Patents

Literature

135results about How to "Improve cutting yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

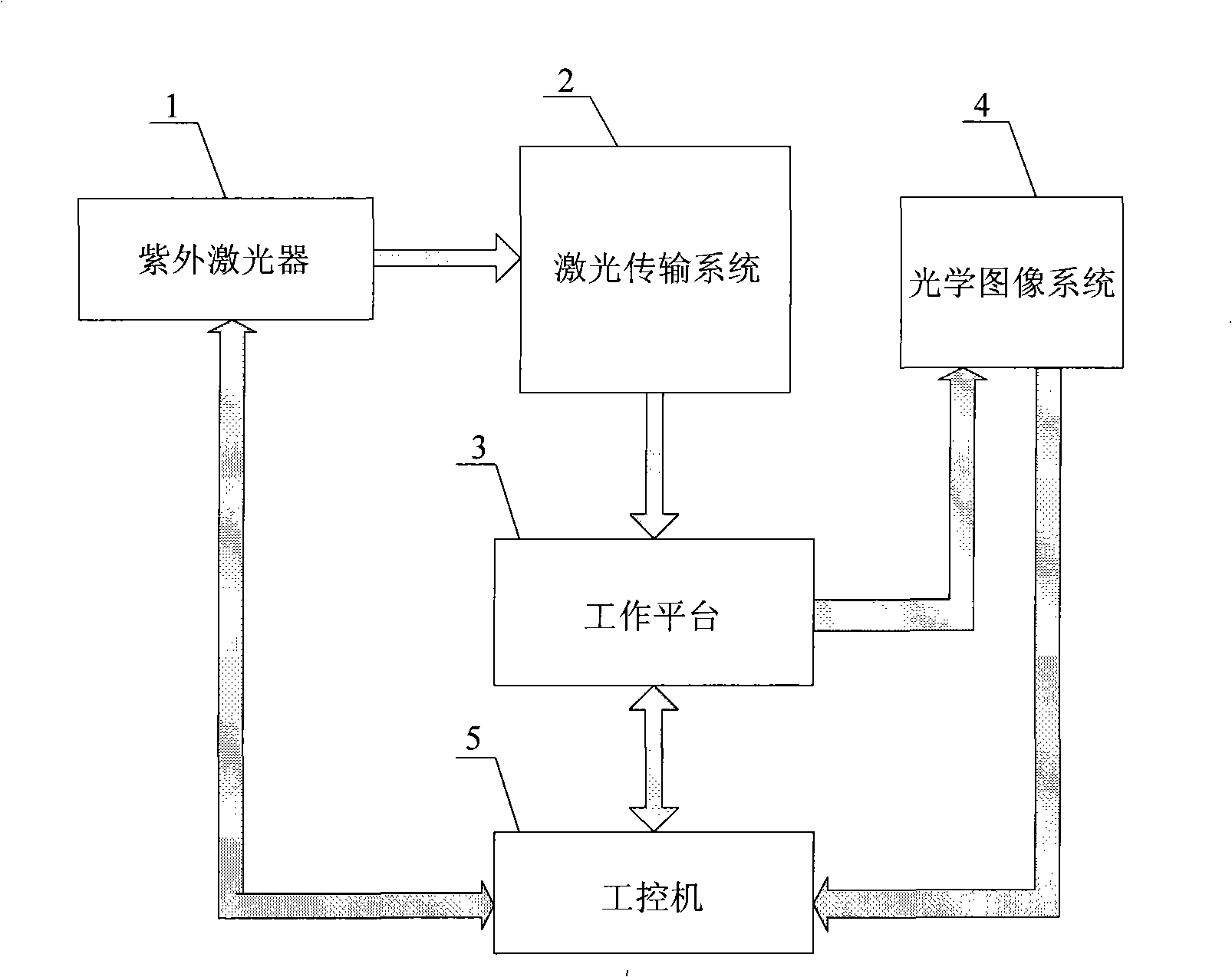

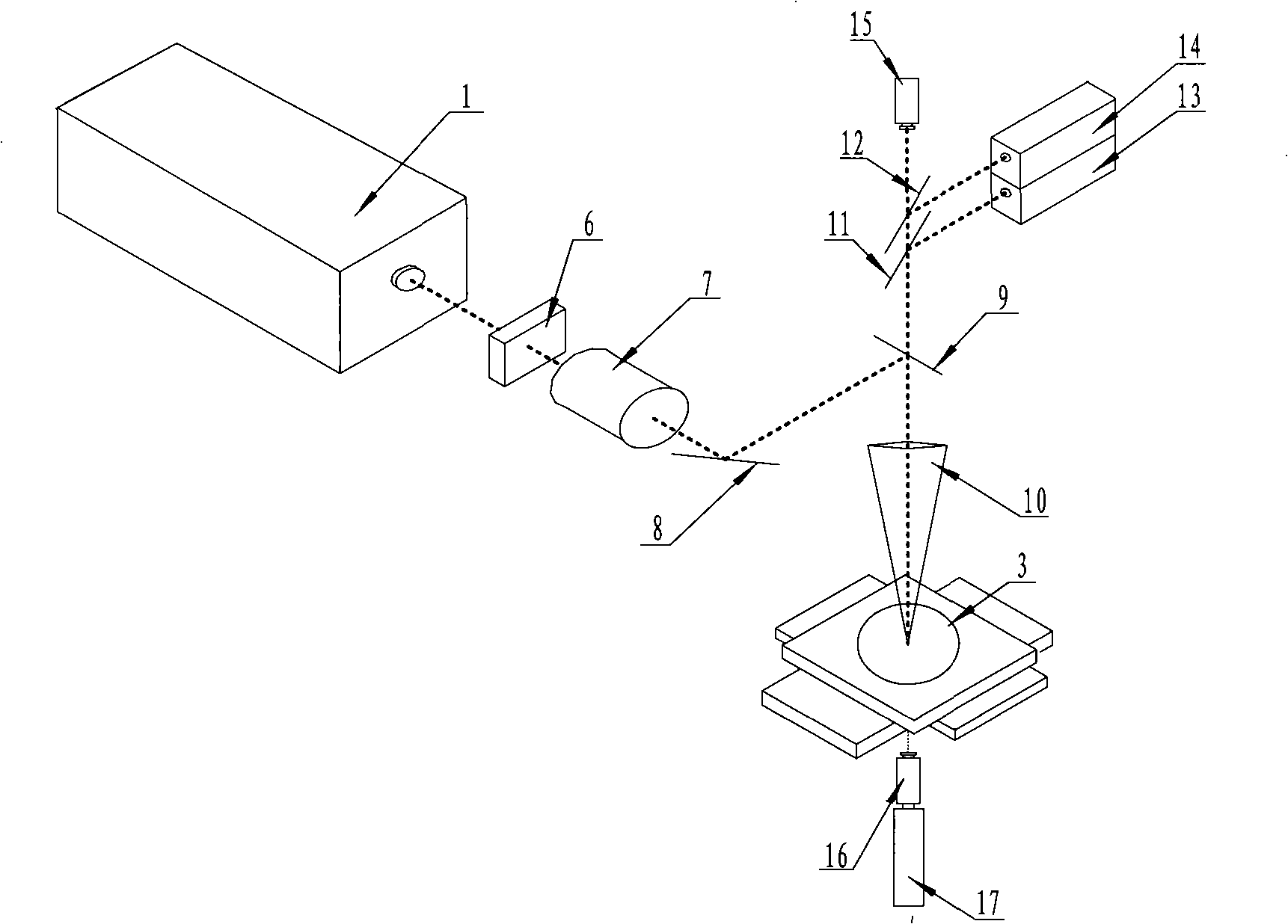

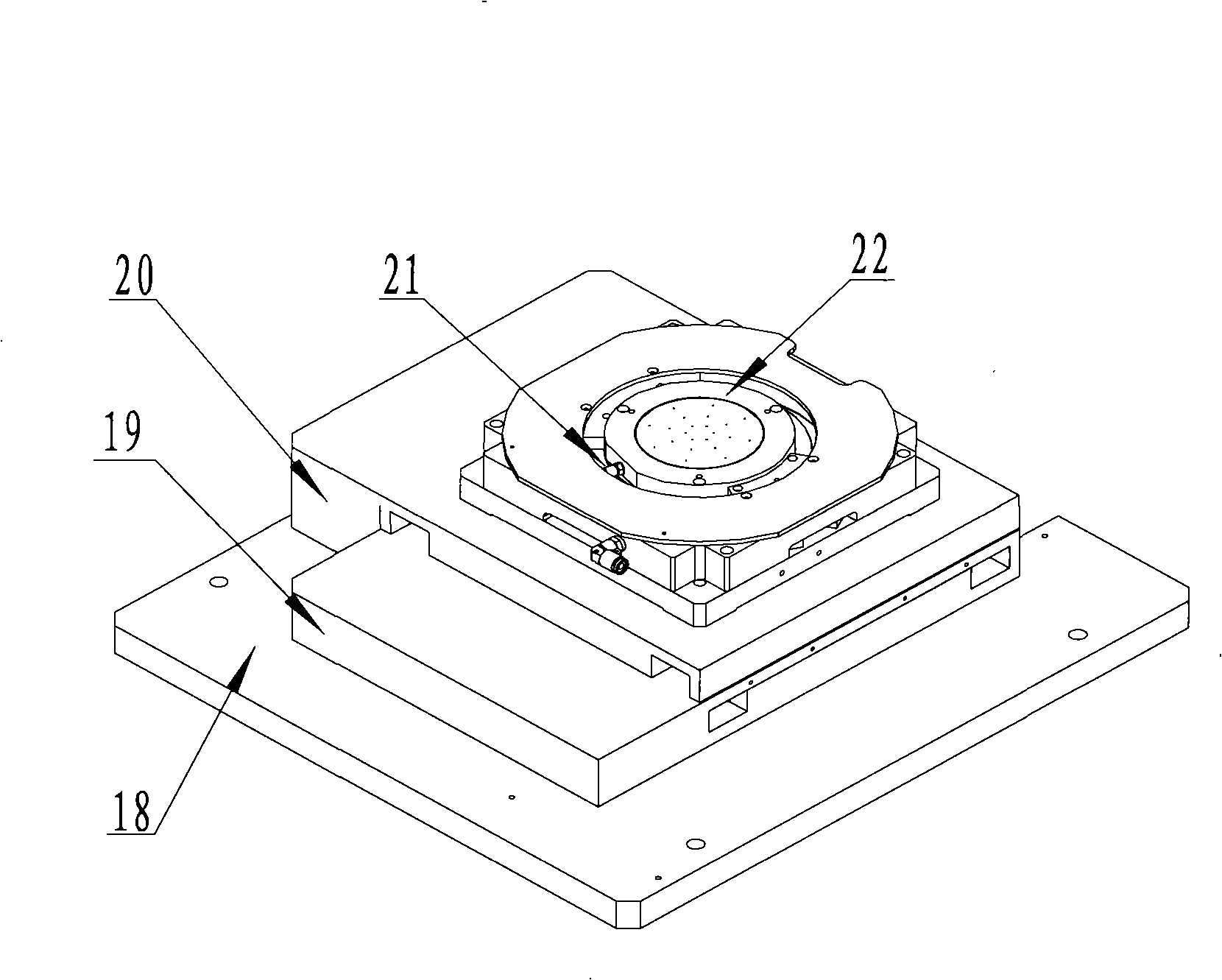

Design method for ultraviolet laser machining apparatus for cutting wafer

ActiveCN101318264AHigh vibration stability and positioning accuracyImprove cutting yieldSemiconductor/solid-state device manufacturingLaser beam welding apparatusOptical pathEnergy distribution

The invention relates to a design method for ultraviolet laser processing equipment used in the wafer cutting; lasers emitted by an ultraviolet laser are injected to a laser transmission system which can vertically inject focus spots with high energy density to a processing platform; the laser energy distribution focused on the surface of the processing platform is controlled by adjusting optical components in the laser transmission system; the wafer that is about to be processed is positioned and the cutting tracks are planned by an optical image system before the laser cutting; a laser optical axis keeps still and the processing platform carries out the linear motions along an X axis and a Y axis during the laser processing; an industrial computer conveys control instructions to the laser while the laser conveys state information to the industrial computer, and the optical image system transmits the taken image information of the work piece surface to the industrial computer to carry out the image processing. The design method adopts an optical path design with simple and complete functions, controls the spot energy distribution of the laser processing platform conveniently and flexibly and can be applied to the semi-conductor wafer sheet cutting of a plurality of materials and specifications.

Owner:SUZHOU DELPHI LASER +1

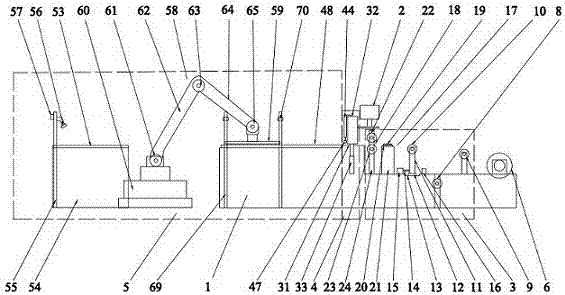

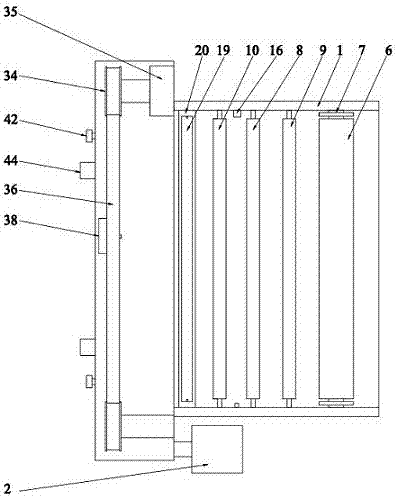

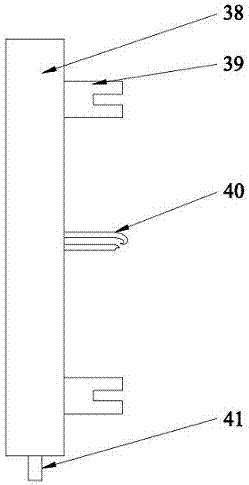

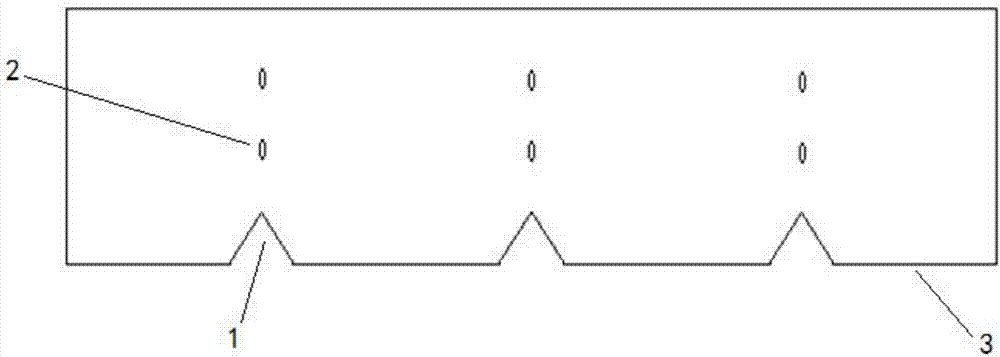

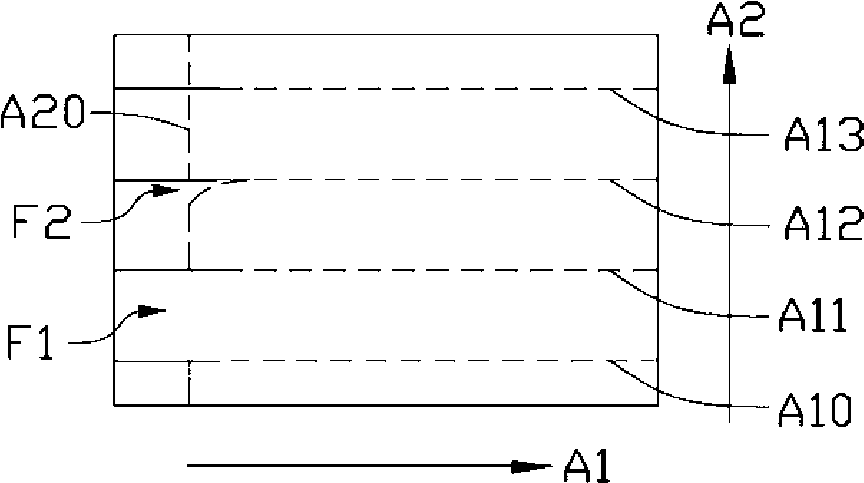

Full-automatic cloth cutting device

ActiveCN107354708AImprove cutting yieldReduce intensitySevering textilesMetal working apparatusHydraulic cylinderControl system

The invention relates to the field of cloth processing equipment, in particular to a full-automatic cloth cutting device which comprises a machine frame and a power distribution console. The machine frame is provided with a cloth feeding device, a cloth cutting device and a cloth collecting device. The front end of the cloth feeding device is provided with a raw material roller. The full-automatic cloth cutting device is characterized in that the cloth feeding device comprises a first cloth supporting roller, a tension roller, a second mop roller, a cloth pressing mechanism and a driving mechanism. The cloth cutting device comprises a cutting platform and a cutting lifting table which are connected through a cutting hydraulic cylinder. The cutting lifting table is provided with a linear guideway, a synchronizing wheel, a synchronous belt, a cutting knife, a limiting switch and a cloth pressing roller. The cloth collecting device comprises a belt conveying platform, an image collector, an automatic cloth detection platform, an industrial camera and a robot cloth collecting mechanism. The robot cloth collecting mechanism comprises a mechanical hand, a sucker mechanism and a control system. The sucker mechanism comprises a sucker support and a vacuum sucker. The full-automatic cloth cutting device can implement automatic calibration, automatic cloth cutting, automatic cloth collection and cloth detection, and the cutting yield and working efficiency are greatly improved.

