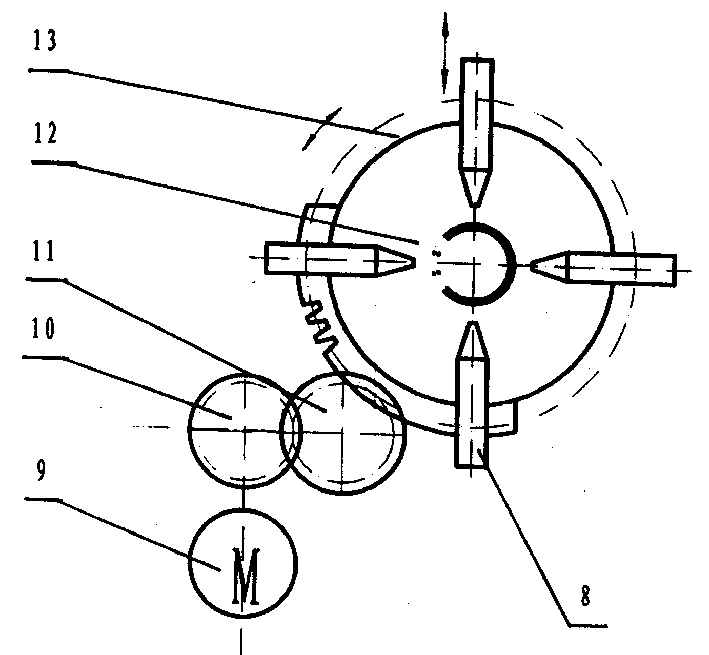

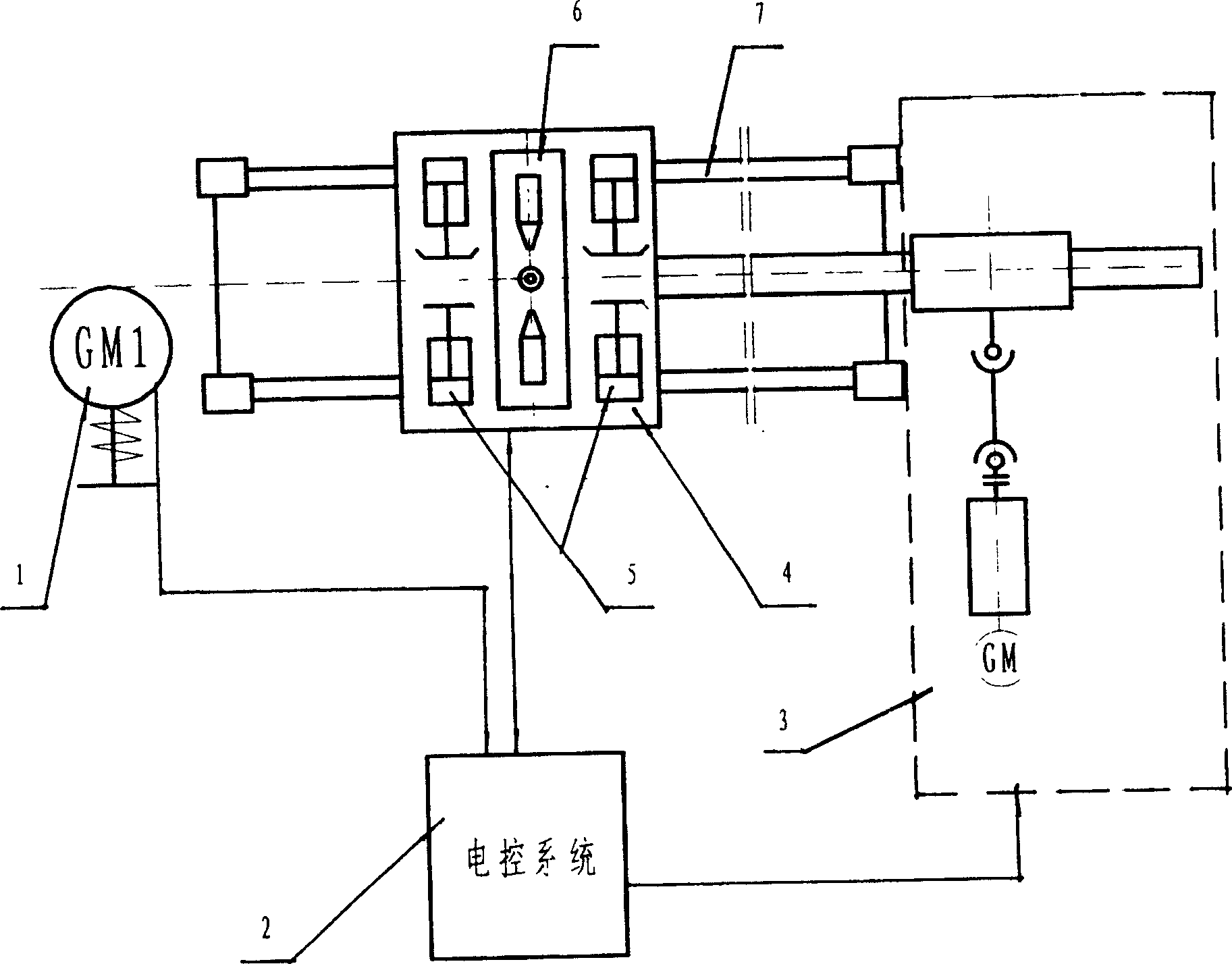

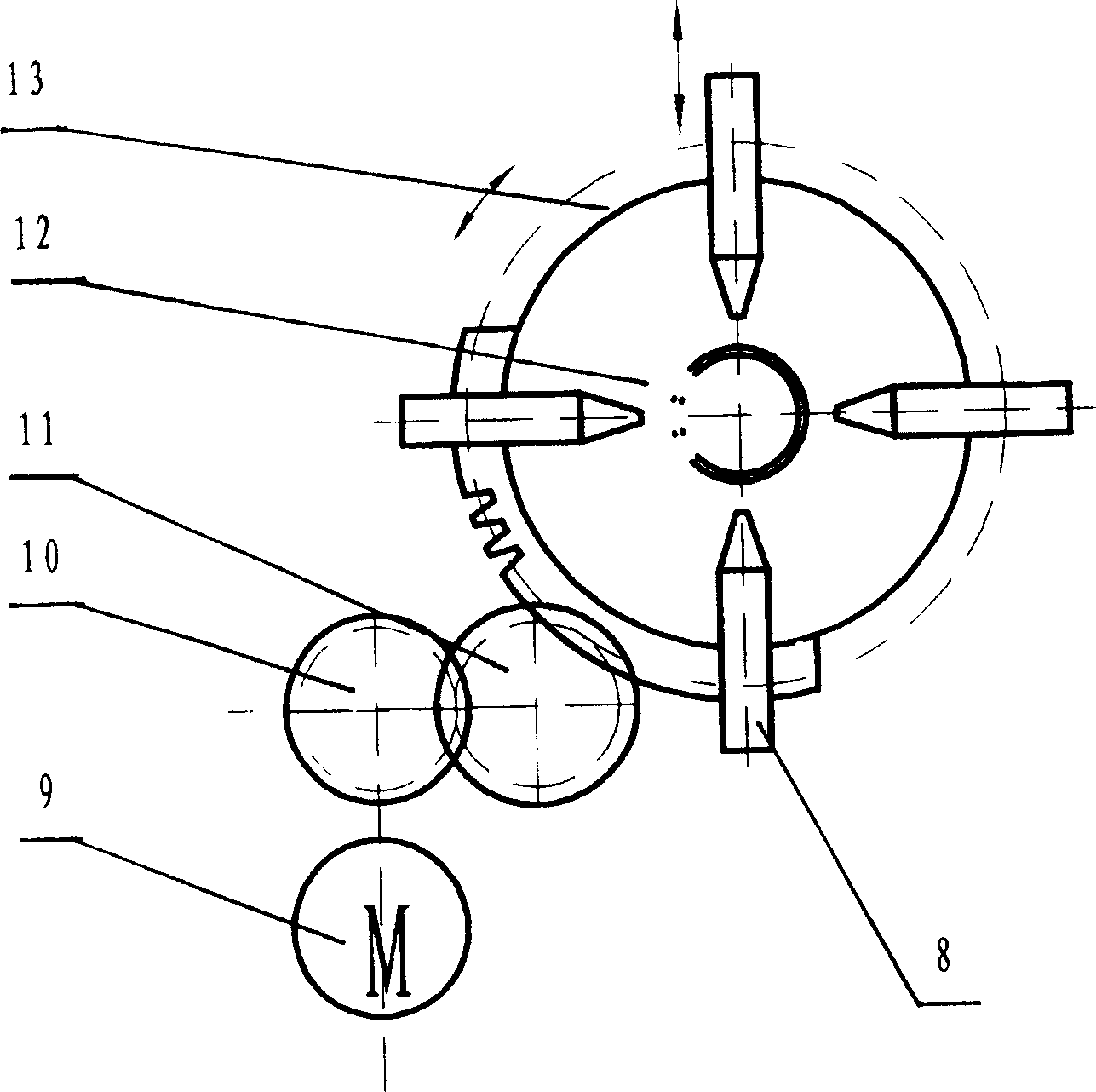

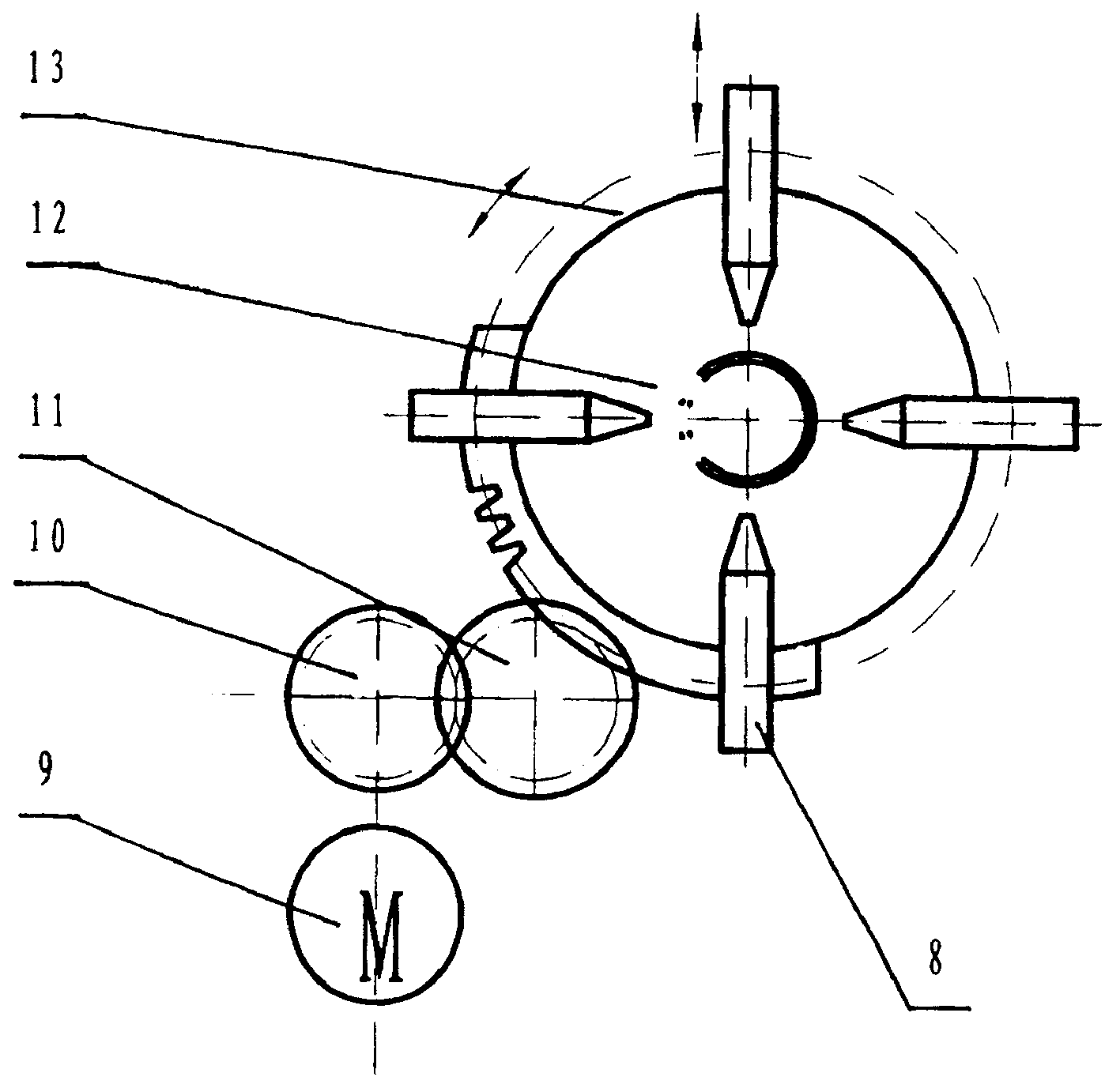

Plusma tracking ruled fly-saw

InactiveCN1465464AAvoiding Vulnerable HazardsFast cutting speedWelding/cutting auxillary devicesAuxillary welding devicesControl systemElectrical control

The present invention relates to a plasma tracking ruled fly-saw, including fly-saw car, speed-measuring device, electric control system, driving system, holding device and guideway base, in which the driving system is connected with fly-saw car positioned on the guideway base, the speed-measuring device is connected with electric control system, on the fly-saw car a plasma cutting device is mounted, and the described plasma cutting device is formed from plasma gun mounted on the contouring frame, and the external edge of the contouring frame is connected with rotating motor by means of driving device.

Owner:天津市东恒自动化工程有限公司

Tape system with a longitudinal filament for slitting film

ActiveUS9751232B2Trend downEasy loadingProtective equipmentFilm/foil adhesivesEngineeringMechanical engineering

A vehicle is wrapped by an adhesive film which is then slit by applying first tape to the vehicle having a longitudinally extending filament carried by the tape at a position spaced from the side edges. A second tape is applied over the film at the first tape body so as to bridge to each side of the filament and pulling the filament so as to tear through the film and the first ad second tapes body with the second tape applying a force to the film acting to reduce tendency of the film to pull away from the object during the cutting by the filament as the filament is pulled.

