Flame cutting gas taking natural gas as raw material

A technology of flame cutting and natural gas, which is applied in the field of metal flame cutting, can solve problems such as unstable performance, damage to resources, and complex production process, and achieve the effects of high social and economic benefits, smooth cut section, and complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

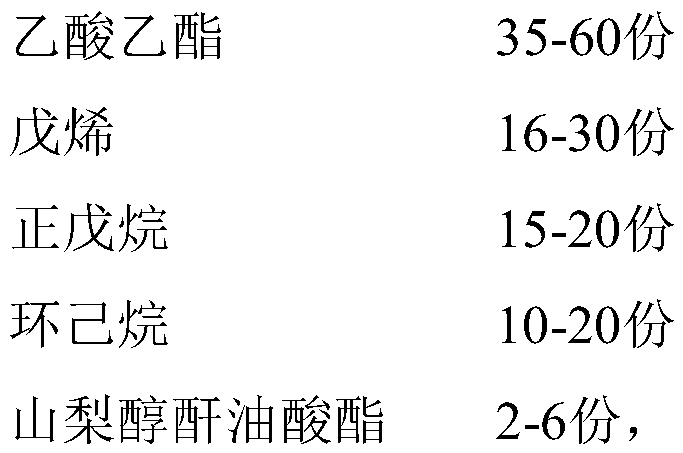

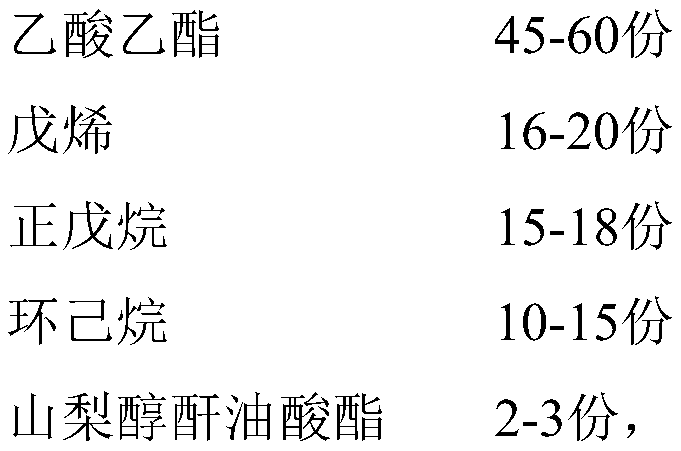

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a flame cutting gas using natural gas as a raw material, which is composed of the following components by weight: 99.7 parts by weight of liquefied natural gas and 0.3 parts by additive; the additive is composed of the following components by weight : Ethyl acetate (46 parts), pentene (18 parts), n-pentane (18 parts), cyclohexane (15 parts), sorbitan oleate (3 parts).

[0031] The method for preparing flame cutting gas using natural gas as a raw material includes the following steps:

[0032] Step 1. The raw material components of the additives are ethyl acetate (46 parts), pentene (18 parts), n-pentane (18 parts), cyclohexane (15 parts), and sorbitan oleate (3 parts) Add to the container, mix and filter to obtain the additives.

[0033] Step 2. Add 0.3 parts of additives to 99.7 parts of liquefied natural gas in the LNG tank, mix for 40 minutes after adding, and obtain flame cutting gas with natural gas as raw material in liquid phase.

[0034] The me...

Embodiment 2

[0040] This embodiment provides a flame cutting gas using natural gas as a raw material, which is composed of the following components in parts by weight: 99.6 parts by weight of liquefied natural gas, 0.4 parts by weight of additives; the additive is composed of the following parts by weight of components : Ethyl acetate (52 parts), pentene (16 parts), n-pentane (16 parts), cyclohexane (13 parts), sorbitan oleate (3 parts). The preparation method is the same as in Example 1.

Embodiment 3

[0042] This embodiment provides a flame cutting gas using natural gas as a raw material, which is composed of the following components by weight: 99.5 parts by weight of liquefied natural gas, 0.5 parts by weight of additives; the additive is composed of the following parts by weight of components : Ethyl acetate (50 parts), pentene (17 parts), n-pentane (15 parts), cyclohexane (15 parts), sorbitan oleate (3 parts). The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com