Owner:WEIHAI BAOWEI NEW MATERIAL TECH CO LTD

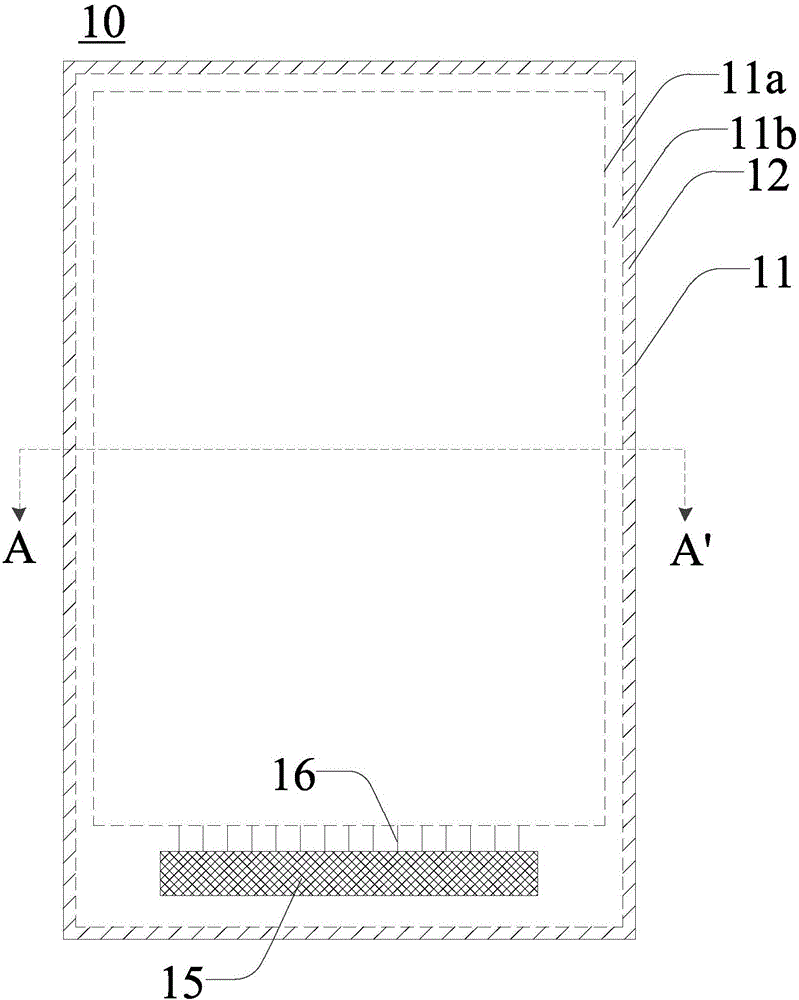

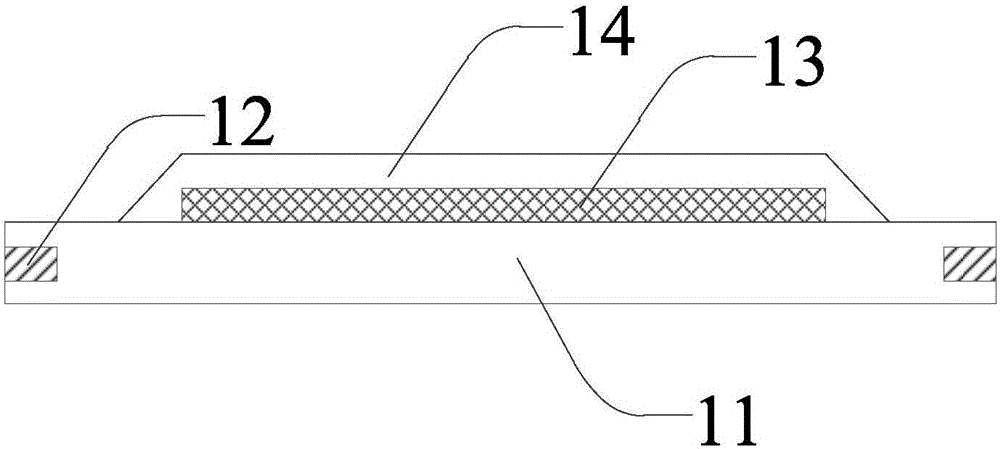

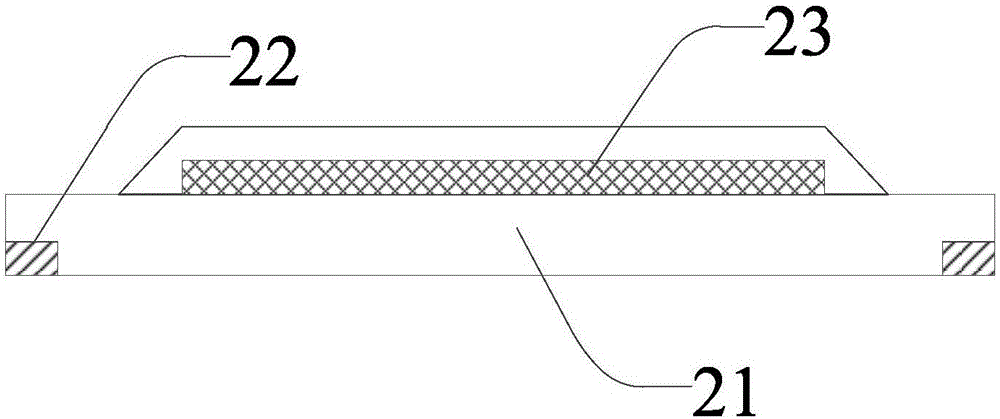

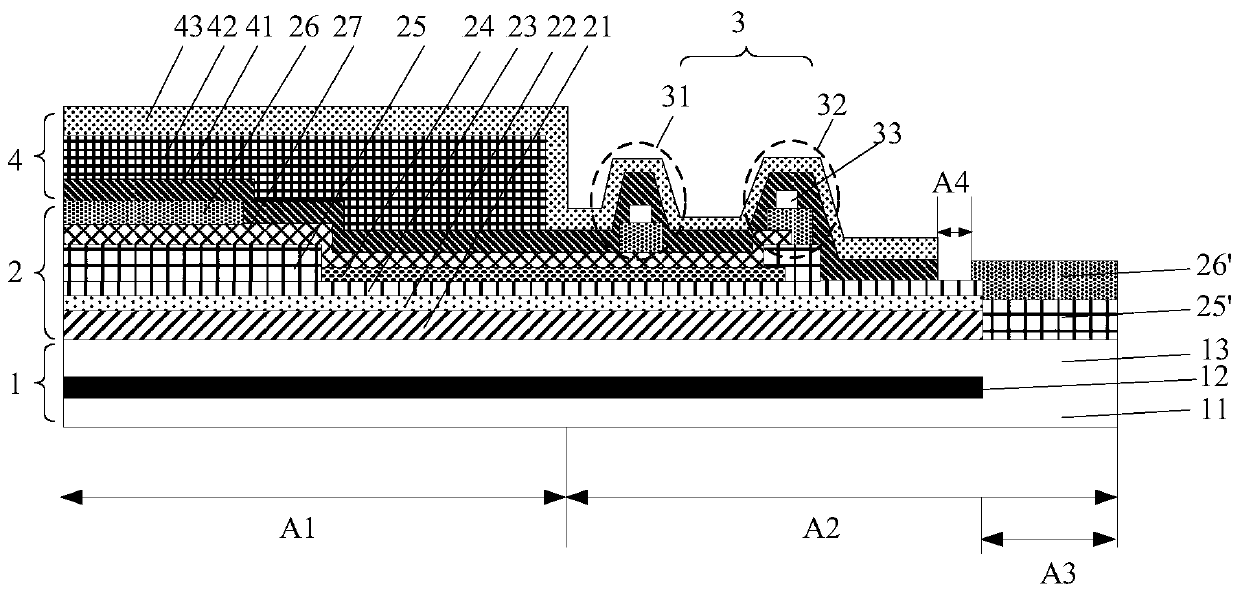

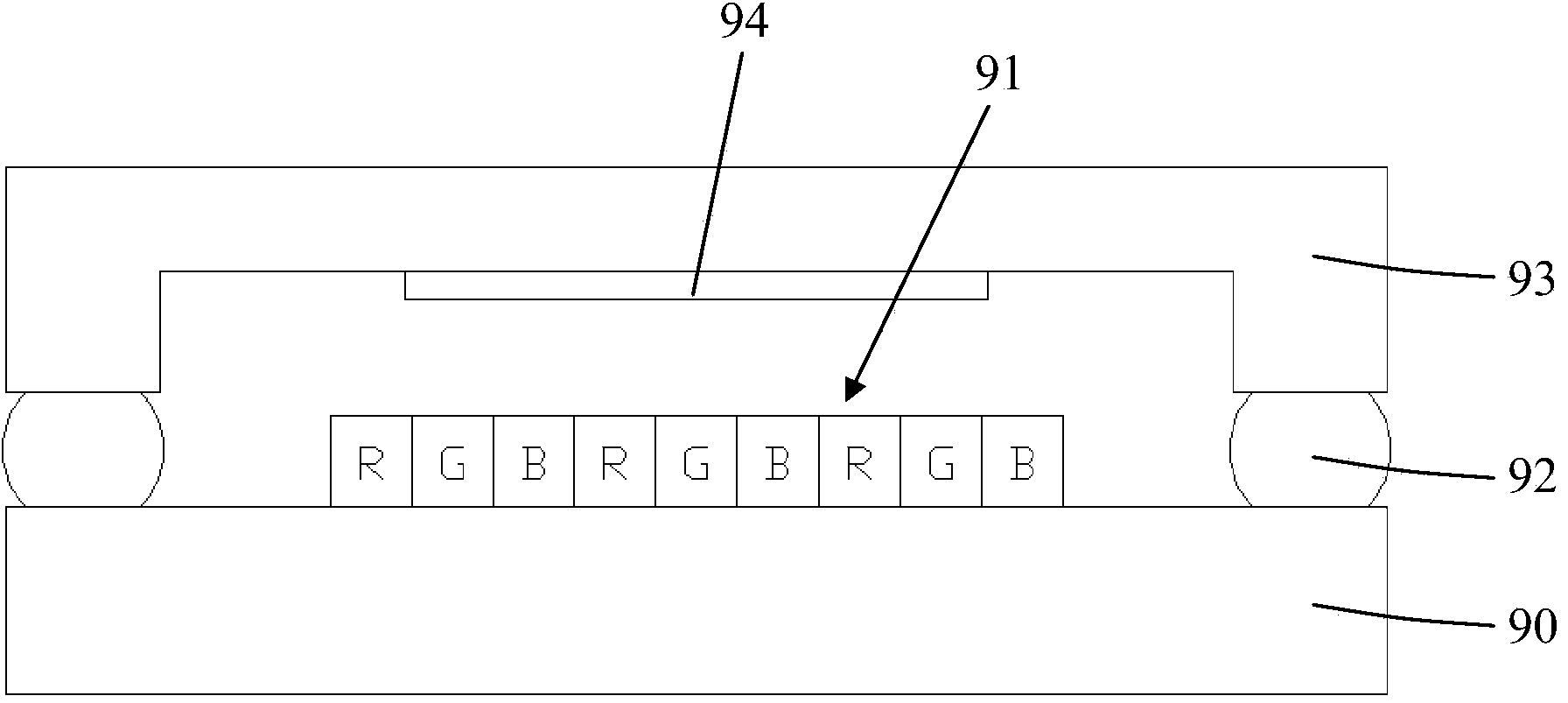

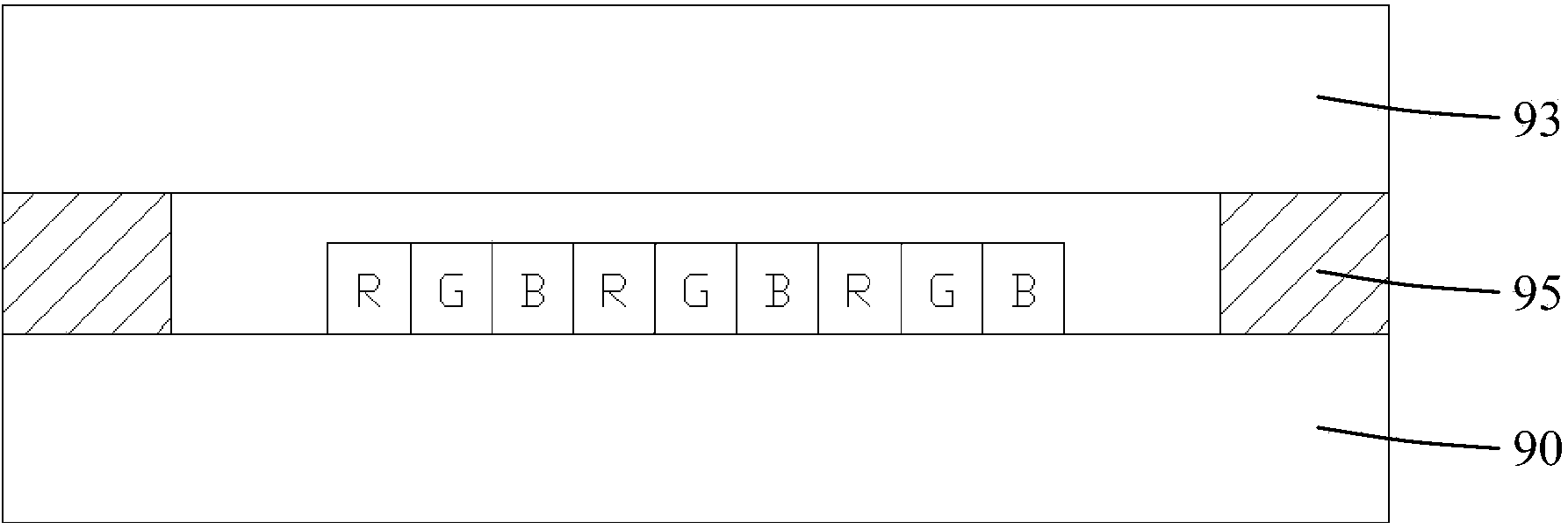

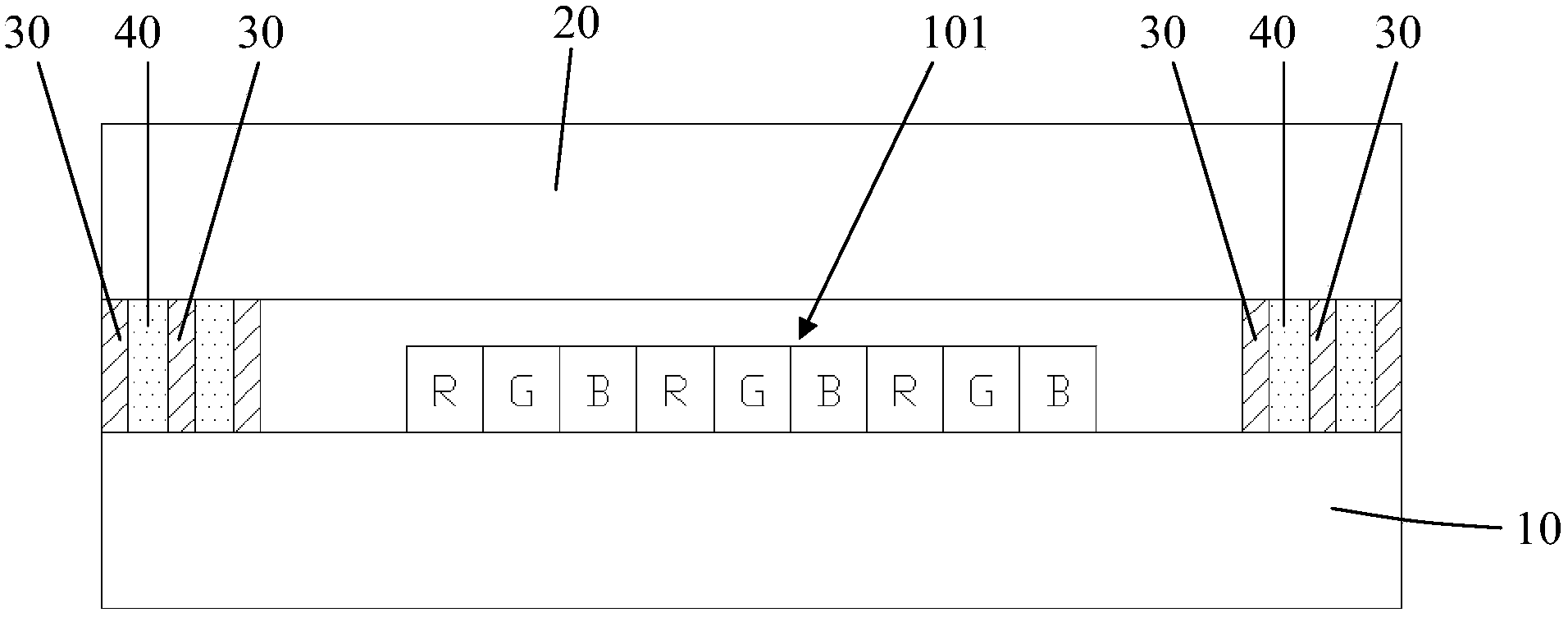

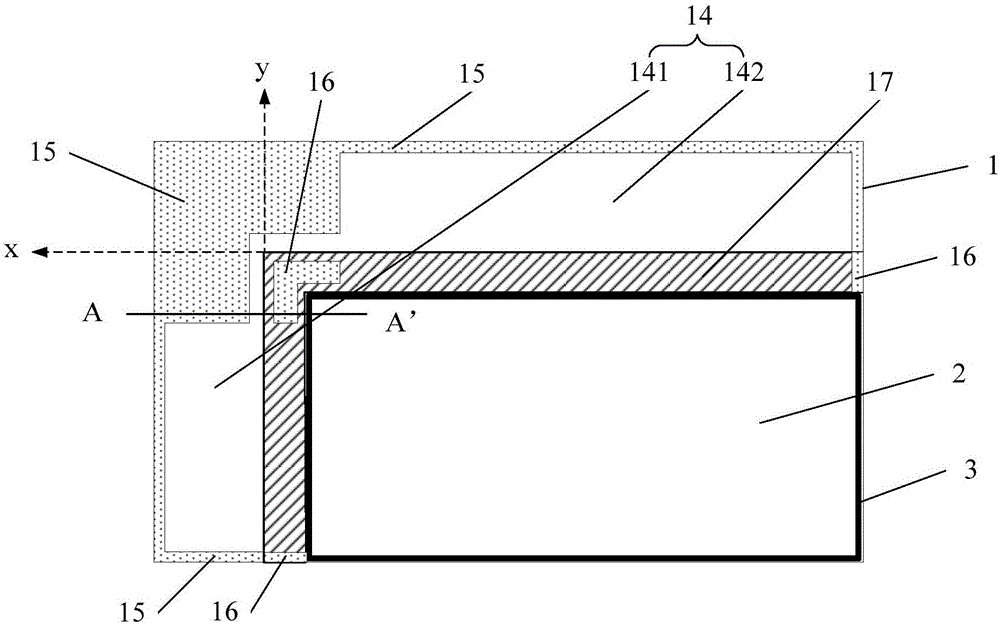

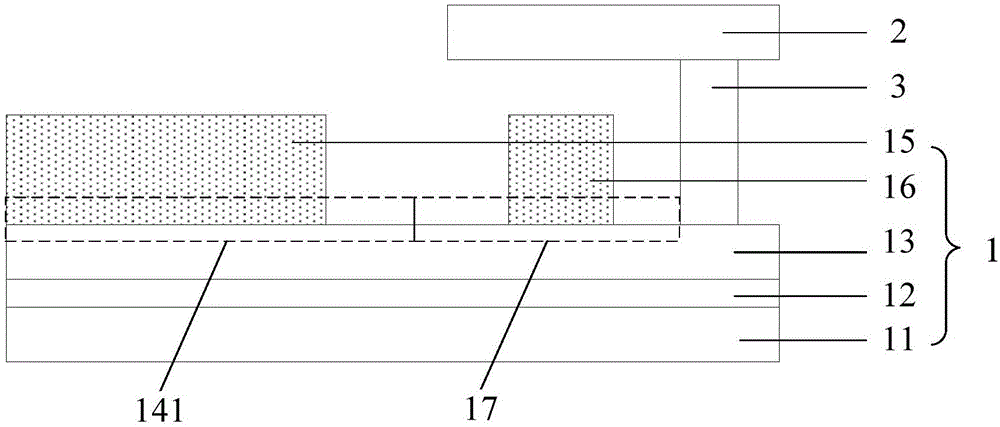

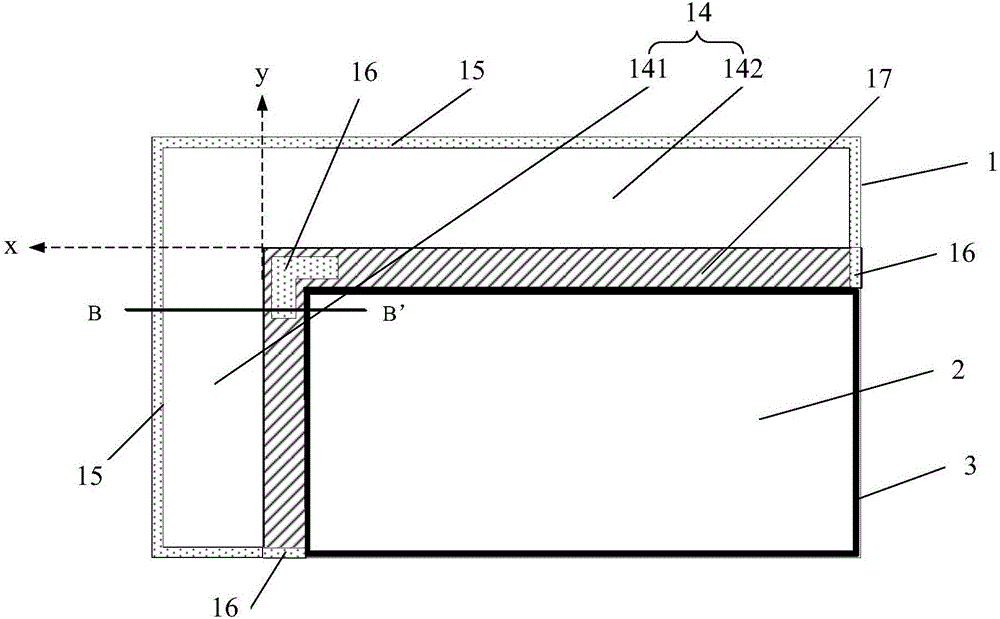

Display panel, display panel motherboard and manufacturing method thereof

InactiveCN106409875ADecreased heat absorptionAvoid damageFinal product manufactureSolid-state devicesEngineeringAbsorption effect

The invention provides a display panel, a display panel motherboard and a manufacturing method thereof. The display panel comprises a substrate comprising a display region and a frame region surrounding the display region; a display element arranged on the substrate and in the display region; and a heat-conductive pattern layer arranged in the frame region of the substrate, wherein at least a part of the heat-conductive pattern layer is embedded in the substrate, and the heat-conductive pattern layer surrounds the display region. In the cutting process of the display panel motherboard, the generated heat can be absorbed or exported by the heat-conductive pattern layer, so that damage to the display element and a film encapsulation layer can be reduced; and meanwhile, reduction of heat conduction and heat absorption performance due to melt and breakage of the heat-conductive pattern layer can be prevented, and thus heat conduction and heat absorption effects of the heat-conductive pattern layer are ensured, and cutting qualified rate is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