Owner:3M INNOVATIVE PROPERTIES CO

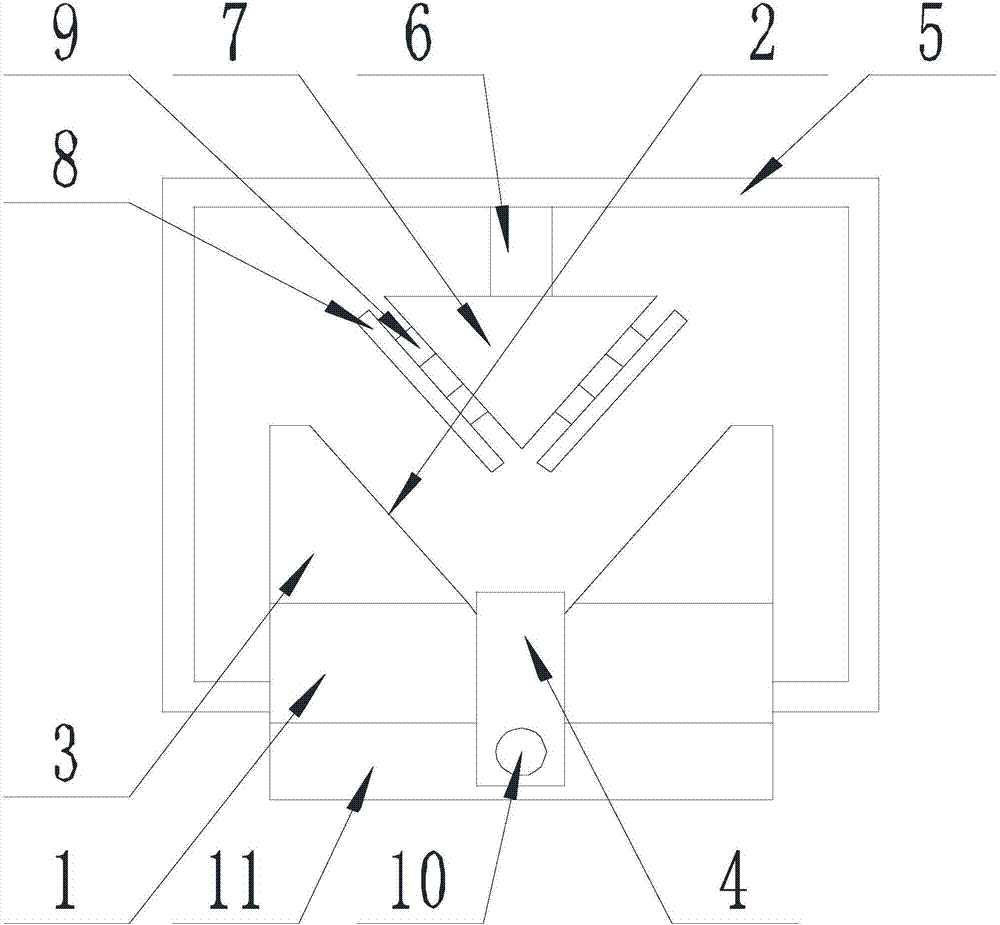

Technology method for improving angle cutting quality of equal angle steel

InactiveCN107234466AAvoid cut qualityIncrease the number of repairsWork clamping meansPositioning apparatusEngineeringRejection rate

The invention discloses a process method for improving the quality of corner cutting of equilateral angle steel, which comprises the following steps: step A: selecting a corner cutting machine; step B: fixing a fixed block on the workbench of the corner cutting machine; step C: drawing on the angle steel Upper chamfering line; step D: place the angle steel in the V-shaped through groove, and make the angle to be cut off on the angle steel be located at the place where the right angle is inverted on the through groove, and the chamfer line is located on the side where the right angle is away from the through groove; step E: Start the driving device, make the opposite sides of the limiting plates contact both ends of the angle steel, and fix the angle steel between the limiting plates; Step F: Start the angle cutting machine, and cut off the corners on the angle steel. In this way, through the above method, the angle steel for corner cutting can be fixed to prevent the side away from the cutting point from turning up when the angle steel is cutting the corner, which will reduce the quality of the angle steel incision, and even make the edge distance of the corner cutting not comply with the process regulations. Increase the repair times of angle steel and reduce the scrap rate of angle steel.

Owner:四川宇桥铁塔有限公司

Insert with replaceable cutting edge and corner milling cutter with replaceable cutting edge

ActiveUS7500810B2Easy to shapeImprove flatnessTransportation and packagingMilling cuttersMilling cutterEngineering

A replaceable-blade cutting insert for corner milling cutters has a first and second surface; a third and fourth surface connected to a first side edge and a second side edge thereof respectively; and a fifth and sixth surface connected to a first edge and a second edge of the first surface and the second surface respectively. The first surface is used as rake face, the third surface is used as an outer perimeter flank face, and the fifth surface is used as a forward flank face. A twisted surface is disposed on a section of the third surface, forming a ridge line that acts as a main cutting edge intersecting with the first surface and interposed between the third and first surface. The first and second surface can be positioned with a height offset relative to each other so that at least one set of diagonal corners are projected.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Numerical control cutting method for preventing inner hole notch of thick plate part

PendingCN113172300AAvoid injuryReduce the workload of manual modificationGas flame welding apparatusNumerical controlThick plate

The invention provides a numerical control cutting method for preventing an inner hole notch of a thick plate part. Geometric figures of parts are modified in batches by means of programming in AutoCAD software; an arc blowout point, a kerf compensation and a cutting parameter during numerical control flame cutting are set reasonably, such that a crater in an inner hole cutting guidance position of the thick plate part is avoided, and a cutting notch is prevented from being generated at the inner hole cutting arc blowout point to hurt the part, and therefore, the technical problem that the crater occurs on a cut steel plate of a numerical control flame cutter is solved. The geometric figures of parts are modified in batches by means of programming, such that the workload of manual modification is reduced. The arc blowout point, the kerf compensation and the cutting parameter during numerical control flame cutting are set reasonably, such that the crater in an inner hole cutting guidance position of the thick plate part is avoided, and the cutting notch is prevented from being generated at the inner hole cutting arc blowout point to hurt the part, and thus, manpower and material resources consumed to polish and smoothen the edge of the inner hole manually after repair welding of the cutting notch are reduced. The method is suitable for serving as the cutting method for preventing the inner hole notch of the thick plate part.

Owner:中国船舶集团渤海造船有限公司

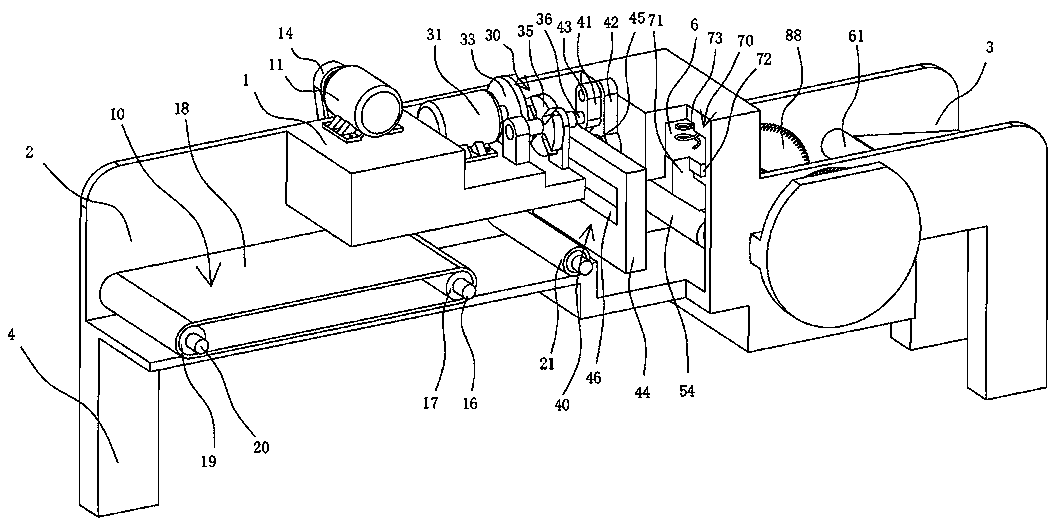

Efficient multi-cutter cutting machine for workpiece rotation

PendingCN111559023AReduce lossShort contact lengthWorking accessoriesFine working devicesIndustrial engineeringCutting tool

The invention discloses an efficient multi-cutter cutting machine for workpiece rotation. The efficient multi-cutter cutting machine comprises a base and a rack arranged above the base, wherein the base is provided with a crystal support assembly used for supporting workpieces; a cutting assembly used for cutting the workpieces is arranged above the rack and comprises cutting tool bits, a diamondwire drive mechanism and a walking drive assembly, wherein the cutting tool bits are used for achieving workpiece cutting through diamond wires, the diamond wire drive mechanism is used for driving the diamond wires in the cutting tool bits to move to achieve cutting action, and the walking drive assembly is used for moving the cutting tool bits; and a plurality of cutting tool bits are arranged and sequentially arranged in the length direction of the workpieces, and the distances between the cutting tool bits and the workpieces are different. According to the multi-cutter cutting machine produced through the scheme, the cutting process is smooth, the phenomena of edge breakage and the like are avoided, the whole operation process can be rapidly finished by one person, multi-person cooperative operation is not needed, the cut workpieces can be separated, the efficient multi-cutter cutting machine can be used for single-cutter cutting and can also achieve multi-cutter cutting, and applicability and expansibility are very high.

