Novel laser cutting machine

A laser cutting machine, a new technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high labor intensity, low work efficiency, high labor cost, etc., and achieve stable cutting quality, high cutting efficiency, The effect of short loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

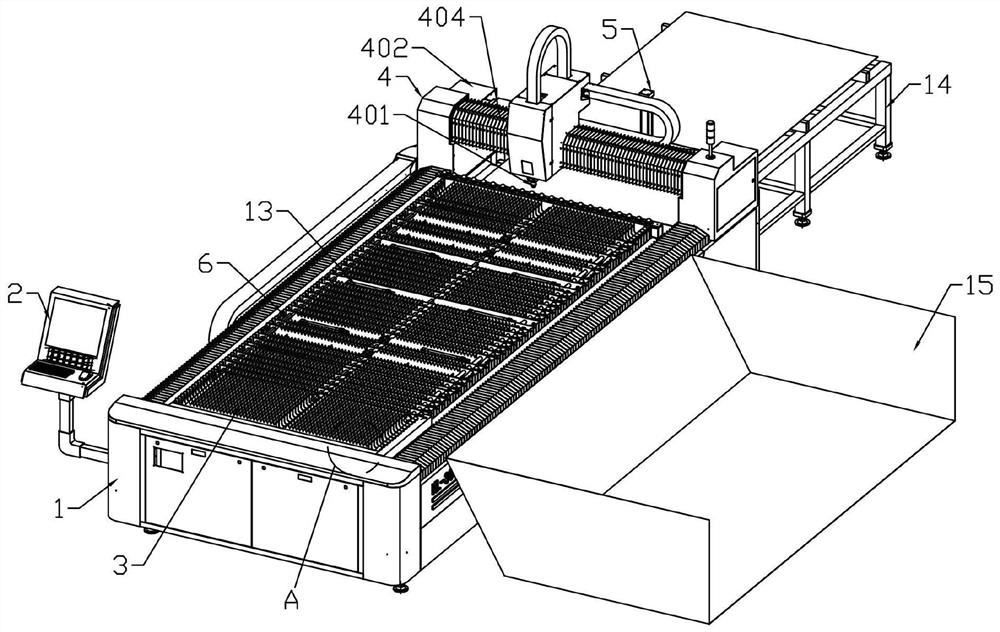

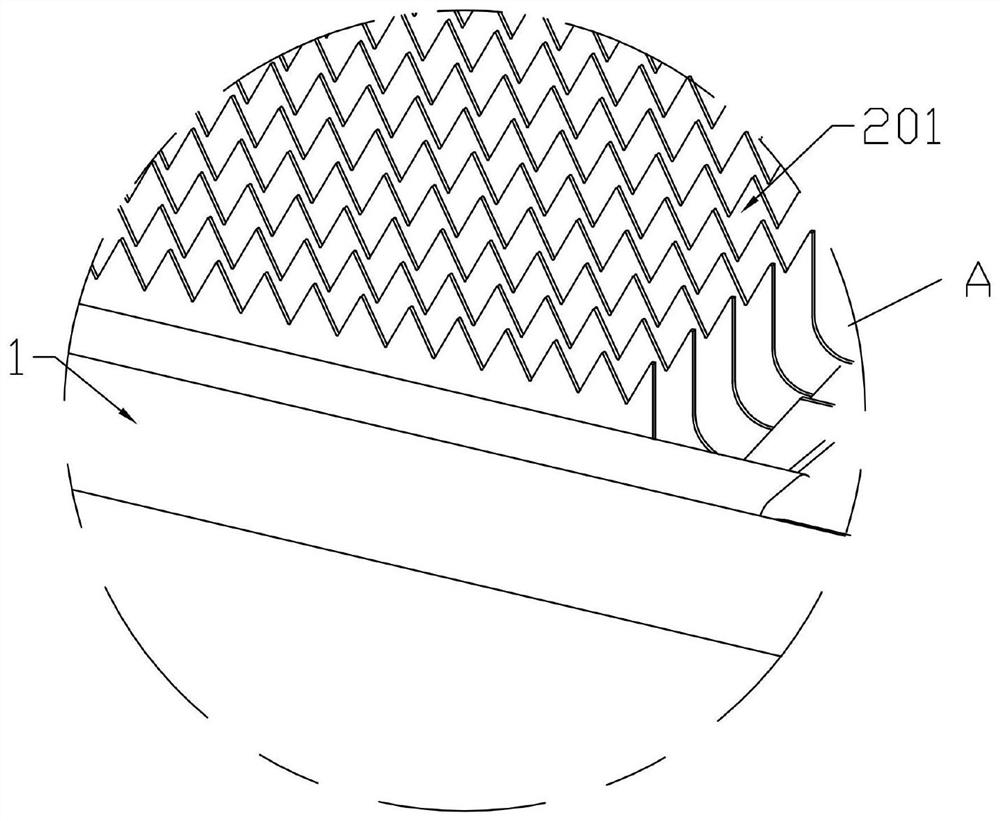

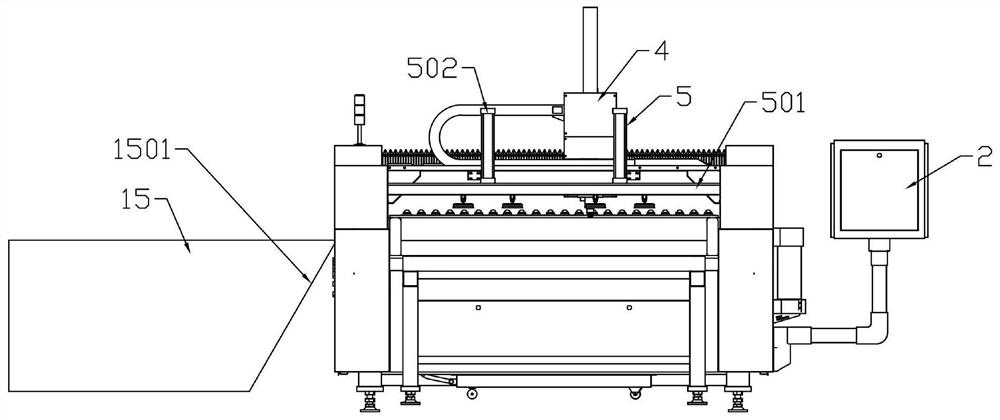

[0027] Specific Example 1: See figure 1 with figure 2 , in the embodiment of the present invention, a new type of laser cutting machine includes a frame 1, a working platform 2 and a laser device 4 arranged on the frame 1, a control panel 2 is provided on the outside of the frame 1, and the laser The device 4 is slidably connected on the frame 1, and also includes a feeding device 5 and a turning and unloading device 6. The feeding device 5 is arranged on the right side of the working platform 2 for picking up materials and transporting them to the working platform 2. The overturning and unloading device 6 is movably connected under the working platform 2 , and the overturning and unloading device 6 passes through the working platform 2 for dumping materials on the working platform 2 . The working platform 2 is composed of several supporting brackets 201 arranged at intervals in the transverse direction. The supporting brackets 201 are provided with sawtooth protrusions, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com