Brittle substrate and laser cutting method therefor

A brittle substrate, laser cutting technology, applied in the field of brittle substrates, laser cutting non-metallic or brittle substrates, can solve the problems of affecting cutting accuracy, difference in growth distance, poor cutting yield of glass substrates, etc., and achieve high cutting yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

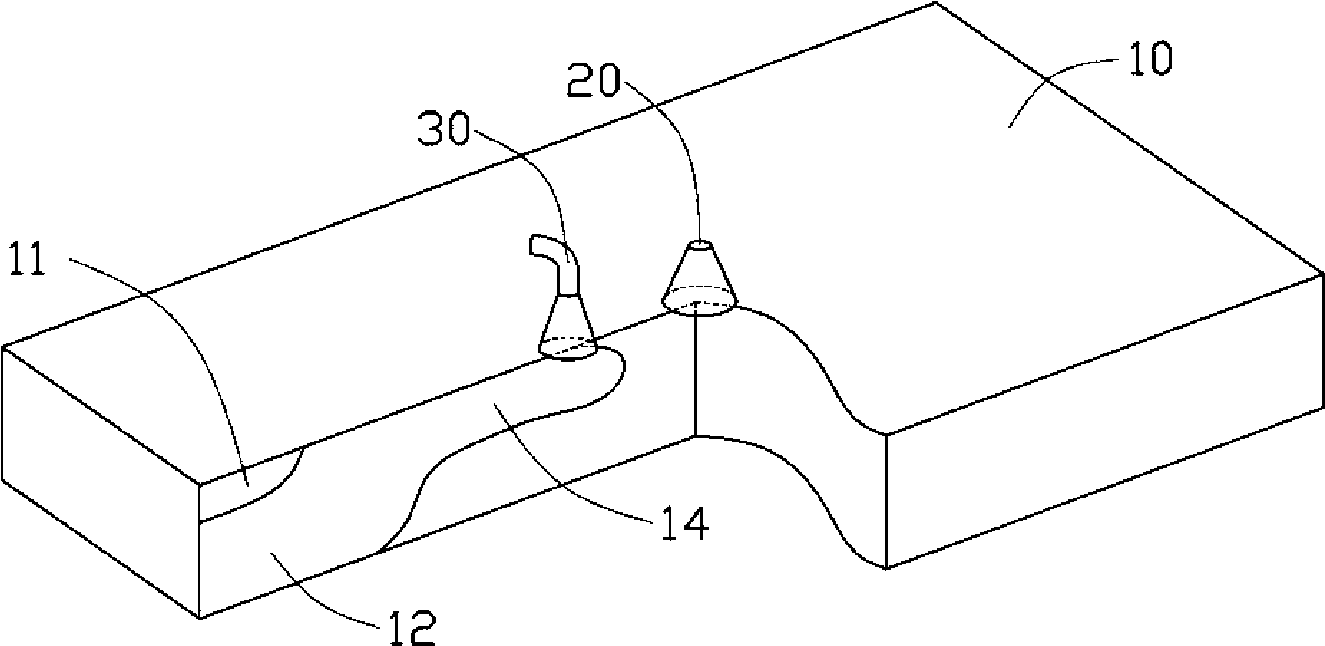

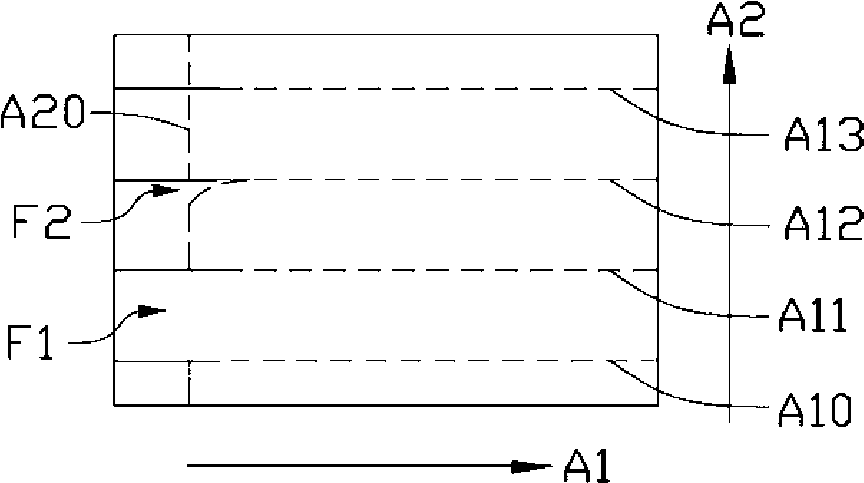

[0020] see Figure 3 to Figure 5 , the method for laser cutting a brittle substrate provided by an embodiment of the present invention includes the following steps.

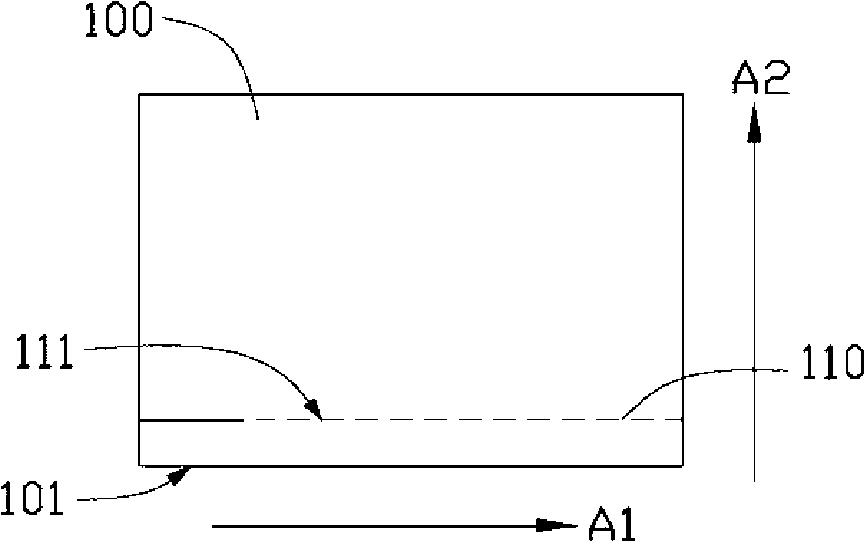

[0021] Such as image 3 As shown, a brittle substrate 100 is provided, and a first cutting line 110 is formed on the brittle substrate 100 adjacent to an edge 101 of the brittle substrate 100 by a laser cutting process, and the first cutting line 110 extends along the direction A1. Wherein, the brittle substrate 100 is usually a non-metallic substrate such as a ceramic substrate, a glass substrate, a quartz substrate, a glass silicon wafer, or a light emitting diode wafer. The brittle substrate 100 can be a square plate (such as image 3 shown), or other shapes according to actual needs, such as round pieces. The laser cutting process generally includes the steps of: (a) u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com