Owner:QINGDAO GAOCE TECH CO LTD

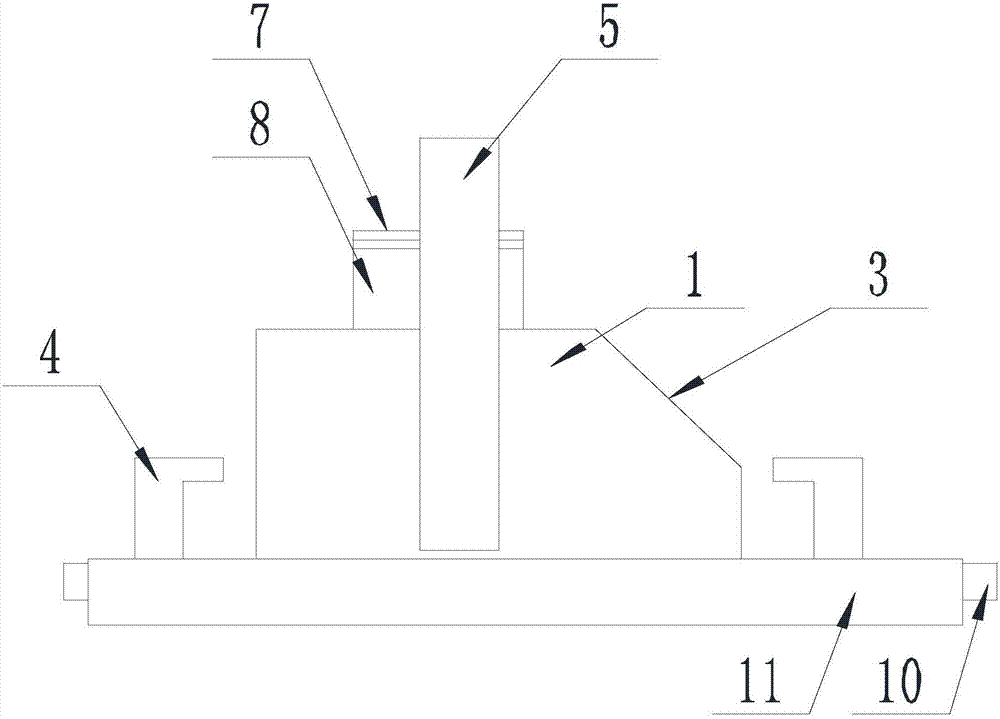

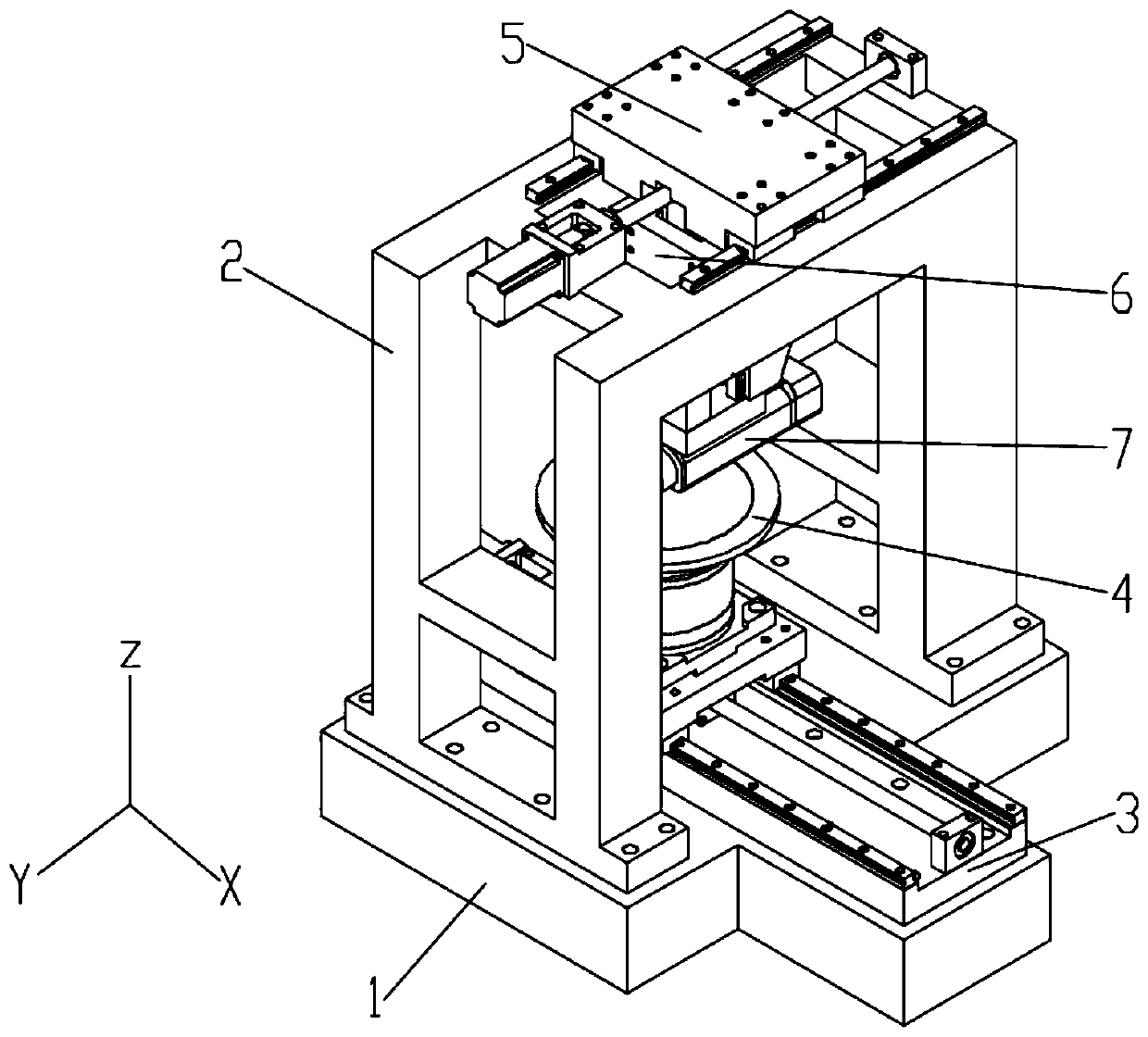

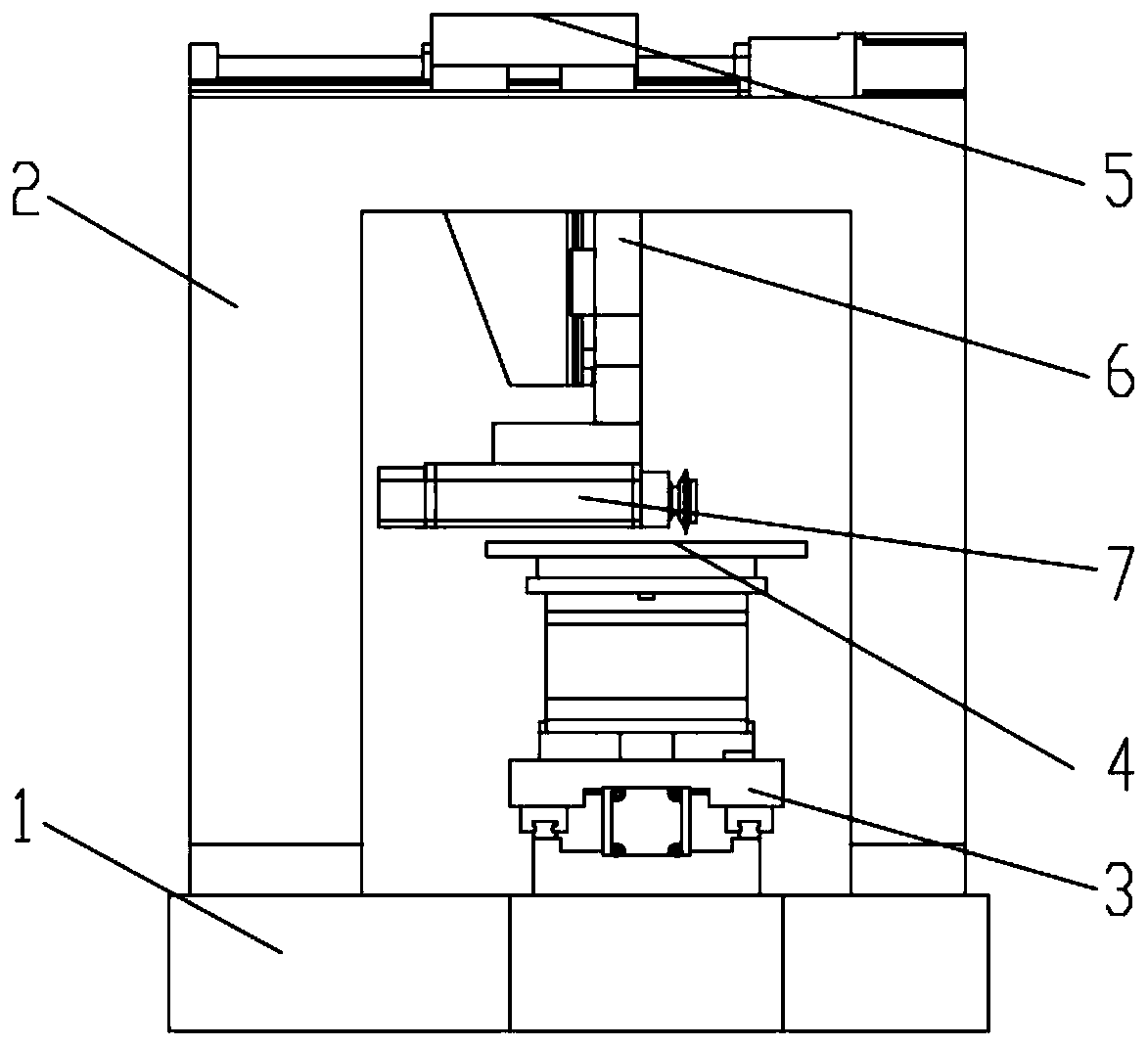

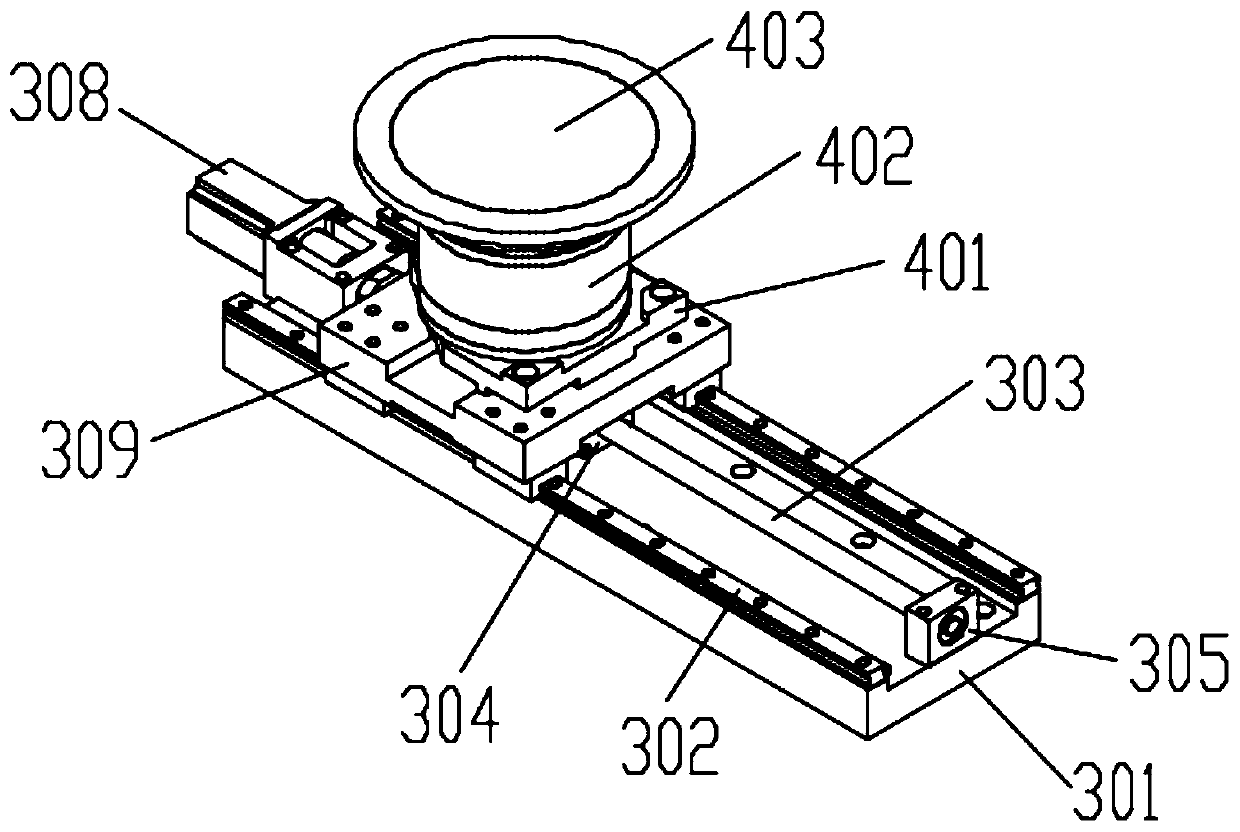

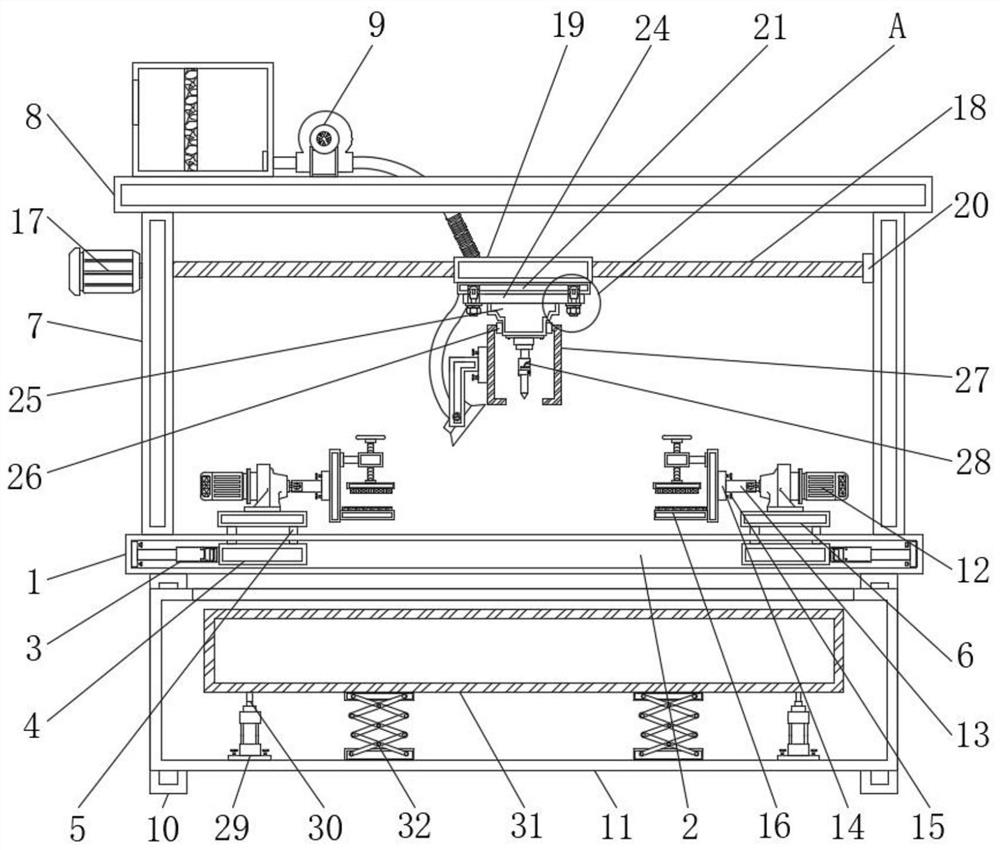

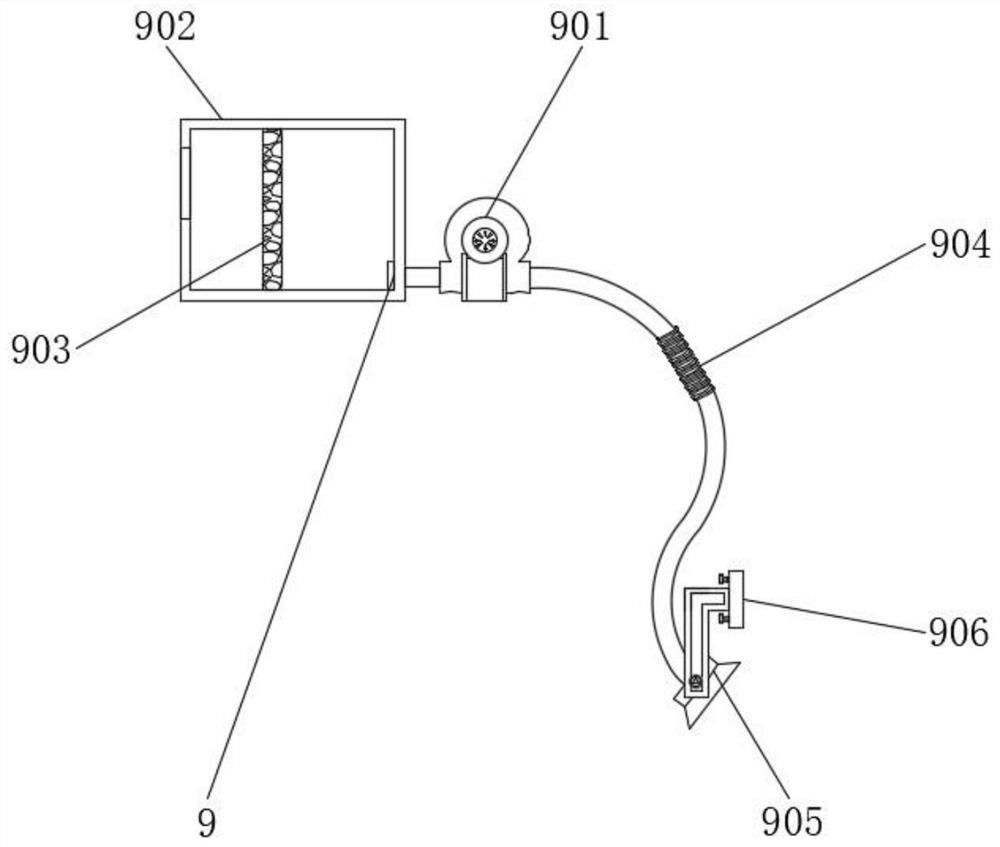

Double-gantry type structure slice cutting machine symmetrical about YZ plane

InactiveCN111230689ACompact structureImprove machining accuracyGrinding carriagesGrinding drivesPhysicsInertia force

The invention relates to a double-gantry type structure slice cutting machine symmetrical about a YZ plane. The double-gantry type structure slice cutting machine comprises a base, the base is provided with an X-axis linear motion module along the X axis, the X-axis linear motion module is provided with an Rz-axis rotation module, the part, on the two sides of the X-axis linear motion module, of the base is parallelly provided with two gantries at intervals in the X-axis direction, the top of the position between the two gantries is provided with a Y-axis linear motion module along the Y axis,the Y-axis linear motion module is provided with a Z-axis linear motion module along the Z axis, the bottom of the Z-axis linear motion module is provided with a main shaft module located above the Rz-axis rotation module, and the two gantries, the Y-axis linear motion module, the Z-axis linear motion module and the main shaft module are integrally symmetrical about the YZ plane. Compared with single-gantry structures in the prior art, by means of the double-gantry type structure slice cutting machine symmetrical about the YZ plane, influence of heat, self weight, motion inertia force, vibration and other factors can be reduced, and the machining precision of the slice cutting machine is improved.