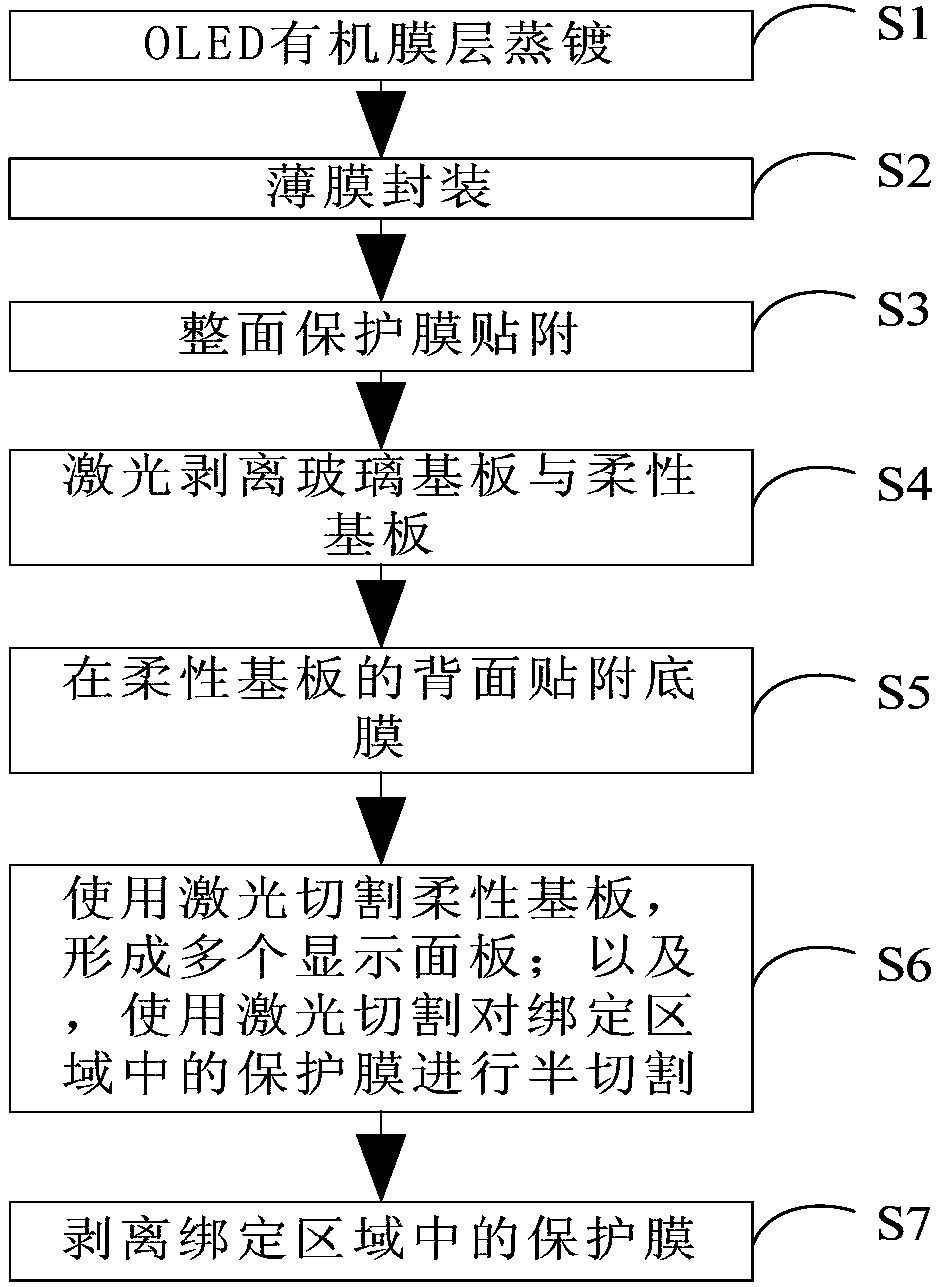

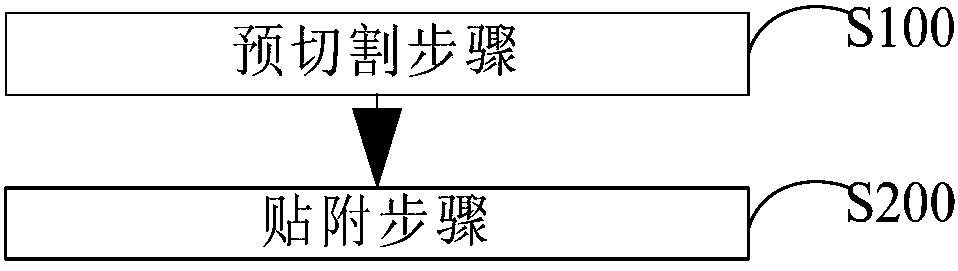

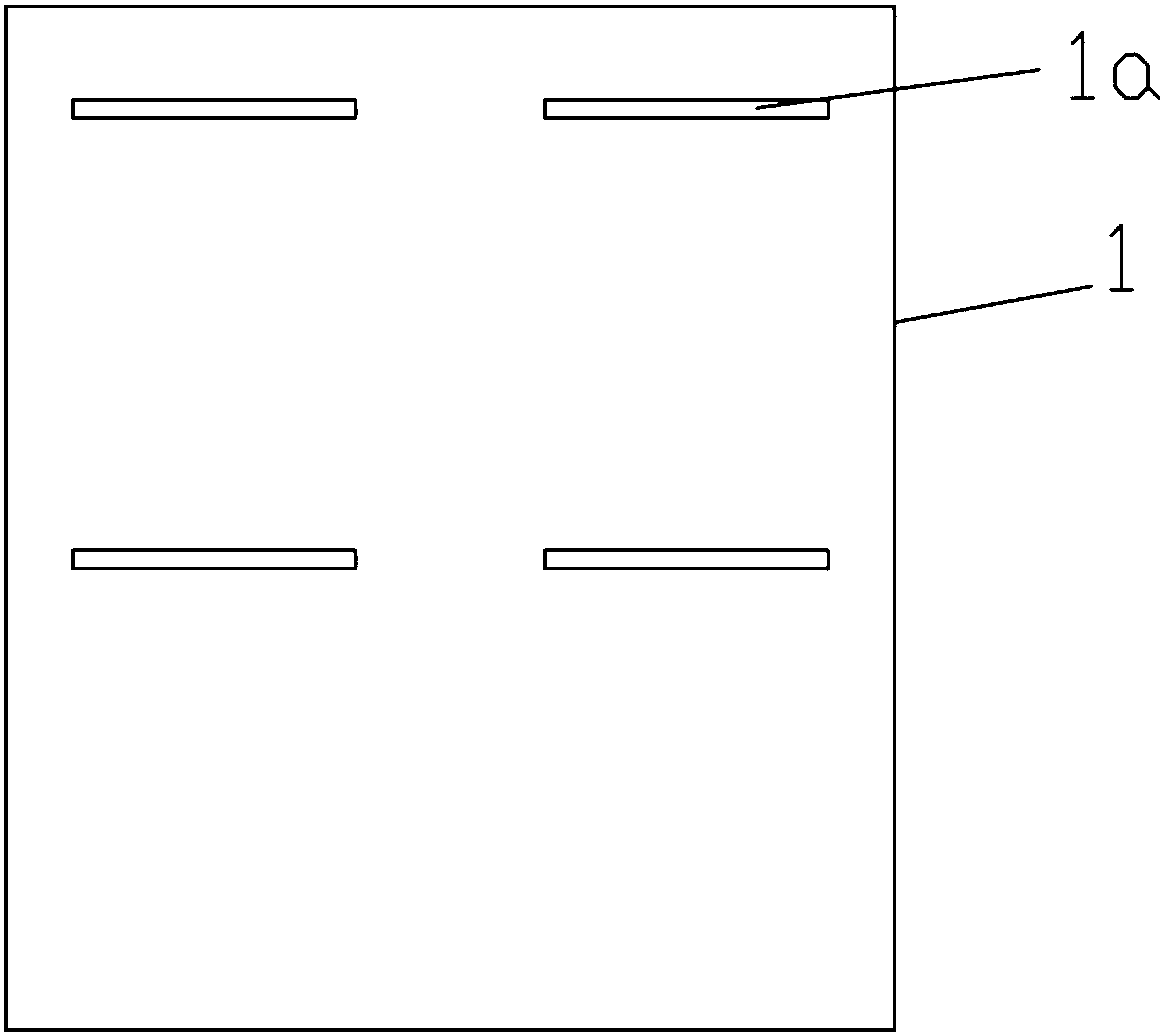

Coating attaching method, display panel and manufacturing method of display device

ActiveCN107650484AAvoid cutsAvoid the problem that the film layer cannot be cutLamination ancillary operationsLaminationDisplay deviceEngineering

The invention provides a coating attaching method, a display panel and a manufacturing method of a display device. The coating attaching method includes: a step of pre-cutting: cutting a coating alongthe thickness direction to remove a part corresponding to a first zone in a binding area of the display panel; a step of attaching: aligning the coating after being cut and the display panel, and attaching the film onto a to-be-attached surface of the display panel to enable an area where the removed part of the coating is located to correspond to the first zone of the display panel. By the technical scheme, the problem that a lead in the binding area is cut off or the coating cannot be cut off can be avoided, so that cutting yield and automated operation are improved.

Owner:BOE TECH GRP CO LTD

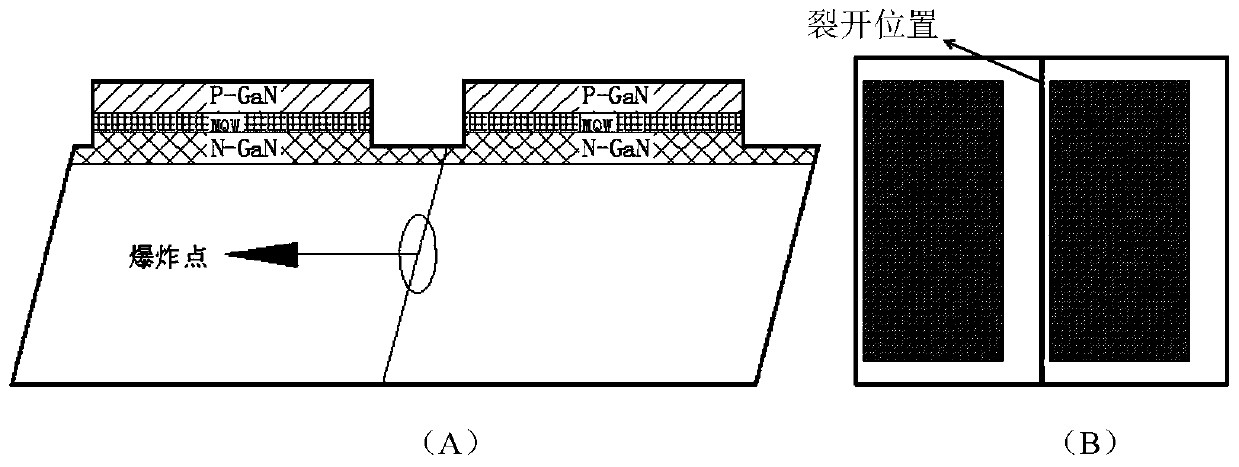

Method for cutting sapphire substrate LED chip through lasers

InactiveCN107538136AAvoid twinsAvoid chippingLaser beam welding apparatusSemiconductor devicesScriberOptoelectronics

According to a method for cutting a sapphire substrate LED chip through lasers, a paddle with the depth being 20-40 [mu]m is cut in the face, with an electrode, of a wafer through an ultraviolet laserwafer scriber; and modified layers are formed in the mode that an invisible laser wafer scriber is utilized to act on the interior of the wafer, that is, the different modified layers are formed in the mode that the lasers are focused on the positions, with different depths, of the wafer through adjustment of the laser focus depth of the invisible laser wafer scriber, and cracks generated throughstress releasing of the modified layers can be connected together. The sapphire substrate wafer machined through the method is cleaved in the direction of the cracks through a piece cleavage machine,so that the sapphire substrate wafer is cut into independent light emitting units, and thus, cutting is completed. According to the method for cutting the sapphire substrate LED chip through the lasers, the sapphire substrate wafer with the large thickness and size is cut, the cutting yield of the sapphire substrate wafer can be effectively increased, the cut chip is prevented from generating thephenomena of crystal twin, edge breakage and oblique cracking, and the appearance yield rate of the cut chip is effectively increased.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

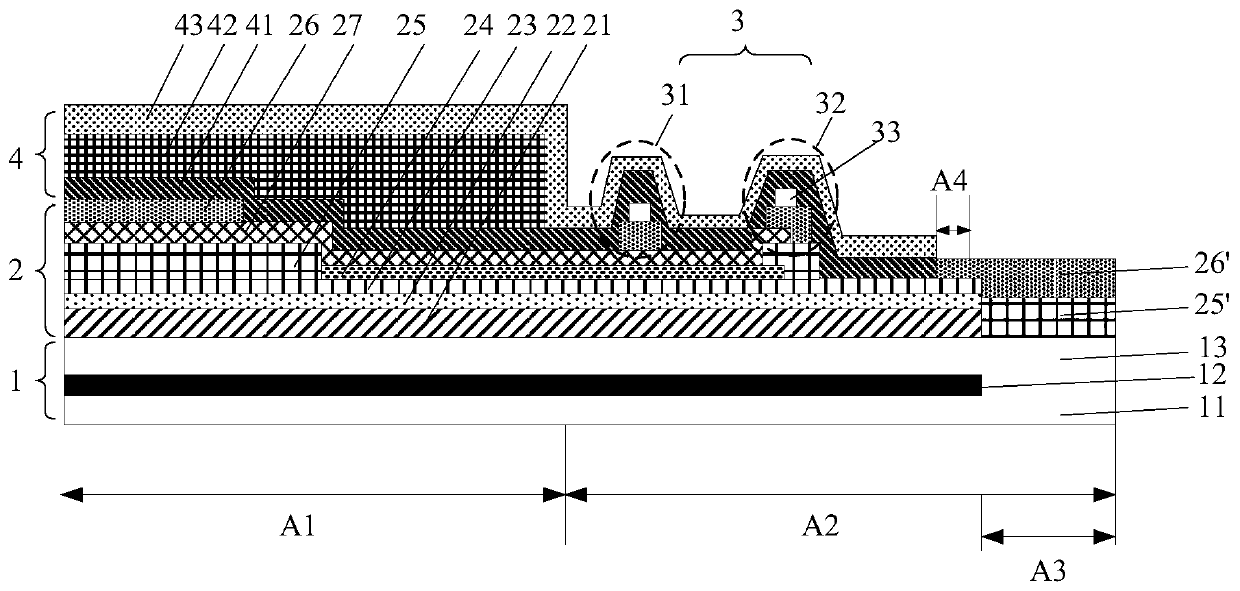

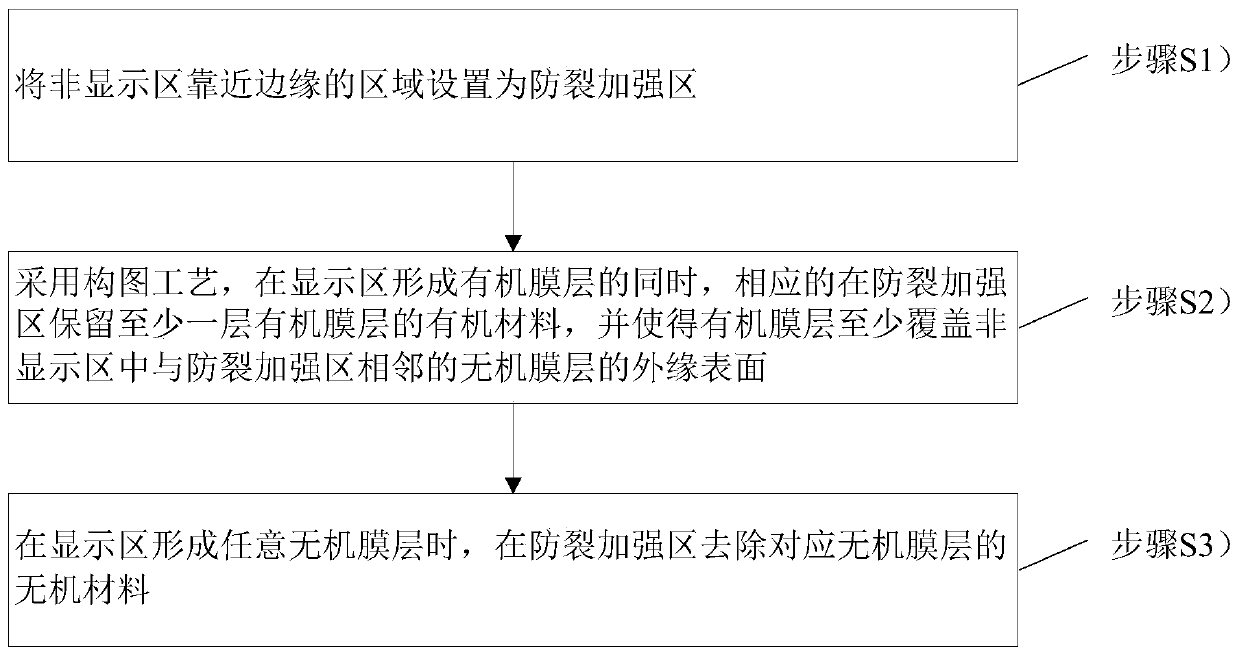

Display substrate, preparation method thereof and display device

ActiveCN109728200AImprove the display effectImprove impact resistanceSolid-state devicesPhotomechanical apparatusOrganic filmDisplay device

The invention relates to a display substrate, a preparation method thereof and a display device, and belongs to the technical field of display. The display substrate comprises a substrate, and dividedinto a display area and a non display area positioned in the periphery of the display area, the display area includes multiple pixel areas, each pixel area is provided with a pixel structure, each pixel structure comprises organic and inorganic film layers arranged in a stacked way, the region, close to the edge, of the non display area serves as an anti-cracking reinforcement region which is only provided with the organic film layer, and the organic film layer at least covers the outer surface of the inorganic film layer adjacent to the anti-cracking reinforcement region. Thus, the inorganicfilm layer is fundamentally prevented from a crack caused by an outside force, crack transfer is eliminated, and further, the framework is narrowed, the anti-impact performance of the display substrate is improved, the cutting energy is reduced, the cutting yield rate is improved, and the cutting effect is improved.

Owner:BOE TECH GRP CO LTD +1

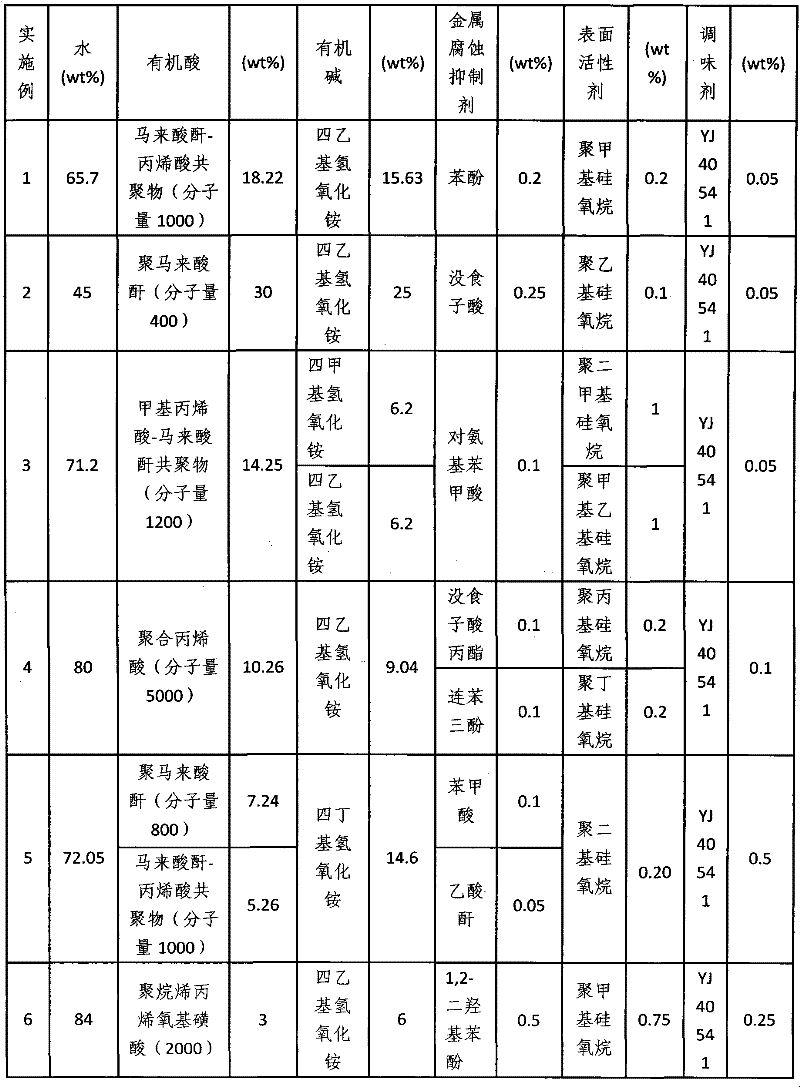

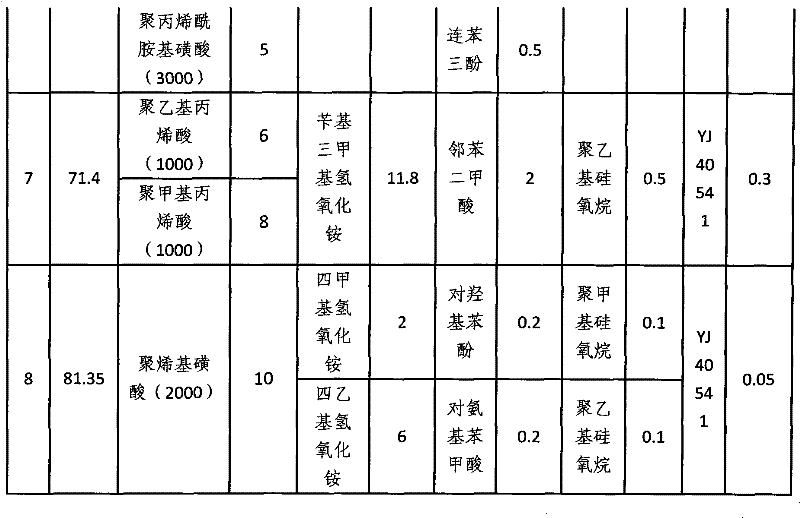

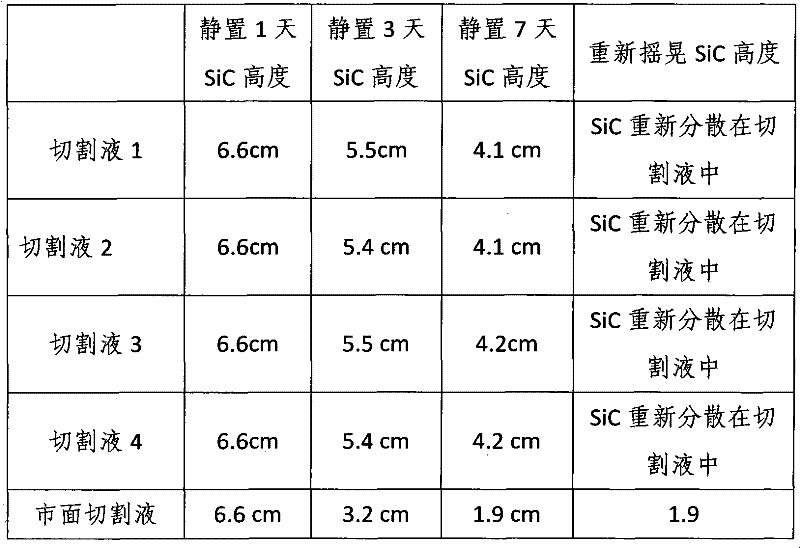

Solar silicon wafer cutting liquid

InactiveCN102093925AGood dispersionGuarantee stabilitySemiconductor/solid-state device manufacturingBase-materialsPolyethylene glycolSlurry

