Cutting method of tempered glass and cutting preset structure of tempered glass

A technology of strengthening glass and cutting method, which is applied in the direction of glass cutting device, glass production, glass manufacturing equipment, etc., can solve the problems of low cutting yield, strengthened glass 100 is easy to crack irregularly, etc., and achieves the goal of improving cutting yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The aforementioned and other technical contents, features and functions of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

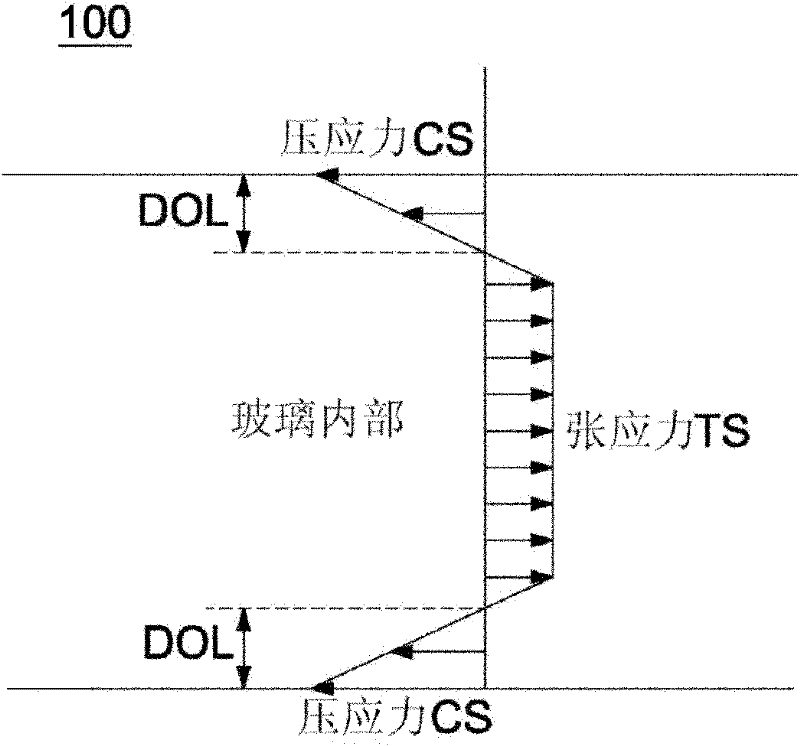

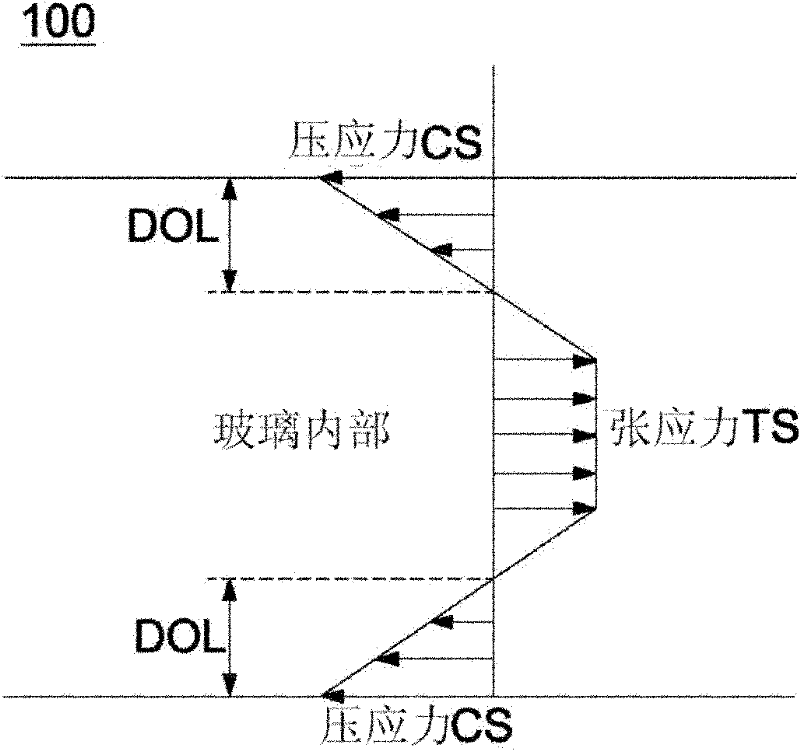

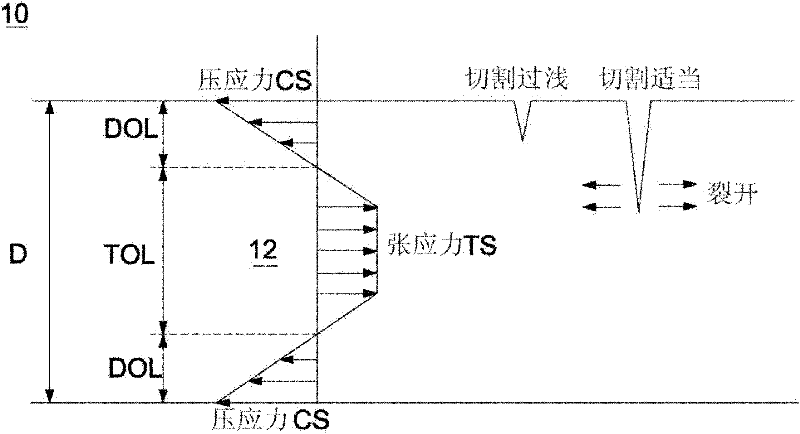

[0022] Such as figure 2 As shown, the strengthened glass 10 according to an embodiment of the invention first strengthens a glass substrate 12 through strengthening treatment. For example, the strengthening treatment may be a chemical ion strengthening treatment. In the process of chemical ion strengthening treatment, the glass substrate 12 to be strengthened can be placed in molten potassium salt, so that the potassium ions can ion-exchange with the sodium ions on the surface of the glass substrate 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com