Owner:无锡立朵科技有限公司

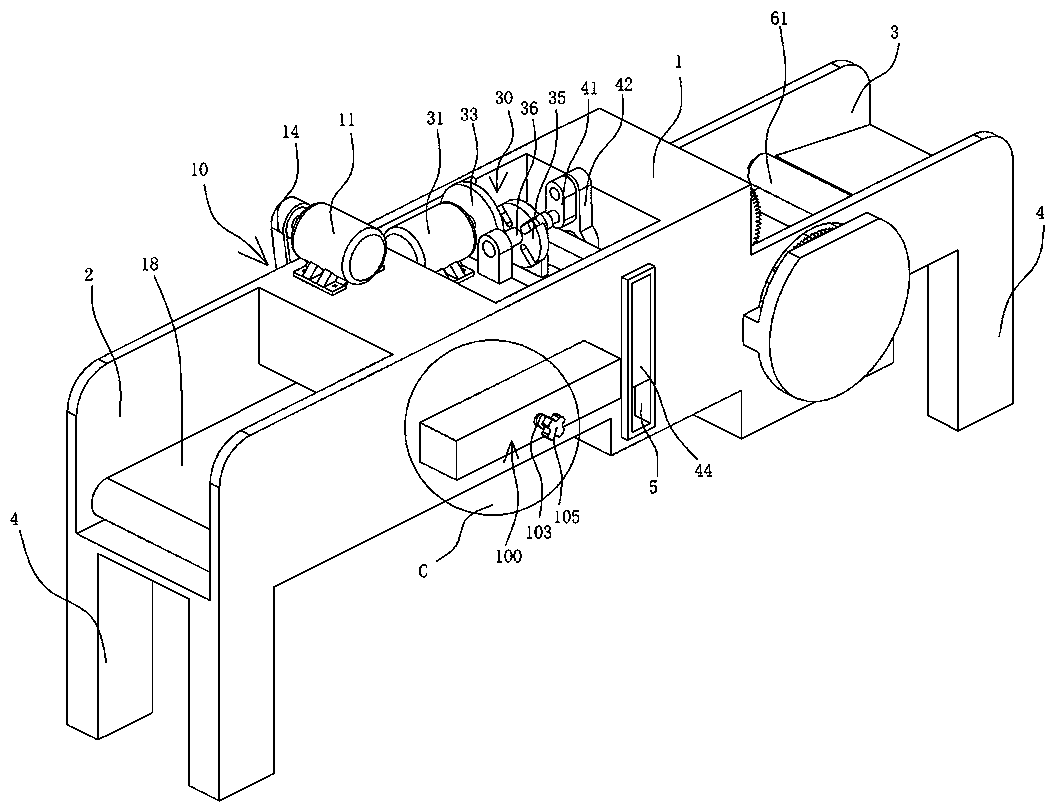

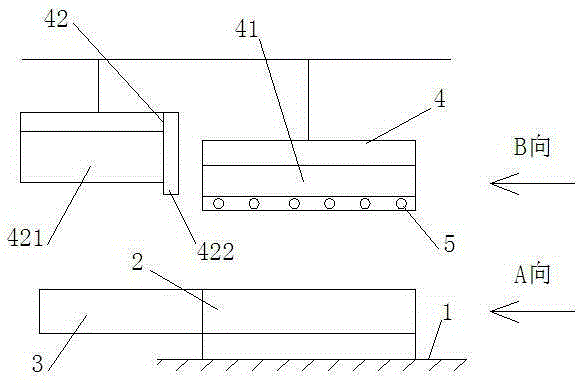

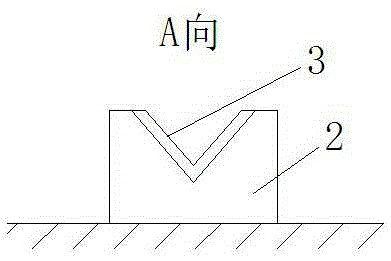

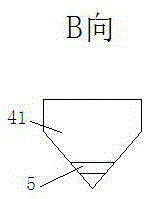

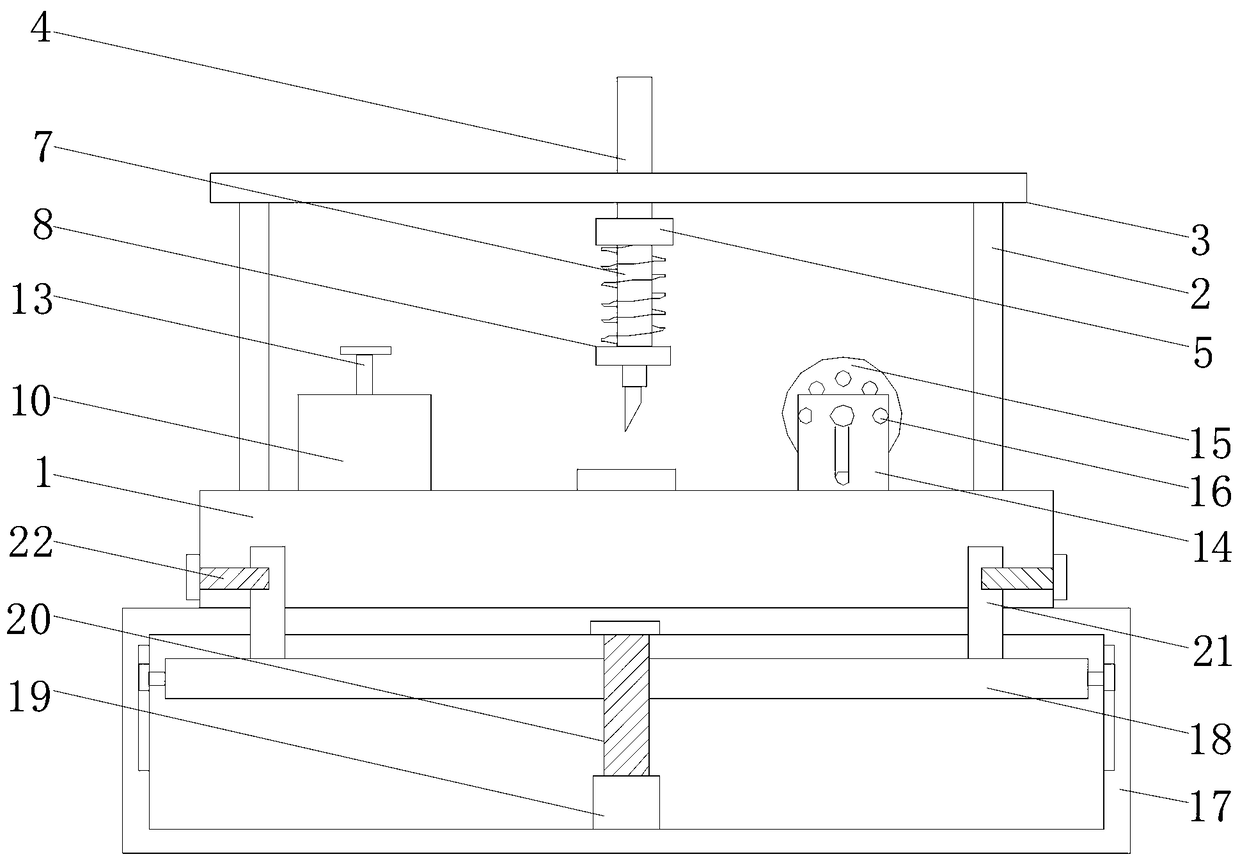

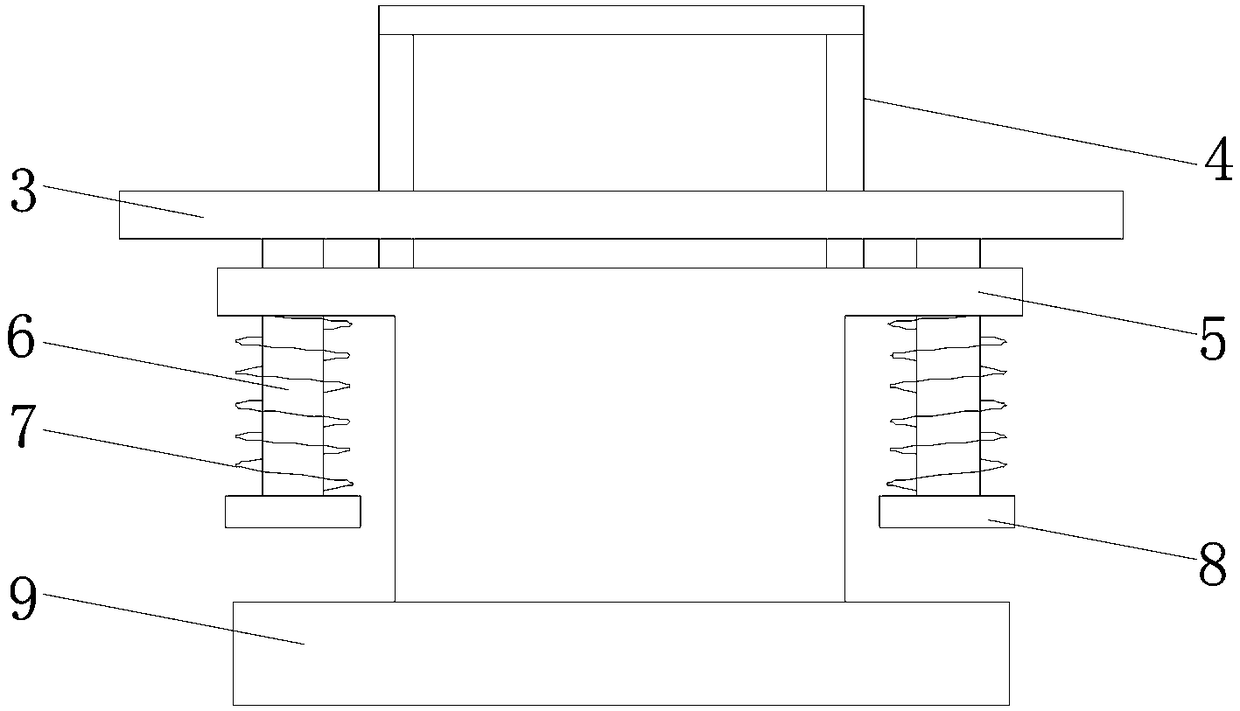

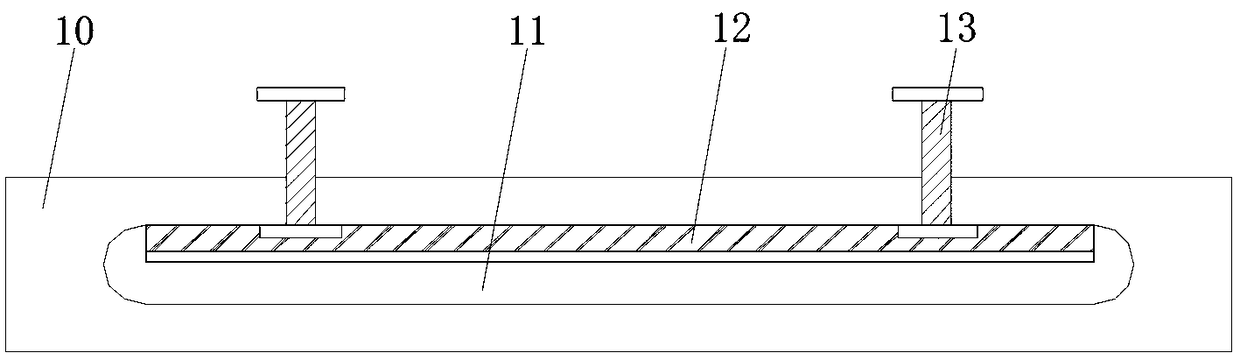

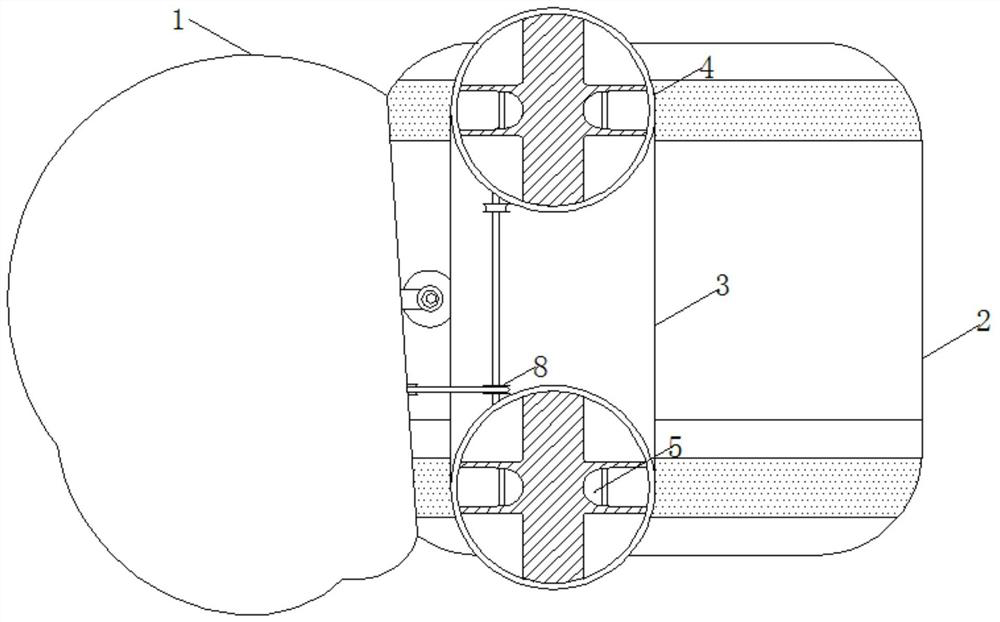

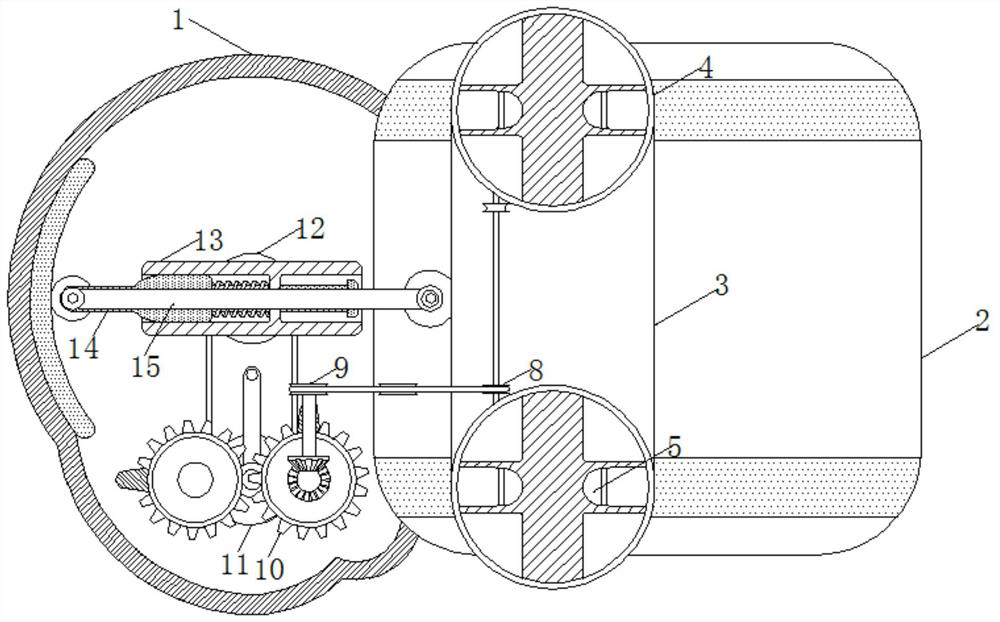

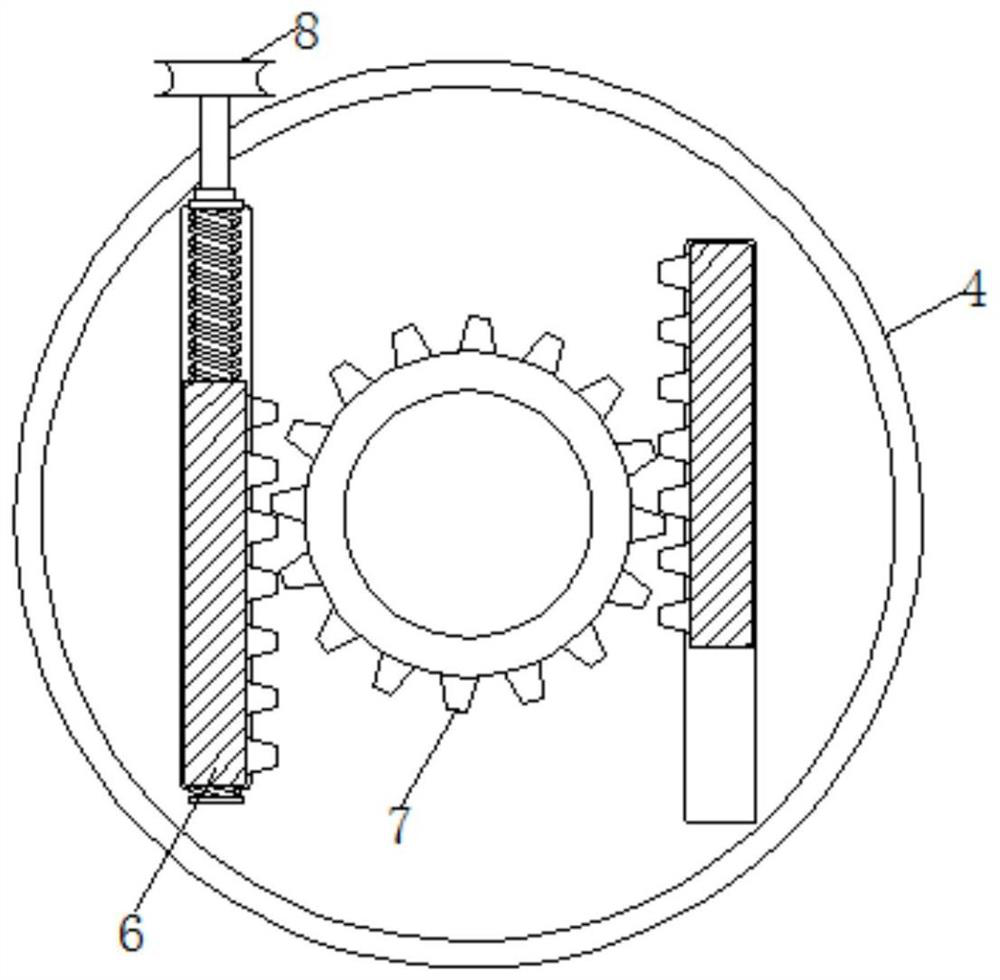

Cutting device for angle steel

InactiveCN105234478ASmall vibrationUnlikelyNibbling shearing machinesShearing machine accessoriesMechanical engineeringEngineering