The invention discloses solar silicon wafer cutting liquid. The solar silicon wafer cutting liquid contains polyethylene glycol, a dispersant, a surfactant, a defoamer and a chelating reagent. The solar silicon wafer cutting liquid can improve the dispersibility and the redispersibility of silicon carbide so as to ensure the stability and the durability of slurry, can realize 100 percent recovery of the silicon carbide, greatly reduces the cost, can reduce the surface damage of a slice and the pollution of mechanical stress, thermal stress and metal ions to a silicon wafer, contributes to subsequent cleaning of the silicon wafer, improves the conversion efficiency of a rear-end solar battery, can effectively improve the thickness error of the silicon wafer and improves cutting yield.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Cutting fluid for water-soluble monocrystalline silicon wafers or polycrystalline silicon wafers

ActiveCN102021070AImprove wettabilityAvoid wafer surface damage or crackingLubricant compositionSolventWater soluble

The invention discloses a cutting fluid for water-soluble monocrystalline silicon wafers or polycrystalline silicon wafers, relating to the production technology field of the water-soluble cutting fluid for photovoltaic material monocrystalline silicon or polycrystalline silicon. The cutting fluid mainly comprises polyethylene alkanediol segmented copolymers (molecular weight: 200 to 800), fluorocarbon surfactants or fluosilicic surfactants, wetting-dispersing agents, polar solvents and antibacterial agents. The cutting fluid provided by the invention has the advantages of greatly reducing the surface tension of the cutting fluid under an extremely low concentration, greatly improving the wettability of the cutting fluid on abrasive materials, and avoiding the surface damage or rupture ofthe silicon wafers caused by the reunited abrasive materials, thereby facilitating the improvement of the cutting precision and cutting yield, and meanwhile, the cutting fluid also reduces the cleaning difficulty of the wafer. The cutting fluid can be simultaneously suitable for the machining on monocrystalline silicon and polycrystalline silicon, and the cutting yield can reach 97 percent.

Owner:南通宏申化工有限公司 +1

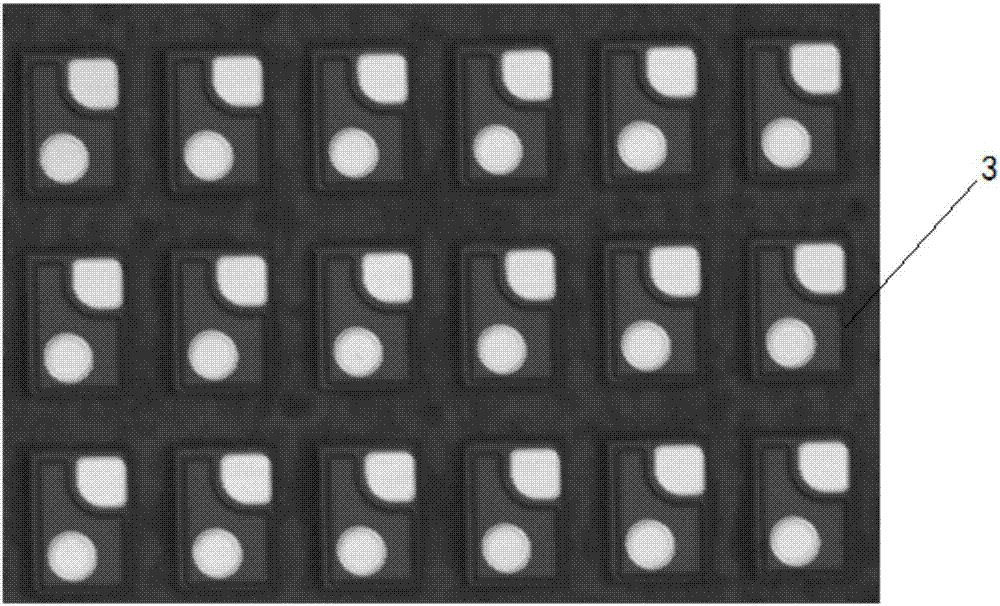

Packaging structure of OLED device and method thereof

InactiveCN103904253AReduce widthConstant widthSolid-state devicesSemiconductor/solid-state device manufacturingGlass coverMaterials science

The invention discloses a packaging structure of an OLED device and a method thereof. The method comprises the following steps: (1) providing a glass substrate and preparing an OLED light unit on the glass substrate; (2) providing a glass cover plate, and coating the periphery of the surface with a plurality of layers of glass cement material in the radial direction at equal intervals, wherein the periphery of the surface is close to the edge of the glass cover plate; (3) conducting curing processing on the glass cement material; (4) attaching the glass cover plate to a glass substrate; (5) conducting sintering processing on the glass cement material, and sealing the glass cover plate to the glass substrate. Due to the fact that instant energy produced during sintering of the glass cement material is in direct proportion to the width of the glass cement material, the glass cover plate is coated with the glass cement material at equal intervals to reduce the integral width of the glass cement material, thermal stress caused by instant high temperature in the sintering process can be reduced or diffused, and the cutting yield and sintering success rate are increased.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

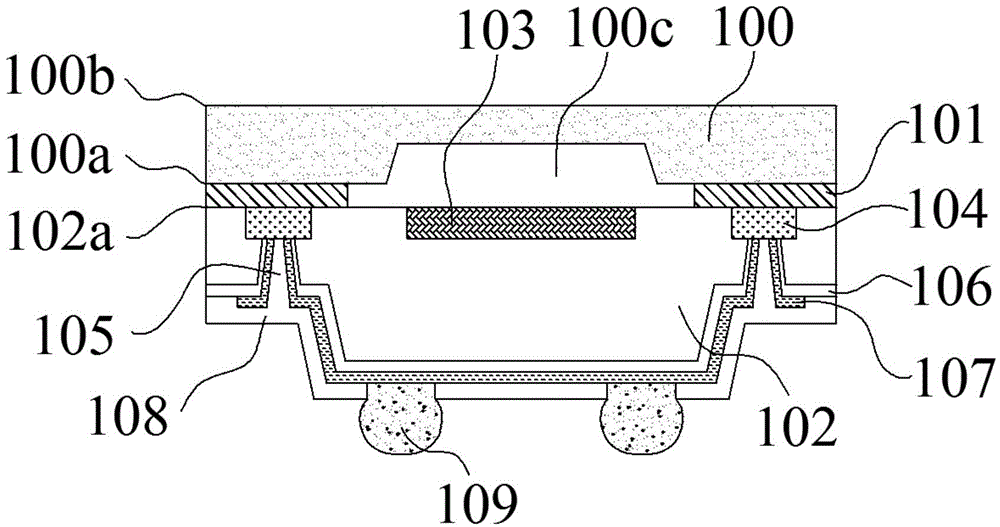

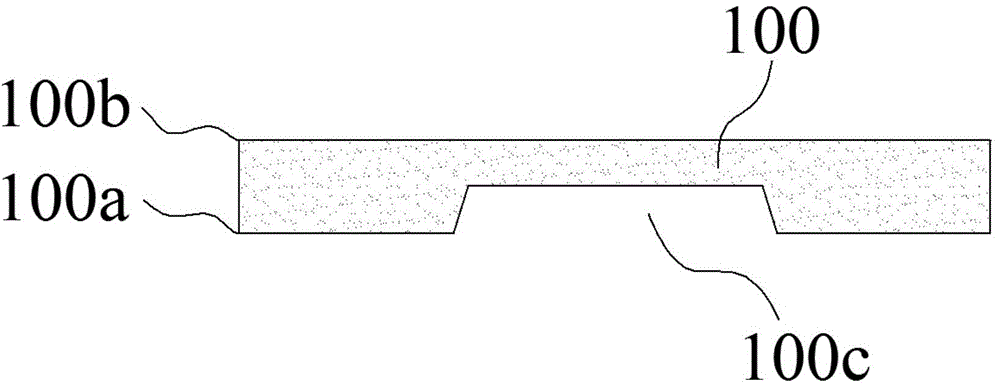

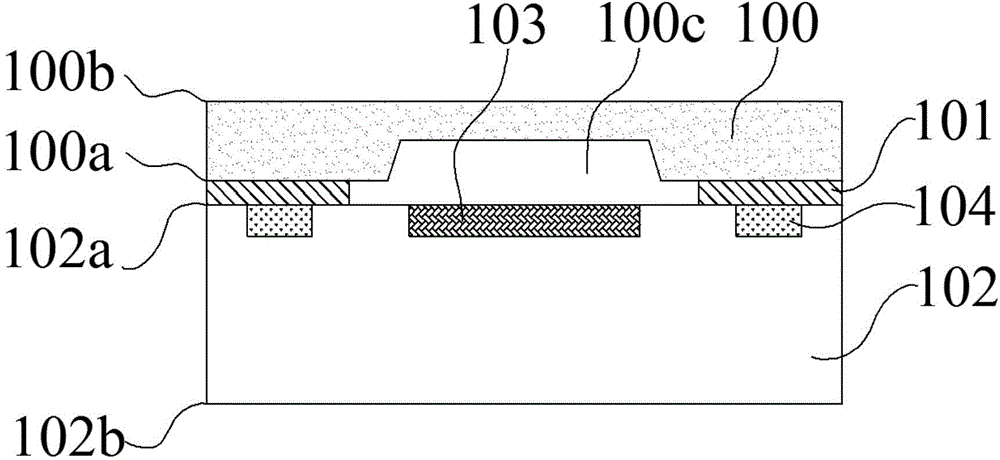

Low-thickness and low-cost chip size package with cavity

InactiveCN104409422AImprove reliabilityReduce thicknessTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesRedistribution layerChip size

The invention discloses a low-thickness and low-cost chip size package with a cavity, and belongs to the field of packaging of semiconductors. The package structure comprises a cover plate, a wafer, a function region, bonding pads, bonding glue, silicon through holes, a redistribution circuit layer and a solder ball, wherein a cavity structure is formed in the front surface of the cover plate; the wafer comprises a wafer front surface and a wafer back surface; the function region and the bonding pads are distributed on the wafer front surface; the bonding pads are distributed on the periphery of the function region and are communicated with one another; the bonding glue is positioned between the cover plate and the wafer; the cover plate and the wafer are bonded together by the bonding glue; the bonding pads are exposed via the silicon through holes, so that the bonding pads are communicated with the a follow-up redistribution layer; the redistribution circuit layer is positioned on the wafer back surface and comprises a passivation layer, a metal layer and a solder layer; the bonding pads are communicated with the solder ball via the redistribution circuit layer; and the solder ball is positioned on the redistribution circuit layer of the wafer back surface. The thickness of the package is reduced, and the stress in the structure is also reduced. Moreover, the yield of a cutting process and the reliability of the package are improved.

Owner:BEIJING UNIV OF TECH

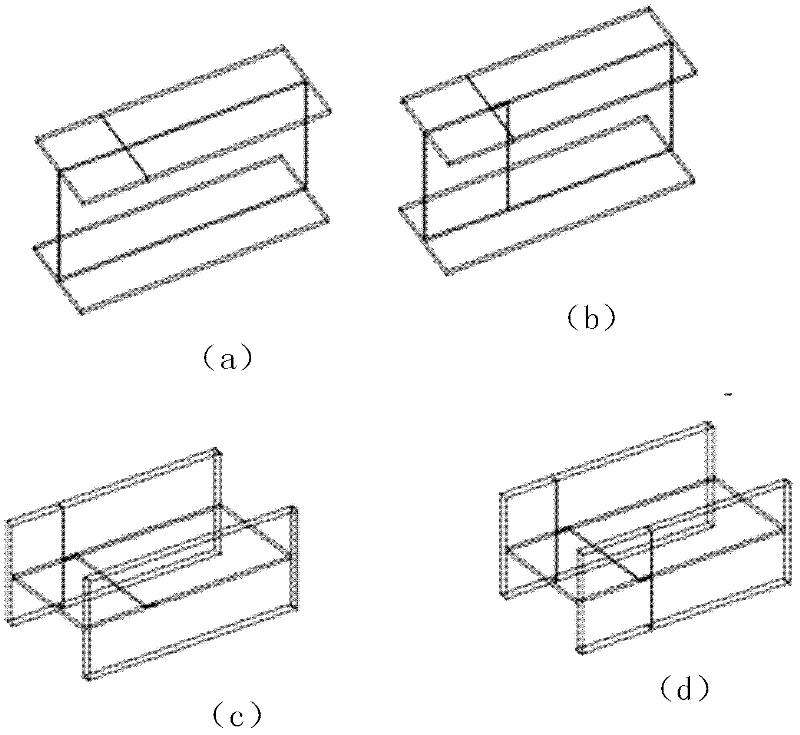

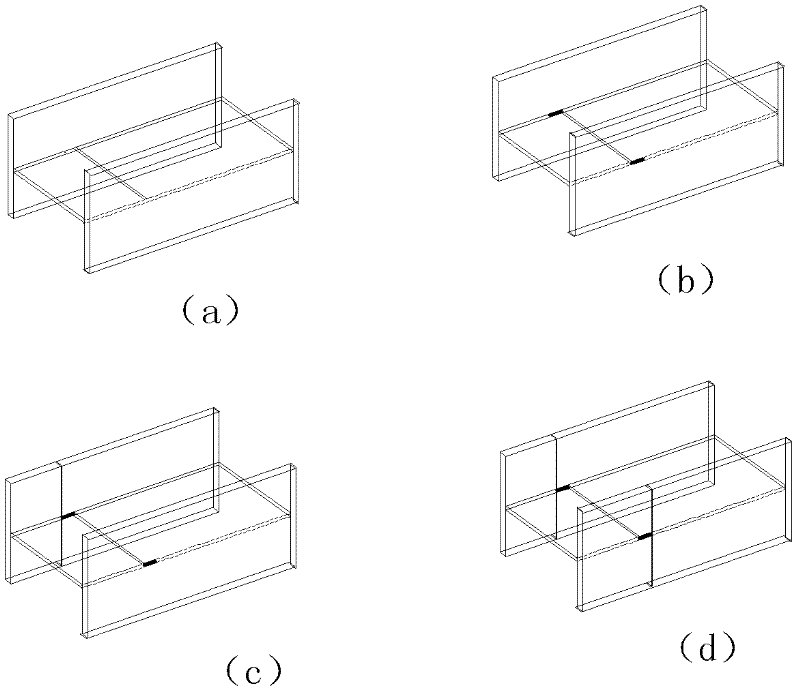

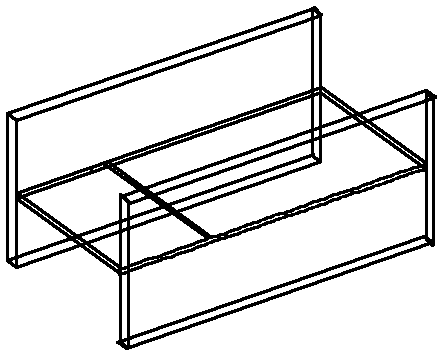

Cutting method of Z-shaped notch of H-shaped steel

ActiveCN102632313AGuaranteed internal stressMaintain internal stress balanceGas flame welding apparatusEngineeringInternal stress

The invention relates to a cutting method of a Z-shaped notch of H-shaped steel. The H-shaped steel is placed in the horizontal direction of a web plate. One cutting method comprises the following steps: firstly, cutting the web plate of the H-shaped steel according to the middle cutting edge of the Z-shaped notch; then cutting joints of the web plate of the H-shaped steel and wing plates at two sides respectively according to cutting edges at two sides of the Z-shaped notch so as to peel off partial connection between the web plate and the wing plates at two sides; and finally cutting the wing plates at two sides to form two sections of H-shaped steel with Z-shaped notches. The other cutting method is basically the same as the cutting method, and the only difference between the two cutting methods is that the execution sequence of the first cutting step and the second cutting step is changed. The technical scheme provided by the invention can be used for effectively avoiding adverse effects caused by internal stress in the cutting process and reducing the investment in lifting operation, thereby improving the cutting yield of the H-shaped steel, improving the working efficiency, and reducing the construction cost.

