End head cutting device for blank part of gear shaft

A cutting device and technology of blank parts, applied in metal processing and other directions, can solve the problems of uneven cutting of gear shafts and affect the processing of gear shafts, etc., achieve efficient and accurate cutting, improve cutting yield, and promote the effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

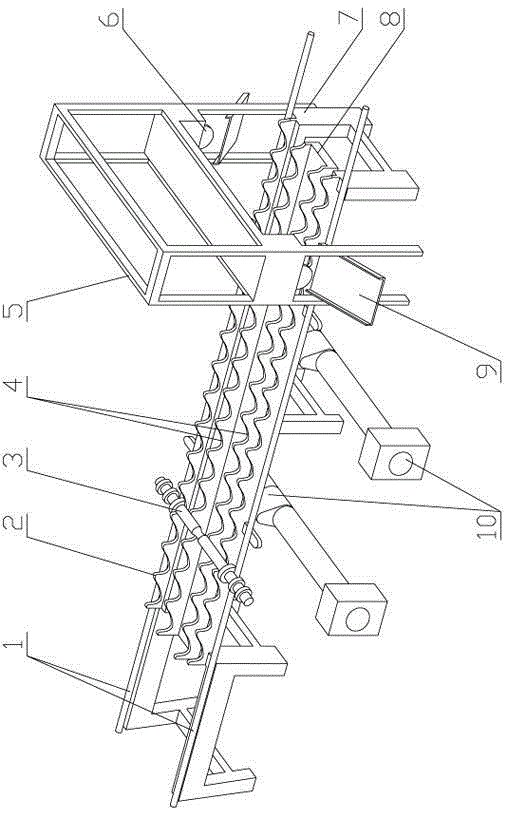

[0012] see figure 1 , figure 2 , the present invention is a cutting device for the end of a gear shaft blank, which has a base bracket 7, two rows of fixed conveying teeth 2 are symmetrically arranged on the front and rear sides of the base bracket, and a movable plate 8 is arranged between the two rows of fixed conveying teeth , two rows of movable conveying teeth 4 are arranged symmetrically on both sides of the movable plate, and the tooth tops of the movable conveying teeth and the tooth tops of the fixed conveying teeth are alternately arranged. The bottom of the movable plate is provided with a cam transmission mechanism 10. The teeth move up and down intermittently under the drive of the cam transmission mechanism; a positioning round steel 1 is provided on the outside of both sides of the fixed conveying teeth, and a cutting bracket 5 is arranged across the two sides of the positioning round steel. A set of cutting machine 6 is respectively provided on the front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com