The invention relates to a cutting device for angle steel. The cutting device comprises a rack (1) and a V-shaped positioning block (2) arranged on the rack (1). The angle steel (3) is placed in the V-shaped positioning block (2). A cutter (4) which is located at the upper portion of the V-shaped positioning block (2) and corresponds to the V-shaped positioning block (2) is arranged on the rack (1). The cutter (4) comprises a positioning block (41) and a cutting knife (42). The section of the positioning block (41) is in a V shape, and corresponds to the inner wall of the angle steel (3) to position the angle steel (3). The section of the cutting knife (42) is in a V shape. The cutting knife (42) comprises a knife body (421) and a blade (422). The blade (422) is arranged on one side of the knife body (421) and protrudes out of the knife body (421). The positioning block (41) is lower than the cutting knife (42). The cutting device for the angle steel is simple in structure, and can well cut the angle steel.

Owner:扬州市邗江科达涂装有限公司

Wire cutting device with clamping mechanism

InactiveCN109306616AGood stabilization effectPlay the role of cuttingSevering textilesMetal working apparatusWire cuttingEngineering

The invention discloses a wire cutting device with a clamping mechanism. The wire cutting device comprises a platform, supporting rods are fixedly connected to the top of the platform, the tops of thesupporting rods are fixedly connected with a top plate, a movable handle is arranged on the top of the top plate, and the bottom of the movable handle is fixedly connected with a cutter holder. The bottom of the top plate is fixedly connected with fixing rods, the bottoms of the fixing rods are fixedly connected with baffles, the bottom of the cutter holder is provided with springs, the outer surfaces of the fixing rods are sleeved with the springs, a cutter is welded to the bottom of the cutter holder, and the top of the platform is fixedly connected with a clamping base. By arranging the clamping base, a strip-like opening, a rubber plate, a bolt, a fixed plate, a winding roller, an insertion rod, a fixing frame, a movable plate, a motor, a screw, clamping rods and threaded pins, the problems are solved that an existing wire cutting device is not provided with the clamping mechanism, during cutting, a nylon product is easy to loosen, when the nylon product is cut, the cutting platform can shake, and the stability is poor.

Owner:睢宁德宇商贸有限公司

Plasma tracking ruled fly-saw

InactiveCN1253283CAvoiding Vulnerable HazardsFast cutting speedMetal sawing devicesWelding/cutting auxillary devicesLow noiseControl system

A plasma tracking fixed-length flying saw, including a flying saw trolley, a speed measuring device, an electrical control system, a driving system, a fixture and a guide rail base, the driving system is connected to the flying saw trolley sitting on the guide rail base, and the speed measuring device is connected to the electrical control system. A plasma cutting device is installed on the flying saw trolley. The plasma cutting device is composed of a plasma gun installed on a profiling frame, and the outer edge of the profiling frame is connected with a rotating motor according to a transmission device. The advantages of the present invention: 1. Adopt no less than two plasma guns to cut at the same time, which speeds up the cutting speed and shortens the synchronous stroke, making it possible for plasma cutting to be used for online dynamic tracking and cutting to length; 2. Simple structure, low weight Lightweight, compatible with cutting pipes and steel profiles of different shapes, easy to change varieties; 3. Low noise, good incision quality, no burrs; 4. Less iron filings, safe, avoiding the danger of easy injury after the saw blade is broken; 5. The utility model has the advantages of high efficiency, low consumption cost and good development prospect.

Owner:天津市东恒自动化工程有限公司

Plastic extruding plate cutting machine

PendingCN107599027AAvoid loss of cut qualityLow costMetal working apparatusAnnular cutterEngineering

The invention discloses a plastic extruding plate cutting machine. Annular cutter edges are arranged on the upper side and the lower side of the plastic extruding plate correspondingly. The plastic extruding plate is cut through self rotating of the annular cutter edges and transverse moving of a rack. The cutter edges do not need to move vertically, and the equipment cost is saved, and for some thick plastic extruding plates, the fact that the cutter quality is reduced due to deformation of the plastic extruding plate can be avoided. A strip-shaped notch is formed in a worktable, and the cutting operation of the plastic extruding plate corresponds to the strip-shaped notch. Pressing devices are arranged on the worktable and located on the two sides of the strip-shaped notch, and the position to be cut of the plastic extruding plate can be firmly fixed, and the cutting quality is further improved; and the plastic extruding plates with various width can be cut through adjustment of a mounting seat and replacement of a pressing part, and the equipment cost is further saved.