Owner:中色十二冶金建设有限公司

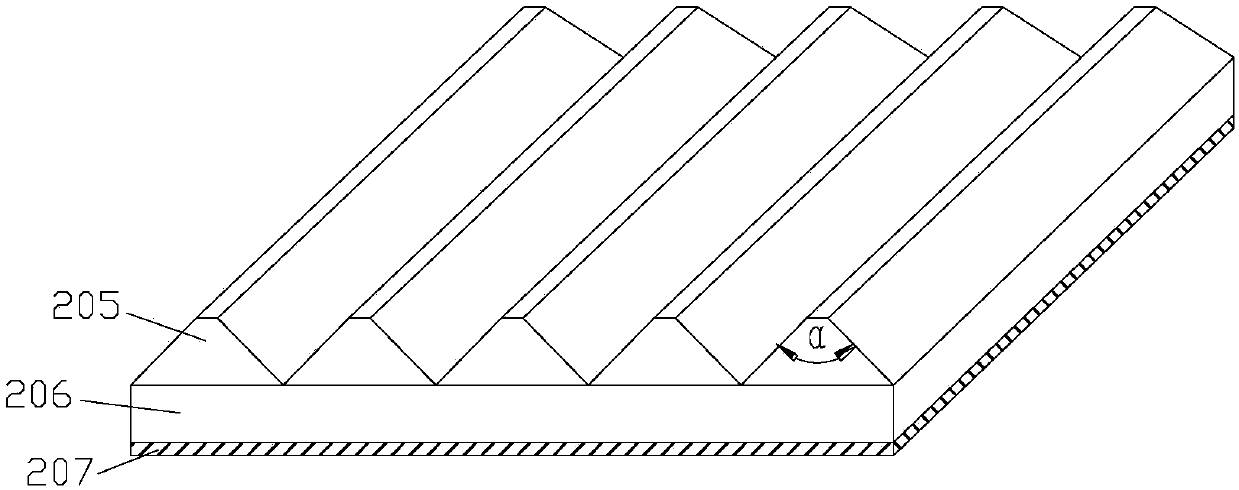

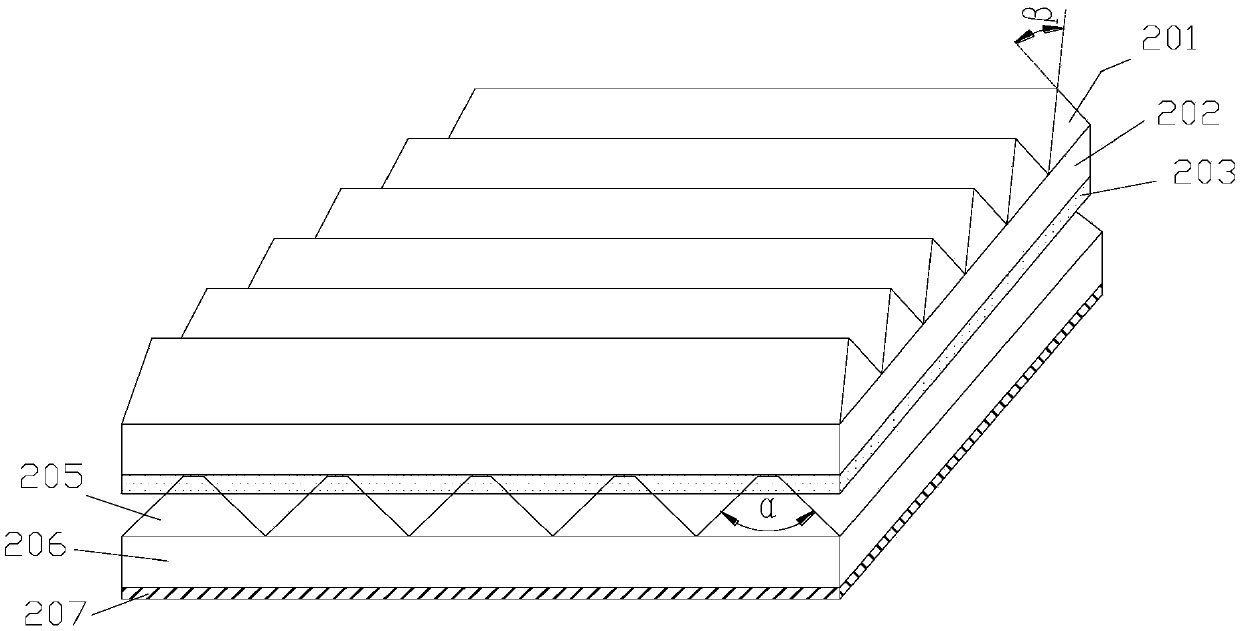

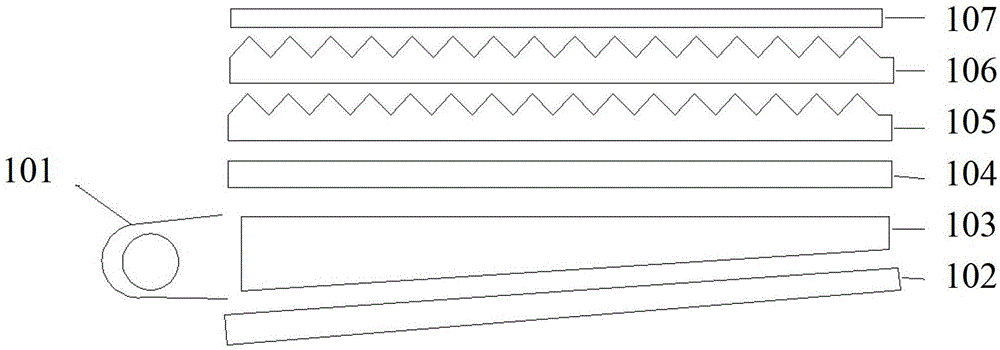

Multi-layer optical film

PendingCN107831561ANot prone to delaminationLess prone to problems such as peelingPrismsDiffusing elementsPrismAdhesion strength

The invention discloses a multi-layer optical film. The film comprises a first layer optical membrane and a second layer optical membrane. The first layer optical membrane is a prism membrane. The second layer optical membrane is one kind of a prism membrane, a diffusion membrane and a micro-lens membrane. The second layer optical membrane is coated with an adhesive layer. The first layer opticalmembrane and the second layer optical membrane are adhered together through the adhesive layer. According to the invention, due to the design of the prism structure, the adhesion strength between themultiple optical membranes can be improved by 50% or more than that of the current optical composite membrane; through the improving of the adhesion strength, the multiple optical membranes are free from problems of difficult layering and difficult stripping in following cutting, assembling and use; the cutting yield is improved; and the module assembly yield is improved.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

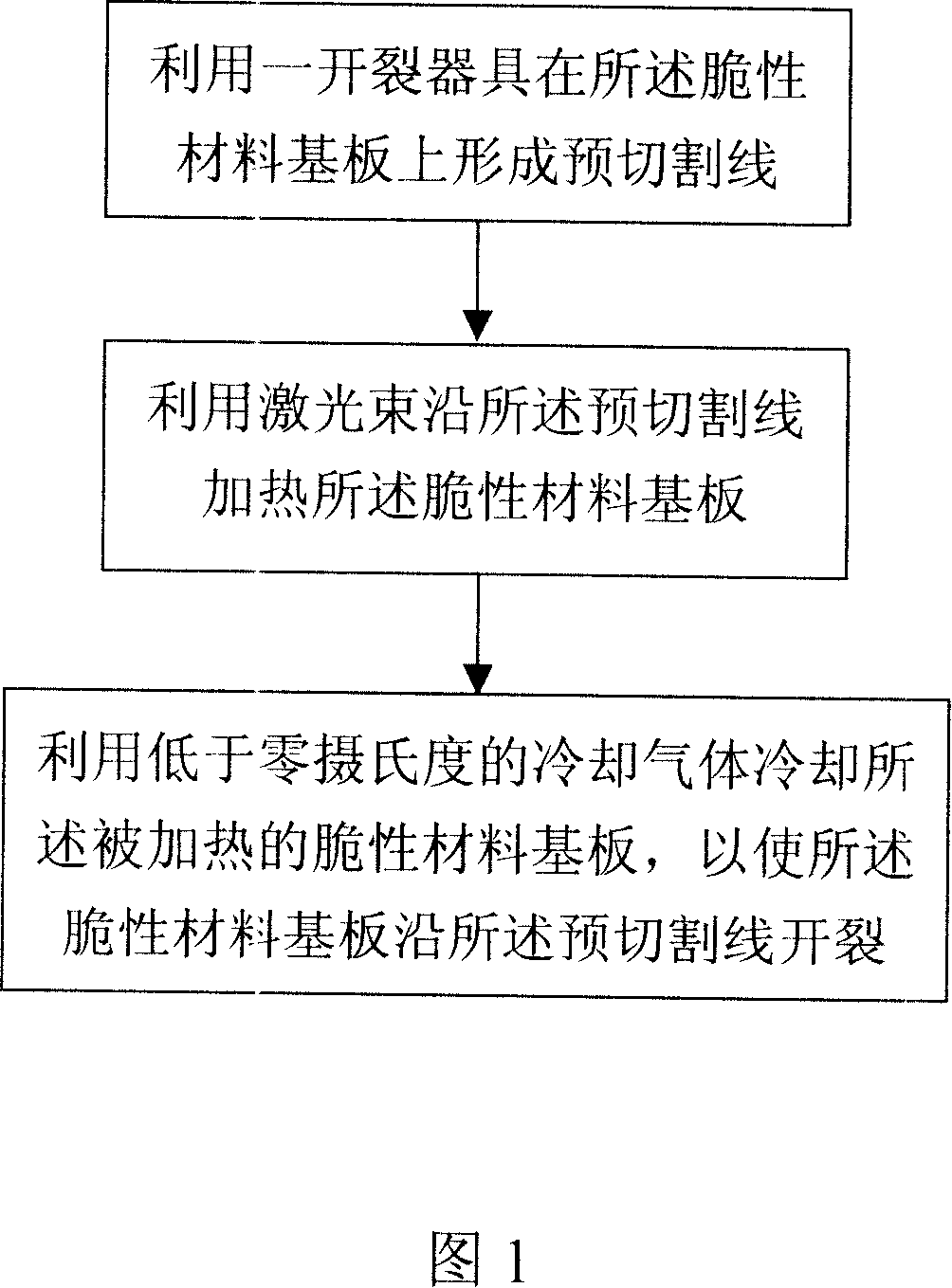

Laser cutting method

InactiveCN101130216AAffect normal workImprove cutting yieldLaser beam welding apparatusProduct gasLaser cutting

The invention discloses a laser cutting method to cut fragile material base, which comprises the following steps: utilizing a cracker to form pre-cutting line on the fragile material base; using laser beam to heat the fragile material base along the pre-cutting line; adopting gas lower than zero deg. c to cool the heat fragile material base without penetrating water among bases to influence the normal work to improve the cutting standard rate; cracking the fragile material base along the pre-cutting line. The invention uses gas not to remain residual drip on the surface of base, which needn't clean the base after cutting due to using gas as cooling flow, therefore reducing the manufacturing cost.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

Silica core connecting method

ActiveCN105329900AReduce wasteImprove cutting yieldSilicon compoundsPolycrystalline siliconMaterials science

The invention discloses a silica core connecting method which is used for connecting and recovering a first fracture silica core and a second fracture silica core. The silica core connecting method comprises a step A of heating the first fractured end of the first fracture silica core and the second fractured end of the second fracture silica core to 1100-1250 DEG C; a step B of causing the first fractured end to be in contact with the second fractured end, continuing heating the first fractured end and the second fractured end to 1300-1350 DEG C, and causing the first fractured end to be in fusion connection with the second fractured end; a step C of cooling the first fractured end and the second fractured end which are in fusion connection, and connecting and recovering the first fracture silica core and the second fracture silica core. According to the silica core connecting method, the fractured silica cores can meet the required length after being connected and recovered and can react in a reduction furnace to generate polycrystalline silicon, the production requirements are met, the silica core waste is reduced greatly, and the cutting yield is improved.

Owner:YELLOW RIVER PHOTOVOLTAIC IND TECH CO LTD

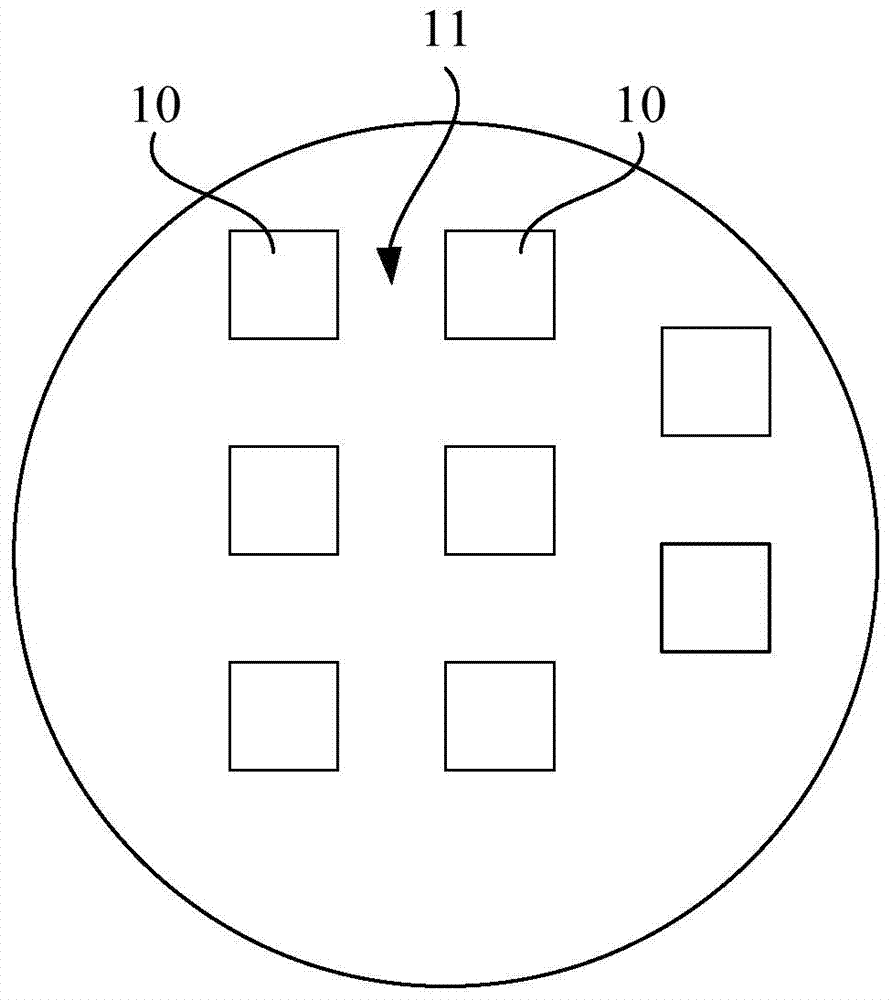

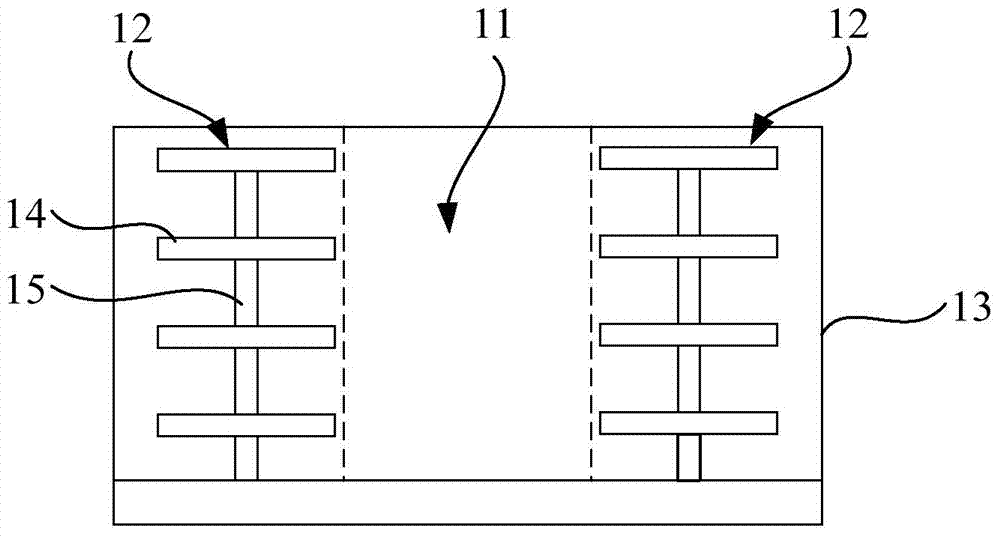

Semiconductor device and forming method thereof and method for improving cutting yield of wafer

ActiveCN104752325AGood interconnect performanceImprove cutting yieldSemiconductor/solid-state device detailsSolid-state devicesInterconnectionEngineering

Disclosed are a semiconductor device and a forming method thereof and a method for improving the cutting yield of a wafer. The forming method comprises providing the wafer, wherein the wafer is divided into a plurality of chip areas and cutting channels and every cutting channel is located between the two corresponding adjacent chip areas; forming an interlayer dielectric layer on the wafer; forming a plurality of layers of interconnection metal layers and plugging layers corresponding to the chip areas in the interlayer dielectric layer, wherein every two adjacent interconnection metal layers are electrically connected with each other through the corresponding plugging layer; forming a plurality of layers of pseudo plugging layers corresponding to the cutting channels in the interlayer dielectric layer, wherein every pseudo plugging layer comprises a plurality of pseudo plugs. When the semiconductor device is cut along the cutting channels, the stress produced at the position of every cutting channel is mainly applied to the corresponding pseudo plugs, the stress cannot be produced on or only small stress can be produced on the interlayer dielectric layer portion of the corresponding chip areas and the plugging layers in the interlayer dielectric layer portion, and accordingly fractures of the interlayer dielectric layer portion of the corresponding chip areas and the plugging layers in the interlayer dielectric layer portion are prevented, the good interconnection performance of the interconnection metal layers and the plugging layers of the chip areas is ensured, and accordingly the cutting yield of the wafer is significantly improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Wafer cutting method

InactiveCN105448826AAvoid chippingFragmentation Problems OvercomeSemiconductor/solid-state device manufacturingFine working devicesEngineeringSolvent

The invention relates to a wafer cutting method, and the method comprises the steps: A1, providing a wafer, and forming a trench in the wafer; A2, filling the trench with a temporarily selected material, so as to support the trench; A3, grinding of the back surface of the wafer, so as to expose the temporarily selected material; A4, removing the temporarily selected material, and exposing the trench, so as to complete the cutting of the wafer. In order to solve a problem that the grinding in the DRIE cutting technology causes the crack of the contour of the trench, the invention provides the new DRIE cutting method. In the method, the cavity of the trench is filled through temporary bonding glue after DRIE, the bonding glue is solidified through soft bake, and the back grinding is carried out, thereby enabling the edge of the wafer to be supported in a grinding process and not to be cracked. After grinding, a corresponding solvent is used for removing the temporary bonding glue, thereby solving a crack problem and improving the cutting efficiency and yield.

Owner:SEMICON MFG INT (SHANGHAI) CORP

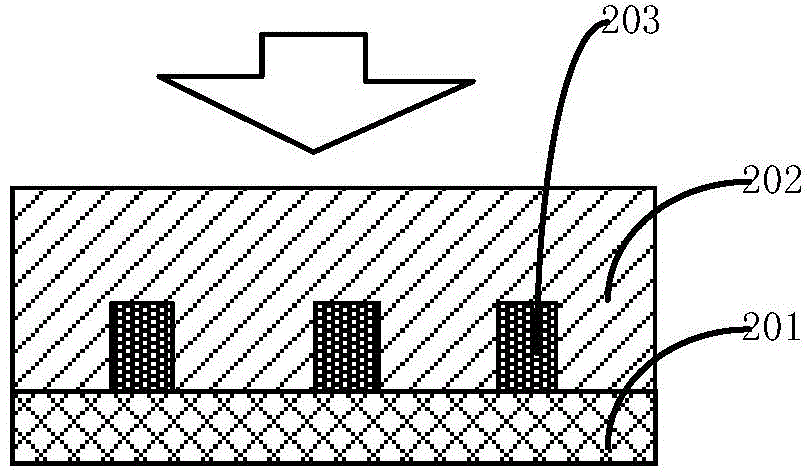

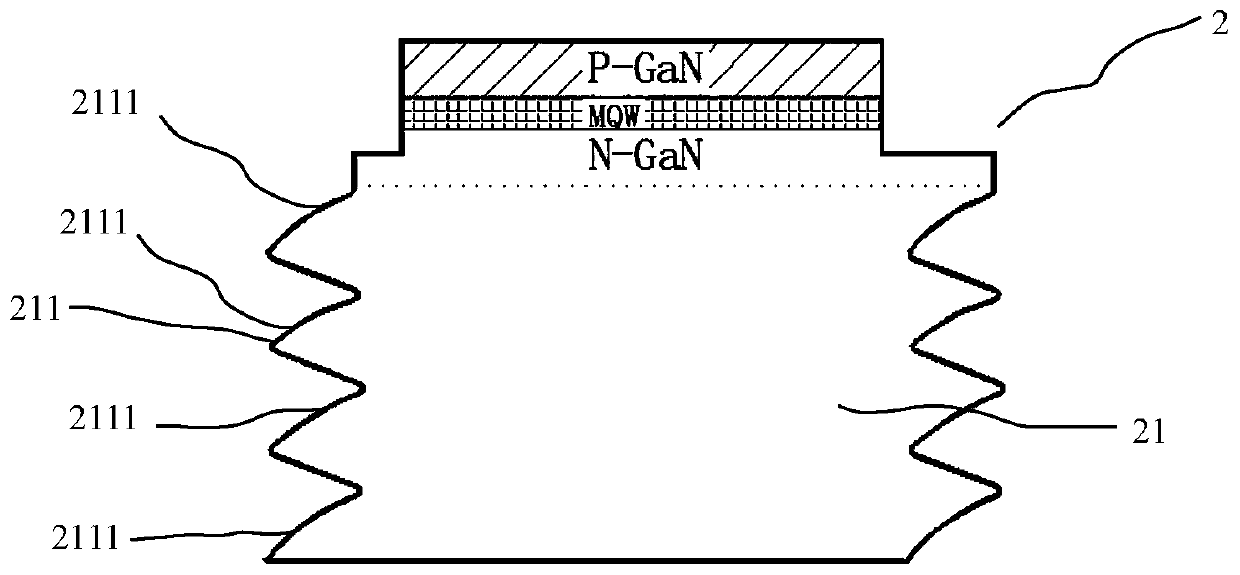

LED chiplet and LED chip invisible cutting method

InactiveCN110291627AImprove cutting yieldHigh outputSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBrightness perception

The present invention relates to the field of LED chip technology, and particularly relates to an LED chiplet and an LED chip invisible cutting method. The LED chiplet is disclosed, wherein the side surface of a substrate of the LED chiplet is provided with a plurality (three or more) of spaced laser scratches along the thickness direction of the substrate, and the side surface of the substrate is arranged in an up-and-down manner along the thickness direction of the substrate. The method is also provided, including a step S1) of forming a plurality of (three or more) laser scratches spaced along the thickness direction of the substrate inside the substrate in a cutting passage by adopting invisible cutting. According to the LED chiplet and the method, the yield of chiplet cutting is increased, substrate inclination is reduced, and the width of cutting passage lines can be reduced, thus increasing the yield from one chip. Side light extraction is increased, the light emitting angle is increased and forward-direction light is increased, thus increasing the brightness of the chiplet.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

