Multi-layer optical film

A multi-layer optical film and optical film technology, applied in optics, optical components, lenses, etc., can solve the problem of low bonding strength and achieve the effect of improving the cutting yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

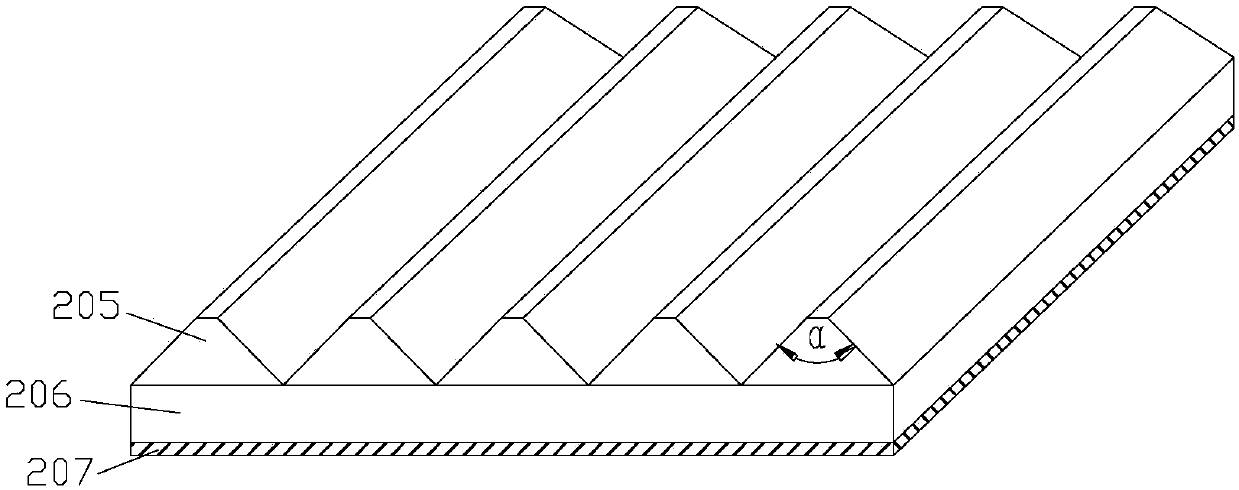

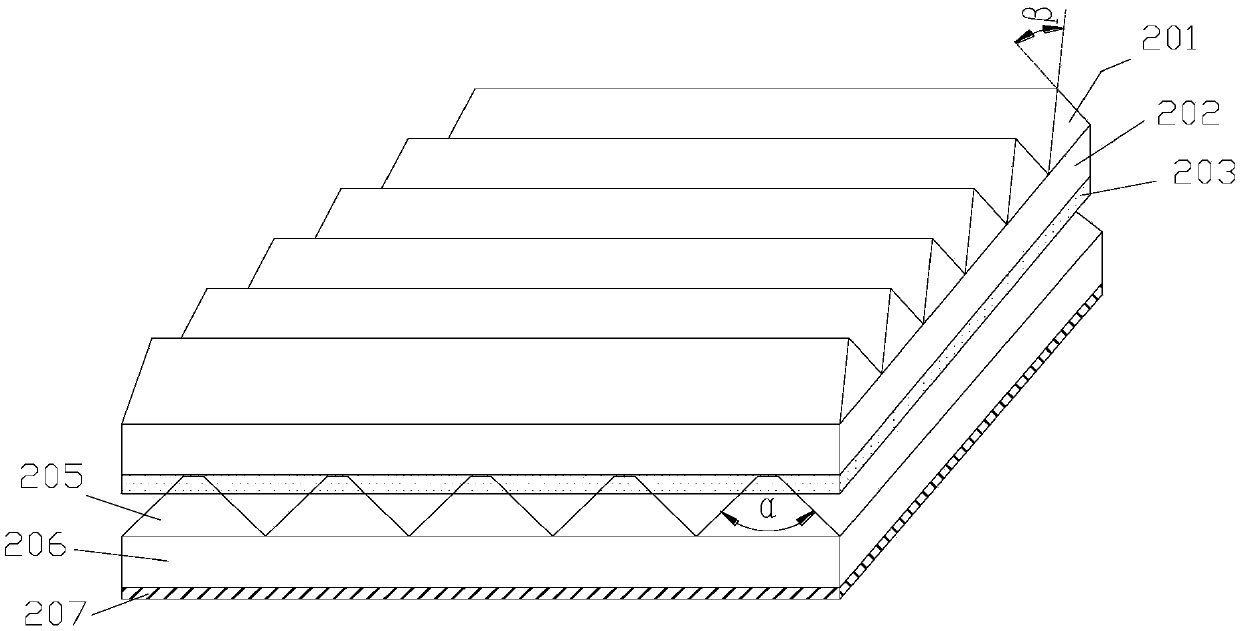

[0030] attached figure 1 with attached figure 2 It is the schematic diagram of embodiment 1.