Owner:KAIPING COLD MAGIC AIR CONDITIONING EQUIP

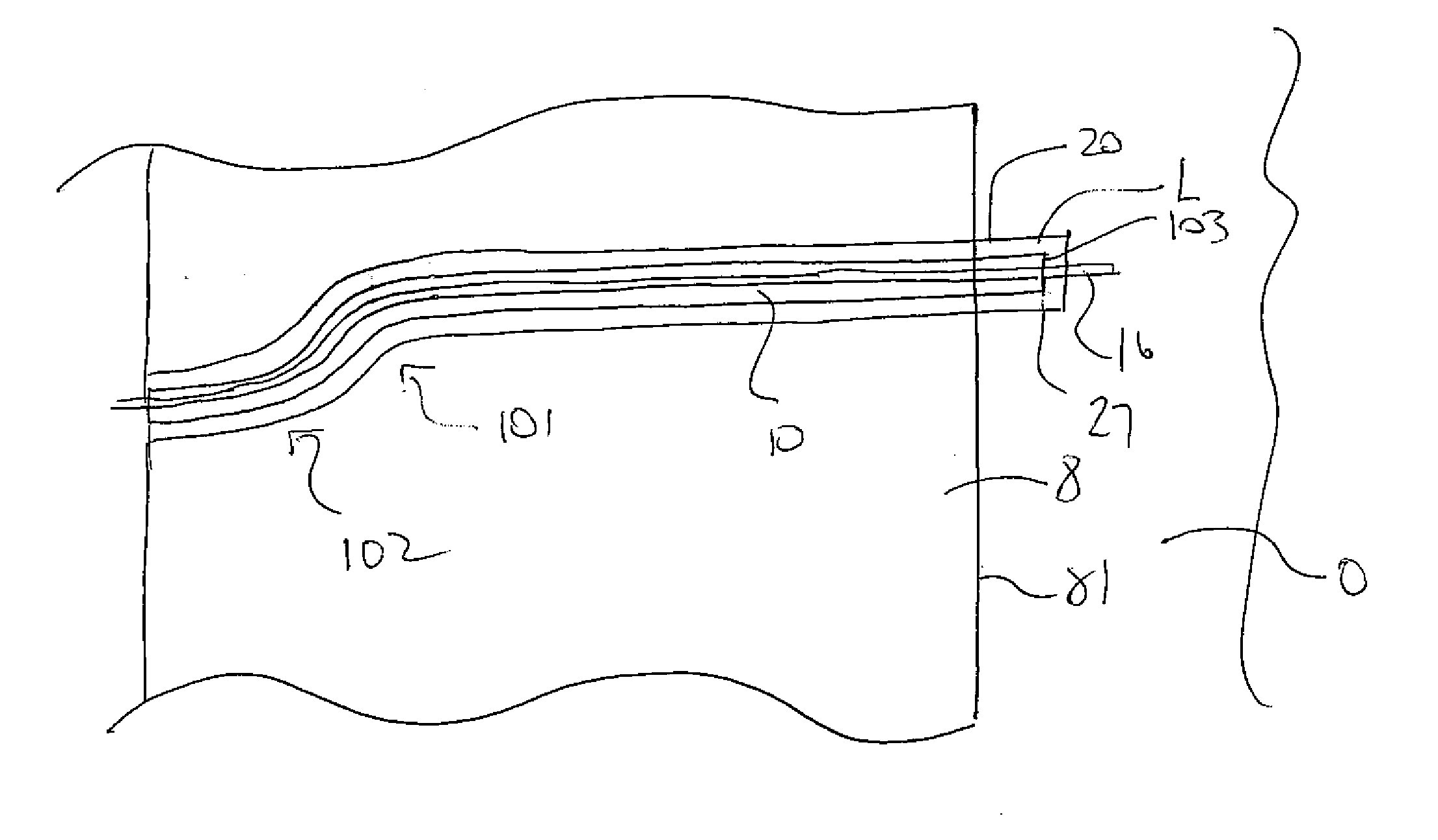

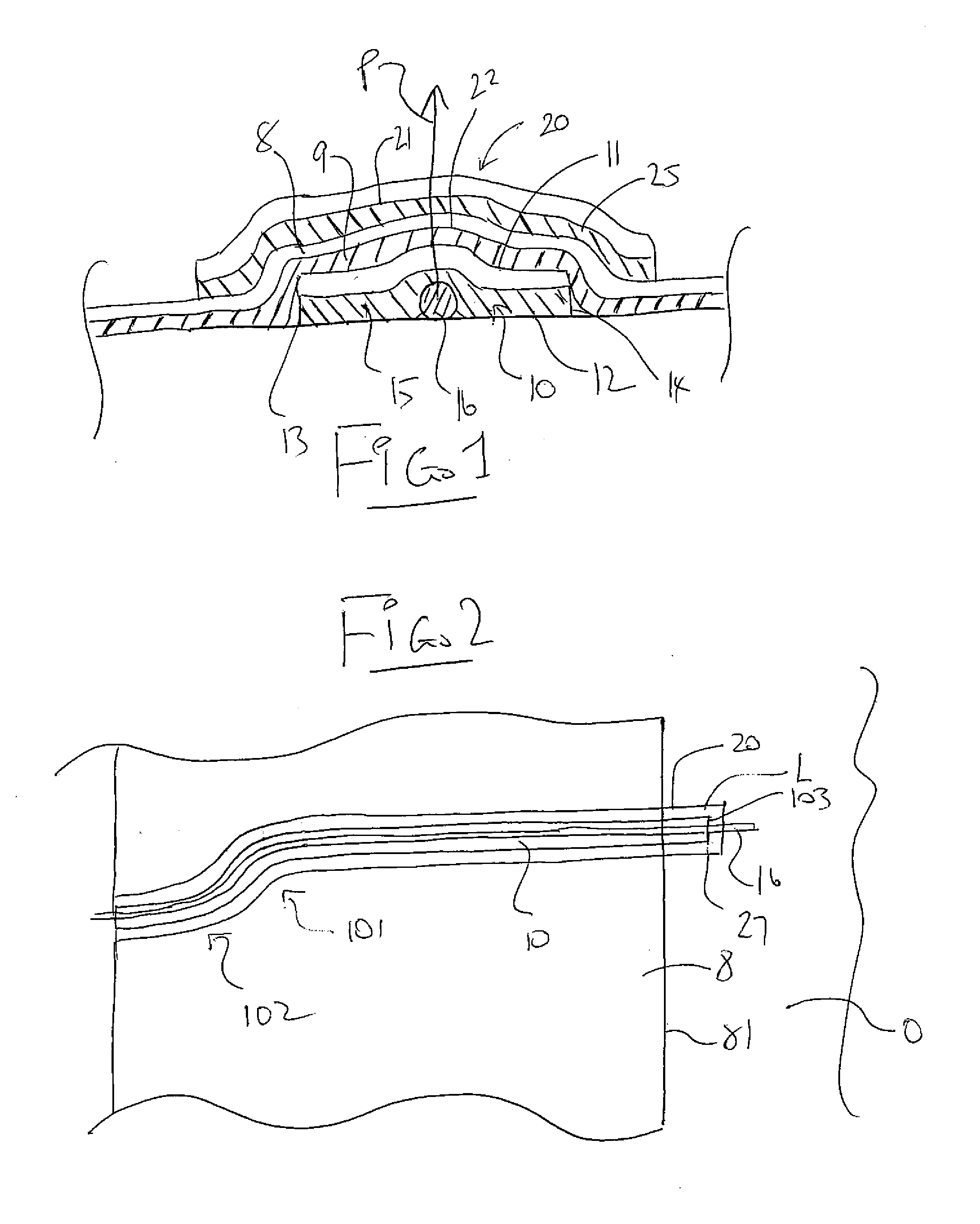

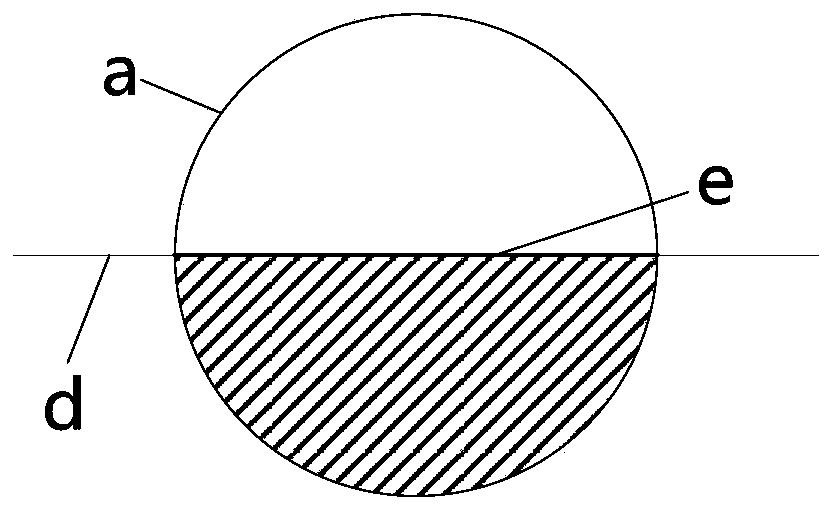

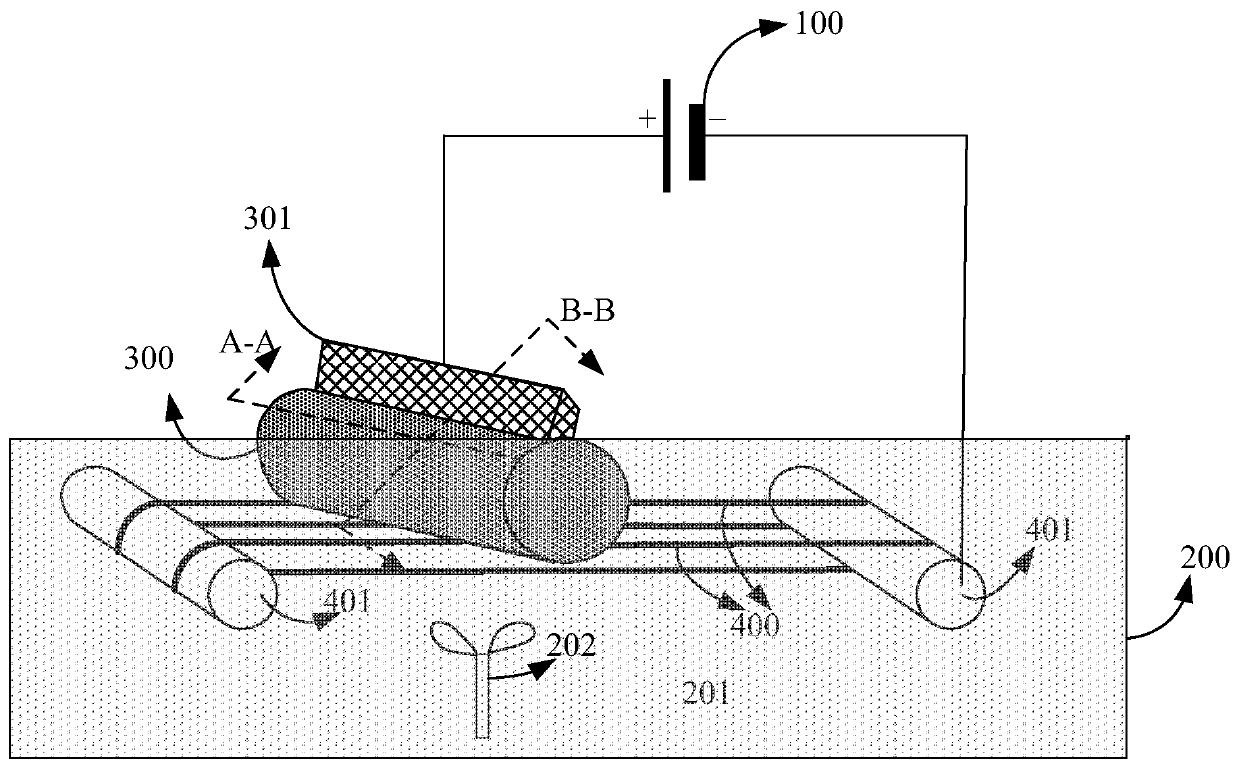

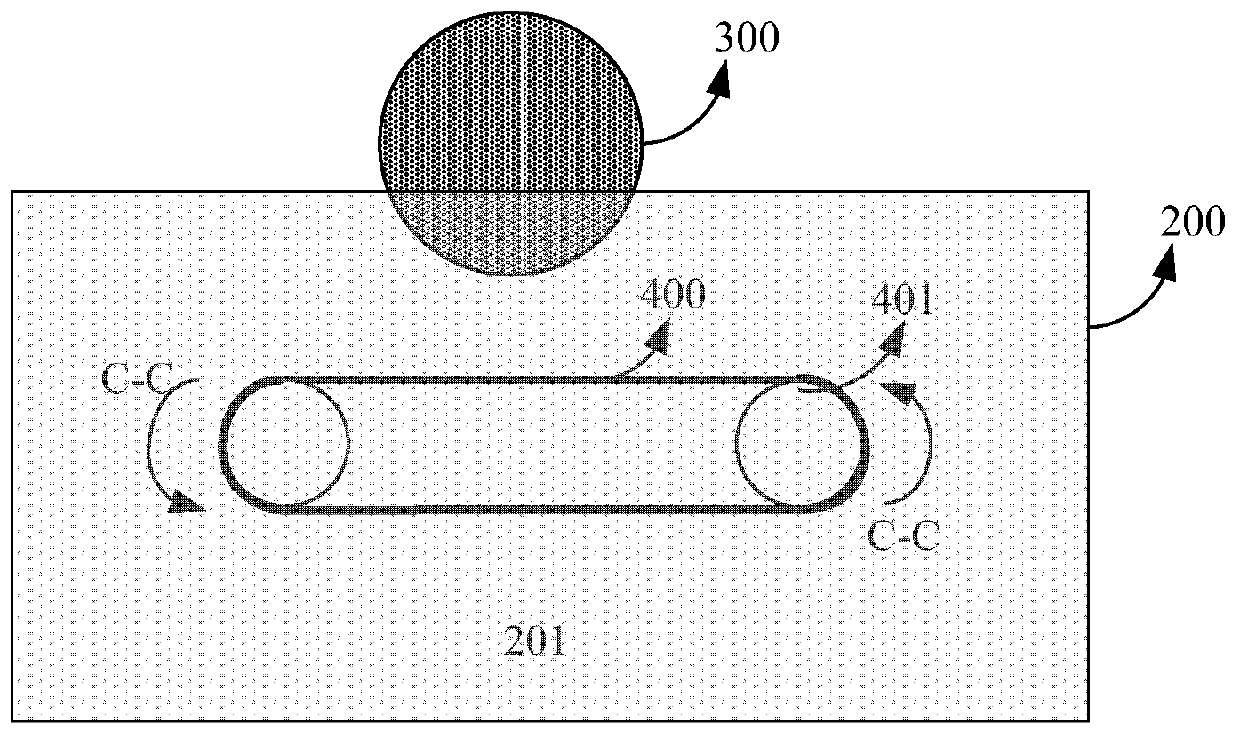

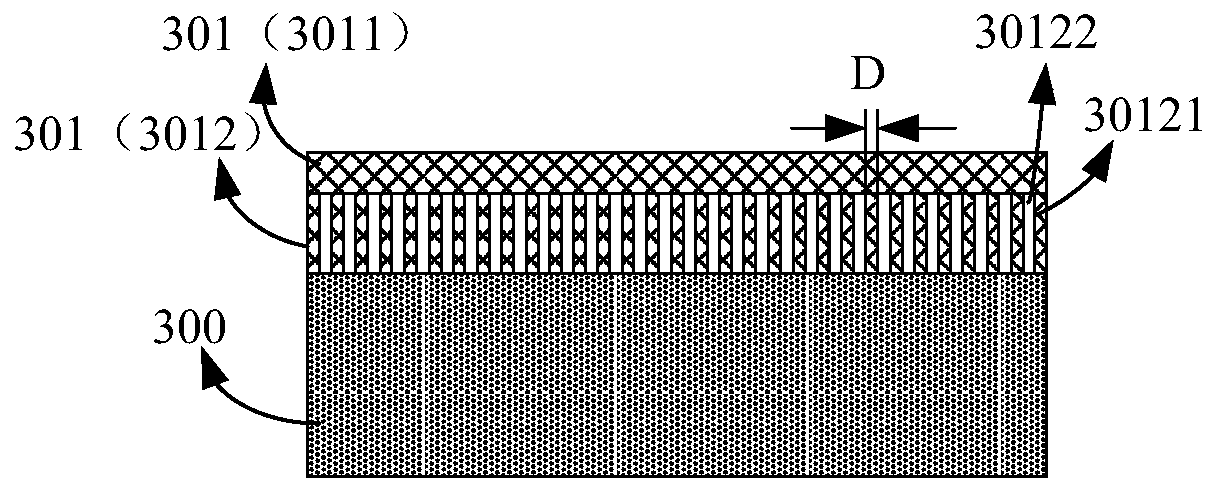

Crystal bar slicing device

InactiveCN111267245AAvoid cut qualityAffect slice qualityFine working devicesEngineeringMaterials science

The invention provides a crystal bar slicing device. The device comprises a power supply, an electrolytic tank, an anode and a cathode; the electrolytic tank is used for storing electrolyte; the anodecomprises a crystal bar, and the crystal bar is electrically connected with the power supply; the cathode comprises at least one linear electrode, the linear electrode is contained in the electrolytic tank and electrically connected with the power supply, the length direction of the linear electrode and the axial direction of the crystal bar are arranged in a crossed mode, and the linear electrode does not make contact with the crystal bar; when the power supply is switched on between the anode and the cathode, the crystal bar is sliced through the relative movement between the linear electrode and the crystal bar; and an auxiliary convection device is also arranged in the electrolytic tank and is used for enhancing flow of the electrolyte in the electrolytic tank. According to the crystal bar slicing device disclosed by the invention, the auxiliary convection device is arranged in the electrolytic tank, so that flowing of the electrolyte in the electrolytic tank is enhanced, and influences of the condition that H2 is attracted to the linear electrode on the cutting rate and cutting quality of the crystal bar are reduced.

Owner:ZING SEMICON CORP +1

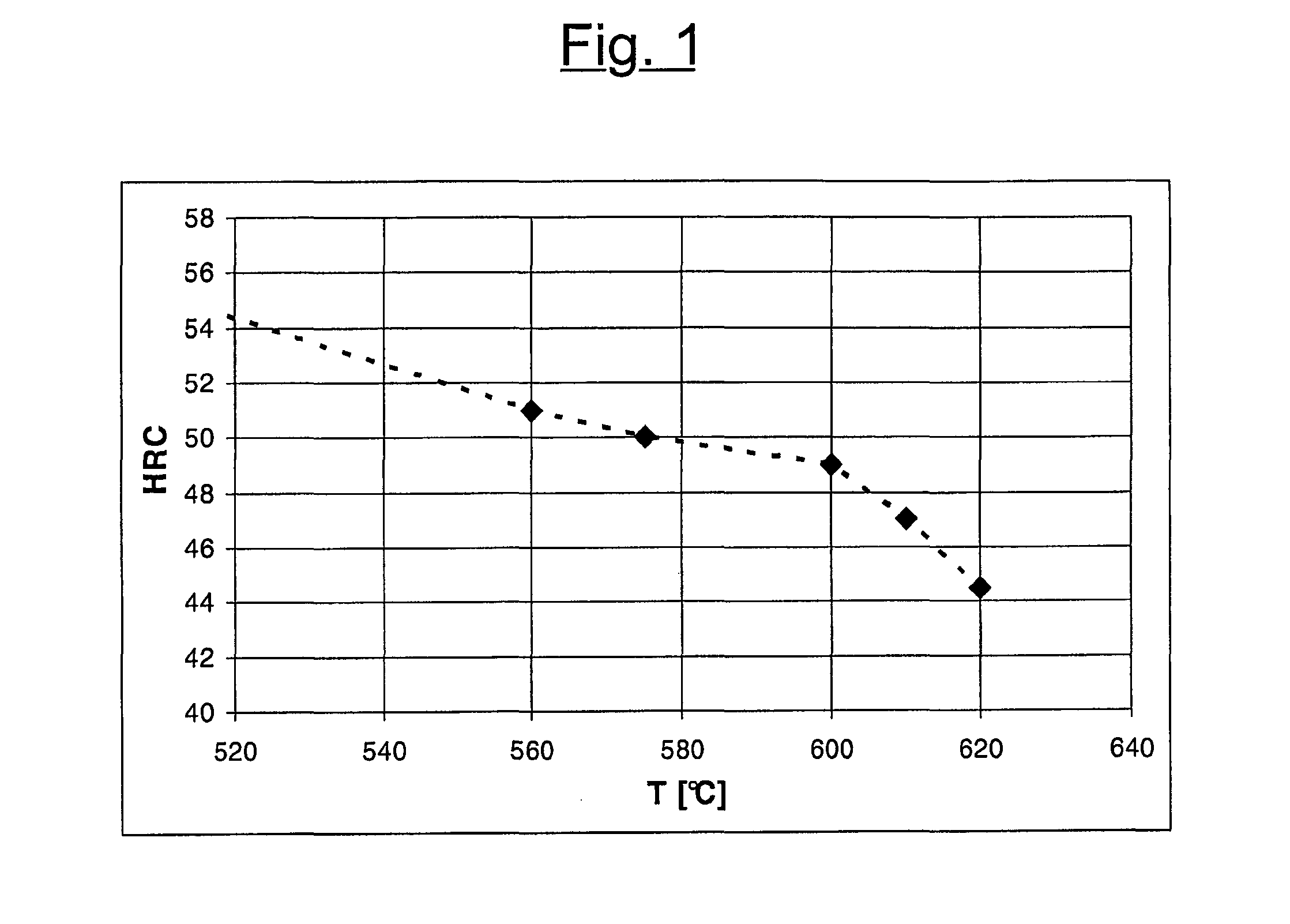

Granulator blades with a high wear resistance and sharpening method thereof

Granulator blades with a high wear resistance made of cold work tool steel, preferably with a high vanadium content and thermally treated after machining, at a temperature ranging from 500° C. to 700° C. The sharpening of the blades is effected by abrading the blades against the surface of the die plate, under suitable operating conditions.

