Cutting system and cutting method

A technology of cutting system and cutting method, which is applied in glass cutting device, glass manufacturing equipment, glass production, etc., can solve the problem of different warpage of glass substrate cutting line position, unsatisfactory cutting flatness, and sharp cutting yield Reduce and other problems, to achieve the effect of improving cutting compatibility, improving cutting accuracy and cutting yield, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

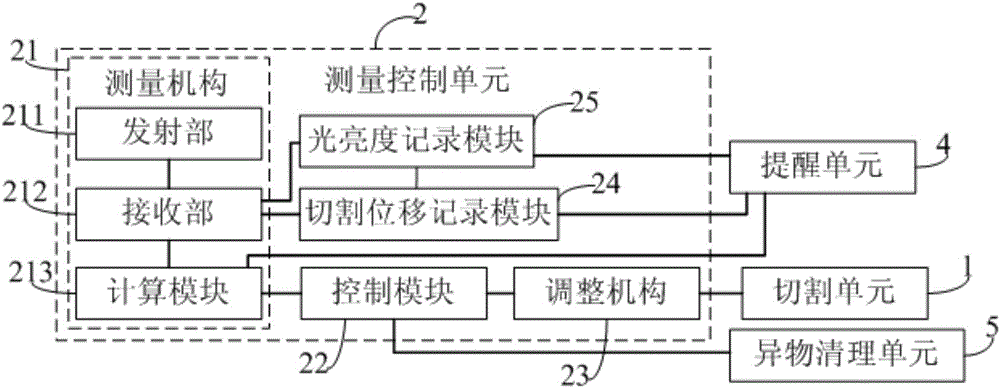

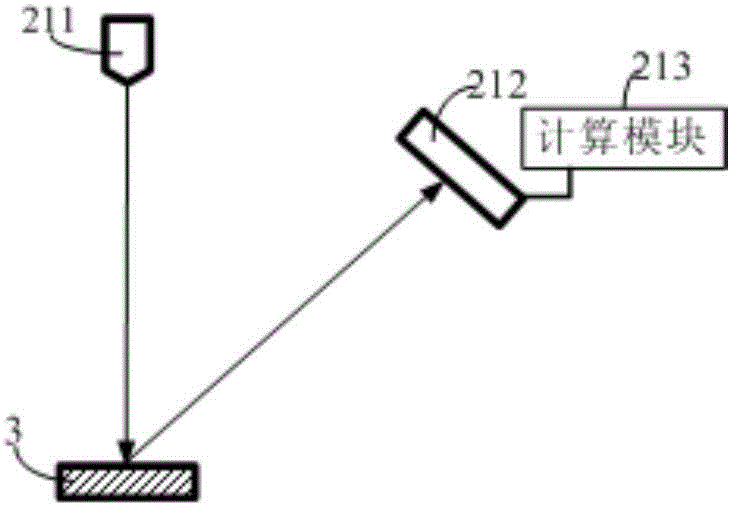

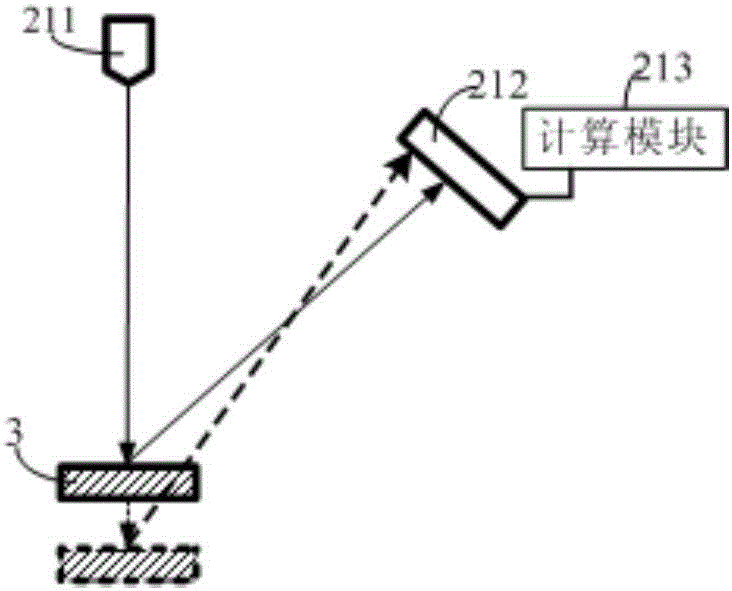

[0052] This embodiment provides a cutting system, such as figure 1 As shown, it includes a cutting unit 1 for laser cutting the display substrate, and also includes a measurement control unit 2 for measuring the distance between the laser focus of the cutting unit 1 and the surface of the display substrate in real time, and when the measurement result is not zero , adjust the distance between the laser focus and the surface of the display substrate to zero in real time.

[0053] By setting the measurement control unit 2, the laser focal point of the cutting unit 1 can be kept just falling on the surface of the display substrate during the cutting process, thereby not only avoiding the impact of the flatness of the base platform used to support the display substrate during cutting on the cutting accuracy and The influence of the cutting quality, and avoid the influence of the flatness of the display substrate itself on the cutting accuracy and cutting quality, especially avoid ...

Embodiment 2

[0083] This embodiment provides a cutting system. The difference from Embodiment 1 is that the measurement control unit in this embodiment does not include a cutting displacement recording module and a brightness recording module.

[0084] Correspondingly, the cutting method in this embodiment also does not include the steps of recording the displacement position data of the laser focus of the cutting unit along the cutting line on the display substrate and recording the brightness data of each displacement position of the laser focus on the cutting line .

[0085] Other structural configurations of the cutting system and other steps of the cutting method in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0086] Beneficial effects of Embodiment 1-2: The cutting system provided by Embodiment 1-2, by setting the measurement control unit, can keep the laser focus of the cutting unit just falling on the surface of the display substrate durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com