[0031] The thickness of the base film 206 of the first optical film is 125 μm; the distance between the prism structures 205 is 60 μm, the angle α between the two sides is 90°, and the flat angle platform width at the top is 3 μm; the thickness of the back coating 207 is 5 μm, and the haze is 8%.

[0032] The second optical film is a prism film, the thickness of the base film 202 is 125 μm; the distance between the prism structures 201 is 24 μm, and the angle β between two sides is 90°.

[0033] The included angle between the prism orientation of the first optical film and the prism orientation of the second optical film is 90°.

[0034] The adhesive layer 203 has a thickness of 2 μm. The back of the second optical film prism film is coated with an adhesive layer 203 , then bonded to the first optical film, and cured by ultraviolet light.

Embodiment 2

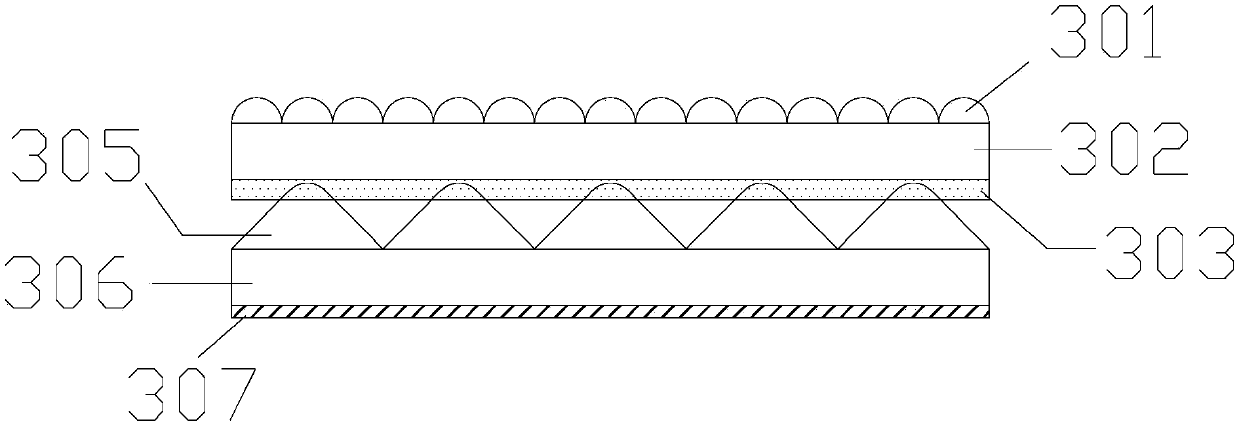

[0036] attached image 3 with attached Figure 4 It is the schematic diagram of embodiment 2.

[0037] The thickness of the base film 306 of the first optical film is 188 μm; the pitch of the prism structure 305 is 50 μm, the angle γ between the two sides is 93°, and the radius of the top fillet is 5 μm; the thickness of the back coating 307 is 4 μm, and the haze is 15%.

[0038] The second optical film is a microlens film, the thickness of the base film 302 is 100 μm, and the radius of the microlens hemisphere 301 is 25 μm.

[0039] The adhesive layer 303 has a thickness of 1 μm. The second optical film microlens film is coated with an adhesive layer 303 on the back, and then bonded to the first optical film and cured by thermal curing.

Embodiment 3

[0041] attached Figure 5 with attached Figure 6 It is the schematic diagram of embodiment 3.

[0042] The first optical film base film 406 has a thickness of 250 μm. The pitch of the prism structure 405 is 70 μm, the angle δ between the two sides is 88°, the width of the flat-angle platform is 5 μm, and the depth of the rough structure of the platform is 1 μm; the thickness of the back coating 407 is 6 μm, and the haze is 20%.

[0043] The second optical film is a diffusion film, the thickness of the base film 402 is 75 μm, the thickness of the diffusion layer 401 is 18 μm, and the haze is 80%.

[0044] The thickness of the adhesive layer 403 is 3 μm. Coat the adhesive layer 403 on the back of the diffusion film of the second optical film, then attach it to the first optical film, and cure it by ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com