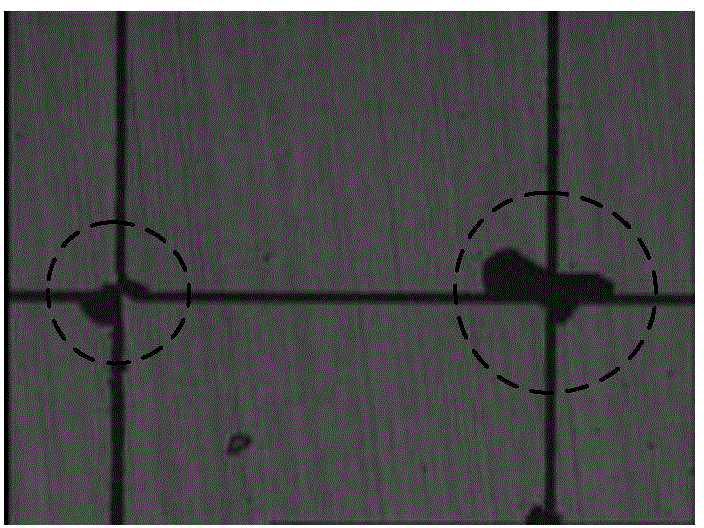

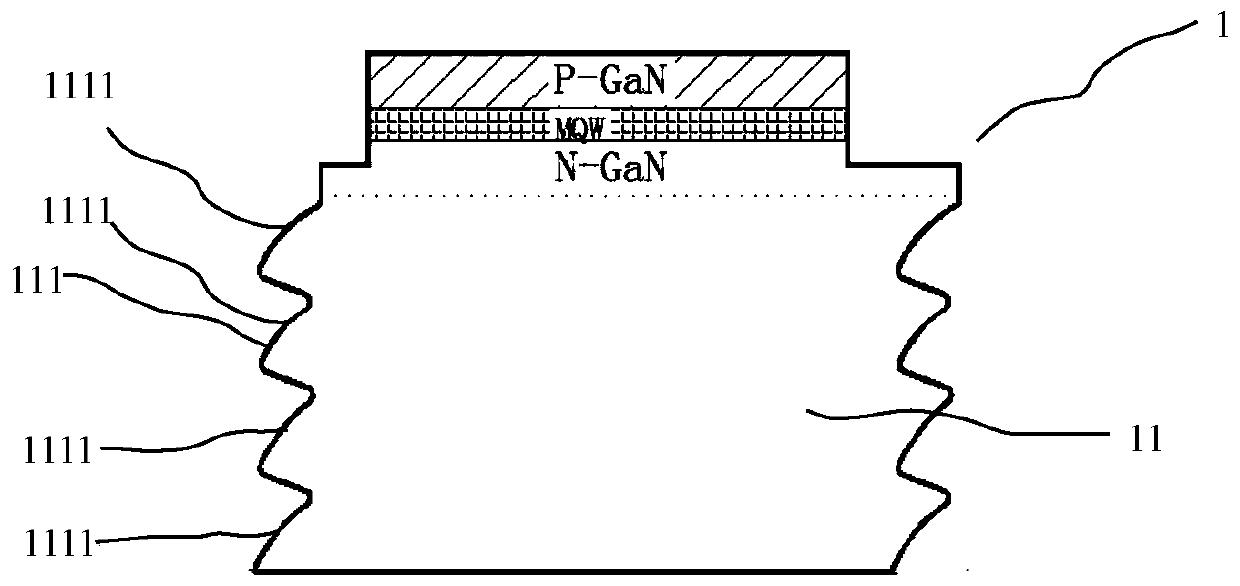

Laser cutting method for sapphire substrate LED chip

InactiveCN105127605AReduce oblique crackingImprove cutting yieldLaser beam welding apparatusLaser cuttingOptoelectronics

A laser cutting method for a sapphire substrate LED chip comprises the following steps: (1) cutting at the position close to the bottom inside the LED chip under the invisible cutting laser action, so as to form a first modified layer; (2), enabling laser to focus at the upper part of the first modified layer through increasing the laser focus depth, and cutting to form a second modified layer connected with the first modified layer vertically; (3) increasing the laser focus depth again to form a third modified layer, forming N modified layers through similar operation, and enabling stress released by the last modified layer to extend to the surface of the chip to form cracks, wherein the N is greater than or equal to 2; (4) applying external force to the LED chip wafer in the directions of the cracks, so as to divide the chip into independent light-emitting units. When the method is used for cutting a thicker wafer of a sapphire substrate, the cutting yield can be effectively increased, and inclined sapphire cracks are reduced.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

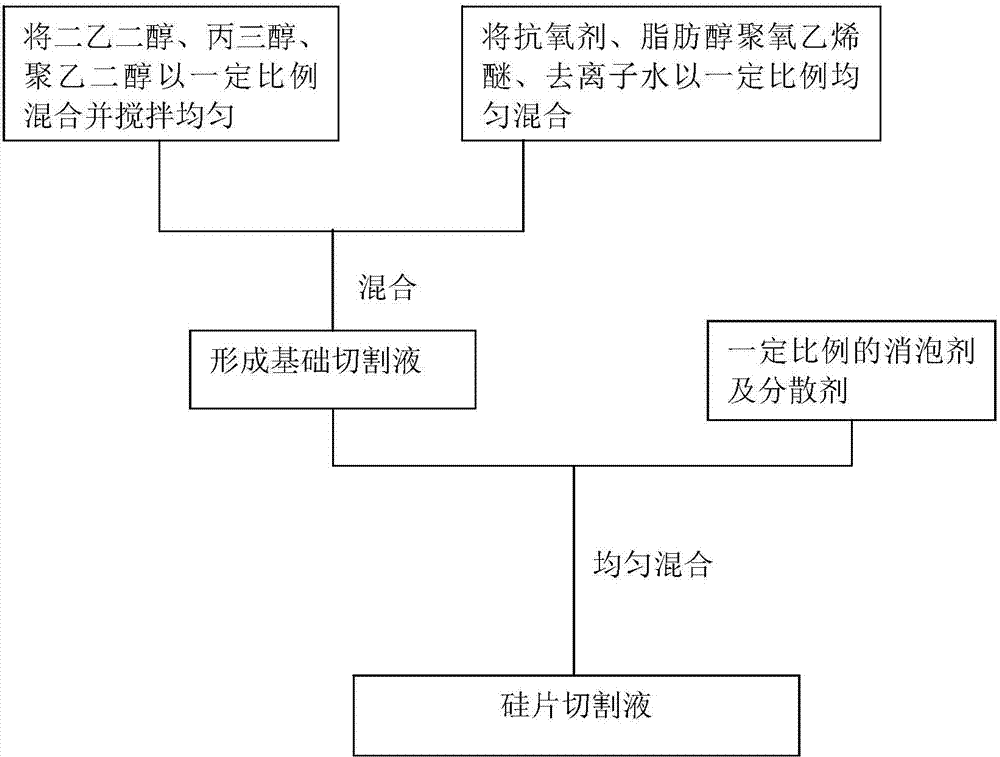

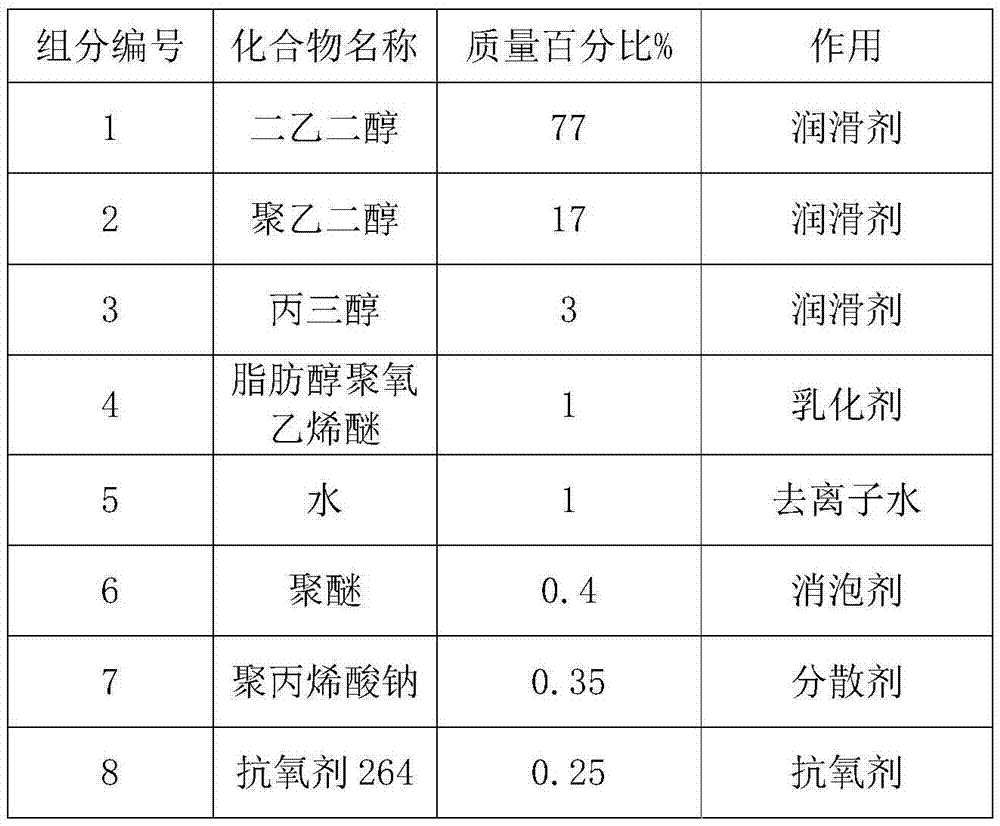

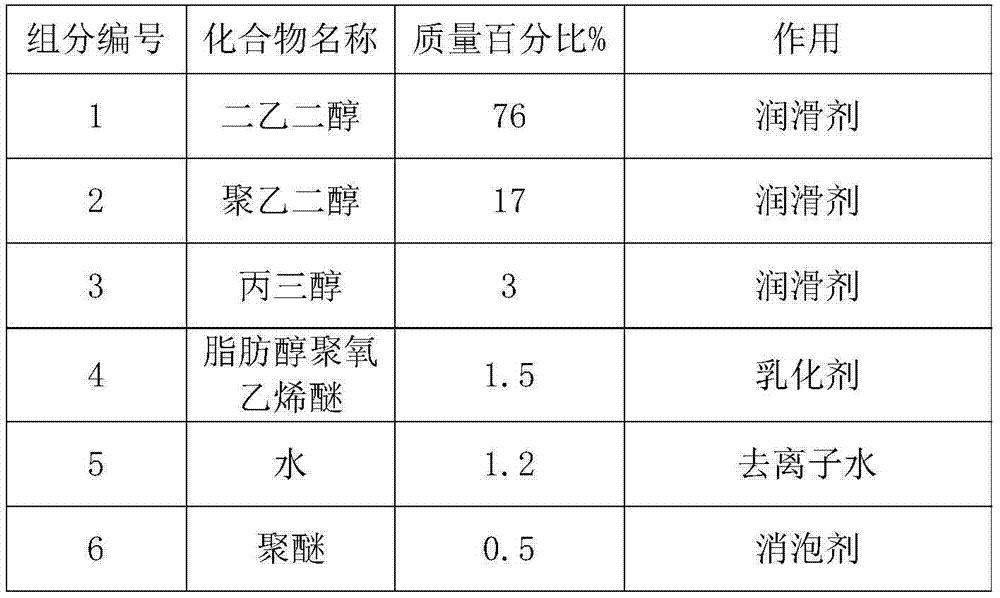

Silicon slice cutting fluid and preparation method thereof

The invention belongs to the technical field of new energy resources of photoelectric materials, relates to a silicon slice cutting fluid and a preparation method thereof, and provides a silicon slice cutting fluid to overcome the defects that an existing silicon slice cutting fluid is high in cost, and relatively poor in dispersion and redispersion abilities on silicon carbide micro-powder. The silicon slice cutting fluid comprises the following raw materials in percentage by weight: 76wt%-80wt% of diethylene glycol, 15wt%-17wt% of polyethylene glycol, 2wt%-3.5wt% of glycerol, 0.5wt%-1.5wt% of fatty alcohol-polyoxyethylene ether, 0.7wt%-1.2wt% of deionized water, 0.2wt%-0.5wt% of a defoaming agent, 0.2wt%-0.5wt% of a dispersing agent and 0.1wt%-0.3wt% of an antioxidant. The main raw material is diethylene glycol, so that the preparation process is simple, easy to operate and low in cost; the dispersibility and the redispersibility of the silicon carbide micro-powder are effectively improved; the stability and the durability of slurry are ensured; the silicon slice cutting fluid has a good lubricating effect; the surface loss during cutting is effectively reduced; the cutting yield is improved; and the silicon slice cutting fluid is suitable for a silicon slice cutting process.

Owner:LESHAN TOPRAYCELL

2mm silk-screen strengthened glass and wood plank combined kitchen cabinet door board production technology

InactiveCN101429841AIncrease brightnessImprove flatnessScreen printersLaminationScreen printingEngineering

The invention provides a cabinet door plate manufacturing process with the combination of 2mm silk-screen printing toughened glass and wooden plates. The process comprises five main steps of performing strengthening treatment, checking strengthening degree, testing cutting performance, printing the glass silk-screen with needed colors and bonding a plate; the cabinet door plate manufactured by the process keeps the thickness and appearance requirements of the prior door plate, because the cabinet door plate does not increase too much weight, a hinge arranged between the door plate and a cabinet body is not damaged; and due to the combination of the printing surface of glass and a dampproof plate, the colors are shown because of the high transparency property of glass, so that the colors do not fall off due to external force. Therefore, the process meets the requirements of the cabinet door plate industry on strong color adhesive force and improves the fineness and mirror surface effect of the surface of the door plate, and due to the high hardness property of the glass, the cabinet door plate also has the advantages of high surface strength, scratch resistance, easy cleaning and the like.

