Multilayer compound prismatic lens

A multi-layer composite and prism sheet technology, applied in the direction of prism, lamination, lamination device, etc., can solve the problems of lower pass rate of backlight module yield, film damage, dust mixed, etc., to improve the cutting yield , easy to operate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

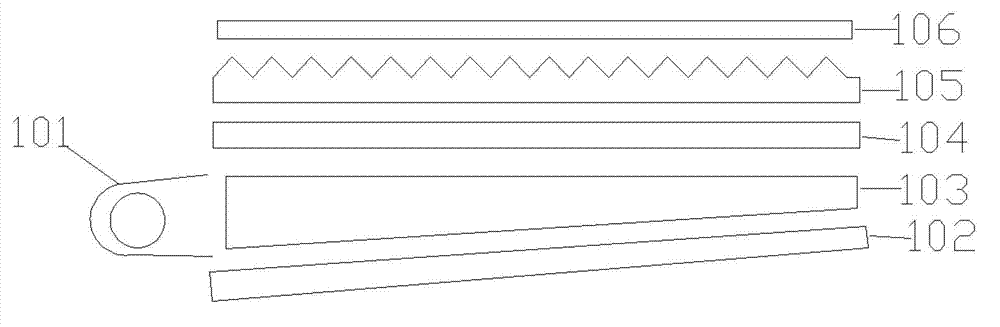

[0028] The preparation method of the multilayer composite prism sheet provided by the invention comprises the following steps:

[0029] (1) Preparation of prism sheet;

[0030] (2) Preparation of diffusion membrane;

[0031] (3) Coat a layer of adhesive on the lower surface of the prism sheet substrate of the prism sheet, and age in an oven for 1-30 minutes to form an adhesive layer; The adhesive layer and the diffusion layer of the diffusion film are combined together; the finished product is rolled up and aged in a drying room at 50°C for 3-40 hours.

[0032] The prism sheet and diffusion film in the above steps (1) and (2) can be ready-made products purchased from the market, or can be prepared according to the existing technology.

[0033] Test the brightness of gained multilayer composite prism sheet according to following method:

[0034] Brightness test: Put the film to be tested into a 24-inch backlight module, light up the module with a 24V voltage, and test the br...

Embodiment 1

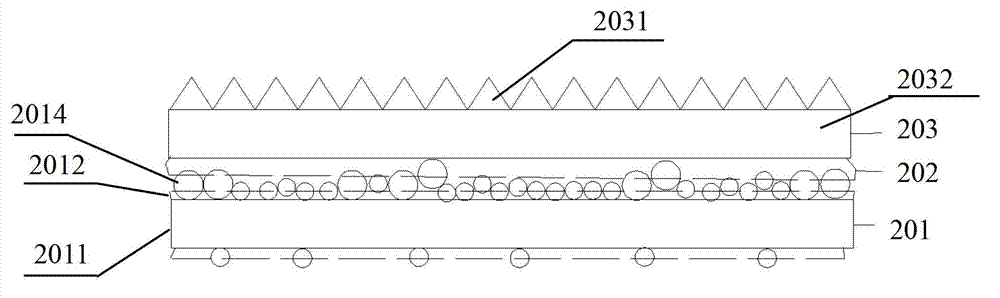

[0036] Material: The model of the lower diffusion film is BS507, produced by Japan Megumi Co., Ltd.,

[0037] The model of the prism sheet is SOS, which is produced by South Korean LG Electronics.

[0038] The preparation method is as follows:

[0039] The polyurethane adhesive is coated on the lower surface of the prism sheet SOS to form an adhesive layer with a thickness of 3 μm (the maximum particle size of BS507 diffusion particles is about 20 μm), and the adhesive layer is then combined with the upper surface of the diffusion film BS507 (diffusion glue) layer) composite to obtain the multilayer composite prism sheet of the present invention.

Embodiment 2

[0041] Material: The model of the lower diffusion film is BS507, produced by Japan Megumi Co., Ltd.,

[0042] The model of the prism sheet is SOS, which is produced by South Korean LG Electronics.

[0043] The preparation method is as follows: a layer of polyurethane adhesive is coated on the lower surface of the prism sheet SOS to form a 6 μm thick adhesive layer (the maximum particle size of BS507 diffusion particles is about 20 μm), and the adhesive layer is then combined with the upper surface of the diffusion film BS507 (diffusion glue layer) compound, obtain the multi-layer composite prism sheet of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com