Mixed additive and fretsaw cutting fluid prepared from same

A technology of mixing additives and cutting fluids, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of poor stability of cutting fluids, large wafer surface damage, low productivity, etc., to ensure stability and durability, and good cooling and lubricating effect, reducing the effect of surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0023] The present invention is further illustrated below with examples, but the present invention is not limited thereto. In the following examples, the percentages are all mass percentages.

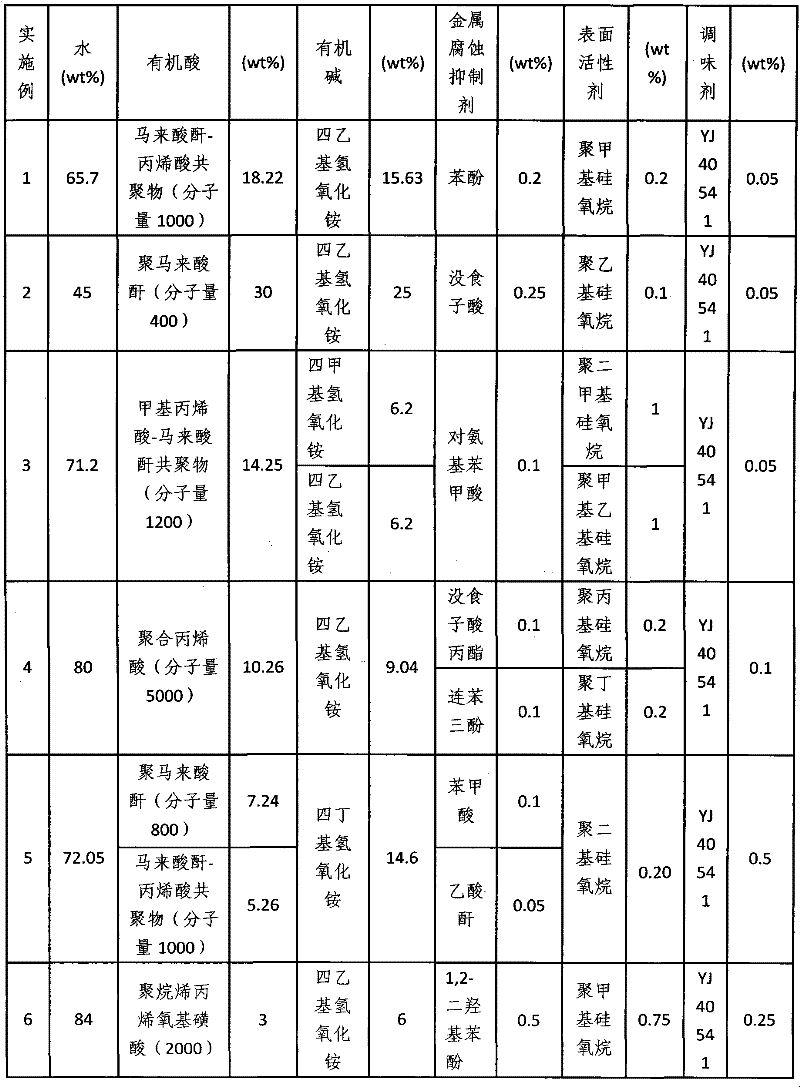

[0024] Table 1 has provided the formula of the cleaning liquid embodiment 1~8 that is used for thick film photoresist of the present invention, presses listed component and its content in Table 1, organic base is added dropwise to organic base within 1 hour. in the acid, and keep stirring; after the dropwise addition of the organic base, continue to stir for 30 minutes; then add the metal corrosion inhibitor and stir for 20 minutes; ) was added and continued to stir for 30 minutes to obtain a mixed additive for wire saw cutting fluid.

preparation Embodiment 1~8

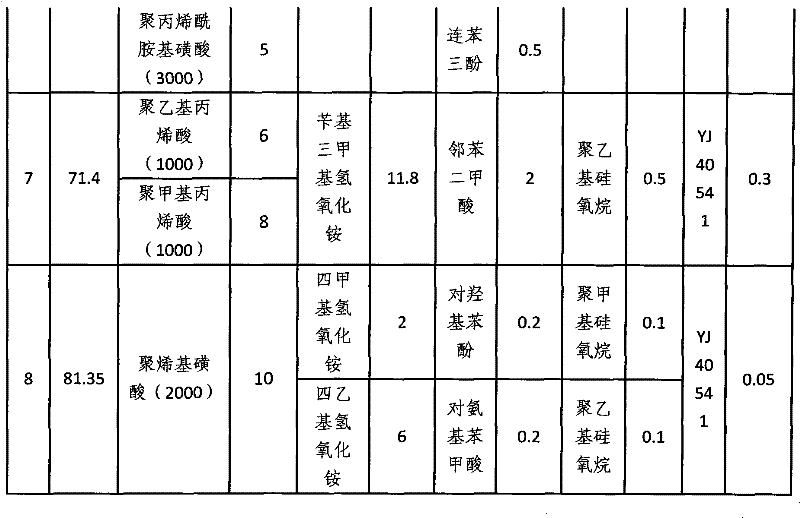

[0026]

[0027]

preparation Embodiment 2

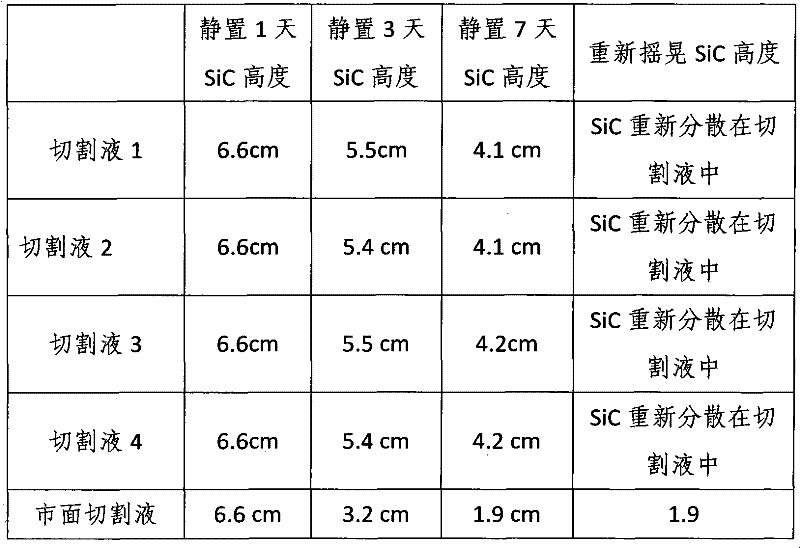

[0029] According to the proportions in Table 2, add this mixed additive into an oily cutting base, such as polyethylene glycol, and stir for 30 minutes to obtain a cutting fluid for wire saw cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com