Owner:杨淑权

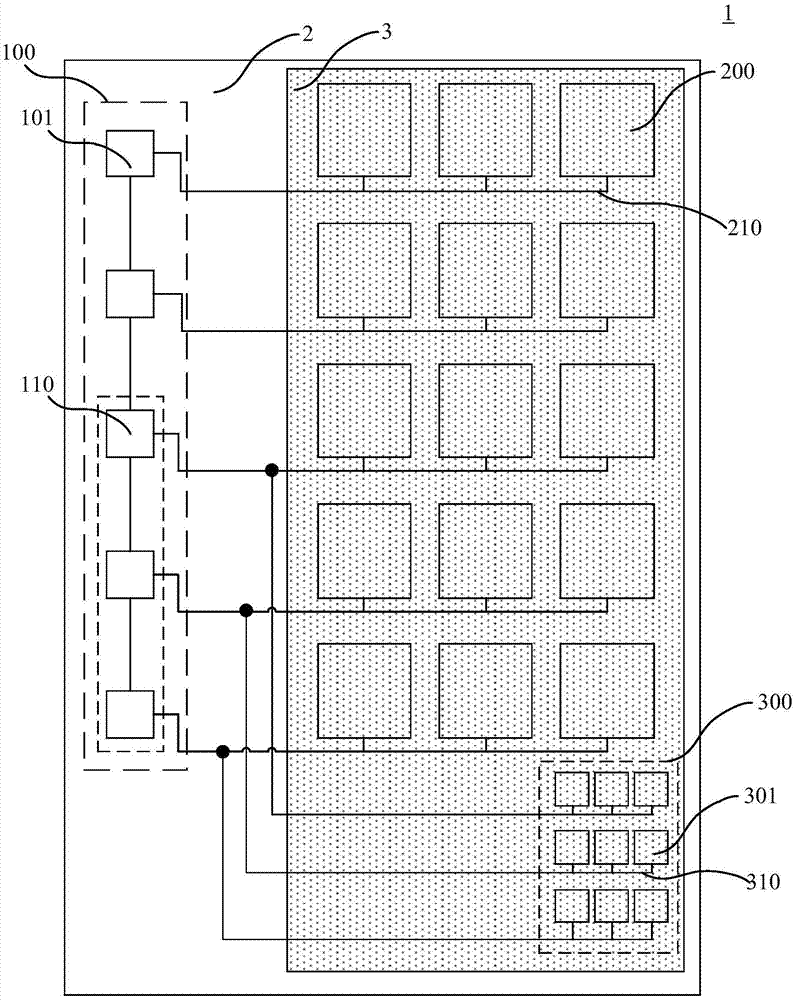

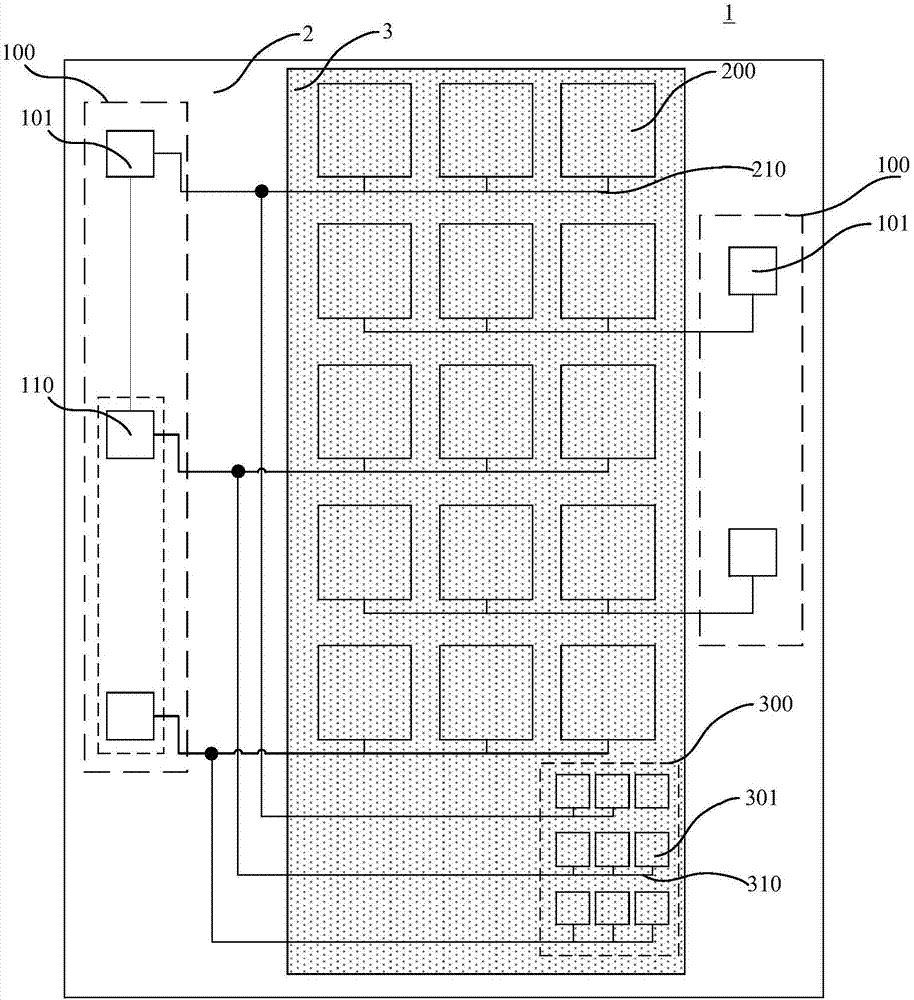

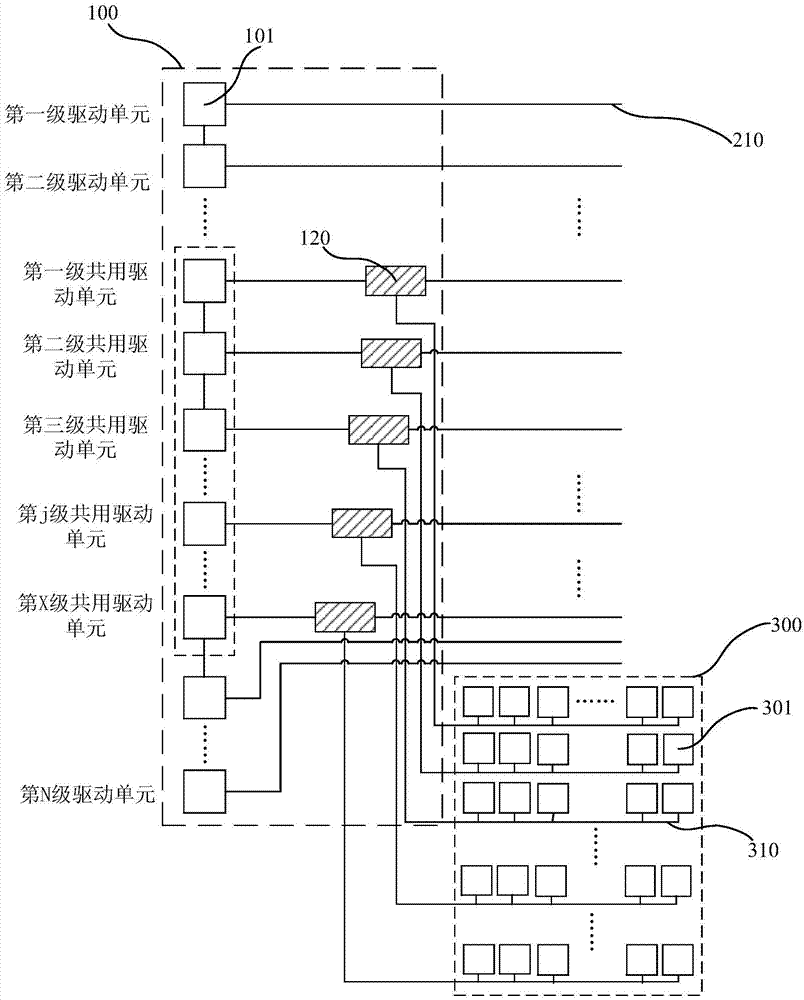

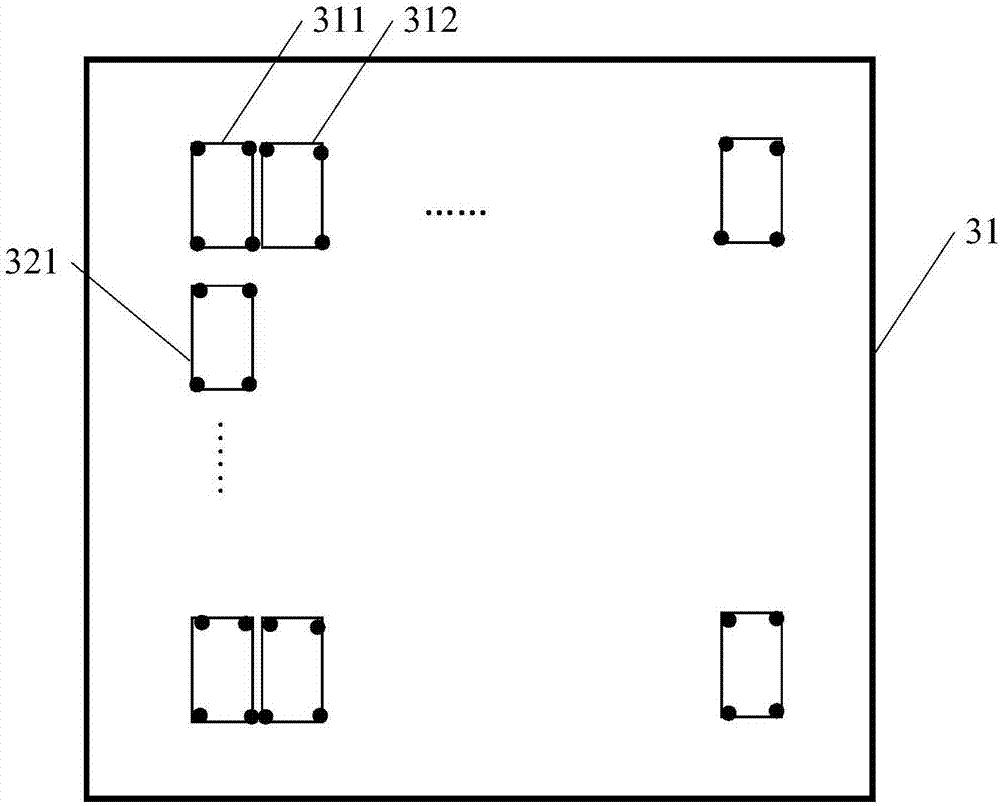

Array substrate, touch control panel, touch display device and driving method of array substrate

ActiveCN107450215AReduce manufacturing costReduce border widthStatic indicating devicesPrint image acquisitionDisplay deviceComputer science

An embodiment of the invention provides an array substrate, a touch control panel, a touch display device and a driving method of the array substrate and relates to the field of display and used for reducing border width of the display device. The array substrate comprises at least one driving circuit, one fingerprint unit arranged in a display area and multiple display units, the display units are arranged in array, and each row of the display units corresponds to one display grid line; the fingerprint unit comprises multiple fingerprint electrodes arranged in array and X fingerprint grid lines, and each row of the fingerprint electrodes corresponds to one fingerprint grid line; each driving circuit comprises N-level mutual cascaded driving units, any one level driving unit is connected with at least one display grid line, the X-level driving units are reused as X-level shared driving units, the j-level shared driving unit is connected with the j-level fingerprint grid line, and driving electric signals are provided through the fingerprint units; 1 is smaller than and equal to X smaller than and equal to N, 1 is smaller than and equal to j smaller than and equal to X, and j, X and N are positive integers.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

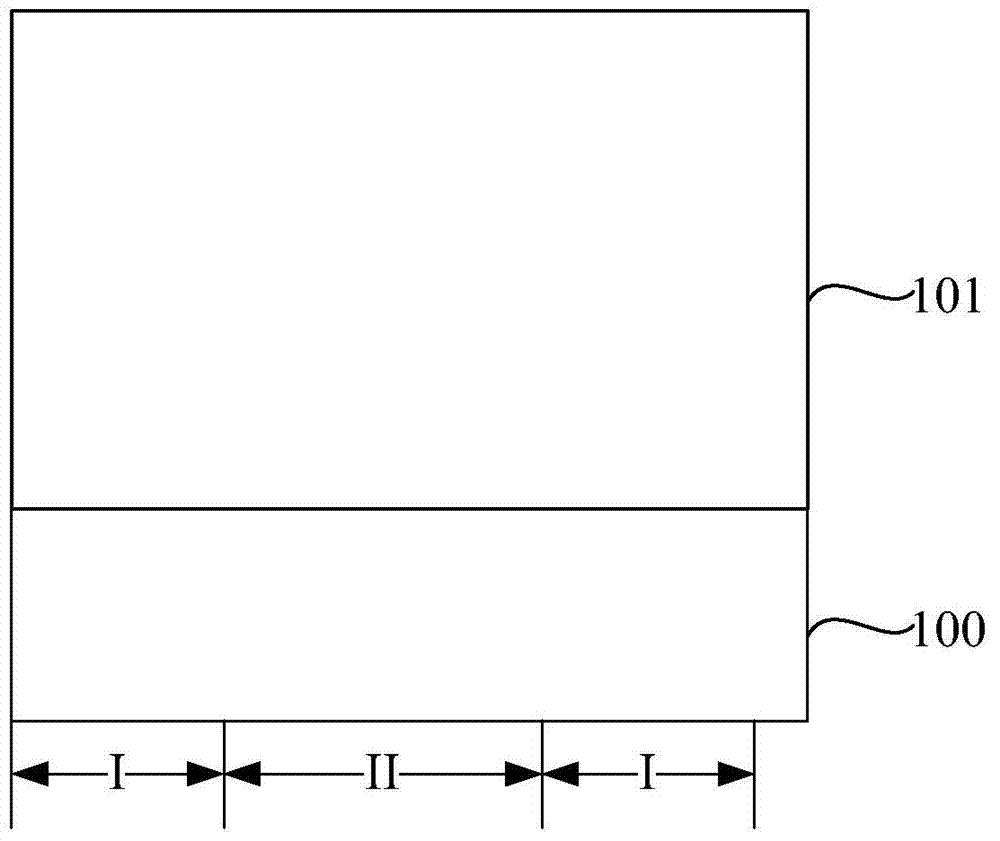

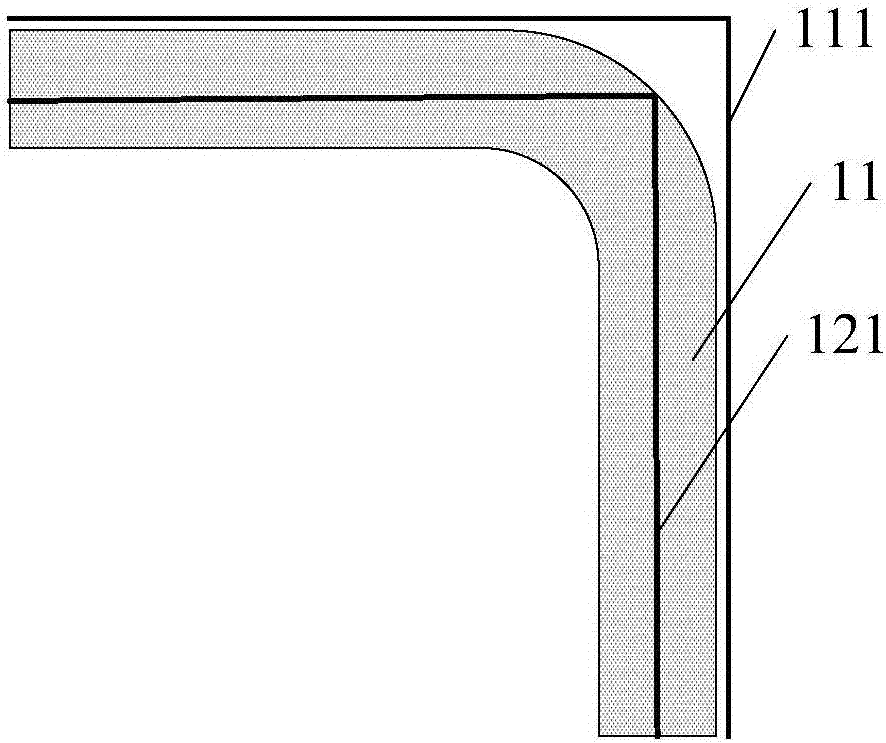

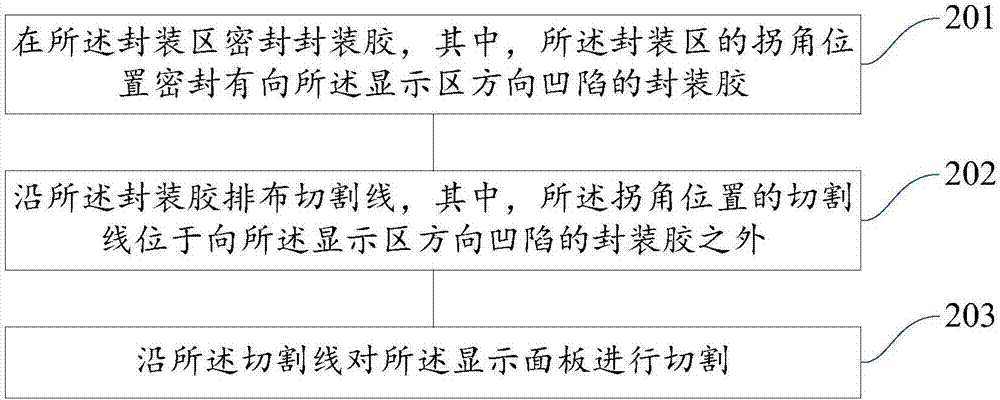

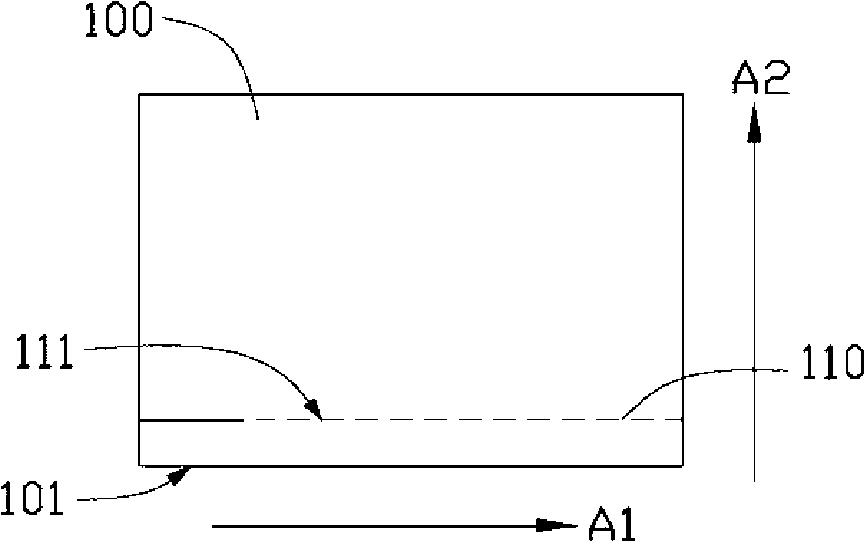

Display panel manufacturing method, display panel and display device

ActiveCN106876609AImprove cutting yieldEliminate the effects ofSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSurface plate

The embodiments of the invention provide a display panel manufacturing method, a display panel and a display device, and relate to the technical field of display. The display panel comprises a display area and a package area around the display area. The package area is sealed with package resin. The corners of the package area are sealed with package resin recessed towards the display area, and a cutting line is arranged along the package resin. The cutting line at the corners is disposed outside the package resin recessed towards the display area, and the display panel is cut along the cutting line. In order to get a narrow-bezel display panel, the package resin at the corners of the package area is designed in such a way that the package sin is recessed towards the display area, and thus, the cutting line at the corners is disposed outside the package resin. The problem that package reliability test fails as the package area can easily crack at the corners is eliminated, and the cutting yield of the display panel is increased.

Owner:BOE TECH GRP CO LTD +1

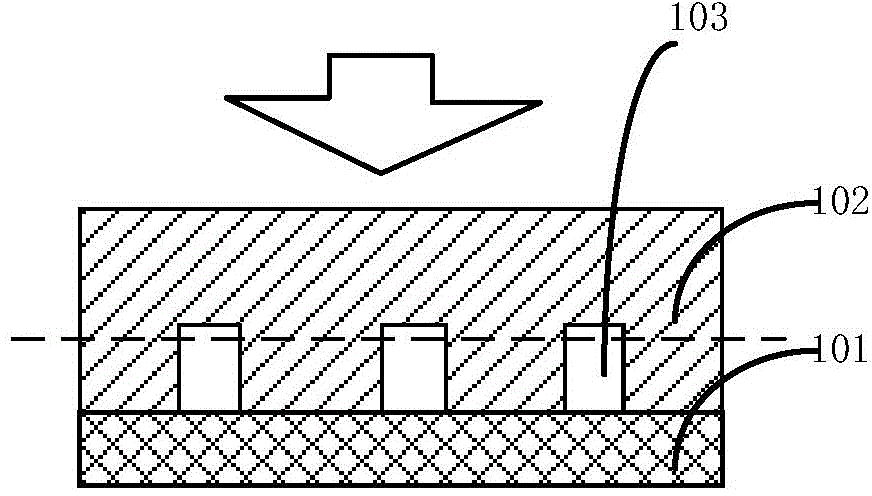

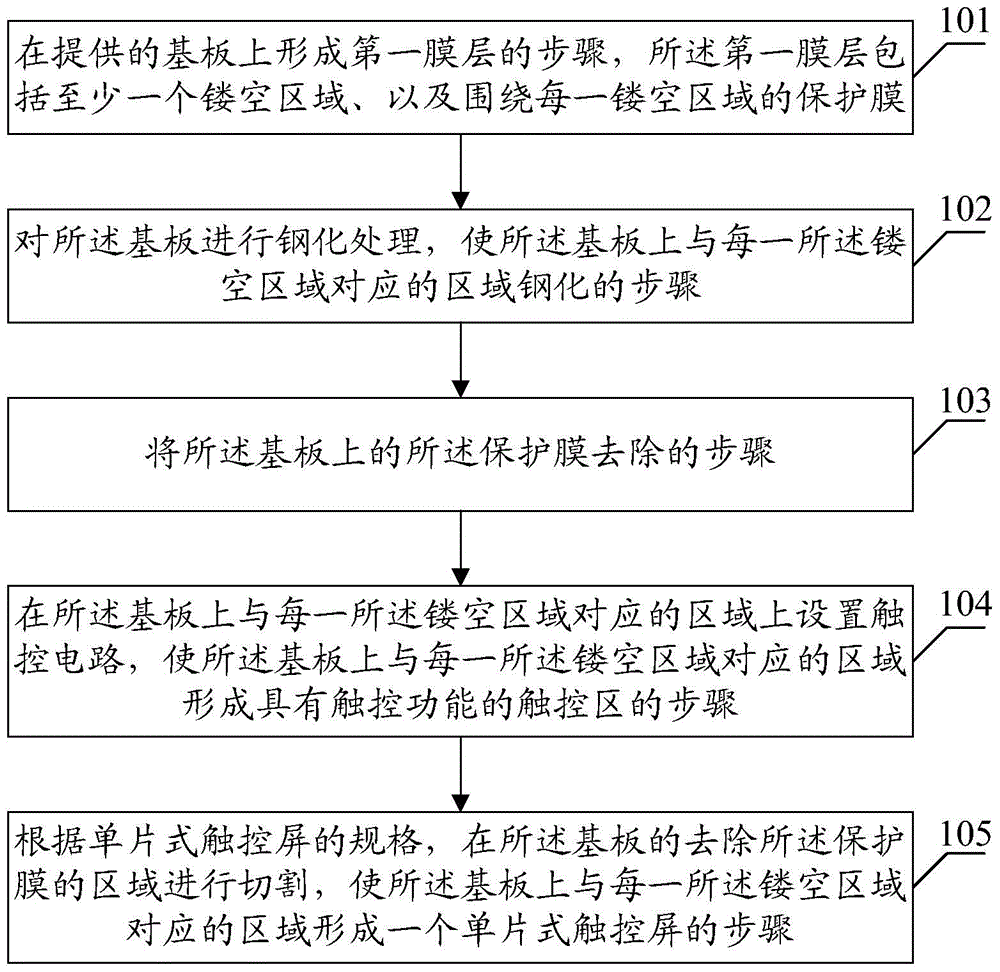

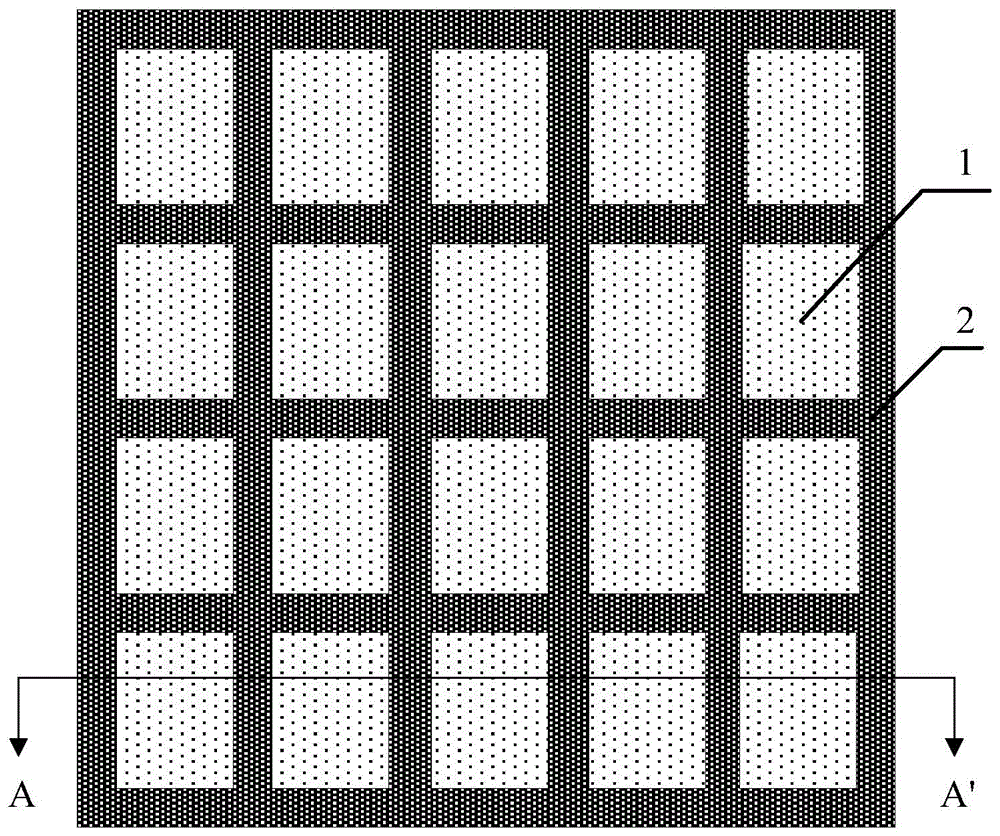

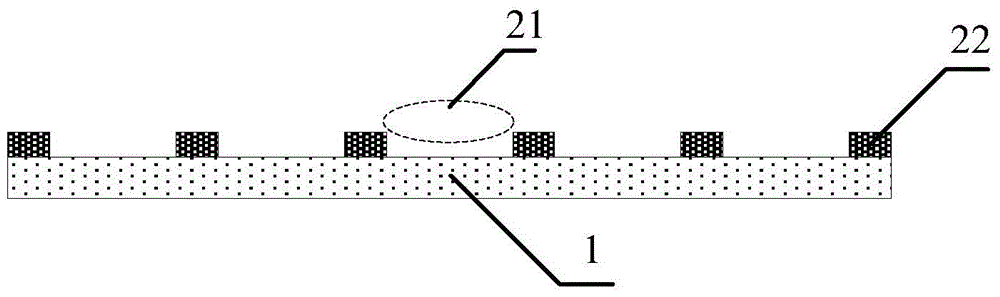

Manufacturing method of monolithic touch control screen

ActiveCN103941906ANo stress reliefImprove cutting yieldCoatingsGlass tempering apparatusTectorial membraneBiochemical engineering