Owner:POLIMERI EUROPA SPA

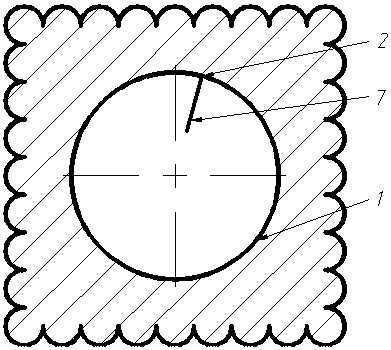

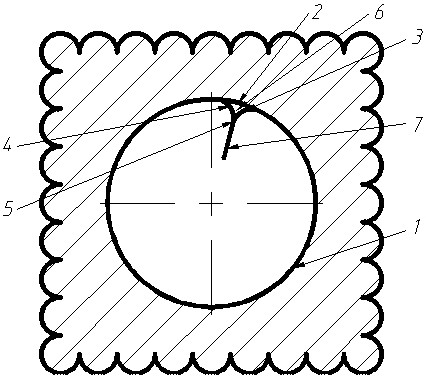

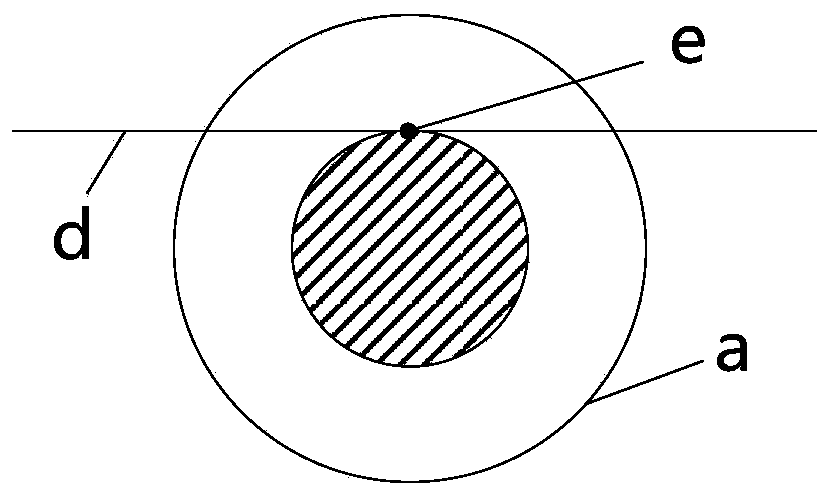

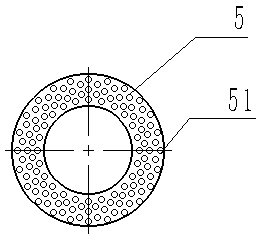

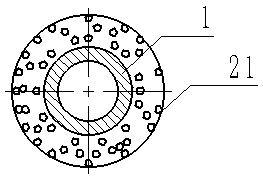

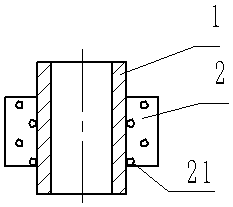

A kind of wire saw beads with uniform distribution of abrasive particles and manufacturing method

ActiveCN107283650BEven consumptionEvenly distributedMetal sawing devicesMetal sawing tool makingGraphiteAlloy

The invention discloses a hot-press sintering rope saw bead string with evenly-distributed grinding particles. The bead string is composed of a casing work layer and a base body, and is characterized in that the grinding particles on the casing work layer are evenly distributed in the space. The casing work layer is formed through stacking, hot pressing and sintering of a plurality of layers of cutting unit rings. The grinding materials in cutting unit ring blanks are arranged in order along the circumference concentric with the center axes of the cutting unit rings. According to the manufacturing process of the bead string, the cutting unit ring blanks with the evenly-distributed single-layer grinding materials are manufactured in an alloy die cold pressing manner; string beads are strung to the base body according to the uniform same direction; the string beads are placed in a graphite sintering die, and the rope saw bead string with the grinding particles evenly distributed in the space is obtained through hot-press sintering forming; and the grinding materials are evenly distributed in the whole space, uniform consumption of the string beads is guaranteed, eccentric wear scrapping caused by uneven grinding particle distribution is avoided, and the problem about the cutting quality caused by eccentric wear scrapping is solved. The usage amount of the grinding particles is reduced, and cost is saved. Orderly distribution of diamonds can be conducted without a bonding agent or an auxiliary template or the like, and quality guaranteeing and high efficiency are achieved.

Owner:福建天石源科技股份有限公司

Intelligent optical fiber laser cutting machine with high safety

PendingCN113787263AAvoid indentationAvoid health effectsLaser beam welding apparatusEngineeringStructural engineering

The invention discloses an intelligent optical fiber laser cutting machine with high safety. The intelligent optical fiber laser cutting machine comprises a base, a cavity is formed in the base, electric push rods are fixedly mounted on the two sides of the inner wall of the cavity, a sliding block is fixedly connected to one side of the cavity, a connecting rod is welded to the upper end of the sliding block, and the connecting rod penetrates through the base to be welded with a movable seat; and the movable seat is slidably connected with the base through a sliding block, side plates are welded to the two sides of the upper end of the base, a transverse plate is welded to the upper ends of the side plates, a purification mechanism is arranged at the upper end of the transverse plate, and supporting legs are welded to the two sides of the lower end of the base. Under the action of an exhaust fan, a gas collection tank, a gas purification plate, a telescopic hose, an air suction cover and a mounting frame, some poisonous and harmful gas or smoke dust generated during cutting can be absorbed and purified through the gas purification plate, the influence on the health of the respiratory tract of an operator is avoided, and the safety performance of the optical fiber laser cutting machine is greatly improved.

Owner:JIANGSU HUYUN LASER EQUIP CO LTD

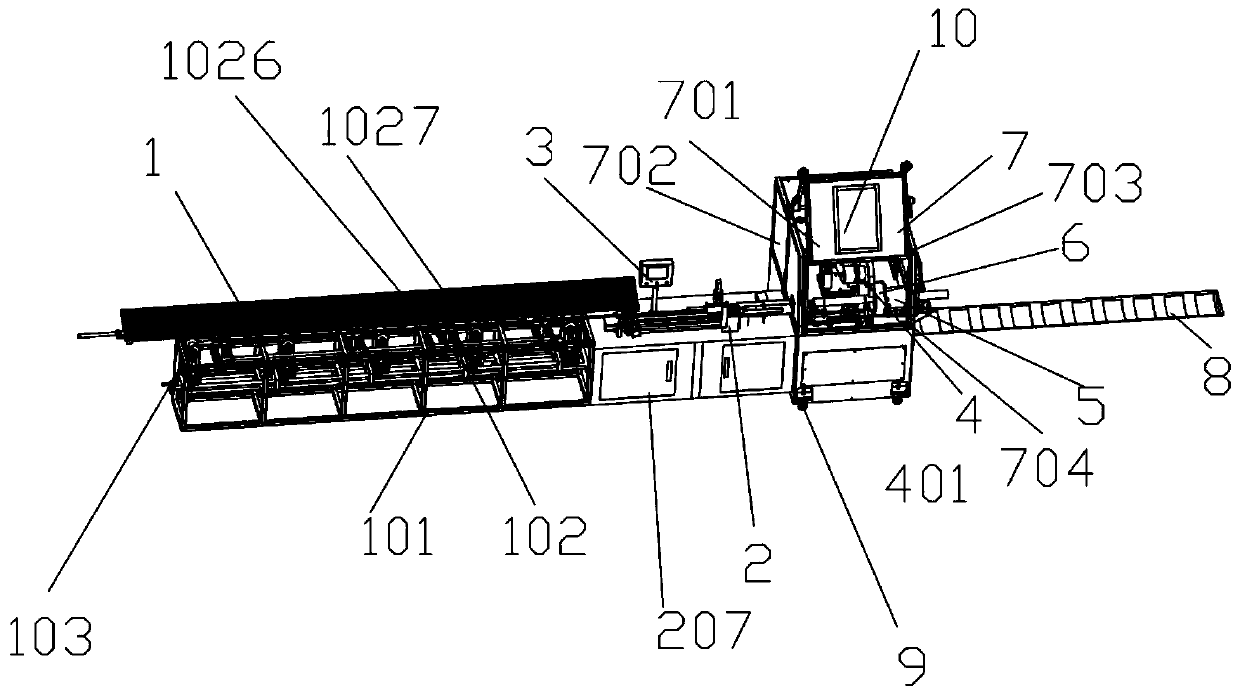

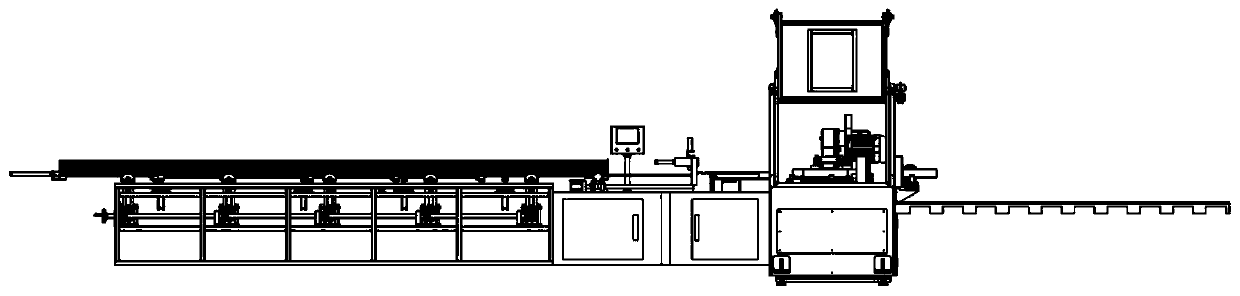

Novel laser cutting machine

PendingCN112846547AHigh degree of automationShort loading and unloading timeLaser beam welding apparatusPhysicsEngineering

The invention provides a novel laser cutting machine which comprises a rack, a working platform and a laser device which are arranged on the rack, wherein the laser device is slidably connected to the rack, the novel laser cutting machine further comprises a feeding device and an overturning discharging device, the feeding device is arranged on the right side of the working platform and used for taking and conveying materials to the working platform, and the overturning discharging device is movably connected to the lower portion of the working platform, penetrates through the working platform and is used for dumping materials on the working platform. According to the novel laser cutting machine, the automation degree is high, the automatic feeding and discharging mode is adopted, the feeding and discharging time is short, one person can operate multiple machines, the cutting efficiency is high, the cutting quality is stable, in addition, the feeding device and the laser device are of an integrated structure, the installation space is saved, assembling is easy and convenient, the maintenance cost is reduced, plates are always kept in the middle when entering the working platform in the feeding process, and the cutting effect is guaranteed.