The invention discloses a manufacturing method of a monolithic touch control screen. The manufacturing method of the monolithic touch control screen aims to solve the problem of stress release in the cutting process after tempering of a glass base plate in the OGS touch control screen production process in the prior art to improve the yield of single screen cutting and production efficiency. The method includes a step of forming a first film layer on a provided base plate, wherein the first film layer comprises at least one hollow-out area and a protection film around each hollow-out area; a step of conducting tempering processing on the base plate to achieve the tempering of the corresponding area of each hollow-out area on the base plate; a step of removing the protection film on the base plate. According to the manufacturing method, the protection film is arranged on the glass base plate, the protection film area is not tempered when the glass base plate is tempered, stress release can not be generated in the cutting process, the cutting yield is improved, the process step is simple, and production efficiency is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

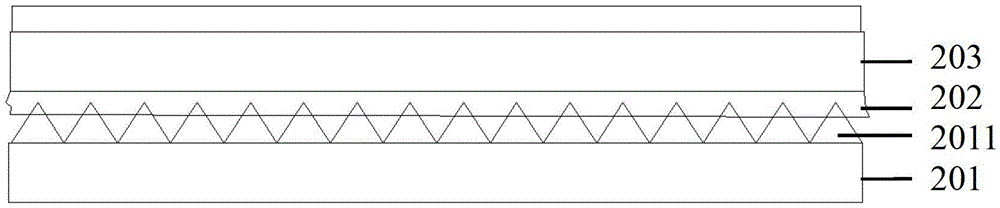

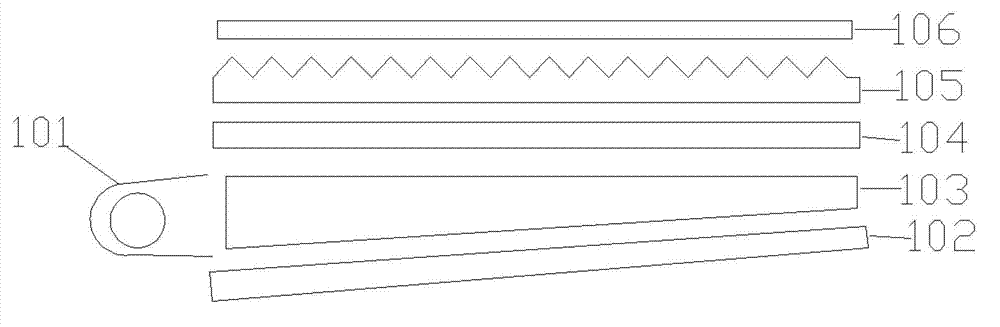

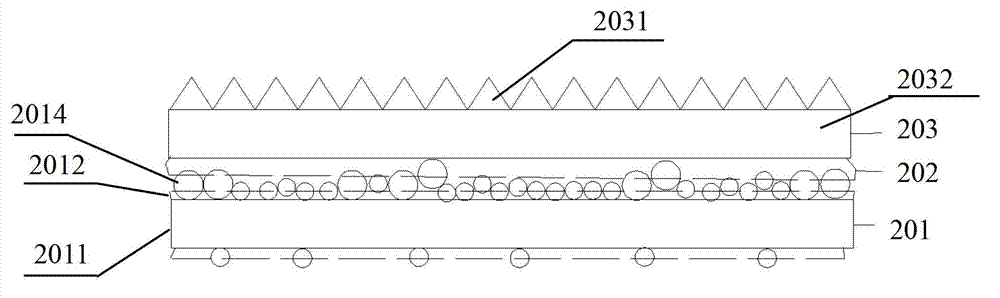

A kind of multi-layer composite prism sheet and preparation method thereof

ActiveCN103149610BReduce interferenceIncrease brightnessPrismsLaminationInterference phenomenonCompound prism

Owner:NINGBO JIANGBEI EXCITON NEW MATERIAL TECH CO LTD

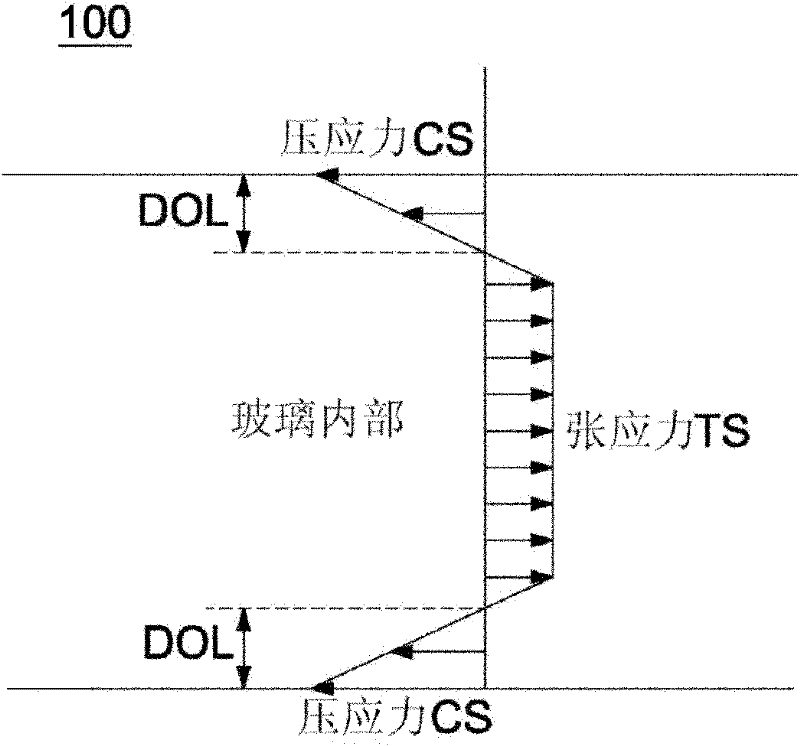

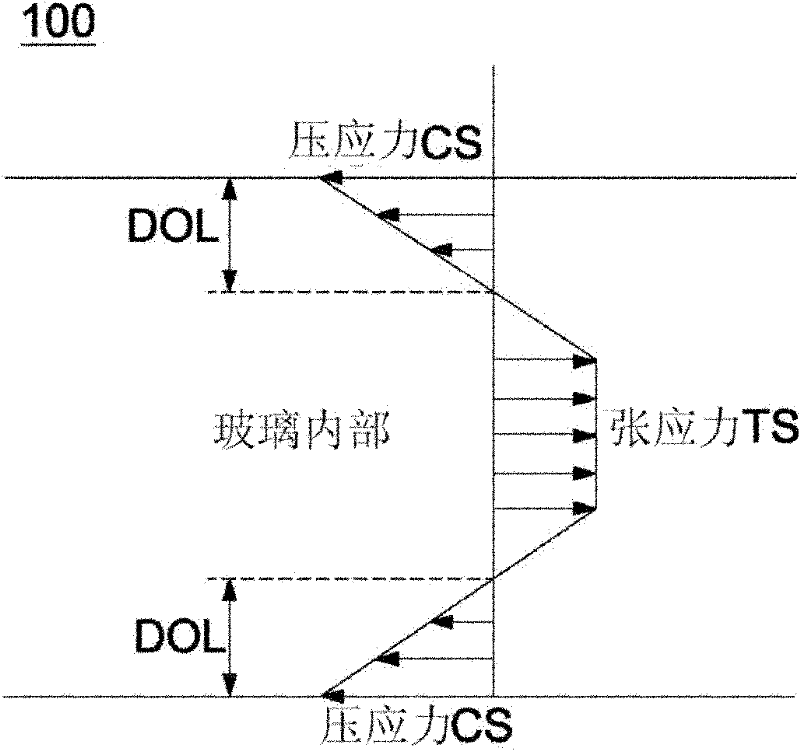

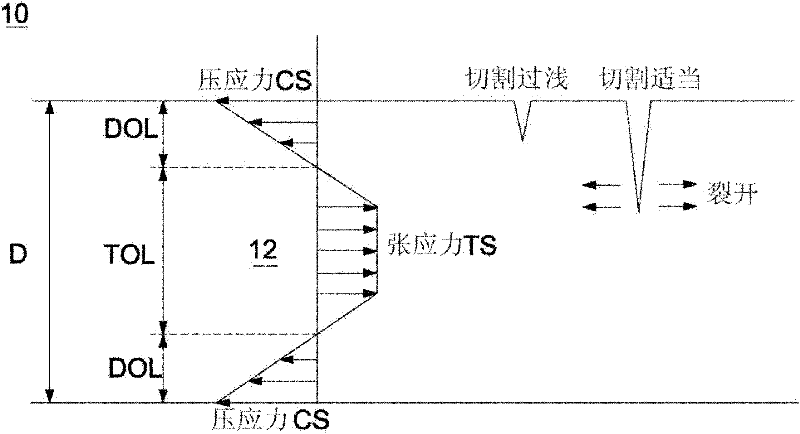

Cutting method of tempered glass and cutting preset structure of tempered glass

InactiveCN102442764AReduced internal tensile stressImprove cutting yieldGlass severing apparatusGlass productionMetallurgyPressure stress

A cutting preset structure of tempered glass is provided, comprising a tempered glass substrate and at least one groove. The glass substrate forms at least one pressure stress layer and a tensile stress layer correspondingly from surface to inside in turn; the groove is formed on the pressure stress layer of the glass substrate and is overlapped with a certain preset cutting path.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

Array substrate, display panel and display device

ActiveCN106711160AHigh strengthAvoid breakingElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

The invention provides an array substrate, a display panel and a display device. The array substrate comprises a line and an insulating layer, wherein the line and the insulating layer are sequentially formed on a liner substrate; a binding area is arranged at one side far away from the line, of the insulating layer of the array substrate; a first protection layer which is at least partially parallel to the edge of the array substrate is arranged inside the binding area of the array substrate. In the process that the array substrate is cut, the first protection layer has a support function for the liner substrate to a certain extent, the strength of the liner substrate can be improved, the liner substrate can be prevented from damage, and thus the cutting pass percent can be increased.

Owner:BOE TECH GRP CO LTD +1

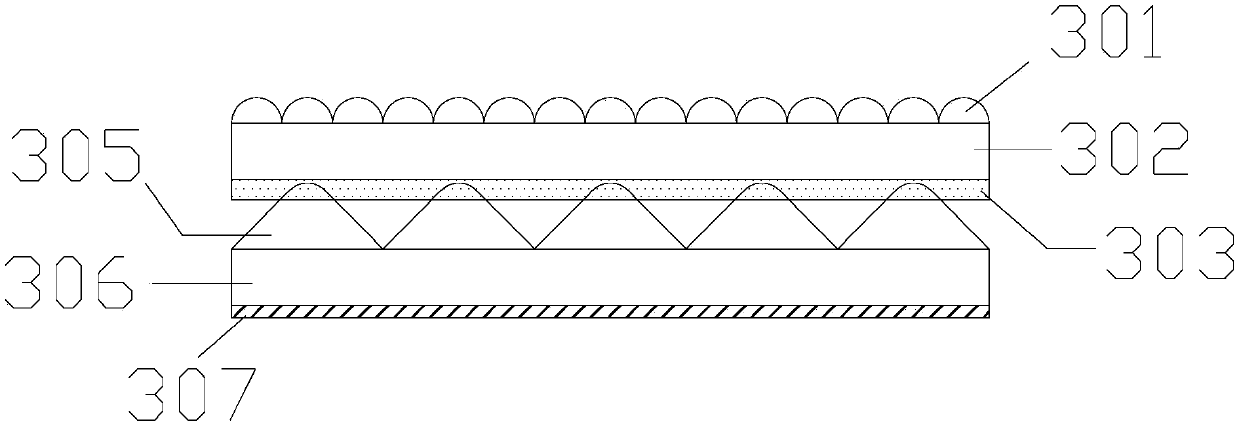

Multilayer compound prismatic lens

InactiveCN103091742AIncrease brightnessSimple processPrismsSynthetic resin layered productsAdhesiveOptical thin film

The invention relates to the technical field of optical thin films, in particular to a multilayer compound prismatic lens. In order to solve the problem that damages of mebrane caused by mutual removal and friction between existing backlight module mebrane or dust and scrap created by cutting are mixed between the membrane, so backlight module pass percent is reduced, the multilayer compound prismatic lens is provided. The prismatic lens comprises a diffusion film, an adhesive layer and a prismatic lens. The prismatic lens comprises a prismatic lens substrate. The prismatic lens substrate is provided with a microprism structure. The diffusion film comprises a diffusion film substrate. The diffusion film substrate is coated with a diffusion adhesive layer. The diffusion adhesive layer comprises diffusion particles and an adhesive. The prismatic lens substrate is composited with the diffusion adhesive layer of the diffusion film through the adhesive layer. The prismatic lens has good optical effects, improves backlight module pass percent and reduces procedures of assembling and cleaning. The multilayer compound prismatic lens is simple in prepared method process and easy to operate.

Owner:NINGBO EXCITON TECH

Mixed additive and fretsaw cutting fluid prepared from same

The invention discloses a mixed additive and a fretsaw cutting fluid prepared from the same. The fretsaw cutting fluid has good dispersibility and capability of re-dispersing the abrasive to ensure the stability and durability of the configured mortar, the fretsaw cutting fluid has good cooling and lubricating functions, the surface damages of slices and the pollutions of mechanical stress, thermal stress and metal ions to the wafers can be reduced, the thickness error of the wafers can be effectively improved, and a thinner cutting line is used to increase the cutting yield.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

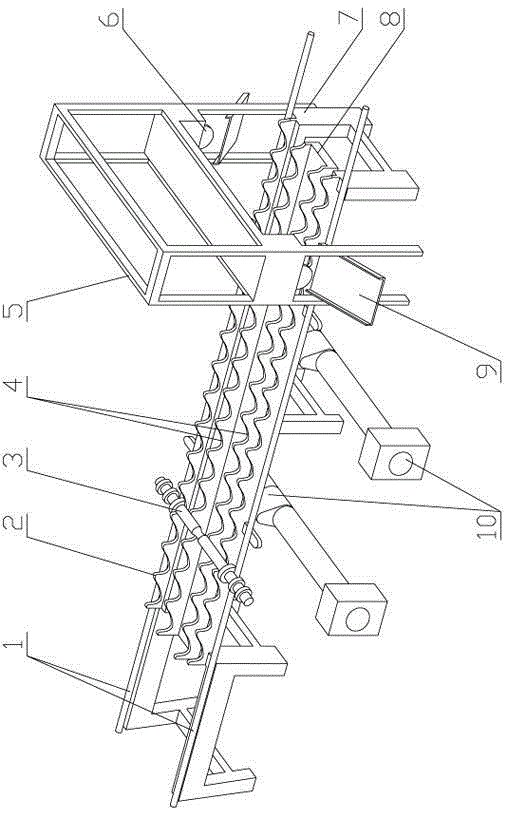

End head cutting device for blank part of gear shaft

The invention is a cutting device for the end of a gear shaft blank, which has a base bracket, two rows of fixed conveying teeth are symmetrically arranged on the front and rear sides of the base bracket, and a movable plate is arranged between the two rows of fixed conveying teeth. There are two rows of movable conveying teeth symmetrically arranged on both sides. The tooth tops of the movable conveying teeth and the tops of the fixed conveying teeth are arranged alternately. The bottom of the movable plate is equipped with a cam transmission mechanism. The movable plate and the movable conveying teeth are driven by the cam transmission mechanism. Make intermittent up and down movements; there is a positioning round steel on both sides of the fixed conveying teeth, a cutting bracket is installed across the two sides of the positioning round steel, and a cutting machine is installed on the front and rear sides of the cutting bracket. , the cutting machine is used to cut the remaining material at both ends of the gear shaft blank conveyed by the movable conveying teeth; the invention has the advantages of simple and compact structure, accurate limit, efficient and precise cutting, and has good promotion and application value, mainly used in The gear shaft blank is being processed.

Owner:HUBEI XINYEGANG STEEL AUTO PARTS

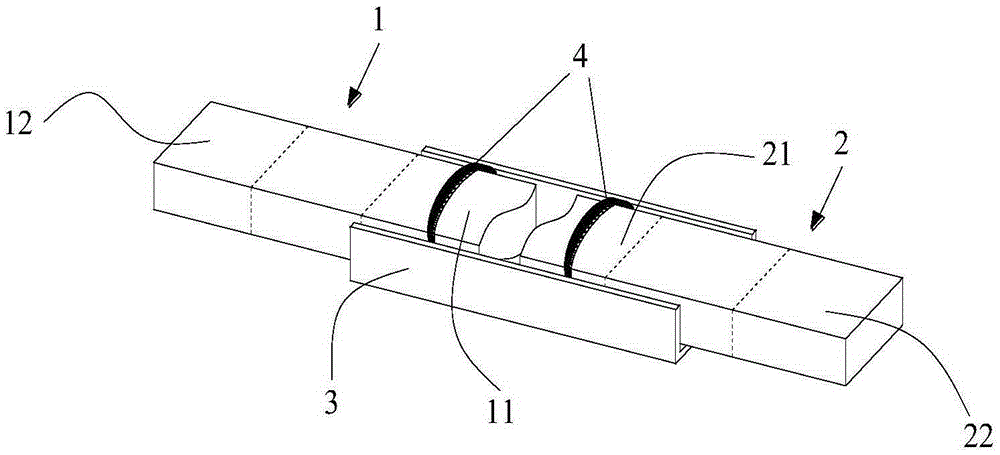

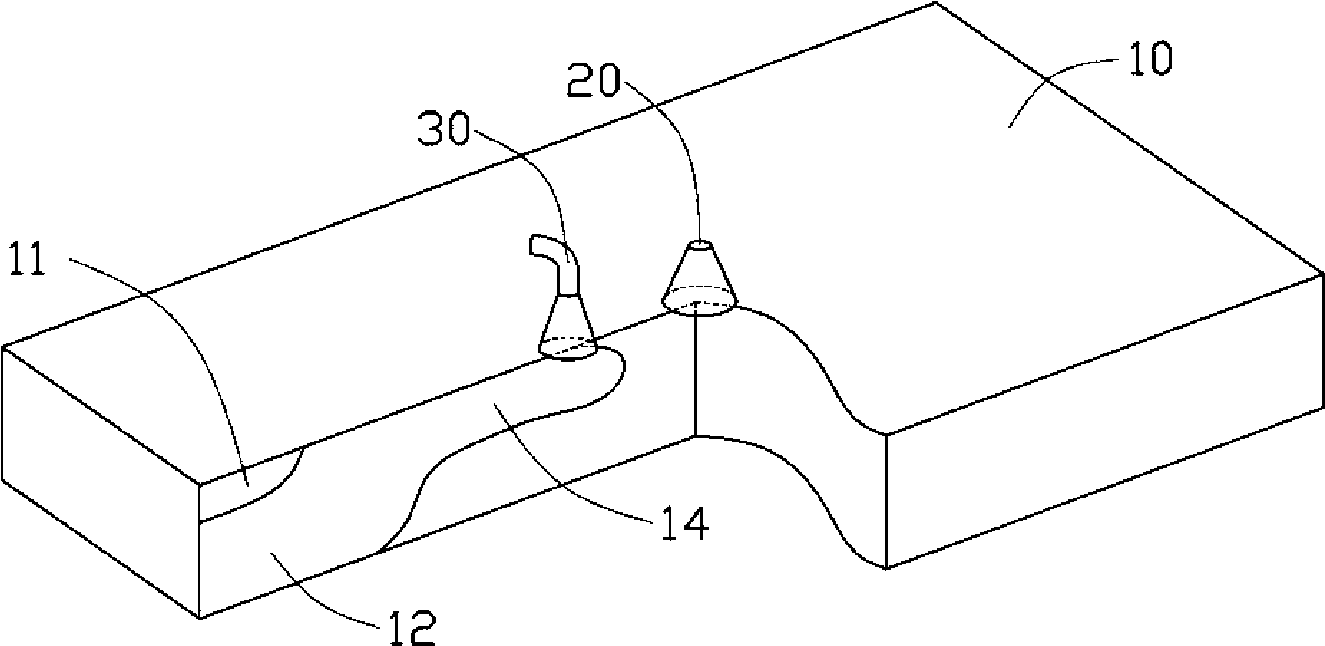

Brittle substrate and laser cutting method therefor

ActiveCN101530951AImprove cutting yieldGlass severing apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a laser cutting method for a brittle substrate, which comprises the following steps that: a brittle substrate is provided; a first cutting line extending along a first direction at the position adjacent to one edge of the brittle substrate is formed by a laser cutting process; an initiate crack starting from the edge and crossing the first cutting line at the position adjacent to the starting end of the first cutting line on the brittle substrate is formed, and the initial crack extends along a second direction different from the first direction; and a second cutting line extending along the second direction is formed along the initial crack on the brittle substrate by the laser cutting process. The invention also provides a brittle substrate manufactured by the method.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com