Owner:东莞市合力激光设备有限公司

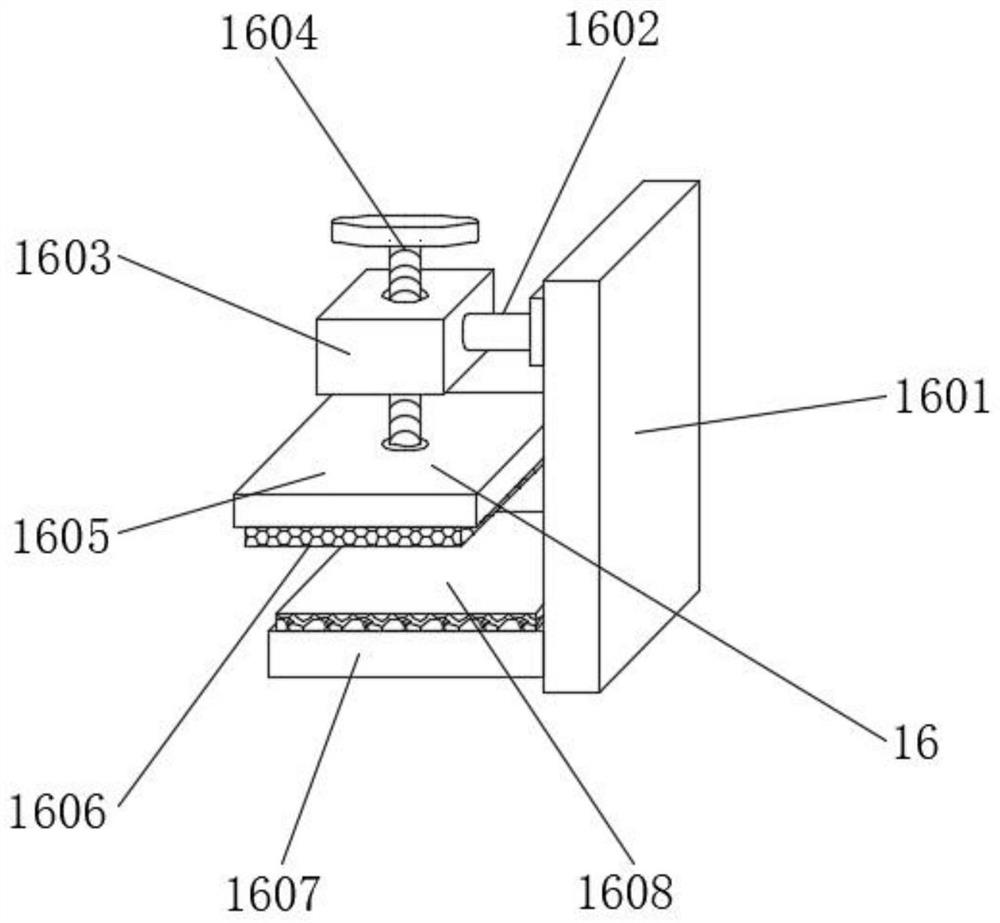

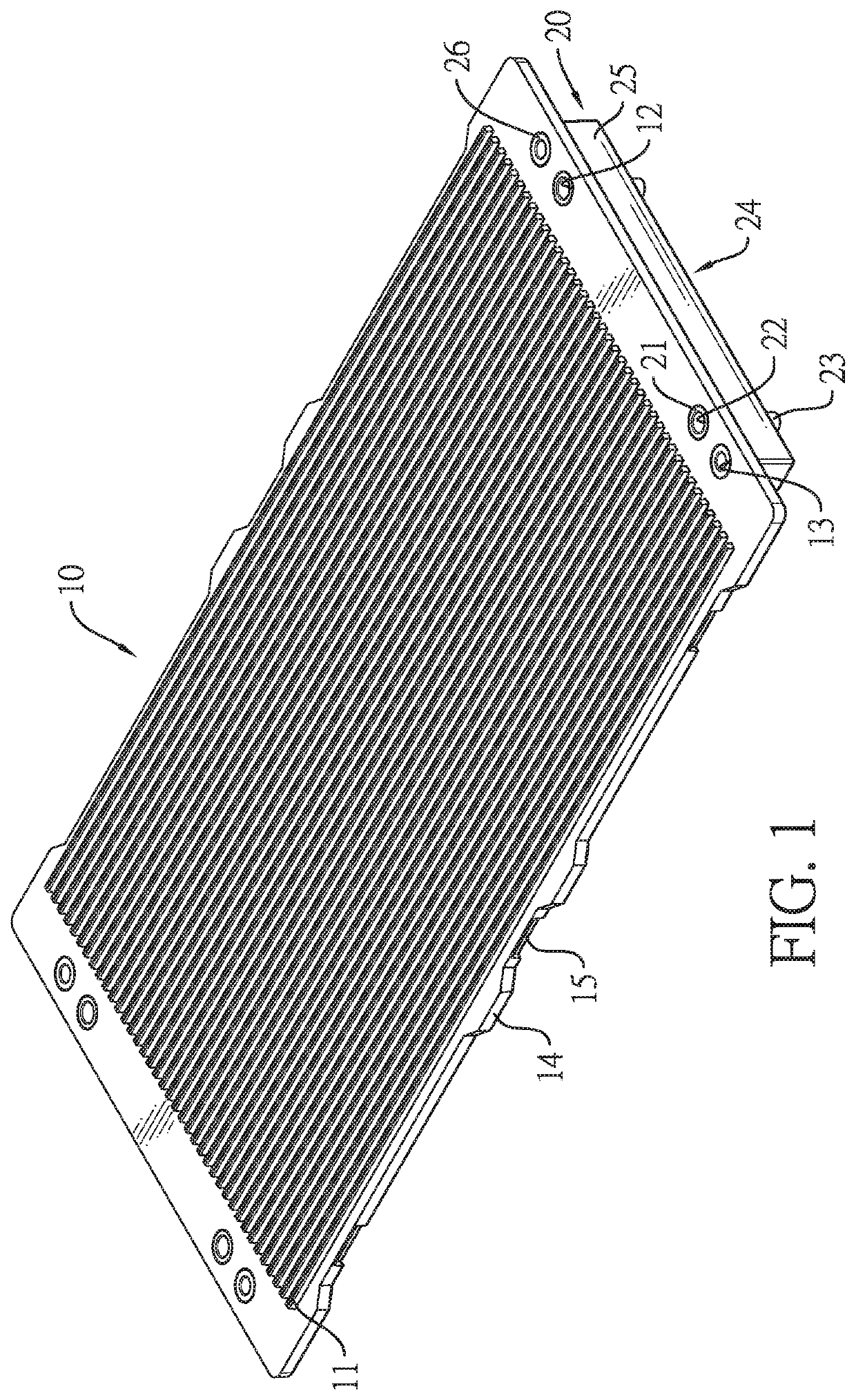

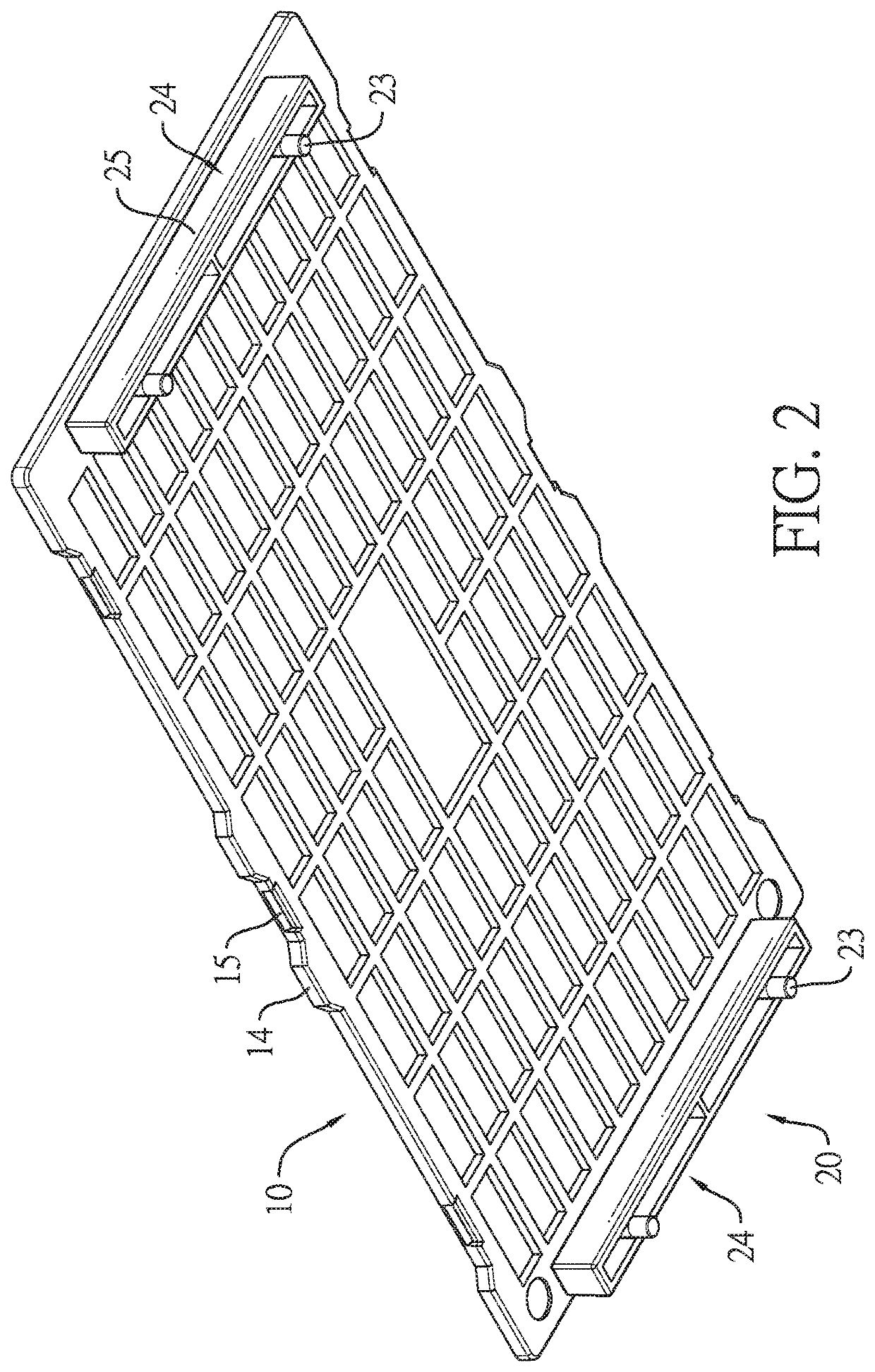

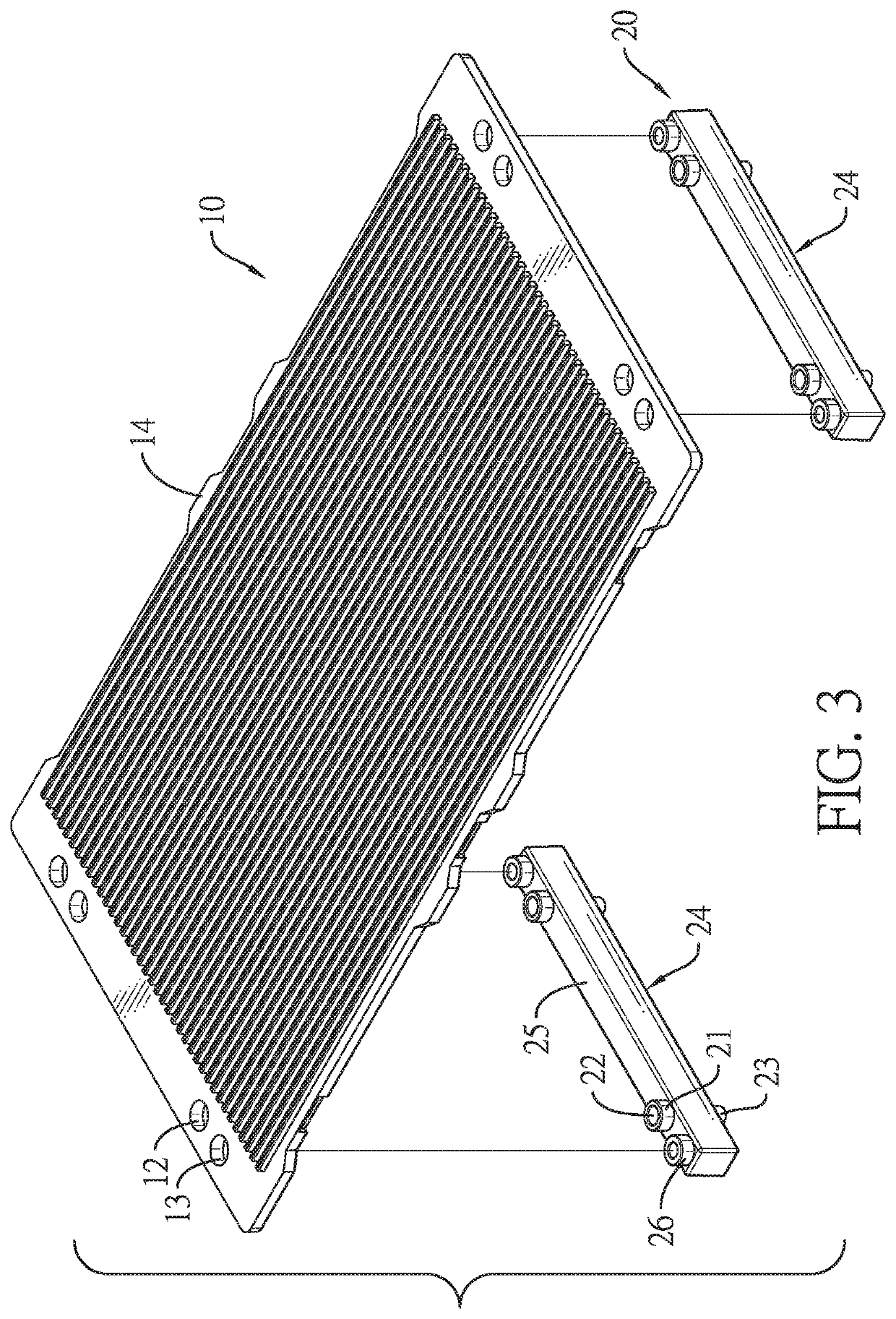

Pad supporting frame

ActiveUS10744666B1Easy to transformAvoid cut qualityMetal working apparatusStampingEngineeringPhysics

Owner:SUN SAME ENTERPRISES

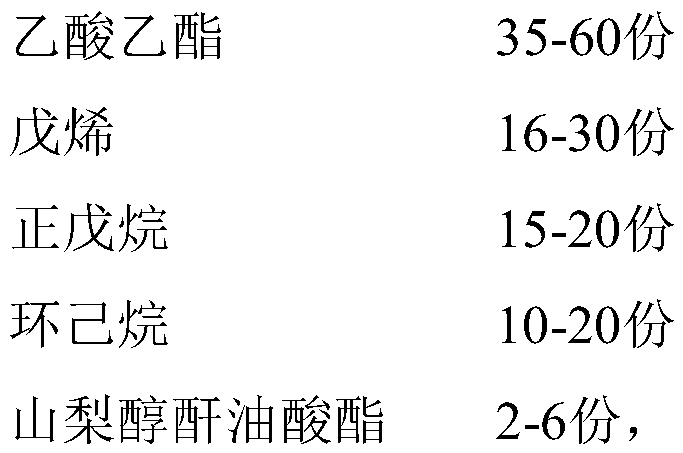

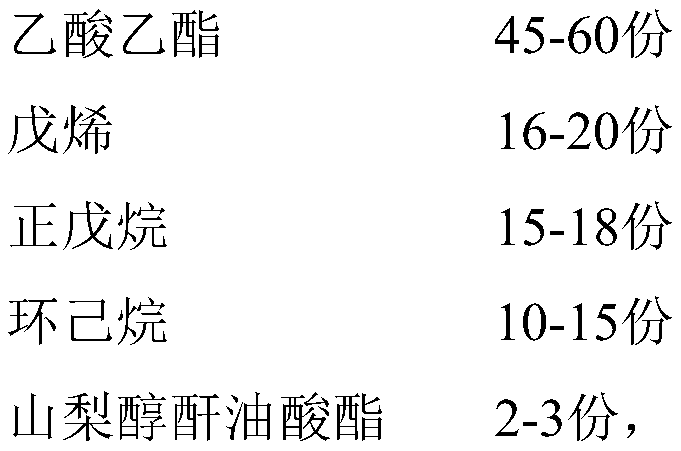

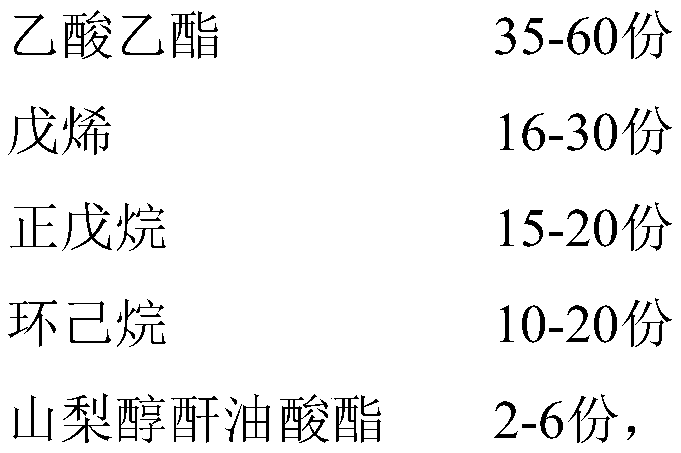

Flame cutting gas taking natural gas as raw material

The invention relates to the technical field of metal flame cutting, in particular to flame cutting gas taking natural gas as a raw material. According to the flame cutting gas taking natural gas as araw material, the flame cutting gas is composed of liquefied natural gas and an additive, and the additive is composed of the following components in parts by weight: 35-60 parts of ethyl acetate, 16-30 parts of pentene, 15-20 parts of n-pentane, 10-20 parts of cyclohexane and 2-6 parts of sorbitan oleate. According to the flame cutting gas, the additive is low in price and easy to purchase, enough intermediate chemicals can be provided for combustion of the natural gas, the combustion speed of the natural gas in oxygen is increased, and then the combustion temperature is increased; the flamecutting gas has the characteristics of simple production process, safety in use, no tempering during cutting and the like, the specific gravity of cutting gas is lower than that of air, and indoor operation can be performed.

Owner:崔旭

Steel wire knitted hose cutting machine and working method thereof

InactiveCN109746579AIncreased sense of securityEnsure no contaminationLaser beam welding apparatusMetallurgyFocal position

The invention discloses a steel wire knitted hose cutting machine and a working method thereof, and belongs to the field of pipeline cutting. The steel wire knitted hose cutting machine includes a feeding mechanism, a feeding clamping mechanism, a hot melting mechanism and a laser cutting device. The hot melting mechanism includes a hot melting plate, a hot melting head, a heating block, a hot-melting heat-dissipation block, a heat insulating plate, a temperature sensor and a hot melting guide pillar; the hot melting plate is arranged in a three-gripper clamping mechanism, the hot melting headis fixedly connected to the hot melting plate, the heating block is arranged on one end of the hot melting head, the hot-melting heat-dissipation block is fixedly connected to the heating block, theheat insulating plate is fixedly connected to the end, with quick heat dissipation, of the hot melting block, the temperature sensor is arranged on the heating block, and the hot melting guide pillaris arranged to penetrate through the hot melting plate; and according to the laser cutting device, the cutting speed is fast, the power demand is low, meanwhile the focal position is placed at the middle of materials, the internal stress change is induced, no traces exists on the surface, meanwhile the cutting surface is smooth, no cutting traces exists, the cutting efficiency is improved, no chemical waste gas, dust and noise pollution exists, and the harm on the environment is avoided.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

A cutting auxiliary device with high safety for whole wood home furnishing processing

ActiveCN111496938BImprove securityIncrease linkageProfiling/shaping machinesReciprocating motionStructural engineering

The invention relates to the technical field of whole wood furniture, and discloses a cutting auxiliary device for whole wood furniture processing with high safety, which comprises a casing, the outer side of the casing is fixedly connected with a base; Perform intermittent reciprocating rotation to provide power source for subsequent fixing operations. The rotation of the first turntable causes the blocks to approach each other and then move away from each other, automatically fixing the wood to prevent the wood from shaking and reducing the cutting quality. It is easy to take the wood or adjust the cutting point of the wood. The rotation of the fourth turntable causes the push rod to drive the connecting plate to perform intermittent reciprocating motion, which automatically pushes the wood to the cutting place, which is conducive to the cutting operation, frees hands, and avoids manual When the material is pushed, the hand may be cut, and the wood will be automatically moved away from the cutting tool after cutting, which greatly reduces the probability of the cutting tool hurting people and ensures the safety of the staff.

Owner:TAISHENG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com